Page 1

Leak Detection

LD2100

User Guide

Version 2.6

Firmware Version 4.1.22

Page 2

Copyright and Trademark Notices

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and

SeaHawk™, Falcon™, and Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The

products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability,

and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

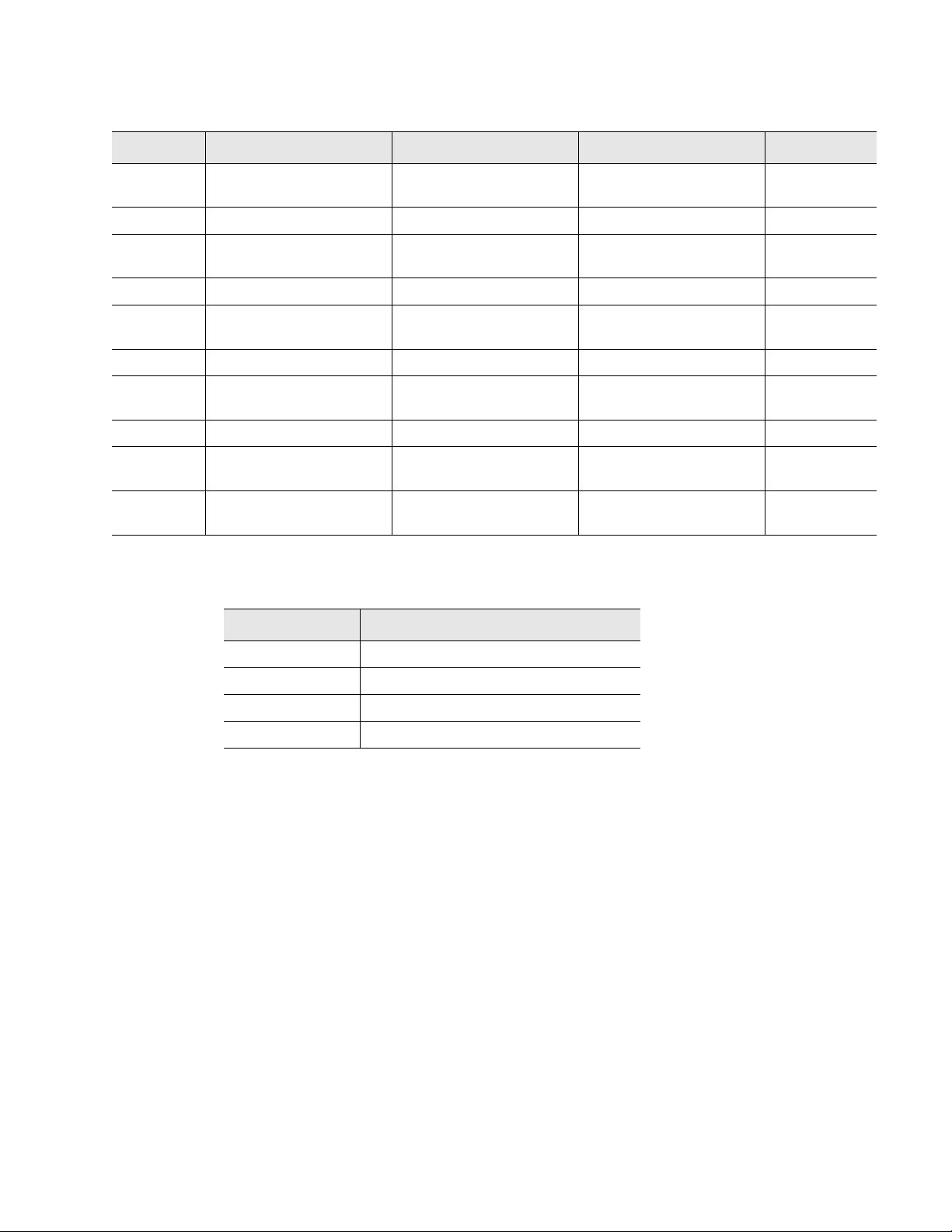

Revision History

Rev. No. Date

1.0 March 2011

2.0 March 2012

2.1 May 2012

2.2 June 2012

2.3 April 2013

2.4 May 2013

2.5 June 2014

2.6 August 2014

2 LD2100 User Guide 800.518.1519

Page 3

Product Registration

Product registration helps RLE Technologies inform owners of:

• Product upgrades

• Firmware enhancements

• New products and technologies

• Special offers available only to registered users

Submit registration information at rletech.com.

Any information provided to RLE Technologies through the registration form will be regarded as

confidential. RLE will not sell or distribute any of the information to third parties.

Technical Support

Personal assistance is available Monday through Friday, from 8:00 a.m. to 5:00 p.m. MST.

A request for assistance may be sent to support@rletech.com.

Otherwise, please call us directly at: 800.518.1519, and request technical support.

The following information is located on the bottom of each LD2100 unit. Please have this information

available whenever a technical support call is placed:

Product Model Number

Product Serial Number

Product Manufacture Date

rletech.com LD2100 User Guide 3

Page 4

RLE Product Warranty

Seller warrants to the Ultimate Purchaser (the purchaser who buys for use and not for resale) that all

products furnished under this order and which are manufactured by Seller will conform to final

specifications, drawings, samples and other written descriptions approved in writing by Seller, and will be

free from defects in materials and workmanship. These warranties shall remain in effect for a period of

twelve (12) months after shipment. If the Seller installs the equipment or supplies technical direction of

installation by contract, said one year shall run from the completion of installation, provided installation is not

unreasonably delayed by Ultimate Purchaser. Parts replaced or repaired in the warranty period shall carry

the unexpired portion of the original warranty. A unit placed with the purchaser on consignment and then

later purchased will be warranted for twelve (12) months from the time the Seller receives notification of the

Purchaser's intent to purchase said consigned item. The foregoing is in its entirety is subject to the provision

that in no case will the total warranty period extend beyond 18 months from date Seller ships equipment

from point of manufacture.

Products are NOT life and safety certified. In no event shall the Seller be liable for loss, damage, or expense

directly or indirectly arising from the use of the units, or from any other cause, except as expressly stated in

this warranty. Seller makes no warranties, express or implied, including any warranty as to merchantability

or fitness for a particular purpose or use. Seller is not liable for and Purchaser waives any right of action it

has or may have against Seller for any consequential or special damages arising out of any breach of

warranty, and for any damages Purchaser may claim for damage to any property or injury or death to any

person arising out of its purchase or the use, operation, or maintenance of the product. Seller will not be

liable for any labor subcontracted or performed by Purchaser for preparation of warranted item for return to

Seller's factory or for preparation work for field repair or replacement. Invoicing of Seller for labor either

performed or subcontracted by Purchaser will not be considered as a liability by the Seller.

The liability of Seller hereunder is limited to replacing or repairing at Seller's factory or on the job site at

Seller's option, any part or parts which have been returned to the Seller and which are defective or do not

conform to such specifications, drawings or other written descriptions; provided that such part or parts are

returned by the Ultimate Purchaser within ninety (90) days after such defect is discovered. The Seller shall

have the sole right to determine if the parts are to be repaired at the job site or whether they are to be

returned to the factory for repair or replacement. All items returned to Seller for repair or replacement must

be sent freight, prepaid to its factory. Purchaser must obtain Seller's Return Goods Authorization prior to

returning items. The above conditions must be met if warranty is to be valid. Seller will not be liable for any

damage done by unauthorized repair work, unauthorized replacement parts, from any misapplication of the

item, or for damage due to accident, abuse, or act of God.

This warranty shall be exclusive of any and all other warranties express or implied and may be modified only

by writing signed by any officer of the Seller. This warranty shall extend to the Ultimate Purchaser but to no

one else. Accessories supplied by Seller but manufactured by others carry any warranty the manufacturers

have made to Seller and which can be passed on to the Ultimate Purchaser.

Seller makes no warranty with respect to whether the products sold hereunder infringe any patent, U.S. or

foreign, and Purchaser represents that any specially ordered products do not infringe any patent. Purchaser

agrees to indemnify and hold Seller harmless from any liability by virtue of any patent claims where

Purchaser has ordered a product conforming to Purchaser's specifications, or conforming to Purchaser's

specific design.

Purchaser has not relied and shall not rely on any oral representation regarding the Product sold hereunder

and any oral representation shall not bind Seller and shall not be part of any warranty.

4 LD2100 User Guide 800.518.1519

Page 5

Contents

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controls and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mount the LD2100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the SeaHawk Leak Detection Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Secure Sensing Cable to the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Apply Power to the LD2100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configure Communication through the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Access the Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configure Network Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configure Communications Through the EIA-232 Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Calibrate Cable Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Test the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Identity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Leak Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Zone Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Virtual Zone Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Physical Zone Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Zone Link/URL Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Web/Map Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Working with a Reference Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

NTP (Network Time Protocol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Email-SMTP/DNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SNMP/Syslog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

EIA-485 Port/Modbus/N2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Bacnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Alarm Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

System/Flash Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Product Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Historical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Save your Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4 Configure the LD2100 as a Modbus Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Connecting Distance Read Panels Using the EIA-485 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connect Distance-Read Panels Through the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Configure Modbus Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

rletech.com LD2100 User Guide 5

Page 6

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Implementation Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Modes of Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Slave Address Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Function Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Data Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Error Check (Checksum) Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5-1.2 Exception Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Packet Communications for the LD2100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Function 03: Read Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Function 04: Read Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Function 06: Preset Single Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Function 16: Preset Multiple Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

RTU Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Restoring Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Preliminary Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Loading Flash Firmware Using MIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Loading Flash Firmware Using TFTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

B Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6 LD2100 User Guide 800.518.1519

Page 7

Figures

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 1.1 LD2100 Leak Detection and Communication . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2.1 LD2100 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2.2 Connecting the Sensing Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2.3 SeaHawk Sensing Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2.4 Secure the Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2.5 LD2100 Log In Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2.6 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2.7 Network/IP Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2.8 Apply Moisture to the Cable for Testing Purposes . . . . . . . . . . . . . . . . . . . . 25

3 Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3.1 LD2100 Web Interface Home Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3.2 Identity Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3.3 Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 3.4 Leak Settings Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 3.5 Zone Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3.6 Virtual Zone Settings Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 3.7 Zone Link/URL Settings Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 3.8 Network/IP Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 3.9 Web/Map Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 3.10 Load a Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3.11 Delete an Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 3.12 Web Configuration Page—Map Alarm Coordinates (Graphical) Link . . . . . . 40

Figure 3.13 Map Coordinates—Text View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 3.14 Map with Location of Leak Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 3.15 Map (Image) Buttons on Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 3.16 Clock Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3.17 NTP Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 3.18 E-mail Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 3.19 SNMP/Syslog Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 3.20 Modbus-Slave, Bacnet-MS/TP Slave, Modbus-Master, N2 Configuration . . 49

Figure 3.21 LCD-240 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 3.22 Bacnet Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 3.23 Alarm Management Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 3.24 System/Flash Management Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 3.25 Historical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 3.26 Alarm History Text File (.txt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 3.27 Trend Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

rletech.com LD2100 User Guide 7

Page 8

Figure 3.28 System Management Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 3.29 Image Buttons on Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 3.30 Saving a Map Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Configure the LD2100 as a Modbus Master . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 4.1 EIA-485 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 4.2 Ethernet Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 4.3 Modbus/EIA-485 Configuration, Modbus Master. . . . . . . . . . . . . . . . . . . . . . 63

Figure 4.4 Zone Configuration Webpage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 4.5 Modbus/Physical Zone Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4.6 LD2100 Home Page Showing Modbus Slaves . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 4.7 Individual Slave Unit Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 7.1 Exit to Bootloader Button on System Management Web Page . . . . . . . . . . . 85

Figure 7.2 Bootloader Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure A.1 System Management Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure A.2 Choosing a Firmware File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure A.3 Firmware Load Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure A.4 Current Firmware Version As Shown in LD2100 Interface . . . . . . . . . . . . . . 89

Figure A.5 Current Firmware Version As Shown in LD2100 Interface . . . . . . . . . . . . . . 90

B Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8 LD2100 User Guide 800.518.1519

Page 9

Tables

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2.1 LD2100 Controls and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 3.1 LD2100 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 3.2 Leak Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 3.3 Zone Settings Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 3.4 Virtual Zone Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 3.5 Zone Link/URL Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 3.6 Network/IP Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 3.7 Web/Map Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 3.8 Clock Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 3.9 NTP Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 3.10 Email Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 3.11 SNMP/Syslog Menu Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 3.12 EIA-485 Port/Modbus Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 3.13 Bacnet Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 3.14 Alarm Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3.15 System/Flash Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3.16 Alarm History Log Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 Configure the LD2100 as a Modbus Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5.1 Exception Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5.2 Read Output Register Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 5.3 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 5.4 Read Input Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 5.5 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 5.6 Status Flags (Register 30001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 5.7 Status Flags (Register 30010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 5.8 Status Flags (Register 30011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 5.9 Status Flags (Even Registers 30012-30040) . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 5.10 Status Flags (Register 30042) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 5.11 Status Flags (Register 30075) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 5.12 Preset Single Register Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 5.13 Preset Multiple Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 5.14 Response Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

rletech.com LD2100 User Guide 9

Page 10

A Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

B Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table B.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10 LD2100 User Guide 800.518.1519

Page 11

1.1. Description

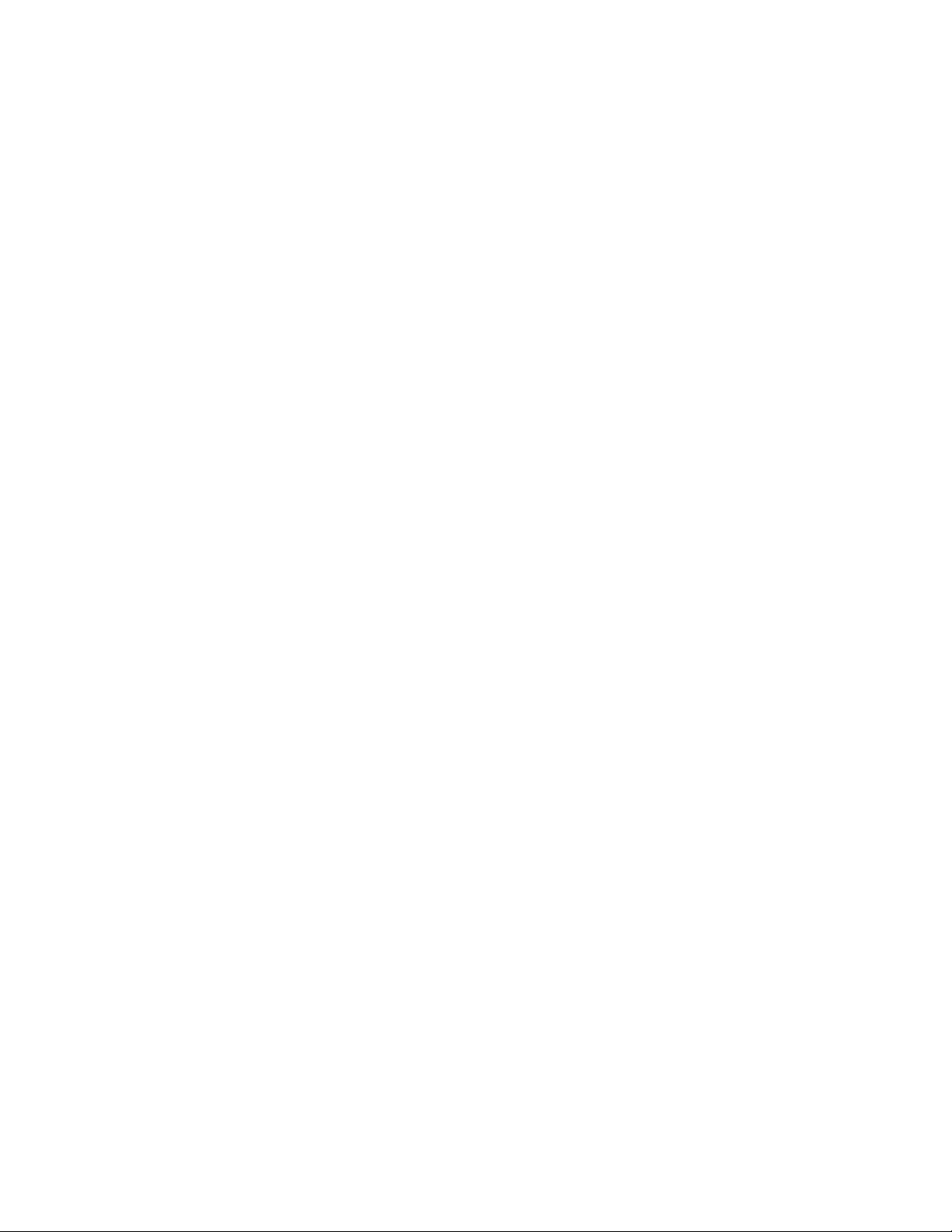

Figure 1.1

LD2100 Leak Detection and Communication

The LD2100 is a complete monitoring system that reports the presence of water and other

conductive liquids.

The LD2100 is an advanced controller that operates in conjunction with SeaHawk sensing

cable and SeaHawk spot detectors. Each LD2100 monitors up to 5,000 feet (1524m) of

sensing cable. When a conductive liquid comes in contact with the sensing cable or spot

detector, the distance to the leak is shown on the LD2100's front panel display.

C HAPTER

CHAPTER 0PRODUCT OVERVIEW

Alarm notifications are distributed via user-configurable Modbus (EIA-485 or TCP/IP),

BACnet (IP), SNMP, SMTP (email), or relay output to an alarm panel.

rletech.com LD2100 User Guide 11

Page 12

1 Product Overview

1.2. Operation

Supervised System

The LD2100 is a supervised system — it continually monitors the leak detection cable and spot

detectors for continuity. In addition to a leak triggering an alarm condition, a cable break or

excess contamination of the cable causes a cable fault indication and activates a relay. The

LD2100 sends alarm notifications to predetermined recipients when an alarm sounds. The

LD2100 produces an alarm during the following conditions:

♦ Leak detection

♦ Cable break

♦ Cable contamination

Distance-Read Leak Detection

When the LD2100's circuitry measures a current in excess of the user-defined leak threshold,

the unit's microprocessor computes the distance to the leak. The LD2100 then annunciates the

leak and logs the alarm in its event log. The summary relay has one output.

User Communication

A Web-based user interface provides information about the LD2100’s conditions. The user

interface can be used on site or remotely via network communications. The chapters and

appendices in this manual describe how to use the interface to accomplish specific

configuration and operation tasks.

The LD2100 also provides Modbus outputs via EIA-485, twisted-pair wire, or TCP/IP, as well

as BACnet/IP or BACnet/MSTP and SNMP outputs.

12 LD2100 User Guide 800.518.1519

Page 13

Installing the LD2100 involves mounting it to a wall in the appropriate location and making

the necessary connections for power, leak detection, and communications.

2.1. Prepare for Installation

Before installing the LD2100, have the following supplies available:

C HAPTER

CHAPTER 1INSTALLATION

Included with the LD2100

♦ Wall mount kit (or purchase optional enclosure, LD-ENC)

♦ Cross-over cable (blue with yellow ends)

♦ 15ft. (4.57m) leader cable

♦ End-of-line terminator (EOL)

Available from RLE, Sold Separately

♦ SeaHawk sensing cable

♦ Non-sensing cable, other accessories

♦ 24VAC power supply (part #WA-AC-24-ST) or 24VDC power supply (part

#PSWA-DC-24)

Information Required

Consult with your IT administrator to determine the following network settings for the

LD2100:

♦ IP address

♦ Subnet mask

♦ Default gateway

rletech.com LD2100 User Guide 13

Page 14

2 Installation

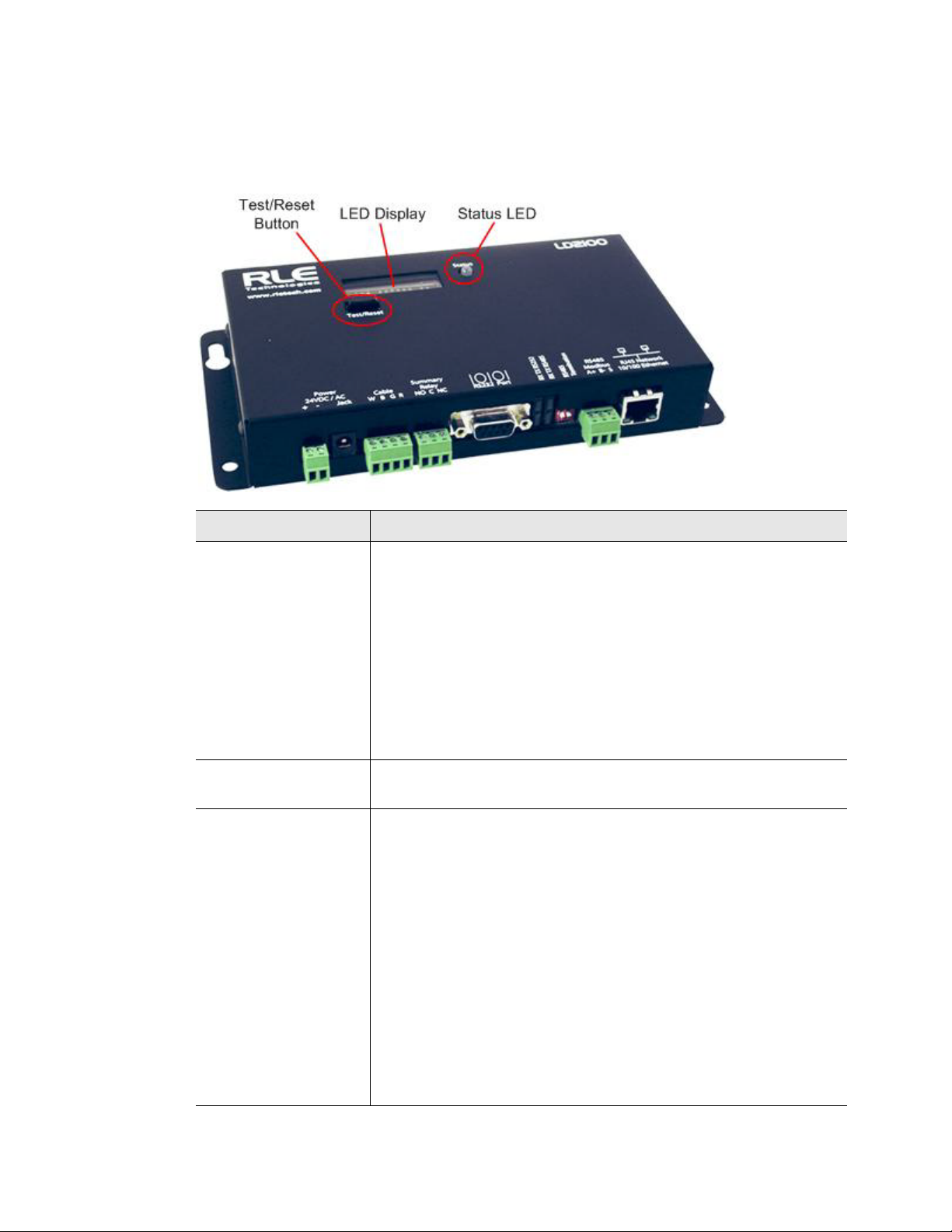

2.2. Controls and Displays

The front of the LD2100 contains the following controls and displays:

Item Description

Digital LED display

• In a normal operating state, this LED displays the

product name with a spinning bar (

|

) to the right of the name.

LD2100

• In an alarm state, the LED displays information about the

alarm condition; for example, if a leak is detected, the LED

displays a message with a leak detection cable distance

included. For example:

Leak detected

250 uA

at 675 ft (or 205.74m)

Note: Current range for a leak: 235 – 302 uA

Status LED Green: The LD2100 is powered on and in a normal operating state.

Red: The LD2100 is in an alarm state.

Test/Reset button If an alarm is sounding, briefly pressing the button turns off the

audible alarm. The Status LED remains red, and the digital LED

display continues to show the alarm condition.

In an alarm condition, whether the alarm is sounding or not,

pressing and holding this button clears the alarm.

In normal operating conditions, pressing the Reset button

causes the display to cycle through four lines:

LeakageC

nnnn uA

Length

nnn ft (or nnn m)

After a short pause, the LD2100 returns to the default display or

continues to display the alarm, depending on the value entered in

the Re-Alarm Interval field on the Leak Settings web page (see

Table 3.2, “Leak Configuration Options” on page 30 for more

information).

Table 2.1

LD2100 Controls and Displays

14 LD2100 User Guide 800.518.1519

Page 15

2.3. Physical Connections

The LD2100 has the following physical connections:

2 Installation

Figure 2.1

LD2100 Connections

TB1: Input Power

Power can be wired to the LD2100 through TB1. Wire the connections as follows:

TB1-1 24VDC positive (+)

TB1-2 24VDC negative (-)

P1: Input Power

RLE recommends powering the LD2100 with 24VDC wall adapter power supply. This power

supply can be purchased directly from RLE, and is offered as RLE part #PSWA-DC-24. P1 is

the connection for this power supply.

To learn more about connecting power to the LD2100, refer to Section 2.6., “Apply Power to

the LD2100” on page 19.

TB2: Cable Interface

SeaHawk sensing cable connects to TB2. Since sensing cable cannot connect directly to a leak

detection controller, the 15-foot (4.57m), non-sensing leader cable (supplied with the LD2100)

must be connected to TB2, and then the sensing cable connected to the leader cable; see

Section 2.5., “Connect the SeaHawk Leak Detection Cable” on page 17.

TB3: Summary Relay

Terminal TB3 is a Form C summary relay output. This relay provides alarm notification when

a leak, cable fault, or cable contamination is detected.

rletech.com LD2100 User Guide 15

Page 16

2 Installation

The three contacts on TB3 are labeled NO, C, and NC. Connect the alarm relay wires to TB3

as follows:

TB3-1 Leak alarm normally open (NO)

TB3-2 Leak alarm common (C)

TB3-3 Leak alarm normally closed (NC)

Both relays (all alarms) can be configured to be latched or unlatched. A latched alarm requires

a manual reset of the system once a leak or cable problem is no longer present.

P4: EIA-232 Connector

The EIA-232 uses a baud rate of 9600. The EIA-232 port is set to 8 databits, no parity, and 1

stop bit (8, N, 1). A straight through cable should be used to connect a terminal or PC to the

LD2100. This connection should only be used for setting the IP address, using advanced

diagnostics, uploading firmware, and troubleshooting. Detailed IP configuration instructions

can be found in Section 2.7., “Configure Communication through the Ethernet Port” on

page 20.

SW3: EIA-485 Termination

Switch SW3 is used when the LD2100 is the last unit on a EIA-485 network. Switch SW3 on

(push to the down position) to place a termination resistor across the + and - terminals of the

EIA-485 port.

TB4: EIA-485 Modbus Port

TB4 connects to an EIA-485 network. A grounded shield contact is provided for connection to

shielded cable. If the shield contact is used, verify the power connector is properly grounded

and there is no voltage potential between units on the network. The EIA-485 port has a

selectable baud rate (9600, 19200, or 38400) and is set to 8 databits, no parity, and 1 stop bit

(8, N, 1). Connect the EIA-485 wires to TB4 as follows:

TB3-1 A (+)

TB3-2 B (-)

TB3-3 Shield

P3: RJ45 Network

A 10/100 BaseT Ethernet connection allows the LD2100 to connect directly to a local area

network. Use a crossover cable (shipped with the LD2100; blue cable with yellow ends) for

initial connection and configuration. The default settings are as follows:

IP Address: 10.0.0.188

Subnet Mask: 255.255.255.0

2.4. Mount the LD2100

The LD2100 is a wall mounted device. Using the wall mount kit (screws and reinforcers,

included) or the LD-ENC wall-mountable enclosure (sold separately), mount the device to the

wall in a convenient location.

16 LD2100 User Guide 800.518.1519

Page 17

2 Installation

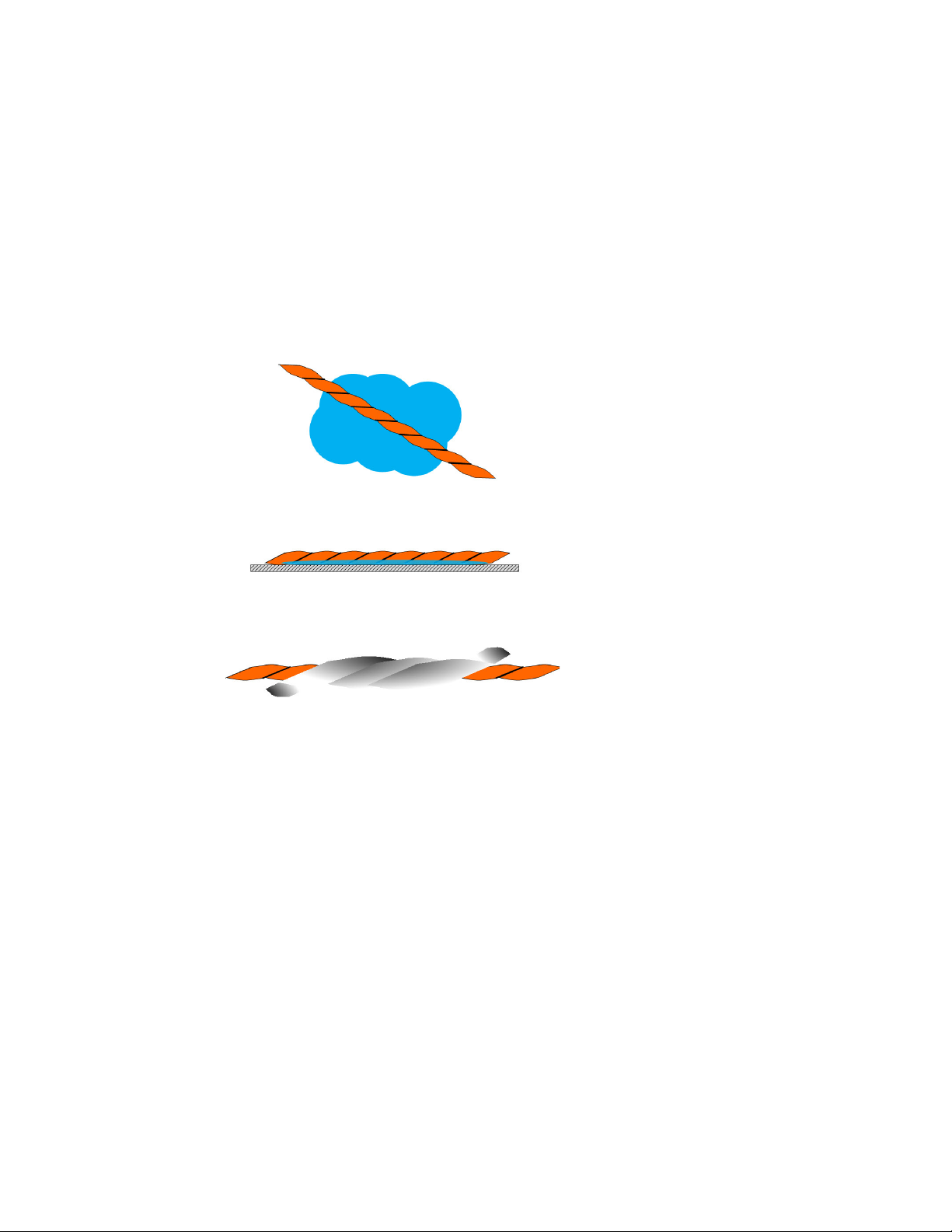

Figure 2.2

Connecting the Sensing Cable

Figure 2.3

SeaHawk Sensing Cable

2.5. Connect the SeaHawk Leak Detection Cable

The LD2100 is shipped with a 15-foot (4.57m) leader cable. Since sensing cable cannot

connect directly to a leak detection controller, one end of this leader cable connects to the

LD2100 controller, and the other end connects to the SeaHawk sensing cable. Connect each

end of the leader cable as follows:

1 With the screws of terminal block connector TB2 on the LD2100 facing up, connect the

four stripped, bare wires of the leader cable to the terminals in this order, from left to right:

white, black, green, red.

Note If the terminal connector is removed from the end of the cable, make sure the wires are in

this same order when the connector is reapplied.

2 Unscrew the end-of-line (EOL) terminator from the other end of the leader cable.

3 Attach the first length of sensing cable to the leader cable.

4 Route the sensing cable according to a cable layout diagram. Attach additional lengths of

sensing cable as needed.

5 Secure the EOL terminator to the unoccupied end of the sensing cable.

rletech.com LD2100 User Guide 17

Page 18

2 Installation

Figure 2.4

Secure the Cable

Note If the EOL terminator is not present at the end of the cable run, a cable fault will register.

If you are using a reference map, compare it with the actual cable installation. Revise any

6

discrepancies created through the physical installation of the cable.

2.5.1 Secure Sensing Cable to the Floor

Secure the sensing cable to the floor with either J-clips (RLE part #JC), or one of the other

approved methods shown in Figure 2.4. Available from RLE and designed specifically for use

with sensing cable, J-clips are the manufacturer's recommended installation method.

♦ Do not use conductive materials, such as Fire Block or caulk, on the sensing cable.

♦ To avoid contaminating the cable, clean the entire floor as much as possible. Use isopropyl

alcohol to clean the spots on the floor where the J-clips will be placed.

♦ Place one J-clip every 5 to 6 feet (1.52 to 1.83m) along the length of the sensing cable and

one at each turn of the cable. Use more J-clips if a tighter configuration is required.

♦ If the cable is installed over an obstruction, clip the cable on both sides, as close to the

obstruction as possible.

♦ The J-clip’s adhesive backing does not work well on porous concrete floors. RLE

recommends using a drop of silicone or another nonconductive adhesive to help secure the

J-clip to the floor.

IMPORTANT Do not install the cable directly in front of an air conditioner. Allow a minimum of 4 to 6 feet

(1.22 to 1.83m) between the unit and the cable. If the cable is too close to the air conditioning

unit’s air stream, the moisture from the humidifier may cause false leak readings. If the cable

must be installed in front of an air conditioning unit, place the J-clips 36 inches (0.91m) apart.

18 LD2100 User Guide 800.518.1519

Page 19

2.6. Apply Power to the LD2100

WARNING

An isolated power supply must be provided for the LD2100. In addition, a

dedicated circuit breaker must be provided within close proximity to the LD2100

and be clearly marked as the disconnecting device for the LD2100 leak detection

controller.

Do not connect 120/230 VAC to the unit, or damage will occur to the circuitry.

1 The LD2100 operates on either 24VAC or 24VDC power. Run a power supply to the

location of the unit.

2 Connect power to either the TB1 or P1 connector on the side of the LD2100.

3 Before applying power to the unit, ensure that all connections are correct and all screw

terminals are secure.

2 Installation

Note RLE recommends the use of a 24VDC wall adapter power supply (part # PSWA-DC-24),

which is available separately.

The LD2100 begins booting when power is applied. The normal operating condition of the

LD2100

LD2100 is for the Status LED to glow green and for the LED display to show

|

spinning bar (

4 Wait approximately one minute for the LD2100 to start up. No alarm should be present. If

) to the right of the product name.

with a

an alarm is present, consult Appendix 7 for troubleshooting information.

5 Go to the LD2100’s user interface to verify the length of the installed leak detection cable.

See Section 2.7., “Configure Communication through the Ethernet Port” on page 20 to set

up network access to the LD2100. See Chapter 3 for instructions for verifying the length of

the installed cable.

rletech.com LD2100 User Guide 19

Page 20

2 Installation

2.7. Configure Communication through the Ethernet

Port

IMPORTANT Consult your IT administrator before performing these steps. If you intend to change the IP

Address or Subnet Mask, obtain appropriate addresses from your IT department.

LD2100 default IP address: 10.0.0.188

LD2100 default subnet mask: 255.255.255.0

2.7.1 Access the Configuration Menu

RLE recommends using the web-based Configuration Menu to configure communications for

the LD2100. If you’d like to use the EIA-232 interface to access the LD2100, refer to

Section 2.8., “Configure Communications Through the EIA-232 Port” on page 22.

1 Plug the crossover cable (included with the LD2100) into the computer that will be used to

configure the LD2100.

Note This cable is not intended to be connected to a network hub, and will not work if it is

connected to a hub.

2

Connect the other end of the crossover cable to the Ethernet port on the back of the

LD2100.

Note Alternatively, you could use the LD2100’s EIA-232 interface to access the LD2100. See

"Configure Communications Through the EIA-232 Port" on page 22.

3

Write down the computer’s current IP address, subnet mask, and default gateway. Change

these items temporarily so that the computer can communicate with the LD2100.

4 Access the LD2100 through a Web browser by typing the LD2100’s default IP address

(10.0.0.188) into the location bar and pressing Enter.

Figure 2.5

5

Enter the following:

LD2100 Log In Prompt

Default User Name: ld2100 (case sensitive)

Default Password: (No default password. Leave this field blank.)

Once you enter this information, the home page for the LD2100’s web interface displays.

20 LD2100 User Guide 800.518.1519

Page 21

2 Installation

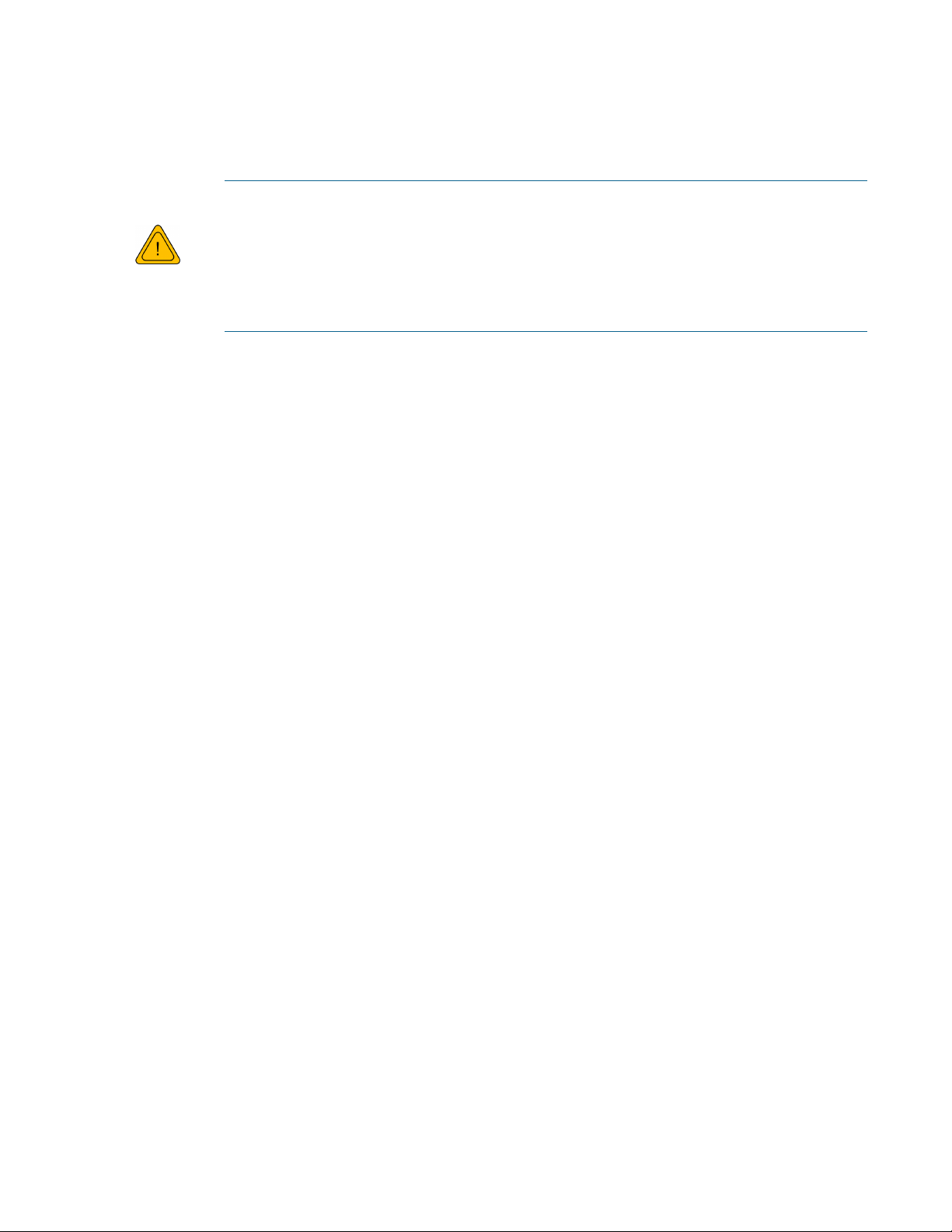

Figure 2.6

Configuration Menu

2.7.2 Configure Network Communications

To configure network communication, set the IP address for the LD2100 to the address

assigned by your IT administrator.

1 From the home page of the LD2100’s web interface, select the Configuration Menu link.

Then, select Network Settings from the Configuration Menu.

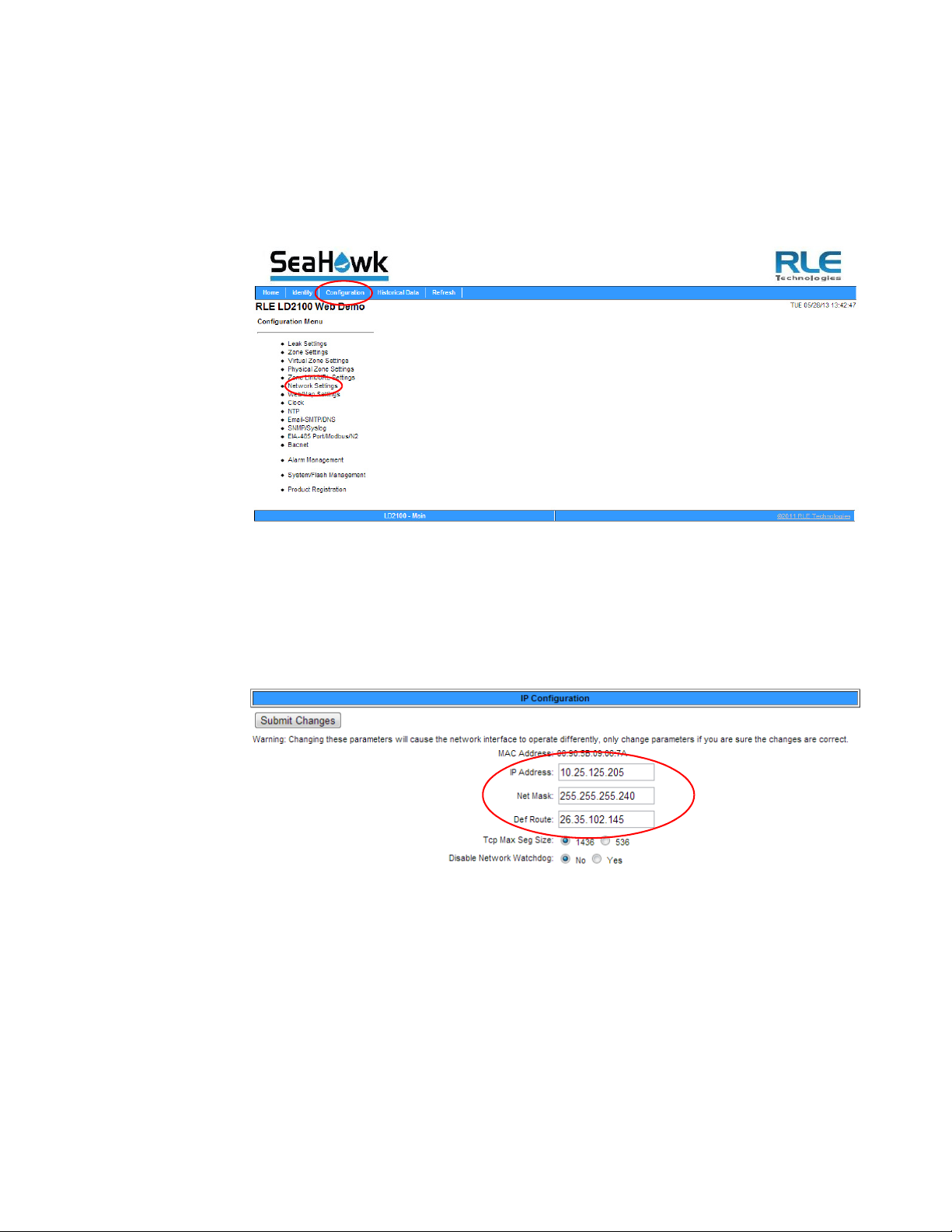

2 The Network/IP Configuration page displays. Enter the values for IP Address, Net Mask

(subnet mask), and Def Route (default gateway) provided by your IT administrator.

Once you enter the values and click the Submit Changes button, the LD2100 saves the

changes and reboots. The system status LED on front of the LD2100 stops flashing.

Figure 2.7

3

Reset the computer that’s connected to the LD2100 to its original IP address and subnet

Network/IP Configuration Page

mask. Disconnect the crossover cable.

The computer and the LD2100 are now both configured to communicate on the network.

4 To verify that the IP address on the LD2100 has been successfully changed, type the new IP

address of the LD2100 into any web browser.

5 When prompted, enter the user name and password to verify network access to the LD2100

(as you did in step 4 in the previous section).

rletech.com LD2100 User Guide 21

Page 22

2 Installation

If the login window for the LD2100 does not display:

a Verify that all cables are firmly attached.

b Verify that you entered the correct IP address for the LD2100.

c Verify that the Status light on the top of the LD2100 is green.

For further troubleshooting information, refer to Chapter 7.

2.8. Configure Communications Through the

EIA-232 Port

You can also use the EIA-232 interface to set the IP address:

1 Connect the EIA-232 port (P4) on the LD2100 to a terminal or PC running terminal

emulation software (HyperTerminal) with a 9-pin male-female straight through serial cable.

2 2. Set the appropriate communication port to 9600 baud, NO parity, 8 data bits, 1 stop

bit, (9600/N/8/1), and no software or hardware flow command.

3 Once the terminal emulation software starts, type

?

and press Enter on the keyboard and the

Main Menu should appear. If the Main Menu does not appear, check the communication

settings and make sure the unit is powered on.

4 From the Main Menu type netcfg to select the Network Configuration Menu.

♦ Enter the new IP address for the LD2100 by typing

xxx.xxx.xxx.xxx

point. For example, type

is the new IP address of the unit. Separate each field with a decimal

ip 10.0.0.50 <Enter>

ip xxx.xxx.xxx.xxx

.

, where

♦ The LD2100 erases a memory block and copies data to flash memory before rebooting.

♦ The LD2100 IP address is now set and the LD2100 can be accessed through a Web

browser using the new IP address.

5 Repeat step 4¨ to change the Subnet Mask and Def Route, if needed, using the commands

xxx.xxx.xxx.xxx

to change the Subnet Mask and

dg xxx.xxx.xxx.xxx

to change the default

gateway.

nm

22 LD2100 User Guide 800.518.1519

Page 23

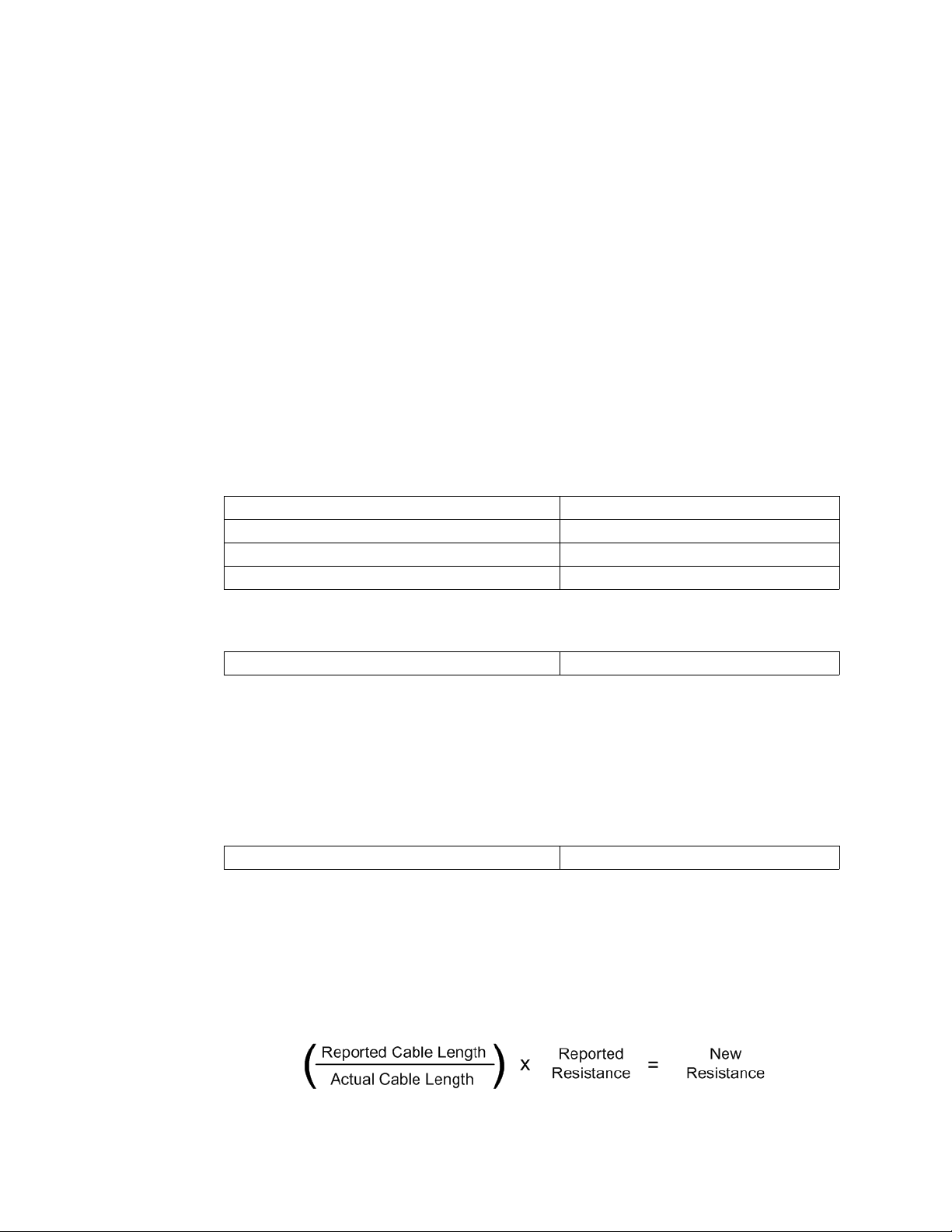

2.9. Calibrate Cable Resistance

Distance-read leak detection systems are resistance-based. RLE’s orange water sensing cable

has a base resistance of 2.8 ohms/foot, while most other sensing cables, including RLE’s green

chemical resistant sensing cable, have a resistance of 4.0 ohms/foot.

The resistance of each length of sensing cable may be slightly more or less than the base

resistance due to manufacturing variances. For this reason, the cable length displayed on the

home page of the web interface may be slightly more or less than the actual length of cable

installed.

A system configured using base resistance values will still be very accurate. If you wish to fine

tune the resistance value of your LD2100 system to make it more precise, you may do so. This

will increase the accuracy of the system, and bring the LD2100’s reported installed cable

length value in line with the actual length of cable installed.

1 Ensure the LD2100 has been powered and has all the sensing cable attached to it, with no

alarms present.

2 Gather and record the following data from the home page of the web interface:

Cable Length (as reported by the LD2100)

Cable Current

Leg 1 Resistance

Leg 2 Resistance

2 Installation

Record the resistance per foot setting, as reported by the LD2100. This can be found on the

Leak Configuration page of the web interface (Configuration > Leak Settings).

Reported Resistance per Foot

3 Note the actual (physical + simulated) length of cable physically connected to the system.

For your reference:

♦ WCCS simulates 50 ft. ♦ XCON simulates 150 ft.

♦ SDZ simulates 50 ft. ♦ Nonsensing cable does not add

any length to a system

Record this sum:

Actual length of cable connected to LD2100

4 Verify the current reading on the cable from the recorded value above. This value must be

less than 15 μA in order to calibrate the system. If the current is higher than 15μA, clean the

cable. Isopropyl alcohol works well to remove any contamination that might have gotten

onto the cable during installation.

5 To calculate the most accurate resistance value for the system, divide the reported cable

length by the actual cable length, and multiply the quotient by the reported resistance.

rletech.com LD2100 User Guide 23

Page 24

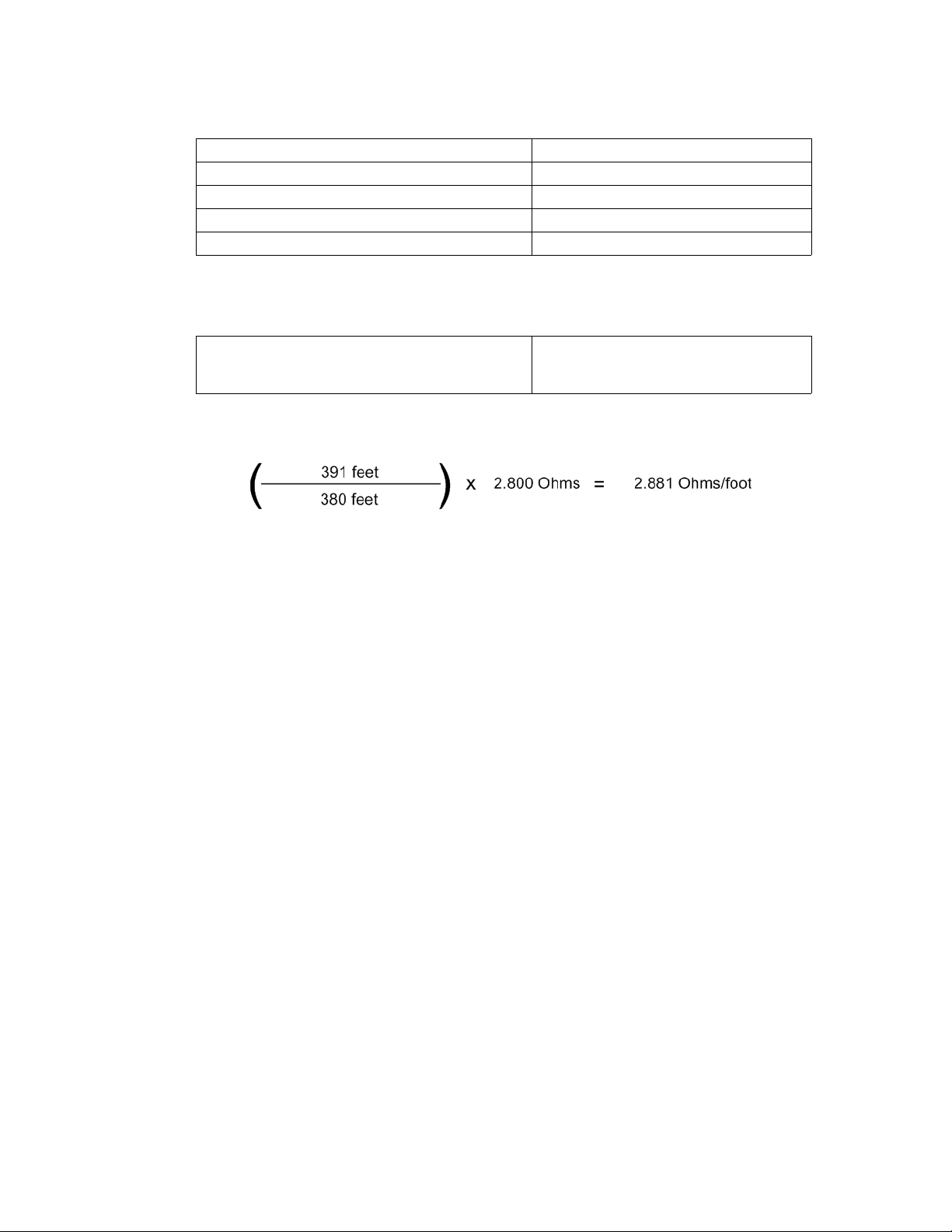

2 Installation

For example:

Cable Length (as reported by the LD2100) 391 feet

Cable Current 0 μA

Leg 1 Resistance 1088 Ohms

Leg 2 Resistance 1095 Ohms

Reported Resistance 2.800 Ohms/foot

One 15 foot leader cable (leader cable does not count toward the total length of cable

installed), one weighted cable connector (simulates 50 feet of cable), and one 330 foot

section of cable are connected to the system.

Actual length of cable connected to LD2100

380 feet

0 feet + 50 feet + 330 feet

The actual resistance of the cable installed with this LD2100 is 2.881 ohms per foot.

6 Go to the Leak Configuration page (Configuration>Leak Settings) and enter the newly

calculated Resistance Per Foot value. Click Submit Changes once you have made all your

changes to this web page.

When using the web interface, remember to click the Submit Changes button to save the

adjusted resistance value.

In our example, adjusting the resistance value changed the reported cable length from 391

feet to 380 feet. This improves the accuracy of the system because the reported cable length

more closely matches the physical length of cable connected to the system.

24 LD2100 User Guide 800.518.1519

Page 25

2.10. Test the System

Now that the system is calibrated, test a few spots before mapping the system.

Note If the LD2100 is already connected to a BMS or NMS, notify monitoring personnel before you

begin testing the system.

1

To verify the LD2100’s accuracy, test three points within the length of sensing cable - one

at the beginning, one in the middle of the length, and another near the end of the length of

cable.

There are a variety of ways to simulate a leak:

2 Installation

♦ Pour a small puddle of water on the

cable while it rests on the floor.

♦ Dunk the cable in a cup of water.

♦ Soak a paper towel or rag and wrap it

loosely around the cable. This is

popular if the cable is used in pipe

applications. Be careful to wrap the

wet cloth loosely around the cable.

Do not put pressure on the cable.

IMPORTANT - To avoid inaccurate

readings, do not grip the cable with

your hand.

Figure 2.8

2 Verify that the LD2100 reports the leaks within a few feet of their actual physical location.

3 Remove the simulated leak source and return the system to its normal operating state.

Apply Moisture to the Cable for Testing Purposes

rletech.com LD2100 User Guide 25

Page 26

2 Installation

26 LD2100 User Guide 800.518.1519

Page 27

C HAPTER

CHAPTER 2WEB INTERFACE

Use the LD2100’s web interface to configure and monitor the status of the system.

To access the LD2100’s web interface, type the device’s IP address into your web browser’s

location bar. Once you navigate to the IP address, a login prompt asks for a username and

password. Enter the appropriate information, which is either the default user name (no

password), or a user name and password assigned by your system administrator.

3.1. Home Page

The home page features vital system information, including current alarm status, the reported

length of sensing cable connected to the system, the last time the system went into alarm, and

the running system uptime. The image to the right of the table can be customized, and can be

linked to interactive floor maps.

Figure 3.1

rletech.com LD2100 User Guide 27

LD2100 Web Interface Home Page

Page 28

3 Web Interface

Field Description

Alarm Status If the controller is in an alarm state, details regarding the alarm are

noted in this field. The field is color coded to indicate the type of

alarm.

Cable Length The length of cable connected to the controller, as calculated by the

LD2100.

Cable Current The amount of current running on the sensing cable.

Leg 1 Resistance The resistance of Leg 1 is displayed in Ohms.

Leg 2 Resistance The resistance of Leg 2 is displayed in Ohms.

Leak Alarm Delay

Count

Contamination

Alarm Delay Count

Re-alarm

Countdown

Last Alarm Time The last time an alarm was detected

sysUp Time The amount of time that has passed since the system was last

Table 3.1

LD2100 Home Page

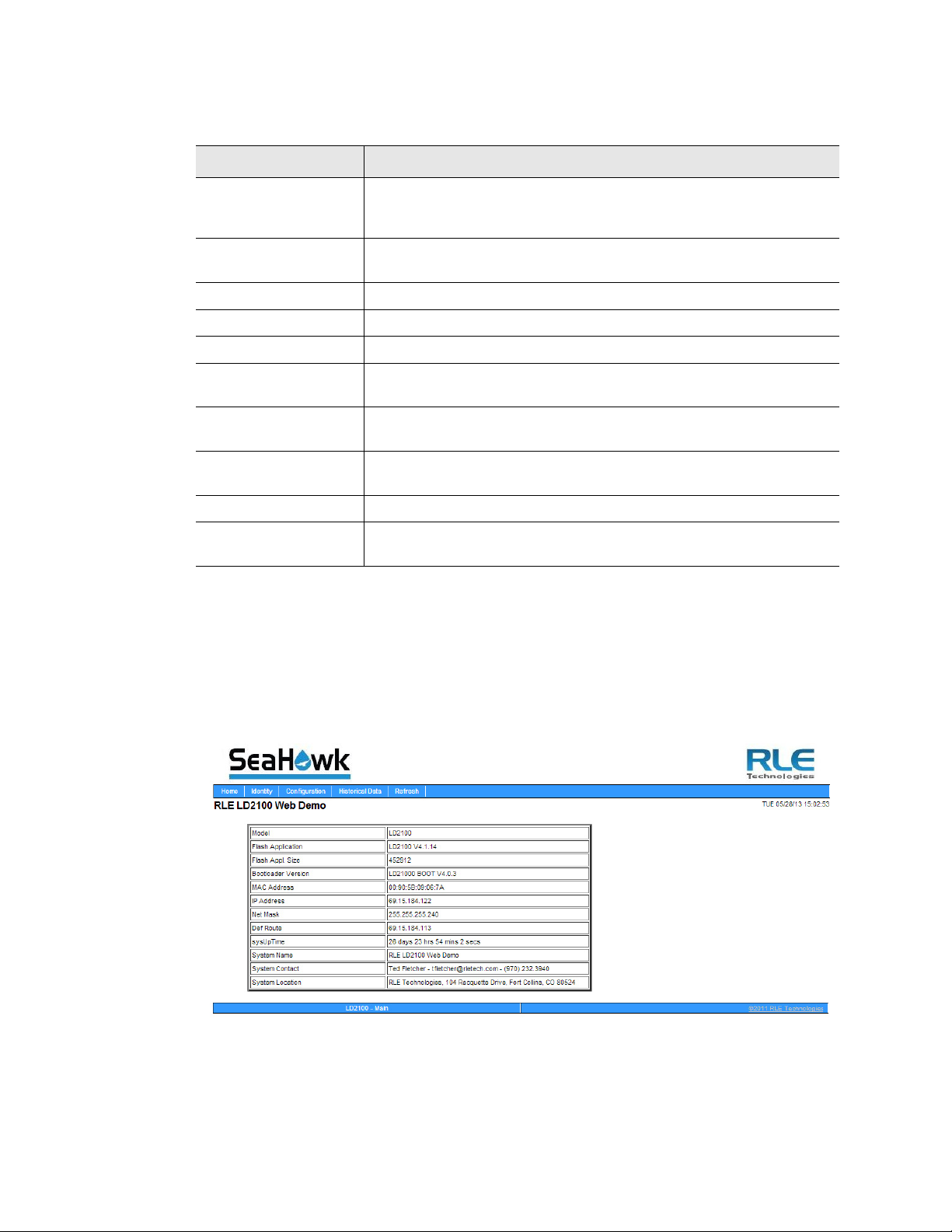

3.2 Identity

The Identity link displays basic LD2100 information, including model number, system name,

contact information, firmware version, and IP address. Most of these values can be adjusted

through the Configuration screens. This page is intended for reference only, not system

adjustment.

The amount of time (in seconds) that passes between the time a

leak is detected and when it is annunciated.

The amount of time (in seconds) that passes between the time a

contamination alarm is detected and when it is annunciated.

The amount of time remaining before an alarm is re-annunciated.

reset or powered on.

Figure 3.2

28 LD2100 User Guide 800.518.1519

Identity Page

Page 29

3.3 Configuration

The Configuration link provides access to a series of sub-menus from which users can adjust

system settings.

3 Web Interface

NOTE

Figure 3.3

Configuration Page

If any of the fields within the sub-menus are edited, be sure to click the Submit

Changes button to save the changes. If you edit the fields and navigate from the

web page without clicking the Submit Changes button, all changes will be lost.

rletech.com LD2100 User Guide 29

Page 30

3 Web Interface

3.3.1 Leak Settings

Use the Leak Configuration page to fine tune system variables, including leak and

contamination thresholds, latching and unlatching alarms, and sensing cable resistance.

Figure 3.4

Option Description

Leak Trip Point The threshold for the amount of water required to trigger a leak

Contamination Trip

Point

Leak Settings Configuration

alarm. Adjust this number to adjust the sensitivity of the leak alarm.

A lower number yields a more sensitive system, so the system will

trigger a leak alarm with less water present.

A higher number produces a less sensitive system, so more water

is required to trigger an alarm.

Enter a value between 25 and 295 microamps.

Default setting: 150uA

The threshold for the amount of contamination required to trigger a

cable contamination alarm. Adjust this number to adjust the

sensitivity of the contamination alarm.

A lower number yields a more sensitive system, so the system will

trigger a contamination alarm with less contamination present.

A higher number produces a less sensitive system, so more

contamination is required to trigger an alarm.

Enter a value between 20 and 295 microamps.

Default setting: 50uA

Table 3.2

30 LD2100 User Guide 800.518.1519

Leak Configuration Options

Page 31

3 Web Interface

Option Description

Leak Alarm Delay The amount of time that passes between the time a leak is detected

and the annunciation of the leak alarm.

The leak trip point must be exceeded for the duration of this delay.

Default setting: 20 seconds

Contamination

Alarm Delay

The amount of time that passes between the time a contamination

is detected and the annunciation of the contamination alarm.

The contamination trip point must be exceeded for the duration of

this delay.

Default setting: 40 seconds

Resistance Per Foot The resistance per foot (or meter) of cable determines the

LD2100’s ability to accurately detect the cable length installed and

calculate distances to leaks. Adjust this value to fine-tune the

accuracy of a distance-read leak detection system.

RLE’s orange water sensing cable has a base resistance of 2.800

ohms per foot. Most other sensing cables, including RLE’s green

chemical-resistant sensing cable, have a base resistance of 4.000

ohms per foot. Consult the sensing cable’s datasheet for further

information.

The resistance value must be entered as a 4-digit number between

2.000 and 4.250, with one number in the tens place and three

numbers past the decimal point (x.xxx).

Default setting: 2.800 ohms per foot

Re-Alarm Interval The LD2100 can be set to re-alarm - after a leak or contamination

has been detected, the alarm will be re-sent at a defined interval

until the alarm condition has been resolved. The re-alarm triggers

both the audible alarm and the direct notification alarm.

Enter a number from 0 to 24. A 0 in this field turns off the re-alarm

option, so only one alarm notification will be sent for each alarm.

Default setting: 0 (disabled)

Measurement

Display

Select either feet or meters to calibrate the LD2100 to the preferred

unit of measure. All distance calculations will adjust accordingly.

Default setting: Feet

Table 3.2

rletech.com LD2100 User Guide 31

Leak Configuration Options

Page 32

3 Web Interface

Option Description

Latching Alarms A non-latching alarm resets itself once a detected leak or

contamination has been resolved.

A latching alarm must be manually acknowledged before its

annunciation clears, even if the detected leak or cable problem is

no longer present.

Select Yes (latching) or No (non-latching).

Default setting: No (non-latching alarms)

Audible Alarm Select Enabled to activate the audible alarm annunciation. Disable

this option to deactivate the audible alarm annunciation.

Default setting: Disabled

Length Calibration

Factor

Table 3.2

Leak Configuration Options

Reserved for manufacturer’s use only.

Set Cable Relay Button - Used to troubleshoot the controller, this button simulates 8060

ohms of leak detection cable (approximately 2878 feet of 2.8 ohms/foot cable) for up to 5

minutes. Push the button and then look at the web interface home page. If the controller is

functioning properly, the cable length will register approximately 2878 feet, and the leg 1

and leg 2 resistance will be approximately 8060 ohms.

32 LD2100 User Guide 800.518.1519

Page 33

3 Web Interface

3.3.2 Zone Settings

You can set up the LD2100 to identify different areas where leak detection cable or spot

detectors are installed. Each area is called a zone. Up to 32 zones can be configured on the

LD2100 - the LD2100 itself is the master controller, and up to 31 slave units can connect to it.

Dividing a leak detection system into zones helps locate leaks quickly. It can also simplify

troubleshooting by allowing you to isolate different sections of cable and different rooms or

other defined areas. The LD2100 uses two different types of zones:

♦ Physical zone. A physical zone consists of a single SeaHawk distance read controller,

including the LD2100 and other RLE distance read controllers attached to it, and the

attached sensing cable. In a scenario where additional controllers are attached, the LD2100

acts as a Modbus master to other controllers. To configure physical zones, including setting

up the LD2100 as a Modbus master attaching additional controllers, follow the instructions

in Chapter 4.

♦ Virtual zone. A virtual zone is a labeled reference point in a leak detection system. A

virtual zone can consist of a room, a drip pan containing a spot detector under an air handler

unit, a combination of rooms and components, or any other defined area whose

identification would help in the location of leaks.

If you wish to establish virtual zones, go to Configuration>Zone Settings. The Zone

Configuration page displays. Select the desired zone settings.

Figure 3.5

Option Description

Zones 0 - 32 Enter an integer from 0 to 32 to indicate the number of virtual zones

Modbus Zone Traps Select the Enable radio button to enable SNMP traps for the Leak

Enable Alarm Relay

for Modbus Slaves

Table 3.3

Zone Configuration

you want to configure.

Detection Modbus master. Default: Disable.

Select the Enable radio button to activate the summary alarm when a

leak detection slave unit goes into an alarm. Default: Disable

Zone Settings Configuration Options

rletech.com LD2100 User Guide 33

Page 34

3 Web Interface

3.3.3 Virtual Zone Settings

Once you’ve designated how many virtual zones you’d like to have, you need to provide the

necessary information to define where the virtual zones are in your installation. Do this on the

Virtual Zone Settings page.

Figure 3.6

Option Description

Zone # A fixed number, 1 - 32, used to designate the Zone.

Label Type a descriptive label for the zone, 30 characters or less.

End Distance Record the sensing cable’s distance measurement at the END of

Table 3.4

Virtual Zone Settings Configuration Page

the zone.

Zone 1 starts at 0 feet / meters, and you designate the end point for

Zone 1. Zone 2 starts at zone 1’s ending distance; you designate

where Zone 2 ends. Each subsequent zone begins where the

previous zone ends.

Virtual Zone Configuration Options

3.3.4 Physical Zone Settings

Physical zones represent actual pieces of hardware that are connected to the LD2100. You’ll

use the Physical Zone Settings page to designate specific information about these physical

zones, but first you’ll need to designate the LD2100 as a Modbus Master and connect slave

devices to the LD2100. For complete physical zone configuration information, refer to

Chapter 4.

34 LD2100 User Guide 800.518.1519

Page 35

3 Web Interface

3.3.5 Zone Link/URL Settings

If you’ve connected slave devices to the LD2100, you may want access to additional

information for each of these units.

To fill this need, users can designate up to 32 links to appear on the LD2100’s home page.

Links will appear on the lower left side of the screen, below the tables of information, and

each link can connect to a specific URL. Use this page to configure all the links you’d like to

see on the home page.

Figure 3.7

Option Description

Zone A fixed number, it designates the zone associated with the link.

Link Text Users can designate links to appear on the LD2100’s home page.

URL This is the URL that the link on the home page will connect to.

Table 3.5

rletech.com LD2100 User Guide 35

Zone Link/URL Settings Configuration Page

Links will appear on the lower left side of the screen, below the

tables of information.

Additional links can be configured through the Zone Link/URL

Settings configuration link.

Enter the text for the first link here.

Enter the appropriate URL here.

Zone Link/URL Settings

Page 36

3 Web Interface

3.3.6 Network Settings

The Network/IP page displays the assigned MAC address and allows users to configure

common network information. Editing this information will change the way the web interface

operates. Only change this information if you have been in contact with your network

administrator, and are sure the changes are correct.

Figure 3.8

Option Description

MAC Address The MAC address is a unique identifier set by the manufacturer,

IP Address Set the IP address for the LD2100, so it can communicate on your

Net Mask Designate the device’s Subnet Mask. Contact your IT department

Def Route Designate the device’s default route (default gateway). If you do not

Http Port Some ISPs use alternate http ports as an added security measure.

Network/IP Configuration Page

and is non-editable.

network. If you do not have an IP address for the device, obtain one

from your IT department.

Default IP address: 10.0.0.188

for further information.

Default subnet mask: 255.255.255.0

have a default route, obtain one from your IT department.

Default device route: 10.0.0.1

Edit this field in accordance with your ISPs security settings.

Default: 0 = Port 80

Tcp Max Seg Size The LD2100 defaults to 1436 packet size for web page data. Users

may select 536 for limited bandwidth or VPN applications.

Default: 1436

Disable Network

Watchdog

Table 3.6

36 LD2100 User Guide 800.518.1519

Network/IP Configuration Options

The network watchdog is used to reboot the device if excessive

network traffic or errors are detected.

Default: No

Page 37

3 Web Interface

3.3.7 Web/Map Settings

Use this page to establish passwords and a username for the web interface, to customize the

web interface’s home page with your own graphics and links, and to create an interactive leak

detection map.

Figure 3.9

Option Description

Web Username Designate a username used to access the web interface.

Web Password Read

Only

Web Password

Read/Write

Table 3.7

Web/Map Configuration Page

Default username: ld2100

Two separate passwords can be configured on the LD2100.

The Read Only password allows users to access the LD2100’s web

interface and view the conditions of the system, but does not allow

users to make changes to the LD2100’s configuration.

Default password: field is left blank (no password required)

The second configurable password on the LD2100 provides users

with expanded access.

The Read/Write password allows users to view the conditions of the

system and make changes to the LD2100’s configuration.

Default password: field is left blank (no password required)

Web/Map Configuration Options

rletech.com LD2100 User Guide 37

Page 38

3 Web Interface

Option Description

Web Refresh Rate Decide how often the web page refreshes - checks for new data

and reloads the web page - when left in an open web browser.

Enter a value from 10 to 999 seconds. If you enter 0, the screen will

not refresh on its own - you’ll have to click the refresh button on

your web browser or press F5 to refresh the screen.

Default setting: 10 seconds

Main Page Image One image appears on the right side of the home page. Images are

uploaded through the Map page of the web interface. Select an

image from the drop down list of uploaded images.

Default setting: Seahawk

Main Page/Zone 1

Link Text

Main Page/Zone 1

Link URL

Floor Map #1 Link

Text

Floor Map #2 Link

Text

Floor Map #1

Interactive

Table 3.7

Web/Map Configuration Options

Users can designate links to appear on the LD2100’s home page.

Links will appear on the lower left side of the screen, below the

tables of information.

Additional links can be configured through the Zone Link/URL

Settings configuration link.

Enter the text for the first link here.

This is the URL that the link on the home page will connect to.

Enter the appropriate URL here.

Links to two floor maps can be displayed on the LD2100’s home

page. These links display under the image on the right side of the

screen. The maps themselves are loaded on the

Configuration>System/Flash Management Screen.

Enter the text for the link to the first map here.

Enter the text for the link to the second map here.

While the LD2100 can display two maps, only one of the maps can

be interactive. If you’d like Map #1 to be interactive, designate that

here.

3.3.7.1 Working with a Reference Map

The LD2100 allows users to upload up to 2 maps of their facilities - one of which can be

populated with interactive leak detection data. This provides users with a real-time view of

their facility, including the physical location and status of their leak detection equipment, and

a visual indication of any active alarms.

Through the mapping process, the LD2100 creates an overlay for an uploaded map image. It

superimposes the locations of your equipment - based on coordinates you designate - over the

top of your map image. This overlay is created through the links at the bottom of the Web/Map

Settings page. Once uploaded and populated, the map is accessible through the buttons

generated on the right side of the LD2100 home page.

38 LD2100 User Guide 800.518.1519

Page 39

3 Web Interface

Do not attempt to map your facility until your monitoring area is completely assembled - all of

your leak detection equipment is in place, tested, and functional.

You can draw a map yourself, or RLE can create the map from a sketch or mechanical drawing

that you provide. When creating your own map and image file, keep in mind that the image

file must be:

♦ 500kb or less in size.

♦ 4000 x 4000 pixels or less.

♦ A .png, .jpg, or .gif formatted file.

Load A Map

Before you can create the interactive overlay, you need to upload the map image file.

1 In the user interface, go to Configuration>System/Flash Management.

The System Management web page displays.

Figure 3.10

2

If you want the map to be interactive so you can set reference points for ease of leak

Load a Map

location, use the Image Index pull-down to select to upload an image to index 1.

If you want to upload a map that you will use for reference, select index 2.

Note If you upload another image to one of the two index locations where an image is already

present, the image currently in that location is overwritten.

3

Click the Choose File button to locate the file on the computer’s hard disk or on a network

drive.

4 Click the Upload button.

5 If desired, repeat these instructions to upload a second image file to the other index

location.

Return to the Web/Map Settings Configuration page. In the Floor Map #1 Link Text field, type

a title for the map. Do the same for the second image, if you have loaded one.

rletech.com LD2100 User Guide 39

Page 40

3 Web Interface

Delete an Image

If you uploaded a map or other image that you decide not to use, and you aren’t planning on

replacing it with another image, delete the image by going to Configuration>System/Flash

Management and click the button for the index location that contains the image (Image index 1

or 2).

Figure 3.11

Delete an Image

Mark Reference Points on the Map

Now that you have uploaded the map, it’s time to mark reference points on the map that you

can refer to if a leak occurs. These reference points are the overlay mentioned earlier - the

LD2100 places this data over the top of your image, to pinpoint alarms in real-time.

Since the LD2100 never actually edits your map, if you should need to update your map

image, previously designated map points will not need to be reconfigured. As long as you do

not change size of your map, previously mapped coordinates should not need to be adjusted

when you upload a new version of your map.

To mark reference points:

1 In the user interface, go to Configuration>Web/Map Settings.

The Web Configuration page displays.

Figure 3.12

40 LD2100 User Guide 800.518.1519

Web Configuration Page—Map Alarm Coordinates (Graphical) Link

Page 41

3 Web Interface

Clicking on a map’s

reference point

2 Select the Yes radio button for Floor Map #1 Interactive.

3 Click the Map Alarm Coordinates - Graphical link near the bottom of the web page.

An enlarged view of the map displays.

4 In the “Enter a distance” box at the top of the web page, type 0 to set the reference point for

the beginning of the cable.

5 Click on the map to designate the location of the 0 point of the cable. The cursor displays as

cross hairs.

When you click on the map, the distance and the x-y coordinates of the location are stored

in the LD2100’s memory.

6 Enter the next distance to be recorded and click on the map in the corresponding location.

Repeat this step for each reference point you want to add to the map.

Note It is recommended that you enter the cable distance each time the cable changes direction.

If any coordinates need to be adjusted, you can fine tune them through the Map Alarm

7

Coordinates - Text link on the Map Configuration page. Click this link to display all the

mapped coordinates and the distance readings associated with them.

Figure 3.13

rletech.com LD2100 User Guide 41

Map Coordinates—Text View

Page 42

3 Web Interface

Location of

leak displays

as red square

When a leak occurs, its location will be shown on the map.

Figure 3.14

Map with Location of Leak Shown

View an Enlargement of the Map

Maps are available from the home page and can be viewed at any time. Once you have given

the map a title, the title appears on the Home page as an active button below the map image. If

you have uploaded and titled two images, two buttons appear below the main map (the map

loaded into Image index 1). To view an enlargement of an image, click the button for the

image you want to enlarge. The enlarged image displays in a new browser window.

Figure 3.15

42 LD2100 User Guide 800.518.1519

Map (Image) Buttons on Home Page

Page 43

3 Web Interface

3.3.8 Clock

Use this link to adjust the date and time as needed. Click the Submit Changes button to save

all modifications.

Figure 3.16

Option Description

Date Adjust the current date, in mm/dd/yy format.

Time Adjust the current time in hh:mm:ss format.

Day A non-configurable field, the day of the week is generated based on

Table 3.8

Clock Configuration Page

the date.

Clock Configuration Options

rletech.com LD2100 User Guide 43

Page 44

3 Web Interface

3.3.9 NTP (Network Time Protocol)

NTP, or Network Time Protocol, is used to synchronize clocks of computer systems. NTP

synchronizes the time of a computer or device (the LD2100) with another computer or

referenced time source. NTP maintains a high level or accuracy and reliability in time stamped

events.

Figure 3.17

Option Description

NTP Server The IP address or hostname of the NTP server with which your

Update Interval Designate how often you’d like the LD2100 to access and

Select Time Zone Select the time zone in which this particular LD2100 resides.

Daylight Savings

Time

DST Begin Date Set the day DST begins at your location.

NTP Configuration Page

LD2100 will synchronize. Public NTP servers include us.pool.ntp.org

and time.nist.gov

Default setting: blank

synchronize with the NTP server. Enter a 0 to disable this feature.

Default setting: 0 (disabled)

Default setting: Western European (UTC + 0)

Enable or disable Daylight Savings Time, and designate at which

time DST goes into effect in your time zone.

Default setting: Disabled

Default setting: Second Sunday - March

DST End Date Set the day DST ends at your location.

Default setting: First Sunday - November

Table 3.9

44 LD2100 User Guide 800.518.1519

NTP Configuration Options

Page 45

3.3.10 Email-SMTP/DNS

Configure email and SMTP setting through this page.

3 Web Interface

Figure 3.18

Option Description

Access Type Select LAN to send alerts through a local network connection. Select

Options -

Email

Contamination

Alarms

Primary DNS Server Enter the IP address for the primary DNS server, as provided by your

Table 3.10

E-mail Configuration Page

None to disable the email feature.

Default setting: LAN

The LD2100 will send alerts for leak and cable break alarms. Decide

if you’d also like to receive email alerts for contamination alarms. If

so, check this box. If false alarms are often detected on your system,

you may want to disable this function

Default setting: checked (contamination alarms enabled)