Page 1

RP-3R Pump for

GX-3R and GX-3R Pro

Operator’s Manual

Part Number: 71-0495

Revision: P3

Released: 12/2/21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Product Warranty

RKI Instruments, Inc. warranties gas alarm equipment sold by us to be free from defects in materials,

workmanship, and performance for a period of one year from date of shipment from RKI Instruments,

Inc. Any parts found defective within that period will be repaired or replaced, at our option, free of

charge. This warranty does not apply to those items which by their nature are subject to deterioration

or consumption in normal service, and which must be cleaned, repaired, or replaced on a routine basis.

Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repair

procedures not in accordance with the operator’s manual. This warranty indicates the full extent of our

liability, and we are not responsible for removal or replacement costs, local repair costs, transportation

costs, or contingent expenses incurred without our prior approval.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC., INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and

representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor, and our warranty is limited to the replacement of parts or our complete goods.

RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pump Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rubber Sample Nipple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Hose & Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Switching Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the Hydrophobic Disk Filter and Wire Mesh Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARNING: Understand manual before operating and for proper battery type. Substitution of

components may impair intrinsic safety. To prevent ignition of a hazardous

atmosphere, batteries must only be changed in an area known to be nonhazardous.

Not tested in oxygen enriched atmospheres (above 21%).

CAUTION: Read and understand the GX-3R and GX-3R Pro Operator’s Manual before using the

RP-3R.

RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Overview

This manual describes: the RP-3R pump, RP-3R maintenance, and operation of the RP-3R with the

GX-3R and GX-3R Pro. A parts list at the end of this manual lists replacement parts and accessories

for the RP-3R.

Specifications

Table 1 lists specifications for the RP-3R pump.

Power Supply 1 AA size alkaline

Operating Time Higher-flow mode: 10 hours minimum at 25°C

Sample Flow Rate Higher-flow mode: 0.50 LPM (liters per minute)

Table 1: Specifications

Lower-flow mode: 16 hours minimum at 25°C

Lower-flow mode: 0.35 LPM (liters per minute)

Maximum Tube Length

for Optional Sample Hose

Operating Temperature &

Humidity

Dimensions 29 (D) x 82 (W) x 96 (H) mm, rubber sample nipple not included

Weight Approximately 120 g (including alkaline battery)

Alarm Indications Low Flow & Low Battery

Safety/Regulatory (when

used with the GX-3R or

GX-3R Pro)

100 feet

-20°C to +50°C, 0 - 95% Relative Humidity (non-condensing)

(Certificate Number Presafe 17 ATEX 11584)

AT EX

• II1G Ex ia IIC T4 Ga (-20°C to +50°C Toshiba LR6)

• II1G Ex ia IIC T4 Ga (-20°C to +40°C Duracell MN1500)

• II1G Ex ia IIC T3 Ga (-20°C to +50°C Duracell MN1500)

IECEx

• Ex ia IIC T4 Ga (-20°C to +50°C Toshiba LR6)

• Ex ia IIC T4 Ga (-20°C to +40°C Duracell MN1500)

• Ex ia IIC T3 Ga (-20°C to +50°C Duracell MN1500)

(Certificate Number IECEx PRE 17.0070)

4 RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Description

Figure 1: Component Location

RESET

PO WER

FLOW

Inlet Fitting

Battery Cap

Exhaust Fitting

Buzzer Openi ng

Rubber Sam ple

Nipple

Front

Bottom

RP-3R

Retaini ng Tab Le ver

Sensor Adapter

POWER

The RP-3R pump is a sample drawing accessory for the GX-3R and GX-3R Pro. It consists of the

pump unit and the rubber sample nipple.

Pump Unit

The pump unit is housed in a red plastic case. The silver inlet fitting on the right side of the pump unit

allows for connection of a rubber sample nipple or a hose and probe. The inlet fitting’s clear holder

retains 2 hydrophobic membranes and a mesh disk.

The black cap at the bottom right of the pump unit allows for battery compartment access. The pump

unit needs one AA alkaline battery.

The exhaust fitting is located on the bottom left of the pump unit, next to the battery compartment.

A POWER button, a buzzer opening, a POWER LED, and a FLOW LED are located along the middle

front of the pump unit.

The sensor adapter at the top of the pump unit mates to the GX-3R or GX-3R Pro. There are different

sensor adapters for each instrument type. When installed, the text on the front of the GX-3R/GX-3R

Pro and RP-3R should be facing the same way.

RP-3R 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

A black retaining tab lever on the left side of the RP-3R makes installing/removing the GX-3R or

GX-3R Pro easier.

Rubber Sample Nipple

A cone-shaped 4-inch long rubber sample nipple is included with the RP-3R. It can be installed by

pushing the larger end over the inlet fitting. The smaller end can be inserted in a hole or some other

access point to sample the environment.

Optional Hose & Probe

A sample hose and probe (optional accessories) may be connected to the inlet fitting. Sample hose

lengths are available from 10 feet to 100 feet (see Parts List at the end of the manual).

CAUTION: Sample hose lengths of more than 100 feet are not recommended for the

RP-3R because of flow rate reduction.

Normal Operation

1. Start up the GX-3R or GX-3R Pro and enter normal operation as described in the appropriate

Operator’s Manual.

2. Press the black retaining tab lever on the left side of the RP-3R.

WARNING: Installing the GX-3R or GX-3R Pro onto the RP-3R without pressing the black

retaining tab lever may result in damage to the RP-3R.

3. Be sure the front labels on the GX-3R or GX-3R Pro are facing the same way as the front labels on

the RP-3R.

4. When viewing the GX-3R or GX-3R Pro and RP-3R from the front, engage the RP-3R’s righthand retaining clip with the GX-3R or GX-3R Pro.

5. Push the left side of the GX-3R or GX-3R Pro down until the instrument is seated in the RP-3R.

Release the black retaining tab lever and ensure that both retaining clips are fully engaged. When

fully engaged, the GX-3R or GX-3R Pro should not move around at all.

CAUTION: If the RP-3R is not fully engaged, the unit will not respond to the target gases properly.

6 RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Figure 2: Connecting the RP-3R to the GX-3R

A

I

R

POWE R

RESETRESET

POWE R

POWERPOWER

FLOW

P

O

W

E

R

M

O

D

E

C

O

/

H

2

S

L

E

L

O

2

G

X

-

3

R

3. Pushleft side down

until fully seated

RP-3R

2. Engageright-hand

retainingcl ip.

1. Pushblack retainingtab

lever toward pumpunit

RP-3R 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

6. Attach the rubber sample nipple or optional hose and probe to the inlet fitting.

Figure 3: Connecting the Optional Hose and Probe

GX-3R

POWER

RESET

FLOW

RP-3R

POWERPOWER

POW ER

MODE

AIR

7. Turn on the RP-3R by pressing and holding the POWER button until the RP-3R beeps and the

POWER LED turns green.

WARNING: While the GX-3R or GX-3R Pro is installed in the RP-3R, the pump must be on for

the GX-3R or GX-3R Pro to function as a gas detection monitor.

8. Go to the area to be sampled.

Rubber sample nipple

: Insert the rubber sample nipple into the vessel or enclosed area. Allow the

RP-3R to sample for 90 seconds before observing the reading on the GX-3R or GX-3R Pro.

Hose and probe

: Hold the probe in the area to be sampled. If necessary, the hose and probe may be

lowered into the sample area. Allow the pump unit to sample for 90 seconds before observing the

reading on the GX-3R or GX-3R Pro.

NOTE: The hose and probe do not have their own hydrophobic filters. Take care to not draw liquid

through the hose and probe.

9. Monitor the GX-3R or GX-3R Pro’s gas readings and take appropriate action if gas alarms occur.

10. When sampling is complete, turn off the RP-3R by pressing and holding the POWER button until

the RP-3R sounds a long beep and the POWER LED turns off.

11. Turn off the GX-3R or GX-3R Pro.

12. Press the black retaining tab lever on the left side of the RP-3R.

8 RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

WARNING: Removing the GX-3R or GX-3R Pro from the RP-3R without pressing the black

A

I

R

RESETRESET

POWER

POWERPOWER

FLOW

POWER

P

O

W

E

R

M

O

D

E

C

O

/

H

2

S

L

E

L

O

2

G

X

-

3

R

2. Pull up on left side

RP-3R

1. Push black retaining tab

le v er t oward pump uni t

Figure 4: GX-3R Removal

retaining tab lever may result in damage to the RP-3R.

13. Pull up on the left side of the GX-3R or GX-3R Pro when viewing the instrument from the front.

RP-3R 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Switching Flow Rates

The RP-3R can operate in a higher-flow mode (standard) or a lower-flow mode.

Higher-flow mode FLOW LED steadily yellow

Lower-flow mode FLOW LED flashes yellow

1. With the RP-3R turned on, press and hold the POWER button for 1 second.

2. The FLOW LED will change state (ie. from flashing to steady or vice versa).

NOTE: At temperatures below -10°C, the RP-3R must operate in higher-flow mode. If operating in

lower-flow mode, the RP-3R will automatically switch to higher-flow mode at -10°C. Any

attempt to switch to lower-flow mode will be blocked.

Flow Mode LED Indication

Alarms

The table below outlines the alarms that may occur on the RP-3R.

Alarm Type

Low Battery POWER

Dead Battery POWER

Low Flow

NOTE: A low flow alarm

may get combined with a

low or dead battery alarm

since a low battery voltage

may cause the pump to

stop working.

Visual

Indications

LED

flashing

LED

flashing

FLOW LED

quickly

flashing

Audible

Indications

none none Replace the battery.

constant

buzzer

intermittent

buzzer

Other

Indications

none Replace the battery.

pump stops • Check the rubber sample

Recommended Action

nipple and filters to make

sure they are clear.

• If a hose and probe are

used, check them for

kinks or obstructions.

• Press and release the

POWER button to reset

the alarm.

• If the low flow condition

persists, the pump may

need servicing.

10 RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Maintenance

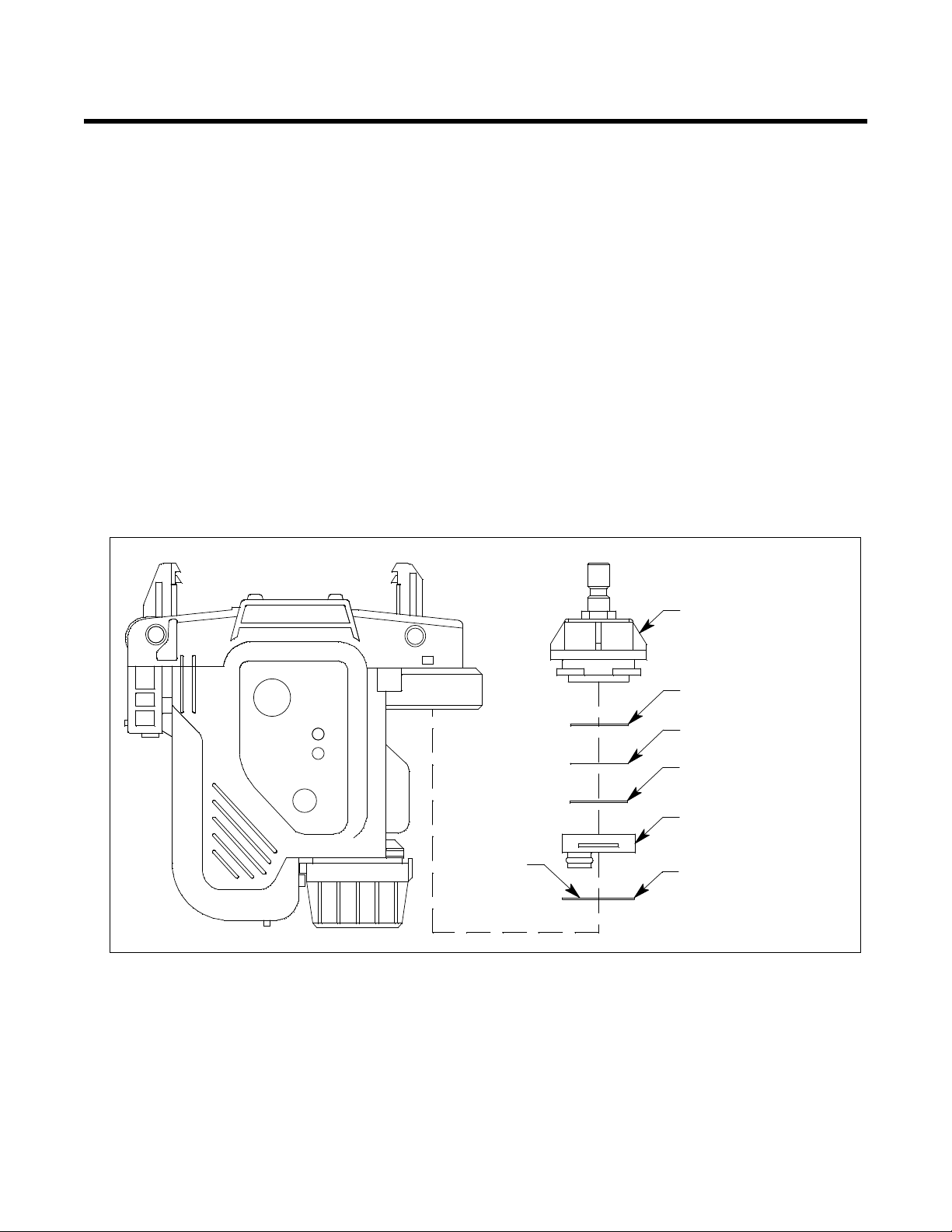

Figure 5: Changing the Hydrophobic & Wire Mesh Filters

Filter Holder

Clear Spacer (for GX-3R

Versio ns Onl y)

POW ER

Hole in

Spacer

FLOW

Hydrophobic Di s k Fi lter

Hydrophobic Disk Filter

Rubber Gasket

RP-3R

RESET

POW ER

Wire Mesh Disk

POWER

Replacing The Battery

1. Push down and rotate the black battery cap counterclockwise until it stops.

2. Pull the battery cap away from the pump unit.

3. Remove the old battery.

4. Insert the new AA alkaline battery + end first into the pump unit. The battery orientation is shown

on the back of the pump unit.

5. Reinstall the black battery cap by pushing it down and turning it clockwise until it stops.

Replacing the Hydrophobic Disk Filter and Wire Mesh Disk

1. Grasp the clear filter holder (under the inlet fitting) and turn it 1/4 of a turn counterclockwise.

2. Pull the filter holder away from the pump unit.

3. The hydrophobic disk filters and wire mesh disk are located in the pump unit and are retained by a

rubber gasket. Gently pull out the rubber gasket with needle nose pliers taking care not to damage

the gasket. The GX-3R version of the RP-3R has a clear spacer below the gasket that may come

out. The GX-3R Pro version of the RP-3R does not have this spacer.

4. Remove the old hydrophobic filters and/or wire mesh disk from the gasket. A hydrophobic filter is

located on either side of the wire mesh disk.

5. Install the new hydrophobic filters and/or wire mesh disk making sure a hydrophobic filter is

located on each side of the wire mesh disk.

RP-3R 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

6. For the GX-3R version: If the clear spacer below the rubber gasket came out when you removed

the gasket, reinstall the spacer. Be sure the hole in the spacer lines up with the hole in the housing.

7. Reinstall the gasket/filters/mesh into the pump unit.

8. Align the two tabs on the bottom of the filter holder with the two slots in the pump unit. Push the

filter holder into the pump unit and turn it 1/4 turn clockwise until it snaps into place.

Parts List

Table 2 lists replacement parts and accessories for the RP-3R pump.

Table 2: Parts List

Part Number Description

07-2006 Gasket, filter/screen retaining

07-6051 O-ring, for battery compartment

17-1001RK Rubber sample nipple

21-1833RK Filter holder, clear plastic, with inlet fitting

21-1957 Battery cap

21-1958 Clear spacer underneath the filter/screen retaining gasket, for GX-3R versions only

33-0159RK Hydrophobic disk filter

33-1112RK Wire mesh disk filter

49-1120RK AA alkaline battery

80-0009RK-XX Sample hose (optional). Replace “XX” with length in feet. Available lengths for the

RP-3R are 10, 15, 20, 25, 30, 35, 40, 45, 50, 60, 75, 100 feet.

80-0150RK Sample probe with dust filter (optional)

12 RP-3R

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...