Page 1

SeaHawk Sensing Cable Installation Guidelines

Thank you for purchasing SeaHawk sensing cable. This guide outlines sensing cable

installation.

If you need further assistance, please contact RLE Technologies via our website http://www.rletech.com/ or call us at 800-518-1519, Option 2.

v2.0

(10/2012)

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and Seahawk™, Falcon™, and Raptor™ are trademarks of

Raymond & Lae Engineering, Inc. The products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability, and other terms

and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

Test the SeaHawk Sensing Cable and Controller

Before you lay any SeaHawk sensing cable in an installation, it is wise to connect the cable to the controller and ensure proper

communications.

1. Attach the leader cable to the controller.

2. Connect the sensing cable to the leader cable.

3. Attach the end-of-line terminator to the end of the last run of sensing cable.

4. Turn on the controller and test the sensing cable. The easiest way to test the cable is to pour a 2” (5cm) puddle of

water on the oor and put a strand of sensing cable in the puddle. If you’re not able to pour a puddle of water on the

oor, wrap a clean damp cloth or paper towel around a small section of cable. Do not hold the cloth or towel with your

hand - this creates uneven pressure on the cable and can cause erratic readings on distance read controllers. Once the

cable is dampened, the controller should alarm within a reasonable time. This time may vary depending on controller

type and the alarm time frame set within the controller.

Do not saturate a section of cable - the cable will go into alarm with a very small amount of water, and if you saturate

the cable fully, it will take a longer for the cable to dry and the alarm to reset.

5. Once the cable passes the initial test, proceed to the sensing cable installation.

Install SeaHawk Sensing Cable on Floors

SeaHawk sensing cable is durable, exible, and designed to mitigate false alarms. While installation is fairly straightforward - lay

the sensing cable according to the precongured layout on your map and secure the sensing cable to the oor with J-clips - keep

the following guidelines in mind to avoid complications:

• Do not install sensing cable that is damaged or dirty - while the cable is designed to mitigate false alarms, visibly dirty

cable will need to be cleaned before installation. If your sensing cable needs to be cleaned, refer to the Sensing Cable

Care and Maintenance Guide.

• Do not run sensing cable through contaminants - ie. dirty or greasy areas. The oor must be clean of contaminants for

the sensing cable to function properly and for J-clips to adhere. If necessary, clean the oor before installation.

• Avoid laying sensing cable in the direct downstream of air conditioning units - these units discharge moisture, which will

skew leak detection readings. Place the cable 4 to 6 feet (1.2 to 1.8m) away from air conditioning units to avoid false

alarms and contamination.

• Tools or heavy objects can damage sensing cable. Avoid rolling, dropping, or setting heavy items on sensing cable.

Whenever possible, install sensing cable out of the way of foot trafc.

• Use J-clips to secure the sensing cable. J-clips are nylon cable clips with a self-adhesive backing. J-clips hold sensing

cable securely in place without pinching or binding the cable, which can cause false alarms.

• J-Clips should be placed 5 to 6 feet apart throughout an installation, and 3 feet apart when cable is routed in front of

CRAC units. Because the J-clip’s adhesive backing does not work well on porous concrete oors, apply a drop of silicone

or another nonconductive adhesive to help secure the J-Clip to the oor.

• Ensure the sensing cable is installed directly on the oor, and there are no gaps between the cable and the oor. Use

additional J-clips as necessary to avoid large gaps.

Page 2

Install SeaHawk Sensing Cable on Pipes

Since SeaHawk sensing cable is very exible, it can be installed around pipes. This can help pinpoint leaks in a wide variety of

applications. Verify whether your pipe installation is horizontal or vertical. Cable is installed differently in each application.

If sensing cable is installed on horizontal pipes:

• Run the cable along the bottom of the pipe and secure it with cable ties or tape every two to three feet (0.6 to 0.9m).

If sensing cable is installed on vertical pipes:

• Wrap the cable around the pipe at a 30 - 45 degree angle, repeating the angle at appropriate spacing as you move down

the pipe. Use cable ties every 3 to 5 feet (0.9 to 1.5m) to secure the cable to the pipe.

If the sensing cable is installed on chilled water lines, wrap the pipes with insulation after installing the cable. This helps control

condensation, which can trigger alarms.

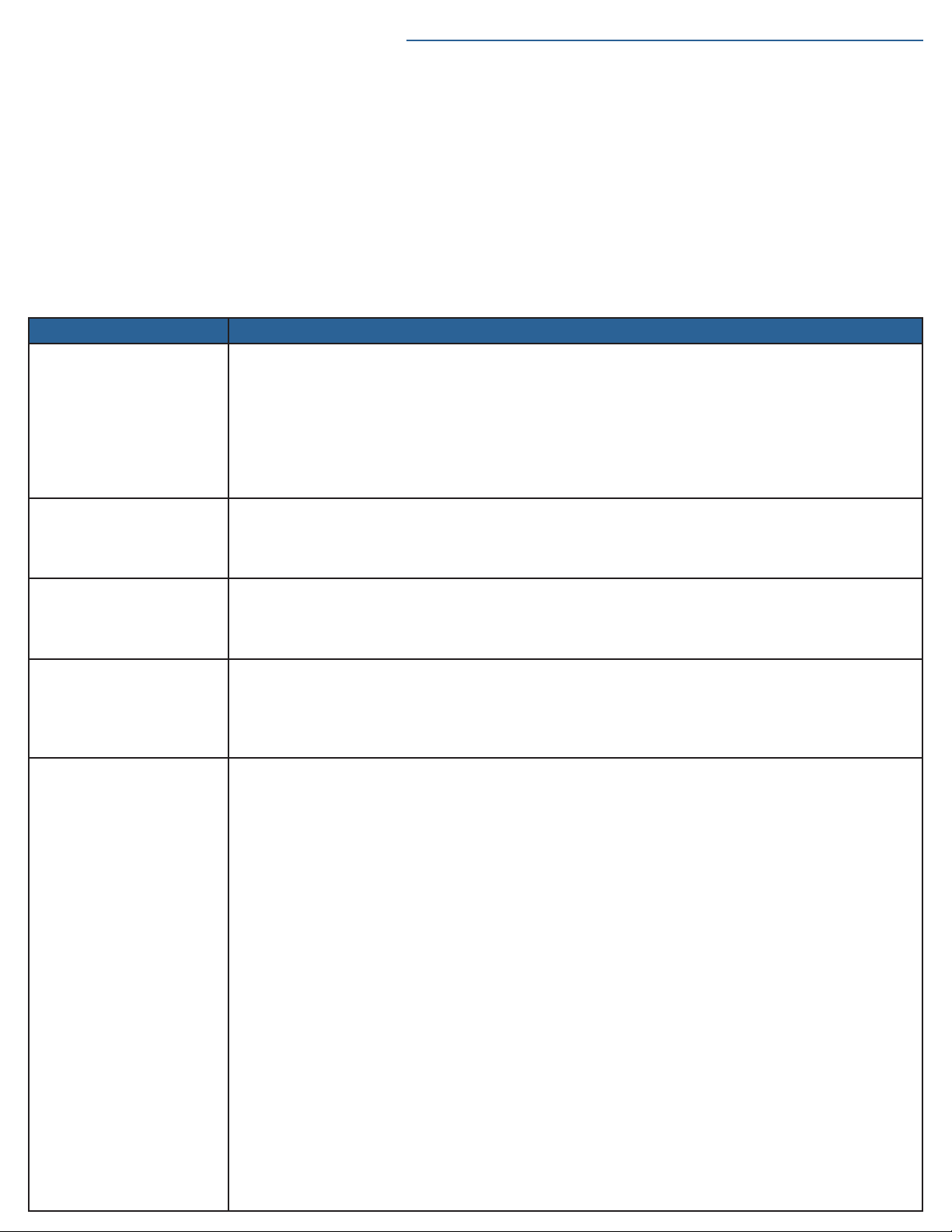

SeaHawk Sensing Cable FAQ

Question Response

How do I secure sensing

cable to the oor?

My water leak detection

cable touches metal. Is

this a problem or potential

problem?

The sensing cable is routed

so that it has to cross over

itself. Can this cause false

alarms?

If I suspect a bad section

of sensing cable, how can

I verify that it is ok without

sending it back to RLE for

warranty evaluation?

My system shows an alarm

condition, but a leak is not

found at location shown

on display. The system will

not clear. It is in alarm all

the time!

RLE recommends the use of J-clips. J-clips are nylon cable clips with a self-adhesive backing.

J-clips hold sensing cable securely in place without pinching or binding the cable, which can cause

false alarms.

J-Clips should be placed 5 to 6 feet apart throughout an installation, and 3 feet apart when cable is

routed in front of CRAC units. Because the J-clip’s adhesive backing does not work well on porous

concrete oors, apply a drop of silicone or another nonconductive adhesive to help secure the

J-Clip to the oor.

In general, no. The two water sensing wires are covered by a nonconductive polymer weave. This

weave isolates the cable from metal surfaces. However, as with all electrical wires and cable, avoid

sharp objects that can slice or pierce through the insulation and nonconductive polymer weave.

Crossing sensing cables will not cause false alarms, but it can cause a false distance reading if a

leak occurs at the crossover point. If the cables must cross, use a 10 foot section of non-sensing

cable to jump over the section of sensing cable.

It can be very difcult to remove sensing cable, so verify the cable is working before you attempt

to remove it and return it to the manufacturer. Use either a cable tester (RLE part # LDCE) or

request a Cable Break Alarm assessment document from RLE to determine which section of cable

may be faulty.

The most common causes for this condition includes:

1. Water is touching the cable in two places at the same time. The distance reading is an

average of the two values. For example, if leaks are detected at 200 feet and at 100 feet, the

system would register a leak at 150 feet ( (200 + 100)/2 = 150 ). This is a common problem

when, after an alarm sounds, the operator resets the system without recording the rst value

displayed. It is very rare that water will touch two places on the same cable at the exact same

time. This situation is true for all systems which measure distance. Check the Alarm History

log for the rst incidence of the leak.

2. The cable has been exposed to high humidity, or the dew point has been reached. This is

especially common when two or more air conditioners share the same under-oor space.

Problems of this nature can be resolved as follows:

a. Fix the air conditioners. This is sometimes easier said than done as most people believe if

the unit is on and cooling, it is working properly. Extensive investigation may have to be

done just to prove the air conditioner is faulty.

b. Turn the sensitivity adjustment on the controller to its least sensitive setting. This should

keep the system from alarming, but will not resolve the air conditioner problem.

c. Move the cable at least 10’ away from the front of the air conditioner.

d. Cover the sensing cable in front of the air conditioner with spiral wrap (plastic covering

which allows water in but keeps dew point from condensing water on the cable).

3. A cable has been contaminated either chemically (oor sealing chemicals dissolve and damage

cable), or physically (small metallic chips from lings or solder around pipes or wires from

electrical installation). This requires replacement of the cable.

4. The cable has become damaged - most often from a oor tile being dropped on it. Damaged

cable must be repaired or replaced.

Loading...

Loading...