Rl flo-master GALVANIZED STEEL SPRAYER User Manual

I

F YOU HAVE ANY QUESTIONS OR CONCERNS, OR ARE MISSING PARTS

DO NOT RETURN SPRA YER TO THE STORE!

PLEASE CALL OUR CONSUMER HOTLINE AT 1-800-253-4642

Y ear Round: Mon. – Fri., 8:00 a.m. to 7:00 p.m., ET

March 1 – August 31: Sat. and Sun., 10:00 a.m. to 4:00 p.m., ET

Or write us at: Root-Lowell Manufacturing Co., 1000 Foreman Rd.

P.O. Box 289, Lowell, MI 49331

Visit us on the internet:

e-mail: service@rlflomaster.com

Owners’ Manual

Galvanized Steel Sprayer

Model 227D

WARNING!!! THIS PRODUCT IS DESIGNED TO SPRAY CHEMICALS THAT MAY BE HARMFUL

AND COULD CAUSE SERIOUS PERSONAL INJURY IF INHALED OR BROUGHT INTO CONTACT

WITH THE USER. FAILURE TO READ AND FOLLOW OWNERS’ MANUAL INSTRUCTIONS BEFORE

USE AND/OR MISUSE OF THIS PRODUCT COULD RESULT IN EXPLOSIVE FAILURE

WITH MAJOR INJURIES.

www.rlflomaster.com

• ALWAYS water test sprayer before each use.

• ALWAYS wear long sleeve shirts, long pants, goggles, gloves and durable shoes.

• ALWAYS READ AND FOLLOW label instructions for the chemicals to be applied.

• AFTER USE release pressure and clean the sprayer.

• ALWAYS RELEASE pressure in sprayer before servicing.

• DO NOT alterthesprayeroranycomponents.

• DO NOT spray flammable, caustic (i.e. acids, chlorines and bleach), corrosive, heated or self-heating solutions

with this sprayer.

• DO NOT store liquids in the sprayer.

• NEVER overfill. Fill to a maximum of approximately 3” below top of tank.

ASSEMBLY INSTRUCTIONS

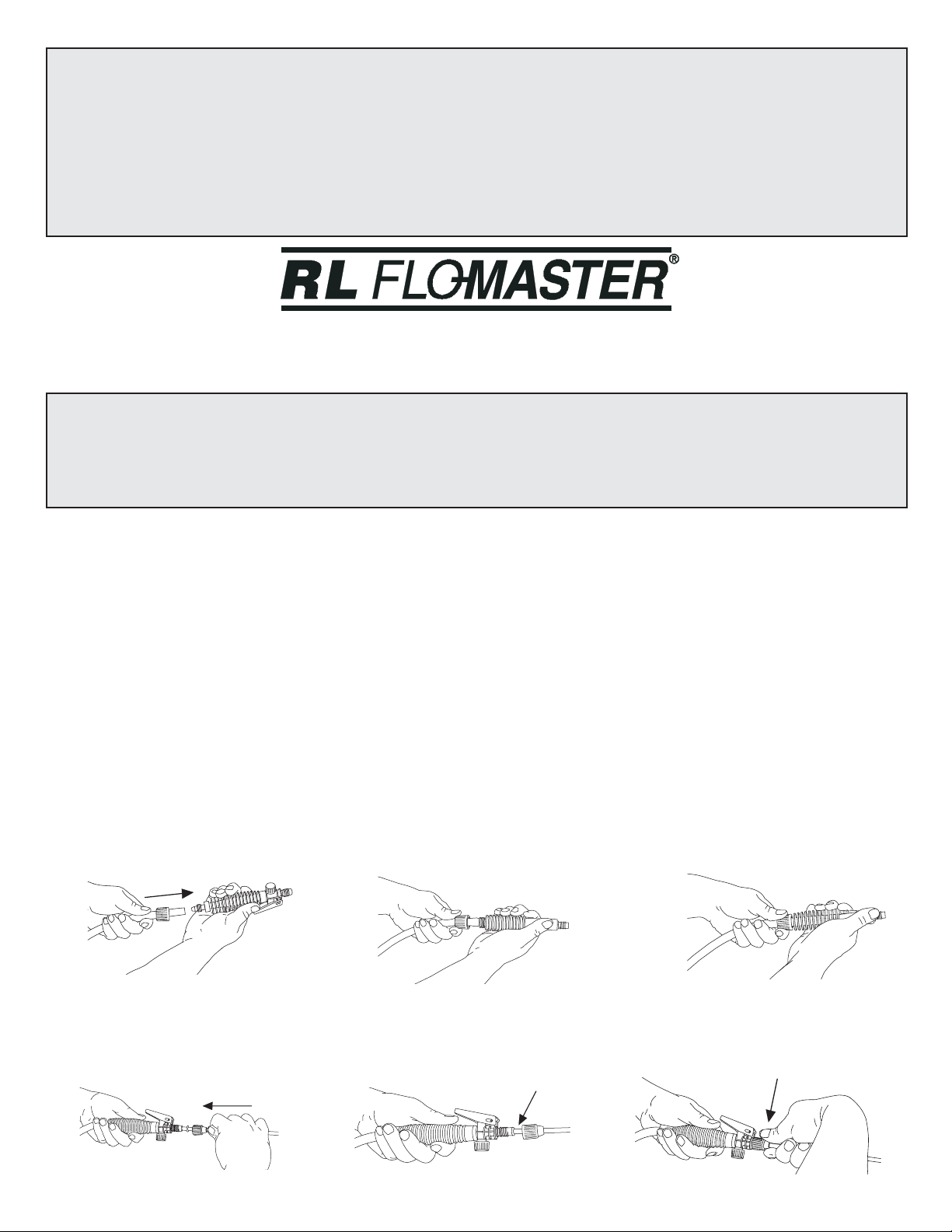

A. FLOW CONTROL TO HOSE

1. Remove the flow control hose nut from the flow control and slide over the hose.

2. Push the hose over the pointed end of the flow control until it touches the threads.

3. Screw the flow control hose nut onto the flow control. Firmly hand tighten.

1 2 3

B. WAND TO FLOW CONTROL

1. Push the wand into the flow control until it stops.

2. Slide the o-ring down until it touches the flow control.

3. Screw the wand nut onto the flow control. Firmly hand tighten.

1 2 3

TO ENSURE CORRECT ASSEMBLY, TEST SPRAYER WITH

WATER B EFORE USING.

OPERATING INSTRUCTI ON S

A. FILLING THE SPRAYER

1. Remove the pump assembly from the tank by turning counter-clockwise.

2. Prepare the spray solution following the instructions listed on the chemical manufacturers’ label. Mix only the

amount of solution to be sprayed.

3. DO NOT spray flammable, caustic (i.e. acids, chlorines and bleach), corrosive, heated or s elf-heating solutions

with this sprayer.

4. Screw the pump assembly back into the tank by turning clockwise. Firmly hand tig hten.

5. DO NOT overfill. Fill to a maximum of approximately 3” below top of tank.

B. PRESSURIZING THE SPRAYER

1. To operate the pump, unlock the pump handle by turning counter-clockwise. Be careful not to loosen the pump

from the tank.

2. To create pressure, stroke up and down.

3. Lock the pump handle back into the pump assembly by turning clockwise.

WARNING!!! To prevent ejected pump assembly and/or solution from striking and injuring you, never

stand with your face or body directly over the top of the tanks when pumping or loosening the pump.

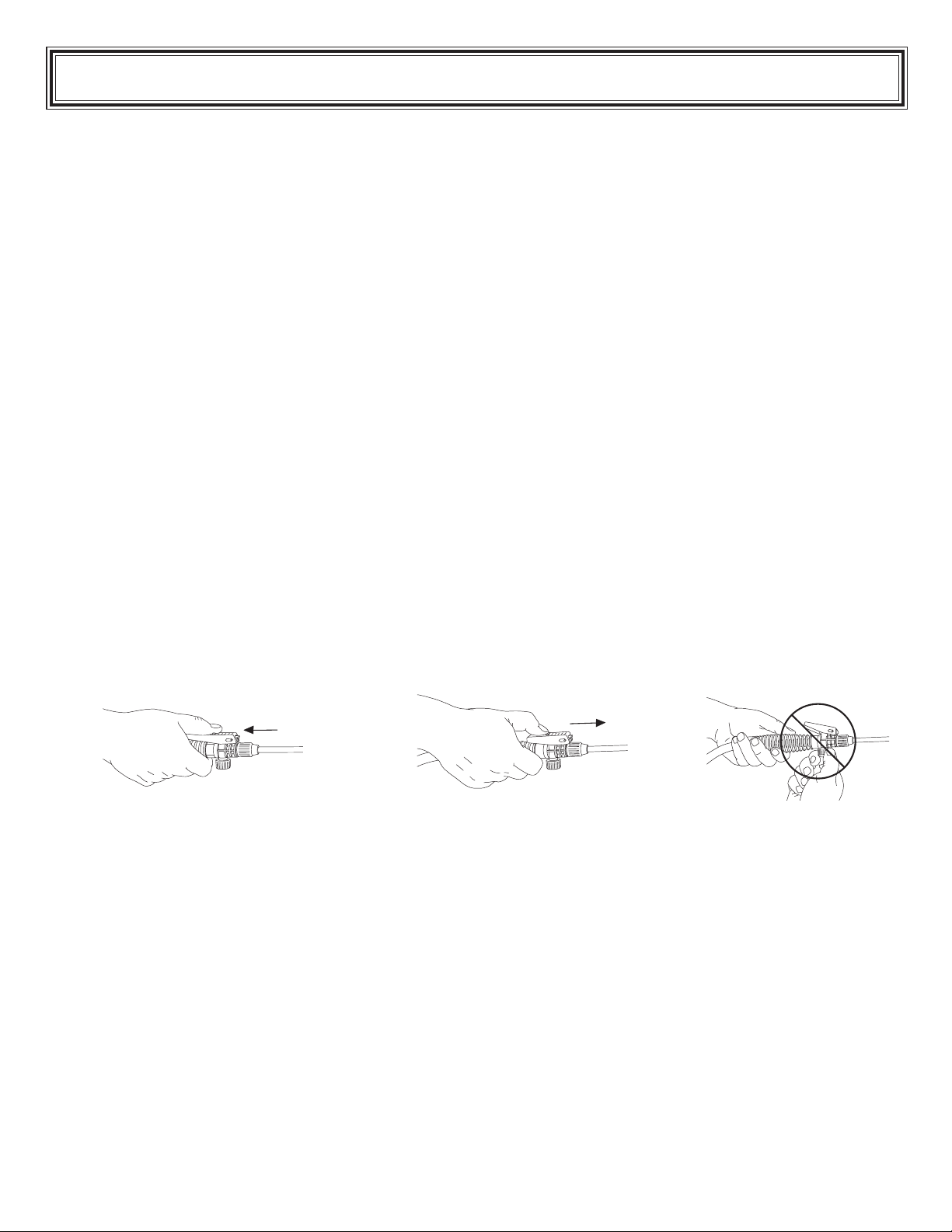

C. SPRAYING

1. To start spraying, squeeze the flow control lever.

2. To stop spraying, r elease the flow control lever while pulling back on the lever.

3. To spray continuously, squeeze the flow control lever and slide forward to lock on.

4. If your sprayer has an adjustable cone nozzl e, screw it clockwise for a fine mist and counter-clockwise for a

coarse stream. Flat fan nozzles are not adjustable.

5. DO NOT r emove flow control cap while spraying.

6. ALWAYS wear long sleeve shirts, long pants, goggles, gloves and durable shoes.

2 3 5

D. RELEASING PRESSURE

1. To release pressure from the tank, turn the tank upside down, and then squeeze the flow control lever until all the

air pressure is gone. If your sprayer has a pressure relief valve, turn yellow knob clockwise until all air pressure

is gone.

2. If your sprayer is clogged and the pressure will not release using the flow control, do the following:

a. Place a rag over the top of the sprayer and pump.

b. While firmly pushing down on the pump handle, slowly turn counter-clockwise.

3. ALWAYS RELEASE pressure in sprayer before servicing.

4. NEVER leave pressurized sprayer unattended.

E. CLEA NING

1. Do not store ch emicals in th e ta nk. If the che mical is stored in the tank, it can clog the system as it d ries and

destroy the seals and other components.

2. To prolong its life, clean the sprayer after each use. After using water-based products, rinse thoroughly wit h

soapy water then clean water, being sure to flush out the hose and flow control. After spraying solvent or oilbased products, follow the chemical manufacturers’ recommended cleaning procedure, following up with a

thorough rinsing and flushing of the sprayer, hose and flow control with soapy water then clean water.

Loading...

Loading...