Page 1

Eagle 2 Maintenance Data

Loader

Operator’s Manual

Part Number: 71-0191RK

Revision: D

Released: 5/29/14

www.rkiinstruments.com

Page 2

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be

free from defects in materials and workmanship, and performance for a

period of one year from date of shipment from RKI Instruments, Inc.

Any parts found defective within that period will be repaired or

replaced, at our option, free of charge. This warranty does not apply to

those items which by their nature are subject to deterioration or

consumption in normal service, and which must be cleaned, repaired,

or replaced on a routine basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and valves Filter elements

Fuses

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repairs procedures not in accordance with the

instruction manual. This warranty indicates the full extent of our

liability, and we are not responsible for removal or replacement costs,

local repair costs, transportation costs, or contingent expenses incurred

without our prior approval.

This warranty is expressly in lieu of any and all other warranties and

representations, expressed or implied, and all other obligations or

liabilities on the part of RKI Instruments, Inc. including but not limited

to the warranty of merchantability or fitness for a particular purpose. In

no event shall RKI Instruments, Inc. be liable for indirect, incidental,

or consequential loss or damage of any kind connected with the use of

its products or failure of its products to function or operate properly.

This warranty covers instruments and parts sold to users only by

authorized distributors, dealers, and representatives as appointed by

RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused

by the operation of this gas monitor and our warranty is limited to

replacement of parts or our complete goods.

Warranty

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installing the Eagle 2 Maintenance Data Loader Program . . . . . . . . . . . . . . . . 3

IrDA Downloading Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing an IrDA Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Windows® Wireless Link Operation Note. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Launching the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connecting an Eagle 2 to the Maintenance Data Loader Program . . . . . . . . . 8

Control Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Get Current Eagle 2 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Select Distributed File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Transmit New Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Station and User Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conversion Table Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PID Sensor Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Obtaining a Relative Response Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table of Contents

Page 4

Introduction

CAUTION: Read and understand this manual befor e using the Eagle

Using an advanced detection system consisting of up to six gas

sensors, the Eagle 2 Personal Gas Monitor detects the presence of

combustible gases, oxygen (O

hydrogen sulfide (H

and easy-to-use design make it ideally suited for a wide range of

applications as described in the Eagle 2 Operator’s Manual. Please

read the Eagle 2 Operator’s Manual first before using the Eagle 2

Maintenance Data Loader Program.

2 Maintenance Data Loader Program. Also read and

understand the Eagle 2 Operator’s Manual included

with the Eagle 2 portable gas monitor.

), carbon monoxide (CO), and

2

S) simultaneously. The Eagle 2’s compact size

2

The Eagle 2 Maintenance Data Loader Program allows you to change

various instrument parameters not accessible in the Eagle 2’s user

interface. It also allows you to s ave parameter configuration fil es based

on instruments’ parameter settings that can be viewed or used to

update another instrument’s parameter settings.

The purpose of this manual is to explain how to use the Eagle 2

Maintenance Data Loader Program. You will learn how to:

• install and launch the program

• install the downloading cable (if needed)

• connect to the Eagle 2 with the program

• change parameters in the Eagle 2

• save parameter configuration files that can be opened, viewed, and

edited in a word processing program

• save parameter configuration files that can be uploaded to an

instrument to change its parameter settings

• upload parameter configuration files to an instrument to change its

Before you get started, be sure to review system requirements in the

1 • Introduction

parameter settings

Page 5

next section.

CAUTION: The Eagle 2 detects oxygen deficiency and elevated

levels of oxygen, combustible gases, carbon monoxide,

and hydrogen sulfide, all of which can be dangerous or

life threatening. When using the Eagle 2, you must

follow the instructions and warnings in the Eagle 2

Operator’s Manual to assure proper and safe operation

of the unit and to minimize the risk of personal injury.

CAUTION: The operator of this instrument is advised that if the

equipment is used in a manner not specified in this

manual, the protection provided by the equipment may

be impaired.

System Requirements

To use the Eagle 2 Maintenance Data Loader Program, your personal

computer must meet the following requirements:

• Operating Systems: Windows® 2000, Windows® XP, or

®

Windows

• Processor: IBM

• Memory: 32 MB RAM minimum

• Available Hard Disk Space: 32 MB minimum

• CD-ROM Drive

• Infrared port or USB port and a USB/IrDA adapter cable

Vista.

®

compatible PC running Pentium® 2 or higher.

System Requirements • 2

Page 6

Installing the Eagle 2 Maintenance Data

Loader Program

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Insert the Eagle 2 Maintenance Data Loader Program Installation

CD in your computer’s CD-ROM drive.

NOTE: If you have an Eagle 2 Product CD instead of an Eagle 2

Maintenance Data Loader Prog ram Instal lation CD, insert th e

Product CD and navigate to the Maintenance Program folder.

When you open the folder, double click on setup.exe, then

continue with step 4.

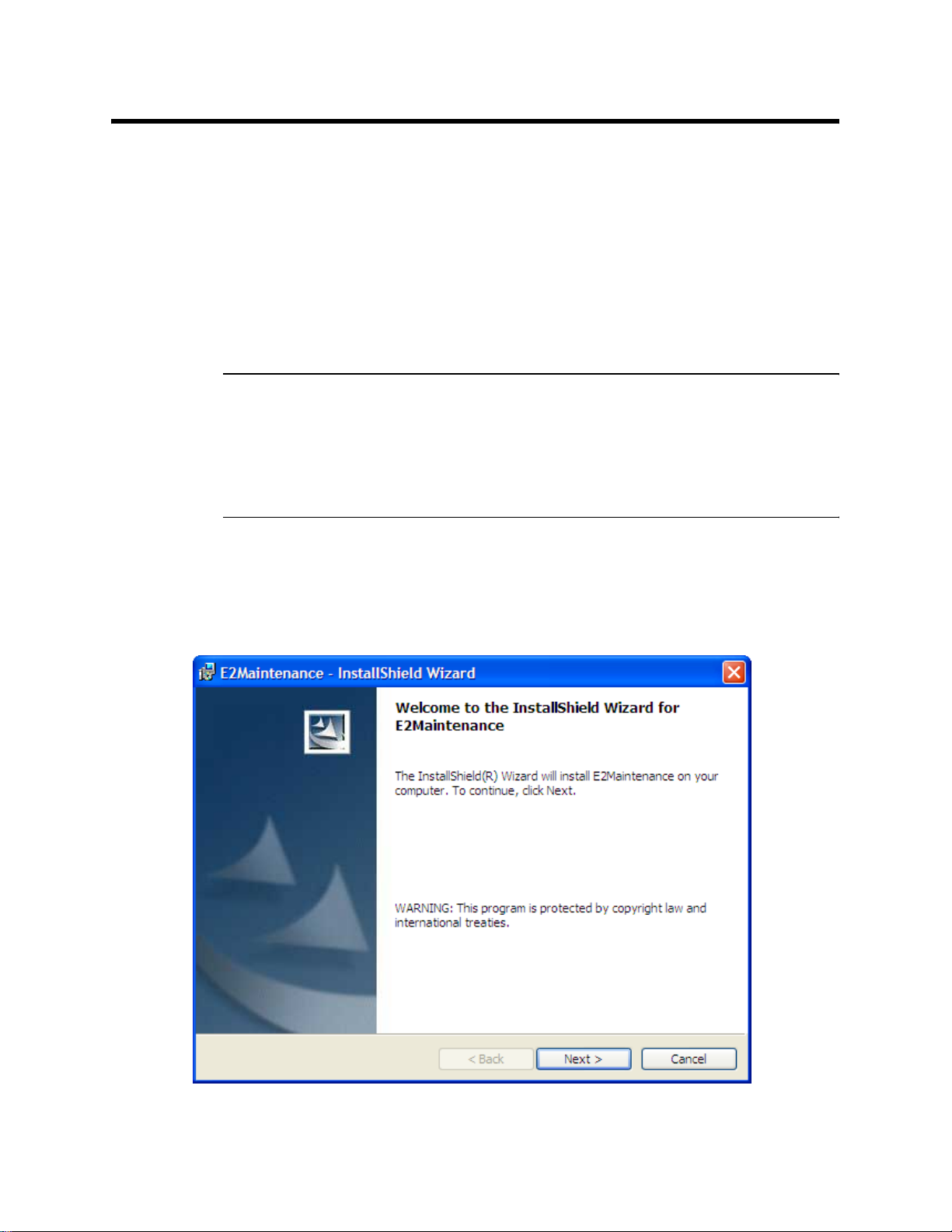

4. After a few seconds, a screen appears indicating that the

InstallShield Wizard is preparing to install the E2 Maintenance

Setup, then the E2 Maintenance InstallShield Wizard window

appears to guide you through installation.

Figure 1: Eagle 2 User Setup Installation Program

3 • Installing the Eagle 2 Maintenance Data Loader Program

Page 7

5. Follow the on-screen instructions in the InstallShield Wizard

Window to install the program.

6. If the InstallShield Wizard finds versions of Windows

your computer newer than those in the installation CD, it will ask

you if you want to keep these newer files. Click Yes.

7. When the InstallShield Wizard indicates that installation is

complete, click the Finish button.

8. Eject the installation CD from the CD-ROM drive and store it in a

safe place.

IrDA Downloading Cable

The Eagle 2 communicates with a computer via an on-board infrared

communication port that complies with IrDA protocol standards.

®

files on

NOTE: If your computer has a built-in infrared port, you do not need

an adapter cable to download data.

If your computer does not have an infrared port, you will need to

install an IrDA/USB adapter cable on your computer to use the Eagle 2

Maintenance Data Loader Program with your Eagle 2. The IrDA/USB

cable is available from RKI Instruments, Inc. See the Spare Parts List

at the end of this manual for the RKI part number. This cable can also

be found on many electronic supply websites.

®

Some versions of Windows

drivers loaded in Windows

already have several infrared device

®

and will automatically recognize a cable

during the installation process and guide you in installing the drivers.

Other versions of Windows

®

will require you to load device drivers

provided by the manufacturer of the cable during the installation

process. RKI makes no warranty for the operation or compatibility of

the drivers with any particular device.

IrDA Downloading Cable • 4

Page 8

Installing an IrDA Adapter Cable

After installing the Eagle 2 Maintenance Data Loader Program,

connect the IrDA/USB cable to your computer and follow the

manufacturer’s instructions for installing the cable on your computer.

Make sure the cable is compatible with your Windows® operating

system.

If you do not have instructions from the cable manufacturer for

installing your cable, see your Windows documentation. In general,

you must go to the Control Panel and use the Add Hardware Wizard to

install the cable drivers.

Windows

®

Wire less Link Operation Note

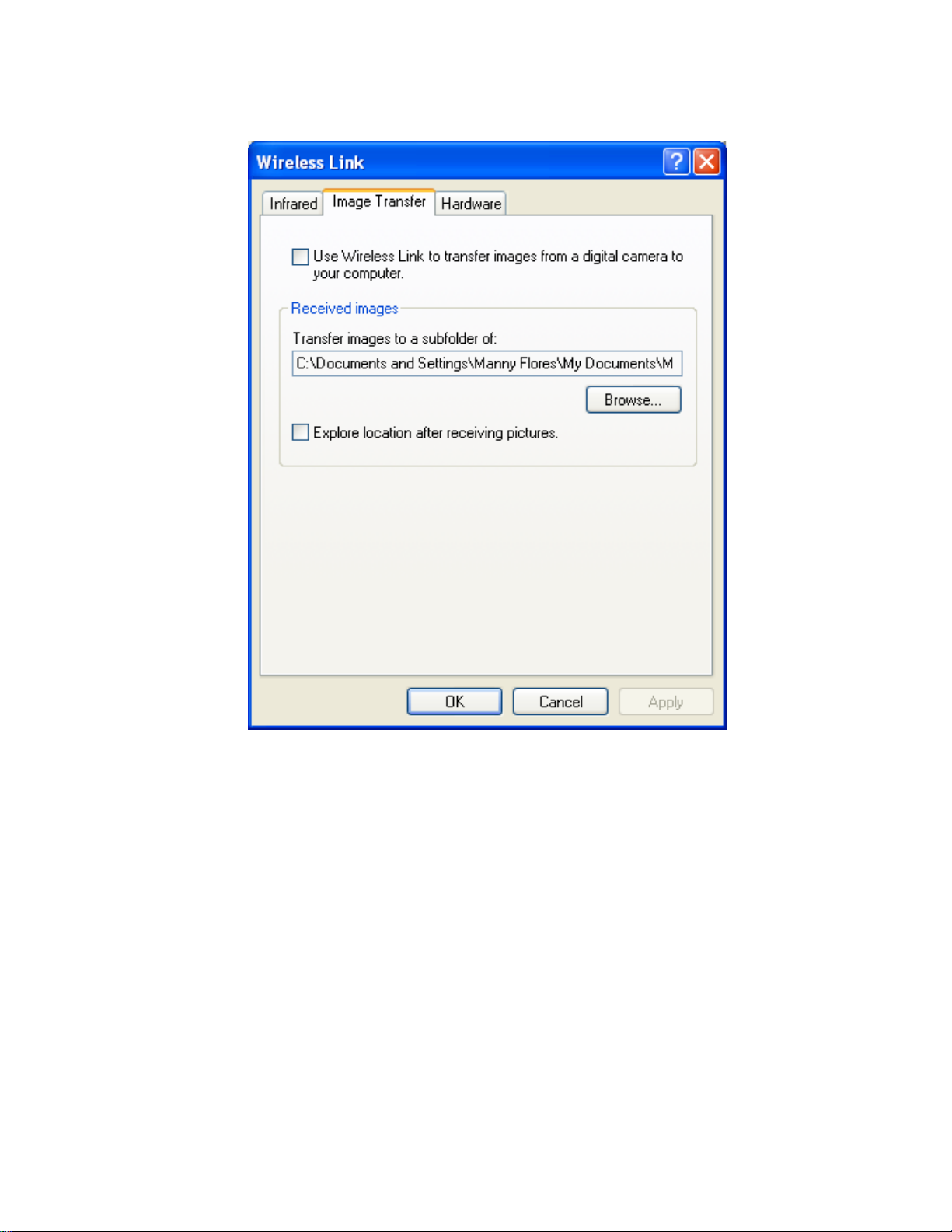

When using an IrDA adapter cable and the Eagle 2 Maintenance Data

Loader Program on a Windows

®

computer, it is necessary to make a

special setting in the Wireless Link Configuration window for proper

communication between the Eagle 2 and the Eagle 2 Maintenance Data

Loader Program. This must be done before attempting to use the

program. Follow these steps to make this setting:

®

1. Click Start on the Windows

Icon Tray.

2. If Control Panel is available to select in the Start menu, select it.

The Control Panel will appear.

If Contr ol Panel is not selectable in the Start menu but Settings is,

select Settings, then select Control Panel. The Control Panel will

appear.

3. Double click on Wireless Link. The Wireless Link Configuration

window will appear.

4. Click on the Image Transfer tab.

5. Deselect the selection box for “Use Wireless Link to transfer

images from a digital camera to your computer.”

5 • IrDA Downloading Cable

Page 9

Figure 2: Image Transfer Tab

6. Click OK.

7. Close the Control Panel window.

IrDA Downloading Cable • 6

Page 10

Launching the Program

1. Click Start in the Windows® Icon Tray, then select Programs,

then select Eagle 2 Maintenance Data Loader. Your operating

system may also have a shortcut installed in the Start menu.

2. The Main Window will appear.

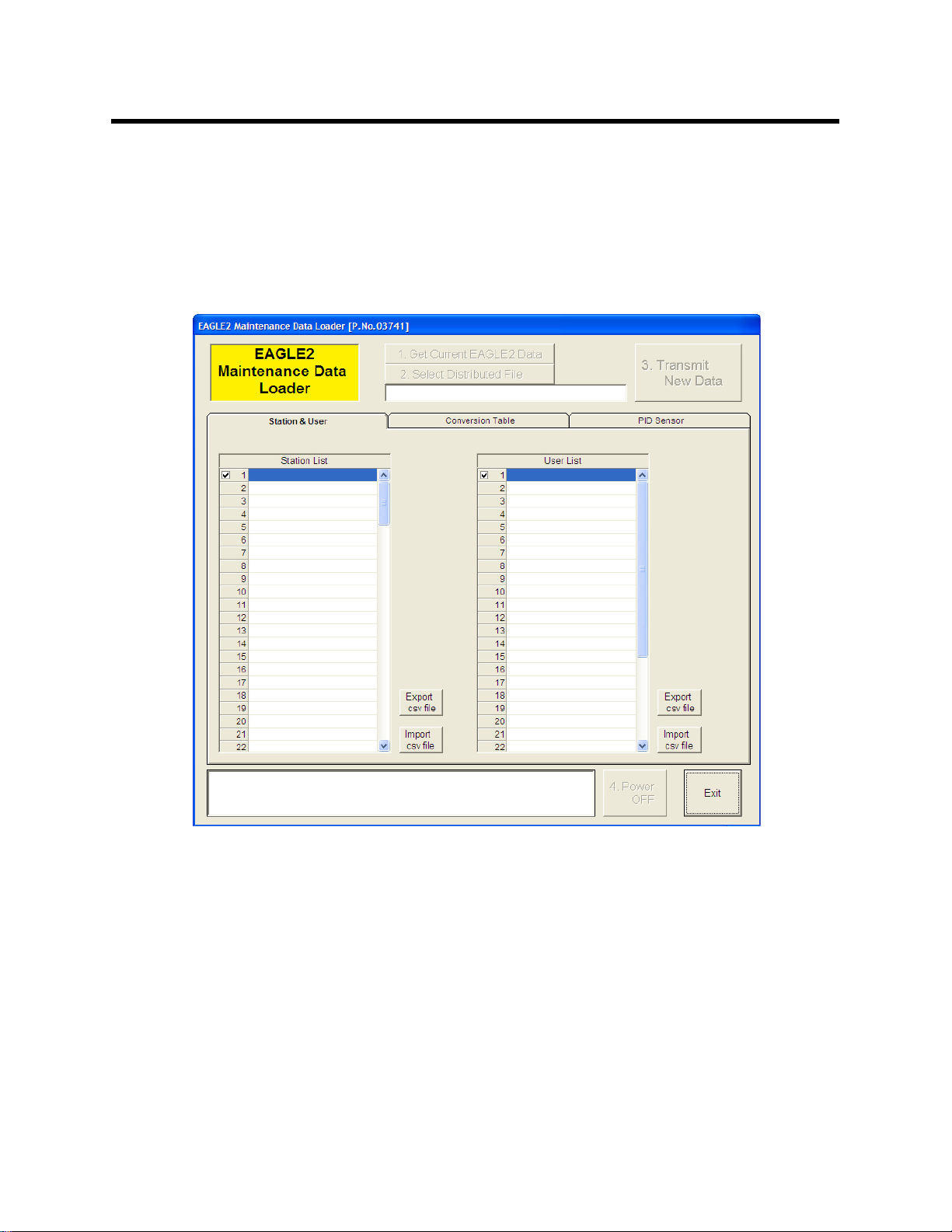

Figure 3: The Main Window

3. For convenience, make a shortcut of the Eagle 2 Maintenance Data

Loader Program and place it on the Windows

Windows

7 • Launching the Program

®

®

desktop. See your

documentation for information about making shortcuts.

Page 11

Connecting an Eagle 2 to

the Maintenance Data

Loader Program

Follow these steps to connect an Eagle 2 to the Maintenance Data

Loader Program:

1. Launch the Eagle 2 Maintenance Data Loader Program as

described in “Launching the Program” on page 7. The Main

Window displays.

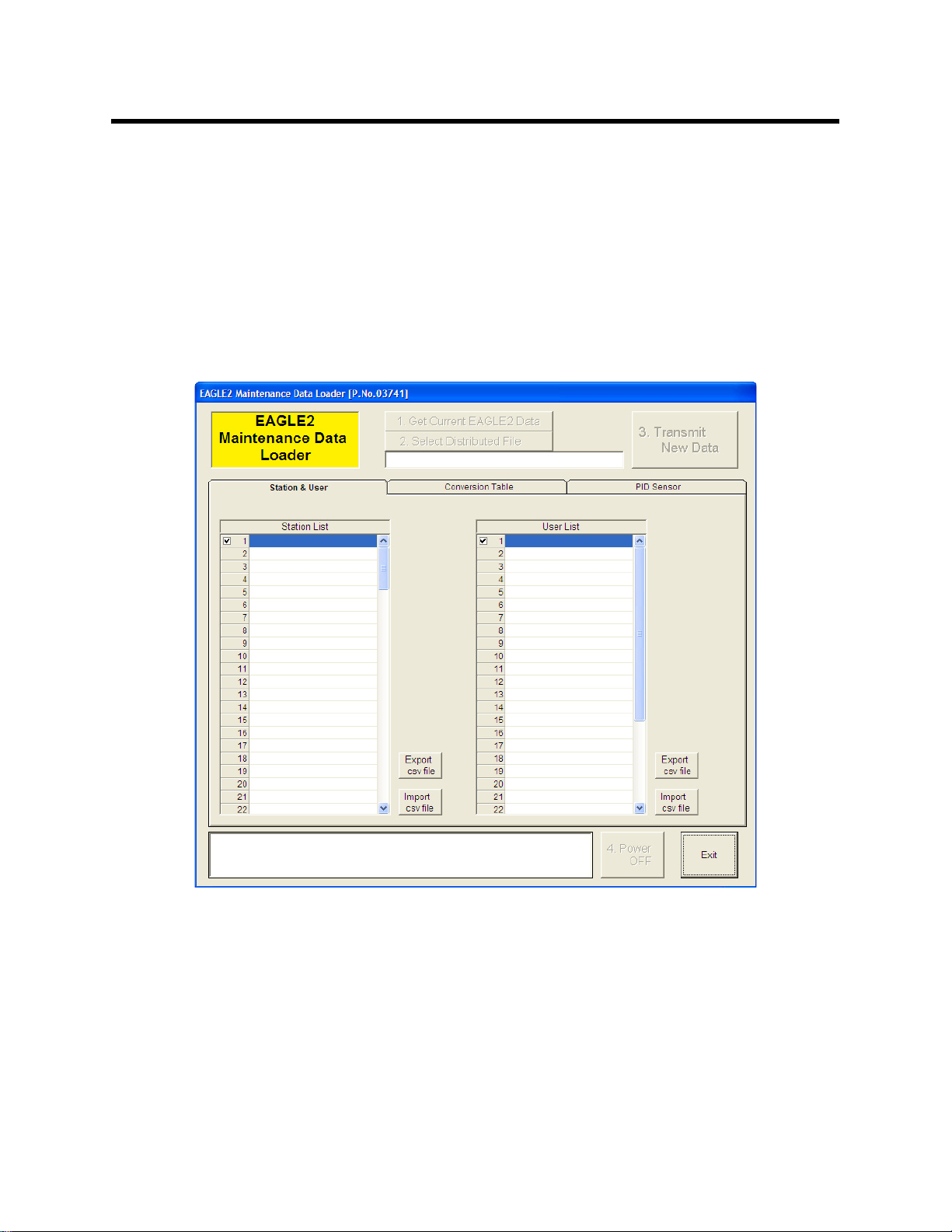

Figure 4: The Main Window

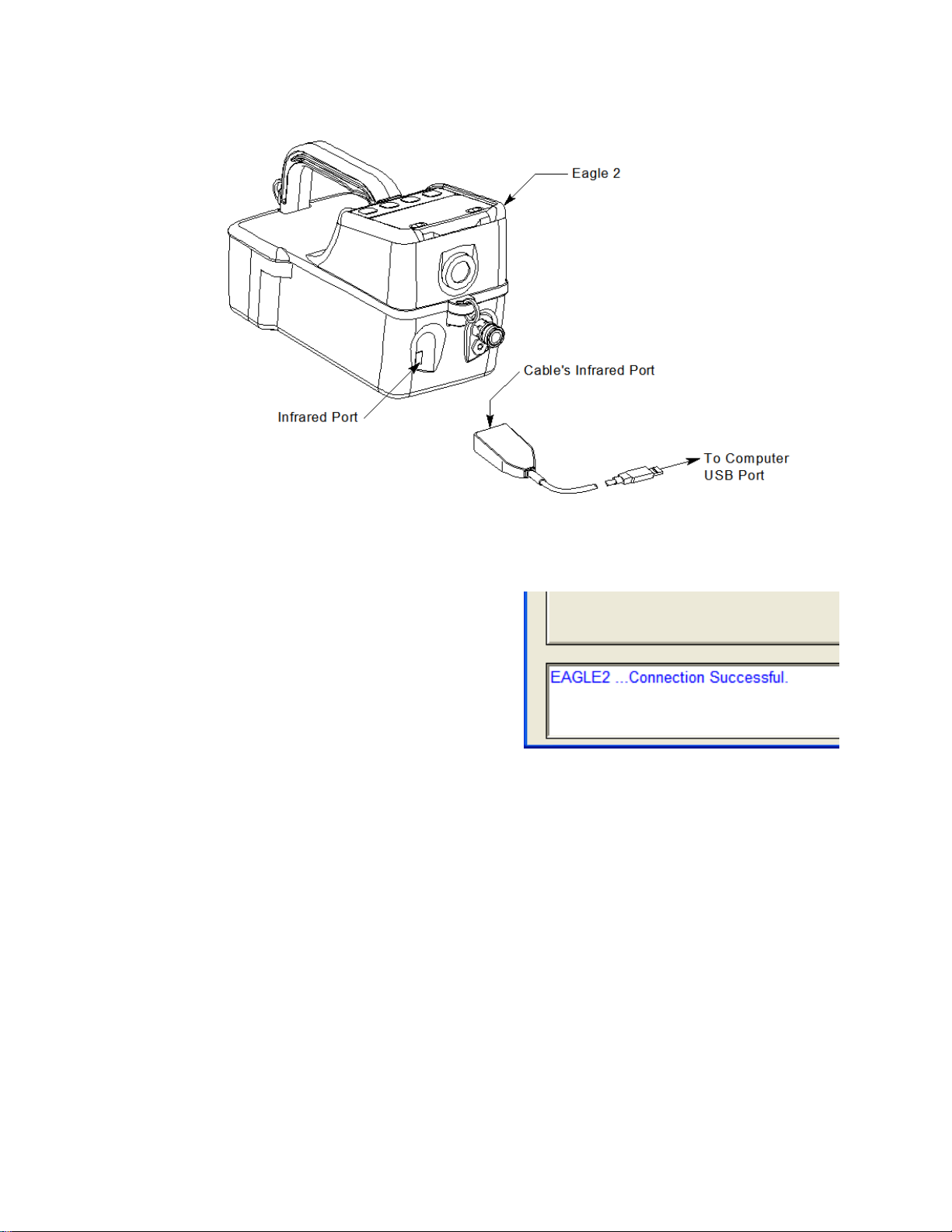

2. Place the Eagle 2 within an inch or two of the infrared port on your

computer aligning the infrared port on the front of the Eagle 2 with

the infrared port on your computer.

If your computer does not have a built in infrared port, place the

Eagle 2 within an inch or two of the infrared port on the IrDA

adapter cable as shown in Figure 5 below, aligning the infrared

port on the front of the Eagle 2 with the infrared port on the cable.

Connecting an Eagle 2 to the Maintenance Data Loader Program • 8

Page 12

Figure 5: Aligning the Eagle 2 with the Cable Infrared Port

3. Press and hold the POWER

ENTER RESET button on

the Eagle 2 until you hear a

beep, then release it. The

Eagle 2 will begin it’s power

up sequence. If a successful

connection between the

Eagle 2 and the computer

occurs, the Get Current

EAGLE 2 Data control

button becomes active.

Figure 6: Connection Mes-

sage

You can now retrieve the connected instrument’s configuration

information using the Get Curr ent EAGLE 2 Data comma nd bu tto n.

You must retrieve the connected instrument’s configuration

information before you can perform operations such as saving the

instrument’s user and station IDs, catalytic combustible user defined

relative response gas list, or PID user defined relative response gas list

parameter configuration to a file and changing the instrument’s

parameter configuration.

9 • Connecting an Eagle 2 to the Maintenance Data Loader Program

Page 13

Control Buttons

There are 5 control buttons on the mai n sc reen: Get Current EAGLE

2 Data, Select Distributed File, Transmit New Data, Power OFF,

and Exit. These buttons are used for communication between the

Eagle 2 and the Eagle 2 Maintenance Data Lo ader Program.

Get Current EAGLE 2 Data

Use Get Current EAGLE 2 Data to load a connected instrument’s

user and station IDs, catalytic combustible user defined gases, and PID

user defined gas parameter configuration into the Maintenance Data

Loader Program so they can be updated if desired. Follow these steps

to retrieve a connected instrument’s parameter configuration and

update parameters that are available in the Eagle 2 Status area:

1. Launch the Eagle 2 Maintenance Data Loader Program as

described in “Launching the Program” on page 7.

2. Connect the Eagle 2 to the Maintenance Data Loader Program as

described in “Connecting an Eagle 2 to the Maintenance Data

Loader Program” on page 8.

Control Buttons • 10

Page 14

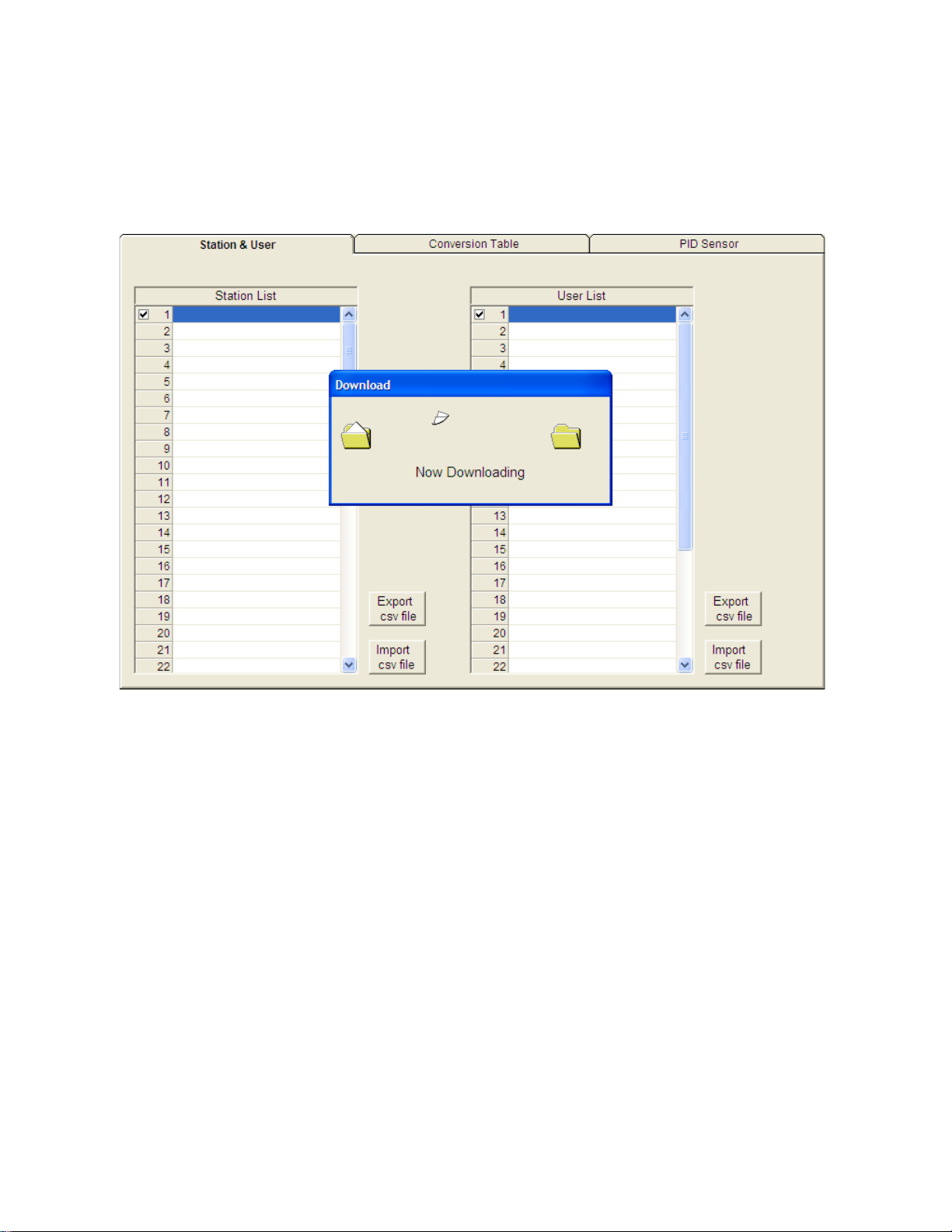

3. Click Get Current EAGLE 2 Data to retrieve the instrument’s

user and station ID, catalytic combustible user defined gases, and

PID user defined gas parameter configuration. The program

indicates that it is downloadi ng information from the instrument.

Figure 7: Instrument Information Downloading

4. The instrument’s user and station ID, catalytic combustible user

defined gases, and PID user defined gas parameter configuration

are now loaded in the Maintenance Data Loader Program and the

parameters are available for updating.

Select Distributed File

This control button only becomes active after data has been

downloaded to the Maintenance Data Loader Program. The function

controlled by this button is not needed for normal field use of the

program. This function and the text field below it are for use by field

service personnel with a factory program at their disposal to generate a

distributed file.

11 • Control Buttons

Page 15

Transmit New Data

After information has been updated in the pa rameter ta bs, thi s button is

used to upload that data to the Eagle 2.

NOTE: The Transmit New Data button transfers data from all tabs at

once. T o prevent the transmitting of empty parameter fields, it

is advisable that you download data from the instrument

before pressing the Transmit New Data button.

Power OFF

This button is used to turn off the Eagle 2 after all desired updates have

been made.

Exit

This button closes the Eagle 2 Maintenance Data Loader Program. Be

sure to turn off the Eagle 2 instrument before closing the Maintenance

Data Loader Program to prevent the Eagle 2 from remaining on and

draining battery voltage.

Control Buttons • 12

Page 16

Station & User Tab

The Station & User tab displays a list of Station IDs and User IDs. The

first time the Eagle 2 is connected to the Maintenance Data Loader

Program, this list will be blank. No Station IDs or User IDs are loaded

into the Eagle 2 at the factory. These are user-defined parameters that

may only be configured using the Maintenance Data Loader Program.

Up to 128 Station IDs and up to 32 User IDs may be defined.

13 • Station & User Tab

Figure 8: Station & User Tab

Page 17

CSV Files

Press to generate Station csv file

Press to generate User csv file

To edit the Station ID or User ID list, you will need to import a csv

(comma separated values) file into the program. A Station csv file and

a User csv file are provided with the program. In addition, you can

generate csv files for editing from the program. To access them, you

must press the “Export csv file” button for the Station and User IDs in

the Station and User tab.

Figure 9: Station csv File

Station & User Tab • 14

Page 18

The csv files can be opened, edited, and saved using a word processing

program such as Word, WordPad, or Notepad. The Station and User

csv files consist of the Station or User ID number and its associated

name. Below is an example of a Station csv file opened in WordPad.

Figure 10: Station csv File

Any existing Station or User IDs will be displayed. Undefined Station

or User IDs will appear as dashes. To edit a Station or User ID, delete

either the existing name or the dashes and replace them with the

desired name. The name may consist of any letter, number, or

character. If desired, you can save multiple Station and User ID files.

Loading User and Station IDs

To load new User and Station IDs, do the following:

1. Launch the Eagle 2 Maintenance Data Loader Program and

connect and instrument as described in “Connecting an Eagle 2 to

the Maintenance Data Loader Program” on page 8.

2. Download the instrument data to the program by pressing Get

Current EAGLE 2 Data.

3. Locate an existing Station or User csv file or generate a new one

for editing. To generate a new one, press “Export csv file” in the

Station and User tab for both the Station ID and User ID lists and

save the files in a convenient place.

15 • Station & User Tab

Page 19

4. Open the saved files in Word, WordPad, or Notepad, enter new

Station or User IDs, and save the files.

5. In the Station and User tab, press “Import csv file” for both the

Station ID and User ID and select the respective newly edited csv

file for each.

Press to import Station csv file

Press to import User csv file

Figure 11: Import csv File

6. Once the Station ID and User ID lists have been generated, select

the Station or User ID that will be loaded in the Eagle 2 as the

current one by clicking on it. A check mark will appear next to the

appropriate Station or User ID.

7. T o upload the new information from the Management Data Loader

Program to the Eagle 2, press Transmit New Data.

8. Turn off the Eagle 2 by pressing the Power OFF button

Station & User Tab • 16

Page 20

Conversion Table Tab

The Conversion Table tab is used to view the pre-defined relative

response gases for the catalyti c combustible channel and to edit or add

user-defined gases. The pre-defined gases can be found in the

Pre-Defined Table tab while the user-defined gases can be found under

the User-Defined Table tab.

Figure 12: Conversion Table

There are 8 columns in both the Pre-Defined Table tab and the UserDefined Table tab:

•No

This column represents the gas number. The gas numbers are 1-30.

•Name

This is what will appear in the Relative Response list of gases. The

name can be up to 3 characters long and the characters must be

upper case letters or numbers. No special characters may be used in

the Name column.

• Long Name

The Long Name column is used to better describe the target gas. It

17 • Conversion Table Tab

Page 21

may contain any character in upper- or lower-case.

•Factor

This value is the response factor for the listed gas relative to

methane. The factor for each pre-defined gas is factory defined.

The factor for any user-defined gases must be obtained through

testing as described in “Obtaining a Relative Response Factor” on

page 28. Even if not all of the user-defined catalytic combustible

channels are being defined, the Factor column must have a valid

number entered. A valid number for the Factor is a value between

0.01 and 25.00.

•1st

This column is for the low alarm point of each gas in ppm units.

• 2nd

This column is for the high alarm point of each gas in ppm units.

•Ratio

The ratio is the ppm value of the LEL for each gas. This value is

specific to each gas and can be easily determined. The maximum

value it may be set to is 150,000 ppm. If an invalid number is

entered, the box will turn red when the csv file is imported back

into the Maintenance Data Loader Program.

NOTE: If you define a gas whose LEL is above 50,000 ppm, the

%LEL reading in Measuring Mode will reflect the defined

ppm ratio, but the ppm reading in Measuring Mode will not

indicate above 50,000 ppm. For example, if you set the ratio

to be 150,000 ppm and set the catalytic combustible channel

to display the reading in ppm, the gas reading will not

indicate higher than 50,000 ppm, the equivalent of 33 %LEL

and 5% volume for this ratio, but will continue to indicate

%LEL readings up to 100 %LEL and %volume readings up to

15 %volume, the equivalent of 150,000 ppm, if the display

units are changed to %LEL or %volume. In addition, all

adjustable ppm parameters cannot be set higher than 50,000

ppm.

Conversion Table Tab • 18

Page 22

• Volt

This value determines the sensor voltage for the catalytic

combustible sensor. It can be set to 1.3 or 2.4. When set to 1.3, the

sensor is in methane elimination mode. When set to 2.4, the sensor

is reading at full response. Even if not all of the user-defined

catalytic combustible channels are being defined, the Volt column

must have a valid number entered. A valid number for the Volt

column is either 1.3 or 2.4.

While the pre-defined gases may not be edited, the 5 user-defined

gases may be edited by doing the following:

1. With the Maintenance Data Loader Program running, click on the

Conversion Data tab and then click on the User-Defined Table tab.

Figure 13: User-Defined Table

NOTE: Make sure you have downloaded the data from the EAGLE 2

to avoid erasing its data when updating the instrument using

the Transmit New Data button.

2. If no user-defined gases have been previously defined for the

connected instrument, the columns in User-Defined Table will be

19 • Conversion Table Tab

Page 23

blank. Any previously defined gases will appear.

3. Export the current data by pressing the “Export csv file” button.

Choose the file path you wish to save the file in.

4. Open the csv file using Notepad, Word, or WordPad. The example

below shows a csv file opened in WordPad. The list of gases are

associated with the numbers 1-5.

Figure 14: CSV File

If there were no previously defined gases, the csv file will appear

as the following:

Figure 15: Blank CSV File

5. The values in the csv file are all separated by commas. These

values are in the same order as the columns in the Maintenance

Conversion Table Tab • 20

Page 24

Data Loader Program. The first value is the gas number , the second

is the gas name, etc.

6. Edit the values you wish to change and save and close the file.

7. Return to the Maintenance Data Loader Program with the User-

Defined Table tab still up and press “Import csv file”.

8. Choose the file you just edited and press “Open”.

9. The values you entered in the csv file will appear in the User-

Defined Table.

10.If the program finds anything wrong with the values that were

entered, the box containing those values will turn red. Make sure

that you have entered valid characters for each field.

11.Once all of the data you wish to enter has been entered and is

correct, transmit the new data to the connected instrument by

pressing Transmit New Data.

21 • Conversion Table Tab

Page 25

PID Sensor Tab

The PID Sensor tab is used to view the pre-defined relative response

gases and to view or define the 1 user-defined relative response gas.

Every gas has a low and high range which are displayed in the Low

Range tab and High Range tab, respectively.

Figure 16: PID Sensor

There are 13 columns in both the High and Low Range tabs:

•No

This column represents the gas number. They are numbered 1-17.

•Name

This is what will appear in the Relative Response list of gases. The

name can be up to 3 characters long and the characters must be

upper case letters or numbers. No special characters may be used in

the Name column.

• Long Name

The Long Name column is used to better describe the target gas. It

may contain any character in upper- or lower-case.

PID Sensor Tab • 22

Page 26

• Full Scale

This is the full scale value for the target gas.

•Point

The point value indicates to what decimal place the gas readings are

shown. A value of 1/1 indicates a r eading to th e “ones” plac e whil e

a value of 1/100 indicates a reading to the “hundredths” place.

• Unit

The unit describes what units the gas reading is provided in. All

units are in ppm. While this parameter may be changed in the csv

file, units of ppm are the only acceptable units and changing this

parameter to %LEL or %vol will change the unit box to red.

• Digit

The digit is the increment of the gas readings.

•1st

This column is for the low alarm point of each gas in ppm units.

• 2nd

This column is for the high alarm point of each gas in ppm units.

• STEL

The STEL column displays the STEL values for each gas.

•TWA

The TWA column displays the TWA values for each gas.

• AutoCal

The AutoCal values are those that come up during the auto

calibration procedure. They are default values that may be changed

if the gas concentration in the calibration cylinder is different.

•Factor

This value is the Relative Response Factor for the PID channel. The

factor for each pre-defined gas is factory de fined. The factor for the

user defined gas must be obtained from Table 4 on page 29 or

through testing as described in “Obtaining a Relative Response

Factor” on page 28. A valid character for the Factor is a value

between 0.01 and 25.00.

23 • PID Sensor Tab

Page 27

There are limitations for the full scale and increment values that

depend on the factor for both the high range and the low range. Table 2

and Table 3 below list these limitations.

Table 1: High Range PID

Factor

Full Scale

(ppm)

Increment

0.25-0.49 500 0.2

0.50-0.74 1000 1

0.75-0.99 1500 1

1.00-1.24 2000 1

1.25-1.49 2500 1

1.50-1.99 3000 2

2.00-2.49 4000 2

2.50-4.99 5000 2

5.00-7.49 10000 10

7.50-9.99 15000 10

10.00-14.49 20000 10

15.00-24.49 30000 20

25.00 50000 20

Table 2: Low Range PID

Factor

Full Scale

(ppm)

Increment

0.20-0.29 10.00 0.01

0.30-0.39 15.00 0.01

0.40-0.49 20.00 0.01

0.50-0.59 25.00 0.01

0.60-0.79 30.00 0.02

0.80-0.99 40.00 0.02

PID Sensor Tab • 24

Page 28

Table 2: Low Range PID

Factor

Full Scale

(ppm)

Increment

1.00-1.99 50.00 0.02

2.00-2.99 100.0 0.1

3.00-3.99 150.0 0.1

4.00-5.99 200.0 0.1

6.00-7.99 300.0 0.2

8.00-9.99 400.0 0.2

10.00 500.0 0.2

While the pre-defined gases may not be edited, the 1 user-defined gas

may be edited by doing the following:

1. With Maintenance Data Loader Program running, click on the PID

Sensor tab and then click on the High Range tab.

25 • PID Sensor Tab

Figure 17: High Range Tab

Page 29

NOTE: Make sure you have downloaded the data from the EAGLE 2

to avoid erasing its data when updating the instrument using

the Transmit New Data button.

2. If no user-defined PID gas has been previously defined for the

connected instrument, the name and long name will both appear as

PID for the High Range and Low Range tabs. The full scale, digit,

and factor values will appear as shown in Table 4 below. The rest

of the fields will contain asterisks (*****).

Table 3: Default Values for User Defined PID Gas

Full Scale (ppm) Digit Factor

High Range

Low Range

3. Export the current data by pressing the “Export csv file” button.

2000 2 1.00

50.00 0.02 1.00

Choose the file path you wish to save the file in.

Figure 18: Save As

PID Sensor Tab • 26

Page 30

4. Open the csv file using Notepad, Word, or WordPad. The example

below shows a csv file opened in WordPad. The user defined PID

gas is number 17.

Figure 19: CSV File

5. The values in the csv file are all separated by commas. These

values are in the same order as the columns in the Maintenance

Data Loader Program. The first value is the gas number , the second

is the gas name, etc.

6. Edit the values you wish to change and save the file.

7. Return to the Maintenance Data Loader Program with the High

Range tab still up and press “Import csv file”.

8. Choose the file you just edited and press “Open”.

9. The values you entered in the csv file will appear in the High

Range tab.

10.If the program finds anything wrong with the values that were

entered, the box containing those values will turn red. Make sure

that you have entered valid characters for each field.

NOTE: The Name and Long Name for the Low Range and High

Range tabs must agree. If they do not, the program will keep

the Low Range Name and Long Name and change the High

11.Repeat step 1-step 10 for the Low Range tab.

12.Once all of the data you wish to enter has been entered and is

27 • PID Sensor Tab

Range to agree with it.

Page 31

correct, transmit the new data to the connected instrument by

pressing “Transmit New Data”.

Obtaining a Relative

Response Factor

If the gas that you want to monitor on the catalytic combustible or PID

channel is not included in the catalytic or PID relative reasponse lists,

you may define up to 5 gases for the catalytic combustible channel

using the Conversion Table tab and 1 gas for the PID channel using the

PID Sensor tab. Testing must be done using the desired target gas in

order to obtain the response factor value for the catalytic combustible

channel. To determine the relative response factor value for the PID

channel, first look in T able 4 for the desired gas. If the desired gas does

not appear in the table, you must obtain the response factor through the

testing procedure described below.

To determine the relative response factor value for the catalytic or PID

channels, do the following:

1. For determining the catalytic combustible channel relative

response factor, calibrate the catalytic combustible channel to

methane. For determining the PID channel relative response factor ,

calibrate the PID channel to isobutylene.

2. Obtain a gas sample of known concentration for the target gas you

wish to define. The sample needs to be at least 10% of the full

scale but RKI Instruments, Inc. recommends using 50% of the full

scale. If the concentration tested results in an overscale reading,

test a lower concentration.

3. Apply the gas sample to the EAGLE 2 and take note of the reading.

If the gas sample is of 50 %LEL concentration and the EAGLE 2

display shows a reading of 25 %LEL, then the factor for that gas is

2. Conversely, if the gas sample is of 50 %LEL concentration and

the EAGLE 2 display shows a reading of 100 %LEL, then the

factor for that gas is 0.5. This conversion factor value is what you

will enter in the Factor column of the gas you are defining.

Table 4 below has 4 columns:

• Gas/VOC-The most common name for the VOC (volatile organic

Obtaining a Relative Response Factor • 28

Page 32

compound)

• CAS No.-Sometimes it is easier to identify a VOC from the

internationally recognized CAS (Chemical Abstracts Service)

number

• Formula-Molecular formula for each VOC

• Response Factor (RF)-The relative response factor for each gas.

This is the value that is plugged into the Eagle 2 Maintenance Data

Loader Program.

Some abbreviations that appear in the table are:

• ZR-No response

• NV-Cannot be measured

Table 4: Response Factors Relative to Isobutylene

Gas/ VOC CAS No. Formula Relative

Response

Acetaldehyde 75-07-0 C2H4O 4.9

Acetic Acid 64-17-7 C2H4O2 36

Acetic Anhydride 108-24-7 C4H6O3 4

Acetone 67-64-1 C3H6O 0.7

Acetonitrile 75-05-8 CH3CN ZR

Acetylene 74-86-2 C2H2 ZR

Acrolein 107-02-8 C3H4O 4

Acrylic Acid 79-10-7 C3H4O2 2.7

Acrylonitrile 107-13-1 C3H3N ZR

Allyl alcohol 107-18-6 C3H6O 2.1

Allyl chloride 107-05-1 C3H5Cl 4.5

Ammonia 7664-41-7 NH3 8.5

Amyl acetate, n- 628-63-7 C7H14O2 1 . 8

Amyl alcohol 71-41-0 C5H12O 3.2

Aniline 62-53-3 C6H7N 0.5

Anisole 100-66-3 C7H8O 0.5

Arsine 7784-42-1 AsH3 2.5

Asphalt, petroleum fu m es 8052-42-4 1

Benzaldehyde 100-52-7 C7H6O 0.9

Benzene 71-43-2 C6H6 0.5

Benzenethiol 108-98-5 C6H5SH 0.7

Benzonitrile 100-47-0 C7H5N 0.7

Benzyl alcohol 100-51-6 C7H8O 1.3

Benzyl chloride 100-44-7 C7H7Cl 0.6

Benzyl formate 104-57-4 C8H8O2 0.8

29 • Obtaining a Relative Response Factor

Page 33

Gas/ VOC CAS No. Formula Relative

Response

Biphenyl 92-52-4 C12H10 0.4

Bis(2,3-epoxypropyl) ether 7/5/38 C6H10O3 3

Boron trifluoride 7637 07 2 BF3 ZR

Bromine 7726-95-6 Br2 20

Bromine pentafluoride 7789-30-2 BrF5 ZR

Bromobenzene 108-86-1 C6H5Br 0.7

Bromochloromethane 74-97-5 CH2ClBr ZR

Bromoethane 74-96-4 C2H5Br 5

Bromoethyl methyl ether, 2- 6482-24-2 C3H7OBr 2.5

Bromoform 75-25-2 CHBr3 2.8

Bromopropane, 1- 106-94-5 C3 H 7Br 1. 3

Bromotrifluoromethane 75-63-8 CF3Br ZR

Butadiene 106-99-0 C4H6 0.8

Butadiene diepoxid e, 1, 3- 146 4- 53-5 C4H6O2 4

Butane, n- 1 06-97-8 C4H10 46

Butanol, 1- 71-36-3 C4H10O 4

Buten-3-ol, 1- 598-32-3 C4H8O 1.2

Butene, 1- 1 06-98-9 C4H8 1.3

Butoxyethanol, 2- 111-76-2 C6H14O2 1.1

Butyl acetate, n- 123-86-4 C6H12O2 2.4

Butyl acrylate, n- 141-32-2 C7H12O2 1.5

Butyl lactate 138-22-7 C7H14O3 2.5

Butyl mercaptan 109-79-5 C4H10S 0.5

Butylamine, 2- 513-49-5 C4H11N 0.9

Butylamine, n- 109-73-9 C4H11N 1

Camphene 565-00-4 C10H16 0.5

Carbon diox i de 124-38-9 CO2 ZR

Carbon disulfide 75-15-0 CS2 1.4

Carbon monoxide 630-08-0 CO ZR

Carbon tetrabromide 558-13-4 CBr4 3

Carbon tetrachloride 56-23-5 CCl4 ZR

Carbonyl su l phide 463-58-1 COS ZR

Carvone, R- 6485-40-1 C10H14O 1

Chlorine 7782-50-5 Cl2 ZR

Chlorine dioxide 10049-04-4 ClO2 1

Chlorine trifluoride 7790-91-2 ClF3 ZR

Chloro-1,1,1,2-

tetrafluoroethane

Chloro-1,1,1-trifluo ro ethane, 2- 75-88-7 C2H2ClF3 ZR

Chloro-1,1,2,2tetrafluoroethane

Chloro-1,1,2-trifluoro et hane, 1- 421-04-5 C2H2ClF3 ZR

Chloro-1,1-difluoroethane, 1- 75-68-3 C2H3ClF2 ZR

Chloro-1,1-difluoroethane, 1- 75-68-3 C2H3ClF2 ZR

Chloro-1,1-difluoroethane, 2- 338-65-8 C2H3ClF2 ZR

Chloro-1,2,2-trifluoroethane 431-07-2 C2H2ClF3 ZR

2837-89-0 C2HClF4 ZR

354-25-6 C2HClF4 ZR

Obtaining a Relative Response Factor • 30

Page 34

Gas/ VOC CAS No. Formula Relative

Response

Chloro-1,3-butadie ne, 2- 126-99-8 C4H5Cl 3.2

Chloro-1-fluoroethane, 1- 1615-75 -4 C2H4ClF ZR

Chloro-2-fluoroethane, 1- 762-50-5 C2H4ClF ZR

Chloroacetaldehyde 107-20-0 C2H3OCl ZR

Chlorobenzene 108-90-7 C6H5Cl 0.5

Chlorodifluoromethane 75-45-6 CHClF2 ZR

Chloroethane 75-00-3 C2H5Cl ZR

Chloroethanol 2- 107-07-3 C2H5ClO 10

Chloroethyl methyl ether, 2- 627-42-9 C3H7ClO 2.6

Chlorofluoromethane 593-70-4 CH2ClF ZR

Chloroform 67-66-3 CHCl3 ZR

Chloromethane 74-87-3 CH3Cl ZR

Chloropentafluoroethane 76-15-3 C2ClF5 ZR

Chlorotoluene, o- 95-49-8 C7H7Cl 0.5

Chlorotoluene, p- 108-41-8 C7H7Cl 0.5

Chlorotrifluoroethylene 79-38-9 C2ClF3 1

Chlorotrifluoromethane 75-72-9 CClF3 ZR

Citral 5392-40-5 C10H16O 1

Citronellol 26489-01-0 C10H20O 1

Cresol, m- 108-39-4 C7H8O 1.1

Cresol, o- 95-48-7 C7H8O 1.1

Cresol, p- 106-44-5 C7H8O 1.1

Crotonaldehyde 4170-30-3 C4H6O 1

Cumene 98-82-8 C9H12 0.6

Cyanamide 420-04-2 CH2N2 ZR

Cyanogen bromide 506-68-3 CN Br ZR

Cyanogen chloride 506-77-4 CNCl ZR

Cyclohexane 110-82-7 C6H12 1.3

Cyclohexanol 108-93-0 C6H12O 2.9

Cyclohexanone 108-94-1 C6H10O 1.1

Cyclohexene 110-83-8 C6H10 0.8

Cyclohexylamine 108-91-8 C6H13N 1

Cyclopentane 287-92-3 C5H10 4

Decane, n- 124-18-5 C10H22 1

Diacetone alcoho l 123-42-2 C6H12O2 0.8

Dibenzoyl peroxide 94-36-0 C14H10O4 0.8

Diborane 19287-45-7 B2H6 ZR

Dibromochloromethane 124-48-1 CHBr2Cl 10

Dibromodifluoromethane 75-61-6 CF2Br2 ZR

Dibromoethane 1,2- 106-93-4 C2H4Br2 2

Dibromotetrafluoroethane ,

1,2Dibutyl hydrogen phosphate 107-66-4 HC8H18

Dichloro-1,1,1-trifluoroethane,

2,2-

124-73-2 C2F4Br2 ZR

4

PO4

306-83-2 C2HCl2F3 ZR

31 • Obtaining a Relative Response Factor

Page 35

Gas/ VOC CAS No. Formula Relative

Response

Dichloro-1,1-diflu oroethane,

1,2Dichloro-1,2,2-trifluoroethane,

1,2Dichloro-1,2-diflu oroethane,

1,2Dichloro-1-fluoroet ha ne, 1, 1- 1717-00-6 C2H3Cl2F ZR

Dichloro-1-fluoroet ha ne, 1, 1- 1717-00-6 C2H3Cl2F ZR

Dichloro-1-fluoroet ha ne, 1, 2- 430-57-9 C2H3Cl2F ZR

Dichloro-1-propene, 2, 3- 78 -8 8- 6 C3H4Cl2 1.4

Dichloro-2,2,-difluoroethane,

1,1Dichloroacetylene 7572-29-4 C2Cl2 5

Dichlorobenzene o- 95-50-1 C6H4Cl2 0.5

Dichlorodifluoromethane 75-71-8 CCl2F2 ZR

Dichloroethane 1,2- 107-06-2 C2H4Cl2 ZR

Dichloroethane, 1,1- 75-34-3 C2H4Cl2 ZR

Dichloroethene, 1,1- 75-35-4 C2H2Cl2 1

Dichloroethene, cis -1,2- 156-59-2 C2H2Cl2 0. 8

Dichloroethene, tra ns- 1, 2- 540-59-0 C2H2 Cl2 0.7

Dichloroethylene 1,2- 540-59-0 C2H2Cl2 0.8

Dichlorofluoromethane 75-43-4 CHFCl2 ZR

Dichloromethane 75-09-2 CH2Cl2 39

Dichloropropane, 1,2- 78-87-5 C3H6Cl2 ZR

Dichlorotetrafluoroet hane, 1,1- 374-07-2 C2Cl2F4 ZR

Dichlorotetrafluoroet hane, 1,2- 76-14-2 C2Cl2F4 ZR

Dicyclopentadiene 77-73-6 C10H12 0.9

Diesel Fuel 68334-30-5 0.8

Diethyl ether 60-29-7 C4H10O 0.9

Diethyl maleate 141-05-9 C8H12O4 2

Diethyl pht halate 84-66-2 C12H14O4 1

Diethyl sulphate 64-67-5 C4H10SO4 3

Diethyl sul phide 352-93-2 C4H10S 0.6

Diethylamine 109-89-7 C4H11N 1

Diethylaminoethanol, 2- 100-37-8 C6H15ON 2.7

Diethylaminopropylamine, 3- 104-78-9 C7H18N2 1

Difluoroethane, 1,1- 75-37-6 C2H4F2 ZR

Difluoroethane, 1,2- 624-72-6 C2H4F2 ZR

Difluoromethane 75-10-5 CH2F2 ZR

Dihydrogen selenid e 7783 07 5 H 2Se 1

Dihydroxy benzene, 1,2 120-80- 9 C6H6O2 1

Dihydroxy benzene, 1,3 108-46- 3 C6H6O2 1

Diisobutylene 107-39-1 C8H16 0.6

Diisopropyl ether 108-20-3 C6H14O 0.7

Diisopropylamine 108-18-9 C6H15N 0.7

Diketene 674-82-8 C4H4O2 2.2

Dimethoxymethane 109-87-5 C3H8O2 1.4

1649-08-7

354-23-4 C2HCl2F3 ZR

631-06-1

79-35-6

C2H2Cl2F2

C2H2Cl2F2

C2H2Cl2F2

ZR

ZR

ZR

Obtaining a Relative Response Factor • 32

Page 36

Gas/ VOC CAS No. Formula Relative

Response

Dimethyl cyclohexane, 1,2- 583-57-3 C8H16 1.1

Dimethyl di sulphide 624-92-0 C2H6S2 0.2

Dimethyl ether 115-10-6 C2H6O 1.3

Dimethyl ph t halate 131-11-3 C10H10O4 1

Dimethyl sulphate 77-78-1 C2H6O4S ZR

Dimethyl sulphide 75-18-3 C2H6S 0.5

Dimethylacetamide N,N- 127-19-5 C4H9NO 1.3

Dimethylamine 124-40-3 C2H7N 1.4

Dimethylaminoethanol 108-01-0 C4H11NO 1.5

Dimethylaniline, NN- 121-69-7 C8H11N 0.6

Dimethylbutyl acetat e 108-84-9 C8H16O2 1.6

Dimethylethylamine, NN- 598-56-1 C4H11N 0.8

Dimethylformamide 68-12-2 C3H7NO 0.9

Dimethylheptan-4-one, 2,6- 108-83-8 C9H18O 0.8

Dimethylhydrazine, 1,1- 57-14-7 C2H8N 2 1

Dinitrobenzene, m- 99-65-0 C6H4N2O4 3

Dinitrobenzene, o- 528-29-0 C6H4N2O4 ZR

Dinitrobenzene, p- 100-25-4 C6H4N2O4 5

Dinonyl phthalate 84-76-4 C26H42O 4 1

Dioxane 1,2- C4H8O2 1.5

Dioxane 1,4- 123-91-1 C4H8O2 1.5

Dipentene 138-86-3 C10H16 0.9

Diphenyl ether 1 01-84-8 C12H10O 0.8

Disulphur decafluoride 5714-22-7 S2F10 ZR

Disulphur dichloride 10025-67-9 S2Cl2 3

Di-tert-butyl-p-cresol 2409-55-4 C11H16O 1

Divinylbenzene 1321-74-0 C10H10 0.4

Dodecanol 112-53-8 C12H26O 0.9

Enflurane 13838-16-9

Epichlorohydrin 106-89-8 C3H5ClO 8

Epoxypropyl isop ro pyl ether,

2,3Ethane 74-84-0 C2H6 ZR

Ethanol 64-17-5 C2H6O 8.7

Ethanolamine 141-43-5 C2H7NO 3

Ethoxy-2-propanol, 1- 1569-02-4 C5H10O2 2

Ethoxyethanol, 2- 110-80-5 C4H10O2 29.8

Ethoxyethyl acetate, 2- 111-15-9 C6H12O3 3

Ethyl (S)-(-)-lactate 97-64-3 C5H10O3 3

Ethyl acet ate 141-78-6 C4H8O2 3.6

Ethyl acrylate 140-88-5 C5H8O2 2

Ethyl amine 75-04-7 C2H7N 1

Ethyl benzene 100-41-4 C8H10 0.5

Ethyl butyrate 105-54-4 C6H12O2 1

Ethyl chloroformate 541-41-3 C3H5O2Cl 80

Ethyl cyanoacrylate 7085-85-0 C6H7O2N 1.5

Ethyl decanoate 110-38-3 C12H24O2 1.8

Ethyl form ate 109-94-4 C3H6O2 30

4016-14-2 C6H12O2 1.1

C4H2F5ClO

ZR

33 • Obtaining a Relative Response Factor

Page 37

Gas/ VOC CAS No. Formula Relative

Response

Ethyl hexanoate 123-66-0 C8H16O2 2.6

Ethyl hexanol, 2- 105-76-7 C8H18O 1.5

Ethyl hexyl acrylate , 2- 103-11-7 C11H20O2 1

Ethyl mercaptan 75-08-1 C2H6S 0.7

Ethyl octanoate 106-32-1 C10H20O2 2.3

Ethylene 74-85-1 C2H4 8

Ethylene dinitrate 628-96-6 C2H4O6N2 ZR

Ethylene glycol 107-21-1 C2H6O2 20

Ethylene oxide 75-21-8 C2H4O 15

Ferrocene 102-54-5 C10H10Fe 0.8

Fluorine 7782-41-4 F2 ZR

Fluoroethane 353-33-6 C2H5F ZR

Fluoromethane 593-53-3 CH3F ZR

Formaldehyde 50-00-0 CH2O ZR

Formamide 75-12-7 CH3ON 2

Formic acid 64-18-6 CH2O2 ZR

Furfural 98-01-1 C5H4O2 1.4

Furfuryl alcohol 98-00-0 C5 H 6O2 2

Gasoline vapors 8006-61-9 1.1

Gasoline vapors 8006-61-9 0.8

Gasoline vapors 92 octane 8006-61-9 0.8

Germane 7782-65-2 GeH4 10

Glutaraldehyde 111-30-8 C5H8O2 0.9

Halothane 151-67-7

Helium He ZR

Heptan-2-one 110-43-0 C7H14O 0.7

Heptan-3-one 106-35-4 C7H14O 0.8

Heptane n- 142-82-5 C7H16 2. 1

Hexachloroethane 67-72-1 C2Cl6 ZR

Hexafluoroethane 76-16-4 C2F6 ZR

Hexamethyldisilazane,

1,1,1,3,3,3-.

Hexamethyldisiloxane. 107-46-0

Hexan-2-one 591-78-6 C6H12O 0.8

Hexane n- 1 10-54-3 C6H14 4.2

Hexene, 1- 592-41-6 C6H12 0.9

Hydrazine 302-01-2 H4N2 3

Hydrazoic acid 7782-79-8 HN3 ZR

Hydrogen 1333-74-0 H2 ZR

Hydrogen bromide 10035-10-6 HBr ZR

Hydrogen chloride 7647-01-0 HCl ZR

Hydrogen cyanide 74-90-8 HCN ZR

Hydrogen fluoride 7664- 39-3 HF ZR

Hydrogen peroxide 772 2- 84-1 H2O2 4

Hydrogen sulfide 6/4/83 H2S 4

999-97-3

CF3CHBrCl

C6H19NSi2

C6H18OSi2

ZR

1

0.3

Obtaining a Relative Response Factor • 34

Page 38

Gas/ VOC CAS No. Formula Relative

Response

Hydroquinone 123-31-9 C6H6O2 0.8

Hydroxypropyl acryl at e 2- 999 -61 -1 C6H10O3 1.5

Iminodi(ethylamine) 2,2- 111-40-0 C4H13N3 0. 9

Iminodiethanol 2,2' - 111-42-2 C4H11NO2 1.6

Indene 95-13-6 C9H8 0.5

Iodine 7553-56-2 I2 0.2

Iodoform 75-47-8 CHI3 1.5

Iodomethane 74-88-4 CH3I 0.4

Isoamyl acetate 123-92-2 C7H14O2 1.6

Isobutane 75-28-5 C4H10 8

Isobutanol 78-83-1 C4H10O 3.5

Isobutyl acetate 110-19-0 C6H12O2 2.3

Isobutyl acrylate 106-63-8 C7H12O2 1.3

Isobutylene 115-11-7 C4H8 1

Isobutyraldehyde 78-84-2 C4H8O 1.2

Isocyanates, all NV

Isodecanol 25339-17-7 C10H22O 0.9

Isoflurane 26675-46-7

Isononanol 2452-97-9 C9H20O 1.5

Isooctane 565-75-3 C8H18 1.1

Isooctanol 26952-21-6 C8H18O 1.7

Isopentane 78-78-4 C5H12 6

Isophorone 78-59-1 C9H14O 0.8

Isoprene 78-79-5 C5H8 0.7

Isopropanol 67-63-0 C3H8O 4.4

Isopropyl acetate 108-21-4 C5H10O2 2.2

Isopropyl chloroformate 108-23-6 C4H7O2Cl 1.6

Jet Fuel JP-4 0.8

Jet Fuel JP-5 0.7

Jet Fuel JP-8 0.7

Kerosene 8008-20-6 0.8

Ketene 463-51-4 C2H2O 3

Liquefied petroleum gas 68476-85-7 ZR

Maleic anhydride 108-31-6 C4H2O3 2

Mercaptoacetic acid 68-11-1 C2H4O2S 1

Mercury 7439-97-6 Hg NV

Mercury alkyls NV

Mesitylene 108-67-8 C9H12 0.3

Methacrylic acid 79-41-4 C4H6O2 2.3

Methacrylonitrile 126-98-7 C4H5N 5

Methane 74-82-8 CH4 ZR

Methanol 67-56-1 CH4O 200

Methoxyethanol, 2- 109-86-4 C3H8O2 2.7

Methoxyethoxyethanol, 2- 111-77-3 C5H12O3 1.4

Methoxymethyl ethoxy-2-

propanol

Methoxypropan-2-ol 107-98-2 C4H10O2 3

34590-94-8 C7H16O3 1.3

C3H2ClF5O

ZR

35 • Obtaining a Relative Response Factor

Page 39

Gas/ VOC CAS No. Formula Relative

Response

Methoxypropyl acetate 108-65-6 C6H12O3 1.2

Methyl acetate 79-20-9 C3H6O2 5.2

Methyl acrylate 96 -3 3- 3 C4H6O2 3.4

Methyl bromide 74-83-9 CH3Br 1.9

Methyl cyanoacrylate 137-05-3 C5H5O2N 5

Methyl ethyl ketone 78-93-3 C4H8O 0.8

Methyl ethyl ketone p er oxi des 1338-23-4 C8H 18O2 0.8

Methyl formate 107-31-3 C2H4O2 ZR

Methyl isobutyl ketone 108-10-1 C6H12O 0.8

Methyl isocyanate 624-83-9 C2H3NO ZR

Methyl isothiocyan at e 556-61-6 C2H3NS 0.6

Methyl mercaptan 74-93-1 CH 4S 0.7

Methyl methacryl ate 80-62-6 C5H8O2 1.6

Methyl propyl ketone 107-87-9 C5H10O 0.8

Methyl salicylate 119-36-8 C8H8O3 1.2

Methyl sulphide 75-18-3 C2H6S 0.5

Methyl t-butyl ether 1634-04-4 C5H12O 0.8

Methyl-2-propen- 1-ol, 2- 51 -4 2- 8 C4H8O 1.1

Methyl-2-pyrrolidinone, N- 872-50-4 C5H9NO 0.9

Methyl-4,6-dinitrophenol, 2- 534-52-1 C7H6N2O5 3

Methyl-5-hepten- 2- one, 6- 110-93-0 C8H14O 0.8

Methylamine 74-89-5 CH5N 1.4

Methylbutan-1-ol , 3 - 123 -51 -3 C5H 12O 3.4

Methylcyclohexane 108-87-2 C7H14 1.1

Methylcyclohexanol, 4- 589-91-3 C7H14O 2.4

Methylcyclohexa n o ne 2- 583-60-8 C7H12 O 1

Methylheptan-3-one, 5- 541-85-5 C8H16O 0.8

Methylhexan-2-one, 5- 110-12-3 C7H14O 0.8

Methylhydrazine 60-34-4 CH6N2 1.3

Methyl-N-2,4, 6-

tetranitroaniline, NMethylpent-3-en- 2- one, 4- 141-79-7 C6H10O 0.7

Methylpentan-2-ol , 4- 108 -11-2 C6H14O 2.8

Methylpentane-2 ,4-diol, 2- 107-41-5 C6H14O2 4

Methylpropan-2-ol, 2- 75-65-0 C4H10O 3.5

Methylstyrene 25013-15-4 C9H10 0.5

Mineral oil 8042-47-5 0.8

Mineral spirits 64475-85-0 0.8

Naphthalene 91-20-3 C10H8 0.4

Nitric oxide 10102-43-9 NO 8

Nitroaniline 4- 100-01-6 C6H6N2O2 0.8

Nitrobenzene 98-95-3 C6H5NO2 1.7

Nitroethane 79-24-3 C2H5NO2 ZR

Nitrogen dioxide 10102-44-0 NO2 10

Nitrogen trichloride 10025-85-1 NCl3 1

Nitrogen trifluoride 7783-54-2 NF3 ZR

Nitromethane 75-52-5 CH3NO2 ZR

Nitropropane, 1- 108-03-2 C3H7NO2 ZR

479-45-8 C7H5N5O8 3

Obtaining a Relative Response Factor • 36

Page 40

Gas/ VOC CAS No. Formula Relative

Response

Nitropropane, 2- 79-46-9 C3H7NO2 ZR

Nitrous oxide 10024-97-2 N2O ZR

Nonane, n- 111-84-2 C9H20 1. 3

Norbornadiene, 2,5 - 121 -46-0 C7H8 0.6

Octachloronaphthalene 2234-13-1 C10Cl8 1

Octane, n- 111-65-9 C8H18 1.6

Octene, 1- 111-66-0 C8H16 0.7

Oxalic acid 144-62-7 C2H2O4 ZR

Oxalonitrile 460-19-5 C2N2 ZR

Oxydietha nol 2,2- 111-4 6-6 C4H10O3 4

Oxygen O2 ZR

Ozone 10028-15-6 O3 ZR

Paraffin wax, fume 8002-74-2 1

Paraffins, normal 6477 1- 72-8 1

Pentacarbonyl iron 13463-40-6 FeC5O5 1

Pentachloroethane 76-01-7 C2HCl5 ZR

Pentachlorofluoroethane 354-56-3 C2Cl5F ZR

Pentafluoroethane 354-33-6 C2HF5 ZR

Pentan-2-one 107-87-9 C5H10O 0.8

Pentan-3-one 96-22-0 C5H10O 0.8

Pentandione, 2,4- 123-54-6 C5H8O2 0.8

Pentane, n- 109-66-0 C5H12 7.9

Peracetic acid 79-21-0 C2H4O3 2

Perchloryl fluoride 7616-94-6 Cl03F ZR

Perfluoropropane 76-19-7 C3F8 ZR

Petroleum ether 0.9

Phenol 108-95-2 C6H6O 1.2

Phenyl propene, 2- 98-83-9 C9H10 0.4

Phenyl-2,3-epoxypropyl ether 122-60-1 C9H10O2 0.8

Phenylenediamine, p- 106-50-3 C6H8N2 0.6

Phosgene 75-44-5 COCl2 ZR

Phosphine 7803-51-2 PH3 2

Picoline, 3- 108-99-6 C6H7N 0.9

Pinene, alpha 80-56-8 C10H16 0.3

Pinene, beta 127-91-3 C10H16 0.3

Piperidine 110-89-4 C5H11N 0.9

Piperylene 504-60-9 C5H8 0.7

Prop-2-yn-1-ol 107-19-7 C3H4O 1.3

Propan-1-ol 71-23-8 C3H8O 4.8

Propane 74-98-6 C3H8 ZR

Propane-1,2-diol, total 57-55-6 C3H8O2 10

Propene 115-07-1 C3H6 1.4

Propionaldehyde 123-38-6 C3H6O 1.7

Propionic acid 79-09-4 C3H6O2 8

Propyl acetate, n- 109-60-4 C5H10O2 2.5

Propylene dinitrate 6423-43-4 C3H6N2O6 ZR

37 • Obtaining a Relative Response Factor

Page 41

Gas/ VOC CAS No. Formula Relative

Response

Propylene oxide 75-56-9 C3H6O 7

Propyleneimine 75-55-8 C3H7N 1.3

Pyridine 110-86-1 C5H5N 0.8

Pyridylamine 2- 504-29-0 C5H6N2 0.8

Silane 7803-62-5 SiH4 ZR

Sodium fluoroacetate 62-74- 8

Styrene 100-42-5 C8H8 0.4

Sulphur dioxide 9/5/46 S O 2 ZR

Sulphur hexafluorid e 2551- 62-4 SF6 ZR

Sulphur tetrafluoride 7783-60-0 SF4 ZR

Sulphuric acid 7664-93-9 H2SO4 ZR

Sulphuryl fluoride 2699-79-8 SO2F2 ZR

Terphenyls C18H14 0.6

Terpinolene 586-62-9 C10H16 0.5

Tert-butanol 75-65-0 C4H10O 2.6

Tetrabrom oethane, 1, 1,2,2- 79-27- 6 C2H2Br4 2

Tetracarbonylnickel 13463-39-3 NiC4O4 1

Tetrachloro-1,2-

difluoroethane, 1,1, 2, 2Tetrachloro-1-fluoroethane,

1,1,2,2Tetrachloro-2,2difluoroethane, 1,1, 1, 2Tetrachloro-2-fluoroethane,

1,1,1,2Tetrachloroethane, 1,1,1,2- 630-20-6 C2H2Cl4 ZR

Tetrachloroethane, 1,1,2,2- 79-34-5 C2H2Cl4 ZR

Tetrachloroethylene 127-18-4 C2Cl4 0.7

Tetrachloronapht halenes, all

isomers

Tetraethyl orthosilicate 78-10-4

Tetraethyllead 78-00-2 C8H20Pb ZR

Tetrafluoroethane, 1, 1, 1,2- 8 11-97-2 C2H2F4 ZR

Tetrafluoroethane, 1, 1, 2,2- 3 59-35-3 C2H2F4 ZR

Tetrafluoroethylene 116-14-3 C2F4 1

Tetrafluoromethane 75-73-0 CF4 ZR

Tetrahydrofuran 109-99-9 C4H8O 1.6

Tetramethyl orthos ilicate 681-84-5

Tetramethyl succ in oni tri le 3333-52-6 C8H12N2 1

Therminol 1

Thionyl chloride 9/7/19 SOCl2 ZR

Toluene 108-88-3 C7H8 0.5

Toluene-2,4-diisocyanate 584-84-9 C9H6N2O2 1.6

Toluenesulphony l chl or ide, p- 98-59- 9 C7H7SO2

Toluidine, o- 95-53-4 C7H9N 0.5

Tributyl phosphate 126-73-8

76-12-0 C2Cl4F2 ZR

354-14-3 C2HCl4F ZR

76-11-9 C2Cl4F2 ZR

354-11-0 C2HCl4F ZR

20020-02-4 C10H4Cl4 1

C2H2O2FNa

C8H20O4Si

C4H12O4Si

Cl

C12H27O4P

ZR

2

ZR

3

5

Obtaining a Relative Response Factor • 38

Page 42

Gas/ VOC CAS No. Formula Relative

Response

Tributylamine 102-82-9 C12H27N 1

Trichloro-1,1-difluoroethane,

1,2,2Trichloro-1,2-difluoroethane,

1,1,2Trichloro-2,2-difluoroethane,

1,1,1Trichloro-2-fluoroethane,

1,1,2Trichlorobenzene 1,2,4- 120-82-1 C6H3Cl3 0.6

Trichloroethane, 1,1, 1- 71-55-6 C2H3C l3 ZR

Trichloroethane, 1,1, 2- 79-00-5 C2H3C l3 ZR

Trichloroethylene 79-01-6 C2HCl3 0.7

Trichlorofluoromethane 75-69-4 CCl3F ZR

Trichloronitromethane 76-06-2 CCl3NO2 ZR

Trichlorophenoxyacetic acid,

2,4,5Trichloropropane 1,2,3- 9 6-18-4 C3H5Cl3 ZR

Trichlorotrifluoroetha ne, 1,1,1- 354-58-5 C2Cl3F3 ZR

Trichlorotrifluoroetha ne, 1,1,2- 76-13-1 C2Cl3F3 ZR

Triethylamine 121-44-8 C6H15N 0.9

Trifluoroethane, 1,1,1- 420 -46 -2 C2H3F3 ZR

Trifluoroethane, 1,1,2- 430 -66 -0 C2H3F3 ZR

Trifluoroethanol, 2,2, 2- 75-89-8 C2H3F3O ZR

Trifluoromethane 75-46-7 CHF3 ZR

Trimethylamine 53-50-3 C3H9N 0.5

Trimethylbenzen e m i xt ur es C9H 12 0.3

Trimethylbenzen e, 1, 3, 5- 108-67-8 C9H12 0.3

Trinitrotoluene 2,4,6- 118-96-7 C7H5N3 O6 ZR

Turpentine 8006-64-2 C10H16 0.6

TVOC 1

Undecane, n- 1120-21-4 C1 1H 2 4 0.9

Vinyl acetate 108-05-2 C4H6O2 1.1

Vinyl bromi de 593-60-2 C2H3Br 1

Vinyl chloride 75-01-4 C2H3Cl 2.1

Vinyl-2-pyrrolidinone, 1- 88 -1 2- 0 C6H9NO 0.9

Xylene mixed isomer s 1330-20-7 C8H10 0.4

Xylene, m- 108-38-3 C8H10 0.4

Xylene, o- 95-47-6 C8H10 0.6

Xylene, p- 106-42-3 C8H10 0.6

Xylidine, all 1300-73-8 C8H11N 0.7

354-21-2 C2HCl3F2 ZR

354-15-4 C2HCl3F2 ZR

354-12-1 C2HCl3F2 ZR

359-28-4 C2H2Cl3F ZR

93-76-5 C8H5O3Cl 3 1

39 • Obtaining a Relative Response Factor

Page 43

Spare Parts List

Table 5: Spare Parts List

Part Number Description

47-5027RK Cable, USB/IrDA adapter

71-0154RK EAGLE 2 Operator’s Manual

71-0191RK EAGLE 2 Maintenance Data Loader Program Operator’s

Manual (this document)

71-8003RK Eagle 2 Product CD, Includes the Eagle 2 Data Logger

Management Program, the Eagle 2 Maintenance Program,

and Operator’s Manuals for Each

Spare Parts List • 40

Loading...

Loading...