Page 1

S

EA

RLE Technologies

RLE Technologies

H

AWK

LD5000

U

U

U

s

s

s

e

e

e

r

r

r

G

G

G

u

u

u

i

i

i

d

d

d

e

e

e

RLE Technologies • 208 Commerce Drive, Fort Collins, CO 80524 • 800.518.1519 • 970.484.6650 (fax) • www.rletech.com

Page 2

Page 3

LD5000

Page 4

©2006 RLE Technologies 11005 Rev 5.1 (03/2006)

Page 5

User Guide: LD5000 Table of Contents

TABLE OF CONTENTS

Chapter 1: Product Overview ........................................................................................................................................ 1

1-1 Description......................................................................................................................................................1

1-2 Operation.........................................................................................................................................................1

1-3 Mechanical Description...................................................................................................................................1

1-4 Installation.......................................................................................................................................................1

1-5 Floor Map........................................................................................................................................................1

1-6 LCD User Interface.........................................................................................................................................2

Chapter 2: Connections and Settings.............................................................................................................................4

2-1 Display Board .................................................................................................................................................5

2-2 Leak Detection Board .....................................................................................................................................5

2-3 Microprocessor Board.....................................................................................................................................6

2-4 Input Power.....................................................................................................................................................6

2-5 Power ON/OFF Switch ...................................................................................................................................6

2-6 RS-232 Connector...........................................................................................................................................6

2-7 Switches .......................................................................................................................................................... 7

Chapter 3: Installation ...................................................................................................................................................9

3-1 Installing the Unit............................................................................................................................................9

3-2 Connecting the Water Leak Detection Cable ..................................................................................................9

3-3 Apply Power to the Unit ...............................................................................................................................11

Chapter 4: 4-20MA output testing...............................................................................................................................12

Chapter 5: LCD Default Display.................................................................................................................................13

Chapter 6: LCD Main Menu........................................................................................................................................14

6-1 Status Option.................................................................................................................................................14

6-2 Setup Menu ...................................................................................................................................................14

6-3 Log/Data........................................................................................................................................................15

6-4 System...........................................................................................................................................................16

6-5 Reset Menu ...................................................................................................................................................17

6-6 Comms Command.........................................................................................................................................17

Chapter 7: LCD Setup Menu.......................................................................................................................................18

7-1 TripPoints......................................................................................................................................................18

7-2 Clock Option .................................................................................................................................................18

7-3 Re-Alarm.......................................................................................................................................................18

7-4 Ft/M Function ...............................................................................................................................................19

7-5 Calibrate........................................................................................................................................................19

7-6 FcDft Option ................................................................................................................................................. 20

Chapter 8: Mapping the Cable.....................................................................................................................................21

8-1 Mapping Directions.......................................................................................................................................21

Chapter 9: RS-232 Interface Startup ...........................................................................................................................23

Chapter 10: RS-232 Main Menu .................................................................................................................................24

10-1

Function Commands ..........................................................................................................................24

Chapter 11: RS-232 Function Commands................................................................................................................... 27

11-1

SC - System Configuration.................................................................................................................27

11-2

LS - Leak Status .................................................................................................................................27

11-3

CA - Current Alarms..........................................................................................................................27

11-4

AH - Alarm History............................................................................................................................28

11-5

CH - Clear Alarm History ..................................................................................................................29

11-6

TD - Trend Data Table (Leakage Current).........................................................................................29

11-7

CT - Clear Trend Data Table..............................................................................................................30

11-8

TI - Display Date/Time ......................................................................................................................30

11-9

NS - Network Status (RS-485)...........................................................................................................31

11-10

MR - Reset Modbus Status Counters .................................................................................................31

11-11

ND - Network Display (RS-485)........................................................................................................32

11-12

MT – Modbus Display (Trace)...........................................................................................................32

www.rletech.com 970.484.6510 i

Page 6

Table of Contents User Guide: LD5000

Chapter 12: System Configuration.............................................................................................................................. 33

12-1

System Name - 1................................................................................................................................ 33

12-2

Clock - 2 ............................................................................................................................................ 34

12-3

RS-485 Baud - 3 ................................................................................................................................ 34

12-4

Relays - 4........................................................................................................................................... 35

12-5

Cable Feet/Meters - 5 ........................................................................................................................ 38

12-6

Calibration - 6.................................................................................................................................... 38

12-7

LCD Setup -7..................................................................................................................................... 39

12-8

Diagnostics - 8................................................................................................................................... 40

12-9

Mapping Mode - 9 ............................................................................................................................. 40

Chapter 13: Calibration Menu .................................................................................................................................... 44

13-1

Display Leg1 and Leg2 - 1 ................................................................................................................ 45

13-2

Cable Length Offset - 2 ..................................................................................................................... 46

13-3

Leak Distance Offset - 3.................................................................................................................... 47

13-4

Cable Length - 4 ................................................................................................................................ 48

13-5

Cable Resistance - 5 .......................................................................................................................... 49

13-6

Calculate Leak Distance Offset - 6.................................................................................................... 50

13-7

Calculate Cable Resistance - 7 .......................................................................................................... 51

13-8

Calculate Cable Length Offset - 8 ..................................................................................................... 52

13-9

Step Calibrate - 9 ............................................................................................................................... 53

13-10

Auto Calibrate - 10 ............................................................................................................................ 54

13-11

Cable Leak Threshold - 11 ................................................................................................................ 55

13-12

Cable Contamination Threshold - 12................................................................................................. 56

13-13

Use Default Values - 13..................................................................................................................... 57

13-14

Change Calibration Password - 14..................................................................................................... 58

13-15

Change LCD User Password - 15...................................................................................................... 59

13-16

Leak Alarm Delay (seconds) - 16...................................................................................................... 60

13-17

Contamination Alarm Delay (seconds) - 17 ...................................................................................... 61

13-18

Trend Interval (minutes) - 18............................................................................................................. 62

13-19

Exit - 19 ............................................................................................................................................. 63

Chapter 14: Diagnostics Menu ................................................................................................................................... 64

14-1

Cable Readings - 1............................................................................................................................. 64

14-2

Dip Switch Readings - 2.................................................................................................................... 65

14-3

Force 4 to 20mA Output - 3............................................................................................................... 66

14-4

Cable Relay On - 4 ............................................................................................................................ 67

14-5

Cable Relay Off - 5............................................................................................................................ 67

14-6

Output Leak Relay (K1) On - 6 ......................................................................................................... 68

14-7

Output Leak Relay (K1) Off - 7 ........................................................................................................ 68

14-8

Output Fault Relay (K2) On - 8......................................................................................................... 69

14-9

Output Fault Relay (K2) Off - 9 ........................................................................................................ 69

Appendix A: Modbus Communication....................................................................................................................... 70

A-1 Implementation Basics ................................................................................................................................. 70

A-2 Packet Communications for the LD5000 ..................................................................................................... 71

A-3 Modbus Dip Switch Settings for the LD5000 .............................................................................................. 73

A-4 RTU FRAMING........................................................................................................................................... 74

A-5 LD5000 LCD Modbus Status Screen (Comms) ........................................................................................... 74

A-6 LD5000 LCD Modbus Status RS-232.......................................................................................................... 75

Appendix B: Bootloader Firmware V1.2.................................................................................................................... 77

B-1 Permanent Code ........................................................................................................................................... 77

B-2 Diagnostic Commands.................................................................................................................................. 77

B-3 Updating the Flash Firmware. ...................................................................................................................... 77

Appendix C: Preventive Maintenance ........................................................................................................................ 79

Appendix D: Troubleshooting .................................................................................................................................... 80

Appendix E: Technical Specifications........................................................................................................................ 82

ii 970.484.6510 www.rletech.com

Page 7

User Guide: LD5000 List of Figures and Tables

LIST OF FIGURES AND TABLES

Figure 1-1 LD5000 LCD Interface

Figure 1-3 LD5000 Enclosure Interior .......................................................................................................................... 3

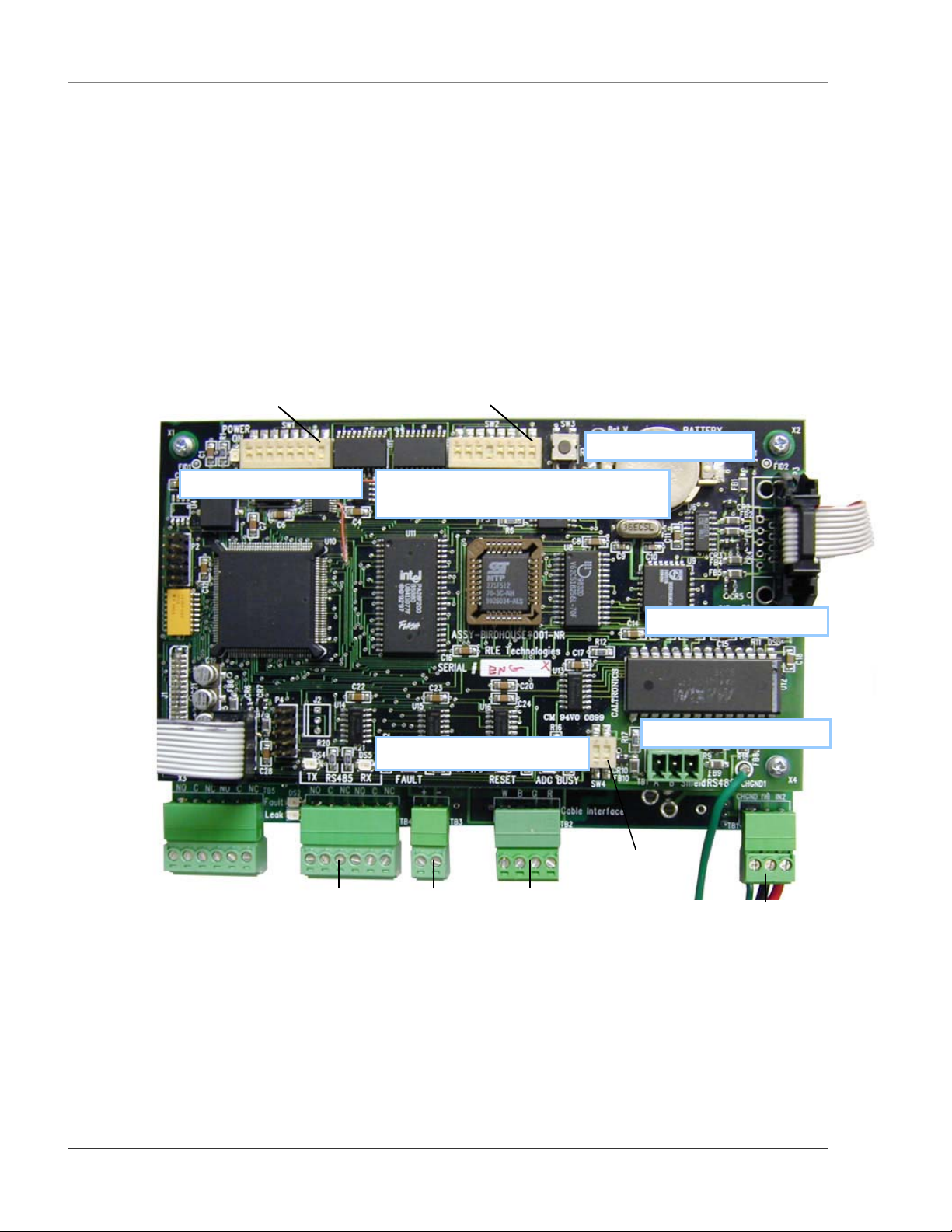

Figure 2-1 LD5000 Leak Detection Boards ..................................................................................................................4

Figure 3-2 Cable Installation Methods ........................................................................................................................10

Figure 4-1 4-20mA Testing ........................................................................................................................................12

Table 1: Exception Codes...........................................................................................................................................70

Table 2: Read Output Registers Packet Structure........................................................................................................71

Table 3: Output Registers...........................................................................................................................................71

Table 4: Read Input Registers Packet Structure ..........................................................................................................72

Table 5: Input Registers...............................................................................................................................................72

Table 6: Status Flags (Register 30001):.......................................................................................................................72

Table 7: Preset Single Register Packet Structure.........................................................................................................72

Table 8: Preset Multiple Registers Packet Structure ...................................................................................................73

Table 9: Baud rate .......................................................................................................................................................73

Table 10: Modbus Slave Address................................................................................................................................ 73

Table 11: Query Sample.............................................................................................................................................74

Table 12: Response Sample........................................................................................................................................74

Figure 1-2 R2 Contrast Adjustment...................................................................2

www.rletech.com 970.484.6510 iii

Page 8

Page 9

User Guide: LD5000 Chapter 1: Product Overview

CHAPTER 1: PRODUCT OVERVIEW

1-1 DESCRIPTION

The LD5000 is a complete monitoring system that detects and reports the presence of water and other

conductive liquids. The LD5000 couples RLE distance read leak detection cable with an advanced control

panel. Each LD5000 monitors up to 5,000 feet of leak detection cable. When a conductive liquid comes in

contact with the water leak detection cable an alarm sounds and the distance to the leak is shown on the

LD5000’s four line display.

The LD5000 allows a single person to perform the mapping of the cable - the process of determining the

relationship between a known point along the cable and the value as measured by the LD5000.

1-2 OPERATION

When the LD5000’s analog circuitry measures a current in excess of the user-defined leak threshold, the

unit’s microprocessor computes the distance to the leak. The unit then annunciates the leak and logs the

alarm in its event log. The leak relay and fault relay each have two outputs. An additional 4-20mA output

allows the device to interface with third party management systems.

The LD5000 produces an alarm in the following conditions:

• Leak Detected

• Cable Break

• Loss of Communications

The LD5000 is a supervised system - it continually monitors the cable for continuity. A cable break or

excess contamination of the cable causes a cable break indication and activates a relay.

1-3 MECHANICAL DESCRIPTION

The LD5000 with LCD is built with three circuit boards:

• The display board is connected to the microprocessor board with a ten conductor ribbon cable. The

display board is mounted on the inside of the unit’s door.

• The microprocessor board is mounted on top of the leak detection board. A reset switch is

provided to reset the microprocessor without cycling power to the unit.

1-4 INSTALLATION

The LD5000 with LCD is a wall mounted device. Before applying power to the unit, insure that all

connections are correct and all screw terminals are secure. The EMI suppression core must be installed on

the leader cable that exits the LD5000 to conform to CE standards.

1-5 FLOOR MAP

Users may purchase a water leak detection cable reference map with their LD5000. Once all the water leak

detection cable is installed, compare this reference map with the actual cable installation. Note any

discrepancies and return the map to the original author for correction. Keep a copy for use until the

updated map can be reinstalled near the control panel.

www.rletech.com 970.484.6510 1

Page 10

Chapter 1: Product Overview User Guide: LD5000

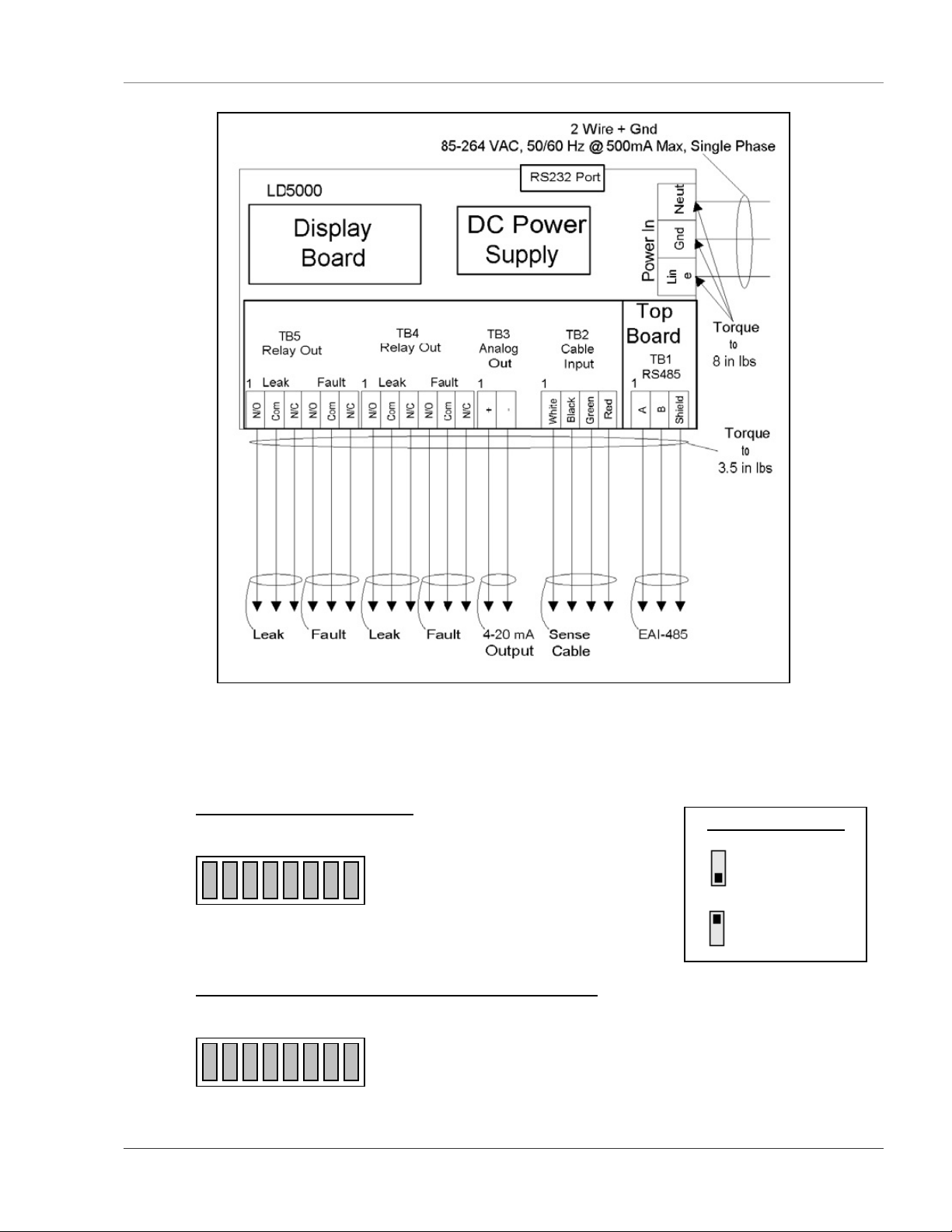

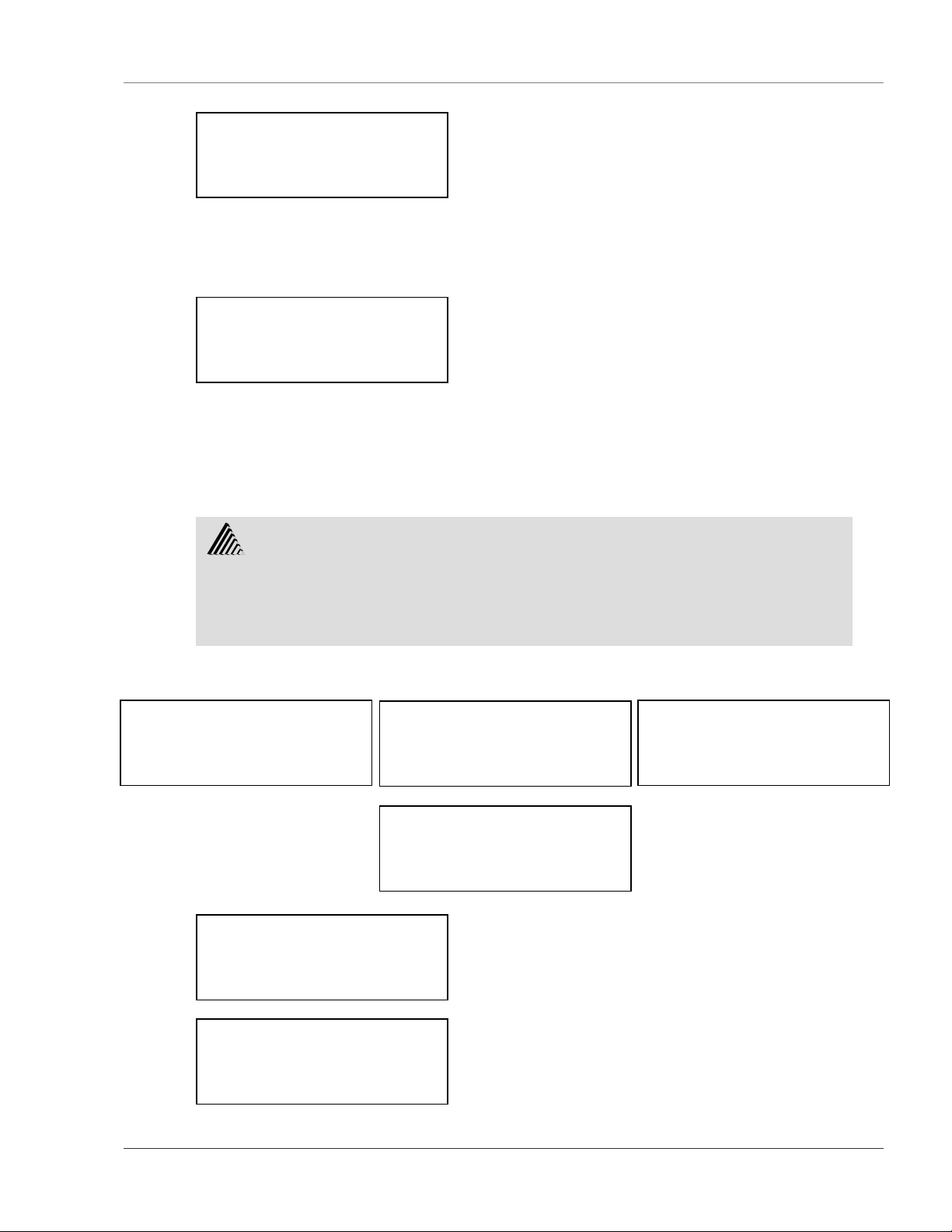

1-6 LCD USER INTERFACE

The LD5000’s LCD is a 4 line by 20 character backlit display with a six button keypad. The interface’s

menu structure is as follows:

¾ Main Menu

o Status

Current Cable Status

Cable Length

Cable Current

o Setup – (Password Protected)

Trip Points

• Detection Trip

• Contamination Trip

Clock

Re-Alarm

Ft/M

• Calibrate

• FCDft

o Log/Data

History

Trend

HistClr

TrndClr

o System (Water Leak Detection Cable mapping)

View Map

StartMap

o Reset

Reset

Update

FaultRly

LeakRly

o Modbus

Navigate through the menu(s) with the left and right arrows. Esc cancels any action and returns to the

previous menu. Enter (↵

change the values. Further LCD interface information can be found beginning on pages 13-17. If any of

the LD5000’s passwords are lost or misplaced, contact RLE Technologies to help reset the passwords.

) selects a submenu and commits changes. The - (minus) and + (plus) keys

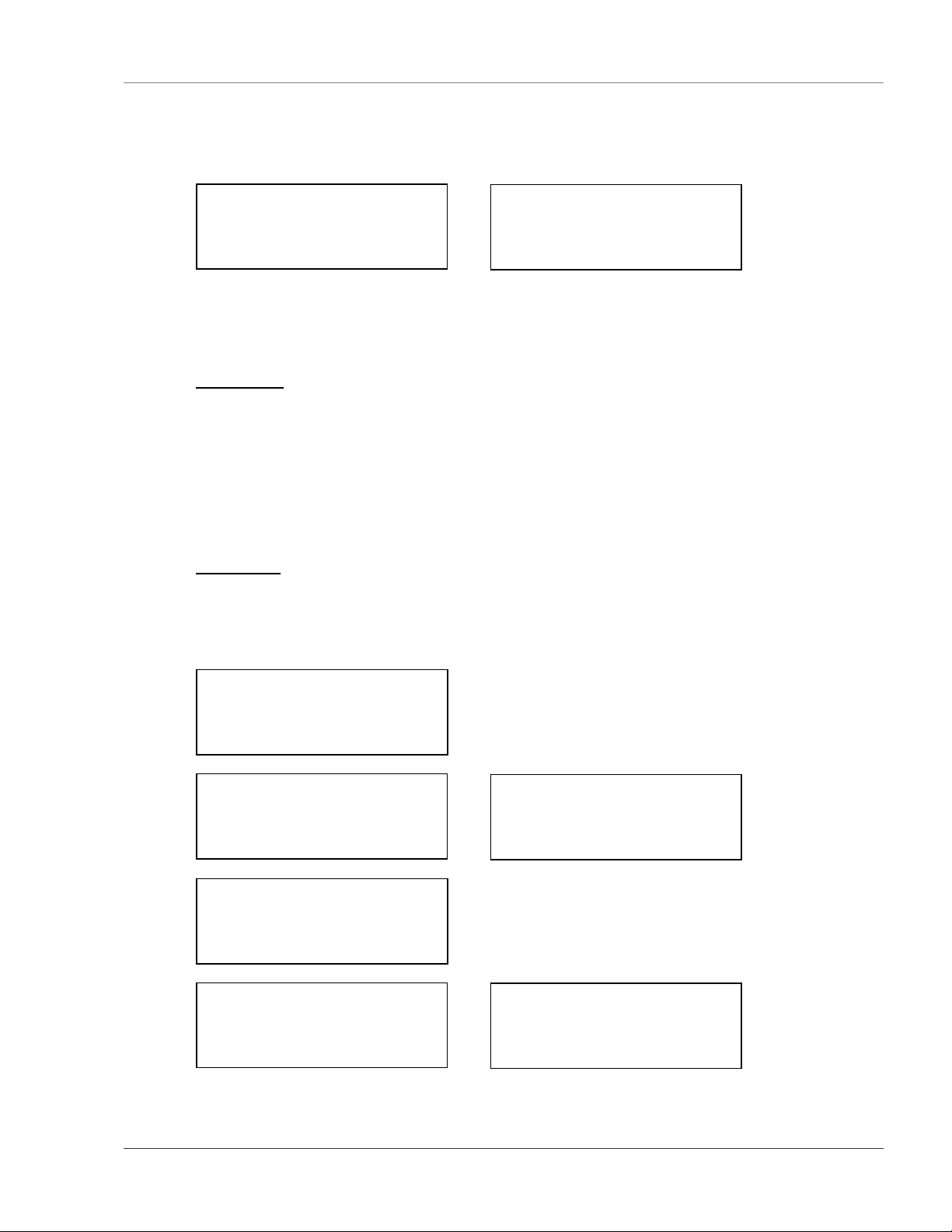

Figure 1-1 LD5000 LCD Interface Figure 1-2 R2 Contrast Adjustment

2 970.484.6510 www.rletech.com

Page 11

User Guide: LD5000 Chapter 1: Product Overview

Power Supply & Power Switch

Power Input Terminal Block

RA-232 Serial Cable Interface

Figure 1-3 LD5000 Enclosure Interior

Warning!

• A dedicated circuit breaker must be provided in the building within

close proximity to the RLE unit and be clearly marked as the

disconnecting device for this unit.

www.rletech.com 970.484.6510 3

Page 12

Chapter 2: Connections and Settings User Guide: LD5000

play,

CHAPTER 2: CONNECTIONS AND SETTINGS

The LD5000 is comprised of three boards. All three boards are accessed when the device’s front cover is

opened. The display board is located on the inside of the door. The microprocessor board is stacked on top

of the leak detection board. Since the leak detection board is longer than the microprocessor board, the

connectors on the leak detection board extend past the end of the microprocessor board. These two boards

are secured to the inside of the unit.

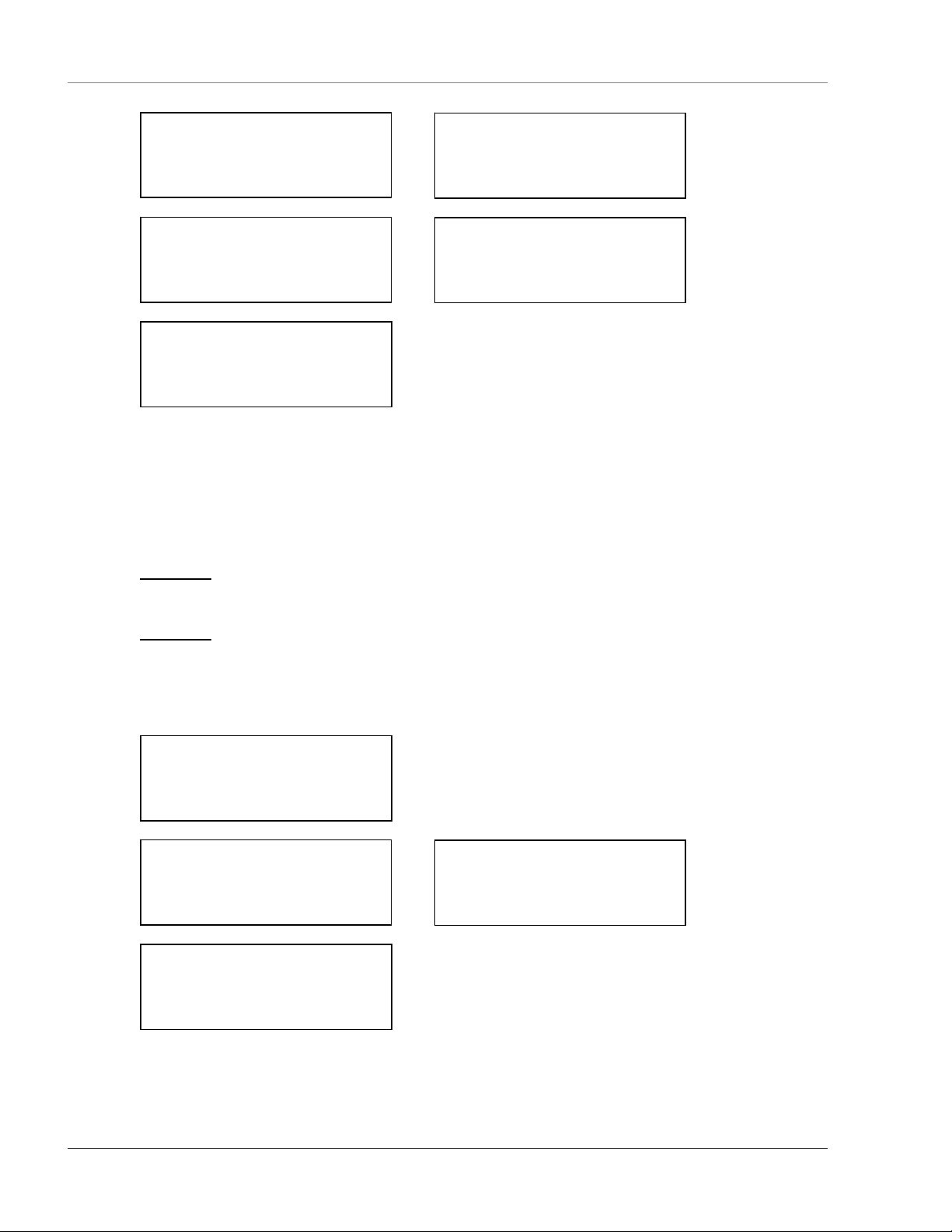

The connectors on the leak detection board, found at the bottom of the following photograph, are labeled

TB1 through TB5. The connectors on the microprocessor board are labeled TB1 and P3. The switches on

the microprocessor board are labeled SW1 through SW4.

Pin 1 Pin 1

–

–

-

SW2 – RS-485 and RS-232 Baud Rate,

Dis

and 4-20mA Output Settings

TB5 – Fault/Leak

Relay Outputs

TB4 – Fault/Leak

Relay Outputs

Figure 2-1 LD5000 Leak Detection Boards

SW4 – Termination Setting

TB3 –

4-20mA

Output

TB2 – Cable

Interface

Pin 1

–

-

–

-

TB1 – 24V

Input Power

4 970.484.6510 www.rletech.com

Page 13

User Guide: LD5000 Chapter 2: Connections and Settings

2-1 DISPLAY BOARD

2-1.1 R2: Contrast

This dial adjusts the 4x20 LCD’s contrast. Turn the knob clockwise or counterclockwise to adjust the

contrast as necessary.

2-2 LEAK DETECTION BOARD

2-2.1 TB1: Input Power

This is a factory wired three position connector with the following connections (for reference only):

TB1-1 ground

TB1-2 24VDC negative (-)

TB1-3 24VDC positive (+)

2-2.2 TB2: Cable Interface

The Water Leak Detection Cable connects to TB2. A fifteen foot Non-Sensing cable is provided to connect

the LD5000 to the Water Leak Detection Cable. Connect the cable wires to TB2 as follows:

TB2-1 White wire

TB2-2 Black wire

TB2-3 Green wire

TB2-4 Red wire

2-2.3 TB3: 4-20mA Output

A 4-20mA loop powered output is provided on TB3.

Four mA = no alarm

Five mA = leak at 0 distance

19mA = full scale distance specified by SW2 positions 6-8 (see page 14)

20mA = cable fault

Connect the 4-20mA wires to TB3 as follows:

TB3-1 4-20mA positive (+)

TB3-2 4-20mA negative (-)

2-2.4 TB4 & TB5: Relays

Terminals TB4 and TB5 are Form C Relay Outputs. Each terminal has two outputs. TB4 provides a

connection to one of the leak alarm relay outputs and one of the fault relay outputs; TB5 provides a second

set of contacts for the same leak and fault alarms.

The six contacts on TB4 and TB5 are labeled Leak NO, Leak C, Leak NC, Fault NO, Fault C, and Fault

NC. Connect the alarm relay wires to TB4 and TB5 as follows:

TB4-1 Leak alarm normally open (NO)

TB4-2 Leak alarm common (C)

TB4-3 Leak alarm normally closed (NC)

TB4-4 Fault alarm normally open (NO)

TB4-5 Fault alarm common (C)

TB4-6 Fault alarm normally closed (NC)

TB5-1 Leak alarm normally open (NO)

TB5-2 Leak alarm common (C)

www.rletech.com 970.484.6510 5

Page 14

Chapter 2: Connections and Settings User Guide: LD5000

TB5-3 Leak alarm normally closed (NC)

TB5-4 Fault alarm normally open (NO)

TB5-5 Fault alarm common (C)

TB5-6 Fault alarm normally closed (NC)

Two LEDs, labeled Fault and Leak, are located between TB4 and TB5. They indicate the status of the

relays. The leak detection relay is activated when a leak is detected. The cable break relay is activated

when a cable fault is detected.

Both relays can be configured to be unsupervised or supervised. If the relay is set to supervised, the relays

will be closed as long as no alarm condition exists. A leak, cable trouble, or power failure will cause the

appropriate relay to open.

The relays can also be configured to latched or unlatched. A latched alarm requires a manual reset of the

system once a leak or cable problem is no longer present.

2-3 MICROPROCESSOR BOARD

2-3.1 TB1: RS-485 Connector

TB1 connects the RS-485 network. A grounded shield contact is provided for connection to shielded cable.

If the shield contact is used, verify the power connector is properly grounded and there is no voltage

potential between units on the network. The RS-485 port is set to no parity, 8 databits, 1 stop bit (n, 8, 1).

Connect the RS-485 wires to TB1 on the top PC board as follows:

TB1-1 A (+)

TB1-2 B (-)

TB1-3 Shield

2-4 INPUT POWER

The LD5000 mounted in the metal enclosure requires an 85-264VAC connection (2 wire & ground).

Connect the 85-264VAC to the input terminal block. Connect the 85-264VAC to the input terminal block.

Warning!

Do not apply power until connections are complete.

2-5 POWER ON/OFF SWITCH

An internal power switch is used to power the unit on and off. This switch contains an integrated breaker

rated at two amps.

2-6 RS-232 CONNECTOR

The RS-232 port uses only the transmit, receive, and ground pins (2, 3 and 5). The manufacturer sets the

baud rate at 9600. The user may adjust the baud rate through SW2 on the microprocessor board. The RS232 port is set to no parity, 8 databits, 1 stop bit (n, 8, 1).A straight through cable should be used to connect

a terminal or PC to the LD5000.

6 970.484.6510 www.rletech.com

Page 15

User Guide: LD5000 Chapter 2: Connections and Settings

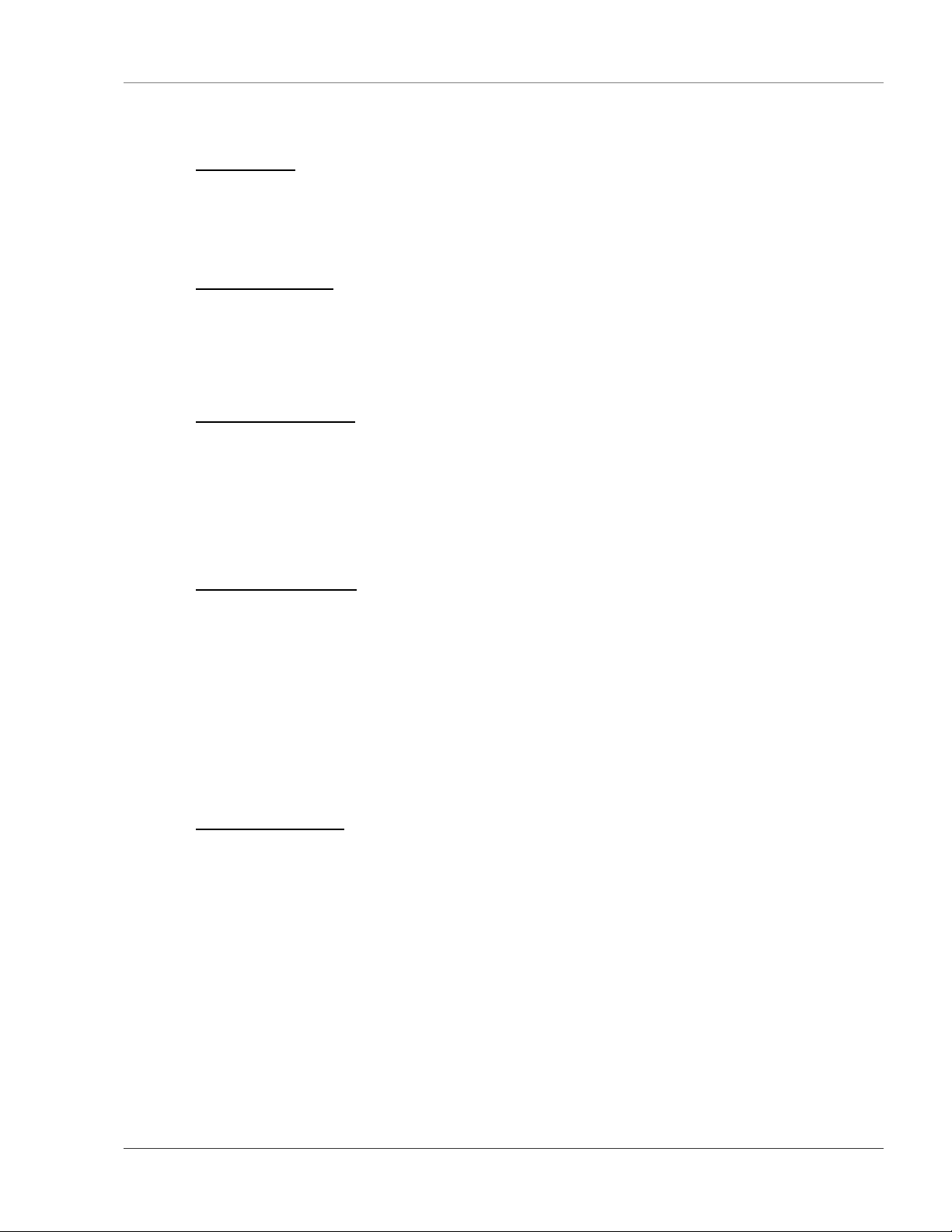

Figure 2-2 LD5000 Wiring Diagram

2-7 SWITCHES

2-7.1 SW1: Setting RS-485 Address

8 7 6 5 4 3 2 1

SW1, positions 1 through 8, are used to set the RS-485 address. The

address can range from 00000001 to 11111111.

2-7.2 SW2: Baud Rate Settings, LCD Display, 4-20mA Scale

8 7 6 5 4 3 2 1

For All SW Settings:

1 – Switch is on.

0 – Switch is off.

www.rletech.com 970.484.6510 7

Page 16

Chapter 2: Connections and Settings User Guide: LD5000

Baud rate settings for the RS-232 port and the RS-485 port are both set through this dip switch. The RS232 baud rate is set with switch positions 1 and 2. The RS-485 baud rate is set with switch positions 3 and

4.

2-7.2.1 SW2, Positions 1 & 2

The manufacturer sets the baud rate of the RS-232 connection to 9600 baud. Manipulating the positions of

switches 1 and 2 adjusts the baud rate as follows:

21

(Switch position)

01 = 1200

10 = 2400

00 = 9600

11 = 19,200

2-7.2.2 SW2, Positions 3 & 4

The manufacturer sets the baud rate of the RS-485 connection to 9600 baud. Users can set the baud rate

using SW2, positions 3 and 4, and manipulating them as follows:

43

(Switch position)

00 = 1200

10 = 9600

01 = 2400

11 = 19,200

2-7.2.3 SW2, Position 5

SW2, position 5 enables or disables the LCD.

0 = Disable

1 = Enable

2-7.2.4 SW2, Position 6-8

SW2, positions 6 through 8, designate the length of cable attached to the LD5000. This insures the 420mA output readings are correct for the LD5000 system. Without an accurate length setting, the unit

would not return the proper 4-20mA reading to diagnose the condition of the cable.

Switch settings are listed below. If the length of cable falls between two amounts, use the settings for the

higher of the two amounts:

876

(Switch position)

000 = 0 - 500 ft. (0 - 152.4 m)

001 = 0 - 1000 ft. (0 - 304.8 m)

010 = 0 - 1500 ft. (0 - 457.2 m )

011 = 0 - 2000 ft. (0 - 609.6 m)

100 = 0 - 2500 ft. (0 - 762.0 m)

101 = 0 - 3000 ft. (0 - 914.4 m)

110 = 0 - 4000 ft. (0 - 1219.2 m)

111 = 0 - 5000 ft. (0 - 1524.0 m)

2-7.3 SW4 - Termination Setting

SW4-1 is used to set termination on the unit. ON (down) indicates termination and OFF (up) indicates no

termination.

8 970.484.6510 www.rletech.com

Page 17

User Guide: LD5000 Chapter 3: Installation

CHAPTER 3: INSTALLATION

3-1 INSTALLING THE UNIT

The LD5000 is a wall mounted device. To secure the device to the wall, first remove the aluminum back

panel and all electronics from the enclosure. There are knockouts on the top and bottom of the enclosure

designed to accommodate .5” conduit. Remove as many as necessary. There are two holes in the top back

of the unit spaced 10.5” apart. Use drywall anchors to secure the unit to the wall. Put two more drywall

anchors through the two holes in the bottom back of the unit. Reinstall the back panel and reconnect the

electronics.

3-2 CONNECTING THE WATER LEAK DETECTION CABLE

The LD5000 is packaged with a 15’ length of leader cable. One end of this leader cable connects into the

LD5000. This end of the cable is finished with a terminal connector. The other end features a mating

connector which connects with the leak detection cable. The end of the cable is finished with a removable

end terminator.

Attach (clip) the plastic EMI Suppression core to the 15’ leader cable. The plastic core should slide freely

once it is placed on the cable. Make sure the core is located close to the end of the leader cable that

attaches to the LD5000 terminal block connection (TB2). Connect the 15' leader cable with the EMI

Suppression core to the LD5000; plug the terminal connector into the cable interface terminal block TB2.

From left to right, with the screws of the connector facing up, the wires that screw into the terminal

connector should be colored white, black, green, and red. If the terminal connector is removed from the

end of the cable, make sure the wires are in this same order when the connector is reapplied.

Once the leader cable is plugged into the terminal blocks, it is ready to be connected to the leak detection

cable. To do this, unscrew the end terminator from the end of the leader cable. Attach the first length of

water leak detection cable to the leader cable. Route the water leak detection cable according to the cable

layout diagram, if provided. Lay the cable according to the following guidelines. Secure the end

terminator on the unoccupied end of the leak detection cable.

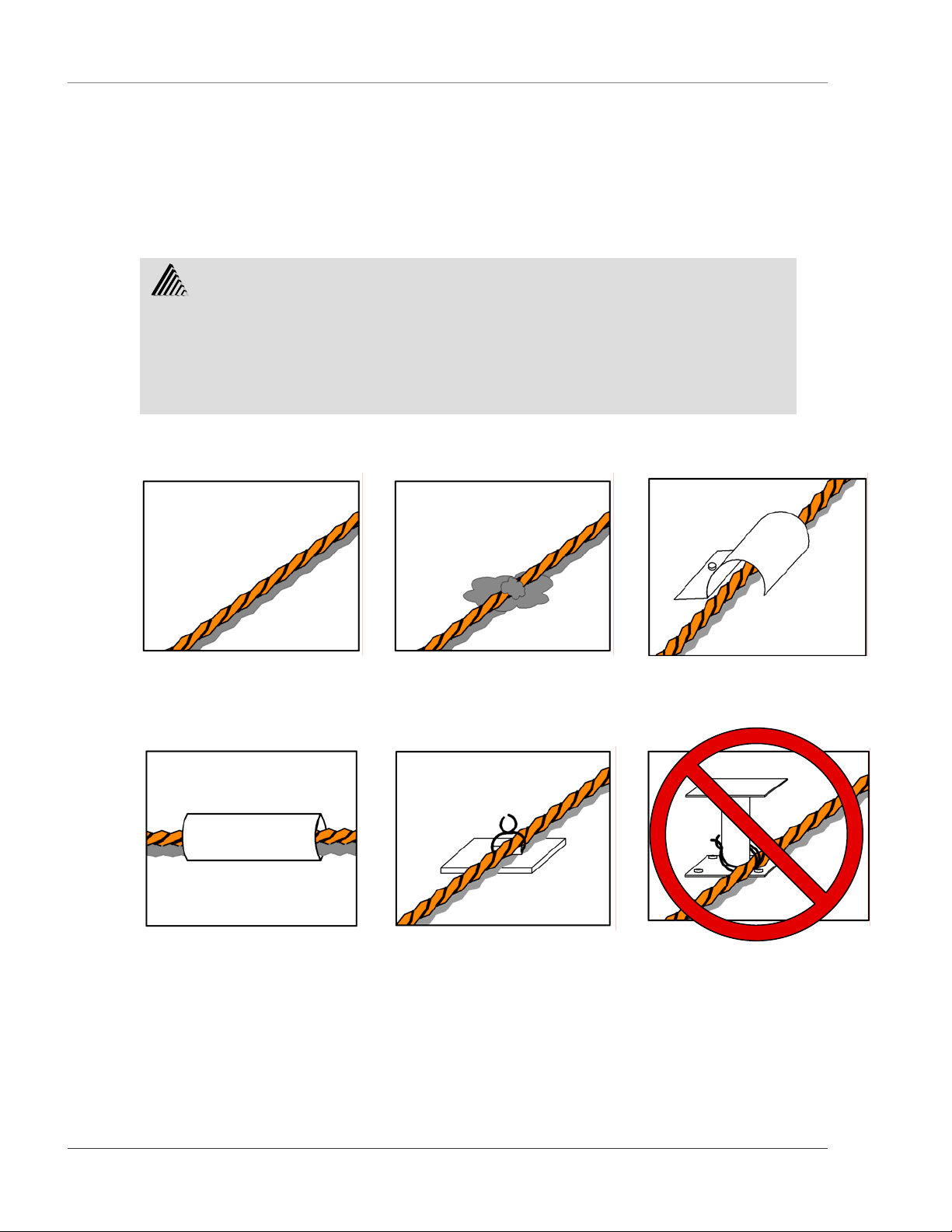

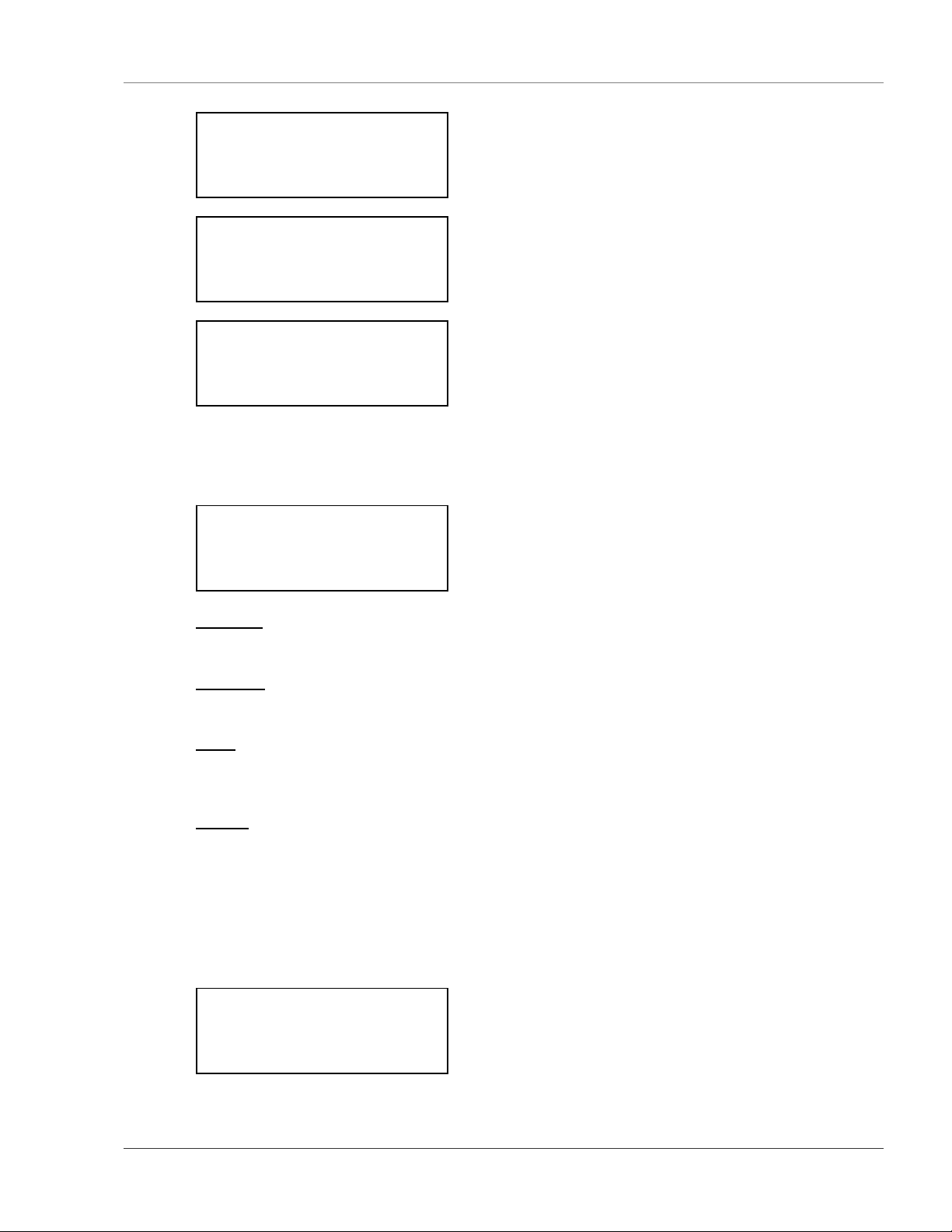

Figure 3-1 Water Leak Detection Cable

3-2.1 Securing Cable to the Floor

Secure the cable to the floor with either J-clips or one of the other approved methods shown in Figure 3-2

Cable Installation Methods. J-clips are the manufacturer’s recommended installation method and can be

installed as follows:

• Place one J-clip every three feet along the length of the water leak detection cable and one at each

turn of the cable.

www.rletech.com 970.484.6510 9

Page 18

Chapter 3: Installation User Guide: LD5000

• If the cable is installed over an obstruction, clip the cable on both sides, as close to the obstruction

as possible.

• Do not install the cable directly in front of an air conditioner. Allow a minimum of six feet

between the unit and the cable. If the cable is too close to the air conditioning unit’s air stream, the

moisture from the humidifier may cause false leak readings. If the cable must be installed in front

of an air conditioning unit, place the J-clips 12 to 18 inches apart.

NOTE:

3-2.1.1 Recommended Cable Installation

It is important to finish the end of the leak detection cable with the end

terminator. If the end terminator is not present, a cable fault will register.

Note any variances between the cable layout diagram and the actual cable

installation.

Laid freely on the floor.

Only recommended in

spaces with no access.

Secured to floor with J-clips.

Secured to floor with mastic. Installed in protective covering.

Secured to floor with tie wrap.

Figure 3-2 Cable Installation Methods

Secured to pedestal with tie wrap.

Do Not Secure as Shown

10 970.484.6510 www.rletech.com

Page 19

User Guide: LD5000 Chapter 3: Installation

3-3 APPLY POWER TO THE UNIT

Once the leak detection cable is connected to the unit, power may be applied.

Warning!

• A dedicated circuit breaker must be provided in the building within

close proximity to the RLE unit and be clearly marked as the

disconnecting device for this unit.

The LD5000 operates on 85-264VAC power. An AC power supply should be run to the location of the

unit. Before applying power to the unit, make sure the AC breaker switch is turned off.

Once the power is turned off, strip the end of the AC supply so the three wires inside are exposed. Strip the

end of each of the three wires and feed the end of the power supply into the LD5000 enclosure. The three

wires must now be inserted into the terminal block in the lower right corner of the enclosure. As is labeled

in the enclosure, the live power line is placed inside the left hand opening of the terminal block. The Earth

ground line is placed into the terminal block’s center station. The neutral line is placed into the opening on

the right side of the terminal block.

Once all the wires are placed inside the terminal block, tighten the three screws across the bottom of the

terminal block until the wires are securely held in place. Turn the AC supply back on. Flip the LD5000’s

power switch on to activate the unit. Wait approximately one minute. No alarm should be present.

On the LCD, enter the Status menu. Press Enter (↵) twice. The cable length is displayed. If this reading

varies by more than ±5% of the actual length of cable installed, verify the installation.

Use the switch settings on page 8 to set the cable length scale for the analog 4-20mA loop. Set the clock,

system name, relay configuration, feet/meters, LCD setup (re-alarm time, password), etc.

Wait at least 30 minutes before calibrating the LD5000. Calibrate the LD5000 through the front panel

Setup Menu (page 14) or through the RS-232 configuration port System Configuration Menu (page 33).

Auto calibration is recommended.

Map the cable per the instructions in Chapter 8: Mapping the Cable beginning on page 21.

www.rletech.com 970.484.6510 11

Page 20

Chapter 4: 4-20MA output testing User Guide: LD5000

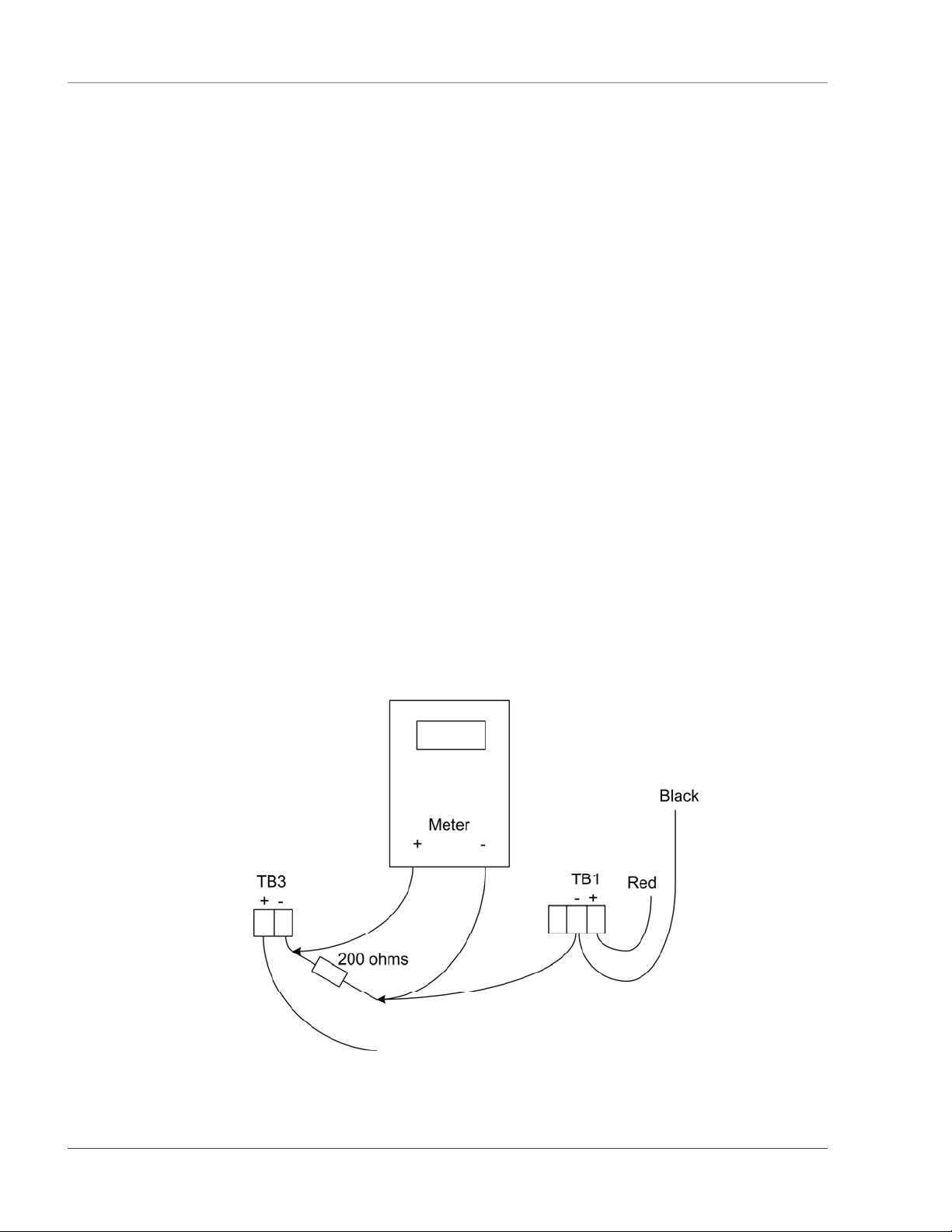

CHAPTER 4: 4-20MA OUTPUT TESTING

The LD5000’s 4-20mA output is loop powered and tested by the manufacturer. The manufacturer

guarantees its performance upon delivery. Should the 4-20mA output need to be tested in the field, follow

these steps. The following procedure is performed with the cable connected, unless otherwise indicated.

1. Remove the two position plug from TB3.

2. Remove any wires from the terminal and install a 200Ohm resistor to TB3-2. Then apply

+24V to TB3-1 and ground of the 24V supply to the other side of the resistor.

3. Reinstall the plug on TB3.

4. With the system on and no alarms present, measure the DC voltage across the resistor. A

value of 0.8VDC should register. This equates to 4mA, or normal operation.

5. Remove the water leak detection cable and wait for the unit to activate its cable trouble alarm.

Measure the DC voltage across the resistor. A value of approximately 4.0VDC should be

measured. This equates to 20mA, or a fault alarm. Reconnect the water leak detection cable.

6. Place water on the end of the water leak detection cable. Measure the DC voltage across the

resistor. The value will be proportional to the length of cable set on the dip switches. A value

of approximately 3.8V, which equates to 19mA, will be read if the length of the cable is

identical to the length set by the switches. Dry the cable.

7. Place water on the start of the cable. Measure the DC voltage across the resistor. A

measurement of approximately 1.2VDC, or 5mA, should be measured. This corresponds to a

leak at zero distance. Dry the cable.

8. Remove the resistor from the plug and reattach any wires as necessary.

Figure 4-1 4-20mA Testing

12 970.484.6510 www.rletech.com

Page 21

User Guide: LD5000 Chapter 5: LCD Default Display

S

CHAPTER 5: LCD DEFAULT DISPLAY

When the LD5000 is powered up, diagnostics are performed. The boot ROM and flash program code are

verified. While these diagnostics are being performed, the following text is displayed on the LCD:

****** LD5000 ******

* RLE Technologies *

** Copyright 2000 **

************************

Once the diagnostics are complete, the LCD alternates between the following panels:

** LD5000 Display **

* RLE Technologies *

* Copyright 1999 *

01/10/01 09:44:32

Any time a screen within the LCD interface is left idle for more than one minute, it will return to this

default display.

ystem Status:

Normal

Press a Key For Menu

www.rletech.com 970.484.6510 13

Page 22

Chapter 6: LCD Main Menu User Guide: LD5000

CHAPTER 6: LCD MAIN MENU

A limited selection of system set-up, configuration, and display functions begin in the Main Menu. For a

more comprehensive selection of functions, use the RS-232 interface.

The LCD is accompanied by a six button control panel. The - (minus) and + (plus) keys are used to

decrease and increase values on the display. The left and right arrow keys are used to move the cursor

through the display. The Esc key backs the display up one menu level at a time. The Enter (↵) key selects

an option and commits changes.

From the Main Menu, use the left and right arrow keys to position the arrow on the LCD in front of the

appropriate menu choice. Press the Enter (↵) key to select the option.

*** Main Menu ***

->Status Setup

Log/Data System

Reset Comms

6-1 STATUS OPTION

The Status option displays the Cable Status Screens. The first screen of this option shows the current

status of the cable. The second screen, accessed by pushing the Enter (↵) key when the cursor is next to

the down option, displays the length of the cable monitored by the LD5000 and the leakage current on the

cable. A threshold for the current reading can be set through the TripPoints option in the Setup Menu.

This will help avoid false leak readings due to cable contamination. Press the Esc key to exit the cable

status screen and return to the Main Menu.

** Cable Status **

System Normal

->Down

** Cable Status **

Length: 300ft

Current: 0 uA

Up ->Down

** Cable Status **

Contam Dly: 0/120

Leak Delay: 0/20

->Up

6-2 SETUP MENU

The Setup option displays the password protected Setup Menu. Use the - (minus) and + (plus) keys to enter

the correct numerical values. Use the right and left arrow keys to move to the next position in the

password sequence. Press the Enter (↵) when the password is correct. The manufacturer’s default

password for this menu is 1234. To disable this feature, enter 0000 as the password in the Calibration

Menu section of the RS-232 interface.

14 970.484.6510 www.rletech.com

Page 23

User Guide: LD5000 Chapter 6: LCD Main Menu

T

T

A

A

E

The Setup Menu allows authorized users to configure the LD5000’s settings. This menu is described in

greater detail in Chapter 7: LCD Setup Menu. Press the Esc key to exit the Setup Menu and return to the

Main Menu.

nter Password:

0000

^

** Setup Menu **

->TripPoints Clock

Re-Alarm Ft/M

Calibrate FcDft

6-3 LOG/DATA

The Log/Data option displays the Log/Data Menu. This menu provides a view of the History Log and the

Trend Data and an option to clear both the History Log and the compiled Trend Data.

6-3.1 History Log

The History Log displays the most recent 100 events recorded by the unit. Events are displayed in the

following manner: Number-Status-Description

Date Time whereas:

Number is a sequential event number assigned to the event.

Status is R = Returned to normal, A = Alarm, or F = Forced to Normal.

Description is a detail of the nature of the event.

Date is the date the event occurred.

Time is the time at which the event occurred.

6-3.2 Trend Data

The Trend Data displays the leakage current on the cable. One measurement is taken at the user set interval

(1 min - 1440 min; factory default is 1440 min (1day)). The log retains the 288 most recent entries.

Analyzing the Trend Data can help determine the location of long term contamination build up

(degradation), etc. on the cable. Press the Esc key to exit the Log/Data Menu and return to the Main Menu.

** Log/Data Menu **

-> History Trend

HistClr TrendClr

TrndIntv

larm Log: 23/23

023-R-System Booted

01/10/01 09:54:11

->Down Up

** Log/Data Menu **

History ->Trend

HistClr TrendClr

->Up

rend Data: 1/4

TD001-Leakage=0uA

01/10/01 16:02:56

Down ->Up

larm Log: 21/23

021-A-Leak @ 55ft

01/10/01 10:15:27

Down ->Up

rend Data: 2/4

TD002-Leakage=0uA

01/11/01 16:02:56

Down ->Up

www.rletech.com 970.484.6510 15

Page 24

Chapter 6: LCD Main Menu User Guide: LD5000

M

M

M

M

C

C

T

T

rend Data: 3/4

TD003-Leakage=0uA

01/12/01 16:02:57

Down ->Up

lear the Alarm Log?

Accept -> Cancel

odify Trend

Interval

1440 Minutes

+/- then (Enter)

6-4 SYSTEM

The System option displays the System Menu. This menu allows a user to map the water leak detection

cable that is attached to the LD5000. Mapping the cable is a key step in pinpointing a leak. Cable should

not be mapped until it is properly installed in its intended area, and the system is calibrated for the length of

cable installed. Whenever additions or adjustments are made to the water leak detection cable, the cable

should be remapped.

6-4.1 ViewMap

The ViewMap option allows the user to view the current system map.

rend Data: 4/4

TD004-Leakage=0uA

01/12/01 16:02:56

Down ->Up

lear the Trend Log?

Accept -> Cancel

6-4.2 StartMap

The StartMap option begins the mapping process:

For a complete set of LCD interface cable mapping instructions, refer to Chapter 8: Mapping the Cable.

Press the Esc key to exit and return to the Main Menu.

** System Menu **

->ViewMap StartMap

apping Data: 1/6

Pnt#1 Dist=68ft

Pnt#2 Dist=176ft

->Up

apping Data: 5/6

Pnt#5 Dist=494ft

Pnt#6 Dist=675ft

->Down

apping Data: 3/6

Pnt#3 Dist=247ft

Pnt#4 Dist=378ft

->Down ->Up

16 970.484.6510 www.rletech.com

Page 25

User Guide: LD5000 Chapter 6: LCD Main Menu

M

** System Menu **

ViewMap ->StartMap

** System Menu **

Begin Mapping Mode?

Mapping Mode On

Press any key to

End Mapping Mode

6-5 RESET MENU

The Reset option displays the Reset Menu. This menu allows the operator to reset the system, reset individual relay outputs and update alarms.

** Reset Menu **

->Reset ->Update

Fault Rly Leak Rly

6-5.1 Leak Rly

This command silences the leak relay output. A new leak will retrigger this alarm.

6-5.2 Fault Rly

This command silences the fault relay output. A new cable fault will retrigger this alarm.

6-5.3 Reset

This command forces all alarms off. If an alarm condition is still present after the Reset command is

executed, the alarm is reactivated. However, it will not be reentered in the Alarm History Log.

6-5.4 Update

This command updates and resets all alarms. This command forces all alarms off. If an alarm condition is

still present after the Update command is executed, the alarm is reactivated and another entry is made in the

Alarm History Log.

6-6 COMMS COMMAND

This command displays Modbus information like the address, baud rate, and other statistics. The

information can be reset by pressing Enter (↵). Press Esc to exit.

odbus Adr:001 600

4in: 0 Out: 0

Min: 0 Out: 0

->Reset

www.rletech.com 970.484.6510 17

Page 26

Chapter 7: LCD Setup Menu User Guide: LD5000

S

M

M

M

M

CHAPTER 7: LCD SETUP MENU

The Setup Menu allows authorized users to adjust the LD5000’s settings. Each menu option displays a

different adjustable parameter. Press Esc to exit the Setup Menu and return to the Main Menu.

** Setup Menu **

->TripPoints Clock

Re-Alarm Ft/M

Calibrate FcDft

7-1 TRIPPOINTS

The TripPoints option allows users to modify the detection and contamination trip points for the LD5000.

These trip points help the system avoid false alarm readings. Throughout this menu, the user can also set

the leak alarm and contamination alarm delays (20 to 3600 seconds). Press Esc to exit the TripPoint Menu

and return to the Setup Menu.

** TripPoint Menu **

->Leak LeakDelay

Contam ContDelay

odify Detection

TripPoint: 150 uA

odify Leak Alarm

Delay:

20 Seconds

+/- then (Enter)

** TripPoint Menu **

Leak LeakDelay

->Contam ContDelay

odify Contamination

TripPoint: 050 uA

odify Contamination

Alarm Delay:

120 Seconds

+/- then (Enter)

7-2 CLOCK OPTION

The Clock option allows users to modify the LD5000’s date and time settings. Press Esc to exit the Set

Clock function and return to the Setup Menu.

et Clock:

01/10/01 10:51

^ ^

7-3 RE-ALARM

The Re-Alarm option allows users to determine the number of minutes between annunciations of the same

alarm. Enter 000 to disable this feature. Factory default is “0” (disabled). Press Esc to exit and return to

the Setup Menu.

18 970.484.6510 www.rletech.com

Page 27

User Guide: LD5000 Chapter 7: LCD Setup Menu

C

C

S

E

E

C

L

E

nter Realarm (Min):

000

^

7-4 FT/M FUNCTION

The Ft/M function designates whether the unit’s distance readings are displayed in feet or meters. Press

Esc to exit and return to the Setup Menu.

elect Feet / Meters

->Feet Meter

7-5 CALIBRATE

The Calibrate option allows users to manually input the number of feet of cable connected to the LD5000.

This automatically calibrates the system to the cable length entered. Enter the exact cable length attached

to the system to ensure accurate calibration. Press the Esc key to exit and return to the Setup Menu.

NOTE

nter Cable Length:

^^

Range (901-1101)

1000ft

able Auto Calibrate

Step 1 of 4

able Auto Calibrate

:

Step 2 of 4

It may be necessary to restore the system to factory defaults before

calibrating, or if the following error message is received on the LCD display:

“Error Length Not in Range Press Any Key To Return”

eak Detected Alarm

Can’t Calibrate

Press Any Key

To Return

rror

Length Not In Range

Press Any Key

To Return

able Break Alarm

Can’t Calibrate

Press Any Key

To Return

www.rletech.com 970.484.6510 19

Page 28

Chapter 7: LCD Setup Menu User Guide: LD5000

C

C

E

R

able Auto Calibrate

:

Step 3 of 4

****** LD5000 ******

* RLE Technologies *

** Copyright 2000 **

************************

able Auto Calibrate:

Step 4 of 4

Cable Auto Cal Done

Saving Changes. .

7-6 FCDFT OPTION

The FCDFT option will allow the user to restore the LD5000 to factory calibration default settings.

estore Factory

Defaults?

->Accept Cancel

rasing Data . .

Writing Data . .

Done, Press any key

to continue

20 970.484.6510 www.rletech.com

Page 29

User Guide: LD5000 Chapter 8: Mapping the Cable

y

CHAPTER 8: MAPPING THE CABLE

After the water leak detection cable is laid in the desired configuration, the cable can be mapped. Mapping

the cable improves the accuracy of the LD5000 and makes it easier to locate a leak.

The LD5000 computes the distance from the control panel to the leak along the length of water leak

detection cable attached to the unit. In most cases, the water leak detection cable is laid in a curved or

serpentine pattern. This may make it difficult to locate a leak when given a linear distance. To help

alleviate this problem, identify a series of easily accessible, evenly spaced points along the cable length.

Number the points, and record their locations on the leak detection reference map. Refer to the directions

below and use the numbered points to map the cable. Then, when the unit detects a leak, the location of the

leak can be determined by comparing the distance shown on the control panel with the known positions

along the cable as recorded on the reference map.

NOTE

The system must be calibrated prior to mapping.

8-1 MAPPING DIRECTIONS

1) If a reference is not provided by RLE Technologies, create a drawing that represents the floor

plan. This drawing must include the room layout (walls, doors, and other permanent structures),

the water leak detection cable routing path and any jumper sections of non-sensing cable.

2) Physically identify points along the cable routing path. The points should be easily accessible and

evenly spaced. Number the points and record their location on the reference map.

3) Using the front panel of the LD5000:

• Select System and press Enter (↵).

• Select StartMap and press Enter (↵).

• Select Accept to start mapping and press Enter (↵).

4) To test, wrap a damp paper towel or sponge around the cable at one of the previously mapped

points. The LD5000 produces a short beep within approximately 30 seconds. The LCD displays

the LD5000’s calculated distance to the leak. Remove the paper towel and dry the cable. Within

approximately 20 seconds, the LD5000 produces a long beep indicating the short is removed and

the system has returned to normal.

TIP

If the individual mapping the cable is not in a position to hear the

audible alarm, wait two minutes between each point. This ensures the

s

stem has had time to stabilizer.

5) Go to the next point and repeat the above steps until all points along the cable are mapped and

tested.

6) When mapping is complete, press any key on the LD5000 to exit the mapping mode. This

LD5000 displays Mapping Mode Off. Press any key again to save the map and return to the

System Menu.

www.rletech.com 970.484.6510 21

Page 30

Chapter 8: Mapping the Cable User Guide: LD5000

g

7) Select ViewMap on the LCD and record the LD5000’s reading next to each point on the reference

map.

8) Mount the leak detection reference map alongside to the LD5000 control panel or the remote

display. When a leak or cable break occurs, refer to the map and the distance displayed on the

LD5000 to determine the physical location of the leak.

Warning!

Loss of power will cause all mappin

data to be lost.

22 970.484.6510 www.rletech.com

Page 31

User Guide: LD5000 Chapter 9: RS-232 Interface Startup

CHAPTER 9: RS-232 INTERFACE STARTUP

Make sure the RS-232 port is connected to a PC or terminal with a straight through cable (see section 2-6

RS-232 Connector on page 6). Run terminal emulation software and make sure the settings match the

LD5000 RS-232 port configuration. When the LD5000 is powered up, diagnostics are performed. The

boot ROM and flash program code are verified. Output similar to the screen displayed below should

appear on the terminal or terminal emulation software. Once the system reaches this point, press the Enter

(↵) key to display the Main Menu.

RLEbh Firmware V1.1 BOOTUP - THU 03/06/03 10:58:24

uP last reset by: external signal

Diagnostics in progress

Serials: Passed

Ram: Passed

Clock: Passed

VPP = 5.04 Passed

Flash Blank Check:

Parm1= Has Data

Parm2= Has Data

Prgm = Has Data

Prgm Flash checksum: 6C32/6C32 Valid

Power Supplies:

24V: 22.66

15V: 15.17

Passed

Flash Code will start in 5 seconds

Press any key to abort Flash Code

LD5000 V2.3 B0 03/06/03

SYSTEM BOOTED @ 03/06/03 10:58:32

Copyright 2003, Raymond & Lae Engineering Inc.

Loading Block 2

DATA LOADED

LD5000 Diagnostics

Initializing Cable ADC: Passed

<LD5000>

www.rletech.com 970.484.6510 23

Page 32

Chapter 10: RS-232 Main Menu User Guide: LD5000

CHAPTER 10: RS-232 MAIN MENU

Once the startup processes are complete, press the Enter (↵) key to access the Main Menu. All system setup, configuration, and display functions begin in the Main Menu. Two letter commands display

information requested, execute commands selected, and display submenus for additional inquiry and

system configuration functions.

** LD5000 Help **

SC - LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

10-1 FUNCTION COMMANDS

Once the startup processes are complete, press the Enter (↵) key to access the Main Menu. All system setup, configuration, and display functions begin in the Main Menu. Two letter commands display

information requested, execute commands selected, and display submenus for additional inquiry and

system configuration functions. These commands include:

10-1.1 SC - System Configuration

SC displays a submenu that lists all items in the System Configuration Menu. System Configuration

options are discussed in further detail starting on page 33.

10-1.2 LS - Leak Status

LS displays the current leak cable status.

10-1.3 SL - Silence Leak Relay

SL silences the leak relay output. A new leak will re-trigger this alarm.

10-1.4 SF - Silence Fault Relay

SF silences the fault relay output. A new cable fault will re-trigger this alarm.

10-1.5 SR - Silence All Relays

SR silences all relay outputs.

10-1.6 CA - Current Alarms

CA displays all active alarms present on the unit.

24 970.484.6510 www.rletech.com

Page 33

User Guide: LD5000 Chapter 10: RS-232 Main Menu

10-1.7 RA - Reset Alarms

RA resets all alarm relays. This command forces all alarms off. If an alarm condition is still present after

the RA command is executed, the alarm is reactivated. If an alarm is still active after the RA command is

executed, it will not be reentered in the Alarm History Log.

10-1.8 UP - Update Alarms

UP updates and resets all alarms. This command forces all alarms off. If an alarm condition is still present

after the UP command is executed, the alarm is reactivated and another entry is made in the Alarm History

Log.

10-1.9 AS - Alarm Silence sundry

AS silences the audible alarm on the LCD.

10-1.10 AH - Alarm History

AH displays the Alarm History Log.

10-1.11 CH - Clear Alarm History

CH clears the Alarm History Log.

10-1.12 TD - Trend Data Table

TD displays the Trend Data Table, which monitors and displays leakage current.

10-1.13 CT - Clear Trend Data Table

CT clears all records from the Trend Data Table.

10-1.14 TI - Display Date/Time

TI displays the LD5000’s current date and time.

10-1.15 NS - Network Status (RS-485)

NS displays the unit’s RS-485 network connection status.

10-1.16 MR - Reset Modbus Status

MR clears all the RS-485/Modbus counters.

10-1.17 ND - Network Display (RS-485)

ND displays the network diagnostics and all commands, requests, and data associated with them. This

feature is usually used by a service technician.

10-1.18 MT - Modbus Display

MT displays the Modbus packets.

10-1.19 EX - Exit

EX is used to enter the Bootloader command section. The unit will stop monitoring cable and allow

firmware updates to be loaded. To restore normal operation after updating firmware, type RUN and press

the Enter (↵) key on the keyboard, or power the unit off and then back on again.

www.rletech.com 970.484.6510 25

Page 34

Chapter 10: RS-232 Main Menu User Guide: LD5000

Warning!

• The Bootloader section is designed for experienced technicians or

users responsible for maintaining the system. Exit immediately if you

are not trained in the use of the Bootloader commands.

• Contact the manufacturer for more information regarding the

commands in this section.

26 970.484.6510 www.rletech.com

Page 35

User Guide: LD5000 Chapter 11: RS-232 Function Commands

CHAPTER 11: RS-232 FUNCTION COMMANDS

11-1 SC - SYSTEM CONFIGURATION

Please see page 33 for more information about System Configuration options.

11-2 LS - LEAK STATUS

Menu selection LS displays the current leak status.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

LS

Cable Length: 4995ft

Sense Cable Current: 0uA

No Leak!

<LD5000>

11-3 CA - CURRENT ALARMS

Menu selection CA displays the current alarm status.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

CA

LD5000

03/14/05 14:02:30 Leak Detected at 701ft

<LD5000>

www.rletech.com 970.484.6510 27

Page 36

Chapter 11: RS-232 Function Commands User Guide: LD5000

11-4 AH - ALARM HISTORY

Menu selection AH displays the alarm history log of the last 512 events. The oldest alarm is listed at the

top of the list. The most recent alarm is listed at the bottom of the list.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

*Note: The Alarm History Log displayed above has been shortened for the purpose of this user guide.

*AH

Alarm History Entries = 512

AH059-04-ALM -03/14/03 11:35:42 Zone 1: Leak Detected at 3575ft

AH060-04-RTN -03/14/03 11:36:14 Zone 1: No Leak

AH061-04-ALM -03/14/03 11:37:05 Zone 1: Leak Detected at 4648ft

AH062-04-RTN -03/14/03 11:37:37 Zone 1: No Leak

AH063-04-ALM -03/14/03 11:38:17 Zone 1: Leak Detected at 5003ft

AH064-04-RTN -03/14/03 11:38:49 Zone 1: No Leak

AH065-07-RTN -03/14/03 11:55:54 System Booted

AH066-04-ALM -03/14/03 12:00:46 Zone 1: Leak Detected at 254ft

AH067-04-RTN -03/14/03 12:02:05 Zone 1: No Leak

AH068-07-RTN -03/14/03 12:02:36 System Booted

AH069-03-ALM -03/14/03 12:59:54 Zone 1: Cable Fault

AH070-03-RTN -03/14/03 13:00:11 Zone 1: Cable Fault

AH071-04-ALM -03/14/03 13:01:31 Zone 1: Leak Detected at 1ft

AH072-04-RTN -03/14/03 13:02:03 Zone 1: No Leak

AH073-04-ALM -03/14/03 13:03:38 Zone 1: Leak Detected at 348ft

AH074-04-RTN -03/14/03 13:04:10 Zone 1: No Leak

AH075-04-ALM -03/14/03 13:04:45 Zone 1: Leak Detected at 700ft

AH076-04-RTN -03/14/03 13:10:46 Zone 1: No Leak

AH077-04-ALM -03/14/03 13:11:21 Zone 1: Leak Detected at 1054ft

AH078-04-RTN -03/14/03 13:12:40 Zone 1: No Leak

<LD5000>

28 970.484.6510 www.rletech.com

Page 37

User Guide: LD5000 Chapter 11: RS-232 Function Commands

11-5 CH - CLEAR ALARM HISTORY

Menu selection CH clears the alarm history log. Type Yes, Y, or y to clear the log. Type No, N, or n to

exit this option without clearing the log.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

CH

Are you sure (yes or no)? >y

ok

11-6 TD - TREND DATA TABLE (LEAKAGE CURRENT)

Menu selection TD displays the trend log data for the cable (leakage current). Data is logged by the trend

interval set by the user (default is 24 hours). The oldest trend entry is listed first. The most recent trend

entry is listed last. Analyzing the Trend data can help determine the location of long term contamination

build up (degradation), etc. on the cable.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

TD1

Cable Leakage Current Trend Data Table Entries = 3

TD001-03/06/03 15:37:31 Leakage=0uA

TD002-03/07/03 15:37:28 Leakage=0uA

TD003-03/08/03 15:37:30 Leakage=0uA

<LD5000>

www.rletech.com 970.484.6510 29

Page 38

Chapter 11: RS-232 Function Commands User Guide: LD5000

11-7 CT - CLEAR TREND DATA TABLE

Menu selection CT clears the trend data table. Type Yes, Y, or y to clear the data. Type No, N, or n to exit

this option without clearing the table.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

CT

Are you sure (yes or no)? >y

ok

11-8 TI - DISPLAY DATE/TIME

Menu selection TI displays the date and time as measured by the LD5000.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

TI

03/18/03 14:38:10

<LD5000>

30 970.484.6510 www.rletech.com

Page 39

User Guide: LD5000 Chapter 11: RS-232 Function Commands

11-9 NS - NETWORK STATUS (RS-485)

Menu selection NS displays the LD5000’s network status.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

**RS-485 Statistics**

Baud Rate: 9600

InChars: 97495

OutChars: 327713

Errors: 0

**ModBus Statistics**

Address: 1 9600b

Packets in: 10912

Packets for me: 10140

Packets not for me: 772

Packets out: 10140

CRC errors: 0

Other errors: 0

11-10 MR - RESET MODBUS STATUS COUNTERS

Type MR<CR> from the RS-232 configuration port to clear all the 485/Modbus counters.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

Modbus stats reset to zero

www.rletech.com 970.484.6510 31

Page 40

Chapter 11: RS-232 Function Commands User Guide: LD5000

11-11 ND - NETWORK DISPLAY (RS-485)

Menu selection ND displays the LD5000’s network diagnostic. This shows all commands, requests, and

data passed through the RS-485 connection. A service technician may use this feature for diagnostic

purposes.

Press any key to turn the display off.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

ND

ok

RS-485 Monitor on <press any key to turn off!>

<LD5000>

{02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3} {02} {04} {00} {00} {00} {03} {B0} {38} Modbus wakeup

{A3}

11-12 MT – MODBUS DISPLAY (TRACE)

Type MT <CR> from the RS-232 configuration port to display the Modbus packets.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

MT

Modbus trace/display is on <press any key to turn off!>

<LD5000>

ins: 02 04 00 00 00 03 B0 38

mbreg matches: 3

Outs: 02 04 06 00 00 00 00 00 01 B5 A3

ins: 02 04 00 00 00 03 B0 38

mbreg matches: 3

Outs: 02 04 06 00 00 00 00 00 01 B5 A3

ins: 02 04 00 00 00 03 B0 38

mbreg matches: 3

Outs: 02 04 06 00 00 00 00 00 01 B5 A3

ins: 02 04 00 00 00 03 B0 38

mbreg matches: 3

Outs: 02 04 06 00 00 00 00 00 01 B5 A3

ins: 02 04 00 00 00 03 B0 38

mbreg matches: 3

Outs: 02 04 06 00 00 00 00 00 01 B5 A3

32 970.484.6510 www.rletech.com

Page 41

User Guide: LD5000 Chapter 12: System Configuration

y

CHAPTER 12: SYSTEM CONFIGURATION

The System Configuration Menu displays a submenu that lists all the items for the system setup and

configuration.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

SC

LD5000 System Configuration Menu

1. System Name: LD5000

2. Clock: 01/05/01 14:54:29

3. RS-485 Baud: 9600

4. Relays

5. Cable Feet/Meters: (Feet)

6. Calibration

7. LCD Setup

8. Diagnostics

9. Mapping Mode

10. Exit

Enter Menu Selection >

12-1 SYSTEM NAME - 1

Menu selection 1 allows a user to enter a descriptive name for the system up to a maximum of 64

characters.

** LD5000 Help **

SC – LD5000 System Configuration

LS - Leak Status

SL - Silence Leak Relay

SF - Silence Fault Relay

SR - Silence All Relays

CA - Current Alarms

RA - Reset Alarms

UP - Update Alarms

AS - Alarm Silence (LCD)

AH - Alarm History

CH - Clear Alarm History

TD - Trend Data Table (Leakage Current)

CT - Clear Trend Data Table

TI - Display Date/Time

NS - Network Status (RS-485/Modbus)

MR - Reset Modbus Status (RS-485)

ND - Network Display (RS-485)

MT - Modbus Display

EX - Exit

SC

LD5000 System Configuration Menu