Page 1

RND Components Thick Film SMD Resistors

Resistor Assortments, SMD, E24, RND

RND 1550402WGFE024KIT in size 0402 1% tolerance

RND 1550402WGJE024KIT in size 0402 5% tolerance

RND 1550603SAFE024KIT in size 0603 1% tolerance

RND 1550603SAJE024KIT in size 0603 5% tolerance

RND 1550805S8FE024KIT in size 0805 1% tolerance

RND 1550805S8JE024KIT in size 0805 5% tolerance

RND 1551206S4FE024KIT in size 1206 1% tolerance

RND 1551206S4JE024KIT in size 1206 5% tolerance

Thick film SMD Resistors, 0402, RND

RND 1550402WGF0000TCE…

Thick film SMD Resistors, 0603, RND

RND 1550603SAJ0000T5E…

Thick film SMD Resistors, 0805, RND

RND 1550805S8J0000T5E…

Thick film SMD Resistors, 1206, RND

RND 1551206S4J0000T5E…

RND components 2016

Page 2

1.0 Scope:

ǃ

ˣ

烉

ɗ

This specification for approve relates to the Lead-Free Thick Film Chip Resistors manufactured

2.0 Ratings & Dimension:

0201

0402

0603

0805ˣ1206ˣ1210ˣ1812ˣ2010ˣ2512

2.1 Dimension & Resistance Range

Type

0201 1/20W 0.60±0.03

0402 1/16W 1.00±0.10

0603

0805

1206

1210

70

Power

1/16W

1/10WS

1/10W

1/8WS

1/8W

1/4WS

1/4W

1/3WS

1/2WSS

L W H A B 0.5% 1.0% 2.0% 5.0%

1.60±0.10

2.00±0.15

3.10±0.15

3.10±0.10 2.60±0.20 0.55±0.10

Dimension(mm) Resistance Range

0.30±0.03

0.50±0.05

+0.15

0.80

-0.10

+0.15

1.25

-0.10

+0.15

1.55

-0.10

0.23±0.03 0.10±0.05 0.15±0.05 -- 1¡-10M¡ 1¡-10M¡ 1¡-10M¡

0.35±0.05 0.20±0.10

0.45±0.10 0.30±0.20 0.30±0.20 1¡-10M¡ 0.1¡~33M¡ 0.1¡~33M¡ 0.1¡~100M¡

0.55±0.10 0.40±0.20

0.55±0.10 0.45±0.20 0.45±0.20 1¡-10M¡ 0.1¡~33M¡ 0.1¡~33M¡ 0.1¡~100M¡

0.50±0.25

0.25±0.10 1¡-10M¡ 0.1¡~22M¡ 0.1¡~22M¡ 0.1¡~22M¡

0.40±0.20

0.50±0.20 1¡-10M¡ 0.1¡~10M¡ 0.1¡~22M¡ 0.1¡~100M¡

1¡-10M¡ 0.1¡~33M¡ 0.1¡~33M¡ 0.1¡~100M¡

1812

2010

2512 1W 6.35±0.10 3.20±0.20

1/2W

3/4WS

1/2W

3/4WS

4.50±0.20 3.20±0.20

5.00±0.10 2.50±0.20 0.55±0.10

0.55±0.20

0.55±0.10

0.50±0.20 0.50±0.20 1¡-10M¡ 0.1¡-10M¡ 0.1¡-10M¡ 0.1¡-10M¡

0.60±0.25

0.60±0.25 0.50±0.20 1¡-10M¡ 0.1¡~33M¡ 0.1¡~33M¡ 0.1¡~33M¡

0.50±0.20 1¡-10M¡ 0.1¡~22M¡ 0.1¡~22M¡ 0.1¡~22M¡

Page 2016/03/02--Version: 1

Page 3

2.2 Ratings

ɗ

DŽ

DŽ

DŽ

Type

Power

70

Max

Working

Voltage

Max

Overload

Voltage

Dielectric

withstanding

Voltage

Resistance

Value of

Jumper

Rated

Current of

Jumper

Rated

Max

Current of

Jumper

Operating

Temperature

0201 1/20W 25V

0402 1/16W 50V

0603

0805

1206

1210

1812

2010

1/16W

1/10WS

1/10W

1/8WS

1/8W

1/4WS

1/4W

1/3WS

1/2WSS

1/2W

3/4WS

1/2W

3/4WS

75V 150V 300V <50m¡ 1A 2A -55ć~155ć

150V 300V 500V <50m¡ 2A 5A -55ć~155ć

200V 400V 500V <50m¡

200V 500V 500V

200V 500V

200V 500V 500V

50V

100V

-- <50m¡ 0.5A 1A -55ć~155ć

100V <50m¡

<50m¡

500V

<50m¡ 2A 10A -55ć~155ć

<50m¡

1A 2A -55ć~155 ć

2A

2A 10A -55ć~155ć

2A 10A -55ć~155ć

10A -55ć~155ć

2512 1W 200V 500V

3.0 Structure:

500V

<50m¡ 2.5A 10A -55ć~155ć

Page 2016/03/02--Version: 1

Page 4

4.0 Marking:

(1) For 0201 and 0402 size. Due to the very small size of the resistor’s body, there is no marking on the

body.

Example:

0201ǃ0402

(2) Ʋ2%,r5%Tolerance:The first two digit s are significant figures of resistance and the third denotes number of

zeros following

Example:

333 o 33K:

(3) Ʋ2%ˣr5%Tolerance: Below 10: show as following, read alphabet”R” as decimal point.

Example:

2R2 o 2.2:

(4) Ʋ0.5%ˣr1% Tolerance: 4 digits, first three digits are significant; forth digit is number of zeros. Letter r is decimal

point.

2701 o 2.7K: 10R0 o 10:

(5) standard E-24 and not belong to E-96 series values(in Ʋ0.5%ˣƲ1%tolerance)of 0603 size the marking is the

same as 5% tolerance but marking as underline

333 o 33K: 680 o 68:

(6) Product below 1ȟ,show as following, the first digit isȾRȿwhich as decimal point.

R300o0.3ȟ

(7) Standard E-96 series values (Ʋ0.5%ˣ±1% tolerance) of 0603 size. Due the small size of the resistor’s body, 3

digits marking will be used to indicate the accurate resistance value by using the following multiplier &

resistance code.

Multiplier code:

Code A B C D E F G H X Y Z

Multiplier 10

Coding formula

0

101 102 103 104 105 106 107 10-1 10-2 10

-3

First two digits------------Resistance code Third digit-------------------Multiplier code

Page 2016/03/02--Version: 1

Page 5

EXAMPLE: 1.96K:=196u101:------29B 12.4:=124u10-1:-----10X

:

:

:

:

STANDARD E-96 VALUES AND 0603 RESISTANCE CODE

VALUE CODE

100 01 178 25 316 49 562 73

102 02 182 26 324 50 576 74

105 03 187 27 332 51 590 75

107 04 191 28 340 52 604 76

110 05 196 29 348 53 619 77

113 06 200 30 357 54 634 78

115 07 205 31 365 55 649 79

118 08 210 32 374 56 665 80

121 09 215 33 383 57 681 81

124 10 221 34 392 58 698 82

127 11 226 35 402 59 715 83

130 12 232 36 412 60 732 84

133 13 237 37 422 61 750 85

137 14 243 38 432 62 768 86

140 15 249 39 442 63 787 87

143 16 255 40 453 64 806 88

147 17 261 41 464 65 825 89

150 18 267 42 475 66 845 90

154 19 274 43 487 67 866 91

158 20 280 44 499 68 887 92

162 21 287 45 511 69 909 93

165 22 294 46 523 70 931 94

169 23 301 47 536 71 953 95

174 24 309 48 549 72 976 96

VALUE CODE

VALUE CODE

VALUE CODE

(8) 0ȟMarking:

Normally for 0201 and 0402 size, no marking on the body:

Normally, the making of 0: 0603, 0: 0805, 0: 1206, 0: 1210, 0: 1812, 0: 2010, 0: 2512 resistors as

following

Page 2016/03/02--Version: 1

Page 6

5.0 Derating Curve:

Resistors shall have a power rating based on continuous load operation at an ambient temperature from -55ɗ to

70ć. For temperature in excess of 70ć, the load shall be derate as shown in figure 1

Figure 1

5.1 Volt age rating:

Resistors shall have a rated direct-current (DC) continuous working

Voltage or an approximate sine-wave root-mean-square (RMS) alternating-current (AC) continuous working

voltage at commercial-line frequency and waveform corresponding to the power rating, as determined from the

following formula:

RCWV =

Where: RCWV commercial-line frequency and waveform (Volt.)

P = power rating (WATT.) R = nominal resistance (OHM)

In no case shall the rated DC or RMS AC continuous working voltage be greater than the applicable

maximum value.

The overload voltage is 2.5 times RCWV or Max. Overload voltage whicheve r is l ess.

R Pu

6.0 Performance Specification:

Characteristic Limits

0201:

1:ูR10:: r400PPM/ɗ

>10:: r200PPM/ɗ

0402~2512:

˖Temperature

Coefficient

Provided Specially:

˖ Short-time

overload

0.1:ูR烋1ȍ: r800PPM/qC

1:ูRู10:: r400PPM/qC

10:<Rู100:: r200PPM/qC

100ȍ<R<10M:: r100PPM/qC

10MȍʀRู100Mȍ: ±200PPM/qC

0603:1ȍ~10ȍ:r200PPM/qC

0805,1206:1ȍ~10ȍ:r100PPM/qC

Ʋ0.5%,r1% Ʋ(1%+0.1ȟ)

Ʋ2%,r5% Ʋ(2%+0.1ȟ)

<50mȍ Apply max Overload current for 0ȟ

Test Method

(JIS-C-5201& JIS-C-5202)

4.8 Natural resistance changes per temp. Degree centigrad e

R

2-R1

ǘ 10

R

1(T2-T1

)

R1: Resistance value at room temperature. (T

R2: Resistance value at room temp. plus 100ɗ (T

6

(PPM/ɗ)

)

1

)

2

4.13 Permanent resistance change after the application of a

potential of 2.5 times RCWV for 5 seconds.

ī Dielectric

withstanding

voltage

No evidence of flashover mechanical

damage, arcing or insulation breaks

down.

Page 2016/03/02--Version: 1

4.7 Resistors shall be clamped in the trough of a 90ɗ

metallic v-block and shall be tested at ac potential

respectively specified in the given list of each product type

for 1 minute.

Page 7

˖ġ īSolderability 95% coverage Min.

4.17 Test temperature of solder: 245ɗ±3ɗ dipping time in

solder: 2-3 seconds.

Wave soldering condition:

(2 cycles Max.)

Pre-heat: 100~120 ,30±ɗ 5 se c.

Suggestion solder temp.: 235~255 ,10ɗ sec. (Max.)

Peak temp.: 260ɗ

Reflow soldering condition:

(2 cycles Max.)

Pre-heat:150~180 ,90~120ɗ sec.

Suggestion solder temp.: 235~255 ,20~40ɗ sec.

Peak temp.: 260ɗ

Soldering temp

reference

˖!Temperature

cycling

Electrical characteristics shall be

satisfied. Without distinct deformation

in appearance.

Ʋ0.5%,r1%

(95 % coverage Min.)

Ʋ(0.5%+0.05 :)

Ʋ2%,r5% Ʋ(1.0%+0.05 :)

Hand sol

dering condition:

The soldering iron tip temperature should be less than

300 and maximum contract time should be 5 sec.ɗ

4.19 Resistance change after continuous five cycles for duty

cycle specified below:

Step Temperature Time

1-55ɗƲ3ɗ 30 mins

2 Room temp. 10 --- 15 mins

3+155ɗƲ2ɗ 30 mins

4 Room temp. 10 --- 15 mins

˖!Soldering

heat

Terminal

bending

ī Insulation

resistance

˖!Humidity

( steady state )

˖ *Load life

in humidity

Resistance change rate is:

Ʋ(1.0%+0.05ȟ)

Ʋ(1.0%+0.05ȟ)

1,000 Mȟ or more

Ʋ0.5%,r1% Ʋ(0.5%+0.1:)

Ʋ2%,r5% Ʋ(3.0%+0.1:)

Ʋ0.5%,r1% Ʋ(1.0%+0.1:)

Ʋ2%,r5% Ʋ(3.0%+0.1:)

4.18 Dip the resistor into a solder bath having a temperature

of 260ɗr5ɗ and hold it for 10s1 seconds.

4.33 Twist of test board:

4.6 The measuring voltage shall be ,measured with a direct

voltage of (100Ʋ15)V or a voltage equal to the dielectric

withstanding voltage., and apply for 1min

4.24Temporary resistance change after 240 hours exposure

in a humidity test chamber controlled at 40±2ɗ and 90-95%

relative humidity,

7.9 Resistance change after 1,000 h ours (1.5 ho urs “ON”,0.5

hour “OFF”) at RCWV in a humidity chamber controlled at

40ɗƲ2ɗ and 90 to 95% relative humidity.

<50mȍ Apply to rated current for 0ȟ

˖ *Load life

Ʋ0.5%,r1% Ʋ(1.0%+0.1:)

Ʋ2%,r5% Ʋ(3.0%+0.1:)

4.25.1 Permanent resistance change after 1,000 hours

operating at RCWV with duty cycle 1.5 hours “ON”, 0.5 hour

“OFF” at 70ɗƲ2ɗ ambient.

<50mȍ Apply to rated current for 0ȟ

The resistors of 0ȟ only can do the characteristic noted of *

The resistors of 0201 only can do the characteristic noted of ˖

Y/x = 3/90 mm for 60Seconds

Page 2016/03/02--Version: 1

Page 8

7.0 Explanation of Part No. System: 51'

The standard Part No. includes 14 digits with the following explanation:

st ~4th

7.1 1

digits

This is to indicate the Chip Resistor.

Example: 0201, 0402,0603,0805,1206,1210,2010,1812,2512

7.2 5th~6th digits:

7.2.1 This is to indicate the wattage or power rating. To dieting the size and the numbers,

The following codes are used; and please refer to the following chart for detail:

W=Normal Size; S=Small Size; U= Ultra Small Size; Ⱦ1ȿ~ȾGȿto denotesȾ1ȿ~Ⱦ16ȿas

Hexadecimal:

1/16W~1W:

Wattage 1/32 3/4W 1/2 1/3 1/4 1/8 1/10 1/16 1/20W 1

Normal Size WH 07 W2 W3 W4 W8 WA WG WM 1W

Small Size / 07 S2 S3 S4 S8 SA SG / 1S

7.2.2 For power rating less or equal to 1 watt, the 5th digit will be the letters W or S to represent the

size required & the 6th digit will be a number or a letter code.

Example: WA=1/10W; S4=1/4W-S

7.3 The 7th digit is to denote the Resistance Tolerance. The following letter code is to be used for

indicating the standard Resistance Tolerance.

D=Ʋ0.5% F=Ʋ1% G=Ʋ2% J=Ʋ5% K= Ʋ10%

7.4 The 8th to 11th digits is to denote the Resistance Value.

7.4.1 For the standard resistance values of 5%&10% series, the 8th digit is Ⱦ0ȿ,the 9th & 10th

digits are to denote the significant figures of the resistance and the 11th digit is the number of zeros

following;

For the standard resistance values of 2% series in, the 8th digit to the 10th digits is to denote the

significant figures of the resistance and the 11th digit is the zeros following.

7.4.2 The following number s and the letter codes are to be used to indicate the number of zeros in the

11th digit:

0=10

0

1=101 2=102 3=103 4=104 5=105 6=106 J=10-1 K=10-2 L=10

-3

M=10-4

7.4.3 The 12th, 13th & 14th digits.

The 12th digit is to denote the Packaging Type with the following codes:

C=Bulk in (Chip Product) T=Tape/Reel

7.4.4 The 13th digit is normally to indicate the Packing Quantity of Tape/Reel packaging types. The

following letter code is to be used for some packing quantities:

4=4000pcs 5=5000pcs C=10000pcs D=20000pcs E=15000pcs

Chip Product: BD=B/B-20000pcs TC=T/R-10000pcs

7.4.5 For some items, the 14th digit alone can use to denote special features of additional information

with the following codes:

E= For ȾEnvironmental Protection, Lead Free typeȿ.

S= Provided Specially.

Page 2016/03/02--Version: 1

Page 9

8.0

Ʋ

Ȝ

Ordering Procedure:

0 8 0 5 W 8 J 0 4 7 4 T 5 E

(Example: 51'0805 1/8W

5% 470KȟT/R-5000)

Product Type:

Digits with chip

resistor types

as follows:

0201

0402

0603

0805

1206

1210

1812

2010

2512

Wattage:

Normal size:

WH=1/32W

WM=1/20W

WG=1/16W

WA=1/10W

W8=1/8W

W4=1/4W

W2=1/2W

1W=1W

Small size:

SA=1/10WS

S8=1/8WS

S4=1/4W-S

S3=1/3WS

U2=1/2WSS

07=3/4W-S

Toler a n c e :

D=±0.5% F=±1%

G=±2% J=±5%

Resistance Value:

5% series:

The 1st digit will be

“0”;the2

for the significant figures of

the resistance and the 4

digit indicate the numbers

of zeros following.

0.5%ˣ1%ˣ2%series:

The 1st to 3

the significant figures of the

resistance and 4th digit

denotes number of zeros

following.

J=10

nd

& 3rd digits are

rd

digits are for

-1

; K=10-2; L=10-3

Packing Type:

T=Tape/Reel

th

Packing

quantity:

1=1000PCS

2=2000PCS

3=3000PCS

4=4000PCS

5=5000PCS

C=10000PCS

D=20000PCS

The amount of

packaging

product type,

please refer to

Special Feature:

E= Lead Free

S= Provided Specially

9.0 Packaging:

9.1 Tapping Dimension:

Unit: mm

+0.1

Type A B CƲ0.05

0201 0.40Ʋ0.05 0.70Ʋ0.05 2.00 1.50 1.75 3.50 4.00 8.00 0.42

0402 0.65Ʋ0.20 1.15Ʋ0.20 2.00 1.50 1.75 3.50 4.00 8.00 0.45

D

-0

EƲ0.1 FƲ0.05 GƲ0.1 WƲ0.2 TƲ0.1

Page 2016/03/02--Version: 1

Page 10

Unit: mm

Ȝ

I

I

˖

+0.1

Type A Ʋ0.2 B Ʋ0.2 CƲ0.05

0603 1.10 1.90 2.00 1.50 1.75 3.50 4.00 8.00 0.67

0805 1.65 2.40 2.00 1.50 1.75 3.50 4.00 8.00 0.81

1206 2.00 3.60 2.00 1.50 1.75 3.50 4.00 8.00 0.81

1210 2.80 3.50 2.00 1.50 1.75 3.50 4.00 8.00 0.75

D

-0

EƲ0.1 FƲ0.05 GƲ0.1 WƲ0.2 TƲ0.1

Unit: mm

+ 0.1

Type Ar0.2 Br0.2 Cr0.05

1812 3.50 4.80 2.00 1.50 1.50 1.75 5.50 4.00 12.00 1.00

2010 2.90 5.60 2.00 1.50 1.50 1.75 5.50 4.00 12.00 1.00

2512 3.50 6.70 2.00 1.50 1.50 1.75 5.50 4.00 12.00 1.00

9.2 Peeling Strength of Top Cover Tape

D

- 0

Test Condition: 0.1 to 0.7 N at a peel-off speed of 300 mm / min.

+0.1

D1

Er0.1 Fr0.05 Gr0.1 Wr0.2 TƲ0.1

-0

Page 2016/03/02--Version: 1

Page 11

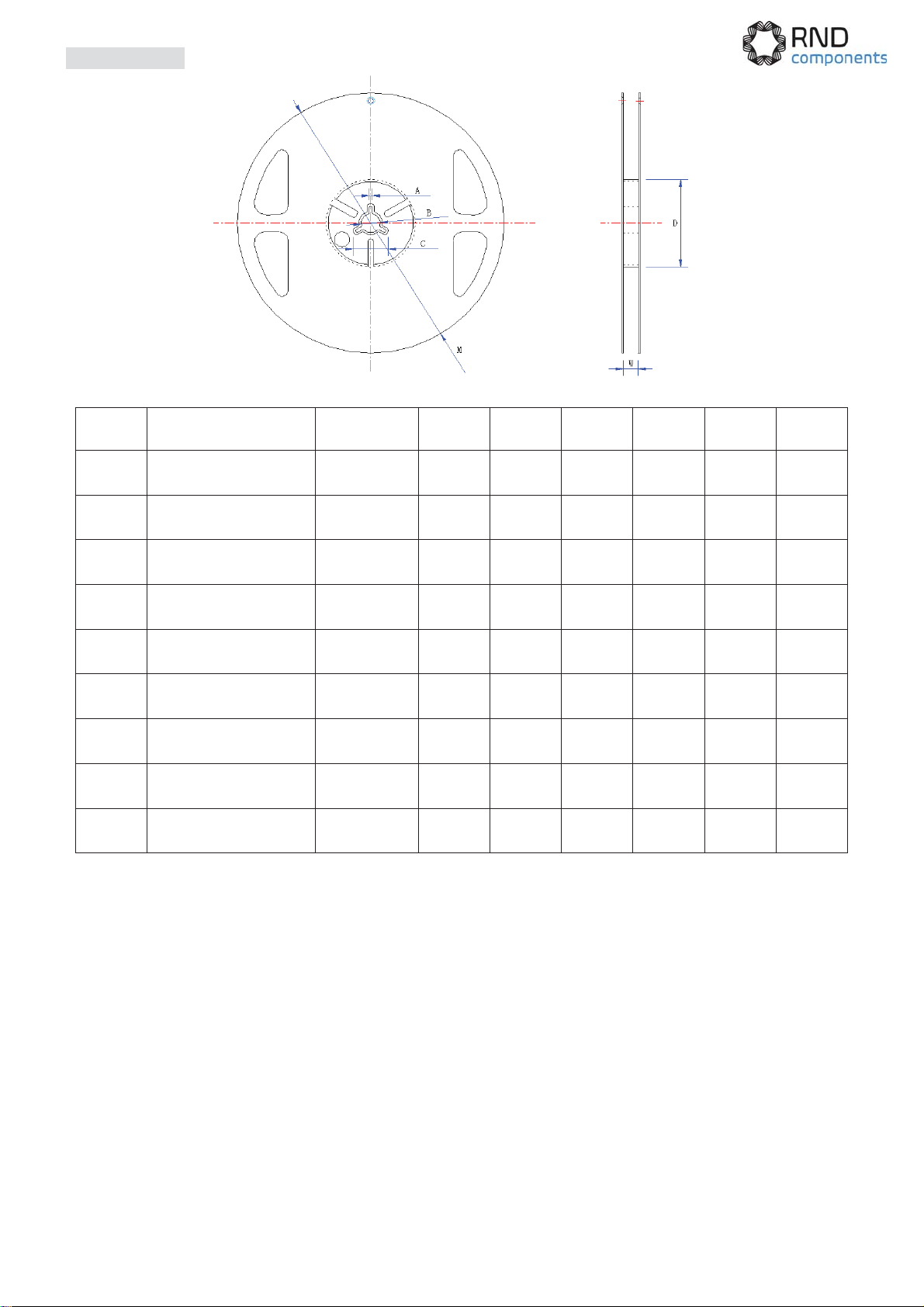

9.3 Dimension:

r

Unit: mm

Type Taping Qty/Reel

0201 Paper 10,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

0402 Paper 10,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

0603 Paper 5,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

0805 Paper 5,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

1206 Paper 5,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

1210 Paper 5,000pcs 2.0 13.0 21.0 60.0 178.0 10.0

2010 Paper or Embossed 4,000pcs 2.0 13.0 21.0 60.0 178.0 13.8

1812 Embossed 4,000pcs 2.0 13.0 21.0 60.0 178.0 13.8

2512 Embossed 4,000pcs 2.0 13.0 21.0 60.0 178.0 13.8

0.5 Br0.5 Cr0.5 Dr1 Mr2 Wr1

A

Page 1 2016/03/02--Version: 1

Page 12

10.0: Note Matter

˖

10.1 Environment Related Substance.

This product complies to EU RoHS directive, EU PAHs directive, EU PFOS directive and

Halogen free.

10.2 Ozone layer depleting substances.

Ozone depleting substances are not used in our manufacturing process of this product.

This product is not manufactured using Chloro fluorocarbons (CFCs), Hydrochlorofluorocarbons

(HCFCs), Hydrobromofluorocarbons (HBFCs) or other ozone depleting substances in any phase

of the manufacturing process.

10.3 Storage Condition

The performance of these products, including the solderability, is guaranteed for a year from the

date of arrival at your company, provided that they remain packed as they were when delivered

and stored at a temperature of 5ɗ~35ɗand a relative humidity of 25%~75%RH.

Even within the above guarantee periods, do not store these products in the following

conditions.Otherwise, their electrical performance and/or solderability may be deteriorated, and

the packaging materials (e.g. taping materials) may be deformed or deteriorated, resulting in

mounting failures.

1. In salty air or in air with a high concentration of corrosive gas, such as Cl2, H2S, NH3, SO2,

or NO2.

2. In direct sunlight.

10.4 The products are used in circuit board thickness greater than 1.6mm. If customers use less than

the thickness of the circuit board that you should confirm with the company, in order to

recommend a more suitable product.

Page 1 2016/03/02--Version: 1

Loading...

Loading...