Page 1

BrakeMaster 9100 and 9160

for motorhomes with air or air over hydraulic brakes

Installation Instructions

ROADMASTER, Inc. • 6110 NE 127th Ave. • Vancouver, WA 98682 • 800-669-9690 • fax 360-735-9300 • roadmasterinc.com

Towing and Suspension Solutions

Page 2

WELCOME TO THE ROADMASTER FAMILY!

hese instructions have been prepared to acquaint you with the installation of your BrakeMaster, and to

T

provide you with important safety information. Read these instructions, as well as the owner’s manual and all

accompanying literature, completely. Understand how to install and operate your BrakeMaster, and carefully follow

the instructions and safety precautions.

Your BrakeMaster has a one-year limited warranty. To qualify for your warranty, fill out and return the enclosed

product registration card within 30 days of purchase.

We thank you for your patronage and greatly appreciate your discerning taste.

TABLE OF CONTENTS

Safety definitions ..............................inside front cover

Before you begin the installation

(installer’s checklist) .............................................. 1

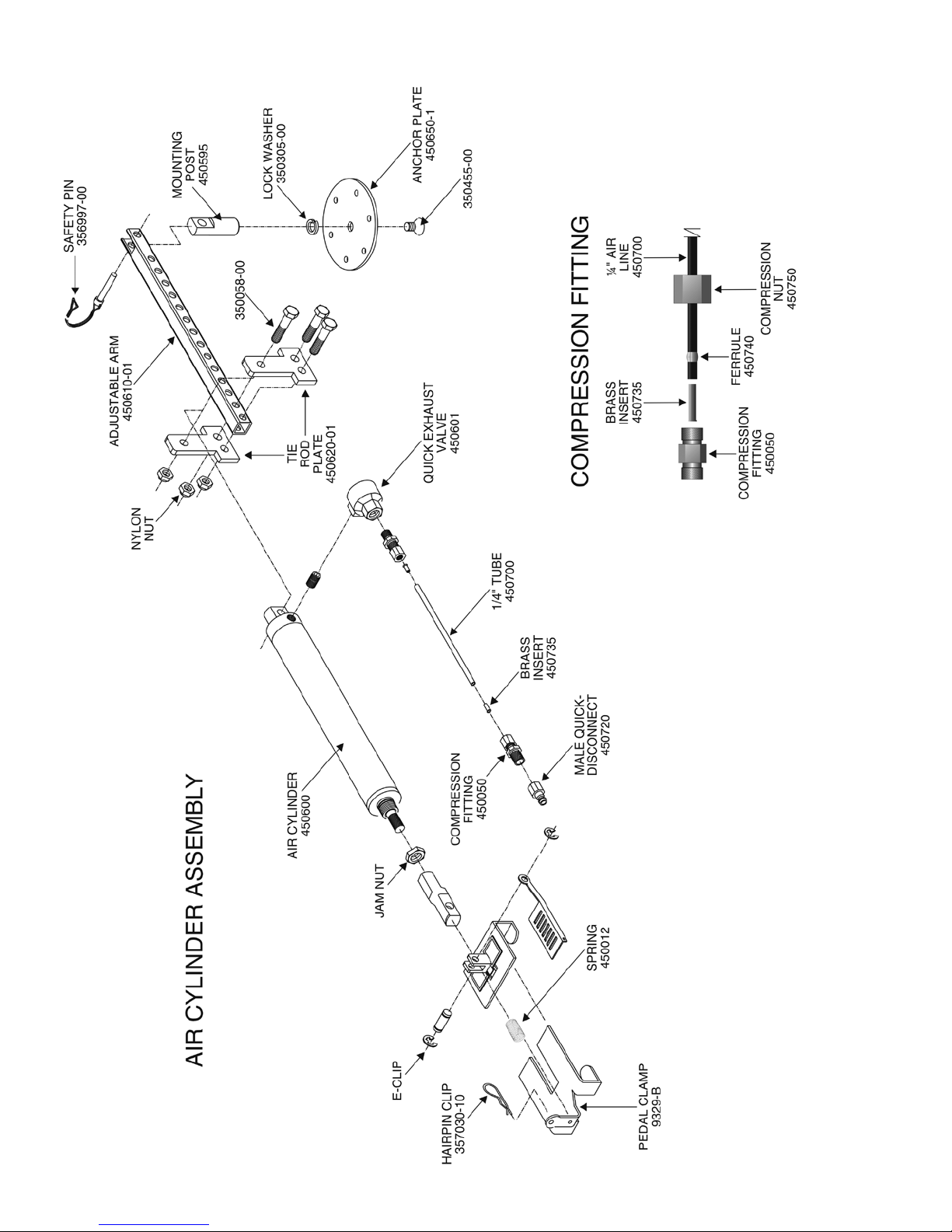

Air cylinder assembly and

compression fitting parts ....................................... 2

Install the air cylinder anchor plate ........................ 3-5

Install the break away system ................................ 6-7

Install air lines in the towed vehicle .......................8-9

Install the motorhome monitor system ................ 10-11

Install the motorhome air line ............................. 12-13

System test ......................................................... 14-15

Brake light solutions ................................................ 16

Ford ‘neutral tow’ vehicles .................................. 17-18

Troubleshooting ....................................................... 19

Vehicle-specific components .................................... 20

Index ........................................................................ 21

IMPORTANT NOTICE!

Safety Definitions

Statements in these instructions identified as follows are of special significance:

WARNING indicates a potentially hazardous situation which, if not avoided, could result in property

damage, serious personal injury, or even death.

Red type is used to emphasize warnings of particular significance.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in property

damage, or minor or moderate personal injury.

Red type is used to emphasize cautions of particular significance.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

Red type is used to emphasize cautions of particular significance.

NOTE

Refers to important information and is placed in italic

type. It is recommended that you take special notice of

these items.

Page 3

BEFORE YOU BEGIN THE INSTALLATION…

fore it can be towed — verify that removing the fuse(s)

will not disrupt power to BrakeMaster, or otherwise af-

These instructions pertain to the initial installation only. Operating instructions are contained in

the owner’s manual.

Read all instructions before installing or operating the BrakeMaster system. Failure to understand

how to install or operate BrakeMaster could result in

property damage, personal injury or even death.

1. ALWAYS CHECK THE ROADMASTER WEBSITE —

www.roadmasterinc.com — for vehicle-specific information. Select ‘Vehicle-Specific Info,’ enter the motorhome

and towed vehicle make, model and year, then select

‘Braking Systems’ and scroll down the page.

2. If the battery must be disconnected for towing,

a stop light switch must be installed. ROADMASTER

manufactures stop light switch kits for a number of vehicles; to see if one is available for any specific vehicle,

visit www.roadmasterinc.com and select ‘Vehicle-Specific Info,' enter the vehicle make, model and year, then

select ‘Braking Systems' and scroll down the page.

Note: if a stop light switch kit is listed on the website

for any particular vehicle, it is required.

Note: an Automatic Battery Disconnect (part number

765) is available for vehicles which must be towed with

the battery disconnected. If you choose to install the

Automatic Battery Disconnect, a stop light switch is still

required; the Brake-Lite Relay is not required.

3. If the vehicle to be towed has an ‘active’ (or,

‘continuous power assist’) braking system, or if the

vehicle is not equipped with power brakes — order

the optional Brake Pressure Reducer (part number

900002) to adapt the vehicle to the BrakeMaster system.

Vehicles with ‘active’ brake systems include several

hybrid vehicles, such as some models of the Ford Escape hybrid and the Mercury Mariner hybrid, as well

as the H3 Hummer. These vehicles, and others with

these systems, are designed so that even when the

vehicle is set to ‘tow’ mode, the braking system is still

active, thus requiring minimal pressure to engage the

brakes.

If the vehicle to be towed has an ‘active’ braking system, or if the vehicle is not equipped with

power brakes, install the optional Brake Pressure

Reducer.

If the reducer is not installed, BrakeMaster will

apply excessive force to the towed vehicle’s brake

pedal, causing severe tire and/or brake system damage, as well as other, consequential damage.

fect the installation or operation.

5. Optional seat adaptor brackets are required for

some towed vehicles and simplify the installation for

others. Determine if a seat adaptor bracket is required,

or if one is available, for the towed vehicle — visit

www.roadmasterinc.com and select ‘Vehicle-Specific

Info,' enter the vehicle make, model and year, then

select ‘Braking Systems' and scroll down the page.

6. Test-fit the brake pedal clamp — although the

pedal clamp fits the vast majority of vehicles, in rare

circumstances, it may require additional adjustment. If

the pedal clamp does not attach to the brake pedal as

described on page 3, call the ROADMASTER Technical

Service Department at 800-669-9690.

7. Check the towed vehicle’s brake lights — Brake-

Master must function when all adjustments have been

made to prepare the vehicle for towing. These adjustments may include: turning the ignition key to the “tow”

position; pulling fuses; disconnecting the battery; and

setting the transmission to a particular gear or in a

particular sequence.

However, some vehicles’ brake lights will not operate

when these adjustments have been made.

Check to see if this is the case: after all adjustments

have been made, apply the brakes, and check to see

if the brake lights illuminate. If the brake lights do not

illuminate, a two-prong stop light switch and 10-amp

fuse must be installed.

ROADMASTER manufactures stop light switch kits

for a number of vehicles; to see if one is available for

any specific vehicle, visit www.roadmasterinc.com.

Note: check the owner’s manual to see if the vehicle

is equipped with an “automatic shut down” feature. If

this is the case, ensure that the vehicle is not in automatic shut down mode before performing this test.

Note: if you must install a Brake-Lite Relay — see

step 8, below — a stop light switch is not required.

8. An optional Brake-Lite Relay may be required.

Refer to “Brake light solutions” for instructions on how

to determine if the relay must be installed.

Note: a stop light switch (see steps 2 and 7 above)

and a Brake-Lite Relay are mutually exclusive — if you

use one, the other is not necessary.

9. An optional tee may be required to connect the

BrakeMaster air line to the motorhome brake relay valve

or air booster housing. Refer to “Install the motorhome

air line.”

These tees are available in two sizes: ½" (part number 450076) and 3/8" (part number 450077).

10. If the motorhome is equipped with air over hydraulic brakes — an additional amount of air line (part

number 450700) may be required.

4. If fuse(s) must be removed from the vehicle be-

1

Page 4

2

Page 5

INSTALL THE AIR CYLINDER ANCHOR PLATE

To determine where the anchor plate will be installed,

first attach the pedal clamp to the brake pedal. Follow

steps one through six below…

1. At the towed vehicle, slide the driver’s seat back,

as far as it will go.

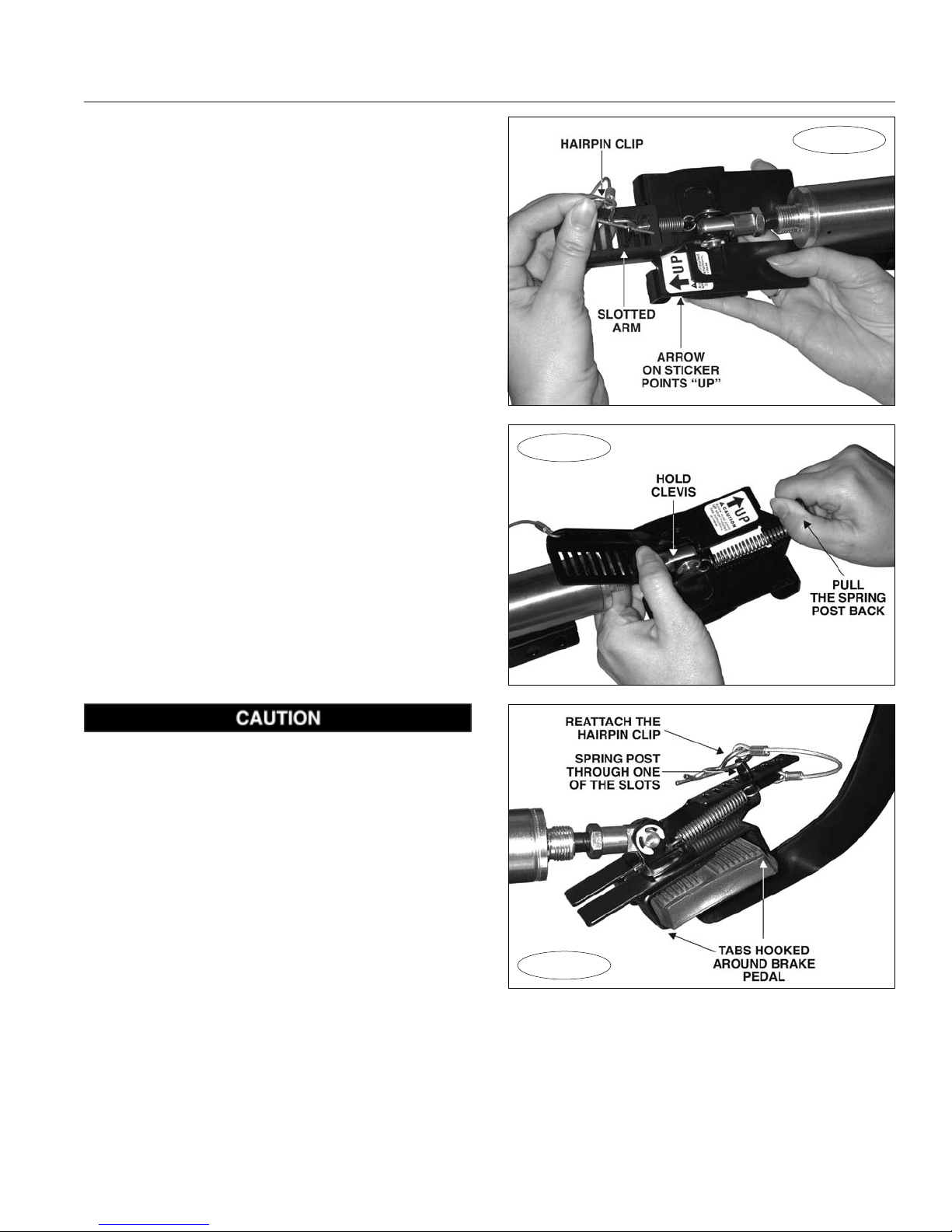

2. Verify that the pedal clamp is right side up, as shown

in Figure 1 — the arrow on the sticker will point “Up”

when the pedal clamp is properly positioned.

3. Pull the hairpin clip (Figure 1) out, then lift the slot-

ted arm (Figure 1) up and out of the way.

4. Move the pedal clamp over the brake pedal. Then,

hold the clevis (Figure 2) and pull back on the spring

post (Figure 2), until the tabs under the pedal clamp

are wide enough to clear the brake pedal.

5. Fit the pedal clamp onto the brake pedal, so that

all four tabs are hooked around it (Figure 3). Then,

release the spring post.

Note: on the initial installation, it may be necessary

to adjust the tabs on the pedal clamp — use pliers to

bend any or all of the tabs so that they hook around

and under the towed vehicle’s brake pedal.

Once the tabs have been adjusted to a specific

brake pedal, no further adjustment to the pedal clamp

is necessary for that vehicle.

If BrakeMaster is switched between towed vehicles,

always check the pedal clamp on the initial installation.

Verify that all four tabs are hooked around and under

the brake pedal. If necessary, bend the tabs to fit, as

described above.

Figure 2

Figure 1

Make certain that all four tabs on the pedal clamp

are securely hooked around the brake pedal (Figure

3). If the tabs are loose when the vehicle is towed,

the pedal clamp can rotate out of position and hold

the brake pedal down, even when BrakeMaster is

not activated, which will cause tire and/or brake

damage, or other consequential, non-warranty damage.

6. Swing the slotted arm back over the spring post, fit

the spring post through one of the slots, and reattach

the hairpin clip (Figure 3).

7. Now that the pedal clamp is in place, attach the

anchor plate (Figure 4) —

Note: optional seat adaptor brackets are required

for some towed vehicles and simplify the installation

for others. Before attaching the anchor plate, determine if a seat adaptor bracket is required — visit

www.roadmasterinc.com. Select ‘Vehicle-specific Info,'

enter the vehicle make, model and year, then select

‘Braking Systems’ and scroll down the page.

Choose a mounting point under the driver’s seat as

Figure 3

far back as possible — ideally, the anchor plate should

be concealed when the driver's seat is moved forward,

and visible only when the driver's seat has been moved

back as far as it will go.

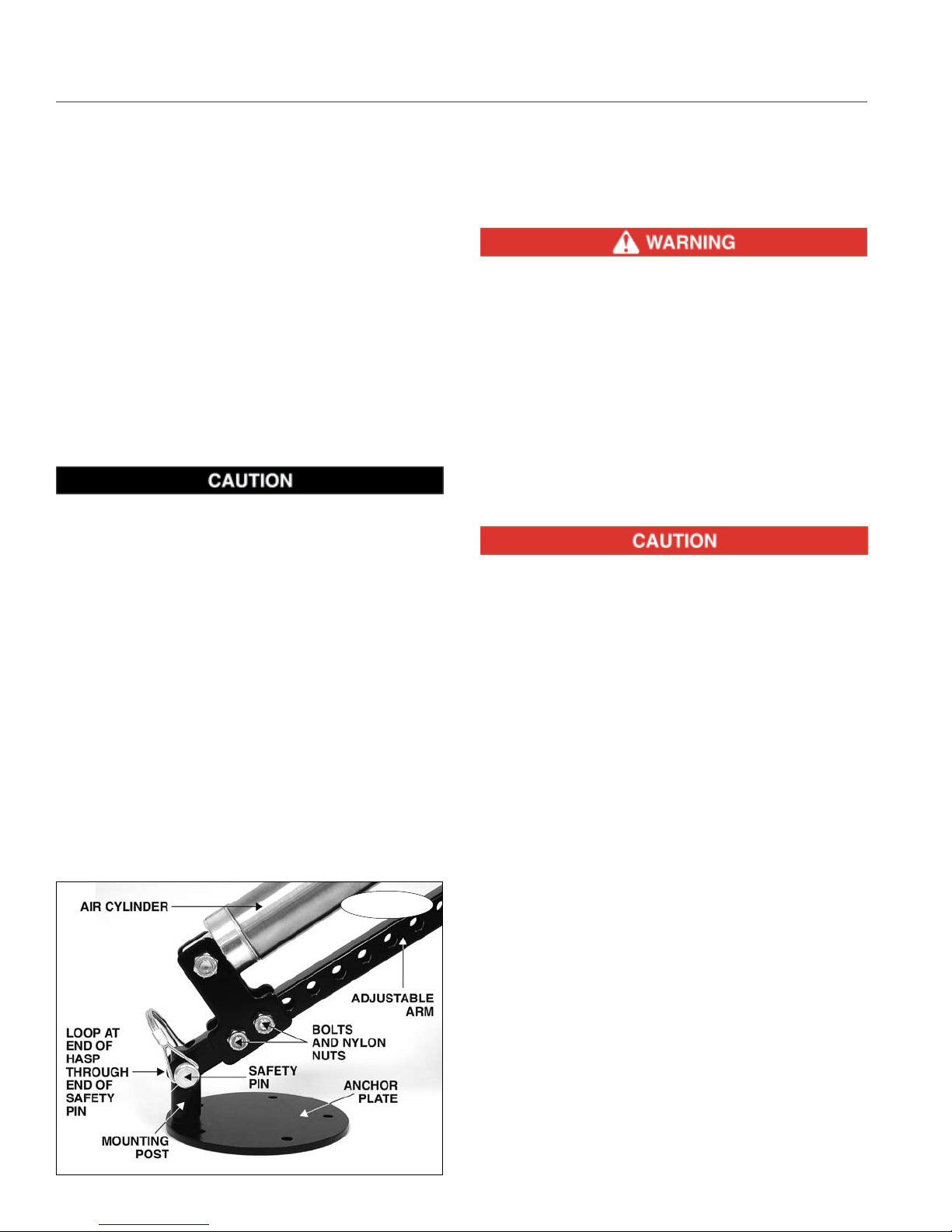

BrakeMaster is shipped with the air cylinder at the

shortest position. If necessary, lengthen the reach of

the air cylinder, to position the anchor plate at the point

you have chosen — remove the two bolts and nylon nuts

continued on next page

3

Page 6

INSTALL THE AIR CYLINDER ANCHOR PLATE

continued from preceding page

(Figure 4) attaching the cylinder to the adjustable arm

(Figure 4). Slide the air cylinder (Figure 4) up the adjustable arm until the anchor plate is over the point you

have chosen. Replace the two bolts and nylon nuts.

Note: if BrakeMaster is switched between towed

vehicles, it may be necessary to lengthen or shorten

the reach of the air cylinder, as described above.

Note: if the vehicle is equipped with an automatic

pedal positioning system, adjust the brake pedal to its

farthest extension (as close as possible to the driver’s

seat) before positioning the air cylinder and the mounting post. This will eliminate the possibility of positioning

the anchor plate too close to the brake pedal.

8. Next, if necessary, move the air cylinder to the left

or the right, until the mounting post (Figure 4) is directly

in line with the brake pedal.

The air cylinder must be mounted directly in line

with the brake pedal. If it is mounted at an angle

to the brake pedal (to one side or the other), the

air cylinder may jam in the extended position when

BrakeMaster is activated, which will cause severe

brake system damage, as well as other consequential, non-warranty damage.

Note: the anchor plate can be rotated clockwise or

counterclockwise, if necessary, to clear any obstructions

— to rotate the anchor plate, remove the air cylinder

and lock the plate in a vise. Use a half-inch open-end

wrench to loosen the mounting post, while holding the

retaining screw (at the bottom of the plate) with an Allen

wrench. Do not turn the retaining screw with the Allen

wrench, as you may damage the wrench or the screw.

When the mounting post is loose, rotate the anchor

plate. Then, tighten the mounting post.

9. Before attaching the anchor plate, verify that the

Figure 4

following conditions are met:

A. Make certain that the pedal clamp is not de-

pressing the towed vehicle’s brake pedal — examine the

brake pedal, and also check the towed vehicle’s brake

lights, to make certain they are not illuminated.

Make certain that the pedal clamp is not depress-

ing the towed vehicle’s brake pedal.

If the pedal clamp is pushing the brake pedal

down, the brakes will be applied continuously when

BrakeMaster is connected, which will cause severe

tire and/or brake system damage, as well as other

consequential, non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

B. When it is connected, the air cylinder must be

pulled back toward the anchor plate in order to insert

the safety pin (Figure 4) through the mounting post.

The air cylinder must be pulled back when it is

connected, in order to create sufficient spring tension to keep the weight of the cylinder off the brake

pedal. If the cylinder is not pulled back when it is

connected, the weight of the cylinder may cause

the pedal clamp to depress the towed vehicle’s

brakes continuously, which will cause excessive

brake wear, brake system damage, or other consequential, non-warranty damage.

C. The pedal clamp must be flat against the brake

pedal and properly secured with the hairpin clip (Figure

3).

D. Make certain that there is sufficient clearance

between the mounting post and the bottom of the seat

to allow the seat to slide properly.

10. Once the four conditions in step 9 (above) are met,

attach the anchor plate. (It may be helpful to remove the

driver’s seat to facilitate the rest of the installation.)

The anchor plate can be attached on top of the

carpet, or underneath it.

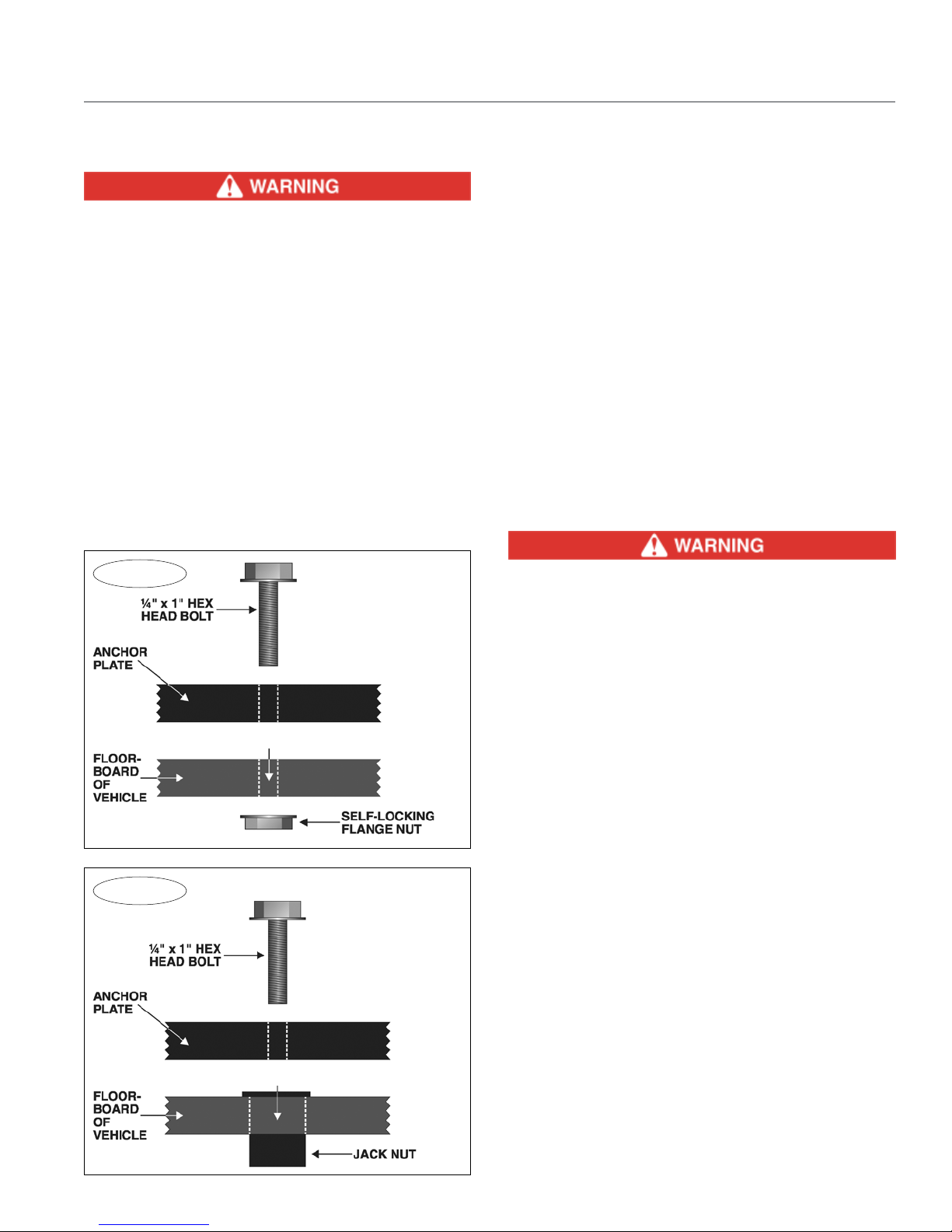

A. To mount the plate on top of the carpet, first

use the anchor plate as a template and mark the five

holes to be drilled.

Before drilling, make certain that the retaining screw

(at the bottom of the mounting post) is fully tightened.

(To tighten the screw, reverse the instructions in step 8,

above.) Also, make certain that you will not drill through

any wiring or electrical components underneath the

carpeting, or damage any components on the other

continued on next page

4

Page 7

INSTALL THE AIR CYLINDER ANCHOR PLATE

continued from preceding page

side of the floorboard.

Do not drill through any wiring. The air bag sensor wire may be located under the driver’s seat.

Drilling into this wire may disable the air bag system, or may cause the air bags to deploy immediately, which may cause severe personal injury.

Failure to follow these instructions may cause

property damage, personal injury or even death.

Next, drill five ¼" holes at the points you marked.

Drill through the carpet and the floorboard. Use caution

to prevent the drill bit from catching on threads in the

carpet and unraveling it.

B. If mounting the anchor plate underneath the

carpet, cut a small flap in the carpet to allow the mount-

ing post to protrude through it.

As described above, use the anchor plate as a template, and drill five ¼" holes through the floorboard.

Figure 5

STANDARD

INSTALLATION

DRILL 1/4" HOLE

11. Next, attach the anchor plate as shown in Figure

5, using the provided ¼" x 1" hex head bolts and selflocking flange nuts.

12. If you find that tightening the flange nut on a bolt

is difficult due to a tube, channel or other obstruction

under the floorboard, use one of the provided jack nuts

to attach the bolt. Refer to Figure 6.

Note: if one or more jack nuts are used, the anchor

plate cannot be mounted on top of the carpet.

To attach a bolt with a jack nut, drill a ½" hole

through the floorboard at the point you marked in step

10.

Note: do not drill out the hole in the anchor plate.

Next, insert the jack nut into the hole (See Figure

6) and bolt through the anchor plate, using one of the

¼" x 1" hex head bolts.

13. This completes the anchor plate installation. You can

leave the air cylinder assembly in place — it must be

attached to install an air line fitting in a later step — or

you can remove it, if it interferes with the installation.

Automatic pedal positioning systems may affect

the towed vehicle braking system.

Determine if the vehicle to be towed is equipped

with pedal presets. Proper connection of the braking system may be affected by these presets; if the

vehicle is so equipped, note the original installed

position and return to that position before towing

the vehicle.

If the brake pedal is not at the original installed

position when the vehicle is towed, the pedal clamp

may apply excessive braking force, which will damage the brake system and/or electrical system, and

may cause brake or electrical system failure, as well

as other non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

Figure 6

DRILL 1/2" HOLE

JACK NUT

INSTALLATION

NOTE: DO NOT

DRILL OUT THE

HOLE IN THE AN-

CHOR PLATE!

5

Page 8

INSTALL THE BREAK AWAY SYSTEM

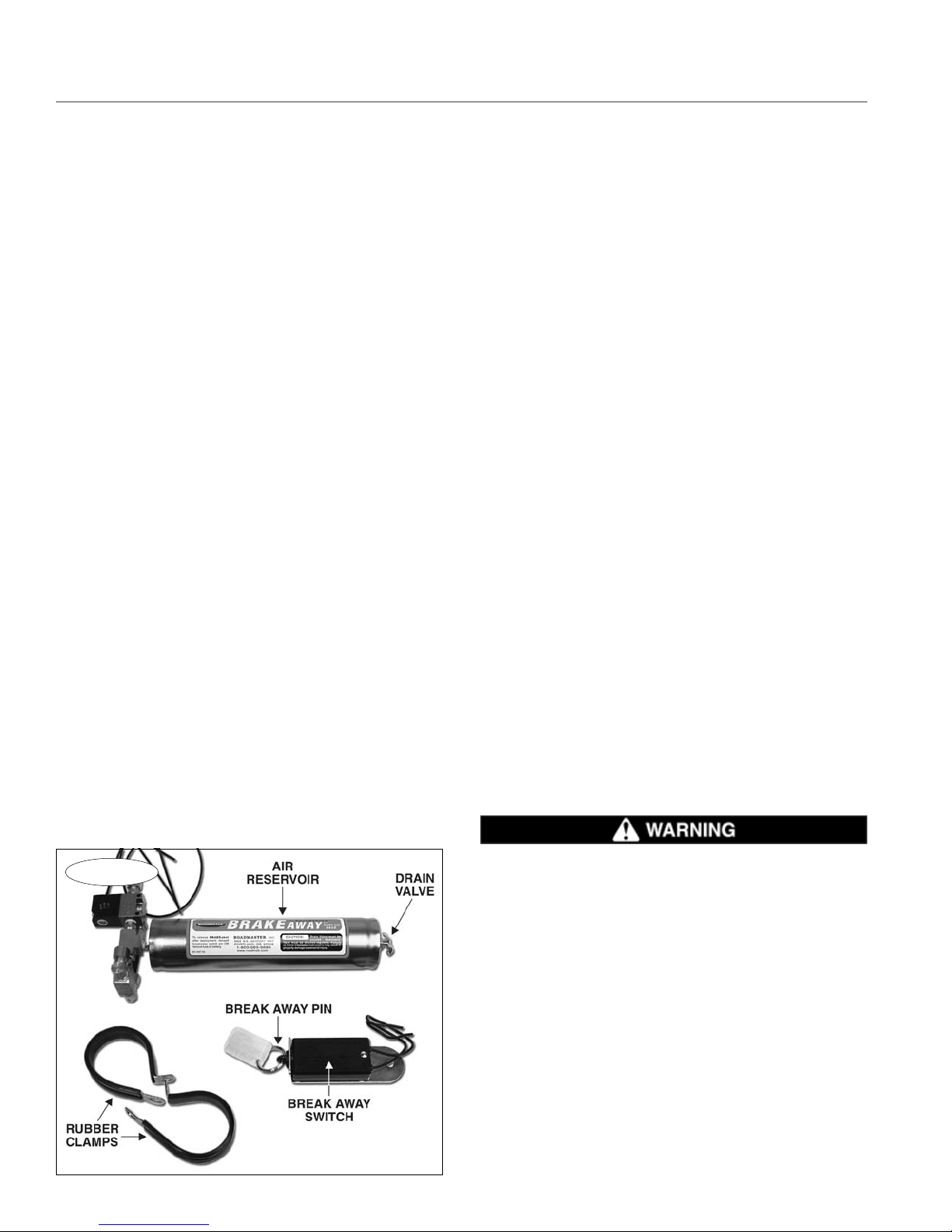

Note: the BrakeAway™ system is included with the

9160; it is an optional accessory for the 9100.

Step One

Install the air reservoir

1. First, choose a location for the air reservoir (Figure

7). The air reservoir is mounted in the towed vehicle,

most often in the engine compartment, but it may be

attached anywhere an air line can be routed from the

top of the air reservoir to the front of the vehicle, and

where the drain valve (Figure 7), at the bottom of the

reservoir, is easily accessible.

Choose a location that meets the following conditions:

• An air line will be attached to the reservoir in a later

step. One end will be routed to the driver’s side of the

passenger compartment; the other end will be routed

to the front of the vehicle. This air line cannot be closer

than two feet from any heat source, such as the engine

or exhaust system, which might damage the air line.

• The air reservoir must be mounted away from any

moving parts, so that the air reservoir will not be damaged by, or interfere with, the proper operation of any

components.

• Choose a location that will allow the bottom of the

air reservoir to be mounted lower than the top, so that

any accumulated water can be drained from the tank.

The reservoir cylinder does not have to be perfectly

straight up and down, but the drain valve must be the

lowest part of the reservoir.

• The reservoir will be attached with two of the sup-

plied ¼" x 1" hex bolts and nuts. Choose a location

that will allow you sufficient access to tighten the hex

nuts from the other side.

Note: because the air reservoir will be charged with

compressed air, it cannot be mounted inside the pas-

senger compartment of the vehicle.

2. Once you have chosen a location for the air res-

ervoir, fold the two rubber clamps (Figure 7) over the

cylinder. Press the ends of each clamp together, until

the pre-drilled holes align.

Test-fit the reservoir and slide the clamps up or down

the cylinder, if necessary, until the pre-drilled holes are

both over a surface where the hex bolts and nuts will

hold each clamp in place. Mark the center of each hole

for drilling, and set the reservoir aside.

Before drilling, make certain you will not damage

any components on the other side. Then, drill a ¼"

hole through the two points you have marked.

Before attaching the clamps, rotate the top of the

reservoir so that the two wires at the solenoid valve

(Figure 10), as well as the two brass air compression

fittings (Figure 10), will be easily accessible.

Position the reservoir and clamps over the two holes,

and secure the reservoir in place with one of the ¼" x

1" hex bolts and nuts at each clamp.

Step Two

Mount the break away switch

1. Mount the break away switch (Figure 7) at the front

of the vehicle, on the driver’s side. Choose an area you

can easily reach, with a surface of sufficient strength to

hold the switch firmly in place, so that the break away

pin (Figure 7) will pull freely from the switch. Mount the

switch in a horizontal position, with the break away pin

facing toward the motorhome.

Ensure that the break away pin can be pulled freely away from the towed vehicle, without any obstructions.

Figure 7

6

Do not attach the break away switch to the tow

bar or the tow bar bracket. If the tow bar or bracket

fails, the break away switch will separate with it,

preventing the break away system from activating.

If the towed vehicle separates, the brakes will not

be applied, which may cause property damage, personal injury or even death.

Step Three

Connect the wiring

Note: if the vehicle’s battery must be disconnected

for towing and an automatic battery disconnect has

been installed, additional modifications are necessary. If

a ROADMASTER Dinghy Battery Manager (part number

continued on next page

Page 9

INSTALL THE BREAK AWAY SYSTEM

Connect the wiring

continued from preceding page

765) has been installed, follow the instructions included

with the kit.

1. Using one of the blue butt connectors, attach one

end of the supplied length of 14-gauge black wire to

the end of either one of the two wires extending from

the break away switch. (If necessary, strip ¼" to 3/8" of

insulation from the end of the wires before connecting

them.)

Next, route the wire to the positive terminal on the

towed vehicle’s battery (Figure 8), avoiding moving

parts, sharp edges or “hot” components such as the

engine or exhaust system. Where appropriate, use one

or more of the included wire ties to secure the wire in

place.

2. Cut the wire and strip ¼" to 3/8" of insulation from

the end of the wire. Crimp either end of the supplied

yellow 10-amp fuse onto the end of the wire. Strip the

insulation from one end of the remaining length of wire;

crimp the other end of the fuse onto the wire.

3. If necessary, cut the wire again, leaving no more

than six inches, and strip ¼" to 3/8" of insulation from

the end of the wire. Crimp the larger (3/8") ring terminal

onto the end of the wire, and attach the ring terminal to

the positive terminal on the towed vehicle’s battery.

the 10-amp fuse must be within six inches of the

positive terminal. If the 10-amp fuse is farther than

six inches, a short circuit may cause significant

damage to the towed vehicle’s electrical system, an

electrical fire, or other consequential, non-warranty

damage.

4. Now, connect the remaining wire at the break away

switch to either one of the two wires extending from the

top of the solenoid valve on the air reservoir (Figures

8 and 10). If necessary, use the remaining length of

14-gauge black wire to reach the top of the solenoid

valve. As before, strip the ends of the wires before connecting them with the supplied blue butt connectors.

Where appropriate, use one or more of the included

wire ties to secure the wire in place.

5. Crimp the smaller (#10) ring terminal onto the end

of the remaining wire extending from the top of the

solenoid valve, and attach the ring terminal to any good

chassis ground. (If necessary, use another butt connector, and any remaining 14-gauge black wire, to extend

the length of the ground wire.)

6. If the battery must be disconnected for towing, install

a battery switch to the positive battery cable, as shown

in Figure 9. Connect the stop light switch wiring to the

battery switch.

In order to prevent damage from a short circuit,

Figure 8

Figure 9

7

Page 10

INSTALL AIR LINES IN THE TOWED VEHICLE

1. Find a suitable location at the front of the towed

vehicle to attach the preassembled male quick coupler

(Figure 10). Choose an area within easy reach, with

a surface of sufficient strength to hold the mounting

bracket firmly in place.

Do not attach a female quick coupler at the front

of the towed vehicle. The female quick couplers

have an internal check valve to prevent air from

escaping. If air pressure is not released, the BrakeMaster pedal clamp will not retract when the system

is activated, which will cause severe brake system

damage, or a brake fire, as well as other consequential, non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

2. Attach the bracket with two of the supplied ¼" nuts

and bolts, with the male quick coupler pointing away

from the towed vehicle.

Note: the weather covers will prevent dirt or debris

from entering the lines. Keep the fittings covered when

the braking system is not in use.

3. Connect one end of the air line to the male quick

coupler compression fitting (Figure 10) — first, if necessary, trim the end of the air line, to make a smooth and

straight cut. Then slide the compression nut and the

ferrule (Figure 10) over the air line. Position the ferrule

¼" from the end of the air line.

Next, slide one of the brass inserts (Figure 10) into

the end of the line.

Note: if the brass inserts are omitted, the fittings will

not be airtight.

Now, push the air line into the compression fitting,

as far as it can go. Then push the ferrule into the compression fitting, and tighten the compression nut onto

the fitting.

Note: if the compression nut is overtightened, the fitting will not be airtight. After completing the installation,

check all the fittings for air leaks — see “System test.”

4. Tape the open end of the air line. Then, route the air

line from the male quick coupler to the break away air

reservoir, avoiding moving parts, sharp edges or “hot”

components such as the engine or the exhaust system.

Do not kink the air line, or bend it to the extent that it

crimps or creases.

Note: if the break away system was not installed,

route the air line through the engine compartment and

through the firewall — see step 7 below.

Do not position the air line closer than two feet

from any heat source. The heat will soften the plastic, which will cause the air line to rupture.

If the air line is ruptured, the supplemental braking system will not function.

Do not kink the air line, or bend it to the extent

that it crimps or creases — air pressure will be substantially reduced, or blocked entirely, at the kink

in the line.

If the air pressure is reduced, the supplemental

braking system will not function, or may only function intermittently.

Where appropriate, use wire ties to secure the air

line in place.

5. At the top of the break away air reservoir (Figure

11), cut the air line to length and attach the open end

to the brass “air in” compression fitting (Figure 11). Use

the same method described in step 3 (above) to attach

the air line.

6. Next, attach the end of another section of air line

to the brass “air out” compression fitting on the top of

the break away air reservoir (Figure 11 ). Use the same

method described in step 3 (above) to attach the air

line.

7. Tape the open end of the air line. Then, route the

air line from the break away air reservoir through the

engine compartment and to the driver’s side of the firewall. As before, avoid moving parts, sharp edges or

continued on next page

Figure 10

8

Figure 11

Page 11

INSTALL AIR LINES IN THE TOWED VEHICLE

continued from preceding page

“hot” components such as the engine or the exhaust

system. Do not kink the air line, or bend it to the extent

that it crimps or creases.

Where appropriate, use wire ties to secure the air

line in place.

8. Next, look for a pre-existing hole in the firewall (or,

if there is sufficient space, a pre-existing wiring grommet) on the driver’s side, to route the air line through

the firewall.

If there is no pre-existing hole or grommet with sufficient space, drill a ½" hole through the firewall.

Drill from the engine compartment or from the interior of the vehicle, whichever is more convenient.

Before drilling, make certain you will not damage any

components on the other side of the firewall.

9. Fit the included firewall grommet into the ½" hole,

and push the end of the air line through.

10. The air line will be connected to the preassembled

female quick coupler without the orange shield base

(Figure 12).

Find a likely mounting point for the bracket on the

driver’s side — choose an area within easy reach, with

a surface of sufficient strength to hold the mounting

bracket firmly in place.

The bracket and quick coupler must not present

an obstacle or hazard to the driver of the vehicle, or

otherwise interfere with the operation of the vehicle.

Two common mounting points are: 1) under the

dashboard, on the kick panel; or 2) far enough under

the front of the driver’s seat so that the quick coupler

is accessible when the seat is slid back, but concealed

when the seat is slid forward.

Or, depending on the interior design of the vehicle,

there may be a more suitable mounting point.

Before attaching the bracket, first connect the

BrakeMaster air cylinder assembly. Make certain that

the male quick coupler at the end of the air line will

reach the point you have chosen to attach the female

quick coupler, without kinking either of the air lines.

Note: the quick exhaust valve on the air cylinder

(see page 2) may be rotated, if this provides an easier

connection.

Before attaching the coupler, make certain you will

not damage any components on the other side.

If you have chosen to attach the bracket under the

driver’s seat, make certain that the female quick coupler

and bracket will not interfere with the normal movement

of the driver’s seat, or affect any adjustments to the

driver’s seat.

• If you have chosen to attach the bracket to the kick

panel, attach it with two of the supplied ¼" nuts and

bolts, with the female quick coupler pointing toward the

rear of the towed vehicle.

• If you have chosen to attach the bracket under the

driver’s seat, route the air line from the firewall to the

front edge of the driver’s seat. Remove the rocker panel

or side trim (or, detach the carpeting) and conceal the

air line underneath it.

Move the driver’s seat back, as far as it will go.

Attach the bracket with two of the supplied ¼" nuts

and bolts, with the female quick coupler pointing toward

the front of the vehicle.

11. Cut the air line to length and attach it to the com-

pression fitting on the female quick coupler. Use the

same method described in step 3 (above) to attach the

air line.

12. Seal the firewall grommet with a silicone sealant.

Reattach the rocker panel (or side trim or carpeting),

if it was removed.

13. Find a suitable location at the rear of the motorhome,

near the center, to attach the remaining preassembled

female quick coupler (with the orange shield base —

Figure 13). Attach the bracket with two of the supplied

¼" nuts and bolts, with the female quick coupler pointing away from the motorhome.

Note: the weather covers will prevent dirt or debris

from entering the lines. Keep the fittings covered when

the braking system is not in use.

TOWED VEHICLE MOTORHOME

Figure 12

Figure 13

9

Page 12

INSTALL THE MOTORHOME MONITOR SYSTEM

Step One

Wire the towed vehicle

Note: there are two lengths of black wire in this kit,

each with a female bullet connector at one end. Use

the short length of wire in this step.

1. Choose a mounting point at the front of the vehicle,

near the male quick coupler you attached in step 2,

“Install air lines in the towed vehicle,” for the end of

the harness with the female bullet connector. Attach the

connector with one or more of the included wire ties.

Allow enough slack so that a male bullet connector can

be plugged into and out of it.

2. Once the female bullet connector is attached, route

the monitor wiring harness through the engine compartment, to the driver’s side of the firewall. Use the same

route as the air line, if that is convenient. As before,

avoid lines, hoses, moving parts or “hot” components

such as the engine or exhaust systems. Where appropriate, use wire ties to secure the wiring harness

in place.

3. Route the monitor wiring harness through the same

hole as the air line.

4. Before connecting the monitor wiring harness to the

brake light wire, determine if the optional Brake-Lite

Relay must be installed — refer to “Brake light solutions,”

in these instructions, for information on how to identify

the type of brake and turn signals in the vehicle. Then,

test the towed vehicle’s brake lights, as described in

“Brake light solutions.”

Several wiring alternatives are available to you,

based on the type of brake and turn signals in the

vehicle, and the results of the test.

5. Next, locate the towed vehicle’s brake light switch

and, with a test light, find the “cold” side of the brake

light switch. (The “cold” side of the switch does not

register voltage unless the brakes are applied.) With a

12-volt meter, verify that you have found 12 VDC+.

Then, remove the vehicle’s brake light fuse, located in

the vehicle’s fuse panel.

Failure to remove the brake light fuse from the

vehicle’s fuse panel may cause the vehicle’s theft

deterrent system, or other electrical system indicators, to be activated if the brake pedal is depressed

during the installation. This may require non-warranty repair to the vehicle.

6. Cut the brake light wire, a few inches downstream

from the “cold” side of the brake light switch.

If the Brake-Lite Relay is required…

(see step 4, above)

Install the Brake-Lite Relay now. The instructions

are included with the kit. After the Brake-Lite Relay is

installed, proceed to Step Two, “Wire the motorhome”

(below).

If the Brake-Lite Relay is not required…

(see step 4, above)

7. If necessary, trim the monitor wiring harness, then

attach the monitor wire to the brake light wire, using

the supplied yellow butt connector.

8. Ensure that the monitor wiring harness will not pres-

ent an obstacle or hazard to the driver of the vehicle,

or interfere with the operation of the vehicle. Use one

or more wire ties, if necessary, to secure the wiring

harness out of the way.

9. Reinstall the brake light fuse, which you removed

in step 5.

continued on next page

10

Figure 14

Page 13

INSTALL THE MOTORHOME MONITOR SYSTEM

continued from preceding page

Step Two

Wire the motorhome

Note: there are two lengths of black wire in this kit,

each with a female bullet connector at one end. Use

the long length of wire in this step.

Note: some motorhomes are manufactured with auxiliary wires pre-strung from the rear of the motorhome

to the dashboard, for aftermarket accessories such as

this. Call the manufacturer.

1. Attach the end of the black wire with the female bullet connector to the back of the motorhome, near the

female quick coupler you attached in step 13, “Install

air lines in the towed vehicle.”

Attach the connector with one or more of the included wire ties. Allow enough slack so that a male

bullet connector can be plugged into and out of it.

2. Once the female bullet connector is attached, route

the wire from the back of the motorhome to the underside of the dashboard. Avoid lines, hoses, moving parts

(slideouts, sliding generators, sliding battery trays) or

“hot” components such as exhaust systems. Where

appropriate, use wire ties to secure the wire to the

undercarriage.

Step Three

Attach the LED

1. Choose an area on the motorhome dashboard to

mount the LED. Look for a mounting point away from

pre-existing wires or components, where the LED can

be easily seen by the driver.

2. Drill a 5/16" hole through the dashboard at the point

you have chosen. Before drilling, make certain you will

not damage any components on the other side.

3. Center the LED decal (Figure 15) over the hole, and

press it down. Or, you may choose to omit the decal,

depending on your preferences.

4. From the top of the dashboard, slide the LED through

the hole, wires first, until the base of the bulb (Figure

15) is flush to the top of the dash.

5. From the underside of the dash, fit both of the wires

through the speed nut (Figure 15). Then push the speed

nut up, against the dash, to secure the LED in place.

6. Connect to power — Trim the black wire, which you

routed from the back of the motorhome. (Save the excess; you may use it in the next step.) Then, connect

the black wire to the red LED wire, using one of the

included butt connectors.

7. Connect to ground — Connect the ground wire from

the LED to any good chassis ground, using the included

Figure 15

ring terminal. (If necessary, use any excess wire from

the preceding step to extend the length of the ground

wire.)

Step Four

Connect the patch cord between

the motorhome and the towed vehicle

Note: the patch cord is the six-foot length of air line

and wiring, covered in blue plastic loom.

1. Connect the male and female quick couplers at

either end of the air line to the corresponding quick

couplers on the motorhome and towed vehicle.

Push the couplers together until the housing (Figures

12 and 13) on the female coupler slides forward and

‘clicks,’ locking the couplers together.

(To disconnect the couplers, pull back on the housing on the female coupler until the couplers release.)

Never pull back on the housing to connect the couplers — this will prevent the couplers from locking. The

couplers may disconnect during towing, preventing

the supplemental braking system from functioning.

2. Connect the male bullet connectors at either end

of the monitor wire to the female bullet connectors on

the motorhome and towed vehicle monitor wiring harnesses.

11

Page 14

INSTALL THE MOTORHOME AIR LINE

There are three possible connection points for the

motorhome air line —

• If the motorhome has air brakes, the line can be

attached to an open port at the air brake relay valve.

• If the motorhome has air over hydraulic brakes, the

line can be attached to an open port at the main brake

air booster housing.

• If there is no open port, a tee must be used.

In this step, you will attach the motorhome air line

at one of these three points, then route it to the rear

of the motorhome.

1. Support and block the motorhome. Then, release

the parking brake.

The motorhome must be safely and securely sup-

ported and blocked.

With the parking brake released, the motorhome

may unexpectedly roll forward or backward, especially if it is on an incline, if it is not blocked.

If the motorhome is equipped with an air suspension system and a line to the air suspension system

is inadvertently opened, or if the motorhome’s air

suspension system is turned off, the motorhome

will lower to the ground.

Failure to follow these instructions may cause

property damage, personal injury or even death.

The motorhome’s parking brake must be released,

in order to test and identify the correct port.

If an incorrect port is chosen, the motorhome

brake system will be severely damaged. A brake fire

or other non-warranty damage may also occur.

2. Start the motorhome engine and allow the air brake

system to completely charge up to operating pressure.

3. If the motorhome has air brakes — find the air

brake relay valve (Figure 16), which is typically located

near the master cylinder. There should be one or more

open ports with threaded plugs (Figure 16).

If the motorhome has air over hydraulic brakes —

find the main brake air booster housing (Figure 17), which

is typically located near the front axle. There should be

an open plug (Figure 17) threaded into the air booster

housing.

4. Test to verify that you have located the correct port

(an assistant will be necessary for this test, to press and

release the motorhome brake pedal)…

The air brake system contains pressurized air,

which may cause severe eye or ear injury when it is

released. Wear appropriate eye and ear protection

before loosening any plugs, and while attaching the

air line.

5. First, slowly loosen the plug — do not remove it en-

tirely. Then instruct the assistant to depress the motorhome brake pedal several times. Pressurized air should

escape from the port each time the brake pedal is depressed.

If pressurized air is only released when the brake

pedal is depressed, you have located a port to attach the

BrakeMaster air line.

6. Turn the motorhome engine off. Remove the original

fitting from the port, and thread the appropriate-sized

fitting (½" and 3/8" fittings are provided) into the port.

Use a liquid Teflon® sealant to seal the pipe threads

(Do not use liquid Teflon on any compression fittings).

Proceed to step 8 (below).

7. If an open port is not available — Not all relay

valves or air booster housings will have an empty port

available. If this is the case, the BrakeMaster air line

continued on next page

12

Figure 17

Figure 16

Page 15

INSTALL THE MOTORHOME AIR LINE

continued from preceding page

must be connected with a tee to the service port at the

relay valve or air booster housing.

ROADMASTER manufactures tees for this purpose (Figure 18), in ½" (part number 450076) and 3/8"

sizes (part number 450077). Matching compression fittings are provided in the BrakeMaster kit.

The correct port should be identified as the “service

brake” port. First, with the motorhome brakes released,

disconnect the factory air line from the service port —

push down on the locking collar and then pull out. (If

the ports are not identified, follow steps 4 and 5 above

to identify the service port.)

Next, remove the factory fitting from the service

brake port.

Clean the factory fitting. Apply a liquid Teflon sealant to the threads on the male fitting of the new tee,

and thread it into the port. Use either one of the two

female fittings on the new tee to reinstall the factory

fitting, and then the factory air line.

Use the compression fitting provided with the ROADMASTER tee to attach the BrakeMaster air line to the

remaining female fitting. Use the same method described in step 3 under “Install air lines in the towed

vehicle” to attach the air line.

Proceed to step 9 (below).

Where appropriate, use wire ties to secure the air

line in place.

10. Connect the air line to the female quick coupler

at the rear of the motorhome. Use the same method

described in step 3 under “Install air lines in the towed

vehicle.”

11. The BrakeMaster installation is complete. Before the

supplemental braking system is operated for towing,

proceed to the next section — “System test.”

To finish the installation…

8. Now that the fitting is in place, connect one end of

the remaining length of air line to the fitting. Use the same

method described in step 3 under “Install air lines in the

towed vehicle.”

9. Tape the open end of the remaining length of air

line. Then, route the air line from the relay valve (or air

booster housing) to the female quick coupler at the rear

of the motorhome. As before, avoid moving parts, sharp

edges or “hot” components such as the engine or the

exhaust system. Do not kink the air line, or bend it to the

extent that it crimps or creases.

Do not position the air line closer than two feet

from any heat source. The heat will soften the plasic, which will cause the air line to rupture.

If the air line is ruptured, the supplemental braking system will not function.

Do not kink the air line, or bend it to the extent

that it crimps or creases — air pressure will be substantially reduced, or blocked entirely, at the kink

in the line.

If the air pressure is reduced, the supplemental

braking system will not function, or may only function intermittently.

Figure 18

13

Page 16

SYSTEM TEST

Always deplete the stored vacuum in the towed

vehicle’s power brake system before towing — pump

the brake pedal several times.

Depending on the make and model of the towed

vehicle, it may be necessary to pump the brake

pedal repeatedly to deplete the vacuum.

If the vacuum is not released, the supplemental

braking system will apply excessive braking force

when it is activated, which will cause severe tire

and/or brake system damage to the towed vehicle.

1. The motorhome and towed vehicle must be station-

ary for the system test, and ready for towing…

• Connect and attach the tow bar to the motorhome

and towed vehicle.

• According to the manufacturer, make all adjustments

necessary to prepare the vehicle for towing. These adjustments may include: turning the ignition key to the

“tow” position; pulling fuses; disconnecting the battery;

and setting the transmission to a particular gear or in

a particular sequence.

To prevent the towed vehicle from rolling, connect and attach the tow bar to both vehicles before

shifting the towed vehicle’s transmission into the

proper gear for towing.

• Connect the patch cord between the two vehicles

— both the air line quick couplers and the motorhome

monitor bullet connectors — see Step Four, “Connect the

patch cord between the motorhome and the towed vehicle,” under “Install the motorhome monitor system.”

• Attach the air cylinder to the brake pedal and mount-

ing post (or seat bracket adaptor) — see “Install the air

cylinder anchor plate.” Connect the male quick coupler

at the end of the air line on the air cylinder to the female

quick coupler at the end of the air line mounted in the

passenger compartment.

• Clip one end of the steel break away cable to the

break away pin (Figure 7); clip the other end of the

cable to the rear of the motorhome, close to the center.

2. Block the motorhome’s wheels, then release the

parking brake. Turn the motorhome engine on, and

leave it running.

3. After the air brake system is completely charged,

check for leaks in the air system: Have an assistant

apply the motorhome brakes and continue to hold the

brake pedal down.

Cover each joint, fitting and connection in the air

system with a leak check solution.

The air system now contains pressurized air,

which may cause severe eye or ear injury if it is

inadvertently released. Wear appropriate eye and

ear protection before adjusting the air system connections and fittings.

Tighten any fittings, if necessary, and repeat until

all connections are airtight.

4. Confirm the proper operation of the braking system:

depress and hold the motorhome brake pedal down.

At the towed vehicle, the air cylinder shaft and pedal

clamp will extend. Then, release the brake pedal. The

air cylinder shaft and pedal clamp will retract.

5. Confirm that the motorhome monitor is function-

ing: the LED will illuminate after the motorhome brake

pedal is depressed, and stop when the brake pedal is

released.

If the LED does not turn on and off as described

above, identify and correct the cause before using the supplemental braking system. Refer to the

Troubleshooting section for possible causes.

The LED is the only indication of braking activity at the motorhome. Severe damage to the towed

vehicle, a loss of vehicular control, or other consequential, non-warranty damage can occur if the

driver of the motorhome is unaware that the supplemental braking system is not functioning properly.

Failure to follow these instructions may cause

property damage, personal injury or even death.

6. Confirm the proper operation of the break away

system —

First, charge the break away air reservoir — with the

motorhome engine on, the air compressor completely

charged and the parking brake released, depress the

brake pedal for 15 seconds — apply firm pressure.

The break away air reservoir must be charged,

as described above, every time the motorhome and

towed vehicle are connected.

If the air reservoir is not charged, the break away

system will not apply braking pressure if the towed

vehicle separates from the motorhome, which may

cause property damage, personal injury or even

death.

continued on next page

14

Page 17

SYSTEM TEST

continued from preceding page

Next, remove the break away pin (Figure 7) at the

front of the break away switch. The air cylinder and

pedal clamp will extend, confirming the proper operation of the break away system.

To retract the air cylinder and pedal clamp, reconnect the break away pin.

Before towing, charge the break away air reservoir,

as described above.

7. Confirm the proper operation of the towed vehicle’s

brake lights and turn signals —

A. Depress the motorhome brake pedal; confirm

that the towed vehicle’s brake lights illuminate. Activate

both of the motorhome turn signals; confirm that the

towed vehicle’s turn signals activate.

If the towed vehicle’s brake lights and turn signals

do not operate in tandem with the motorhome’s, you

must install a non-intrusive lighting system or re-wire

the towed vehicle. See “Brake light solutions.”

B. With one of the motorhome turn signals acti-

vated, depress the motorhome brake pedal. Confirm

that the towed vehicle’s brake lights and turn signal

both illuminate.

If the towed vehicle’s brake lights override the turn

signal, you must install a non-intrusive lighting system

or re-wire the towed vehicle. See “Brake light solutions.”

By law, a towed vehicle’s turn signals and brake

lights must operate in tandem with the motorhome’s,

as described above. If they do not, drivers behind

the towed vehicle will not be alerted when the motorhome stops or turns, which may cause an accident.

If the towed vehicle’s brake lights and turn signals do not operate in tandem with the motorhome’s,

either install a non-intrusive lighting system or rewire the towed vehicle according to the next section, “Brake light solutions.” Then, test for proper

operation, as described in step 6, above.

Failure to follow these instructions may cause

property damage, personal injury or even death.

15

Page 18

BRAKE LIGHT SOLUTIONS

A supplemental braking system will affect the op-

eration of the vehicle’s tow lighting system. Use the

information below to determine if optional accessories

must be installed in a vehicle which has been wired for

towing — or, if no lighting system has been installed,

which systems are appropriate.

1. First, identify the type of brake and turn signals in

the vehicle. There are two types — combined or separate. In a combined system (Figure 19), the brake

light does the flashing for the turn signal; in a separate

system (Figure 19), there are amber or red turn signal

lights which are separate from the brake lights.

2. Next, test to see if the towed vehicle’s brake lights

will illuminate with the engine off — turn the ignition key

to the “tow” position, press the brake pedal, and check

the brake lights.

3. Based on whether or not the brake lights illuminate,

and the type of brake and turn signals, there are three

possibilities:

1) the brake lights illuminate and the towed vehicle

has combined lighting;

2) the brake lights illuminate and the towed vehicle

has separate lighting; or

3) the brake lights do not illuminate.

Choose from the appropriate list below to install

either an optional accessory or another lighting system.

(If you choose to install a Brake-Lite Relay, a taillight

wiring kit or magnetic lights, the installation instructions

are included with the kits. If you choose to install a

system of diodes and rewire the vehicle’s turn signals,

taillights and brake lights for towing, wiring diagrams

are available online, at www.roadmasterinc.com.)

1. If the brake lights illuminate and the

towed vehicle has combined lighting…

…one of the three alternatives below is required.

A. A system of diodes (the vehicle’s turn signals, tail-

lights and brake lights have been rewired for towing)

Figure 19

with an optional Brake-Lite Relay.

(This method cannot be used in Ford vehicles with

‘neutral tow’ kits. See “Ford ‘neutral tow’ vehicles,” in

these instructions.)

B. Install a “bulb and socket set” (also called a “taillight

wiring kit,” part number 155).

C. Install a magnetic tow light system (part number

2100 or 2120).

2. If the brake lights illuminate and the

towed vehicle has separate lighting…

…one of the four alternatives below is required.

A. A system of diodes (the vehicle’s turn signals, taillights and brake lights have been rewired for towing)

with an optional Brake-Lite Relay.

(This method cannot be used in Ford vehicles with

‘neutral tow’ kits. See “Ford ‘neutral tow’ vehicles,” in

these instructions.)

B. A system of diodes with the diodes jumped. This

method is also used to wire Ford vehicles with ‘neutral

tow’ kits. See Figure 21.

C. Install a “bulb and socket set” (also called a “taillight

wiring kit,” part number 155).

D. Install a magnetic tow light system (part number

2100 or 2120).

3. If the brake lights do not illuminate…

…an optional stop light switch must be installed.

ROADMASTER manufactures stop light switch kits for

a number of vehicles; visit www.roadmasterinc.com and

select ‘Vehicle-Specific Info,’ enter the vehicle make,

model and year, then select ‘Braking Systems’ and

scroll down the page.

Any one of the following tow lighting systems must

also be installed with the stop light switch:

• a system of diodes (the vehicle’s turn signals, taillights and brake lights have been rewired for towing)

• a “bulb and socket set” (also called a “taillight

wiring kit,” part number 155)

• a magnetic tow light system (part number 2100 or

2120)

16

Page 19

FORD ‘NEUTRAL TOW’ VEHICLES

Some Ford vehicles, such as the Explorer, are

equipped with a ‘neutral tow’ kit. Use the instructions

below to wire these vehicles for supplemental braking,

and for towing.

To wire the vehicle

for supplemental braking…

If BrakeMaster is to be installed in any Ford

vehicle with a ‘neutral tow’ kit, do not install a

Brake-Lite Relay. Using a Brake-Lite Relay in these

vehicles may prevent disengagement of the transmission for towing, causing severe damage to the

transmission.

Install a diode, rather than a Brake-Lite Relay,

according to the instructions below.

1. Locate the towed vehicle’s brake light switch and,

with a test light, find the “cold” side of the brake light

switch. (The “cold” side of the switch does not register

voltage unless the brakes are applied.) With a 12-volt

meter, verify that you have found 12 VDC+.

Then, remove the brake light fuse, located in the

vehicle’s fuse panel.

Failure to remove the brake light fuse from the

vehicle’s fuse panel may activate the vehicle’s theft

deterrent system, or other electrical system indicators, if the brake pedal is pressed during the

installation. This may require non-warranty repair

to the vehicle.

2. Next, cut the brake light wire, a few inches down-

stream from the “cold” side of the brake light switch.

3. Install the diode in line, as shown in Figure 20.

Mount the diode under the dashboard, a few inches

away from the brake light switch.

4. Reinstall the brake light fuse, which you removed

in step 1.

5. Test to verify that the diode has been properly in-

stalled — the towed vehicle’s brake lights will illuminate

when the brake pedal is pressed.

To wire the vehicle for towing…

There are three methods available which will allow

a towed vehicle’s turn signals, brake lights and running

lights to work in conjunction with the motorhome’s: 1)

install a taillight wiring kit (also called a ‘bulb and socket

kit,’ part number 155); 2) install magnetic tow lights

(part number 2100 or 2120); or 3) wire the vehicle’s

turn signals, taillights and brake lights for towing.

Instructions for the third method are below; instructions for the first two methods are included with the

kits.

1. After you have installed a diode downstream from

the brake light switch (Figure 20), wire the vehicle’s

turn signals, taillights and brake lights for towing by

installing six diodes.

Before installing the diodes, verify that the towed

vehicle has separate brake and turn signals — on each

side, there are amber or red turn signal lights which

are separate from the brake lights (Figure 19).

Note: if the motorhome has combined brake and

turn signals, use Figure 21 to wire the towed vehicle.

If the motorhome has separate brake and turn signals,

visit www.roadmasterinc.com. Use the ‘Separate towed

vehicle to ‘separate’ motorhome’ wiring diagram, under

‘Tech Support.’

Note: if a 3-to-2 converter has been installed in a

motorhome with separate brake and turn signals, wire

the towed vehicle according to Figure 21.

To test for a 3-to-2 converter, use a test light to find

the turn signal and brake light circuits on the motorhome

electrical socket. If the same circuit energizes both the

turn signals and the brake lights, a 3-to-2 converter

has been installed. If the turn signal and brake lights

continued on next page

Figure 20

17

Page 20

FORD ‘NEUTRAL TOW’ VEHICLES

continued from preceding page

have separate circuits, a 3-to-2 converter has not been

installed.

2. First, cut the factory turn signal, taillight and brake

light wires, as close to the lights as possible.

3. Next, install the six diodes in line, as close to the

lights as possible, as shown in Figure 21.

CAUTION

Attach the diodes as close to the vehicle’s lights

as possible, to avoid interaction with other circuits

which may be tied into the center brake light, the

running lights, the turn signals or the brake light

wires. Attaching the diodes farther away may cause

the towed vehicle’s lights to work improperly, and

may also cause damage to other electrical components in the vehicle.

4. On each side, jump the brake and turn signal diodes,

as shown in Figure 21.

CAUTION

Unless the brake and turn signal diodes are

jumped, the towed vehicle’s brake light circuits will

‘override’ the motorhome’s turn signals — the towed

vehicle’s turn signals will not operate in conjunction with the motorhome’s turn signals, as required

by law.

5. Test to verify that the diodes have been properly

installed…

A. If the motorhome has a ‘combined’ lighting system…

1. The towed vehicle’s turn signals and brake lights

will both flash (per side) when the motorhome’s turn

signal is on; and

2. When the motorhome’s turn signal and brake

signal are both on (per side), the towed vehicle’s brake

lights will stay illuminated, while the turn signal flashes.

B. If the motorhome has a ‘separate’ lighting system, the towed vehicle’s turn signals and brake lights

will illuminate identically to the motorhome’s.

Figure 21

18

Page 21

TROUBLESHOOTING

Symptom

The motorhome monitor LED does not illuminate,

even though the brakes in the towed vehicle are being

applied.

Solution

1. The monitor LED will not illuminate during very light

braking.

2. Make certain that the monitor patch cord is securely

connected between the two vehicles.

3. The towed vehicle-to-motorhome electrical cord

must also be connected — the monitor system uses it

for the ground wire.

4. The monitor LED is connected to the towed vehicle’s

brake light circuit. If the fuse in the circuit is blown,

the LED will not illuminate. Check the towed vehicle’s

brake lights — if they illuminate when the brake pedal

is depressed, the fuse is good.

5. Did you install the optional Brake-Lite Relay? If so,

make certain that the monitor wire is connected to the

towed vehicle’s brake light wire after the brake light

switch, but before the Brake-Lite Relay — connecting

the wire anywhere else will prevent the monitor LED

from functioning.

Symptom

Nothing happens after proper installation.

Solution

1. The motorhome engine must be running, and the

parking brake must be released. If the engine is off,

there may be insufficient air pressure to activate BrakeMaster. If the parking brake is on, pressurized air is

prevented from entering the BrakeMaster air lines.

2. Check the air line connections. Remove the weather

covers from the quick couplers at both vehicles, and

gently tug on the air line to verify that the quick couplers

are connected.

Check to make certain that the air cylinder quick

coupler is connected to the air line in the passenger

compartment.

3. Follow the air lines from the motorhome back to the

air cylinder in the towed vehicle. Inspect the entire line

for deformities caused by excessive heat, and/or kinks

in the line, which would restrict the air flow — replace

the entire section of air line if any are found.

Disconnect the quick couplers to confirm that they

are allowing air to flow through them.

Symptom

The BrakeMaster air cylinder will extend and depress

the towed vehicle’s brake pedal. However, it will not

retract when the motorhome brake pedal is released.

Solution

1. One of the air lines may be damaged or kinked.

Follow the air lines from the motorhome back to the air

cylinder in the towed vehicle. Inspect the entire line for

deformities caused by excessive heat, and/or kinks in

the line, which would restrict the air flow — replace the

entire section of air line if any are found.

2. Make certain that the air cylinder has been installed

directly in line with the brake pedal. If it is mounted at

an angle to the brake pedal (to one side or the other),

the air cylinder may jam in the extended position.

3. Dirt or debris can enter the air lines if the weather

covers are not used over the quick couplers. It may

accumulate at the quick exhaust valve (see page two)

on the air cylinder, preventing the valve from venting air

out of the air cylinder. Disassemble the quick exhaust

valve and make certain it is not jammed.

Symptom

The towed vehicle brakes abruptly the first time

BrakeMaster is activated, ‘flat-spotting’ the tires. Also,

after towing, there may be excessive brake dust on the

wheels of the towed vehicle, and/or an unusual odor

near the towed vehicle’s brakes.

Solution

1. The stored vacuum in the towed vehicle’s power

brake system must be depleted before towing — pump

the brake pedal several times. Depending on the make

and model of the towed vehicle, it may be necessary

to pump the brake pedal repeatedly.

Deplete the vacuum in the power brakes every time

the towed vehicle’s engine has been started — typically,

when the vehicle is connected for towing.

The engines in some vehicles, such as the Saturn

Vue, must be started periodically during towing. If the

towed vehicle’s engine must be started periodically,

always deplete the vacuum in the vehicle’s power brake

system before you resume towing.

Refer to the caution statement on page 14.

2. If the towed vehicle has an ‘active’ (or, ‘continuous

power assist’) braking system, order the optional Brake

Pressure Reducer (part number 900002) to adapt the

vehicle to the BrakeMaster system.

Vehicles with ‘active’ brake systems include several

hybrid vehicles, such as some models of the Ford Escape

hybrid and the Mercury Mariner hybrid, as well as the H3

Hummer. These vehicles, and others with ‘active’ braking

systems, are designed so that even when the ignition is

turned to the ‘tow’ position, the braking system is still

active.

If the Brake Pressure Reducer is not installed,

BrakeMaster will apply excessive force to the towed

vehicle’s brake pedal.

3. If the towed vehicle does not have power brakes,

order the optional Brake Pressure Reducer (part number 900002) to adapt the vehicle to the BrakeMaster

system.

BrakeMaster is designed to work with vehicles that

have a power brake system (even though the power

brakes are not activated while towing).

If the reducer is not installed, BrakeMaster will apply

excessive force to the towed vehicle’s brake pedal.

19

Page 22

VEHICLE-SPECIFIC COMPONENTS

Automatic Battery Disconnect

If you tow a Jeep Liberty, Jeep Wrangler or any other

vehicle which must be towed with the battery cable disconnected, install the Automatic Battery Disconnect (part

number 765).

Fully automatic ‘connect and forget’ operation eliminates

the necessity to disconnect the cable — the vehicle

can be towed, then disconnected and driven, without

any further adjustment to

the battery.

The Automatic Battery

Disconnect also provides:

1) a constant charged current to the battery while the

vehicle is being towed, preventing supplemental braking

systems or other aftermarket accessories from draining the

battery; and 2) a positive current source for break away

systems or other accessories which must be connected

to the battery.

• preassembled for easy installation

• marine-grade high-amperage solenoid and contacts

• 100% duty cycle

• extends battery life

• works on virtually all 12-volt batteries

Brake Pressure Reducer

With the Brake Pressure Reducer (part number 900002),

you can install BrakeMaster in a hybrid, a Hummer H3,

or in any vehicle with an

‘active’ (or, ‘continuous

power assist’) braking

system.

Working in conjunction with these braking

systems, the Brake Pressure Reducer delivers a

correspondingly reduced

braking pressure that

eliminates over-braking issues associated with these

hybrids and Hummers.

In addition to BrakeMaster, the Brake Pressure Reducer

will work in other supplemental braking systems which use

pressurized air to brake the towed vehicle.

Stop light switch kits

If a towed vehicle’s brake lights do not function, install

this stop light and 10-amp fuse. With the stop light switch

i n p l a c e ,

t h e t o w e d

v e h i c l e ’ s

brake lights

will work in

tandem with

the motorhome’s, and

the motorhome monitor will transmit accurate braking

information.

ROADMASTER manufactures stop light switch kits for

a number of vehicles; for the most current list, visit the

ROADMASTER website at www.roadmasterinc.com and

select ‘Products,’ ‘Supplemental Braking Systems,’ ‘Braking Accessories, and ‘Stop Light Switch Kits.’

Air line tees

If the motorhome's air brake relay valve (or air booster

can) does not have an open

port, use either a ½" tee (part

number 450076) or a 3/8"

tee (part number 450077)

to attach the BrakeMaster

air line.

Brake-Lite Relay

Necessary in the majority of towed vehicles, the

Brake-Lite Relay (part number 88400) allows the towed

vehicle’s brake lights and

turn signals to both work

in tandem with the motorhome’s, as required by

law.

20

Page 23

INDEX

‘Active’ braking systems ............................................ 1

Air cylinder

Adjustable arm ....................................................... 4

Anchor plate

Initial installation ............................................. 3-5

Parts list................................................................. 2

Air lines

Checking for leaks in the system ........................ 14

Connecting to compression fittings........................ 8

Brake lights, towed vehicle

Testing for proper operation ................................ 15

Wiring methods .................................................... 16

Brake light switch — test to find

“cold” side ............................................................ 10

Break away system

Connecting the break away cable ....................... 14

Air reservoir — choosing a mounting location ........ 6

Initial installation ................................................. 6-7

Testing ............................................................ 14-15

Combined brake and turn signal

lights — definition (Figure 18) ............................... 16

Compression fittings — connecting air lines to ........... 8

Couplers, connecting and disconnecting ................. 11

Ford “neutral tow” vehicles ................................. 17-18

Fuses

Removing from towed vehicle

prior to installation ............................................. 1

Removing brake light fuse

during motorhome monitor installation ............ 10

LED, motorhome monitor

Attaching during initial installation ....................... 11

Proper function .................................................... 14

Warning statement ............................................... 14

Magnetic tow lights .................................................. 16

Motorhome monitor — Initial installation .............. 10-11

“Neutral tow” kit, Ford — wiring instructions ........ 17-18

Patch cord — connecting between

motorhome and towed vehicle ............................. 11

Pedal clamp

Attaching ................................................................ 3

Tabs, adjusting....................................................... 3

Power brakes — releasing vacuum —

cautionary statement ........................................... 14

Quick couplers, connecting and disconnecting........ 11

Safety definitions ..............................inside front cover

Seat adaptor brackets — website address

to determine if one must be installed ................ 1, 3

Separate brake and turn signal

lights — definition (Figure 18) ............................... 16

System test ......................................................... 14-15

Taillight wiring system .............................................. 16

Vacuum, power brakes —

cautionary statement ........................................... 14

21

Page 24

“We get your towed car there,

while stopping safely along the way.”

All illustrations and specifications contained herein are

based on the latest information available at the time of publication. ROADMASTER, Inc. reserves the right to make

changes, at any time, without notice, in material, specifications and models, or to discontinue models.

Towing and Suspension Solutions

ROADMASTER, Inc. • 6110 NE 127th Ave. • Vancouver, WA 98682 • 800-669-9690 • fax 360-735-9300 • roadmasterinc.com

851809-10 01/10 © 2010 ROADMASTER, Inc.

Loading...

Loading...