Page 1

Cable Construction Guide

v 1.2

(09/2014)

© Raymond & Lae Engineering, Inc. 2011. All r ights reserv ed. RLE® is a registered trademark and Seahawk™, Falcon™, an d

Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The products sold by Raymond & Lae Engineering, Inc. are

subject to the limited warranty, limited liability, and other terms and conditions of sale set forth at rletech.com.

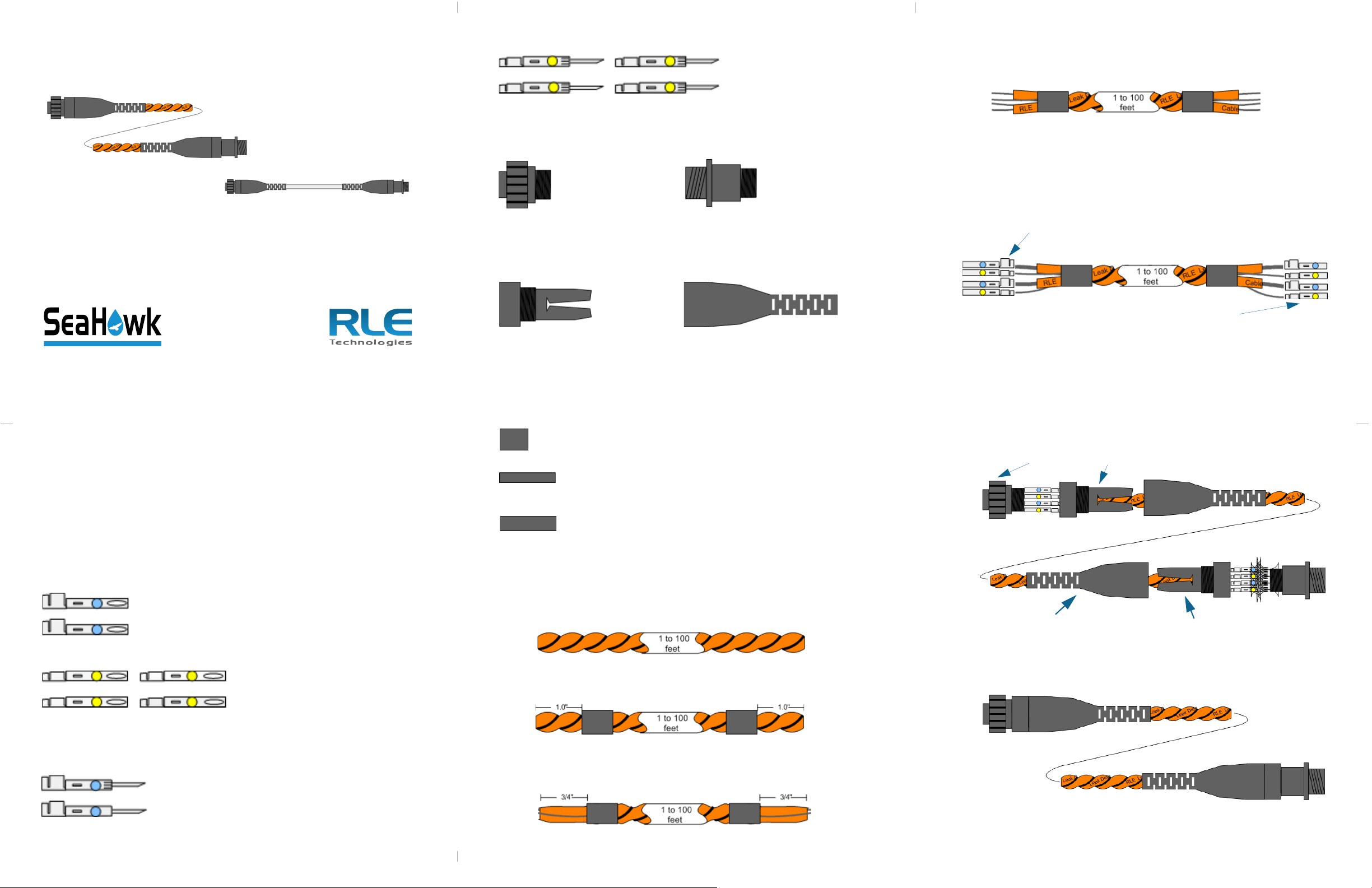

66101-2, RLE Part #3257 (Blue Dot)

(2 per sensing cable) Sockets

66105-2 RLE Part #3254 (Blue Dot)

(2 per sensing cable, 4 per non-sensing cable) Sockets

66099-2, RLE Part #3256 (Blue Dot)

(2 per sensing cable) Pins

206060-1, RLE Part #1298

Plug

206153-1, RLE Part #1294

Receptacle

207490-1, RLE Part #2410

Grip (2 per cable)

207489-1, RLE Part #2409

Boot (2 per cable)

Shrink Tubing

3/8 x 1/2 (2 per sensing cable)

RLE Part #1151

3/16 x 1 (2 per non-sensing cable),

RLE Part #2505

1/4 x 1 (2 per non-sensing cable),

RLE Part #2550

Part #1295 (2) small black wires - Crimp

Part #1300 (2) large orange wires - Crimp

Part #1296 (2) small black wires - Crimp

Part #1299 (2) large orange wires - Crimp

Part #1298 Plug

Part #2409 Grip

Part #2410 Boot

Part #2409 Grip

Thank you for purchasing the SeaHawk sensing and non-sensing cable construction

kit (part number CCK-LD). This guide describes how to use this kit to construct cables

in the length required for your application.

If you need further assistance, contact RLE Technologies at support@rletech.com or

call us at 800.518.1519,

4

Split the orange carrier as far as the shrink tube and strip them 3/8”.

Note: If you are not going to put the pins or sockets on at this time, leave the

strip plug on the wires.

5

Crimp the connector sockets (RLE Part #1295 & 1300) on one side (slide

back the black braiding to expose approximately 1/8” of the silver wire

before crimping). Crimp the connector pins (RLE Part #1296 & 1299) on the

opposite side (slide back the black braiding to expose approximately 1/8” of

the silver wire before crimping).

Supplies for Installation

Sold Separately

♦ SeaHawk Leak Detection Sensing Cable, LD-SC-xx

♦ SeaHawk Non-Sensing Cable, LD-NSC-xx

♦ Cable Connector Kit, CCK-LD

♦ Pin Crimp Tool, SCPC

♦ Cable Stripper, SCCS

Contents of This Kit

Sensing Cable Assembly

(Orange Cable, RLE #1227)

1

Spool the cable to the desired length (1’ minimum to 100’ maximum).

2

Slide the 3/8 x 1/2 inch (Part# 1151) shrink tube over each end of the

sensing cable. Shrink it with a heat source 1 inch from each end.

6

Slide the grips (2) (Part #2409) and boots (2) (Part #2410) over both ends

as shown below. Snap the sockets into the plug (Part #1298) and the pins

into the receptacle (Part #1294) as follows: Orange wire with writing in pin 1,

Orange wire with-out writing in pin 4, The black braided wires as they fall

into pin 2 & 3 respectively.

7

Screw the grips onto the plug and receptacle, and tighten by hand. Screw

the boots onto the grips, and tighten by hand.

3

Using dikes or needle nose pliers, untwist the orange carrier above the

shrink tube. Trim both ends to 3/4”.

Page 2

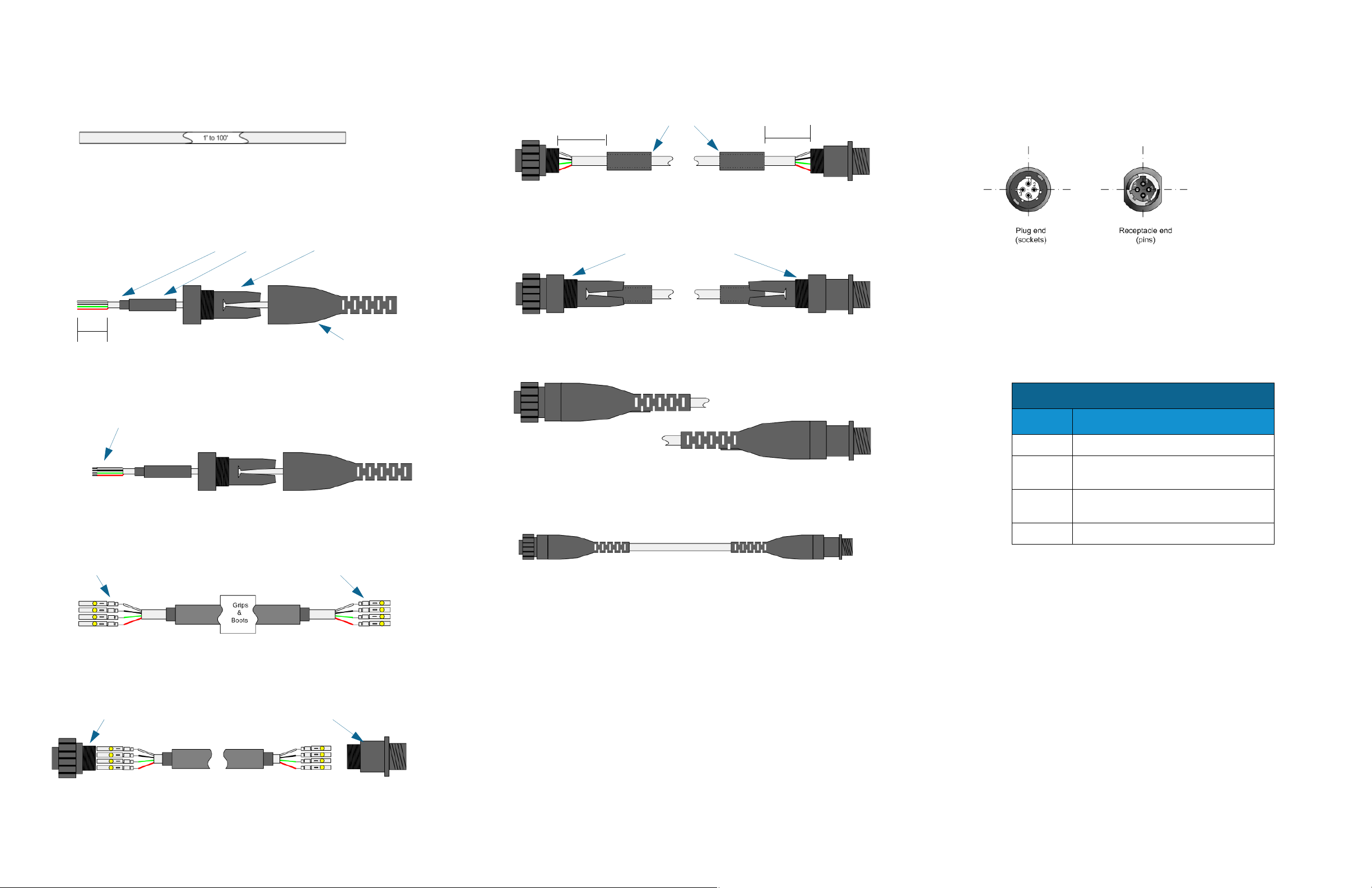

Non-Sensing Cable Assembly

Shrink Tube Part #2505 & 2550

Grip Part #2409

Boot Part #2410

0.60”

Strip 0.10” (8 places, 4 per side)

Part #1295 Socket (4)

Part #1295 Pin (4)

Part #1298 Plug

Part #1294 Receptacle

Shrink 1.00” from plug

and receptacle

1.00”

1.00”

Screw grips onto plug & receptacle

(White 4-conductor, plenum-rated cable, RLE #1657)

1

Spool the cable to the desired length (1' minimum to 100' maximum

recommended).

2

Strip the white jacket off of both ends (0.60") to expose the wires inside.

Place a boot (Part #2410), a grip (Part #2409) and the shrink tubing (Part

#2428 & 2550) over each end of the cable.

Note: Install in the previously stated order.

6

Shrink the heat shrink tubes with a heat source 1 inch from the plug and

receptacle as shown below.

Note: Place the smaller shrink tube inside the larger one and shrink together.

7

Screw the grips onto the plug and receptacle as shown below.

8

Screw the boots onto the grips as shown below.

Testing Cable Once It’s Complete

All the sensing cables produced at RLE are tested for quality and continuity

before they are shipped. When you create your own cables, you should test them

as well.

Pin and socket mapping for the cable connectors is as follows:

To test your finished cable, you will need an ohmmeter with a pointed probe tip

on one lead and a miniclip or microclip on the other lead.

1

Insert the probe tip in the connector socket.

2

Attach the miniclip to the corresponding connector pin. If the cable has

been constructed properly, the ohmmeter will register values according to

the table below:

3

Strip the wires 0. 1 0” on bo th sid e s.

4

Crimp the connector sockets (Part #1295) on one side. Crimp the connector

pins (Part #1296) on the opposite side.

5

Snap the sockets into the plug (Part #1298). Snap the pins into the

receptacle (Part #1294). White: pin 1; Black: pin 2; Green: pin 3; Red: pin 4.

9

The finished cable should look like the one below.

Cable Pin Resistance Values

Pin Resistance +/- 10%

1 Less than 0.1 ohm per foot

2 2.8 ohms per foot (orange cable)

4.0 ohms per foot (purple cable)

3 2.8 ohms per foot (orange cable)

4.0 ohms per foot (purple cable)

4 Less than 0.1 ohm per foot

Loading...

Loading...