Page 1

Beacon 110 Gas Monitor

Operator’s Manual

Part Number: 71-0110RK

Revision: J

Released: 6/26/20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Product Warranty

RKI Instruments, Inc., warrants gas alarm equipment sold by us to be free from defects in materials,

workmanship, and performance for a period of one year from date of shipment from RKI Instruments,

Inc. Any parts found defective within that period will be repaired or replaced, at our option, free of

charge. This warranty does not apply to those items which by their nature are subject to deterioration

or consumption in normal service, and which must be cleaned, repaired, or replaced on a routine basis.

Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repair

procedures not in accordance with the operator’s manual. This warranty indicates the full extent of our

liability, and we are not responsible for removal or replacement costs, local repair costs, transportation

costs, or contingent expenses incurred without our prior approval.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

THIS W ARRAN T Y IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF RKI INSTRUMENTS, INC.,

INCLUDING BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC., BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL LOSS OR

DAMAGE OF ANY KIND CONNECTED WITH THE USE OF ITS PRODUCTS OR

FAILURE OF ITS PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and

representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor, and our warranty is limited to the replacement of parts or our complete goods.

2 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Beacon 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

External Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Optional Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3: Installation & Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting the Beacon 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring the Beacon 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 - 20 mA Signal Output Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Viewing and Resetting Min/Max Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Battery Charging (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5: Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Viewing & Changing Beacon 110 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Beacon 110 Operator’s Manual 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Chapter 6: Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Selecting the Detector Head Input and Gas Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibration Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix A: Control Button Quick Reference Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Chapter 1: Introduction

Overview

This chapter briefly describes the Beacon 110 Gas Monitor. This chapter also describes the Beacon 110

Operator’s Manual (this document). Table 1 at the end of this chapter lists the specifications for the

Beacon 110.

About the Beacon 110

The Beacon 110 is a fixed mount, single channel continuous-monitoring gas monitoring controller. All

user adjustable parameters may be accessed using push button switches. Both direct connect (internal

amplifier type) detector heads and 4 - 20 mA transmitter (remote amplifier type) detector heads may be

used with the Beacon 110.

The Beacon 110 displays the current gas reading on an LCD display which is visible through a window

in the door. It includes audible and visual alarms that warn you of hazardous gas conditions. The alarm

circuit includes two levels of gas alarms. The fail circuit alerts you to failures in the gas detector heads

or Beacon 110. The Beacon 110 provides a 4 - 20 mA signal proportional to the target gas reading for

use by a recording device. Three sets of relay contacts, two controlled by the gas alarms and one by the

fail alarm, rated at 10 amps 115 VAC, 10 amps 220 VAC, and 10 amps 30 VDC are available for

controlling devices such as lights or horns or for controlling higher rated relays.

Three operating modes allow you to display and change setup and calibration settings and change the

detector head input type. They are Calibration Mode, Configuration Mode, and Input Mode.

About this Manual

The Beacon 110 Operator’s Manual uses the following conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in injury or death.

Beacon 110 Operator’s Manual 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Specifications

Table 1 lists specifications for the Beacon 110.

Input Power 100/115/220V ~ ±10%, 50/60Hz, 0.2/0.2/0.1A

Construction (housing) Fiberglass/polyester with lexan window (NEMA 4X)

Dimensions 8.5 in. H x 6.5 in. W x 4.5 in. D

Weigh t 4.2 lbs.

Safety/Regulatory

Environmental Conditions • For indoor or outdoor locations (Type 4X)

Table 1: Beacon 110 Specifications

or

24 V ± 10%, 0.5A

(216 mm H x 165 mm W x 108 mm D)

C US

186718

• -20°C to 50°C (-4°F to 122°F) ambient

• Maximum relative humidity of 80%

• Main supply voltage fluctuations not exceeding ± 10% of nominal

• DC supply voltage fluctuations not exceeding ±10% of nominal

• Overvoltage Category II, Pollution Degree 2

Relays • Relay contacts rated for 10A @ 115/220V~ resistive or 10A @ 30V

User Controls • Three push button control switches

Signal Output • 4 to 20 mA, 500 ohms impedance max

resistive

• SPDT Form C

• One ON/OFF toggle switch

• One push button reset switch

6 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Chapter 2: Description

Overview

This chapter describes external and internal components of the Beacon 110 gas monitor.

External Description

This section describes the housing and all external components of the Beacon 110. For the purposes of

this description, the housing door is considered the front of the monitor.

Housing

The Beacon 110’s fiberglass housing is weather- and corrosion-resistant. It is suitable for installation

where general purpose equipment is in use. The housing door is hinged on the left side and is secured

by two latches on the right side. The display screen and status lights are visible through a window in

the housing door. Four mounting feet are attached to the back of the housing (one at each corner). The

mounting feet allow installation to a vertical surface. Two conduit hubs on the bottom of the housing

are for external wiring connections. In some cases, the instrument is shipped with the gas detector

already installed in the right conduit hub and factory wired to the appropriate terminals inside the unit.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason.

CAUTION: To avoid electrical interference, do not route detector and power wiring through the

same conduit hub.

Buzzer

The buzzer is on the bottom center of the housing in front of the reset switch. The buzzer sounds

audible alarms to warn you of gas alarms and instrument failures.

Reset Switch

The reset switch is on the bottom of the housing behind the buzzer. The reset switch serves three

functions:

• You can reset the alarm circuits for “latched” alarms after an alarm 1 or alarm 2 condition passes.

• You can silence the buzzer during an alarm 1 or an alarm 2 condition. You cannot silence a fail

condition.

• You can acknowledge and turn off the optional strobe in an alarm 1 or alarm 2 condition if it has

been installed and setup for this type of operation.

• You can display and reset the minimum and maximum readings that the Beacon 110 has

experienced since the last min/max reset or startup.

Beacon 110 Operator’s Manual 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Internal Description

DC Power

Polyfuse

Relay (3X)

Detector/

Transmitter

Terminal

Strips

Main PCB

Power

Sw itch

AC Fuses

Power Supply

Reset Switch

Control

Terminal

Strip

Alarm Terminal

Strip

Buzzer

Conduit Hubs (2X)

Control PCB

AC IN

Terminal

Strip

Figure 1: Beacon 110 Component Location

This section describes the internal components of the Beacon 110.

Main Printed Circuit Board (PCB)

8 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

The main PCB is mounted inside the housing. The main PCB includes the power supply, terminal

strips, relays, fuses, and power switch.

Power Supply

The power supply is located on the left side of the main PCB. It takes AC line voltage supplied to the

Beacon 110 and converts it to 24 VDC which is used to run the Beacon 110.

www.GlobalTestSupply.com

Page 9

Terminal Strips

The Beacon 110 includes terminal strips for external and factory wiring connections. See “Wiring the

Beacon 110” on page 17 for detailed wiring procedures.

• AC In Terminal Strip. The AC in terminal strip is a 3-point terminal strip located in the lower left

corner of the main PCB. It facilitates wiring from the AC power source. Table 2 lists the function

of each terminal.

Table 2: Terminal Assignments for the AC In Terminal Strip

Terminal Connects to:

L Hot (line) wire from AC power source.

N Neutral wire from AC power source.

GEarth ground

• Alarm Terminal Strip. The 9-point alarm terminal strip is located along the bottom edge of the

main circuit board to the right of the AC in terminal strip (see Figure 1). It facilitates wiring

external alarm devices (horn, strobe, etc.) to the alarm relay contacts and includes common (C),

normally closed (NC) and normally open (NO) terminals for fail, alarm 1, and alarm 2.

• Controller Terminal Strip. The 8-point controller terminal strip is located along the bottom edge

of the main circuit board to the right of the alarm terminal strip (see Figure 1). The controller

terminal strip facilitates various internal and external wiring connections. Table 3 lists the function

of each terminal.

Table 3: Terminal Assignments for the Controller Terminal Strip

Terminal Connects to:

Alarm Buzzer + & - Factory installed buzzer (factory-wired)

Alarm Reset (2) Reset switch (factory-wired)

4 - 20 mA Output + + connection of 4 - 20 mA output

4 - 20 mA Output - - connection of 4 - 20 mA output

EXT DC (24V BATT) +

EXT DC (24V BATT) -

1

*

If DC power is used as the primary power source, do not make wiring connections to the

AC terminal strip.

+ connection from 24 VDC power source

- connection from 24 VDC power source

1

(or 24 V backup battery)

1

(or 24 V backup battery)

• Detector/Transmitter Terminal Strips. Three adjacent terminal strips are located along the right

side of the main circuit board above the controller terminal strip (see Figure 1). These three

terminal strips facilitate wiring connections to a detector or a 4 - 20 mA transmitter. The lower 4point terminal strip is labelled LEL and is used to wire a combustible detector. The middle 2-point

terminal strip is labelled Oxy and is used to wire an oxygen detector. The top 3-point terminal strip

is labelled AMP and is used to wire 4 - 20 mA transmitters or direct connect preamp type

detectors. Although terminal strips are present for various types of detectors, only one detector

head at a time may be wired to the Beacon 110.

Beacon 110 Operator’s Manual 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Ground Stud

The threaded ground stud is used for making connections to earth ground. It is connected through the

main PCB to the G (ground) terminal on the AC in terminal strip. A kep nut on the stud may be

removed for installation of one or more lugs to make wiring connections. This stud is typically used to

connect the shield drain wire of shielded cable to earth ground at the Beacon 110.

Relays

The Beacon 110 includes three alarm relays located above the alarm terminal strip. They are from left

to right Fail, Alarm 1, and Alarm 2. The relays are form C, single-pole, double-throw (SPDT) and

rated for 10 amps at 115/220 VAC (resistive) or 10 amps at 30 VDC (resistive).

NOTE: You can select normally energized (N.EN) or normally de-energized (N.DE-EN) settings for

the alarm 1 and alarm 2 relays. See “Chapter 5: Configuration Mode” on page 31.

The fail relay is factory set as normally energized and is not user adjustable.

AC & DC Circuit Protection

Two AC fuses are used in the Beacon 110. The two fuses are located on the left side of the main PCB,

above the AC power terminal strip and below the power supply. They cut off the incoming AC power

in the event of a short circuit or other electrical fault which causes a high current draw in the Beacon

110. They are housed in vertical fuse holders and are held in the holder by a quarter turn cover. They

are labelled as F1 (left fuse) and F2 (right fuse) on the PCB silk-screen and are rated at 3 A, 250 V.

A polyswitch is used to protect the DC power input. It is located to the right of the relays and is

labelled on the PCB silkscreen as PS3. In the event of a short circuit or other electrical fault which

causes a high current draw in the Beacon 110, the polyswitch will interrupt the DC power if the unit is

powered from DC. When the fault situation is corrected, the polyswitch resets and the unit will

continue to operate. The polyswitch is not user serviceable.

Power Switch

The power switch is located to the right of the power supply and above the relays (see Figure 1 on page

8). The power switch turns the incoming AC power source on and off at the Beacon 110. When the

switch is up, the power switch is on.

CAUTION: The DC power input has no on/off switch and is not affected by the position of the power

switch.

Control PCB

The LCD display and control buttons are located on the control PCB. It is installed on the main PCB

with three standoffs. The control PCB is connected to the main PCB with the display cable which is a

ribbon cable terminated with 20 position rectangular connectors on each end. The display cable

connects to the control PCB on the back of the top edge and to the main PCB directly below the control

PCB.

10 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Figure 2: Control PCB Component Location

UP/YES DOWN/NO

ENTER

F

A1 A2

Control Switches

Fail LED

Alarm 1 LED

Alarm 2 LED

LCD Display

Contrast

Potentiometer

LCD Display

The LCD display is located at the top of the control PCB. It indicates the current gas reading and

displays messages and parameters in the Beacon 110’s operating modes.

Contrast Potentiometer

The contrast potentiometer is located to the right of the LCD display. It is used to adjust the contrast of

the LCD. If the background of the LCD appears so dark that the characters are not visible or if the

characters are too dim, turn the adjustment screw on the potentiometer clockwise or counterclockwise

until the desired visibility is obtained.

Control Buttons

The Beacon 110 includes three push button switches that allow you to enter the Beacon 110’s

operating modes, navigate through the modes, update settings, and save changes to the settings. The

push button switches are located along the bottom edge of the control PCB (see Figure 2). The UP/

YES button is on the left, the DOWN/NO button is in the middle, and the ENTER button is on the

right.

Table 4: Beacon 110 Control Button Functions

Switch Function

UP/YES • Saves settings

• Changes the displayed setting

• Enters Calibration Mode

• Enters Input Mode (press with DOWN/NO button)

• Enters Configuration Mode (press with ENTER button)

Beacon 110 Operator’s Manual 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Table 4: Beacon 110 Control Button Functions

Switch Function

DOWN/NO • Cancels setting changes

• Changes the displayed setting

• Enters Input Mode (press with UP/YES button)

• Displays the Information Screen

ENTER • Initiates operations

• Enters Configuration Mode (press with UP/YES button)

• Accepts displayed parameters

Status LEDs

The Beacon 110 includes three active status LEDs that are located above the display (see Figure 1 on

page 8). Two LEDs, labelled RX and TX, to the right of those described below, are not active.

• Fail LED

The fail LED turns on when the Beacon 110 is experiencing a fail condition. A fail condition can

be caused by a detector failure or low detector signal.

• Alarm 1 LED

The alarm 1 LED is on when the Beacon 110 is experiencing an alarm 1 condition.

• Alarm 2 LED

The alarm 2 LED is on when the Beacon 110 is experiencing an alarm 2 condition.

12 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Optional Accessories

Strobe Terminal Strip

Figure 3: Strobe Terminal Strip Location

This section describes the optional accessories available for the Beacon 110. Both optional accessories

are wired to the Strobe Terminal Strip as shown below.

Beacon 110 Operator’s Manual 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Alarm Strobe

Figure 4: Beacon 110 with Alarm Strobe

Alarm Strobe

The Beacon 110 can be ordered with a red alarm strobe light installed on the top of the housing. The

Beacon 110 retains its NEMA 4X rating with the strobe installed. Strobe operation can be programmed

in Configuration Mode (see “Chapter 5: Configuration Mode” on page 31). The outline and mounting

dimensions of the Beacon 110 with the optional alarm strobe mounted are the same as the standard

Beacon 110 without the strobe. See Figure 6 for outline and mounting dimensions.

Horn/Strobe

The Beacon 110 can be ordered with a horn/strobe. This optional horn/strobe allows the user to have

both a strobe and a horn connected to the “Strobe” terminals of the Beacon 110. If the horn/strobe is

not factory installed, it also allows the user to mount the horn/strobe away from the Beacon 110 so that

it can be somewhere more visible/audible. Strobe operation can be programmed in Configuration

Mode (see “Chapter 5: Configuration Mode” on page 31).

14 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

+

Dimensions S hown in Inches

-

5.97

6.81

4.83

6.17

Strobe Terminal Strip

Figure 5: Horn/Strobe Wiring and Dimensions

NOTE: See “Chapter 3: Installation & Startup” on page 16 for complete Beacon 110 installation

instructions.

CAUTION: Do not adjust the strobe b rightness or the horn volume at the strobe/horn, as this ma y

overload the Beacon 110 strobe control circuit.

The optional horn/strobe is generally not factory installed and needs to be installed by the user. The

following instructions describe the installation of the horn/strobe. If the horn/strobe is factory installed,

the following instructions do not apply.

1. Mount the horn/strobe in the desired location.

2. Install an appropriately rated cable bushing or conduit to the left conduit hub on the bottom of the

Beacon 110 housing.

3. Install an appropriately rated cable bushing or conduit at the horn/strobe.

4. Run a cable or wires in conduit from the horn/strobe to the Beacon 110 through the left conduit

hub.

5. Connect the wires to the strobe terminal strip as shown in the figure below.

Beacon 110 Operator’s Manual 15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Chapter 3: Installation & Startup

1.83

4.00

.30 Dia. x .50Slot, 4X

1.70

7.20

3/4 Conduit Hub (2X)

Note: AllDimensions in Inches

3.03

1.47

10.00 8.94 8.50

4.50

Figure 6: Beacon 110 Dimensions

Overview

This chapter describes procedures to mount the Beacon 110 Gas Monitor, make wiring connections to

the monitor, and start up the monitor.

WARNING: Perform all installation and start-up procedures in a “fresh air” environment

(environment known to be free of combustible gas, toxic gas, and of normal oxygen

content). The Beacon 110 is not in operation as a gas m onitoring system until the

start-up procedure is complete.

Mounting the Beacon 110

Perform the following procedure to install the instrument housing at the mounting site.

16 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

1. Select the mounting site. When you select the mounting site consider the following factors:

• Is an AC or DC power source available?

• Is there enough room to open the housing door and make wiring connections through the con-

duit hubs at the bottom of the housing?

• Are the display screen and status lights visible?

2. If necessary, close and latch the housing door.

3. Position the monitor on a vertical surface at eye level (4 1/2 to 5 feet from the floor).

4. Insert 1/4 in. or 5/16 in. screws through the slots in the mounting feet at each corner of the housing

to secure the housing to the mounting surface.

Wiring the Beacon 110

This section describes procedures to connect the AC power source, DC power source, external

alarm(s), recorder, and detector head.

WARNING: Make all connections to the Beacon 110 before you plug in or turn on the AC or DC

power source. Before you make any wiring adjustments, always verify that all

power sources are not liv e.

Routing Wiring Into the Beacon 110 Housing

Wiring must be brought into the housing through one of the two factory-installed conduit hubs on the

bottom of the housing.

drill into the Beacon 110 housing for any reason. Drilling the Beacon 110 housing and routing

Do not

wiring through holes not factory drilled will void the warranty

• Damage to internal components from the drilling process.

• Moisture damage to internal components from poorly sealed holes.

• Unpredictable Beacon 110 behavior due to EMI/RFI interference caused by wires routed across

the PCBs.

• Possible shorting of Beacon 110 components due to wires routed across the PCBs.

and could result in:

Connecting the AC Power Source

NOTE: If you are using DC power as the primary power source, go to the next section, “Connecting

the DC Power Source”.

The AC in terminal strip will accept 24 - 14 AWG wire. All connections to building electrical systems

must be installed in accordance with local requirements and must be installed by qualified personnel. If

this equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired. Install an appropriate switch or circuit breaker in the AC line close to the

Beacon 110 that meets the local electrical code and within easy reach of the operator. The switch or

circuit breaker must be marked as the disconnecting device for the Beacon 110.

Perform the following procedure to connect the AC power source to the Beacon 110.

Beacon 110 Operator’s Manual 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Figure 7: AC Power Wiring

Ground

Neutral

Hot (Line)

AC In

Terminal

Strip

L

GN

100 VAC, 50/60 Hz

or

115 VAC, 50/60 Hz

or

220 VAC, 50/60 Hz

WARNING: Verify that the p ower so urce is unplugged or t urned o f f bef or e you continu e with this

procedure.

1. Turn off or unplug all incoming power to the Beacon 110.

2. Open the housing door, then place the power switch in the OFF position.

CAUTION: The power switch does not control DC input power.

3. Install an appropriately rated cable bushing or conduit to the left conduit hub on the bottom of the

Beacon 110 housing.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

4. Locate the 3-point AC in terminal strip in the lower left corner of the main PCB (see Figure 1 on

page 8). The terminals are labelled L, N, and G.

5. Guide the AC power cord or wires through the left conduit hub on the bottom of the Beacon 110

housing.

CAUTION: Do not route power and detector he ad wiring through the same conduit hub. The power

wiring may disrupt the transmission of the detector head signal to the monitor.

6. Connect the AC wires to the AC power terminal strip as shown in Figure 7 below.

Connecting the DC Power Source

WARNING: Verify that the p ower so urce is unplugged or t urned o f f bef or e you continu e with this

procedure.

DC power may be used as a primary power source. If DC power (connected to the External DC In

terminals) is the primary power source, DO NOT connect AC power to the AC In terminal strip.

A 24 VDC battery (connected to the External DC in terminals) may also be used as a backup power

source if AC power (connected to the AC In terminal strip) is the primary power source. If your

18 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Figure 8: DC Power Wiring

EXT DC

(24V BATT)

+ -

+

-

24 VDC

External DC In Terminals

on Controller Terminal Strip

Beacon 110 does not include the battery charging feature, you may use a self contained 24 VDC

backup that keeps its batteries charged while AC power is on and recharges the batteries when AC

power returns after a power failure. If your Beacon 110 includes the battery charging feature, see

“Battery Charging (Optional)” on page 26 for a complete description of this feature and what type of

battery to use.

WARNING: The External DC In terminals on the controller termin al strip are only intended for

connecting a battery or a 24 VDC supply to the Beacon 110. Do not connect any

horns or st robes to the External DC In terminals on the controller terminal strip.

1. Turn off or unplug all incoming power to the Beacon 110.

2. Open the housing door, then place the power switch in the OFF position.

CAUTION: The power switch does not control DC input power.

3. Locate the DC power terminals on the controller terminal strip in the lower right corner of the

main PCB (see Figure 1 on page 8). They are labelled EXT DC + and EXT DC -.

4. Install an appropriately rated cable bushing or conduit to the left conduit hub on the bottom of the

Beacon 110 housing.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

5. Guide a DC power cord or wires through the conduit hub.

CAUTION: Do not route power and detector he ad wiring through the same conduit hub. The power

6. Connect the DC wires to the controller terminal strip as shown in Figure 8.

NOTE: The Beacon 110 will operate from the DC input down to 18.5 volts. If a self contained

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

wiring may disrupt the transmission of the detector head signal to the monitor.

backup battery is used, see its operator’s manual for a description of its recharging

characteristics. If your Beacon 110 includes the battery charging feature and a backup

battery is used, the Beacon 110 will recharge the battery when AC power has returned after

a power failure. See “Battery Charging (Optional)” on page 26 for a complete description of

the battery charging feature.

Beacon 110 Operator’s Manual 19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

NO NC C

Beacon 110

Alarm Terminal Strip

(+) H

(-) N

External Power

Source

External Alarm Device

ALARM-1

NO NC C

FAIL

NO NC C

ALARM-2

Figure 9: Typical Alarm Device Wiring

Connecting External Alarms

Perform the following procedure to connect external alarms to the Beacon 110. The relays are form C,

single-pole, double-throw (SPDT) and rated for 10 amps at 115/220 VAC (resistive) or 10 amps at 30

VDC (resistive).

WARNING: Do not conn ect external alarms to the External DC In terminals on the controller

terminal strip.

1. Turn off or unplug all incoming power to the Beacon 110.

2. Open the housing door, then place the power switch in the OFF position.

CAUTION: The power switch does not control DC input power.

3. Locate the alarm terminal strip. See Figure 1 on page 8.

4. Install an appropriately rated cable bushing or conduit in the left conduit hub on the bottom of the

Beacon 110 housing. This hub is typically used for power wiring and may already have conduit or

other fittings installed because of this.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

5. Guide the wiring of the external alarm through the left conduit hub on the bottom of the Beacon

110 housing.

CAUTION: Do not route the external alarm wiring and detector wiring through the same conduit

hub. The external alarm wir ing ma y disr upt the tra nsmiss ion of t he dete ctor s ignal t o

the Beacon 110.

6. Connect the leads from the external alarm to the appropriate terminals on the alarm terminal strip

as shown in Figure 9 to obtain the desired operation.

7. Repeat steps 5 and 6 for additional alarm devices.

20 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Figure 10: Recorder Output Wiring

4-20 mA

OUTPUT

Recording Device,

500 Ohms Max

Impedance

Connecting Recorders

Perform the following procedure to connect an analog signal recording device to the Beacon 110. The

output at the recorder output terminals is a 4 - 20 mA signal that is proportional to the detection range

of the detector head connected to the Beacon 110.

1. Turn off or unplug incoming power to the Beacon 110.

2. Open the housing door, and locate the recorder output terminals on the controller terminal strip.

See Figure 1 on page 8. They are labelled 4 - 20 mA OUTPUT + and 4 - 20 mA OUTPUT -.

3. Place the power switch in the off position.

CAUTION: The power switch does not control DC input power.

4. Install an appropriately rated cable bushing or conduit in the left conduit hub on the bottom of the

Beacon 110 housing. This hub is typically used for power wiring and may already have conduit or

other fittings installed because of this.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

5. Guide the wiring from the recording device through the left conduit hub on the bottom of the

Beacon 110 housing.

6. Connect the leads from the recording device to the analog output terminal strip as shown in

Figure 10 below.

Connecting RKI Detector Heads

Perform the following procedure to connect an RKI detector head to the Beacon 110.

1. Turn off or unplug power to the Beacon 110.

2. Open the Beacon 110 door and place the power switch in the off position.

3. See the detector head operator’s manual for instructions on how to connect the detector head to a

controller.

4. Install an appropriately rated cable bushing or conduit in the right conduit hub on the bottom of the

Beacon 110 housing.

Beacon 110 Operator’s Manual 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

5. Route the wires in conduit or shielded cable from the detector head through the right conduit hub

into the Beacon 110. See Table 5 below for wire size and distance guidelines.

6. Unshielded twisted pair cable in conduit or shielded twisted pair cable is recommended for all the

direct connect detector heads. For the LEL detector, pair and twist the R & B wires and the W & G

wires. Shielded cable or wires in conduit are recommended for the 2-wire and 3-wire 4 - 20 mA

transmitters.

7. Connect the wires from the detector head to the appropriate detector/transmitter terminals. See the

detector head operator’s manual and the Beacon 110 Detector Head Specifications sheet for

detector head connections to the Beacon 110. If shielded cable is used, connect the cable shield’s

drain wire at the Beacon 110 to the ground stud on the main PCB.

CAUTION: Do not route power and detector he ad wiring through the same conduit hub. The power

wiring may disrupt the transmission of the detector head’s to the Beacon 110.

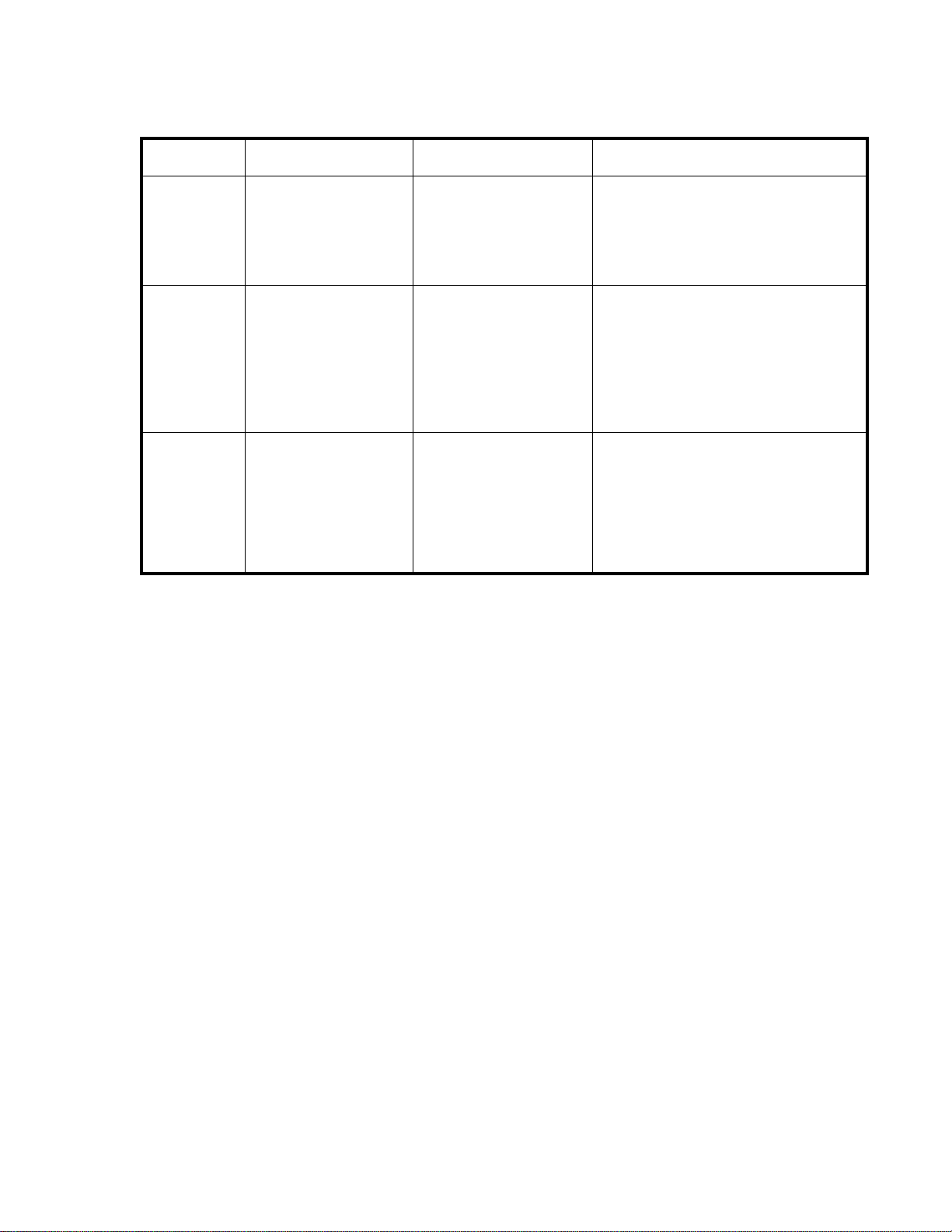

Table 5: Wire Size Guidelines for RKI Detector Head Wiring

Number of

Detector Head Type

Direct Connect LEL 4 500 ft. 1,000 ft. 2,000 ft.

Direct Connect Oxygen 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect H2S 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect CO 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect ESM-01 type 2 500 ft. 1,000 ft. 2,000 ft.

2-Wire 4 - 20 mA Transmitter 2 2,500 ft. 5,000 ft. 8,000 ft.

3-Wire 4 - 20 mA Transmitter 3 2,500 ft. 5,000 ft. 8,000 ft.

Wires to

Controller

Max Distance

to Controller

w/18 Gauge

Wire

Max Distance

to Controller

w/16 Gauge

Wire

Max Distance

to Controller

w/14 Gauge

Wire

Connecting User-Supplied 4 to 20 mA Transmitters

The Beacon 110 may be used with a user supplied 2-wire or 3-wire source type 4 - 20 mA transmitter

which runs on 24 VDC. When this is done, the Beacon 110 is normally setup at RKI Instruments with

the following parameters: item name (example: Pressure), unit of measure (example: PSI), and full

scale (example: 100). For example, a Beacon 110 can be setup for “Pressure” with units of “PSI” and a

full scale of “100” PSI.

Perform the following procedure to connect a 4 to 20 mA transmitter that you supply to the Beacon

110.

1. Turn off or unplug power to the Beacon 110.

2. Open the Beacon 110 door and turn off the power switch.

22 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

3-Wire Connection 2-Wire Connection

(DC Ground)

4 - 20 mA

+ 24 VDC

4 - 20 mA

+ 24 VDC

3-wire 4 - 20 mA

Transmitter

2-Wire 4 - 20 mA

Transmitter

BLK

GRN

WHT

RED

GRN

WHT

L

E

L

A

M

P

O

X

Y

S

BLK

GRN

WHT

RED

GRN

WHT

L

E

L

A

M

P

O

X

Y

S

Figure 11: Generic 4 - 20 mA Transmitter Wiring

3. See the transmitter’s instruction manual for instructions on how to connect wires to the transmitter.

4. Install an appropriately rated cable bushing or conduit in the right conduit hub on the bottom of the

Beacon 110 housing.

CAUTION: Only use the two factory installed conduit hubs on the bottom of the housing for wire

entry into the housing. Do not drill the housing for any reason. See “Routing Wiring

Into the Beacon 110 Housing” on page 17 for more information.

5. Route the wires from the transmitter through the right conduit hub into the Beacon 110.

6. Connect the wires from the transmitter to the AMP terminal strip. Figure 11 below illustrates

typical transmitter wiring connections. See the transmitter instruction manual for controller

terminal connections. If shielded cable is used, connect the cable shield’s drain wire at the Beacon

110 to the ground stud on the main PCB.

CAUTION: Do not route power and transmitter wiring through the same conduit hub. The power

wiring may disrupt the transmission of the transmitter’s signal to the Beacon 110.

Start Up

Introducing Incoming Power

Perform the following procedure to place the Beacon 110 into normal operation.

1. Complete the mounting and wiring procedures described earlier in this chapter.

2. Complete all installation procedures described in the detector head or user supplied

4 - 20 mA transmitter operator’s manual.

3. Verify that all wiring connections are correct and secure and that the Beacon 110’s power switch is

in the OFF position.

Beacon 110 Operator’s Manual 23

Find Quality Products Online at: sales@GlobalTestSupply.com

4. Plug in or turn on the incoming power source (AC or DC).

5. Turn on the power switch if AC power is used as primary power.

www.GlobalTestSupply.com

Page 24

METHANE

0 %LEL

6. The LCD display will indicate the firmware version when the Beacon 110 is first powered up and

will then count down a one minute warm-up period before normal operation begins. During

normal operation, the display will indicate the current gas reading and target gas. Verify that the

display is indicating the current gas reading and target gas after the warm-up period is complete

and normal operation begins, for example:

NOTE: To prevent unwanted alarms during warm up, the alarm circuits are not active during the

warm-up period.

7. Perform the start-up procedure for the RKI detector head or user supplied 4 - 20 mA transmitter as

described in the detector head or transmitter operator’s manual.

24 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Chapter 4: Operation

METHANE

0 %LEL

Overview

This chapter describes the Beacon 110 in normal operation. This chapter also describes the Beacon 110

in alarm 1, alarm 2, and fail conditions and suggests response to these conditions.

Normal Operation

Normal operation is defined as follows:

• The start-up procedure is complete.

• The Beacon 110 is not indicating an alarm 1, alarm 2, or fail condition.

• The Beacon 110 is not in Calibration, Configuration, or Input Mode.

During normal operation, the Beacon 110 simultaneously displays the current gas reading, unit of

measure, and target gas. The example below illustrates a typical LEL Beacon 110.

4 - 20 mA Signal Output Operation

The output at the 4 - 20 mA output terminals is a 4 - 20 mA signal that is proportional to the detection

range of the Beacon 110. During normal operation, this signal tracks the gas concentration on the

LCD.

There are several circumstances where the signal output will not track the display reading but will

behave as follows:

• When the Beacon 110 is in its warm-up period, the signal output will be fixed at 4 mA (zero) for

all gas types except oxygen. For oxygen types, the output will be fixed at 17.4 mA (20.9% oxygen)

while the Beacon 110 is in warm-up.

• When the Beacon 110’s gas type is changed, the Beacon 110 will enter Configuration Mode for

you to verify the parameter settings. When you exit Configuration Mode, the display will indicate

NEEDS CALIBRATION and will continue to indicate this until Calibration Mode is entered and

a calibration is performed. In this situation, the signal output will be fixed at 3.5 mA for all

versions other than oxygen and 17.4 mA for oxygen versions from the time Gas Type Mode is

entered until the Beacon 110 is calibrated and returns to normal operation.

• If you enter Calibration Mode, Configuration Mode, or Gas Type Mode, the signal output will be

fixed at 3.5 mA for all versions other than oxygen and 17.4 mA for oxygen versions until the

Beacon 110 returns to normal operation.

• If the Beacon 110’s input power decreases below 18.5 volts so that the Beacon 110 is in a low

power alarm, the signal output is fixed below 2.4 mA until the low power alarm is cleared.

Beacon 110 Operator’s Manual 25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

• If the Beacon 110 goes into a fail condition, after a 30 second delay, the signal output is fixed

below 2.4 mA until the fail alarm is cleared. During the 30 second delay, the output follows the

detector output. In the case of a downscale reading, the displayed gas reading will only go as low

as -10% of full scale but the signal output will continue to track the reading even if it’s lower than

-10% of full scale.

Viewing and Resetting Min/Max Readings

The reset switch may be used to view and reset the minimum and maximum gas readings.

NOTE: Minimum and maximum readings are reset if the instrument is turned off.

1. While the Beacon 110 is in normal operation, press and hold the reset switch button for 5 seconds.

2. The display will indicate the minimum reading on the bottom display line and the maximum

reading on the top display line for about 3 seconds before indicating <RESET> TO CLEAR.

3. To return to normal operation without resetting the minimum and maximum readings, do not press

the reset switch button and allow the unit to return to normal operation. It will return to normal

operation in about 5 seconds.

To reset the minimum and maximum readings, press and hold the reset switch button while the

<RESET> TO CLEAR message is on the display until the display indicates Min/MAX Is

RESET. Release the reset switch button.The unit will then return to normal operation in about 5

seconds.

Battery Charging (Optional)

The Beacon 110 has an optional backup battery charging feature. In order for this feature to be

included, the Beacon 110 must be ordered with this feature. Consult RKI Instruments, Inc. for ordering

information.

The battery charging circuit is designed to charge lead acid type batteries. If AC power is used as

primary power and a backup battery is connected to the Beacon 110’s EXT DC/24V BATT terminals

as shown in Figure 8 on page 19, the battery charging feature will charge the battery if it is depleted

and keep it charged with a charge current of approximately 100 mA.

CAUTION: When a battery is used as backup power and the charging feature is included in the

Beacon 110, do not use a non-rechargeable battery or backup battery that has a

charging feature. Use RKI backup battery 49-8102RK or an appropriately rated 24

VDC rechargeable lead acid type battery.

26 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Alarm Indications

NOTE: The Beacon 110 includes alarm on and alarm off delay settings for alarm 1 and alarm 2. The

alarm indications described in this section operate according to the factory set alarm

settings. See Table 7 on page 32 for all the factory settings.

Table 6: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

1

Alarm 1

Alarm 2

Fail • Disconnected or misconnected

Increasing (decreasing for O

ing at or above the alarm 1 setpoint

1

Increasing gas reading at or above the

alarm 2 setpoint

detector head wiring

• Display reading at -10% of full

scale or lower

• Defective components

) gas read-

2

• Alarm 1 LED is on

• Gas reading alternates with

ALARM-1 message

• If installed and set to activate

for alarm 1, strobe flashes

• Alarm 2 LED is on

• Gas reading alternates with

ALARM-2 message

• If installed and set to activate

for alarm 2, strobe flashes

• Fail LED is on

• FAI L message replaces gas

reading

• If installed, strobe flashes

NOTE: There is a 30

second delay on the fail indications.

Low Power DC power source less than 18.5 volts. • Fail LED is on

• LowPower message and

actual voltage of incoming DC

power

Audible

Indication

•Pulsing

tone

•Pulsing

tone

• Steady

tone

•None

1

If the Beacon 11 0 is in both an ala rm 1 and an alarm 2 condition, both alarm LEDs are on and the

*

display alternates between the gas reading and the ALMS 1&2 message.

NOTE: You can select normally energized (N. EN) or normally de-energized (N. DE-EN) alarm 1

and alarm 2 relay settings in Configuration Mode. The following sections describe the

standard factory setting for these relays which is N. DE-EN.

The fail relay is set as normally energized in the firmware and is not user-adjustable.

Beacon 110 Operator’s Manual 27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Alarm 1 Condition

Alarm 1 Condition Indications

When the gas reading reaches the alarm 1 setpoint, the Beacon 110 senses an alarm 1 condition. The

Beacon 110 alerts you to an alarm 1 condition as follows:

• The alarm 1 LED turns on.

• The gas reading alternates with the ALARM-1 message.

• The buzzer sounds a pulsing tone.

• The alarm 1 relay energizes.

• If the optional strobe is installed and set to operate for alarm 1, it flashes.

Responding to an Alarm 1 Condition

1. Follow your established procedure for a low level combustible or toxic gas condition or a

decreasing oxygen concentration condition.

2. Oxygen alarms are factory set as self-resetting and will automatically clear when the oxygen

reading rises above the alarm 1 setpoint.

3. Alarms for all other gas types are factory set as latching. After the gas reading falls below (or rises

above for oxygen) the alarm 1 setpoint, press the reset switch to reset the alarm 1 circuit. Resetting

the alarm 1 circuit silences the buzzer, turns off the alarm 1 LED, returns the LCD to the normal

operation screen, de-energizes the alarm 1 relay, and turns off the strobe if it is installed and set to

operate for alarm 1.

NOTE: If the reset switch is pressed while the Beacon 110 is in an alarm 1 condition, the buzzer will

be silenced and the alarm 1 LED will flash. If the strobe is installed and its alarm 1

operation is set to CanReset in Configuration Mode, the strobe will turn off.

You cannot de-energize the alarm 1 relay until the gas reading falls below (above for

oxygen) the alarm 1 setpoint.

Alarm 2 Condition

Alarm 2 Condition Indications

When the gas reading reaches the alarm 2 setpoint, the Beacon 110 senses an alarm 2 condition. The

Beacon 110 alerts you to an alarm 2 condition as follows:

• The alarm 2 LED turns on.

• The gas reading alternates with the ALARM-2 message.

• The buzzer sounds a pulsing tone.

• The alarm 2 relay energizes.

• If the optional strobe is installed and set to operate for alarm 2, it flashes.

NOTE: If the Beacon 110 is in both an alarm 1 and alarm 2 condition, both the alarm 1 and alarm 2

LEDs will be on, the gas reading will alternate with the ALMS 1&2 message, and both

alarm relays will energize.

28 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Responding to an Alarm 2 Condition

1. Follow your established procedure for a high level combustible or toxic gas condition or an

increasing oxygen concentration condition.

2. Oxygen alarms are factory set as self-resetting and will automatically clear when the oxygen

reading rises above the alarm 2 setpoint.

3. Alarms for all other gas types are factory set as latching. After the gas reading falls below the

alarm 2 setpoint, press the reset switch to reset the alarm circuit. Resetting the alarm circuit

silences the buzzer, turns off the Alarm 2 LED, returns the LCD to the normal operation screen,

de-energizes the alarm 2 relay, and turns off the strobe if it is installed and set to operate for alarm

2.

NOTE: If the reset switch is pressed while the Beacon 110 is in an alarm 2 condition, the buzzer will

be silenced and the alarm 2 LED will flash but all other indications will remain unchanged.

If the strobe is installed and its alarm 2 operation is set to CanReset in Configuration Mode,

the strobe will turn off.

You cannot de-energize the alarm 2 relay until the gas reading falls below the alarm 2

setpoint.

Fail Condition

Fail Condition Indications

The Beacon 110 indicates a fail condition for any of the following:

• The detector head wiring is disconnected or incorrectly connected.

• The display reading is -10% of full scale or lower.

When the Beacon 110 senses a fail condition, it alerts you as follows:

• The fail LED turns on.

• The gas reading is replaced by the FAIL message.

• The buzzer sounds a steady tone.

• The fail relay de-energizes.

• If installed, the strobe flashes.

NOTE: The fail alarm has a 30 second delay.

Responding to a Fail Condition

NOTE: A fail condition cannot be reset using the reset switch.

1. Verify that the detector head wiring is correctly and securely connected.

2. If the detector head includes a replaceable plug-in sensor, verify that the replaceable plug-in sensor

is properly installed.

3. If necessary set the zero reading for your detector head as described in “Calibration Mode” on

page 38.

Beacon 110 Operator’s Manual 29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Low DC Power Alarm

Low DC Power Alarm Indications

This section describes the audible and visual indications for a low DC power condition and suggests

response to a low DC power condition. This condition only applies when DC power is used as a

primary or backup power source.

The Beacon 110 senses a DC low power condition when the DC power source is 18.5 volts or less.

WARNING: While in a low power condition, the Beacon 110 is not an active gas monitor.

When the Beacon 110 senses a low DC power condition, it alerts you as follows:

• The fail LED turns on.

• The message LowPower is indicated on the top line of the LCD and the input voltage is displayed

on the bottom line of the LCD.

NOTE: The low DC power alarm cannot be cleared using the reset switch.

When the DC input voltage increases to 19.0 volts, the low DC power alarm is cleared and the Beacon

110 will begin its warm-up sequence.

Responding to a Low DC Power Condition

If DC power is the

1. For a temporary DC power source, disconnect primary DC power at the Beacon 110, then connect

a 24 VDC battery.

2. Determine and correct the cause of primary DC power loss.

When the DC power source rises above 19.0 volts, the Beacon 110 begins the warm up process.

3. Verify that the Beacon 110 enters normal operation after its warm-up sequence.

If DC power is the

1. If a non-rechargeable battery is used for backup, replace the battery.

2. Determine and correct the cause of primary AC power loss. When backup DC or primary AC

power is restored, the Beacon 110 begins the warm up process.

If the Beacon 110 was purchased with the battery charging feature, when AC power is restored, the

Beacon 110 charges the backup battery with a charge current of approximately 100 mA until it is

fully recharged. Charge time varies depending on the battery size and how much the battery was

depleted. Once the battery is fully charged, the Beacon 110 maintains the charge with the 100 mA

charge current.

3. Verify that the Beacon 110 enters normal operation after its warm-up sequence.

primary power source:

backup power source:

30 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Chapter 5: Configuration Mode

Enter

Config?

Overview

This chapter describes how to view and change Beacon 110 parameters using Configuration Mode. It

is accessed using the program buttons.

Configuration Mode includes a 5-minute time-out feature. If you do not press a control button for 5

minutes, the Beacon 110 automatically returns to normal operation.

NOTE: If the Beacon 110 returns to normal operation because of a time-out, it enters a warm-up

period just as it does when it is first turned on.

If you are installing a new Beacon 110, it has been set up at the factory. Use Configuration

Mode only if you want to change the Beacon 110’s setup. If you want to change the detector

type see “Chapter 6: Input Mode” on page 34.

Viewing & Changing Beacon 110 Parameters

1. While in normal operation, simultaneously press and hold the UP/YES and ENTER buttons for 5

seconds to enter Configuration Mode. Release the buttons when the following screen appears.

2. If you want to exit Configuration Mode, press and release the DOWN/NO button and the Beacon

110 will return to normal operation.

If you want to continue in Configuration Mode, press and release the UP/YES button. The target

gas and the full scale will be displayed for a few seconds before the first adjustable parameter, the

alarm 1 setpoint, is displayed.

3. If you want to change the currently displayed parameter, use the UP/YES and DOWN/NO buttons

to adjust it to the desired setting, then press ENTER to continue to the next parameter.

If the currently displayed parameter is OK, press the ENTER button to proceed to the next

parameter.

Table 7 lists the Beacon 110 parameters you can set. Table 7 also lists the factory set value for each

parameter.

Beacon 110 Operator’s Manual 31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Table 7: Configuration Parameters

Parameter

(Factory Set Value)

ALARM-1 (level)

See the Beacon 110 Detector Head

Specification Sheet for the detector

head installed

ALARM-1 (activation)

(Decrease for oxygen, Increase for all

other types)

ALARM-1 (relay action)

(N. DE-EN)

ALARM-1 (relay reset)

(SELF-RST for oxygen, LATCH for

all other channel types)

A1Strobe

(None if no strobe is installed, Non

Reset if a strobe is installed)

Description

The gas reading at which the Beacon 110 initiates an alarm 1 condition.

Indicates if the alarm 1 circuit is activated by gas readings increasing (Increase)

or decreasing (Decrease) to the ALARM-1 Level.

If set as N. DE-EN, the alarm 1 relay is de-energized in normal operation and

energizes when an alarm 1 condition is initiated.

If set as N. EN, the alarm 1 relay is energized in normal operation and de-energizes when an alarm 1 condition is initiated.

If set as LATCH, you must press the reset switch to reset the alarm 1 circuit

after the alarm 1 condition passes.

If set as SELF-RST, the Beacon 110 automatically resets the alarm 1 circuit

after the alarm 1 condition passes.

If set as None, there is no strobe operation.

If set as NonReset, it is not possible to turn off the strobe with the reset switch

while the Beacon 110 is in an alarm 1 condition.

If set as CanReset, the strobe can be turned off while the Beacon 110 is in an

alarm 1 condition by pressing the reset switch.

A1 OnDy (alarm 1 on delay)

(1 secs)

A1 OffDy (alarm 1 off delay)

(0 sec.)

ALARM-2 (level)

See the Beacon 110 Detector Head

Specification Sheet for the detector

head installed

ALARM-2 (activation)

(Increase)

ALARM-2 (relay action)

(N. DE-EN)

ALARM-2 (relay reset)

(SELF-RST for oxygen, LATCH for

all other channel types)

The amount of time the Beacon 110 delays activation of the alarm 1 circuit once

an alarm 1 condition is initiated.

The amount of time the Beacon 110 delays turning off the alarm 1 circuit once

an alarm 1 condition passes. This parameter appears only if the alarm 1 relay

reset setting is set to SELF--RST.

The gas reading at which the Beacon 110 initiates an alarm 2 condition.

Indicates if the alarm 2 circuit is activated by gas readings increasing (Increase)

or decreasing (Decrease) to the ALARM-1 Level.

If set as N. DE-EN, the alarm 2 relay is de-energized in normal operation and

energizes when an alarm 2 condition is initiated.

If set as N. EN, the alarm 2 relay is energized in normal operation and de-energizes when an alarm 2 condition is initiated.

If set as LATCH, you must press the ENTER button to reset the alarm 2 circuit

after the alarm 2 condition passes.

If set as SELF-RST, the Beacon 110 automatically resets the alarm 2 circuit

after the alarm 2 condition passes.

32 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Table 7: Configuration Parameters (Continued)

Parameter

(Factory Set Value)

A2Strobe

(None if no strobe is installed, Non

Reset if a strobe is installed)

A2 OnDy (alarm 2 on delay)

(2 min for oxygen, 1 secs for all other

channel types)

A2 OffDy (alarm 2 off delay)

(0 sec.)

ZeroSupp

(0.0% of the detection range in terms

of the detection units for carbon

dioxide channel types, 0.5% oxygen

for oxygen channel type, 2.0% of the

detection range in terms of the

detection units for all other channel

types)

FILTER

(5 secs)

Description

If set as None, there is no strobe operation.

If set as NonReset, it is not possible to turn off the strobe with the reset switch

while the Beacon 110 is in an alarm 2 condition.

If set as CanReset, the strobe can be turned off while the Beacon 110 is in an

alarm 2 condition by pressing the reset switch.

The amount of time the Beacon 110 delays activation of the alarm 2 circuit once

an alarm 2 condition is initiated.

The amount of time the Beacon 110 delays turning off the alarm 2 circuit once

an alarm 2 condition passes. This parameter appears only if the alarm 2 relay

reset setting is set to SELF-RST.

The zero suppression feature helps prevent “jumpy” readings near the fresh air

reading.

For example, if the zero suppression setting for a combustible detector is 2.0%

LEL, the Beacon 110 will display a reading of 0% LEL for gas readings from 2% LEL to 2% LEL.

The filter feature helps “smooth out” jumpy or noisy signals from the detector.

You can set the filter from 0 seconds to 60 seconds in 5 seconds increments.

The displayed gas reading is the average reading over the previous time period

defined by the filter setting. So if the filter is set to 5 seconds, the displayed gas

reading is the average over the past 5 seconds.

CAL Time

(15 mins)

The calibration time-out sets the amount of time after the last button push while

in Calibration Mode that the Beacon 110 will wait before returning to normal

operation. If the calibration time-out is set to 15 mins, then Beacon 110 will

return to normal operation automatically 15 minutes after the last button push.

4. When you have scrolled through all the adjustable parameters, SAVE IT? YES/NO appears on the

display.

5. To save the adjustments made, press and release the UP/YES button. Config Saved is indicated on

the display for a few seconds and the Beacon 110 returns to normal operation.

If you do not wish to save the adjustments, press and release the DOWN/NO button. The DO

OVER? YES/NO message will display. Press and release the DOWN/NO button. The ABORT?

YES/NO message will display.Press the UP/YES button to return to normal operation.

Beacon 110 Operator’s Manual 33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Chapter 6: Input Mode

Select

Input?

Overview

This chapter describes how to use Input Mode to select the Beacon 110’s detector head input type and

the gas type. The detector head input type determines whether a direct connect type or a 4 - 20 mA

type of detector head will be used and the gas type determines the target gas and detection range.

Input Mode includes a 5-minute time-out feature. If you do not press a button for 5 minutes, the

Beacon 110 automatically returns to normal operation.

NOTE: If the Beacon 110 enters normal operation because of a program time-out, it enters a warm-

up period just as it does when it is first turned on.

Selecting the Detector Head Input and Gas Type

1. While in normal operation or during the warm-up sequence, press and hold the UP/YES and

DOWN/NO buttons for five seconds. Release them when the following screen appears.

2. If you want to exit Input Mode, press and release the DOWN/NO button. The Beacon 110 will

indicate NO CHANGE and return to normal operation without making any changes to the

detector head input type or gas type.

If you want to continue in Input Mode, press and release the UP/YES button. The top display line

will indicate Input? and the bottom display line will indicate the detector head input type choice.

3. Use the DOWN/NO button to scroll through the choices of input types. Table 8 below lists the

choices of input type for the Beacon 110.

34 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Table 8: Beacon 110 Detector Head Input Types

Detector Head Input Type Description

OXY DIR An OXY DIR detector head is an oxygen detector head in which the

oxygen detector is wired to the Beacon 110 with 2 wires using the

OXY GRN and WHT terminals from the detector/transmitter terminal

strips. All calibration adjustments are made at the Beacon 110.

TOX DIR A TOX DIR detector head is connected to the Beacon 110 with 2

wires using the AMP + and S terminals from the detector/transmitter

terminal strips. All calibration adjustments are made at the Beacon

110.

LEL DIR An LEL DIR detector head is a combustible gas detector head in

which the combustible gas detector is wired to the Beacon 110 with 4

wires using the LEL BLK, GRN, WHT, and RED terminals from the

detector/transmitter terminal strips. All calibration adjustments are

made at the Beacon 110.

4 - 20 mA A 4 - 20 mA detector head is connected to the Beacon 110 with 2 or 3

wires, depending on the detector head model, using the AMP +, S, and

- terminals on the detector head terminal strip. All calibration adjustments are made at the detector head.

4. When the desired detector head input type is on the display, press and release the UP/YES button.

The display will ask SAVE IT? YES/NO.

5. If you want to discard the detector head input type change, press and release the DOWN/NO

button. The display will ask DO OVER? YES/NO. Press the DOWN/NO button. The display will

ask ABORT? YES/NO. Press the UP/YES button. The display will indicate Aborting INPUT

and then NO CHANGE before indicating Select GasType?.

NOTE: If your Beacon 110 is configured as direct connect oxygen and the detector head input type

selection is aborted, the Beacon 110 will return to normal operation after indicating NO

CHANGE.

If you want to save the input type selection, press and release the UP/YES button. The display will

indicate Input Updated for a few seconds if you changed the input type and then the display will

indicate Gas Type? on the top display line and the gas type choice on the bottom display line. If

you did not change the input type from the current type, the display indicates NO CHANGE and

then Select GasType?.

NOTE: If you selected OXY DIR, the Beacon 110 will enter Configuration Mode after pressing and

releasing the UP/YES button since the gas type and full scale are pre-defined for a direct

connect oxygen type input. Skip to step 10.

Beacon 110 Operator’s Manual 35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

6. If you changed the input type above, you must select a gas type. Proceed to step 7.

If you did not change the input type, you can decide if you want to select the gas type. If you do

not want to select the gas type, press and release the DOWN/NO button. The display will indicate

NO CHANGE and the Beacon 110 will return to normal operation with the previous setup. If you

do want to select the gas type, press the UP/YES button and the display will indicate GasType? on

the top display line and the gas type choice on the bottom display line.

7. Use the DOWN/NO button to scroll through the choices of gas types. When you come to the

desired choice, press the UP/YES button to select it.

If you selected one of the defined gas types such as OXYGEN or CO, the display will ask SAVE

IT? YES/NO. Proceed to step 8.

If you selected the OTHER gas type, the display will indicate GAS NAME on the top display line

and bottom line will be blank with the cursor flashing in the far left. Proceed to step 9.

8. If you did not change the input type above and want to discard the gas type selection, press and

release the DOWN/NO button. The display will ask DO OVER? YES/NO. Press the DOWN/NO

button. The display will ask ABORT? YES/NO. Press the UP/YES button. The display will

indicate Aborting Gas Type, then NO CHANGE and the Beacon 110 will return to normal

operation.

If you want to save the gas type selection, press and release the UP/YES button. The display will

indicate Gas Type Updated, show the target gas and the detection range for a few seconds, then

the Beacon 110 will enter Configuration Mode so that the parameter settings in Configuration

Mode can be verified or changed.

9. Perform the following steps to define the gas name, detection range, and units if you selected the

OTHER gas type.

• With GAS NAME on the top display line and the cursor flashing in the far left on the bottom

display line, use the UP/YES and DOWN/NO buttons to select a character for the first

character of the gas name and press ENTER to save it. The cursor will move to the next

position. Repeat this process until the last character is saved.

• The display will ask SAVE IT? YES/NO. Press and release the UP/YES button. The display

will indicate RANGE . . . on the top display line prompting you to enter a full scale value

and the bottom line will be blank with the cursor flashing on the far left.

• Use the UP/YES and DOWN/NO buttons to enter a number for the first digit of the full scale

value and press ENTER to save it. The cursor will move to the next position. Repeat this

process until you have entered the full scale value, for example 30.0, leaving extra positions

blank before pressing ENTER.

• When you have pressed ENTER for the last time, the display will ask SAVE IT? YES/NO.

Press and release the UP/YES button. The display will indicate UNITS? on the top line and

the units choice on the bottom line of the display.

• Use the DOWN/NO button to scroll through the choices until you find the desired units. (If

you select the OTHER choice, perform the same procedure described above for entering the

gas name and range.)

• Press the UP/YES button to save the units. The Beacon 110 will proceed to Configuration

Mode.

36 Beacon 110 Operator’s Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

10. While in Configuration Mode press and release the ENTER button to accept the displayed

parameter setting and move to the next one. Use the UP/YES and DOWN/NO buttons to adjust a

setting. See “Chapter 5: Configuration Mode” on page 31 for a complete description of

Configuration Mode.

11. When you have reviewed and accepted the last item in Configuration Mode by pressing the

ENTER button, display will ask SAVE IT? YES/NO.

12. To save the configuration settings, press and release the UP/YES button.The display will indicate

Config Saved and the Beacon 110 will begin its warm-up sequence.

To discard the settings and review them again, press the DOWN/NO button. The display will ask

DO OVER? YES/NO. Press the UP/YES button and the display will indicate Re-do Config, then

display the target gas and the detection range for a few seconds before returning to Configuration

Mode. Repeat steps 6 - 8 until the settings are as desired.

13. After the Beacon 110 completes its warm-up sequence, the display will indicate CAL NEEDED,

the buzzer will sound a steady tone, the strobe (if installed) will flash, the fail relay will activate,

and the fail LED will turn on. Since the input type and/or gas type has been changed, a successful

calibration must be performed before the Beacon 110 can enter normal operation.

NOTE: If the input type was set as 4 - 20 mA, the Beacon 110 will enter normal operation since

calibration is done at the detector for a 4 - 20 mA type input.

14. Press and release the UP/YES button to enter Calibration Mode. Normally, you must hold the UP/

YES button for 5 seconds to enter Calibration Mode, but since a calibration is required, only a

momentary push is needed to enter Calibration Mode after changing the gas type.

15. See “Calibration Mode” on page 38 for calibration instructions.

NOTE: When calibrating a Beacon 110 after changing the gas type, the Beacon 110 will not ask if

you want to calibrate, or whether you want to perform a fresh air adjustment, span

adjustment or zero adjustment. Since a complete calibration is required, the calibration

sequence will proceed without asking if you want to perform certain operations.

Beacon 110 Operator’s Manual 37

Find Quality Products Online at: sales@GlobalTestSupply.com