R

R

4

.

RKC INSTRUMENT INC.

®

Temperature Controller

Z100/

Z

00

RS100/RS400

Instruction Manual

IMR02Y03-E1

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of

electricity, process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for explanation

purpose.

RKC is not responsible for any damage or injury that is caused as a result of using this

instrument, instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments

made by imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC

makes no warranty expressed or implied, with respect to the accuracy of the information.

The information in this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without

prior written approval from RKC.

Various symbols are used on the equipment, they have the following meaning.

: Alternating current

: Reinforced insulation

: Safety precaution

This symbol is used where the instruction manual needs to be consulted for the safety of

operator and equipment. Carefully read the cautions in this manual before using the

instrument.

Windows is a trademark of Microsoft Corporation.

Modbus is a registered trademark of Schneider Electric.

Company names and product names used in this manual are the trademarks or registered trademarks

of the respective companies.

All Rights Reserved, Copyright 2015, RKC INSTRUMENT INC.

Safety Precautions

Pictorial Symbols (safety symbols)

Various pictorial symbols are used in this manual to ensure safe use of the product, to protect you and

other people from harm, and to prevent damage to property. The symbols are described below.

Be sure you thoroughly understand the meaning of the symbols before reading this manual.

: This mark indicates precautions that must

be taken if there is danger of electric shock,

fire, etc., which could result in loss of life or

injury.

This mark indicates that if these precautions

:

and operating procedures are not taken,

damage to the instrument may result.

: This mark indicates that all precautions

should be taken for safe usage.

To prevent injury to persons, damage to the instrument and equipment, a

suitable external protection device shall be required.

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to the instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to the instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction may

occur and warranty is void under these conditions.

IMR02Y03-E1

i-1

This product is intended for use with industrial machines, test and measuring equipment.

(It is not designed for use with medical equipment and nuclear energy plant.)

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take additional measures.

This instrument is protected from electric shock by reinforced insulation. Provide reinforced

insulation between the wire for the input signal and the wires for instrument power supply,

source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock to operating personnel.

All precautions described in this manual should be taken to avoid damage to the instrument

or equipment.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

All wiring must be in accordance with local codes and regulations.

To prevent instrument damage as a result of failure, protect the power line and the

input/output lines from high currents with a suitable overcurrent protection device with

adequate breaking capacity such as a fuse, circuit breaker, etc.

A malfunction in this product may occasionally make control operations impossible or

prevent alarm outputs, resulting in a possible hazard. Take appropriate measures in the end

use to prevent hazards in the event of malfunction.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dissipation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to the instrument display, do not rub with an abrasive material or push the

front panel with a hard object.

When disposing of each part used for this instrument, always follows the procedure for

disposing of industrial wastes stipulated by the respective local community.

For Proper Disposal

i-2

IMR02Y03-E1

Symbols

Pictorial Symbols (safety symbols)

: This mark indicates important information on installation,

handling and operating procedures.

: This mark indicates supplemental information on installation,

handling and operating procedures.

: This mark indicates where additional information may be located.

Character Symbols

0 1 2 3 4 5 6 7 8 9

Minus Period

0 1 2 3 4 5 6 7 8 9 - .

A B (b) C c D (d) E F G H I J K

A b C c d E F G H I J K

L M N (n) O (o) P Q (q) R (r) S T t U u

L M n o P q r S T t U u

V W X Y Z

Degree

/

Prime

*

(Asterisk)

V W X Y Z @

Dimly lit

8

Highlighted

8

Flashing

8

Other Symbols

EX

OP

IMR02Y03-E1

: Parameters operatable during the “Expanded display mode”

: Parameters operatable when optional functions are supplied

For the display mode, refer to 9. DISPLAY FUNCTION (P. 9-1).

i-3

NOTICE

Safety Precautions ................................................................................................................ i-1

Pictorial Symbols (safety symbols) ............................................................................... i-1

WARNING ........................................................................................................................ i-1

CAUTION .......................................................................................................................... i-2

For Proper Disposal .............................................................................................................. i-2

Symbols ................................................................................................................................. i-3

Pictorial Symbols (safety symbols) ............................................................................... i-3

Character Symbols ....................................................................................................... i-3

Other Symbols .............................................................................................................. i-3

Contents

1. OUTLINE ............................................................................ 1-1

Page

The chapter 1 describes features, package contents, model code, etc.

1.1 Features ....................................................................................................... 1-2

1.2 Checking the Product ................................................................................... 1-3

1.3 Model Code .................................................................................................. 1-4

Suffix code ................................................................................................................ 1-4

Quick start code 2 (Initial setting code) ..................................................................... 1-7

1.4 Parts Description .......................................................................................... 1-8

Front panel view ....................................................................................................... 1-8

Bottom view .............................................................................................................. 1-9

1.5 Input/Output and Function Blocks ............................................................... 1-10

1.6 Handling Procedure to Operation ............................................................... 1-11

2. MOUNTING ........................................................................ 2-1

The chapter 2 describes mounting cautions, dimensions and mounting procedures.

2.1 Mounting Cautions ........................................................................................ 2-2

2.2 Dimensions ................................................................................................... 2-3

2.3 Procedures of Mounting and Removing ....................................................... 2-4

Mounting position of mounting bracket ..................................................................... 2-4

Mounting procedures (Standard type) ...................................................................... 2-5

Mounting procedures (Waterproof/Dustproof type) [Only RZ100/400]...................... 2-6

Removal procedures ................................................................................................ 2-7

i-4

IMR02Y03-E1

3. WIRING .............................................................................. 3-1

The chapter 3 describes wiring cautions, wiring layout and wiring of terminals.

3.1 Wiring Cautions ............................................................................................ 3-2

3.2 Terminal Layout ............................................................................................ 3-5

RZ100/RS100 ........................................................................................................... 3-5

RZ400/RS400 ........................................................................................................... 3-5

Isolations of input and output .................................................................................... 3-6

3.3 Wiring of Each Terminal ............................................................................... 3-7

Power supply ............................................................................................................ 3-7

Measured input (Thermocouple/RTD) ...................................................................... 3-7

Output 1 (OUT1)/Output 2 (OUT2)/Output 3 (OUT3)................................................ 3-8

Current transformer (CT) input (optional) ............................................................... 3-10

Communication (optional) ....................................................................................... 3-10

Page

3.4 Handling of the Terminal Cover (Optional) ................................................. 3-11

Mounting procedures .............................................................................................. 3-11

Removing procedures ............................................................................................ 3-12

4. BASIC OPERATION AND PARAMETER LIST ................ 4-1

The chapter 4 describes basic operations, different types of modes, switching between modes, and

changing/storing the set values.

4.1 Mode Types and Switching........................................................................... 4-2

4.1.1 Switching between modes ...................................................................................... 4-2

4.1.2 Input type and input range display .......................................................................... 4-3

4.2 Parameter Types and Switching ................................................................... 4-4

4.2.1 Scrolling through parameters .................................................................................. 4-4

4.2.2 Parameter list .......................................................................................................... 4-8

Monitor display mode ............................................................................................... 4-8

SV setting mode ....................................................................................................... 4-8

Communication setting mode ................................................................................... 4-9

Parameter setting mode ......................................................................................... 4-10

Initial setting mode ................................................................................................. 4-12

4.3 Changing Set Value .................................................................................... 4-18

4.4 Protecting Setting Data ............................................................................... 4-19

IMR02Y03-E1

i-5

5. OPERATION ...................................................................... 5-1

The chapter 5 describes Operating precautions, Setup procedures and Parameter setting that are

required before operation.

5.1 Operating Precautions .................................................................................. 5-2

5.2 Setup Procedures ......................................................................................... 5-4

5.3 Initial Setup before Operation ....................................................................... 5-5

5.3.1 Initial setting of setup example 1 (Setting parameters related to the alarm) ............ 5-6

5.3.2 Initial setting of setup example 2

(Setting parameters related to the input, control, output and alarm) ....................... 5-8

5.4 Setting the Control Set Value [Set value (SV)] ........................................... 5-12

5.5 Setting the Alarm Set Value ........................................................................ 5-13

5.6 Tuning the PID Parameters (Execution of AT) ............................................ 5-14

Page

6. INPUT FUNCTION ............................................................. 6-1

The chapter 6 describes input related functions, setting contents and setting procedure based on

the key words related to inputs

.

6.1 Changing Input ............................................................................................. 6-2

6.2 Correcting Input ............................................................................................ 6-7

6.3 Removing Input Noise .................................................................................. 6-8

6.4 Changing Error Handling at Input Error ...................................................... 6-10

7. OUTPUT FUNCTION ......................................................... 7-1

The chapter 7 describes output related functions, setting contents and setting procedure based on

the key words related to outputs.

7.1 Changing Output Assignment ....................................................................... 7-2

7.2 Limiting Output ............................................................................................. 7-6

7.3 Changing Proportional Cycle Time ............................................................... 7-8

7.4 Changing Alarm Output (Energize/De-energize) ........................................ 7-12

7.5 Monitoring Manipulated Output Value ........................................................ 7-15

8. SETTING AND KEY OPERATION .................................... 8-1

The chapter 8 describes display related functions, setting contents and setting procedure based on

the keywords related to setting and key operation.

8.1 Limiting the Setting Range of Set Value (SV) ............................................... 8-2

8.2 Continuing the Control when Entering the Initial Setting Mode ..................... 8-5

8.3 Restricting Key Operation ............................................................................. 8-7

i-6

IMR02Y03-E1

9. DISPLAY FUNCTION ........................................................ 9-1

The chapter 9 describes display related functions, setting contents and setting procedure based on

the key words related to Display.

9.1 Releasing the Display Restriction of the Parameters .................................... 9-2

9.2 Changing the Display Position of STOP during the Control Stop ................. 9-4

9.3 Hiding the Display of the Set Value (SV) ...................................................... 9-6

10. ALARM FUNCTION ....................................................... 10-1

The chapter 10 describes alarm related functions, setting contents and setting procedure based on

the key words related to alarms.

Page

10.1 Using Alarm Function .............................................................................. 10-2

10.1.1 Setting procedure for alarm function ................................................................... 10-2

Setting example: Set the Alarm 1 (Model code: RZ100-MNM*NNN/N) ................ 10-3

10.1.2 Changing alarm type ........................................................................................... 10-8

10.1.3 Setting a differential gap in alarm ac tion ........................................................... 10-14

10.1.4 Preventing alarm from turning on due to a transient abnormal input ................ 10-16

10.1.5 Keeping the alarm state (Interlock function) ...................................................... 10-19

10.1.6 Releasing the alarm state (Interlock release) .................................................... 10-21

10.2 Using Control Loop Break Alarm (LBA) ................................................. 10-23

Setting example: Setting Control loop break alarm (LBA) on Alarm 2

(Model code: RZ100-MNM*NNN/N) ................................................................... 10-24

10.3 Using Heater Break Alarm (HBA) (Optional) .......................................... 10-32

10.3.1 Setting procedure for Heater break al arm (HBA) .............................................. 10-32

Setting example: Set the Heater break alarm 1 (HBA1)

(Model code: RZ100-MNM*TNN/N) ................................................................... 10-33

10.3.2 Setting the heater break alarm (HBA) set value ................................................ 10-38

10.3.3 Changing the current trans former (CT) type ..................................................... 10-40

10.3.4 Preventing Heater break alarm (HBA) from turning on due to

a transient abnormal input ................................................................................ 10-42

10.3.5 Keeping the Heater br eak alarm (HBA) state (Interlock function) ..................... 10-44

10.3.6 Releasing Heater break alarm (HBA) state (Interlock release) ......................... 10-45

10.4 Keeping the Alarm State in STOP Mode ............................................... 10-46

10.5 Checking Alarm ON State ...................................................................... 10-48

IMR02Y03-E1

i-7

11. CONTROL FUNCTION .................................................. 11-1

The chapter 11 describes control related functions, setting contents and setting proce dure based on

the key words related to controls.

11.1 Running/Stopping control (RUN/STOP transfer) ..................................... 11-2

11.2 Changing Control Action .......................................................................... 11-4

11.3 Setting PID Values Automa tically (Autotun i ng) ....................................... 11-8

11.4 Setting PID Values Automatically (Startup tuning) ................................ 11-10

11.5 Setting PID Values Manually .................................................................. 11-14

11.6 Controlling with ON/OFF Action ............................................................. 11-19

11.7 Controlling with Heat/Cool Action .......................................................... 11-24

11.8 Increasing Control Response/Suppressing Overshoot (Fine tuning) ..... 11-29

Page

12. COMMUNICATION FUNCTION (OPTIONAL) .............. 12-1

The chapter 12 describes Host communication including connection, setting, protocol and

communication data.

12.1 Outline ..................................................................................................... 12-2

12.2 Connections ............................................................................................. 12-4

12.2.1 Wiring for host communication ......................................................................... 12-4

12.2.2

12.3 Setting ..................................................................................................... 12-8

12.3.1 Description of each parameter ............................................................................ 12-8

12.3.2 Setting procedure................................................................................................ 12-9

12.3.3 Communication requirements ........................................................................... 12-10

12.4 RKC Communication Protocol ............................................................... 12-12

12.4.1 Polling ............................................................................................................... 12-12

12.4.2 Selecting ........................................................................................................... 12-18

12.5 Modbus Protocol .................................................................................... 12-22

12.5.1 Message format ................................................................................................ 12-22

12.5.2 Function code ................................................................................................... 12-23

12.5.3 Communication mode ....................................................................................... 12-23

12.5.4 Slave responses ............................................................................................... 12-24

12.5.5 Calculating CRC-16 .......................................................................................... 12-25

12.5.6 Register read and write ..................................................................................... 12-28

12.5.7 Caution for handling communication data ......................................................... 12-32

Connections for loader communication (Only RZ100/400) .............................. 12-7

i-8

12.6 Communication Data List ....................................................................... 12-33

12.6.1 Reference to communication data list ............................................................... 12-33

12.6.2 Communication data [RKC communication/Modbus] ........................................ 12-34

IMR02Y03-E1

13. TROUBLESHOOTING ................................................... 13-1

The chapter 13 describes Error displays and countermeasures for errors.

13.1 Error Displays .......................................................................................... 13-2

Input error displays ................................................................................................. 13-2

Self-diagnostic error ............................................................................................... 13-3

13.2 Solutions for Problems ............................................................................. 13-4

Displays .................................................................................................................. 13-5

Control related errors ............................................................................................. 13-6

Operation related errors ......................................................................................... 13-8

Alarm related errors ................................................................................................ 13-8

Control loop break alarm (LBA) related errors ........................................................ 13-9

Heater break alarm (HBA) related errors ................................................................ 13-9

Communication related errors .............................................................................. 13-10

Page

13.3 Verifying Instrument Information ............................................................ 13-12

How to display the information ............................................................................. 13-12

How to check ........................................................................................................ 13-13

14. SPECIFICATIONS ......................................................... 14-1

A. APPENDIX........................................................................ A-1

A.1 Parameters to be Initialized/Changed at the time of changing set values .. A-2

A.1.1 Data to be initialized .............................................................................................. A-2

A.1.2 Data to be automatically converted ....................................................................... A-5

A.2 Replacing the Waterproof/Dustproof Gasket (Option of RZ100/400) ......... A-7

A.3 Current Transformer (CT) Dimensions (Optional) .................................... A-10

A.4 Information about RoHS six hazardous and restricted substances .......... A-11

INDEX [Alphabetical order] ................................................ B-1

INDEX [Character order] ..................................................... B-5

IMR02Y03-E1

i-9

MEMO

IMR02Y03-E1

i-10

OUTLINE

This chapter describes features, package contents, model code, etc.

1.1 Features ........................................................................................... 1-2

1.2 Checking the Product ....................................................................... 1-3

1.3 Model Code ...................................................................................... 1-4

1.4 Parts Description .............................................................................. 1-8

1.5 Input/Output and Function Blocks .................................................. 1-10

1.6 Handling Procedure to Operation ................................................... 1-11

IMR02Y03-E1 1-1

1. OUTLINE

1.1 Features

This high performance digital controller has the following features:

Panel space saving: 60 mm depth (RZ400 and RS400), 63 mm (RZ100 and RS100)

Sampling cycle 0.25 seconds

Incorporates Autotuning (AT) for easy setting of PID values

Automatically calculates the PID values to provide fast stabilization.

“Fine tuning” that changes responsiveness

A new 6 level Fine tuning allows the operator to control response from fast to slow by changing th e Fine tuning setting

(3 to 3) while the PID constant remains unchanged.

Startup tuning eliminates autotuning time

Conventional autotuning time is eliminated by startup tuning which calcu lates optimum PID values immediately upon

startup.

Freely assignable outputs

This instrument can incorporate up to three outputs. Each output port can be freely configured for control outputs

(heating and cooling outputs) and alarm outputs (including heater break alarm outputs).

Easy parameter setup via USB loader port (only RZ100/400)

A user can easily save parameter settings to a PC and copy parameters to other controllers with the USB port, a

COM-K2 converter, and dedicated PROTEM2 software for the RZ100/400.

(Loader communication is available only while RZ100/400 are powered.)

Download the software from the official RKC website:

http://www.rkcinst.com

IP66 waterproof and dustproof protection for severe environments (option of RZ100/400)

Waterproof and dustproof construction (IP66) applies to the front part of the instrument when properly installed on the

panel.

1-2 IMR02Y03-E1

1.2 Checking the Product

Before using this product, check each of the following:

Model code

Check that there are no scratches or breakage in external appearance (case, front panel, or terminal, etc.)

Check that all of the items delivered are complete. (Refer to below)

RZ100/400

Accessories Q’TY Remarks

Instrument 1

Mounting bracket (with screw) 2

RZ100/RZ400 Instruction Manual

(IMR02Y02-E)

1 Enclosed with RZ100/400 (for English)

RS100/400

1. OUTLINE

Accessories Q’TY Remarks

Instrument 1

Mounting bracket (with screw) 2

RS100/RS400 Instruction Manual

(IMR02Y04-X)

1 Enclosed with RS100/400 (for English/Chinese)

Applicable to both models

Accessories Q’TY Remarks

RZ100/RZ400/RS100/RS400

Instruction Manual (IMR02Y03-E1)

Gasket

KRB100-39 (RZ100)

KFB400-36 (RZ400)

Terminal cover

KCA100-517 (RZ100/RS100)

KFB400-58 (RZ400/RS400)

Front cover

KRB100-315 (RZ100/RS100) [Soft cover]

KRB100-36 (RZ100/RS100) [Hard cover]

KRB400-36 (RZ400/RS400) [Hard cover]

CT (Current transformer for heater break alarm)

CTL-6-P-N [for 0 to 30 A] or

CTL-12-S56-10L-N [for 0 to 100 A]

This manual

1

(sold separately)

1 Option of RZ100/400

(Waterproof/Dustproof type)

1 Optional (sold separately)

1 Optional (sold separately)

Depending

on the order

quantity

Option (sold separately)

This manual can be downloaded from

the official RKC website:

http:// www.rkcinst.com/english/

manual_load.htm

IMR02Y03-E1

If any of the above are missing, damaged, or if your manual is incomplete, please contact RKC

sales office or the agent.

1-3

1. OUTLINE

1.3 Model Code

Check that the product received is correctly specified by referring to the following model code list:

If the product is not identical to the specifications, please contact RKC sales office or the agent.

Suffix code

RZ100

RZ400

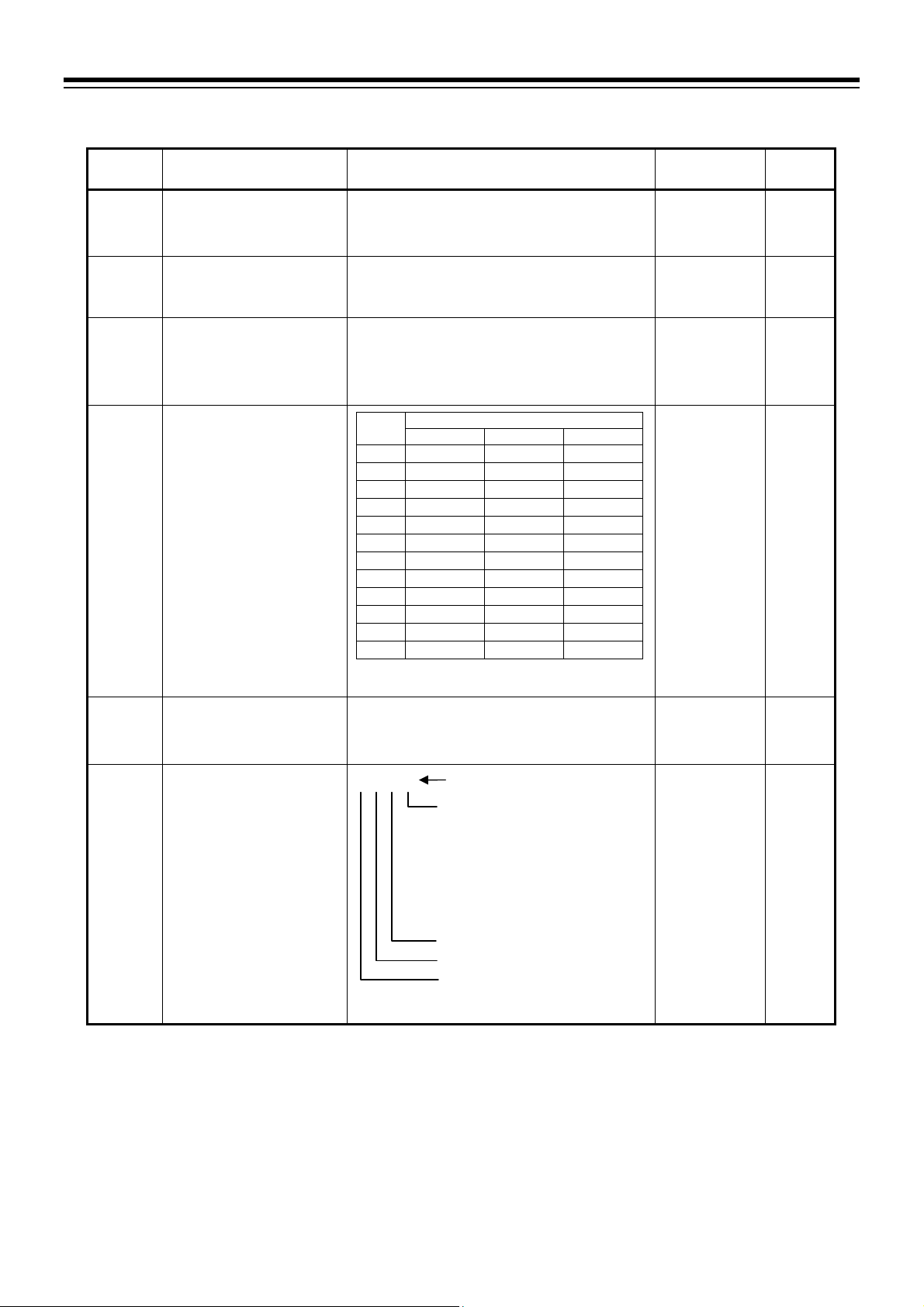

(1) (2) (3) (4) (5) (6) (7) (8) (9)

Output 1 (OUT1)

Output 2 (OUT2)

Output 3 (OUT3)

Current transformer (CT)

input

(Optional)

Communication function

(Optional)

Waterproof/Dustproof 1

(Optional)

Quick start code

RS100

RS400

-□ □ □*□ □ □ /□-□ □□□

Specification

(1) (2) (3) (4) (5) (6) (7) (8) (9)

None N

Relay contact output M

Voltage pulse output V

Current output (0 to 20 mA DC) 7

Current output (4 to 20 mA DC) 8

None

Relay contact output M

Voltage pulse output V

Current output (0 to 20 mA DC) 7

Current output (4 to 20 mA DC) 8

None N

Relay contact output M

None

CTL-6-P-N (2 points) T

CTL-12-S56-10L-N (2 points) U

None N

RS-485 (RKC communication) 5

RS-485 (Modbus) 6

None

Waterproof/Dustproof (IP66) 1

Quick start code not specified

Specify quick start code 1 3 1

Specify quick start code 1 and 2 2

2

N

Mandatory Optional

N

Suffix code

N

N

Control method

[Quick start code 1]

Measured input and Range

[Quick start code 1]

1

Always “N” for RS100/400.

1-4

No specify quick start code

PID control with AT (Reverse action) F

PID control with AT (Direct action) D

Heat/Cool PID control with AT G

Heat/Cool PID control with AT (for Extruder [air cooling]) A

Heat/Cool PID control with AT (for Extruder [water cooling]) W

No specify quick start code No code

Refer to Input Range Code Table

No code

IMR02Y03-E1

2

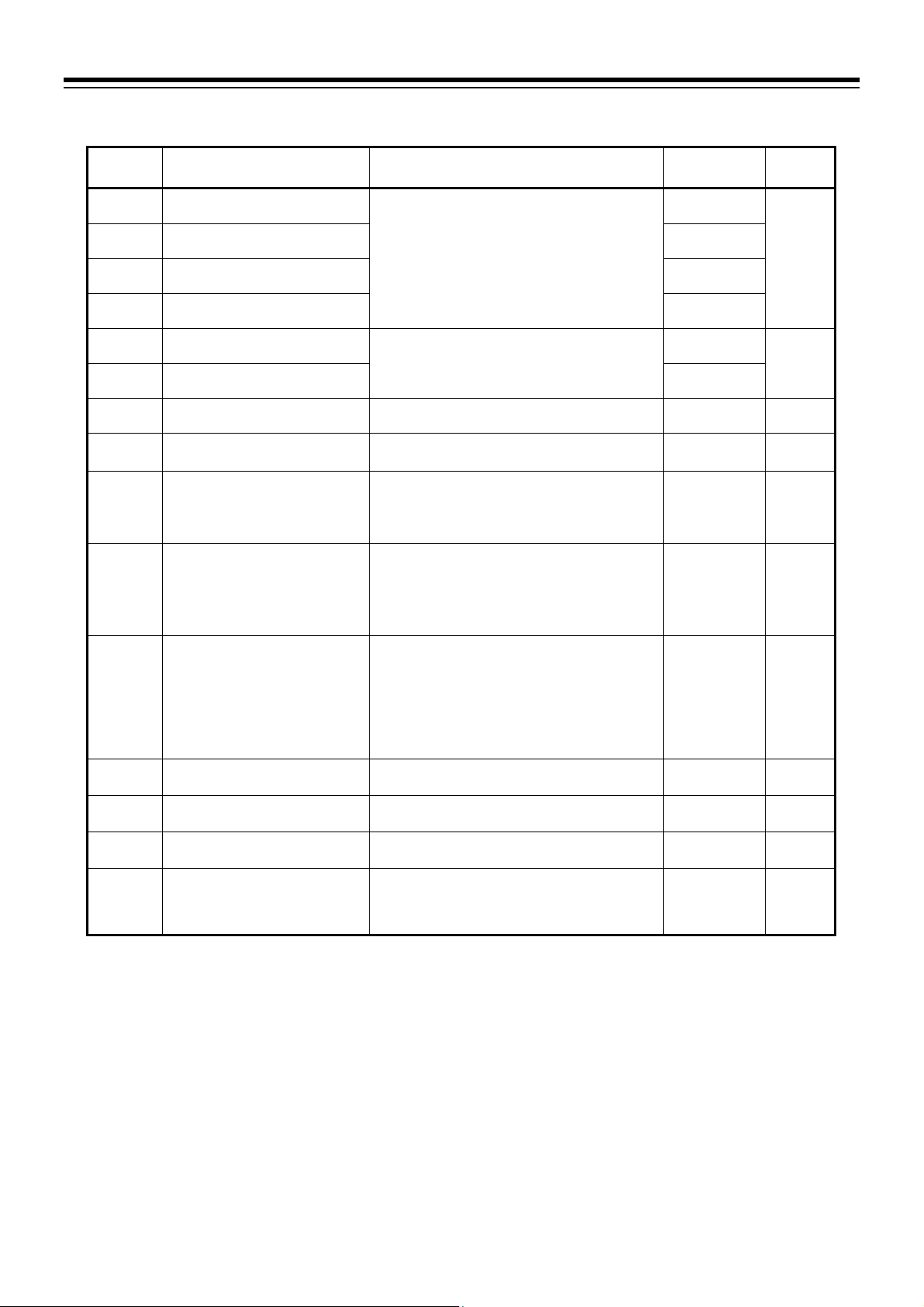

If Quick start code is not specified, control action, input range and outputs are factory configured as follows dep ending on with or

without outputs.

With/Without output(s)

Control

Output 1

(OUT1)

1 × - - → F K02

2 × × - → A K02

3 × - × → F K02

4 × × × → A K02

5 - × - → F K02 -

6 - × × → F K02 -

7 - - × → F K02 - -

8 - - - → F K02 - - -

3

If Quick start code 1 is specified, output contents are configured as follows depending on with or without output(s).

×: with output -: without output

(Content of range code is not limited)

Output 1

(OUT1)

1 × - - F or D Specified code →

2 × × - F or D Specified code →

3 × - × F or D Specified code →

4 × × × F or D Specified code →

5 - × - F or D Specified code → -

6 - × × F or D Specified code → -

7 - - × F or D Specified code → - -

8 - - - F or D Specified code → - - -

9 × × -

10 × × ×

×: with output -: without output

Output 2

(OUT2)

With/Without output(s) User specified setting

Output 2

(OUT2)

Output 3

(OUT3)

Output 3

(OUT3)

Control

method

code

G, A or

W

G, A or

W

method

code

Specified code →

Specified code →

Range

code

Range code Output

Output

Control output

Control output

Control output

Control output

(heat-side)

(heat-side)

(heat-side)

(heat-side)

Factory setting

1

(OUT1) Output 2 (OUT2) Output 3 (OUT3)

- -

Control output

(cool-side)

-

Control output

(cool-side)

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

Factory setting

1

(OUT1) Output 2 (OUT2) Output 3 (OUT3)

Control output

(heat-side)

Control output

(heat-side)

Control output

(heat-side)

Control output

(heat-side)

Control output

(heat-side)

Control output

(heat-side)

- -

Alarm 1 output

(Deviation high)

-

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

Control output

(cool-side)

Control output

(cool-side)

-

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

-

Alarm 2 output

(Deviation high)

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

Alarm 2 output

(Deviation high)

Alarm 2 output

(Deviation high)

Alarm 1 output

(Deviation high)

Alarm 1 output

(Deviation high)

-

-

-

To use alarm output, relay contact output must be specified.

1. OUTLINE

IMR02Y03-E1

1-5

1. OUTLINE

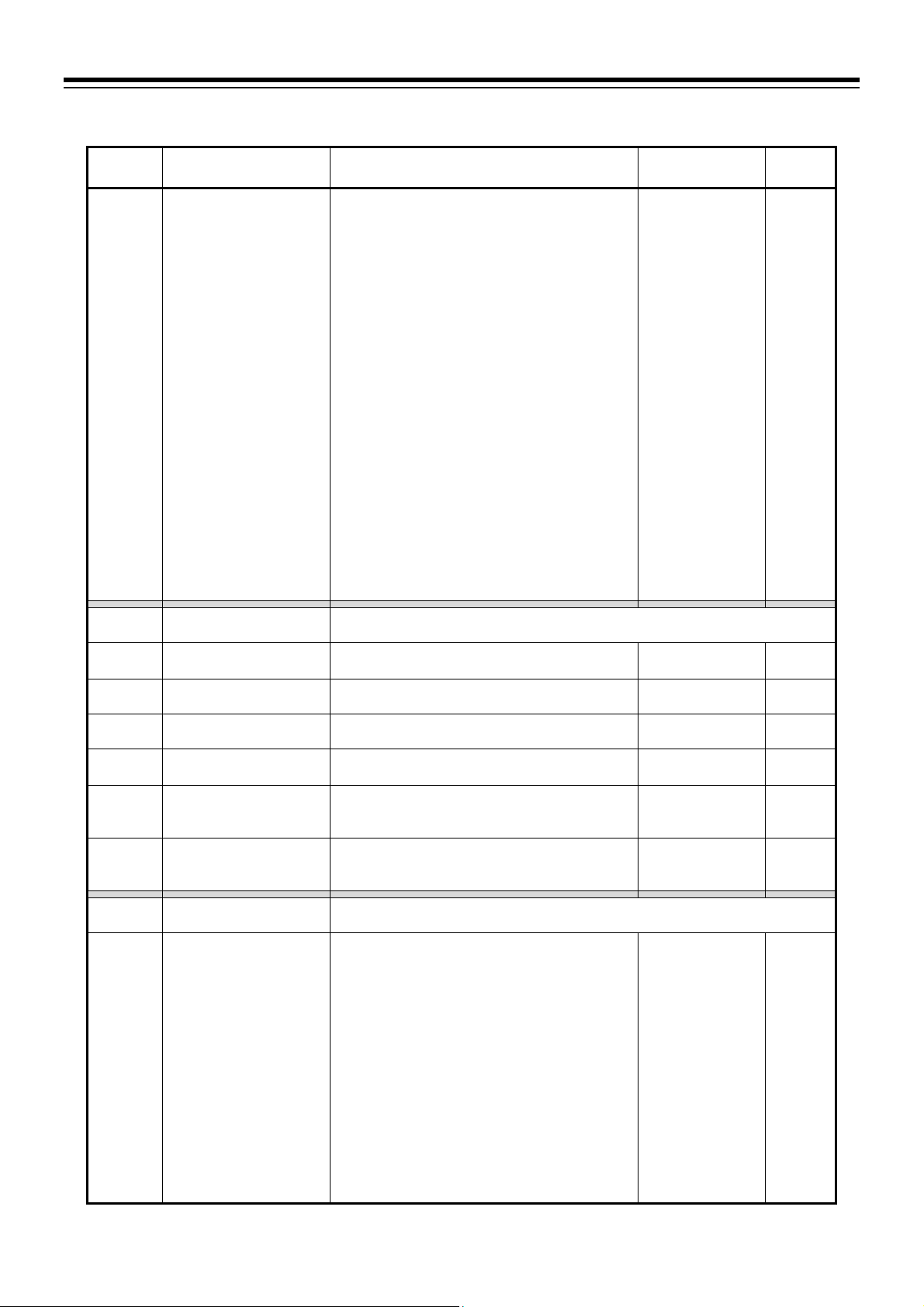

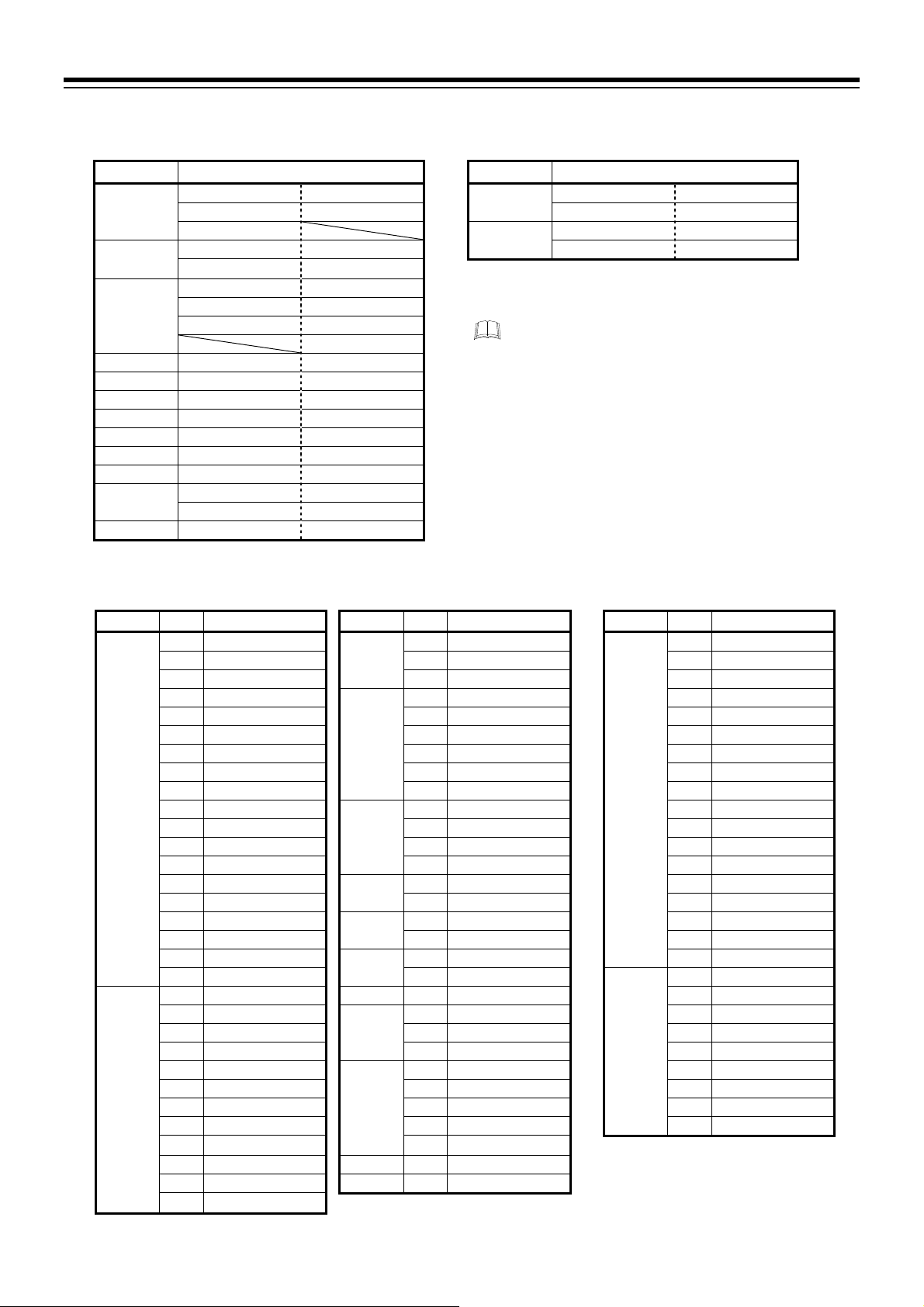

Input Range Code Table

Thermocouple (TC) input RTD input

Input type Code Range Input type Code Range Input type Code Range

K K01 0 to 200 C J JA7 0 to 300 F Pt100 D01 199.9 to 649.0 C

K02 0 to 400 C JB9 328 to 2192 F D02 199.9 to 200.0 C

K03 0 to 600 C JC8 199.9 to 550.0 F D03 100.0 to 50.0 C

K04 0 to 800 C T T01 199.9 to 400.0 C D04 100.0 to 100.0 C

K05 0 to 1000 C T02 199.9 to 100.0 C D05 100.0 to 200.0 C

K06 0 to 1200 C T03 100.0 to 200.0 C D06 0.0 to 50.0 C

K07 0 to 1372 C T04 0.0 to 350.0 C D07 0.0 to 100.0 C

K09 0.0 to 400.0 C T05 199.9 to 300.0 C D08 0.0 to 200.0 C

K10 0.0 to 800.0 C T06 0.0 to 400.0 C D09 0.0 to 300.0 C

K13 0 to 100 C R R01 0 to 1600 C D10 0.0 to 500.0 C

K14 0 to 300 C R02 0 to 1769 C DA1 199.9 to 999.9 F

K17 0 to 450 C R04 0 to 1350 C DA3 199.9 to 200.0 F

K20 0 to 500 C RA1 0 to 3200 F DA4 199.9 to 100.0 F

K41 200 to 1372 C S S01 0 to 1600 C DA5 199.9 to 300.0 F

K43 199.9 to 400.0 C S02 0 to 1769 C DA6 0.0 to 100.0 F

KA1 0 to 800 F B B01 400 to 1800 C DA8 0.0 to 400.0 F

KA2 0 to 1600 F B02 0 to 1820 C DA9 0.0 to 500.0 F

KA3 0 to 2502 F E E01 0 to 800 C DB2 199.9 to 900.0 F

KC8 100.0 to 752.0 F E02 0 to 1000 C JPt100 P01 199.9 to 649.0 C

J J01 0 to 200 C N N01 0 to 1200 C P02 199.9 to 200.0 C

J02 0 to 400 C

J03 0 to 600 C W02 0 to 2320 C P05 100.0 to 200.0 C

J04 0 to 800 C WA1 0 to 4000 F P06 0.0 to 50.0 C

J05 0 to 1000 C PL II A01 0 to 1300 C P07 0.0 to 100.0 C

J06 0 to 1200 C A02 0 to 1390 C P08 0.0 to 200.0 C

J07 199.9 to 300.0 C A03 0 to 1200 C P09 0.0 to 300.0 C

J10 0 to 450 C AA1 0 to 2400 F P10 0.0 to 500.0 C

JA1 0 to 800 F AA2 0 to 2534 F

JA2 0 to 1600 F U U01 199.9 to 600.0 C

JA3 0 to 2192 F L L01 0 to 400 C

JA6 0 to 400 F

W5Re/

W26Re

W01 0 to 2000 C P04 100.0 to 100.0 C

1-6

IMR02Y03-E1

1. OUTLINE

Quick start code 2 (Initial setting code)

Quick start code 2 tells the factory to ship with each parameter preset to the values detailed as specified by

the customer. Quick start code 2 is not necessarily specified when ordering, unless the preset is requested.

These parameters are software selectable items and can be re-programmed in the field following procedures

found in the manual.

□ □ -□ -□ □ -□ □

(A) (B) (C) (D) (E) (F) (G)

Specifications

None N

Deviation high A

Deviation low B

Deviation high/low C

Band D

Deviation high with hold action E

Deviation low with hold action F

Deviation high/low with hold action G

Process high H

Process low J

Alarm 1 type

Alarm 2 type

Control output

assignment

Output assignment of

c

Alarm 1

Output assignment of

Alarm 2 c

Output assignment

of Heater break

alarm 1 c

Output assignment

of Heater break

alarm 2 c

a

Control loop break alarm (LBA) can be specified only for Alarm 2.

b

Control output assignment (code 3 and 4) are available only for Heat/Cool PID control.

c

Alarm output assignment cannot overlap the control output assignment.

Process high with hold action K

Process low with hold action L

Deviation high with re-hold action Q

Deviation low with re-hold action R

Deviation high/low with re-hold action T

Band (High/Low individual setting) U

SV high V

SV low W

Deviation high/low (High/Low individual setting) X

Deviation high/low with hold action (High/Low individual setting) Y

Deviation high/low with re-hold action (High/Low individual setting) Z

Monitor during RUN 4

None N

Alarm 2 (The code is same as Alarm 1 type)

Control loop break alarm (LBA) a 2

PID control: Output 1 (OUT1)

Heat/Cool PID control: Heat-side control output: Output 1 (OUT1)

Cool-side control output: Output 2 (OUT2)

PID control: Output 2 (OUT2)

Heat/Cool PID control: Heat-side control output: Output 2 (OUT2)

Cool-side control output: Output 1 (OUT1)

Heat-side control output: Output 1 (OUT1)

Cool-side control output: Output 3 (OUT3)

Heat-side control output: Output 2 (OUT2)

Cool-side control output: Output 3 (OUT3)

No assignment N

Output 1 (OUT1) 1

Output 2 (OUT2) 2

Output 3 (OUT3) 3

No assignment N

Output 1 (OUT1) 1

Output 2 (OUT2) 2

Output 3 (OUT3) 3

No assignment N

Output 1 (OUT1) 1

Output 2 (OUT2) 2

Output 3 (OUT3) 3

No assignment N

Output 1 (OUT1) 1

Output 2 (OUT2) 2

Output 3 (OUT3) 3

Quick start code 2 (Initial setting code)

(A) (B) (C) (D) (E) (F) (G)

1

2

3 b

4 b

IMR02Y03-E1

1-7

1. OUTLINE

A

A

V

A

A

8

V

A

A

1.4 Parts Description

This section describes various display units and the key functions.

Front Panel View

Measured value (PV) display [Green]

Set value (SV) display [Orange]

Measured value (PV) display [Green]

Set value (SV) display [Orange]

OUT1 to OUT3 lamp [Green]

Set (SET) key

AT lamp [Green]

ALM lamp [Red]

Set (SET) key

RZ100/RS100

PV

888

S

888.8

T OUT1 OUT2

RZ1

00

Shift key

PV

RZ400

OUT3

LM

8888

S

8888

T OUT1 OUT2

Shift key

OUT3

LM

T lamp [Green]

OUT1 to OUT3 lamp [Green]

LM lamp [Red]

Up key Down key

RS400

(Only key appearance is different)

Up key Down key

1-8

IMR02Y03-E1

Display units

Measured value (PV) display [Green] Displays Measured value (PV) or various parameter symbols.

Set value (SV) display [Orange] Displays Set value (SV) or various parameter set values.

Indication lamps

AT lamp [Green]

OUT1 lamp [Green] Lights when Output 1 (OUT1) is turned on.*

OUT2 lamp [Green] Lights when Output 2 (OUT2) is turned on.*

OUT3 lamp [Green] Lights when Output 3 (OUT3) is turned on.*

ALM lamp [Red]

* Lamp indication becomes as follows for current output: For an output of less than 0 %: Extinguished

For an output of more than 100 %: Lit

For an output of more than 0 % but less than 100 %: Dimly lit.

Flashes when Autotuning (AT) is activated. (After AT is completed: AT lamp will go out)

Lights during Startup tuning (ST) execution. (After ST is completed: AT lamp will go out)

Lights when Alarm 1, Alarm 2, Heater break alarm 1 or Heater break alarm 2 is turned on.

Operation keys

Set (SET) key Used for calling up parameters and set value registration.

Shift key

Down key Decreases numerals.

Up key Increases numerals.

Shifts digits when settings are changed.

Used to switch monitor items, RUN/STOP, and modes.

To avoid damage to the instrument, never use a sharp object to press keys.

Bottom View

1. OUTLINE

Loader communication connector is supplied as standard on RZ100/400 only.

RZ100 RZ400

Loader communication connector

Loader communication

connector

(Supplied as standard

on RZ100/400 only)

Setting and monitoring on a personal computer (PC) is possible if the controller is connected with

our cable to a PC via our USB communication converter COM-K2 (sold separately)

Our communication software

(Loader communication is available only while RZ100/400 are powered.)

1

For the COM-K2, refer to the official RKC website.

2

Only available as a download from the official RKC website:

http://www.rkcinst.com

2

must be installed on the PC.

1

.

IMR02Y03-E1

1-9

1. OUTLINE

communicatio

)

)

1.5 Input/Output and Function Blocks

This section describes the input/output and function blocks of the instrument.

Measured

input

TC

RTD

PV monitor

Input processing

PV digital filter

PV bias

CT input

CT1 *

CT2 *

Current value

monitor

Current capture

processing

RUN/STOP transfer

(Front key,

RS-485

Communication

function

*

Protocol selections

Loader

communication

Use our COM-K2 for a connection to a PC.

n

RKC

communication

Modbus

Set value

SV

Control processing

PID control

Heat/Cool PID control

ON/OFF control

Autotuning (AT)

Startup tuning (ST)

Fine tuning

Direct/Reverse action

Output limiter

Alarm processing

Temperature alarm

Heater break alarm

(HBA) *

Control loop break alarm

(LBA)

Monitor during RUN

Communication

processing

Control output

(heat-side)

Control output

(cool-side)

Comprehensive

alarm state

Delay timer

Energized

/De-energized

Interlock release

MV monitor

Output

limiter

Output

limiter

Interlock

(Front key,

communication

Marked

Control output

Alarm output

assignment

Control output

Alarm output

assignment

Control output

Alarm output

assignment

: Monitor display

: Only RZ100/400

*: Optional

Control output

or

Alarm output

Relay contact

Voltage pulse

Current

OUT1

Control output

or

Alarm output

Relay contact

Voltage pulse

Current

OUT2

Control output

or

Alarm output

Relay contact

OUT3

1-10

IMR02Y03-E1

1.6 Handling Procedure to Operation

After installation and wiring, follow the procedure below to configure settings required for operation.

* Change the PID constants manually when the optimum PID constants cannot be calculated by AT or ST because of

characteristic variations of the controlled system.

Power ON

Set operation conditions?

To change pre-set conditions

Initial Setting

Operation Setting

Tuning Type?

Autotuning (AT)

Change from PID to AT

Refer to 11.3 Setting PID Values

Automatically (Autotuning) (P. 11-8).

Refer to 5.6 Tuning the PID Parameters

(Execution of AT) (P. 5-14).

AT lamp flashes

AT End

When the AT is finished, the

controller will automatically

return to PID control.

Conditions specified at time of ordering are acceptable

Refer to 5.3 Initial Setup before Operation (P. 5-5).

Refer to 5.4 Setting the Control Set Value [Set value (SV)] (P. 5-12).

Refer to 5.5 Setting the Alarm Set Value (P. 5-13).

Startup tuning (ST)

ST Setting

ST Execution

During ST execution:

AT lamp lights

AT lamp

turns off

ST End

When the ST is finished, the

controller will automatically

return to PID control.

Operation *

Refer to 11.4 Setting PID Values

Automatically (Startup tuning) (P. 11-10).

AT lamp

turns off

1. OUTLINE

IMR02Y03-E1

1-11

MEMO

1-12 IMR02Y03-E1

MOUNTING

This chapter describes mounting cautions, dimensions and mounting procedure s.

2.1 Mounting Cautions ........................................................................... 2-2

2.2 Dimensions ...................................................................................... 2-3

2.3 Procedures of Mounting and Removing ........................................... 2-4

IMR02Y03-E1 2-1

2. MOUNTING

2.1 Mounting Cautions

To prevent electric shock or instrument failure, always turn off the power before

mounting or removing the instrument.

(1) This instrument is intended to be used under the following environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

Allowable ambient temperature: 10 to 55 C

Allowable ambient humidity: 5 to 95 %RH

(Absolute humidity: MAX.W.C 29.3 g/m

Installation environment conditions: Indoor use

Altitude up to 2000 m

Short-term temporary overvoltage: 1440 V

Long-term temporary overvoltage: 490 V

3

dry air at 101.3 kPa)

(3) Avoid the following conditions when selecting the mounting location:

Rapid changes in ambient temperature which may cause condensation.

Corrosive or inflammable gases.

Direct vibration or shock to the mainframe.

Water, oil, chemicals, vapor or steam splashes.

Excessive dust, salt or iron particles.

Excessive induction noise, static electricity, magnetic fields or noise.

Direct air flow from an air conditioner.

Exposure to direct sunlight.

Excessive heat accumulation.

(4) Mount this instrument in the panel considering the following conditions:

Provide adequate ventilation space so that heat does not build up.

Ensure at least 50 mm space on top and bottom of the instrument for maintenance and environmental

reasons.

Do not mount this instrument directly above equipment that generates large amount of heat (heaters,

transformers, thyristor units, large-wattage resistors.)

If the ambient temperature rises above 55 C, cool this instrument with a forced air cooling fan, cooling

unit, etc. Cooled air should not blow directly on this instrument.

In order to improve safety and the immunity to withstand noise, mount this instrument as far away as

possible from high voltage equipment, power lines, and rotating machinery.

High voltage equipment: Do not mount within the same panel.

Power lines: Separate at least 200 mm.

Rotating machinery: Separate as far as possible.

For correct functioning mount this instrument in a horizontal position.

(5) If this instrument is permanently connected to equipment, it is important to include a switch or

circuit-breaker into the installation. This should be in close proximity to the equipment and within easy

reach of the operator. It should be marked as the disconnecting device for the equipment.

2-2 IMR02Y03-E1

2. MOUNTING

2.2 Dimensions

Panel thickness: 1 to 10 mm

(When mounting multiple instruments close together, the panel strength should be checked to ensure proper

support.)

RZ100/RS100

L1

L1

45

45

*3

0.6

0

*3

0.6

0

0.6

0

0.6

0

0.6

0

45

25

*4

0.6

0

45

0.8

0

92

30

*4

0.8

0

92

(Unit: mm)

Individual mounting

25

44.8

48

*2

Close horizontal mounting

48

44.8

48.2

63.7

7.9

1

*1

63

79.1

L1 = 48 n 3

n = Number of controllers (2 to 6)

RZ400/RS400

(Unit: mm)

44.8

48

*2

96

91.8

*1

7.9

1

60

70.1

*1 Gasket (optional) [Waterproof/Dustproof] (only RZ100/400)

*2 Terminal cover (optional) [sold separately]

*3 To keep the instrument as waterproof as possible, make sure that the panel surface has no burr or distortion where the hole is to

be cut out.

*4 Remove the gasket. When multiple RZ100/400 are mounted close to one another IP66 water-proof protection will no longer

assured.

Individual mounting

25

Close horizontal mounting

110.6

L1 = 48 n 3

n = Number of controllers (2 to 6)

IMR02Y03-E1

2-3

2. MOUNTING

2.3 Procedures of Mounting and Removing

The mounting position of the mounting brackets

Mounting positions for a single controller

* If mounting brackets are installed on the sides of the Waterproof/Dustproof type controller as shown

in the figure (marked with *), sufficient Waterproof/Dustproof performance cannot be obtained.

RZ100/RS100 RZ400/RS400

Mounting positions for close mounting

RZ100/RS100 RZ400/RS400

When two or more controllers are mounted closely, the optional waterproof/dustproof feature is

no longer assured.

2-4

IMR02Y03-E1

Mounting procedures (Standard type)

2. MOUNTING

1. Prepare the panel cutout as specified in Fig. 2.1.

(Panel thickness: 1 to 10 mm)

Refer to 2.2 Dimensions (P. 2-3).

2. Insert the instrument through the panel cutout. (Fig. 2.2)

3. Insert the mounting bracket into the mounting groove of the

instrument. (Fig. 2.3)

Fig. 2.1

Mounting

holes

Fig. 2.2

Fig. 2.3

Panel

Panel

4. Push the moun ting bracket forward until the bracket is firmly

secured to the panel. (Fig. 2.4)

5. Tighten the screw for the mounting bracket with a Phillips

screwdriver.

Do not overtighten the screw. (Fig. 2.5)

Recommended tightening torque: 0.15 Nm [1.5 kgfcm]

6. The other mounting bracket should be installed in the same

way as described in 3 to 5.

Fig. 2.4

Fig. 2.5

IMR02Y03-E1

2-5

2. MOUNTING

Mounting procedures (Waterproof/Dustproof type) [Only RZ100/400]

The front of the instrument conforms to IP66 [Specify when ordering] when mounted on the panel. For

effective Waterproof/Dustproof, the gasket must be securely placed between the instrument and the panel

without any gap. If gasket is damaged, please contact RKC sales office or the agent.

1. Prepare the panel cutout as specified in Fig. 2.6.

(Panel thickness: 1 to 10 mm)

Refer to 2.2 Dimensions (P. 2-3).

Fig. 2.6

Panel

2. Set the waterproof/dustproof gasket (optional) on the case

from the back side of the instrument as shown in Fig. 2.7.

Insert the instrument through the panel cutout.

3. Insert the mounting bracket into the mounting groove of the

instrument. (Fig. 2.8)

For waterproof and dustproof protection, two

mounting brackets must be placed on the top and

the bottom side of the instrument. If the

mounting brackets are placed on the sides of the

controller, waterproof and dustproof protection

will not be guaranteed.

4. Push the mounting bracket forward until the bracket is

firmly secured to the panel. (Fig. 2.9)

5. Tighten the screw for the mounting bracket with a Phillips

screwdriver.

Do not overtighten the screw. (Fig. 2.10)

Recommended tightening torque: 0.15 Nm [1.5 kgfcm]

6. The other mounting bracket should be installed in the same

way as described in 3 to 5.

For replacing of the gasket, refer to APPENDIX A.2 Replacing the Waterproof/Dustproof

Gasket (Option of RZ100/400) (P. A-7).

Mounting

holes

Fig. 2.7

Gasket

Fig. 2.8

Fig. 2.9

Fig. 2.10

2-6

IMR02Y03-E1

Removal procedures

2. MOUNTING

1. Turn the power OFF.

2. Remove the wiring.

3. Loosen the screw of the mounting bracket.

4. Remove the mounting bracket by pulling it up (Fig. 2.12 )

and forward (Fig. 2.12 ) while holding the rear (Fig. 2.11).

5. The other mounting bracket(s) should be removed in the

same way as described in 3 and 4.

6. Pull out the instrument from the mounting cutout while

holding the front panel frame of this inst r ument. (Fig. 2.13)

Use long-nose pliers to remove mounting brackets

from the instrument that is installed in a narrow place

or installed tightly in a vertical position.

Fig. 2.11

Rear of mounting

bracket

Fig. 2.12

Fig. 2.13

Pull out

Front panel frame

1

2

Panel

IMR02Y03-E1

2-7

MEMO

2-8 IMR02Y03-E1

WIRING

This chapter describes wiring cautions, wiring layout and wiring of terminals.

3.1 Wiring Cautions ................................................................................ 3-2

3.2 Terminal Layout ............................................................................... 3-5

3.3 Wiring of Each Terminal ................................................................... 3-7

3.4 Handling of the Terminal Cover (Optional) ..................................... 3-11

IMR02Y03-E1 3-1

3. WIRING

3.1 Wiring Cautions

To prevent electric shock or instrument failure, do not turn on the power until all wiring

is completed. Make sure that the wiring is correct before applying power to the

instrument.

For thermocouple input, use the appropriate compensation wire.

For RTD input, use low resistance lead wire with no difference in resistance between the three lead wires.

To avoid noise induction, keep input signal wire away from instrument power line, load lines and power

lines of other electric equipment.

If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise filter.

Shorten the distance between the twisted power supply wire pitches to achieve the most effective

noise reduction.

Always install the noise filter on a grounded panel. Minimize the wiring distance between the noise

filter output and the instrument power supply terminals to achieve the most effective noise reduction.

Do not connect fuses or switches to the noise filter output wiring as this will reduce the effectiveness

of the noise filter.

Allow approximately 5 seconds for contact output after the instrument is turned on. Use a delay relay when

the output line is used for an external interlock circuit.

Power supply wiring must be twisted and have a low voltage drop.

This instrument is not provided with an overcurrent protection device (fuse). If a fuse is required for safety,

install a fuse close to the instrument.

Fuse type: Time-lag fuse

Fuse rating: Rated voltage 250 V, Rated current 1 A

Use the solderless terminal appropriate to the screw size.

Screw size: M3 7 (With 5.8 5.8 square washer)

Recommended tightening torque:

Fig. 3.1

φ

5.9 MAX

φ

3.2 MIN

φ 5.0

0.4 N・m (4 kgf・cm)

Applicable wire: Solid/twisted wire of 0.25 to 1.65 mm

Specified dimension: Refer to Fig. 3.1

2

5.6 mm

9.0 mm

Specified solderless terminals:

Circular terminal with isolation V1.25-MS3

(M3 screw, width 5.6 mm, hole diameter 3.2 mm)

Make sure that during field wiring parts of conductors cannot come into contact with adjacent conductive

parts.

3-2 IMR02Y03-E1

3. WIRING

When wiring RZ100/RZ400/RS100/RS400, wire from the left direction toward the backside terminals as

shown in Fig. 3.2.

For RZ100/RS100, the wiring surfaces of the central and the right side lines of terminals are inclined to

make it easier to wire from the left side.

When using the terminal cover (Figs. 3.2, 3.5), it is not possible to wire from the right side.

When wiring from the left and right with a close mounting, there are cases where adjacent instruments

cannot be wired.

Fig. 3.2: Wiring direction

Wire from the left side

(RZ100/RS100)

(RZ100/RS100 is used in the example shown, but the wiring directions are the same for RZ400/RS400.)

When equipped with a terminal cover

(RZ100/RS100)

It is not possible

to wire from the

right side.

Wire from

the left side

Up to two solderless terminal lugs can be connected to one terminal screw.

However, reinforced insulation cannot be assured in this case.

Fig. 3.4: Image of how to bend each solderless terminal lug

(RZ100/RS100)

(RZ100/RS100 is used in the example shown, but restrictions for crossover wiring are the same for RZ400/RS400.)

Panel

Top view

If solderless terminal lugs other than the recommended dimensions are used, terminal screws may

not tighten. In that case, bend each solderless terminal lug before wiring.

If the terminal screw is forcibly tightened, it may be damaged.

In case of RZ100/RS100, if two solderless terminal lugs are connected to one terminal screw, a

terminal cover cannot be used.

IMR02Y03-E1

3-3

3. WIRING

Caution for using the terminal cover:

To prevent electric shock or instrument failure, always turn off the power before mounting or removing

the terminal cover.

When mounting and removing the terminal cover, apply pressure very carefully to avoid damage to the

terminal cover.

If a solderless terminal lug touches the RZ400/RS400 common terminal cover, remove the projection

from the terminal cover by manually bending it back and forth until it breaks off.

(Fig. 3.5)

Fig. 3.5: Image of how to close the terminal board with the terminal cover and to remove projections.

(Only RZ400/RS400)

This section illustrates

how to manually

remove projections

from the terminal

cover if a terminal lug

touches the cover.

RZ400/RS400

Terminal cover

Terminal cover

For the mounting and removing of the terminal cover, refer to 3.4 Handling of the Terminal Cover

(Optional) (P. 3-11).

3-4

IMR02Y03-E1

3.2 Terminal Layout

The terminal layout is as follows.

RZ100/RS100

3. WIRING

Power supply voltage

[Refer to P. 3-7]

100 to 240 V AC

Output 2 (OUT2)

[Refer to P. 3-8]

Relay contact/Voltage pulse/Current

Output 1 (OUT1)

[Refer to P. 3-8]

Relay contact/Voltage pulse/Current

RZ400/RS400

Power supply voltage

[Refer to P. 3-7]

100 to 240 V AC

Output 2 (OUT2)

[Refer to P. 3-8]

Relay contact/Voltage pulse/Current

Output 1 (OUT1)

[Refer to P. 3-8]

Relay contact/Voltage pulse/Current

Unused

Output 3 (OUT3)

[Refer to P. 3-8]

Relay contact

Measured input

[Refer to P. 3-7]

Thermocouple/RTD

To prevent malfunctioning, do not connect wires to unused terminals.

1

2

3

4

5

6

10

11

12

Communication *

[Refer to P. 3-10]

RS-485

713

14

15

16

17

18

Current transformer (CT) input 2 (CT2) *

Current transformer (CT) input 1 (CT1) *

[Refer to P. 3-10]

1

2

3

4

5

6

7

8

9

8

9

10

11

12

* Optional

13

14

15

16

17

18

19

20

21

Unused

Output 3 (OUT3)

[Refer to P. 3-8]

Relay contact

Measured input

[Refer to P. 3-7]

Thermocouple/RTD

Communication *

[Refer to P. 3-10]

RS-485

Unused

22

23

24

* Optional

Current transformer (CT) input 2 (CT2) *

Current transformer (CT) input 1 (CT1) *

[Refer to P. 3-10]

IMR02Y03-E1

3-5

3. WIRING

1

3

Isolations of input and output

For the Input/Output isolation block of this instrument, refer to the following:

Power supply

Isolated

Isolated IsolatedIsolated

MCU

2

Non-Isolated

Output 3

(OUT3)

CT input

(CT1, CT2)

Communication

(RS-485)

3

Isolated

Output 11

(OUT1)

Output 2

(OUT2)

Isolated Isolated

Measured input

Non-Isolated

Loader

communication

1

Outputs are isolated if OUT1 or OUT2 is “relay contact output.” If both outputs are not “relay contact output,” outputs

are not isolated.

2

Loader communication is supplied on RZ100/400 only.

3

Current transformer input and communication are optional functions.

3-6

IMR02Y03-E1

A

12

3.3 Wiring of Each Terminal

Always check the polarity of each terminal prior to wiring.

Power supply

3. WIRING

713

8

9

10

11

12

RZ400/RS400

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Connect the power to terminal numbers 1 and 2.

100-240 V AC power supply type

L

C

100-240 V

1

2

N

RZ100/RS100

1

2

14

3

15

4

16

5

17

18

6

Power supply voltage for the controller must be within the range shown below.

Power supply type Power consumption

85 to 264 V AC (including voltage variation)

[Rating: 100 to 240 V AC]

Power supply frequency: 50/60 Hz

RZ100/RS100: 5.1 VA max. (at 100 V AC)

7.6 VA max. (at 240 V AC)

RZ400/RS400: 5.9 VA max. (at 100 V AC)

8.4 VA max. (at 240 V AC)

If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise filter.

Power supply wiring must be twisted and have a low voltage drop.

This instrument is not provided with an overcurrent protection device (fuse). If a fuse is required for safety,

install a fuse close to the instrument.

Fuse type: Time-lag fuse

Fuse rating: Rated voltage 250 V, Rated current 1 A

Measured input (Thermocouple/RTD)

For the measured input type, terminals 10 through 12 are allocated to the measured input.

713

8

9

10

11

12

RZ400/RS400

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Thermocouple input

11

TC

12

RTD input

A

RTD

B

B

10

11

RZ100/RS100

1

2

14

3

15

4

16

5

17

18

6

The input types (input group) are as follows.

Input group Input type

Thermocouple (TC) input K, J, T, S, R, E, B, N (JIS C1602-1995), PLII (NBS),

W5Re/W26Re (ASTM-E988-96), U, L (DIN43710-1985)

RTD input Pt100 (JIS C1604-1997),

JPt100 (JIS C1604-1997, JIS C1604-1981 of Pt100)

For thermocouple input, use the appropriate compensation wire.

For RTD input, use low resistance lead wires with no difference in resistance between the three lead wires.

To avoid noise induction, keep input signal wire away from instrument power line, load lines and power

lines of other electric equipment.

IMR02Y03-E1

3-7

3. WIRING

Output 1 (OUT1)/Output 2 (OUT2)/Output 3 (OUT3)

Terminals 5 and 6 are for output 1 (OUT1); Terminals 3 and 4 are for output 2 (OUT2); Terminals 8 and 9

are for output 3 (OUT3).

Connect an appropriate load according to the output type. (Specify when ordering)

Output 2 (OUT2)

Output 1 (OUT1)

Output 1 (OUT1) Outpu t 2 (OUT2) Output 3 (OUT3) Wiring example

OUT

NO

RZ100/RS100

5

6

RZ400/RS400

16

14

15

17

18

NO

713

8

9

10

11

12

OUT

Output 3 (OUT3)

3

4

NO

OUT

Output 2 (OUT2)

Output 1 (OUT1)

Output 3 (OUT3)

8

Load

9

1

2

3

4

5

6

7

8

9

10

11

12

~

13

14

15

16

17

18

19

20

21

22

23

24

OUT

5

NO

6

1

2

3

4

5

6

Relay contact output

Voltage pulse output

OUT

5

6

OUT

3

4

~

SSR Load

OUT

5

0/12 V DC

6

OUT

5

6

Current output

OUT

3

4

~

Actuator Load

: The dotted box diagram describes the output state inside the instrument.

OUT

5

0 to 20 mA DC

6

Outputs are isolated if output 1 (OUT1) or output 2 (OUT2) is “relay contact output.” If both outputs are

“relay contact output,” outputs are not isolated.

Number of outputs and output types must be specified when ordering. The specifications of each output are

as follows.

Specification code

OUT1 OUT2 OUT3

N N N

M M M

V V

7 7

8 8

Output type Specifications

None

Relay contact output Refer to the table on the next page.

Voltage pulse output 0/12 V DC (Allowable load resistance: 500 or more)

Current output

0 to 20 mA DC (Allowable load resistance: 500 or less)

4 to 20 mA DC (Allowable load resistance: 500 or less)

3-8

IMR02Y03-E1

When output type is a relay contact, specification may be different depending on the assigned

output type.

Type Output terminal Output type Specification of relay contact output

RZ100

RS100

RZ400

RS400

RZ400

RS400

RZ100

RS100

RZ400

RS400

Output 1 (OUT1)

Output 2 (OUT2)

Output 3 (OUT3)

Output 3 (OUT3)

Output 1 (OUT1)

Output 2 (OUT2)

Output 1 (OUT1)

Output 2 (OUT2)

Output 3 (OUT3)

Control output

Control output

Alarm output,

Heater break

alarm output

Contact type: 1a contact

Contact rating (Resistive load): 250 V AC

Electrical life: 100,000 times or more (Rated load)

Mechanical life: 20 million times or more

(Switching: 300 times/min)

Contact type: 1a contact

Contact rating (Resistive load): 250 V AC

Electrical life: 300,000 times or more (Rated load)

Mechanical life: 50 million times or more

(Switching: 180 times/min)

Contact type: 1a contact

Contact rating (Resistive load): 250 V AC

Electrical life: 150,000 times or more (Rated load)

Mechanical life: 20 million times or more

(Switching: 300 times/min)

3 A, 30 V DC 1 A

3 A, 30 V DC 1 A

1 A, 30 V DC 0.5 A

It is possible to specify the following uses for output when ordering. (Output reassignment is possible after

the receipt of the delivery.)

Output assignment list [for PID control]

Control output Alarm 1 output Alarm 2 output

No assignment

Output 1 (OUT1) Output 2 (OUT2) or Output 3 (OUT3) *

Output 2 (OUT2) Output 1 (OUT1) or Output 3 (OUT3) *

Any one of outputs 1,2, and 3

(OUT1, 2, 3) *

Heater break alarm 1

(HBA1) output

* Output assignment can be overlapped. Overlapped outputs are produced as OR output.

Heater break alarm 2

(HBA2) output

Not available

3. WIRING

Output assignment list [for Heat/Cool PID control]

Control output

Heat-side output Cool-side output

No assignment No assignment

Output 1 (OUT1) Output 2 (OUT2) Output 3 (OUT3) *

Output 2 (OUT2) Output 1 (OUT1) Output 3 (OUT3) *

Output 1 (OUT1) Output 3 (OUT3) Output 2 (OUT2) *

Output 2 (OUT2) Output 3 (OUT3) Output 1 (OUT1) *

Alarm 1 output Alarm 2 output

Any one of outputs 1,2, and 3

(OUT1, 2, 3) *

* Output assignment can be overlapped. Overlapped outputs are produced as OR output.

Heater break alarm 1

(HBA1) output

Not available

Heater break alarm (HBA) output is an optional function.

Heater break alarm 2

(HBA2) output

IMR02Y03-E1

3-9

3. WIRING

Current transformer (CT) input (optional)

Models that were specified with a current transformer (CT) when ordering can use the following terminal

numbers.

RZ100/RS100: Terminal No. 16 to 18 (CT1, CT2)

RZ400/RS400: Terminal No. 22 to 24 (CT1, CT2)

When using CT input, connect CTs to the relevant terminals.

Current transformer model code: CTL-6-P-N [Input range: 0 to 30 A] (sold separately)

CTL-12-S56-10L-N [Input range: 0 to 100 A] (sold separately)

Current transformer (CT) input is not isolated from the measured input.

RZ100/RS100

CT input

CT2

CT1

COM

RZ400/RS400

CT input

CT2

CT1

COM

RZ100/RS100

1

16

17

18

22

23

24

2

3

4

5

6

RZ400/RS400

1

2

3

4

5

6

7

8

9

10

11

12

713

8

14

9

15

10

16

11

17

12

18

13

14

15

16

17

18

19

20

21

22

23

24

If the current transformer (CT) was replaced, adjust the CT ratio. (Refer to P. 10-40)

Communication (optional)

With Communication function, terminals 13 through 15 are allocated to Communication.

713

8

9

RZ400/RS400

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

RS-485

SG

T/R (A)

T/R (B)

13

14

15

RZ100/RS100

1

2

14

3

15

4

5

6

10

16

11

17

12

18

For the wiring, refer to 12. COMMUNICATION FUNCTION (P. 12-1).

3-10

IMR02Y03-E1

3.4 Handling of the Terminal Cover (Optional)

When mounting and removing the terminal cover, take the following steps:

To prevent electric shock or instrument failure, always turn off the power before

mounting or removing the terminal cover.

When mounting and removing the terminal cover, apply pressure very carefully to avoid

damage to the terminal cover.

Mounting procedures

3. WIRING

1. Check the mounting direction of the terminal cover.

2. Push the protrusions of terminal cover into the insertion slots for mounting the terminal cover.

Inserting slot

Terminal cover

RZ100/RS100 terminal cover

Protrusions

RZ400/RS400 commo n t e rminal cov e r

Drawing of RZ400/RS400 with terminal caver

Drawing of RZ100/RS100 with terminal caver

This section of RZ400/RS400

terminal cover can be removed

by bending it.

Remove unnecessary part(s)

depending on the wiring

condition.

IMR02Y03-E1

3-11

3. WIRING

Removal procedures

Release the protrusions of terminal cover from the insertion slots () shown in the following figure, and

then pull the terminal cover () to remove it from the case.

3-12

IMR02Y03-E1

BASIC

OPERATION

AND

PARAMETER LIST

This chapter describes basic operations, different types of modes, switching

between modes, and changing/storing the set values.

4.1 Mode Types and Switching .............................................................. 4-2

4.1.1 Switching between modes ................................................................... 4-2

4.1.2 Input type and input range display ....................................................... 4-3

4.2 Parameter Types and Switching ...................................................... 4-4

4.2.1 Scrolling through parameters ............................................................... 4-4

4.2.2 Parameter list ....................................................................................... 4-8

4.3 Changing Set Value ....................................................................... 4-18

4.4 Protecting Setting Data .................................................................. 4-19

IMR02Y03-E1 4-1

4. BASIC OPERATION AND PARAMETER LIST

A

4.1 Mode Types and Switching

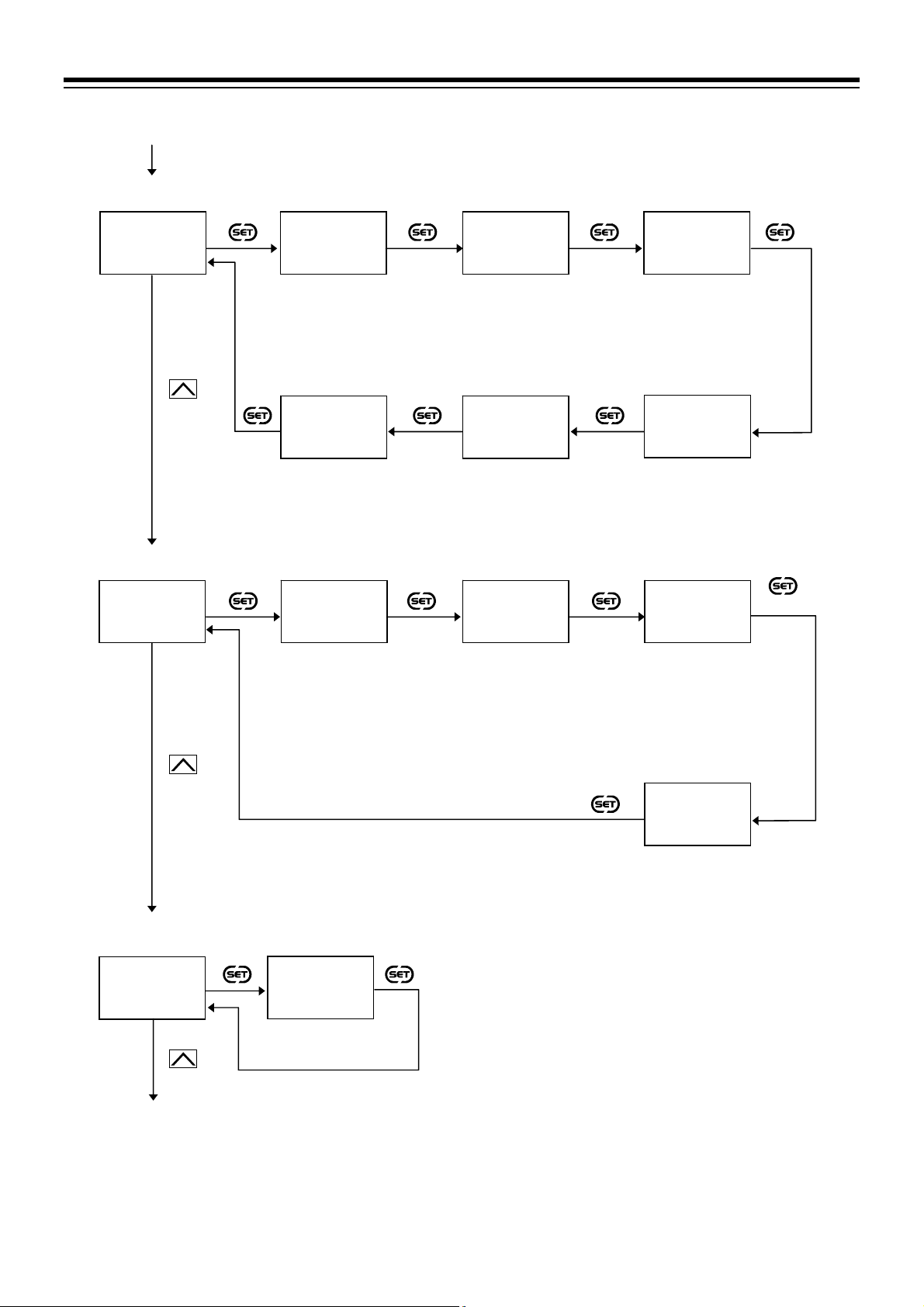

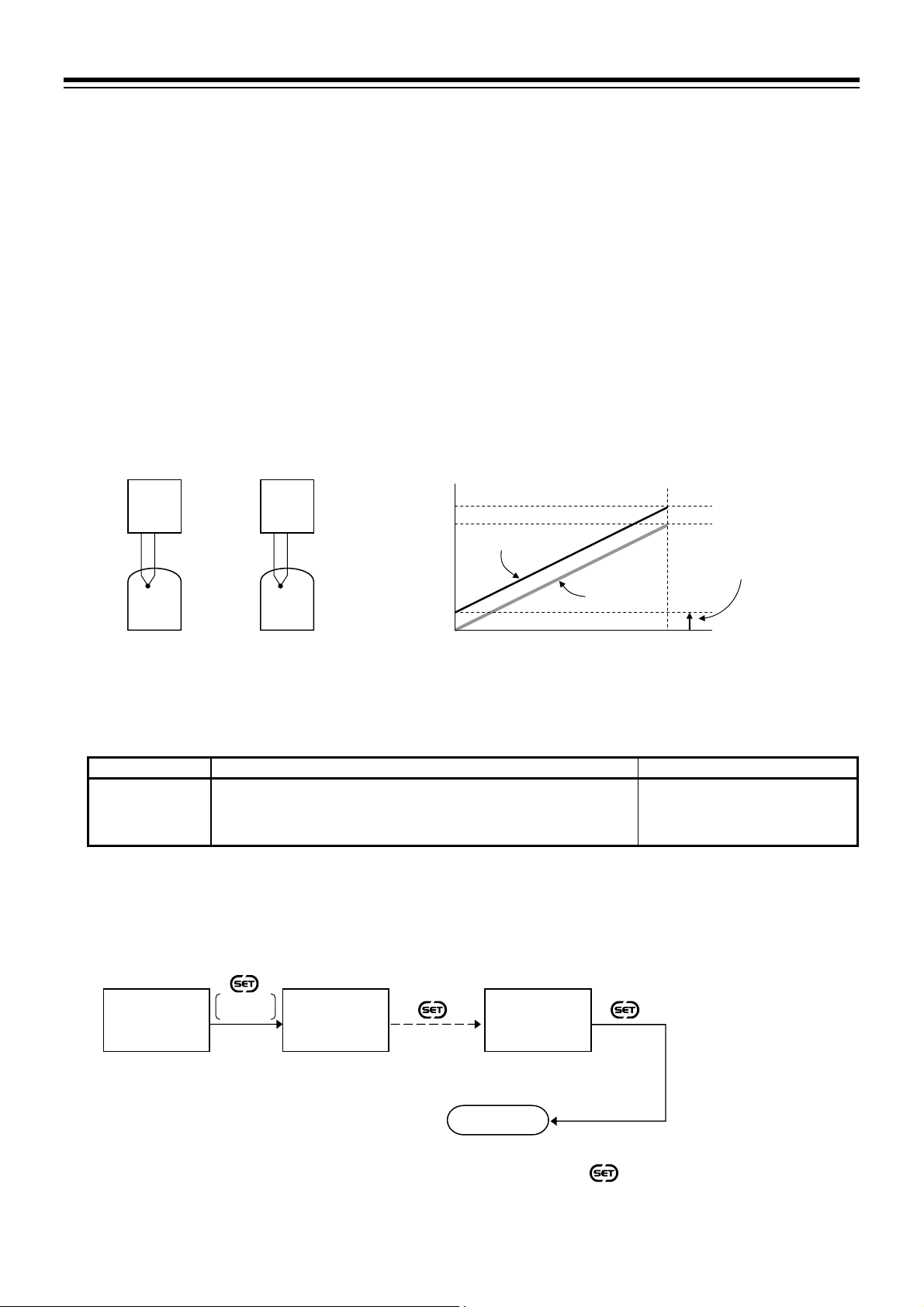

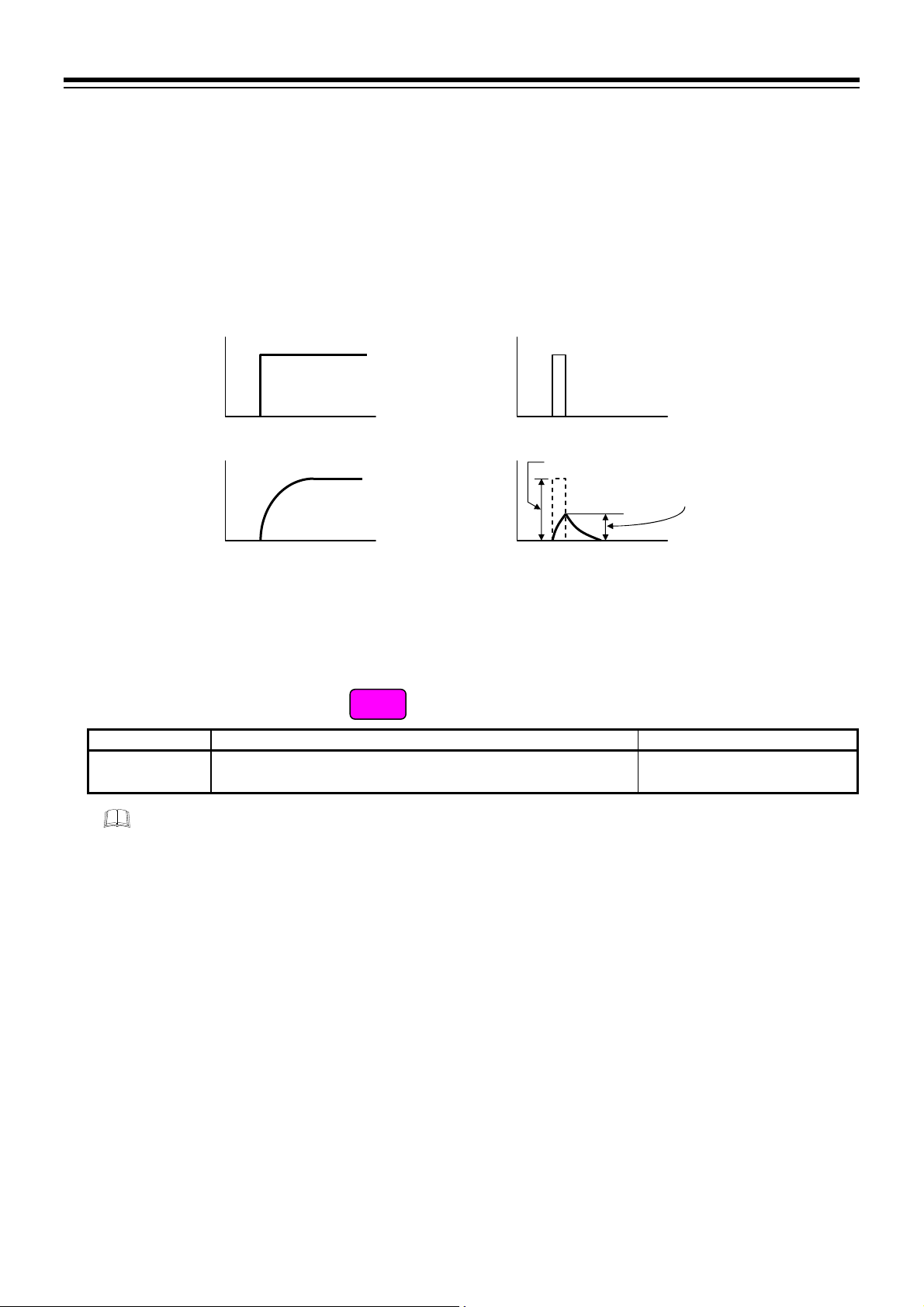

4.1.1 Switching between modes