Rl flo-master 612BU, 612 User Manual

Model 612BU & 612 VI Back Pack

Operations & Service Instructions

DANGER!!

Failure to observe

become corroded, weakened and/or burst under pressure. This can result in

and/or unexpected discharge of spray material. Do not use gasoline, kerosene or other flammable in this sprayer as it is not

designed nor intended for such usage.

CAUTIONS

and to follow instructions for use and maintenance can cause tank, hose or other parts to

SERIOUS INJURY

from forcible ejection of parts

CAUTION!!

Before using any pesticide or other spray chemicals in this sprayer, THOROUGHLY READ THE LABEL ON THE CHEMICAL

CONTAINER AND FOLLOW THE MANUFACTURER’S GUIDELINES/DIRECTIONS FOR USE INCLUDING THE NEED FOR

PROTECTIVE CLOTHING. Some spray materials are dangerous and should not be used in this sprayer as they can damage

the sprayer and cause

SERIOUS BODILY INJURY OR PROPERTY DAMAGE.

• DO NOT use sprayer if tank or hose is damaged, discolored or brittle, or hose is loose or excessively soft.

• DO NOT use hot or boiling liquids in this sprayer as this may weaken tank, hose or pump.

• DO NOT leave residue or spray material in tank after using sprayer. Read instructions “How to Clean.”

• DO thoroughly inspect both inside and outside of sprayer before each use. BE SURE hose is securely attached to the

tank and flow control valve.

• DO wear protective clothing and goggles during use.

• DO empty, clean and drain both tank and hose after each use according to directions.

• DO dispose of unused spray materials/chemicals according to chemical manufacturer guidelines.

• DO use only appropriate RL FLO-MASTER replacement parts. Improper parts may not fit correctly and/or may be

weakened by spray chemicals and fail under pressure, resulting in

high pressure discharge of spray materials.

SERIOUS INJURY

from forcible ejection of parts or

• DO be sure pump collar and pump cap are securely tightened down before each use. FAILURE TO DO SO COULD

RESULT IN

•

BEFORE making any repairs, be sure sprayer is completely de-pressurized.

SERIOUS INJURY

FROM FORCIBLE EJECTION OF SPRAY MATERIAL.

INITIAL ASSEMBLY INSTRUCTIONS FOR POLY FLOW CONTROL (model 612BU):

1. Be sure to first insert pink siphon tube into white hose insert otherwise sprayer will not operate.

2. Lubricate (with grease or petroleum jelly), the o-ring on the hose insert and slide into tank until fully seated.

3. Slide tank nut to threaded connection and securely screw onto tank.

4. Attach the flow control to the hose by unscrewing the flow control nut from the back of the flow control. Slide it directly

onto the end of the hose.

5. Push the hose onto the back of the flow control all the way past the barb and up to the threads and screw together. Hand

tighten only.

6. Push the extension rod into the flow control until it stops. Slide extension nut o-ring to the flow control and screw together.

Hand tighten only.

HOW TO ASSEMBLE STRAPS:

1. Put the shoulder straps together forming a loop at the bottom.

2. Place the loop under the bar at the top of the tank. Hold on to the loop with one hand, then with the other hand, bring the

shoulder strap pads over the top of the bar and through the loop and snug by pulling.

3. Take one end of the strap and put it through the square loop on the bottom of the tank, then bring it back around to the

front. Do the same with the other side. Then snap together making the waist belt.

4. Be sure to adjust the strap to your liking before filling the the tank with liquid.

HOW TO FILL:

1. Open sprayer by turning cap counter clockwise.

2. Add measured sprayer material.

3. Thread cap on firmly to ensure an air tight seal.

HOW TO CARRY:

1. Be sure strap is securely attached to the sprayer.

2. Place sprayer on your back by inserting right arm under shoulder strap and left arm under opposite strap. Snap closed in

front so that tank is securely and comfortably on your back

3. Adjust straps as necessary.

HOW TO PRESSURIZE:

1. A few strokes of the operating lever will provide sufficient pressure to start spraying. Rate of pumping may be slowed

down when the stroke begins to meet resistance.

2. Air pressure build-up in cylinder may not allow liquid to pass through. Relieve air build-up by squeezing flow control lever

then pump operating lever. Repeat process again if nescessary.

3. Test pressure by spraying some liquid. If necessary, adjust spray pattern. For fine mist screw nozzle in (counter

clockwise) and out (clockwise) for a coarse stream.

4. As pressure drops during use, add pressure as necessary. 5 strokes per minute provides enough pressure for cone

pattern. 10 strokes per minute provides pressure for stream pattern.

HOW TO MAINTAIN:

1. Always empty, clean and drain tank and hose immediately after each use.

2. Fill tank about 1/4 full with clean water.

3. Replace cap and shake tank to clean inside. Pressurize the tank with a few strokes and spray some liquid through the

nozzle to clean our hose and the rest of the discharge line. Be sure that the hole in the nozzle and the two ports on the

nozzle body are completely clean.

4. Open tank and drain it. Drain discharge line by holding flow control valve open.

5. Hang tank upside down and store with cap off.

HOW TO SERVICE:

• If air or liquid leaks at fill cap:

Inspect valve button in fill cap. Clean seating surfaces and, if necessary, replace with parts from maintenance kit 612RK.

• If flow control valve leaks:

Clean and examine flow control o-ring, replace if damaged. Make sure extension is pushed all the way into the flow control

and securely screwed onto flow control.

• Bad spray pattern or low spray volume:

Remove nozzle and extension and clean, replace if clogged or damaged.

• Nozzle leaks when flow control closed:

Clean and examine flow control o-ring, replace flow control if necessary.

If sprayer fails to pressurize:

Service Pump:

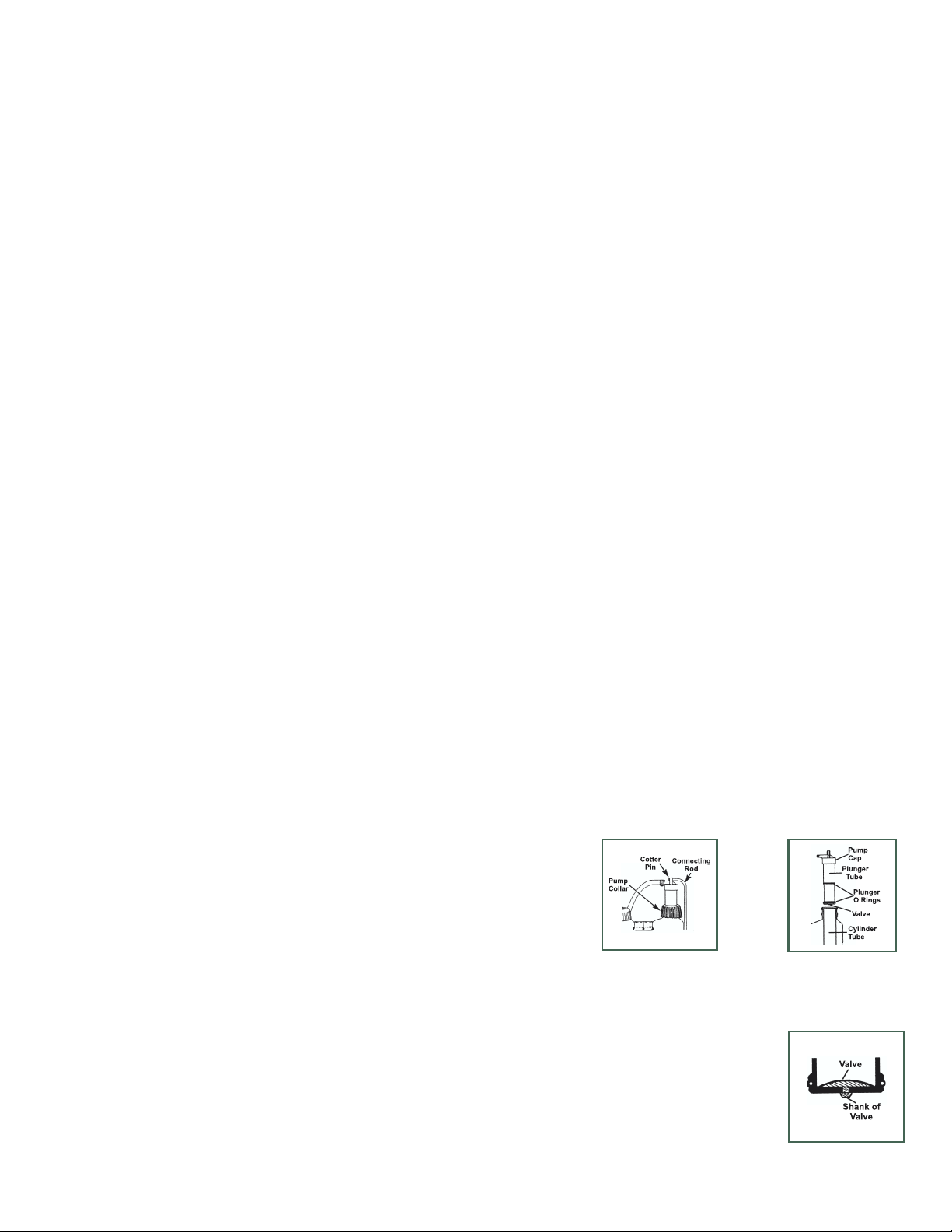

1. Remove cotter pin from hose end of connecting rod and pull rod away

from cylinder (fig. 1).

2. Pull plunger tube out of cylinder tube (fig 2). Clean and lubricate plunger

o-rings with petroleum jelly or replace part if worn.

3. Ensure that large siphon tube is fully seated into cylinder, then reassemble.

Inspect check valves in base of plunger tube and cylinder tube.

1. Unthread pump cap from plunger tube; remove valve by pushing ii into the cylinder. Clean surfaces or

replace valve using kit 612RK.

2. Replace valve by dropping in cylinder bottom side up. Use blunt object (i.e broom handle) to position

valve over hole in cylinder base and push in (fig. 3). Pull shank of valve through the hole; do not use

sharp object to maneuver valve. Be sure whole shank is through hole or valve will dislodge under

pressure.

3. Unthread pump collar from tank. Pull cylinder tube from tank.

Loading...

Loading...