Page 1

GasWatch 2

Operator’s Manual

Part Number: 71-0065RK

Revision: F

Released: 2/2/11

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual

before operating instrument. Improper use of the

gas monitor could result in bodily harm or death.

Periodic calibration and maintenance of the gas

monitor is essential for proper operation and correct readings. Please calibrate and maintain this

instrument regularly! Frequency of calibration

depends upon the type of use you have and the

sensor types. Typical calibration frequencies for

most applications are between 1 and 3 months,

but can be required more often or less often

based on your usage.

GasWatch 2 Operator’ s Manual

Page 3

Warranty

RKI Instruments, In c. warrants the GasWatch 2 sold by us to be free from

defects in materials, workmanship, and performance for a period of two

years from the date of shipment from RKI Instruments, Inc. This includes

the instrument and the original sensors. Replacement parts are warranted

for 1 year from the date of their shipment from RKI Instruments, Inc. Any

parts found defective within their warranty period will be repaired or

replaced, at our option, free of charge. This warranty does not apply to

those items which by their nature are subject to deterioration or

consumption in normal service, and which must be cleaned, repaired, or

replaced on a routine basis. Examples of such items are:

Absorbent cartridges

Filter elements, disks, or sheets

Pump diaphragms and valves

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, o r r epair procedures not in accordance w i th t he instruction

manual. This warranty indicates the full extent of our liability, and we are

not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER OBLIGATIONS

OR LIABILITIES ON THE PART OF RKI INSTRUMENTS, INC. INCLUDING BUT NOT

LIMITED TO THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE

FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO

FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributors, dealers, and representatives as appointed by RKI

Instruments, Inc.

We do not assume indemn ification for any accident or damage caused by

the operation of this gas monitor and our warranty is limited to replacement

of parts or our complete goods.

GasWatch 2 Operator’s Manual Warranty

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wristband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sensor Cap/.Sensor Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Charcoal Filter Disk in GW-2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Printed Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Alarm Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Buzzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lithium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Performing a Fresh Air Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning Off the GasWatch 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Measuring Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Displaying the Peak, STEL, & TWA (GW-2C & GW-2H) . . . . . . . . . . . . . . . . . . 11

Displaying Min and Max (GW-2X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Displaying and Setting the Alarm Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting the Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Fresh Air Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Span (Zero for GW-2X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table of Contents GasWatch 2 Operator’ s Manual

Page 5

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacing the Lithium Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replacing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing the Sensor Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing the Charcoal Filter Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing the Wristband. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Appendix A: MRI Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

WARNING: Understand manual before operating. Substitution of

components may impair intrinsic safety. To prevent

ignition of a hazardous atmosphere, batteries must only

be changed in an area known to be nonhazardous. Not

tested in oxygen en riched atmospheres (abo ve 21%).

GasWatch 2 Operator’s Manual Table of Contents

Page 6

Introduction

Using an advanced microprocessor controlled detection system, the

GasWatch 2 Personal Single-Gas Monitor detects the presence of either

carbon monoxide (CO), hydrogen sulfide (H2S), or oxygen (O2). The

GasWatch 2’ s comp act size and easy-to-use design make s it ideally suited

for a wide range of applications, including sewage treatment plants,

tunnels, hazardous waste sites, petrochemical facilities, oil fields, mines,

and chemical plants. The GasWatch 2 is even small enough to be worn

comfortably o n the wris t like a watch. The GasWatch 2 offers a full rang e of

features, including:

• Hands free gas monitori n g

• Compact “watch type” design

• Fast, accurate response with digital liquid crystal display (LCD)

• Visual, audible, and vibration alarms

• Microprocessor control for reliability, ease of use, and advanced

capabilities

• Peak, STEL, and TWA indication for GW-2C & GW-2H

• Minimum and maximum indication for GW-2X

• STEL, TW A, an d ov er ran ge al ar m s

• Sensor fail alarm

• Displays current time

• Over 3,000 hours of operation from 1 battery

• CSA classified for Class I, Division I, Groups A, B, C, and D hazardous

atmospheres

WARNING: The GasWatch 2 detects carbon monoxide, hydroge n

sulfide, or oxygen deficiency and elevated levels of

oxygen, all of which can be dangerous or life threatening.

When using the GasWatch 2, you must follow the

instructions and warnings in this manual to assure

proper and safe operation of the unit and to minimize the

risk of personal injury. Be sure to maintain and calibrate

the GasWatch 2 as described in this manual.

1 • Introduction GasWatch 2 Operator’s Manual

Page 7

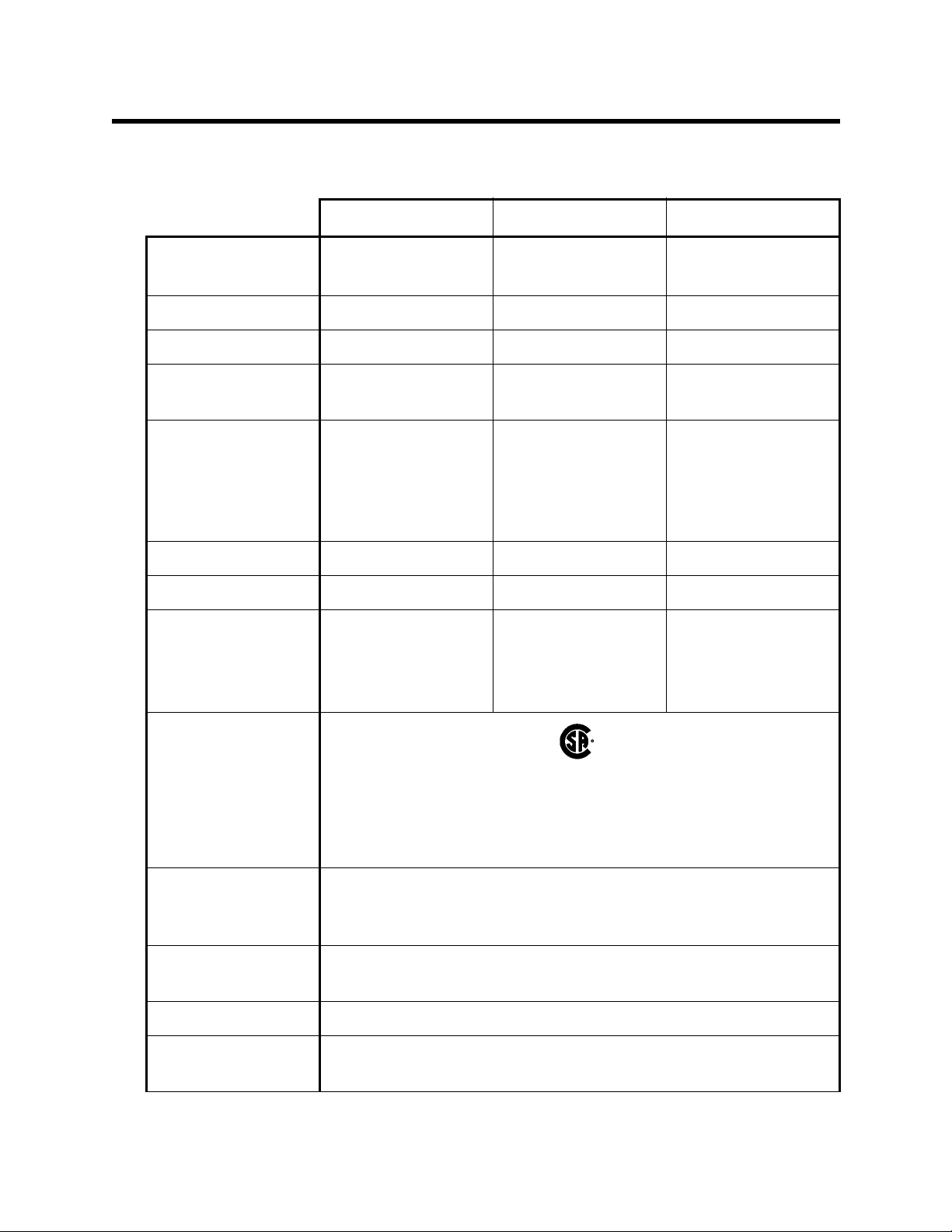

Specifications

Table 1: GasWatch 2 Specifications

GW-2C GW-2H GW-2X

Target Gas Carbon Monoxide

(CO)

Hydrogen Sulfide

(H2S)

Oxygen

(O2)

Detection Range 0 to 500 ppm 0 to 100.0 ppm 0 to 40.0% vol.

Display Increment 1 ppm 0.5 ppm 0.1% vol.

Detection

Electro Chemic al Electro Chemic al Galvanic Cell

Principle

Alarm Points Low 25 ppm

High 50 ppm

TWA 25 ppm

STEL 200 ppm

Low 10.0 ppm

High 30.0 ppm

TWA 10.0 ppm

STEL 15.0 ppm

Low 19.5% vol.

(decreasing)

High 23.5% vol.

(increasing)

Sampling Method Diffusion Diffusion Diffusion

Response Time T90 in 30 seconds T90 in 30 seconds T90 in 20 seconds

Accuracy ± 5% of reading or

± 5 ppm CO

(whichever is

greater)

± 5% of reading or

± 2 ppm H2S

(whichever is

greater)

± 0.5% O

2

Safety/Regulatory

C US

186718

CSA classified, “C/US”, as Intrinsically Safe. Exia. Class I,

Groups A, B, C, & D. Class I, Zone 0, Group IIC.

Temperature Code T4.

Power Tw o AAA size Alka line Batte ries Standard, Duracell M N2400

or PC2400, Eveready Energizer E92 or EN92

Continuous

Approximately 3,000 Hours With No alarms or Backlighing

Operating Hours

Case High-impact Plastic, Dust Proof and Weather Resistant

Standard

Wristband

Accessory

GasWatch 2 Operator’s Manual Specifications • 2

Page 8

Table 1: GasWatch 2 Specifications

GW-2C GW-2H GW-2X

Optional

Accessories

Dimensions and

Weight

Operating T emp. &

Humidity

• Belt Clip

• Hard Hat Clip

• Lapel Clip

Dimensions: 2.5 (H), 1.7 (W), 0.9 (D) inches

Weight: 2 oz.

-10°C - 40°C, below 85% RH (non condensing)

3 • Specifications GasWatch 2 Operator’ s Manual

Page 9

Description

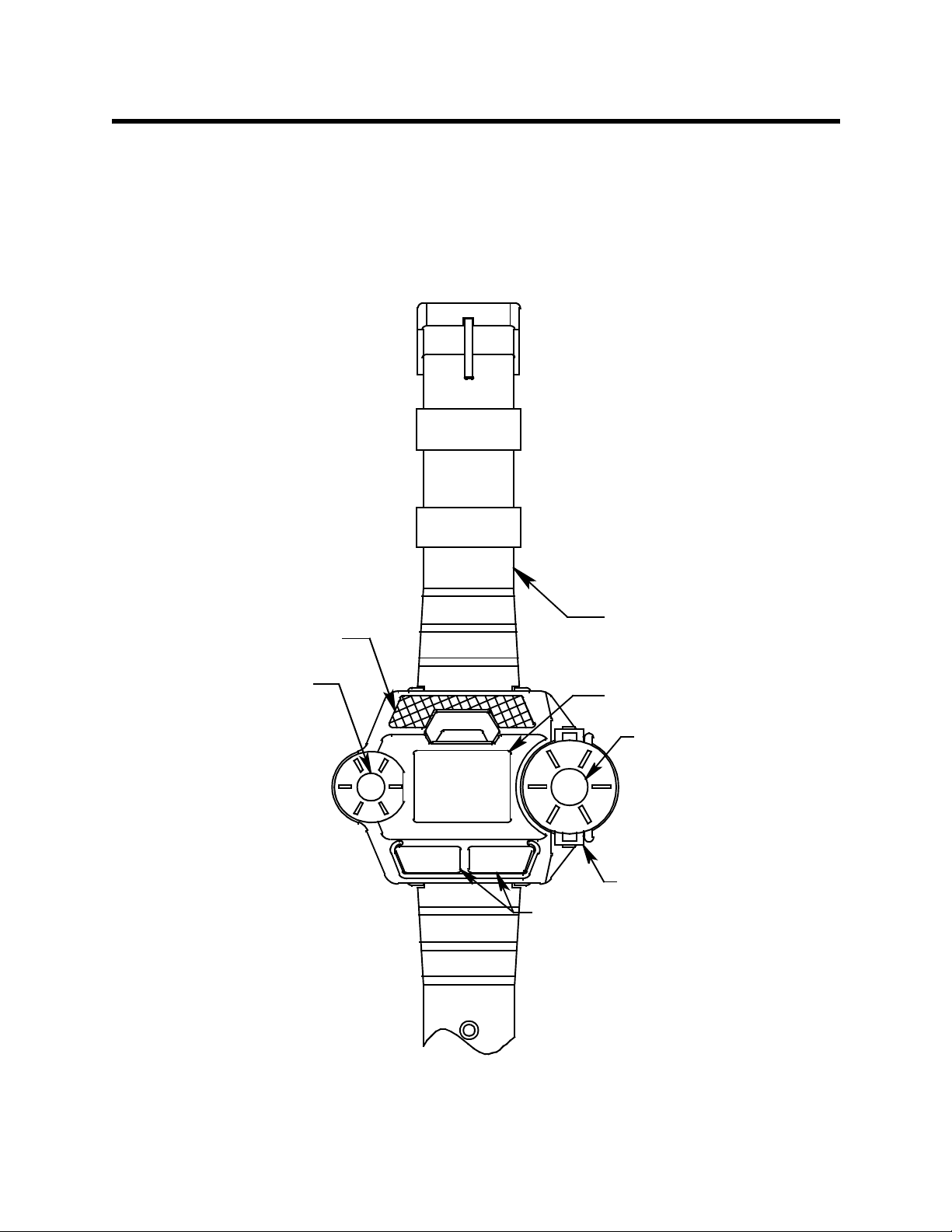

This section describes the components of the GasWatch 2. These

components include the GasWatch 2’s case, wristband, sensor cap and

sensor cover, charcoal filter disk (in the GW-2C), sensor, LCD, control

buttons, printed circuit boards, alarm lights, buzzer, vibrator, and lithium

battery.

Alarm LED Lens

Buzzer Opening

POWER

MODE

Wristband

LCD Display Window

Sensor Diffusion

Port

AIR

Sensor Cap

Control Buttons

Figure 1:Components of the GasWatch 2

GasWatch 2 Operator’s Manual Description • 4

Page 10

Case

The GasWatch 2’s sturdy, high -im pact plastic case is suitable for use in

many environmen ta l condit ions, in doors and out. The uni t is dust pr oof and

weather resistant. The case has two halves, the top case and the bottom

case. They are held together by four screws in the bottom case. The case

is a different color depe nding on the model. The GW-2C for CO is red, the

GW-2H for H2S is orange, and the GW-2 X for oxyg en is bl ue .

The digital LCD is visible through the top case. It displays gas

concentrations, battery level, time, and other readings including TWA,

STEL, and peak gas levels. Below the LCD are two black control buttons.

The button on th e left is labeled POWER/MODE. The b utto n on the right is

labeled AIR.

To the left of the LCD is the buzzer, which is located inside the unit. To the

right of the LCD is the sensor cap which retains the sensor. Above the LCD

is a frosted lens through which the alarm lights are visible.

A battery cover is located on the bottom case and is held in place by two

screws. The wristband attaches to the bottom case.

Wristband

The GasWatch 2 comes with a wristband as a standard accessory so the

unit may be worn as a watch and allow hands-free gas monitoring. The

wristband is held in place with the sam e type of spring ba rs that are used i n

a watch. The spring bars are protected by hollow tubes which fit into the

wristband. Optional accessories are available from RKI Instruments, Inc.

that can be used in place of the wristband such as a belt clip.

Sensor Cap/Sensor Cover

The sensor cap snaps onto the right side of the case and retains the

sensor. It also retains the sensor cover which is a round hydrophobic disk

membrane which protects the sensor from dirt and weather. A gasket

installed on the sensor seals against the sensor, sensor cover, and sensor

cap.

Charcoal Filter Disk in GW-2C

The GW-2C includes a charcoal filter disk which is located in a recessed

area of the sensor gasket be neath the sensor cove r . The charcoal fil ter disk

removes gases from the sampled air that will cause a response on the CO

sensor such as H2S and certain hydrocarbons. If false or elevated CO

readings are noticed, especial l y in the presence of H2S, change the

charcoal filte r disk (see the Maintenance section for instructions).

5 • Description GasWatch 2 Operator’s Manual

Page 11

Sensor

The GasWatch 2 uses either an oxygen, CO, or H2S sensor . The sensor is

protected by the white sensor cover which is held in place by the sensor

cap and sensor gasket. The sensor cover allows ambient air to diffuse past

it to the sensor. The three sensors used in the three GasWatch 2 models

use different detection principles as described below.

Oxygen Sensor

The oxygen sensor is a galvanic type of sensor. A membrane covers the

cell and allows gas to diffuse i nto the cell at a rate proportion al to the par tial

pressure of oxygen. The oxygen react s in the cell and prod uce s a volta ge

proportion al to the concentration of oxygen. The voltage is measured by

the GasWatch 2’s circuitry, converted to a measurement of gas

concentration, and displayed on the LCD.

CO and H2S Sensors

The CO and H

precious metal electrodes in an acid electrolyte. A gas permeable

membrane covers the sensor face and allows gas to diffuse into the

electrolyte. The gas reacts in the sensor and produces a c urrent

proportional to the concentration of the target gas. The current is amplified

by the GasWatch 2’s circuitry, converted to a measurement of gas

concentration, and displayed on the LCD.

S sensors are electrochemical sensors that consist of two

2

LCD

The LCD is visible through the top case. Target gas concentrations, the

time, battery condition, and alarm indications are displayed on the LCD.

When either of the control buttons is pressed, the LCD backlight comes on

for 20 seconds.

Control Buttons

Below the LCD are the two control buttons. They are POWER/MODE and

AIR. They turn on the power to the GasWatch 2 and turn it off. They control

what is displayed on the LCD, including ti me, gas concentrations, peak,

TWA, and S TEL re adin gs, as well as othe r messag es. They a lso allow yo u

to perform a fresh air adjustment, change alarm points, change the time,

and calibrate the instrument. The functions performed by the control

buttons are summarized in the following table:

GasWatch 2 Operator’s Manual Description • 6

Page 12

Table 2: The Control Buttons of the GasWatch 2

Button Function

• Turns the unit on and off.

• Turns the LCD back light on.

• Displays STEL and TWA readings (GW-2H & GW2C).

• Displays peak readings (high for GW-2H & GW-2C

POWER/MODE

and low & high for GW-2X).

• Resets the alarm circuit (gas alarms).

• Enters Calibration Mode with the AIR button.

• Enters Alarm Adjustment Mode with the AIR

button.

• Enters Time Adjustment Mode with the AIR button.

• Turns the LCD back light on.

• Adjusts LCD r eadings w hen a fresh air adju stment

is performed.

• Enters Calibration Mode with the POWER/MODE

button.

AIR

• Enters Alarm Adjustment Mode with the POWER/

MODE button.

• Enters Time Adjustment Mode with the POWER/

MODE button.

• Increases settings when the unit is in Alarm

Adjustment Mode, Time Adjustment Mode, or

Calibration Mode.

Printed Circuit Boards

The primary function of the GasWatch 2’s two printed circuit boards are to

amplify the current or voltage signal sent to them from the gas sensor,

convert the signal to a meaningful measurement of gas concentration,

display the gas concentration on the LCD, store peak, STEL, and TWA

readings, and activate th e alarm cir cuit if an ala rm point h as been reac hed.

They monitor battery level, battery failure, and sensor failure. They also

control the GasW atch 2’ s time funct ion and the vari ous operati ng modes of

the unit.

NOTE: The printed circuit boards co ntain no user serviceab l e parts.

7 • Description GasWatch 2 Operator’s Manual

Page 13

Alarm Lights

The GasWatch 2 has two alarm lights located above the LCD. The alarm

lights are two red LEDs that al ert you to gas, low battery, and sensor failure

alarms. They are visible through a frosted lens.

Buzzer

A solid-state electronic buzzer is mounted inside the GasWatch 2. An

opening on the left side of the top case allows the buzzer’s sound to

resonate from the case. The buzzer sounds for gas alarms, unit

malfunctions, low batter y volt age, and as an indi cator du ring nor mal use of

the various display options of the GasWatch 2.

Vibrator

A vibrating motor ( vibrator) is m ounted in side the GasW atch 2. The vibrator

vibrates momentarily during the power-up sequence and for gas alarms.

Lithium Battery

A 3.0 volt coin type lithium battery powers the GasWatch 2. The battery will

run the unit for approximately 3,000 hours when no alarms have been

activated during that time period. The battery icon on the LCD shows the

charge remaining in the battery. When the GasWatch 2 detects a low

battery voltage, a low battery warning is activated. When the GasWatch 2

determines that the battery is too low for normal operation, a dead battery

alarm is activated. The battery can be replaced by removing the battery

door in the bottom case. See the maintenance section of this manual for

instructions about replacing the battery.

GasWatch 2 Operator’s Manual Description • 8

Page 14

Start Up

This section explains how to start up the GasWatch 2 and to get it ready for

operation.

Start-up Procedure

1. Press and hold the POWER/MODE button for one second to turn on the

GasWatch 2 . The the bu zzer sounds br iefly, the vibrator vibrate s briefly,

all elements of display are activated, and the alarm lights and LCD

backlight turn on for a few seconds.

2. The GasWatch 2 then displays the target gas and time before

displaying the battery voltage. The buzzer sounds again after the

battery voltage is displayed.

CAUTION: If the unit is in low battery warning, change the battery

immediately. If the unit is in dead battery alarm, change the

battery before attempting to use the unit.

3. The gas sensor inside the GasWatch 2 begins operating and the

concentration of the t arget ga s is displayed on the LCD. The GasW a tch

2 is now in Measuring Mode. The target gas is displa yed in the

appropriate units (see specifications) and the current time is displayed

at the bottom of the LCD.

NOTE: Wh en using the GasWatch 2 for the first time, check the current

time and verify that it is correct for your time zone. If it is not, set

the time as described in “Setting the Time”.

Performing a Fresh Air Adjustment

Before using the GasWatch 2, it is a recommended to set the fresh air

reading for the target gas to ensure accurate gas readings in the

monitoring environment.

1. Find a fresh air environment. This is an environment free of toxic or

combustible gases and of normal oxygen content (20.9%).

2. With the unit on and in Measuring Mode, pr ess and h old the AIR butto n

for about three seconds to allow the GasWatch 2 to set the fresh air

reading.

While you are pressing the AIR button, the LCD displays “hold”, a

prompt for you to keep pressing the AIR button.

9 • Start Up GasWatch 2 Operator’ s Manual

Page 15

3. When the fresh air readings have be en set, the L CD displ ays “Adj” f or 2

seconds which prompts you to release the AIR button . The unit will set

the reading to 0 ppm for the GW-2C and GW-2H and to 20.9% oxygen

for the GW-2X.

4. The unit then returns to normal operation and the display indicates the

current gas concentration.

Turning Off the GasWatch 2

1. Press and hold the POWER/MODE button for about five seconds to

turn off the unit. The buzzer will pulse wh ile the POWER/MODE button

is being pressed before the unit turns off.

2. Release the button when the LCD is blank. The unit is off.

GasWatch 2 Operator’s Manual Start Up • 10

Page 16

Operation

This section describes the normal operation of the GasWatch 2. It explains

how the unit can be used to displa y peak, STEL, a nd TWA readings for the

GW-2C and GW-2C, and minimum and maximum readings for the GW-2X.

It also covers alarm indications.

Measuring Mode

After you have powered up the GasWatch 2 and performed a fresh air

adjustment follo wing the instr uctions of the previ ous section, “Start Up”, the

GasWatch 2 is in Measuring Mode.

In Measuring Mode, the battery level, time, and target gas concentration

are displaye d on the LCD. The battery icon has four bars visible when the

battery is full. As the battery charge dec re ases, the ba rs will di sappe ar. On

the GW-2C, CO is displayed in parts per million (ppm). On the GW-2H, H2S

is displayed in ppm. On the GW-2X, oxygen is displaye d as volume percent

(%).

Battery

level

Gas concentration

0

Time

Figure 2: LCD in Measuring Mode

NOTE: The time is displayed in military format with the hour going from 0

to 24.

21:19

Displaying the Peak, STEL, and TWA (GW-2C & GW-2H)

You can display the Peak, STEL, and TWA readings on the GW-2C and

GW-2H when the GasWatch 2 is in Measuring Mode using the POWER/

MODE button. STEL is an acronym for short-term exposure limit, and it is

the average reading of the target gas (H2S or CO) during the last 15

minutes. TW A is an acr on ym for time- wei g hte d aver ag e, and it is the

average reading for the target gas (H2S or CO) during the last eight (8)

hours. If eight (8) hours has not elapsed since the unit was turned on, the

TWA is still calculated over eight hours, with the missing time assigned a

zero (0) value for the readings. Similarly, if the unit has not been on for 15

minutes, the missing time is assigned a 0 val ue and the STEL is calculated

over 15 minutes. The Peak, STEL, and TWA readings are cleared when

the unit is turned off.

ppm

11 • Operation GasWatch 2 Operator’s Manual

Page 17

1. Make sure the GasWatch 2 is in Measuring Mode. The current gas

concentration should be displayed on the LCD.

2. Press and release the POWER/MODE button to enter Peak Display

Mode. This will activate the LCD backlight and display the Peak

reading. A small Peak symbo l is displayed in the up per lef t corner of the

LCD.

3. Press and release the POWER/MODE button again to enter STEL

Display Mode. This will display the STEL reading. The word “STEL” is

displayed in the middle of the LCD above the reading.

4. Press and release the POWER/MODE button again to enter TWA

Display Mode. This will display the TWA reading. The word “TWA” is

displayed in the middle of the LCD above the reading.

5. Press and release the POWER/MODE button once again to return to

Measuring Mode.

NOTE: If you do not press a button for 20 seconds while displaying the

Peak, STEL, or TWA readings, the unit will return to Measuring

Mode automatically and the backlight wil l turn off.

Displaying the Min and Max (GW-2X)

You can display the minimum (Min) and maximum (Max) readings on the

GW-2X when the GasWatch 2 is in Measuring Mode using the POWER/

MODE button. The Min and Max readings are cleared when the unit is

turned off.

1. Make sure the GasWatch 2 is in M easuring Mode. The oxygen

concentration should be displayed on the LCD.

2. Press and release the POWER/MODE button to enter Min Display

Mode. This will activate the LC D backli gh t an d displ a y the M in re ading.

A small Min symbol is displayed in the upper left corner of the LCD.

3. Press and release the POWER/MODE button again to enter Max

Display Mode. This will display the Max reading. A small Max symbol is

displayed in the upper left corner of the LCD.

4. Press and release the POWER/MODE button once again to return to

Measuring Mode.

NOTE: If you do not press a button for 20 seconds while displaying the

Min or Max readings, the unit will return to Me asuring Mode

automatically and the backlight wi ll turn off.

GasWatch 2 Operator’s Manual Operation • 12

Page 18

Alarms

This section covers alarm indications. It also tells you how to reset the

GasWatch 2 after an alarm has occurred and how to respond to an alarm

condition.

Alarm Indications, GW-2C & GW-2H

The GW-2C and the GW-2H will sound an alarm and the unit will vibrate

when the target gas concentration, CO or H2S, rises above the low alarm

point. The GasWatch 2 als o sounds an alarm and v i brates when the high

alarm point, the STEL alarm point, or the TWA alarm point is reached. It

also has a low batter y warni ng, a de ad batt ery al arm, an over rang e ala rm,

a sensor failure alarm, and a syst em fa ilure a lar m. Se e Ta ble 3 b elo w for a

description of each alarm indication.

Alarm Indications, GW-2X

The GW-2X will sound an alarm and the unit will vibra te when the oxygen

concentration fall s be lo w the l ow al ar m point or rises above the hi gh al ar m

point. It also has a low battery warning, a dead battery alarm, an over

range alarm, a sensor failure alarm, and a system failure alarm. See

Table 3 below for a description of each alarm indication.

The table below summarizes the types of ala r ms produced by the

GasWatch 2.

Table 3: Alarm Types and Indications

Alarm T ype LCD Indications Other Indications

Low Alarm

Concentration of gas

rises above the low

alarm point, or for the

GW-2X, falls below

the low alarm point.

High Alarm

Concentration of gas

rises above the high

alarm point.

• Gas reading

flashes.

• Back light turns on.

• Gas reading

flashes.

• Back light turns on.

• Pulsing tone once

per second.

• Unit vibrates once

per second.

• Alarm lights flash

once per second.

• Pulsing tone twice

per second.

• Unit vibrates twice

per second.

• Alarm light flashes

twice per second.

13 • Operation GasWatch 2 Operator’s Manual

Page 19

Table 3: Alarm Types and Indications

Alarm T ype LCD Indications Other Indications

TWA or STEL

(GW-2C & GW-2H

Only)

Concentration of CO

or H2S rises above the

• Back light turns on.

• TWA or STEL

blinks to the left of

the battery icon.

• If the unit is in both

TWA alarm and

TWA or STEL alarm

point.

STEL alarm, both

TWA an d STEL will

be displayed.

Over Range • Gas reading

replaced by blinking

brackets.

• Back light turns on.

Low Battery Warning • Last remaining bar

on the right in

battery icon

flashes.

• Pulsing tone once

per second.

• Unit vibrates once

per second.

• Alarm light flashes

once per second.

• Pulsing tone once

per second.

• Unit vibrates once

per second.

• Alarm light flashes.

•None

Dead Battery Alarm • Gas reading

replaced by FAIL.

• Battery icon

flashes.

Sensor Failure • Gas reading

replaced by FAIL.

System Failure • Gas reading

replaced by FAIL.

• Time replaced by

SYS below FAIL.

• Double Pulsing

Tone (two pulse s i n

quick succession)

once a second.

• Double Pulsing

Tone (two pulse s i n

quick succession)

once a second.

• Double Pulsing

Tone (two pulse s i n

quick succession)

once a second.

GasWatch 2 Operator’s Manual Operation • 14

Page 20

Resetting Gas Alarms

To reset a gas alarm, press the POWER/MODE button after the gas

reading falls below the low alarm point (or above for the GW-2X). If a TWA

or STEL alarm has been activated, i t c annot be reset unless you turn off

the unit.

NOTE: Even though the gas concentration may have ret urned to normal

or may have fallen below the alarm point, the alarm indications will

continue until you have reset the alarm using the MODE/POWER

button.

Responding to Alarms

This section describes response to gas, over range, battery, sensor failure,

and system failure alarms.

Responding to Gas Alarms

1. Follow your estab lished procedure for an increasing gas condition or a

decreasing oxygen condition.

2. Reset the alarm using the POWER/MODE button once the alarm

condition has been cleared.

Responding to an Over Range Alarm

WARNING: An over range condition may indicate an extreme toxic

gas or oxygen concentration. Confirm the gas

concentration with a different GasWatch 2 or with another

gas detecting device.

1. Follow your estab lished procedure for an increasing gas condition.

2. Reset the alarm using the MODE/POWER button once the alarm

condition has cleared.

3. Calibrate the GasWatch 2 as described in the calibration section of this

manual.

4. If the over range condition contin ues, you may need to replace the

sensor.

5. If the over range condition continues after you have replaced the

sensor, contact RKI Instruments, Inc. for further instructions.

15 • Operation GasWatch 2 Operator’s Manual

Page 21

Responding to Battery Alarms

WARNING: The GasWatch 2 is not operational as a gas monitoring

device during a dead battery alarm. Take the GasWatch 2

to a non-hazardous area and change the battery as

described in “Changing the Lithium Battery”.

The GasWatch 2 is fully functional in a low battery warning condition.

However, only a couple of days of operation may remain depending on

certain condi tion s such as a l arm occurrences. Change the battery as soo n

as possible when a low battery warning occurs as described in “Changing

the Lithium Battery”.

NOTE: Alarms and the back light feature consume battery power and

reduce the amount of operating time remaining.

Responding to a Sensor Failure Alarm

1. Try calibrating the sensor first, as described in “Calibration”, before

replacing it.

2. If the sensor failure continues, replace the sensor as described in

“Replacing a Sensor”.

3. If the sensor failure condition continues after you have replaced the

sensor, contact RKI Instruments, Inc. for further instructions.

Responding to a System Failure Alarm

1. If a system failure occurs, try turning off the unit an d turning it on again.

2. If the unit is still in system failure, contact RKI Instruments, Inc. for

further instructions.

GasWatch 2 Operator’s Manual Operation • 16

Page 22

Displaying and Setting the Alarm

Points

The GasWatch 2 allows you to display and set the alarm poi nts. There is a

Low Alarm point and a High alarm point on all three models. The GW-2C

and GW-2H also have ST EL and TWA alarm points. The alarm points and

their factory settings for the three GasWatch 2 models are summarized in

the table below:

Table 4: Alarm Points of the Four Target Gasses

Model Low Alarm High Alarm STEL TWA

GW-2C (CO) 25 ppm 50 ppm 200 ppm 25 ppm

GW-2H (H

GW-2X (O2) 19.5%

In the table above, Lo w Alarm and High Alarm for the GW-2C and GW-2H

refer to a rising concentration of the target ga ses. The Low Alarm is

triggered at the Low Al arm concen tration list ed in the t able. For the GW -2C

that would be 25 ppm CO, a nd for t he GW -2H that woul d be 10.0 ppm. The

High Alarm is triggered when the High Alarm co ncentration is reache d.

For the GW-2X, Low Alarm is triggered when the concentration of oxygen

falls below 19.5%. When the concentration of oxygen rises above 23.5%,

High Alarm is activated.

S) 10.0 ppm 30.0 ppm 15.0 ppm 10.0 ppm

2

Decreasing

23.5%

Increasing

N/A N/A

Display and Adjust the Alarm Points

1. Make sure the GasWatch 2 is turn ed off. The LCD should be blank.

2. Press and hold the AIR button, then press a nd hold the POW ER/MODE

button.

1 7 • D i s p l a y i n g a n d S e t t i ng t h e A l a r m P o i n t s GasWatch 2 O perator’s Manual

Page 23

3. As soon as segme nts appear on the disp lay (approximately one

second), release the AIR button. Wh en the unit “beeps,” release the

POWER/MODE button to put the GasWatch 2 into Alarm Point

Adjustment Mode. The LCD should display the Low Alarm setting for

the target gas and the battery level.

Rising

Alarm

.

Battery

level

Alarm point

10.0

Alarm

Name

Figure 3: LCD in Alarm Adjustment Mode, GW-2C & GW-2H

Falling

Alarm

LO

.

19.5

Alarm

Name

Figure 4: LCD in Alarm Adjustment Mode, GW-2X

LO

ppm

Battery

level

Alarm point

%

NOTE: If the LCD should show “CAL” in the lower left corner, the

GasWatch 2 is in Calibration Mode. You will need to press and

hold the POWER/MODE button to turn off the unit. Begin again

with step 2 above.

4. Use the POWER/MODE button to cycle through the alarm points by

pressing and releasing. If you press and hold the POWER/MODE

button, you may tur n of f t he uni t. Wh en an alar m po int is displ ayed, u se

the AIR button to increase the alarm point. If you pass the desired

setting, continue increasing the alarm point until it reaches the

maximum setting and it will “wrap around” to the minimum setting.

5. If you adjust an alarm setting, press the POWER/MODE button to save

the new setting. The next alarm point will be di splayed.

GasWatch 2 Operator’s Manual Displaying and Setting the Alarm Points • 18

Page 24

NOTE: You can only cycle through the alarm points once before the

GasWatch 2 goes into its startup sequence followed by Measuring

Mode. If you want to cycle through the alarm points again, press

and hold the POWER/MODE button to turn off the GasWatch 2.

Then begin with ste p 2 a bove to put t he unit back i nto A larm Poin t

Adjustment Mode.

6. When you are finished viewing or adjusting the alarm point settings,

press and release the POWER button repeatedly until the ROM number

for your unit appears on the LCD. The ROM is the component that

contains the software that runs the GasWatch 2. The GasWatch 2 will

then go into its startup sequence followed by Measuring Mode.

1 9 • D i s p l a y i n g a n d S e t t i ng t h e A l a r m P o i n t s GasWatch 2 O perator’s Manual

Page 25

Setting the Time

The GasWatch 2 allows you to set the time.

1. Make sure the GasWatch 2 is on and in Measuring Mode.

2. Press and hold the Air button, then press and hold the POWER/MODE

button to put the GasWatch 2 into Time Adjustment Mode. Relea se the

buttons when the word “SEt” appears on the LCD. Belo w “SEt”, the time

will be displayed and the hour in the time will be flas hing.

Hour

Battery

level

SEt

21:19

Figure 5: LCD in Time Adjustment Mode

Minute

3. Use the AIR button to increase the hour to the desired setting. If you

pass the desired setting, continue to increase the hour until it reaches

23 and then wraps around to 0, then set to the desired setting.

4. Press the POWER/MODE button to accep t the hour setting. The minute

starts flashing.

5. Use the Air button to increase the minute setting to the desired setting.

6. Press the POWER/MODE button to accept the minute setting and

return to Measuring Mode.

GasWatch 2 Operator’s Manual Setting the Time • 20

Page 26

Calibration

This section covers the calibration of the GasWatch 2. Setting the fresh air

reading is described first followed by setting the span (GW-2C and GW-2H)

and zero (GW-2X) reading. You are told what is needed to complete the

task, how to assemble the calibration kit, and how to set the sp a n (zero fo r

GW-2X) reading.

WARNING: Use a 0.5 LPM (liters per minute) fixed flow regulator

Setting the Fresh Air Reading

You will need to set the fresh air reading first before setting the span (zero

for GW-2X) reading.

1. Find a fresh-air en vironment. This is an environment free of toxic or

when calibrating. Use of a different flow rate may

adversely affect the accuracy of the calibration.

combustible gases and of normal oxygen content (20.9%).

2. Turn on the GasWatch 2 by pressing and hol d i ng the POWER/ MOD E

button for one second. Allow the unit to finish its warm-up sequence.

3. Press and hold the AIR button for about three seconds to allow the

GasWatch 2 to set the fresh air reading. It will set the reading on the

GW-2C and GW-2H to 0 ppm and on the GW-2X it will set the reading

to 20.9% oxygen.

4. While you are pressing the AIR button, the LCD displays “Hold”, a

prompt for you to keep pressing the AIR button.

5. When the fresh air reading has been set, the LCD displays “Adj”, which

prompts you to release the AIR button.

Setting the Spa n (Zero for GW-2X) Reading

This section tells you how to set the span re ading on the GW-2C and GW2H and the zero reading on the GW-2X using the Calibration Mode.

Preparation

Set the fresh air reading as described in “Setting the Fresh Air Reading.”

You will also need the supplies listed below. A calibration kit is available

from RKI Instruments, Inc. for each GasWatch 2 model for this purpose

(see “Parts List”).

• A gas cylinder with an appropriate concentration of the target gas for

the GW-2C or GW-2H, or a cylinder of 100% nitrogen for the GW-2X.

21 • Cali bration GasWatch 2 Operator’ s Manual

Page 27

NOTE: On the GW-2X, instead of 100% nitrogen (0% oxygen), it is

allowable to use an oxygen concentration of up to 19.5% to set

the zero reading.

• To carry out the calibration, you will need a fixed-flow regulator with an

on/off knob and a flow rate of 0.5 LPM (liters per mi nute), nonabsorbent tubing, and the calibration adapter that will fit over the

GasWatch 2’s sensor.

Assembling the Calibration Kit

WARNING: Calibrate the GasWatch 2 in a non-hazardous

environment.

1. Attach the calibration adapter to the unit. It opens up like a clothes pin

and fits over the sensor area and retains itself over the sensor.

2. Attach the calibration tubing to the calibration adapter, then attach the

opposite end of the tubing to the regulator.

Setting the Span Readings for the Target Gas

1. Make sure you have set the fresh air reading and have set up the

calibration kit as described in the procedure above.

2. Make sure the GasWatch 2 is off.

3. Press and hold the AIR button, then press a nd hold the POW ER/MODE

button. Release both buttons when you hear a “beep.” The unit is in

calibration mode and the LCD displays “CAL” in the lower left and the

battery level in the upper right. It also displays the gas concen tration the

unit expects you to use, the calibration value, when setting the span or

zero reading.

4. If necessary, use the AIR button to adjust the calibration value to the

desired setting. The calibration value must match the gas concentration

in the calibration cylinder.

5. Press the POWER/MODE button to accept the calibration value and

proceed to the calibration screen. The current gas reading is displayed.

6. Attach the regulator to the gas cylinder.

7. Turn the regulator knob counterclockwise to open the regulator.

NOTE: If you wish to cancel the span or zero adjustment process, press

and hold the AIR button for about 3 seconds. The unit will cancel

the span or zero adjus tment and begin its startup s equence.

GasWatch 2 Operator’s Manual Calibration • 22

Page 28

8. Let the gas flow for one minute and then press the POWER/MODE

button. The unit will adjust the span (GW-2C or GW-2H) or zero (GW2X) based on the calibration value that was saved in step 5 above.

9. Turn the regulator knob clockwise to close the regulator.

10.Remove the regulator from the gas cylinder and the calibration adapter

from the unit. As soon as the unit makes the calibration adjustment, it

will begin its startup sequence and then en ter Measuring Mode.

NOTE: If the gas reading is high enou gh (low enough for the GW-2X)

when the unit enters Measuring Mo de, an alarm condition will

occur. Reset the alarm using the POWER/MODE button when the

gas reading falls below (rises above for the GW-2X) the alarm

point.

23 • Cali bration GasWatch 2 Operator’ s Manual

Page 29

Maintenance

This section describes troubleshooting procedures for the GasWatch 2. It

also describes how to change the GasWatch 2’s battery as well as how to

replace the sensor cover and gas sensor.

WARNING: RKI Instruments, Inc. recommends that service,

Troubleshooting

The troubleshooting table describes error messages, symptoms, probable

causes, and recommended action for problems you may encounter with

the GasWatch 2.

calibration, and repair of RKI instruments be performed

by personnel properly trained for this work. Replacing

sensors and other parts with original equipment does not

affect the intrinsic safety of the instrument.

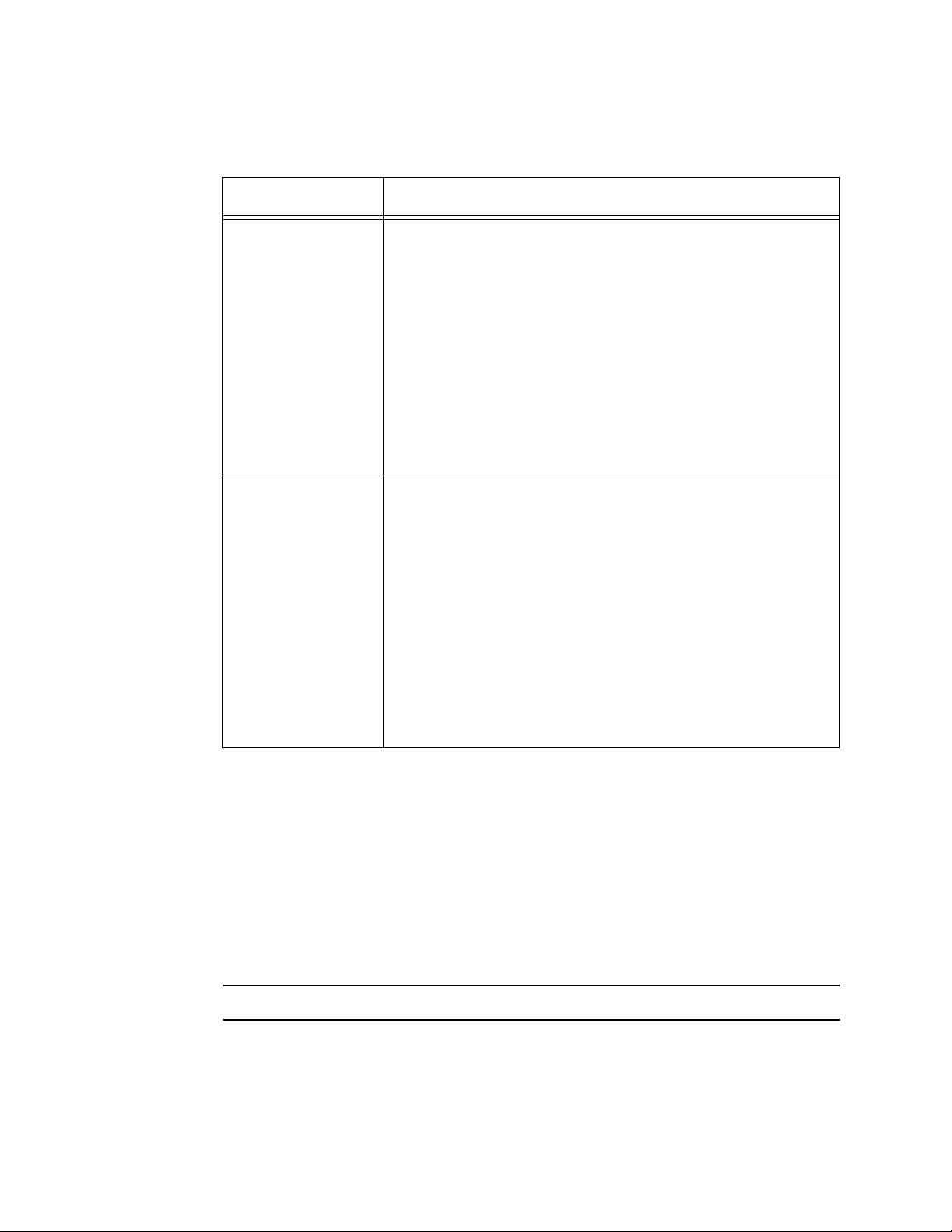

Table 5: Troubleshooting the GasWatch 2

Symptoms

• The LCD is

blank.

• The LCD shows

abnormally high

or low readings

but other gas

detection

instruments do

not.

Probable

Causes

• The unit may

have been

turned off.

• The battery

may need to

be replaced.

• The unit may

need to be

recalibrated.

• The sensor

may need

replacement.

Recommended Action

1. To turn on the unit, press

and hold the MODE/

POWER button.

2. If the unit does not turn on,

replace the battery.

3. If the difficulties continue,

contact RKI Instruments,

Inc. for further instruction.

1. Recalibrate t he unit.

2. Replace the sensor and

calibrate the unit.

3. If the difficulties continue,

contact RKI Instrument s for

further instruction.

GasWatch 2 Operator’s Manual Maintenance • 24

Page 30

Table 5: Troubleshooting the GasWatch 2

Symptoms

• “FAIL” displays

during span or

zero adjustment.

Probable

Causes

• The calibration

value may not

match the

cylinder gas

concentration.

• The sample

gas is not

reaching the

sensor

because of a

bad

connection.

• The calibration

cylinder may

be out of gas

or is outdated.

• The sensor

may need

replacement.

Recommended Action

1. Check all calibration tubing

for leaks or for any bad

connections.

2. Make sure the GasW atch 2

has been properly set up

for calibration.

3. Verify that the calibration

cylinder contains an

adequate supply of fresh

test sample.

4. If the fail condition

continues, replace the

sensor.

5. If the difficulties continue,

contact RKI Instruments,

Inc. for further instruction.

• “FAIL SYS” is

indicated on the

LCD

• A microprocessor failure has

occurred.

1. Turn off the unit and turn it

on again.

2. If difficulties continue,

contact RKI Instruments,

Inc.

Replacing the Lithium Battery

WARNING: Replace the lithium battery in a non-hazardous

environment.

Replace the lithi um battery when the bat tery icon indicate s

that the unit is in low battery warning. When in low battery

warning, only one battery level indication bar remains and it

is flashing.

NOTE: Use a CR 2450 battery manufactured by Sony, Eveready, Maxell

Hitachi, or Toshiba to maintain the CSA classification of the

GasWatch 2.

25 • Maintenance GasWatch 2 Operator’s Manual

Page 31

1. Verify that the GasWatch 2 is off.

2. On the back of the unit, unscrew the two screws that retain the battery

cover far enough so you can pull the cover away from th e bo ttom case.

The screws are held captive in the battery cover if you do not unscrew

them too far.

Battery Cover

Lithium Battery,

CR 2450

+

Note: Shown w/out

wristband.

Figure 6: Changing the Battery

3. Carefully remove the old battery.

4. Carefully install the new battery, type CR 2450, noting the polarity

indications on the battery cover and in the battery compartment. The

negative (-) side of the battery goes in first.

5. Reinstall the battery cover.

NOTE: When the battery is changed, since all power to the unit is lost

when the old battery is removed, the clock is reset to 0:00 when

the new battery is installed. The clock must be set to the correct

time after the battery is changed.

6. Press the POWER/MODE button for a few seconds.

7. The display will indicate “SET” and show the ti me as 0 :00 w it h th e h our

flashing.

8. Use the AIR button to increase the hour to the desired setting. If you

pass the desired setting, continue to increase the hour until it reaches

23 and then wraps around to 0, then set to the desired setting.

GasWatch 2 Operator’s Manual Maintenance • 26

Page 32

9. Press the POWER/MODE button to accep t the hour setting. The minute

starts flashing.

10.Use the Air button to increase the minute setting to the desired setting.

11. Press the P OWE R/ MOD E but ton to acce pt the minute setting. The unit

will begin its startup sequence and the enter Measurin g Mode.

Replacing the Sensor

WARNING: Replace the sensor in a non-hazardous environment.

1. Verify that the GasWatch 2 is off.

2. With a flat blade screw driver, gently pry off the sensor cap. It snaps

onto the top case with two tabs.

3. Remove the sensor gasket with the sensor cover from the sensor.

Sensor Cap

Sensor Cover

Charcoal Filter

Disk (GW-2C Only)

Sensor Gasket

Sensor

Note: Shown w/out

wristband.

Figure 7: Removing the Sensor Cap, Gasket, and Cover

4. Carefully remove the old sensor from the sensor socket.

NOTE: Th e sensors in th e GW -2C (CO sensor) and G W- 2H (H2S sensor)

are keyed and can only be inserted in the socket one way. Note

the orientation of the old sensor before you remove it. The sensor

in the GW-2X is not keyed.

27 • Maintenance GasWatch 2 Operator’s Manual

Page 33

Tab

Align slots in CO

and H2S sensor

RKI

POWER

MODE

Note: Oxygen sensor is not keyed.

Unit shown w/out wristband.

AIR

Tab

with tabs in case.

Figure 8: Replacing the Sensor

5. Carefully insert the replacement sensor in the socket. Make sure the

sensor face with the colored ring is facing up.

CAUTION: When replacing the sensor, verify that the sensor is properly

aligned with its socket before inserting it into the socket. The

CO and H2S sensors have alignment slots w hich match up

with alignment tabs in the sockets. Forcing a sensor into its

socket may damage the sensor or the socket.

6. Reinstall the sensor gasket with the se nsor cover over the sensor.

7. Reinstall the sensor cap.

8. Calibrate the new sensor as described in the calibration section of this

manual.

Replacing the Sensor Cover

WARNING: Replace the sensor cover in a non-hazardous

environment.

1. Verify that the GasWatch 2 is off.

2. With a flat blade screw driver, gently pry off the sensor cap. It snaps

onto the top case with two tabs.

3. Remove the old sensor cover from its recess in the sensor gasket.

4. Install the new sensor cover into the recess in the sensor gasket.

5. Reinstall the sensor cap.

GasWatch 2 Operator’s Manual Maintenance • 28

Page 34

Replacing the Charcoal Filter Disk

WARNING: Replace the charcoal filter disk in a non-hazardous

environment.

1. Verify that the GasWatch 2 is off.

2. With a flat blade screw driver, gently pry off the sensor cap. It snaps

onto the top case with two tabs.

3. Remove the old charcoal filter from its recess in the sensor gasket.

4. Install the new charcoal filter into its recess in the sensor gasket.

5. Replace the sensor cover into its recess in the sensor gasket.

6. Reinstall the sensor cap.

Replacing the Wristband

CAUTION: Wear protective eye wear when removing or replacing the

spring bars from the GasWatch 2. The spring bars may

become projectiles travelling at high speed in any direction if

not handled carefully while bei ng removed or installed.

1. Remove the old wristband from the unit.

Use a spring bar tool to remove the spring bars from the unit. A spring

bar tool may be purchased from a jewelry supply shop or may be

purchased from RKI Instruments, Inc. (see Parts List at the end of this

manual).

The spring bars have a ridge at the end which are accessible between

the case and the wristband. Use the spring bar tool to catch this ridge

and push the spring bar away from it s hole in the case. The wr i st ban d

will compress to allow you to push the spring bar far enough so it will

come out.

29 • Maintenance GasWatch 2 Operator’s Manual

Page 35

Wristband

Use spring bar

tool to remove

spring bars.

POWER

MODE

AIR

Figure 9: Removing the Spring Bars

2. Remove the spring bars from the old wristband.

The spring bar is protected by a hollow sleeve that is inserted in the

wristband. The hollow sleeve may remain inside the old wrist band

when the spring bar comes out. Be sure to remove the outer sleeve

from the wrist band.

3. Insert the hollow sleeves and spring bars into the new wristband.

4. Install the new wristband on to the unit with a spring bar tool.

GasWatch 2 Operator’s Manual Maintenance • 30

Page 36

Parts List

Table 6 lists replacement parts and accessories for the GasWatch 2.

Table 6: Parts List

Part Number Description

06-1248RK Calibration kit tubing (specify leng th in feet)

07-0029RK Sensor gasket

07-6007RK O-rin g for battery cover

10-1097RK Screw, for battery cover

10-1100RK S crew, self tapping, for case

10-1100RK-02 Replacement kit, 8 case screws & 4 battery

cover screws

13-0105RK Wristband

13-0204RK Spring bar w/hollow sleeve to retain wr istband

21-1834RK Sensor cap

33-0166RK Sensor cover disk membrane, 10 pack

33-7106RK Charcoal filter disk, 10 pack

49-1404RK Lithium battery, 3.0 volt, coin type, CR 2450

81-1050RK Regulator with gauge and knob, fixed flow, 0.5

LPM, for 58/34 liter aluminum cylinder, 103 liter

steel cylinder

81-1051RK Regulator with gauge and knob, fixed flow, 0.5

LPM, for 17/34 liter steel cylinder

81-1104RK Calibration adapter

81-0064RK-01 Calibration cylinder, 50 ppm CO in air, 34 liter

steel

81-0078RK-01 Calibration cylinder, 100% nitrogen,34 liter, steel

81-0151RK-04 Calibration cylinder, 25 ppm H

S in nitrogen,

2

aluminum

81-GW2C-LV Calibration kit for GW-2C, one 34 liter steel gas

cylinder (50 ppm CO in air), regulator , calibration

cup, case, tubing

31 • Part s List GasWatch 2 Operator’ s Manual

Page 37

Table 6: Parts List

Part Number Description

81-GW2H-LV Cali bration kit for GW-2H, one 3 4 li te r al u minum

gas cylinder (25 ppm H

S in nitrogen), regul ator ,

2

calibration c up, case, & tubin g

81-GW2X-LV Calibration kit for GW-2Xone 34 liter steel gas

cylinder (100% nitrogen), regulator, calibration

cup, case, tubing

82-0001RK Spring bar tool

ES-1821 Carbon monoxide senso r

ES-1821L Carbon monoxide sensor, for low humidity use

ES-1827 Hydrogen sulfide sensor

ES-1827L Hydrogen sulfide sensor, for low humidity use

OS-BM2 Oxygen sensor

Appendix A: MRI Applications

When the GasWatch 2 is used in MRI applications or applications where a

strong magnetic field is present on a regular basis, the magnetic field will

cause damage to the instruments’s buzzer over time. This damage may

eventually render the buzzer inoperable.

WARNING: In MRI or similar applications, do not rely on the buzzer

for alarm indications. The GasWatch 2 also uses a

vibrator and visual indications for alarms. Make sure you

are using these indications when using the GasWatch 2

for this type of application.

The damage caused to th e buzzer by a magn etic fiel d in these applic ations

is not covered unde r warranty.

GasWatch 2 Operator’s Manual Appendix A: MRI Applications • 32

Loading...

Loading...