Page 1

Instruction Manual

for

FORMALDEHYDE GAS DETECTOR

MODEL FP-30/FP-40

This instrument is sold and serviced by RKI Instruments, Union City, CA

For questions, parts, or service please contact RKI at (800) 754-5165.

Please read and understand this instruction manual before operating this

instrument.

Part Number: 71-0085RK

Revision: P3

Released: 8/27/03

Page 2

1

Table of Contents

1.1 Start-up Operation 2

1.2 Installation of the Detection TAB 3

1.3 Detection Method 4

1.4 High Density Gas Detection 4

1.5 Memory of Stored Detection Results 4

1.6 Battery Voltage Check 7

1.7 Preliminary Sample-Draw 7

1.8 Purge Cycle 8

1.9 Completion of Detection 8

2.1 Storage of Detection TAB 9

2.2 Handling of Detection TAB 9

4.1 Battery Replacement 12

4.2 Daily Check / Regular Check 12

4.3 Replacement of parts 12

4.4 Storage and Treatment After Long Term Storage 12

13

6

6.1 Specifications 14

6.2 Accessories 14

6.3 Spare Parts List 14

7

15

Page 3

2

1 OPERATION

1.1 Start-Up Operation

Press ON/OFF switch for 2 seconds to turn instrument on and start warm-up and self-diagnosis .

The program and instrument display function one of the following two ways:

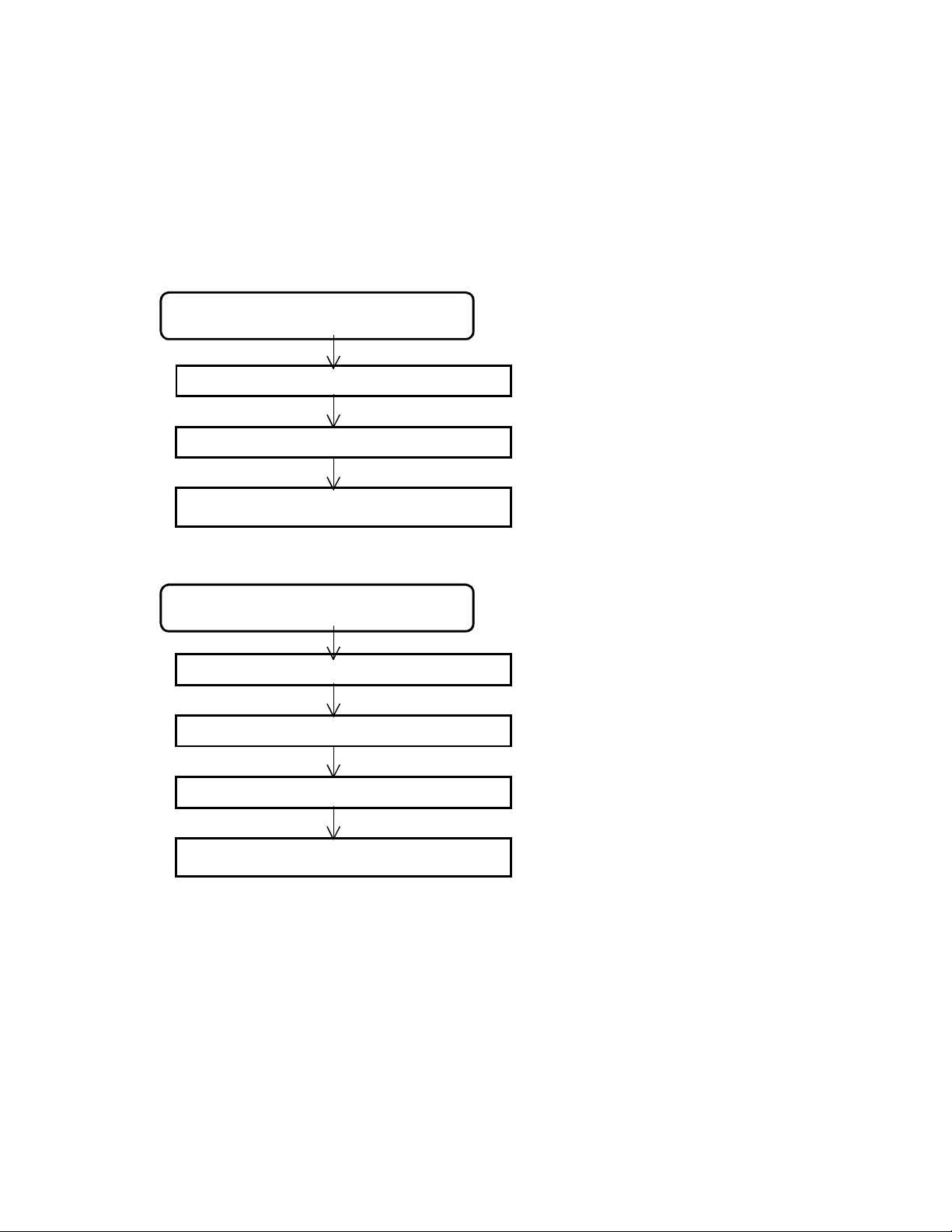

If the detection TAB is not installed before start-up:

Press ON/OFF switch for 2 seconds

BATT E--------l------F Shows the battery capacity

Approx 5 sec

STAND BY OK Standby Condition

Approx 5 sec

SET TAB

If the detection TAB is installed before start-up

Waiting for TAB to be installed and

selected

Press ON/OFF switch for 2 seconds

BATT----------l----F Shows the battery capacity

Approx 5 sec

SELF-DIAGNOSIS Self-diagnosis : Sensor check

Approx 5 sec

STAND BY OK Standby Condition

Approx 5 sec

SELECT TAB No

Select the detection TAB for desired range

using up/down button.

Page 4

3

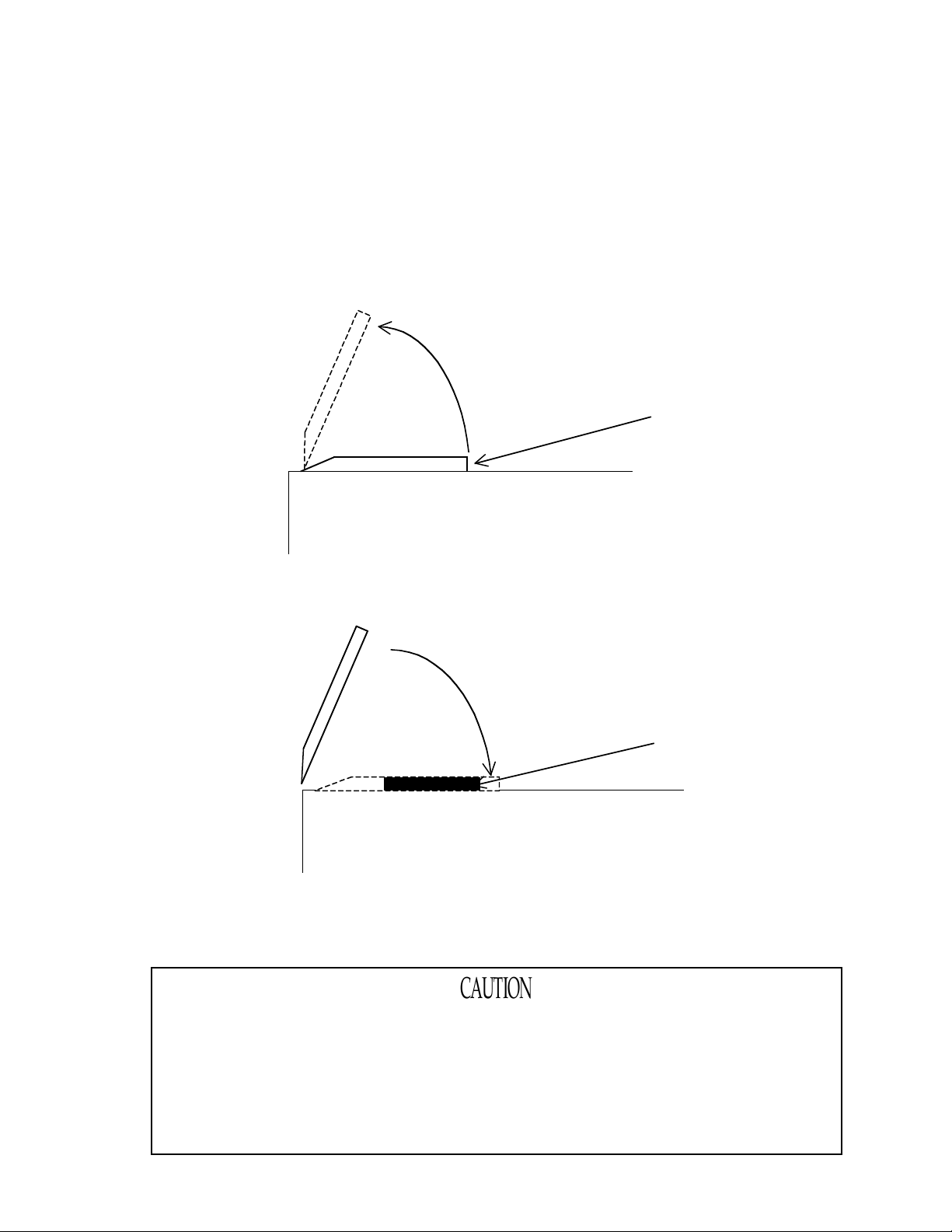

1.2 Installation of Detection Tab

L

D

I

C

I

The detection TAB comes packaged in a sealed foil wrapper. Remove it from the wrapper. The detection

surface of the TAB is protected by a plastic cover that fits over the TAB. Remove this cover. The

detection TAB must only be handled by its edges or backside. Do not touch the indented center section

of the TAB.

1. Open the detection TAB cover.

ift up this way.

etection TAB cover

nstrument (Side view)

2. Place the TAB into the slot under the cover, indented face down, and then close the cover

slowly.

lose the cover.

Detection TAB

nstrument (Side view)

3. Press the center of detection TAB cover with finger to assure proper TAB seating.

When closing the detection TAB cover, close it slowly to avoid pinching finger.

Do not allow the lid to slam shut since that may cause damage to the

instrument.

When installing the detection TAB, do not allow water drops or dust to get in

the TAB port area.

Page 5

4

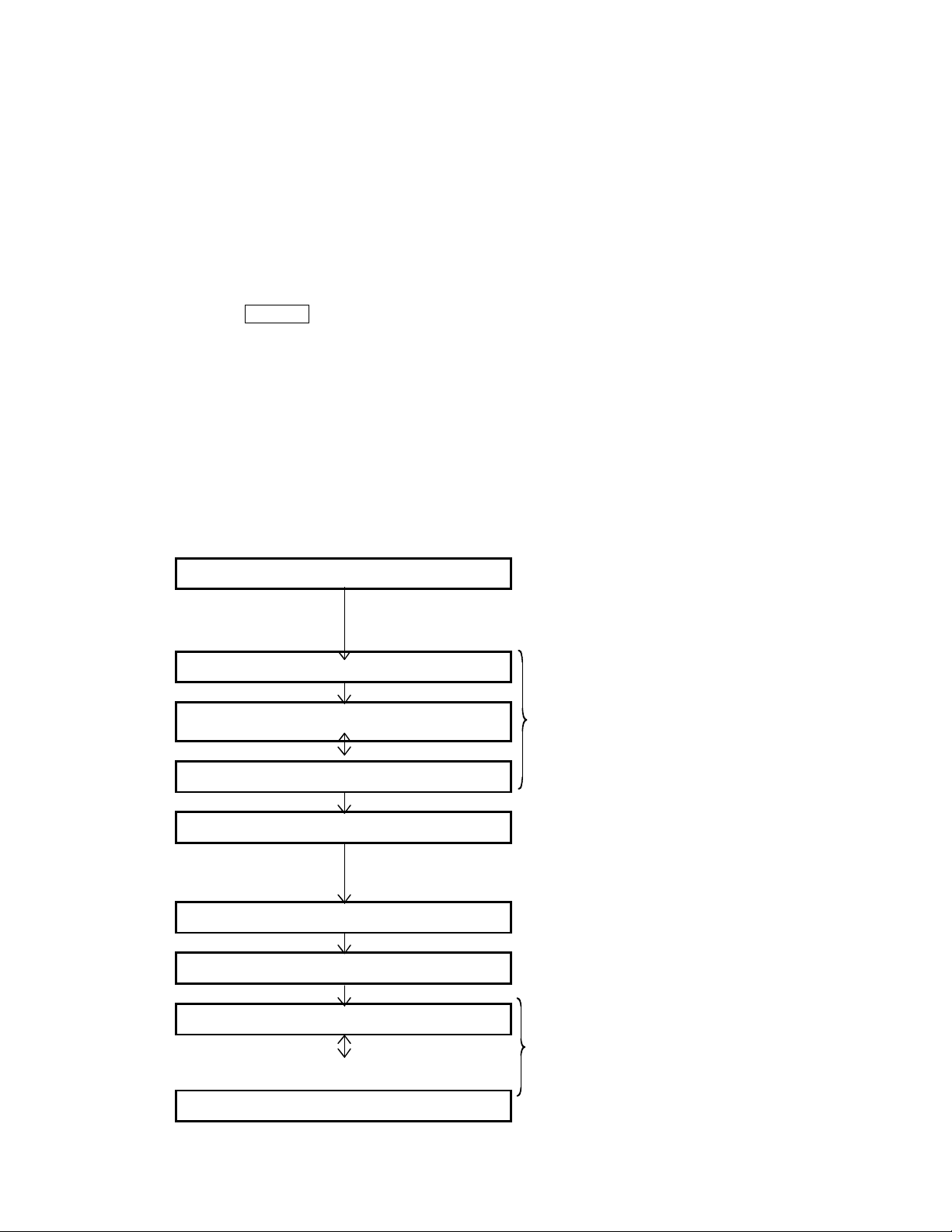

1.3 Detection Method

Gas detection

• Detection waiting condition

The instrument waits in this mode until the detection TAB is installed.

• Installation of the detection TAB

Install the detection TAB.

• Selection of the detection range

Select the detection range by pressing up/down keys.

• Detection starts

Press START

minutes or 30 minutes (as selected).

• Display of detection result

After the detection cycle is completed, the average gas reading during the detection cycle is

shown as the detection result.

• Display of memory number

The number recorded for this reading in the memory is displayed.

• Completion of detection

The gas reading and message will alternately be shown until the used detection

tab is removed. Buzzer sounds every one second until used tab is removed.

Display example

switch to start the pump and start the detection cycle. Cycle is either 15

SET 1 Detection waiting condition

2 Install the detection TAB

SELECT TAB No

008 : HCHO START

008 : HCHO PUSH

008 : HCHO 1800 4 Start

Counting down the detection time. (Sec.)

008 : HCHO 0.100 5 Display of detection result

MO5 REGISTERED 6 Memory number display

REMOVE TAB

beep beep 7 Completion of detection

2 Select the detection TAB (time/range

selection) using the up/down keys.

008 : HCHO 0.100

Page 6

5

NOTE

Only one type of detection TAB is used in the FP-30 & FP-40, but the TAB may be used

for three different detection ranges. For the FP-30, select the TAB No. according to the

desired detection range. The FP-40 can only be used for one detection range.

Detection range Measuring time TAB No.

0 - 0.4 ppm (FP-30) 30 min. 008

0 – 1.0 ppm (FP-30 15 min. 009

0 - 0.6 ppm (FP-40) 3 min 010

• Do not remove tab during detection.

If TAB is removed during detection, the detection is interrupted, and that

cycle cannot be restarted with a new TAB. The error message TAB is

displayed. The old TAB must be discarded and replaced with a new one

before a new cycle is started.

• When the detection range is changed for a new cycle, be sure to exhaust

the inside gas by pre-sample drawing from the instrument (see Section

1.7 Preliminary Sample Draw Mode) to flush out any residual gas

concentrations inside the unit. If high-density gas remains inside the FP30 then it may affect the next gas detection cycle.

• Do not suck water or oil into the instrument since this will cause pump and

instrument damage.

• When detecting gas, confirm that the pump is working by listening to the

humming sound of the pump or confirming that the pump is sucking. If the

pump is not sucking, no gas detection will occur.

• Do not block the gas outlet, or else an incorrect gas reading may result.

Page 7

6

1.4 High Density Gas Detection

If high-density gas is detected, the instrument and any sample hose must be flushed out with fresh air

before installing a new detection tablet. If a new detection tab is installed immediately without flushing

the instrument (and sample hose) out with fresh air, the wrong answer will occur since detection will

start immediately when the new tab in installed. (SEE PRELIMINARY SAMPLE DRAW, STEP 1.7)

1.5 Memory of Stored Gas Detection Results

1.5.1 Checking Stored Data

The past detection results can be displayed by pressing DATA

condition or detection finished condition.

The detection results will be stored into the instrument memory (up to 99 readings maximum). The

memory can be retrieved by using the UP and DOWN keys. When power is off, the memory is retained.

To return to the detection waiting condition or detection finished condition, press DATA

When the DATA

The detection result memory can store only the past 99 readings. If the memory is full, the display will

say:

For deletion of measuring results stored in memory, see the next page.

If there is no stored data, the display will say:

switch is pressed, the most recent record is displayed.

M05 : HCHO 0.100

DATA FULL

DATA EMPTY

switch when in the detection waiting

switch again.

Page 8

7

1.5.2 Deleting the Memory of Stored Detection Results

To delete the memory:

While in the data display screen described above in 1.5.1, press the START

simultaneously. The message to delete the stored detection results is displayed.

Then, when START

If DATA

deleting the data.

Display every 4 sec.

Display every 1 sec.

switch is pressed instead, the instrument will return to the previous condition without

• It is impossible to delete an individual detection result.

• All detection results are deleted simultaneously, and once deleted they are

switch is pressed, all the stored detection results are deleted.

DELETE START

Display every 1 sec.

DELETE PUSH

STORE DATA

STORE PUSH

not recoverable.

+ DATA switches

1.6 Battery Voltage Check

By pressing DATA switch for 3 sec while in detection waiting condition or detection finished mode,

the current battery voltage can be checked. If 20 seconds elapses without any switch being pressed

while in the battery voltage check screen, the instrument will return to the state it was in, either

detection standby condition or detection finished mode.

To return to the detection waiting or detection finished mode, press DATA

BATT E----------l------F

switch again.

1.7 Preliminary Sample Draw Mode

When detection gas mode is changed, or if a high gas concentration was last detected with the

instrument, it is possible the next gas detection test will be influenced by high-density gas

remaining inside the instrument. To prevent this, it is necessary to flush the instrument using the

preliminary sample-drawing mode.

Page 9

8

Preliminary sample drawing method

With detection TAB removed, press START

Preliminary sample drawing is made for about 5 sec to flush out the previous sample, and the following

message is displayed until completion.

Previous sample drawing

Preliminary sample drawing must be done in fresh air , or in the air of the room

switch.

you will check next.

1.8 Purge Cycle

When sample-drawing an adsorptive gas continuously, there is the possibility the gas will be adsorbed

onto the inside of the tubing, especially if a high concentration of gas is encountered. If a high

concentration of gas is encountered, the system must be purged in known fresh air before taking a

reading. After purge, the gas detection cycle will start automatically.

Purging method

Mount the detection TAB, select the purge cycle by using UP and DOWN keys. A used TAB may be

used for the purge cycle.

PURGE S T A R T

PURGE P U S H

When START switch is pressed, the purging starts. for 10 minutes

PURGE 600

When 10 min (600 sec.) passes, the purge cycle is finished and the unit is ready to start the next gas

detection cycle.

REMOVE TAB

Count down 600 sec.

1.9 Completion of Detection

HOW TO TURN INSTRUMENT POWER OFF

To turn instrument off, press and hold ON/OFF

When pressing ON/OFF

Also, if 5 minutes passes without any button being pressed, or when 5 minutes has elapsed since the last

operation, the power will shut off automatically.

switch, the buzzer sounds about 9 times.

switch for about 3 sec.

Page 10

9

2 ABOUT THE DETECTION TAB

The Gas Detection Tablet is a unique detection method developed by our company. The tablet contains a

paper impregnated with special chemicals that will darken if exposed to a specific gas.

Proper storage of the tablet is critical. If tablet is not stored correctly, the detection results will not be

accurate.

2.1 Storage of Detection TAB

Detection TAB must be used within the storage period indicated on the package.

Use of tablets beyond their expiration date can result in incorr ect readings.

Leave detection TAB in its package until ready for use. Once a tablet is removed

from its packet, it will begin drying out, and also it may respond to gas in the local

environment causing error if used for any actual test.

Follow the storage instructions on the detection TAB package. Detection tabs must be stored in a

refrigerator for longest life.

If detection tab is removed from its package and not used right away, it must be discarded. It will give

an incorrect reading if used later. Prolonged exposure to air or background gas will dry out the tablet or

cause it to become discolored, either of which will cause an incorrect reading.

2.2 Handling of Detection TAB

Do not touch the test paper of the detection TAB.

____ ___Test paper (White) Ring (Black) TAB No & Gas name etc

Do not touch the test paper with your finger; this will cause an incorrect reading.

Page 11

1

Always use a new detection TAB for readings

For each gas test, be sure to use new detection TAB. TABS are intended for one time use only, and

should not be opened until immediately before you intend to use them. If an already used TAB is

attempted to be used, an error message “TAB” may be shown. But, even if the error message is not

displayed, the detection result will not be correct if an old TAB is used.

Use TAB immediately after removing from package.

After unpacking the detection TAB, it is subject to gas response and dust, which discolors the TAB due

to response to the measured. To maintain accuracy, start measurement immediately after unpacking.

_

Check that the number of the detection TAB corresponds to the TAB number of

displayed on FP-30 during the Start Measurement display.

If the TAB used is not the same TAB number the instrument believes you are using, the reading will not

be correct.

0

Page 12

1

3 SELF DIAGNOSIS FUNCTION

A Self-diagnosis function is provided with this instrument.

Each self-diagnosis mode has a unique alarm, display, and buzzer sound.

Types of self-diagnosis and alarm pattern

Self diagnosis Buzzer Display

Power on

Low battery precaution No sound Flickering “B” at left

During gas detection

Failure of pump connection Continuous PUMP FAILURE

Low battery voltage Continuous REPLACE BATTERY

System error No sound SYSTEM ERROR

Sensor failure Continuous FAIL

Lower battery voltage Continuous REPLACE BATTERY

TAB detachment No sound RESET TAB

TAB FAILURE

Defective TAB Continuous

and

REPLACE TAB

1

Page 13

1

4 MAINTENANCE

4.1 Battery Replacement

When replacing batteries, replace all 4 batteries at the same time.

• Turn power off.

• Remove the carrying case from instrument.

• Press the battery cover slightly and slide it off.

• Remove all 4 batteries and install the new batteries. Take care to use correct polarity and

battery type.

• After replacing batteries, replace cover and carrying case.

4.2 Daily Check/Regular Check

Daily check

• Checking switches, display and body for any physical damage.

• Pump suction check. Is pump running sound normal ?

• Check battery voltage.

• Sensor check: Instrument performs a sensor check duding warm up whenever first turned

on.

4.3 Replacement of Parts

The following parts have a limited life and it is recommended that they be replaced regularly.

Pump : About 1 year (field replaceable)

Sensor : About 5 years (factory replaceable only. Requires special tools and calibration)

4.4 Storage and Treatment After Long Term Storage

Store in a cool dry place and out of direct sunlight.

If storing for a long period, remove batteries before storage.

2

Page 14

1

5 TROUBLE SHOOTING

This trouble-shooting guide cannot cover all possible malfunctions. The most likely problems and

causes are listed below.

Symptom (Message) Cause Treatment

Low battery (REPLACE BATTERY) Battery voltage is low. Replace Batteries

Sensor failure (FAIL)

Pump failure

(PUMP FAILURE)

System error of instrument

(SYSTEM ERROR)

Detachment of TAB

(RESET TAB)

Failure of TAB.

(TAB FAILURE)

(REPLACE TAB)

Power will not turn on.

Excessive shock such as

dropping, or extensive use

for a long time.

Remove the detection TAB

during sensor check.

Excessive shock such as

dropping, or extensive use

for a long time.

Possible influence by high

EMI or RFI signal, or other

electrical problem.

Remove TAB.

The initial condition of

TAB is not normal.

Batteries need replacement

or no batteries installed.

Battery polarity is wrong.

On/Off switch not held long

enough.

Turn on power again and repeat

the sensor check. If it does not

recover, return to factory for

repair.

Replace TAB and turn on the

power. Re-check the sensor.

Turn power on again.

If not recovered, replace pump or

return unit to factory for repair.

Turn power on again. If not

recovered, return to factory for

repair.

Remove /replace tab after gas

detection cycle is complete.

Use new TAB.

Replace or install batteries

correctly.

Press switch for approx. 2 sec.

(Until instrument turns on)

Pump not working.

Sample cannot be drawn

The battery capacity is too

low.

The sampling hose is

disconnected or clogged.

Replace batteries and try again.

Check the connection of sampling

hose. Check for clogged hose.

3

Page 15

1

6 SPECIFICATIONS

6.1 Specifications

Model______

Detection principle Photoelectric photometry method

Display method Digital display by LCD.

Sampling method Sample-drawing by pump

Memory function 99 points logged. (Automatic recording after detection)

Ambient temp -10 to +40 C, 90% RH (Non-condensing)

Power source AA size Dry battery, 4 ea.

Continuous duty

Regulatory NOT explosion proof or intrinsically safe.

Dimensions

W eight Approx. 550g (Including instrument and batteries)

FP-30, FP-40

Approx. 12 hours (with Alkaline battery, no alarm or illumination and

at 20 C

Approx. 85(W)

protrusions)

190(H) 40(D) mm (not including instrument

6.2 Accessories

Standard accessories:

• Carrying case

• AA size battery

• 1 pack of 20 tablets

• Instruction manual

Optional accessories_

• Additional detection tablets (20 / pack)

• Software for data logger

• Exclusive cable for data logger

6.3 Spare Parts List

Part Number Description

65-TAB-008 Detection TAB, type 008/009/010

71-0085RK Operator’s Manual (this document)

4

Page 16

1

6.4 7 DETECTION PRINCIPLE

P

G

G

The Gas detection TAB test paper is treated with special chemicals and an illuminating agent.

When gas is blown onto the TAB paper face, the paper emits illumination by chemical reaction, and this

causes the paper to change color. The amount of color change is determined by the level of

formaldehyde exposure, and the time of exposure.

For example, when formaldehyde (HCHO) contacts the paper, chemicals impregnated into the

paper combine with HCHO to form compounds, and these compounds change the paper from white to

yellow color.

The instrument creates a light beam that reflects off the test paper at the end of the detection cycle. The

intensity of the light beam is affected by the color or darkness of the detection TAB paper, and this

intensity is measured by a light sensor. The level of light intensity measured is correlated (from an

exposure curve stored in the instrument) to a particular level of Formaldehyde exposure to the tab. This

concentration is then displayed at the end of the detection cycle.

Detection

TAB

Light (LED)

Chamber

AS IN

AS OUT

hoto sensor (Photo diode)

5

Loading...

Loading...