Page 1

SeaHawk LD310 Quick Start Guide

Thank you for purchasing a SeaHawk

LD310 single-zone leak detection

controller. This guide outlines device

installation and operation.

If you need further assistance, please

visit the support section of our website http://www.rletech.com/support/ or call

us at 800.518.1519.

v1.2

(09/2013)

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and Seahawk™, Falcon™, and Raptor™ are

trademarks of Raymond & Lae Engineering, Inc. The products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited

liability, and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

Supplies for Installation

Included with the LD310

15 foot (4.57m) leader cable

End-of-line terminator (EOL)

Wall mounting hardware

Available from RLE, sold separately

SeaHawk sensing cable, up to 300 feet (91.4m)

100-240V to 5VDC power supply (WA-DC-5-ST)

Mount the Device

Remove the cover from the LD310 to expose the mounting holes. Use the

provided hardware to mount the LD310 in the desired location.

Connect the Sensing Cable

Leader cable is used to connect sensing cable to the LD310, since sensing cable

cannot connect directly to the device.

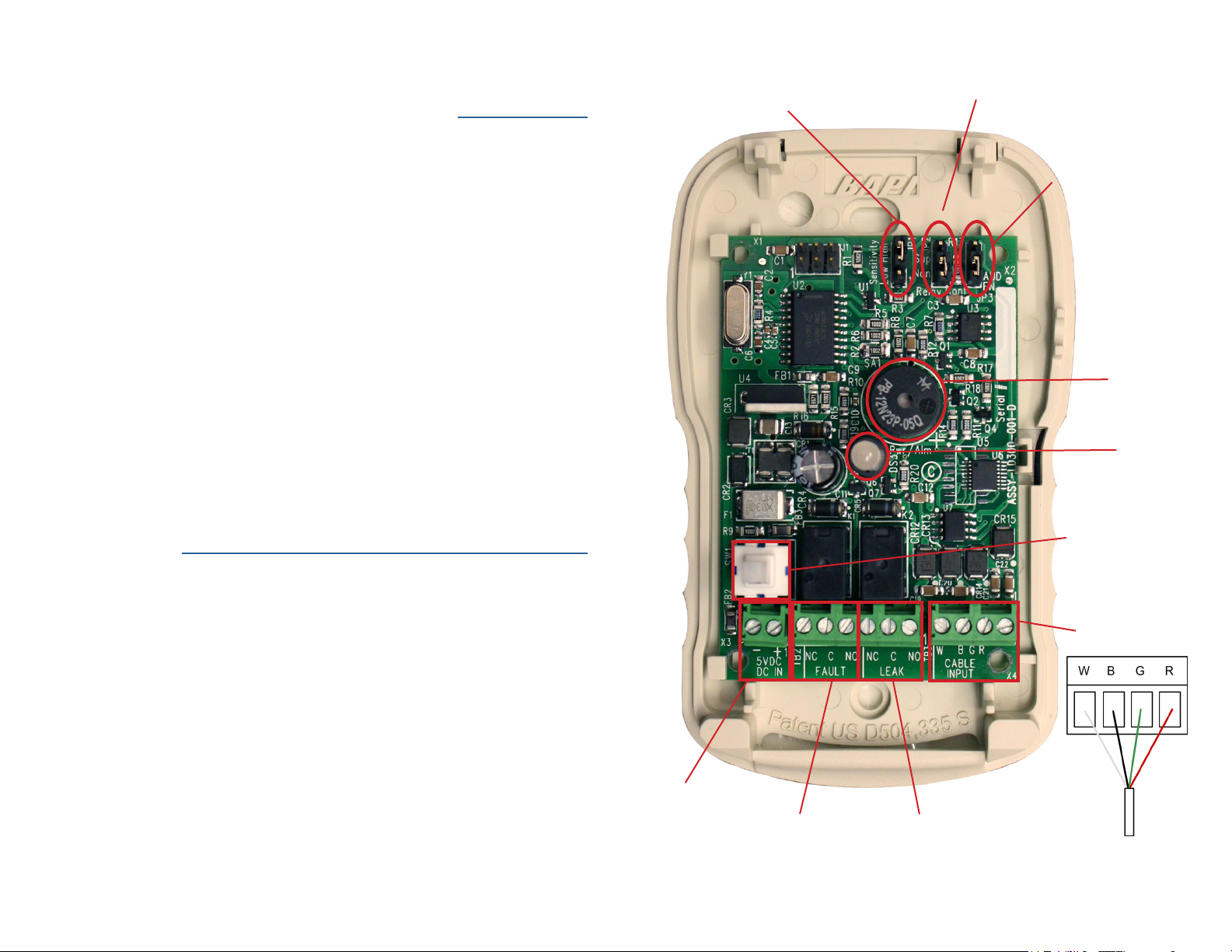

1. Insert the four stripped wires of the leader cable into the appropriate slots in

the Cable Input terminal block at the bottom right corner of the LD310:

White wire: insert into pinout labeled W

Black wire: insert into pinout labeled B

Green wire: insert into pinout labeled G

Red wire: insert into pinout labeled R

2. Unscrew the EOL from the end of the leader cable.

3. Attach the length of sensing cable to the leader cable.

4. Route the sensing cable according to your cable layout diagram.

5. Secure the EOL to the unoccupied end of the sensing cable.

Connect the Relay Outputs

The LD310 can be used as a stand-alone device, but it does have two Form

C relay outputs that communicate leak and fault status to another device or

system. If you wish to use the relay outputs, wire them at this time.

Connect the Power and Modbus Relay Output

The LD310 requires a 5 VDC power supply. To avoid product damage or personal

injury, wire power to the slots labelled + and – in the DC IN terminal blocks.

Establish all wiring connections, including sensing cable, relay outputs, and

power before you activate the board’s power supply.

Program Jumpers

The LD310 has three sets of three-pin jumpers. JP1 is used to congure the

sensitivity of the leak setting. JP2 congures the relay outputs. JP3 congures

the audible alarm. If you change the jumpers, you must cycle power to the

LD310 in order for it to recognize the change.

JP1

Set the Leak Sensitivity

Jumper spans top 2 pins High sensitivity - most sensitive - system alarms with .5” (13mm)

wetted cable

Jumper is not installed Medium sensitivity - system alarms with 2” (51mm) wetted cable

Jumper spans bottom 2 pins Low sensitivity - least sensitive - system alarms with 6” (152mm)

wetted cable

JP2

Congure the Relay Outputs

Jumper spans top 2 pins Relays are supervised - the relays remains ON until either power is

disabled or an alarm is detected - at which time the relays turn OFF.

Jumper spans bottom 2 pins Relays are non-supervised - the relays remains OFF until an alarm is

detected - at which time the relays turns ON.

JP3

Congure the Audible Alarm

Jumper is not installed Audible alarm is disabled. This is the LD310’s default setting.

Jumper spans bottom 2 pins Audible alarm is enabled.

LED

The LD310 has one LED, which is used to report a variety of conditions.

Power On / Normal - The LED is on and displays a solid green color during

normal operation with no alarm present.

Cable Break - The LED ashes orange while the audible alarm sounds. Once

the alarm silence button is pushed, the LED will continue to ash orange slowly

until the cable break is resolved.

Page 2

Leak - The LED ashes red while the audible alarm sounds. Once the alarm

silence button is pushed, the LED will continue to display a solid red color until

the leak is resolved and the cable is dry.

Audible Alarm and Silence/Test/Reset Button

By default, the audible alarm on the LD310 is disabled. To activate the audible

alarm, rst loosen the screws at the bottom of the enclosure and remove the

unit’s lid. Remove the warning sticker from the top of the audible alarm, move

the jumper on J3 so it covers the bottom two pins, and cycle power to the unit.

Replace the LD310’s lid and tighten the screws to secure it.

The LD310 has one push-button switch, which is used to silence the audible

alarm and to test and reset the system.

The audible alarm sounds when a cable break or leak is detected. When the

audible alarm is activated, push the button once to silence the alarm.

Test mode allows the LD310 to test its internal components. To initiate test

mode, push and hold the button for approximately 5 seconds - when the LED

ashes red and green, the audible alarm sounds, and the relays activate (change

state) the test is complete. Release the button.

JP1

Leak Sensitivity

Top 2 Pins - Most sensitive

No Jumper - Medium sensitivity

Bottom 2 Pins - Least sensitive

JP2

Relay Output Conguration

Top 2 Pins - Supervised

Bottom 2 Pins - Non-supervised

JP3

Audible Alarm

Top 2 Pins - Disabled

Bottom 2 Pins - Enabled

Audible

Alarm

When you release the button after the test cycle, the entire unit resets and the

LED returns to green. If there was a leak or cable break present before you

ran the test and that leak or break is still present, the unit will alarm for this

condition again after a few seconds.

Test the System

Once the LD310 is set up, you should test the system. If the LD310 is connected

to a BMS or NMS, notify monitoring personnel before you test.

To verify the LD310’s functionality, test three points within the length of sensing

cable - one at the beginning, one in the middle of the length, and another near

the end of the length of cable.

There are a variety of ways to simulate a leak.

• Pour a small puddle of water on the cable while it rests on the oor.

• Dunk the cable in a cup of water.

• Wet a paper towel or rag and wrap it loosely around the cable. This is

popular if the cable is used in pipe applications. Be careful to wrap the wet

cloth loosely around the cable. Do not put pressure on the cable.

Remove simulated leak sources. Return the system to its normal operating state.

To test the cable fault alarm, remove the end-of-line terminator (EOL) from

the end of the sensing cable. This will cause a cable break, which should be

reported appropriately by the LD310. Once the cable break alarm is veried,

reapply the EOL and ensure the system returns to its normal operating state.

5VDC

Power

Input

Cable Fault

Relay Output

Leak

Relay Output

LED

Silence/Test/Reset

Push-Button Switch

Leader Cable /

Sensing Cable Input

Be sure the leader

cable is wired

into the correct

pinouts.

Loading...

Loading...