Page 1

F200 Quick Start Guide

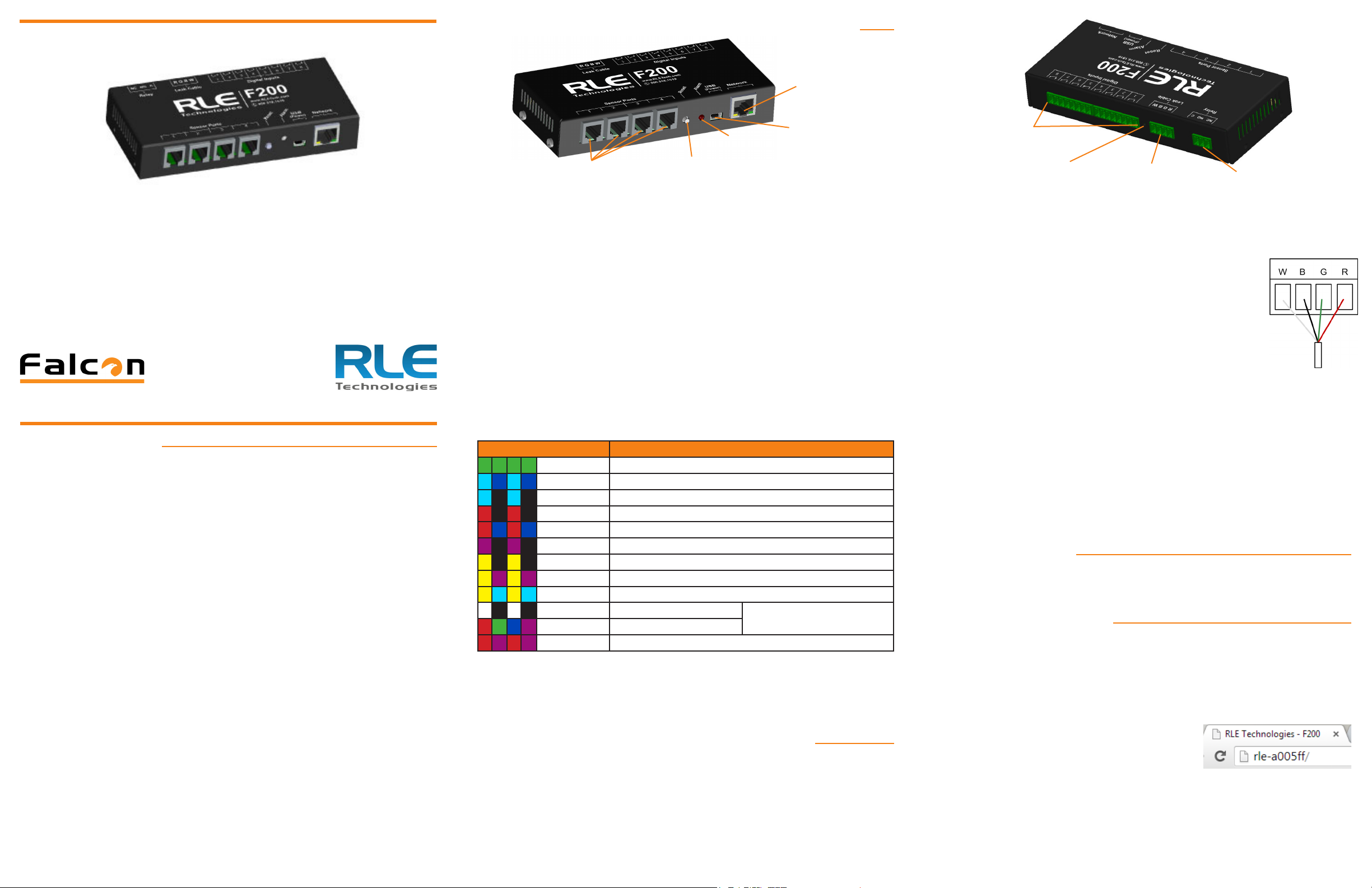

F200: Front Connections, Silence/Reset Button, and LED

Network

Connection

Thank you for purchasing a Falcon F200. This guide describes how to install and

congure your unit.

If you need further assistance, please access the F200 support page on our

web site, email our support staff directly - support@rletech.com, or call us at

800.518.1519.

v2.8

(06/2014)

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and Seahawk™, Falcon™, and Raptor™ are trademarks

of Raymond & Lae Engineering, Inc. The products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability, and

other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

Installation Supplies

Included with the F200

F200 device

Network cable

USB cable; USB mini B to USB A

5V USB wall wart

Available from RLE, sold separately

Temperature sensors

Temperature/humidity sensors

Conductive uid or chemical sensing cable, plus leader cable kit and EOL terminator

1U rack mount kit

Network Communications Information

The F200’s serial number is found on the back of the unit, on a small white sticker

located under the connections for the digital inputs.

• F200 Serial Number________________________________________

Consult your IT administrator and determine the following network settings for your

F200:

• IP Address _______________________________________________

• Subnet Mask _____________________________________________

• Default Gateway __________________________________________

** Wire all connections, sensors, and power to the F200 rst - then access the

web interface to congure the device and designate parameters and notication

methods for your wired sensors, inputs, and relays.

Power

1-Wire Sensor

Connections

Silence/Reset

Button

Status

LED

Connection

1-Wire Sensor Connections

Plug in your temperature and temperature/humidity sensors. They click into place

in the sensor ports on the front of the unit.

Power Connection

The F200 is powered through its mini USB port. Using the included cable, plug the

mini end of the USB cable into the power jack on the F200. Plug the enclosed USB

wall charger into a standard wall outlet and plug the UBS cable into it. The F200

can also be powered by a USB connection on a server or another computer - just be

sure the computer is plugged into a wall outlet, preferably one protected by a UPS.

Network Connection

Plug the network cable into an available network port and then into the network

connection on the F200.

Status LED

There are a variety of alarm and alert patterns and colors programmed for the

F200’s LED. Use the following chart to determine which alarms are active.

Blink Pattern Status Description

Solid Green Normal status - no alarms are present

Lt. Blue/Blue Alarm - Leak detection cable break

Lt. Blue/Off Alarm - A leak has been detected

Red/Off Alarm - Temperature

Red/Blue Alarm - Humidity

Magenta/Off Alarm - Digital input

Yellow/Off No network connection

Yellow/Magenta Debug connection is active

Yellow/Lt. Blue Conguration mode is active

White/Off Unit is booting*

Mixed Firmware update is executing*

Red/Magenta Call RLE - the F200 has an internal error

* Do not access or congure the

F200 while these alerts are active.

Alarm Silence/Reset Button

If the audible alarm is active, push this button to silence it. Use the web interface

or LED to determine the alarm condition. Advanced functions are also assigned to

this button - consult the support section of RLE’s website for more information.

F200: Rear Connections and Conguration Button

Digital Inputs

The F200 can monitor eight digital inputs, each of which connects to the F200

through a 2-wire connection on the back of the unit. When you’re looking at the

back of the unit, note that input 1 is on the right side of the terminal blocks and

input 8 is on the left side of the terminal blocks.

To connect your digital inputs to the F200, loosen the screws on the appropriate

slots on the terminal block connector and insert the two wires from your digital

input - one in each slot. Tighten the screws to secure the connections.

Digital Input

Connections

Conguration

Button

Leak Detection

Leader Cable

Connection

Relay

Output

Leak Detection Sensing Cable

Since leak detection sensing cable cannot connect directly to a controller, leader

cable is used to connect leak detection cable to the F200.

1. Remove the 4-pin terminal block connector from the back of the unit.

2. Insert the four stripped wires of the leader cable into the

appropriate slots in the terminal block connector - from left to

right: white, black, green, and red. Tighten the screws on the

terminal block connector to secure the leader cable. Plug the

connector - with the wires in the correct order - into the leak

detection leader cable connection.

3. Unscrew the EOL from the end of the leader cable.

4. Attach the length of sensing cable to the leader cable.

5. Route the sensing cable according to your cable layout diagram.

6. Secure the EOL to the unoccupied end of the sensing cable.

Relay Output

The F200 has one relay output - use this to control an external device in the event

of an alarm condition. Loosen the screws on the appropriate slots on the terminal

block connector and insert the wires for your relay output into the correct slots NC-NO-C. Tighten the screws to secure the connections.

Conguration Button

The conguration button is located on the back of the unit and is used for advanced

troubleshooting. Consult the support section of RLE’s website for more information.

Mount the Controller

Once all connections have been wired to the F200, mount the device in an

appropriate location. RLE recommends a secure mounting option, through either

the keyhole cutouts on the enclosure or through the optional 1U rack mount kit.

Establish Communications

Through DHCP, the F200 can be set up to communicate on your network.

**Please NOTE: If DHCP is not available on your network, the F200 will default to

an IP address of 10.0.0.188. If this is the case at your facility, skip steps 1-3, enter

the default IP address into your web browser address bar, and proceed to step 4.

1. Plug the enclosed network cable into an available network port, and then into

the Network connection on the F200. As soon as you plug the network cable

into the powered F200, DHCP assigns the F200 an IP address.

2. Using a computer running on the same subnet

as the F200, open a web browser. In the web

browser’s address bar, type rle-serialnumber/

where serial number is the actual serial number

of your F200 - for example, rle-a005ff/. Be sure to place the backslash

after the serial number. This will ensure the browser executes a DNS

lookup instead of a web search.

3. Press enter. The browser will nd the newly installed F200 and allow you to

access the F200’s web interface.

4. You may either leave the IP address as it is or change it to an IP address

provided by your IT department. If you’d like to change the IP address, click

Page 2

the Setup tab and then click on the Network link. Type the desired address into

the IP address eld and click the Save Settings button.

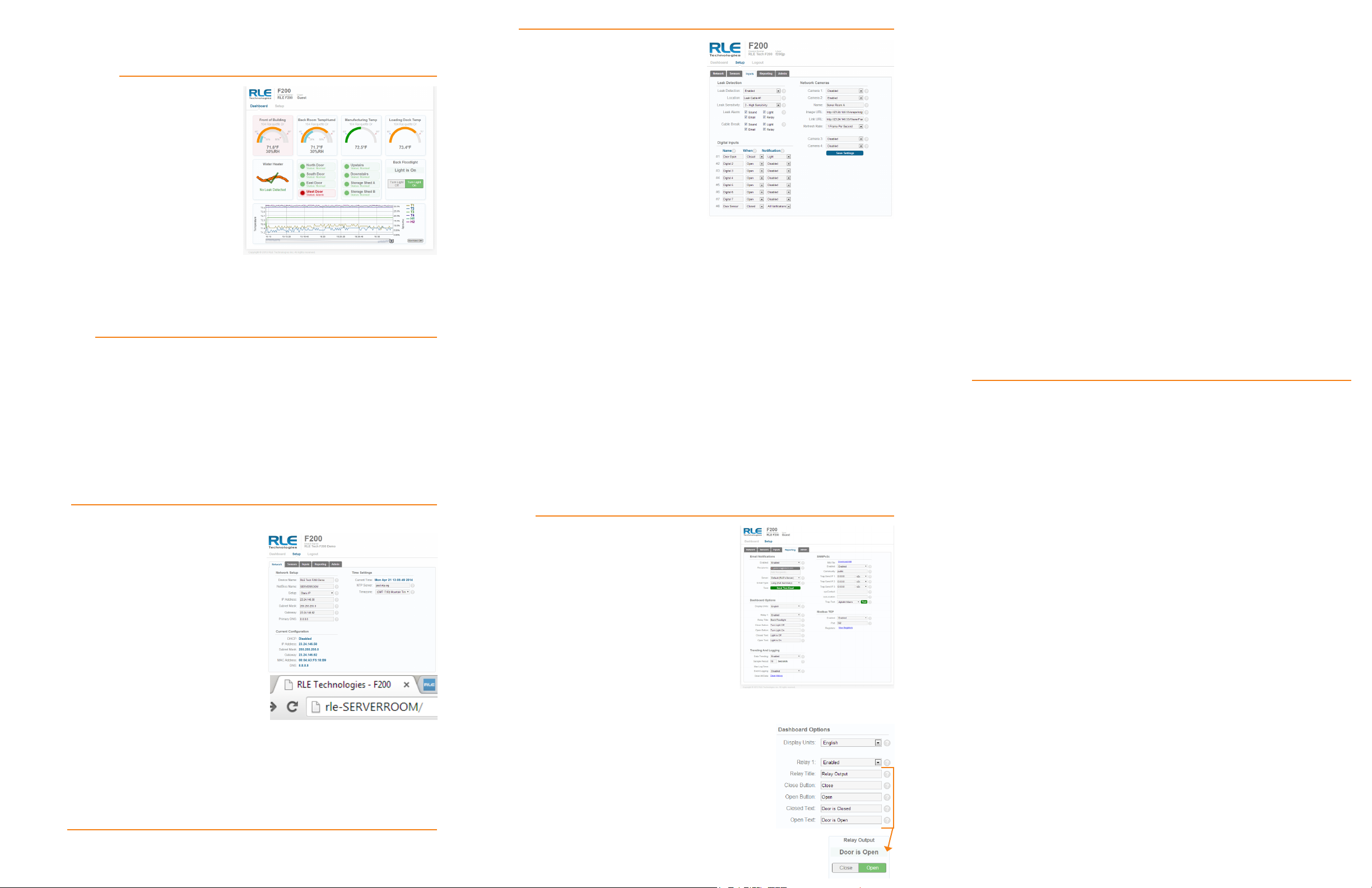

Web Interface

Dashboard

The Dashboard is your main point of contact

for the F200. Accessible from any web

browser or mobile device, the Dashboard

display includes the status of all sensors,

digital inputs, and sensing cables connected

to and monitored by the F200.

As you connect sensors to the F200, their

information appears on the Dashboard.

If you have leak detection sensing cable

connected to the F200, you will need to use

the Inputs tab on the Setup menu to enable

the leak detection monitoring. Then it too will appear on the Dashboard. Other

items that can be congured to display on the Dashboard include digital inputs, a

button to control the relay output, and displays from IP web cameras. Congure

these items on the Sensors, Inputs, and Reporting tabs of the web interface.

Inputs

Leak Detection

The F200 monitors up to 200 feet of leak

detection cable, congured in a single

zone. If you have leak detection

cable connected to the F200 you will

need to use this menu to enable the

leak detection monitoring. Once leak

detection is enabled, the leak detection cable

icon will appear on the F200’s Dashboard.

Use the inputs tab to set the sensitivity for

the cable - if you select high sensitivity,

the F200 will alarm when it contacts a

smaller amount of water. If you select low

sensitivity, the F200 will need to come in contact with a larger amount of water

before it issues an alarm. Then establish notication parameters for a detected leak

or cable break and save your changes.

Digital Inputs

Use the inputs tab to name your digital inputs and to congure alarm and

notication parameters (email, audible, enable relay output, etc.) for each input.

Trending and Logging

Once trending is enabled, a graph will appear on the Dashboard. To examine the

points on the graph in greater detail, use your mouse to highlight a section of the

graph and zoom into it, or use the slider bars beneath the graph to adjust the range

of the graph. Double click anywhere on the graph to return to the default view.

The sample period designates the amount of time that passes between logged data

points on the trending graph, and can be set from one second to one day. The

F200 records up to 86,400 points - a shorter sample period records more closely

grouped points for a shorter overall period of time, while a larger sample period

charts data points spaced farther apart, but over a greater overall period of time.

The trending log is downloadable as a CSV le.

Enabling event logging generates a table on the Dashboard that logs all major

alarm events with a date and time stamp, as well as the return to normal date and

time for each event.

SNMPv2 and Modbus TCP

The F200 can be congured to communicate via SNMPv2 and Modbus TCP. If you

wish to use this functionality, congure the settings on this page. Note that links in

these headings allow you to download the SNMPv2 MIB le and to view the current

readings of all the F200’s Modbus TCP registers.

Setup Menus

Use the menus in the Setup tab to congure your F200. When you begin typing

changes into any of the elds, they will turn either green to indicate your changes

are acceptable, or red, to indicate your changes cannot be submitted. If a eld

turns red, you’ve likely typed more characters than the eld can accept, or you’ve

entered a character that can’t be used in that eld. Once you delete the excess or

offending character, the eld will turn green again.

When you edit a section, a Save Settings button appears at the bottom of that

section. Click this button to save your changes. Changes will neither be saved

nor implemented until you click the Save Settings button.

Network

Use the network tab for settings including the device name, NetBios name, IP

address, primary DNS, and NTP server.

The NetBios name is used to identify resources

on a local network. The default NetBios name

is the F200’s serial number. The F200’s NetBios

name can also be used - only on a local network

- to quickly access the F200’s web interface. Edit

the NetBios name as you’d like - it must be 15

characters or less, in all capital letters. Save your

changes. Then, in the web browser’s address

bar, type rle-netbiosname/ and press enter - but

replace the netbiosname text with the actual

NetBios name of your F200. For example, the

NetBios name of the F200 is SERVERROOM, type

rle-SERVERROOM/ in the address bar. Place a

backslash after the NetBios name. This ensures the browser executes a DNS

lookup instead of a web search. Press enter to access the web interface.

You can choose to use DHCP to obtain an IP address, or to assign the F200 a static

IP. If you choose static IP, ll in the blanks with information provided by your

network administrator and remember to save your settings.

Sensors

Use the sensors tab to congure information, alarm parameters, and alarm

notication (email, audible, activate relay output, etc.) for each 1-wire sensor that is

currently connected to the F200.

Keep in mind the “When” box will tell the F200 when to send an alarm. For

instance, if your digital input is normally open, the F200 should generate an alarm

when that contact is closed. So for that input, you’d select “Closed” in the When

drop down, and then decide what notication action the F200 should take.

Network Cameras

Want to view your remote facility any time, from anywhere? Use a web camera.

Once you have one installed and running in your facility, you can link to it from the

F200. Enable the webcam capabilities and use the elds to name the camera and

direct the F200 to its streaming image. You can also enter a URL that will take

users directly to the webcam. The F200 can provide views to four cameras. Once

each camera is enabled, it will appear on the F200’s Dashboard.

Reporting

Email Notications

Use this feature to send email alerts when the F200

goes into alarm. Enable email notications and

enter the email addresses in the Recipients box.

Recipients will receive all email alerts generated by

the F200.

Once you save any changes made within this

section, a test email button appears. Send a test

email to ensure your notications are working

correctly, and that your spam lter hasn’t blocked

the incoming email notications.

Dashboard Options

Use the Reporting tab to designate English (Fahrenheit) or metric (Celsius) units.

Relay Output

When you enable the relay output, a button to control

the relay output appears on the Dashboard. The button

allows approved users to open and close the relay output

from the F200’s Dashboard. Use the options to congure

the button’s labels. Any alarm condition that is

congured to change the state of the relay output

will override the manual button control of the

relay. If an alarm is active, you cannot turn off the alarm with

the manual relay control button.

A separate document, available in the Support section of RLE’s website, further

details the F200’s Modbus capabilities.

Admin

Firmware Updates

When you click the Check for Updates button, the F200 will check with RLE to see

if it needs a rmware update. If it does, it will download and install the rmware

on its own, and then reboot itself once the rmware is installed. Once the reboot

is complete, the F200 will be ready to resume its operations. Please be sure not to

access or congure the F200 while it’s downloading and installing new rmware.

System Controls

The reboot button allows users to remotely reboot the F200. Use the Identify

button to make the unit’s LED ash and its audible alarm to sound. This helps

users connect a web interface with an actual physical unit.

Users

Two types of users can be congured on the F200. Up to eight usernames can

be congured in each of the two categories. Each username can be used by only

one user at a time. It is very important for each user to have their own

username:

• Admin User - Admin Users can view and edit the F200’s Setup screens.

• Normal User - Normal (Read Only) Users can only view the F200’s Dashboard.

There are three login congurations:

• Never - Users are never required to log in. Anyone can view the Dashboard

and Setup screens, and anyone can change the F200’s conguration through

the Setup screens.

• To Change Settings - A login is NOT required to view the Dashboard. Only

users logged in as Admin Users can view and edit the Setup screens.

• Always - All users are required to log in. Normal Users can only view the

Dashboard. Admin Users can also view and edit Setup screens.

A relay control checkbox is also located on this page. If you check this checkbox,

only Admin users will be able to operate the Relay button on the Dashboard.

Logout

If you’re logged in to the F200 and have nished your conguration work, click this

link. It will log you out of the device and return the view via your workstation back

to its read-only state.

Loading...

Loading...