Page 1

72-2102-07

Beacon 200

Operator’s Manual

Part Number: 71-0364

Revision: A

Released: 12/11/17

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before operating

instrument. Improper use of the 72-2102-07 Beacon 200 could

result in bodily harm or death.

Periodic calibration and maintenance of the 72-2102-07 Beacon

200 is essential for proper operation and correct readings. Please

calibrate and maintain this 72-2102-07 Beacon 200 regularly!

Frequency of calibration depends upon the type of use you have

and the sensor types. Typical calibration frequencies for most

applications are between 3 and 6 months, but can be required

more often or less often based on your usage.

72-2102-07 Beacon 200 Operator’s Manual

Page 3

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free

from defects in materials, workmanship, and performance for a period of

one year from date of shipment from RKI Instruments, Inc. Any parts found

defective within that period will be repaired or replaced, at our option, free

of charge. This warranty does not apply to those items, which by their

nature, are subject to deterioration or consumption in normal service, and

which must be cleaned, repaired, or replaced on a routine basis. Examples

of such items are as follows:

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repair procedures not in accordance with the operator’s

manual. This warranty indicates the full extent of our liability, and we are

not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF

RKI INSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF

ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR

OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized

distributors, dealers, and representatives as appointed by RKI Instruments,

Inc.

We do not assume indemnification for any accident or damage caused by

the operation of this gas monitor, and our warranty is limited to the

replacement of parts or our complete goods.

72-2102-07 Beacon 200 Operator’s Manual

Page 4

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the Beacon 200 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

External Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3: Installation and Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting the Beacon 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring the Beacon 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Starting Up the Beacon 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Recorder Output Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarm Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Viewing & Resetting Min/Max Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 5: Channel Control and Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Enable/Disable Channel(s) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Channel Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

View System Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

72-2102-07 Beacon 200 Operator’s Manual

Page 5

Chapter 6: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Calibration Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjusting Strobe/Horn Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacing Components of the Beacon 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

72-2102-07 Beacon 200 Operator’s Manual

Page 6

Chapter 1: Introduction

Overview

This chapter briefly describes the 72-2102-07 Beacon 200. This chapter

also describes the 72-2102-07 Beacon 200 Operator’s Manual (this

document). Table 1 at the end of this chapter lists the specifications for the

72-2102-07 Beacon 200.

About the Beacon 200

The 72-2102-07 Beacon 200 is a fixed-mounted, continuous-monitoring

gas detection instrument. This gas monitor is capable of detecting gas at

two locations. It includes an 8 foot AC power cord and 2 H

heads each on a user-defined length of cable.

S detector

2

The Beacon 200 displays the current gas readings on an LCD display

which is visible through the window in the cover (front face) and provides a

4 - 20 mA signal which indicates the target gas reading for use by a

recording device or programmable controller. Three sets of relay contacts,

two controlled by the gas alarms and one by the fail alarm, rated at 115

VAC 10 amps are available for controlling devices such as lights or horns

or for controlling higher rated relays. The alarm 1 relay is factory wired to

the strobe/horn and is not available for field use.

Two instrument programs allow you to display and change channel and

calibration settings. They are the Channel Control & Setup Program and

the Calibration Program.

1 • 72-2102-07 Beacon 200 Operator’s Manual

Page 7

About this Manual

!

The Beacon 200 Gas Monitor Operator’s Manual uses the following

conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in injury or

Caution: refer to accompanying documentation

death.

~ Vac (AC voltage)

Vdc (DC voltage)

72-2102-07 Beacon 200 Operator’s Manual • 2

Page 8

Specifications

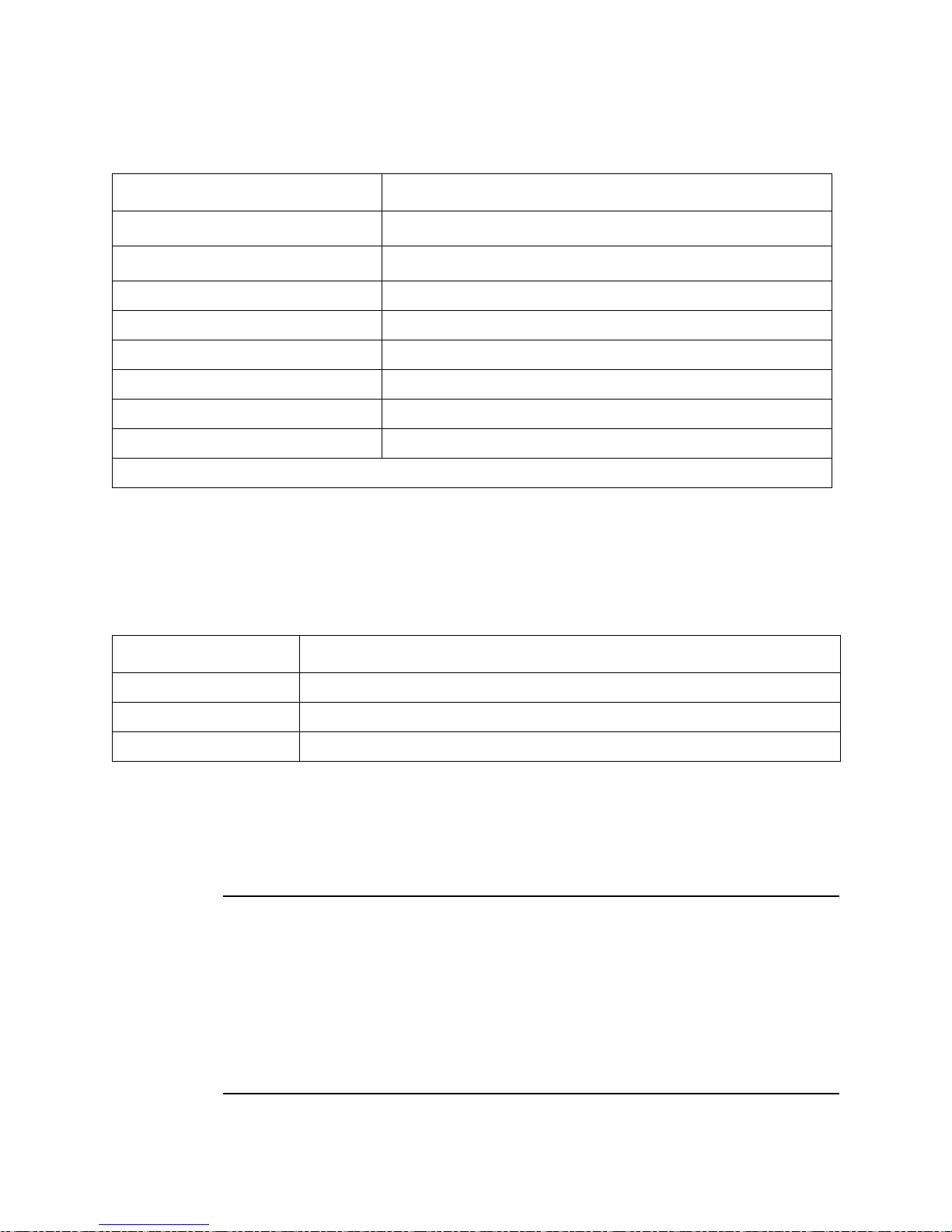

Table 1 lists specifications for the 72-2102-07 Beacon 200.

Description Specification

Table 1: 72-2102-07 Beacon 200 Specifications

Input Power

Construction (housing) Fiberglass/polyester with lexan window (NEMA 4X)

Controller Dimensions 21.0 in. H x 8.5 in. W x 7.00 in. D

Weight 20 lbs.

Environmental Conditions • -20°C to 50°C (-4°F to 122°F) max. ambient

Relays • Relay contacts rated for 10A @ 115/220V~ resistive or10A @ 30V

User Controls • Reset switch

Detection Range 0 to 100 PPM (parts per million) H

Alarm 1 Setpoint

Alarm 2 Setpoint

Response Time 90% in 30 seconds

115/220V ~ ±10%, 50/60Hz, 0.5/0.3A

or

24 V +10% -8%, 0.6A

(533 mm H x 216 mm W x 178 mm D)

• Maximum humidity of 80% relative

resistive

• SPDT Form C

• Program buttons: ESCAPE, UP/YES, DOWN/NO, and ENTER

2

10 ppm

2

50 ppm

1

S

2

Accuracy ± 5% of reading or ± 2 ppm H

1

The AC voltage input is factory set. The standard input is 115 V~.

*

2

*

The alarm setpoints shown are factory settings but they can be changed in the Channel Control and Setup

Program.

S (whichever is greater)

2

WARNING: When using the Beacon 200, you must follow the

instructions and warnings in this manual to assure

proper and safe operation of the Beacon 200 and to

minimize the risk of personal injury. Be sure to maintain

and periodically calibrate the Bea con 200 as de scribed in

this manual.

3 • 72-2102-07 Beacon 200 Operator’s Manual

Page 9

Chapter 2: Description

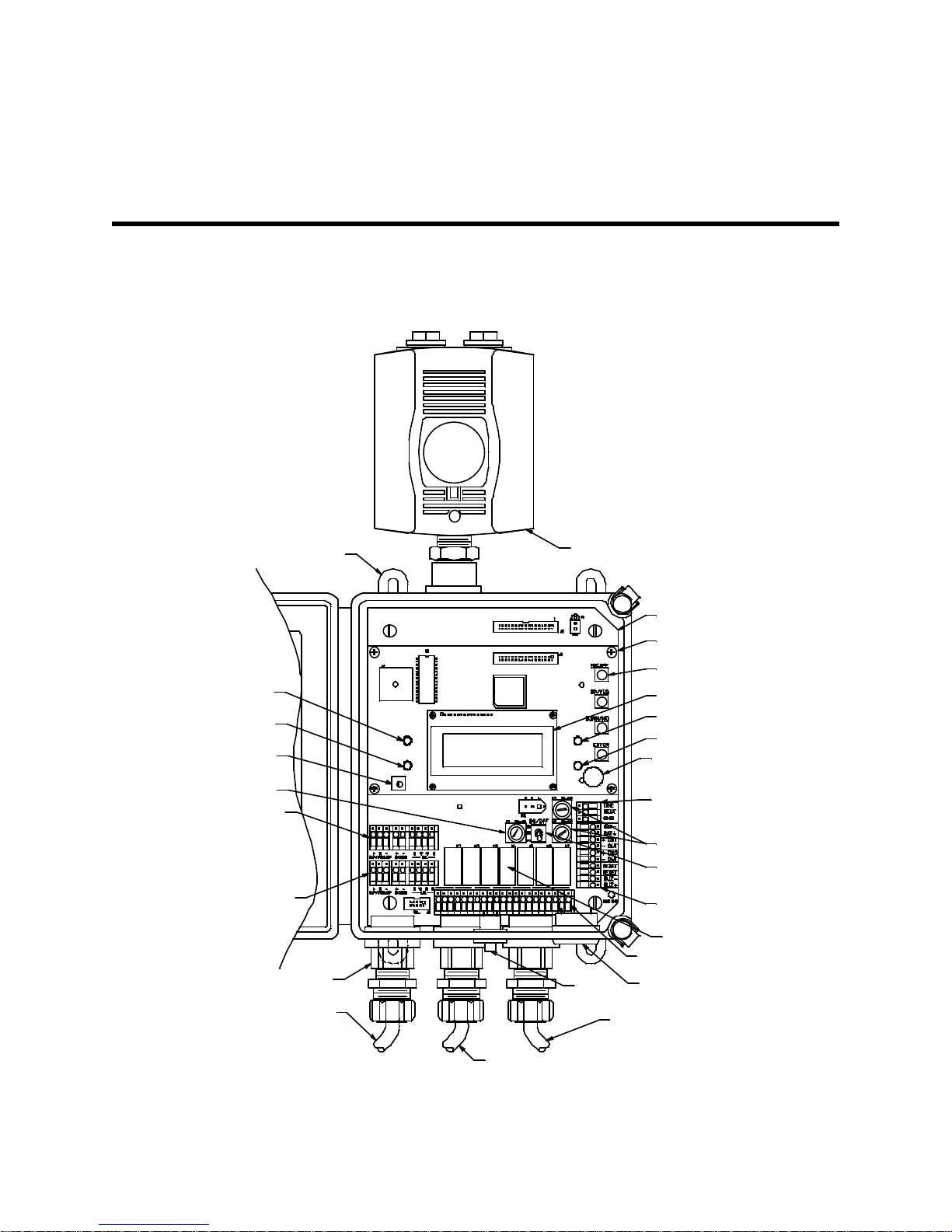

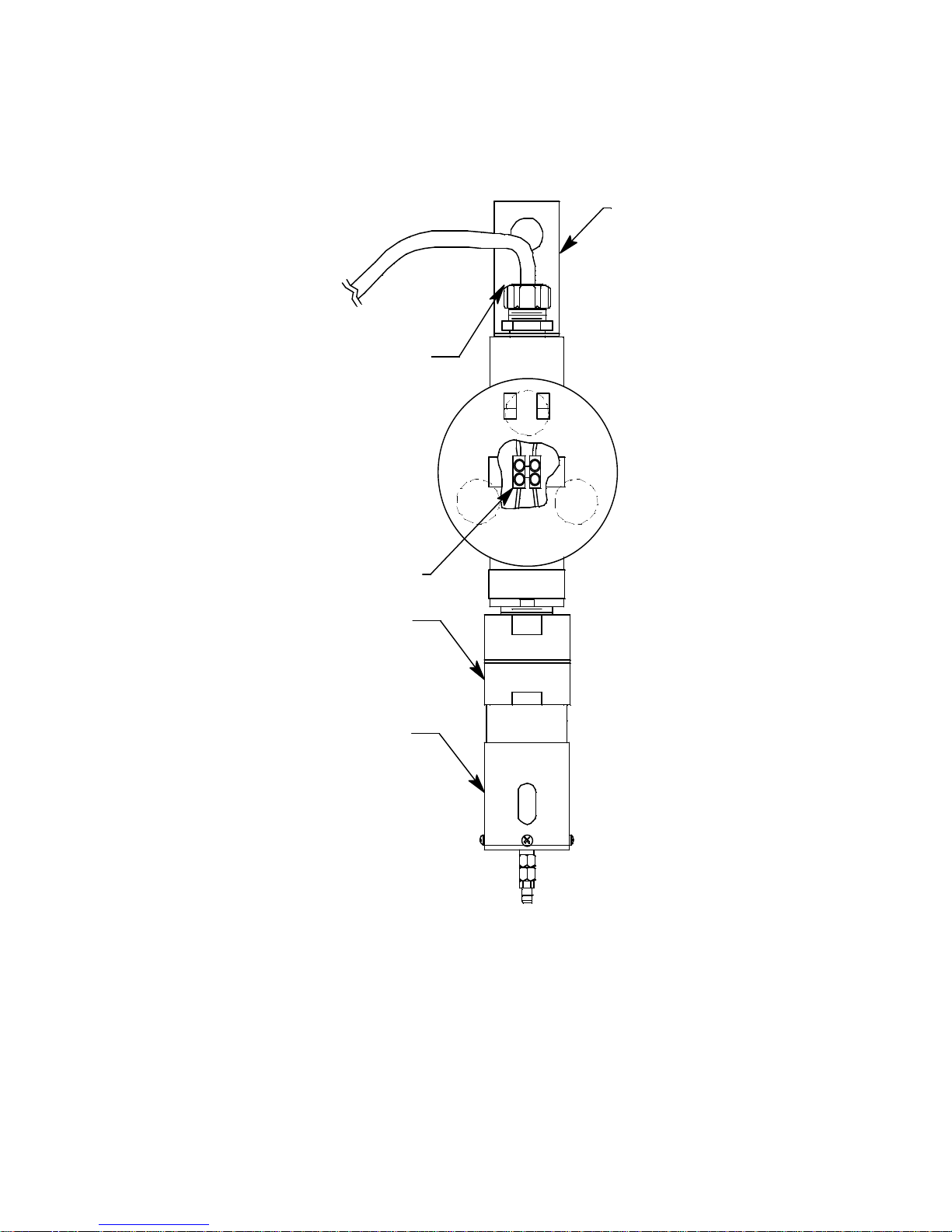

Figure 1. Beacon 200 Component Location

Buzz er

COM-FAIL

NON C C

CH2-A 1

NO NC CNONC C

COM-A1CH2-A2

NO NC C

CH1-A1

Main P CB

Display PC B

Program

Button (4)

AC In

Terminal

Stri p

Fuses, AC

Fail LED

Pilot LE D

NO NC C

COM-A2

Controller

Terminal Strip

Alarm Terminal S trip

Rela ys

Detector/

Transmitter

Terminal Strip,

Channel 1

Alarm

1LED

Display Contrast

Adjust Pot

Detector/

Transmitter

Terminal Strip,

Channel 2

Button

Repeater

Buzz er

Fuse, DC

MountingF oot, 4X

Horn/Strobe

AC PowerC ord

Reset

Switch

Conduit H ub ( 3X)

Power Switch

NON C CNO NC C

CH1-A2

Display

Alarm 2

LED

H2S Detector C able Channel 2 ( user-defined cablel ength)

H2S Det ector Cable Channel1

(user-defined cable length)

Overview

This chapter describes external and internal components of the Beacon

200.

72-2102-07 Beacon 200 Operator’s Manual • 4

Page 10

External Description

This section describes the housing and all external components of the

Beacon 200. For the purposes of this description, the housing door is

considered the front of the monitor.

Housing

The Beacon 200’s fiberglass housing is weather- and corrosion-resistant. It

is suitable for installation where general purpose equipment is in use. The

housing door is hinged on the left side and is secured by two latches on the

right side. The display screen and status lights are visible through windows

in the housing door. Four mounting feet are attached to the back of the

housing (one at each corner). The mounting feet allow you to install the

housing to a vertical surface. Three conduit hubs on the bottom of the

housing are for external wiring connections.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason.

CAUTION: To avoid electrical interferen ce, do not r oute detec tor head a nd

power wiring thro ugh the same conduit hub.

Reset Switch

The reset switch is on the bottom of the housing. It is in front of the conduit

hubs. The reset switch serves three functions:

• Resets the alarm circuits for “latched” alarms after an alarm 1 or alarm 2

condition passes.

You can set each channel for latched or self-resetting alarms in the

Channel Control & Setup Program.

• Silences the buzzer during an alarm 1 or alarm 2 condition. You cannot

silence failure alarms.

• Displays and resets the minimum and maximum gas concentration

values.

Buzzer

The buzzer is on the bottom of the housing. It is on the far right. The buzzer

sounds audible alarms to warn you of gas alarms and instrument failures.

5 • 72-2102-07 Beacon 200 Operator’s Manual

Page 11

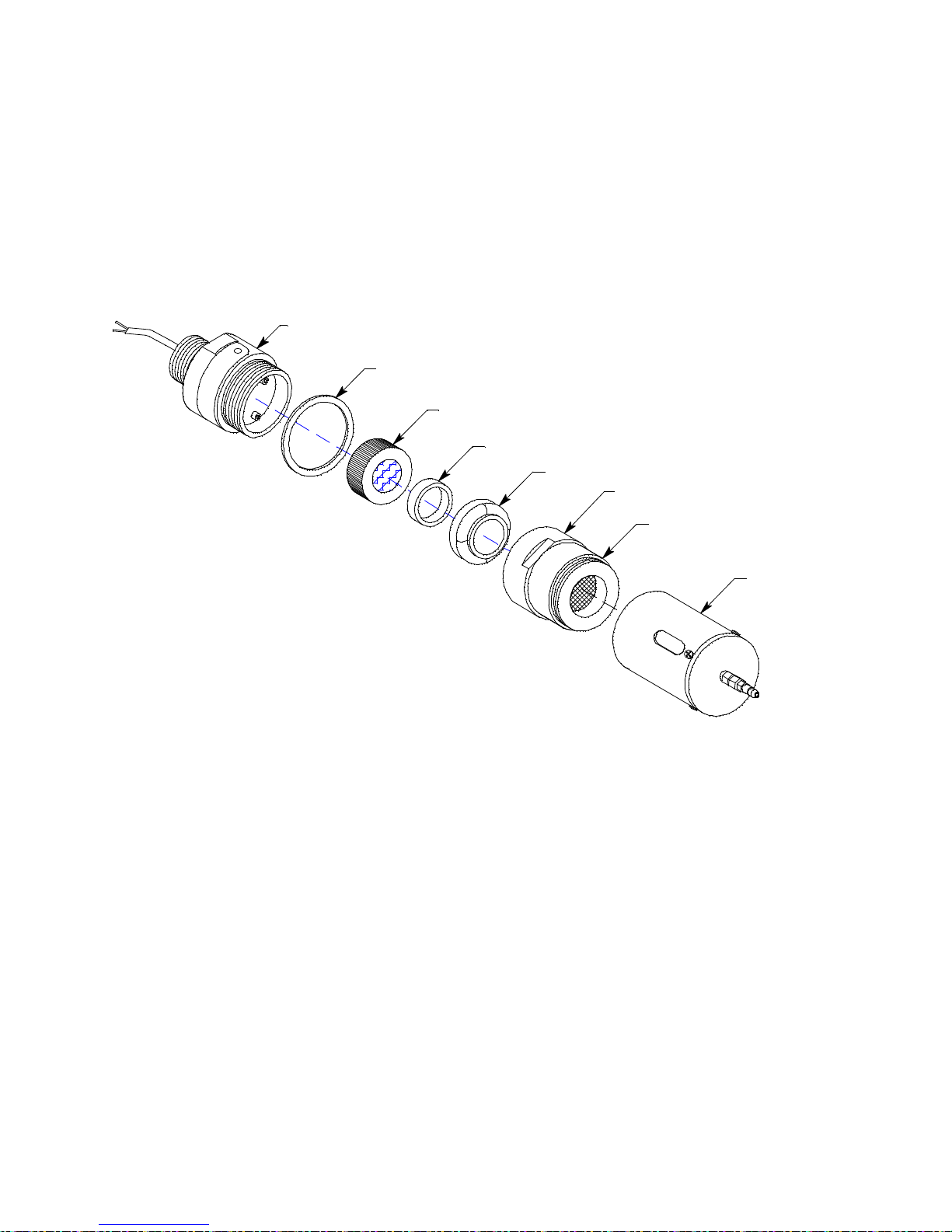

H2S Detector Junction Boxes and Cables

Cable Bushing

To Beacon 200

Mounting Bracket

H2S Detector

(FactoryWired )

Calibration Cup/

Splash Guard

Terminal Strip

Figure 2. H2S Junction Box Component Location

Each of the two H2S detectors consists of a junction box with a mounting

bracket, the detector, and the calibration cup/splash guard.

The two H

S detectors are factory wired through the left and middle cable

2

bushings of the Beacon 200 and has a user-defined length of cable for

remote installation. The mounting bracket at the top of each junction box is

used to mount the junction box. The junction box protects the detector

wiring connections. Three spacers installed on the back of the junction box

control the distance of the junction box from a mounting surface and

ensure that there is enough room to perform a calibration. A cover on the

front of the junction box allows access to the interior of the junction box.

72-2102-07 Beacon 200 Operator’s Manual • 6

Page 12

The detector housing body protects the sensing components within the

Cap Gasket

Detector HousingBody

Calibration Cup/

Splash Guard

Flame

Arrestor

Guard

Detector

HousingCap

H2S Plug-in Sensor

Rubber Boot

Spacer

Figure 3. H2S Detector Component Location

housing body. Use the removable cap near the bottom of the housing body

to access the sensor for maintenance or replacement. The cap protects the

sensor from damage and includes a flame arrestor which contains any

sparks which may occur within the detector housing body. A cap gasket

seals the interface between the housing body and cap. A flame arrestor

guard is permanently bonded to the cap.

The calibration cup/splash guard is screwed onto the bottom of the flame

arrestor guard.

The sensor is secured within the sensor housing by four pins. Through a

series of chemical and electrical reactions, the sensor produces an

electrical output that corresponds to the detection range of the detector. A

pre-amplifier, located between the sockets and two interconnect wires,

conditions the sensor’s signal before the signal reaches the controller. A

rubber boot and spacer are installed on the sensor face to ensure that the

sensor remains plugged into the detector housing body.

AC Power Cord

An 8 foot AC power cord is factory-wired through the right cable bushing of

the Beacon 200. One end of the cable is connected to the AC In terminal

strip.

7 • 72-2102-07 Beacon 200 Operator’s Manual

Page 13

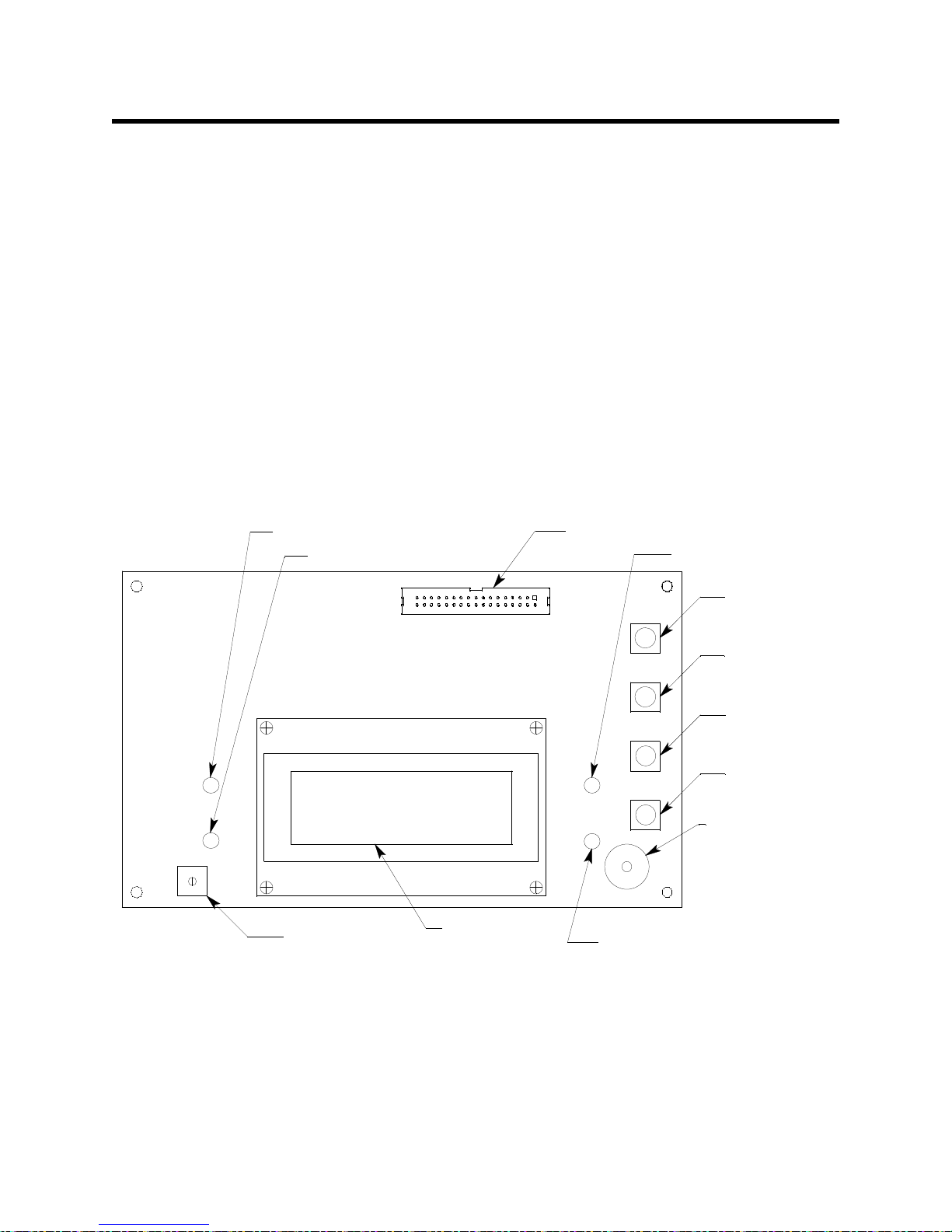

Internal Description

J1

UP/YES Button

ENTE R Button

DOWN/NO Button

Display Cable Connector

PILOT Light

FAIL Light

Displ ay Scree n

Button Repe ater

Buzzer

ALARM 2 Li gh t

ESCAPE Bu t to n

ALARM 1 Li gh t

Display Contrast

Adjust Pot

Figure 4. Display Board Component Location

This section describes the internal components of the Beacon 200. See

Figure 1 on page 4 for a view of the internal components.

Display Printed Circuit Board (PCB)

The display PCB is mounted to the power supply mounting plate which is in

turn mounted to the main PCB. The power supply mounting plate and main

PCB are described below. The display PCB includes the display, the status

lights, and the program buttons.

Display

The display simultaneously indicates the channel number, current gas

reading, measuring unit, and target gas of all active channels.

The display also indicates messages, settings, and other data when you

are operating the instrument programs.

72-2102-07 Beacon 200 Operator’s Manual • 8

Page 14

Status Lights

The Beacon 200 includes four status lights that indicate the current status

of the monitor. The status lights are to the left and right of the display (see

Figure 4).

• Pilot Light. The pilot light is on when the Beacon 200 is receiving

incoming power.

• Fail Light. The fail light turns on when the Beacon 200 is experiencing

a fail condition. A fail condition can be caused by a failure within the

Beacon 200 or detector head wired to the Beacon 200. See “Chapter 6:

Maintenance” on page 37 for instructions to respond to a fail condition.

• Alarm 1 Light. The alarm 1 light is on when the Beacon 200 is

experiencing an alarm 1 gas condition.

• Alarm 2 Light. The alarm 2 light is on when the Beacon 200 is

experiencing an alarm 2 gas condition.

Program Buttons

The Beacon 200 includes four program buttons that allow you to enter the

instrument programs, navigate through the programs, update instrument

and channel settings, and save changes to the program settings. When a

program button is pressed, a buzzer located on the display PCB beeps.

The program buttons are near the right edge of the display PCB (see

Figure 4).

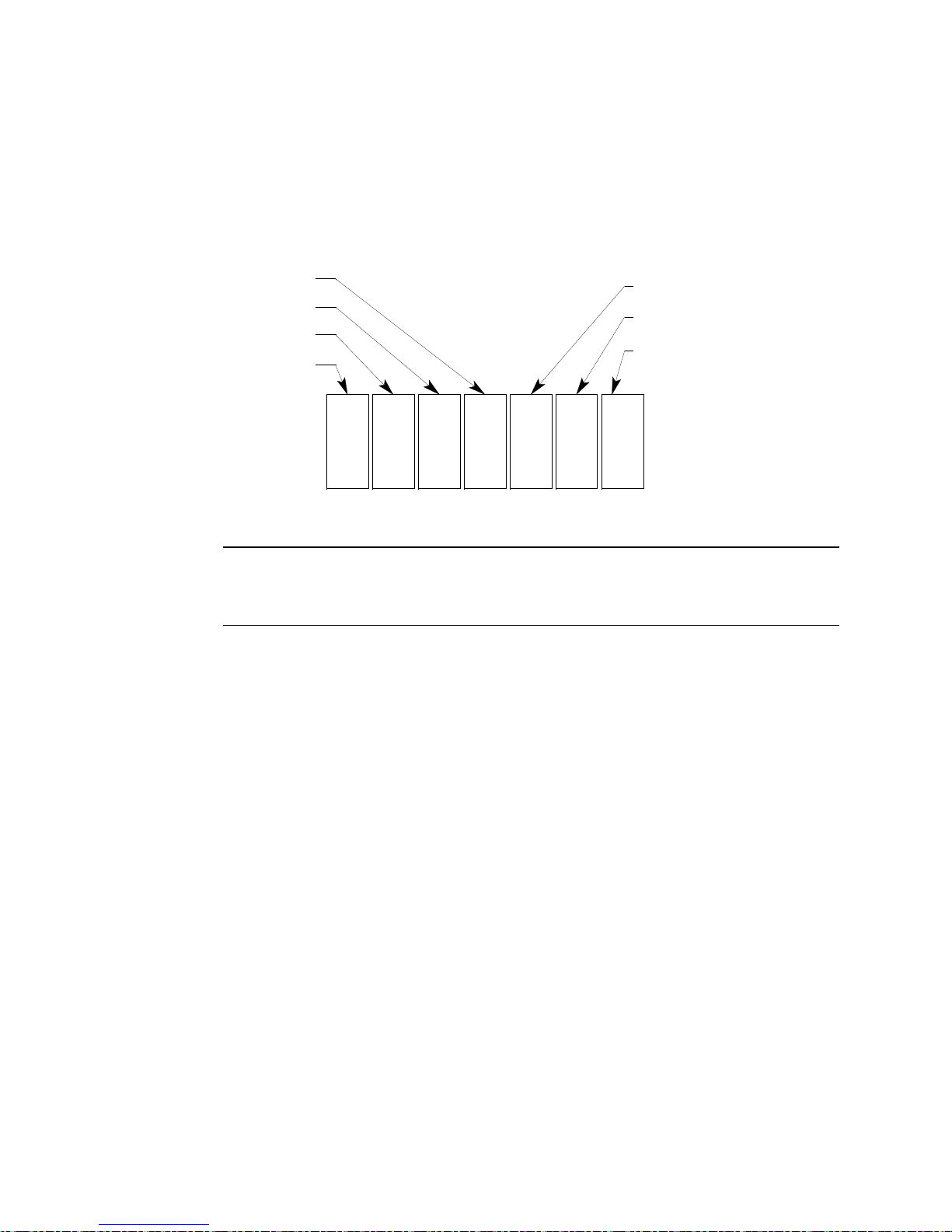

Table 2: Beacon 200 Program Button Functions

Button Function

ESCAPE • Moves backward through the program menus

• Cancels changes you make in the program menus

• Enters the Channel Control and Setup program (press with the ENTER button)

UP/YES • Accepts the displayed setting and proceeds to the next setting

• Changes the displayed setting

• Enters the Calibration program (press with the ENTER button)

DOWN/NO • Allows you to update the displayed setting

• Changes the displayed setting

ENTER • Saves changes you make in the programs

• Enters the Channel Control and Setup program (press with ESCAPE button)

• Enters the Calibration program (press with the UP/YES button)

9 • 72-2102-07 Beacon 200 Operator’s Manual

Page 15

Main PCB

The main PCB is mounted inside the housing. The power supply mounting

plate is mounted to the main PCB with four standoffs and the display PCB

is mounted to the power supply mounting plate with four standoffs. The

main PCB includes the terminal strips, relays, fuses, and power switch.

Terminal Strips

The Beacon 200 includes four terminal strips for external wiring

connections. See “Wiring the Beacon 200” on page 17 for detailed wiring

procedures.

• Detector/Transmitter Terminal Strips. Two detector/transmitter

terminal strips are located near the bottom left corner of the main circuit

board (see Figure 1). These two 9-point terminal strips facilitate wiring

connections to the detectors. Only one detector head at a time may be

wired per channel. The top terminal strip is for channel 1 and the bottom

terminal strip is for channel 2. The H2S detectors are factory wired to

these terminal strips.

• Alarm Terminal Strip. The alarm terminal strip is located along the

bottom edge of the main circuit board (see Figure 1). This 21-point

terminal strips facilitates wiring connections to external alarm devices

(horn, strobe, etc.). Terminals are provided for individual channels as

well as common alarm relay contacts. The horn/strobe is factory wired

to this terminal strip.

• Controller Terminal Strip. The 10-point controller terminal strip is near

the lower right edge of the main circuit board (see Figure 1). The

controller terminal strip facilitates various internal and external wiring

connections. Table 3 lists the function of each terminal.

72-2102-07 Beacon 200 Operator’s Manual • 10

Page 16

Table 3: Terminal Assignments for the Controller Terminal Strip

Terminal Connects to:

BAT -

BAT +

+ CH1 OUT + connection of 4 - 20 mA output, channel 1

- CH 1 OUT - connection of 4 - 20 mA output, channel 1

+ CH2 OUT + connection of 4 - 20 mA output, channel 2

- CH2 OUT - connection of 4 - 20 mA output, channel 2

RESET (2) Reset switch (factory-wired)

BUZ-/BUZ+ Internal buzzer (factory-wired)

1 If DC power is used as the primary power source, do not make wiring connections to the AC terminal strip.

- connection from 24 VDC power source

+ connection from 24 VDC power source

1

(or 24 V backup battery)

1

(or 24 V backup battery)

• AC In Terminal Strip. The AC In terminal strip is a 3-point terminal strip

located above the controller terminal strip (see Figure 1). It facilitates

wiring from the AC power source. The 8 foot AC power cord is factory

wired to this terminal strip. Table 4 lists the function of each terminal.

Table 4: Terminal Assignments for the AC In Terminal Strip

Terminal Connects to:

LINE Hot wire from AC power source.

NEUT Neutral wire from AC power source.

GND Earth ground

Relays

The Beacon 200 includes four channel relays (two per channel) and three

common relays. Both sets of relays are single-pole, double-throw (SPDT)

and are rated for 10 amps at 250 VAC (resistive).

NOTE: You can select normally energized (NE) or normally de-energized

(NDE) settings for each channel in the Channel Control and Setup

program. This section describes the default setting: normally deenergized.

The alarm 1 and alarm 2 common relays are factory-set as NDE

and the fail common relay is factory-set as NE. The alarm 1, alarm

2, and fail common relays’ NE/NDE settings are not useradjustable.

11 • 72-2102-07 Beacon 200 Operator’s Manual

Page 17

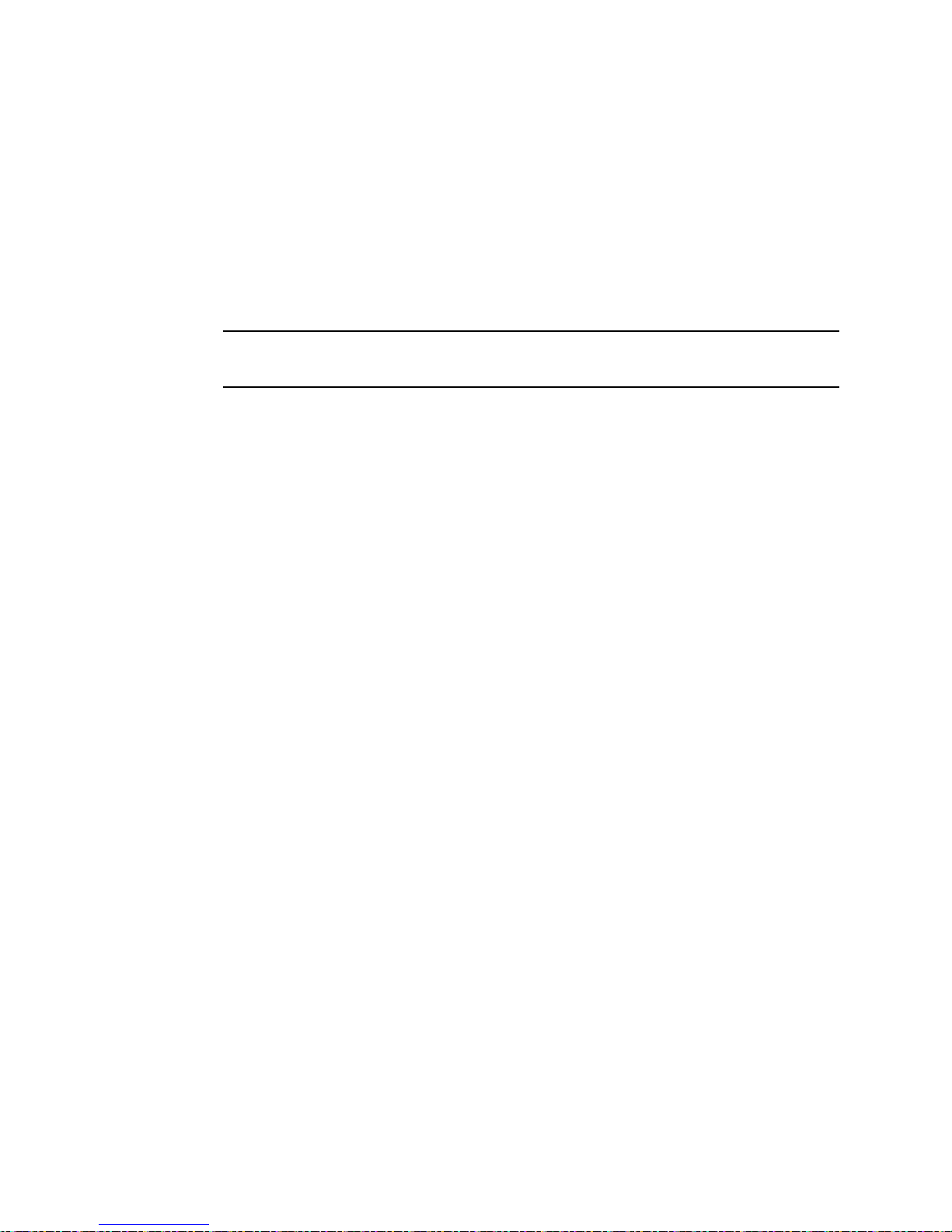

• Channel relays. The four channel relays are above the alarm terminal

K1 K2 K3

Common Alarm 1

Common Alarm 2

Common Fail

K5 K6 K7

K4

Channel 2 , Ala rm 2

Channel 2 , Ala rm 1

Channel 1 , Ala rm 2

Channel 1 , Ala rm 1

Figure 5. Beacon 200 Channel Relay Allocation

strip (see Figure 1). These relays are dedicated to specific channels

and alarm levels.

For example, the channel 1, alarm 1 relay energizes if channel 1

recognizes an alarm 1 condition. Figure 4 below illustrates the

allocation of the channel relays.

NOTE: The alarm 2 channel relays may be set to operate as individual

channel fail relays. See “Configure Channel Settings Menu” on

page 34 for instructions.

• Common relays. The three common relays, alarm 1, alarm 2, and fail,

are to the left of the controller terminal strip (see Figure 1). These relays

are common for both channels.

For example, the alarm 1 common relay energizes if either channel 1 or

channel 2 recognizes an alarm 1 condition. The common alarm 1 relay

is factory wired to the strobe/horn and is not available for customer use.

Fuses

There are three fuses that are used in the Beacon 200. Two of them are AC

fuses and one of them is a DC fuse.

• AC Fuses. The two fuses located directly to the left of the controller

terminal strip are the AC fuses. They cut off the incoming AC power in

the event of a short circuit or other electrical fault which causes a high

current draw in the Beacon 200. They are housed in vertical fuse

holders and are held in the holder by a quarter turn cover. They are

labelled as F2 (top fuse) and F3 (bottom fuse) on the PCB silk-screen

and are rated at 3 A, 250 V.

• DC Fuse. The fuse located to the left of the power switch is the DC

fuse. It cuts off incoming DC power in the event of a short circuit or

72-2102-07 Beacon 200 Operator’s Manual • 12

Page 18

other electrical fault which causes a high current draw in the Beacon

200. It is also housed in a vertical fuse holder and is held in the holder

by a quarter turn cover. It is labelled as F1 on the PCB silk-screen and

is rated at 6A, 250 V.

Power Switch

The power switch is located above the relays and to the left of the DC fuses

(see Figure 1). The power switch turns the incoming AC power source on

and off at the Beacon 200. When the switch is up, the power switch is on.

NOTE: The DC power input has no on/off switch and is not affected by the

position of this switch.

Power Supply

The power supply is mounted to the power supply mounting plate which is

located behind the display PCB. The power supply mounting plate is

mounted to the main PCB with four standoffs. The power supply receives

the AC input from the external power source and converts it to a DC

voltage that is usable by the Beacon 200 circuitry.

13 • 72-2102-07 Beacon 200 Operator’s Manual

Page 19

Chapter 3: Installation and Start Up

Overview

This chapter describes procedures to mount the Beacon 200, make wiring

connections to the monitor, and start up the monitor.

WARNING: Perform all installation and start-up procedures in a

“fresh air” environment (known to be free of combustible

gas, toxic gas, and of normal oxygen content). The

Beacon 200 is not in operation as a gas monitoring

system until the start-up procedure is complete.

Mounting the Beacon 200

Perform the following procedure to install the Beacon 200 at the mounting

site.

72-2102-07 Beacon 200 Operator’s Manual • 14

Page 20

Mounting

Feet, 4X

8.0 Max

Ø .31 x .50 slot, 4X

RESET

Buzzer

.41

3/4 Conduit

Hubs ( 3X)

3/4 Cable

Bushings (2X)

FAIL

PILOT

Reset

Switch

7.00

6.45

AL AR M 2

AL AR M 1

4.83

8.5 0

6.00

10.50

10. 94

BEACON 200

GAS MON ITOR

Figure 6. Beacon 200 Outline and Mounting Dimensions

1. Select the mounting site. When you select the mounting site consider

the following factors:

• Is an AC or DC power source available?

• Is there enough room to open the housing door and make wiring

connections through the conduit hubs at the bottom of the housing?

• Are the display screen and status lights visible?

15 • 72-2102-07 Beacon 200 Operator’s Manual

Page 21

2. Close and latch the housing door.

Figure 7. H2S Detector Outline and Mounting Dimensions

Det ector Cable

Channel 2

.75

Ø.75

14.2 Max

To Middl e

Cable

Bushing

1.50

Detector Cable

Channe l 1

To Lef t

Cable

Bushing

3. Position the monitor on a vertical surface at eye level (4 1/2 to 5 feet

from the floor).

4. The Beacon 200 is shipped with the mounting feet positioned behind

the housing. Loosen the screws that secure the feet to the housing,

rotate the feet to their mounting position (as shown in Figure 6), then

tighten the screws.

5. Insert 1/4 in. or 5/16 in. screws through the slots in the mounting feet at

each corner of the housing to secure the housing to the mounting

surface (see Figure 6).

6. Hang each H2S detector junction box using the mounting bracket.

Ensure that the detectors are facing down.

72-2102-07 Beacon 200 Operator’s Manual • 16

Page 22

Wiring the Beacon 200

Figure 8. Beacon 200 Factory Wiring Diagram

Strobe / H orn

To P1

To P2

AC

Power

Cord

BAT -

Main P CB

Po wer

Su pply

CH2

OUT

RESET

+S +

LELOXYGENAMP/PREAMP

NO N C C

BUZ +

+

CH1

OUT

+

RESET

COM- A1CH2- A2CH 2-A1

NONC C N ON C CN ON C C

Channel 2

Channel 1

BlackRed

+S +

OXYGENAMP/PREAMP LEL

BlackRed

Bu zzer

BUZ

+V

V+AD J

L(AC)

N(AC)

G(AC)

COM

COM

GND

NEUT

LINE

COM- FAILCOM- A2

NO NC C

Detector Wiring

RWG B

+V

Detector

Cabl e

Conduit Hub s

NOTUSED NOT USED

Detector

Cabl e

RWG B

NO NC C

Reset Switch

CH1- A2

Alarm Relay Wiring

NO N C C

CH1-A1

BAT +

The detector leads, junction box connections, and strobe/horn wiring are all

factory wired.

17 • 72-2102-07 Beacon 200 Operator’s Manual

Page 23

WARNING: Make all connections to the Beacon 200 before you

connect the DC power source. Before you make any

wiring adjustments, always verify that all power sources

are not live.

Routing Wiring Into the Beacon 200 Housing

Wiring must be brought into the housing through one of the three factoryinstalled conduit hubs on the bottom of the housing.

Do not drill into the Beacon 200 housing for any reason. Drilling the Beacon

200 housing and routing wiring through holes not factory drilled will void the

warranty and could result in:

• Damage to internal components from the drilling process.

• Moisture damage to internal components from poorly sealed holes.

• Unpredictable Beacon 200 behavior due to EMI/RFI interference

caused by wires routed across the PCBs.

• Possible shorting of Beacon 200 components due to wires routed

across the PCBs.

Connecting the AC Power Source

NOTE: If you are using DC power as the primary power source, go to the

next section, “Connecting the DC Power Source.”

The 8 foot AC power cord is routed through the right-hand cable bushing

on the bottom of the housing and is factory wired to the AC In terminal strip.

Additional wiring is not necessary.

Connecting the DC Power Source

WARNING: V erify that the power source is unplugged or turned off at

the power source end before you continue with this

procedure.

DC power may be used as a primary power source. It may also be used as

a backup power source with a 24 VDC battery if AC power is the primary

power source. If DC power is the primary power source, DO NOT connect

AC power.

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door, then place the power switch in the OFF

position. Locate the DC power terminals on the controller terminal strip

72-2102-07 Beacon 200 Operator’s Manual • 18

Page 24

(see Figure 1). They are labelled BAT - and BAT +

+

24 VDC ± 2.5 VDC

BAT

BAT +

Controller Terminal Strip

Figure 9. DC Power Wiring

3. Install an appropriately rated cable bushing or conduit to one of the

unused conduit hubs on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 18 for more information.

4. Guide a DC power cord or wires through the selected conduit hub.

CAUTION: Do not route power and det ector head wiring through the same

conduit hub. The p ower wiring may disrupt the transmi ssi on of

the detector head signal to the monitor.

CAUTION: When a batter y is used as backup power, the Beacon 200

trickle charges the battery. Do not use a non-rechargeable

battery as backup power. Use RKI backup battery 49-8102RK

or an appropriately rate d re cha rg ea bl e le ad acid type battery.

5. Connect the DC wires to the controller terminal strip as shown in

Figure 7.

NOTE: If a 24 VDC battery is used as a backup power source, as long as

AC power is on the Beacon 200 will keep a trickle charge on the

battery to maintain its charge. If AC power is interrupted, the

Beacon 200 will operate from the DC backup battery until the

battery voltage drops to 21.5 volts or less, or until AC power is

restored. Battery recharge time will vary depending on how much

the battery was drained.

19 • 72-2102-07 Beacon 200 Operator’s Manual

Page 25

Connecting External Alarms

CNCNO

CH 1-A1

Beacon 200 Alarm

Terminal Strip

(-) N

External

Power

Source

(+) H

Ex te rn al Alar m D ev i ce

Figure 10. Typical External Alarm Wiring, Single Device

Perform the following procedure to connect external alarm devices to the

Beacon 200. The common alarm 1 terminals are factory wired and are not

available for field use.

NOTE: The alarm terminal strip includes terminals for channel alarms

and common alarms. Channel alarms are activated by one

particular channel. Common alarms are activated by either of the

two channels.The example used in this procedure describes

connecting an external alarm device to one of the channel alarm

terminals: the channel 1, alarm 1 terminals.

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door, then place the power switch in the OFF

position. Locate the alarm terminal strip (see Figure 1).

3. Guide the wiring of the external alarm device through the cable bushing

on the right-most conduit hub on the bottom of the Beacon 200 housing.

The power wiring should already be installed through this cable

bushing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 18 for more information.

4. Connect the leads from the external alarm device and power to the

alarm terminals as shown in Figure 10.

72-2102-07 Beacon 200 Operator’s Manual • 20

Page 26

5. Repeat steps 4 and 5 for additional external alarm devices.

NO NC C NO NC C NO NC CNO NC CNO NC C

COM-A1 COM-A2 COM-FAILCH1-A 2 CH2-A1 CH2-A2

Alarm Devices

Alarm

Device

Power

Alarm

Terminal Strip

NO NC C

NO NC C

CH1-A 1

Contact Rating of 10 Amps at 115/220 V~ Resistive or

10A @ 30V Resistive for Each Set of Alarm RelayContacts.

Figure 11. Typical External Alarm Wiring, Multiple Devices

Connecting a Recorder

Perform the following procedure to connect an analog recording device to

the Beacon 200. The output at the recorder output terminals is a 4 - 20 mA

signal that is proportional to the detection range of the applicable detector

head.

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door, then place the power switch in the OFF

position. Locate the recorder output terminals on the controller terminal

strip (see Figure 1).

21 • 72-2102-07 Beacon 200 Operator’s Manual

Page 27

3. Guide the wiring from the recording device through the cable bushing

+

+

CH2

OUT

CH1

OUT

+

RecordingDevice#2,

1Kohm Max

Impedance

RecordingDevice#1,

1Kohm Max

Impedance

+

Figure 12. Recorder Output Wiring

on the right-most conduit hub on the bottom of the Beacon 200 housing.

The power wiring should already be installed through this cable

bushing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 18 for more information.

4. Connect the wires from the recording device to the recorder output

terminals as shown in Figure 12.

72-2102-07 Beacon 200 Operator’s Manual • 22

Page 28

Starting Up the Beacon 200

Perform the following procedure to place the Beacon 200 into normal

operation.

1. Complete the mounting and wiring procedures described earlier in this

chapter.

2. Verify that all wiring connections are correct and secure and that the

Beacon 200’s power switch is in the OFF position.

3. Plug in or turn on the incoming power source (AC or DC) at the power

source end.

4. Place the Beacon 200’s power switch in the ON position. RKI

INSTRUMENTS BEACON 200 appears on the display for a few

seconds, then WARMING UP appears for each active channel. The

warm-up period will last for one minute.

NOTE: To prevent unwanted alarms during warm up, the alarm circuits

are not active while the WARMING UP message is displayed.

5. Verify that the PILOT light is on. If the PILOT light is not on, see

“Troubleshooting” on page 49.

6. The H2S detectors will begin operating once power is introduced to the

Beacon 200.

23 • 72-2102-07 Beacon 200 Operator’s Manual

Page 29

Chapter 4: Operation

1: 0 ppm H2S

2: 0 ppm H2S

Overview

This chapter describes the Beacon 200 in normal operation. This chapter

also describes the Beacon 200 in alarm 1, alarm 2, and fail conditions and

suggests responses to these conditions.

Normal Operation

Normal operation is defined as follows:

• The start-up procedure is complete.

• The Beacon 200 is not indicating an alarm 1, alarm 2, or fail condition.

• The Beacon 200 is not running the Channel Control & Setup or

Calibration Programs.

During normal operation, the Beacon 200 simultaneously displays the

current gas reading, unit of measure, and target gas for each active

channel.

The PILOT light is on during normal operation indicating that the Beacon

200 is receiving incoming power.

72-2102-07 Beacon 200 Operator’s Manual • 24

Page 30

Recorder Output Operation

The output at the recorder output terminals is a 4 - 20 mA signal for each

active channel that is proportional to the detection range of the channel. A

channel that is set as CHANNEL NOT USED or CHANNEL DISABLED in

the Channel Control & Setup Program (see “Chapter 5: Channel Control

and Setup Program” on page 32) has an output of 0 mA.

There are several special circumstances where the recorder output will

behave as follows:

• When a channel is in WARMUP after the Beacon 200 is turned on, the

recorder output will be at 4 mA.

• If the Beacon 200 is being powered by a battery and is in low battery

alarm, the recorder output for each channel will be 0 mA.

• When a channel is added or a channel type changed, the display will

indicate NEEDS CALIBRATION for that channel when the Beacon 200

is first turned on and will continue to indicate this until the channel is

calibrated. In this situation, the recorder output will be at 3.2 mA until

the channel is calibrated.

• If a channel goes into a fail condition, the recorder output will be 0 mA.

• If you enter any of the instrument programs, such as the Calibration

Program, the recorder output will hold at the value it was at when you

entered the program was entered until you return to normal operation.

25 • 72-2102-07 Beacon 200 Operator’s Manual

Page 31

Alarm Indications

This section describes the Beacon 200 in alarm 1, alarm 2, and fail

conditions and suggests response to these conditions. Table 5 below lists

the alarm indications for each condition.

NOTE: The Beacon 200 includes alarm on and alarm off delay settings for

each channel and level of gas alarm. The alarm indications

described in this section operate according to the factory set delay

settings. See “Configure Channel Settings Menu” on page 34 for

all the factory settings.

Table 5: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

Alarm 1

Alarm 2

Fail • Disconnected or misconnected

Low Battery

*1If the Beacon 200 is in both an alarm 1 and an alarm 2 condition, both alarm lights are on and the display

*

1

1

alternates between the gas reading and the ALARM-1 ALARM-2 messa ge.

2

If DC power is use d as primary or backup power source.

Increasing gas reading at or above the

alarm 1 setpoint

Increasing gas reading at or above the

alarm 2 setpoint

detector wiring

• Display reading below -10% of full

scale or lower

• Defective components

2

No AC power and DC power source

(primary or backup) less than 21.5 volts.

• ALARM 1 light is on

• Gas reading flashes and

alternates with ALARM-1

message

• Strobe/horn turns on

• ALARM 2 light is on

• Gas reading flashes and

alternates with ALARM-2

message

• FAIL light is on

• FAIL message flashes in

place of gas reading

• FAIL light is on

• SUPPLY VOLTAGE IS TOO

LOW LOW POWER

STANDBY message and

actual voltage of incoming

DC power

Audible

Indication

Pulsing tone

Pulsing tone

Steady tone

None

72-2102-07 Beacon 200 Operator’s Manual • 26

Page 32

NOTE: You can select normally energized (NE) or normally de-energized

(NDE) channel relay settings in the Channel Control & Setup

menu. The following sections describe the default setting for the

channel relays which is NDE.

Common alarm 1 and alarm 2 relays are factory-set as NDE, and

the common fail relay is factory set as NE. The common relays’

NE/NDE settings are not user-adjustable.

Alarm 1 Condition

This section describes the audible and visual indications for an alarm 1

condition and suggests response to an alarm 1 condition.

Alarm 1 Condition Indications

When the gas reading of an active channel reaches the alarm 1 setpoint,

the Beacon 200 senses an alarm 1 condition. The Beacon 200 alerts you to

an alarm 1 condition as follows:

• The ALARM 1 light turns on.

• The gas reading in alarm 1 condition flashes and alternates with the

ALARM-1 message.

• The buzzer sounds a Pulsing tone.

• The common alarm 1 relay energizes and the strobe/horn activates.

• The applicable alarm 1 channel relay energizes.

Responding to an Alarm 1 Condition

This section suggests response to an alarm 1 condition.

1. Follow your established procedure for a low level H

S condition.

2

2. Alarms are latching. After the gas reading falls below the alarm 1

setpoint, press the reset switch to reset the alarm 1 circuit. Resetting

the alarm 1 circuit silences the buzzer, turns off the ALARM 1 light,

resets the channel display, de-energizes the common and channel

alarm 1 relays, and turns off the strobe/horn.

NOTE: To silence the buzzer while in an alarm 1 condition, press the

reset switch.

You cannot de-energize the alarm 1 relays and consequently the

strobe/horn until the gas reading falls below the alarm 1 setpoint.

27 • 72-2102-07 Beacon 200 Operator’s Manual

Page 33

Alarm 2 Condition

This section describes the audible and visual indications for an alarm 2

condition and suggests response to an alarm 2 condition.

Alarm 2 Condition Indications

When the gas reading of an active channel reaches the alarm 2 setpoint,

the Beacon 200 senses an alarm 2 condition. The Beacon 200 alerts you to

an alarm 2 condition as follows:

• The ALARM 2 light turns on.

• The gas reading in alarm 2 condition continues to flash and alternates

with the ALARM-2 messages.

• The buzzer sounds a Pulsing tone.

• The common alarm 2 relay energizes.

• The applicable alarm 2 channel relay energizes.

Responding to an Alarm 2 Condition

This section suggests response to an alarm 2 condition.

1. Follow your established procedure for a high level H2S condition.

2. Alarms are latching. After the gas reading falls below the alarm 2

setpoint, press the reset switch to reset the alarm circuit. Resetting the

alarm circuit turns off the ALARM 2 light, and de-energizes the common

and channel alarm 2 relays.

NOTE: To silence the buzzer while in an alarm 2 condition, press the

reset switch.

You cannot de-energize the alarm 2 relays until the gas reading

falls below the alarm 2 setpoint.

Fail Condition

This section describes the audible and visual indications for a fail condition

and suggests response to a fail condition.

Fail Condition Indications

The Beacon 200 senses a fail condition for any of the following:

• The detector head wiring to the Beacon 200 is disconnected or

incorrectly connected.

• The detector head’s detector is disconnected or incorrectly connected.

72-2102-07 Beacon 200 Operator’s Manual • 28

Page 34

• The display reading is -10% of full scale or lower.

• The Beacon 200 or detector head is malfunctioning.

When the Beacon 200 senses a fail condition, it alerts you as follows:

• The FAIL light turns on.

• The gas reading for the failing channel is replaced by the FAIL

message.

• The buzzer sounds a steady tone.

• The common fail relay de-energizes.

NOTE: If you elected to use the channel’s alarm 2 relay as an individual

fail relay in the Channel Control & Setup menu, the relay deenergizes in a fail condition. See “Chapter 5: Channel Control and

Setup Program” on page 32 for a description of this setting.

Responding to a Fail Condition

This section suggests response to a fail condition.

1. Verify that the detector head wiring to the Beacon 200 is correctly and

securely connected.

2. Verify that the detector head’s detector is correctly and securely

connected.

3. See the troubleshooting guide in the detector head instruction manual.

Low Battery Condition

This section describes the audible and visual indications for a low battery

condition and suggests response to a low battery condition. This condition

only applies when DC power is used as a primary or backup power source.

NOTE: When a 24 VDC battery is used as a backup power source, the

Beacon 200 keeps the battery charged by providing a trickle

charge from the AC power source. If AC power is interrupted, the

Beacon 200 will operate from the DC backup battery until the

battery voltage drops to 21.5 volts or less, or until AC power is

restored.

29 • 72-2102-07 Beacon 200 Operator’s Manual

Page 35

Low Battery Condition Indications

The Beacon 200 senses a low battery condition when:

• AC power is disconnected, misconnected, or interrupted

AND

• the DC power source is 21.5 volts or less

When the Beacon 200 senses a low battery condition, it alerts you as

follows:

• The FAIL light turns on.

• The top display screen displays the SUPPLY VOLTAGE IS TOO LOW,

LOW POWER STANDBY message and the actual voltage of incoming

DC power.

Responding to a Low Battery Condition

This section suggests response to a low battery condition.

• If DC power is the primary power source:

1. For a temporary DC power source, disconnect primary DC power at

the Beacon 200, then connect a 24 VDC backup battery.

2. Determine and correct the cause of primary DC power loss.

When the DC power source rises above 22.0 volts, the Beacon 200

begins the warm up process.

• If DC power is the backup power source:

1. Replace or recharge the 24 VDC backup battery to resume backup

power capability.

2. Determine and correct the cause of primary AC power loss.

When backup DC or primary AC power is restored, the Beacon 200

begins the warm up process. When AC power is restored, the Beacon

200 charges the backup battery until it is fully recharged. Charge time

varies depending on the battery size and how much the battery was

depleted. Once the battery is fully charged, the Beacon 200 reverts to

a trickle charge to maintain the battery charge.

72-2102-07 Beacon 200 Operator’s Manual • 30

Page 36

Viewing & Resetting Min/Max

Readings

The Reset switch may be used to view and reset the minimum and

maximum gas readings for the active channel(s).

1. While the Beacon 200 is in normal operation, press and hold the Reset

switch button for 3 seconds.

2. The display will indicate MIN / MAX Display Press RESET when done

viewing . . . for 5 seconds before displaying the minimum and

maximum readings for the active channel(s). The minimum reading is

on the left and the maximum is on the right side of the display for each

channel.

3. Press and release the Reset switch button to exit the min/max screen.

The display will indicate To RESET Min/MAX values Press and HOLD

RESET Button for 10 seconds and then return to normal operation.

• To return to normal operation without resetting the minimum and

maximum readings, do not press the Reset switch button and allow

the unit to return to normal operation.

• To reset the minimum and maximum readings, before the unit

returns to normal operation press and hold the Reset switch button

until the display indicates Min/Max Values Have Been Reset.

Release the Reset switch button.The unit will then return to normal

operation.

31 • 72-2102-07 Beacon 200 Operator’s Manual

Page 37

Chapter 5: Channel Control and Setup Program

Overview

The Channel Control & Setup Program allows viewing of and changes to

instrument setup parameters. It is accessed using the program buttons.

The Channel Control & Setup Program includes three menus as described

in Table 6.

Table 6: Channel Control & Setup Program Menus

Menu Function

Enable/Disable Channel(s) Configures channels as enabled, disabled, or not used

Configure Channel Settings Configures alarm settings, noise filter setting, and zero

suppression setting for each channel

View System Information Displays the firmware version number and the instrument

operating voltage

To enter the Channel Control & Setup Program, simultaneously press and

hold the ESCAPE and ENTER buttons for approximately 5 seconds.

The Channel Control & Setup Program menu includes a 5-minute time-out

feature. If you do not press a button for 5 minutes, the Beacon 200

automatically returns to normal operation.

NOTE: If the Beacon 200 returns to normal operation because of a

program time-out, the active channels enter a warm-up period just

as they do when the unit is first turned on.

If you are installing a new system, the channels have been setup

at the factory for the ordered detector heads. Use the Channel

Control & Setup Program only if you want to disable or enable a

channel, delete a channel, or change channel settings. If a

channel is being added or a channel is being changed from one

type to another, contact RKI Instruments, Inc. for additional

documentation required to define the channel type.

72-2102-07 Beacon 200 Operator’s Manual • 32

Page 38

Enable/Disable Channel(s) Menu

1. From normal operation, simultaneously press and hold the ESCAPE

and ENTER buttons for approximately 5 seconds to enter the Channel

Control & Setup Program. Release the buttons when the Control &

Setup Program Proceed? [YES] or [NO] message appears on the

display screen.

2. Press the UP/YES button to continue.

3. Press the UP/YES or DOWN/NO button until the 1) Enable/Disable

Channel(s) message appears on the display screen, then press the

ENTER button.

4. Use the UP/YES and DOWN/NO buttons to select the channel you

want to enable or disable, then press the ENTER button.

5. Press the DOWN/NO button. The CHANNEL USAGE setting displays

on the display screen.

6. Use the UP/YES and DOWN/NO buttons to display the setting you

want, then press the ENTER button to select the setting. The table

below describes the three available settings.

Table 7: Beacon 200 Channel Usage Settings

Setting Description

CHANNEL ENABLED The Beacon 200 displays gas readings and initiates gas and channel failure alarms

when appropriate.

Use this setting for normal operation when the channel has a detector head wired to

it.

CHANNEL DISABLED The Beacon 200 displays DISABLED for the channel and the channel’s alarm circuit

is not active.

Use this setting when the channel has a detector head wired to it, but gas readings

and alarms are not required for the channel (for example if the detector head requires

maintenance or is malfunctioning).

CHANNEL NOT USED The Beacon 200 leaves the channel blank on the display screen.

Use this setting when the channel does not have a detector head wired to it.

7. Press the ESCAPE button, then press the DOWN/NO button to return

to normal operation.

33 • 72-2102-07 Beacon 200 Operator’s Manual

Page 39

Configure Channel Settings

Con f iguration for

CHANNEL 1

has nbee

comple ted

eSav Se t t i ngs

?

[

Y

/N

]

Menu

This section describes how to view and change channel parameters for the

installed gas channels.

1. Simultaneously press and hold the ESCAPE and ENTER buttons for

approximately 5 seconds to enter the Channel Control & Setup

Program. Release the buttons when the Control & Setup Program

Proceed? [YES] or [NO] message appears on the display screen.

2. Press the UP/YES button to continue.

3. Press the UP/YES or DOWN/NO button until the 2) Configure Channel

Setting(s) message appears on the display screen, then press the

ENTER button.

4. Use the UP/YES and DOWN/NO buttons to select the channel for

which you want to set parameters, then press the ENTER button.

5. Press the UP/YES button until the parameter you want to set appears

on the display screen. The screen will display the current setting and

ask if it is OK.

Table 8 lists the parameters you can set for a channel. Table 8 also lists

the factory set value for each parameter.

NOTE: Use the ESCAPE button to go back to a previously displayed

parameter.

6. If the setting is not OK and you want to change the it, press the DOWN/

NO button. The parameter is now adjustable.

7. Use the UP/YES or DOWN/NO button to update the parameter, then

press the ENTER button to continue.

8. Repeat steps 5 through 7 to set any other channel parameters.

9. Press the UP/YES button until the following message appears on the

display screen.

72-2102-07 Beacon 200 Operator’s Manual • 34

Page 40

10.Press the UP/YES button to save the configuration. The screen will

then return to the Channel Control & Setup menu.

11.To view or change the Channel 2 settings, scroll to the Configure

Channels Menu and repeat steps 4 through 10.

12.To exit the Channel Control & Setup menu, press ESCAPE to return to

the screen which asks Control & Setup Program Proceed? [YES] or

[NO].

13.Press the DOWN/NO button to return to normal operation.

Table 8: Channel Setting Parameters

Parameter

(Factory-Set Value)

ALARM-1 Level

(10 ppm H

ALARM-1 ON DELAY

(1 sec)

ALARM-1 OFF DELAY

(0 sec)

ALARM-1 (activation)

(INCREASING)

ALARM-1 Relay (action)

(NORMALLY DE-ENERGIZED)

S)

2

Description

The gas reading at which the Beacon 200 initiates an alarm 1 condition.

The amount of time the Beacon 200 delays activation of the alarm 1

circuit once an alarm 1 condition is initiated.

The amount of time the Beacon 200 delays turning off the alarm 1 circuit

once an alarm 1 condition passes.

Indicates if the alarm 1 circuit is activated by gas readings INCREASING

or DECREASING to the ALARM-1 Level.

Note: Changing this parameter will affect the operation of the factory

installed strobe/horn. Do not change this parameter from the factory

setting.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 1 relay is de-

energized in normal operation and energizes when an alarm 1 condition

is initiated.

If set as NORMALLY ENERGIZED, the channel’s alarm 1 relay is

energized in normal operation and de-energizes when an alarm 1

condition is initiated.

Note: Changing this parameter will affect the operation of the factory

installed strobe/horn. Do not change this parameter from the factory

setting.

ALARM-1 Relay (reset)

(LATCHING)

ALARM-2 Relay (used for)

(ALARM-2 Condition)

ALARM-2 Level

(50 ppm H

ALARM-2 ON DELAY

(1 sec)

S)

2

35 • 72-2102-07 Beacon 200 Operator’s Manual

If set as LATCHING, you must press the RESET button to reset the

alarm 1 circuit after the alarm 1 condition passes.

If set as SELF RESETTING, the Beacon 200 automatically resets the

alarm 1 circuit after the alarm 1 condition passes.

If set as ALARM-2 Condition, the channel’s alarm 2 relay activates

when an alarm 2 condition is initiated for the channel.

If set as FAIL Condition, the channel’s alarm 2 relay activates when a

fail condition is initiated for the channel.

The gas reading at which the Beacon 200 initiates an alarm 2 condition.

The amount of time the Beacon 200 delays activation of the alarm 2

circuit once an alarm 2 condition is initiated.

Page 41

Table 8: Channel Setting Parameters (Continued)

Parameter

(Factory-Set Value)

ALARM-2 OFF DELAY

(0 sec)

ALARM-2 (activation)

(INCREASING)

ALARM-2 Relay (action)

(NORMALLY DE-ENERGIZED)

ALARM-2 Relay (reset)

(LATCHING)

NOISE FILTER

(3)

Description

The amount of time the Beacon 200 delays turning off the alarm 2 circuit

once an alarm 2 condition passes.

Indicates if the alarm 2 circuit is activated by gas readings INCREASING

or DECREASING to the ALARM-2 Level.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 2 relay is de-

energized in normal operation and energizes when an alarm 2 condition

is initiated.

If set as NORMALLY ENERGIZED, the channel’s alarm 2 relay is

energized in normal operation and de-energizes when an alarm 2

condition is initiated.

If set as LATCHING, you must press the RESET button to reset the

alarm 2 circuit after the alarm 2 condition passes.

If set as SELF RESETTING, the Beacon 200 automatically resets the

alarm 2 circuit after the alarm 2 condition passes.

The noise filter feature helps “smooth out” jumpy or noisy signals from

the detector head. You can set the noise filter from 1 to 8.

A setting of 8 produces the greatest amount of smoothing but also

responds slowest to changes in the response reading.

A setting of 1 responds fastest to changes in the response reading but

produces the least amount of smoothing.

ZERO SUPPRESSION

(2% of full scale)

View System Information Menu

The View System Information Menu consists of only one display screen

which indicates the version number of the firmware that is running the

instrument and the system voltage. The system voltage is the voltage that

is directly running the instrument’s circuitry.

The zero suppression feature helps prevent “jumpy” readings near the

fresh air reading.

For example, if the zero suppression setting on the H

full scale, the Beacon 200 will display a reading of 0 ppm for gas

readings from -2 ppm to 2 ppm.

S channel is 2% of

2

72-2102-07 Beacon 200 Operator’s Manual • 36

Page 42

Chapter 6: Maintenance

Overview

This chapter describes use of the Calibration Program and corrective

maintenance procedures for the Beacon 200. It includes a troubleshooting

guide for problems you may encounter with the Beacon 200. Procedures to

replace components of the Beacon 200 are at the end of this chapter.

Calibration Program

The Calibration Program is used to calibrate the Beacon 200’s active

channel.

Calibration Program Flow

Figure 13 below illustrates the general flow of the Calibration Program. See

the next section, Preparing for Calibration, for instructions to enter the

Calibration Program. In general, the program screens provide instructions

to guide you through the program. At any point in the calibration program,

the ESCAPE key may be used to either return to the previous screen or

abort a process.

37 • 72-2102-07 Beacon 200 Operator’s Manual

Page 43

Calibrate

Channel 1 Y / N?

Calibration

Timeout Selection

ENTER

Normal Operation

Appl y Gas to

Ch. 1 & Ch. 2

Detectors

Select Cal. Gas

Concentration for

Channel 2

Span

Channel 1 Y / N?

Span

Channel 2 Y/N?

Press Enter to

Adjust Span

Select Cal. Gas

Concentration for

Channel 1

Air Adjust Channel

1

Calibration

Program Enter

ENTER/ESCAPE

ESCA PE

Calibrate

Channel 2 Y/N?

Air Adjust Channel

2

Figure 13. Calibration Flow Chart

NOTE: The following procedure assumes that the target gas is present in

a high enough concentration to affect the fresh air (zero) reading.

If a fresh air environment can be verified, applying zero air to the

detector is not necessary when setting the zero reading.

This section describes how to calibrate the H

S detectors. It includes

2

procedures to prepare for calibration, set the fresh air reading, set the span

reading, and return to normal operation. It describes calibration using a

calibration kit that includes calibration gas, sample tubing, and a fixed flow

regulator with an on/off knob. RKI Instruments, Inc. recommends using a

0.5 LPM (liters per minute) fixed flow regulator. The calibration cup/splash

guard is part of the detector assembly in the Beacon 200.

Preparing for Calibration

1. Simultaneously press and hold the ENTER and UP/YES buttons for

approximately 5 seconds to enter the Calibration Program. Release the

buttons when the CALIBRATION PROGRAM... message displays and

asks if you want to continue or return to normal operation.

72-2102-07 Beacon 200 Operator’s Manual • 38

Page 44

NOTE: While in the Calibration Program, the alarm status of the Beacon

200 will be locked in the state it was when the Calibration Program

was entered.

2. Press the ENTER button to continue and display the Calibration Timeout setting.

The Beacon 200 will remain in the Calibration Program for the amount

of time indicated by the Calibration Time-out setting or until you exit the

program. If necessary, adjust the setting using the UP/YES and DOWN/

NO buttons. Make sure you have allotted enough time to perform the

calibration procedure. Consider the type of detector head installed and

the distance from the Beacon 200 when determining the time required.

NOTE: If you do not accept a Time-out setting and stay at this screen or

press ESCAPE and do not press control buttons again, then the

Beacon 200 will exit the Calibration Program and begin its warmup period 5 minutes after the last button was pushed. This warmup period functions as if the unit were just powered up.

3. Press the ENTER button to accept the Time-out setting, start the Timeout period and continue in the Calibration Program.

Adjusting the Fresh Air Reading

1. The display asks if you want to calibrate channel 1. Press the UP/YES

button to continue with calibrating channel 1.

If you press the DOWN/NO button, the display will skip to channel 2.

2. The display will ask if you want to calibrate channel 2. Press the UP/

YES button to continue with calibrating channel 2.

If you press the DOWN/NO button, the calibration of channel 1 will

continue if you selected it or if you did not select channel 1, the unit will

return to the first calibration program screen which asks if you want to

continue or escape the program.

3. If you pressed the UP/YES button for either channel, the unit will display

the following message for a few seconds before continuing: Expose

Dectector(s) To Fresh Air. . . When Done Press ENTER. Then the

display will alternate between the gas reading for the selected

channel(s) and the message FRESH AIR ENTER to ACCEPT

ESCAPE to ABORT above the time remaining in the calibration Timeout. The following instructions assume you pressed the UP/YES button

for both channels.

4. Screw the fixed flow regulator into the zero air calibration cylinder.

39 • 72-2102-07 Beacon 200 Operator’s Manual

Page 45

5. Use the calibration kit sample tubing to connect the fixed flow regulator

to the calibration cup/splash guard of the first detector.

6. Turn the regulator knob counterclockwise to open the regulator.

7. Allow zero air to flow for two minutes.

8. Turn the regulator knob clockwise to close the regulator. The Beacon

200 will continue to display the minimum gas response on the display

and retain the response level in its memory.

9. Disconnect the sample tubing from the first detector and connect it to

the calibration cup/splash guard hose barb of the second detector.

10.Turn the regulator knob counterclockwise to open the regulator.

11.Allow zero air to flow for two minutes.

12.Turn the regulator knob clockwise to close the regulator. The Beacon

200 will continue to display the minimum gas response on the display

and retain the response level in its memory.

13.Press the ENTER button at the Beacon 200. The unit will adjust the

zero reading and display the message Fresh Air Adjust Passed for:

Channel 1 Channel 2 before continuing.

14.If you applied zero air to the detector, unscrew the regulator from the

zero air calibration cylinder.

15.If you applied zero air to the detectors, leave the sample tubing

connected to the regulator and move it from the second detector to the

first detector’s calibration cup/splash guard.

If you did not apply zero air to the detectors, use the calibration kit

sample tubing to connect the fixed flow regulator to the calibration cup/

splash guard of the first detector.

NOTE: If the fresh air adjustment fails, see “Troubleshooting” on page 49

for recommended actions.

Adjusting the Span Setting

1. The display asks if you want to perform a span operation on channel 1

by applying gas. Press the UP/YES button to continue with adjusting

the span on channel 1.

If you press the DOWN/NO button, the unit will skip to channel 2.

2. The display asks if you want to perform a span operation on channel 2

by applying gas. Press the UP/YES button to continue with adjusting

the span on channel 2.

If you press the DOWN/NO button, the span of channel 1 will continue if

72-2102-07 Beacon 200 Operator’s Manual • 40

Page 46

you selected it or if you did not select channel 1, the unit will return to

the first calibration program screen which asks if you want to continue

or escape from the Calibration Program.

3. If you pressed the UP/YES button for either channel, the display will

prompt you for the span gas concentration that will be used for the first

selected channel. The following instructions assume you pressed UP/

YES button for each channel.

4. Adjust the displayed concentration for channel 1 up or down as needed

using the UP/YES and DOWN/NO buttons so that it matches the

concentration in the calibration cylinder.

5. Press the ENTER button to accept the calibration gas concentration for

Channel 1 and continue.

6. The display will then prompt you for the span gas concentration that will

be used for channel 2. Adjust the displayed concentration up or down

as needed using the UP/YES and DOWN/NO buttons so that it matches

the concentration in the calibration cylinder.

7. Press the ENTER button to accept the calibration gas concentration for

Channel 2 and continue.

8. The unit will display the message Expose Dectector(s) To Gas. . .

When Done Press ENTER for a few seconds. It will then alternate

between the gas readings for both channels and the message

APPLYING GAS ENTER to ACCEPT ESCAPE to ABORT above

the time remaining in the calibration time-out.

9. Screw the calibration gas cylinder onto the fixed flow regulator.

10.Turn the regulator knob counterclockwise to open the regulator.

11.Allow calibration gas to flow for one minute.

12.Turn the regulator knob clockwise to close it. The Beacon 200 will

continue to display the maximum gas response on the display and

retain the response level in its memory.

13.Disconnect the sample tubing from the first detector and connect it to

the calibration cup/splash guard hose barb of the second detector.

14.Turn the regulator knob counterclockwise to open the regulator.

15.Allow the calibration gas to flow for one minute.

16.Turn the regulator knob clockwise to close the regulator. The Beacon

200 will continue to display the maximum gas response on the display

and retain the response level in its memory.

17.Press the ENTER button at the Beacon 200 to proceed with the

calibration adjustment.

If the Beacon 200 is able to successfully make the calibration

41 • 72-2102-07 Beacon 200 Operator’s Manual

Page 47

adjustment, it will display the message Cal Passed for: Channel 1

Channel 2. It will then return to the first calibration program screen

which asks if you want to continue or escape from the program. Press

ESCAPE to return to normal operation.

If the Beacon 200 is not able to make the calibration adjustment, it will

display the message Not Enough Response! CAL Failed for:

Channel 1 Channel 2, then return to the first calibration program

screen which asks if you want to continue or escape from the program.

Press ENTER to start the calibration process again or ESCAPE to

return to normal operation.

18.Unscrew the H2S calibration gas cylinder from the fixed flow regulator

and disconnect the sample tubing from the calibration cup/splash guard

hose barb.

NOTE: Be sure to allow enough time between the application of

calibration gas and returning to normal operation for the gas

reading to return to normal levels to avoid false alarms. The alarm

circuits are active when the Beacon 200 returns to normal

operation.

19.Store the components of the calibration kit in a safe place.

72-2102-07 Beacon 200 Operator’s Manual • 42

Page 48

Adjusting Strobe/Horn Volume

Push Up Here

Push Out

Captive

Screw

Top

Base

Figure 14. Top Case Removal

The horn volume on the strobe/horn can be adjusted by doing the

following:

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door of the Beacon 200, then place the power switch

in the OFF position.

3. Loosen the captive screw at the bottom front of the strobe/horn.

4. Grasp the top and bottom of the strobe/horn and push up and out in

order to remove the cover.

43 • 72-2102-07 Beacon 200 Operator’s Manual

Page 49

5. Turn the cover over and locate the Audio Select switch at the top of the

6

AUDIO

SELECT

Audio Select Switch

Strobe Brightness Switch

(DO NOT ADJUST)

4

3

2

1

CANDELLA SELECT

5

Figure 15. Strobe/Horn Cover

cover as shown in the figure below.

6. The Audio Select switch can be set at any number between 1 and 6.

Numbers 1-3 all produce an intermittent buzzing sound with 1 being the

loudest and 3 being the quietest. Numbers 4-6 all produce a steady

buzzing sound with 4 being the loudest and 6 being the quietest. The

factory setting is 2.

7. Turn the Audio Select switch so that the selection arrow is pointing to

the desired number.

8. Place the cover over the base and push in and down in order to reinstall

the cover. Make sure that the cover is sealed to the base by the gasket.

9. Screw the captive screw at the bottom front of the strobe/horn back in.

72-2102-07 Beacon 200 Operator’s Manual • 44

Page 50

Replacing Components of the

Beacon 200

This section describes how to replace the fuses, the plug-in H2S sensor,

and the entire H2S detector.

Replacing the Fuses

The Beacon 200 includes three fuses: one DC and two AC fuses.

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door of the Beacon 200, then place the power switch

in the OFF position.

3. Locate the vertical fuse holders on either side of the power switch.

The DC fuse which is labelled F1 on the PCB silk-screen is on the left

of the power switch. The AC fuses are labelled F2 and F3 and are on

the right of the power switch.

4. Use a flat-blade screwdriver to rotate the applicable fuse holder 1/4

turn counterclockwise. The fuse holder releases from the socket.

5. Remove the fuse holder from the socket, then remove the fuse from

the fuse holder.

CAUTION: Verify that the r eplace ment fuse i s the same t ype and rating a s

the fuse you are replacing.

6. Install the appropriate replacement fuse in the fuse holder, then place

the fuse holder in the socket.

7. Push the fuse holder into the socket, then turn the holder 1/4 turn

clockwise to secure it in the socket.

8. Plug in or turn on all incoming power to the Beacon 200 at the power

source end.

9. Place the Beacon 200’s power switch in the ON position, then verify

that the PILOT light is on.

10. Close and secure the housing door.

Replacing the Plug-In H2S Sensor

1. Turn off or unplug all incoming power to the Beacon 200 at the power

source end.

2. Open the housing door of the Beacon 200, then place the power switch

45 • 72-2102-07 Beacon 200 Operator’s Manual

Page 51

in the OFF position.

3. Unscrew the calibration cup/splash guard from the detector.

4. Unscrew the detector housing cap from the housing body. Make sure

not to lose the cap gasket. See Figure 3 for an illustration of the H2S

detector.

5. Unplug and remove the sensor with the rubber boot and spacer

attached.

6. Remove the rubber boot and spacer from the old sensor.

7. Install the spacer and rubber boot onto the replacement sensor’s face.

8. Carefully match the replacement sensor’s male pins with the 4-socket

pattern in the top section and plug it in.

9. Make sure the cap gasket is in place and screw the detector housing

cap back onto the housing body.

10.Screw the calibration cup/splash guard back onto the detector housing

cap.

11.Plug in or turn on all incoming power to the Beacon 200 at the power

source end.

12.Place the Beacon 200’s power switch in the ON position, then verify

that the PILOT light is on.