GasWatch 3 for

Hydrogen Sulfide

Operator’s Manual

Part Number: 71-0511

Revision: P3

Released: 12/1/21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

WARNING

Read and understand this instruction manual before operating

instrument. Improper use of the gas monitor could result in

bodily harm or death.

Maintenance of the gas monitor is essential for proper

operation and correct readings.

Bump test the instrument before each day’s use with a known

concentration of the target gas. A bump test can be done in User

Mode’s BUMP item or by applying gas in Measuring Mode.

The instrument does not need to be calibrated unless it does not

pass the User Mode bump test or does not respond

appropriately, as defined by the user, in Measuring Mode. For

more information about bump test and calibration

requirements, see IEC 60079-29-2.

GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

About the GasWatch 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Alarm LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Infrared Communications Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alligator Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Watch Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Calibration Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

IrDA/USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3: Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Turning On the GasWatch 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Performing a Demand Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Turning Off the GasWatch 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Measuring Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Monitoring an Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Responding to Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chapter 4: Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Tips for Using Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Peak Screen (PEAK). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

STEL Screen (STEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TWA Screen (TWA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User ID Screen (USER ID). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Station ID Screen (STN ID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Last Successful Calibration Date (CAL.DATA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Last Successful Bump Test Screen (BP.DATA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Date/Time Screen (DATE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Temperature Screen (TEMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Alarm Points Screen (ALARM--P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adjusting the Buzzer Volume (BUZZ.VOL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5: User Mode and Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Entering User Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Tips for Using User Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Performing a Bump Test (BUMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Performing a Calibration (GAS CAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Setting Calibration Parameters (CAL SET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Setting Bump Test Parameters (BUMP.SET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarm Settings (ALARM--P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Updating the Lunch Break Setting (LUNCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting the Confirmation Beep and Non-Compliance Indicator (BEEP) . . . . . . . . . . . . . 61

Updating the Backlight Time (BL TIME). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Turning the Key Tone On/Off (KEY.TONE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Display Mode Items (DISP.SET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Zero Suppression (ZERO.SUP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Zero Follower (ZERO.FLW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Turning Easy Calibration On/Off (E-CAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Setting the Date/Time (DATE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Turning the Password On/Off (PASS-W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Viewing the ROM/SUM (ROM/SUM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Entering Measuring Mode (START) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Chapter 6: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing the Humidity Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Replacing the Hydrophobic Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

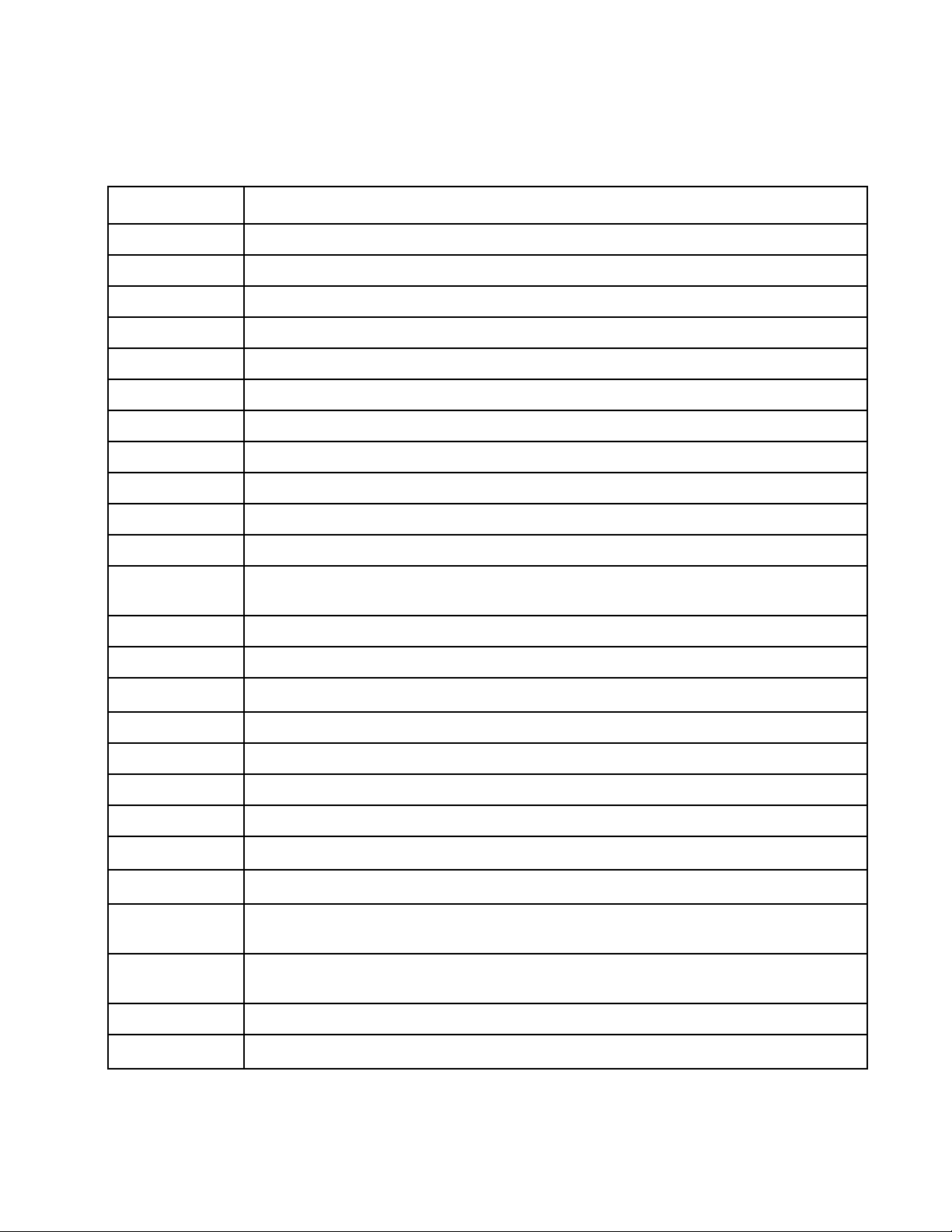

Chapter 7: General Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Appendix A: Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Entering Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tips for Using Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Performing a Calibration (GAS CAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Performing a Gas Test (GAS.TEST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Sensor/Battery Replacement Date (SEN.DATE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Performing a Bump Test (BUMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Setting Alarms to Latching or Self-Resetting (LATCH) . . . . . . . . . . . . . . . . . . . . . . . . . 80

Turning the Demand Zero Function On/Off (D.ZERO). . . . . . . . . . . . . . . . . . . . . . . . . . 81

Turning the Auto Zero Function On/Off (A.ZERO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Turning the ID Display Function On/Off (ID DISP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Turning the Zero Suppression On/Off (ZERO.SUP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Turning the Zero Follower On/Off (ZERO.FLW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

User Mode Zero Suppression (ZSUP.DSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

User Mode Zero Follower (ZFLW.DSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Cylinder Setting (CYL.DISP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Setting the Date/Time (DATE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Turning the Password On/Off (PASS-W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Viewing the ROM/SUM (ROM/SUM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Performing a Default (M.DEF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Entering Measuring Mode (START) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Appendix B: Gas Select Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Entering Gas Select Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Tips for Using Gas Select Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Saving the Alarm Points (SAVE-AP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Turning the Calibration Max Span On/Off (MAX.SPAN) . . . . . . . . . . . . . . . . . . . . . . . . 88

Stealth and Vibrator Settings (STEALTH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Exiting Gas Select Mode (START). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

WARNING: Understand manual before operating. This is an intrinsically safe product.

Substitution of components may impair intrinsic safety. To prevent ignition

of a hazardous atmosphere, batteries must only be changed or charged in

an area known to be nonhazardous. Not tested in oxygen enriched

atmospheres (above 21%).

AVERTISSEMENT:Comprendre le manuel avant de l'utiliser. Ceci est un produit

intrinsèquement sûr. La substitution de composants peut nuire à la sécurité

intrinsèque. Pour éviter l'inflammation d'une atmosphère dangereuse, les

batteries ne doivent être remplacées ou chargées que dans une zone non

dangereuse. Non testé dans des atmosphères enrichies en oxygène (plus de

21%).

GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1: Introduction

Overview

This chapter briefly describes the GasWatch 3 gas monitor. This chapter also describes the

GasWatch 3 Operator’s Manual (this document). Table 1 at the end of this chapter lists the

specifications for the GasWatch 3.

About the GasWatch 3

Using an advanced detection system, the GasWatch 3 personal gas monitor detects the

presence of hydrogen sulfide (H2S). The GasWatch 3’s compact size and easy-to-use design

make it ideally suited for a wide range of applications, including sewage treatment plants,

utility manholes, tunnels, hazardous waste sites, power stations, petrochemical refineries,

mines, paper mills, drilling rigs, and fire fighting stations. The GasWatch 3 offers a full range

of features, including:

• Liquid crystal display (LCD) for complete and understandable information at a glance

• Ultrabright alarm LEDs

• Distinctive audible/vibrating alarms for dangerous gas conditions and audible alarms for

unit malfunction

• Microprocessor control for reliability, ease of use, and advanced capabilities

• Data logging functions

• Alarm trend data

• STEL, TWA, and over range alarms

• Peak reading

• Built-in time function

• Lunch break feature

• CSA “C/US” classification for Class I, Division I, Groups A, B, C, and D hazardous

atmospheres

WARNING: The Model GasWatch 3 detects elevated levels of hydrogen sulfide which

can be dangerous or life threatening. When using the GasWatch 3, you

must follow the instructions and warnings in this manual to assure proper

and safe operation of the unit and to minimize the risk of personal injury.

Be sure to maintain and periodically calibrate the GasWatch 3 as described

in this manual.

AVERTISSEMENT:Le modèle GasWatch 3 détecte les niveaux élevés de sulfure

d'hydrogène qui peuvent être dangereux ou mettre la vie en danger.

Lorsque vous utilisez le GasWatch 3, vous devez suivre les instructions et

les avertissements de ce manuel pour assurer un fonctionnement correct et

en toute sécurité de l'appareil et pour réduire les risques de blessures.

Assurez-vous de maintenir et d’étalonner périodiquement le GasWatch 3

comme décrit dans ce manuel.

6 • Chapter 1: Introduction GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Specifications

Lowest Detectable Limit (LDL) 0.5 ppm

Table 1: Standard Sensor Specifications/Alarm Points

Detection Range 0 - 200 ppm

Reading Increment 0 - 30.0 ppm: 0.1 ppm

31 - 200 ppm: 1 ppm

Warning Factory Setting 5.0 ppm

Alarm Factory Setting 30.0 ppm

Alarm H Factory Setting 100 ppm

STEL Alarm 5.0 ppm

TWA Alarm 1.0 ppm

Indication Accuracy • 0 - 100 ppm: ± 5% of reading or ± 2 ppm

H

S (whichever is greater)

2

• 101 - 200 ppm: ± 20% of reading

Table 2: GasWatch 3 Specifications

Sampling

Method

Response Time T90 Within 10 Seconds

Display Graphics LCD Display

Operating

Temperature

& Humidity

Safety/

Regulatory

Power Supply CR2450 button cell battery

Continuous environment: -20°C to 50

Temporary environment (up to 15 minutes): -20°C to 60

• ATEX: II 1G Ex ia IIC T4 Ga

Certificate Number Presafe DEKRA 18ATEX0130

• IECEx: Ex ia IIC T4 Ga

Certificate Number IECEx DEK 18.0082

• CSA classified, “C/US”, as Intrinsically Safe. Exia. Class I, Groups A, B, C, & D.

Temperature Code T3A.

Certificate Number CSA 19 CA70213062

Diffusion

°

C/10 to 90% RH

C US

186718

°

C/0 to 95% RH

Continuous

Operating

Hours

@ 25 °C

4,000 hours in Measuring Mode (Non Alarm Operation, Fully Charged)

GasWatch 3 for H2S Chapter 1: Introduction • 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Case High-impact Plastic, RF Shielded, Dust and Weather Proof (IP66/68)

Standard

Accessories

Optional

Accessories

Dimensions

and Weight

• Alligator clip

• Watch band

• Calibration cup

• Datalogging and Setup Programs (Windows

• IrDA/USB Cable for connecting to a computer when using the Datalogging and Setup

Programs (not needed if computer has an infrared port)

About this Manual

The GasWatch 3 Operator’s Manual uses the following conventions for notes, cautions, and

warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

®

7, 8, and 10

Approximately 42(H) x 63(W) x 22(D) mm (1.7”H x 2.5”W x 0.9”D)

Approximately 45 g (1.6 oz.)

WARNING: Describes potential danger that can result in injury or death.

8 • Chapter 1: Introduction GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2: Description

Figure 1: Component Location

Alarm LEDs and IrDA Port

Sensor Retainer

Sensor Opening

LCD

Buzzer

Opening

AIR Button

POWER/MODE Button

Overview

This chapter describes the GasWatch 3 instrument and its accessories.

Instrument Description

Case

The GasWatch 3’s sturdy, high-impact plastic case is radio frequency (RF) resistant and is

suitable for use in many environmental conditions, indoors and out. The case is dust proof and

water resistant. A clear plastic window is located on the front of the case for viewing the LCD.

The sensor retainer is located on the right side of the case and allows access to the filters and

sensor.

LCD

A digital LCD (liquid crystal display) is visible through a clear plastic window in the top case.

The LCD shows the gas reading. The LCD also shows information for each of the GasWatch

3’s operating modes.

GasWatch 3 for H2S Chapter 2: Description • 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Control Buttons

Two control buttons, AIR and POWER/MODE, are located below the LCD.

Table 3: GasWatch 3 Control Button Functions

Button Function(s)

AIR • turns on LCD backlight

• resets alarm condition if LATCH is set to ON in Maintenance Mode

• enters User Mode, Maintenance Mode, and Gas Select Mode when used

with POWER/MODE

• activates the demand zero function (adjusts the GasWatch 3’s fresh air

reading)

• changes the value of a parameter available for adjustment

• scrolls through parameter options

POWER/MODE • turns the GasWatch 3 on and off

• turns on LCD backlight

• enters and scrolls through Display Mode

• enters instructions into the GasWatch 3’s microprocessor

• resets alarm condition if LATCH is set to ON in Maintenance Mode

• enters User Mode, Maintenance Mode, and Gas Select Mode when used

with AIR

Alarm LEDs

The two alarm LEDs above the LCD alert you to gas, low battery, and failure alarms.

Buzzer

One solid-state electronic buzzer is located inside the case. Sound exits the case through a

hole in the middle front of the case. The buzzer sounds for gas alarms, malfunctions, and low

battery voltage. It also provides feedback for button presses and while in Display, User,

Maintenance, or Gas Select Mode.

Vibrator

A vibrating motor inside the GasWatch 3 case vibrates for gas alarms and unit malfunctions.

NOTE: If STEALTH is set to ON, the vibrator only functions when VIB in the STEALTH

Gas Select Mode item is set to ON (see pg.89).

Sensor

The sensor retainer holds the sensor in its socket. The H2S sensor is an electrochemical cell

that consists of two precious metal electrodes in a dilute acid electrolyte. A gas permeable

membrane covers the sensor face and allows gas to diffuse into the electrolyte. The gas reacts

in the sensor and produces a current proportional to the concentration of the target gas. The

GasWatch 3’s circuitry amplifies the current, converts the current to a gas concentration, and

displays the concentration on the LCD.

10 • Chapter 2 : Description GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Filters

Humidity Filter (White)

A white humidity filter covers the H2S sensor. The filter absorbs humidity in the sampling

environment to prevent unstable readings around 0 ppm H2S. For users with a 1 ppm H2S

alarm setpoint, the filter should be replaced every 6 months, if you notice a drift on the zero

reading, or if the filter appears dirty (whichever is sooner). For users with a 2 ppm or higher

H2S setpoint, the filter does not necessarily need to be replaced.

Hydrophobic Filter

The white, circular hydrophobic filter sits on the filter gasket, covering the sensor port and the

humidity filter.

Infrared Communications Port

An infrared (IR) communications port is located at the top of the instrument, near the LEDs.

Logged data transmits through the port in standard IrDA protocol. A computer’s infrared port

or an IrDA/USB cable connected to a USB port can be used to download data to the GasWatch

3 Datalogging Program. See the GasWatch 3 Datalogging Program operator’s manual for data

logging and downloading instructions.

Battery

A user-replaceable CR2450 button cell battery powers the GasWatch 3. At 25°C the battery

lasts at least 4,000 hours (166 days). The battery icon in the upper right of the LCD shows

remaining battery life.

A low battery warning activates when the GasWatch 3 detects a low battery voltage. The

GasWatch 3 sounds a dead battery alarm when battery voltage is too low for Measuring Mode.

NOTE: Use of batteries not specified by RKI Instruments, Inc. compromises the CSA

classification and may void the warranty. See “Replacing the Battery” on page 68.

WARNING: To prevent ignition of a hazardous atmosphere, the battery must only be

changed in an area known to be nonhazardous.

AVERTISSEMENT:Pour éviter l'inflammation d'une atmosphère dangereuse, la batterie

ne doit être remplacée que dans une zone non dangereuse.

GasWatch 3 for H2S Chapter 2: Description • 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Standard Accessories

Alligator Clip

Base Clip

Figure 2: Alligator Clip

Figure 3: Watch Band

Alligator Clip

An alligator clip is installed to a base clip that attaches to spring bars on the back of the

GasWatch 3. Use the alligator clip to attach the GasWatch 3 to clothing or a belt. Teeth in the

alligator clip’s jaws prevent slipping. The alligator clip can be rotated to change the

instrument’s orientation.

Optional Accessories

Watch Band

The adjustable watch band allows the GasWatch 3 to be worn on the wrist. The watch band

attaches to spring bars that are protected by hollow tubes.

12 • Chapter 2 : Description GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Calibration Cup

FLOW

Figure 4: Calibration Cup

The calibration cup installs over the sensor. You must use the calibration cup when performing

a bump test, calibration, or gas test.

IrDA/USB Cable

Unless your computer has a built-in IrDA port, a IrDA/USB cable is needed to establish

communication between the GasWatch 3 and the Datalogging Program or the Setup Program.

GasWatch 3 for H2S Chapter 2: Description • 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 3: Measuring Mode

RESUME

SEC

5

YES .MODE

SEC

5

NO .AIR

SEC

5

Overview

This chapter explains how to use the GasWatch 3 to perform confined space entry monitoring

or general area monitoring in Measuring Mode.

Start Up

This section explains how to start up the GasWatch 3, get it ready for operation, and turn it off.

Turning On the GasWatch 3

To illustrate certain functions, the following description of the GasWatch 3 start up sequence

assumes that the following items in User Mode are turned on: LUNCH, CAL.RMDR, and

BP.RMDR in User Mode, and ID DISP and A.ZERO in Maintenance Mode. If any of these

items are turned off, then the corresponding screens do not appear.

1. Press and briefly hold down POWER/MODE. Release the button when you hear a beep.

2. If LUNCH is set to ON (factory setting if OFF, see pg.60), the Lunch Break Screen

appears. The unit counts down from 5 seconds.

a. Continue Accumulating: To continue accumulating peak and time-weighted average

(TWA) readings from the last time the GasWatch 3 was used, press and release

POWER/MODE or allow the countdown to reach 0. The short-term exposure limit

(STEL) reading is reset each time the GasWatch 3 is turned on.

b. Reset Accumulation: To reset the accumulation of peak and time-weighted average

(TWA) readings, press and release AIR before the countdown reaches 0.

14 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3. If CAL.RMDR is set to ON (factory setting) and a calibration is due, the screen that

CAL - LMT

CAL

CAL - LMT

FAIL

NEXT .CAL

d

0

appears next depends on how CAL.EXPD is set in User Mode (see pg.53). The three

possible screens are described below. If a calibration is not due, the instrument displays

the number of days left until a calibration is due.

CAL.EXPD set to

CONFIRM (factory setting)

LCD

Sound Buzzer sounds double pulsing

tone

Action • Option A, Perform calibration

Press and release POWER/

MODE to enter User Mode

and perform a calibration. The

instrument takes you straight

to the calibration start screen

in User Mode’s GAS CAL\ACAL(E-CAL) item. See pg.43

for calibration instructions.

NOTE: If Password Protection

is set ton On (factory setting is

Off) using the GW-3 Config Pro-

gram, you will be prompted for a

password to enter User Mode.

If the calibration is success-

ful, the screen above will not

appear again until the unit is

due for calibration. If the cali-

bration is not successful, the

screen above will again appear

in the startup sequence.

• Option B, Bypass message

continue without performing a

calibration, press and release

AIR.

: To

CAL.EXPD set to

CANT.USE

Buzzer sounds double pulsing

tone

The GasWatch 3 cannot be used

:

until a successful calibration is

performed. Press and release

POWER/MODE to enter User

Mode and perform a calibration.

The instrument takes you straight

to the calibration start screen in

User Mode’s GAS CAL/A-CAL

(E-CAL) item. If you don’t press

POWER/MODE, the instrument

automatically goes to the calibra-

tion start screen after 6 seconds.

See pg.43 for calibration instruc-

tions.

NOTE: If Password Protection is

set ton On (factory setting is Off)

using the GW-3 Config Program,

you will be prompted for a pass-

word to enter User Mode.

If the calibration is successful,

the screen above will not appear

again until the unit is due for cali-

bration. If the calibration is not

successful, the screen above will

again appear in the startup

sequence.

CAL.EXPD set to

NONE

None

• Option A, Perform calibration

If you want to enter User

Mode and perform a

calibration, press and release

POWER/MODE. The

instrument takes you straight

to the calibration start screen

in User Mode’s GAS CAL/ACAL (E-CAL) item.

• Option B, Bypass message

To continue without

performing a calibration, wait

a few seconds for the

instrument to continue with its

startup sequence.

:

:

Find Quality Products Online at: sales@GlobalTestSupply.com

GasWatch 3 for H2S Chapter 3: Measuring Mode • 15

www.GlobalTestSupply.com

4. If BP.RMDR is set to ON (factory setting is OFF) and a bump test is due, the screen that

BP - LMT

CAL

BP - LMT

FAIL

NEXT .BP

d

0

10:42

2 . 13

2019

appears next depends on how BP.EXPD is set in User Mode (see pg.57). The three

possible screens are described below. If a bump test is not due, the instrument displays the

number of days left until a bump test is due.

BP.EXPD set to

CONFIRM (factory setting)

LCD

Sound Buzzer sounds double pulsing

tone

Action • Option A, Perform bump test

Press and release POWER/

MODE to enter User Mode

and perform a bump test. The

instrument takes you straight

to the bump test start screen in

User Mode’s BUMP item. See

pg.38 for bump test

instructions.

NOTE: If Password Protection

is set ton On (factory setting is

Off) using the GW-3 Config Pro-

gram, you will be prompted for a

password to enter User Mode.

If the bump test is successful,

the screen above will not

appear again until the unit is

due for bump testing. If the

bump test is not successful,

the screen above will again

appear in the startup sequence.

• Option B, Bypass message

continue without performing a

bump test, press and release

AIR.

: To

BP.EXPD set to

CANT.USE

Buzzer sounds double pulsing

tone

The GasWatch 3 cannot be used

:

until a successful bump test is

performed. Press and release

POWER/MODE to enter User

Mode and perform a bump test.

The instrument takes you

straight to the bump test start

screen in User Mode’s BUMP

item. If you don’t press

POWER/MODE, the instrument

automatically goes to the bump

test start screen after 6 seconds.

See pg.38 for bump test instruc-

tions.

NOTE: If Password Protection

is set ton On (factory setting is

Off) using the GW-3 Config Pro-

gram, you will be prompted for a

password to enter User Mode.

If the bump test is successful, the

screen above will not appear

again until the unit is due for

bump testing. If the bump test is

not successful, the screen above

will again appear in the startup

sequence.

BP.EXPD set to

NONE

None

• Option A, Perform bump test

If you want to enter User

Mode and perform a bump

test, press and release

POWER/MODE. The

instrument takes you straight

to the bump test start screen in

User Mode’s BUMP item.

• Option B, Bypass message

To continue without

performing a bump test, wait

a few seconds for the

instrument to continue with its

startup sequence.

:

:

5. The Date/Time Screen appears for a few seconds.

Find Quality Products Online at: sales@GlobalTestSupply.com

16 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

www.GlobalTestSupply.com

6. The Battery Voltage Screen appears for a few seconds. An “AL-L” at the bottom of the

AL-L

2.9

V

bAtt

H2S

ppm

F .S .

200.0

H2S

ppm

WARNING

5.0

H2S

ppm

ALARM

30.0

H2S

ppm

ALARM H

100.0

H2S

ppm

STEL

5.0

H2S

ppm

TWA

1.0

H2S

ppm

UID_001

Id

USER

SID_001

Id

StN

SENSOR

FAIL

H2S

ppm

screen indicates that the alarms are set to latching. An “AL-A” at the bottom of the screen

indicates that the alarms are set to auto reset. See pg.80 for a description of how to change

this parameter.

7. The following screens display for 1 second each: Gas Name, Full Scale, Warning Setpoint,

Alarm Setpoint, Alarm H Setpoint, STEL Setpoint, and TWA Setpoint.

8. If ID DISP is set to ON (factory setting is OFF, see pg.82), the User ID Screen appears

for a few seconds, followed by the Station ID Screen.

9. If the GasWatch 3 experiences a sensor failure during start up, a screen indicating that the

sensor failed appears and the buzzer sounds a double pulsing tone once per second.

Find Quality Products Online at: sales@GlobalTestSupply.com

GasWatch 3 for H2S Chapter 3: Measuring Mode • 17

You cannot acknowledge the failure and continue to Measuring Mode. Replace the failed

sensor as soon as possible.

www.GlobalTestSupply.com

10. If A.ZERO is set to ON (factory setting is OFF, see pg.81), the instrument prompts you to

A.ZERO

YES .MODE

NO .AIR

PASS- -W

0 0 0 0

10:42

0.0

H2S

ppm

do an auto zero. An auto zero operation sets the reading to 0 ppm.

WARNING: Make sure that the instrument is in a known fresh air environment (an

environment free of combustible or toxic gases and of normal oxygen

content, 20.9%) before performing an auto zero operation. If you perform

an auto zero operation in an area with gases present, the adjustment will

not be accurate.

You must press and release the POWER/MODE button to perform an auto zero function.

If you do not press any key, after 15 seconds, the instrument enters Measuring Mode

without performing an auto zero.

If Password Protection is turned On (factory setting is Off) using the GW-3 Setup

Program, a user-set password is required to perform an auto zero. When the password

screen appears, adjust each digit with the AIR button and press and release the POWER/

MODE button to move on to the next digit. Once the password is entered, the instrument

performs the auto zero.

11. The GasWatch 3 is now monitoring for gas in Measuring Mode. The Measuring Mode

Screen displays the current gas reading.

18 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Performing a Demand Zero

PASS- -W

0 0 0 0

PASS- -W

0 0 0 0

Perform a demand zero before using the GasWatch 3. This sets the reading to 0 ppm.

1. Find a fresh-air environment. This is an environment free of toxic or combustible gases

and of normal oxygen content (20.9%).

2. Turn on the unit as described above in “Turning On the GasWatch 3”.

3. Press and hold AIR. The buzzer pulses and the LCD prompts you to continue holding AIR

(if KEY.TONE is set to ON in User Mode).

4. Continue to hold AIR until the LCD prompts you to release it. The GasWatch 3 sets the

fresh air reading. Start up is complete and the unit is now ready for monitoring.

5. If Password Protection is turned On (factory setting is Off) using the GW-3 Setup

Program, a user-set password is required to perform a demand ero. When the password

screen appears, adjust each digit with the AIR button and press and release the POWER/

MODE button to move on to the next digit. Once the password is entered, the instrument

performs the demand zero.

Turning Off the GasWatch 3

1. Press and hold POWER/MODE.

2. OFF appears on the display and the buzzer pulses for about five seconds (if KEY.TONE

is set to ON in User Mode).

3. Release the button when OFF disappears from the display.

If Password Protection is turned On (factory setting is Off) using the GW-3 Setup

Program, a user-set password is required to turn off the GasWatch 3. When the password

screen appears, adjust each digit with the AIR button and press and release the POWER/

MODE button to move on to the next digit. Once the password is entered, the instrument

turns off.

Measuring Mode Operation

When the GasWatch 3 completes its startup sequence, it is in Measuring Mode. In Measuring

Mode the GasWatch 3 continuously monitors the sampled atmosphere and displays the gas

GasWatch 3 for H2S Chapter 3: Measuring Mode • 19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

concentration. The GasWatch 3 is in Normal Operation if there are no alarm indications.

S. 10:42

0.0

H2S

ppm

10:42

0.0

H2S

ppm

Heart Symbol: The heart symbol on the right side of the LCD indicates the operation status

and flashes when normal. A microprocessor error causes the heart symbol to stop flashing or

to disappear.

Check Mark: If BP.RMDR is set to ON and if a bump test is not due, a check mark appears in

the lower left corner of the LCD.

“S”: If the instrument is operating in Stealth Mode, an “S.” appears at the bottom of the LCD.

Backlight: In a low-light environment, press and release either button to turn on the display

backlight. See pg.62 to program backlight duration.

Confirmation/Non-Compliance Indicator: If the BEEP item in User Mode is set to anything

other than OFF, the GasWatch 3 gives periodic indications to confirm that it’s operating or to

indicate a non-compliance (see pg.61).

Monitoring an Area

1. Start up the GasWatch 3 as described above in “Start Up” on page 14. It is now in

Measuring Mode.

2. Take the GasWatch 3 to the monitoring area.

3. Wait at least 15 seconds.

20 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Alarms

4. If a reading is observed, allow the reading to stabilize to determine the gas concentration

present.

5. If a gas alarm occurs, take appropriate action. See pg.23.

This section covers alarm indications in Measuring Mode. It also describes how to reset the

GasWatch 3 after an alarm occurs and how to respond to an alarm condition.

NOTE: False alarms may be caused by radio frequency (RF) or electromagnetic (EMI)

interference. Keep the GasWatch 3 away from RF and EMI sources such as radio

transmitters or large motors.

Alarm Indications

The GasWatch 3 buzzer sounds an alarm, the LEDs flash, and the vibrator pulses when any

sort of alarm condition or failure occurs. If the GasWatch 3 is operating in Stealth Mode, the

buzzer does not sound and the vibrator’s operation depends on the VIB setting in Gas Select

Mode’s STEALTH item. See pg.89 for more information.

NOTE: If an alarm condition occurs while you are in Display Mode, the GasWatch 3

automatically returns to the Measuring Mode screen.

The table below summarizes the types of alarms produced by the GasWatch 3 and their

indications.

Table 4: Alarm Types and Indications

Alarm Type Visual Indications Other Indications

Warning

Concentration of gas rises above

the Warning setting.

Alarm

Concentration of gas rises above

the Alarm setting.

Alarm H

Concentration of gas rises above

the Alarm H setting.

• Gas reading flashes

• WARNING appears at the bottom of

the LCD

• Alarm LEDs flash once per second

• Backlight turns on

• Gas reading flashes

• ALARM appears at the bottom of the

LCD

• Alarm LEDs flash twice per second

• Backlight turns on

• Gas reading flashes

• ALARM H appears at the bottom of

the LCD

• Alarm LEDs flash twice per second

• Backlight turns on

• High-low tone sounds

once per second

• Vibrator pulses once per

second

• High-low tone sounds

twice per second

• Vibrator pulses twice per

second

• High-low tone sounds

twice per second

• Vibrator pulses twice per

second

GasWatch 3 for H2S Chapter 3: Measuring Mode • 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table 4: Alarm Types and Indications

Alarm Type Visual Indications Other Indications

TWA or STEL

Concentration rises above the TWA

or STEL alarm setting.

Over Range

Minus Over Range

Low Battery Warning

• Gas reading flashes

• TWA or STEL appears at the bottom

of the LCD

• Alarm LEDs flash once per second

• Backlight turns on

• Gas reading is replaced with a

flashing

• Gas name and units flash

• OVER appears at the bottom of the

LCD

• Alarm LEDs flash twice per second

• Backlight turns on

• Affected channel’s gas reading is

replaced with a flashing

• Gas name and units flash

• M OVER appears at the bottom of

the LCD

• Alarm LEDs flash twice per second

• Backlight turns on

• The last bar in the battery icon

disappears and the battery icon starts

flashing

• High-low tone sounds

once per second

• Vibrator pulses once per

second

• High-low tone sounds

twice per second

• Vibrator pulses twice per

second

• High-low tone sounds

twice per second

• Vibrator pulses twice per

second

None

Dead Battery Alarm

Sensor Failure

Clock Failure

System Failure

• Gas reading disappears. FAIL

BATTERY appears on the LCD.

• Alarm LEDs flash once per second

• FAIL SENSOR appears on the LCD.

• Alarm LEDs flash once per second

• FAIL 050 CLOCK appears on the

LCD

• Alarm LEDs flash once per second

•FAIL SYSTEM and an error code

appear on the LCD

• Alarm LEDs flash once per second

Double pulsing tone sounds

once per second

Double pulsing tone sounds

once per second

Double pulsing tone sounds

once per second

Double pulsing tone sounds

once per second

22 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Responding to Alarms

This section describes response to gas, over range, battery, sensor failure, clock failure, and

system failure alarms.

Responding to Gas Alarms

1. Follow your established procedure for an increasing gas condition.

2. Reset the alarm as necessary or allowed.

a. If LATCH is set to ON (factory setting) in Maintenance Mode, the gas reading must

fall below an alarm setting before you can reset the alarm condition using POWER/

MODE or AIR.

If Password Protection is set to On using the GW-3 Config Program, you must press

AIR and POWER/MODE at the same time and then enter a user-set password to reset

the gas alarm.

b. If LATCH is set to OFF in Maintenance Mode, the alarm condition automatically

resets when gas reading falls below an alarm setpoint.

Responding to Over Range Alarms

WARNING: An over range condition may indicate an extreme hydrogen sulfide

concentration. Confirm the gas concentration with a different GasWatch 3

or with another gas detecting device.

AVERTISSEMENT:Un dépassement de la plage peut indiquer une concentration extrême

en sulfure d'hydrogène. Confirmez la concentration de gaz avec un

GasWatch 3 différent ou avec un autre dispositif de détection de gaz.

1. Follow your established procedure for an extreme gas condition.

2. Reset the alarm using POWER/MODE or AIR once the alarm condition clears if LATCH

is set to ON (factory setting) in Maintenance Mode.

If Password Protection is set to On using the GW-3 Config Program, you must press AIR

and POWER/MODE at the same time and then enter a user-set password to reset the over

range alarm.

3. Calibrate the GasWatch 3 as described on pg.43.

4. If the over range condition continues or if you are not able to successfully calibrate the

unit, you may need to replace the sensor.

5. If the over range condition continues after you replace the sensor, contact RKI

Instruments, Inc. for further instructions.

GasWatch 3 for H2S Chapter 3: Measuring Mode • 23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Responding to Battery Alarms

CLOCK

050

FAIL

SYSTEM

031

FAIL

WARNING: The GasWatch 3 is not operational as a gas monitoring device during a

dead battery alarm. Take the GasWatch 3 to a non-hazardous area and

replace the battery as described in “Replacing the Battery” on page 68.

The GasWatch 3 is fully functional during a low battery warning. However, only 10 days of

operating time remain. The amount of time depends on LCD backlight use and alarm

frequency. Replace the battery as described on pg.68 as soon as possible.

NOTE: Alarms and the LCD backlight consume battery power and reduce the amount of

operating time remaining.

Responding to Sensor Failure Alarms

1. Calibrate the sensor as described on pg.43.

2. If the sensor failure continues, replace the sensor as described on pg.72.

3. If the sensor failure condition continues after replacing the sensor, contact RKI

Instruments, Inc. for further instructions.

Responding to Clock Failure Alarms

A clock failure alarm occurs if the unit’s internal clock malfunctions.

1. Press and release POWER/MODE to continue into Measuring Mode.

CAUTION: There is no datalogging function if you operate the instrument after a clock

failure.

2. Attempt to set the date using the DATE item in User Mode (see pg.64).

3. If the date cannot be set correctly, contact RKI Instruments, Inc. as soon as possible.

Responding to System Failure Alarms

1. If a system failure occurs, the system failure screen displays an error code as shown

below:

24 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2. The error code meanings are shown in the table below:

Table 5: Error Code Explanation

Error Code Explanation

000 ROM failure

010 RAM failure

020 FRAM failure

031 FLASH memory failure

082 Temperature sensor failure

3. If the error code is anything but 031, the instrument cannot be used. Contact RKI

Instruments, Inc. as soon as possible.

If the error code is 031, press and release POWER/MODE to continue into Measuring

Mode if the instrument must be used temporarily.

CAUTION: There is no datalogging function if you operate the instrument after a 031

system failure. Contact RKI Instruments, Inc. as soon as possible.

Data Logging

The GasWatch 3 logs Measuring Mode gas readings, alarm data, and calibration data to its

internal memory. Logged data can be download it to a computer via the infrared

communications port on the front of the unit.

The data logging capacity depends on how often the GasWatch 3 stores data and how often the

GasWatch 3 is turned on and off. The table below illustrates how much data logging time is

available for the various interval times. It assumes that the unit is only turned on once and

there are no alarms. The data logging interval time must be set using the GasWatch 3

Datalogging Program.

Table 6: Data Logging Capacity

Interval Time Data Logging Capacity

10 seconds 10 hours

20 seconds 20 hours

30 seconds 30 hours

1 minute 60 hours

3 minutes 180 hours

5 minutes 300 hours

10 minutes 600 hours

GasWatch 3 for H2S Chapter 3: Measuring Mode • 25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

To utilize the GasWatch 3’s downloading capability, you need:

• PC with Windows 7, Windows 8, or Windows 10

• IrDA port or IrDA/USB cable (cable available from RKI Instruments, Inc.)

• GasWatch 3 Datalogging Program

For a complete description of the Datalogging Program and procedures for downloading data

to a computer, see the GasWatch 3 Datalogging Program Operator’s Manual.

26 • Chapter 3 : Measurin g Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 4: Display Mode

This section describes Display Mode which is accessible from Measuring Mode. See Table 7

below for a list of Display Mode’s menu items, a short description of each item, and the page

number for further description.

Table 7: Display Mode Menu Items

Display Mode

Menu Item

PEAK (pg.28) Displays the Peak reading.

STEL (pg.28) Displays the STEL reading.

TWA (pg.29) Displays the TWA reading.

USER ID

A

(pg.29)

STN ID

A

(pg.30)

CAL.DATA

B

(pg.31)

BP.DATA

C

(pg.31)

DATE (pg.32) Displays the current date and time.

TEMP (pg.32) Displays the current temperature.

ALARM--P

(pg.32)

View and/or change the User ID.

View and/or change the Station ID.

Displays the last calibration date.

Displays the last bump test date.

View alarm points.

Description

BUZZ.VOL

D

(pg.33)

A

Only appears if DISP.SET is set to ON in User Mode (factory setting) and if ID DISP is set to ON in

Maintenance Mode (factory setting is OFF).

B

Only appears if CAL.RMDR is set to ON in User Mode (factory setting).

C

Only appears if BP.RMDR is set to ON in User Mode (factory setting is OFF).

D

Only appears if DISP.SET is set to ON in User Mode (factory setting).

Set the buzzer volume to LO or HI (factory setting).

Tips for Using Display Mode

• To enter Display Mode and scroll from one item to the next or skip an item when a

question is asked, press and release POWER/MODE.

• To enter an item, press and release AIR.

• To change a flashing parameter, press and release AIR. To reverse the movement in a list

(ie. from down to up or vice versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then release both buttons.

GasWatch 3 for H2S Chapter 4: Display Mode • 27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

• To exit from an entered-information screen and go back to Measuring Mode, press and

PEAK

72.0

H2S

ppm

HOLD

CLR

RELEASE

CLR

STEL

3.2

H2S

ppm

release POWER/MODE until you get to the Measuring Mode screen.

NOTE: Each screen displays for 20 seconds. If you do not press a button within 20 seconds,

the GasWatch 3 automatically returns to Measuring Mode.

Peak Screen (PEAK)

The peak screen displays the highest concentration detected since the GasWatch 3 was turned

on. The peak reading is stored until a higher level is detected, the peak reading is cleared, or

the GasWatch 3 is turned off.

The lunch break feature enables the GasWatch 3 to save the peak reading when it is turned off

so it can continue with the same peak when it is turned on again (see pg.14).

To clear the peak reading, do the following:

NOTE: If Password Protection is set to On using the GW-3 Series Setup Program, the

peak reading cannot be cleared.

1. After entering Display Mode, press and release POWER/MODE until PEAK appears.

2. Press and hold AIR until the screen prompts you to release it.

3. The peak reading is reset and the unit returns to the Peak Screen.

If you do not want to clear the peak reading, release AIR before the above screen sequence

occurs. The unit returns to the Peak Screen.

STEL Screen (STEL)

The STEL Screen displays the short term exposure limit (STEL) reading. The STEL reading

is the average reading over the last 15 minutes.

28 • Chapter 4 : Display Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

TWA Screen (TWA)

TWA

0.7

H2S

ppm

UID_001

Id

USER

CHG / AIR

Id

USER

NO / MODE

Id

USER

UID_001

Id

USER

The TWA Screen displays the time weighted average (TWA) reading.

The TWA reading is the average reading over the last 8 hours. If 8 hours have not elapsed

since the last time the TWA reading was cleared, the average is still calculated over 8 hours.

The missing readings are assigned a value of 0. If LUNCH is set to OFF (factory setting), the

TWA is cleared when the GasWatch 3 is turned off.

If LUNCH is set to ON, the GasWatch 3 remembers the TWA reading when it is turned off

and can continue accumulation when it is turned on again (see pg.14).

Changing the User ID (USER ID)

This screen only appears if DISP.SET in User Mode is set to ON (factory setting) and if ID

DISP in Maintenance Mode is set to ON (factory setting is OFF).

Use this screen to select a user ID from the 128 user IDs that are stored in the GasWatch 3’s

memory. Before a user ID is selected on a brand new instrument, the user ID is “----------”.

The factory-installed user IDs have a “U_ID_XXX” format.

The user ID provides a way to identify the GasWatch 3 user during a data logging session.

User IDs can only be selected in this menu item. In order to edit the 128 user IDs, you must

use the GasWatch 3 Datalogging Program or GasWatch 3 Setup Program.

1. After entering Display Mode, press and release POWER/MODE until the USER ID

screen sequence appears.

2. To change the User ID, press and release AIR. The current User ID flashes.

GasWatch 3 for H2S Chapter 4: Display Mode • 29

Find Quality Products Online at: sales@GlobalTestSupply.com

3. Use AIR to scroll to the desired User ID.

4. Press and release POWER/MODE to save the User ID and return to the USER ID screen

in Display Mode.

www.GlobalTestSupply.com

Changing the Station ID (STN ID)

SID_001

Id

StN

CHG / AIR

Id

StN

NO / MODE

Id

StN

SID_001

Id

StN

This screen only appears if DISP.SET in User Mode is set to ON (factory setting) and if ID

DISP in Maintenance Mode is set to ON (factory setting is OFF).

Use this screen to select a station ID from the 128 station IDs that are stored in the GasWatch

3’s memory. Before a station ID is selected on a brand new instrument, the station ID is

“----------”. The factory-installed station IDs have a “S_ID_XXX” format.

The station ID provides a way to identify the GasWatch 3 location during a data logging

session.

User IDs can only be selected in this menu item. In order to edit the 128 user IDs, you must

use the GasWatch 3 Datalogging Program or GasWatch 3 Setup Program.

1. After entering Display Mode, press and release POWER/MODE until the STN ID screen

sequence appears.

2. To change the Station ID, press and release AIR. The current Station ID flashes.

3. Use AIR to scroll to the desired Station ID.

4. Press and release POWER/MODE to save the Station ID and return to the STN ID screen

in Display Mode.

30 • Chapter 4 : Display Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Last Successful Calibration Date (CAL.DATA)

CAL .DATA

dISP

YES / AIR

dISP

NO / MODE

dISP

CAL .DATA

1 . 1

2019

BP .DATA

dISP

YES / AIR

dISP

NO / MODE

dISP

The CAL.DATA screen shows the date of the last successful calibration. This screen only

appears if CAL.RMDR is set to ON (factory setting).

1. After entering Display Mode, press and release POWER/MODE until the CAL.DATA

screen sequence appears.

2. Press AIR to enter the CAL.DATA screen. The date of the last successful calibration

displays.

3. Press and release POWER/MODE to return to the CAL.DATA screen in Display Mode.

Last Successful Bump Test Date (BP.DATA)

The BP.DATA screen shows the date of the last successful bump test. This screen only

appears if BP.RMDR is set to ON (factory setting is OFF).

1. After entering Display Mode, press and release POWER/MODE until the BP.DATA

screen sequence appears.

GasWatch 3 for H2S Chapter 4: Display Mode • 31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2. Press AIR to enter the BP.DATA screen. The date of the last successful bump test

BP .DATA

1 . 1

2019

10:42

2 .13

2019

TEMP

24C

ALARM--P

dISP

YES / AIR

dISP

NO / MODE

dISP

displays.

3. When you are done viewing the last bump test date, press and release POWER/MODE to

return to the BP.DATA screen in Display Mode.

Date/Time Screen (DATE)

The DATE screen shows the instrument’s date and time.

Temperature Screen (TEMP)

The TEMP screen shows the surrounding area’s temperature.

Alarm Points Screen (ALARM--P)

The Alarm Points Screen shows the gas alarm settings.

1. After entering Display Mode, press and release POWER/MODE until the ALARM--P

screen sequence appears.

32 • Chapter 4 : Display Mode GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2. Press and release AIR. The Full Scale Setting screen appears.

F .S .

200.0

H2S

ppm

WARNING

5.0

H2S

ppm

ALARM

30.0

H2S

ppm

ALARM H

100.0

H2S

ppm

STEL

5.0

H2S

ppm

TWA

1.0

H2S

ppm

AIR AIR

AIR AIR

AIR

AIR

BUZZ .VOL

HI

CHG / AIR

HI

NO / MODE

HI

3. Use AIR to scroll through the Warning, Alarm, Alarm H, STEL, and TWA settings.

4. Press and release POWER/MODE to return to the Alarm Points Screen.

Adjusting the Buzzer Volume (BUZZ.VOL)

The BUZZ.VOL screen allows you to adjust the volume of the instrument’s buzzer. This

screen only appears if DISP.SET in User Mode is set to ON (factory setting).

HI (factory setting): Buzzer volume is high.

LO: Buzzer volume is low.

1. While in Display Mode, press and release POWER/MODE until BUZZ.VOL appears.

The current setting displays on the top line.

2. Press and release AIR. The current setting flashes.

GasWatch 3 for H2S Chapter 4: Display Mode • 33

3. Use AIR to display the desired setting.

4. Press and release POWER/MODE to save the setting and return to the BUZZ.VOL item

in Display Mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 5: User Mode and Calibration

Overview

This section describes the GasWatch 3 in User Mode. See Table 8 below for a list of the items

found in User Mode, the page that the item’s instructions can be found on, and a short

description of the item.

Table 8: User Mode Menu Items

User Mode

Menu Item

BUMP (pg.38) Perform a bump test.

BUMP Perform a bump test.

START Begin the warmup sequence and enter Measuring Mode.

ESCAPE Return to the BUMP menu item.

GAS CAL (pg.43) Perform a fresh air adjustment, perform a span adjustment, change the calibration gas con-

centration.

AIR (pg.43) Perform a fresh air adjustment.

A-CAL

(pg.44) or

E-CAL

(pg.48)

depending on

E-CAL User

Mode setting*

ESCAPE Return to the GAS CAL item in User Mode.

CAL SET (pg.52) Change parameters related to calibration.

A-CAL (or

E-CAL)

START Begin the warmup sequence and enter Measuring Mode.

CAL-P Set the calibration gas concentration.

ESCAPE Return to the A-CAL item in the GAS CAL menu.

Description

Perform a span adjustment.

CAL.RMDR

(pg.52)

CAL.INT

(pg.53)

CAL.EXPD

(pg.53)

ESCAPE Return to the CAL SET item in User Mode.

ON

(factory setting): The instrument notifies the user upon startup when

a calibration is due. Notification type depends on CAL.EXPD setting

below. CAL.DATA screen appears in Display Mode.

OFF

: No notification upon startup when a calibration is due.

CAL.DATA screen does not appear in Display Mode.

How often the instrument needs to be calibrated.

Options: 1 - 1000 days (factory setting is 90 days)

Defines what action must be taken if a calibration is due upon startup.

CONFIRM

that calibration is due and continue to Measuring Mode.

CANT.USE

tion is performed.

NONE

continues.

(factory setting): Press and release AIR to acknowledge

: Cannot enter Measuring Mode until a successful calibra-

: A screen indicates that calibration is due but warmup sequence

34 • Chapter 5 : User Mode a nd Calibration GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table 8: User Mode Menu Items

User Mode

Menu Item

BUMP.SET

(pg.54)

Description

Change parameters related to bump testing.

SETTING

(pg.55)

BP.RMDR

(pg.57)

GAS.TIME How long gas is applied during a bump test.

Choices: 30 (factory setting), 45, 60, 90 seconds

CHECK Percentage of calibration gas concentration that the

bump test reading must be within in order to pass bump.

Options: 10%, 20%, 30%, 40%, 50% (factory setting)

CAL.TIME How long gas is applied during a calibration.

GAS.TIME is deducted from this time.

Options: 90 (factory setting) or 120 seconds

A-CAL ON

ESCAPE Return to the SETTING item in the BUMP SET menu.

: The instrument notifies the user upon startup when a bump test is

ON

due. Notification type depends on BP.EXPD setting below. BP.DATA

screen appears in Display Mode.

OFF

(factory setting): No notification upon startup when a bump test is

due. BP.DATA screen does not appear in Display Mode.

(factory setting): If a bump test fails, a calibration

automatically starts.

: If a bump test fails, a calibration does not auto-

OFF

matically start.

BP.INT

(pg.57)

BP.EXPD

(pg.57)

ESCAPE Return to the BUMP SET item in User Mode.

ALARM-P

(pg.58)

LUNCH (pg.60) ON

Set alarm points (WARNING, ALARM, ALARM H, STEL, TWA) and/or reset all alarms

to their default settings.

readings at startup.

OFF

ings every time it’s turned on.

How often the instrument needs to be bump tested.

Options: 0 - 30 days (factory setting is 30 days)

Defines what action must be taken if a bump test is due upon startup.

CONFIRM

that bump test is due and continue to Measuring Mode.

CANT.USE

is performed.

NONE

continues.

: Lunch break feature is on. Instrument asks if you want to resume TWA and PEAK

(factory setting): Lunch break feature is off. Instrument resets TWA and PEAK read-

(factory setting): Press and release AIR to acknowledge

: Cannot enter Measuring Mode until a successful bump test

: A screen indicates that bump test is due but warmup sequence

GasWatch 3 for H2S Chapter 5: User Mode and Calibration • 35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table 8: User Mode Menu Items

User Mode

Menu Item

BEEP (pg.61) Set confirmation beep parameters.

BEEP.SEL

(pg.61)

BEEP.INT

(pg.62)

ESCAPE Return to the BEEP item in User Mode.

BL TIME (pg.62) How long the back light stays on after the last button press.

Options: 0 - 255 seconds or OFF. The factory setting is 30 seconds.

LED: LEDs flash and instrument vibrates based on interval defined in

BEEP.INT to confirm instrument is still operating.

BUZZER

defined in BEEP.INT to confirm instrument is still operating.

LED+BUZ

on interval defined in BEEP.INT to confirm instrument is still operat-

ing.

BMP/CAL

bump test or calibration is due regardless of whether BP.RMDR and/or

CAL.RMDR are set to ON.

OFF

or that a bump test or calibration is due.

Confirmation alert interval. Confirmation type defined in BEEP.SEL.

Options: 0.5 minute and 1 to 99 minutes in 1 minute increments. The

factory setting is 5 minutes.

: Buzzer sounds and instrument vibrates based on interval

: LEDs flash, buzzer sounds, and instrument vibrates based

: LEDs flash based on interval defined in BEEP.INT if

(factory setting): No alerts to confirm instrument is still operating

Description

KEY.TONE

(pg.63)

DISP.SET (pg.63) OFF

ZERO.SUP

(pg.63)**

ZERO.FLW

(pg.64)***

E-CAL (pg.64) XX seconds

DATE (pg.64) Set the instrument’s date and time.

PASS-W (pg.65) ON

ROM/SUM

(pg.66)

START (pg.66) Press and release POWER/MODE to begin the warmup sequence and enter Measuring

* If a CYL SEL screen appears in A-CAL/E-CAL, CYL.DISP is set to ON in Maintenance Mode.

** Only appears if ZSUP.DSP is set to ON in Maintenance Mode.

*** Only appears if ZFLW.DSP is set to ON in Maintenance Mode.

ON

(factory setting): Buzzer sounds when button is pressed.

OFF

: Buzzer does not sound when button is pressed.

: USER ID, STN ID, and BUZZ.VOL items do not appear in Display Mode.

ON

(factory setting): BUZZ.VOL item appears in Display Mode. USER ID and STN ID

items appear if ID DISP in Maintenance Mode is also set to ON.

ON

(factory setting): Not intended for field adjustment. The suppression value is 2 ppm.

ON

(factory setting): Not intended for field adjustment.

: E-CAL appears in GAS CAL instead of A-CAL.

OFF

(factory setting): E-CAL does not appear in GAS CAL.

: User Mode is password-protected. Factory-set password is 0405.

OFF

(factory setting): User Mode is not password-protected.

View the firmware information for the GasWatch 3’s sensor board and main board.

Mode.

36 • Chapter 5 : User Mode a nd Calibration GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

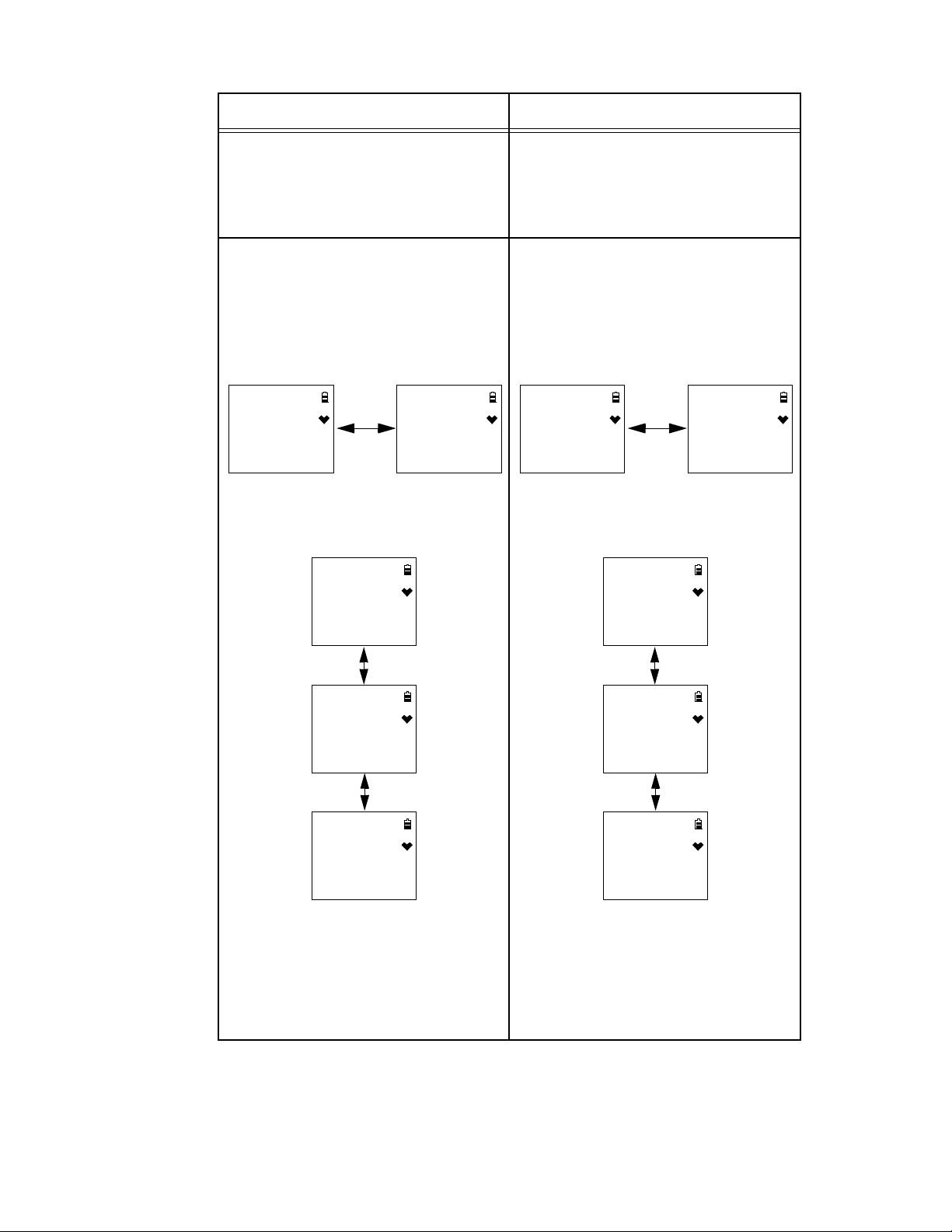

Entering User Mode

PASS-W set to OFF PASS-W set to ON

BUMP

PASS - W

0 0 0 0

BUMP

WARNING: The GasWatch 3 is not in operation as a gas detector while in User Mode.

1. Take the GasWatch 3 to a non-hazardous location and turn it off if it is on.

2. Press and hold AIR, then press and hold POWER/MODE. When you hear a beep, release

the buttons.

3. The screen that appears depends on the setting of User Mode’s PASS -W item.

If PASS-W is set to OFF (factory setting), continue with Step 6.

If PASS-W is set to ON, continue with Step 4.

4. If PASS-W is set to ON in User Mode, a password screen appears and the first digit

flashes. The factory-set password is 0405 but it can be changed.

5. Use AIR to select each password number then press POWER/MODE to save it and move

on to the next number. To go back a number, press and hold AIR and POWER/MODE for

a few seconds. To reverse the direction of change (ie. from increasing to decreasing or vice

versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then release both buttons.

6. The BUMP item displays.

7. Use AIR to move through the User Mode items.

GasWatch 3 for H2S Chapter 5: User Mode and Calibration • 37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Tips for Using User Mode

• To scroll from one item to the next, press and release AIR. To reverse the scrolling

direction:

a. Press and hold AIR.

b. Immediately press POWER/MODE and then release both buttons.

c. The scrolling direction returns to the original direction when you exit and reenter a

menu.

• To skip an item when a question is asked, press and release AIR.

• To enter an item and to save any changes, press and release POWER/MODE.

• To change a flashing parameter, press and release AIR. To reverse the direction of change

(ie. from increasing to decreasing or vice versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then release both buttons.

• To exit an entered item without saving a change, press and hold AIR and POWER/MODE

for a few seconds.

Performing a Bump Test (BUMP)

Bump test the instrument before each day’s use with a known concentration of the target gas.

The instrument does not need to be calibrated unless it does not pass the bump test.

To bump test the GasWatch 3, you need:

• Calibration gas cylinder (RKI Instruments recommends using 25 ppm H2S)

• 0.25 LPM fixed flow regulator

• Non-absorbent tubing

• Calibration cup

1. Confirm that the GasWatch 3’s calibration gas value matches the concentration listed on

the calibration gas cylinder as described on pg.51.

2. Install the calibration cup onto the GasWatch 3. The calibration cup has an indicated flow

direction. Be sure the calibration cup is installed in the correct direction and that it is

pushed on all the way.

3. Use the tubing to connect the regulator to the inlet of the calibration cup.

38 • Chapter 5 : User Mode a nd Calibration GasWatch 3 for H2S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

4. While in User Mode, press AIR to scroll to BUMP.

BUMP

BUMP

25.0

H2S

ppm

APLY 30

0.0

H2S

ppm

BUMP 30

0.0

H2S

ppm

5. Press and release POWER/MODE. The display shows the calibration value (see pg.51 if

the calibration value does not match the calibration gas cylinder’s concentration).

6. It is important to vent the regulator while installing it onto the cylinder. Venting the

regulator during installation helps prevent air from getting into the cylinder and degrading

the gas. Open the 0.25 LPM regulator by turning the knob counterclockwise and install it

onto the cylinder.

7. Press and release POWER/MODE.

8. The gas reading flashes, the bottom of the screen alternates between “APLY” and

“BUMP”, and the bottom of the screen counts down from the time set in

BUMP.SET\SETTING\GAS.TIME.

To back out of the gas application screen without performing the bump test, press and

release AIR and POWER/MODE together.

GasWatch 3 for H2S Chapter 5: User Mode and Calibration • 39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

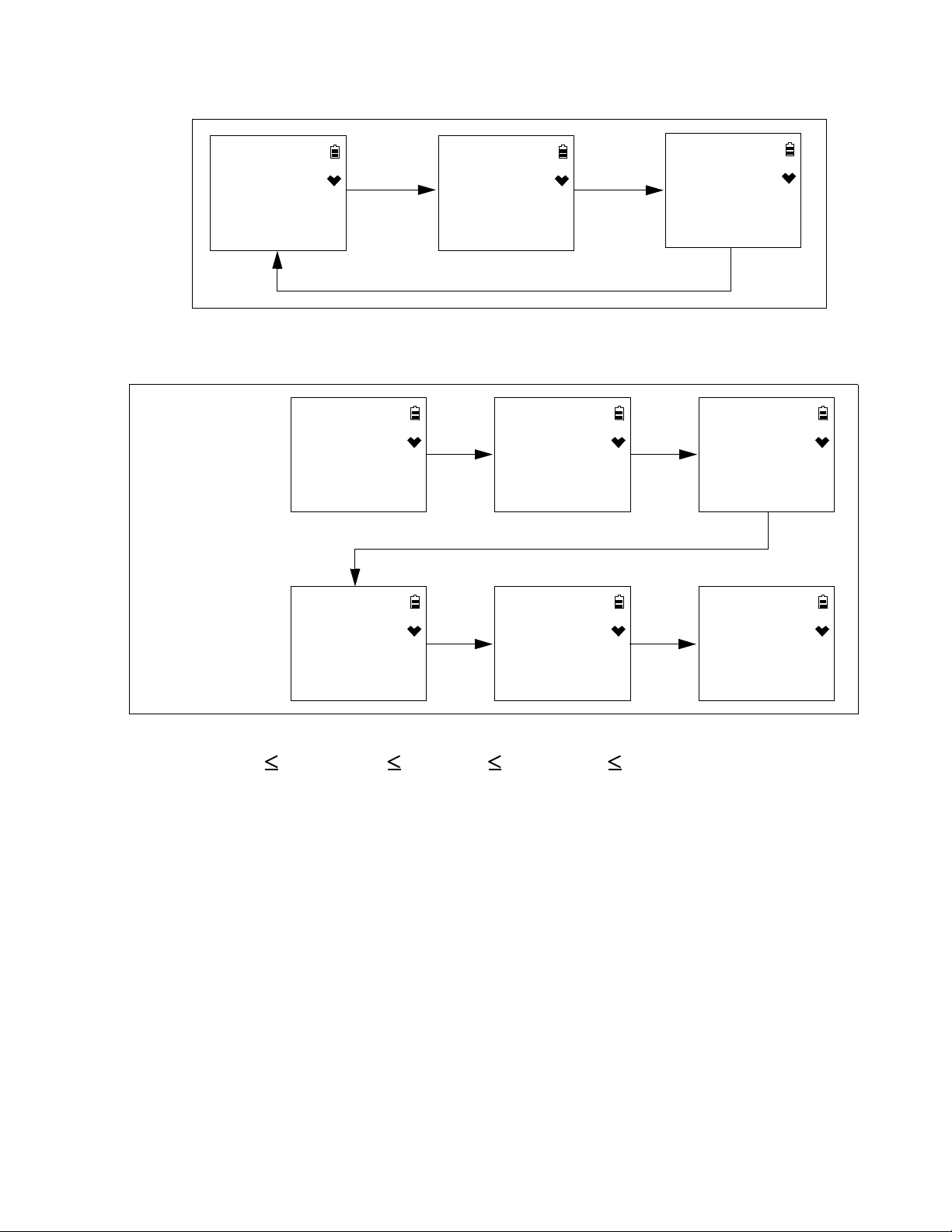

9. At the end of the countdown, the instrument analyzes the results. Follow the flow chart to

Figure 5: Bump Test Flow Chart

Bump test passed?

Y N

A-CAL On?

Calibration passed?

Y N Y N

(default is on)

Y N

A B C

E F

D

Y N

Auto start after successful

bump

set to on? (default is on)

*NOTE: Auto start after successful bump/cal parameters set using Datalogging or Setup Programs.

set to on? (default is on)

Auto start after successful

cal

AIR

BMP/CAL

P

H2S

ppm

BMP /

23.5

H2S

ppm

AIR

BMP/CAL

P

H2S

ppm

BMP /

23.5

H2S

ppm

determine the bump test outcome.

Option A from Flow Chart Option B from Flow Chart

Find Quality Products Online at: sales@GlobalTestSupply.com

40 • Chapter 5 : User Mode a nd Calibration GasWatch 3 for H2S

• Bump test passed

• Auto Start After Successful Bump set to

ON (factory setting)

1. The instrument indicates that the bump

test passed. Use AIR to scroll between

the bump test result and the bump test

gas reading.

2. Close the regulator.

3. Unscrew the regulator.

4. Remove the calibration cup.

5. Press and release POWER/MODE to

enter Measuring Mode.

• Bump test passed

• Auto Start After Successful Bump set to

OFF (factory setting is ON)

1. The instrument indicates that the bump

test passed. Use AIR to scroll between

the bump test result and the bump test

gas reading.

2. Close the regulator.

3. Unscrew the regulator.

4. Remove the calibration cup.

5. Press and release POWER/MODE to

6. Press and release POWER/MODE to

return to the START item in the BUMP

menu.

enter Measuring Mode.

www.GlobalTestSupply.com

Option C from Flow Chart Option D from Flow Chart

AIR

BMP/CAL

F

H2S

ppm

BMP /

2.5

H2S

ppm

APLY 60

2.5

H2S

ppm

CAL 60

2.5

H2S

ppm

AIR

AIR

BMP / CAL

F F

H2S

ppm

BMP /

2.5

H2S

ppm

/ CAL

4.0

H2S

ppm

• Bump test failed