Metal Oxide Film Resistors

Axial Connections

Metal Oxide Film Resistors 1/2W, 5% Components

High safety standard, high purity ceramic core

Excellent non-ame coang

Stable performance in diverse environment, meet EIAJ-RC2655A requirements

Too low or too high ohmic value can be supplied on a case to case basis

Solderability: 95%

Temperature Cycling: ±(2.0% +0.05Ω) Max, with no evidence of mechanical damage

Original package: 5000 pcs

D Max. 3.5 mm

L Max. 10 mm

PT 52 mm

SPECIFICATION:

Rated output 0.5 W

Tolerance ±5 %

Temperature coecient 350 ppm/°C

Rated voltage 400 V

Housing type Axial

PRODUCT RANGE:

Art. Nr. Resistance

RND 155MOR0W2J0101A10 100 Ω

RND 155MOR0W2J0102A10 1 kΩ

RND 155MOR0W2J010JA10 1 Ω

RND 155MOR0W2J0153A10 1.5 kΩ

RND 155MOR0W2J0182A10 1.8 kΩ

RND 155MOR0W2J0221A10 220 Ω

RND 155MOR0W2J0224A10 220 kΩ

RND 155MOR0W2J022JA10 2.2 Ω

RND 155MOR0W2J0333A10 33 kΩ

RND 155MOR0W2J0334A10 330 kΩ

RND 155MOR0W2J043JA10 4.3 Ω

RND 155MOR0W2J0473A10 47 Ω

RND 155MOR0W2J047JA10 4.7 Ω

RND 155MOR0W2J047KA10 0.47 Ω

RND 155MOR0W2J0503A10 50 kΩ

RND 155MOR0W2J050KA10 0.5 Ω

RND 155MOR0W2J0513A10 51 kΩ

RND 155MOR0W2J062KA10 0.62 Ω

RND 155MOR0W2J0680A10 68 Ω

RND 155MOR0W2J0682A10 6.8 kΩ

Distrelec Group AG, Grabenstrasse 6, 8606 Nänikon, Switzerland, T +41 44 944 99 11, info@distrelec.com, distrelec.com

1. Scope:

g

g

This specification for approval relates to Metal Oxide Film Fixed Resistors manufactured by

ROYALOHM 's specifications.

2. Type designation:

The type designation shall be in the following form :

(Ex.)

MOR 1/4W J 100Ω

Type Power Rating Resistance Nominal

3. Ratings:

Ratings shall be shown in the table 1.

Type

MO-25 0.25W 250 V 400 V 250 V

MO-50 0.50 W 250 V 400 V 250 V

MO-100 1 W 350 V 600 V 350 V

Normal

size

Small

size

MO-200 2 W 350 V 600 V 350 V

MO-300 3 W 500 V 800 V 500 V 5Ω--100KΩ

MO-500 5 W 750 V 1,000 V 750 V 5Ω--150KΩ

MO-700 7 W 750 V 1,000 V 750 V 20Ω--150KΩ

MO-800 8 W 750 V 1,000 V 750 V 30Ω--200KΩ

MO-900 9 W 750 V 1,000 V 750 V 50Ω--200KΩ

MO-50-S 0.50 W 250 V 400 V 250 V

MO-100-S 1 W 350 V 600 V 350 V

MO-200-S 2 W 350 V 600 V 350 V

MO-300-S 3 W 350 V 600 V 350 V

MO-500-SS 5 W 500 V 800 V 500 V 5Ω--100KΩ

MO-500-S 5 W 500 V 800 V 500 V 5Ω--150KΩ

Rated

Power

at 70℃

Table 1

Max.

Working

Volta

e

Max.

Overload

e

Volta

Tolerance Resistance

Dielectric

Withstanding

Resistance

Range

0.3--50K

0.3--50K

0.3--50K

0.3--50K

0.3--50K

0.3--50K

0.3--50K

0.3--50K

Operating Temp.

Range

-55℃ -- +155℃

3.1 Power rating:

Resistors shall have a power rating based on continuous full load operation at an

ambient temperature of 70 ℃. For temperature in excess of 70 ℃ , the load shall be

derated as shown in the figure 1.

3.2 Voltage rating:

Resistors shall have a rated direct-current (DC) continuous working voltage or an approximate

sine-wave root-mean-square (RMS) alternating-current (AC) continuous working voltage at commercialline frequency and waveform corresponding to the power rating , as determined from the

following formula :

RCWV = √P x R

Were : RCWV = Rated DC or RMS AC continuous working voltage at commercial-line frequency and

waveform (volt)

P = Power Rating (watt)

R = Nominal Resistance (ohm)

Page 1. 2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

In no case shall the rated DC or RMS AC continuous working voltage be greater

than the applicable maximum value.

Figure 1.

3.3 Nominal resistance :

Effective figures of nominal resistance shall be in accordance with E-24

series, and resistance tolerance shall be shown by table 1.

4. Construction :

No.

1 Basic Body Rod Type Ceramics

2 Resistance Film 0.1Ω ≤ R ≤ 12Ω : CNP film

Name Material

10Ω ≤ R ≤ 100kΩ : Metal oxide film

R > 100kΩ : Carbon film

3 End Cap Steel (Tin plated iron surface)

4 Lead Wire Annealed copper wire coated with tin

5 Joint By welding

Normal size:

6 Coating

7 Color Code Non-Flame epoxy resin

--Insulated & Non-Flame Paint (Color : Gray )

Small size:

--Insulated & Non-Flame Paint (Color : Sea-Blue )

Page 2. 2017/02/08--Version 1.

5. Characteristics :

Metal Oxide Film Fixed Resistors

Characteristics Limits

Test Methods

( JIS C 5201-1 )

Must be within the specified 5.1 The limit of error of measuring apparatus

DC. Resistance tolerance. shall not exceed allowable range or 5% of

resistance tolerance

5.2 Natural resistance change per temp.

Resis.Range T.C.R. (PPM/℃)

Temperature 0.1Ω ~ 12Ω

coefficient 12.1Ω ~ 100K R

101K ~ 1M R

1.1M ~ 10M

±200

±350

-700

-1500

Resistance change rate is 5.5 Permanent resistance change after the

Short time

Normal Size : ± (1% + 0.05Ω) Max.

overload Small Size : ± (2% + 0.05Ω) Max. or the max. overload voltage respectively specified

degree centigrade.

R

2-R1

6

x 10

1(t2-t1)

1: Resistance value at room temperature (t1)

R

2: Resistance value at room temp. plus 100 ℃ (t2)

(PPM/℃)

application of a potential of 2.5 times RCWV

with no evidence of mechanical damage in the above list, whichever less for 5 seconds

Dielectric No evidence of flashover 5.7 Resistors shall be clamped in the trough

withstanding mechanical damage, arcing or of a 90° metallic V-block and shall be tested at

voltage insulation break down AC potential respectively specified in the table 1.

for 60 + 10/ -0 seconds

6.1 Direct load :

Resistance to a 2.5 kgs direct load for 10 secs.

in the direction of the longitudinal axis of the

terminal leads

Terminal With no evidence of mechanical

Twist test :

strength damage Terminal leads shall be bent through 90 ° at

point of about 6mm from the body of the

resistor and shall be rotated through 360°

about the original axis of the bent terminal in

alternating direction for a total of 3 rotations

2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

Characteristics Limits

Test Methods

( JIS C 5201-1 )

Resistance change rate is 6.4 Permanent resistance change when leads

Resistance to

soldering heat evidence of mechanical damage

Solderability 95 % coverage Min. from concentrated pinholes.

Resistance to No deterioration of protective trichroethane completely for 3 minutes with

solvent coatings and markings ultrasonic

Temperature Resistance change rate is

cycling

± (1% + 0.05Ω) Max. with no

± (2% + 0.05Ω) Max.

with no evidence of mechanical 2 Room temp.

damage 3

immersed to 3.2 mm to 4.8 mm from the body

in 350℃ ± 10 ℃ solder for 3 ± 0.5 seconds

6.5 The area covered with a new , smooth

clean , shiny and continuous surface free

Test temp. of solder : 245℃ ± 3℃

Dwell time in solder : 2 ~ 3 seconds

6.9 Specimens shall be immersed in a bath of

7.4 Resistance change after continuous

5 cycles for duty shown below:

Step

1

4 Room temp.

Temperature Time

-55℃ ± 3℃

+155℃ ± 2℃

30 mins

10~15 mins

30 mins

10~15 mins

7.9 Resistance change after 1,000 hours

Load life in

humidity

Load life

Pulse overload Normal Size : ± (2% + 0.05Ω) Max. (1 second "on", 25 seconds "off" ) at 4 times

Resistance value

Less than 100KΩ

100KΩ or more test chamber controlled at 40 ℃ ± 2 ℃

Resistance value

Less than 100KΩ

100KΩ or more 70℃ ± 2℃ ambient

Resistance change rate is 5.8 Resistance change after 10,000 cycles

Small Size : ± (5% + 0.05Ω) Max. with no

evidence of mechanical damage RCWV or the max. pulse overload voltage

△R/R

± 5 %

± 10 %

△R/R

± 5 %

± 10 %

operating at RCWV with duty cycle of

(1.5 hours "on", 0.5 hour "off") in a humidity

and 90 to 95 % relative humidity

7.10 Permanent resistance change after

1,000 hours operating at RCWV with duty

cycle of (1.5 hours "on", 0.5 hour "off") at

Page 4. 2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

6. Dimension : Unit : mm

Normal size

Part No. Style

MOR0W4 MOR-25 1/4W (0.25W) 2.5 7.5 0.54 28

MOR0W2 MOR-50 1/2W (0.50W) 3.5 10 0.54 28

MOR01W MOR-100 1W 5 12 0.70 25

MOR02W MOR-200 2W 5.5 16 0.70 28

MOR03W MOR-300 3W 6.5 17.5 0.75 28

Power Rating at

70 ℃

D (Max.) L (Max.) H ± 3

Dimension (mm)

d ± 0.05

MOR05W MOR-500 5W 8.5 26 0.75 38

MOR07W MOR-700 7W 8.5 32 0.75 38

MOR08W MOR-800 8W 8.5 41 0.75 38

MOR09W MOR-900 9W 8.5 54 0.75 38

Small size

Part No. Style

MOR0S2 MOR-50-S 1/2W (0.50W) 2.5 7.5 0.54 28

MOR01S MOR-100-S 1W 3.5 10 0.54 28

MOR02S MOR-200-S 2W 5 12 0.70 25

MOR03S MOR-300-S 3W 5.5 16 0.70 28

MOR05U MOR-500-SS 5W 6.5 17.5 0.75 28

MOR05S MOR-500-S 5W 8 25 0.75 38

Power Rating at

70 ℃

D (Max.) L (Max.) H ± 3

Dimension (mm)

d ± 0.05

Painting method:

Welding point, terminal and lead wire, is permissible to be exposed without the outer coated cover.

The extent should be within 1/2 of the are angle.

2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

7. Marking :

7.1 For MO 1/4W, 1/2W, 1W, 2W, 3W, 5W and all of small size

Resistors shall be marked with color coding

colors shall be in accordance with JIS C 0802

7.2 For MO 7W, 8W, 9W

Code description and regulation

1. Wattage rating.

Nominal resistance value.

2.

3. Resistance Tolerance.

G : ± 2 %

J

: ± 5 %

K : ± 10 %

7.3 Label :

Label shall be marked with following items:

(1) Type and style

(2) Nominal resistance

(3) Resistance tolerance

(4) Quantity

(5) Lot number

(6) PPM

Example :

Metal Oxide Film Fixed Resistors

Watt : 1/4W Val : 100R

Q'TY : 5,000 Tol : 5%

Lot : 702312 PPM :

ROYALOHM

Pb Free

2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

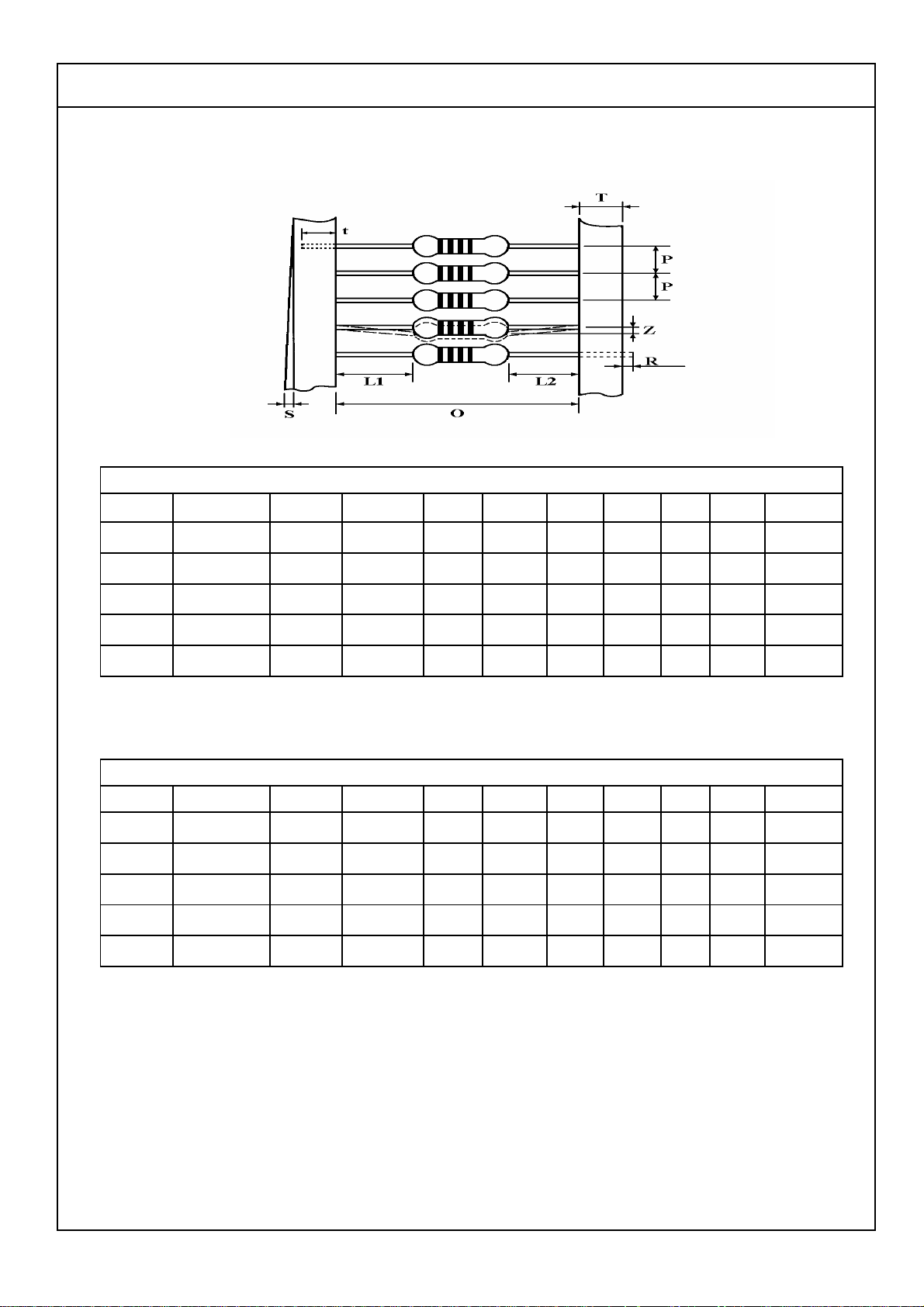

8. Packing specification :

8.1 Taping dimension :

Dimensions (mm)

Normal size

Part No. Style Style O P L1-L2 T Z R t S

MOR0W4 MOR-25 PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR0W2 MOR-50 PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR01W MOR-100 PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR02W MOR-200 PT-64 64 ± 1 10 ± 0.5 1 Max. 6 ± 1 1 Max. 0 5 ± 1 0.5 Max.

MOR03W MOR-300 PT-64 64 ± 1 10 ± 0.5 1 Max. 6 ± 1 1 Max. 0 5 ± 1 0.5 Max.

Small size

Part No. Style Style O P L1-L2 T Z R t S

MOR0S2 MOR-50-S PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR01S MOR-100-S PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR02S MOR-200-S PT-52 52 ± 1 5 ± 0.3 1 Max. 6 ± 1 1 Max. 0 4 ± 1 0.5 Max.

MOR03S MOR-300-S PT-64 64 ± 1 10 ± 0.5 1 Max. 6 ± 1 1 Max. 0 5 ± 1 0.5 Max.

MOR05U MOR-500-SS PT-64 64 ± 1 10 ± 0.5 1 Max. 6 ± 1 1 Max. 0 5 ± 1 0.5 Max.

2017/02/08--Version 1.

8.2 Tape in box packing :

Dimension (mm)

Metal Oxide Film Fixed Resistors

Bandoliers may also be

contained in a cardboard

box ("Ammopack")

Part No. Style Style

MOR0W4 MOR-25 PT-52 250 75 96 5,000

MOR0W2 MOR-50 PT-52 260 85 70 1,000

MOR01W MOR-100 PT-52 262 86 80 1,000

MOR02W MOR-200 PT-64 262 92 108 1,000

MOR03W MOR-300 PT-64 256 92 80 500

Part No.

MOR0S2 MOR-50-S PT-52 250 75 96 5,000

MOR01S MOR-100-S PT-52 260 85 70 1,000

MOR02S MOR-200-S PT-52 262 86 80 1,000

MOR03S MOR-300-S PT-64 262 92 108 1,000

Style

Style

L (C) W (A) H (B)

±5 ±5 ±5

L (C) W (A) H (B)

±5 ±5 ±5

Quantity Per

Box (pcs.)

Quantity Per

Box (pcs.)

MOR05U MOR-500-SS PT-64 256 92 80 500

"Ammopack" is an abbreviation of "ammunition pack"

2017/02/08--Version 1.

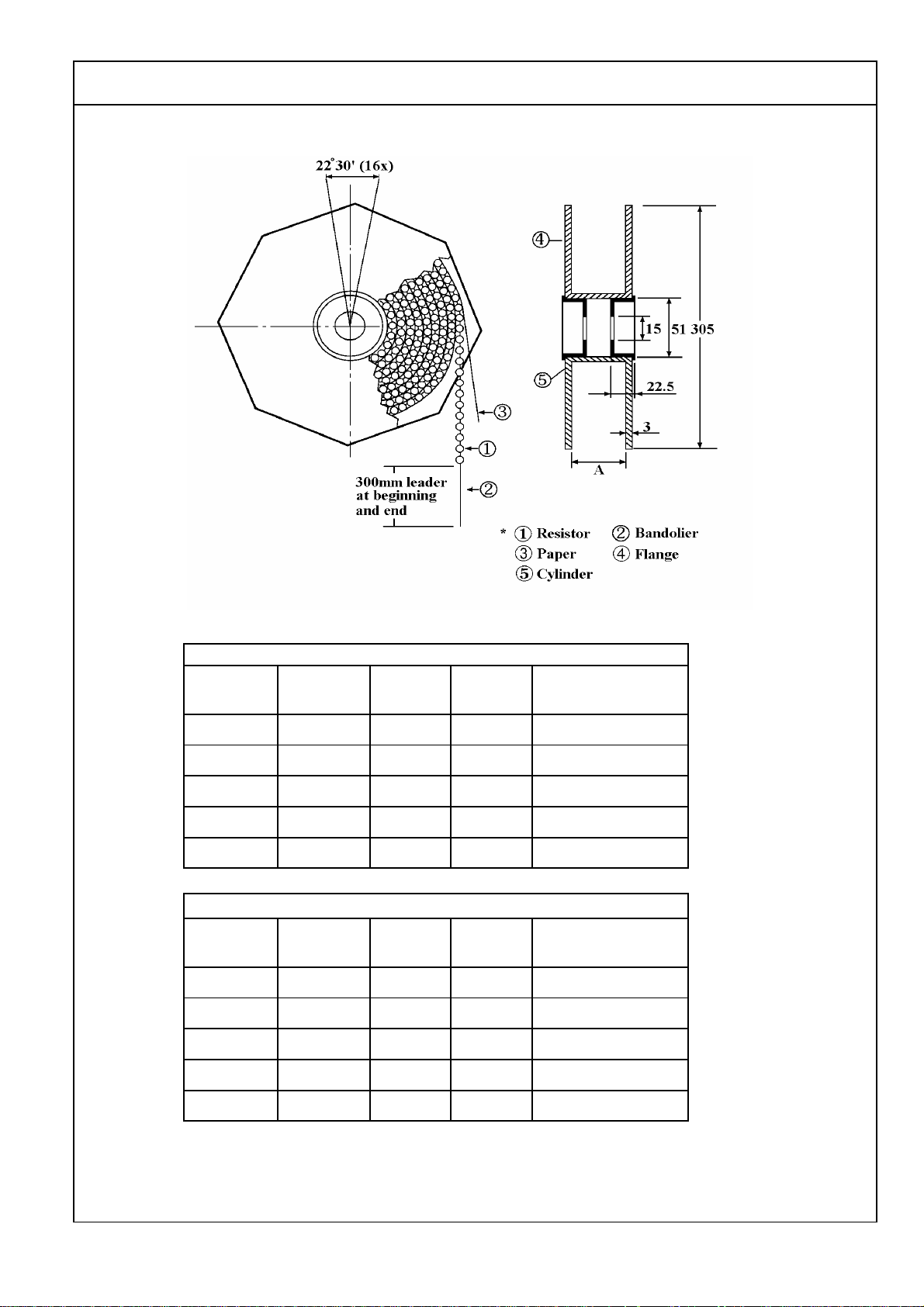

8.3 Tape on reel packing :

Metal Oxide Film Fixed Resistors

Dimension (mm) :

Normal size

Part No. Type

MOR0W4 MOR-25 PT-52 73 ± 2 5,000

MOR0W2 MOR-50 PT-52 73 ± 2 2,500

MOR01W MOR-100 PT-52 73 ± 2 2,500

MOR02W MOR-200 PT-64 81 ± 5 1,000

MOR03W MOR-300 PT-64 81 ± 5 500

Style

Across

Flange (A)

Quantity Per Reel

Small size

Part No. Type

MOR0S2 MOR-50-S PT-52 73 ± 2 5,000

MOR01S MOR-100-S PT-52 73 ± 2 2,500

MOR02S MOR-200-S PT-52 73 ± 2 2,500

MOR03S MOR-300-S PT-64 81 ± 5 1,000

Style

Across

Flange (A)

Quantity Per Reel

MOR05U MOR-500-SS PT-64 81 ± 5 500

2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

8.4 Bulk in inner box packing ( in plastic bag )

Inner Box of Plastic bag.

Dimension : Unit : mm

Q'ty /

Part No.

MOR07W MOR-700 8 32 3,200 150 x 75 x 33 392 x 515 x 283 18

MOR08W MOR-800 10 300 1,800 200 x 171 x 113 520 x 215 x 250 13

MOR09W MOR-900 10 300 1,800 200 x 171 x 113 520 x 215 x 250 15

Type

Q'ty /

Bag (pcs.)

Inner

Box

(pcs.)

Q'ty /

Carton

(pcs.)

Inner Box Size

L x W x H (±5)

Carton Box

Carton Box Size

L x W x H (±5)

Gross Wt.

± 2 Kgs.

2017/02/08--Version 1.

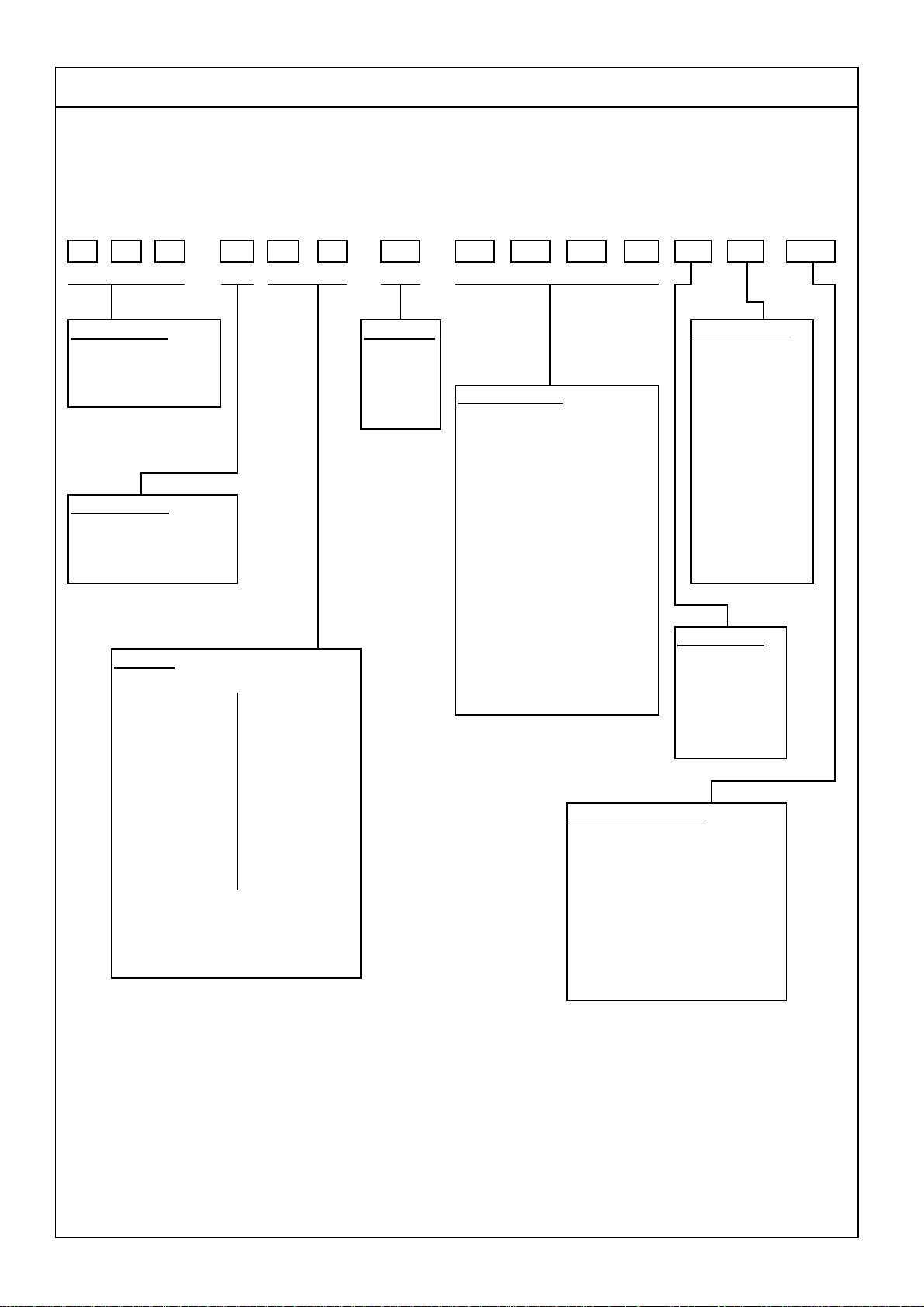

Part Number System

Explanation of Part Number System

(Metal Oxide Film Fixed Resistors)

123 5 6 11

MO R W 4 1

Product Type: Tolerance:

MOR = Metal Oxide Film

Fixed Resistor

Special Feature:

0 = Standard Product "J" ~ 0.1, "K" ~ 0.01 D = 20,000pcs

I = Non-Inductive Product

Wattage:

Normal size: Small size:

W4 = 1/4W S2 = 1/2W-S

W2 = 1/2W 1S = 1W-S

1W = 1W 2S = 2W-S

4 7 8 9 10 12 13

0 J 010 A5 0

Packing Quantity:

F ~ ± 1%

G ~ ± 2%

J ~ ± 5%

K ~ ± 10%

Resistance Value:

E-24 series: the 1

E--96 Series: the 1

nd

the 2

the significant figures of the A = 500pcs

resistance and the 4

the number of zeros following: C = 10,000pcs

Ex.: 4.7Ω ~ 47J, 4.7KΩ ~ 472

are significant figures of

resistance and the fourth

one denotes number of zeros

following: A = Tape/Box

Ex.: 1.33KΩ = 1331

st

digit is"0",

& 3rd digits are for

th

indicate

st

to 3rd digits

1 = 1,000pcs

2 = 2,000pcs

3 = 3,000pcs

4 = 4,000pcs

5 = 5,000pcs

B = 2,500pcs

0 = for Bulk/Box

packing

Packing Type:

T = Tape/Reel

B = Bulk/Box

P = Tape/Box of

PT-26mm

2W = 2W 3S = 3W-S

3W = 3W 5S = 5W-S

5W = 5W

7W = 7W

8W = 8W

9W = 9W

Extra Small size:

5U = 5W-SS

Addition Information:

0 = PT-52mm, NIL for PT-26mm

8 = PT-58mm

9 = PT-64mm

7 = Lead wire(H) 38mm

A = PT-83mm

C = PT-73mm

D = PT-71mm

14

Sample:

MO 1/4W +/- 5% 100Ω T/B 5,000 PT-52mm → MOR0W4J0101A50

2017/02/08--Version 1.

Metal Oxide Film Fixed Resistors

Environment Related Substance

This product complies to EU RoHS directive, EU PAHs directive, EU PFOS directive and Halogen free.

Ozone layer depleting substances.

Ozone depleting substances are not used in our manufacturing process of this product.

This product is not manufactured using Chloro fluorocarbons (CFCs), Hydrochlorofluorocarbons (HCFCs),

Hydrobromofluorocarbons (HBFCs) or other ozone depleting substances in any phase of the manufacturing process.

Storage Condition

The performance of these products, including the solderability, is guaranteed for a year from the date

of arrival at your company, provided that they remain packed as they were when delivered and stored

at a temperature of 25°C ± 10°C and a relative humidity of 60%RH ± 10%RH, chemical and dust free atmosphere

Even within the above guarantee periods, do not store these products in the following conditions.

Otherwise, their electrical performance and/or solderability may be deteriorated, and the packaging materials

(e.g. taping materials) may be deformed or deteriorated, resulting in mounting failures.

1. In salty air or in air with a high concentration of corrosive gas, such as Cl

2. In direct sunlight

, H2S, NH3, SO2, or NO

2

2

2017/02/08--Version 1.

Loading...

Loading...