Page 1

Leak Detection

LD5100

User Guide

Page 2

Copyright and Trademark Notices

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and

Seahawk™, Falcon™, and Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The

products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability,

and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html..

Revision History

Rev. No. Date

3.0 June 2010

3.1 February 2011

Note: As necessary, blank pages are added to make the page count even.

rletech.com 2 970.484.6510

Page 3

Product Registration

Product registration helps RLE Technologies inform owners of:

• Product upgrades

• Firmware enhancements

• New products and technologies

• Special offers available only to registered users

Submit registration information on the Support/Product Registration webpage at www.rletech.com.

Any information provided to RLE Technologies through the registration form will be regarded as

confidential. RLE will not sell or distribute any of the information to third parties. To read our Privacy

Policy, please visit our website: www.rletech.com.

Technical Support

Personal assistance is available Monday through Friday, from 8:00 a.m. to 5:00 p.m. MST.

For more information, please download the Product User Guide located on the Products/LD5100

section on our website at www.rletech.com.

A request for assistance may be sent to support@rletech.com.

Otherwise, please call us directly at: (970) 484-6510, and press “2” for technical support.

The following information is located on the bottom of each LD5100 unit. Please have this information

available whenever a technical support call is placed:

Product Model Number

Product Serial Number

Product Manufacture Date

970.484.6510 3 rletech.com

Page 4

RLE Product Warranty

Seller warrants to the Ultimate Purchaser (the purchaser who buys for use and not for resale) that all

products furnished under this order and which are manufactured by Seller will conform to final

specifications, drawings, samples and other written descriptions approved in writing by Seller, and will be

free from defects in materials and workmanship. These warranties shall remain in effect for a period of

twelve (12) months after shipment. If the Seller installs the equipment or supplies technical direction of

installation by contract, said one year shall run from the completion of installation, provided installation is not

unreasonably delayed by Ultimate Purchaser. Parts replaced or repaired in the warranty period shall carry

the unexpired portion of the original warranty. A unit placed with the purchaser on consignment and then

later purchased will be warranted for twelve (12) months from the time the Seller receives notification of the

Purchaser's intent to purchase said consigned item. The foregoing is in its entirety is subject to the provision

that in no case will the total warranty period extend beyond 18 months from date Seller ships equipment

from point of manufacture.

Products are NOT life and safety certified. In no event shall the Seller be liable for loss, damage, or expense

directly or indirectly arising from the use of the units, or from any other cause, except as expressly stated in

this warranty. Seller makes no warranties, express or implied, including any warranty as to merchantability

or fitness for a particular purpose or use. Seller is not liable for and Purchaser waives any right of action it

has or may have against Seller for any consequential or special damages arising out of any breach of

warranty, and for any damages Purchaser may claim for damage to any property or injury or death to any

person arising out of its purchase or the use, operation, or maintenance of the product. Seller will not be

liable for any labor subcontracted or performed by Purchaser for preparation of warranted item for return to

Seller's factory or for preparation work for field repair or replacement. Invoicing of Seller for labor either

performed or subcontracted by Purchaser will not be considered as a liability by the Seller.

The liability of Seller hereunder is limited to replacing or repairing at Seller's factory or on the job site at

Seller's option, any part or parts which have been returned to the Seller and which are defective or do not

conform to such specifications, drawings or other written descriptions; provided that such part or parts are

returned by the Ultimate Purchaser within ninety (90) days after such defect is discovered. The Seller shall

have the sole right to determine if the parts are to be repaired at the job site or whether they are to be

returned to the factory for repair or replacement. All items returned to Seller for repair or replacement must

be sent freight, prepaid to its factory. Purchaser must obtain Seller's Return Goods Authorization prior to

returning items. The above conditions must be met if warranty is to be valid. Seller will not be liable for any

damage done by unauthorized repair work, unauthorized replacement parts, from any misapplication of the

item, or for damage due to accident, abuse, or act of God.

This warranty shall be exclusive of any and all other warranties express or implied and may be modified only

by writing signed by any officer of the Seller. This warranty shall extend to the Ultimate Purchaser but to no

one else. Accessories supplied by Seller but manufactured by others carry any warranty the manufacturers

have made to Seller and which can be passed on to the Ultimate Purchaser.

Seller makes no warranty with respect to whether the products sold hereunder infringe any patent, U.S. or

foreign, and Purchaser represents that any specially ordered products do not infringe any patent. Purchaser

agrees to indemnify and hold Seller harmless from any liability by virtue of any patent claims where

Purchaser has ordered a product conforming to Purchaser's specifications, or conforming to Purchaser's

specific design.

Purchaser has not relied and shall not rely on any oral representation regarding the Product sold hereunder

and any oral representation shall not bind Seller and shall not be part of any warranty.

rletech.com 4 970.484.6510

Page 5

Contents

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mechanical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cable Reference Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

LCD User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Connections and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

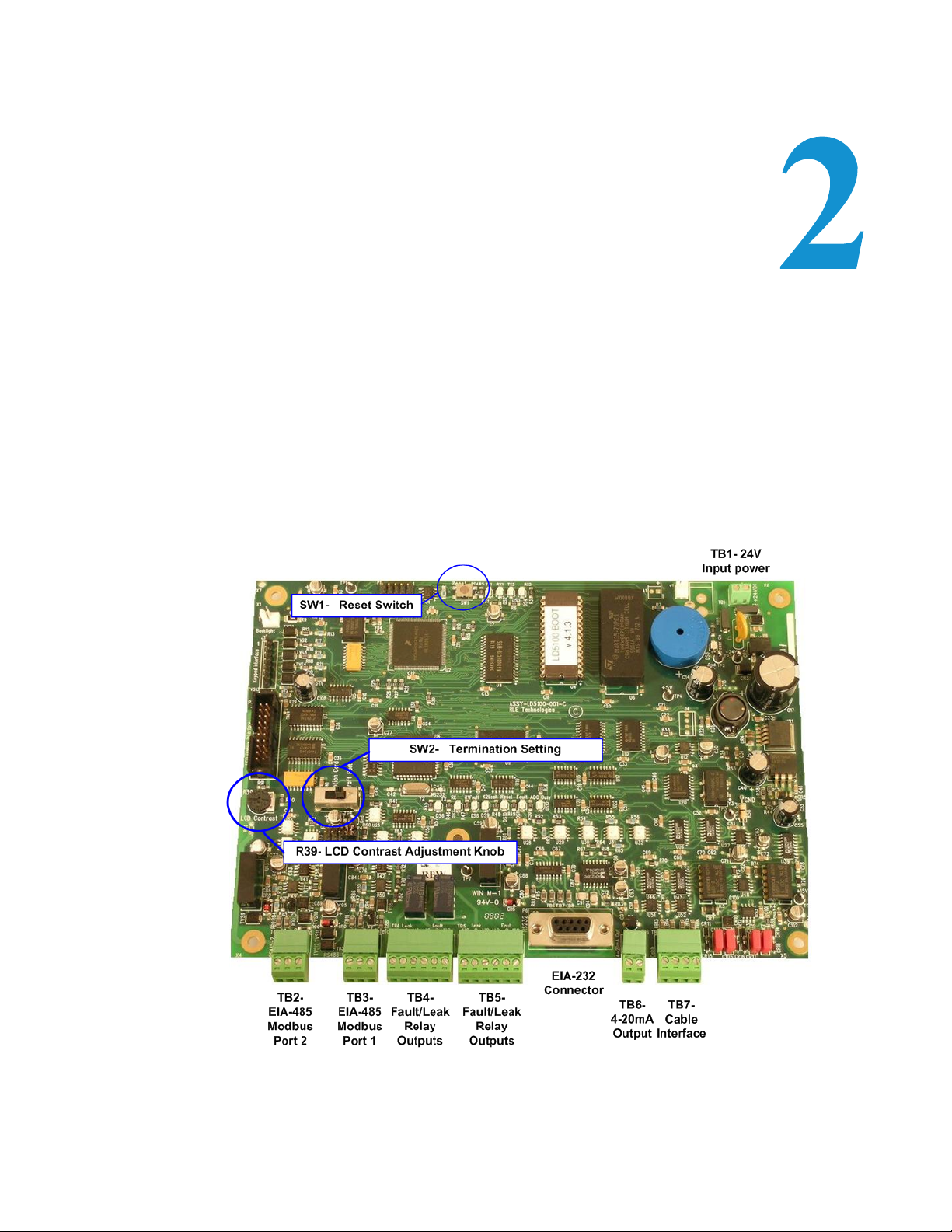

Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SW1: Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SW2: Termination Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

R39: Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TB1: Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TB2 and TB3: RS485 Modbus Port 2 and 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TB4 & TB5: Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RS232 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TB6: 4-20mA Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TB7: Cable Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Installing the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the SeaHawk Water Leak Detection Cable (SC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Securing Cable to the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Apply Power to the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 4-20mA Output Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 LCD Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Default/Idle Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

View Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cable Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Contamination Delay (ContamDly). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Leak Delay (LeakDly). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Leg 1 Resistance (Leg1 Res). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Leg 2 Resistance (Leg2 Res). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cable Relay or Cable Test Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Alarm History/Trend Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Alarm History Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Trend Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Erase Alarm History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

rletech.com 5 970.484.6510

Page 6

Erase Trend log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Comm Port Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

View Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Leak Trip Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contamination Trip Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Leak Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contamination Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Re-Alarm Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Latching Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Supervised Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-20MA Max Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Feet / Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cable Test Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Restore Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Resistance/Foot (Res/Ft) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Zone Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Point Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Comm Port Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 Mapping the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mapping Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 EIA-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SC – System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Modify LCD Password – 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Zone Setup – 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Diagnostics – 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Other Main Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Implementation Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Modes of Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Slave Address Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Function Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Data Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Error Check (Checksum) Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Exception Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Packet Communications For The LD5100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Function 03: Read Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Function 04: Read Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Function 06: Preset Single Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Function 16: Preset Multiple Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

RTU Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Updating the Flash Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

B Leak Detection Modbus Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connecting Distance Read Panels to the LD5100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Configuring the LD5100 Via the Local Display (LCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Configuring the LD5100 Via the EIA-232 (Craft) Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

970.484.6510 6 rletech.com

Page 7

C Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

D Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

970.484.6510 7 rletech.com

Page 8

Notes:

970.484.6510 8 rletech.com

Page 9

Figures

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

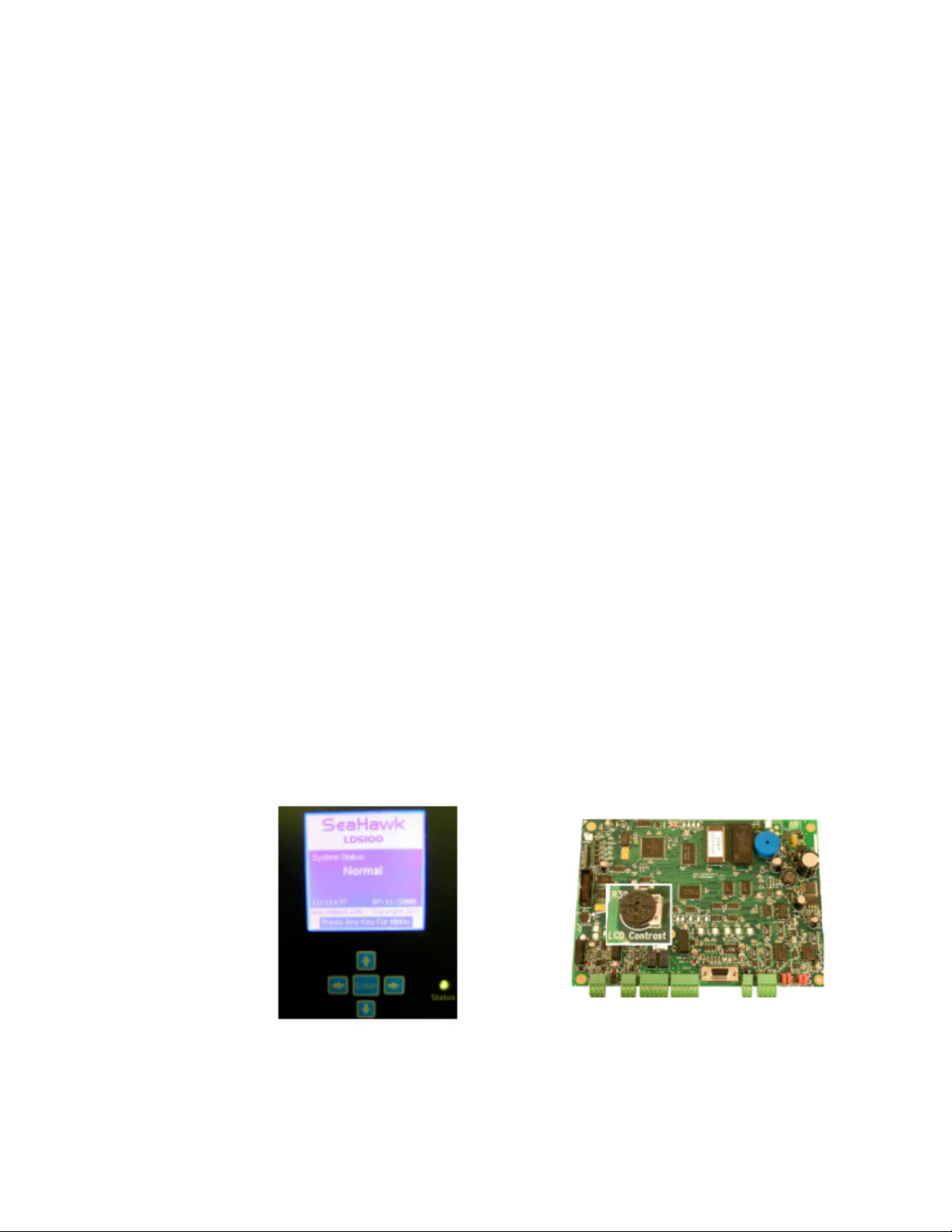

Figure 1.1 LD5100 LCD Interface and the R39 Contrast Adjustment (left to right) . . . . . . 17

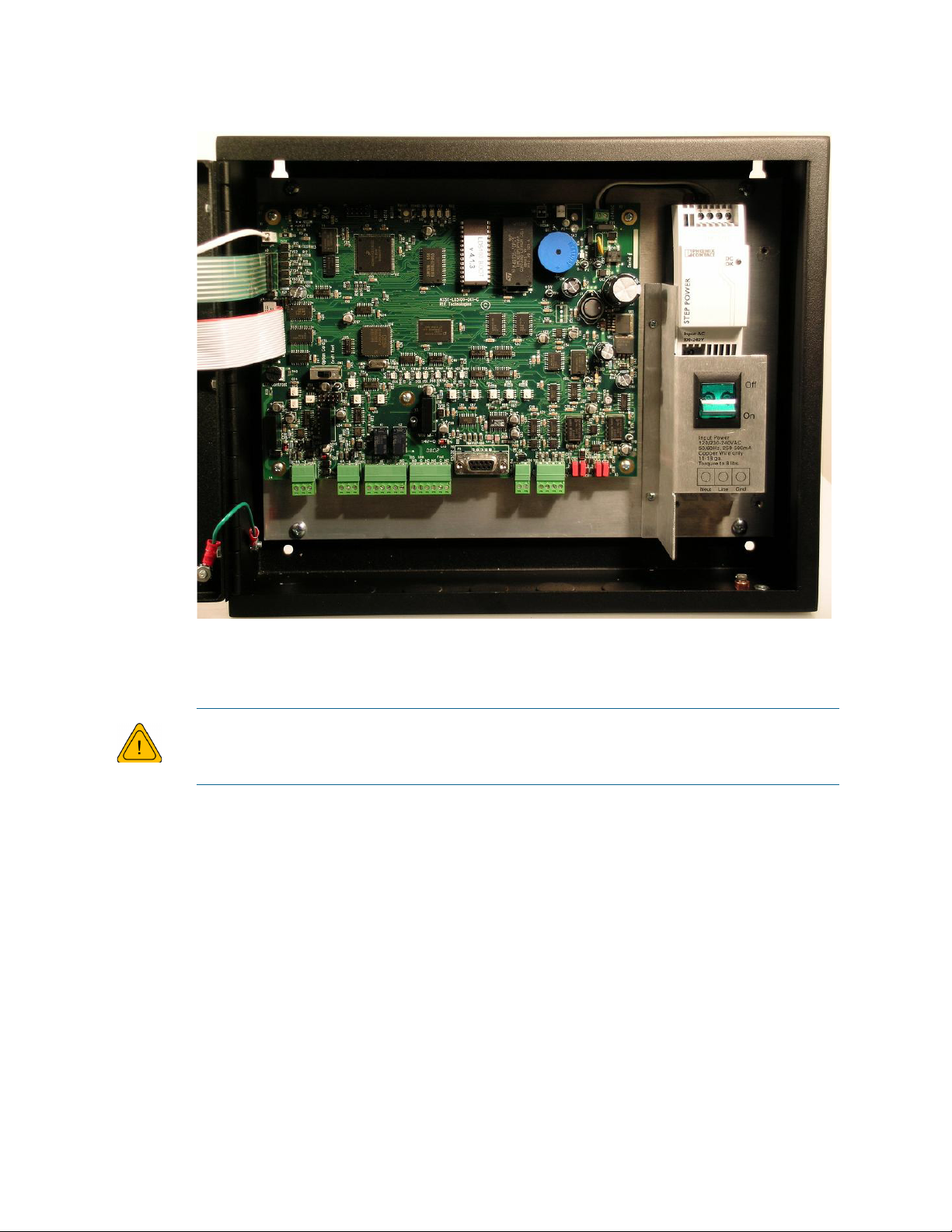

Figure 1.2 LD5100 Enclosure Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Connections and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2.1 LD5100 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2.2 Cable Connections to the Sensing Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2.3 AC Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 3.1 Water Leak Detection Cable (SC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 3.2 Cable Installation Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3.3 Lower Right Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 4-20mA Output Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 4.1 4-20mA Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 LCD Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5.1 LD1500 Bootup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5.2 LD5100 Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 5.3 LD5100 Main Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 5.4 LD5100 Default/Unconfigured View Zones Menu . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5.5 LD5100 Cable Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5.6 LD5100 Cable Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 5.7 Comm Port Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5.8 System Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5.9 Example Configuration for Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 5.10 Example of the Main Screen during a Specific Condition . . . . . . . . . . . . . . . . . 39

Figure 5.11 Comm Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 Mapping the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7 EIA-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 7.1 EIA-232 Bootup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 7.2 EIA-232 Main Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 7.3 EIA-232 SC Function Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 7.4 EIA-232 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

A Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

B Leak Detection Modbus Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Figure B.1 LD5100 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure B.2 Sample Set-up Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure B.3 Configuration Menu from EIA-232 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 63

rletech.com 9 970.484.6510

Page 10

C Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

D Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

970.484.6510 10 rletech.com

Page 11

970.484.6510 11 rletech.com

Page 12

Notes:

970.484.6510 12 rletech.com

Page 13

Tables

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Connections and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 4-20mA Output Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 LCD Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Mapping the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 EIA-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 7.1 Diagnostic Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 7.2 Other Main Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 8.1 Exception Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 8.2 Read Output Registers Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 8.3 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 8.4 Read Input Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 8.5 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 8.6 Status Flags (Register 30001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 8.7 Status Flags (Register 30010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 8.8 Status Flags (Register 30011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 8.9 Status Flags (Register 30012 - 30033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 8.10 Preset Single Register Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 8.11 Preset Multiple Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 8.12 Query Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 8.13 Response Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

B Leak Detection Modbus Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

D Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table D.1 Troubleshooting Problems with the LD5100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table E.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

rletech.com 13 970.484.6510

Page 14

Notes:

970.484.6510 14 rletech.com

Page 15

1.1. Description

The LD5100 is a complete monitoring system that detects and reports the presence of water

and other conductive liquids. The LD5100 couples SeaHawk Water Leak Detection Cable

(SC) with an advanced control panel. Each LD5100 monitors up to 5000 feet (1,524m) of SC

cable. When a conductive liquid comes in contact with the SC cable an alarm sounds and the

distance to the leak is shown on the LD5100's LCD front panel display.

C HAPTER

CHAPTER 0PRODUCT OVERVIEW

The LD5100 allows a single person to perform the mapping of the cable - the process of

determining the relationship between a known point along the cable and the value as measured

by the LD5100.

1.2. Operation

When the LD5100's analog circuitry measures a current in excess of the user-defined leak

threshold, the unit's microprocessor computes the distance to the leak. The unit then

annunciates the leak and logs the alarm in its event log. The leak relay and fault relay each

have two outputs. An additional 4-20mA output allows the device to interface with third party

management systems.

The LD5100 is a supervised system - it constantly monitors the cable for continuity. A cable

break or excess contamination of the cable causes a cable break indication and activates a

relay. The LD5100 sends alarm notifications to predetermined recipients when an alarm

sounds. The LD5100 produces an alarm in the following conditions:

Leak Detected

Cable Break (or Cable Fault)

Cable Contamination

Loss of Communications

www.rletech.com 15 970.484.6510

Page 16

1 Product Overview

1.3. Mechanical Description

The LD5100 is built with two circuit boards:

The display board is connected to the main board with a 20 wire ribbon cable and two

power wires. The display board is mounted on the inside of the unit's door.

The main board is mounted inside and on the back of the enclosure. A reset switch is

provided to reset the microprocessor without cycling power to the unit.

1.4. Installation

The LD5100 with LCD is a wall mounted device. Before applying power to the unit, ensure

that all connections are correct and all screw terminals are secure.

1.5. Cable Reference Map

Users may purchase a Water Leak Detection Cable Reference Map (part # FM1114) with their

LD5100. Once all the SC cable is installed, compare this reference map with the actual cable

installation. Note any discrepancies and return the map to the original author for correction.

Keep a copy for use until the updated map can be reinstalled near the control panel.

1.6. LCD User Interface

The LD5100’s LCD is a 160x160 pixel resolution backlit display with a five button keypad.

The default password for the system setup is 1234. The interface's menu structure is as

follows:

Main Menu

– View Zones

– Cable Status

– Alarm History/Trend

– Alarm History

– Trend

– Erase Alarm History

– Erase Trend Log

Comm Port Status

View Map

System Setup - Password Protected

– Leak TripPoint

– Contam TripPoint

– Leak Delay

– Contam Delay

www.rletech.com 16 970.484.6510

Page 17

– Re-Alarm Delay

– Latching Alarms

– 4-20MA Max Range

– Feet/Meters

– Language

– Cable Test Relay

– Restore Defaults

– Clock

– Res/Ft

– Zone Setup

– Point Mapping

– Comm Port Settings

– Port1 Type

– Port1 Addr

1 Product Overview

– Port1 Baud

– Port2 Type

– Port2 Addr

– Port2 Baud

– Reset

Navigate through the menu(s) with the up, down, left and right arrows. Where indicated on

the LCD submenus, the left arrow navigates left on menus or cancels any action and returns to

the previous menu. The enter arrow selects a submenu and commits changes. Further LCD

interface information can be found in Chapter 5, “LCD Interface” on page 31.

Figure 1.1

www.rletech.com 17 970.484.6510

LD5100 LCD Interface and the R39 Contrast Adjustment (left to right)

Page 18

1 Product Overview

WARNING

Figure 1.2

LD5100 Enclosure Interior

A dedicated circuit breaker must be provided in the building within close proximity

to the LD5100 and be clearly marked as the disconnecting device for this unit.

www.rletech.com 18 970.484.6510

Page 19

C HAPTER

CHAPTER 0CONNECTIONS AND SETTINGS

The LD5100 is comprised of two boards. The two boards are accessed when the device's front

cover is opened. The display board is located on the inside of the door. The main board is the

large board on the left side of the enclosure.

Figure 2.1

www.rletech.com 19 970.484.6510

LD5100 Main Board

Page 20

2 Connections and Settings

2.1. Main Board

The connectors on the main board, found at the bottom of Figure 2.1, are labeled TB2 through

TB7. The connector on the power board is labeled TB3. The reset switch on the main board is

labeled SW1. The termination setting on the main board is labeled SW2.

2.1.1 SW1: Reset Switch

The Reset switch is provided to reset the microprocessor without cycling power to the unit.

2.1.2 SW2: Termination Setting

The Termination Setting switch must ALWAYS be set to the far right. This enables the RS232

port to work properly.

2.1.3 R39: Contrast

This adjustment knob adjusts the 160x160 LCD's contrast. Turn the adjustment knob

clockwise or counterclockwise to adjust the contrast as necessary.

2.1.4 TB1: Input Power

This is a factory wired two position connector with the following connections (for reference

only):

TB1-1 24VDC negative (-)

TB1-2 24VDC positive (+)

2.1.5 TB2 and TB3: RS485 Modbus Port 2 and 1

Terminals TB2 and TB3 connect to a RS485 network. A grounded shield contact is provided

for connection to shielded cable. If the shield contact is used, verify the power connector is

properly grounded and there is no voltage potential between units on the network. The RS485

ports are set to no parity, 8 databits, 1 stop bit (n, 8, 1). Connect the RS485 wires to TB2 or

TB3 on the main board as follows:

TB2-1 A (+)

TB2-2 B (-)

TB2-3 Shield

www.rletech.com 20 970.484.6510

Page 21

2 Connections and Settings

2.1.6 TB4 & TB5: Relays

Terminals TB4 and TB5 are Form C Relay Outputs. Each terminal has two outputs. TB4

provides a connection to one of the leak alarm relay outputs and one of the fault relay outputs;

TB5 provides a second set of contacts for the same leak and fault alarms.

The six contacts on TB4 and TB5 are labeled Leak NO, Leak C, Leak NC, Fault NO, Fault

C, and Fault NC. Connect the alarm relay wires to TB4 and TB5 as follows:

TB4-1 Leak alarm normally open (NO)

TB4-2 Leak alarm common (C)

TB4-3 Leak alarm normally closed (NC)

TB4-4 Fault alarm normally open (NO)

TB4-5 Fault alarm common (C)

TB4-6 Fault alarm normally closed (NC)

TB5-1 Leak alarm normally open (NO)

TB5-2 Leak alarm common (C)

TB5-3 Leak alarm normally closed (NC)

TB5-4 Fault alarm normally open (NO)

TB5-5 Fault alarm common (C)

TB5-6 Fault alarm normally closed (NC)

Two LEDs, labeled K1Fault and K2Leak, are located above TB4 and TB5 in the LED status

strip near the center of the main board. They indicate the status of the relays On/Off. The leak

detection relay is activated when a leak is detected. The cable break relay is activated when a

cable fault is detected.

These relays are set to factory defaulted to Unsupervised; see 5.8.7, “Supervised Relays” on

page 37, for Supervised Relays function.

Both relays (all alarms) can be configured to be latched or unlatched. A latched alarm requires

a manual reset of the system once a leak or cable problem is no longer present.

2.1.7 RS232 Connector

The RS232 port uses only the transmit, receive, and ground pins (2, 3 and 5). The baud rate is

9600. The RS232 port is set to no parity, 8 databits, 1 stop bit (n, 8, 1). A straight through

cable should be used to connect a terminal or PC to the LD5100.

2.1.8 TB6: 4-20mA Output

A 4-20mA loop powered output is provided on TB6. The maximum range (20 mA) can be set

to 1000, 2500, or 5000 feet. Connect the 4-20mA wires to TB6 as follows:

TB6-1 4-20mA positive (+)

TB6-2 4-20mA negative (-)

www.rletech.com 21 970.484.6510

Page 22

2 Connections and Settings

2.1.9 TB7: Cable Interface

The SeaHawk Water Leak Detection Cable (SC) connects to TB7. A 15 foot (4.57m) nonsensing leader cable (part # LC-KIT) is required to connect the LD5100 to the SC cable.

Connect the cable wires to TB7 as follows:

TB7-1 White wire

TB7-2 Black wire

TB7-3 Green wire

TB7-4 Red wire

Figure 2.2

Cable Connections to the Sensing Cable

www.rletech.com 22 970.484.6510

Page 23

2 Connections and Settings

WARNING

2.1.10 AC Power Input

The LD5100 mounted in the metal enclosure requires either a 120 VAC (105-125 VAC) or

230 VAC (205-250 VAC) connection (2 wire & ground). Connect the ground and power wires

to the AC power terminal block. Connect the AC power input as follows:

AC Power Block TB1-1Neutral

AC Power Block TB1-2Line

AC Power Block TB1-3Ground

Figure 2.3

AC Power Input

Make sure the dedicated breaker is in the off position before connecting the AC

power wires to the LD5100.

www.rletech.com 23 970.484.6510

Page 24

2 Connections and Settings

Notes:

www.rletech.com 24 970.484.6510

Page 25

3.1. Installing the Unit

The LD5100 is a wall mounted device. To secure the device to the wall, first remove the

aluminum back panel and all electronics from the enclosure. There are knockouts on the top

and bottom of the enclosure designed to accommodate. 5 inch (12.7mm) conduit. Remove as

many as necessary. There are two holes in the top back of the unit spaced 11 inches (.28m)

apart. Use drywall anchors or suitable anchors depending on the wall construction, to secure

the unit to the wall. Put two more anchors through the two holes in the bottom back of the unit.

Reinstall the back panel and reconnect the electronics.

C HAPTER

CHAPTER 0INSTALLATION

3.2. Connecting the SeaHawk Water Leak Detection Cable (SC)

The LD5100 requires a leader cable kit (part #LC-KIT; purchased separately) which includes

a 15 foot (4.57m) leader cable. One end of this leader cable connects into the LD5100. This

end of the cable has four stripped, bare wires. The other end features a mating connector which

connects with the Sea Hawk Leak Detection Cable (SC). The end of the cable is finished with

a removable end terminator (EOL).

Note A Leader Cable Kit (part #LC-KIT) is required to connect the LD5100 to the SeaHawk Leak

Detection Cable (SC). The kits are not included with the LD5100 and can be purchased

separately.

Connect the 15 foot (4.57m) leader cable to the LD5100. From left to right, with the screws of

the terminal block connector facing up, the wires that screw into the terminal connector should

be colored white, black, green, and red. If the terminal connector is removed from the end of

the cable, make sure the wires are in this same order when the connector is reapplied.

www.rletech.com 25 970.484.6510

Page 26

3 Installation

WARNING

Once the leader cable is plugged into the terminal block, it is ready to be connected to the SC

cable. To do this, unscrew the EOL terminator from the end of the leader cable. Attach the first

length of the SC cable to the leader cable. Route the SC cable according to a cable layout

diagram, if provided. Lay the cable according to the cable installation guidelines on pages 9-

10. Secure the EOL terminator on the unoccupied end of the last section of SC cable.

Figure 3.1

Water Leak Detection Cable (SC)

3.2.1 Securing Cable to the Floor

Secure the SC cable to the floor with either J-clips (Part #JC) or one of the other approved

methods shown in Figure 3.2. Available from RLE and designed specifically for use with the

SC cable, J-clips are the manufacturer's recommended installation method and can be installed

as follows:

Place one J-clip every 3 feet (.914m) along the length of the SC cable and one at each turn

of the cable.

If the cable is installed over an obstruction, clip the cable on both sides, as close to the

obstruction as possible.

Do not install the cable directly in front of an air conditioner. Allow a minimum of 6

feet (1.83m) between the unit and the cable. If the cable is too close to the air

conditioning unit's air stream, the moisture from the humidifier may cause false

leak readings. If the cable must be installed in front of an air conditioning unit,

place the J-clips 3 feet (0.914m) apart.

Note It is important to finish the end of the SeaHawk Water Leak Detection Cable (SC) with the end

terminator (EOL). If the EOL terminator is not present, a cable fault will register. Note any

variances between the cable layout diagram and the actual cable installation.

www.rletech.com 26 970.484.6510

Page 27

3 Installation

WARNING

Figure 3.2

Cable Installation Methods

3.3. Apply Power to the Unit

Once the SC is connected to the unit, power may be applied

A dedicated circuit breaker must be provided in the building within close proximity

to the LD5100 and be clearly marked as the disconnecting device for this unit.

The LD5100 operates between100 - 240 VAC power. An AC power supply should be run to

the location of the unit. Before applying power to the unit, make sure the AC breaker switch is

turned off.

Once the power is turned off, strip the end of the AC supply so the three wires inside are

exposed. Strip the end of the line and neutral wires and feed the ends to the power supply

inside the LD5100 enclosure. The two power wires must now be inserted into the terminal

block in the lower right corner of the enclosure (Power Supply TB1). As indicated in the

enclosure, the line power wire is positioned on the center side of the terminal block (Line).

The neutral wire is placed into the opening on the left side of the terminal block (Neut). The

earth ground line is placed the right side of the terminal block (Gnd).

www.rletech.com 27 970.484.6510

Page 28

3 Installation

Figure 3.3

Lower Right Terminal Block

Once the three wires are connected inside the terminal block, turn the AC power supply back

on. The LD5100 should begin booting up. Wait approximately one minute. No alarm should

be present.

On the LCD, press any key for the main menu. Enter the Cable Status menu. The cable length

is displayed. If this reading varies by more than ±5% of the actual length of cable installed,

verify the installation.

Through the LCD submenus, you may set the clock, system name, alarm configuration, feet/

meters, etc.

Wait at least 30 minutes before calibrating the LD5100. Calibrate the LD5100 through the

front panel System Setup menu.

Map the cable per the instructions in Chapter 6, “Mapping the Cable” on page 41.

www.rletech.com 28 970.484.6510

Page 29

C HAPTER

Figure 4.1

4-20mA Testing

CHAPTER 04-20MA OUTPUT TESTING

The LD5100’s 4-20mA output is loop powered and tested by the manufacturer. The

manufacturer guarantees its performance upon delivery. Should the 4-20mA output need to be

tested in the field, follow these steps. The following procedure is performed with the cable

connected, unless otherwise indicated.

1 Remove the two position plug from TB6.

2 Remove any wires from the terminal and

install a 200Ohm resistor to TB6-2. Then

apply +24V to TB6-1 and ground of the

24V supply to the other side of the

resistor.

3 Reinstall the plug on TB6.

4 With the system on and no alarms present,

measure the DC voltage across the

resistor. A value of 0.8VDC should

register. This equates to 4mA, or normal

operation.

5 Remove the SeaHawk Leak Detection

Cable (SC) and wait for the unit to activate

its cable trouble alarm. Measure the DC

voltage across the resistor. A value of approximately 4.0VDC should be measured. This

equates to 20mA, or a fault alarm. Reconnect the SC cable.

6 Place water on the end of the SC cable. Measure the DC voltage across the resistor. The

value will be proportional to the length of cable measured by the LD5100. A value of

approximately 4.0V, which equates to 20mA, will be read if the length of the cable is

identical to the length read by the LD5100. Dry the cable.

7 Place water on the start of the cable. Measure the DC voltage across the resistor. A

measurement of approximately 0.8VDC, or 4mA, should be measured. This corresponds to

a leak at zero distance. Dry the cable.

8 Remove the resistor from the plug and reattach any wires as necessary.

www.rletech.com 29 970.484.6510

Page 30

4 4-20mA Output Testing

Notes:

www.rletech.com 30 970.484.6510

Page 31

5.1. Default/Idle Display

When the LD5100 is powered up, diagnostics are performed. The boot ROM and flash program

code are verified. While these diagnostics are being performed, the following text is displayed

on the LCD:

C HAPTER

CHAPTER 0LCD INTERFACE

Figure 5.1

www.rletech.com 31 970.484.6510

LD1500 Bootup Screen

Page 32

5 LCD Interface

Once the diagnostics are complete, the LCD displays the following screen:

Figure 5.2

LD5100 Main Screen

Any time a screen within the LCD interface is left idle for more than one minute, it will return to

this default display.

The LCD is accompanied by a five button control panel. The up, down, left and right arrow

keys are used to move the cursor through the display and change corresponding values. Key

legends are displayed at the bottom of the LCD in submenus. The left arrow key is often used as

a “back” button to navigate to a previous screen. The Enter key selects an option and commits

changes.

5.2. Main Menu

From the Main Menu, use the up and down arrow keys to position the arrow on the LCD in

front of the appropriate menu choice. Press the Enter key to select a menu.

Figure 5.3

www.rletech.com 32 970.484.6510

LD5100 Main Menu Screen

Page 33

5.3. View Zones

The View Zones menu will display the available (or user configured) 12 zones of cable and

their appropriate labels. These zones are lengths of cable that a user may configure for the

LD5100 to display during an alarm.

5 LCD Interface

Figure 5.4

LD5100 Default/Unconfigured View Zones Menu

5.4. Cable Status

The Cable Status option displays the Cable Status screen. This screen shows information about

the SeaHawk Leak Detection Cable (SC) attached to the LD5100.

Figure 5.5

LD5100 Cable Status Screen

5.4.1 System Status

During a no alarm condition, the System Status will display Normal. The System Status will

change during an alarm condition and display either a Leak or Cable Break alarm.

www.rletech.com 33 970.484.6510

Page 34

5 LCD Interface

5.4.2 Cable Length

The length of cable installed on the LD5100, in either feet or meters. To change units refer to

5.8.9, “Feet / Meters” on page 37.

5.4.3 Current

This label shows the current on the SC cable. A current will register if there is any conductive

material (e.g., water) detected on the cable.

5.4.4 Contamination Delay (ContamDly)

The Contamination Delay is a counter that begins when the contamination trip point is passed;

see 5.8.4, “Contamination Delay” on page 37 for configuration.

5.4.5 Leak Delay (LeakDly)

The Leak Delay is a counter that begins when the Leak Trip Point is passed; see 5.8.3, “Leak

Delay” on page 37 for configuration.

5.4.6 Leg 1 Resistance (Leg1 Res)

The resistance measured on the first of two legs of the SC cable. Primarily used for advanced

diagnostic purposes.

5.4.7 Leg 2 Resistance (Leg2 Res)

The resistance measured on the second of two legs of the SC cable. Primarily used for advanced

diagnostic purposes.

5.4.8 Cable Relay or Cable Test Relay

The Cable Relay is used to simulate 2500 feet (762m) of cable on the LD5100. This is used

when the SC cable must be disconnected from the LD5100 unit for maintenance or adjustments

without causing a cable break alarm, see 5.8.11, “Cable Test Relay” on page 38 for

configuration.

5.4.9 Firmware Version

This is the version of the firmware that is currently installed and running on the LD5100.

www.rletech.com 34 970.484.6510

Page 35

5.5. Alarm History/Trend Log

The Alarm History/ Trend Log Screen allows users to view the alarm history, trend log, and

erase data from both.

5 LCD Interface

Figure 5.6

LD5100 Cable Status Screen

5.5.1 Alarm History Log

The Alarm History Log displays the most recent 100 events recorded by the unit. Events are

displayed in the following manner:

Date Time

Description whereas:

Date is the date the event occurred.

Time is the time at which the event occurred.

Description is a detail of the nature of the event.

5.5.2 Trend Log

The Trend Log displays the leakage current on the cable. One measurement is taken at the user

set interval (1 min - 1440 min; factory default is 1440 min, or 1 day). The log retains the 288

most recent entries. Analyzing the trend data can help determine the location of long term

contamination build up, or degradation, on the cable.

5.5.3 Erase Alarm History

Erase Alarm History will clear all events log in the history table.

5.5.4 Erase Trend log

Erase Trend log will clear all trend data logged in the trend table.

www.rletech.com 35 970.484.6510

Page 36

5 LCD Interface

5.6. Comm Port Status

The Comm Port Status menu displays the settings and diagnostics of both of the LD5100's

RS485 Modbus ports. This screen will display each port's Modbus address and packets

counters. Press Enter to reset all packet counters displayed.

Figure 5.7

Comm Port Status Screen

5.7. View Map

The View Map option displays all currently mapped points of the LD5100; see Chapter 6,

“Mapping the Cable” on page 41.

5.8. System Setup

The System Setup option displays the System Setup menu. This screen is password protected.

The default password is 1234.

Figure 5.8

www.rletech.com 36 970.484.6510

System Setup Menu

Page 37

5 LCD Interface

5.8.1 Leak Trip Point

The Leak Trip Point option allows users to modify the leak detection trip point for the LD5100.

This trip point helps the system avoid false alarm readings.

5.8.2 Contamination Trip Point

The Contamination Trip Point option allows users to modify the contamination trip point for

the LD5100. This trip point helps the system avoid false alarm readings.

5.8.3 Leak Delay

The Leak Delay is a timer that begins to count down when a leak alarm condition is met. This

timer delays the alarm from registering for a set amount of time. The timer can be set from 5 to

990 seconds.

5.8.4 Contamination Delay

The Contamination Delay is a timer that begins to count down when a leak alarm condition is

met. This timer delays the alarm from registering for a set amount of time. The timer can be set

from 5 to 990 seconds.

5.8.5 Re-Alarm Delay

The Re-Alarm Delay is a counter that, upon expiring, will re-annunciate the last silenced alarm

condition. This counter can be set from 0 (disable) to 24 hours.

5.8.6 Latching Alarms

The Latching Alarms option allows the alarm relays to be set as latching or non-latching. A

latched alarm requires a manual reset of the system once a leak or cable problem is no longer

present.

5.8.7 Supervised Relays

The Supervised Relays option allows users to configure the Leak and Fault relays to be

supervised or unsupervised. A supervised relay is normally activated and will deactivate upon

alarm or loss of power.

5.8.8 4-20MA Max Range

The 4-20mA Max Range allows the user to select the cable range for the 4-20mA output. This

value can be set to 1000, 2500, or 5000 feet (305m, 762m, and 1524m).

5.8.9 Feet / Meters

The Feet/Meters option designates whether the LD5100's distance readings are displayed in

feet or meters.

www.rletech.com 37 970.484.6510

Page 38

5 LCD Interface

5.8.10 Language

The Language option designates whether the LD5100's LCD menus are displayed in English or

French.

5.8.11 Cable Test Relay

The Cable Test Relay option activates the internal test circuit to simulate 2500 feet (762m)

cable. This allows the SC cable to be removed from the LD5100 without causing alarms. The

Cable Test Relay will stay on for 300 seconds and a counter will be displayed.

5.8.12 Restore Defaults

The Restore Defaults option will reset all configurations back to the original factory defaults.

5.8.13 Clock

The Clock option allows users to set the time and date for the LD5100.

5.8.14 Resistance/Foot (Res/Ft)

The Res/Ft option allows users to precisely calibrate the LD5100. Users can adjust the ohms per

foot until the cable length displayed matches the actual cable length installed. The default value

is 2.800 ohms per foot.

www.rletech.com 38 970.484.6510

Page 39

5.9. Zone Setup

The Zone Setup menu will display a table of configured zones. A zone is a set length of cable

that may have a name or description assigned to it. Upon alarm, if a leak distance falls within a

zone’s boundary, the zone's description will appear on the main screen. Zones are configured

by entering the starting distance for the zone, followed by the zone label. The zone’s end

boundary is set by the next zone's starting distance.

5 LCD Interface

Figure 5.9

Note Zone 1 starts at 0 feet/meters and ends at Zone 2’s starting distance.

Example Configuration for Zone 1

Figure 5.10 is an example of the main screen during a leak at 500 feet (152.4m), in Zone 1,

labeled Server Room.

Figure 5.10

Example of the Main Screen during a Specific Condition

www.rletech.com 39 970.484.6510

Page 40

5 LCD Interface

5.10. Point Mapping

The Point Mapping menu allows users to map points on the LD5100. Mapped points help users

to create reference maps for a cable layout. For more details about how to map the cable on the

LD5100 see Chapter 6, “Mapping the Cable” on page 41.

5.11. Comm Port Settings

The Comm Port Settings menu allows users to configure both of the LD5100’s RS485 Modbus

ports. The LD5100 is only configurable as a Modbus slave device. Both ports may have their

addresses and baud rates set in this menu. Both addresses may be different and can be

configured from 0 (disabled) to 254. Both baud rates can be different and can be configured as

1200, 2400, 9600 (default), or 19200.

To set the ports, use the up and down arrows to navigate to the desired Port #. Then push the

right arrow to select the field. Use the up and down arrows to select the desired setting.

The Leak Detection Master option enables slave units to activate the LD5100 when they are

triggered into an alarm state. This function is beneficial when the LD5100 is a remote system

that does not have personnel in the immediate vicinity to monitor the alarm status.

When using the leak detection master option, the LD5100 relays can be activated according to

the slave unit alarm. If the slave has a leak alarm or a cable break alarm, the LD5100 leak or

cable relay will change state, respectively (i.e. it will trigger that an alarm is present. The zone

will then appear on the LCD and an alarm state will be reported to the top level of the system.

Figure 5.11

Comm Port

www.rletech.com 40 970.484.6510

Page 41

C HAPTER

CHAPTER 0MAPPING THE CABLE

After the SeaHawk Water Leak Detection Cable (SC) is laid in the desired configuration, the

cable can be mapped. Mapping the cable improves the accuracy of the LD5100 reference map

and makes it easier to locate a leak.

To ensure the cable has been installed properly, RLE recommends testing the cable in a few

spots before mapping the system,.

The LD5100 computes the distance from the control panel to the leak along the length of SC

cable attached to the unit. In most cases, the SC cable is laid in a curved or serpentine pattern.

This may make it difficult to locate a leak when given a linear distance. To help alleviate this

problem, identify a series of easily accessible, evenly spaced points along the cable length.

Number the points, and record their locations on the cable reference map (part #FM1114)

provided by RLE, or refer to the directions for creating a map below (6.1., “Mapping

Directions” on page 42). Use the numbered points to map the cable. Then, when the unit

detects a leak, the location of the leak can be determined by comparing the distance shown on

the control panel with the known positions along the cable as recorded on the reference map.

Note Calibrate the LD5100 prior to mapping by adjusting the Resistance per Foot reading; see

5.8.14, “Resistance/Foot (Res/Ft)” on page 38 for more details. This allows the LD5100

measured cable length to accurately reflect the actual cable length installed.

www.rletech.com 41 970.484.6510

Page 42

6 Mapping the Cable

WARNING

6.1. Mapping Directions

1 If a cable reference map (part #FM114) was not ordered from RLE Technologies, LD5100

users must create a drawing that represents the floor plan. This drawing must include the

room layout (walls, doors, and other permanent structures), the SC cable routing path, any

jumper sections of non-sensing cable (NSC) and any weighted cable connectors/simulators

(WCCS). Marking up a CAD drawing of the Facility works the best.

2 Physically identify points along the cable routing path. The points should be easily

accessible and evenly spaced. Number the points and record their location on the reference

map. Note where the connectors are located along the cable run.

3 Using the front panel of the LD5100, select Point Mapping and press Enter.

4 To test the map, wrap a wet paper towel or sponge or pour a small puddle of water around

the cable at one of the previously mapped points. The LD5100 produces a short beep within

approximately 30 seconds. The LCD displays the LD5100's calculated distance to the leak.

Remove the paper towel and dry the cable. Within approximately 20 seconds, the LD5100

produces a long beep indicating the short is removed and the system has returned to normal.

Tip If the individual mapping the cable is not in a position to hear the audible alarm, wait two

minutes between each point. This ensures the system has had time to stabilize.

Loss of power or re-entering the Point Mapping menu will cause all mapping data

to be lost (reset).

5 When mapping is complete, press the Left arrow key on the LD5100 to exit the mapping

mode.

6 Select View Map on the LCD and record the LD5100's reading of each point on the

reference map.

7 Mount the cable reference map alongside to the LD5100 control panel or the remote

display. When a leak or cable break occurs, refer to the map and the distance displayed on

the LD5100 to determine the physical location of the leak.

www.rletech.com 42 970.484.6510

Page 43

C HAPTER

WARNING

CHAPTER 0EIA-232 INTERFACE

The EIA-232 Interface is used primarily for advanced diagnostic and configuration.

The Bootloader section is designed for experienced technicians or users

responsible for maintaining the system. EXIT IMMEDIATELY if you are not

trained in the use of the Bootloader commands.

Contact the manufacturer for more information regarding the commands in this

section.

7.1. Boot Up

Make sure the EIA-232 port is connected to a PC or terminal with a straight through cable (not

provided). Run terminal emulation software (i.e., HyperTerminal) and make sure the settings

match the LD5100 EIA-232 port configuration; see 2.1.7, “RS232 Connector” on page 21 for

port configuration details. When the LD5100 is powered up, diagnostics are performed. The

boot ROM and flash program code are verified. Output similar to Figure 7.1 should appear on

the terminal or terminal emulation software.

www.rletech.com 43 970.484.6510

Page 44

7 EIA-232 Interface

Figure 7.1

EIA-232 Bootup Screen

7.2. Main Menu

Once the system is entirely booted, press the Enter key on your PC or terminal to display the

Main Menu.

Figure 7.2

EIA-232 Main Menu Screen

www.rletech.com 44 970.484.6510

Page 45

7.3. SC – System Configuration

The SC function command displays a submenu that lists all items in the System Configuration

Menu.

7 EIA-232 Interface

Figure 7.3

EIA-232 SC Function Screen

7.3.1 Modify LCD Password – 1

Selection 1, Modify LCD Password, will allow users to set a new LCD password for the

System Setup LCD menu. A four digit number must be entered in place of the default 1234

password. A password of 0000 will disable all password protection on the LD5100.

7.3.2 Zone Setup – 2

Selection 2, Zone Setup, will allow users to configure zones. Zones are lengths of cable that

may have a label, or description, associated with them.

Zones begin by the Zone Distance, or starting length, and end with the next zone's beginning

Zone Distance; Note: Zone 1 always starts with Zone Distance of 0 ft. Enter a Zone Distance

in the format dxx where xx is the zone number. A user will then be prompted to enter the

beginning length for the zone. For example, to set Zone 2 to begin at 1000 feet (305m), type

d2 and press Enter. Then type 1000 and press Enter when prompted for zone distance.

Enter a zone’s description in the format lxx where xx is the zone number. A user will then be

prompted to enter the description for the zone. A description can be up to fifteen characters in

length.

www.rletech.com 45 970.484.6510

Page 46

7 EIA-232 Interface

7.3.3 Diagnostics – 3

Selection 3, Diagnostics, will allow users to open the LD5100's Diagnostic menu. This menu

is primarily used for advanced diagnostics and troubleshooting.

Figure 7.4

EIA-232 Diagnostics Menu

The options available on the Diagnostics Menu are described in Table 7.1.

Table 7.1

Option Description

Cable Readings – 1 Selection 1 displays the current cable readings, including

Set 4-20mA Output – 2 Selection 2 allows a user to manually set the 4-20mA

Cable Relay On – 3 Selection 3 turns the internal cable test relay on.

Cable Relay Off – 4 Selection 4 turns the internal cable test relay off.

Output Relay K1 On – 5 Selection 5 turns the Leak relay on.

Output Relay K1 Off – 6 Selection 6 turns the Leak relay off.

Output Relay K2 On – 7 Selection 7 turns the Fault relay on.

Output Relay K2 Off – 8 Selection 8 turns the Fault relay off.

Diagnostic Menu Options

both cable length and any present current leakage.

output to test its function.

www.rletech.com 46 970.484.6510

Page 47

7.4. Other Main Menu Functions

The remainder of the functions available from the Main Menu of the EIA-232 interface are

described in Table 7.2.

7 EIA-232 Interface

Table 7.2

Option Description

LS – Leak Status LS displays the current cable readings, including both

AR – Alarm Reset AR resets all alarm relays. This command forces all alarms

AH – Alarm History AH displays the Alarm History Log.

CH – Clear Alarm History CH clears the Alarm History Log.

TD – Trend Data Table TD displays the Trend Data Table, which monitors and

CT – Clear Trend Data Table CT clears all records from the Trend Data Table.

TI – Display Date/time TI displays the LD5100’s current date and time

MT ON – Measurement Trace OnMT ON displays advanced manufacturer diagnostics of the

MT OFF – Measurement

Trace Off

MBT – Modbus Trace On MBT shows Modbus trace.

Other Main Menu Functions

cable length and any present current leakage.

off. If an alarm condition is still present after the AR

command is executed, the alarm is reactivated. If an alarm

is still active after the AR command is executed, it will not

be re-entered in the Alarm History Log.

displays leakage current.

microprocessor.

MT OFF turns off the display of advanced manufacturer

diagnostics of the microprocessor.

MBS – Modbus Stats MBS shows Modbus stats.

EX – Exit EX is used to enter the Bootloader command section. The

unit will stop monitoring cable and allow firmware updates

to be loaded. To restore normal operation after updating

firmware, type RUN and press the Enter (<-|) key on the

keyboard, or power the unit off and then back on again.

www.rletech.com 47 970.484.6510

Page 48

7 EIA-232 Interface

Notes:

www.rletech.com 48 970.484.6510

Page 49

CHAPTER 0MODBUS COMMUNICATION

This document describes the Modbus communications protocol as supported by the LD5100

Water Leak Detection System. It includes details and information on how to configure the

LD5100 for communications via Modbus network.

8.1. Implementation Basics

C HAPTER

The LD5100 is capable of communicating via the half-duplex RS485 serial communication

standard. The LD5100 is configured to act as a slave device on a common network. The

RS485 medium allows for multiple devices on a multi-drop network. The LD5100 is a slave

only device and will never initiate a communications sequence.

8.1.1 Modes of Transmission

The Modbus protocol uses ASCII and RTU modes of transmission. The LD5100 supports only

the RTU mode of transmission, with 8 data bits, no parity and one stop bit. Every Modbus

packet consists of four fields:

Slave Address Field

Function Field

Data Field

Error Check Field (Checksum)

8.1.1.1 Slave Address Field

The slave address field is set by the going into local 160x160 display on the front panel. Go to

COMM PORT SETTINGS from the Main Menu screen. Select the Modbus Slave address and

the baud rate to be used for either/or EIA-485 Port1 and EIA-485 Port2.

www.rletech.com 49 970.484.6510

Page 50

8 Modbus Communication

8.1.1.2 Function Field

The function field is one byte in length and tells the LD5100 which function to perform. The

supported functions are 03 (Read 4xxxx output registers), 04 (Read 3xxxx input registers), 06

(Preset single register) and 16 (Preset multiple registers).

8.1.1.3 Data Field

The data field of the request is a variable length depending on the function. The data fields for

the LD5100 are 16-bit registers, transmitted high order byte first (big-endian).

8.1.1.4 Error Check (Checksum) Field

The checksum field lets the receiving device determine if the packet has transmission errors.

The LD5100 RTU mode uses a 16-bit cyclic redundancy check (CRC-16).

8.1.2 Exception Responses

If a Modbus master sends an invalid command to the LD5100 or attempts to read an invalid

register, an exception response is generated. The response packet will have the high order bit

of the function code set to one. The data field of the exception response contains the exception

error code.

Table 8.1

Code Name Description

01 Illegal Function The function code is not supported

02 Illegal Data Address Attempt to access an invalid address

03 Illegal Data Value Attempt to set a variable to an invalid value

Exception Codes

www.rletech.com 50 970.484.6510

Page 51

8 Modbus Communication

8.2. Packet Communications For The LD5100

This section covers the registers, their names, and a brief description of what they refer to.

8.2.1 Function 03: Read Output Registers

To read the LD5100 parameter values, the master must send a Read Output Registers request

packet. The Read Output Registers request packet specifies a start register and the number of

registers to read. The start register is numbered from zero (40001 = zero, 40002 = one, etc).

Table 8.2

Read Registers Request Packet Read Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

03 (Function code) (1 byte) 03 (Function code) (1 byte)

Start Register (2 bytes) Byte count (1 byte)

# of registers to read (2 bytes) First register (2 bytes)

Crc Checksum (2 bytes) Second register (2 bytes)

Read Output Registers Packet Structure

…

Crc Checksum (2 bytes)

www.rletech.com 51 970.484.6510

Page 52

8 Modbus Communication

Table 8.3

Output Registers

Register Name Description Units Range

40001 Leak Threshold Trip current for leak alarm Amps 0-65535

40002 Contamination

Trip current for contamination alarm Amps 0-65535

Threshold

40003 Re-Alarm Re-Alarm delay Minutes 0-65535

40004 Latched Alarm Latching Alarms 0=No 1=Yes 0-65535

40005 Silence Alarm Set to 1 to silence audible alarm 1=Silence 0-65535

40006 Reset Alarm Set to 1 to reset alarms 1=Reset

0-65535

Alarm

40007 Spare 0-65535

40008 Spare 0-65535

40009 Spare 0-65535

40010 Month Clock 1-12 0-65535

40011 Day Clock 1-31 0-65535

40012 Year Clock 00-99 0-65535

40013 Hour Clock 0-23 0-65535

40014 Minutes Clock 0-59 0-65535

40015 Seconds Clock 0-59 0-65535

40016 Seconds Leak Alarm Delay 20-3600 0-65535

40017 Seconds Contamination Alarm Delay 20-3600 0-65535

www.rletech.com 52 970.484.6510

Page 53

8 Modbus Communication

8.2.2 Function 04: Read Input Registers

To read the LD5100 input values, the master must send a Read Input Registers request packet.

The Read Input Registers request packet specifies a start register and the number of registers

to read. The start register is numbered from zero (30001 = zero, 30002 = one, etc).

Table 8.4

Read Registers Request Packet Read Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

04 (Function code) (1 byte) 04 (Function code) (1 byte)

Start Register (2 bytes) Byte count (1 byte)

# of registers to read (2 bytes) First register (2 bytes)

Crc Checksum (2 bytes) Second register (2 bytes)

Read Input Registers Packet Structure

…

Crc Checksum (2 bytes)

www.rletech.com 53 970.484.6510

Page 54

8 Modbus Communication

Table 8.5

Input Registers

Register Name Description Units Range

30001 Status Bit level status None 0-65535

30002 Leak Distance Location of leak Ft/Meters 0-65535

30003 Units Unit of measure 1=Ft

0-65535

0=Meters

30004 Leak Current Leakage current on cable Amps 0-65535

30005 Cable Length Installed cable length Ft/Meters 0-65535

30006 Loop1 Res Resistance of cable Ohms 0-65535

30007 Loop2 Res Resistance of cable Ohms 0-65535

30008 Res/Ft Resistance of cable Ohms x1000 0-65535

30009 Version Firmware version xx.xx X 100 0-65535

30010 Virtual Zone Alarm Status Bit Level Status None 0-65535

30011 Modbus Zone Enabled Flags Bit Level Status None 0-65535

30012 Modbus Zone2 Status Bit Level Status None 0-65535

30013 Modbus Zone2 Distance Location of leak Ft/Meters 0-65535

30014 Modbus Zone3 Status Bit Level Status None 0-65535

30015 Modbus Zone3 Distance Location of leak Ft/Meters 0-65535

30016 Modbus Zone4 Status Bit Level Status None 0-65535

30017 Modbus Zone4 Distance Location of leak Ft/Meters 0-65535

30018 Modbus Zone5 Status Bit Level Status None 0-65535

30019 Modbus Zone5 Distance Location of leak Ft/Meters 0-65535

30020 Modbus Zone6 Status Bit Level Status None 0-65535

30021 Modbus Zone6 Distance Location of leak Ft/Meters 0-65535

30022 Modbus Zone7 Status Bit Level Status None 0-65535

30023 Modbus Zone7 Distance Location of leak Ft/Meters 0-65535

30024 Modbus Zone8 Status Bit Level Status None 0-65535

30025 Modbus Zone8 Distance Location of leak Ft/Meters 0-65535

30026 Modbus Zone9 Status Bit Level Status None 0-65535

30027 Modbus Zone9 Distance Location of leak Ft/Meters 0-65535

30028 Modbus Zone10 Status Bit Level Status None 0-65535

30029 Modbus Zone10 Distance Location of leak Ft/Meters 0-65535

30030 Modbus Zone11 Status Bit Level Status None 0-65535

30031 Modbus Zone11 Distance Location of leak Ft/Meters 0-65535

30032 Modbus Zone12 Status Location of leak None 0-65535

30033 Modbus Zone12 Distance Bit Level Status Ft/Meters 0-65535

Registers 30011 through 30033 are dedicated registers for modbus master; see Appendix B, “Leak

Detection Modbus Master” on page 61.

www.rletech.com 54 970.484.6510

Page 55

8 Modbus Communication

Table 8.6

Status Flags (Register 30001)

Bit Description

00 1 = Leak is Detected

01 1 = Cable Break Alarm

02 1 = Contamination is detected

03-15 Spare

Table 8.7

Status Flags (Register 30010)

Bit Description

00 1 = Zone1

01 1 = Zone2

02 1 = Zone3

03 1 = Zone4

04 1 = Zone5

05 1 = Zone6

06 1 = Zone7

07 1 = Zone8

08 1 = Zone9

09 1 = Zone10

10 1 = Zone11

11 1 = Zone12

www.rletech.com 55 970.484.6510

Page 56

8 Modbus Communication

Table 8.8

Bit Description

00 1 = Not enabled

01 1 = Enabled, b1=MBZ2

02 1 = MBZ3

03 1 = MBZ4

04 1 = MBZ5

05 1 = MBZ6

06 1 = MBZ7

07 1 = MBZ8

08 1 = MBZ9

09 1 = MBZ20

10 1 = MBZ11

11 1 = MBZ12

Table 8.9

Status Flags (Register 30011)

Status Flags (Register 30012 - 30033)

Bit Description

00 1= Leak Detected

01 1 = Cable Break

02 1 = Contamination

07 1 = Communication Loss

8.2.3 Function 06: Preset Single Register

To set the LD5100 parameter value, the master must send a Preset Single Register request

packet. The Preset Single Register request packet specifies a register and the data to write to

that register. The register is numbered from zero (40001 = zero, 40002 = one, etc).

Table 8.10

Preset Register Request Packet Preset Register Response Packet

Slave Address (1 byte) Slave Address (1 byte)

06 (Function code) (1 byte) 06 (Function code) (1 byte)

Register (2 bytes) Register (2 byte)

Data (2 bytes) Data (2 bytes)

Preset Single Register Packet Structure

Crc Checksum (2 bytes) Crc Checksum (2 bytes)

www.rletech.com 56 970.484.6510

Page 57

8 Modbus Communication

8.2.4 Function 16: Preset Multiple Registers

To set multiple LD5100 parameter values, the master must send a Preset Multiple Registers

request packet. The Preset Multiple Register request packet specifies a starting register, the