Roberts 10-475 Owner's Manual

1HP Electric Floor Stripper

OWNER’S MANUAL

Arracheur de Sol Électrique de 1 CV

MANUEL D’UTILISATION

Removedor Eléctrico de 1 CF para Pisos

MANUAL DE OPERACIÓN

WARNING!

Read and understand all

instructions. Failure to follow

all instructions listed below

may result in electric shock,

fire and/or serious bodily injury.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

A

VER

TISSEMENT!

Lire et comprendre toutes les

ectives. Le non-r

dir

ectives décrites ci-dessous

dir

peut causer des chocs

électriques, un incendie ou des

blessur

CONSER

POUR RÉFÉRENCE UL

¡ADVER

comprenda todas las

instrucciones. Si no se cumplen

todas las instrucciones

enumeradas a continuación se

puede producir choque

eléctrico, incendio y/o lesiones

físicas graves. CONSERVE

ESTAS INSTRUCCIONES PARA

CONSULTARLAS EN EL FUTURO

es graves. VEUILLEZ

VER CES DIRECTIVES

TENCIA!

espect des

TÉRIEURE.

Lea y

Patented Adjustable Blade Orbit

Lame Réglable Br

Sistema Patentado de Ajuste de la Cuchilla

con Movimiento Orbital

US PATENT 7,152,930

evetée Mouvement Orbitaire

10-475

Introduction

Your Roberts 10-475 Professional Floor Stripper machine was

designed for fast efficient removal of VCT, sheetgoods, carpet

quares, and for removal of dried adhesive from all substrates.

s

It features a patented adjustment system, which provides a

range of blade motions from a side-to-side “slicing” motion,

o a back and forth “ chopping” motion. The operator can

t

select the best blade motion pattern for a variety of jobs.

This operator’s manual contains information on machine

operation, safety, care and maintenance. Please read the

anual thoroughly before you begin operating your Stripper.

m

Contact your Robert’s distributor for spare parts, blades

nd repair.

a

ead this owner's manual completely and make sure you

R

nderstand all of it's safety guidelines.

u

General Safety Instructions

1. KEEP GUARDS IN PLACE and in working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Before

2.

turning on the stripping machine, make sure the keys

and adjusting wrenches have been removed.

KEEP WORK AREA CLEAN. Cluttered areas invite

3.

accidents.

4.

ALWAYS REMAIN ALERT WHEN STRIPPER IS IN USE.

Inattention on the part of the operator may lead to

serious injury.

5.

DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations or expose

them to rain. Keep work area well lit.

KEEP CHILDREN AWAY. All visitors should remain at a

6.

safe distance from work area.

MAKE WORKSHOP CHILD-PROOF. Unplug power tools

7.

and secure dangerous tools when not in use. Lock tool

cabinets and workshop doors when unattended.

USE THE RIGHT TOOL. Don’t force a tool or attachment

8.

to do a job for which it was not designed. It has been

designed to operate at maximum safety and

performance levels.

9.

USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating.

use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

WEAR PROPER APPAREL. Do not wear loose clothing,

10.

neckties, rings, bracelets or other jewelry which may get

caught in moving par

recommended. Wear protective hair covering if you have

long hair. Do not wear sandals or open-toe shoes.

11.

ALWAYS USE SAFETY GLASSES AND EAR PROTECTION.

Everyday eyeglasses only have impact-resistant lenses,

they ar

for commercial stripping operations.

DON’T OVERREACH. Keep proper footing and balance at

12.

all times.

13.

MAINTAIN TOOLS WITH CARE. Keep tools clean and in

good working condition for maximum safety

per

changing accessories.

14.

DISCONNECT TOOLS BEFORE SERVICING – when

changing accessories, such as blades, bits, cutters, etc.

e NOT safety glasses. Also use face or dust mask

mance. Follow instr

for

Table 1 shows the correct size to

ts. Non-slip foot wear is

uctions for lubricating and

15. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in OFF position before plugging in.

6.

SE RECOMMENDED ACCESSORIES.Consult the owner’s

1

U

manual for recommended accessories. The use of improper

accessories may increase risk of injury.

7.

AKE SURE YOU USE THE CORRECT BLADEfor the

1

M

material you are cutting.

18.

NEVER STAND ON TOOL. Serious injury could occur if the

tripper is tipped or if the cutting tool is unintentionally

s

ontacted.

c

19.

CHECK DAMAGED PARTS. Before further use of the tool,

damaged part(s), (i.e., guard) should be carefully checked to

determine that it will operate properly and perform its

ntended function. Check for alignment of moving parts,

i

binding of moving parts, breakage of parts, mounting and

any other condition that may affect the stripper’s operation.

A guard or other part that is damaged should be properly

repaired or replaced.

20.

DO NOT ALTER THE PLUG OR USE SA 2-PRONG

RECEPTACLE.

electrical plug.

NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power

21.

off. Don’t leave tool until it comes to a complete stop.

This stripper is equipped with a 3-prong

Electrical Requirements

•

THIS STRIPPER MUST BE CONNECTED TO A GROUNDED

POWER SOURCE while in use to protect the operator from

electrical shock.

• IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electrical

current to reduce the risk of electrical shock. The stripper is

equipped with an electrical cord with a grounding conductor

and a grounding plug. Insert the 3-prong electrical plug into a

3-pole receptacle that is properly installed and grounded in

accordance with all local codes and ordinances.

• DO NOT MODIFY THE PLUG provided if it will not fit the outlet.

Have the proper outlet installed by a qualified electrician.

• IMPROPER CONNECTION OF THE EQUIPMENT-GROUNDING

CONDUCTOR CAN RESULT IN A RISK OF ELECTRIC SHOCK.

The conductor with insulation that is green on the outside

(with or without yellow stripes) is the equipment-grounding

conductor. If repair or replacement of the electrical cord or

plug is necessary, do not connect the equipment-grounding

conductor to a live terminal.

•

CHECK WITH A QUALIFIED ELECTRICIAN or service personnel

if the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

• USE ONLY 3-WIRE EXTENSION CORDS that have 3-prong

grounding plugs and 3-pole receptacles that accept the

stripper’s plug.

• REPAIR OR REPLACE DAMAGED OR WORN CORDS

IMMEDIATELY.

• IF THE PLUG OR RECEPTACLE DOES GET WET, DO NOT

UNPLUG THE CORD. Disconnect the fuse or circuit breaker

that supplies power to the tool. Then, unplug and examine for

presence of water in the receptacle.

•

ONLY UL-LISTED EXTENSION CORDS SHOULD BE USED

WITH THIS PRODUCT.

• DO NOT LET YOUR FINGERS TOUCH THE TERMINALS of plug

when installing or r

•

IMPROPER USE OF EXTENSION CORDS MAY CAUSE

INEFFICIENT OPERATION OF YOUR TOOL, which can result in

overheating. Be sure your extension cord is rated to allow

sufficient current flow to the motor. For the proper gauge for

this stripper, please refer to TABLE 1.

•

THIS MACHINE MUST BE PROPERLY GROUNDED.

The risk of electric shock and bodily injury are greatly

increased if it is not, particularly when used in damp locations

or in proximity to plumbing.

emoving the plug to or fr

om the outlet.

Extension Cords

1. Use only extension cords that are intended for outdoor use.

These extension cords are identified by a marking

“Acceptable for use with outdoor appliances: store indoors

while not in use.” Use only extension cords having an

electrical rating not less than the rating of the product. Do

not use damaged extension cords. Examine extension cord

before using and replace if damaged. Do not abuse

extension cords and do not yank on any cord to disconnect.

eep cord away from heat and sharp edges. Always

K

disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

2.

WARNING - To reduce the risk of electrocution, keep all

onnections dry and off the gound. Do not touch plug with

c

et hands.

w

3. Gound Fault circuit Interrupter (GFCI) protection should be

rovided on the circuit(s) or outlet(s) to be used for the

p

stripper. Receptacles are available having built-in GFCI

protection and may be used for this measure of safety.

4.

Use proper extension cord. Make sure your extension cord

is in good condition. When using an extension cord, be

sure to use a cord heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in

line voltage, resulting in loss power and overheating.

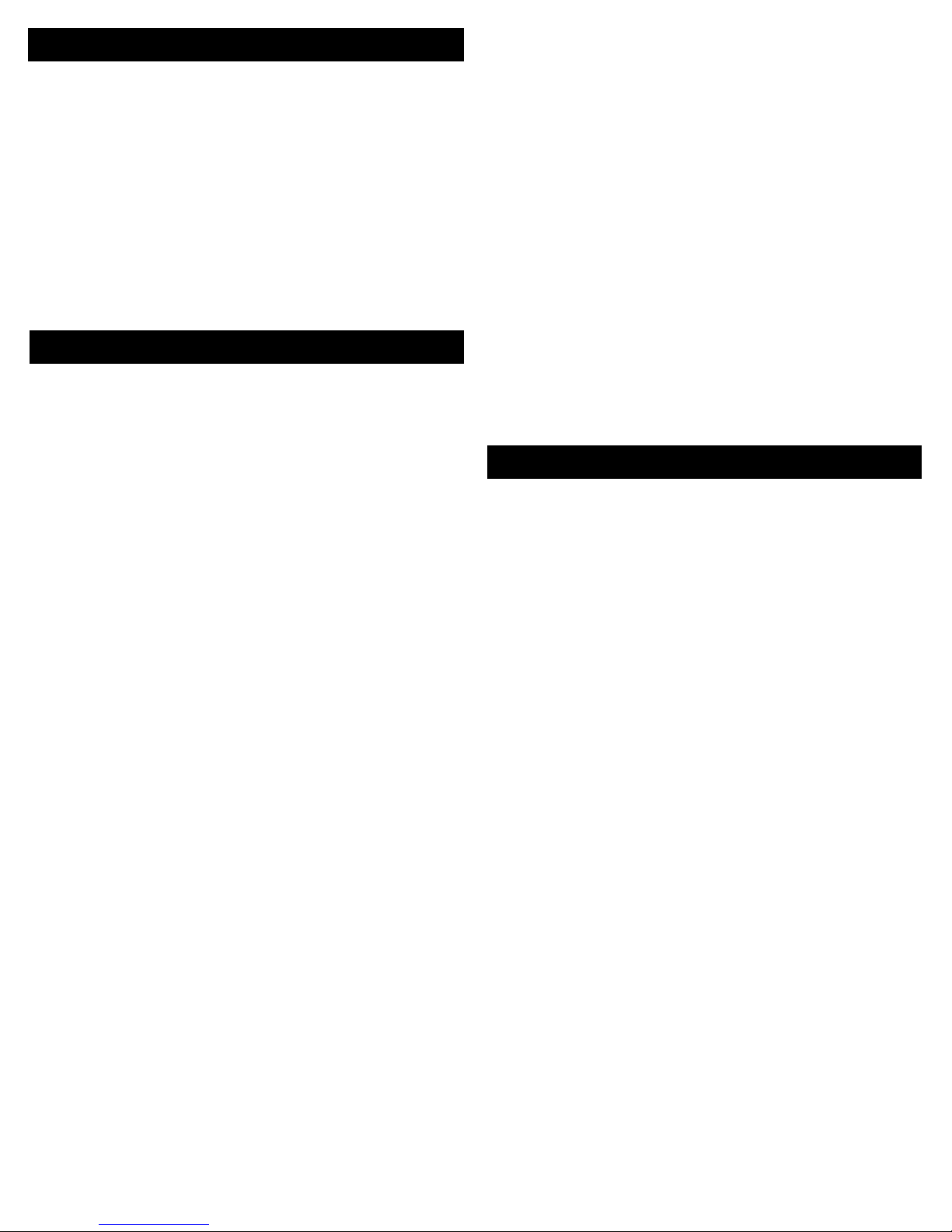

TABLE 1 below shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge.

The smaller the gauge number, the heavier the cord.

NOTE: This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. 1 (B). The

tool has a grounding plug that looks like the plug illustrated

in Fig. 1 (A). The green-colored rigid prongs extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

FIGURE 1

METAL

(A) GROUNDING PIN

(B) GROUNDED

OUTLET BOX

SCREW

Tool Specific Safety Instructions

1. WEAR SAFETY EYE GLASSES, ear protection, work gloves

and safety shoes while operating the floor stripper.

EAR

W

2.

DISCONNECT THE ELECTRIC POWER CORD before changing

stripper blades or making adjustments to the stripper.

3.

DO NOT USE THE STRIPPER IN STANDING WATER OR

PUDDLES.

4.

FOLLOW ALL RECOMMENDATIONS FOR ELECTRICAL

CONNECTIONS

.

5

A

6.

DO NOT LEAVE STRIPPER UNATTENDED unless the machine

is turned off and the power cord disconnected.

andals, soft shoes or open-toe shoes

s

Electric shock can occur.

and use of extension cords.

VOID HITTING NAILSand other metal objects.

DO NOT

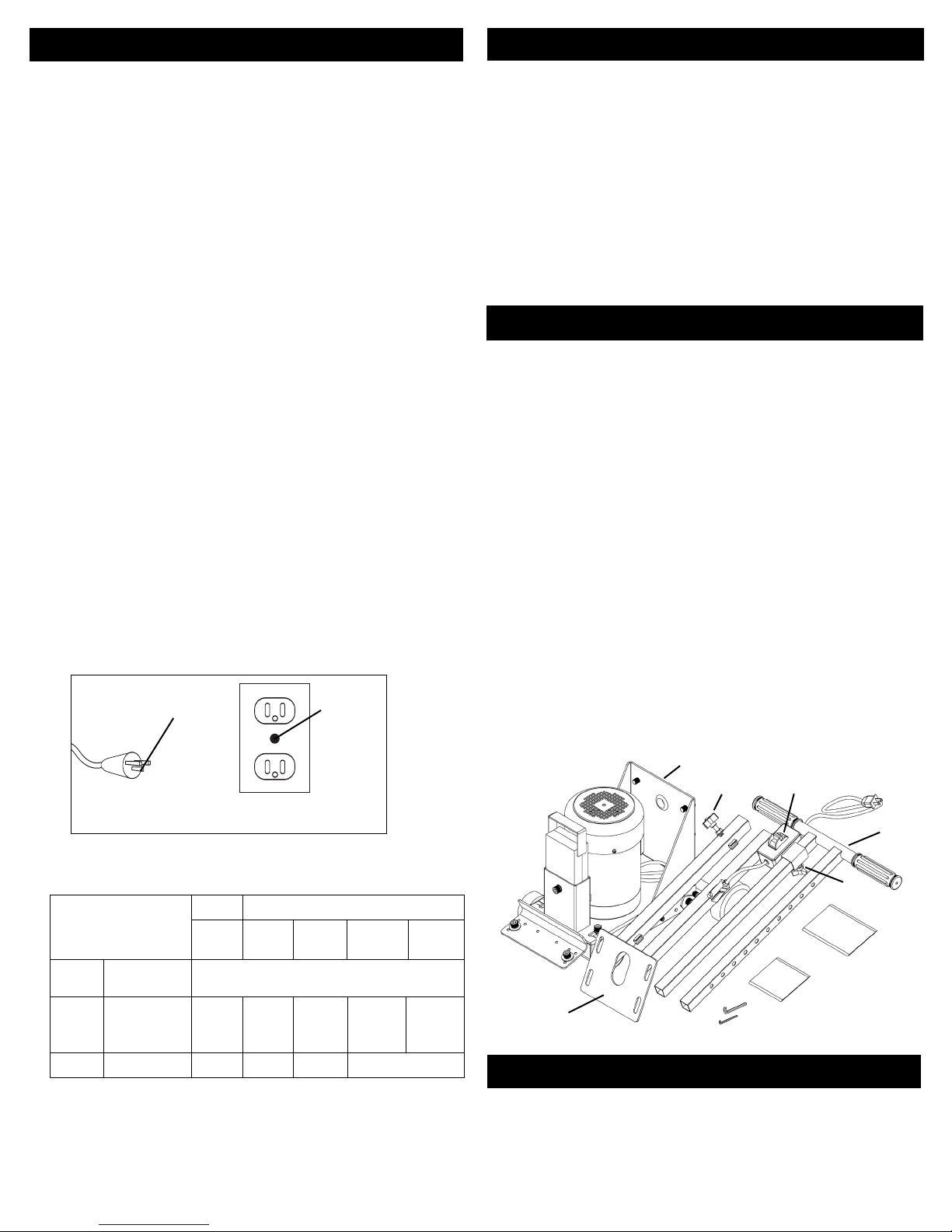

Assembly of the Stripper

1. Remove all parts from the box. Allen hex wrenches are included

for all socket cap bolts used on the stripper machine.

2. Set the motor/blade holder unit (a) upright on solid surface.

Attach the red lower Handle Unit (B) to the upright plate at the

rear of the Motor Unit (A) with four socket cap bolts, lock

washers, and nuts supplied. Tighten the bolts securely with the

ench. For future reference, not that this lower handle can

hex wr

be adjusted up or down to suit the operator’s preference.

3. Lay the upper (silver) handle assembly (c) down, so the leg with

the holes drilled through is to the left, as it appears in the

drawing. Slide the switch box (D) on to the right leg with the

rocker switch facing up, or it can be mounted on the left leg if

you prefer the switch to be in the center.

4. Slide the upper (silver handle assembly (C) into the lower (red)

handle tubes (B).

5. Tighten the switch locking screw (E). Plug the electric cord

from the switch into the motor cord. Set the handle height at

a desired level, and secure it with the pin on the left leg, and

tighten the screw (F) on the right side. Note the pin on the left

side secures the handle at 1-1/2'' increments up and down.

A clip on the right handle leg secures the power cord.

6. For transportation, the handle may be removed easily.

Remove the pin, loosen the right hand screw (F) and unplug

the electric cord.

(A)

(F)

(D)

(C)

TABLE 1

Total length of cord in feet

olts

V

Amper

e Rating

More Not More

Than Than

06

6

10

10 12

12

NOTE: When using an extension cord, ensure all cords are no

smaller than #12 gauge, rated at a 20-amp minimum, and

equipped with 3-prong plugs. Using anything smaller may

result in overheating, loss of power or burn out of the motor.

16

120V 25ft. 50ft. 100ft. 150ft.

240V 50ft. 100ft. 200ft. 300ft.

WG

A

18 16 16 14

18 16 14 12

16 16 14 12

14 12

Not

Recommended

(E)

(B)

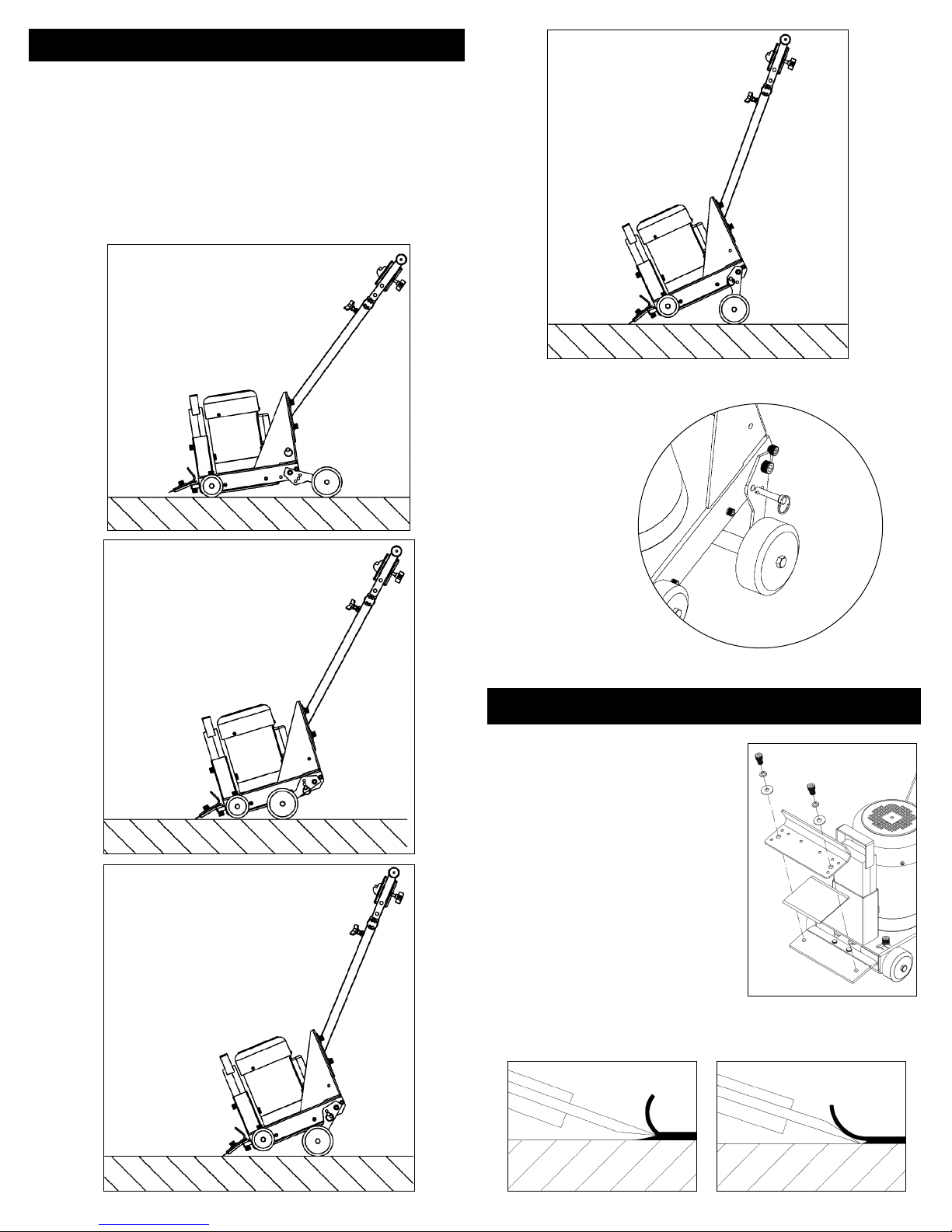

Handle Adjustment

The handle adjusts up and down to provide comfortable

settings. On the left Handle Tube, there is a Locking Pin which

engages holes in the inside (silver) handle tube. The Holes are

spaced at 1-1/2'' increments. It is recommended that the screw

lock on the right handle tube be tightened after the desir

height is selected. This will provide maximum security of the

Handle assembly.

ed

Wheel Adjustment

The rear wheels can be set in three positions to provide the

optimal blade contact angle with the floor. The two Rear

Wheel Adjustment Plates can be adjusted by removing the

two Security Pins, setting the wheel at the desired height,

then reinserting the two pins through holes in the Adjustment

plates and the Frame of the Stripper.

For transport, flip the wheel assembly to the rear of the

Stripper Machine.

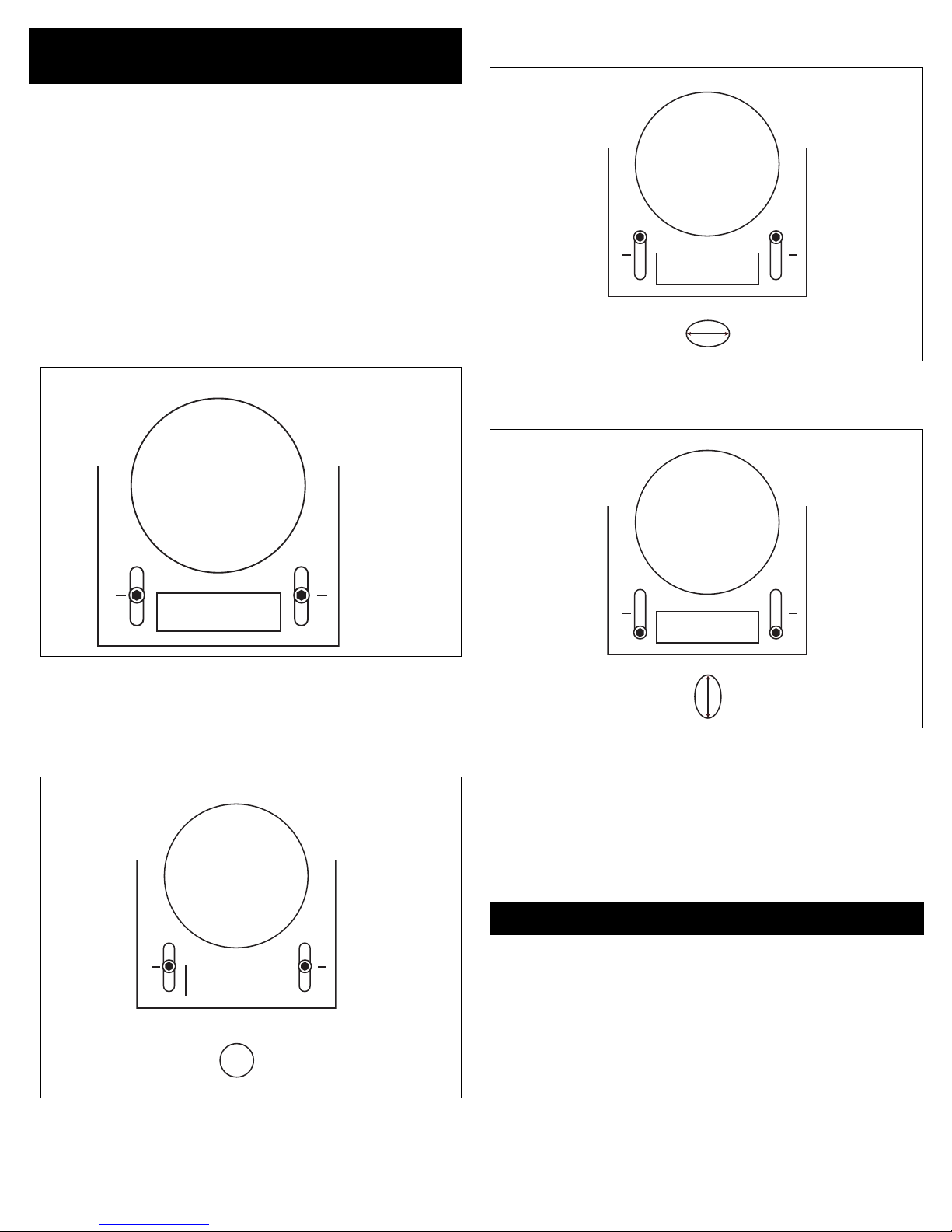

The positions are shown in the illustrations below.

TRANSPORT

HIGHEST

POSITION

SECURITY PIN

For Wheel Height

Adjustment

LOW ANGLE

POSITION

MIDDLE

POSITION

Installing and Changing Blades

Blades are held in place between

the Upper and Lower Blade

Holder plates by two Hex Cap

Bolts. The Lower Blade Holder

Plate is thr

required. To change blades,

loosen the two hex cap bolts;

remove the blade, and install a

new blade. Note the Robert’s

blades are sharpened on both

sides, so the blade can be

reversed to get a sharp edge.

eaded, so nuts are not

BEVEL DOWN FOR

WOOD SURFACE

BEVEL UP FOR

CONCRETE SURFACE

Patented Adjusting Blade

Orbit Motion

he Roberts Floor Stripper can be adjusted to produce different

T

blade motions, from a “slicing” side-to-side orbit, to a

“Chopping” back and forth motion.

he motion is set by sliding the Pivot of the Driver Bar forward

T

r backward.

o

WARNING: DISCONNECT THE ELECTRIC POWER TO YOUR

STRIPPER BEFORE ADJUSTING THE PIVOT!

Two large Hex Cap bolts are located toward the front of the

Stripper base, one on each side, as shown in Figure A. To

adjust the Pivot, loosen both bolts by turning counter-clockwise

with the Allen wrench supplied. Slide the pivot to the desired

blade motion.

If the Pivot is moved to the full back position (Figure A-2), the

blade will move in a side-to-side, or “slicing” motion.

FIGURE

A-2

Motor

Pivot in

BACK

osition

eight Box

W

Blade Orbit

with Pivot in

BACK Position

P

FIGURE A

Motor

Pivot

Adjustment

Weight Box

In the center, the blade motion will be circular in shape, as

most strippers operate. This is shown in Figure A-1.

Bolt

FIGURE

A-1

Motor

By setting the Pivot full forward, as shown in Figure A-3, the

blade will move in a back and forth “chopping” path.

FIGURE

A-3

Motor

Pivot in

FRONT

Weight Box

Blade Orbit

with Pivot in

FRONT Position

The Pivot may be set in any position, to produce the best blade

action for your job. By experimenting with different settings,

you can determine the blade motion you prefer.

Note the blade motion patterns in these illustrations is

exaggerated to show the dif

settings.

CAUTION: TIGHTEN THE TWO HEX CAP BOLTS TIGHTLY

BEFORE CONNECTING THE ELECTRIC POWER AND USING

YOUR STRIPPER!

ferent r

esults for dif

Position

ferent pivot

Care and Maintenance

Weight Box

Blade Orbit Pattern,

with Pivot in

CENTER Position

Pivot

CENTERED

1. As with any major power tool, keep your Roberts Stripper

clean, and do not leave the machine outside in the weather.

2. Inspect the Stripper regularly. If the blade is chipped, cracked, or

dull, replace it. Roberts’s blades are sharpened on two edges, so

the blade can be reversed and used. Check the electrical cord. If

there are cracks or cuts, immediately replace the cord.

3. Occasionally – every couple of months – turn the Stripper upside

down and remove the bottom cover plate, by removing the four

small Cap scr

foreign material. Apply light grease in the slot where the Pivot

slides back and for

4. Some users wrap Duct tape around the rubber wheels so

adhesive can be removed easily.

5. Make sure all bolts and fasteners are tightened. Due to the

mal vibration of Floor Strippers. Fasteners can come loose.

nor

ews. Check for dir

th. Bearings ar

t and debris, and r

e self-lubricating.

emove any

Technical Specifications

Total Weight: 95 lbs ( 43 Kg)

Removable Weight: 14 lbs ( 7Kg )

MOTOR: 1 HP

1,720 RPM (Strokes/minute)

12 Amps

750 Watts

120 V, 60 Hz current

Replacement Parts List

SKU# Description

10-475-01 Blade Holder, Upper Plate

10-475-02 Blade Holder Base

10-475-03 Driver Arm

10-475-04 Driver Pivot Bearing Base Plate

10-475-05 Pivot Bearing Bottom Plate

10-475-06 Counter Balance, w/ set screw

10-475-07 Pivot Bearing

10-475-08 Pivot Bearing Upper Retainer

10-475-09 Pivot Bearing Spacers, (2)

10-475-11 Eccentric Bearing Spacer

10-475-12 Eccentric Bearing Upper Plate

10-475-13 Eccentric Ball Bearing

10-475-14 Eccentric Bearing Housing

10-475-15 Eccentric Collar

10-475-10 Bottom Cover, w/ 4 Bolts

10-475-16 Front Wheel Kit (2), w/ Bolts

10-475-17 Rear Wheel Adjustment Plates (2)

10-475-18 Rear Wheel Shaft

10-475-19 Rear Wheels (2)

10-475-20 Motor Shaft Spacer

10-475-21 Wheel Adjustment Pins (2)

10-475-22 Main Frame Assembly

10-475-23 Weight, 14 lbs, w/ Handle

10-475-24 Blade Adjustment (Pivot Slide) Bolts (2)

SKU# Description

10-475-25 1 HP Motor, w/ Capacitor and Cord

10-475-26 Capacitor

10-475-27 Capacitor Cover

10-475-28 Upper Handle, With Grips

10-475-29 Cord Extension, w/ Security Grommet

10-475-31 Switch Box

10-475-32 Switch

10-475-33 Handle Grips

10-475-34 Power Cord, w/ Security Grommet

10-475-36 Switch Box Adjustment Knob

10-475-37 Handle Knob

10-475-38 Handle Adjust Lock

10-475-39 Cord Clip

10-475-40 Lower Handle Frame

10-475-41 Rubber Grommet

10-475-50 Blade, Double side, 4'' x 4''

10-475-51 Blade, Double side, 4'' x 6''

10-475-52

10-475-53 Blade, Self Dicing, 4'' x 6''

10-475-54 Blade, Self Dicing, 3'' x 9''

10-475-60 Allen Wrench – 5mm

10-475-61 Allen Wrench – 8mm

Blade, Double side, 4'' x 9''

Loading...

Loading...