User Manual

CMS2

1

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

2

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Table of Contents

1 General Warnings and Information for the End User ............................................................................................... 5

1.1 General Safety Warnings .................................................................................................................................... 5

1.3 Operator Position and Dangerous Areas ............................................................................................................ 6

1.4 Dangers and Hazards that cannot be eliminated ............................................................................................... 6

1.5 Personal Protective Equipment .......................................................................................................................... 7

2 Transportation and Storage ....................................................................................................................................... 8

2.1 Transportation and Handling Conditions ........................................................................................................... 8

2.2 Storage ................................................................................................................................................................ 8

3 Warranty, Limitations and Disclaimers ...................................................................................................................... 9

4 Product Presentation ............................................................................................................................................... 11

4.1 Benefits ............................................................................................................................................................. 11

4.2 Product features ............................................................................................................................................... 11

4.2.1 Moisture Sensor......................................................................................................................................... 11

4.2.2 Data Logger ................................................................................................................................................ 12

5 Technical Specification ............................................................................................................................................ 13

5.1 Performance ..................................................................................................................................................... 13

5.2 Electrical Interface ............................................................................................................................................ 13

5.3 Physical Attributes ............................................................................................................................................ 13

5.4 Fluid Characteristics .......................................................................................................................................... 15

5.5 Environment ..................................................................................................................................................... 16

6 Product Installation and General Operation ........................................................................................................... 17

6.1 Installation ........................................................................................................................................................ 17

6.1.1 Physical Procedure .............................................................................................................................. 17

6.1.2 Electrical Interface ..................................................................................................................................... 18

6.1.2 Hydraulic Connection ................................................................................................................................ 24

6.2 General Operation ............................................................................................................................................ 27

6.2.1 Physical Checks .......................................................................................................................................... 27

6.2.2 Front Panel Operation ............................................................................................................................... 28

3

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6.2.3 CMS removal and Product Maintenance ................................................................................................... 30

6.3 CMS Control ...................................................................................................................................................... 31

6.3.1 Computer Connection ............................................................................................................................... 31

6.3.2 PC Software Operation .............................................................................................................................. 32

6.3.3 Settings ...................................................................................................................................................... 33

6.4 Standard Communication Protocols ................................................................................................................. 42

6.4.1 Modbus ...................................................................................................................................................... 42

6.4.2 CAN-bus ..................................................................................................................................................... 46

6.4.3 Analogue 4-20mA Modes .......................................................................................................................... 49

6.5 Disposal ............................................................................................................................................................. 51

7 Troubleshooting / FAQ ............................................................................................................................................ 52

7.1 Misuse of Product ............................................................................................................................................. 52

7.2 Fault Finding ..................................................................................................................................................... 52

7.2.1 LED Flashing / Fault Codes ......................................................................................................................... 52

7.2.2 Test Status ................................................................................................................................................. 53

7.2.3 Other Faults ............................................................................................................................................... 53

7.3 Test Duration .................................................................................................................................................... 54

8 How to Order ........................................................................................................................................................... 55

8.1 Common Features ............................................................................................................................................ 55

9 Related Products ...................................................................................................................................................... 56

9.1 RDU 2.0 ............................................................................................................................................................. 56

9.2 CMSUSBI ........................................................................................................................................................... 56

10 Service and Recalibration ...................................................................................................................................... 57

11 Reference ............................................................................................................................................................... 58

11.1 Further Modbus Information.......................................................................................................................... 58

11.1.1 Modbus Registers .................................................................................................................................... 58

11.1.2 Implementing Modbus ............................................................................................................................ 63

11.2 Further CAN-bus Information ......................................................................................................................... 65

11.2.1 Example Walk through ............................................................................................................................ 65

11.2.2 Messages ................................................................................................................................................. 70

11.3 Measuring Water in Hydraulic and Lubricating Fluids.................................................................................... 73

11.4 ISO4406:1999 Cleanliness Code System ......................................................................................................... 75

4

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

11.5 NAS1638 Cleanliness Code System (now defunct, replaced by SAE AS4059E Table 1) ................................. 76

11.6 SAE AS4059 REV E Cleanliness Classification for Hydraulic fluids .................................................................. 76

11.7 Recommendations .......................................................................................................................................... 77

11.8 Hydraulic System Target Cleanliness Levels ................................................................................................... 78

11.9 New ISO Medium Test Dust and its effect on ISO Contamination Control Standards ................................... 79

11.10 Clean Working Practices ............................................................................................................................... 83

5

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

1 General Warnings and Information for the End User

1.1 General Safety Warnings

Do not operate, maintain or carry out any procedure before reading this manual. Any individual operating the

unit shall wear the following Personal Protective Equipment:

Protective eyewear

Safety shoes

Gloves

Overalls (or other suitable protective clothing)

Before carrying out any machine installation procedures and/or before use, one should scrupulously follow the

instructions listed in this manual. Moreover, it is necessary to comply with the current regulations related to

occupational accident prevention and safety in the workplace.

Notices aimed at the prevention of health hazards for personnel operating the machine are highlighted in this

document with signs having the following meaning:

WARNING

It relates to important information concerning the product, its use or part of this

documentation to which special attention must be paid

DANGER

It means that failure to comply with the relevant safety regulations may result in death,

serious injury or serious property damage.

In order to quickly identify the professionals concerned with reading this manual, the following definitions were

used:

OPERATOR

This is any individual whose task is to use the machine for production purposes. The

operator is aware of all the measures taken by the machine manufacturer in order to

eliminate any source of injury risk in the workplace and takes into account the

operational constraints.

PERSONNEL

INVOLVED IN

SLINGING AND

HOISTING

OPERATIONS

This is any individual whose task is to handle the machine or parts of it. Personnel

involved in slinging and hoisting operations are aware of the issues regarding the safe

transfer of machinery or parts of it and, therefore, uses appropriate lifting equipment,

following the instructions provided by the product manufacturer.

CAUTION

It means that failure to comply with the relevant safety regulations may result in mild

injury or property damage.

6

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

MACHINE SETTER

This is any individual whose task is to set up the machine for its operation. The

machine setter is aware of the measures taken to eliminate all sources of injury risks in

the workplace and takes into account the operational constraints. The machine setter

takes all the appropriate precautions in order to operate in utmost safety conditions.

MAINTENANCE

TECHNICIAN

This is any individual whose task is to carry out maintenance activities on the machine.

The maintenance technician is aware of the possible danger situations that may arise

and takes the appropriate precautions in order to eliminate the risks of accidents in the

workplace.

ELECTRICIAN

This is any individual whose task is to carry out maintenance activities on the electrical

wiring of the machine. The electrician is aware of the possible danger situations that

may arise and takes the appropriate precautions in order to eliminate the risks of

accidents in the workplace.

1.3 Operator Position and Dangerous Areas

No operator is required for operating the unit. However, the following areas are to be considered dangerous: The

ones close to the electric motor because of live equipment with potentially hot surfaces.

WARNING

The unit shall be taken out of service and/or dismantled in accordance with the

current regulations in force in the country where the machinery is installed

WARNING

The machinery is not suitable for outdoor use and all the electrical devices have a

protection class starting from IP 55 upwards.

1.4 Dangers and Hazards that cannot be eliminated

-Electric shock risk on the electric motor; in case of motor malfunction

-Burn risk because of high temperatures

-Accidental oil leaks with consequent risk of slipping

-Hose breakage and resulting lubricant loss

With oil temperatures exceeding 40/45 °C, it is vital to be extremely careful when handling the metal lances/the

hoses and when moving the unit. Avoid direct contact with hot oil and with the filter body.

ALL EQUIPMENT SHOULD BE ALLOWED TO COOL PRIOR TO HANDLING, AFTER IT HAS BEEN IN USE

7

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

1.5 Personal Protective Equipment

When operating the unit, personnel must be wearing safety shoes, gloves and goggles. In general, the PPEs to be

used according to the activities on the machinery are listed in the following table:

Activity

PPEs

Ordinary operation

Shoes, gloves, goggles, overall

Planned maintenance

Shoes, gloves, goggles, overall

8

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

2 Transportation and Storage

2.1 Transportation and Handling Conditions

The unit is shipped in a cardboard box, encased in polyurethane foam.

The packed weight of the CMS and accessories is 2.5kg.

2.2 Storage

The unit should be stored in a suitable location away from the production area when not in use. The unit should

be stored with the caps provided on the ports. This location should not impede any other production or

personnel.

9

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

3 Warranty, Limitations and Disclaimers

RMF Systems warrants that the products that it manufactures and sells will be free from defects in material,

workmanship & performance for a period of 12 months from the date of shipment.

Hardware/Firmware

Should the hardware prove defective during the warranty period, RMF Systems, at its discretion, will either repair

the defective product or replace it with an equivalent product in exchange for the defective unit without charge

for parts, labour, carriage and insurance.

Software

RMF Systems warrants that software will operate substantially in accordance with its functional specification for

12 months from date of shipment provided that the integrity of the operating environment has not been

compromised through misuse, inappropriate handling, abnormal operating conditions, neglect or damage

(unintentional or otherwise) or the introduction of third party product (software or hardware) that in any way

conflicts with the RMF Systems product.

Eligibility

This warranty extends to the original purchaser only or to the end-user client of an RMF Systems authorised

affiliate.

How to obtain service?

To obtain service under the terms of this warranty, the customer is required to notify RMF Systems before the

expiration of the warranty period and to return the item in accordance with RMF Systems product return policy.

Any product returned for warranty repair must be accompanied by a full fault report specifying the symptoms and

the conditions under which the fault occurs. Should RMF Systems incur additional cost as a result of a failure to

complete the appropriate paperwork, an administrative charge may be levied.

Exclusions

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

care. RMF Systems shall not be obligated to provide service under this warranty if:

a) Damage has been caused by a failure to make a full and proper inspection of the product (as described by the

documentation enclosed with the product at the time of shipment) on initial receipt of the product following

shipment;

b) Damage has been caused by the attempts of individuals, other than RMF Systems staff to repair or service the

product;

c) Damage has been caused by the improper use or a connection with incompatible equipment or product

including software applications.

Charges

Under cover of this warranty, RMF Systems will pay the carriage and insurance charges for the shipment of

defective product back to site of manufacture and for its return to the client’s original site of despatch except

when:

a) RMF Systems product return policy has not been followed.

b) Product failure is caused by any of the exclusions described above, when the customer will be liable for the full

cost of the repair (parts and labour) plus all carriage and insurance costs to and from RMF Systems premises.

c) The product is damaged in transit and a contributory cause is inadequate packaging. It is the customer’s

responsibility to ensure that the packaging used to return equipment to RMF Systems is the same, or has

10

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

equivalent protective qualities, to that used to ship the product to the customer in the first instance. Any damage

resulting from the use of inadequate packaging will nullify RMF Systems obligations under this

warranty. Should the customer’s product be damaged in transit following a repair at RMF Systems site, a full

photographic record of the damage must be obtained (packaging and the product) to support any claim for

recompense. Failure to present this evidence may limit RMF Systems obligations under this warranty.

THIS WARRANTY IS GIVEN BY RMF SYSTEMS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, NON INFRINGEMENT OR

FITNESS FOR A PARTICULAR PURPOSE. RMF SYSTEMS LTD SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES ( INCLUDING LOSS OF DATA), WE

SPECIFICALLY DISCLAIM ANY AND ALL WARRANTIES TO CUSTOMERS OF THE CUSTOMER. THE CUSTOMER’S

SOLE REMEDY FOR ANY BREACH OF WARRANTY IS THE REPAIR OR REPLACEMENT, AT RMF SYSTEMS

DISCRETION, OF THE FAILED PRODUCT.

RMF Systems BV maintains a policy of product improvement and reserves the right to modify the specifications

without prior notice.

11

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

4 Product Presentation

The CMS measures and quantifies the numbers of solid contaminants in Hydraulic, Lubrication and Transmission

applications. The CMS-M is designed to be an accurate instrument for permanently installed applications utilising

mineral oil as the operating fluid. Other fluid media versions are available for offshore [N] and aerospace

phosphate ester [S] applications.

The unit can operate using any of the international standard formats ISO 4406:1999, NAS 1638, AS 4059E/F and

ISO 11218.

The CMS incorporates a machine connector for power and PLC connection, capable of RS485, CANBUS or 4-20mA

signaling. A separate connector is also provided for simultaneous computer remote monitoring or settings access

using RS485 or a USB:RS485 interface.

The integrated data logger records up to 4000 test results internally, for use where a computer cannot be

permanently connected.

Simple switched inputs and alarm outputs are provided as alternative means of controlling the testing and

signaling the results. The "full colour’’ front panel led provides a basic indication of the cleanliness level.

The instrument uses the light extinction principle whereby a specially collimated precision LED light source shines

through the fluid and lands on a photodiode. When a particle passes through the beam it reduces the amount of

light received by the diode, and from this change in condition, the size of the particle can be deduced.

4.1 Benefits

− Live real time monitoring

− Manual, automatic and remote control flexibility

− Moisture and temperature sensing

− Multicolour LCD and LED for clear visual indication of any faults and alarms

− Instant result download on USB versions

4.2 Product features

4.2.1 Moisture Sensor

CMS-W models measure water content using a capacitive RH (relative humidity) sensor. The result is expressed as

percentage saturation. 100% RH corresponds to the point at which free water exists in the fluid, i.e. the fluid is no

longer able to hold the water in a dissolved solution. This is also normally the point at which damage occurs in a

hydraulic system, so is an ideal measurement scale that is independent of the fluid characteristics.

The water saturation point (100% RH) is temperature dependent, so the temperature is measured at the same

time. This enables results to be compared meaningfully.

The temperature measured is that of the fluid passing through the unit. Note this may differ from that of the

hydraulic system, depending on flow rate, pipe length and ambient temperature. It is not intended to be an

accurate indication of system temperature, but to provide a reference for the RH measurement. Nevertheless

experience has shown the temperature measured is within a few degrees of that of the hydraulic system, in most

applications.

12

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

4.2.2 Data Logger

The CMS includes a built-in data logger, which adds the facility to log and timestamp test results locally within an

internal memory, even when not connected to a computer.

− Test logging is determined by the log settings (see section 6.3.3).

− Each log entry is time-stamped and contains the CMS serial number, so that it can be identified later.

− The CMS memory has space for around 4000 log entries. When full, the oldest log entry is overwritten.

See section 6.3.1 + 6.3.2 for details of how to download the test log via bespoke windows based software.

4.2.2.1 Data Transfer via USB Stick

The U version of the CMS allows direct download via a USB memory stick. With the CMS powered up, plug the

USB stick into the USB connector at the top of the unit.

The screen / indicator will turn yellow briefly as it writes the test records to the USB stick. When complete, it will

turn green and the stick can be removed. If there is a problem with the data transfer (stick full or corrupt or not

recognised) then the screen / indicator will turn red. If this happens the operator can remove the stick and try

again with an alternative.

The USB stick provided with the unit is pre-formatted for the transfer. Other USB sticks may need to be reformatted (FAT32).

PLEASE NOTE: The USB option is not to be used for anything other than a memory stick

for results download. Any subsequent use other than that intended may cause damage

to the device

13

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

5 Technical Specification

5.1 Performance

Technology LED Based Light Extinction Automatic Optical Contamination Monitor

Particle Sizing >4, 6, 14, 21, 25, 38, 50, 70μm

Analysis range ISO 4406: Code 0 to 25

NAS 1638 Class 00 to 12

AS4059 Rev E Table 1 & 2 Sizes A-F: 000

Please Note: (Lower Limits are Test Time dependent)

If system cleanliness is expected to be above 22/21/18 or approx. NAS 12

Calibration Each unit individually calibrated with ISO Medium Test Dust (MTD) based on ISO 11171,

on equipment certified by I.F.T.S. ISO 11943

Moisture & Temperature Measurement % saturation (RH) and fluid temperature (°C) – Mineral Oil /

Diesel version only

Accuracy ±½ ISO code for 4, 6, 14μm

±1 code for 21, 25, 38, 50, 70μm

±3°C

±3%RH

5.2 Electrical Interface

Supply Voltage 9-36V DC

Supply Current 12V 24V 36V

150mA 80mA 60mA K version

70mA 40mA 30mA NON- K version

Power Consumption 2.2W max

Test Time Adjustable 10 - 3600 seconds (factory set to 120s)

Data Storage Approximately 4000 timestamped tests in the integral CMS memory

Keypad & LCD 6 keys, 128x64 pixels, back-lit graphical display

Communication RS485

Options MODBUS

CANBUS

4-20mA

5.3 Physical Attributes

Dimensions 123mm (H) x 142mm (W) x 65mm (D)

14

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Mounting 2 holes Ø7mm 126mm apart

Weight 1.6kg

Connections G1 M16x2 hydraulic connection

G3 ¼” BSPP Female Port

G4 7/16 UNF Female Port

Seal Material M/N Version – Viton (contact RMF Systems for any fluids that are incompatible with Viton

seals

S Version - Perfluoroelastomer

15

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

5.4 Fluid Characteristics

Fluid compatibility M version - mineral oils, synthetic fluids and diesels

N version – water based/ subsea fluids & M version fluids

S version – Aerospace phosphate esters, Skydrols® and N & M version fluids.

Viscosity ≤ 1000 cSt

Fluid temperature -25°C to +80°C

Operating Flow Rate 20-400ml/min

16

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Maximum Pressure 420barg static (For high frequency pressure pulse applications contact RMF Systems)

Differential Pressure Typically 0.5bar

5.5 Environment

Ambient working temperature -25°C to 80°C non K version / -25°C to 55°C K version

IP Rating IP66

IK Rating IK04

5.6 Wetted Parts List

M version

N Version

S Version

Copper Alloy C46400

Stainless Steel

Stainless Steel

Stainless Steel

Sapphire (Al2O3)

Sapphire (Al2O3)

Sapphire (Al2O3)

Viton

Perfluoroelastomer

Viton

PTFE

PTFE

PTFE

EPDM

FR4

17

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6 Product Installation and General Operation

6.1 Installation

Each CMS supplied consists of the following:

− CMS

− Calibration certificate

− USB Stick which includes: Product User Guides, RMF-View software, accessory product drivers and product

brochures

− Pre-wired 3m cable

− Quick Start Guides

Optional Equipment:

− Circular connector pre-wired with 3m cable

− CMSRDU2 Remote display unit

− 500μm coarse screen filter

− CMSUSBi USB adaptor with pre-wired CMS cable

− CMSETHi RJ-45 adaptor with pre-wired CMS cable

6.1.1 Physical Procedure

− Decide on tapping points in hydraulic circuit

− Locate the unit mechanically and bolt to desired location using fixing holes provided. The CMS must be in a

vertical orientation, with the oil flowing upwards through it

− Wire back to junction box

− Check flow in acceptable range. There needs to be a differential pressure of more than approximately 0.5bar

placed across the CMS, such that a flow of fluid is generated within the range of the unit.

− If there is no suitable differential pressure available, then a flow controller will be needed. One solution is the

pressure compensated flow control valve. This limits the flow to around 200ml/minute for differential

pressures up to 400bar. This should be fitted to the drain side of the CMS (the top fitting).

− Fix mechanically

− Connect hoses or hard pipe from the system

− There must be no extra restriction placed in the drain hose. Do not have a pipe going to a restrictor to

control flow. Any such restrictor must be mounted directly to the CMS drain fitting.

(A)

− Fluid flow must be from the bottom fitting to the top, following the direction of flow arrow on the product

labelling i.e. the bottom fitting is the inlet and the top fitting is the outlet.

− Fit electrical connector, wire back to a junction box.

(A)

This is because any length of pipe between the CMS and a downstream restrictor can act as an accumulator.

Any pressure pulsations (for example from a pump) in the feed to the CMS are then translated into pulsations in

18

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

flow rate, sometimes leading to flow reversals in time with the pulsations. If the flow is very low this can sweep

the same particle backwards and forwards through the sensing volume multiple times, confusing the results.

6.1.2 Electrical Interface

RMF Systems’ separate CMS-USBi product is available for those wishing to have a simple plug and play solution

providing connection of the CMS to a computer. This section is for those wishing to do their own wiring to the

product.

6.1.2.1 Electrical Connectors

The CMS has two circular connectors located on the lower face of the unit. The USBi product can be connected to

either one depending on the installation configuration, see figure 6.1.

Pin

Colour

“Machine” Connector

“Remote” Connector

1

Yellow

RS485+/CANL/4-20mA(A)

RS485+

2

Pink

START INPUT

3 Green

RS485-/CANH/4-20mA(B)

RS485-

4

White

OUTPUT 1

5 Grey

I/O COMMON

6 Brown

OUTPUT 2

7 Blue

DC 0V

DC 0V

8

Red

DC +POWER

DC +POWER

6.1.2.1.1 Remote Connector

The ``remote connector’’ is intended for temporary connection of an external communication device e.g.

CMSUSBi so as to allow data download, remote control or diagnostics using the RMF-View software.

This is the circular connector furthest from the hydraulic connection, see figure 6.1.

This carries RS485 data and can also be used to power the unit temporarily in the event of a system being shut

down, thus no longer providing power to the unit.

This connector doesn’t send alarm signals as shown in the wiring diagram 6.7. If you require a USBI to send alarm

signals it has to be connected to the machine connector.

6.1.2.1.2 Machine Connector

The ``machine connector’’ is intended for permanent connection to the PLC / machine that powers the CMS

during normal operation. It has power connections, a start signal input, two relay outputs, and a data pair that

can be set to RS485, CANbus or 4-20mA signaling modes.

This is the circular connector closest to the hydraulic connection, see figure 6.1.

NOTE: If CANBUS or 4-20mA option has been selected, standard communication with an RS485 adapter (e.g.

USBI) on this port is no longer available.

The right hand port (remote connector) should be used if temporary connection is required.

NOTE: Start signal and relay outputs only apply to this connector.

19

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.1 Connector Orientation

Figure 6.2 Machine Connector External Wiring Example

6.1.2.2 DC Power

DC power is connected to pins 7 and 8 of either circular connector (Red and Blue if using the pre-wired cable). All

the other signals are optional.

Item

Minimum

Maximum

Voltage

9V DC

36V DC

Current

200mA

20

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6.1.2.3 Machine Connector - Serial Interface

An RS485 or CANbus interface can optionally be connected to pins 1 and 3 (yellow and green). This can be PLC

running customer software, or a PC with a RS485 adaptor running the supplied RMF-View software. To provide a

reference the RS485 0V connection should also be linked to the CMS 0V (as shown on figure 6.3).

The standard CMS control protocol is Modbus RTU. Modbus is a freely available open standard for industrial

control. Adapters are available to interface to other industrial control busses. The standard RMF-View software

from RMF Systems itself uses Modbus to communicate with the CMS, but it is also possible for customers to

implement their own controllers (section Modbus).

The CANbus protocol can also be used; see the CANbus section later in the manual.

Figure 6.3a PC Control Example

Figure 6.3b Modbus Controller Example

Figure 6.3a shows a single CMS linked to a PC, using a USB-RS485 adaptor. Figure 6.3b shows a slightly different

method. 100 Ohm termination resistors should be fitted as shown for long cables, for example over 10m. Twisted

pair wiring should be used for any length over 2m.

21

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.4 Multi-Drop Network Example

Figure 6.4 shows how to connect two or more CMS devices to a multi-drop RS485 network. Any termination

resistors should be fitted to the network cable ends only. Spurs off the main RS485 bus should be kept as short as

possible, e.g. below 2m. Normally the pre-wired 3m cable available for the CMS would be used, with a junction

box to connect to the RS485 trunk. Either individual DC supplies can be used to power each CMS, or a single

supply run through the trunk cable.

Figure 6.5 Remote Display Unit Including PC Controller Example

Figure 6.5 shows how to connect the CMS-RDU Remote Display Unit. The RDU is used when the CMS location is

not convenient for an operator. It can control and monitor a remote CMS, as well as allowing an external

controller to be connected to it (for data download, for example).

6.1.2.4 Switched Input and Output Signals

The CMS has one switched input and two switched outputs. These can be used instead of, or in addition to, the

RS485 interface for command and control. The RS485 interface is more flexible but requires more software work

if RMF-View is not used (e.g. control from a PLC). An alternative is to control the CMS via these switched I/O’s,

either from a PLC or using a manual switch and indicators.

22

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.6 Switched I/O Signals

In order to reduce wiring the input and outputs all connect together on one side (see Figure 6.6). However they

are optically isolated from the rest of the system so can be used to switch unrelated signals.

6.1.2.5 Start Signal

The "start signal’’ is an opto-isolated input that can be used to start a test, it can be used to ensure testing only

occurs when the hydraulic system is running. For example, the start signal could be wired to go on and off with

the main hydraulic pump or with a solenoid valve that allows fluid flow. That way the log does not fill up with

invalid tests that were carried out with no flow.

This could be from a push button or a PLC output. The input accepts AC or DC signals, typically derived from the

DC supply voltage. The exact function of this input is determined by the Test Mode setting (section tbc).

Item

Minimum

Maximum

Voltage

9V DC

36V DC

Impedance

10k Ohms

− When the START signal transitions from OFF to ON, the unit will start a new test or restart any test in

progress.

− At the end of the test, the state of the START signal is checked

− If the START signal is still on at the end of a test, another test is started. So that testing continues while

the START signal is held on.

− The switching off of the start signal will operate as a STOP command. That is, it will abort any test in

progress. It will continue to show and report the previous result.

− This new operation mode applies whether or not continuous testing is enabled.

− So for example if "continuous testing" and "stop testing when clean" are both enabled, and if the start

signal is being held on throughout testing, then EITHER the start signal vanishing OR a clean result can

terminate testing.

23

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

− This is not the same thing as the "start signal delimited test" option ("start signal defines test duration" in

user settings when enabled). This is for using the start signal to control the duration of each *single* test,

only.

Other ways to test are:

− From the CMS front panel START button, if fitted (K Keyboard option)

− Via RMF-View or PLC Modbus command

− Periodic automatic testing according to a programmed test mode

6.1.2.6 Alarm Outputs

These are opto-isolated switches that can be used to signal external indicators, PLC inputs or other equipment

(e.g. pump on/off control).

The exact function of these outputs is determined by the Alarm Mode setting (section 6.3.3.9).

The outputs are "voltage free’’ contacts that can switch AC or DC signals up to 36V nominal (60V absolute

maximum peak voltage).

Item

Minimum

Maximum

Voltage

36V DC

Current

0.5A

6.1.2.7 4-20mA Connection

See Figure 6.7 for a schematic.

The two 4-20mA outputs are sourced from the main supply voltage DC+. These may be connected to the 4-20mA

inputs of a process indicator or a PLC. The 0V connection is then also normally connected to the PLC 0V.

The 4-20mA outputs can be converted to 0-5V outputs by connecting a 250 ohm resistor between each output

and 0V. Similarly they can be converted to 0-10V outputs by connecting 500 ohm resistors.

For details of how the test results are represented by the 4-20mA signals, see section 6.4.3.

24

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.7 4-20mA Example

6.1.3 Hydraulic Connection

1 High or Low Pressure Parallel Connection

Figure 6.8 CMS working pressure generated by hydraulic component

25

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

2 Low Pressure, Off-Line Operation

Figure 6.9 CMS working pressure generated by hydraulic component

3 Very Low Flow Systems

Figure 6.10 Entire system flow rate is within the range of the CMS

6.1.3.1 Flow Rate

For the majority of systems, a differential pressure of a few Bar will generate an in-range flow for a CMS

connected using two 1.5 meter lengths of microbore pressure hose. The required differential pressure can be

obtained by taking advantage of an existing pressure drop within the system. Alternatively one can be created by

inserting a check valve. The CMS can then be connected across this differential pressure source.

6.1.3.1.1 Detailed Calculations

In general the flow rate of fluid through the CMS needs to be kept within the range of the unit (see hydraulic

specification 3.2). The CMS measures the flow during operation, so this can be used to check that the flow is

correct.

A flow that is out of range will be indicated by a fault code (see section 7.2).

Note: Results taken with out-of-range flows are not logged.

The flow is entirely generated by the differential pressure between the ends of the pipes used to connect the

CMS. The pressure needed to generate an in-range flow can be estimated by assuming a target flow, and

determining the resulting pressure drop across the CMS and connection piping. Use Figure 6.10 on page 24 to

lookup the CMS pressure drop, and manufacturers’ data to lookup the piping pressure drop at the desired flow.

The sum of these two pressures is the pressure needed.

The user connects the CMS between two points in the hydraulic circuit that have this pressure difference.

In order to use the graph:

− Determine the working viscosity of the fluid, e.g. 30 cSt

− Decide on a desired flow rate. 200ml/minute is normally used since this is in the middle of the CMS flow

range. But 100ml/minute is also suitable and uses less oil

26

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

− Use the figure 6.11 to look up the pressure drop, across the CMS ports, at this flow rate and viscosity. E.g.

at 30cSt and 200ml/minute, this is 0.4 Bar. The maximum and minimum allowed differential pressures

can also be determined using the 400ml/min and 20ml/min lines, respectively.

− Determine the additional pressure drop caused by the piping used to connect the CMS. This may be

negligible for 1/4 inch piping and over, but is very important for microbore hoses. This information can be

found in the manufacturers catalogues. In the case of microbore hoses, at 30 cSt these have a pressure

drop of around 10 Bar per meter per lpm of flow. So a 2m total hose length would add a pressure drop of

2 × 10 × 0.2 = 4 Bar. (So in this case the pressure-flow relationship is mainly dependent on hose

resistance).

− Add the CMS pressure drop to that of the hoses, e.g. 4 + 0.4 = 4.4 Bar

When the required pressure drop has been found:

− See the figures at the start of this section for examples of where the CMS could be connected

− If there is a pair of connections in the hydraulic circuit that operates with a differential pressure near to

that calculated, then the CMS can be connected there

− Alternatively, create the pressure drop by modifying the hydraulic system. For example, insert a check-

valve in the circuit with a 4 bar spring. The "component’’ could also be a filter, a restrictor or even a piece

of piping if it has a suitable pressure drop across it.

− If none of these options is feasible, then an active flow controller will likely be needed, see 6.1.2.3.

− Otherwise connect the CMS across the points identified; taking care to maintain an upward flow of oil

through the unit (this reduces trapped air).

Of course in a real system the pressure and viscosity will vary with temperature and operating conditions. But

since the working flow range of the CMS is very wide, this should not be a problem provided it remains within

range. On the graph the area between upper and lower lines represents the usable operating region for the CMS,

with the middle line being ideal. The differential pressure and the viscosity can vary from the ideal, provided the

system stays within the upper and lower lines. This ensures the flow stays within the working range of 20 - 400

ml/min. It can be seen that the unit will accommodate a 20:1 variation in either viscosity or differential pressure

during operation.

27

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.11 Differential Pressure vs Fluid Viscosity, for various flow rates

6.1.3.2 Manual Flow Control

Another possibility is to fit a simple manual flow control (flow restrictor) to the outlet of the CMS.

− This should only be done where the available pressure is less than twice the maximum value calculated. This

is because the small orifice size needed to control the flow from a pressure larger than this has a risk of

blockage.

− The flow controller must be fitted to the outlet only. If fitted to the inlet it will have a filtering effect.

− The flow controller must be fitted directly to the CMS outlet port.

6.1.3.3 Active Flow Control

This is only needed for operation at high differential pressures, where a too-high flow would otherwise be

generated.

A pressure compensated flow control valve is fitted to the CMS drain outlet. This has the effect of a ``flow

limiter’’, maintaining a constant flow rate even with a varying inlet pressure (provided this pressure stays above a

minimum working value). Below this pressure the valve is wide open so has little effect, i.e. the flow will be less

than the 200ml/min controlled value. This ``minimum working value’’ will be typically 5-10 bar but will vary with

viscosity. For these lower pressures a flow control valve is not needed and other methods are better used to

control flow as previously described.

Figure 6.12 CMS flow actively regulated

6.2 General Operation

6.2.1 Physical Checks

• Oil leaks on and around the unit

• Fatigue in hoses and pipework that might then leak when under system pressure

28

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6.2.2 Front Panel Operation

6.2.2.1 Status LED

All CMS versions have a multi-colour indicator on the front panel, which is used to indicate the status or alarm

state. CMS-K versions also have a screen that changes colour. The alarm thresholds can be set from RMF-View via

the serial interface.

Figure 6.13 Front panel of K version (left) and Non-K version (right) CMS 2

Colour

Shows

Green

Indicates that the test result has passed, i.e. none of the alarm thresholds were

exceeded

Yellow

Indicates that the lower cleanliness was exceeded, but not the upper one

Red

Indicates that the upper cleanliness was exceeded

Blue

Indicates that the upper water content limit was exceeded

Red/ Blue Alternating

Indicates both cleanliness and water content upper limits exceeded

Violet

Indicates that the upper temperature limit was exceeded

Red Flashing White

Various fault codes can be indicated by the LED turning red and then flashing

white a number of times (Section 7.2.1)

Please note: If the codes seem confusing, note that a given colour will only ever be seen if the corresponding limit

has been specifically set by the user. So for example if a maximum temperature limit has not been set, the violet

indication will never be seen. If all that is wanted is a "green or red’’ light, that can be arranged by simply setting

only the cleanliness threshold maximum limit.

If the upper temperature alarm is set, this takes priority over the Contamination and Water alarms. In the event

of an over temperature condition, the LED will turn violet only, whether or not there is also a contamination or

water alarm condition. The rationale is that an over-temperature condition could be immediately catastrophic for

the hydraulic system.

29

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6.2.2.2 Front Panel Operation

6.2.2.2.1 Result Display

CMS-K models have a 6 button keypad and a small graphical LCD. This allows the display of the test result (current

cleanliness level, with water content and temperature if applicable).

The graphical format allows a full display of all codes of the standards supported.

The unit powers up in "Display Mode’’. This displays the test result in the selected format. The table below shows

those available.

The screenshots in the right column are the "detailed’’ version of the display additionally showing the particle

counts and flow rate. The particle sizes and count representation are automatically matched to the selected

format.

Format

Simple View

Detailed View

ISO4406:1999

NAS1638

AS4059E Table 1

AS4059E Table 2

ISO11218

There is also a ``History’’ screen which shows the last 10 results.

The operator can switch between these screens using the ▲ and ▼ keys.

30

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

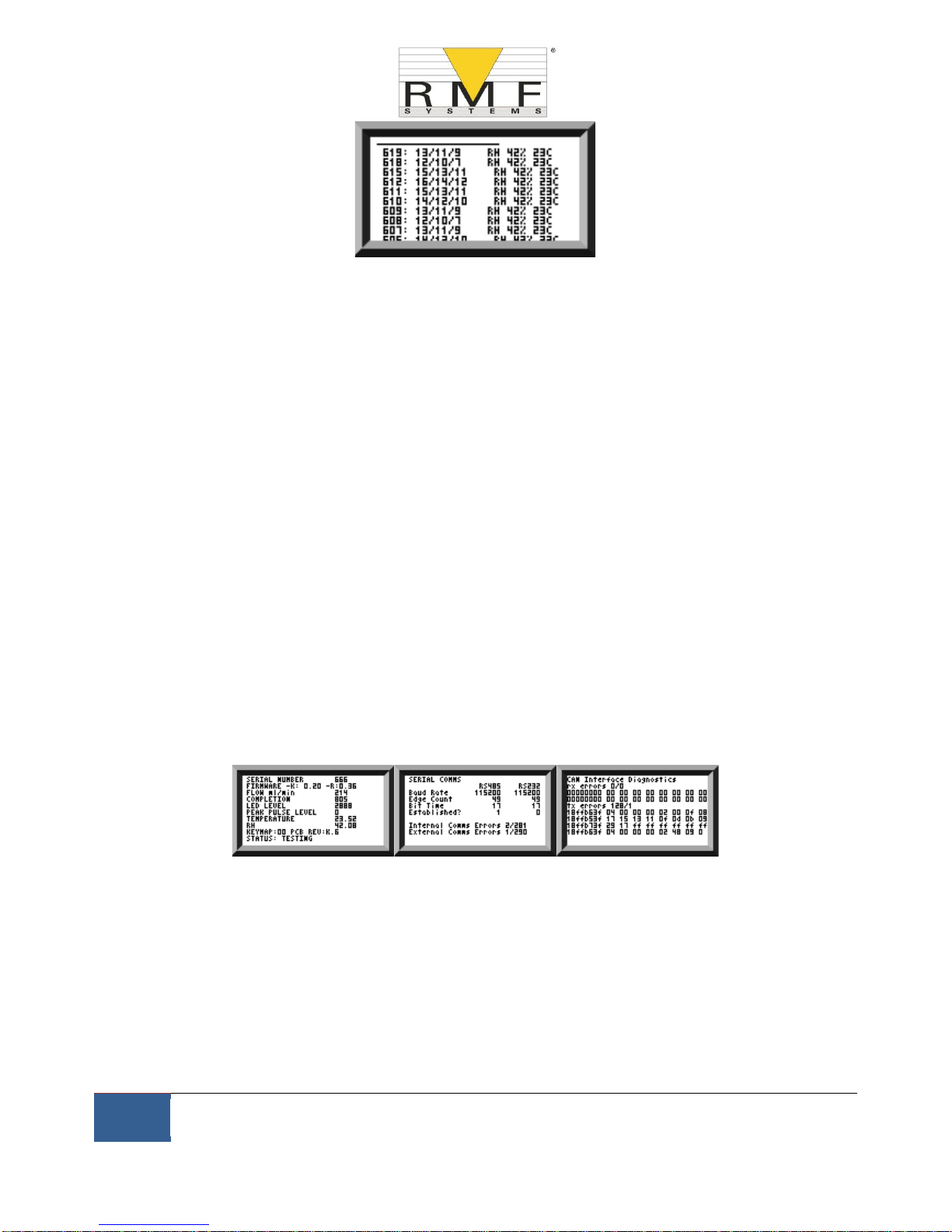

Figure 6.14 History Screen

The progress of a test is denoted by the horizontal line; it grows from left to right as the test progresses. When it

reaches the right hand side a new result is generated.

6.2.2.2.2 Diagnostics Display

Press ◄ or ► to show the diagnostics displays (used when diagnosing problems) shown in figure 6.15. Then

switch between the diagnostics screens using the ▲ and ▼ buttons.

Completion shows a number from 0 to 1000, indicating the test progress.

FLOW ml/min provides an approximate indication of flow rate, updated after each test.

NOTE: This is not a calibrated flow meter and is for indicative purposes only.

This can be helpful when installing the unit or checking operation, to ensure that the flow rate is within the limits

of the unit. The other items are mainly of use to assist in support when reporting problems.

The STATUS line shows the current state of the unit. Any errors such as LOW FLOW will also appear here

(corresponding to the front panel LED fault codes).

The second screen shows diagnostics relating to Modbus serial communications traffic. External Comms Errors

are those between a connected PC and the CMS. Internal Comms Errors are internal to the unit, showing

communications between the CMS keyboard/display circuit board and the sensor itself.

The third screen shows diagnostics related to CAN bus communications.

General Modbus CAN Bus

Figure 6.15 Diagnostics Screens

6.2.3 CMS removal and Product Maintenance

When removing the CMS from the system ensure the system pressure is shut off from the CMS.

Blockages

− If a suspected blockage occurs then flush system fluid in the reverse direction of the CMS.

− If this doesn’t solve the problem then try using Iso-Propyl Alcohol or Petroleum Ether, flushing in the

standard and reverse flow direction.

31

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

− If this doesn’t solve the issue then send to RMF Systems for investigation.

6.3 CMS Control

The CMS can be controlled using the remote control facility included in the RMF-View software package, installed

on a computer. Alternatively customers can use their own computer software.

Since the CMS includes a built-in data logging memory, operators can make use of the remote control facility in

one of two ways:

− Direct Online Operation

The CMS is permanently connected to a computer while tests are carried out. The operator can set parameters,

type a label and initiate the test. They can then monitor the progress of each test. Each test result is displayed and

downloaded into the test database as it is completed.

− Disconnected Operation

Here the CMS operates as a standalone item, performing tests on a schedule or under external command from a

control system. If a permanent record of the results is needed, an operator can connect a computer and use RMFView to download the accumulated test data. The CMS can hold up to 4000 tests in the memory.

6.3.1 Computer Connection

The connection is made using an RS485 adaptor connected to the computer or control device.

The CMSUSBi is included as a pre-wired solution for USB (all modern laptops and PCs). Make the connection, start

RMF-View running and then apply power to the CMS.

Figure 6.16

To access the Remote Device facility in RMF-View, press the Remote Control button (Figure 6.17) on the toolbar.

The Connect dialogue will then appear (Figure 6.18).

32

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.17

Figure 6.18

The first time that this is done, the correct communications port (COM port) on the computer has to be selected,

as detailed below.

− The program scans the computer for available ports, and puts them in a list to choose from - this list is in the

box above the Connect button. Press the arrow on the right hand side of this box and choose the connection on

your computer.

− All working communication ports of the computer are available for selection. Select the one used to connect the

CMS, and then press OK. If you are unsure which port is correct, the device name should be next to the COM port

number. When communication has been established successfully, the remote control dialogue will appear. After a

successful connection, the COM port will be remembered for next time and will appear preselected in the

dialogue. If no COM ports appear, please refer to the fault finding section the manual (7.2).

6.3.2 PC Software Operation

The Remote Control dialogue allows an operator to manually control the CMS from a laptop, using the RMF-View

software. It can also be used to download test results that have accumulated during autonomous (disconnected)

operation.

33

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.19

To perform a test, first optionally edit the Test Reference and press Apply to register the new value. This is a

descriptive label which can be used to identify or group the test later (along with the test number and test

time/date). An example would be a machine number or customer name. The Test Reference can be up to 15

characters in length.

When connected the CMS status should show "Ready". The operator can then press the Start button to begin the

test. The progress bar shows how much of the test has been completed.

The test can be abandoned at any time by pressing the Stop button. If the Start button is pressed during a test,

then the current test is abandoned and a new one started. When the test has finished, the Result area will display

the contamination level in the set format and water content and temperature (if applicable).

After a test the Test Number is automatically incremented and the status of the test is displayed. If the status is

Ready then the operator can press the Start button again to begin a new test.

It is also possible to configure the CMS to automatically begin another test, after an optional delay. In this case

the status will be Testing or Waiting.

The CMS incorporates a data logger, so previous test results can be downloaded into the test database using the

Download New and Download All buttons. The difference between these is that Download New only transfers

results that have never been downloaded before. Download All transfers all results that are stored in the CMS.

Erase Log deletes the test results from the memory of the CMS, see figure 6.19.

When the user has finished operating the CMS the dialogue can be dismissed using the close control (the "X" at

the top right corner of the dialogue) or by pressing the Esc key. Pressing the Settings... button brings up the

Remote Device Settings dialogue.

6.3.3 Settings

The CMS can be reconfigured using the Remote Device Settings dialogue. This is normally done as part of the

installation or commissioning process.

After making any changes, pressing the OK button will update the CMS with the new settings. Or press Cancel to

leave the settings as they were.

34

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.20

NOTE: The CMS has been designed to be a very flexible product, so has a wide range of settings and operating

modes. However the shipped defaults are suitable for most applications and many users can skip this section.

Actual operation is straightforward even when advanced settings are used during initial configuration.

NOTE: Some items may be missing depending on the options fitted to the CMS.

6.3.3.1 General

Some general information about the connected CMS unit is available. The Identification shows the CMS serial

number and software version. The serial number, together with the test timestamp, uniquely identifies the test

record. These two parameters are the ones used to avoid duplication of test records.

Current Time shows the time set on the CMS. It is important that this is correct since this is used to timestamp the

tests. Pressing the Set button automatically synchronizes the CMS time to that on the computer.

The calibration area displays the date last Calibrated and the next Calibration Due date.

6.3.3.2 Test Number

The Test Number can be used to help identify a test within a sequence. However it is automatically reset when

the CMS is powered up, so instead relying on the timestamp (date and time of test) and test reference is

preferred.

35

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.21

NOTE: if the CMS is power cycled at any point then the test numbering sequence automatically resets and begins

again.

6.3.3.3 Test Duration

The length of the test is controlled by the Test Duration, see figure 6.21 for location.

The factory set value of 2 minutes is suitable for most applications, but the user is free to set a different value.

Shorter times will make the CMS more responsive to short-term fluctuations in contamination level. It will also

result in less consistent results for the large particle sizes and clean systems, due to statistical fluctuations in the

number of particles counted.

Longer tests will allow more "stable” results in very clean systems and for the larger particle sizes, since there will

be a larger total number of particles counted during the test. This means that any fluctuations have less of an

effect on the test result.

6.3.3.4 Result Display

Use the selector to choose the preferred display Format (ISO, NAS etc.). This selection is not just cosmetic since it

also determines how the cleanliness alarm targets are to be interpreted, if these are used. See figure 6.21 for the

location, it is defined as the format.

6.3.3.5 Simulated Test

This setting can be used when there is no flow available but communications need to be tested. This is the box

ticked in figure 6.22

Figure 6.22

6.3.3.6 Low Flow Alarm Disabled (Clean Systems)

− It is worth reinforcing that the primary function of the product is to produce a measurement of

cleanliness, and not act as a flow meter. If the unit produces a contamination measurement, then the

flow rate is sufficient enough for it to do so.

36

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

− The CMS needs particles to pass through the flow cell to calculate flow, the dirtier the system is, the more

statistically accurate the flow output becomes.

− Conversely, when placed on a very clean system the unit can have difficulty in working out the flow due

to the very low number of particles passing through the flow cell.

To overcome this, the test has to fulfil certain conditions to create a valid result.

It the low flow alarm has been disabled there must be a minimum of 20 particles >4micron seen during

the test for the flow reading to be shown and the test result to be valid.

If there are less than 20 particles >4micron during the test then the CMS will alarm/fault code even if the

low flow alarm has been disabled.

Note: If the low flow alarm has been disabled, it is preferred that the CMS is installed in such a way that if

the system is shutdown (zero flow) the CMS is also shut down so as not to measure stagnant fluid and

provide erroneous readings.

− It may be necessary that the low flow indicator is turned off if filtration is below 10um (ISO 14/12/10 (NAS

Class 4)), see figure 6.22 for location.

6.3.3.7 Continuous Testing

Figure 6.23

In the Continuous Testing area are settings which control how the CMS decides when to perform and log a test.

Selecting Test Continuously makes the CMS automatically repeat the test, according to the specified Test Interval.

a) Setting an interval longer than the test duration; results in the test being repeated upon each expiry of

that interval. For example, setting a Test Duration of 1 minute and a Test Interval of 10 minutes, results in

a 1 minute test performed every 10 minutes.

NOTE: Test time is part of interval time

b) Setting the interval to a value less than the Test Duration (for example zero); results in a new test being

started immediately after a test finishes.

Log Continuous controls whether tests are logged during continuous testing. This is to avoid the test log being

cluttered by potentially large numbers of unwanted test results. If Log Continuous is not selected, then only the

"final" test in a sequence is logged (see Alarm Modes section and "Stop Testing When Clean" below).4

37

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

If continuous logging is used, then the Log Interval can be set to control the proportion of tests that are actually

logged. For example the CMS could be set to test every 10 minutes, but only log a result hourly. The log interval,

test interval and test duration are distinct parameters that work together to control the test and data logging. So

that, a test duration of 2 minutes, a test interval of 10 minutes, and a log interval of 1 hour could be individually

set. This would result in 2 minute long tests, repeated every 10 minutes, with a test logged hourly.

NOTE: the log interval must land on a test interval or an error will occur, for example the test interval cannot be 2

minutes and the log interval 3 minutes.

Stop Testing When Clean- This is a feature intended for cleaning rigs or "filter trolley" type applications. The CMS

continues testing until the fluid is "clean", at which point an alarm is signaled and testing stops.

Ignore Initial Tests- on start up the number selected here is the number of tests that are ignored before results

are logged. This is designed for systems that are particular dirty or turbulent on startup and it allows the system

to stabilize.

Confirm Target Level before Stopping- this helps to ensure that a test sequence is not terminated too soon, when

there are still a few large particles in the system. When selected, the number in the box is how many successive

"clean" results are needed before testing halts.

4

This feature is intended for a "Filter Trolley" type application where system runs a pump until the oil is

sufficiently clean. Typically only the final "clean" result requires logging.

6.3.3.8 Changing Communication Protocols

Figure 6.24

Selecting the communication button allows you to change how the CMS communicates. See figure 6.25 for the

options.

38

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.25

Selecting a machine interface fixes the output for the machine connector, for example selecting CANbus means

that you can no longer use the machine connector to communicate in Modbus (the default). If you wish to change

back or to a version of 4-20mA then you have to connect to the CMS via the Remote Connector.

See section 6.4 for information on how to communicate with the CMS in the different protocols.

6.3.3.9 Alarms

The CMS has two switched "alarm" outputs that can be used to signal external equipment in various ways,

according to the test results and the alarm settings. There is also a multi- colour front panel light which indicates

how the result compares to the set alarm thresholds.

The alarm settings are comprehensive and flexible, allowing the CMS to be used in many different scenarios.

6.3.3.9.1 Alarm Levels

The various alarm thresholds are set in the Contamination Code Target / Alarm Levels area of the dialogue.

Alarms can be set on combinations of cleanliness codes, water content and temperature. The available codes, and

their interpretation, vary according to the set test Format. For example it is possible to set a threshold of "NAS

11" or "ISO 18/16/15" or "AS4059E 8B-F", etc.

In general there are upper and lower limits that can be set for the cleanliness level, also for water content and

temperature if applicable. An alarm, if enabled, will become active if any of the associated (upper/lower) limits

are exceeded. However if a field is left empty (blank) this is interpreted as a "don’t care" setting.

In the example Figure 6.21 the Upper Alarm is exceeded if the 4μm count is greater than ISO code 23, or the 6μm

greater than ISO code 22, or the 14μm count greater than code 18, or the water content is greater than 80% RH,

or the temperature is greater than 65°C. The lower alarm is never triggered since all the settings are empty.

39

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.24

ISO4406:1999 Alarm Levels

ISO4406:1999 represents cleanliness using codes for the number of particles greater than 4, 6 and 14µm. These

codes can be used as limits for the alarms by selecting the ISO4406:1999 test Format and then entering values as

required. As an extension to ISO4406:1999 it is also possible to specify codes for the other measured sizes too. If

this is not needed then the entries can be left blank.

NAS1638 Alarm Levels

Figure 6.25

NAS1638 can be used by selecting this as the test Format. The headings and boxes for the available settings

change appropriately. NAS1638 represents the overall cleanliness level as a single code, this being the highest of

the individual codes generated for each defined particle size. Hence we have the option of setting a limit on this

overall contamination class (the Basic Class), or we can set individual limits on any combination of the classes for

the defined particle size ranges.

AS4059E Table 2 Alarm Levels

Figure 6.26

40

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

AS4059E Table 2 uses letters instead of numbers to indicate the particle size range, so the settings are labelled

appropriately. The standard specifies ways to represent a cleanliness level using only a subset of the available

particle sizes, for example B-F. The user can achieve this by only entering settings for the sizes desired, leaving the

others empty. So a limit of AS4059 7B-F could be represented simply by entering a value of 7 for B, C, D, E and F.

AS4059E Table 1 / ISO11218 Alarm Levels

Figure 6.27

These two standards are similar except for terminology and reporting format. The actual numeric sizes and class

thresholds are the same.

6.3.3.9.2 Alarm Mode

Figure 6.28

The Alarm Mode sets the precise function of the two switched alarm outputs of the CMS.

This allows the CMS to be used in a variety of situations. Note that the conditions under which the outputs are

turned on are also displayed above the Alarm Mode selector, for each setting.

NOTE: These outputs are distinct from the front panel LED, and that the set alarm mode does not affect the LED.

The set alarm mode determines the function of the two switched outputs only. This setting and this entire section

can be ignored if these outputs are unused, i.e. the user has not connected them to anything.

New modes are occasionally added after a customer request, this means that modes may not all be implemented

unless using the latest firmware revision.

41

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Alarm Mode 0: Warning-Alarm

Output 1

Output 2

Turns on When

>Lower

>Upper

Intended Function

Warning

Alarm

This allows the CMS to switch external warning lights or alarms. Output 1 is the "Warning’’ output, switching on if

any of the Lower limits are exceeded. Output 2 is the "Alarm’’ output, behaving similarly for the upper limit.

Alarm Mode 1: Clean-Dirty

Output 1

Output 2

Turns on When

≤Lower

Upper

Intended Function

Clean

Dirty

This could be used in a cleaning system that attempts to maintain a cleanliness level by switching a pump on and

off.

Output 1 is the "Clean’’ output, coming on when the result is less than or equal to the lower ("Clean’’) limit. This

could be used to stop a cleaning pump.

Output 2 is the "Dirty’’ output, coming on when the result is greater than the upper ("Dirty’’) limit. This could be

used to start the cleaning pump.

Alarm Mode 2: Green-Amber-Red

Output 1

Output 2

Turns on When

<Upper

>Lower

Intended Function

Green

Red

This mode encodes the result in such a way that the internal alarm relays can be used to drive an external remote

3-colour LED indicator. This is a special type of LED containing both red and green emitters, which could be

mounted in a control panel. This external LED will then turn green / amber / red according to the test result – in a

similar way to the built-in one. Output 1 ("Green’’) is turned on when the result is less that the upper limit.

Output 2 ("Red’’) is turned on when the result is greater than the lower limit. If the result is in between, both

outputs are turned on and the LED colour will be amber (i.e. a mixture of red and green light).

Alarm Mode 3: Particles-Water

Output 1

Output 2

Turns on When

Cleanliness>Upper

Water>Upper

Turns off When

Cleanliness ≤lower

Water ≤lower

Intended Function

Cleanliness Alarm

Water Alarm

This is used when separate alarm outputs are needed for particles (cleanliness) and water content.

This mode is able to use both upper and lower limits such that the outputs have ``hysteresis’’. If only the upper or

lower limit is required, then both upper and lower limits should be set to the same value.

Alarm Mode 4: Continue-Clean

Output 1

Output 2

Turns on When

>Lower

≤Lower

Intended Function

Continue Testing

Stop Testing / Clean

This is used for a "cleaning" application where a signal is needed to stop testing (for example to stop a pump or

signal an external controller).

42

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Alarm Mode 5: Tested Not-Clean

Output 1

Output 2

Turns on When

Test Complete

>Lower

Intended Function

Test Complete Signal

“Not Clean” Signal

This is used when controlling tests from a PLC using switched outputs. The PLC gives a start signal, then monitors

the "Test Complete’’ output. If the test has failed it can detect this with the "not clean’’ signal.

``Continuous testing’’ should not be selected for this mode.

Alarm Mode 6: Testing Not-Clean

Output 1

Output 2

Turns on When

Testing

>Lower

Intended Function

Test in progress Signal

“Not Clean” Signal

This is similar to mode 5 above. The difference is that output 1 is active during the test and turns off at test end.

``Continuous testing’’ should not be selected for this mode.

Alarm Mode 7… Customer Requested Modes

Other alarm modes will be defined as and when customers request them.

6.4 Standard Communication Protocols

6.4.1 Modbus

The CMS can be controlled via commands on its serial (RS485) interface, using the Modbus RTU protocol. It is

possible to control every aspect and setting of the CMS, as is done by the RMF-View control software. All results

and counts are available in all supported formats. We suggest using RMF-View to initially configure the CMS and