Page 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in

materials and workmanship, and performance for a period of one year from date of shipment from

RKI Instruments, Inc. Any parts found defective within that period will be repaired or replaced, at

our option, free of charge. This warranty does not apply to those items which by their nature are

subject to deterioration or consumption in normal service, and which must be cleaned, repaired, or

replaced on a routine basis. Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repairs

procedures not in accordance with the instruction manual. This warranty indicates the full extent

of our liability, and we are not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior approval.

Absorbent cartridges Batteries

Pump diaphragms and valves Filter elements

Fuses

THIS WA RR AN T Y IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF RKI INSTRUMENTS, INC.

INCLUDING BUT NOT LIMITED TO THE WA R RA NT Y OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL RKI

NSTRUMENTS, INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR

I

CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE

OF ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR OPERATE

PROPERLY.

This warranty covers instruments and parts sold to users only by authorized distributors, dealers,

and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor and our warranty is limited to replacement of parts or our complete goods.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

About the SDM-6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cautions & Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How to Build a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SDM-6000 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Touch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Instrument Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Gas In/Gas Out Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Left Panel Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mating Slave Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Exhaust Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Air Filter and Exhaust Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Connection Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Accessories Included in Various Bundles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

USB Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SD Card and SD to USB Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Demand Flow Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Calibration Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Calibration Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Optional Accessories, Not Included in Any Bundles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SV-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wall Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3: Preparing to Use the SDM-6000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing the SDM-PC2 Docking Station PC Controller Program . . . . . . . . . . . . . . . . . 25

Setup for Chlorine Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

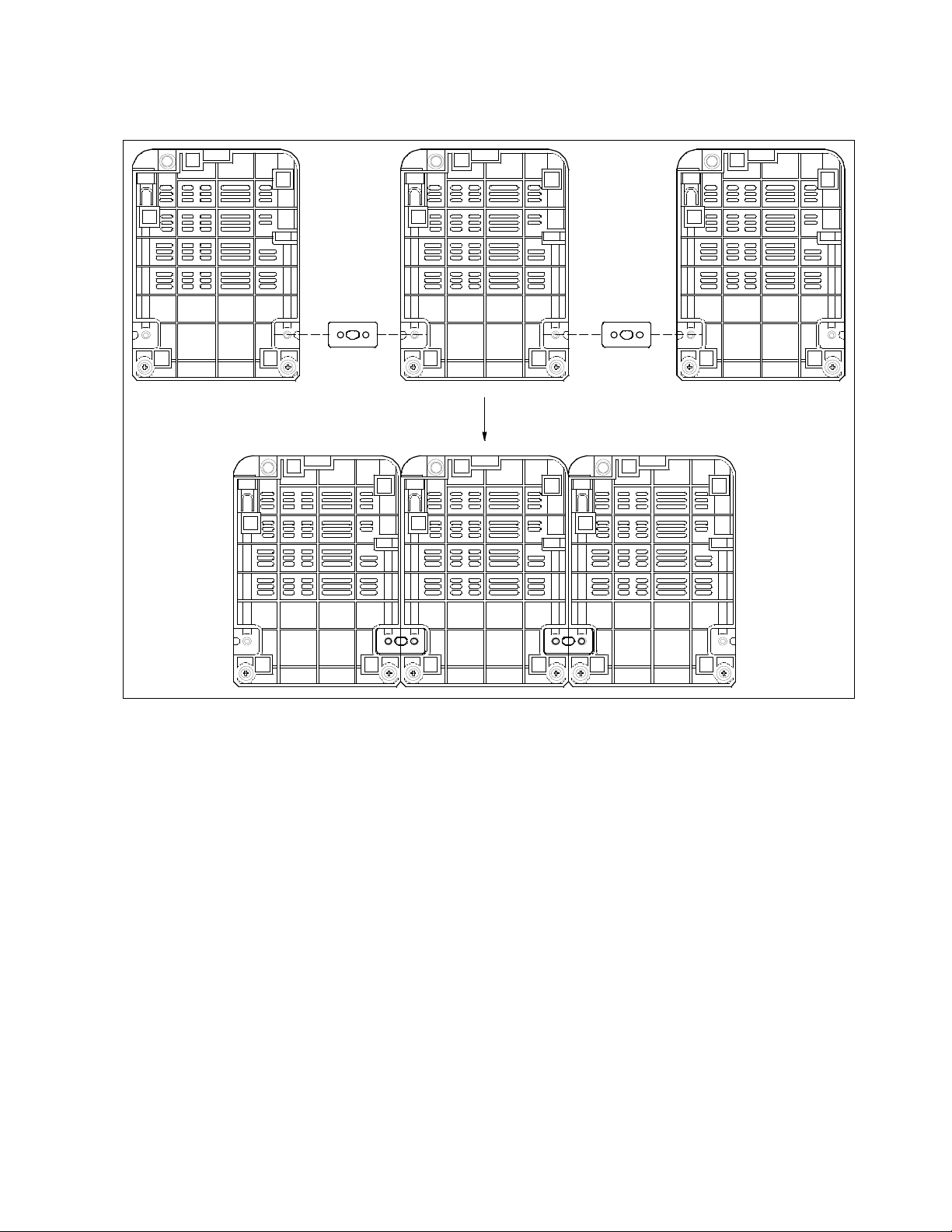

Connecting Multiple SDM-6000s Together, Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting the SV-3, Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting the Printer, Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Hardware Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wall Mounting the SDM-6000, Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting Calibration Gas, No SV-3 Attached. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connecting Calibration Gas, SV-3 Attached. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting Basic Operational Parameters in the Config Menu . . . . . . . . . . . . . . . . . . . . . . . 43

Bump Test Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Calibration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Inlet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

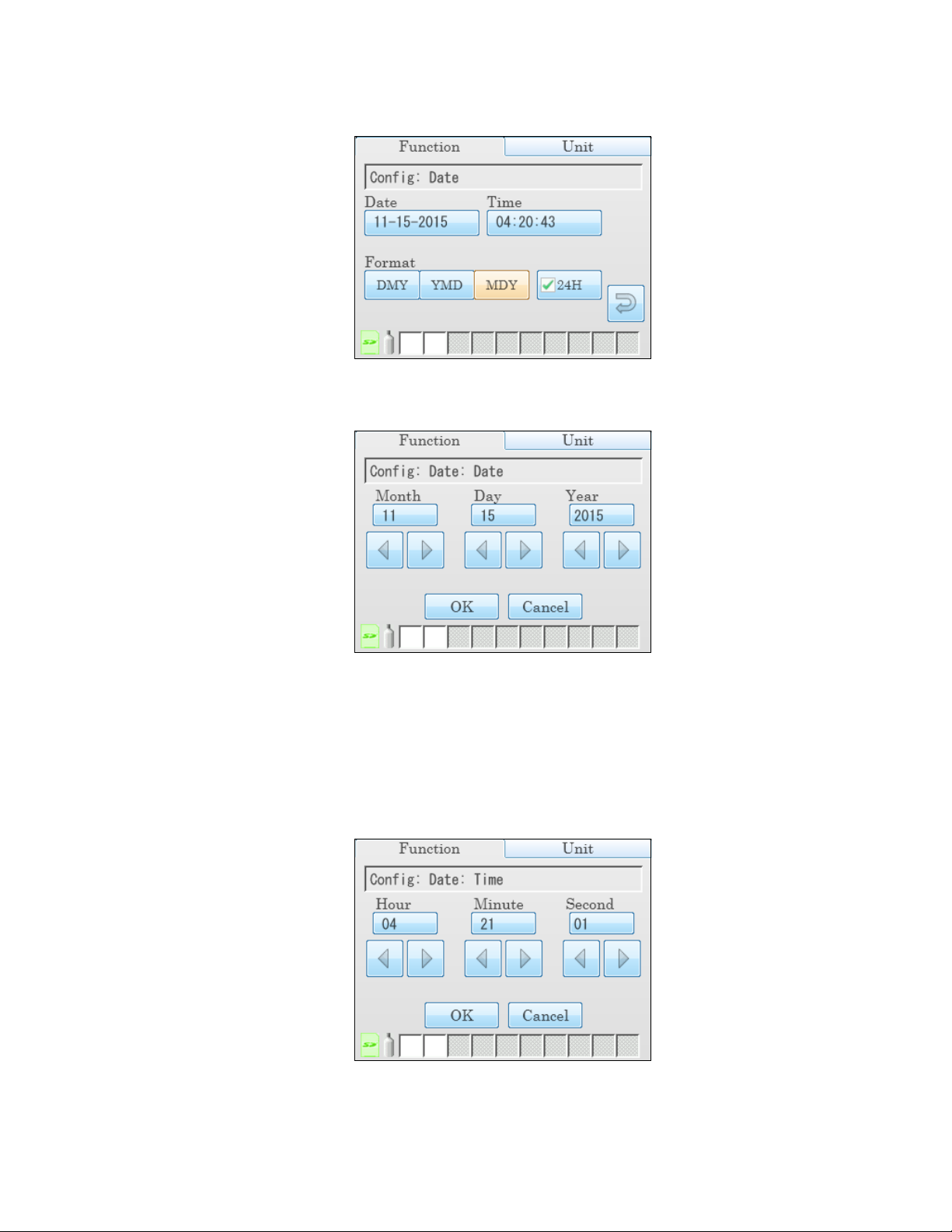

Date, Time, and Date/Time Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

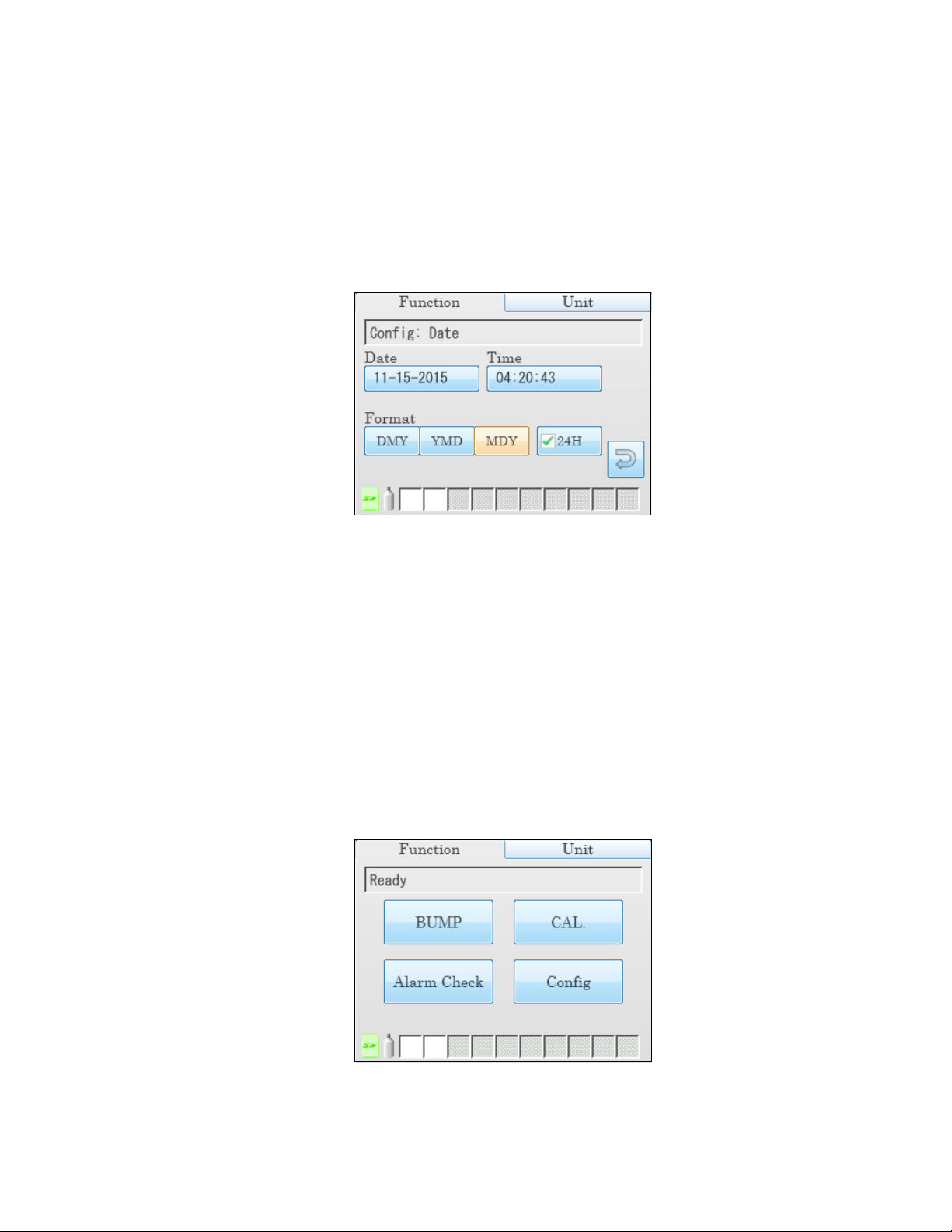

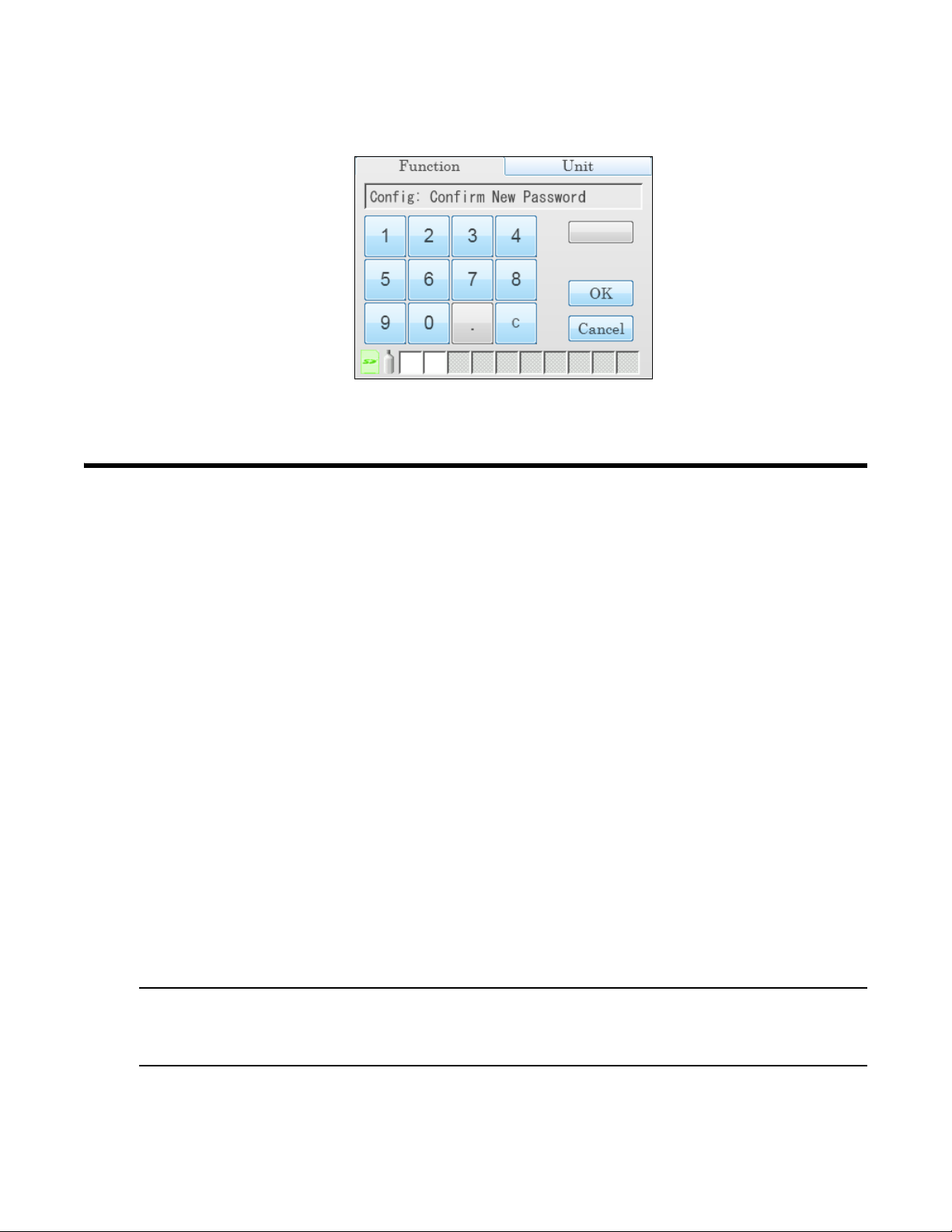

Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Setting Detailed Parameters Using the PC Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Launching the PC Controller Program and Connecting an SDM-6000 . . . . . . .64

Accessing the SDM Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Updating the Data Logger Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Updating the Power Saving Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Updating the Expiration Date Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Updating the Automatic Execution Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

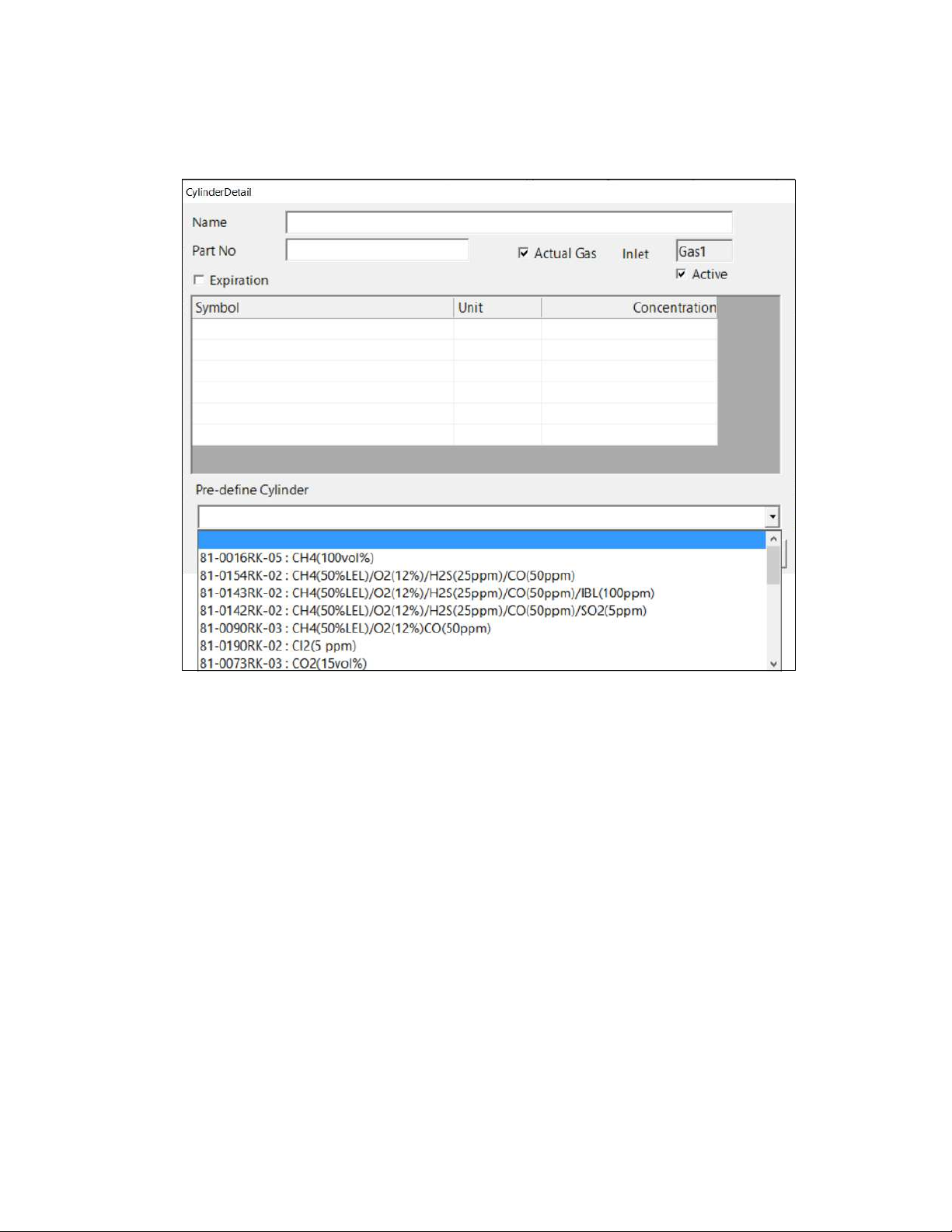

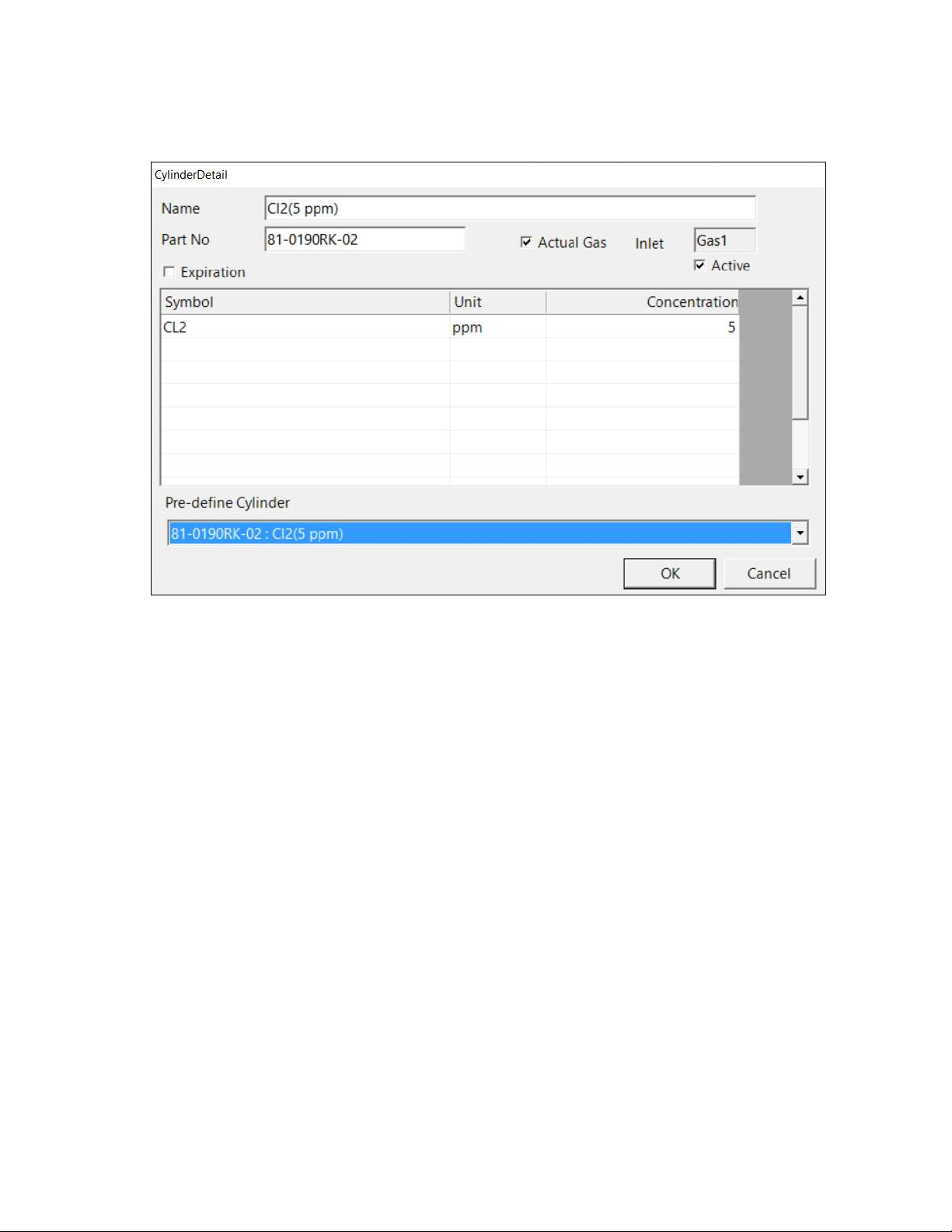

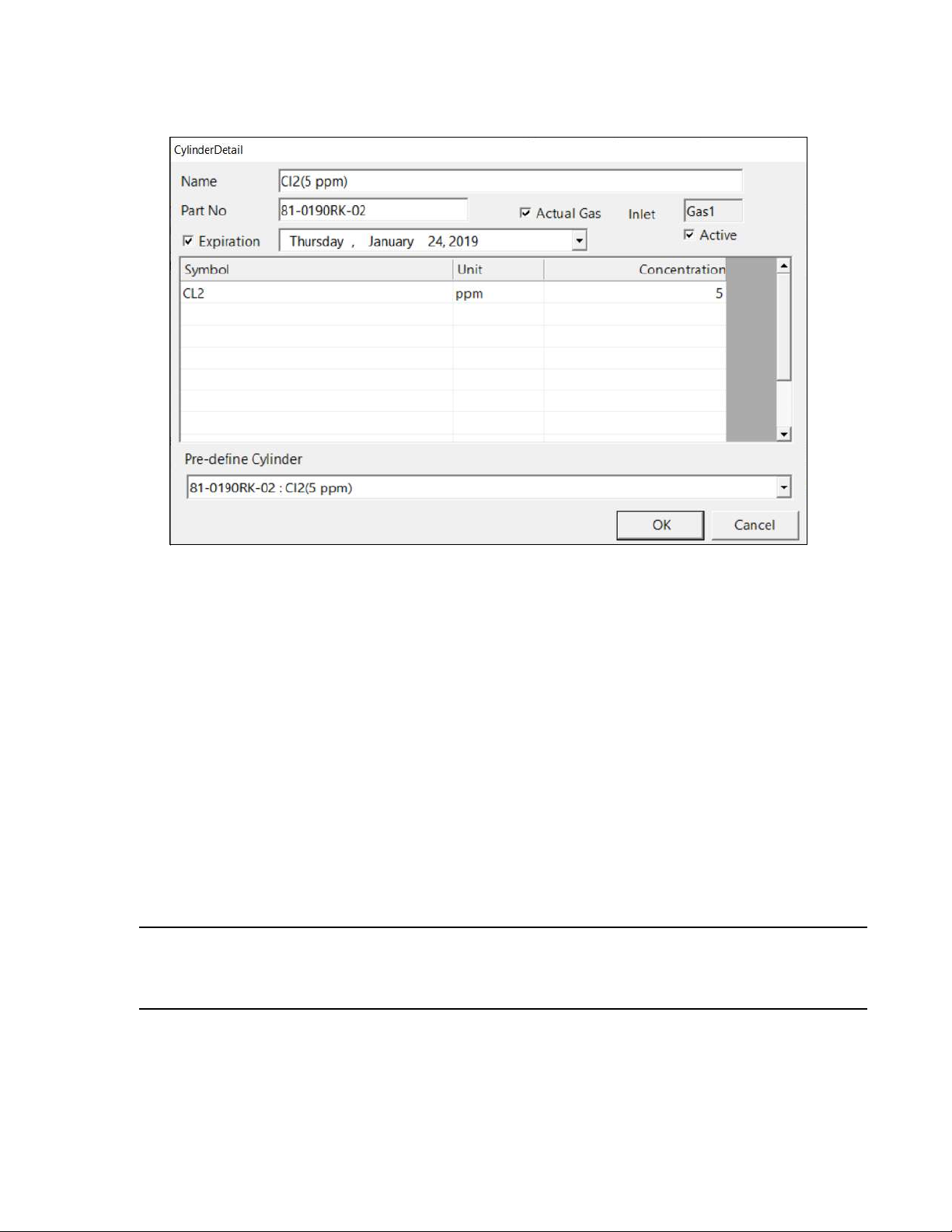

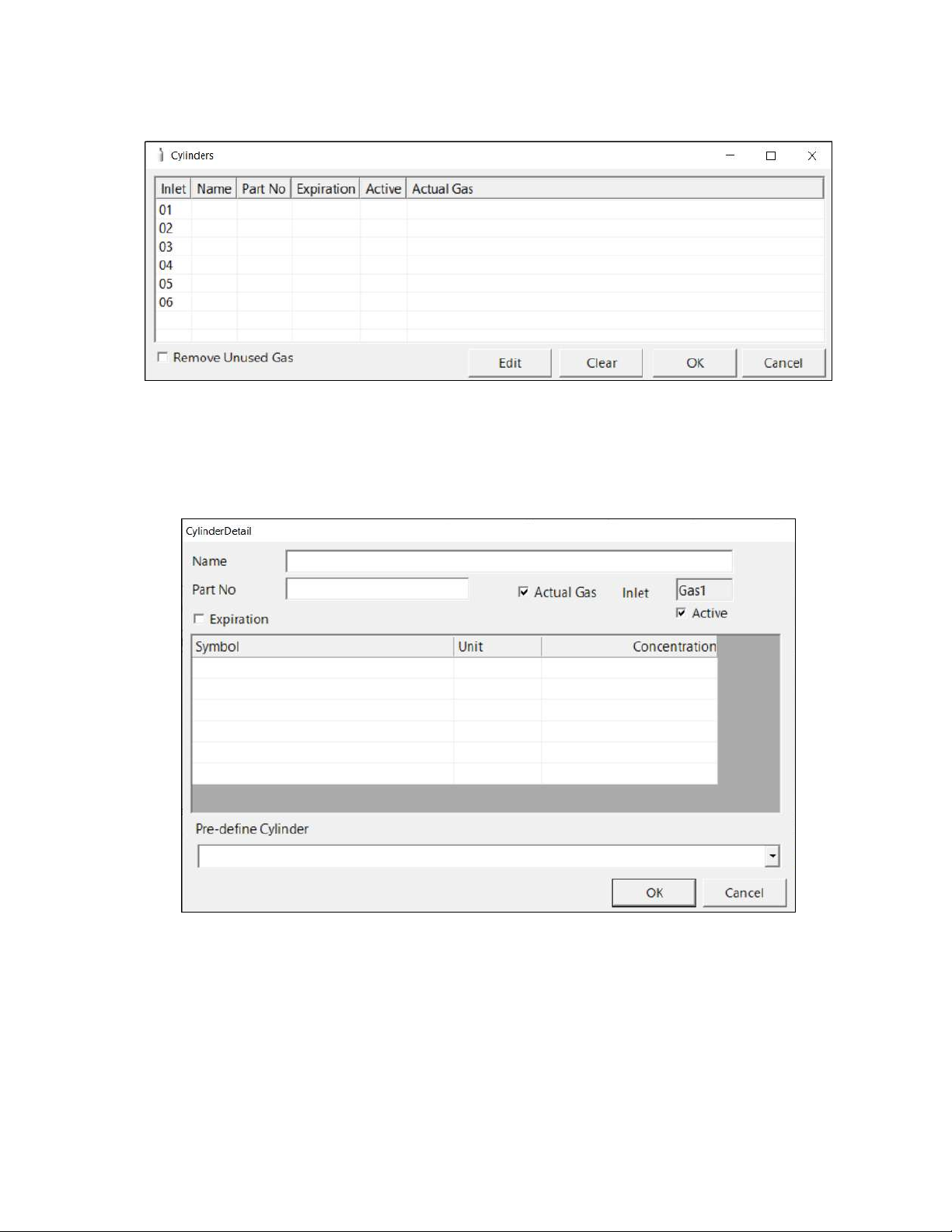

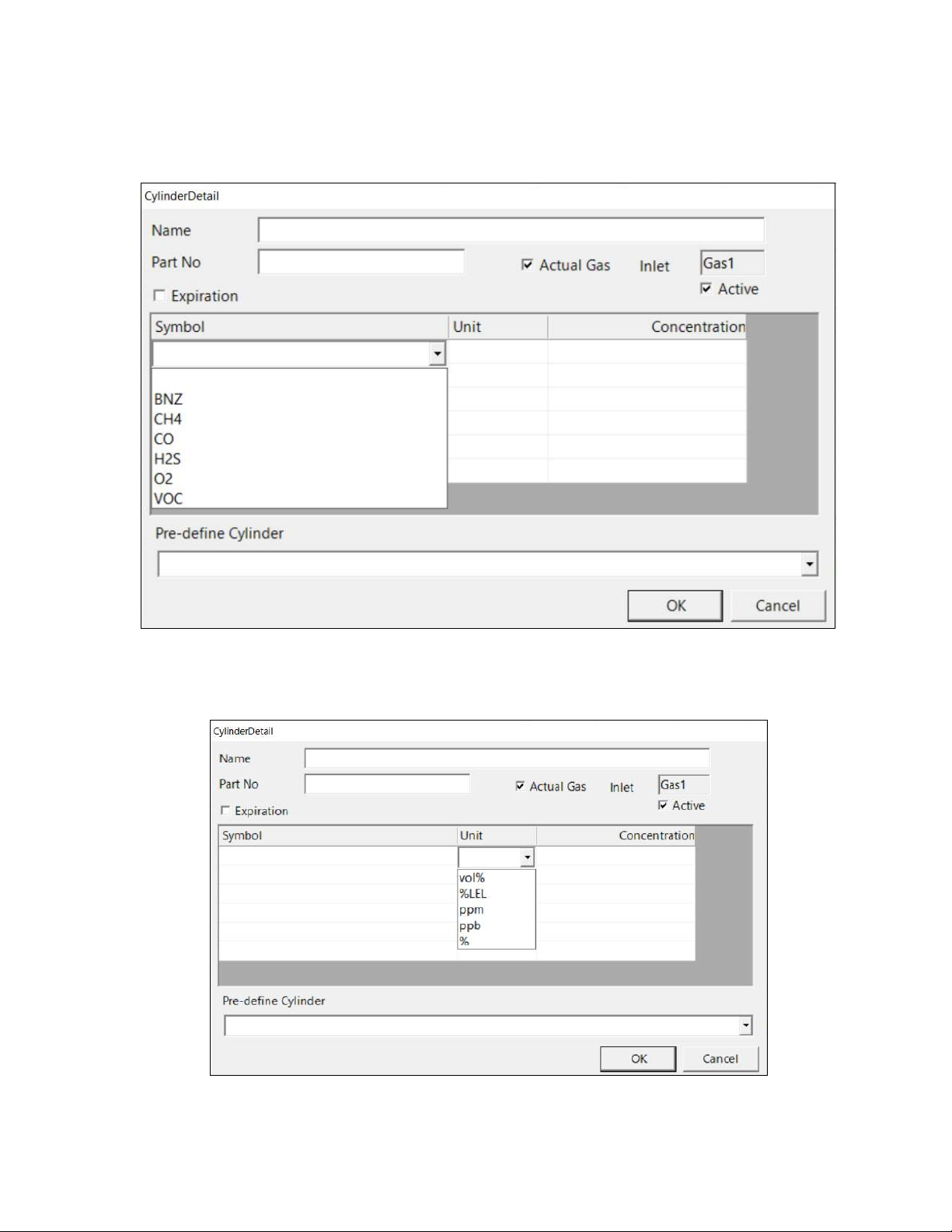

Updating the Cylinders Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Setting Up LAN Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Automatically Initiated Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Turning on an SDM-6000 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Bump Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Alarm Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Charging a GX-6000 in a Docking Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Recharging a Battery Pack After Performing a Test . . . . . . . . . . . . . . . . . . . . . 108

Recharging a Battery Pack Without Performing Any Operations . . . . . . . . . . .109

Batteries Too Drained for Standalone Operation. . . . . . . . . . . . . . . . . . . . . . . . 110

Bump Test, Calibration, and Alarm Check Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Available Memory in the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Test Record Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Transferring Record Files to a Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Chapter 5: Viewing Test Data in a Text Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

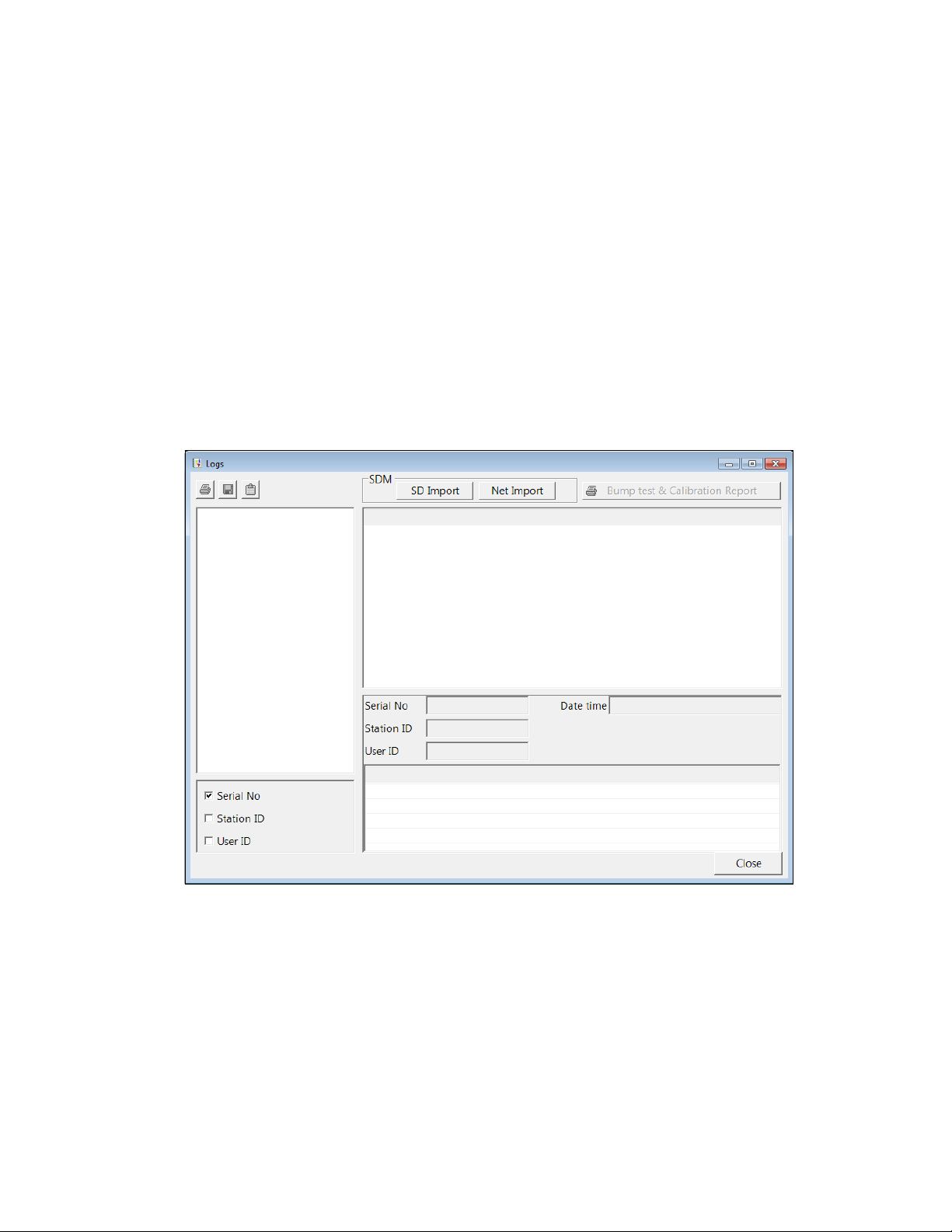

Chapter 6: Importing Data Into the SDM-PC2 PC Program. . . . . . . . . . . . . . . . . . . . . . . . 115

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Importing from an SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Importing Using the LAN Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Viewing Imported Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Exiting the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Chapter 7: Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Appendix A: Setting the Actual Gas Selection Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

One-PID-Sensor GX-6000s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Two-PID-Sensor GX-6000s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Changing a PID Short Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

CAUTION: Read and understand this manual before using the SDM-6000. Also read and

understand the GX-6000 Operator’s Manual.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Chapter 1: Introduction

Overview

This chapter briefly describes the SDM-6000 Docking Station and the SDM-PC2 Docking Station

PC Controller Program. This chapter also describes the SDM-6000 Docking Station Standalone

Configuration Operator’s Manual (this document). Table 1 at the end of this chapter lists the

SDM-6000’s specifications.

About the SDM-6000

The SDM-6000 Docking Station is an advanced, reliable system that can charge, bump test,

calibrate, alarm check, and provide test records for up to 10 GX-6000 portable gas monitors at

once. It is designed to save the test records to an SDHC card (standalone functionality) or to be

connected directly to a computer (PC controlled functionality). If test records are stored to an

SDHC card while operating in the standalone configuration, the PC Controller Program can then

be used with a Windows-based personal computer to retrieve test data files from the SDHC card

or from the computer’s hard drive if the files have been transferred to the hard drive from the

SDHC card. If you are using the PC Controller Program while operating in the PC controlled

configuration, you may retrieve instrument data, bump test, calibrate, and alarm check

instruments. Instrument information and data for each instrument can be viewed directly using the

PC Controller Program and can be printed from the PC Controller Program. For instructions to

use the SDM-6000 in the PC Controlled Configuration, see the SDM-6000 Docking Station PC

Controlled Configuration Operator’s Manual.

The purpose of this manual is to explain how to set up and use the SDM-6000 in Standalone

configuration. It also explains how to use the sections of the PC Controller Program associated

with Standalone use. You will learn how to:

• install and launch the PC Controller Program

• prepare the SDM-6000 for use

• perform a bump test

• perform a calibration

• perform an alarm check

• download instrument data to the SD card

• import instrument data, bump test, calibration, and alarm check records to the PC Controller

Program’s database

• use the SDM-6000 to charge a GX-6000

6 • Chapter 1: Introduction

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

CAUTION: The GX-6000 detects oxygen deficiency and elevated levels of oxygen,

combustible gases, carbon monoxide, and hydrogen sulfide, all of which can be

dangerous or life threatening. When using the GX-6000, you must follow the

instructions and warnings in the GX-6000 Operator’s Manual to assure proper

and safe operation of the instrument and to minimize the risk of personal injury.

CAUTION: The operator of this instrument is advised that if the equipment is used in a

manner not specified in this manual, the protection provided by the equipment

may be impaired.

System Requirements

To use the SDM-PC2 Docking Station PC Controller Program, your personal computer must meet

the following requirements:

• Operating Systems: Windows

• Processor: IBM

• Memory: 32 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• Available USB Port

• SD Card Slot (recommended)

About this Manual

The SDM-6000 Docking Station Standalone Configuration Operator’s Manual uses the following

conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in injury or death.

®

7, Windows® 8, Windows® 10.

®

compatible PC running Pentium® 2 processor or equivalent minimum

Chapter 1: Introduction • 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Cautions & Safety Information

• Use only polyurethane sample tubing with the SDM-6000. Consult RKI Instruments, Inc.

for other materials.

• Do not subject the SDM-6000 to infrared or intense light. This may cause communication

errors.

• Do not expose the SDM-6000 to water.

• Do not subject the SDM-6000 to any hard impact.

Specifications

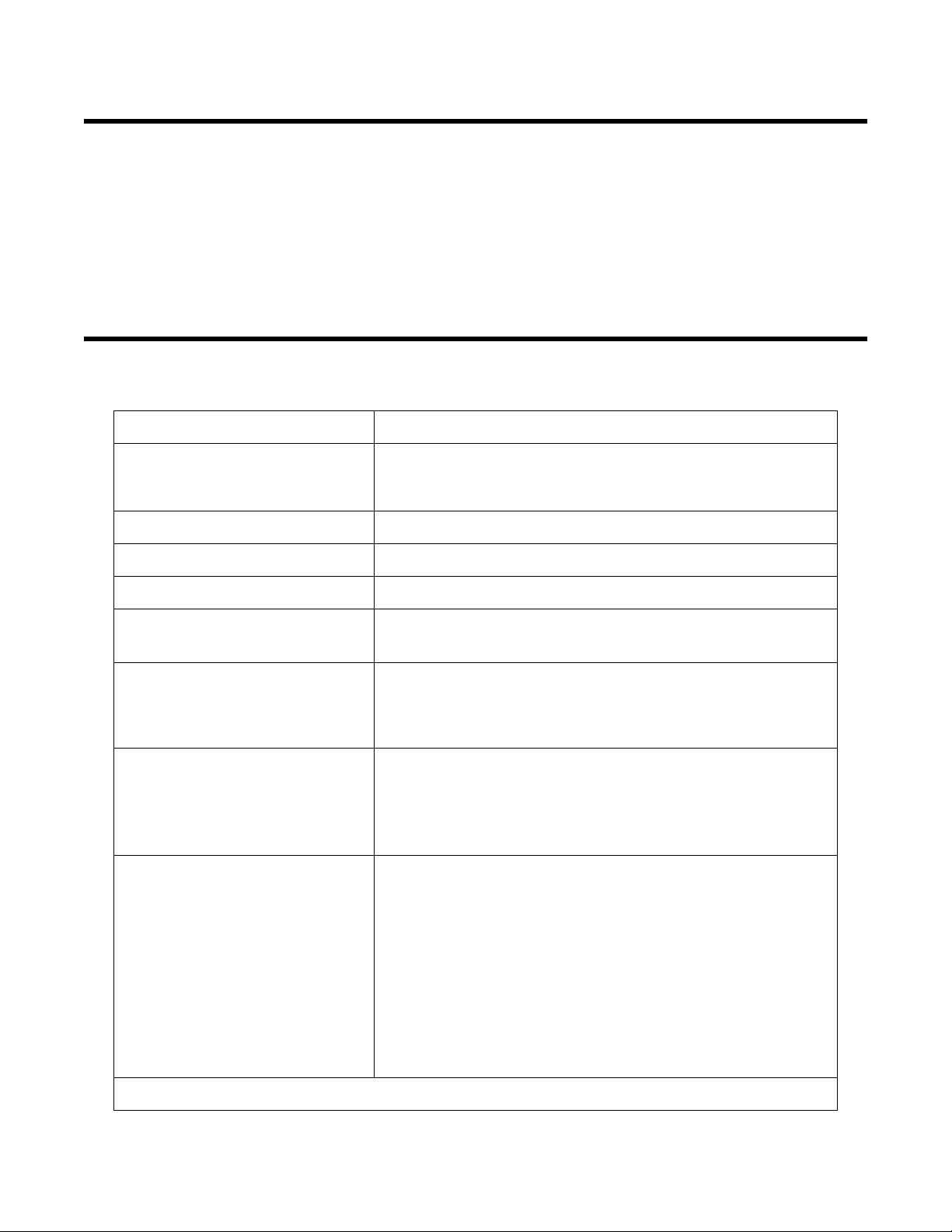

Table 1: Specifications

Input Power 24 VDC

Environmental Conditions • For Indoor Use Only

• 0° C to 40° C, below 95% Relative Humidity, NonCondensing

Applicable Instrument GX-6000

Memory Capacity Dependent on capacity of installed SDHC card

Record Size 1.1 KB (bump test + calibration + alarm check)

Maximum Number of Records

Saved

Number of Calibration Gas

Cylinders

Standard Accessories • Instruction Manual*

Available Accessories •AC Adapter

Dependent on capacity of installed SDHC card

• SV-3 not connected: Up to three calibration gas cylinders per

bump test or calibration at a time

• SV-3 connected: Up to six calibration gas cylinders per bump

test or calibration at a time

• SDM-PC2 Docking Station PC Controller Software*

• Inlet Air Filter

• 10 Foot Long Exhaust Tube

• Connection Brackets

• USB Cable, Type A to Type B

• Ethernet Cable

• SDHC Card and SD to USB Reader

• Demand Flow Regulator

• 3-Foot Long Calibration Tubing

• Calibration Gas Cylinder

•SV-3

•Printer

• Wall Mounting Brackets

•CO

Scrubber

2

8 • Chapter 1: Introduction

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

How to Build a System

Various accessories are included with the SDM-6000 depending on what SDM-6000 bundle is

ordered. See the table below for what’s included with each basic bundle. Other bundles are

available that include different calibration gas cylinders than the 4-gas mix included in the 81SDM6000-04.

For example, if you have 5 separate single-station systems where none of the 5 stations are

connected together, each system will need 1 each of the starred items which means you will have

a total of 5 each of the starred items. For this system, you would need to order 5 81-SDM6000-01

bundles, 5 81-SDM6000-03 bundles, or 5 81-SDM6000-04 bundles depending on additional

accessories desired.

If you have 1 multi-station system with 5 SDM-6000s connected together, you will only need 1

each of the starred items in order to operate all 5 SDM-6000s. For this system, you would need to

order 1 81-SDM6000-02 bundle and 4 81-SDM6000 bundles. Any additional accessories would

need to be ordered separately.

Bundle Part Numbers

Included Items

Docking Station X X X X X

Exhaust Tube, 10 ft. X X X X X

USB Cable* X X X X

Ethernet Cable, 5 ft.* X X X X

Single-Station AC Adapter*

Multi-Station AC Adapter*

SDHC Card with SD to USB Reader* X X X X

Demand Flow Regulator X X

Calibration Tubing, 3 ft. X X X X

Calibration Cylinder Holder X

Calibration Cylinder** X

a

b

81-SDM6000

81-SDM6000-01

XXX

81-SDM6000-02

X

81-SDM6000-03

81-SDM6000-04

* Each system needs only one each of these.

*a

Used only for single-station systems.

*b

Used only for multi-station systems.

** Type of calibration cylinder depends on bundle ordered.

Chapter 1: Introduction • 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Chapter 2: Description

Instrument

Cradle

Gas In/Gas

Out Cover

Status LED

STATUS

Touch Screen

Instruction Label

Figure 1: SDM-6000 Component Location

Overview

This section describes the SDM-6000 docking station’s components, various accessories that may

or may not be included depending on what bundle was ordered, and optional accessories that are

not included in any bundles.

SDM-6000 Components

The SDM-6000 consists of the touch screen, status LED, instrument cradle, gas in/gas out cover,

left panel, mating slave connections, exhaust fitting, air filter, exhaust tubing, and connection

brackets.

10 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

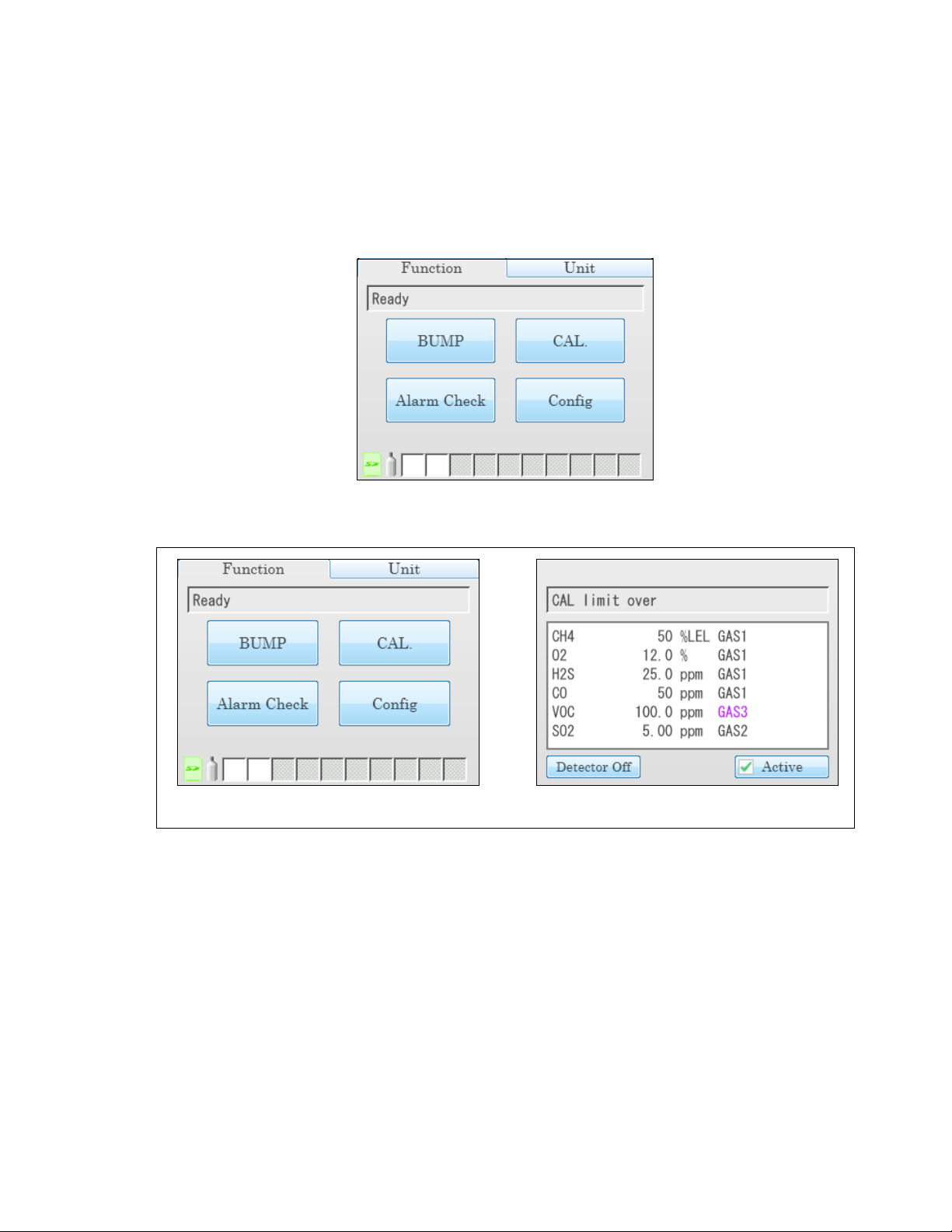

Touch Screen

Figure 2: Single SDM-6000 System Touchscreen

Figure 3: Multi-SDM-6000 System Touchscreens

Master Touchscreen

Slave Touchscreen

The LCD touch screen is located at the bottom front of the SDM-6000. In a single SDM-6000

system, the touch screen includes the Function and Unit Tabs. In a multi-SDM-6000 system, the

master (leftmost) SDM-6000’s touch screen includes the Function and Unit Tabs and any slave

SDM-6000s’ touch screens only display the Unit Tab information. The Function and Unit tabs are

described below in "Function Tab" and "Unit Tab".

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapte r 2 : De s criptio n • 11

Page 12

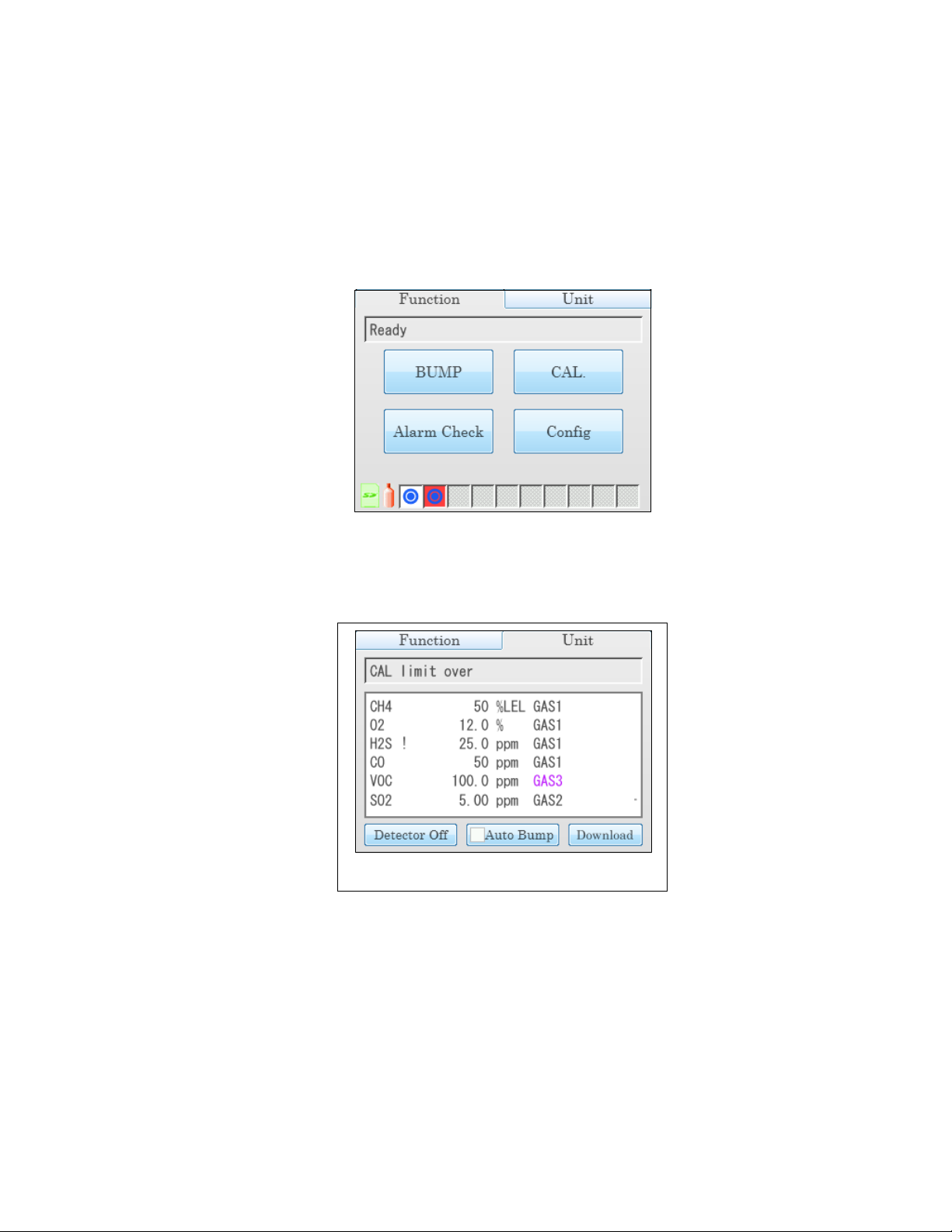

Function Tab

Figure 4: Function Tab

The Function Tab allows the user to:

• initiate a bump test

• initiate a calibration

• initiate an alarm check

• set operational parameters

It is present on the touch screen of a single SDM-6000 system and on the touch screen of the

master (leftmost) SDM-6000 in a multi-SDM-6000 system. It has the same appearance in both

systems. The text field above the BUMP and CAL buttons shows instrument or station status.

SD Card Logo

The SD card logo in the bottom left corner of the Function Tab indicates whether an SD card is

inserted in the SD card slot and the status of an inserted SD card.

Table 2: SD Card Logo Colors

SD Card Logo Color Meaning

Gray No SD card inserted.

Green More than 20% of the SD card’s memory is available.

Yellow Less than 20% but more than 1 MB (approximately 946 tests) of

the SD card’s memory is available.

Red Less than 1 MB (approximately 946 tests) of the SD card’s

memory is available.

Cylinder Logo

The cylinder logo in the bottom left corner of the Function Tab indicates the expiration status of

the calibration cylinders. In order to set up the expiration status, the docking station must be

connected to the PC Controller Program and the cylinder information entered into the Cylinders

Tab. If the docking station is never connected to the PC Controller Program to enter the cylinder

information, then the cylinder icon will always be grey. The table below lists all of the possible

12 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

colors for the cylinder logo and describes their meaning.

Table 3: Cylinder Logo Colors

Cylinder Color Meaning

Grey Expiration date more than 10 days away OR cylinder informa-

tion not set up with PC Controller Program

Yellow Expiration date for one or more cylinders is less than 10 days

away

Red Expiration date for one or more cylinders is today or has already

passed

Station/Instrument Indicator Squares

The ten squares along the bottom of the Function Tab are the Station/Instrument Indicators. They

represent up to ten SDM-6000s and GX-6000s in an SDM-6000 system from left to right. In a

single SDM-6000 system only the leftmost indicator is functional. In a multi-station system, the

leftmost indicator represents the master station and the rest of the indicators represent additional

stations in the system. Colors and icons are used with the indicators to convey SDM-6000 and

GX-6000 status and test and calibration results

If an indicator color is light grey, the same color as the background of the Function Tab, there is

not an SDM-6000 installed in the system for that position. If an indicator color is white with no

icon, an SDM-6000 is installed in that position and the corresponding SDM-6000 has no

instrument connected to it. If an indicator is a color other than light grey and an icon appears in it,

then the corresponding SDM-6000 has an instrument installed and connected to it.

Table 4: Docking Station Indicator Background Colors

Background Color Meaning

White • If no icon is showing, indicates that corresponding SDM-6000

is operating normally

• If icon is showing, indicates that corresponding SDM-6000 is

operating normally and connected instrument is not due for

calibration, inlet assignments are correct, and gas in/gas out

cover is engaged

Orange Calibration due in 10 days or less on connected instrument

Red Calibration due on connected instrument

Yellow Inlet assignment error for connected instrument

Dark Grey Gas in/gas out cover not engaged on connected instrument

Chapte r 2 : De s criptio n • 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Table 5: Docking Station Indicator Icons

Icon Meaning

None GX-6000 is not connected.

GX-6000 is connected and Unit Tab’s Active box is selected.

GX-6000 is connected and Unit Tab’s Active box is not

selected.

Bump test, calibration, or alarm check in process.

Test passed.

Test failed.

Datalogging information being downloaded.

Charging.

GX-6000 problem detected.

14 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

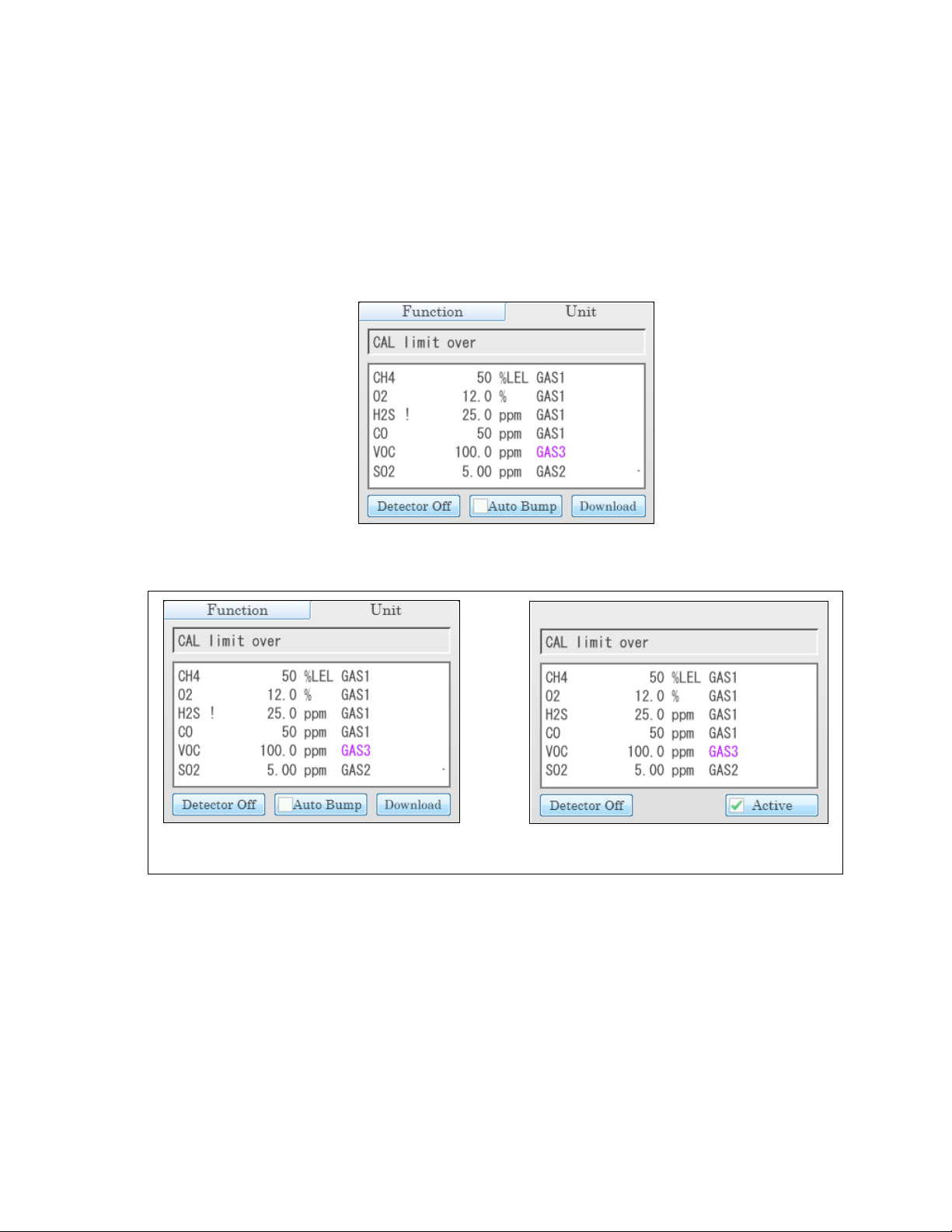

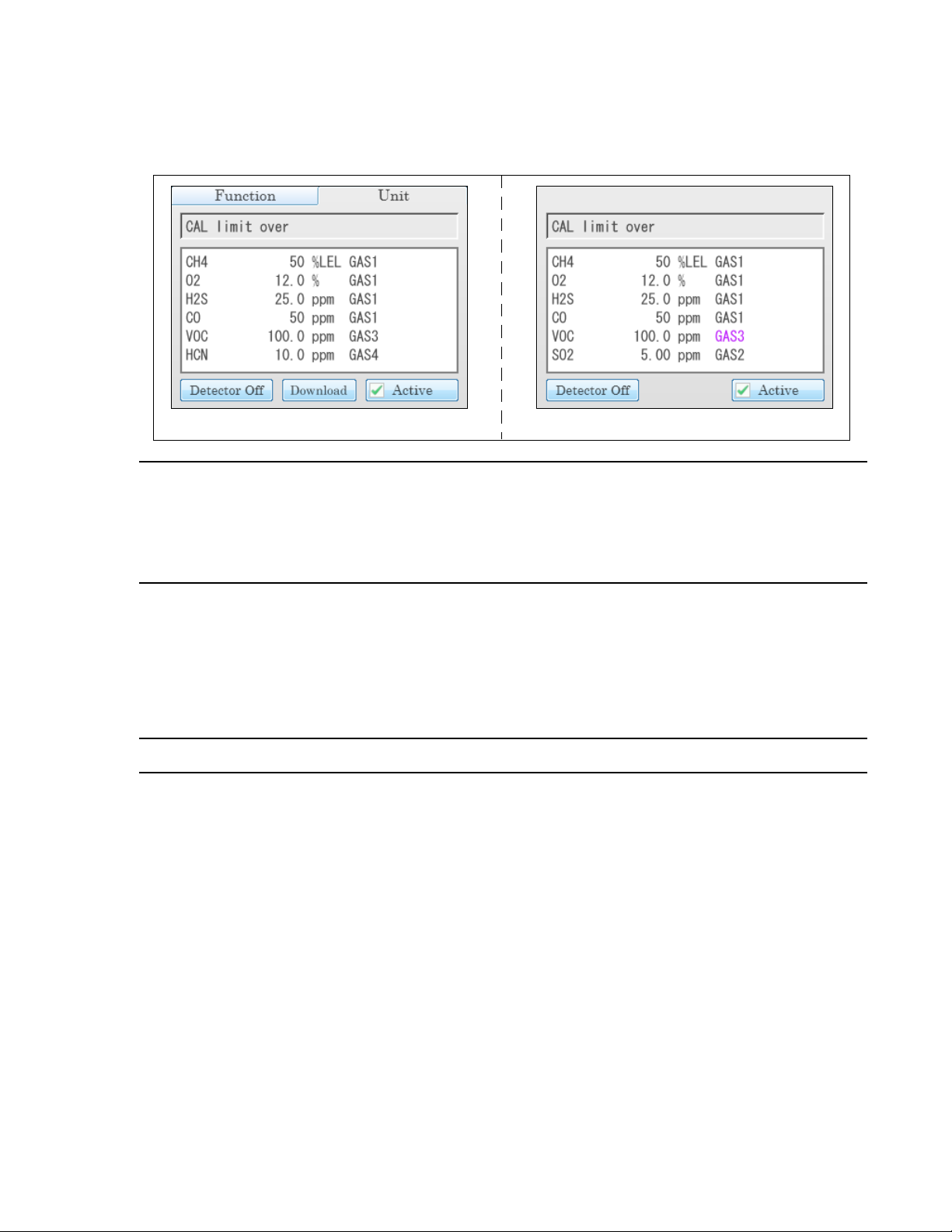

Unit Tab

Figure 5: Unit Tab, Single SDM-6000 System

Figure 6: Unit Tab, Multi-SDM-6000 System

Master SDM-6000

Slave SDM-6000

The Unit Tab shows the gas combination of a connected GX-6000 along with calibration gas

concentration values and the pass/fail status of any tests. Its appearance varies slightly depending

on whether the SDM-6000 is a single station system, the master (leftmost) station in a multistation system, or a slave station in a multi-station system. The text field above the gas

combination which shows instrument or station status and the Detector On/Detector Off button

in the lower left which turns the GX-6000 on and off are common to each variation of the Unit

Tab.

If any of the connected instrument’s sensors are in a sensor life warning condition, a “!” will

appear to the right of the gas name.

When Actual Gas is selected for a PID channel, the gas inlet name on the SDM-6000’s Unit Tab

turns pink. When Actual Gas is deselected for a PID cylinder, the gas inlet name on the SDM6000’s Unit tab is black. Gas inlet names for all other types of sensors (standard 4-gas, ESS-03,

and IR) are always black, regardless of Actual Gas selection.

The Auto Bump selection box appears at the bottom of the screen only in a single station system.

It can be selected or deselected. If selected, a bump test will automatically begin as soon as an

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapte r 2 : De s criptio n • 15

Page 16

instrument is connected regardless of whether or not a bump test is due. If deselected, a bump test

will not automatically begin when an instrument is connected. In a multi-station system, the Auto

Bump selection box will not appear.

The Active selection box appears in the lower right corner of the screen in a multi-station system

and includes or excludes an instrument from any testing. It appears on both the master and slave

stations.

The Download button appears in the lower right corner of the screen in a single station system

and in the lower left corner of the master station’s screen in a multi-station system. It allows you

to manually download instrument data from the instrument to an SD card.

Status LED

The Status LED is located to the right of the touch screen. The table below summarizes the

meaning of the LED’s different colors.

Table 6: Status LED Colors

Status LED Color Meaning

Solid Green No GX-6000 installed

Blinking Green GX-6000 installed and IrDA communication established

Blinking Orange Charging

Solid Orange Charging complete OR SDM-6000 starting up

Solid Red SDM-6000 problem detected

Instrument Cradle

The instrument cradle is a recessed area in the middle of the SDM-6000 that is designed to accept

the GX-6000. Insert the GX-6000 in the instrument cradle with the belt clip facing out before you

perform a bump test, calibration, alarm check or charge a GX-6000. Follow the instructions in this

manual and at the center of the instrument cradle for installing the GX-6000. An infrared (IR) port

at the rear of the panel lines up with the GX-6000’s IR port when it is inserted in the cradle and is

used to communicate with the GX-6000. Charging contacts in the bottom of the cradle line up

with the GX-6000’s charging contacts.

Gas In/Gas Out Cover

The red gas in/gas out cover mates to the GX-6000’s inlet and exhaust fittings and routes

calibration gas to and from the GX-6000. The cover is spring loaded. To connect the cover to the

GX-6000, push it down until it touches the GX-6000 and then release it. It should lock into place.

To release the cover, push it toward the GX-6000 and then release it. It should return to its

unconnected position at the top of the SDM-6000.

16 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Left Panel Components

PC

PRINTERPRINTER

LAN

ON

OFF

USB PC Connector

SD Card Slot

Power Jack

USB Printer Connector

On/Off Switch

LAN Connector

DC24V

GAS Fittings

AIR Fitting

Electrical Connector

Figure 7: Left Panel Component Location

The SDM-6000’s left panel includes the SD card slot, the USB PC connector, the USB printer

connector, the LAN connector, the on/off switch, the power jack, an electrical connector, and the

sample fittings.

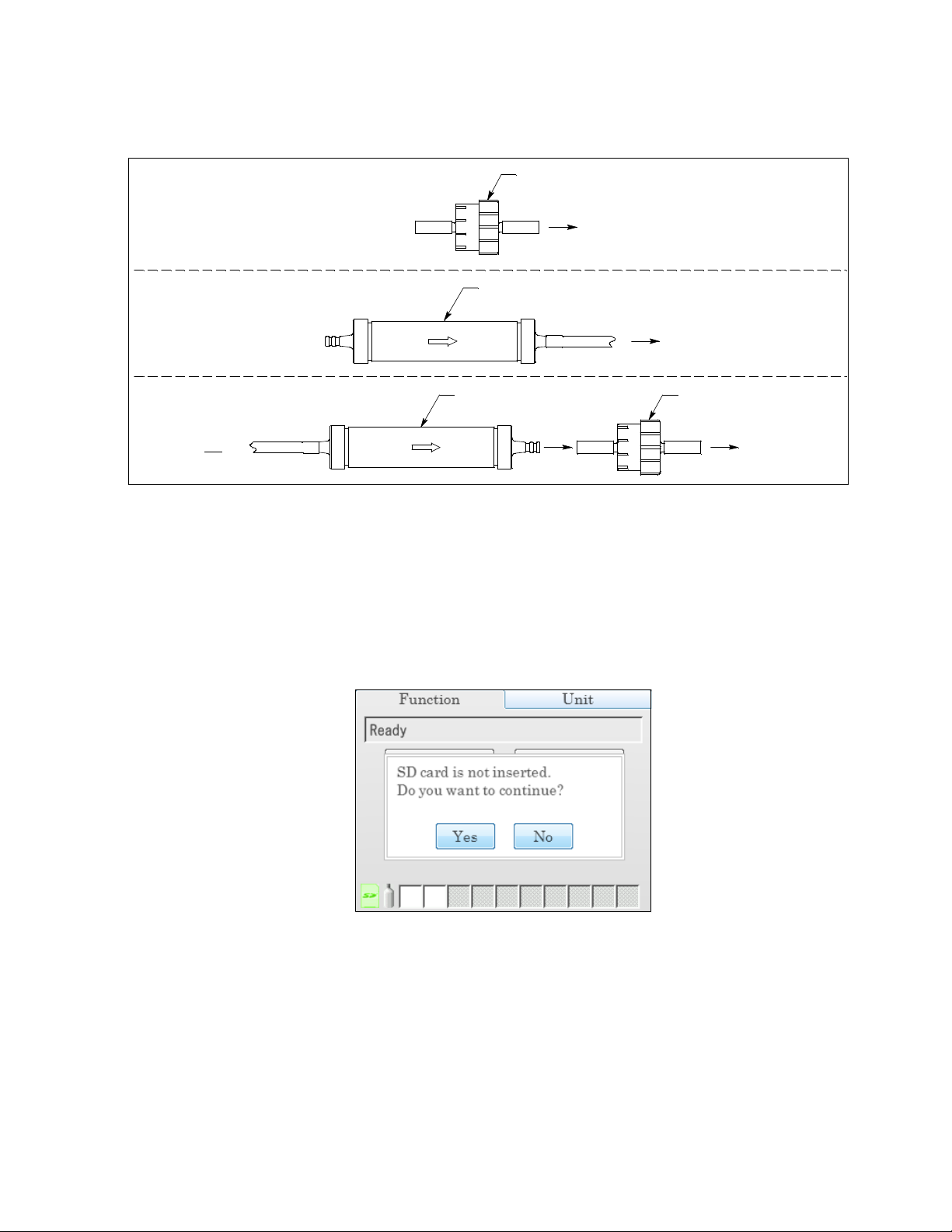

SD Card Slot

The SD card slot at the top of the left side of the SDM-6000 allows for the installation of an

SDHC card. The SDM-6000’s data files are saved to the SD card. If an SD card is not installed, no

data will be saved during testing.

Chapte r 2 : De s criptio n • 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

USB PC Connector

A type B USB connection allows for the SDM-6000 to be connected to a PC using a Type A to

Type B USB cable. Connection to a PC is necessary for setting up the LAN function and for using

the SDM-6000 in its PC controlled configuration. This manual explains how to set up the LAN

function but does not cover PC controlled configuration.

USB Printer Connector

The USB printer connector allows for the optional printer accessory to be connected to the SDM-

6000.

NOTE: The SDM-6000 only supports the Seiko Instruments, Inc. DPU-S245 USB

printer. See “Printer” on page 24 for more information.

LAN Connector

The LAN connector allows for the SDM-6000 to be connected to a building’s network using an

Ethernet cable. This function allows for the SD card’s data to be downloaded to a computer

connected to the same network.

On/Off Switch

The white on/off switch turns the station on or off. Push the top of the switch toward the station to

turn it on. Push the bottom of the switch toward the station to turn it off.

Power Jack

The round power jack is located below the on/off switch. The plug on the end of the AC adapter

cable mates to it.

Electrical Connector

The black electrical connector allows for an electrical connection to another SDM-6000 or to an

SV-3.

Sample Fittings

Four sample fittings are located on the left side of the SDM-6000. The AIR fitting is the rightmost

fitting and the GAS fittings are arranged in a column to the left of the AIR fitting. The bottom to

top order is GAS1, GAS 2, and GAS 3. All four fittings accept 3/16 inch ID tubing.

18 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

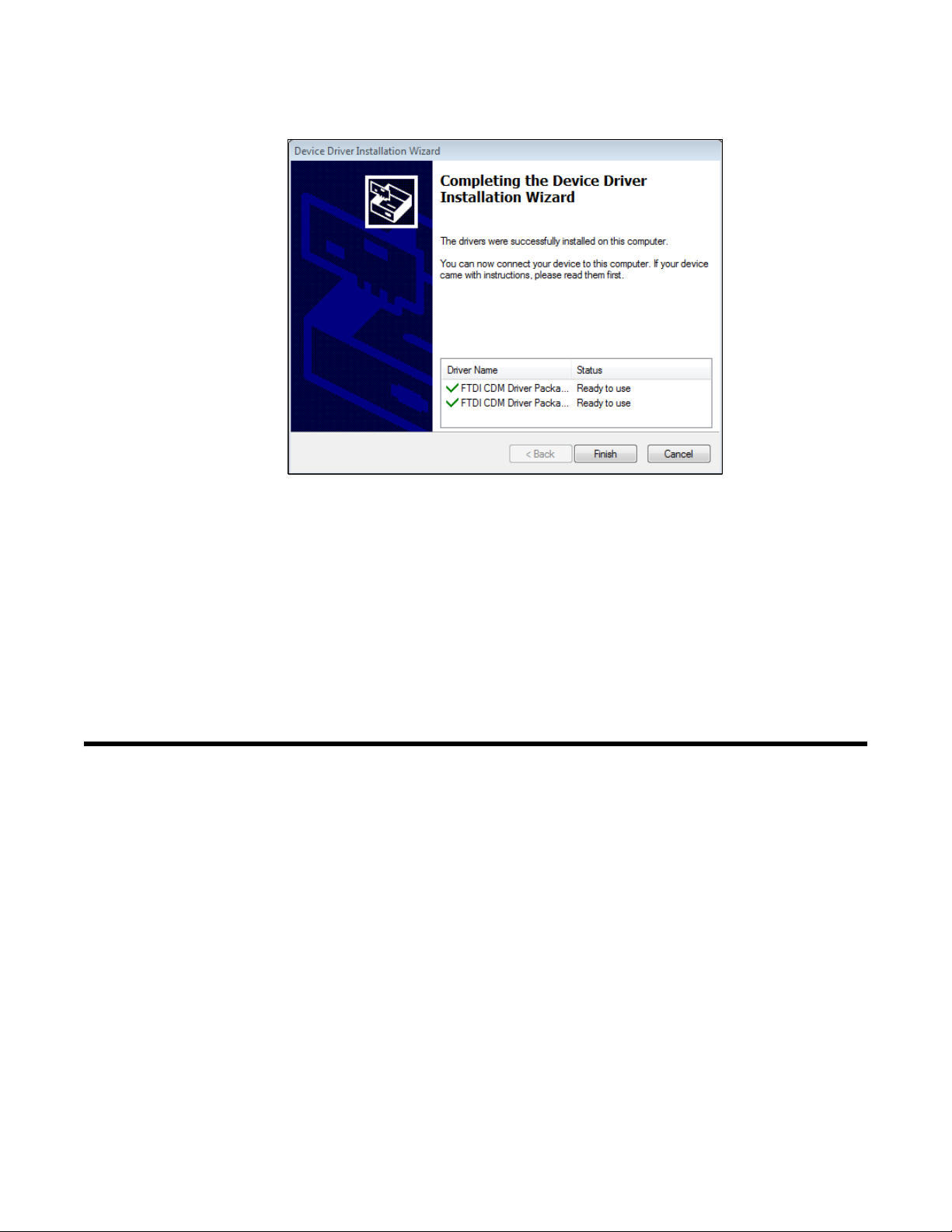

Mating Slave Connections

Mating

Sample

Fittings,

Plugged

Panel RemovedPanel In Place

Mating

Electrical

Connection

Panel

Figure 8: Right Panel Component Location

The right side of the SDM-6000 is shipped from the factory with a small panel attached to it with

two screws. That panel should remain in place if the SDM-6000 is being used alone or if it is the

right-most station in a bank of connected stations. The panel needs to be removed in order to

connect another SDM-6000 to it. Beneath the panel is a mating electrical connection and plugged

mating sample fitting connections.

Chapte r 2 : De s criptio n • 19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Exhaust Fitting

Figure 9: Back Panel Component Location

Exhaust Fitting

An exhaust fitting is located on the SDM-6000’s back panel. It allows routing of the exhausted

calibration gas to a convenient location. This fitting accepts 5/16 inch ID tubing. Even though the

exhaust gas can be routed to an area to be safely dispersed, the docking station should still be

installed in a well ventilated area.

20 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Air Filter and Exhaust Tubing

Exhaust Tubing, 5/16 Inch

ID,10 feet

Particle Filter for Air Inlet

Figure 10: Air Filter & Exhaust Tubing

A cylindrical particle filter with a short length of tubing is supplied with the SDM-6000 for

installation to the AIR fitting on the back panel. The filter keeps particulate contamination out of

the docking station.

A 10 foot length of 5/16 inch ID polyurethane tubing is provided for connection to the exhaust

fitting on the back panel to allow routing of the exhaust to a location such as an open window

where the exhaust can disperse.

WARNING: Do not use an exhaust tube that is longer than 15 feet. The increased flow

restriction caused by a longer tube may affect gas response and cause

inaccurate calibration and bump test results.

Connection Brackets

Each SDM-6000 is provided with 3 connection brackets that are used to mechanically connect

one SDM-6000 to another.

Find Quality Products Online at: sales@GlobalTestSupply.com

Chapte r 2 : De s criptio n • 21

www.GlobalTestSupply.com

Page 22

Accessories Included in Various Bundles

To Power Jack

on SDM-6000

Left Panel

Figure 11: Single-Station AC Adapter

To Power Jack on

SDM-6000 Left Panel

Figure 12: Multi-Station AC Adapter

This section describes all of the accessories that are included as standard with the SDM-6000,

depending on the SDM-6000 bundle purchased. These include: AC adapter, Type A to Type B

USB cable, Ethernet cable, SD card, SD to USB reader, demand flow regulator, calibration

tubing, and a calibration cylinder. You do not need 1 of each of these accessories for every SDM6000 in your installation but every installation needs 1 of each accessory. See pg.9 for information

about what SDM-6000 bundles include these items.

AC Adapter

Single-Station AC Adapter

The single-station AC adapter is a wall plug style adapter with a 5 foot cable. The end of the cable

has a plug that connects to the SDM-6000’s power jack. The AC adapter is rated 100 - 240 VAC

input, 24 VDC 0.63 A output.

Multi-Station AC Adapter

The multi-station AC adapter is a larger adapter with a separate power cord and a plug that

connects to the SDM-6000’s power jack. The adapter is intended to be used when more than 1

SDM-6000 are connected together. Only the master SDM-6000 needs to be plugged into power.

The AC adapter is rated 100 - 240 VAC input, 24 VDC 4.17 A output.

22 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

USB Cable

Figure 13: USB Cable

A Type A to Type B USB cable is used to connect the SDM-6000 to a PC which is required for

setting up the LAN connectivity function of the SDM-6000 or for using the SDM-6000 in the PC

Controlled configuration. If you have a multi-station system, the USB cable only needs to be

plugged into the master (leftmost) station.

Ethernet Cable

A 5 foot length of black Ethernet cable allows for the LAN connectivity function of the SDM6000 to be used. One end of the cable is plugged into the LAN port on the left side of the SDM6000 and the other end is plugged into one of the building’s network ports. If you have a multistation system, the Ethernet cable only needs to be plugged into the master (leftmost) station.

SD Card and SD to USB Reader

The SDHC card needs to be installed in the SD card slot on the left side of the SDM-6000 in order

for data to be saved. If you have a multi-station system, the SD card only needs to be inserted into

the master (leftmost) station’s SD card slot.

The SDHC card can be directly inserted into a computer’s SD card slot if the computer is

equipped with one. If the computer does not have an SD card slot, the provided SD to USB reader

must be used.

Demand Flow Regulator

The demand flow regulator is screwed into the calibration gas cylinder and allows the SDM-6000

to draw gas from the cylinder when the regulator is connected to the SDM-6000 using the 3 feet

of calibration tubing.

Chapte r 2 : De s criptio n • 23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Calibration Tubing

A 3 foot length of 3/16 inch ID polyurethane tubing is provided with bundles that include a

demand flow regulator. This calibration tubing is used to connect the regulator to gas fitting on the

left side of the SDM-6000 or on the left side of the SV-3.

Calibration Gas Sample Tubing, 3/16

Inch ID, 3 feet

Figure 14: Calibration Tubing

Calibration Cylinder

The calibration gas cylinder must be used to calibrate the applicable sensors in a GX-6000. The

particular calibration gas cylinder provided depends on which bundle is ordered.

Optional Accessories, Not Included in Any Bundles

SV-3

The SV-3 increases the number of calibration cylinders that can be used with the SDM-6000 from

3 to 6. It connects to the sample fittings and electrical connector on the left side of the SDM-6000.

If you have multiple SDM-6000s connected together, the SV-3 will be installed on the left-most

SDM-6000.

The SV-3 comes with 2 connection brackets that are used to mechanically connect the SV-3 to the

left-most SDM-6000.

Printer

The printer supported by the SDM-6000 is the Seiko Instruments, Inc. DPU-S245 USB printer. It

allows for quick printing of bump test or calibration results. The printer comes with an AC

adapter and power cord, a battery pack, a USB cable, and a roll of paper. It is connected to the

SDM-6000 via the USB Printer connection on the left side of the SDM-6000.

NOTE: For questions about the printer, contact at

contact.html.

Wall Mounting Brackets

The SDM-6000 can be mounted to the wall, if desired, using 3 mounting brackets. See pg.34 for a

description of how many wall mounting brackets are needed depending on how many SDM6000s are in your system.

24 • Chapter 2: Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Chapter 3: Preparing to Use the SDM-6000

Overview

Setting up the SDM-6000 for use includes: installing the SDM-PC2 Docking Station PC

Controller Program, connecting multiple SDM-6000s together (optional), connecting the SV-3

(optional), connecting the printer (optional), assembling the hardware, wall mounting the station

(optional), connecting calibration gas, setting operational parameters, and setting up the LAN

connectivity (optional). Instructions to complete each of these tasks is in this section.

Although a single SDM-6000 or a bank of SDM-6000s does not need to be connected to the PC

Controller Program for Standalone operation, the PC Controller Program is needed to import and

view data and to access some SDM-6000 setup parameters.

Installing the SDM-PC2 Docking Station PC Controller Software

NOTE: The PC Controller Program is not required for Standalone operation but is

needed to import and view data and to access some setup parameters that cannot

be accessed in the SDM-6000’s Config Menu.

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Go to www.rkiinstruments.com/sdm6000.

4. Click on the Download tab.

5. Click the SDM-PC2 PC Controller Software link.

6. A .zip file will begin to download. Select whether you want to open or save the .zip file.

7. Extract the contents of the .zip file.

8. Double click the setup.exe file.

9. The SDM-PC2 Docking Station PC Controller InstallShield Wizard comes up to guide you

through installation. Click Next to proceed to the License Agreement window.

10. Read the license agreement and click the agreement acceptance selection box, then click

Next to proceed to the Customer Information window.

11. Enter a user name and organization and select if you want to install the program for all users

on the computer or just for your user account, then click Next to proceed to the Destination

Folder window.

Chapter 3: Preparing to Use the SDM-6000 • 25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Figure 15: Device Driver Installation

12. The default installation folder (C:\Program Files\SDM-PC2\) is displayed. If you want to

install the software in the default folder continue with step 13. If you want to install the

software in a different location, click Change and choose a new installation folder and then

continue with step 13.

13. Click Next to proceed to the Ready to Install the Program window.

14. Review the installation settings. If they are OK, click Install and the installation process will

begin. If you want to change installation settings, click Back and change them to the desired

settings.

15. During software installation, the installation program may find newer versions of Windows

files on your computer than those in the downloaded .zip file. If this happens, the installation

software will ask you if you want to keep these newer files. Click Ye s to do so.

16. A Device Driver Window will appear prompting you to install necessary drivers. You cannot

continue the installation without installing the drivers.

17. Click Next to install the drivers. The Wizard will find the appropriate drivers.

26 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

18. Click Finish once the drivers are successfully installed.

Figure 16: Finish Device Driver Installation

The installation will continue.

19. Follow the on-screen instructions to complete software installation.

20. To complete the driver installation, ensure that your docking station (or the master docking

station if you plan to have a bank of them) are connected to your computer.

21. Turn on the docking station by flipping the power switch to the ON position.

22. The first time an SDM-6000 is turned on after being connected to the computer, the SDM6000 needs some time to be recognized by the computer. The status bar will indicate that the

drivers are being configured and will alert you when the SDM-6000 is ready to use.

Setup for Chlorine Testing

There are 5 things to keep in mind when using the SDM-6000 for chlorine bump testing or

calibration.

1. Use 5 ppm Cl2.

2. Dedicate a regulator for Cl2 use. DO NOT USE A Cl2 REGULATOR FOR ANY OTHER

GAS.

3. Do not use an SV-3.

4. SDM-6000s that can be used with Cl2 are marked with a label that says “For Use With Cl2”.

If your SDM-6000 does not have a label indicating that it’s appropriate for use with Cl2, do

not use that SDM-6000 to test Cl2.

Chapter 3: Preparing to Use the SDM-6000 • 27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Figure 17: SDM-6000 Setup for Cl2 Testing

STATUSSTATUSSTATUS

STATUS

For Use With Cl2

STATUSSTATUS

STATUS

STATUS

Cl2 Calibration

Non-Cl2 Calibration

Non-Cl2 Calibration

For Use With Cl2

Cl2 Calibration

Non-Cl2 Calibration

5. If you have a bank of SDM-6000s, the Cl2 SDM-6000 MUST be the first dock in the bank.

Connecting Multiple SDM-6000s Together

Up to 10 SDM-6000s can be connected together. The leftmost SDM-6000 is the master station

and the remaining stations are slave stations. If you remove the leftmost SDM-6000 from the

setup, the station that is now the leftmost station becomes the master but does not retain any of the

settings that the old master had.

CAUTION: If you have a Cl2 SDM-6000, it MUST be the first dock in your bank.

1. Be sure that the SDM-6000s are not connected to power.

2. For every station except the one that will be located on the far right side of the bank:

a. Unscrew the two screws that retain the panel on the right side of the station. The screws

are not captive. Be sure not to lose them.

b. Pull the panel away from the SDM-6000.

28 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

c. Use needle nosed pliers to remove the clear plugs that are installed in the four mating

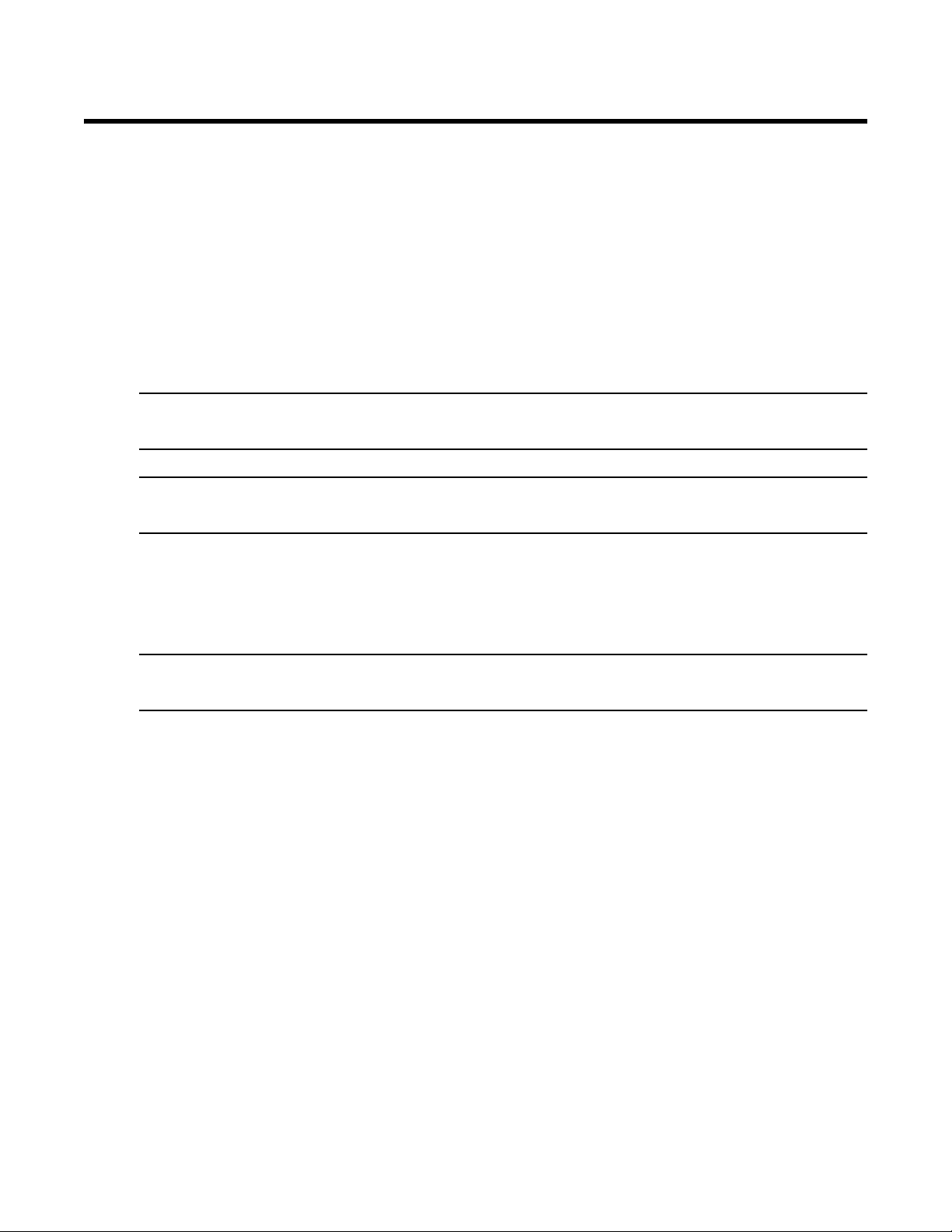

Figure 18: Panel and Plug Removal

Panel In Place Panel Removed Plugs Removed

sample fittings.

d. Save the panel, the screws, and the four plugs in a safe place.

3. Starting with the two left-most stations, line up the mating electrical connections and sample

fitting connections and push the two stations together until the housings are touching.

4. Add stations to the right side of the bank using the same procedure. The last station installed

should be the one that still has a panel on the right side.

Chapter 3: Preparing to Use the SDM-6000 • 29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Figure 19: Connecting SDM-6000s Together, Back Panel

5. Use the provided metal connection brackets and screws to secure the two connection points

on each side of the SDM-6000’s back panel and on the bottom of the SDM-6000 to each

other.

30 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Figure 20: Connecting SDM-6000s Together, Bottom Panel

Chapter 3: Preparing to Use the SDM-6000 • 31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Connecting the SV-3, Optional

Figure 21: Connecting the SV-3

Bottom Panel

Back P anel

CAUTION: Do not connect an SV-3 to an SDM-6000 that will be used for Cl2 testing.

1. Be sure that the SDM-6000(s) are not connected to power.

2. Line up the mating electrical connection and mating sample fitting connections on the SV-3

with the electrical connector and sample fittings on the left side of the left-most SDM-6000.

3. Push the SV-3 toward the SDM-6000 until the housings are touching.

4. Use the provided metal connection brackets and screws to secure the back and bottom of the

SV-3 to the SDM-6000.

32 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Connecting the Printer, Optional

1. If you want to power the printer with the battery pack, install the battery pack.

2. If you want to power the printer with AC power, plug the printer AC adapter’s wall plug into

a wall AC socket.

3. Connect the AC adapter to the printer’s power jack using the provided cord.

4. Connect one end of the printer’s USB cable into the printer’s USB connection. Plug the other

end of the printer’s USB cable into the USB printer connector on the left side of the SDM-

6000. Be sure to use the USB cable provided with the printer. The USB cable provided with

the SDM-6000 does not have appropriately sized USB connections for the printer.

NOTE: If you have any problems setting up the printer, contact Seiko Instruments, Inc. at

http://www.sii.co.jp/sps/eg/contact.html.

Hardware Assembly

The hardware assembly consists of connecting the AC adapter, installing the air filter, and

connecting the exhaust tubing. Perform the following to complete the hardware assembly:

1. Place the SDM-6000(s) on a convenient table top near an AC wall socket in a well ventilated

area. A location near a window that can be opened is best so that the exhaust can be routed to

the window.

2. Connect the AC adapter’s wall plug into a wall AC socket.

3. Insert the round plug on the end of the AC adapter’s output cable into the power jack on the

left side of the SDM-6000.

NOTE: If you have multiple SDM-6000s connected to each other, be sure to plug the

multi-station AC adapter into the master station.

4. Install the air filter so that the arrow on the filter that indicates direction of flow is pointing

towards the AIR fitting.

a. If you are installing the air filter on an SDM-6000, put the green tubing stub that comes

with it on the end with the arrow pointing to it and install the other end of the green tubing

stub on the SDM-6000’s AIR fitting.

b. If you are installing the air filter on an SV-3, the green tubing stub does not need to be

used. Orient the air filter with the arrow pointing toward the SV-3 and insert the air filter

into the AIR recess at the front of the SV-3’s left side and push it in until the SV-3’s latch

secures it in place.

Chapter 3: Preparing to Use the SDM-6000 • 33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Figure 22: Air Inlet Filters

To Air Filter on

SDM-6000 or SV-3

VOC Zero Filter

(no pref erred flow di rection)

CO2 Scrubber

CO2 Scrubber

Instrument(s) with

IR CO2 Sensor

Instrument(s) with PID

Sensor and Suspected

Background VOC

To Air Filter on

SDM-6000 or SV-3

To Air Filter on

SDM-6000 or SV-3

VOC Zero Filter

(no pref erred flow di rection)

Instrument(s) with

PID Sensor and

IR

CO2 Sensor

5. If you are testing any instruments that need a special filter, attach them appropriately as

shown in the figure below.

Wall Mounting the SDM-6000, Optional

6. Install the 10 foot long 5/16 inch ID flexible tube that is included with the SDM-6000 on the

exhaust fitting. A multi-station system must have separate exhausts for each SDM-6000.

Exhaust tubing cannot be manifolded. Route the tube to an area where the exhaust can be

safely dispersed, such as an open window.

CAUTION: The maximum recommended length for the exhaust tube is 15 feet. Do not use

more than 15 feet of tubing or tubing with an ID of less than 5/16 inch for the

exhaust tube or the bump test and calibration accuracy may be adversely

affected. The tube that is shipped with the SDM-6000 has an ID of 5/16 inch and

is 10 feet long.

Single SDM-6000s or multiple SDM-6000s connected together as described on pg.28 can be

mounted to the wall using mounting brackets. The wall mounting brackets are not supplied as

standard with the SDM-6000. If you are wall mounting a bank of SDM-6000s, not every SDM6000 will need wall mounting brackets but each SDM-6000 that will use wall mounting brackets

needs 3. See the figure below to determine how many wall mounting brackets you need to order.

Find Quality Products Online at: sales@GlobalTestSupply.com

34 • Chapter 3: Preparing to Us e the SDM-6000

www.GlobalTestSupply.com

Page 35

Figure 23: Wall Mounting 1-7 SDM-6000s

1 SDM-6000

2-4 SDM-6000s

5-7 SDM-6000s

# of SDM-6000s

w/ SV-3 or w/o SV-3

3 w all mounting brackets

6 w all mounting brackets

9 w all mounting brackets

Total # of wall mounting

brackets necessary

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 3: Preparing to Use the SDM-6000 • 35

Page 36

Figure 24: Wall Mounting 8-10 SDM-6000s

#ofSDM-6000s

w/ SV-3 or w/o SV-3

8-10 SDM-6000s

Total # of wallmounting

brackets necessary

12 wall mounting brackets

NOTE: Be sure that you have installed the exhaust line for each SDM-6000 you intend to

wall mount since access to the exhaust fitting will be very limited once the SDM6000 is mounted to the wall.

1. If you are mounting multiple SDM-6000s, be sure your SDM-6000s are properly connected

and secured to each other. If you are using an SV-3, be sure that it is connected and secured to

the left-most SDM-6000.

36 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

2. Connect the wall mounting brackets to the SDM-6000(s) using the provided screws. The wall

Figure 25: Wall Mounting Bracket Installation

Long Section w/ Bigger Hole

Short S ection w/ Smaller Hole

Long Section w/ Bigger Hole

Short S ection w/ Smaller Hole

mounting brackets are not straight. They have a short section and a long section. The short

section has a smaller hole than the long section. Screw the short section into the SDM-6000

making sure that the long section goes away from the station and is flush with the back of the

SDM-6000.

3. Position the SDM-6000(s) on the wall where you intend to mount them.

4. Screw the wall mounting brackets into the wall. Make sure the mounting screws and the

material they are screwed into are appropriate to support the weight of the system.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 3: Preparing to Use the SDM-6000 • 37

Page 38

Connecting Calibration Gas, No SV-3 Attached

The GAS 1, GAS 2, and GAS 3 fittings on the left side of the docking station are designed to be

used with a calibration gas cylinder that is fitted with a demand flow regulator. The AIR fitting

may be used with a demand flow regulator and a cylinder of zero emissions air, but this is not

normally necessary since the docking station will generally be in a fresh air area.

The type of calibration gas cylinder used for the GAS 1 fitting depends on the gas sensors

installed in the GX-6000. A 4-gas mix, LEL/Oxygen/CO/H2S, is used for the GAS 1 fitting if the

GX-6000 being used with the docking station contains the standard 4 sensors or is a version that

has less than the 4 standard sensors but still has an H2S sensor. If the GX-6000 does not have an

H2S sensor, then a 3-gas mix, LEL/Oxygen/CO, should be used for the GAS 1 fitting in order to

protect the CO sensor’s charcoal filter.

The GAS 2 and GAS 3 fittings are normally used for smart sensors (i.e. PID, ESS-03, etc.). If you

have a smart sensor installed (i.e. PID, ESS-03, etc.), a special cylinder for the target gas of that

sensor needs to be used for calibration. See the tables below for examples of needed cylinders for

various GX-6000 combinations. Keep in mind that if you are going to use a 5-gas cylinder to

calibrate one of the smart sensors, make sure that the special sensor is assigned to GAS 1 (see

pg.53). See pg.122 for part numbers of available cylinders.

If your instrument has no standard sensors, then the GAS 1 fitting may be used for gas to test a

smart sensor.

Table 7: Recommended Gas Cylinders and Gas Ports for Single-Station Use

Instrument Types

3-gas (LEL/Oxy/CO) + low range PID GAS 1: 3-gas mix with LEL/Oxy/CO

3-gas (LEL/Oxy/CO) + high range PID GAS 1: 3-gas mix with LEL/Oxy/CO

Standard 4-gas (LEL/Oxy/H2S/CO) + low range PID GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

Standard 4-gas + high range PID GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

Standard 4-gas + NH3 GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

Standard 4-gas + low range PID + NH3 GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

Recommended Calibration Gas Cylinder

and Gas Inlet Selection

GAS 2: 10 ppm IBL

GAS 2: 100 ppm IBL

GAS 2: 10 ppm IBL

GAS 2: NH3

GAS 2: 10 ppm IBL

GAS 3: NH3

Standard 4-gas + high range PID + NH3 GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

GAS 2: NH3

Standard 4-gas + SO2 GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/SO2

38 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

If you are connecting multiple SDM-6000s together, it is possible to test GX-6000s with different

gas combinations at the same time. In order to completely calibrate all GX-6000s, you cannot

need more than 3 cylinders since the SDM-6000 only has 3 gas ports on its left side. If testing

different GX-6000 combinations at once requires more than 3 cylinders, you will have to test

instruments one at a time and reassign the gas inlets when you change gases or test the gases

common to all instruments at once and then test additional gases separately. The table below

shows some examples of GX-6000 combinations that could be tested together if you have

multiple SDM-6000s connected together. Up to 10 SDM-6000s can be connected together. The

table below only uses 2 GX-6000s as examples.

Table 8: Recommended Gas Cylinders and Gas Ports for Multi-Station Use

Instrument Types

Instrument 1: 3-gas + low range PID

Instrument 2: 3-gas + high range PID

Instrument 1: 3-gas + high range PID

Instrument 2: 3-gas + NH3

Instrument 1: Standard 4-gas + low range PID

Instrument 2: Standard 4-gas + high range PID

Instrument 1: Standard 4-gas + high range PID

Instrument 2: Standard 4-gas + high range PID + NH3

Instrument 1: Standard 4-gas + NH3

Instrument 2: Standard 4-gas + SO2

Instrument 1: Standard 4-gas + SO2

Instrument 2: Standard 4-gas + SO2 + NH3

Recommended Calibration Gas Cylinder

and Gas Inlet Selection

GAS 1: 3-gas mix with LEL/Oxy/CO

GAS 2: 10 ppm IBL

GAS 3: 100 ppm IBL

GAS 1: 3-gas mix with LEL/Oxy/CO

GAS 2: 100 ppm IBL

GAS 3: NH3

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: 10 ppm IBL

GAS 3: 100 ppm IBL

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

GAS 2: NH3

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: NH3

GAS 3: SO2

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/SO2

GAS 2: NH3

Instrument 1 and 2: Standard 4-gas + low range PID

+ NH3

Instrument 1 and 2: Standard 4-gas + high range PID

+ NH3

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: IBL

GAS 3: NH3

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

GAS 2: NH3

To connect calibration gas to the SDM-6000, do the following:

1. If the area around the docking station is not considered a fresh air area (an area free of

combustible and toxic gases and of normal oxygen content, 20.9%) install a tube not longer

than 10 feet on the filter attached to the AIR fitting on the left side of the docking station and

route it to a fresh air area or connect a cylinder of zero air with a demand flow regulator to the

AIR fitting.

Chapter 3: Preparing to Use the SDM-6000 • 39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

NOTE: If any filters are needed for the fresh air adjustment (ie. for PID sensors and IR

CO2 sensors), they will need to be installed somewhere in the air line. See

Figure 22 on page 34.

2. Install the demand flow regulator(s) on the calibration gas cylinder(s).

NOTE: Do not connect pressurized gas directly to the SDM-6000. Be sure to install a

demand flow regulator on the cylinder before connecting it to the SDM-6000.

NOTE: RKI Instruments, Inc. recommends that you dedicate a regulator for use with

chlorine (Cl2) gas and that you do not use that dedicated regulator for any other

gases, particularly hydrogen sulfide (H2S).

3. Connect the demand flow regulator to the appropriate inlet fitting using 3/16 inch ID sample

tubing.

40 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Connecting Calibration Gas, SV-3 Attached

The GAS 1, GAS 2, GAS 3, GAS 4, GAS 5, and GAS 6 fittings on the left side of the SV-3 are

designed to be used with a calibration gas cylinder that is fitted with a demand flow regulator. The

AIR fitting may be used with a demand flow regulator and a cylinder of zero emissions air, but

this is not normally necessary since the docking station will generally be in a fresh air area.

The type of calibration gas cylinder used for the GAS 1 fitting depends on the gas sensors

installed in the GX-6000. A 4-gas mix, LEL/Oxygen/CO/H2S, is used for the GAS 1 fitting if the

GX-6000 being used with the docking station contains the standard 4 sensors or is a version that

has less than the 4 standard sensors but still has an H2S sensor. If the GX-6000 does not have an

H2S sensor, then a 3-gas mix, LEL/Oxygen/CO, should be used for the GAS 1 fitting in order to

protect the CO sensor’s charcoal filter.

The GAS 2, GAS 3, GAS 4, GAS 5, and GAS 6 fittings are normally used for smart sensors (i.e.

PID, ESS-03, etc.). If you have a smart sensor installed (i.e. PID, ESS-03, etc.), a special cylinder

for the target gas of that sensor needs to be used for calibration. See the table below for examples

of needed cylinders for various GX-6000 combinations. Keep in mind that if you are going to use

a 5-gas cylinder to calibrate one of the smart sensors, make sure that the special sensor is assigned

to GAS 1 (see pg.53). See pg.122 for part numbers of available cylinders.

If your instrument has no standard sensors, then the GAS 1 fitting may be used for gas to test a

smart sensor.

The SV-3 is useful for single-station use or multi-station use. If you have multiple GX-6000

configurations, instead of having to reassign GAS 2 or GAS 3 every time you test a different

configuration like you would have to do if an SV-3 was not installed, you can assign the different

gases to GAS 4, GAS 5, or GAS 6.

The gas inlets can be assigned as desired. The table below provides recommendations.

Table 9: Recommended Gas Cylinders and Gas Port for Single- and Multi-Station Use

Instrument Types

Instrument 1: 3-gas + low range PID

Instrument 2: 3-gas + high range PID

Instrument 3: 3-gas + NH3

Instrument 1: 3-gas + high range PID

Instrument 2: 3-gas + NH3

Instrument 3: 3-gas + SO2

Recommended Calibration Gas Cylinder

and Gas Inlet Selection

GAS 1: 3-gas mix with LEL/Oxy/CO

GAS 2: 10 ppm IBL

GAS 3: 100 ppm IBL

GAS 4: NH3

GAS 1: 3-gas mix with LEL/Oxy/CO

GAS 2: 100 ppm IBL

GAS 3: NH3

GAS 4: SO2

Instrument 1: Standard 4-gas + low range PID

Instrument 2: Standard 4-gas + high range PID

Instrument 3: Standard 4-gas + high range PID + NH3

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: 10 ppm IBL

GAS 3: 100 ppm IBL

GAS 4: NH3

Chapter 3: Preparing to Use the SDM-6000 • 41

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

Table 9: Recommended Gas Cylinders and Gas Port for Single- and Multi-Station Use

Instrument Types

Instrument 1: Standard 4-gas + high range PID

Instrument 2: Standard 4-gas + high range PID + NH3

Instrument 3: Standard 4-gas + SO2 + NO2

Instrument 1: Standard 4-gas + NH3

Instrument 2: Standard 4-gas + SO2

Instrument 3: High range PID + NO2

Instrument 1: Standard 4-gas + SO2

Instrument 2: Standard 4-gas + SO2 + NH3

Instrument 3: Low range PID + NO2

Instrument 1 and 2: Standard 4-gas + low range

PID + NH3

Instrument 1 and 2: Standard 4-gas + high

range PID + NH3

Recommended Calibration Gas Cylinder

and Gas Inlet Selection

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

GAS 2: NH3

GAS 3: SO2

GAS 4: NO2

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: NH3

GAS 3: SO2

GAS 4: 100 ppm IBL

GAS 5: NO2

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/SO2

GAS 2: NH3

GAS 3: 10 ppm IBL

GAS 4: NO2

GAS 1: 4-gas mix with LEL/Oxy/H2S/CO

GAS 2: IBL

GAS 3: NH3

GAS 1: 5-gas mix with LEL/Oxy/CO/H2S/IBL

GAS 2: NH3

To connect calibration gas to the SDM-6000, do the following:

1. If the area around the docking station is not considered a fresh air area (an area free of

combustible and toxic gases and of normal oxygen content, 20.9%) install a tube not longer

than 10 feet on the SV-3’s particle filter and route it to a fresh air area or connect a cylinder of

zero air with a demand flow regulator to the SV-3’s particle filter.

NOTE: If any filters are needed for the fresh air adjustment (ie. for PID sensors and IR

CO2 sensors), they will need to be installed somewhere in the air line. See

Figure 22 on page 34.

2. Install the demand flow regulator(s) on the calibration gas cylinder(s).

NOTE: Do not connect pressurized gas directly to the SDM-6000. Be sure to install a

demand flow regulator on the cylinder before connecting it to the SDM-6000.

42 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

NOTE: RKI Instruments, Inc. recommends that you dedicate a regulator for use with

chlorine (Cl2) gas and that you do not use that dedicated regulator for any other

gases, particularly hydrogen sulfide (H2S).

3. Connect the demand flow regulator to the appropriate inlet fitting using 3/16 inch ID sample

tubing.

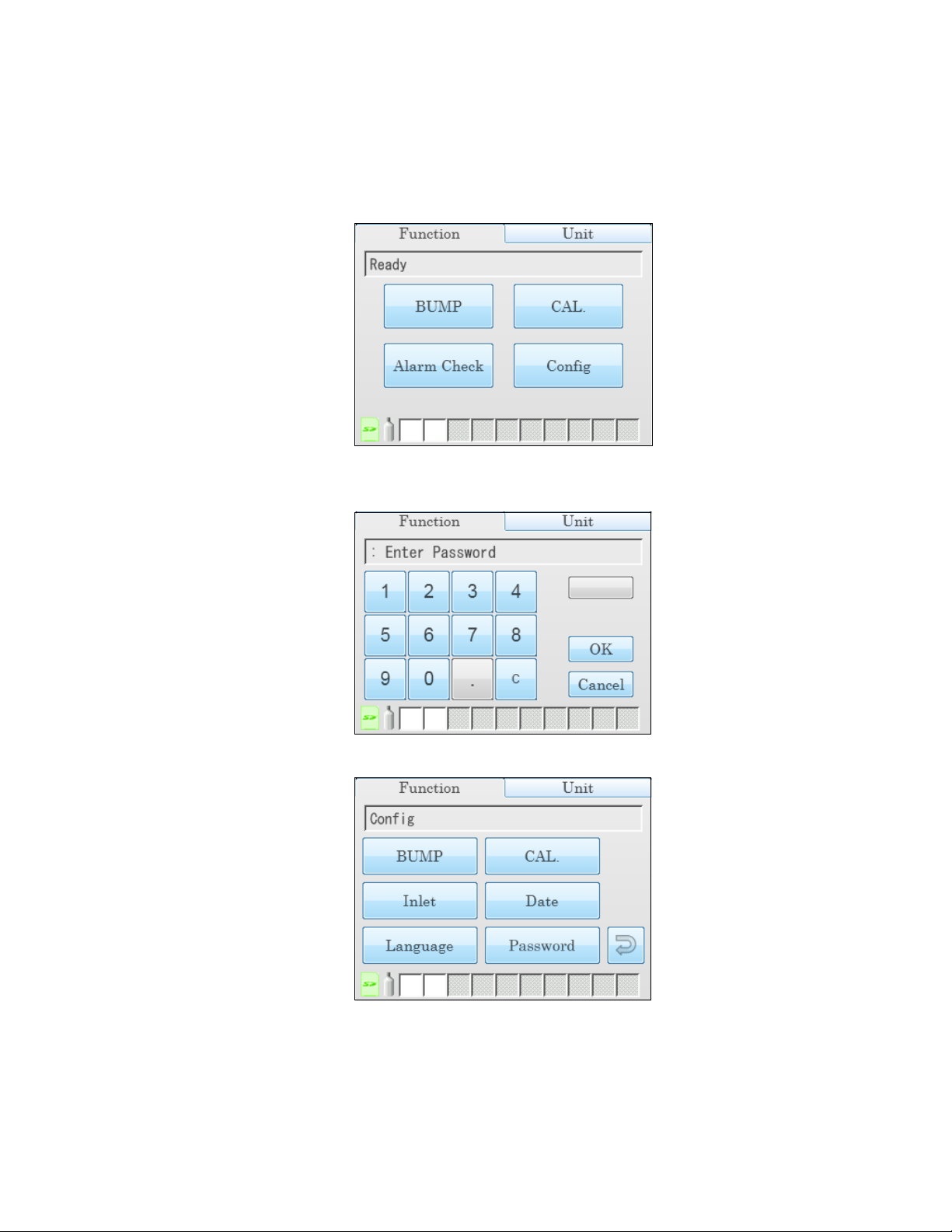

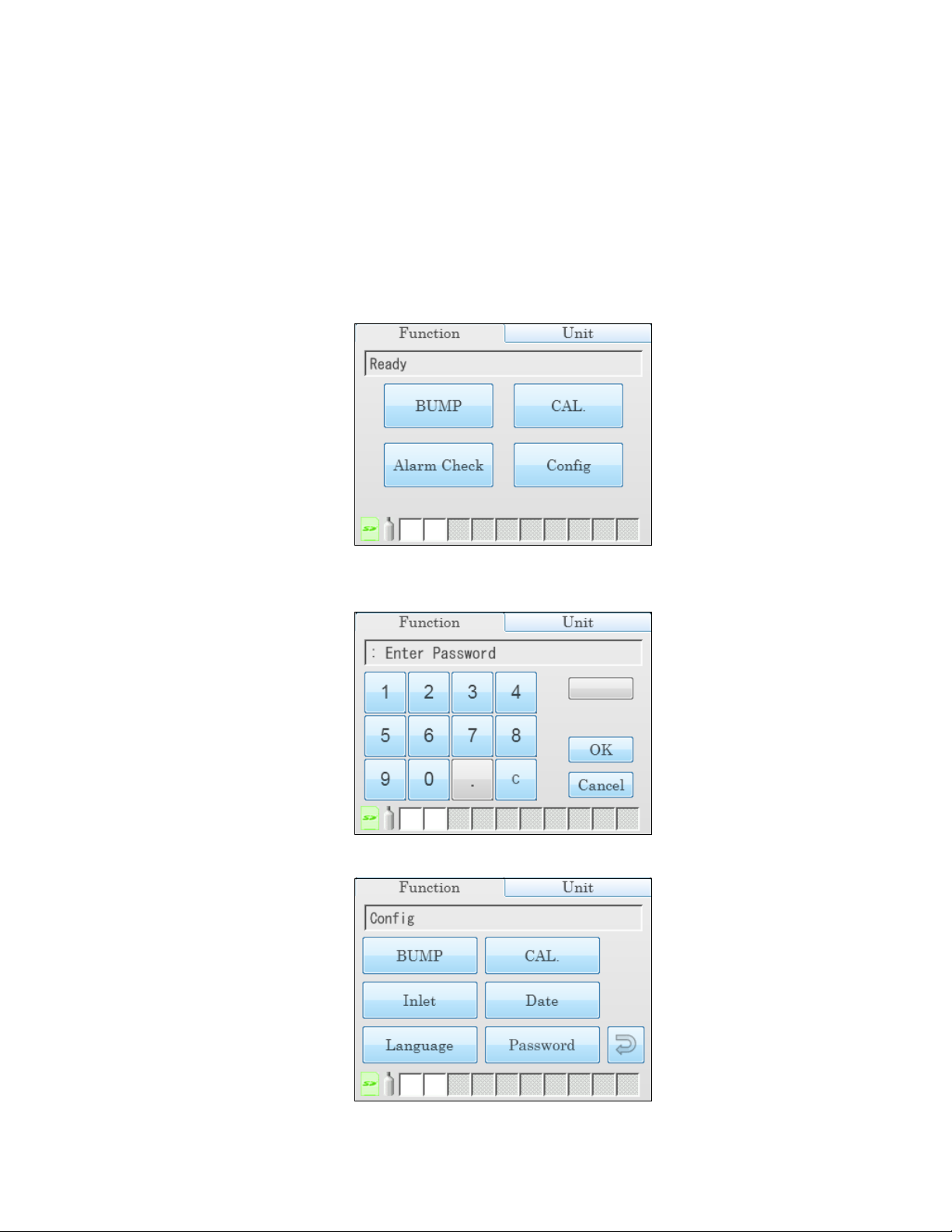

Setting Basic Operational Parameters in the Config Menu

Once the hardware has been assembled, use the Config Menu to confirm or adjust:

• bump test parameters

• calibration parameters

• gas inlet parameters

• date/time parameters and settings (must adjust upon receipt in order for saved data to have

correct date/time)

• language setting

• password setting

The operational parameters are saved in the SDM-6000’s memory. If a parameter is changed, the

change will be in effect for any subsequent tests until the parameter is changed again. If you have

multiple SDM-6000s connected together, the slave SDM-6000s will use the same parameter

values of the master SDM-6000. The parameters cannot be changed for each individual SDM6000 if they are all connected together. If the master SDM-6000 is removed from the installation,

it will retain its settings but the new master SDM-6000 that is now the left-most SDM-6000 will

not remember the old master’s settings.

Chapter 3: Preparing to Use the SDM-6000 • 43

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Bump Test Parameters

There are nine bump test parameters. The table below describes the parameters and shows the

factory settings. If you wish to use the factory settings, then you do not need to make any

parameter adjustments. If you wish to confirm or change the parameter settings, follow the

instructions below.

Parameter Display Tag Available Choices

Pre-Sample Flush Time AIR Flush 15 - 120 seconds in 1

second increments

Calibration Gas Sample

Time

Post-Sample Purge Time AIR Purge 5 - 120 seconds in

Bump Test Check

Toler ance

Fast Bump Fast • On

Automatic

Calibration*

Alarm Check Alarm Check • On

Auto Print Auto Print • On

GAS 20 - 120 seconds in 1

second increments

1 second increments

Tolerance 10% - 50% in

1% increments

•Off

Auto Cal. • On

•Off

•Off

•Off

Factory

Setting

15 seconds

20 seconds

15 seconds

50%

On

On

On

Off

Automatically Bump

Test if Past Due

* Can only be set to On if Manual CAL. in the Calibration section of the Config Menu is also

set to On.

Auto bump if

past due

•On

•Off

Pre-Sample Flush Time (AIR Flush)

The pre-sample flush time is the length of time that the SDM-6000 will draw air through the AIR

fitting before performing an air adjust operation.

Calibration Gas Sample Time (GAS)

The calibration gas sample time is the length of time that the SDM-6000 will draw calibration gas

through each of the gas fittings.

44 • Chapter 3: Preparing to Us e the SDM-6000

Off

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Post-Sample Purge Time (AIR Purge)

The post-sample purge time is the length of time that the SDM-6000 will draw air through the

AIR fitting to purge calibration gas from the system.

Bump Test Check Tolerance (Tolerance)

The bump test check tolerance determines how close the GX-6000 gas reading must be to the

calibration gas concentration for each channel during a bump test in order to pass the bump test. It

is defined as a percentage of the calibration gas concentration. The amount that the GX-6000 gas

reading differs from the calibration gas concentration must be equal to or less than this percentage

of the calibration gas concentration. For example, if the tolerance is set to 50%, and the %LEL

calibration gas concentration is 50% LEL, then the bump test gas reading for the LEL channel on

the GX-6000 must be 50 %LEL ± 25 %LEL.

Fast Bump (Fast)

If Fast is not selected, the gas application during a bump test will continue for the time period

defined by the GAS bump test parameter regardless of the sensor reading(s).

If Fast is selected and the gas reading for the sensor(s) being tested is above the lower tolerance

and below the upper tolerance within 10 seconds, the sensor(s) pass bump testing, the gas

application will be stopped, and the test will move on to the next sensor(s) or to the fresh air

purge. If the gas reading on any of the tested channels is below the lower tolerance or above the

upper tolerance within 10 seconds, the gas application will continue for the time period defined by

the GAS bump test parameter, and the pass/fail status of the sensor(s) will be determined at that

point. Turning Fast on allows calibration gas to be saved when the tested sensors respond quickly

and accurately.

Consider the following scenario as an example.

• 50% LEL methane used for bump testing the combustible gas channel

• GAS bump test parameter set to 20 seconds

• Tolerance set to ± 50%, which means that the acceptable reading range is 25% LEL - 75%

LEL

• Fast selected

Chapter 3: Preparing to Use the SDM-6000 • 45

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

The table below shows possible readings at 10 seconds and the effect on the gas application.

Gas Reading 10 Seconds

Into Fast Bump

15% LEL (-70% of 50% LEL) • Gas application continues for the full 20 seconds

• Pass/fail determined at end of 20 seconds

30% LEL (-40% of 50% LEL) • Gas application stops

• Sensor passes bump testing

60% LEL (+20% of 50% LEL) • Gas application stops

• Sensor passes bump testing

80% LEL (+60% of 50% LEL) • Gas application continues for the full 20 seconds

• Pass/fail determined at end of 20 seconds

Outcome

Automatic Calibration (Auto Cal.)

If Auto Cal. is selected, then the docking station will automatically perform a calibration if a

bump test fails.

NOTE: If Manual CAL. in the calibration configuration is deselected, Auto Cal. cannot

be selected.

Alarm Check

If Alarm Check is selected, a vibrator, LED, and buzzer test is done on the GX-6000 at the end of

the bump test. The vibrator will vibrate, the LEDs will turn on for a few seconds, the buzzer will

sound, and the SDM-6000 will determine if these actions were completed successfully.

Auto Print

The printer must be connected for the Auto Print parameter to have any function. If Auto Print

is selected, the SDM-6000 will automatically print bump test results at the end of a bump test. If

Auto Print is not selected, the SDM-6000 will not automatically print bump test results but the

results can still be printed by pressing the Print button at the end of a bump test.

Automatically Bump Test if Past Due (Auto bump if past due)

If the Auto bump if past due parameter is selected and if the connected GX-6000 is due for a

bump test, the SDM-6000 will automatically perform a bump test 60 seconds after the GX-6000 is

connected. The number of gases used for this bump test depends on the GX-6000’s B--CHECK

setting. If B--CHECK is set to 4GAS, only the standard 4 sensors will be automatically bump

tested. If B--CHECK is set to ALL, all sensors will be automatically bump tested.

If the Auto bump if past due parameter is deselected, an automatic bump test will not be

performed, even if the GX-6000 is due for one.

46 • Chapter 3: Preparing to Us e the SDM-6000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Viewing or Changing the Bump Parameters

Do the following to set the bump test parameters.

1. Turn on the SDM-6000 system. The Function Tab will be displayed on a single station

system’s screen or on the master station’s screen in a multi-station system.

2. Press the Config button. If Password is set to on (factory setting is off), you will be

prompted for a password. Enter the password and press OK to continue.

3. The Configuration Menu will be displayed.

Chapter 3: Preparing to Use the SDM-6000 • 47

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

4. Press the BUMP button. 8 out of 9 bump test parameters and their current settings will be

displayed.

5. The arrow in the upper right corner takes you to the second page that shows the last of the

bump test parameters and its current setting.

6. Adjust the AIR Flush, GAS, AIR Purge, and To le ran ce parameters as described below. The

procedure is the same for each parameter’s adjustment. AIR Flush is shown as an example.