Ultrasonic Flowmeter USM GT400

OPERATING INSTRUCTION

Reliable Measurement of Gas

Read the instructions before starting work!

Manufacturer Our customer service is available for technical queries:

Address RMG Messtechnik GmbH

Otto-Hahn-Str. 5

D-35510 Butzbach

Telephone Switchboard +49 6033 897-0

Telephone Service +49 6033 897-0

Telephone Spare Parts +49 6033 897-173

Fax +49 6033 897-130

E-Mail service@rmg.com

Original Document

Note

The Ultrasonic Flowmeter USM GT400

OPERATING INSTRUCTION 9/4/2018 is the origi

This document may serve as a reference for transla

nal document.

tions into

other languages. Please use in case of any uncertainties the

German version as main reference.

Unfortunately, paper is not updated auto

matically, whereas

technical development continuously advances. Therefore, we

reserve the right to make technical changes in r

representations and specificatio

ns of these operating

egard to the

instructions. The latest version of this manual (and other devices)

downloaded at your convenience from our Internet home-

can be

page:

www.rmg.com

Date created 1/31/2014

1st revision date

2nd revision date

5/12/2014

9/18/2015

9/29/2017

2/16/2018

09/04/2018

September, 4

th

2018

Document version and language

3rd revision date

4th revision date

5th revision date

Document version Ultrasonic Flowmeter USM GT400

Language EN

I Ultrasonic Flowmeter USM GT400 September, 4

th

2018

Contents

1 About this manual

1.1 Objective of the manual ........................... 1

1.2 Specialized knowledge required .............. 2

1.3 Abbreviations ........................................... 2

1.4 Symbols ................................................... 3

1.5 Validity of the manual .............................. 3

2 Brief instructions

2.1 Mechanical connection ............................ 5

2.2 Electrical connection................................ 6

2.3 Start Up.................................................... 7

2.4 Earthing ................................................... 7

2.5 Parameter setting .................................... 8

3 Device overview

3.1 Main components .................................... 9

3.2 Ultrasonic electronics............................. 11

3.3 Arrangement of the

ultrasonic transducers............................ 15

4 Functional principle - Ultrasonic flow

measurement

8 Installation

8.1 Assembly work preparations ................. 78

8.2 Installation of the device........................ 80

8.3 Connecting the device electrically ......... 84

8.4 Installing the pressure connec

8.5 Outdoor installation.............................. 114

tion....... 112

9Start Up

9.1 Comparing meter parameters.............. 115

9.2 Checking functions of the USM ........... 115

9.3 Reading out speed of sound................ 116

10 Operation

10.1 Measuring values and parameters ...... 118

10.2 Calling up and changing the parameters

via the ultrasonic electronic

10.3 Parameterize the USM i

10.4 Modbus communication in detail ......... 141

10.5 List of the measure

parameters .......................................... 143

ment values and

s ............... 121

nterface ......... 131

11 Maintenance

4.1 General description................................ 17

4.2 Correction of the base line..................... 21

4.3 Diagnostic function Speed of Sound...... 24

4.4 Import of gas compositi

4.5 Batch mode............................................ 36

on data.............. 27

5 Safety

5.1 Intended use .......................................... 37

5.2 Layout of instructions............................. 38

5.3 Qualification of the personnel ................ 39

5.4 Safety instructions ................................. 39

5.5 Responsibilities of the operator ...

.......... 46

6 Transport and storage

6.1 Transport ............................................... 47

6.2 Packing the device for transportation

6.3 Storage .................................................. 62

.... 55

7 Construction and Planning

7.1 Connection flanges ................................ 65

7.2 Seals...................................................... 66

7.3 Screws ................................................... 70

7.4 Installation possibilities .......................... 71

7.5 Flow computer ....................................... 75

11.1 Maintenance schedule......................... 146

11.2 Checking the device for leaks

11.3 Checking the device for any signs of

damage................................................ 147

11.4 Changing the battery .

11.5 Changing the transducer

11.6 Changing the ultrasonic elect

11.7 Cleaning the device ............................. 148

11.8 Check the official seal.......................... 149

11.9 Decommissioning and disposal ........... 149

.......................... 147

.............. 146

..................... 147

ronics..... 148

12 Alarm and warning messages

12.1 Alarm messages.................................. 151

12.2 Warning messages...........

12.3 Notes ................................................... 157

12.4 Troubleshooting................................... 157

................... 154

13 Technical specifications

13.1 Performance data................................ 160

13.2 Approved gas types ............................ 160

13.3 Approved measuring range according

to MID.................................................. 161

13.4 Type plate............................................ 162

13.5 Weights and dimensions ..................... 163

September, 4th 2018 Ultrasonic Flowmeter USM GT400 II

Contents

13.6 Inner diameter of connecting

spool pieces......................................... 168

13.7 Official seal diagram ............................ 169

13.8 Transducer types

14 USM GT400 Approval

14.1 Metrological approvals......................... 177

14.2 Pressure devices approval .

14.3 Electromagnetic compatibility ..............177

14.4 Explosion protection approval.............. 177

14.5 Standards, directives and guidelines... 178

15 Index

16 USM GT400 Glossary

17 USM GT400 Attachment

................................. 175

................. 177

18 Lists of parameters and measured

values

III Ultrasonic Flowmeter USM GT400 September, 4th 2018

1 About this manual

1

1.1

About this manual

In this chapter you will be given information on this manual.

Contents 1.

1.1 Objective of the manual ...................................... 1

1.2 Specialized knowledge required

1.3 Abbreviations

1.4 Symbols

1.5 Validity of the manual

Objective of the manual

....................................................... 2

................................................................ 3

........................ 2

.......................................... 3

The manual provides you with the information that is designed for

trouble-free and safe operation.

The ultrasonic gas meter is state of the

manufactured according to the recognized safety standards and

guidelines.

However, risks may arise during us

by observing this manual..

For this reason, you may only use the device as intended and in

cally sound condition.

techni

If the ultrasonic gas meter is not used for it

warranty claims will be void.

art and conceived and

e that can be easily avoided

s intended purpose,

September, 4th 2018 Ultrasonic Flowmeter USM GT400 1

1 About this manual

1.2

Specialized knowledge required

Persons working with or on the device must have the following

knowledge:

• training /

environments.

• the ability

the device. Possible dangers are, e.g., components under

pressure or the result of incorrect installation.

• r

ecognize dangers that could be cau

medium.

• training /

instruments.

• education / instruc

directives to be observed for work that is to be carried out on

the device.

Further information can be found under:

Chapter 5.3, „Qualification of the personnel“ on page 39

education for wo

to correctly ass

education b

tion in all c

rking in potentially explosive

ess dangers and risks when using

sed by the used flow

y RMG for working with gas measuring

ountry-specific standards and

1.3

Abbreviations

The following abbreviations are used:

AGC Automatic Gain Control

ca. circa, approximately

as app. as applicable

max. maximum

MC Measurement Canada

MID Measurement Instruments Directive

min. minimum

SNR Signal to Noise Ratio

SoS Speed of Sound

TD Transducer (ultrasonic transmitter and

receiver)

TNG Transducer of a certain production type.

USE Ultrasonic electronics

USM Ultrasonic gas meter

e.g. For example

2 Ultrasonic Flowmeter USM GT400 September, 4th 2018

1 About this manual

1.4

Symbols

The following symbols are used:

1, 2, ... Marks steps within a work operation.

Marks steps in an illustration that are

described in the text.

(A) Reference to a component (element) marked

with a letter in an illustration.

Marks elements in an illustration. The arrow

points to the element being described.

Print Screen Marks switches, regulators, slides, buttons

Marks a cross-reference that refers to

another part in this manual or in another document.

and other terms from the software are

marked by bold text.

1.5

Validity of the manual

This manual describes the Ultrasonic Flowmeter USM GT400.

The Ultrasonic Flowmeter USM GT400 d

complete on site system. Observe also the instructions of other

components of the site system.

If you find contradicting instructions

evice is only a part of a

, please contact RMG.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 3

1 About this manual

4 Ultrasonic Flowmeter USM GT400 September, 4th 2018

2 Brief instructions

2

2.1

Brief instructions

This chapter does not replace the rest of the operating instructions. It shows only a brief section of t

to make the device ready for operation.

The chapter is only directed at experienced users.

• Observe the chapter safety.

Section 5, "Safety" on

Detailed information for this content can be found under:

Section 7, "Construction and Planning" on page 65

Section 8, "Installation" on page 77

Section 9, "Start Up" on page 115

Section 12.4, "Troubleshooting" on page 157

Mechanical connection

page 37

he steps necessary in order

2.1.1

2.1.2

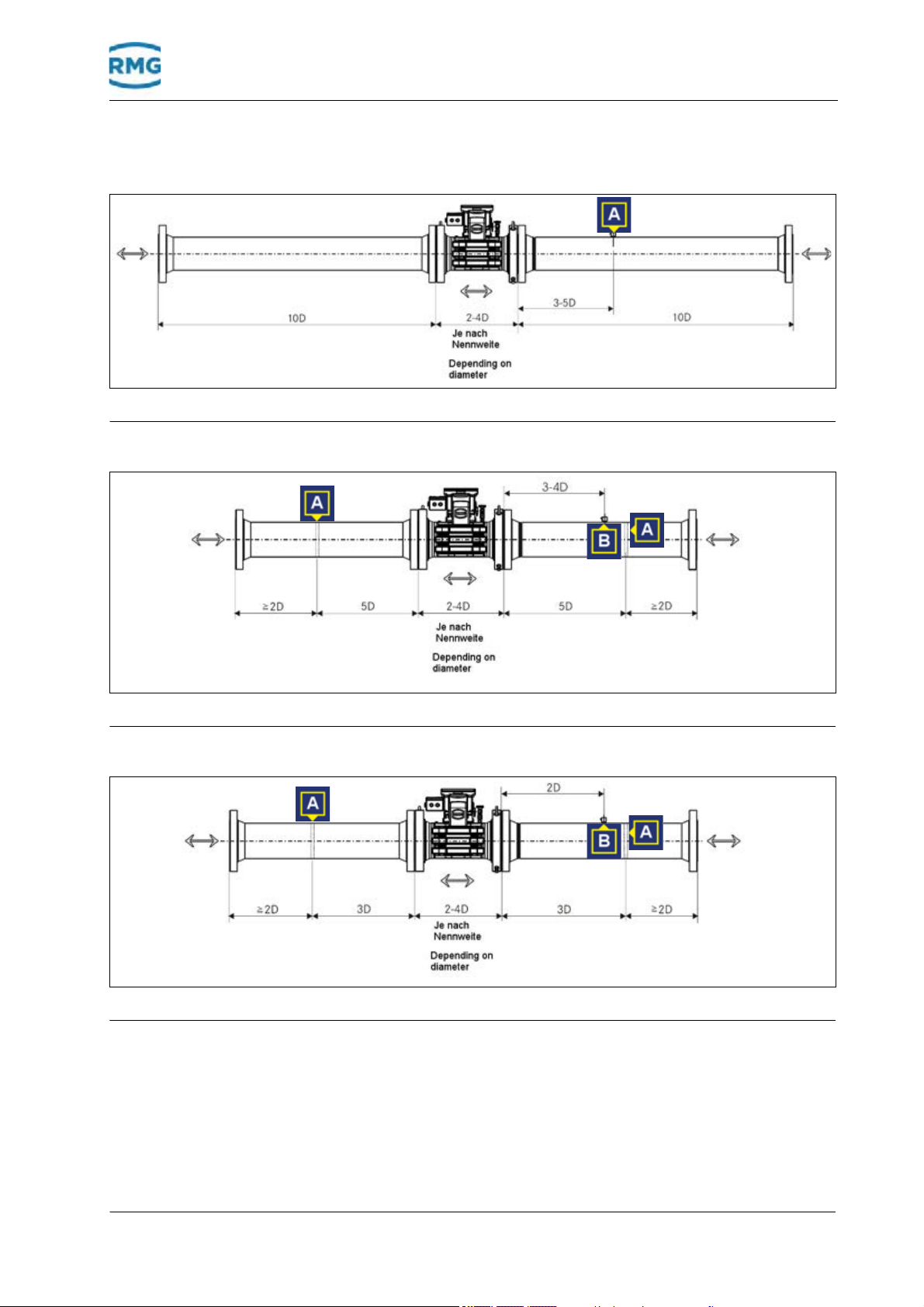

Operating mode Inlet piping Outlet piping Temperature sensor

Unidirectional operation 10 D (no flow conditioner) 3 D 1.5 D to 5 D

Unidirectional operation 3 / 5 D (with RMG or stan-

Bidirectional operation 10 D (no flow conditioner) 10 D (no flow conditioner) 3 D to 5

Bidirectional operation 3 / 5 D (with RMG or stan-

1 Depending on the nominal width.

Connection flanges

1 Make sure that the device and the connection flange have

the same pressure rating / flange standards.

2 Make sure that the device is sealed with the appropriate

seals.

Inlet / outlet piping

dardized flow conditioner)

dardized flow conditioner)

1

1

position

3 D 1.5 D to 5 D

D

3 / 5 D (with RMG or standardized flow conditioner)

1

2 D to 5 D

1

–See also "Inner diameter of connecting spool pieces" on

page 168

September, 4th 2018 Ultrasonic Flowmeter USM GT400 5

2 Brief instructions

2.1.3

2.2

Joining pressure connections

Establish connection with the clamping screw connec-

tion

3 Unscrew the union nut of the clamping screw connection.

4 Remove the blind plug.

5 Push the union nut and clampin

6 Push the pipe into the clamping screw con

stop.

7 Tighten the union nut in order to fix and seal t

Establish connection with the female thread

8 Unscrew

9 Seal the connection in the thread.

the blind plug.

Electrical connection

g ring

s onto the pipe.

nection until the

he pipe.

Fig. 2-1: Connection assignment on the terminal strip

10 Connect the computer to the terminals RS 485-0.

11 Allocate the terminal strips according to the applications.

Option: connect ERZ 2000 (-NG) to RS 485-1.

6 Ultrasonic Flowmeter USM GT400 September, 4th 2018

2 Brief instructions

2.3

2.4

Start Up

Earthing

12 Supply the device with power supply (24 V DC) via the

system.

If the power LED illuminates green permanently,

ready for operation.

If the alarm and warning LED do no

ates trouble-free.

Section 3.1, "Light emitting diodes" on page 14

The USM-GT-400 is supplied without connection box to the North

American

through a flame arrester. The marking of the cable (numbers) is

(always) identical to the terminal assignment.

region, the connection is made to cables that are led

t flash, the device oper-

the device is

A Earthing screw M6 B Earthing screw M6

C Earthing cable

Fig. 2-2: Connect to earth - Ultrasonic gas meters DN150 (6")

and DN100 (4")

September, 4th 2018 Ultrasonic Flowmeter USM GT400 7

2 Brief instructions

A Earthing screw M6 B Earthing screw M6

C Earthing cable

2.5

Fig. 2-3: Connect to earth - Ultrasonic gas meter DN200 (8")

13 Connect the earthing cable according to the ultrasonic gas

meter version DN100 (4") to DN150 (6") or from DN200 (8").

Parameter setting

The device shall be supplied pre-assembled according to customer agreement. Changes to the pre-assembly are more

exten

sive and are therefore not described in this brief instruction.

If this should be necessary, you will then find the description:

Section 10.1.3, "Calibration and Service Switch" on page 119

8 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

3

3.1

Device overview

In this chapter you will receive information on the main components of the ultrasonic gas meter and the arrangement of the

ultrason

Contents 3.

3.1 Main components ................................................ 9

3.2 Ultrasonic electronics

3.3 Arrangement of the ultrasonic transducers

Main components

ic transducers in the housing of the ultrasonic gas meter.

....................................... 11

.... 15

A Covers of the transducer and

transducer lines

C Ultrasonic electronics D Lifting eyes

E Joining flanges F Transducer

G Retaining bolts

Fig. 3-1: Main components of the ultrasonic gas meter

The ultrasonic gas meter consists of the following main

components:

September, 4th 2018 Ultrasonic Flowmeter USM GT400 9

B Covers of the transducer lines

3 Device overview

Covers of the transducers (A and B) The covers protect the connections and the lines of the transduc-

er (TD) against contamination and mech

anical damage.

Ultrasonic electronics (C) The ultrasonic electronics is in a pressur

housing mounted on the ultrasonic gas meter. The ultrasonic

electronics evaluates the data recorded by the transducers. In

addition to the display, the parameters can be shown and evaluated on a computer using the RMGView

Lifting eyes (D) The lifting eyes can be used to safely transport the device using

a

suitable lifting gear.

Connection flange (E) The device is bolted onto the g

flanges.

Transducer (F) The transducers are installed in the housing of the ultrasonic ga

eter and are not visible once installed.

m

Retaining bolts (G) The retaining bolts are mounted when delivering the device. The

retaining bolts

away. The bolts must be mounted to ensure for a safe installation

or de-installation.

secure the product from tipping over or rolling

s line using the connection

a

e tight, encapsulated

USM

software.

s

10 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

3.2

Ultrasonic electronics

A Service and calibration switch B Control panel

C Display D Magnet for operation

E Cover with viewing window F Pressure tight housing

Fig. 3-2: Ultrasonic electronics and displ ay

Device data (readings and parameters) can be set and evaluated

via the display and the operating elements.

Moreover, the device data (readings

shown, evaluated and set using the RMGView

Service and calibration switch (A) The service switch (right switch) is o

vice switch is, e.g., used to ins

The calibration switch (left switch) protects the pa

against unauthorized changes. The device can be configured by

opening the calibration switch.

Control panel (B) The control field comprises buttons that are triggered by pressing

a butto

and status messages are called up using the button.

Display (C) The display shows the readings, warning , alarm and status mes-

sages as well as the parameters.

Magnet for operation (D) The magnet is used to operate the control panel of the ultrasonic

el

above the symbol on the viewing window, this function is

activated.

n or magnetically. Parameters, readings, warning, alarm

ics when the housing is closed. If the magnet is placed

ectron

tall new firmware.

and parameters) can also be

nly for RMG service. The ser-

USM

software.

rameters

September, 4th 2018 Ultrasonic Flowmeter USM GT400 11

3 Device overview

Cover with viewing window and

pressure tight housing (E and F)

Electrical connection

(T

erminal strip)

First line Shows the name of the parameter (coordinates) called-up, e.g.,

The cover and the pressure tight housing encapsulate the ultrasonic electronics against the potentially e

During operation, information can be read through the viewing

window from the display and status indicat

re information on the electrical connection can be found here:

Mo

Chapter 8.3, „Connecting the device electrically“ on page 84

xplosive atmosphere.

ors of the LEDs.

Display screen

Fig. 3-3: Example for a possible disp l ay

p-maximum value (maximum pressure value).

Second line Shows the value of the parameter (

52.00 bar a.

Third line Shows the coordinate designation, e.g., A-06, thus column A, line

06.

The calibration switch is open. The value of the parameter can be

changed.

The calibration switch is closed. The value of the parameter cannot be changed.

Forth line Shows the warning, alarm and status messag

failure

coordin

ates) called-up, e.g.,

es, e.g., -01 power

12 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

Buttons

When the cover is closed, the buttons can be operated through

the glass using the magnets supplied. The cover must not be

opened.

Change to the columns. Jump, e.g., from A to B and back again.

When holding for a longer time, you can change the columns by

quickly scrolling back.

Change or scroll forwards in the lines step by step, e.g., from A01 to A-02.

When holding for a longer time, you can change the lines quickly

scrolling forward.

Change or scroll back in the lines step by step, e.g., from A-01 to

A-02.

When holding for a longer time, you can ch

quick return.

Enter values.

ange the lines with

Reset button

The reset button (A) is for RMG service only. If the reset button is

pressed, the ultrasonic electronics is restarted.

Switches

Calibration switch (A): Activate to change parameters.

Service switch (B): For RMG service only. For in

firmware.

stalling a new

September, 4th 2018 Ultrasonic Flowmeter USM GT400 13

3 Device overview

Light emitting diodes

A Flow B Power (supply voltage)

C Alarm D Warning

E Reset F Service (service switch state)

G Calibration (calibration switch

state)

Fig. 3-4: LEDs of the electronic ultrasonic electronics

LED Illuminates con-

H Button states

flashing

tinuously

Power Voltage supply is

switched on.

Flow Gas flow present. —

Alarm Alarm message is

stored.

Warning Warning message is

stored.

Reset Reset is running.

Calibration Calibration switch is

open.

—

Alarm is active.

Warning is active.

—

—

Service Service switch is

open.

Control panel Panel is being

pressed.

—

—

14 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

3.3

Arrangement of the ultrasonic transducers

Fig. 3-5: Transducer paths and levels of the ultrasonic gas meter

The figure shows the arrangement of the transducers that are located in the ultrasonic gas meter. The arrangement of the

transd

ucers in the three levels is shown in three section

representations.

Four transducers are installed per level. The transducers form

two paths per level for

September, 4th 2018 Ultrasonic Flowmeter USM GT400 15

the measurement.

3 Device overview

16 Ultrasonic Flowmeter USM GT400 September, 4th 2018

4 Functional principle - Ultrasonic flow measurement

v

4

Functional principle - Ultrasonic

flow measurement

Content 4.

4.1 General description ........................................... 17

4.2 Correction of the base line

4.2.1 Base line correction via polynomial ........................ 22

4.2.2 Correction via a piecewise lin

4.3 Diagnostic function Speed of Sound ............... 24

4.3.1 Standard method of SoS calculation ...................... 24

4.3.2 SoS calculation via gas compone

4.3.3 Extended SoS calculation

4.4 Import of gas composition data ....................... 27

4.4.1 Option 4: Data input on fixed defaults .................... 27

4.4.2 Option 4: Data input on fixed defa

4.4.3 Data input via RMGBus

4.4.4 Data via Modbus (USM-GT-400 is SL

4.4.5 Import of data via Modbus (U

31

............................... 21

earization ................. 24

nts ...................... 24

...................................... 25

ults for air .......... 28

.......................................... 30

AVE) ........... 30

SM-GT-400 is Master) ..

4.1

4.5 Batch mode ........................................................ 36

General description

In this chapter, you are provided with information as to how the

ultrasonic gas meter records the data. The necessary formulas

are listed for this purpose.

Figure 4.1 shows the general working principle. Transducer TD1

and TD2 ar

ment and form a measurement path wit

ultrasonic pulse travels along the measuring path from sensor

TD1 to transducer TD2 more quickly than the other way around.

This is caused physically by vector addition of the flow velocity to

the speed of sound, the arrow above the

of flow.

e positioned opposite to each other for the measure-

h distance L. An

shows the direction

September, 4th 2018 Ultrasonic Flowmeter USM GT400 17

4 Functional principle - Ultrasonic flow measurement

: t=

TD12

: t=

TD21

t

TD12

L

c0v cos+

---------------------------------

=

t

TD21

L

c0v cos–

-------------------------------- -

=

v

v

L

2 cos

---------------------

1

t

TD12

-------------

1

t

TD21

-------------

–

=

v

L

2

2 d

-----------

t

TD21tTD12

–

t

TD12tTD21

--------------------------------- -

L

2

2 d

-----------

t

t

TD12tTD21

------------------------------- -

==

Formulas

Fig. 4-1: Two sensors form one path for the measurement

The transit time from TD1 to TD2 (

TD1 (

formula:

Fig. 4-2: Formula, transit time

These transit times of the ultrasonic pulses are determined by the

electronic ultrasonic system. These are used to determine the average velocity

) are calculated according to the following

along the measuring path:

) and from TD2 to

Fig. 4-3: Formula, average path velocity

Legend

18 Ultrasonic Flowmeter USM GT400 September, 4th 2018

v: Average flow velocity

c0: Speed of sound

: Path angle to the pipe

L: Path length

4 Functional principle - Ultrasonic flow measurement

v

i

v

i

=

v

ki

kv

i

=

v

w

wivki

i 1=

6

=

d: Diameter D

(For a center path. Outer paths have a corresponding

value.)

For this calculation, it is important that only the transit times and

the device parameters such as the transducer distance and the

angle of the measuring path to the flow direction are required. All

parameters that include a gas dependency are omitted.

Legend

In order to consider the ave

rage flow profile, in particular an

asymmetrical or swirl-affected flow, a total of 6 paths is measured

in 3 levels with the USM-GT-400 ultrasonic gas meter. The 3 levels can be derived ma

tically via an integration procedure,

thema

the so-called Gauss integration.

"Arrangement of the ultrasonic transducers" on page 15

The respective average path velocities (designated with

for the respective measuring path i) along these measuring paths

results analogically to the fo

Under certain conditions such as, e.g., sm

rmula above.

aller deviations from

the tolerances during the production, it may be necessary to correct the path velocities with a common factor:

Fig. 4-4: Formula, corrected path v elocity

v

k = Correction factor for the path velocities

= Corrected path velocity (m/s)

ki

(This factor is named vw factor d1for the forward

direction and vw factor d2 for back-flow; see

chapter parameter setting 10.5.4)

Thus, one obtains for the average flow velocity:

Fig. 4-5: Formula, flow velocity

Legend

v

w

= Average flow velocity (m/s)

w

= Weighting factor with regard to the flow profile

i

The summation and the weighting specified result from the mathematic Gaussian integration procedure.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 19

4 Functional principle - Ultrasonic flow measurement

i

i

Tu

20;6..1

1

1

1

2

,

Nivv

N

N

j

iiji

i

i

i

v

Tu

i

v

ijv,

N

PF

Quality of installation

The USM-GT-400 provides parameters that allow a rating of the

installation. If the values are within given ranges, then good measurement conditions can be assumed. If the

the accuracy of the reading may be affected by disturbed flow

conditions. Please contact in this case the RMG service.

"Manufacturer" on page I

Turbulence

Due to the actual flow, in particular the turbulence, there will be

characteristic variations (variance

locities (i = 1..6; number of ultra

allow an assessment of the installation. The ultrasonic path averaged turbulence (

) is calculated as follows:

values are outside

) of the individual path ve-

sonic measuring paths), which

Legend

Fig. 4-6: Variance

Fig. 4-7: Turbulence

=

Time averaged flow velocity along the ultrasonic

path

=

Flow velocity along the ultrasonic path

=

20; number of values for turbulence calculation

(named Turb./Perf. count; see chapter parameter)

Typical values at very good flow conditions for

at 2-3%, for the outer paths, the turbulence increases to 4%. If

these values are above 10%, then disturbed conditions can be

assumed affecting the measurement accuracy. At lowest velocities the turbulence calculation is

swit

ched off.

middle paths are

Profile and symmetry factor

For a fully developed flow the middle path (3 + 4) have the highest

velocity, the two outer paths (1 + 2; 5 + 6) are more or less equal.

The profile factor (

20 Ultrasonic Flowmeter USM GT400 September, 4th 2018

) is typically between 1.05 to 1.20; at val-

4 Functional principle - Ultrasonic flow measurement

6521

43

2

vvvv

vv

PF

65

21

vv

vv

SY

MP

600

)(0)(1

,

100..16..1

,

okvokv

MP

ij

ji

ij

ues below 1.00 or above 1.50, the flow conditions should be

checked.

Fig. 4-8: Profile factor

The symmetry factor (SY) usually is between 0.9-1.10; at values

below 0.75 or above 1.25 the flow conditions should be checked.

Fig. 4-9: Symmetry factor

Meter performance

This value (

paths could be measured and involved in the flow c

is calculated on base of the last 20 measurements (same as

turbulence).

Fig. 4-10: Meter performance

The highest value is 100%; under normal conditions it is above

95%. Since 2 measurement paths can fail before the

USM-GT-400 loses its calibrated accuracy,

down to 66%; if the path failure is caused by a defect transducer

an immediate repair of the failed transducers should to be

initiated.

All of these values are given at the display of th

they are identical to the values in the RMGView

) indicates whether the velocity of all ultrasonic

alculation. It

the value may fall

e USM-GT-400;

USM

.

4.2

September, 4th 2018 Ultrasonic Flowmeter USM GT400 21

Correction of the base line

Correction of the baseline for the velocity

There are several influences (eg. Reynolds number) resulting in

a not exactly proportional relation between the measured and according to the formula 4.5 calculated mean v

elocity to the exact

4 Functional principle - Ultrasonic flow measurement

v

wk

vwK

v

1

F

100

---------

+

=

Q

m

vw

D

i

2

4

--------

3600

s

h

-- -

=

Q

mk

kkv

wk

D

i

2

4

--------

3600

s

h

-- -

=

F

1

const G

m2

–

v

w

2

-------------------------------

const G

m1

–

v

w

2

-------------------------------

const G0– const G1–v

w

const G2–v

w

2

++++=

mean velocity. Here the following correction helps to compensate

these variations:

Bild 4-11: Formula, corrected average flow velocity

Legend

Legend

v

K

F = Error from the characteristic curve correction

These values can be used to calculate the process volume flow

rate respectively the corrected process volume flow:

Fig. 4-12: Formula, process volume flow

Fig. 4-13: Formula, corrected process volume flow

Q

= Corrected average flow velocity (m/s)

wk

= Meter factor

V

= Corrected process volume flow

mk

v

D

k

A 4

the device:

4.2.1

Fig. 4-14: Formula - Basic correction of the device

22 Ultrasonic Flowmeter USM GT400 September, 4th 2018

Base line correction via polynomial

Legend

F

= Corrected weighted flow velocity

wk

= Inside pipe diameter

i

= Characteristic curve correction

k

th

degree polynomial permits the so-called basic correction of

1

= Deviation of the error curve (%)

4 Functional principle - Ultrasonic flow measurement

v

wk

vwK

v

1

F

100

---------

+

= v

wkvwKv

1

F

1

100

---------

+

=

F

2

const m2–

Q

m

2

----------------------------

const m1–

Q

m

----------------------------

const 0– const 1–Q

m

const 2–Q

m

2

++++=

K

k

1 F

2

+

100

----------------

=

v

w

const-Gx

The constants const-Gx (x = m2, m1, 0, 1, 2) are calculated from

the measured value pairs of the deviation with the respective flow

velocity.

The calculated correction F

flow velocity for F in the formula above.

Fig. 4-15: Formula, corrected meter factor

The process volume flow and the corrected process volume flow

result, as listed above, from the multiplication of the corresponding velocities with the pipe cross-section. The correction formulas

above are ther

flows.

= Average flow velocity (m/s)

= Constants of the basic correction

(x = m2, m1, 0, 1, 2)

is used for the corrected average

1

efore accordingly easy to transfer to the volume

Polynomial The characteristic curve correctio

Fig. 4-16: Formula, error equation

lso carried out via a 4th

n is a

degree polynomial that represents the error curve of the device.

F

2

Q

m

const-n

The constants Konst-n (n = m2 bis n = 2) are calculated from the

measured value pairs error F

curve correction K

process volume flow.

= Deviation from the error curve (%)

= Flow (m3/h)

= Constants

and flow Qbi. The characteristic

2i

is used for further calculation of the corrected

k

Fig. 4-17: Formula, characteristic curve correction

September, 4th 2018 Ultrasonic Flowmeter USM GT400 23

4 Functional principle - Ultrasonic flow measurement

12TD

t

12TD

t

L

SoS

0

c

2112

2112

0

2

TDTD

TDTD

tt

ttL

cSoS

4.2.2

4.3

Correction via a piecewise linearization

The correction of the base line with a polynomial described in

section 4.2.1 takes into account the typical, characteristic curve

of the USM-GT-400 in an ideal way. This correction is recommended for custody transf

MID is valid. Nevertheless, a comparable accuracy can be

achieved with a piecewise linearization, if a sufficient number of

interpolation points are used. Between the interpolation points, a

simple linear interpolation is used. The correction of the base line

with the piecewise linearization may also be used in all countries

where the MID is valid if the error curve of the raw data mets the

requirements of the ISO 17089.

In order to achiev

points should be placed in the relevant flow rate range. To take

into account the higher gradient of the curve at lower flow rates

the intervals should not be equidistant; recommended are more

points in this lower flow rate range.

a sufficient accuracy most of the measuring

e

etering in all countries where the

er m

Diagnostic function Speed of Sound

4.3.1

4.3.2

The USM-GT-400 can calculate the SoS in 3 different ways.

Standard method of SoS calculation

The first calculation is realized with help of the transit time

and

suring path with the length

speed of sound

Fig. 4-18: Calculation of SoS

This first option is pretty fast and is almost permanently "online"

available.

of the ultrasonic pulses (see above) along the mea-

. It is straight forward to result in the

or

to:

SoS calculation via gas components

The second version of SoS calculation uses pressure, temperature and composition of the gas to determine the SoS according

to the

specifications of the AGA 10 standard (AGA Report No. 10,

24 Ultrasonic Flowmeter USM GT400 September, 4th 2018

4 Functional principle - Ultrasonic flow measurement

Speed of Sound in Natural Gas and Other Related Hydrocarbon

Gases; January, 2003; AGA - American Gas Association). The

calculation is based on statistical considerations of thermodynamics; since it is very complex

Knowing the gas composition precisely values such as density,

sound velocity and other gas properties can be calculated with

very high accuracy.

Depending on the type of gas analyzer it may take 5-10 minutes

to determine the volume fractions

nents accurately. Accordingly, the precise allocation of flow to

gas composition can be done in this time frame only.

, it will not be pres

of the individual gas compo-

ented here.

the

Diagnostic function SoS

The USM-GT-400 determines with highest accuracy the flow rate

of the gas flowing through it. For the payoff the gas quality, respectively the calorific value of the gas resulting from the gas

composition

lows a second billing of the volume flow rate with the "right" ga

composition, ie the "right" calorific value.

is of course of big interest, too. The USM-GT-400 al-

s

4.3.3

This temporal resolution can be achieved receiving permanently

gas composition data from a gas analyzer. A comparison of

the

the two differently calculated SoS‘s in the USM-GT-400 allows

the immediate detection of any deviation; in particular, another

gas composition results in a different SoS. A confirmation of another gas composition then provide

the data of the gas analysis instrument.

The temporal correlation of the actual gas composition (using the

calculated via the gas composition) to the SoS using method

SoS

1 results in the higher temporal resolution for the gas composition, respectively the

Extended SoS calculation

The third possibility SoS calculation is presented under the name

"Extended SoS measurement". This new method is introduced

as an additional determination.

orific value.

cal

s the n

ext comparison with

September, 4th 2018 Ultrasonic Flowmeter USM GT400 25

4 Functional principle - Ultrasonic flow measurement

12TD

t

122112TD

t

122112TD

t

12TD

t

SoS

1212211212

12122112

2112

2112

0

22

2

TDTDTD

TDTD

TDTD

TDTD

ttt

tt

L

tt

ttL

cSoS

Fig. 4-19: Extended SoS calculation

Transducer TD2 receives at first the ultrasonic pulse (light blue)

coming from TD1 at the time (

ed and moves back to TD1 (dark blue). There this puls

reflected, too and reaches TD2 (red) again after the time

(

a new possibility to calculate

Fig. 4-20: Calculation of extended SoS

Due to a 10-times smaller variance of the SoS calculation this

method offers significantly more accurate result compared to the

standard method (version 1). There are 2 reasons for this result;

first, the transmitter / receiver error is eliminated (especially T

the transit time of the pulse in electronic and transducer is different in the individual transducers) and secondly, any

turbulence in medium has lowest influence to the transit time (the

time interval between 12TDt and 21TDt is as short as possible).

Having typical measuring conditions, this method can easily be

applied, but there are conditions at which this method may fail.

). The differences of

). This pulse is partially reflect-

e is

and

:

results in

W

flow

;

The SoS calculation according to method 1 and 3 run simultaneously and controlled using the same criteria. If correct, the result

o

the extended measurement is preferred due to its higher accu-

f

26 Ultrasonic Flowmeter USM GT400 September, 4th 2018

racy. Otherwise, the standard method 1 is used; after any change

4 Functional principle - Ultrasonic flow measurement

the measurement conditions, both methods are revalued again.

If correct the extended SoS calculation will be chosen again.

TW setting

Measurement tolerances and/or errors of the standard method

are permanently controlled using the comparison with the expanded method. Having both values

determined. When the calibration switch is open, the T

the standard measurement can be corrected to the value of the

extended measurement. This is an important adjustment help in

case of a transducer replaced, but also serves as an accurate

path lengths determination between the transducers during the

dry calibration.

a correction for TW can be

-value of

W

4.4

Import of gas composition data

To use the diagnostic function SoS, respectively to calculate it

from the gas composition the USM-GT-400 requires the volume

fractions of the individual gas components in the gas (up to 21

components), the pressure and the temperature. From these

data SoS is calculated using the guidelines of the AGA 10 standard. For the data transfer of the

are available:

gas com

ponents four options

Fig. 4-21: Import of gas composition data

4.4.1

September, 4th 2018 Ultrasonic Flowmeter USM GT400 27

Option 4: Data input on fixed defaults

If there are no live data available for the gas analysis, then the

gas data can be stored as fixed values in the USM-GT-400. For

4 Functional principle - Ultrasonic flow measurement

the AGA-10 calculation these default values are used as fixed

gas shares (AX-20 - AX-44; in chapter 10 the matrix notation of

parameters, measured values and variables will be explained).

To change these values they have to be confirmed by selecting

"Accept new Comp." in parameters AX-11and to be confirmed in

"takeover gas components". Only then they will be taken over as

new values for the AGA-10 calculation.

1. Parameter AX-01 „AGA-10 Sourse“

Default data

2. Setting of the default values of the individual gas components

4.4.2

Parameter AX-20 to AX-

Methane default value ....

....

Propene default value

3. Takeover with parameter AX-1

„Taking over new components“

44

1

„AGA-10 Source“

Option 4: Data input on fixed defaults for air

In mode "default air" fixed values of air composition for the gas

analysis can be used. With the additional parameter "rel. humidity" in AX-06 the water co

mol-% and the remaining components of the air are normalized

to 100%. The unnormalized default values for air are:

Nitrogen: 78.105 mol-%

Oxygen: 20.946 mol-%

Argon: 0.916 mol-%

Carbon dioxide:

ntent and component is calculated in

033 mol-%

0.

Water: 0.0 .. mol-% (calculated)

.

The water content is calculated via the relative humidity

1. Parameter AX-01 "AGA-10 source":

"Default air"

2. Setting of the default values

Paramater AX-06 "relative

All other possibilities to transmit the volume fractions of the

vidual gas components on the USM-GT-400,

of the USM-GT-400.

relative humidity

humidity“

will use interface 2

indi-

Terminal connections

The following figure shows the terminal connections.

28 Ultrasonic Flowmeter USM GT400 September, 4th 2018

4 Functional principle - Ultrasonic flow measurement

Fig. 4-22: Terminal connections

The SoS calculation depends in addition to the gas components

also on the gas pressure and temperature. How to measure the

pressure is described in chapter 8.4; temperature measurement

is given in chapter 7.4. Setting of the parameters AX-02 "SoS

Source Temp." and AX-03 "SoS Source Pressure" allows to select whether these measured values of temperature and pressure

ar

e u

sed for AGA-10 calculation or default values AX-04 and AX-

05.

Fig. 4-23: Pressure and Temperature input

The electric connection of pressure (p) and temperature (T) has

to be done a terminals 26 to 31; AUX1 = p; AUX2 = T.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 29

4 Functional principle - Ultrasonic flow measurement

4.4.3

Data input via RMGBus

The data of a gas chromatograph (eg. RMG GC9000 or GC9300)

can be delivered as RMGBus telegram via the RMGBus protocol.

Therefore, the coordinate AX-01 “SoS AGA-10 source data“ is

set to "Serial port 2" and the serial interface in the mode "RMGBus". Additionally the parameters of the interfaces USM-GT-400

a

the RMGBus master device have to be aligned to each other.

nd

Because the content of the telegram may have data from different

streams, the

AX-09 "Stream selection". Parameter AX-

fixes how many components are part of the telegram. When using a GC9000 this parameter has to be set to "RMGBus" to offer

a correct

1. Parameter J-

2. Setting the parameters of serial 2:

„right“ stream has to be set with the parameter

evaluation for older versions of the software GC9000.

"RMGBus"

J-26 "baud"

27 "bits"

J-

28 "parity"

J-

Opt. Ser2 mode"

25 "

08 "RMGBus mode"

4.4.4

atch RMGBus master:

M

"Serial port 2"

3. Parameter AX-01 "AGA-10 source":

"Serial port 2"

4. Parameter AX-07 "maximum tim

Time in minutes, within which a new telegram has to come

via RMGB

5. Parameter AX-08 "RM

GC9000: "RMGBus"

GC9300: "RMGBus 24 Komp."

6. Parameter AX-09 "Stre

Allows the setting of the

us

GBus mod

am selection":

desired streams.

eout":

e":

Data via Modbus (USM-GT-400 is SLAVE)

The gas data can be written to Modbus USM-GT-400 (USM-GT400 is Slave). Data source can be any field devices that operate

as a Modbus master on the bus. The individual gas components

will be written into the Modbus register of parameters AY- 20 to

AY- 44 . To accept these values for the AGA-10 calculation parameters AX-

will be set as:

11 h

as to be set to "Set new comp.". The parameters

30 Ultrasonic Flowmeter USM GT400 September, 4th 2018

4 Functional principle - Ultrasonic flow measurement

1. Parameter J-25 "Opt. Ser2 mode"

"Modbus"

2. The parameters of serial port 2 have to be adapted to the

setting of the Modbus mas

J-26 "baud"

ter:

J-27 "bits

J-28 "parit

3. The

to the setting of the master. Due to the configuration of the

hardware it has to be set to RS232 or RS485, too:

J-29 "Modbus protocol 2"

J-30 M

4. Par

"Serial port 2"

5. Parameter J-25 "Opt. Ser

"Modbus Master"

"

y"

Modbus has to be set to "RTU" or "ASC

odbus2 HW Fashion

ameter AX-01 "AGA-10

source":

2 mode"

II" according

Fig. 4-24: Import of data via Modbus

4.4.5

September, 4th 2018 Ultrasonic Flowmeter USM GT400 31

Import of data via Modbus (USM-GT-400 is Master)

USM-GT-400 gets the gas data via Modbus. It is Modbus master

and asks continuously if new data are available. In this case, all

the components are re-read and fed to the AGA-10 calculation.

Parameter AX-10 "Modbus Master Target" sets which device the

USM-GT-400 is addressing. If the GC9300 is chosen no Modbus

register needs to be set at AZ-01 to AZ-54 for status and part of

the gas component.

4 Functional principle - Ultrasonic flow measurement

1. Parameter AX-07 "maximum timeout":

Time [minutes] in which a new telegram must

via RMGBus

2. Adjustment of the parame

J-26 "baud"

27 "bits"

J-

28 "parity"

J-

Modbus configuration:

3.

J-29 "Modbus protocol 2"

Mas

ter has to be set to "RTU" or "ASCII"

J-30 M

Hardware configuration can be se

RS485

J-31 "Modbus address 2"

Sla

4. Parameter AX-01 "AGA-10 source":

"Serial port 2"

5. Parameter AX-07 "maximu

odbus2 HW Fashion

ve address of the device with the gas data

r of serial port 2

te

lected as RS232 or

m tim

eout":

have come

Time [minutes] in which a new telegram must

Timeout: During the transfer of data, an ad

available, generating a status signal if no new data arrived within

the adjusted time.

6. Parameter AX-10

"Modbus Master Target": "GC9300"?

If yes, continue after 8, otherwise at 7

7. Parameter AZ-01 - AZ-54

Enter Modbus registers of the gas components and status

the slave device

of

justable time-out is

have come

Treatment of the gas data

The gas data are validated after transmission and optionally normalized. The AGA-10 gas equation

components; it might even accept up to 24 components adding

some (surplus) gas components to other components.

Neo-pentane: added

to n-pentane (see ISO 12213-2)

accepts up to 21 gas

Propene: add

Ethene: added to CO

32 Ultrasonic Flowmeter USM GT400 September, 4th 2018

ed to propane

(see ISO 12213-2)

2

4 Functional principle - Ultrasonic flow measurement

Hexane+: sum of n-hexane, n-heptane, n-octane, n-nonane and

n-decane. If there is only hexane+ in the samples and none of the

above mentioned components, then hexane+ is added to hexane. In case one of these components is > 0

nored.

ig

, then hexane is +

Normalization to 100 mol-%: If

100 mol-%, then the components are normalized to a total of

100 mol-% (can only be applied if the sum

< 110 mol-%). Otherwise, Bit 0 in AW-0

will be set and the calculation takes place with 100 mol-% methane instead.

the sum of gas components isn‘t

is > 0 mol-% and

1 "SOS calculation status"

Fig. 4-25: Sequence of gas components treatment

September, 4th 2018 Ultrasonic Flowmeter USM GT400 33

4 Functional principle - Ultrasonic flow measurement

Example 1

Fig. 4-26: Classification of gas components

The following examples demonstrate the classification of the gas

components into the 21 AGA-10 components

Component Input

mol-%

Methane 35.0 35.0 70.0

Ethane 5.0 5.0 10.0

Propane 1.0 2.0 4.0

Propene 1.0 - -

iso-Pentane 1.0 - -

n-Pentane 1.0 2.0 4.0

CO

2

Ethen 0.8 - -

Hexane+ (5.0) - -

Hexane 3.0 3.0 6.0

0.2 1.0 2.0

AGA-10

unnormalized

mol-%

AGA-10

normalized

mol-%

Nonane 2.0 2.0 4.0

Sum 50.0 50.0 100.0

34 Ultrasonic Flowmeter USM GT400 September, 4th 2018

4 Functional principle - Ultrasonic flow measurement

Example 2

Component Input

mol-%

Methane 80.0 80.0 80.0

Ethane 5.0 5.0 5.0

Propane 2.0 2.0 2.0

n-Butane 1.0 1.0 1.0

neo-Pentane 1.0 - -

n-Pentane - 1.0 1.0

CO

2

Ethen 2.0 - -

Hexane+ 5.0

Hexane - 5.0 5.0

Nitrogen 4.0 4.0 4.0

Sum 100.0 100.0 100.0

- 2.0 2.0

AGA-10

unnormalized

mol-%

AGA-10

normalized

mol-%

Status code of AGA 10 calculation

Coordinate AW-01 gives the status code of the AGA-10

calculation.

This is a bit-coded value represente

d as a hexadecimal code. A

value of "0000h" indicates a AGA-10 calculation with errors. The

meaning of the individual bits are:

Bit Meaning

0

Components invalid

Sum of the un-normalized gas components

is <= 0 or > 110 mol-%

1

Timeout of new gas data exceeded

Within the defined time period in AX-07,

no new gas data

arrived. Possible reason:

• Time too short

• Communication interrupted

• transfer register has not been filled (for Modbus slav

e)

• Wrong RMGBus telegram or wrong stream selection

If there are new gas components latest within three times

of the given timeout time, the error status will be reset.

2

Temperature Error

The temperature measurement is disturbed. Calculation

will be done with the default value.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 35

4 Functional principle - Ultrasonic flow measurement

3

Pressure errors

The pressure measurement is disturbed. Calculation will

be done with the default value.

4

Simulation active

4.5

5

6

7

8

915

The message "188: AGA-10" appears, if the status code is not 0.

The Modbus master function is flexible in order to support PGC's

other manufacturers, too; for example a Siemens PGC. Activating the RS 485 interface as Mod

chapter 10.3.3.

Batch mode

Parameters E-01 "USE09 mode" is set t

no data (results) of the DSP will be accepted

no value

no value

no value

Error AGA 10 calculation

There is an error within the AGA-10

culation is on hold. Reason may be wrong pressure or

temperature values, ...

no value

bus master

o simulation =

calculation. The cal-

is described in

In general, the USM-GT-400 is set for an optimal operation without disturbance. The setting / changing of the batch mode allows

adaptation to disturbed c

at "high-turbulent" flow conditions as well as at "strong background noise" conditions. High turbu

velocity profiles and rapidly changing asymmetries. A "smallest"

batch mode should be chosen. At strong background noise, the

signal detection can be disturbed, too. A "longer" batch mode increases the signal stability significantly

permits a change of the signal duration.

• P1 Number of F-batches per

• ...

• P8 Number of F-batches per

The default values ar

activated. All larger values are squared; F-Batch 2 means there

are 4 signals superimposed. If the F-Batch is active the ring down

time should be chosen as short as possible, preferably to 0 ms.

The slow batch mode can be activated in coordinate AI-09; it is

to be squared for all paths, too.

36 Ultrasonic Flowmeter USM GT400 September, 4th 2018

onditions. The setting allows operation

ent means highly distorted

l

The number of batches

.

measuring path 1

measuring path 8

e 2. 0 and 1 are identical; there is no batch

5 Safety

5

Safety

In this chapter you will receive information on using the device in

a safe manner.

Contents 5.

5.1 Intended use ....................................................... 37

5.2 Layout of instructions

5.3 Qualification of the personnel

5.4 Safety instructions

5.4.1 Hazards during transporting ................................... 40

5.4.2 Hazards during installation

5.4.3 Hazards during start up

5.4.4 Hazards during cleaning

5.4.5 Hazards during maintenance and repairs

5.4.6 Hazards during operation

5.4.7 Hazards for operation in potentially

explosive environments

....................................... 38

.......................... 39

............................................ 39

..................................... 41

.......................................... 43

......................................... 43

.............. 44

....................................... 45

.......................................... 45

5.1

5.5 Responsibilities of the operator ....................... 46

Intended use

The Ultrasonic Flowmeter USM GT400 device is used to measure the flow velocity of the gases in a pipeline and calculate th

operating flow during running operation.

The Ultrasonic Flowmeter USM GT40

as ultrasonic gas meter or device in the following.

When used for its intended purpose, the ultrasonic ga

suitable for use in potentially explosive areas classified as

zone 1.

e

0 is hereafter designated

s meter is

September, 4th 2018 Ultrasonic Flowmeter USM GT400 37

5 Safety

Danger

!

Warning

!

Caution

!

Notice

The device complies with ignition protection class

II 2 G Ex de IIB+H2 T6 Gb, ambient temperature between -40°C

and +55°

or

Class 1, Division 1 Group B, C and

code T5/T6 is -40°C to +40/+55°C..

The ultrasonic gas meter complies with the standards, directives

and gu

Chapter 14.5, „Standards, directives a

C

idelines.

page 178

bient temperature for

D, am

uidelines“ on

nd g

5.2

These technical limits must be maintained for a safe us

ultrasonic gas meter:

Chapter 13, „Technical specifications“ on page 159

Layout of instructions

The following instructions are used:

This warning instruction informs you of potentially hazardous situations that can occur as a result of incorrect operation or human error. If

these situations are not avoided, they can lead to fatal or severest

injuries.

This warning instruction informs you of possible hazardous situations

that can occur as a result of incorrect operation or human error. If

these situations are not avoided, they can lead to fatal or severe inju

ries.

e of the

-

This warning instruction informs you of possible hazardous situations

that can occur as a result of incorrect operation or human error. If

these situations are not avoided, they can lead to slight or minor inju

ries.

This warning instruction informs you of potentially hazardous situations that can occur as a result of incorrect operation or human error.

these situations are not avoided, they can result in material damage to

the device or the vicinity.

This information gives you tips on how to simplify your work. With

this screen, you additionally receive further information on the

device or the work process.

38 Ultrasonic Flowmeter USM GT400 September, 4th 2018

-

If

5 Safety

Danger

!

5.3

Qualification of the personnel

Operating personnel The operating personnel are to use and operate the device within

the scope of the intended purpose.

Maintenance personnel Work on the device must only be carried out by specialist person-

nel that can carry out the respective work assigned to them as a

result of their

applicable regulations. These specialist personnel are familiar

with the legal guidelines for accident prevention and can evaluate

and avoid possible risks by themselves.

• Mechanical installation must only be carrie

respectively qualified specialist personnel.

• Installation on electrical components m

out by qualified electricians.

The specialist personnel require a training especially for

work

ing in potentially explosive env

sonnel are persons that can ver

education according to DIN VDE 0105, IEC 364 or a similar

national standards..

•Initial start up

personal (training by RMG) or by service personal from RMG.

• Maintenance and cleaning mus

respectively qualified specialist personnel.

aining, knowledge and experience as well as the

tr

d out by the

ly be carried

ust on

ironment. Specialist per-

ify a training / further

only be carried out by especially trained

must

t only be c

arried out by the

5.4

Safety instructions

Observe the following safety instructions

Non-observance of these safety instructions can lead to a risk of life

and limb and health of the person as well as damage to the environment or property damage.

Note that the safety instructions in this operating instruction and

on the device cannot cover all possible hazardous situations as

the combination of different circumstances is impossible to predict. To simply follow the instr

be sufficient enough to ensure for correct operation. Always be

observant and also consider the following:

• Befor

• Always

e working with the device for the first time, read through

this ope

instructions carefully.

the plac

rating instruction and, in particular, follow the safety

keep the operating instructions within reach for use at

e of installation.

uctions

specified may not normally

September, 4th 2018 Ultrasonic Flowmeter USM GT400 39

5 Safety

• The operating instruction warns against the residual risks for

users, third parties, devices or other material assets. The

safety instructions used refer to residual risks that cannot be

avoided due to the design.

• For safe operation, t

and followed.

• Oper

• Also obs

• Th

• Se

• Cha

• For safe operation, the technical spec

• For a safe operation, t

ate the device only in a sound state and when observing

operating instruction.

the

erve the local

and assembly guidelines.

e manufacturer is not responsible for any damage that

sult as a consequence of not observing the operating

re

instruction.

rvice and maintenance work or repairs that are not

scribed in the operating instruction must not be carried out

de

without previous consultation with the manufacturer.

nges to the device are forbidden.

observed and followed. Performance limits must not be

exceeded.

scope of its intended use.

he safety

he dev

instructions must be observed

legal accident prevention, installation

ifications must be

ice must only be used in the

5.4.1

The device is exposed to different life phases, su

stallation, start upstart up, operation, maintenance and cleaning.

T

he following sections must be sorte

the life phases.

Hazards during transporting

The device may be damaged when lifting and putting down, tipping over or falling down. By disregarding the load bearing

capacity of t

severe injuries for persons in the vicinity.

• Li

ft the device only on the inten

• Before lifti

• Never stand under suspended loads.

• Observe the weight spe

meter at hand.

he lifting gear, the device may fall. There is a risk of

ng, make sure that the load is safely secured.

ch as, e.g., in-

d thematically according to

ded lifting eyes.

cifications for the ultrasonic gas

40 Ultrasonic Flowmeter USM GT400 September, 4th 2018

5 Safety

5.4.2

Hazards during installation

When you carry out work on electric systems in potentially explosive environments, incorrect work may

• Make sure that no potentially explo

hand before starting work.

If personnel that have insufficient qualifications carry

they can incorrectly assess hazards. Explosions can occur.

• Ca

rry out the work only if you have the respec

tion and are a trained specialist pe

• Carry out the installation

standards:

• CAN/CSA-C22.2 No. 0-1191

• CSA C22.2 No. 30

• CSA C22.2 No. 142

•UL 916

• UL 1203

or similar national standards.

In potentially explosive atmo

still remain as ignition sources for up to one minute after being

switched off.

• Dis

connect the device from the power supply before starting

the ma

• Se

• Cordon-off t

and signs.

• Afte

sta

connect to earth and short-circuit.

• Make

• Make sure that no stripped cable is loca

ing of the ultrasonic electronics and the connection box.

intenance work.

curing against reconnection.

he work area of the device, e.g., using a barrier

r switching off the device, wait at least one minute before

rting work. Ensure that the device is voltage-free. Then

sure that the insulation of t

lead to explosions.

sive atmosphere is at

out work,

tive qualifica-

rson.

according to the following

pheres, dangerous voltages can

s

he cables are intact.

ted outside the hous-

If the device is not installed according to the operating instructio

then there is not enough explosion protection.

• Insta

If you do not use the appropriate

may be damaged. The explosion protection is void.

• Us

• Make

• Use only an Atex or IECEx certified EMC c

September, 4th 2018 Ultrasonic Flowmeter USM GT400 41

ll the device according to the

e tools that have been recommended for the respective

k in the operating instruction.

wor

sure that the performance data of the power connec-

tion comply

nection in the protection categ

metric thread (M20x1.5).

with the specificat

operating instruction.

tool and material, components

ions of the type plate.

able screw con-

ory increased safety with a

n

5 Safety

• Creepage distances and clearances must be maintained.

• Openings for line feeds not used

resistant, anti-self-loosening and twisting safe blind plugs.

• Th

e line insulation must reach to the terminals

ping, the conductor itself mus

• When closing the housing, take car

effective in order to ensure for the protection category IP 66 /

NEMA 4X.

• Hous

• Ob

• Use ca

ing cover or housing with dam

replaced immediately.

serve the applicable national guidelines in the individual

countries

.

bles that match th

e cable glands.

must be sealed by impact

. When strip-

t not be damaged.

e that the seals remain

aged thread must be

Gas may represent a risk to life and limb in dif

pending on the gas type, different hazards may have an effect on

you

with respective consequences. You may experience intoxica-

tion and injuries. There is also a risk of explosion.

• Befor

• Install t

• Ma

The device is exposed to high pressures.

pressure are removed / assembled, the high pressure may escape suddenly causing the component to fly

danger!

• Install t

• With systems subjected to pressure:

If gas escapes at high temperature, there is a risk of life threate

ing burns. You may suffer burn injuries in the event of contact with

h

ot surfaces.

• Allow the comp

• W

e working, inform yourself about the media in the

tem.

sys

he device only when the system is switch

depressurized and secured.

ke sure that there is no potentially explos

at the installation location.

he device only when the system is dep

have t

he assembly work (Hot-Tap

specially trained personnel.

nts to cool down before working in the

one

system.

ear personal protective equipment.

ping) only carried out by

ferent ways. De-

ed off,

ive gas mixture

If components under

around. Mortal

ressurized.

n-

connections not required during ope

If

escape. Risk of explosion and intoxication!

• Before st

plugs according to 94/9/EC.

• Rep

tation with certified blin

500.

42 Ultrasonic Flowmeter USM GT400 September, 4th 2018

rt up, seal all open connections with certified blind

a

lace the blind plugs that have been installed for transpor-

d plugs according to 94/9/EC or NEC

ration remain open, gas will

5 Safety

5.4.3

5.4.4

Hazards during start up

If personnel that have insufficient qualifications carry out work,

they can incorrectly assess the hazards. Explosions can occur.

• Ca

rry out the work only if you have the respec

tion and are a speciali

If the device is not sealed correctly during installation then gas

y escape. Explosions can occur. Danger of poisoning!

ma

• Check th

• Take the system immediately out

leak.

e co

Hazards during cleaning

If the device is not cleaned according to the operating instruction

then the device may be damaged.

• Clean

If you do not use the appropriate tool, components may be damaged. The explosion protecti

• Use tools that have been recommended for the respective

the device only according to

wor

k in the operating instruction.

tive qualifica-

st person.

nnections for leaks.

of operation if you detect a

the operating instruction.

on is void.

Cleaning agents / corrosion protec

health.

• Always wear

• Ensure for good ventilation and do not inhale vapors!

• Observe the safety data sheet!

otective gloves and eye protection.

pr

tion used may be harmful to

September, 4th 2018 Ultrasonic Flowmeter USM GT400 43

5 Safety

5.4.5

Hazards during maintenance and repairs

If personnel that have insufficient qualifications carry out work,

They can incorrectly assess hazards when working. Explosions

can occur.

• Carry out the work

tion and are a trained specialist person.

Flange joining elements, pressure tapping screw connections

valves must not be removed if the system is subject to pres-

and

sure. Components may dangerously spray

cause intoxication and burns. Risk of explosion!

• Fo

r the flange connection, use only the matching combina-

of screw bolts, nuts and sea

tion

tightening torque of the flange connection for this

combination.

• In do

• Use only genuin

ing so, observe the specific

facturer or system operator.

e spare parts from RMG.

It is forbidden to install spare pa

turers. It voids all guaran

explosion protection is no longer ensured.

if you have the respective qualifica-

only

ls. Select the appropriate

ations of the system manu-

rts from third-party manufac-

tees and claims for guarantee. The

. Escaping gas may

When working on live devices in potentially explosi

spheres, resulting sparks may lead to an explosion.

• Only

• Make sure that there is no potentially explosive atmosphere

• Afte

• Chec

Sp

ar

Under normal operating conditions, the transducer cannot be accessed from the outside, thus no sparks can

or friction of the transducer against hard materials.

• Th

• pr

work on de-energized devices when in potentially explo-

sive atmosph

before s

r working provide on pressurized components, leaks may

. Escaping gas may lead to intoxication, Risk of

occur

explosion!

k all components for leaks!

ecial requirements for a safe operation in potentially explosive

eas classified as zone 1:

e transducers are made from tit

rub against the transducers, this can generate a spark thus

leading to an explosion!

event hard objects from kno

transducers.

eres (except for intrinsically safe circuits).

tarting work.

anium. If objects knock or

cking or rubbing against the

ve atmo-

result from impacts

Also observe these warning instructions:

„Hazards during installation“ on page 41

44 Ultrasonic Flowmeter USM GT400 September, 4th 2018

5 Safety

5.4.6

Hazards during operation

If the device is loaded with a pressure that is too high, components may leak and burst.

• Never

Flange joining elements, pressure t

valves must not be removed if the system is subject to pressure.

Components may dangerously spray. Escaping gas may cause

intoxication and burns. Risk of explosion!

• Obs

The device can be heated or cooled

gas. You may be subject to burns when making skin contact with

the device.

• W

Breakages or cracks may be caused to the device if the gas temperature or ambient temperature is o

temperature ranges. Gas escaping may cause intoxication and

burns. Risk of explosion!

• Never

exceed the maximum operating p

cations on the type plate).

erve the specifications of the system ma

system operator.

ear protective gloves that protect against heat and cold for

work.

this

exceed the maximum gas temp

ent temperature of 80°C.

ressure (see specifi-

apping screw connections and

nufacturer or

by the temperature of the

utside the specified

erature and / or ambi-

5.4.7

Hazards for operation in potentially explosive environments

If the device is operated with damaged or missing components

then gas may escape. In event of damaged threads, the ignition

penetration safe gap is no longer guaranteed. Escaping gas may

cause intoxication and burns. Risk of explosion!

• Op

erate the device only in a so

If you carry out technical changes to the

can no longer be guaranteed.

• Use

the device only in its

und and complete state.

device, safe operation

original state.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 45

5 Safety

5.5

Responsibilities of the operator

• You being the operator must ensure that only sufficiently

qualified personnel work on the device.

„Qualification of the personnel“ on page 39

• M

ake sure that all employees that are using the device have

r

ead and understood this operating instruction. Moreover,

you are also obliged to train the personnel at regular intervals

and inform them of the hazards.

• Mak

• The res

• Provide the personnel with the ne

• Using suitable meas

e sure that all work on the de

qualified persons and checked by responsible specialist

personnel.

ponsibilities for installation, operation troubl

ing, maintenance and cleaning must b

equipment.

„Qualification of the personnel“ on page 39

u

res, ensure that that constructive risks

are ruled out when using the device. Inform your personnel

about the risks when using the device.

vice is only carried out by

e clearly specified.

cessary protective

eshoot-

46 Ultrasonic Flowmeter USM GT400 September, 4th 2018

6 Transport and storage

6

Transport and storage

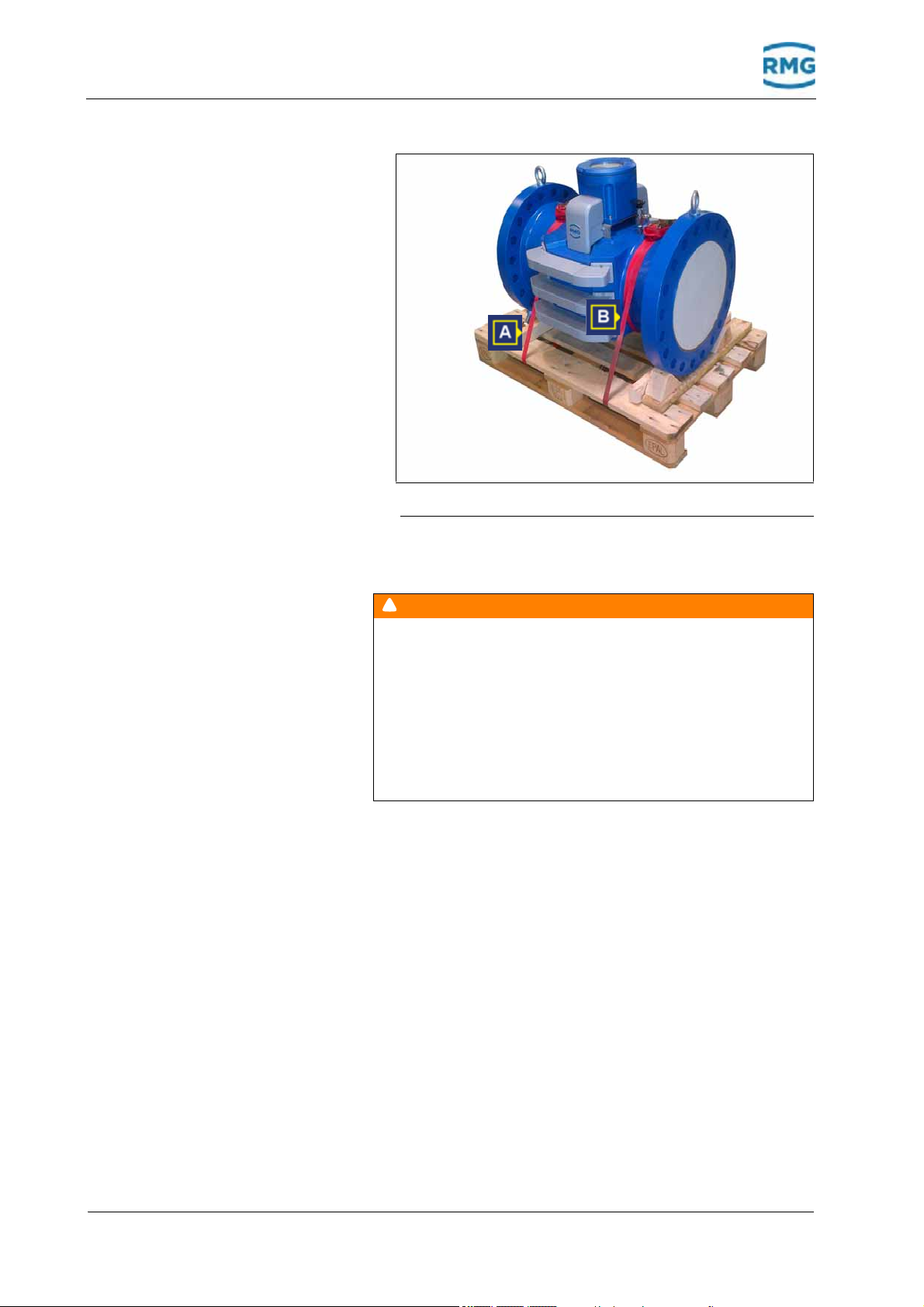

In this chapter you will receive information on the scope of supply,

transport and storage of the device.

Content 6.

6.1 Transport ............................................................ 47

6.1.1 Scope of supply ...................................................... 48

6.1.2 Transporting the device

6.1.3 Unpacking the device

6.1.4 Disposal of packaging material

6.1.5 Prior to installation

6.1.6 Removing the transporting locks

6.2 Packing the device for transportation ............. 55

6.3 Storage