Page 1

Data Cal 2000

Operator’s Manual

Part Number: 71-0097RK

Revision: D

Released: 11/3/11

RKI Instruments, Inc.

Page 2

Warranty

RKI Instruments, In c. warrant s gas alarm equi pment sold by us to be free

from defects in materials and workmanship, and performance f or a

period of one year from date of shipment from RKI Instruments, Inc. Any

parts found de fective within that period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to tho se items which

by their nature are subject to deterioration or consumption in normal

service, and which must be cleaned, repaired, or replaced on a routine

basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and

Filter elements

valves

Fuses

Warrant y is voi ded by abuse including mechanical damage, alteration,

rough handling, or repairs procedures not in accordance with the

instruction manual. This warranty indicates the full extent of our liability,

and we are not responsible for removal or replacement costs, local repair

costs, transportation costs, or contingent expenses incurred without our

prior approval.

HIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

T

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

NSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO THE WARRANTY

I

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributor s, dealers, and represen tatives as appoin ted by RKI

Instruments, Inc.

We do not assume indemnification for any accident or damage caused

by the operation of this gas monitor and our warranty is limited to

replacement of parts or our complete goods.

Warranty

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirement s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Docking Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DM-2001, DM-2003, and DM-2009 Docking Modules . . . . . . . . . . . 7

Communication Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4-Gas Mix Calibration Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Demand Flow Regulator & 3 ft. Tube . . . . . . . . . . . . . . . . . . . . . . . 13

10 ft. Exhaust Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Cal 2000 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the Docking Module Configuration Switches . . . . . . . . . . . 14

Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the Data Cal 2000 Docking S tation Software . . . . . . . . . . . 21

Launching the Data Cal 2000 Software . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview of the Data Cal 2000 Software . . . . . . . . . . . . . . . . . . . . . . . 24

Data Cal 2000 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Main Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table of Contents

Page 4

Setting Up the Data Ca l 2000 Software . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting Up the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Viewing the Pre-Defined Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adding and Updating Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting Up the Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting Instruments to the Data Cal 2000 . . . . . . . . . . . . . . . . . . . 38

Bump Testing Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Calibrating Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Deleting Instrument s From the Main Window . . . . . . . . . . . . . . . . . . . 48

Charging Instruments With The Data Cal 2000 . . . . . . . . . . . . . . . . . . 48

Logs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Deleting Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Alarm Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Event Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Interval Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Memo Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Bump Test Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Instrument/Module Function Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Open Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Edit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Edit Function, Memo Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Download Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Clear Logs Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Reset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table of Contents

Page 5

Power Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Parameter Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Database Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Sensor Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Password Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Optimizing the Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

CAUTION: Read and understand this manual before using the

Data Cal 2000. Also read and understand the

Model GX-2001, Model GX-2003, and Model GX2009 Operator’s Manuals included with each

instrument.

Table of Contents

Page 6

Introduction

The Data Cal 2000 Docking Station is a comprehensive and reliable

system that provides charging, data downloading, configuration updating,

calibration, and bump testing for the GX-2001, GX-2003, and GX-2009

gas detectors. It is designed for use with a Windows-based PC and the

Data Cal 2000 Docking Station Software.

The purpose of this manual is to explain how to set up and use the Data

Cal 2000 Docking Station and the Data Cal 2000 Docking Station

Software. You will learn how to:

• install and launch the software

• install the hardware

• set up the Data Cal 2000 software and hardware

• download data from the GX-2001, GX-2003, and GX-2009

• perform a bump test

• perform a calibration

• view, print, and save data

• change instrument parameters

• change data logging parameters

• use the Data Cal 2000 to charge an instrument

CAUTION: The GX-2001, GX-2003, and GX-2009 detect

oxygen deficiency and elevated levels of oxygen,

combustible gases, carbon monoxide, and

hydrogen sulfide, all of which can be dangerous or

life threatening. When using the GX-2001,

GX-2003, and GX-2009 you must follow the

instructions and warnings in the O perator’s Manual

1 • Introduction

for each instrument to assure proper and safe

operation of the unit and to minimize the risk of

personal injury.

Page 7

CAUTION: The operator of this instrument is advised that if t he

equipment is used in a manner not specified in this

manual, the protection provided by th e equipment

may be impaired.

System Requirements

To use the Data Cal 2000 and the Data Cal 2000 Docking Station

Software, your personal computer must meet the following requirements:

• Operating Systems: Windows® 98, Windows® ME, Windows®

®

2000, Windows NT

• Processor: IBM

equivalent minimum

4.0, or Windows® XP.

®

compatible PC running Pentium® 2 processor or

• Memory: 32 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• CD-ROM Drive

System Requirements • 2

Page 8

Specifications

Table 1: Dat a Cal 2000 Specifications

Input Power 115 VAC, 50/60 Hz

Environmental

Conditions

Number of

Docking Modules

Applicable

Instruments

Number of Calibration Gas

Cylinders

• For Indoor Use Only

• -10° C to 40° C, below 80% Relative Humidity, NonCondensing

Up to 10 docking modules

• GX-2001

• GX-2003

• GX-2009

Up to 5 calibration gas cylinders and one zero air cylinder

3 • Specifications

Page 9

Description

The Data Cal 2000 consists of the following components:

• Data Cal 2000 Docking Station

• DM-2001 Docking Module for GX-2001

• DM-2003 Docking Module for GX-2003

• DM-2009 Docking Module for GX-2009

• RS-232C serial communication cable for connection of the docking

station to a computer

• RS-485 serial communication cables for connection of the docking

station to a docking module and for daisy chain connection of

additional docking modules to each other

• Power cord

• A 4-gas mix calibration cylinder (optional)

• Demand flow regulator with 3 foot tube (optional)

• 10 ft. exhaust tube

• A Windows based PC compatible computer (user supplied) with the

Data Cal 2000 Docking Station Software loaded

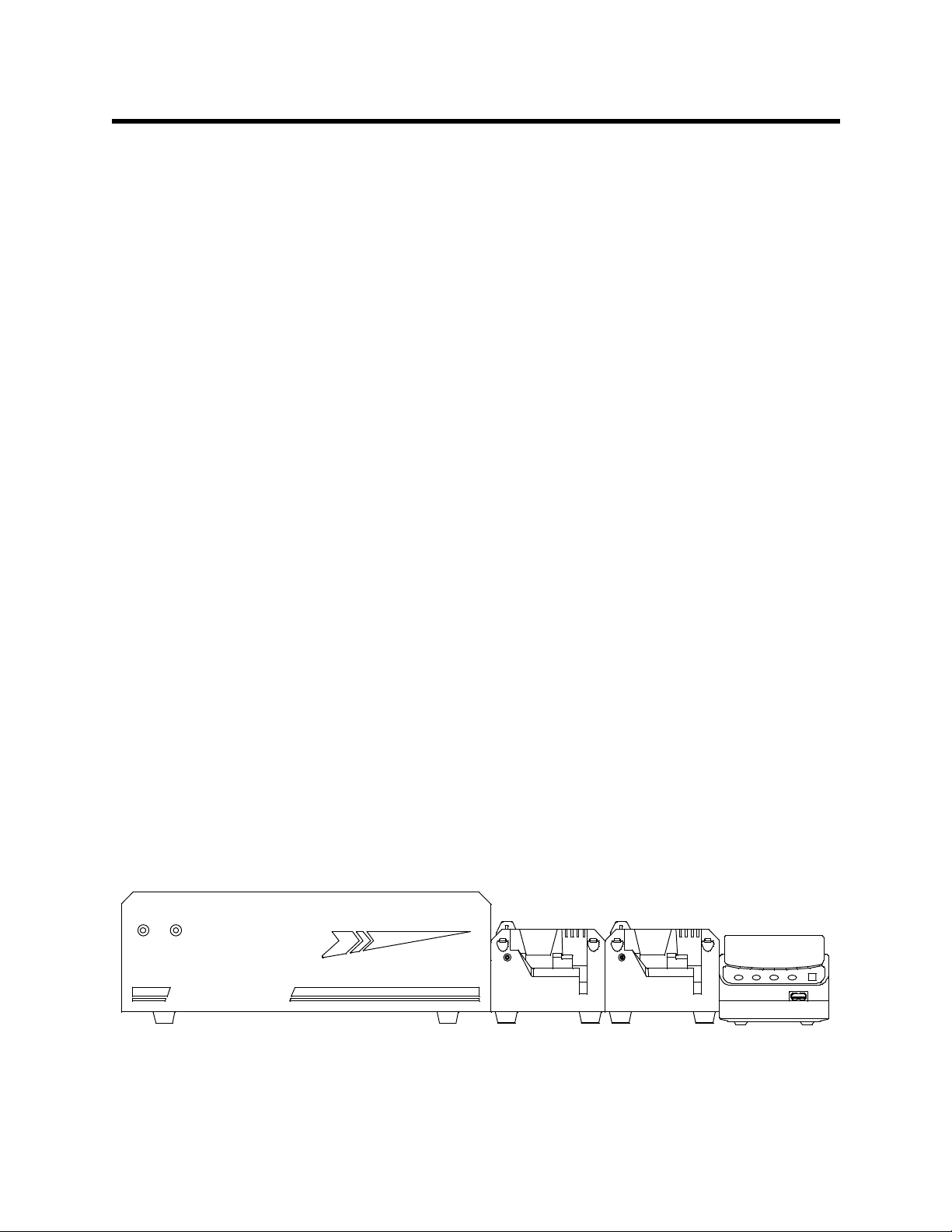

The docking station is designed to be used on a table top with t he DM2001, DM-2003, and/or DM-2009 docking modules extend ing to the rig ht

of the docking station as shown in Figure 1 below. Any combination of

docking modules may be used up to a total of 10. If a laptop computer is

used, it may be placed on top of the docking station if desired.

Up to 1 0 docking modules may b e installed i n any

combination of DM-2001's,DM-2003's, and DM-2009's.

Docking Station

POWER FAULT

Data Cal 2000

DM-2001

DM-2003

DM-2009

Figure 1: Data Cal 2000

Description • 4

Page 10

Docking Station

The docking station manages the calibration, bump test, and informatio n

exchange functions of the Data Cal 2000 once they have been initiated

through the software.The status LED’s are on the front panel. The power

switch and hose barb fittings for connection of calibration gas cylinders

and routing of calibration gas to the docking modules are located on the

back panel. Cable connectors for connecting the docking station to a

computer and to docking modules are also located on the back panel.

Three recesses are located on the right side of the docking station that

mate with tabs on the docking modules. These recesses allow table top

assembly of a docking module to the docking station.

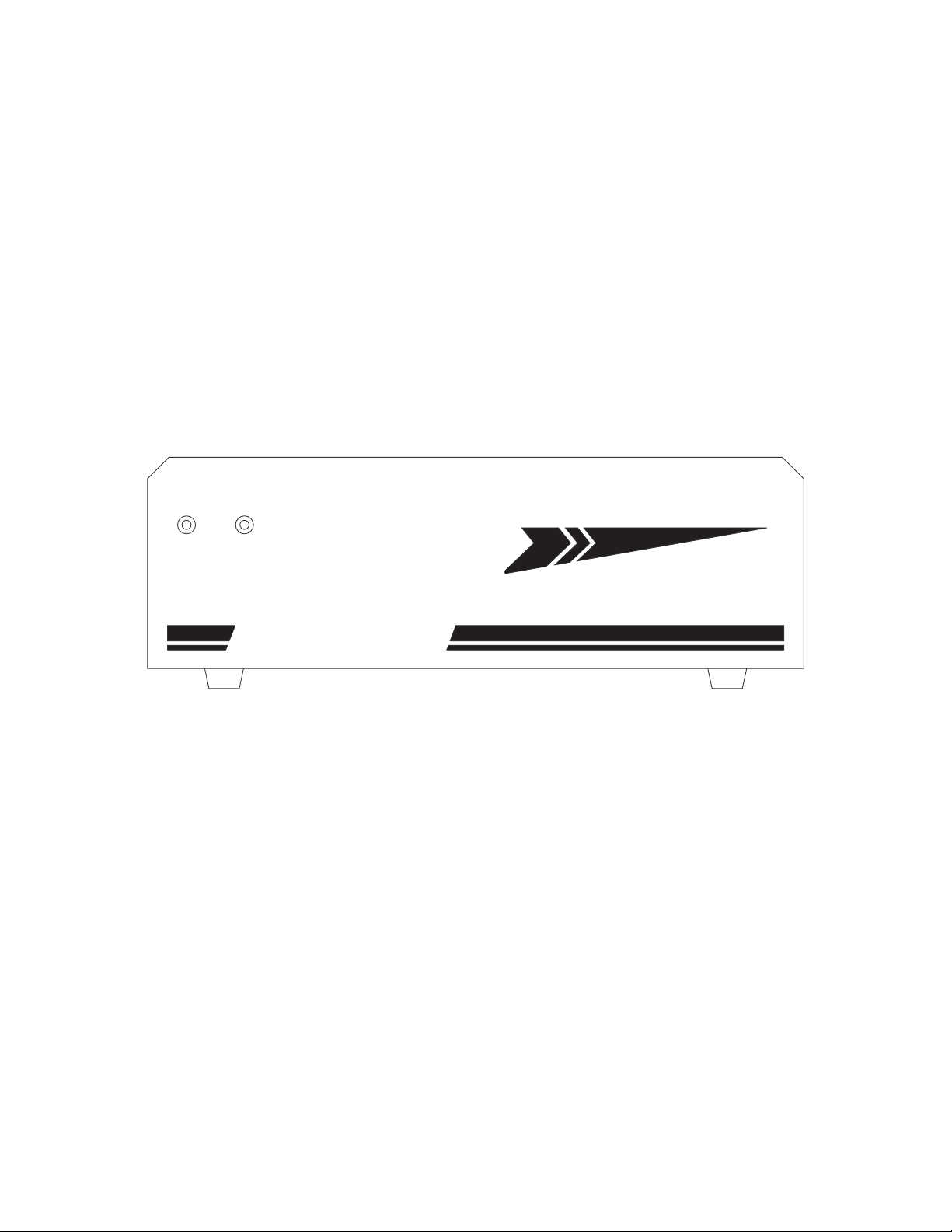

Front Panel

Docking Station

POWER

The two status LED’s are located on the f r ont panel in the upper left

corner. The left LED is green and is the POWER LED. It is on when the

docking station is turned on. The right LED is red and is t he FAULT LED.

It is on when there is a communication error or some hardware problem

that affects communication between the docking station and the

computer or the docking station and the modules.

FAULT

D

ata

Cal 2000

Figure 2: Data Cal 2000 Front Panel

5 • Description

Page 11

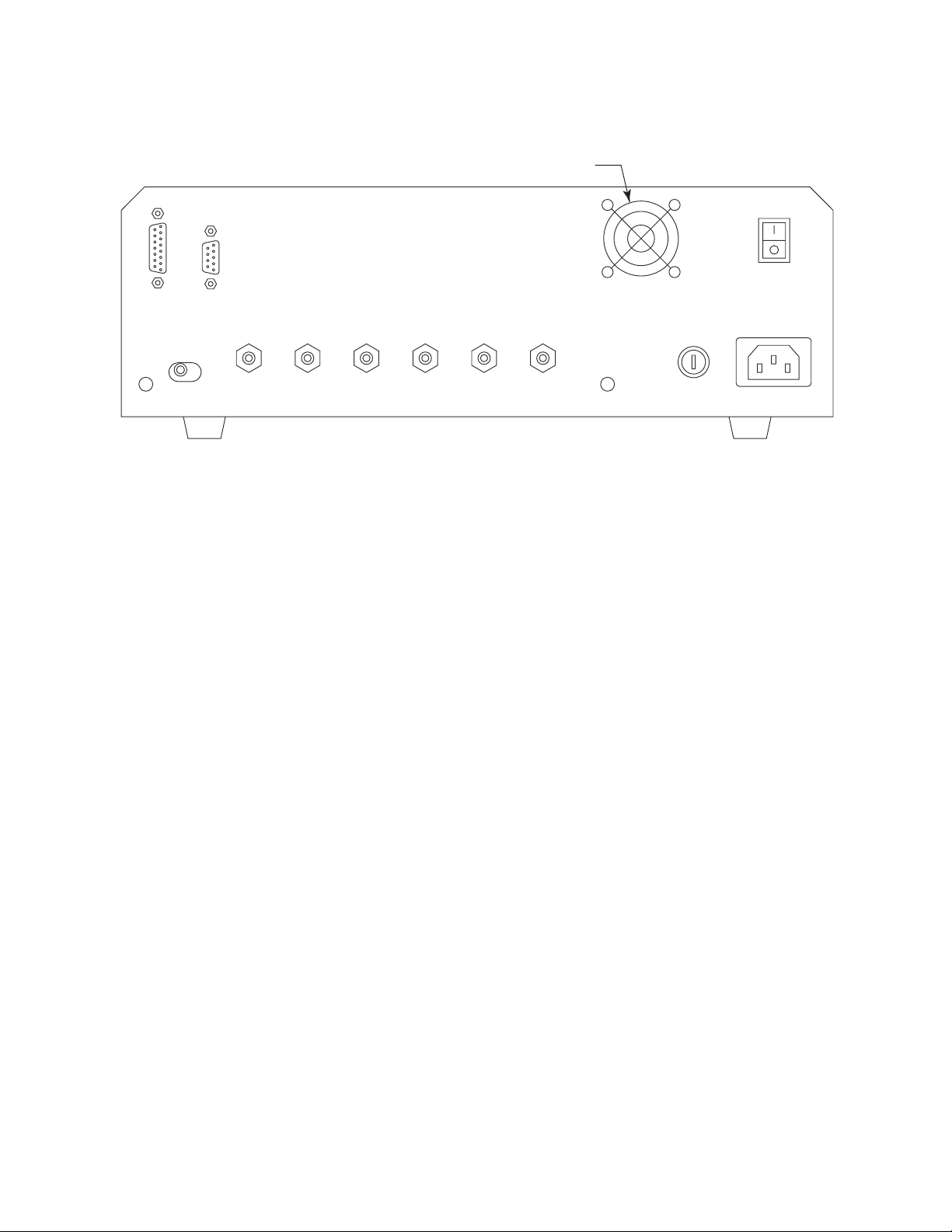

Back Panel

Fan Grill

MODULE

GAS OUT

PC(RS-232C)

AIR GAS1 GAS2 GAS3 GAS4 GAS5

FUSE(5A)

POWER

AC IN

AC100V-AC240V

Figure 3: Data Cal 2000 Back Panel

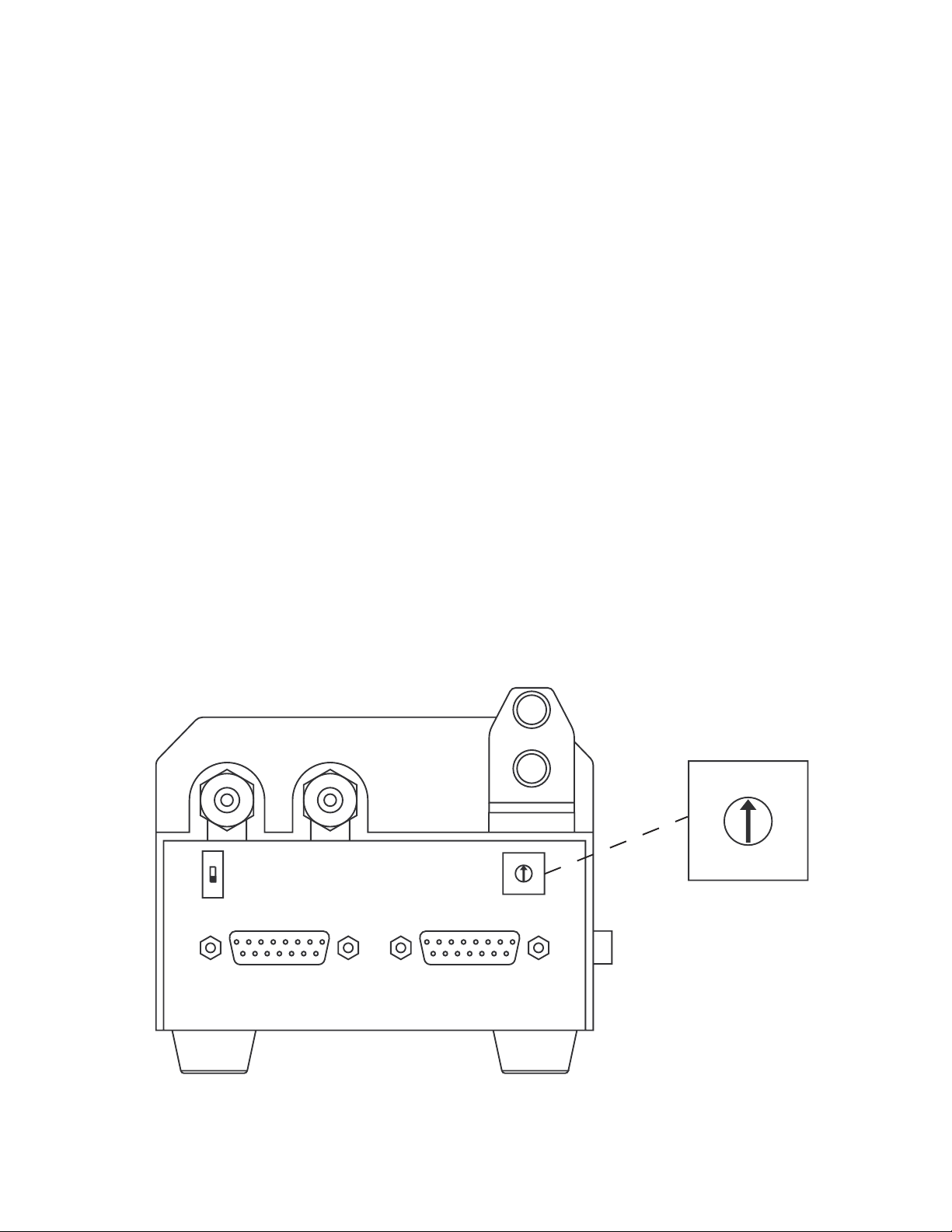

The power switch is a rocker switch and is located in the upper right

corner of the back pan el. The docking st ation is on when the upper half of

the switch, the “1” position, is pressed in, and of f when the lower half of

the switch, the “0” position, is pressed in.

All the gas fittings are located on the back panel. They are hose barb

type fittings that accept 3/16” inner diameter (ID) tubing. At the bottom

left of the back panel is the GAS OUT fitting. This fitting is used to route

calibration gas from the docking st ation to the docking modules. To the

right of the GAS OUT fitting is the AIR fitting. This fit ting is used to draw

fresh air while the Data Cal 2000 is performing a zeroing operati on during

bump testing or calibration.

To the right of the AIR fitting are five additional fittings of the same type

labeled GAS1, GAS2, GAS3, GAS4, and GAS5. These fittings are used

to connect up to 5 calibration gas cylinders that are defined using the

software. Usually, only one or two calibration cylinders will be needed.

Typical gas cylinders needed are a 4-gas mix of %LEL CH

or 3-gas mix of %LEL CH

%volume CH

TC sensor is installed on a GX-2003).

4

/CO and a %volume cylinder of CH4 (if t he

4/O2

4/O2

/CO/H2S

There are three connectors on the back panel. A DB-15 (15 pin)

receptacle in the upper lef t corner is used to connect the docking station

to the docking modules. It is labeled MODULE. A DB-9 (9 pin) plug to the

right of the MODULE connector is used to connect the docking st ation to

the serial port of a computer. It is labeled PC(RS-232C). A 3-pin

Description • 6

Page 12

recessed plug in the lower right corner of the panel is used t o connect an

AC line cord. It is labeled AC IN.

A fuse holder is located to the left of the AC IN connector. It is labeled

FUSE(5A). The fuse holder consists of a panel mounting socket and a

quarter turn fuse holder. The fuse is a 5 amp, 5 mm x 20 mm fuse.

A cooling fan is located inside the docking stat ion on the ri ght side above

the fuse holder. It draws warm air out of the docking st ation to preve nt the

internal electronic components from overheating.

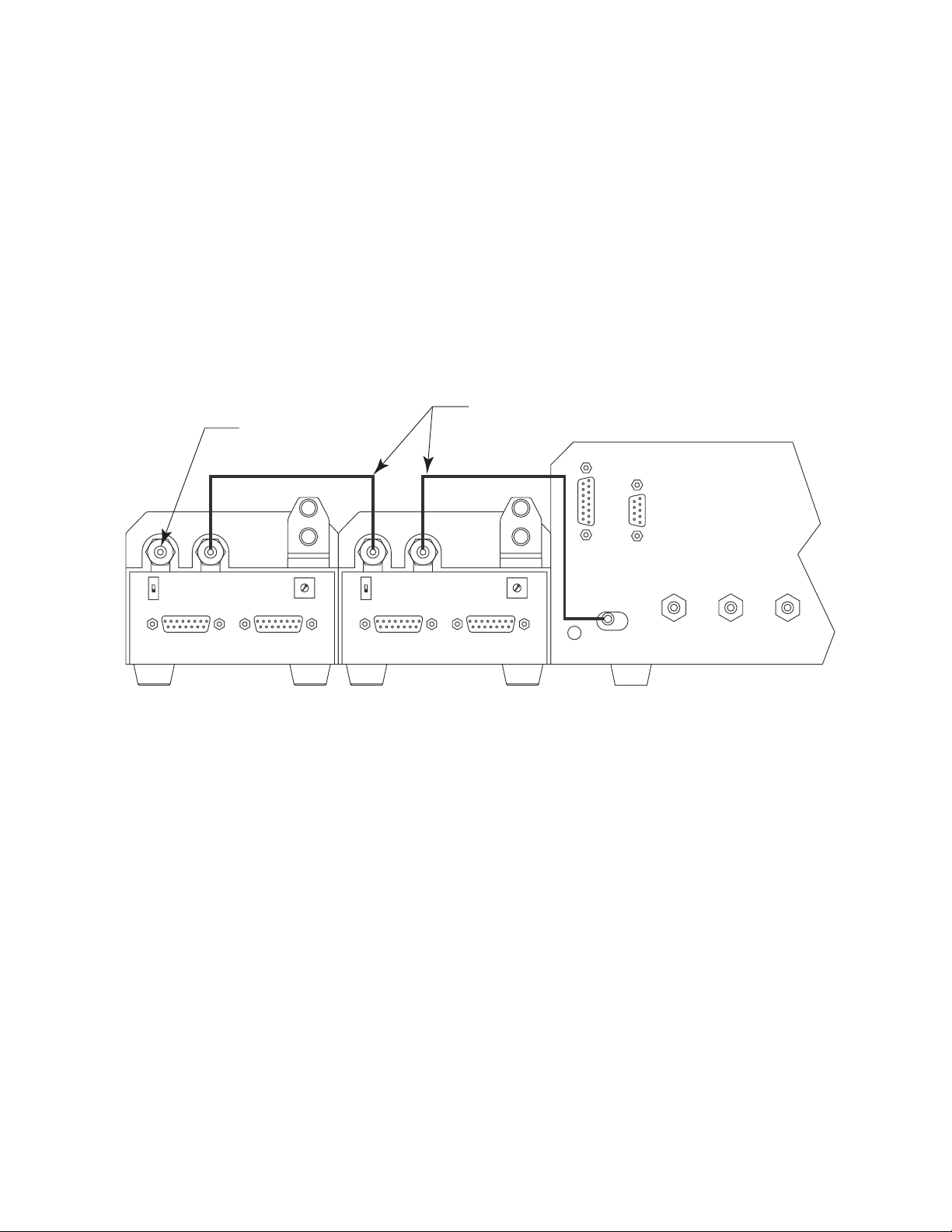

DM-2001, DM-2003, and DM-2009 Docking Modules

The docking modules are used to facilitate communication between a

GX-2001, GX-2003, or GX-2009 and the docking station and computer

and to apply fresh air and calibration gas to an instrumen t during a bump

test or calibration. They are also used to charge an instrument’s

rechargeable battery pack if one is installed. Two multi color LED’s, one

on the left front and one on the right front of a module, indicate the

operation status of the docking module.

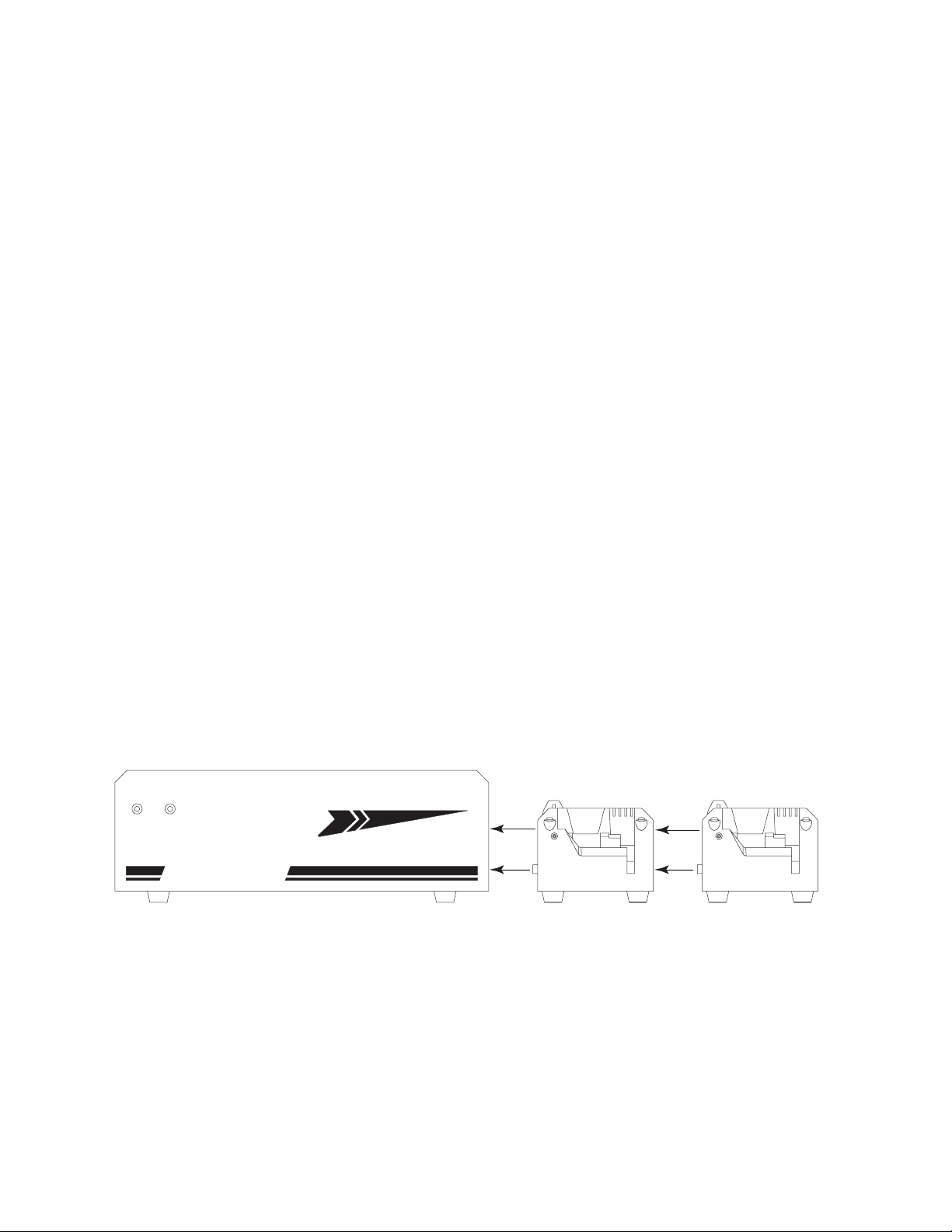

Each module has three connection tabs on the left side near the bottom

of the module and three connection recesses on the right side near the

bottom of the module. The tabs from one module can be pushed into the

recesses on the docking station or on another module to mechanically

connect the module to the docking station or to another module. If

multiple modules are used, one of them will be connected to the docking

station and then each additional module will be connected to the end

module as shown below in Figure 4.

Docking Station

FAULT

POWER

ata

Cal 2000

D

Figure 4: Assembling Docking Modules to Data Cal 2000

Connect any DM-2001s and DM-2003s first and then connect any

DM-2009s. This will allow the exhaust lines for the DM-2001 and

DM-2003 to easily be daisy-chained together and routed to an exhaust

area with a single exhaust tube. Each DM-2009 must have a dedicated

exhaust tube which can be easily routed away without interfering in the

daisy-chain configuration of the DM-2001s and DM-2003s.

7 • Description

Page 13

Calibration Gas

r

T

e

Fittings

Terminator Switch

Exhaust Fittings

ID Switch

Connector for

Cable From Other

Docking Module

Connector for

Cable from Data

Cal 2000 or Othe

Docking Module

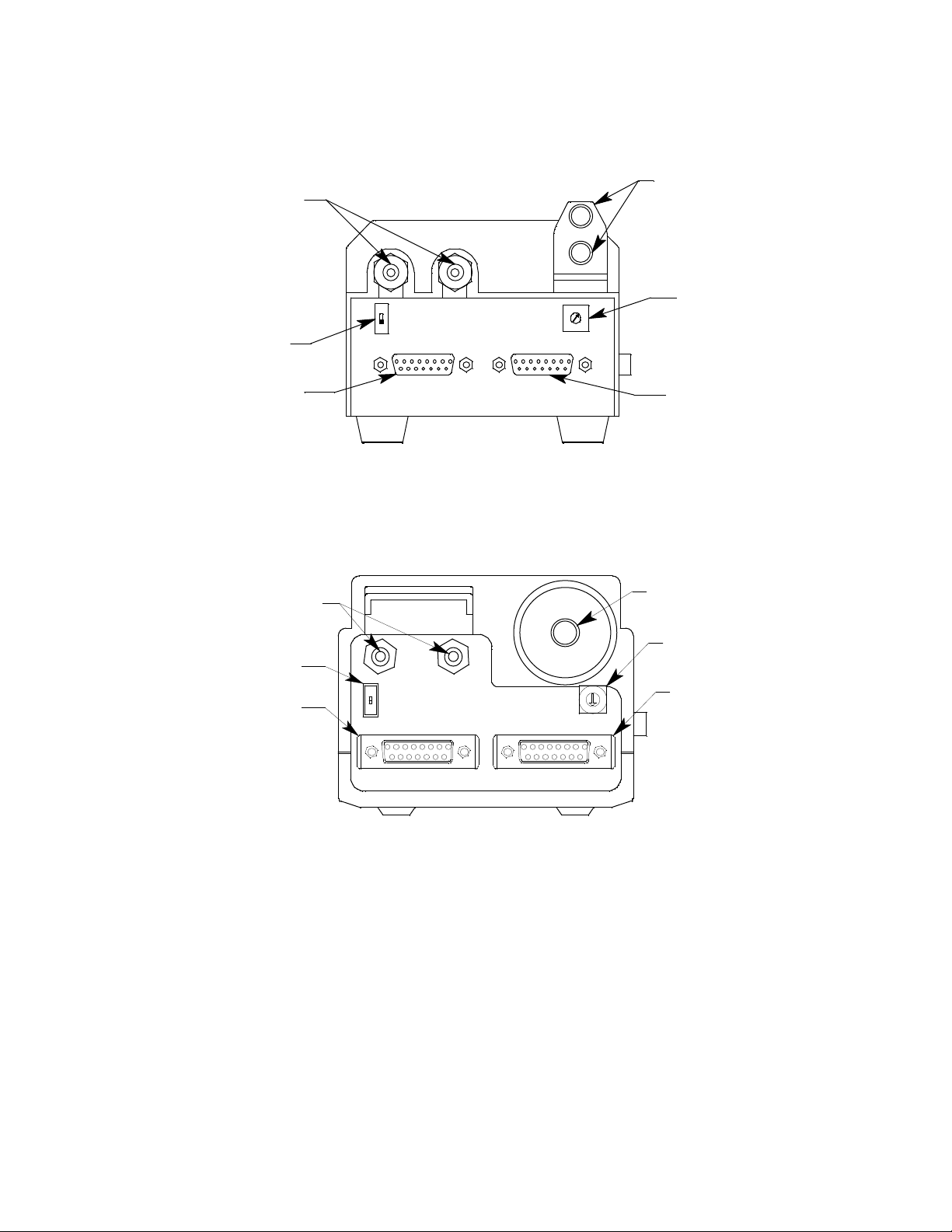

Figure 5: Back of DM-2001 and DM-2003 Docking Module

Calibration Gas

Fittin gs

Exhaust

Fittin g

ID Switch

erminat or Switch

Connector for

Connector for

Cable From

Ot her Docki ng

Module

Cable From

Data Cal 2000

or Other

Docking Modul

Figure 6: Back of DM-2009 Docking Module

Two DB-15 connectors on the back of each module allow connection to

other docking modules or directly to the docking sta tion.

T wo hose barb fittings tha t accept 3/16” ID tubing are loca ted in the upper

left corner of the back of each module and are each labeled CAL. GAS.

They allow sample gas connection t o the module and from t he module to

another module. The right fitting (as viewed from the back) is for

connection to the GAS OUT fitting on the docking station or to the left

fitting of the previous module in the system. The left fitting is for

connection to the next docking module in the system or, if the docking

Description • 8

Page 14

module is the last one in the flow system, it is plugged with a push-on

plug that is supplied with the docking station.

A two port exhaust routing fit ting is located in the upper r ight corner of t he

back of the DM-2001 and DM-2003 modules. It allows routing of the

exhausted calibration gas from all DM-2001 or DM-2003 modules t o the

last module so the exhaust gas can be safely routed to a convenient

exhaust location. The DM-2009 module has only one exhaust fitting.

Exhaust from the DM-2009 may only be routed to an exhaust location

and cannot be routed to another module.

NOTE: Even though the exhaust gas can be routed to an area

to be safely dispersed, the docking station should still be

installed in a well ventilated area.

All three types of modules also includ e a 10-positi on rot ary switch, the ID

switch, above the right DB-15 connector, and a 2-position slide switch,

the terminator switch, above the lef t DB-15 connector. The ID switch set s

the ID number of a module from 0 - 9, for a maximum of 10 module IDs.

The terminator switch is set to the down position if the module is the last

module in the system and to the up position for any other module.

9 • Description

Page 15

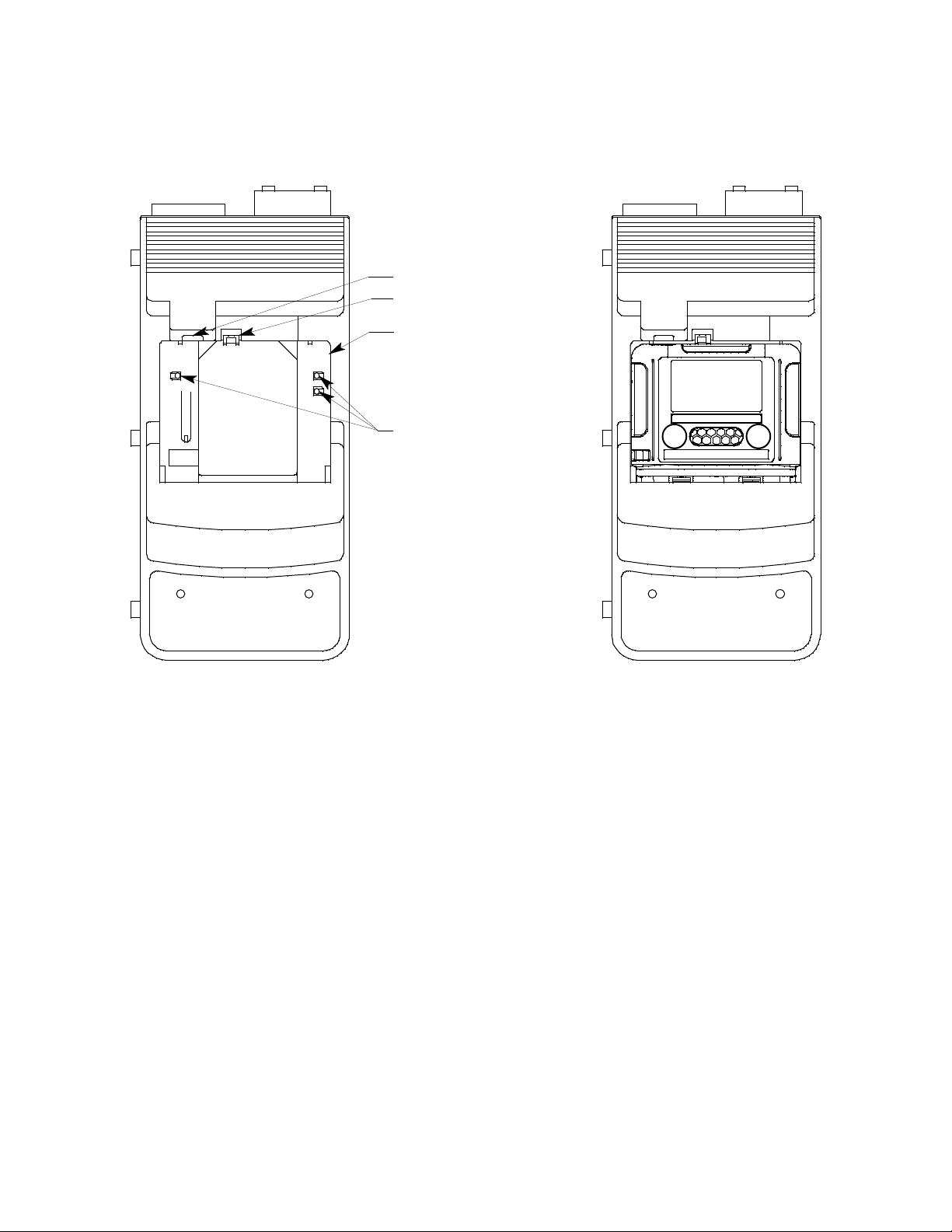

DM-2001 Docking Module

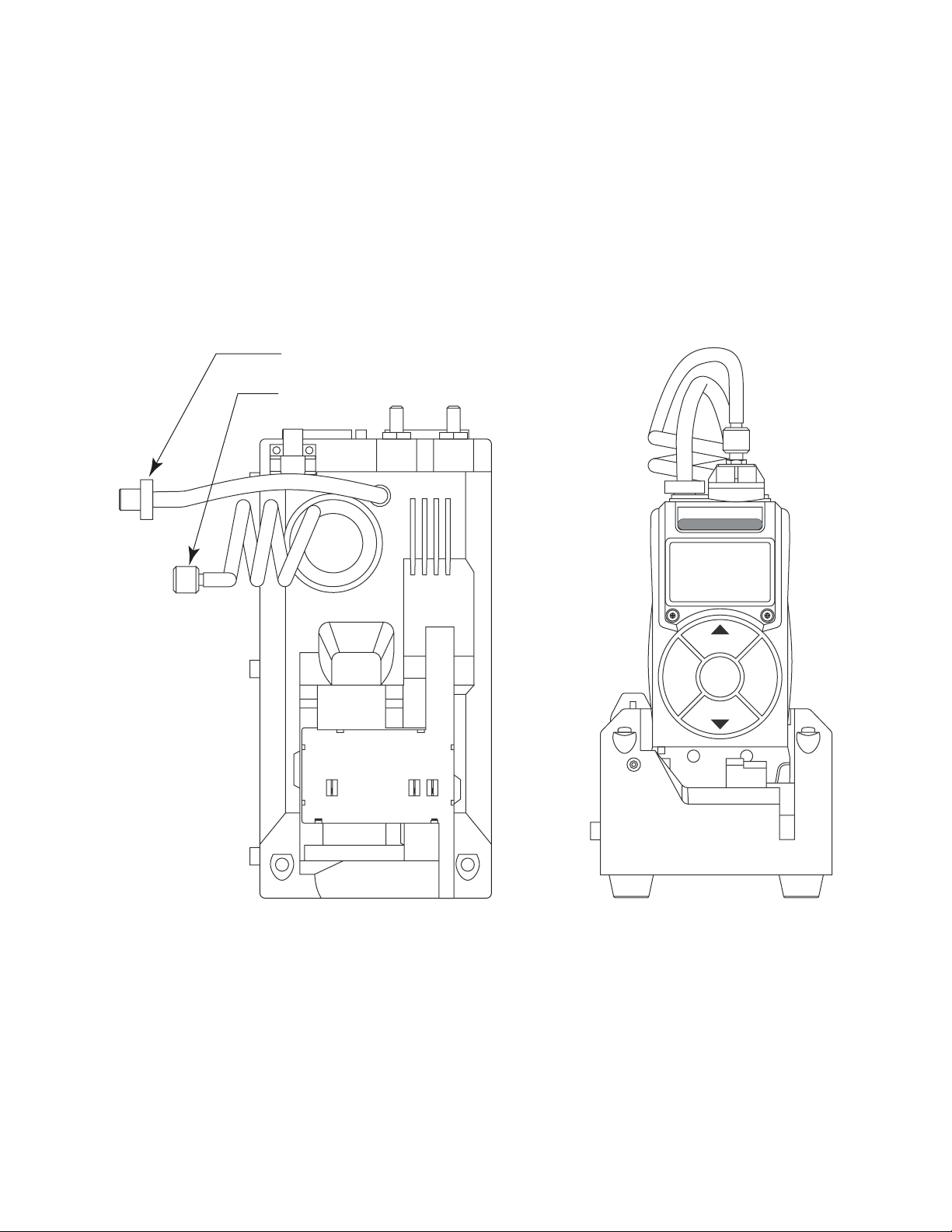

The GX-2001 fits into the DM-2001 module as shown in Figure 7 below.

The module includes a snap-on sample adapter for the GX-2001. The

exhaust port of the adapter is connected to a port on the front left of the

module by a short tube and the adapter’s inlet port is connected to a port

on the top rear of th e module by a coiled t ube. The sample adapte r snaps

onto the sensor side of the GX-2001 before the GX-2001 is installed into

the module.

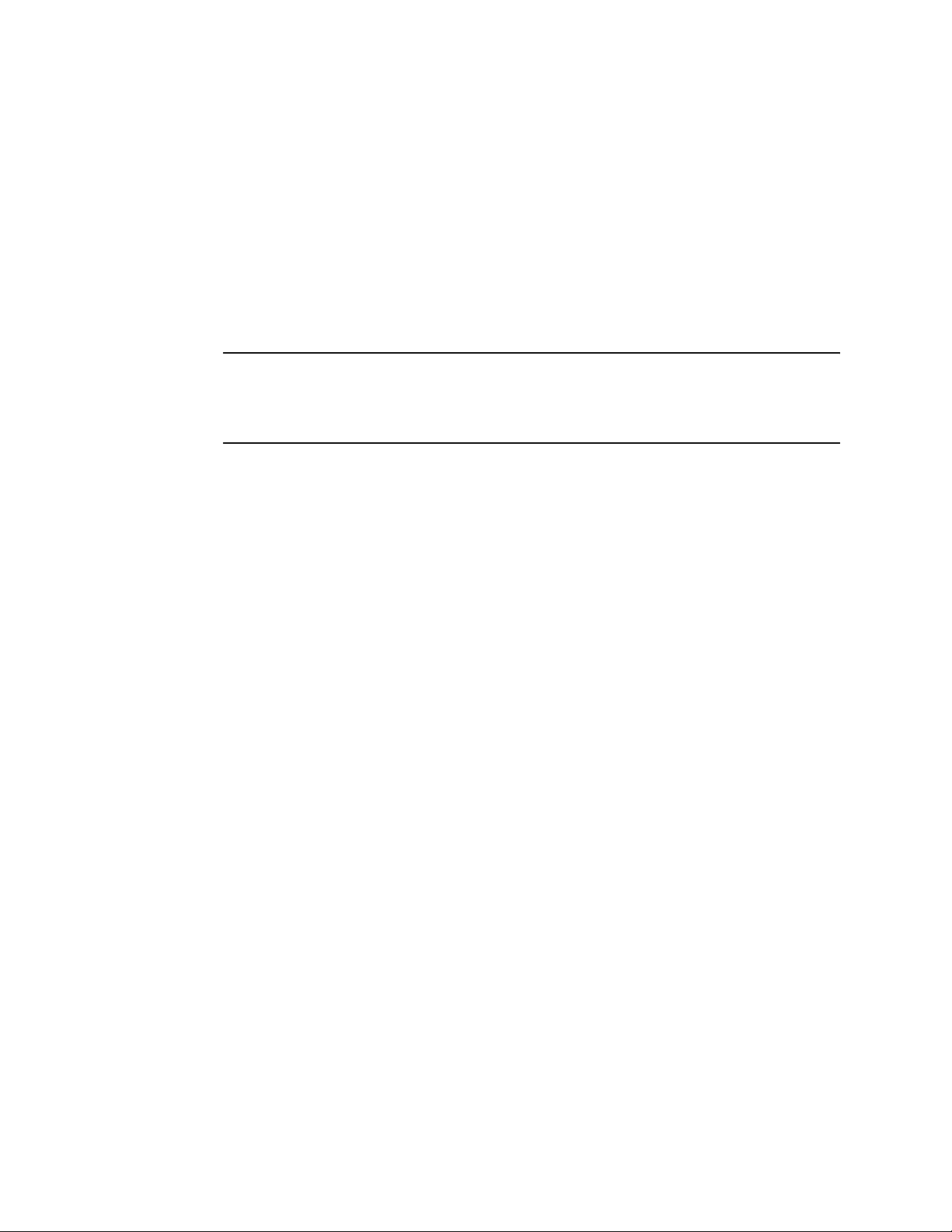

DM-2001 DM-2001

Figure 7: DM-2001 Docking Module

H

HC

CO

O

2

2

S

Description • 1 0

Page 16

DM-2003 Docking Module

Front Vie wTop View

To GX-2003 Exhaust Fitting

The GX-2003 fits into the module as shown in Figure 8 below. A coiled

black tube with a plastic push -on fit tin g resides in a recess in the lef t rea r

corner of the top of the module. The coiled tube routes gas to the

GX-2003 and extends to connect to the GX-2003’s inlet fitting. A straight

green tube comes out of the top of the module to the right of the coiled

tube and also has a plastic push-on fitting on its end. The fitting on this

tube is pushed onto the GX-2003 exhaust fitting and routes gas away

from the GX-2003.

To GX-2003 Inlet Fitting

Figure 8: DM-2003 Docking Module

DISPLAY

(ADJ)

AIR

RESET

SILENCE

(SHIFT)

DM-2003

11 • Description

Page 17

DM-2009 Docking Module

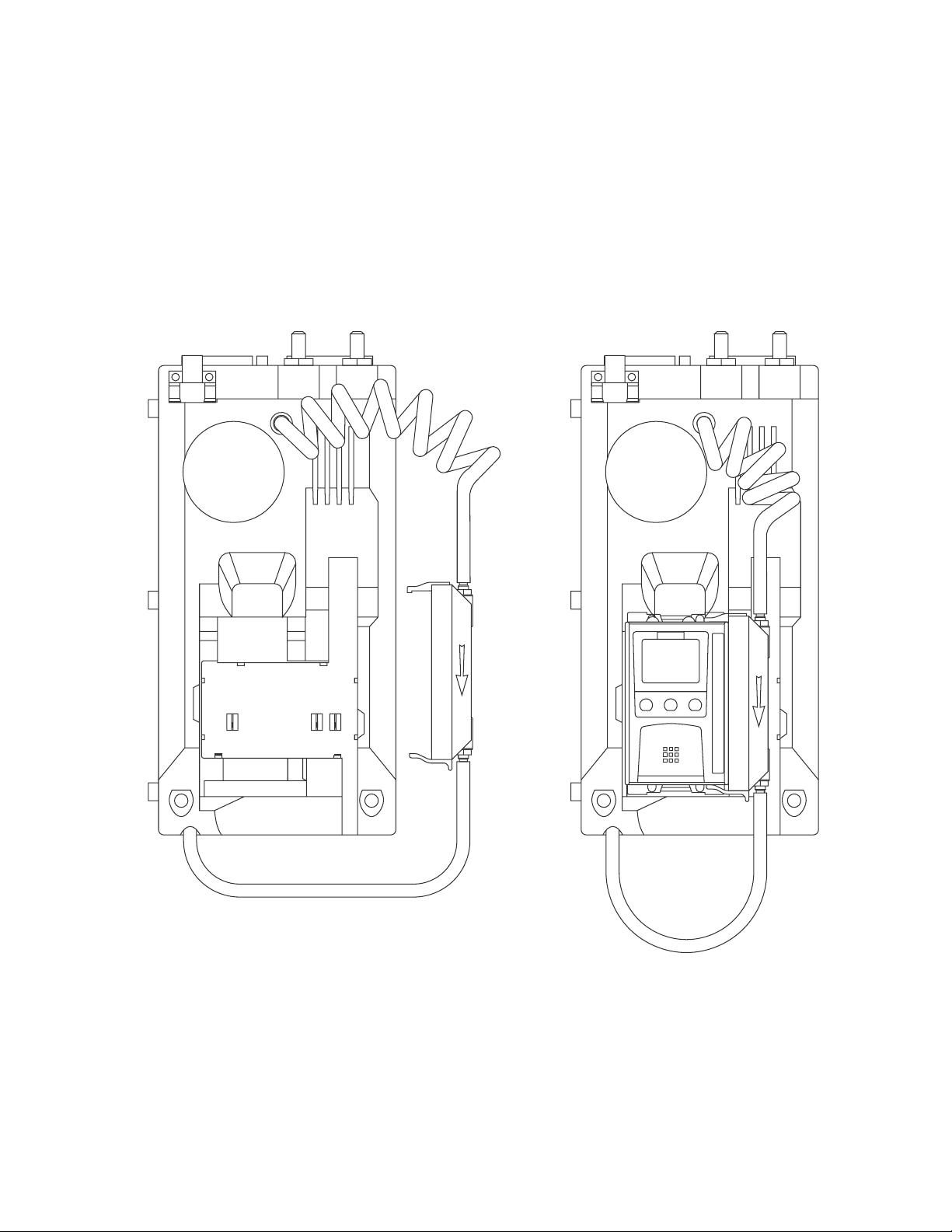

The GX-2009 fits into the module as shown in Figure 9 below.

IR Port

Instrument Retaining

Tab

Instrument Cradle

Charging Contacts

CAL.

DM-2009 DM-2009

POWER

CHAR GE

CAL.

POWER

CHARGE

Figure 9: DM-2009 Docking Module

Communication Cables

The number of communication cables needed depends on how many

docking modules are used. Every system has at least two cable s, an RS232C cable with a DB-9 receptacle on each end (docking st ation cable

supplied with docking station) to connect the docking station to a

computer and an RS-485 cable with a DB-15 plug on each end (docking

module cable supplied with docking module) to connect the docking

station to the first docking module. For every additional docking module,

an additional RS-485 cable is needed to co nnect the additional module to

the previous module.

Description • 1 2

Page 18

Power Cord

A three-pronged AC power cord is provided wit h t he Dat a Cal 2000. O ne

end connects to a standard AC wall outlet and the other end plugs into

the AC power socket on the back of the docking station.

4-Gas Mix Calibration Cylinder

The Data Cal 2000 may be ordered with or without calibratio n gas and a

demand flow regulator. The standard configuration of the Data Cal 2000

includes a demand flow regulator and one 58 liter 4-gas mix calibration

cylinder which typically cont ains 50% LEL CH

CO/25 ppm H

example if you need a % volume CH

S. If another cylinder is required for your system, for

2

cylinder for a 5-sensor G X-2003, it

4

will have to be ordered separately along with an additional demand flow

regulator.

/12.0% oxygen/50 ppm

4

Demand Flow Regulator & 3 ft. Tube

The standard configuration of the Data Cal 2000 includes one demand

flow regulator with 3 feet of flexible polyurethane tubing. The demand

flow regulator screws onto a calibration cylinder and the tube is used to

connect the regulator to the appr opriate calibration gas f itting on the back

of the docking station. When the regulator senses a vacuum at its fitting,

it allows the gas from the cylinder to flow.

10 Foot Exhaust Tube

The Data Cal 2000 comes with a 10 foot 5/16” I.D. exhaust tube. This

exhaust tube is intended to be used as the collective exhaust for any

connected DM-2001s and DM-2003s. Any connected DM-2009s require

their own dedicated exhaust. Another 10 foot 5/16” I.D. tube is

recommended for each connected DM-2009. This extra tubing is not

included in the Data Cal 2000 kit or in the DM-2009 but can be

purchased from RKI Instruments, Inc.

Data Cal 2000 Hardware Setup

There are two parts to preparing the Data Cal 2000 Docking Station for

use: hardware setup and software setup.This section describes

hardware setup. The hardware setup consists of setting the docking

module configuration switches, simple mechanical assembly, cable

installation, and tubing installation.

13 • Data Cal 2000 Hardware Setup

Page 19

Setting the Docking Module Configuration Switch es

The docking module configuration swi tches determine module ID and the

order in which the modules are physically installed. B efore using the Data

Cal 2000, you will need to set the configuration switches as described

below. If you are adding a module or modules to a syst em that is a lready

setup, make sure the system is setup as described below after the new

module or modules are added.

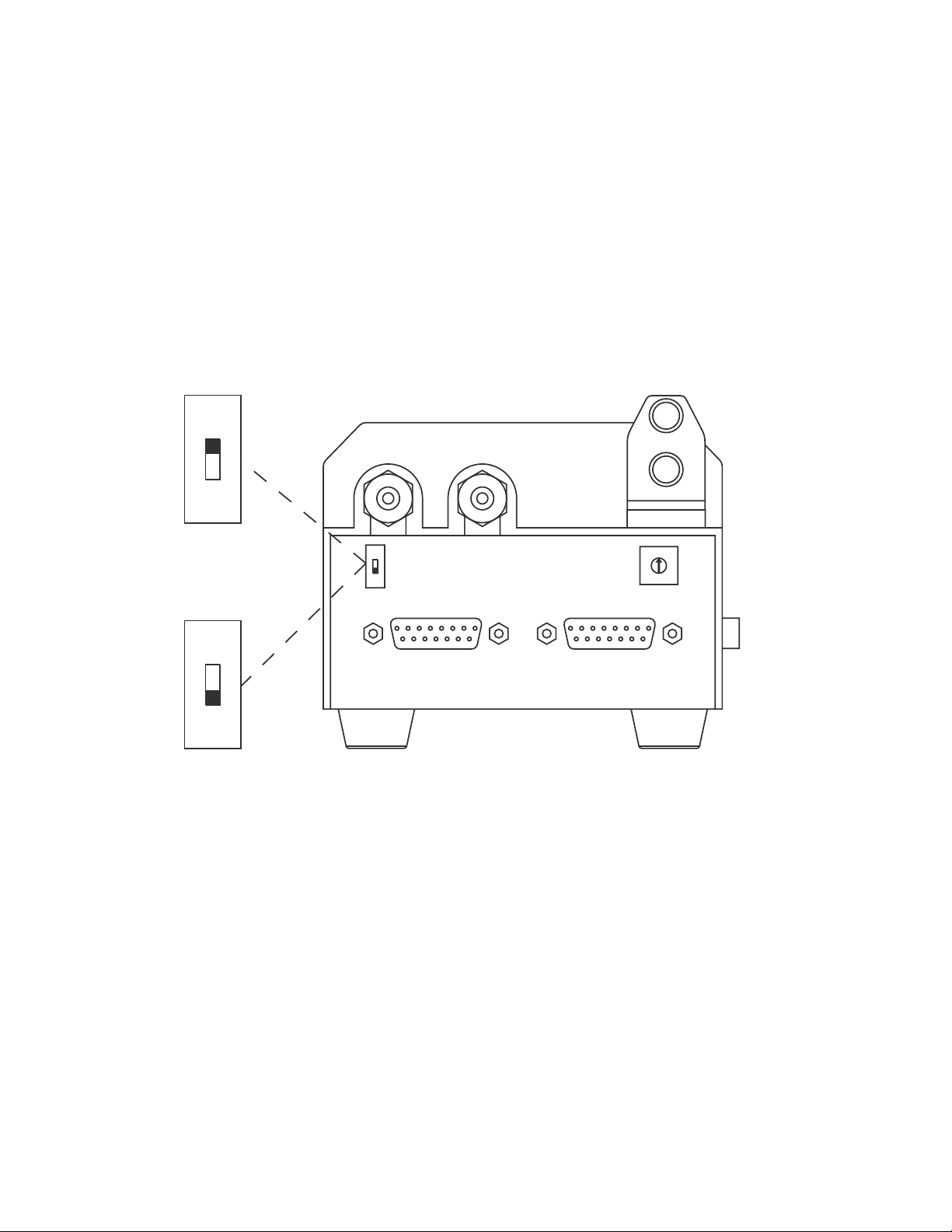

ID Switch

The ID switch is located above the right DB-15 connector on the back of

the docking module. It is a 10 position rot ary switch with settings from 0

to 9. A Data Cal 2000 may have up to 10 docking modules. Each module

in the system must have a unique ID for the system to work properly.

When you receive a Data Cal 2000, set the ID setting f or each modu le in

the system so that no two modules have the same ID. The IDs should be

set sequentially to make it easy to keep track of the IDs. For example, if

you have 5 modules in a system, the IDs should be set to 0, 1, 2, 3, & 4.

Although the system will still operate properly if ID numbers are skipped,

for example using IDs 0, 3, 4, 6, & 8, setting them sequentially makes it

easier to keep track of t he module IDs an d spot du plicate I D sett ings. I f it

is necessary to change the ID on a module, use a small flat blade

screwdriver to adjust the switch to the desired setting. A small arrow in

the middle of the switch points to the current ID setting.

Figure 10: ID Switch Setting

Data Cal 2000 Hardware Setup • 14

0

19

28

37

46

5

Page 20

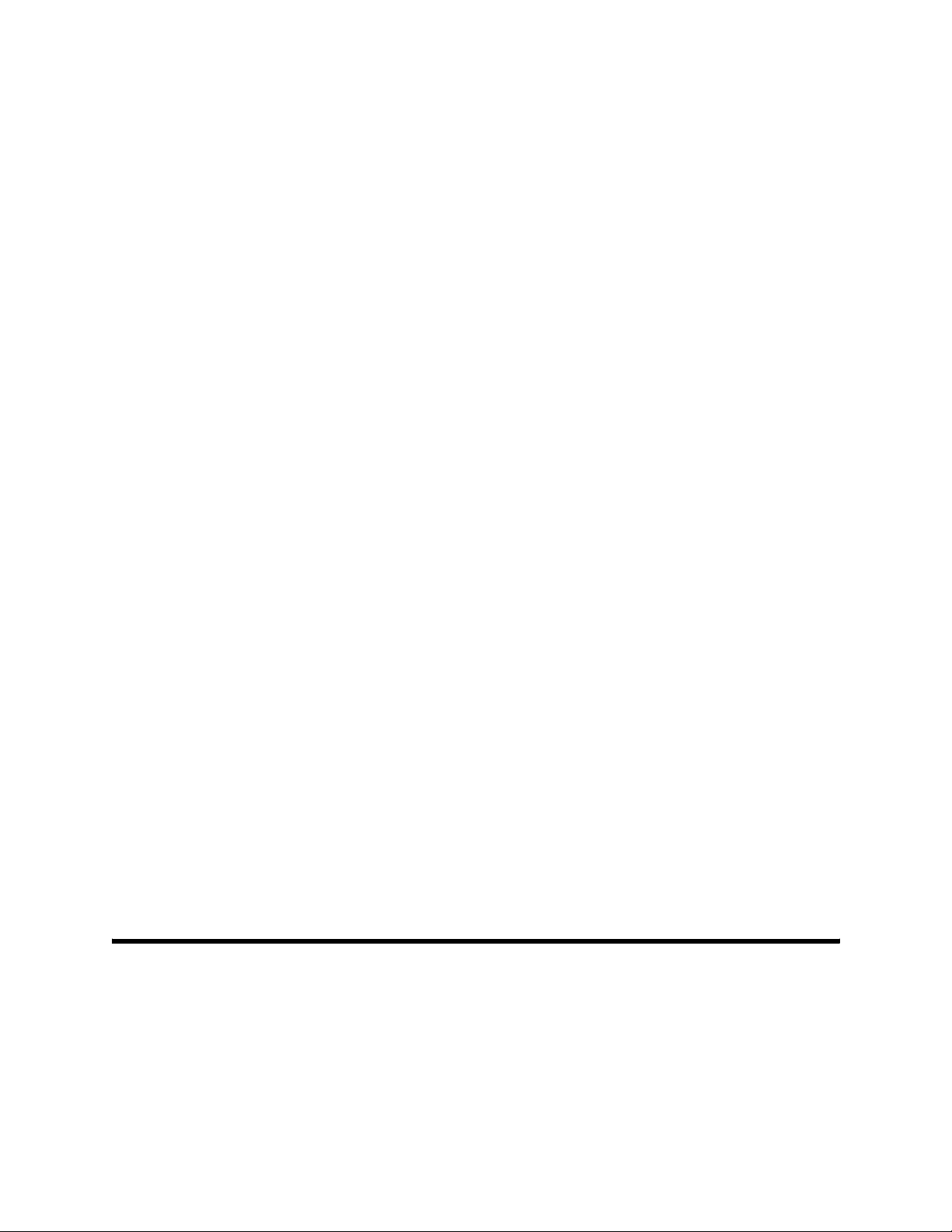

Termination Switch

Set switch to UP position if module IS NOT the last one.

Set switch to DOWN position if module IS the last one.

The termination switch is located above the left DB-15 connector on the

back of the docking module. It is a two position slide switch. The switch

position indicates whether the modu le is physically the last module in t he

installation or not. When the Data Cal 2000 is viewed from the front, the

last module in the installation is the module on the far right and it must

have the termination switch set to the down position for the Data Cal

2000 to operate properly. All other modules in the system must have the

switch set to the up position. If only one module is used in a system, that

module must have the termination switch set to the down position.

Figure 11: Termination Switch Setting

Mechanical Assembly

The Data Cal 2000 is designed for table top use. Perfor m the following

steps to assemble the docking station and docking modules.

1. Find a location that is well ventilated and near a window so that the

exhaust can be routed out of the window.

2. Find a table or other flat surface that is large enough to

accommodate the docking station and the number of modules in

your system.

15 • Data Cal 2000 Hardware Setup

Page 21

3. Place the docking station on the flat surface with enough room to

the right of the docking station (whe n viewed from the fro nt) to fit all

of the docking modules side by side.

4. Place the first docking module to the right of the docking station

and line up the three tabs on the left side of the module with the

three recesses on the right side of the docking station.

5. Push the module toward the docking station so the tabs mate with

the recesses and the module is flush against the docking station. If

only one module is used in your system, then mechanical assembly

is done. If more modules are used in your system, continue with

step 6.

6. Place the next docking module to the right of the installed docking

module and line up the three tabs on the lef t side of the module with

the three recesses on the right side of the installed module.

7. Push the new module toward the installed module so the t abs mate

with the recesses and the new m odul e is fl ush against the installed

module.

8. Repeat steps 6 & 7 for each additional docking module.

CAUTION: Make sure that the last module in the system, the

one on the far right, has the t erminator switch se t to

the down position. If the last module does no t have

the terminator switch set to the down position, the

Data Cal 2000 will not operate properly.

Cable Installation

1. Install the RS-232C cable from the PC connector on the back of the

docking station to the serial port on a computer.

2. Plug the power cord into the power socket on the back of the

docking station. Do not connect the cord to an AC outlet at this

time.

3. Install a RS-485 cable from the MODULE connector on t he back of

the docking station to t he right ( when viewed f rom the b ack) DB- 15

connector on the back of the first module. If only one module is

Data Cal 2000 Hardware Setup • 16

Page 22

used in your system, cable installatio n is done. If more modules are

used in you system, continue with step 4.

4. Install a RS-485 cable between each adjacent module from the left

connector of one module to the right co nnector of t he next modul e.

The module on the end will not have anything connect ed to the left

connector.

Tubing Installation

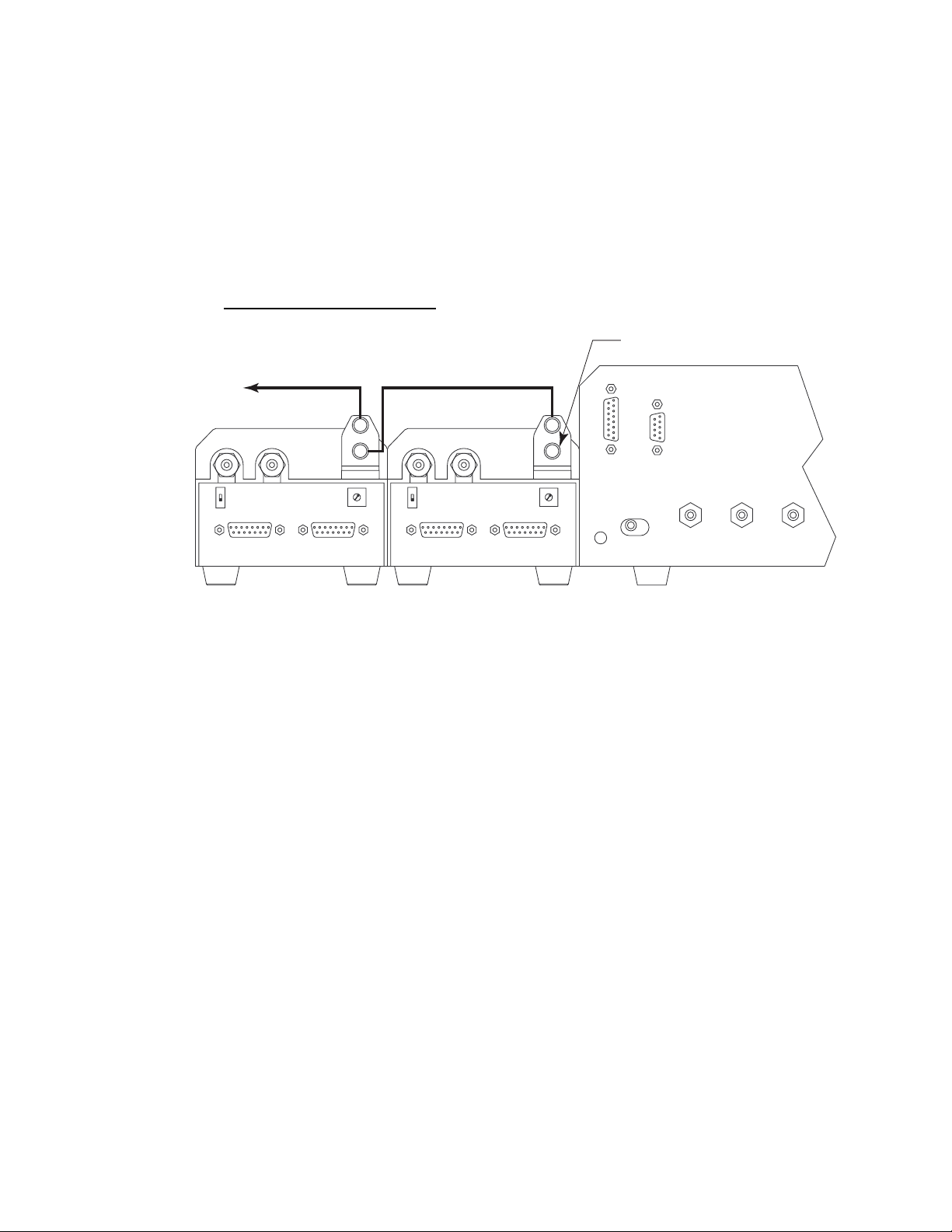

Module CAL. GAS Fitting Connections

Tubing

Install plug on last

CAL. GAS fitting.

MODULE

PC(RS-232C)

AIR GAS1 GAS2

GAS OUT

Figure 12: Calibration Gas Fitting Connections

1. Install a black tube (supplied with the docking station) between the

GAS OUT fitting on the back of the docking station and the right

(when viewed from the back of the module) CAL. GAS fitting on the

first docking module in the system, the one next to the docking

station.

If only one module is to be installed in the system, install the black

fitting plug that is supplied with the system to the left CAL. GAS

fitting of the module. If more modules are used in your system,

continue with step 2.

2. Install a black tube (supplied with the docking module) between t he

left CAL. GAS fitting of the first module and the right CAL. GAS

fitting of the next module in the system.

17 • Data Cal 2000 Hardware Setup

Page 23

3. Repeat step 2 for each successive module in the system until you

Install plug over fitting.

w

get to the last module.

4. Install the black fitting plug on the left CAL. GAS f i tting of the last

module in the system.

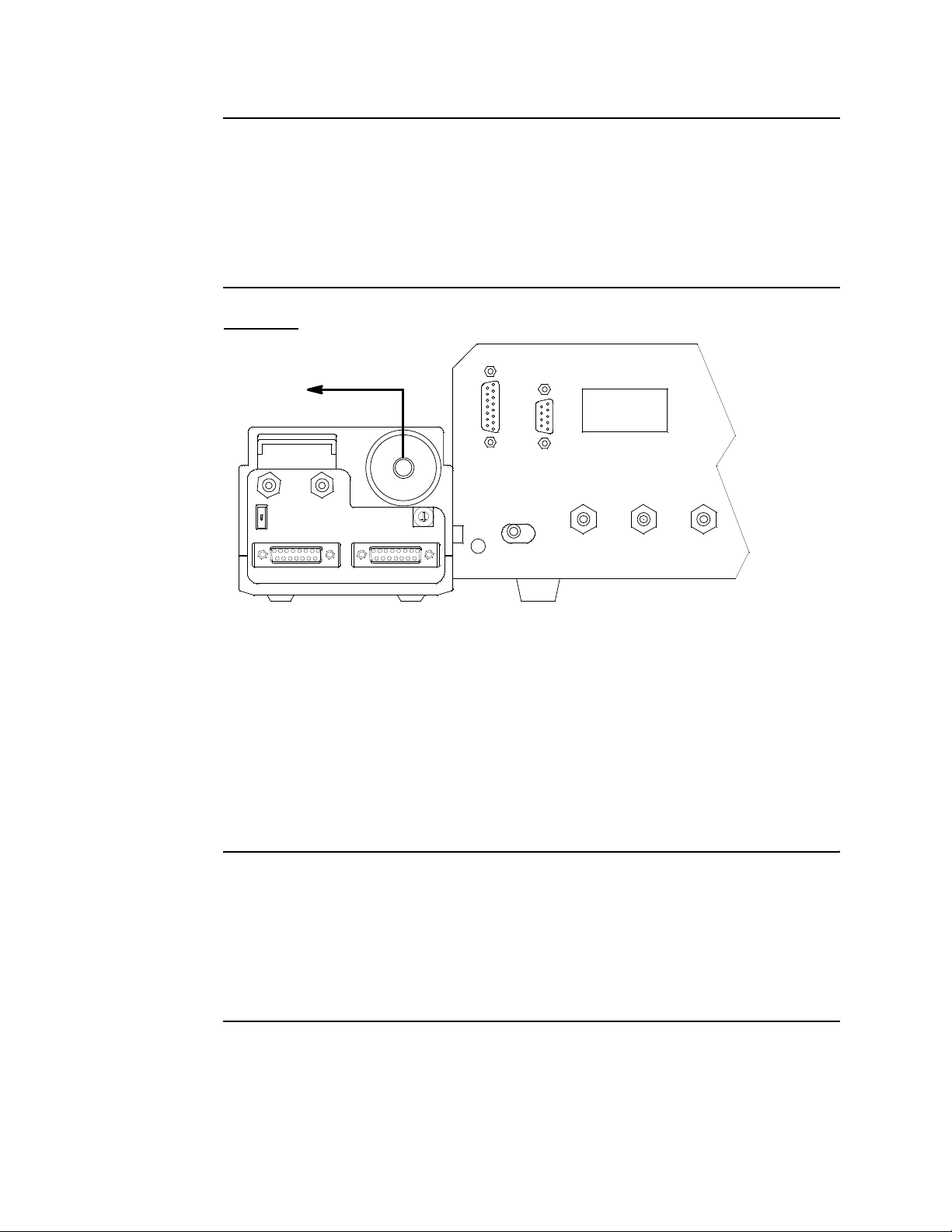

Module Exhaust Fitting Connections

GX-2001 and/or GX-2003

Tubing,

Route to open area

here calibration gas

can be exhausted.

User Supplied

Tubing,Supplied with System

MODULE

PC(RS-232C)

AIR GAS1 GAS2

GAS OUT

Figure 13: Exhaust Fitting Connections

1. Install a clear fitting plug, supplied with the system, on the bottom

port of the exhaust fitting of the first module in the system.

2. Install a clear tube, supplied with the system, between the top

exhaust fitting port on the first module and the bottom exhaust

fitting port on the next module.

3. Repeat step 2 for each successive module in the system until you

get to the last module.

4. On the last module in the system, install the 5/16” ID flexible tube

that is included with the Docking Station on the top exhaust fitting

port and route the tube to a n ar ea whe re the calibrat ion gas can be

safely exhausted.

Data Cal 2000 Hardware Setup • 18

Page 24

CAUTION: The maximum recommended length for the

exhaust tube is 10 feet. Do not use more than 10

feet of tubing for the exha ust tube or bump test and

calibration accuracy will be adversely affected. The

tube that is shipped with the Docking Station is 10

feet long.

GX-2009

MODULE

PPC (RS-232C)

AIR GAS 1 GAS 2

GAS OUT

Route to open area

where calibration gas

can be exhaus ted.

Tubing, User Supplied

Figure 14: Exhaust Fitting Connections

The DM-2009 only has one exhaust fitting instead of two like the

DM-2001 and DM-2003. Each DM-2009 in a Data Cal 2000 system

must have a dedicated exhaust tube.

Install the 5/16” ID flexible tube that is included with the DM-2009

on the exhaust fitting port and route the tube to an area where the

calibration gas can be safely exhausted.

CAUTION: The maximum recommended length for the

exhaust tube is 10 feet. Do not use more than 10

feet of tubing for the exha ust tube or bump test and

calibration accuracy will be adversely affected. The

tube that is shipped with the Docking Station is 10

feet long.

19 • Data Cal 2000 Hardware Setup

Page 25

Docking Station Calibration Gas Fitting Connections

The calibration gas fittings on the back panel of the docking station are

designed to be used with calibration gas cylinders that are fitted with

demand flow regulators. The AIR fitting may be used with a demand flow

regulator and a cylinder of zero emissions air, but this is not normally

necessary since the docking station will generally be in a fresh air area.

The types of calibration gas cylinders used depend on the gas sensors

installed in the GX-2001’s, GX-2003’s, and GX-2009’s being connected

to the docking station. Typically a 4-gas mix will be used if all or most

instruments being connected to the system are 4-gas units. If any

GX-2003’s that a re 5-sen sor unit s a re bei ng connected, a %vo lume CH4

cylinder will also be needed. Use Table 2 below as a guide in determining

which and how many calibration gas cylinders are appropriate for your

system.

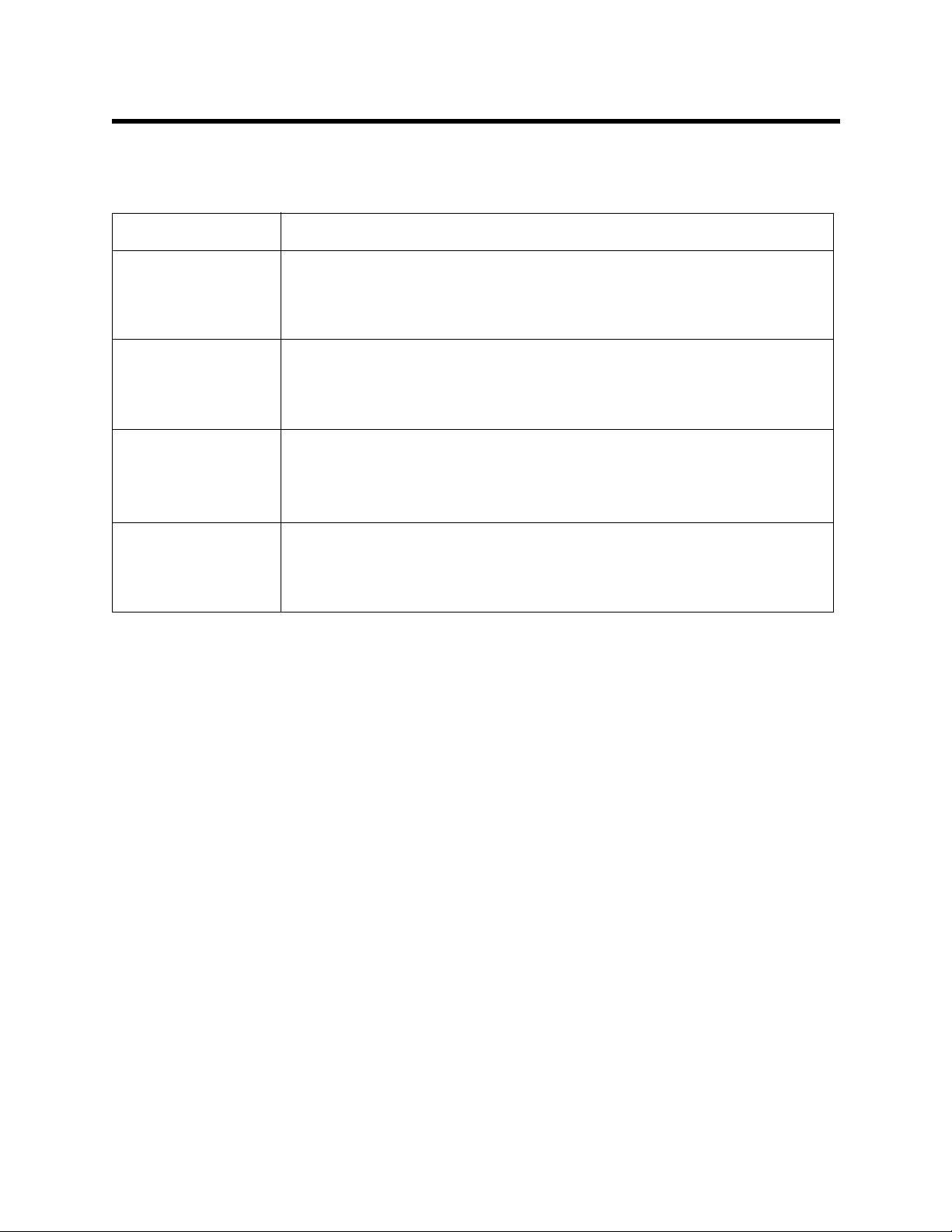

Table 2: Recommended Gas Cylinders

Typical Instrument Types

GX-2001

LEL/Oxy/H2S/CO

GX-2001

LEL/Oxy/CO

GX-2001

LEL/Oxy/H2S

GX-2003

LEL/Oxy/H2S/CO

GX-2003

%V ol CH4/LEL CH4/Oxy/H2S/

CO

GX-2003

LEL/Oxy/CO

Recommended Calibration Gas

Cylinder(s)

4-gas mix with CH4/Oxy/H2S/CO

3-gas mix with CH4/Oxy/CO

4-gas mix with CH4/Oxy/H2S/CO

4-gas mix with CH4/Oxy/H2S/CO

• 4-gas mix with CH4/Oxy/H2S/CO

• %Volume CH4 in air

3-gas mix with CH4/Oxy/CO

GX-2003

LEL/Oxy/H2S

4-gas mix with CH4/Oxy/H2S/CO

Data Cal 2000 Hardware Setup • 20

Page 26

Table 2: Recommended Gas Cylinders

Typical Instrument Types

GX-2009

LEL/Oxy/H2S/CO

GX-2009

LEL/Oxy/CO

GX-2009

LEL/Oxy/H2S

1. If the area around the calibration station is not considered a fresh

air area, an area free of combustible and toxic gases and of normal

oxygen content, 20.9%, install a tube on the AIR fitting on the back

of the docking station and route it to a fresh air area or connect a

cylinder of zero air to the fitting using a demand flow regulator.

2. Install the demand flow regulator(s) on the calibration gas

cylinder(s).

Recommended Calibration Gas

Cylinder(s)

4-gas mix with CH4/Oxy/H2S/CO

3-gas mix with CH4/Oxy/CO

4-gas mix with CH4/Oxy/H2S/CO

3. Connect the demand flow regulator for each calibration gas

cylinder that will be used with th e docking st ation to the desired gas

port, GAS1, GAS2, GAS3, GAS4, or GAS5. These ports must be

defined in the docking station software during the software setup.

See “Setting Up the Solenoids” on page 36.

Installing the Data Cal 2000 Docking

Station Software

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Insert the Data Cal 2000 Docking Station Software Installation CD

into your computer’s CD-ROM drive.

4. The Docking Station InstallShield Wizard comes up to guide you

through installation. Click Next to proceed to the License

Agreement window.

21 • Installing the Data Cal 2000 Docking Station Software

Page 27

5. Read the license agreement and click the agreement acceptance

selection box, then click Next to proceed to the Customer

Information window.

6. Enter a user name and organization, then click Next to proceed to

the Destination Folder window.

7. The default installation folder (C:\ Program Files\Docking S tation\) is

displayed. If you want to install the software in the default folder

continue with step 8. If you want t o install the software in a different

location, click Change and choose a new installation folder now

and then continue with step 8.

8. Click Next to proceed to the Ready to Insta ll the Program window.

9. Review the installation settings. I f t hey are acceptable, click Install

and the installation process will begin. If you want to change

installation settings, click Back and change them to the desired

settings.

10. During software installation, the installation program may find

newer versions of Windows files on your computer than those in

the Installation CD. If this happens, t he insta llation soft ware will ask

you if you want keep these newer files. Click Yes to do so.

11. Follow the on-screen instructions to complete software installation.

Installing the Data Cal 2000 Docking Station Software • 22

Page 28

Launching the Data Cal 2000 Software

1. Click Start on the Windows® Icon Tray, then select Programs/

Docking St ation. The Data Cal 2000 program is launched and the

docking station main program window appears.

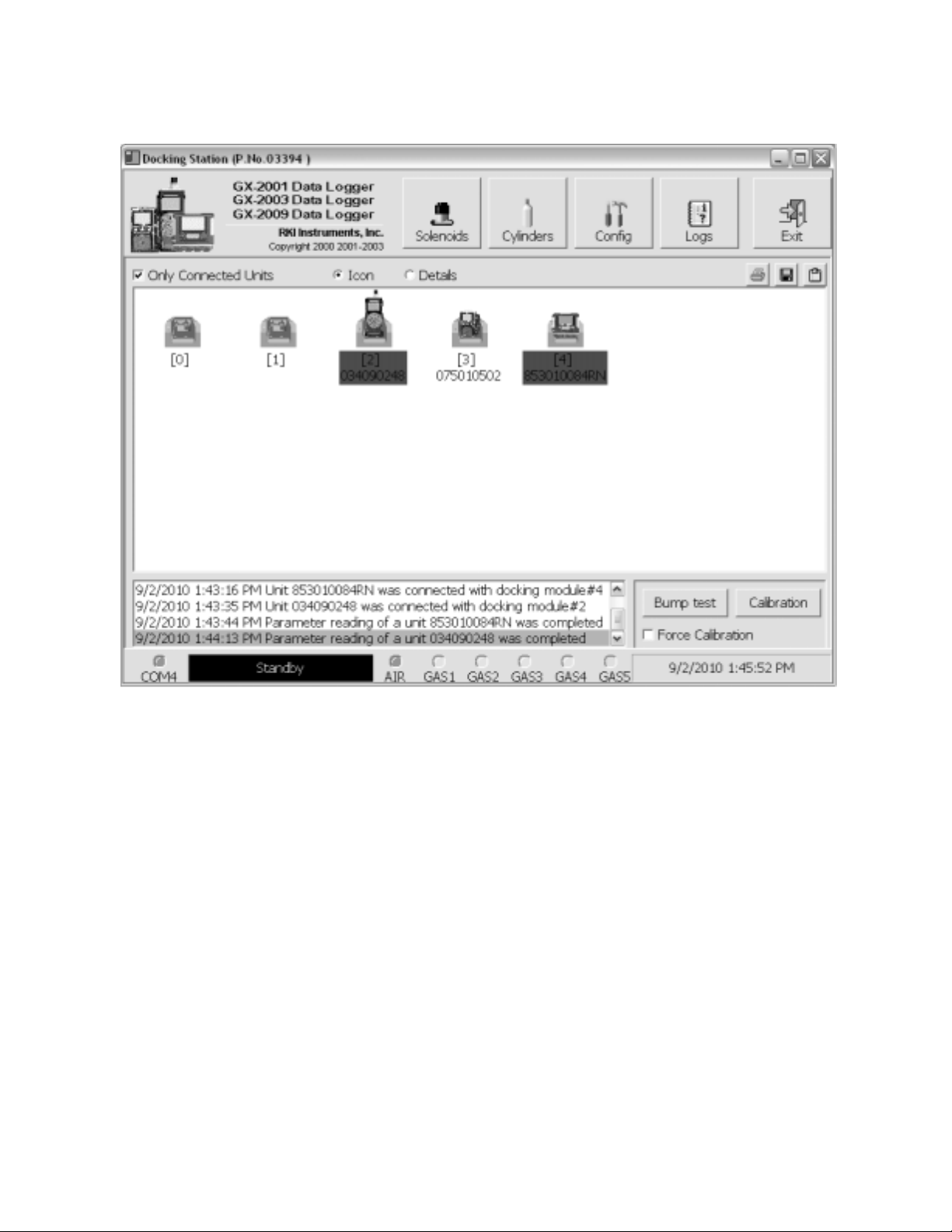

Figure 15: Data Cal 2000 Main Window

NOTE: You can also start the sof tware by double clicki ng on the

Docking Station shortcut that the installation CD puts

on the Windows® Desktop or in the Start menu.

2. If you are starting the software for t he first ti me, a message win dow

appears informing you that a database has been cr eated. When

starting the software for the first time, or if you wish to change the

software setup, proceed to the next section, "Overview of the Data

23 • Launching the Data Cal 2000 Software

Page 29

Cal 2000 Software".

If you have already performed the software setup, proceed to

“Connecting Instruments to the Data Cal 2000” on page 38.

Overview of the Dat a Cal 2000 Software

This section provides a brief overview of the software and a description

of the main program windo w . Inst ructions for usi ng the sof tware are gi ven

in other part s of t his manual . Use this sect ion to become familiar with th e

main program window, but before attempting to use the software, make

sure to perform the software setup as described in “Setting Up the Data

Cal 2000 Software” on page 27.

The Data Cal Docking Station Software is designed to provide manual or

automated data downloading, bump testing, and calibration for the

GX-2001, GX-2003, and GX-2009. It also provides the capability to

update instrument paramet ers such as active channels and alarm point s.

The software compiles a database of the instruments that have been

connected to the Data Cal 2000 which consist s of calibration and bump

test history, logged dat a (if a unit’s data is downloaded), and memos that

record user entered information about an instrument at a particular time.

The GX-2001, the GX-2003, and the GX-2009 are gas monito ring

devices for combustible gas, O

, CO, and H2S. They store logged data

2

and calibration information in t heir internal memor ies. See the Operat or’s

Manual for each instrument for a complete description of each

instrument.

Data Cal 2000 Functions

The Data Cal 2000 softwar e has the following basic functions accessed

or controlled by buttons in the main program screen (see Figure 16):

• Solenoid setup accessed by the Solenoid control button

• Gas cylinder setup accessed by the Cylinders control button

• Software & system configuration accessed by the Config control

button (this function is pa ssword prot ected)

• Data viewing accessed by the Logs control button

• Instrument bump testing controlled by the Bump test button

Overview of the Data Cal 2000 Software • 24

Page 30

• Instrument calibration controlled by the Calibration button

Main Program Window

The main program window is where the current status of the software

operation is shown. Any docking modules and instruments that are

connected to it and any instruments tha t have been but are not currently

connected to it are also shown. The program’s various functions are

initiated or accessed from this screen. The current date and time are

always displayed in the lower right corner of the main window.

Figure 16: Parts of the Main Program Window

Control Buttons

The Solenoids, Cylinders, Config, Logs, and Exit control buttons are

located along the top left of the windo w. The Bump test and Calibration

control buttons are located in the lower right of the window along with a

Force Calibration selection box. The use of these control buttons and the

Force Calibration selection box is described in other parts of this manual.

25 • Overview of the Data Cal 2000 Software

Page 31

Docking Module/Instrument Display Area

The large middle portion of the main window displays docking modules

and instruments that are currently connected to the Data Cal 2000 and

instruments that are in the dat a base. The docking modules are iden tified

by a number that corresponds to the ID switch setting on the back of the

docking module. The instruments are identif ied by their serial number. By

selecting either the Icon selection cir cle or the Details selectio n circle, the

modules and instruments can be displayed either as icons or in a table

format that shows various instrument parameter details such as station

ID, user ID, the next scheduled bump test date, and the next scheduled

calibration date among others. If the Only Connected Units box is

checked, then only instruments that are currently connected to the Data

Cal 2000 will be shown.

Software Status

Three areas of the main window indicate the sof tware sta tus. The smaller

area in the lower left below t he docking module/instru ment display area is

the message window. It displays messages that indicate actions and

status of the software.

Below this area, the communications port that is being used by the

software is shown in the lower left corner. A round communication

indicator is located above the commun i cations port name.

To the right of the communications port indicator is the status field. It

displays the current status of the software. It can indicate that the

software is in standby mode or if it is downloading among other

indications.

Solenoid Indicators

To the right of the status field are 6 round solenoid indicators. They

correspond to the fittings on the back of the docking station. They

indicate whether the corresponding solenoid is activated so it can allow

gas to flow through the fitting it controls and also if the cyl inder connected

to it has expired. See “Adding and Updating Cylinders” on pa ge 33 for an

explanation of how to view and define a cylinder expiration date. The

color of the indicator defines the status as foll ows:

• Green indicates that the solenoid is activated and will allow gas to

flow through the corresponding fitting.

• Yellow indicates that the solenoid is not activated.

Overview of the Data Cal 2000 Software • 26

Page 32

• Orange indicates that the corresponding cylinder will expire in less

than 10 days. When the solenoid is activated, the indicator’s color

will change to green while it is activated and then return to orange

when the solenoid is deactivated.

• Red indicates that the corresponding cylinder’s expiration date has

passed. Although the software will allow use of the cylinder if it is

expired, it is recommended that the expired cylinder be changed as

soon as possible.

W ARNING: If an expired cylinder is used for calibration, the

accuracy of the calibration may be adversely

affected.

Setting Up the Data Cal 2000

Software

Once the software is installed, you must set up the software for your

system. Setting up the Data Cal 2000 software consists of the following

tasks:

• setting up the Dat a Cal 2000 para meter confi guration which includes

parameters such as the number of docking modules and their ID.

NOTE: Only the Parameter tab of the Configuration window is

discussed in this section. See “Configuration Window”

on page 77 for a description of the other tabs in the

Configuration window.

• defining which calibration gas cylinders will be required

• defining which solenoids will control which calibration gas cylinder

If docking modules are added or removed or if the calibration cylinders

being used are different from the defined cyl inders, the setup will have to

be updated.

27 • Setting Up the Data Cal 2000 Software

Page 33

Setting Up the Configuration

1. Launch the software as described in “Launching the Data Cal 2000

Software” on page 23.

NOTE: It is not necessary to turn on the Data Cal 2000 if you

are only performing configuration setup. With the Data

Cal 2000 off, the software will indicate communication

errors in the area below the docking module/instrument

display area. This is normal if the Data Cal 2000 is not

turned on.

2. From the main window, click on the Config button located along

the top of the window.

3. Enter the password and click OK. The default password is

“ABCDE” and is case sensitive. After clicking OK, the Configuration

Window is opened and the Parameter tab will be in the foreground.

Figure 17: Configuration Window

Setting Up the Data Cal 2000 Software • 28

Page 34

4. Select the communication port that will be used in the

Communication section. This is typically COM1 or COM2. Be sure

that the port that is selected is not already being used by some

other device.

5. Select the docking modules that are installed in the Docking

Module section. Ten selection boxes are displayed with the IDs 0

through 9. The IDs on the selection boxes correspond with the IDs

on the docking modules set by the ID switch (See “ID Switch” on

page 14). If modules with IDs 0, 1, and 2 are installed, then

selection boxes 0, 1, and 2 must be selected. If extra boxes are

selected or if the incorrect IDs are selected, communication errors

will result and the software will not work properly.

6. Select the cylinder and solenoid options in the Cylinder & Solenoid

section.

• If the SET Cylinder box is selected, t hen you will be able to ent er

the Solenoids and Cylinders windows b y clickin g the Solenoids

or Cylinders button from the main menu. While in these

windows you will be able to define which cylinders the solen oids

control, update defined cylinders, and add new cylinders. If the

SET Cylinder box is not selected, then the Solenoids and

Cylinders buttons in the main program window will not be

available to click.

• The Expiration Notice will define how many days before a

cylinder expiration date the software will indicate that a cylinder

is nearing the expiration date. It is adjustable from 1 to 180 days.

7. Select the instrument information options in the Instrument

Information section.

• If Change Parameter is selected, you will be able to change

various parameters in connected instruments such as the serial

number and enter memos. See “Edit Function” on page 74 and

“Edit Function, Memo Entry” on page 75.

• The Auto Power OFF Time defines when a connected

instrument will turned off by the Data Cal 2000 after the most

recent operation, such as an automatic download or a manual

bump test. It is defined in seconds with a maximum setting of

29 • Setting Up the Data Cal 2000 Software

Page 35

3600 seconds (1 hour).

8. Select the datalogging options in the Data Logger section.

• If Down Load Data Logger is selected, the software will

automatically download all data from an instrument when it is

connected to the Data Cal 2000 if it is due for download. The

Down Load interval value (see below) determines if an

instrument is due. If Down Load Data Logger and Clear After

Down Load are selected, then all logged data in a downloaded

instrument will be cleared after it is downloaded.

• The Down Load Interval defines how often a unit that is

connected to the Data Cal 2000 will be downloaded if Down

Load Data Logger is selected. If it is set to 0 days, instruments

will be downloaded every time they are connected to the Data

Cal 2000. It is adjustable from 0 to 60 days.

9. Select the bump test options in the Bump Test section.

• Selecting the Manual Bump Test selection box activates the

Bump test button in the main window and allows you to perform

a bump test manually.

• If the Auto Bump Test selection box is selected, the sof tware will

automatically check if a connected instrument is due for a bump

test (see the selection of the bump test interval below) and

perform a bump test if the instrument is due. If Auto Bump Test

is selected, make sure the appropriate calibration gas cylinders

are always connected to the appropriate fittings on the back of

the docking statio n when instruments are being connected to the

Data Cal 2000.

• Set the bump test interva l to the d esired numbe r of days. If Auto

Bump Test is selected, when an instrument is connected to the

Data Cal 2000, if it has not been bump tested in the number of

days defined in the Interval field, it will be bump tested by the

Data Cal 2000. It is adjustab l e from 1 day to 180 days.

• Select the gas exposure time. The gas exposure time defines

the number of seconds that calibration gas is applied to an

instrument during a bump test. It is adjustable from 30 seconds

Setting Up the Data Cal 2000 Software • 30

Page 36

to 90 seconds

• Set the bump test tolerance for each channel. This option for

each channel allows you to set up the criteria for determining if

an instrument passes a bump test. The default value for each

channel for the allowable deviation for a bump test is 30% o f the

gas concentration used in the test. These values are adjust able

from 20% to 50%. If the result of the bump test for a channel is

within the set deviation, then the channel p asses the bump test .

For example, if the tolerance for the CH4(100%LEL) channel is

set to 30% and 50% LEL CH

LEL CH

channel must respond between 35% LEL and 65%

4

is used in the bump test, then the

4

LEL to pass the bump test.

10. Select the cali bration settings in the Calibration section

• Selecting the Manual Calibration selection box activates the

Calibration button in the main window and allows you to

perform a calibration manually.

• If Auto Calibration is selected, the software will automatically

check the last calibration date retrieved from a connected

instrument and compare it to the calibration interval to d etermine

if a connected instrument is due for calibration and calibrate the

instrument if it is due. For a GX-2003 or a GX-2009, the

calibration interval is saved in the instrument and retrieved by

the Data Cal 2000. You can use the Data Cal 2000 software to

update the calibration interval in the GX-2003 or the GX-2009

(see “Edit Function” on page 74). For a GX-2001, the calibration

interval is defined in the Data Cal 2000 software and can be

updated (see “Edit Function” on page 74). If Auto Calibration is

selected, make sure the appropriate calibration gas cylinders

are always connected to the appropriate fittings on the back of

the docking statio n when instruments are being connected to the

Data Cal 2000.

11. Click the OK button to save all changes and return to the main

program window.

31 • Setting Up the Data Cal 2000 Software

Page 37

Viewing the Pre-Defined Cylinders

1. From the main program window , click the Cylinders button located

along the top of the window. The Cylinders window appears.

The Cylinders window lists defined cylinders and has four function

buttons in the lower right corner of the window for ad ding, updating,

or deleting cylinders. When the software is first loaded, there are

two pre-defined cylinders on the list. One is a 58 liter 4-gas mix wit h

25 ppm H2S, 50 ppm CO, 50% LEL CH4, and 12% Oxygen, RKI

part number 81-0154RK-02. This cylinder is included with the Data

Cal 2000. The other is a 58 liter 50% vo lume CH4 cylinder, RKI part

number 81-0013RK-05, that is used to calibrate the %volume TC

sensor if it is installed in a GX-2003. The %volume CH4 cylinder is

not included with the Data Cal 2000 and must be ordered

separately.

Figure 18: Cylinders Window

2. If the pre-defined cylinders are sufficient for calibrating and bump

testing the instruments that will be used with the Data Cal 2000,

click the Close button to return to the main window and proceed to

“Setting Up the Solenoids” on page 36.

If the pre-defined cylinders are not appropriate for t he instruments

that will be used with the Data Cal 2000, proceed to the next

section, "Adding and Updating Cylinders".

Setting Up the Data Cal 2000 Software • 32

Page 38

Adding and Updating Cylinders

Add a cylinder if the correct cylinder for your bump testing and calibratio n

needs is not on the cylinder list. For example, you may have GX-2001’s

that are LEL/Oxy/CO and so do not need to use a 4-ga s mix that includes

S. In this case you would add a 3-gas cylinder to the cylinder list with

H

2

the appropriate gas concentrations.

When you begin using a new cylinder that is already on the cylinder list,

you will need to update the expiration date of the new cylinder. Also,

update the gas concentration of a user defined cylinder if the cylinder you

are using is the same as the defined cylinder, but one of the gas

concentrations is slightly different . For example if the oxygen

concentration in the user defined 4-gas cylinder is defined as 12%, but

the cylinder label for the cylinder you will use states that it is 11.5%,

update the gas concentration for that cylinder.

If you are using a cylinder that has the same gas or gases as one of the

pre-defined cylinders, but is not the same RKI part number as one of t he

RKI cylinders that is pre-defined, add the cylinder to the cylinder list

instead of changing the concentrations of a pre-defined cylinder.

33 • Setting Up the Data Cal 2000 Software

Page 39

Adding a Cylinder to the Cylinder List

1. From the Cylinders window, click the New button. The

CylinderDetail window will appear.

Figure 19: CylinderDetail Window, Adding a Cylinder

2. Put the cursor in the Name field and enter the cylinder name.

3. Click on the drop down box in the Pre-define Cylinder field and

select the blank option. The Symbol (Unit) , Gas Name, and

Concentration fields become active.

4. Click in the top Symbol(Unit) field. A drop down box will appear.

5. Click on the drop down box and select a gas. When the gas is

selected, the name automat ically appears in the Gas Name field for

that gas.

6. Put the cursor in the gas’s Concentration field and enter the

concentration for that gas.

Setting Up the Data Cal 2000 Software • 34

Page 40

7. For each additional gas in the cylinder being entered move to the

next Symbol(Unit) field and repeat steps 4 - 6.

8. If the cylinder will be used for bump testing, click in the Bump test

selection box to place a check in it.

9. If the cylinder will be used for calibrating, click in the Calibration

selection box to place a check in it.

10. Click the OK button. A confirmation window appears.

11. Click Yes to save the new cylinder’s settings and return to the

Cylinders window.

12. Click the Close button to return to the main window.

Updating Existing Cylinder Parameters

1. From the Cylinders window, click on the cylinder in the cylinder list

that you want to update. It will be highlighted.

2. Click the Edit button. The CylinderDetail window for that cylinder

will appear.

Figure 20: Cylinder Detail Window, Editing a Cylinder

35 • Setting Up the Data Cal 2000 Software

Page 41

3. Update the cylinder parameters as desired.

4. Click the OK button. A confirmation window appears.

5. Click Yes to save the changes and return to the Cylinders window.

6. Click the Close button to return to the main window.

Setting Up the Solenoids

The solenoids are located inside the Data Cal 2000 docking st ation. They

control which fitting on the back of the docking st ation is used to draw

gas from a connected cylinder during a bump test or calibration. In the

case of the AIR fitting, it may draw from a zer o air cylinder connected to it

or from the ambient air. Which fitting is used to draw gas at a particular

time during a calibration or bump test is determined by the sof tware

depending on the solenoid cylinder as signment and the version of the

instrument that is being bump tested or calibrated by the Data Cal 2000.

To enter the Solenoids window, click the Solenoids button in the main

program window.

Figure 21: Solenoids Window

When the software is first installed, the solenoids are assigned as

follows:

• the AIR solenoid controls the AIR fitting and it is assigned cylinder

number 0000 which is defined as “air”. This assignment is fixed and

cannot be changed.

Setting Up the Data Cal 2000 Software • 36

Page 42

• The GAS 1 solenoid which controls the Gas 1 fitting is assigned to

Cylinder 0001 which is RKI 4-gas mix 81-00154RK-02.

• The GAS 2 solenoid which controls the Gas 2 fitting is assigned to

Cylinder 0002 which is RKI 50% volume CH4 cylinder 81-0013RK-

05.

• Solenoids GAS 3, GAS 4, and GAS 5 are unassigned.

If you define additional cylinders and wish to assign them to unassigned

solenoids or wish to change the solenoid assignments:

1. From the main program window , click the Solenoids button located

along the top of the window. The Solenoids window appears.

2. Click in the Cylinder Name field of an assigned solenoid or an

assigned solenoid whose assignment you what to change.

3. A drop down arrow will appear in the solenoid position on the far

right.

4. Click on the drop down arrow. A list of defined cylinders wi ll appear.

5. Select the cylinder you want assigned to that solenoid.

6. Click the Apply button to make this change.

7. Repeat steps 2 - 6 for any additional assignments you want to

make.

8. When you are done making assignments, click the OK button. A

confirmation window will appear.

9. Click Yes to save the changes. You will return to the main program

window.

37 • Setting Up the Data Cal 2000 Software

Page 43

Connecting Instruments to the

Data Cal 2000

When an instrument is connected to the Data Cal 2000, the software

automatically retrieves the instrument’s parameters such as serial

number, calibration interval setting, and data logging interval time. It can

also automatically download data, bump test, or calibrate an instrument

depending on whether these items are selected in the parameter tab of

the Configuration window . To connect an instrument or instruments to the

Data Cal 2000, perform the following steps:

1. If necessary, veri fy that the Data Cal 2000 is completely assembled

and connected to your computer as described in “Data Cal 2000

Hardware Setup” on page 13.

2. If necessary, verify that the Data Cal 2000 software has been set

up as described in “Setting Up the Data Cal 2000 Software” on

page 27.

3. With the Data Cal 2000 off, put the instrument(s) to be connected

into an appropriate docking module. Make sure that a GX-2001 is

placed into a DM-2001, a GX-2003 is placed into a DM-2003, and a

GX-2009 is placed into a DM-2009.

• For a GX-2001, attach th e flow adapter cup to the sensor side of

the instrument before inserting it into the DM-2001.

• For the GX-2003, place the instrument into the DM-2003,

connect the plastic fitting on the end of the coiled black tube to

the inlet fitting, and then connect the pl astic fitting on the end of

the straight green tube to the exhaust fitt ing.

• For a GX-2009, place the instrument into the DM-2009. No

secondary connections to the GX-2009 are needed.

4. Turn on the Data Cal 2000 with the power switch on the back panel.

5. Launch the Data Cal 2000 software. The main program window will

appear.

6. Turn on all instrument s that ar e in the docking modules.

Connecting Instruments to the Data Cal 2000 • 38

Page 44

NOTE:As soon as a DM-2003 docking module recognizes t hat a

TRANSMIT

GX-2003 is installed, a solenoid in the DM-2003 that

allows the GX-2003 to draw gas is opened. If a GX-2003

is installed in the docking module when the Data Cal 2000

is turned on, it takes th e DM-2003 about 5 seconds after

turn on to recognize the GX-2003. The solenoid remains

open for 3 minutes and is then closed. Turn on all

GX-2003’s af ter this 5 second period and within 3 minutes

of the solenoid being opened. If the solenoid is closed

when the GX-2003 is turned on, it will go into low flow

alarm because the pump activates for a few seconds

before the GX-2003 is connected with the software.

If a low flow occurs when the GX-2003 is turned on,

disconnect the coiled hose from the inlet fitting, press the

RESET button to reset the low flow alarm, and when the

PC TRANSMIT ST ANDBY O K screen appears, reconnect

the coiled hose to the inlet fitting.

• A GX-2009 will begin its normal startup sequence and after a

few seconds, the display will indicate it is ready t o communicate

with the computer:

PC

NOTE: If the GX-2009 is lef t in the DM-2009 for a long period of

time, the dock pump will run for 12 seconds every 2

minutes in order to keep excess hydrogen generat ed

from the NiMH batteries from affecting the CO sensor.

39 • Connecting Instruments to the Data Cal 2000

Page 45

• A GX-2003 will begin its normal startup sequence and after a

few seconds, the pump will turn of f and the display will indicate it

is ready to communicate with the computer:

PC

TRANSMIT

STAND BY

OK

21:09

• A GX-2001 will begin its normal startup sequence and after a

second or two the display will indicate the following:

Conn

7. The message window in the main program window will indicate

when each unit is connected to the program and what actions are

being taken, for example, paramete r reading or automatic data

downloading. In Figure 22 below, one GX-2001, one GX-2003 and

one GX-2009 are connected to the Data Cal 2000 and their

parameters have been downloaded.

If the Data Cal 2000 software is set up for automatic bump testing or

automatic calibration, the software will determine if any connected

instruments require bump testing or calibration after their

parameters have been retrieved by the sof tware and dat a has been

retrieved (if software is setup for automatic downloading), then

perform bump testing or calibration if necessary.

NOTE: If the software is setup for automatic data downloading,

it may take up to 10 minutes to download each GX-2001

if its memory is full, up to 20 minutes to download each

GX-2003 if its memory is full, and up to 25 minutes to

download each GX-2009.

Connecting Instruments to the Data Cal 2000 • 40

Page 46

Figure 22: Instruments Connected to Data Cal 2000

8. Once all instruments are connected and all a utomatic f unctions ar e

completed, the instruments are available for bump testing,

calibration, data downloading, or parameter updates.

41 • Connecting Instruments to the Data Cal 2000

Page 47

Bump Testing Instruments

The Data Cal 2000 is capable of performing a bump test both manually

and automatically when an instrument is connected to it. When a bump

test is performed, the Data Cal 2000 performs an air adjust operation on

an instrument and then applies calibration gas to the instrument. The

Data Cal 2000 analyzes the response results based on predefined

criteria and determines if the instrument p assed the bump test.

NOTE: Starting in November 2011, Data Cal 2000 Docking

Station Software version 04033 started shipping along

with updated versions of the DM-2009. Any units

shipped prior to November 2011 do not have the ability

to reset the bump test date on a GX-2009 after a

successful bump test. If you are using the GX-2009’s

bump test feature and your Data Cal 2000 is not

resetting the bump test date, contact RKI Instruments,

Inc. to send your DM-2009 in for an update and to

request a new Data Cal 2000 product CD.

The criteria that the Data Cal 2000 uses to determine if the instrument

passes a bump test, whether the Bump Test button is active, and whether

or not the Data Cal 2000 automatically performs a bump test if it is due

on a connected unit is defined in the Configuration window on the

Parameter tab. See "Setting Up the Configuration", instruction 9 on

page 30 for a description of the bump test configuration setup.

To perform a manual bump test on an instrument that is conne cted to t he

software:

1. Ver ify that the appropriate calibration gas cylinder or cylinders is

connected to the appropriate fitting or fittings on the back panel of

the Data Cal 2000. See “Setting Up the Solenoids” on page 36.

2. From the main program window, select the instrument you want to

bump test by clicking on it in the docking module/instrument

window.

To select additional instruments, hold down the Shift key while

clicking each additional instrument. All selected instruments will be

bump tested.

Bump Testing Instruments • 42

Page 48

3. Click the Bump test button. The Data Cal 2000 will initiate a bump

test. During the bump test, the Data Cal 2000 will perform the

following functions:

• It will apply fresh air to the instrument for 45 seconds.

• It will perform a zero operation on the instrument.

• It will apply the necessary calibration gas to the unit for the

number of seconds defined in the Gas Exposure Time setting in

the Parameter Tab of the Configuration Window (see

instruction 9 on page 30). If more than one cylinder is required

for a bump test, such as a %volume CH4 cylinder and a 4-gas

mix cylinder for a 5 sensor GX-2003, then gas from each

cylinder will by applied separately for the required amount of

time.

4. When the bump test is completed, the software will analyze the

results and display the Calibration & Bump test Result window

which shows the bump test results. If the instrument or instrument s

passed the bump test then the following indication is given.

Figure 23: Bump Test Pass Indication

43 • Bump Testing Instruments

Page 49

If the instrument or instruments failed the bump test, then the

following indication is given.

Figure 24Bump Test Fail Indication

5. If the Force Calibration box is checked, then the Data Cal 2000 will

automatically calibrate any instrument or instrument s that fai led the

bump test.

6. To close the result window, click the OK button. For a failed bump

test, if you want to view the test results for each channel, double

click on an instrument in the result window and the software will

take you to the Bump Test area of the Logs window where th e data

for this bump test is saved.

7. After a bump test, the docking modules and instruments will be

automatically displayed in detail format.

Bump Testing Instruments • 44

Page 50

Calibrating Instruments

The Data Cal 2000 is capable of performing a calibration both manually

and automatically on an instrument connect ed to it. Whe n a calibrat ion is

performed, the Data Cal 2000 performs an air adjust operation on an

instrument and then applies calibration gas to the instrument. The Data

Cal 2000 analyzes the calibration results and determines if the

instrument passed the calibration.

To perform a manual calibration on an instrument that is connected to the

software:

1. Veri fy that the appropriate calibration gas cylinder or cylinders are

connected to the appropriate fitting or fittings on the back panel of

the Data Cal 2000. See “Setting Up the Solenoids” on page 36.

2. From the main program window, select the instrument you want to

calibrate by clicking on it in the docking module/in strument window.

To select additional instruments, hold down the Shift key while

clicking each additional instrument. All selected instruments will be

calibrated.

3. Click the Calibration button. The Data Cal 2000 will initiate a

calibration. During the calibration, the Data Cal 2000 will perform

the following functions:

• It will apply fresh air to the instrument for 45 seconds.

• It will perform a zero operation on the instrument.

• It will apply the necessary calibration gas to the unit for 90

seconds. If more than one cylinder is required for a calibration,

such as a %volume CH4 cylinder and a 4-gas mix cylinder for a

5 sensor GX-2003, then gas from each cylinder will be applied

for 90 seconds each.

• After each gas application, a calibration operation will be

performed on the instrument that is appropriate for th at cylinder.

45 • Calibrating Instruments

Page 51

4. When the calibration is completed, the software will analyze the

results and display the Calibration & Bump test Result window

which shows the calibration result s. If the instrumen t or instruments

passed the calibration then the following indication is given.

Figure 25: Calibration Pass Indication

Calibrating Instruments • 4 6

Page 52

If the instrument or instruments failed the calibra tion, then the

following indication is given.

Figure 26: Calibration Fail Indication

5. To close the result window, click the OK button. For a failed

calibration, if you want to view the test results for each channel,

double click on an instrument in the result window and the software

will take you to the Calibration area of the Logs window where the

data for this calibration is saved.

6. After a calibration, the docking modules and instruments will be

automatically displayed in detail format.

47 • Calibrating Instruments

Page 53

Deleting Instruments From the Main

Window

An instrument, along with a ll its associated dat a, can b e de lete d from the

database from the main program window. This function is password

protected to prevent accidental deletion of an instrument from the

database. To delete an instrument from the database from the main

program window, perform the following:

1. From the main program window , click on th e instrument you want to

delete so that it is highlighted.

2. Press the “Delete” key on the keyboard. A password entry window

will appear.

3. Enter the password and click OK. The default password is

“ABCDE” and is case sensitive. A confirmation window will appear.

4. Click OK to complete the deletion of the selected item.

NOTE: Instruments can also be deleted from the database in

the Database tab of the Configuration window. See

“Database Tab” on page 79.

Charging Instruments With The

Data Cal 2000

The Data Cal 2000 can be used to charge the rechargeable bat tery p a ck

in a GX-2001, GX-2003, or GX-2009. The Data Cal 2000 will not

recharge the batteries in an alkaline version of the GX-2003. An

instrument’s battery pack can be recharged after functions such as data

downloading or bump testing are performed on it. It can also be charged

without the Data Cal 2000 Docking Station Software being launched. To

maximize the battery pack run time and the battery pack life, make sure

the battery pack’s charge is as low as possible before recharging it.

To recharge the batteries in an instrument after it is connected to the

Data Cal 2000 and the software has performed functions such as data

downloading or bump testing on it:

1. After all functions have been completed, turn off the instrument.

Deleting Instruments From the Main Window • 48

Page 54

2. The LED on the left front of the docking module will turn off. The

LED on the right front of the module will start blinkin g yellow.

3. If the battery pack is fully charged, th en the blinking yellow LED will

turn solid green in a few minutes.

If the battery pack is drained enough for t he mo dule to charge it,

the right LED will continue to blink yellow while charging is taking

place. The GX-2001 and GX-2003 each take approximately 90

minutes to charge while the GX-2009 will take approximately 3

hours to fully charge.

NOTE: If the GX-2009 is lef t in the DM-2009 for a long period of

time, the dock pump will run for 12 seconds every 2

minutes in order to keep excess hydrogen generat ed

from the NiMH batteries from affecting the CO sensor.

To recharge the batteries in an instrument wit hout launching t he Data Cal

2000 Docking S tation Software:

1. Turn on the docking station. The right LED on the docking module

will start blinking green.

2. Install the instrument into the docking module. If only charging is

being performed, it is not necessary t o inst all the sample ada pter to

a GX-2001 or the sample tubes to a GX-2003. Since the GX-2009

does not require any attachments, it can be installed in the

DM-2009 normally. The right LED on the docking module will start

blinking yellow.

3. If the battery pack is fully charged, th en the blinking yellow LED will

turn solid green in a few minutes.

If the battery pack is drained enough for t he mo dule to charge it,

the right LED will continue to blink yellow while charging is taking

place. The GX-2001 and GX-2003 each take approximately 90

minutes to charge while the GX-2009 will take approximately 3

hours to fully charge.

49 • Charging Instruments With The Data Cal 2000

Page 55

NOTE: If the GX-2009 is lef t in the DM-2009 for a long period of

time, the dock pump will run for 12 seconds every 2

minutes in order to keep excess hydrogen generat ed

from the NiMH batteries from affecting the CO sensor.

Logs Window

Viewing Data

You can view alarm t rend data , calibration dat a, event da ta, interval t rend

data, memos, and bu mp test information in the Logs window. T o ent er the

Logs window, click the Logs button from the main program window.