Page 1

65-2619RK-CH4-4

M2 Transmitter

Operator’s Manual

Part Number: 71-0289RK

Revision: 0

Released: 12/27/13

RKI Instruments, Inc.

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before

operating instrument. Improper use of the gas monitor

could result in bodily harm or death.

Periodic calibration and maintenance of the gas

monitor is essential for proper operation and correct

readings. Please calibrate and maintain this instrument

regularly! Frequency of calibration depends upon the

type of use you have and the sensor types. Typical

calibration frequencies for most applications are

between 6 and 12 months, but can be required more

often or less often based on your usage.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 3

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in

materials, workmanship, and performance for a period of one year fr o m date of shipment

from RKI Instruments, Inc. Any parts found defective withi n tha t period will be repaired

or replaced, at our option, free of charge. This warranty does not apply to those items

which by their nature are subject to deterioration or consumption in normal ser v ice, and

which must be cleaned, repaired, or replaced on a routine basis. Examples of such items

are:

W arranty is voided by abuse including mechanical damage, alteration, rough handling, or

repair procedures not in accordance with the operator’s manual. This warranty indicates

the full extent of our liability , a nd we are not r esponsible for removal or r eplacement costs,

local repair costs, transportation costs, or contingent expenses incurred without our prior

approval.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF

RKI INSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF

ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR

OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors,

dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnificatio n f o r a n y a c c ident or damage caus e d b y t he op e ration of

this gas monitor, and our warranty is limited to the replacement of parts or our complete

goods.

65-2619RK-CH4-4 M2 Tr ans mitt er Oper a tor ’s Ma nual

Page 4

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the M2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

External Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 3: Installation & Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the M2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the M2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Information Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 - 20 mA Signal Output Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 5: Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Viewing & Changing M2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 6: Gas Type Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Selecting the Gas Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 5

Chapter 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibration Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Replacing the IR LEL Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 8: RS-485 Modbus Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wiring the M2 in a Modbus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Using the M2 in a 4-wire Modbus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Modbus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Supported Modbus Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A: Control Button Quick Reference Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix B: PLC and DCS Device Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Appendix C: Function Code 16 Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

(Appendix C available from RKI Instruments, Inc. Not included in manual as normally

provided with M2 detector head.)

65-2619RK-CH4-4 M2 Tr ans mitt er Oper a tor ’s Ma nual

Page 6

Chapter 1: Introduction

Overview

This chapter briefly describes the 65-2619RK-CH4-4 M2 Transmitter. This chapter also

describes the 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual (this document). Table 1

at the end of this chapter lists the specifications for the M2.

About the M2 Transmitte r

The M2 transmitter is a fixed mount, continuous-monitoring detector hea d. All user

adjustable parameters may be accessed using push button switches. In addition,

calibration may be performed non-intrusively by use of a magnetic wand accessory which

activates magnetic switches through a window at the front face of the detector head.

The M2 displays the current gas reading on an LCD display wh ich is visible through the

window in the cover (front face) and provides a 4 - 20 mA signa l which indicates the

target gas reading for use by a gas monitoring controller, recording device, or

programmable controller. The M2 also provides an RS-485 Modbus output. Three sets of

relay contacts, two controlled by the gas alarms and one by the fail alarm, rated at 115

VAC 5 amps are available for controlling devices such as lights or horns or for controlling

higher rated relays.

Four operating modes allow you to display and change setup and calibration settings and

change the gas type. They are Calibration Mode, Configuration Mode, Gas Type Mode,

and Modbus Mode.

About this Manual

The M2 Transmitter Operator’s Manual uses the following conventions for notes, cautions,

and warnings.

NOTE: Describes additional or critical info rmation.

CAUTION: Describes pote ntial damage to equip ment.

WARNING: Describes potential danger that can result in injury or death.

1 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 7

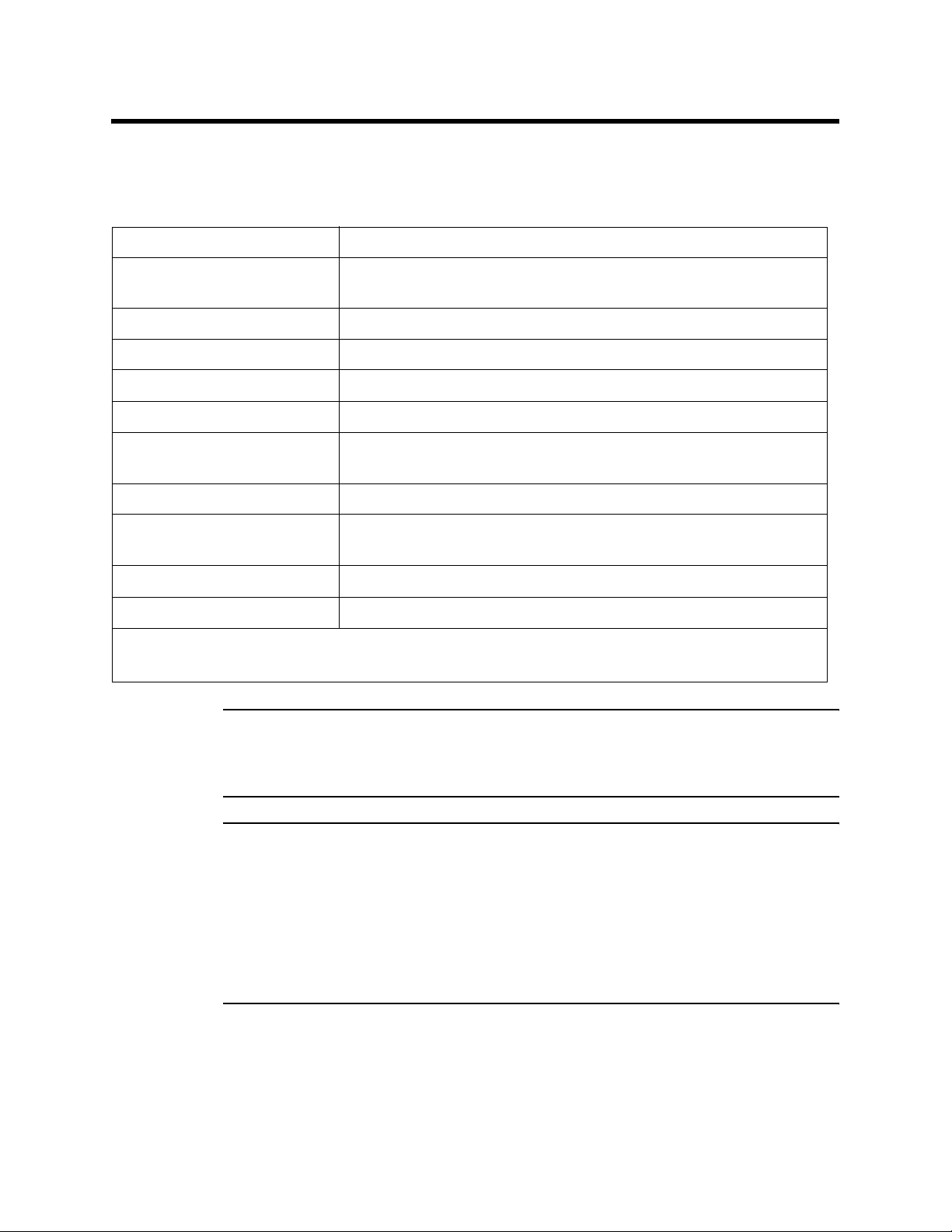

Specifications

Table 1 lists specifications for the M2.

Table 1: M2 Specifications

Target Gas/Detection Range Methane: 0 - 100% LEL, 1% LEL increments

Alarm Settings

(Alarm 1/Alarm 2)

Construction (housing) Explosion-proof Junction Box, NEMA 4

Area Classification Explosion-proof for Class I, Groups B, C, and D

Sampling Method Diffusion

Input Power 19 - 30 VDC

Controls • Three push button switches

Weight 5.5 lbs.

Signal Output • 4 to 20 mA, 500 ohms impedance max

Operating Temperature -20°C to 50°C

Accuracy ± 5% of reading or ± 2% of full scale (whichever is greater)

*

These are the RKI factory settings. You can change the alarm settings in Configuration Mode. See

“Viewing & Changing M2 Parameters” on page 21.

10 %LEL/50 %LEL

• Three magnetic switches for non-intrusive calibrati on

• RS-485 Modbus

WARNING: When using the M2, you must follow the instructions and warnings in

this manual to assure proper and safe operation of the M 2 and to

minimize the risk of personal injury. Be sure to maintain and periodically

calibrate the M2 as described in this manual.

WARNING: M2 det ector heads with firmware version 5.0 or later have a different

Modbus register assignment than M2s wi th previous versions of

firmware. If you are adding M2s with firmware version 5.0 or l ater to an

existing Modbus network installation, confirm what firmware version is

installed in the M2s already in the network and if necessary, take all steps

required to address the differences in Modbus register assignments. See

“Supported Modbus Functions” on page 40 for information on the current

Modbus register assignments. The firmware version i s shown on the

Information Screen described on page 16.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 2

Page 8

Chapter 2: Description

Overview

The M2 combustible gas transmitter utilizes an infrared type of detector which has some

advantages over a catalytic type of combustible detector. The infrared detector will

generally have a longer service life than a catalytic detector, it will require calibration less

often, and it can detect combustible gas even if there is no oxygen in the sample which

allows detection of combus tible gas in an inert atmosphere.

This chapter describes the components of the M2 transmitter. The transmitter is a 4 - 20

mA type detector head. It consists of the combustible gas detector, calibration adapter/

splash guard, terminal PCB, the M2 junction box, and the detector junction box. The two

junction box configuration is in tended for situations where the detector needs to be

installed at an inaccessible location. The detector junction box can be installed at the

inaccessible location and the M2 junction box can be installed in a more readily accessible

area.

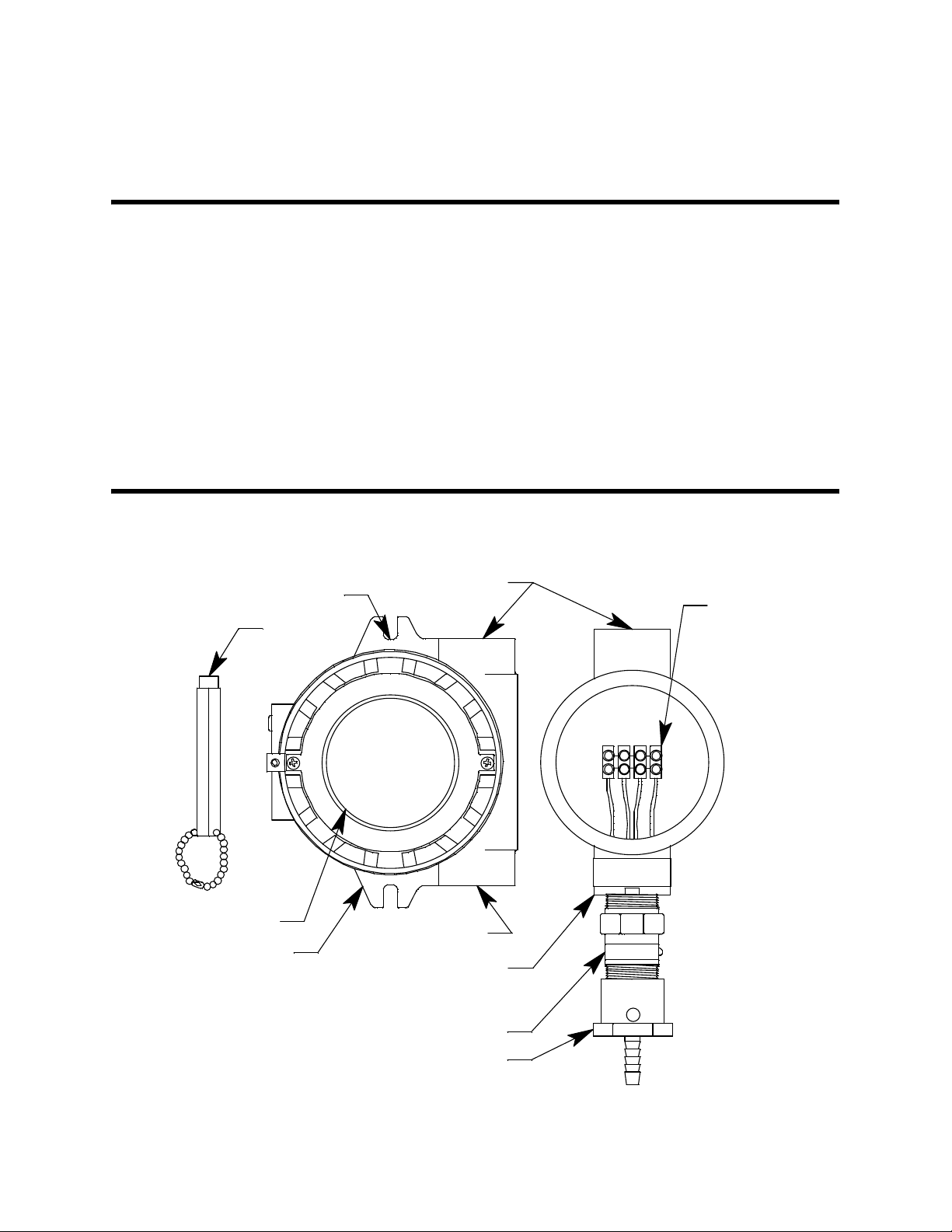

External Description

This section describes the junction boxes and all external components of the M2

transmitter.

Mounting Slot (2x)

Magnetic

Wand

Window

M2 Junction Box

3/4" NPT Conduit Hub

3/4" NPT Conduit Hub

Detector

Junction Box

Terminal

Strip

IR LEL Detector

Calibration Adapter/

Splash G uard

Figure 1: M2 External Component s

3 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 9

M2 Junction Box

The M2’s cast aluminum junction box protects the terminal PCB and wiring connections

made to the terminal PCB. Use the top 3/4’’ conduit hub to connect wiring from the

terminal PCB to external power and/or to an external device, typically an RKI controller.

Use the bottom 3/4” conduit hub to wire the remotely installed IR LEL detector. Use the

junction box’s two mounting slots to mount the M2 to a vertical surface at the monitoring

site. The window in the cover on the front of the junction box allows you to view the LCD

display and use the magnetic wand to actuate the magnetic control switches so you can

perform non-intrusive calibration. Removing the cover allows you to access the interior of

the junction box.

Detector Junction Box

The detector junction box is intended to be installed remotely from the M2 junction box.

The IR LEL detector is factory installed in the bottom 3/ 4” conduit hub. A terminal st rip is

provided for wiring connections and the detector is factory wired to one side of this

terminal strip. The other side of the terminal strip is for user-supplied wiring to the

detector terminal strip located in the M2 junction box. This wiring should go through the

top 3/4” conduit hub. Three spacers installed on the back of the junction box controls the

distance of the junction box from a mounting surface.

Infrared LEL Detector

The infrared LEL detector is made up of a miniature infrared combustible gas LEL

detector housed and encapsulated in a pipe nipple. The pipe nipple has 3/4” NPT thr eads

on each end and a 1 1/4” hex that allows removal or installation of the detector with a

wrench. A por ous flame arr e stor t hat is coat ed wit h a hydr o phobic f ilm that re pels liquids

is on one end of the detector and al lows samp le gas to enter the detector. Four color coded

leads, red, white, green, and black, extend from the other end of the detector. The leads

allow you to connect the detector to the terminal strip.

Calibration Adapter/Splash Guard

A calibration adapter/splash guard is installed on the IR LEL detector. A fitting at the

bottom of the calibration adapter/splash guard allows a length of tubing to be connected

for calibration and routed to a more easily accessible location (near the M2 junction box is

optimal for ease of calibration). The calibration adapter/splash guard also protects the

detector from splashing water or direct water spray.

Magnetic Wand

The magnetic wand is a short plastic rod with a magnet in one end. It is used to actuate

the magnetic control switches on the control PCB while the junction box cover is still

installed so that non-intrusive calibration can be performed.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 4

Page 10

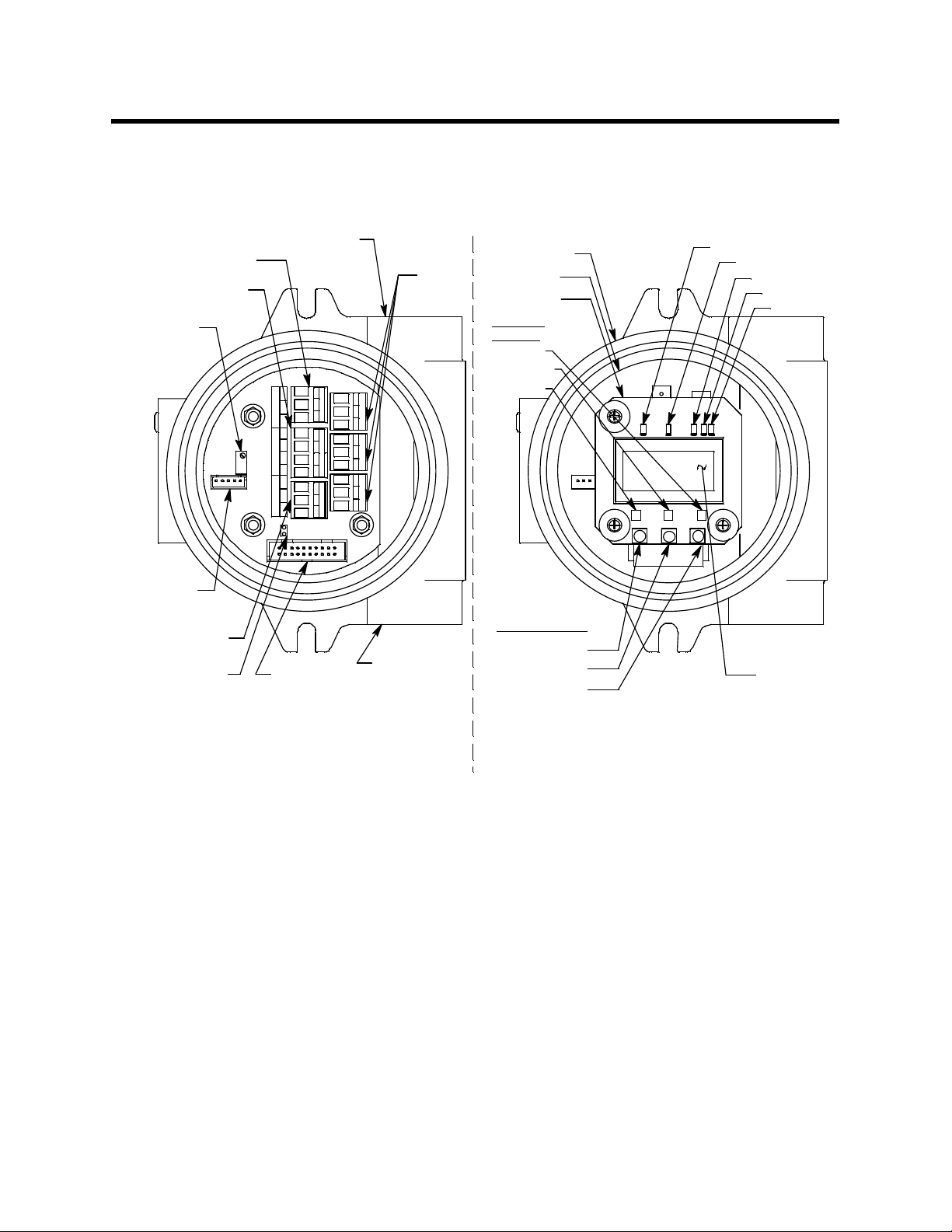

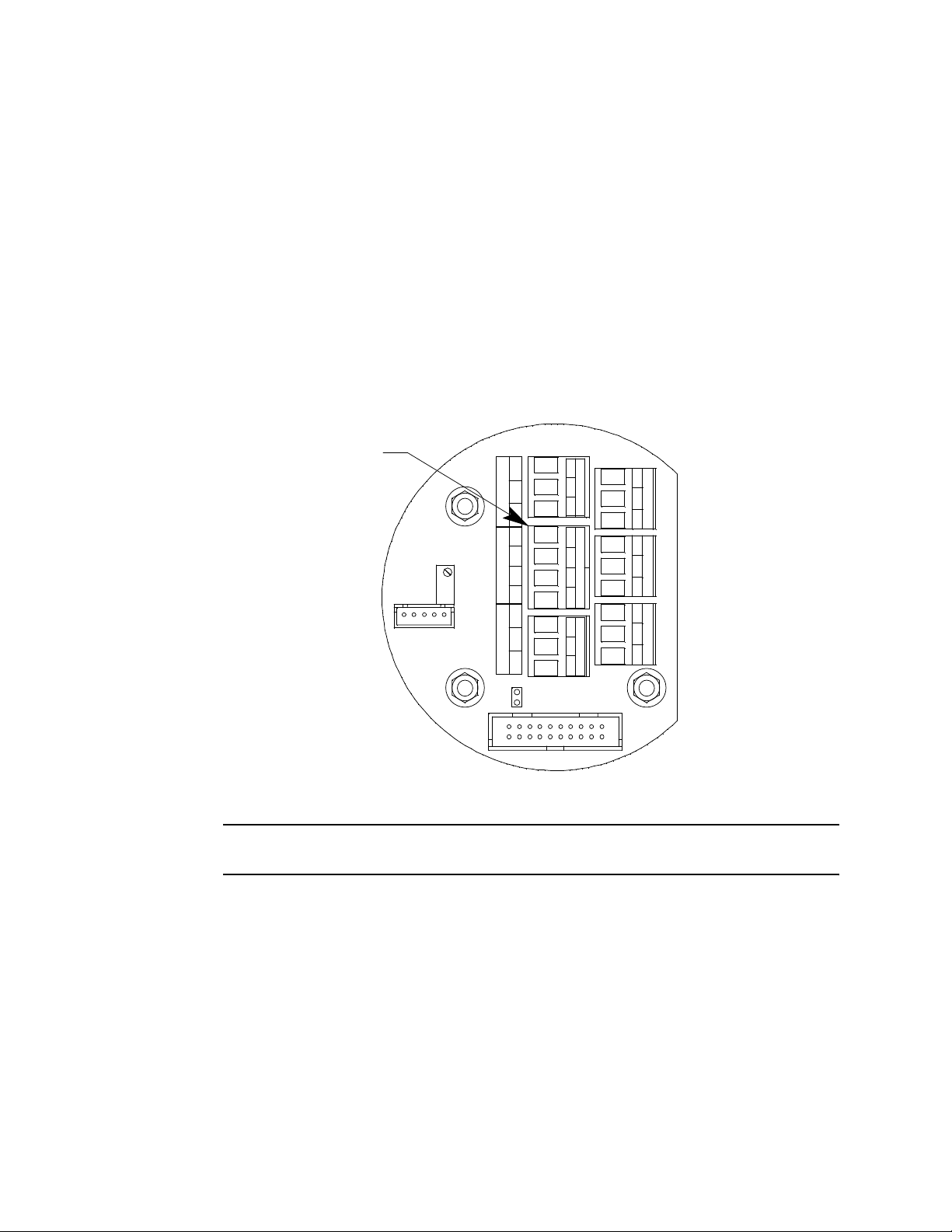

Internal Description

This section describes the interna l components of the M2. The internal components of the

M2 include t he t e rminal PCB which pro v i de s f or all the wiring connections to the M2 and

the control PCB which displays the gas reading and has the control buttons.

3/4" NPT Conduit Ope ni n g

Power/Signal

Terminal Strip

Detector Terminal Strip

Detector

Cur rent Po t

(Factory

Adjust)

Programming

Connector

(Factory Use)

Modbus

Terminal Strip

Termination

Jumper

for Wire Entry

- S +

PWR/SIG

- S +

LEL PWR/SIG

LEL

R W G B

R W G B

R S 485

RS 485

A B C

A B C

Display

Ribbon Cable

Connector

Relay

Terminal

Strips

FAIL

C NC NO

ALARM 1

C NC NO

ALARM 2

C NC NO

3/4" NPT Conduit

Op ening f or

Det e cto r J -Box

Wiring

Junction Box

Terminal PCB

Control PCB

Magnetic

Switches

UP/YES

DOWN/NO

ENTER

Push Button

Contro l Sw itc hes

UP/YES

DOWN/NO

ENTER

Fail LED

Al arm 1 LED

Al arm 2 L ED

RX L ED

TX LED

RKI INS TRUMENTS

M2 TRANSM ITTER

L CD Display

View With Cover and

Control PCB Removed

View With Cover Removed

Figure 2: M2 Internal Component s

Terminal PCB

The terminal PCB is encapsulated in epoxy for protection against moisture and physical

damage. It is mounted into the rear of the junction box with three standoffs and rests on a

thin layer of foam. A banana jack is screwed into each of the standoffs and used for

mounting the control PCB. The terminal PCB converts the electrical output from the

detector to a signal which can be displayed by the LCD display, a 4 - 20 mA signal (that is

proportional to the detection range), and an RS-485 Modbus output signal. The 4 - 20 mA

signal may be used by a recording device, gas monitor controller, or programmable

controller. The Modbus output may be used to connect the M2 to a Modbus network. The

terminal PCB also controls three relays, one fail and two gas alarm relays.

Two columns of plug-in style terminal strips are used to make all wiring connections to

the M2. The column on the left consists of the power/signal, detector, and Modbus

terminal strips. The column on the right consists of the relay terminal strips. A 20 position

connector at the bottom of the terminal PCB is used to connect the terminal PCB to the

5 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 11

control PCB with a ribbon cable. A 5 position connector on the left side of the terminal

PCB is used by factory or field service personnel to program the M2. A factory adjust pot

just above the programming connector is used to set the detector current.

Power/Sign al Terminal Strip

The power/signal terminal strip is a three position plug-in style terminal strip located at

the top of the left terminal column. It is used to connect 24 VDC power to the M2 and to

connect the 4 - 20 mA output signal to a device.

The signal output, the S terminal, does not have to be connected for the M2 to function.

The S terminal is used if you want to connect the 4 - 20 mA output signal to another device

such as a gas monitoring controller, chart recorder, or programmable controller (PLC).

Detector Terminal Strip

The detector terminal strip is a four position plug-in style terminal strip and is the middle

terminal strip in the left terminal column. All four terminals are used to connect the

detector to the M2.

Detector

Terminal Strip

- S +

PWR/SIG

- S +

LEL

R W G B

RS 4 85

A B C

PWR/SIG

LEL

R W G B

RS 485

A B C

C NC NO

C NC NO

C NC NO

FAIL

ALARM 1

ALARM 2

Figure 3: Detect o r Term inal Strip

NOTE: The detector is factory-wired to the M2. See “Wiring the M2 Transmitter” on

page 11 for all wiring procedures related to M2.

Modbus Terminal Str ip

The Modbus terminal strip is a three position plug-in style terminal strip and is the

bottom terminal strip in the left terminal column. It allows connection of the M2 into a

Modbus network.

Relay Terminal Strips

The right column of terminal strips consists of, from top to bottom, the fail, alarm 1, and

alarm 2 relay terminal strips. The y are three-positio n plug-in style terminal strips. The

relay terminal strips are used to connect devices such as lights and horns that are

controlled by the relay contacts. The relay contacts are rated at 115 VAC, 5 amps. The relay

contacts may also be used to control higher rated relays.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 6

Page 12

Termination Jumper

A two pin header with a termination jumper installed is located below the Modbus

terminal strip. The jumper has no function unless the M2 is wired into a Modbus

installation. See “Chapter 8: RS-485 Modbus Output” on page 35 for a description of using

the M2 in a Modbus system.

Control PCB

The LCD display and control switches are located on the control PCB. It is installed on top

of the terminal PCB by lining up its three spacing standoffs with the banana jacks in the

terminal PCB mounting standoffs and pushing it ont o the banana jacks. The jacks retain

the control PCB.

LCD Display

The LCD display is located at the top of the control PCB. It indicates the current gas

reading and displays messages and parameters in the M2’s programs.

Control Buttons

The M2 includes three push button switches that allow you to enter the M2’s operating

modes, navigate through the modes, update settings, an d save changes to the settings.

The push button switches are located along the bottom edge of the control PCB (see

Figure 2). The UP/YES button is on the left, the DOWN/NO button is in the middle, and

the ENTER button is on the right.

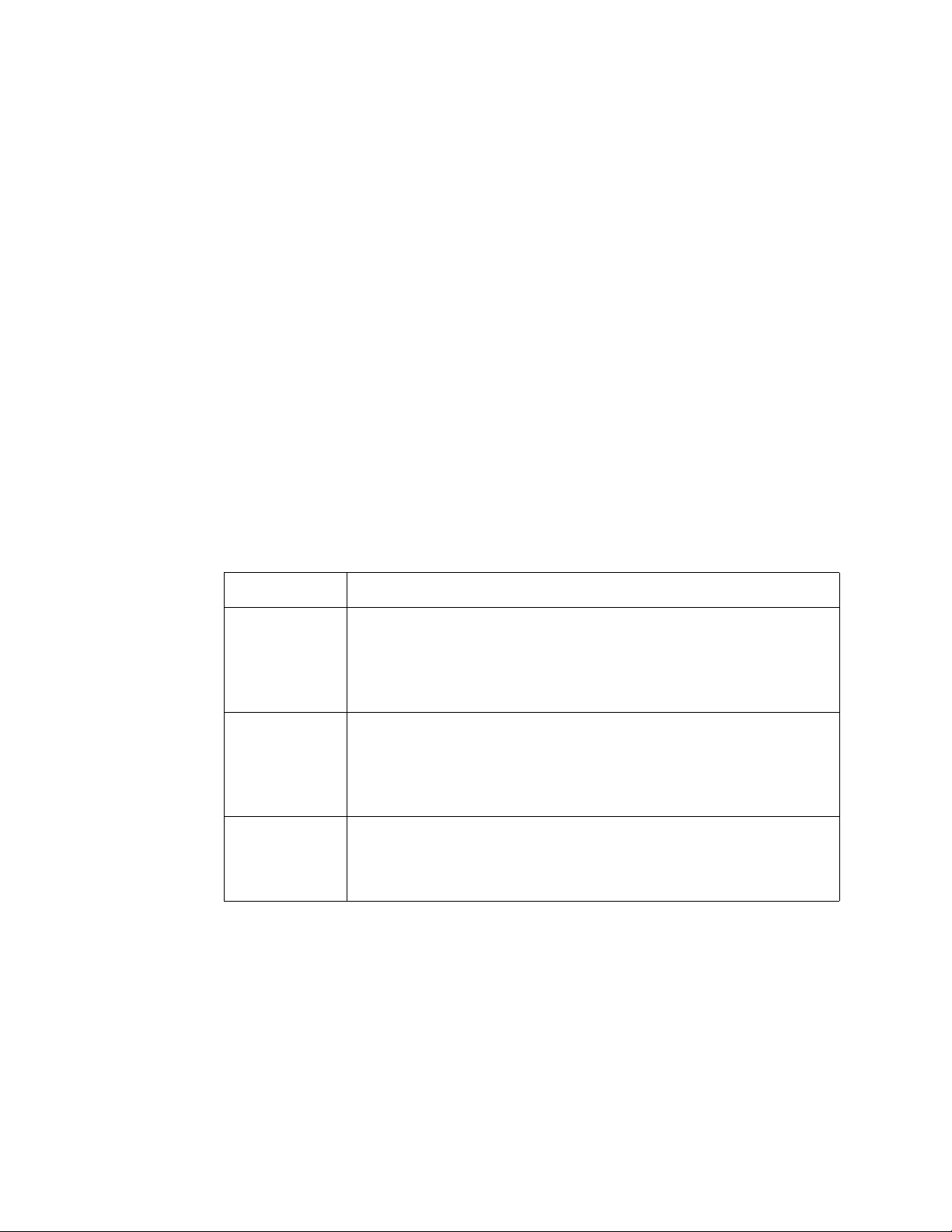

Table 2: M2 Control Button Functions

Switch Function

UP (YES) • Saves settings

• Changes the displayed set t ing

• Enters th e Calibration Program

• Enters Gas Type Mode (press with DOWN/NO button)

• Enters Configuration Mode (pres s with EN TER button )

DOWN (NO) • Cancels setting changes

• Changes the displayed set t ing

• Enters Gas Type Mode (press with UP/YES button)

• Enters Modbus Mode (press with ENTER button )

• Displays the Information Screen

ENTER • Initiates operations

• Enters Configuration Mode (press with UP/YES button)

• Enters Modbus Mode (press w ith DOW N /NO button)

• Functions as an alarm reset switc h

Just above each push button switch is a magnetic switch with the same function as th e

push button switch below it. The magnetic switches are for use in non-intrusive

calibration. They are actuated by bringing the magnetic wand close enough to them to

actuate them. Although the magnetic switches have the same functions as the push button

switches, it is not practical to use them for operations other than calibration because it is

not possible to actuate two magnetic switches at once with only one magnetic wand. Since

displaying the Information Screen only requires the use of one switch, the wand may be

used to show the Information Screen (see “Information Screen” on page 16).

7 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 13

Status LEDs

The M2 includes five status LEDs that are located above the display (see Figure 2).

• Fail LED

The fail LED turns on when the M2 is experiencing a fa il condition. A fail condition

can be caused by a detector failure or low detector signal.

• Alarm 1 LED

The alarm 1 LED is on when the M2 is experiencing an alarm 1 condition.

• Alarm 2 LED

The alarm 2 LED is on when the M2 is experiencing an alarm 2 condition.

• RX & TX LED’s

These LED’s indicate data being received (RX) and transmitted (TX) when the M2’s

Modbus output is operating.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 8

Page 14

Chapter 3: Installation & Startup

b

Overview

This chapter describes procedures to mount the M2 Transmitter in the monitoring

environment and wire it to input power and devices.

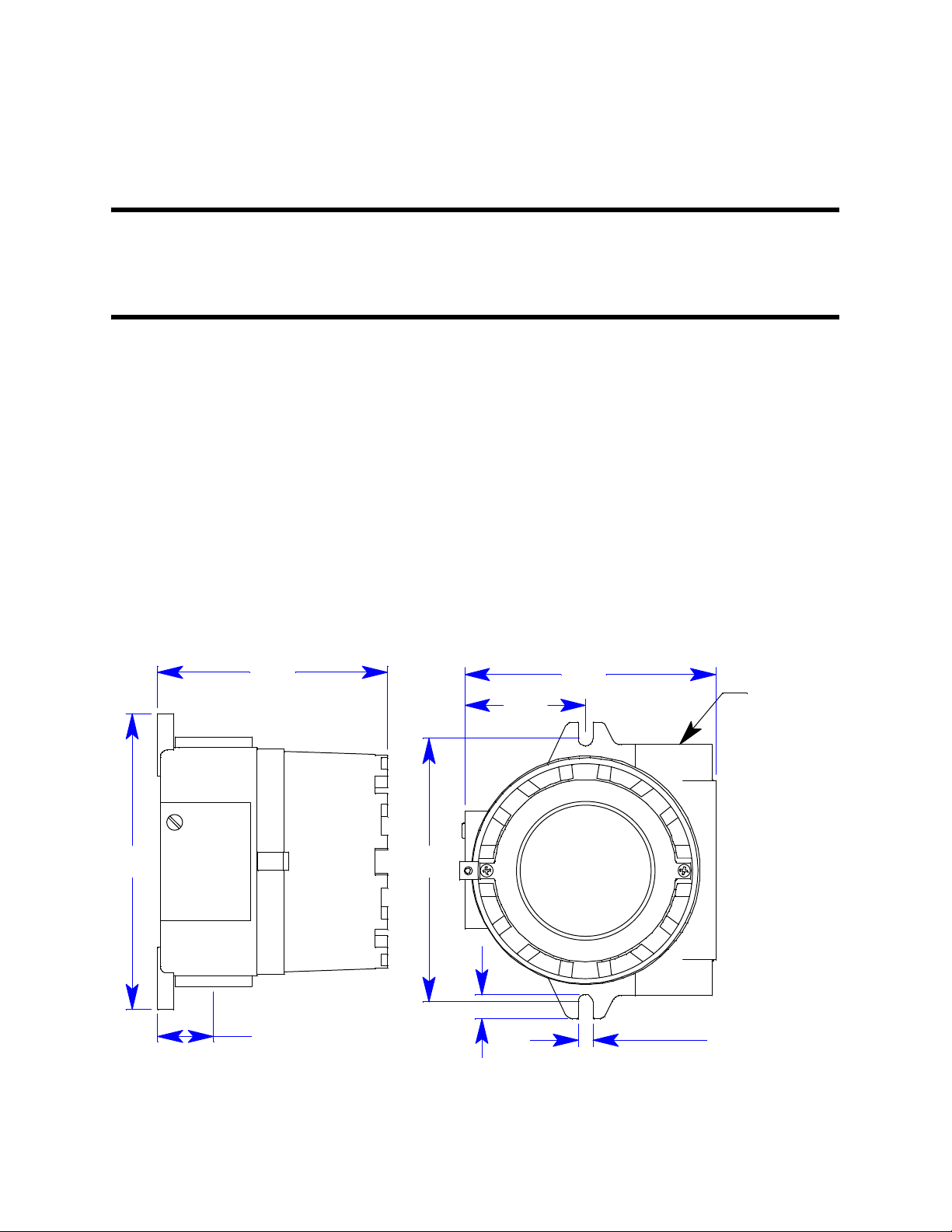

Mounting the M2 Transmitter

1. Select a mounting site that is representative of the monitoring environment. Consider

the following when you select the mounting site.

• For the M2 junction box, select a site where the junction box is not likely to be

bumped or disturbed. Make sure there is sufficient room to perform start-up,

maintenance, and calibration procedures. The site should be easily a ccessible.

• For the detector junction box, select a site where the target gas is likely to be found

first. For lighter gases, mount the detector near the ceiling; for heavier gases,

mount the detector near the floor.

5.86

• The junction boxes should be mounted no further than 200 feet from each other.

2. Use #10 screws through the M2 junction box’s two mounting slots to secure the

junction box to a vertical surface. Figure 4 shows the outline and mounting

dimensions the M2 junction box. Figu re 5 shows the outline and mounting

dimensions for the detector junction box. Mount the detector junction box with the

detector facing down as shown in Figure 5.

4.59

2.41

5.23

5.00

3/4 NPT

Conduit Hu

1.02

.47 (2X)

Figure 4: Outline & Mounting Dimensions, M2 Junction Box

9 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

.30 (2X)

Page 15

r

,

3/4 NPT

Female

3.65

9.00 MA X

.382.70

Rubb e

Spacer

3X

J-Box

IR LEL

Detector

5.25

Cali bration

Adapt er/

Splash Guard

.75

Figure 5: Outline & Mounting Dimensions, Detector Junction Box

3. Install 3/16 inch I.D. flexible po lyurethane tubing to the fitting at the bottom of the

calibration adapter/splash guard and route it to an accessible area that is close to the

M2 junction box. See the “Parts List” on page 45 for available tubing.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 10

Page 16

Wiring the M2 Transmitter

WARNING : Always verify that the power to the M2 is off before you make wiring

connections.

1. Confirm that no power is being applied to the M2.

2. Remove the detector junction box’s cover from the junction box.

3. Remove the M2 junction box’s cover from the junction box.

4. Grasp the control PCB by its edges.

5. Gently pull until the control PCB is pulled away from the banana jacks. Take care not

to pull too hard and damage the cable which connects the control and terminal PCBs.

6. Let the control PCB hang by the cable. The terminal strips are now visible on the

terminal PCB. The control PCB may be left hanging while wiring is done. If desired,

the control PCB may be disconnected from the cable and set aside while wiring.

7. Guide a four-conductor, shielded cable or four wires in conduit through the top

conduit hub of the detector junction box. To make wiring more convenient, use wire

colors that correspond to the detector wire colors: red, white, green, and black.

NOTE: Consult RKI Instruments, Inc. for cable lengths longer than 200 feet.

8. Connect the detector leads to the terminal block in the detector junction box.

9. Secure the detector junction box’s cover to the junction box.

10. Guide the other end of the four-conductor, shielded cable or four wires in conduit

through the bottom conduit hub of the M2 junction box.

11. To gain access to a plug-in termi nal strip for wiring, pull it out of its socket by

grasping the wall between two terminal positions with needle nose pliers and pulling.

Be careful not to exert too much force on the wall to avoid damage to the terminal

strip. The detector terminal strip and th e alarm 1 r elay t ermi nal strip ma y be r emo ved

by grasping them with your fingers if the adjacent terminal strips have been removed.

WARNING: If the M 2 is installed in a hazardous location, use app ropriatel y rated

conduit, conduit fittings, and appropriate construction technique that

complies with the local electrical code.

In addition, use appropriately rated conduit, conduit fittings, and

appropriate construction technique to maintain the NEMA 4

environmental rating of the junction box and avoid water entering the

junction box at the conduit hubs.

12. Pull out the detector terminal strip and connect the four wires to the terminal strip as

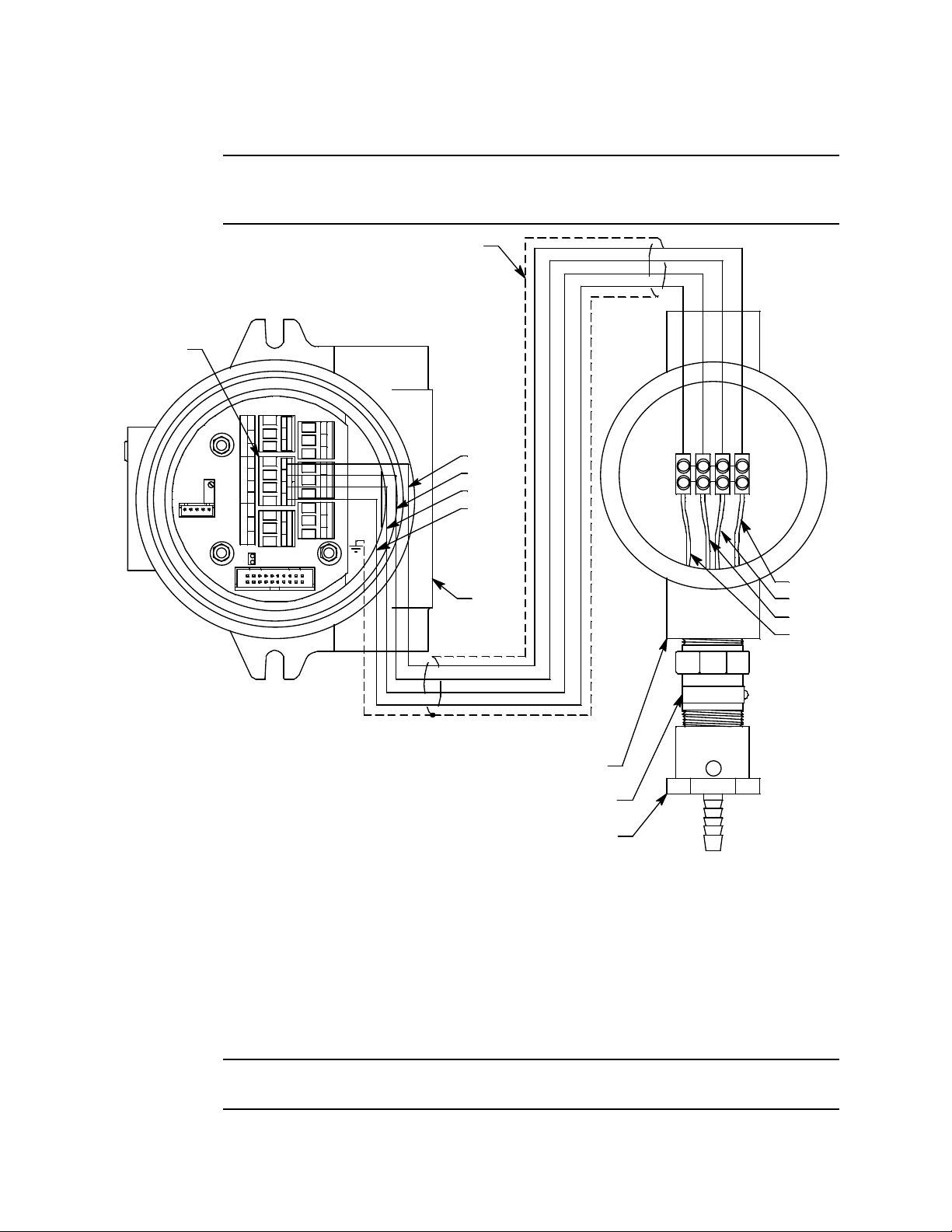

follows (see Figure 6).

• Connect the wire corresponding to the detector ’s red wire to the LEL “R”

terminal.

• Connect the wire corresponding to the detector’s white wire to the LEL “W”

terminal.

• Connect the wire corresponding to the detector’s green wire to the LEL “G”

terminal.

11 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 17

Detector

Terminal

Strip

• Connect the wire corresponding to the detector’s black wire to the LEL “B”

terminal.

CAUTION: If shielded cable is used, leave the cable shield ’s drain wire disconnected and

insulated at the detector junction box. You will connect the opposite end of the cable’s

drain wire to the M2 junction box’s chassis (earth) ground.

Cable

Shield

FAIL

- S +

PWR/SIGRS 485

- S +

LEL

R W G B

A B C

C NC NO

LEL PWR/SIGRS 485

C NC NO

R W G B

ALARM 2 ALARM 1

C NC NO

A B C

Black

Green

White

Red

Black

M2

J-Box

Green

White

Red

DetectorJ-Box

IRLELDetector

Calibration Adapter/Splash Guard

Figure 6: Wiring the Detector to the M2

13. Reinstall the detector terminal strip into its socket.

14. If shielded cable is used between the detector junction box and the M2 junction box,

connect the cable’s drain wire to an available chassis (earth) ground at the M2 junction

box. Do not connect the shield drain wire at the detector junction box.

15. Guide multi conductor shielded cable or cables or wires in conduit through the top

conduit hub of the M2 junction box. The number of cables or wires needed will

depend on whether the M2 is wired to a gas monitoring controller or just to power,

whether any relays are used, and whether the Modbus output is used.

NOTE: If the M2 is being wired to a PLC or DCS device, see “Appendix B: PLC and

DCS Device Wiring” on page 47, then continue with step 8.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 12

Page 18

Use the following recommendations to determine how to wire the M2:

e

1

e

2

e

• If Modbus connections will not be used and only the PWR/SIG connections will

be used, use a two or three conductor shielded cable or two or three wires in

conduit for connections to the power/signal terminal strip depending on whether

or not the signal (S) terminal is used. The S terminal has a 4 - 20 mA output, but if

you do not need to monitor this signal and do not connect to th e S termi na l to

access this signal, the M2 will still function completely.

Table 3: Wire Size for PWR/SIG Connections

Max Distance to Controller

w/18 Gauge Wire

Max Distance to Controller

w/16 Gauge Wire

2,500 ft. 5,000 ft. 8,000 ft.

• If the PWR/SIG connections and one or more relays are used, route the

connections to the M2 in conduit. Use shielded cable in the conduit for the PWR/

SIG connections and unshielded cable or individual wires for the relay

connections. Make sure any wire or cable used for relay wiring is appropriately

rated for the power that it will carry.

CAUTION: If shielded cable is used for the PWR/SIG connections, leave the cable shield’s drain

wire insulated and disconnected at the M2 junction box. You will connect the

opposite end of the cable’s drain wire at the controller or device.

• If the M2 will be wired into a Modbus network, see “Chapter 8: RS-485 Modbus

Output” on page 35.

See Figure 7 below for field wiring connections to the M2.

RKIController

Terminals

(24VDC) +

4-20mAIn (S)

(24 VDC) -

CableShield

See

Detector

Wiring

See

Modbus

Wiring

S

PWR/SIG

LEL

R W G B

A B C

RS 485

FAIL

C NC NO

ALARM 1

C NC NO

ALARM 2

C NC NO

Max Distance to Controller

w/14 Gauge Wire

Alarm Device

Power

Typical Alarm

WiringShown

Fail

Alarm

Devic

Alarm

Alarm

Devic

Alarm

Alarm

Devic

Figure 7: Wiring the M2 Junction Box to a Controller and Alarm Devices

13 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 19

Start Up

16. Re-install the control PCB (and ribbon cable if necessary) . B e sure the ribbon cable is

routed down below the control PCB so it will not be damaged by the cover when it is

screwed back on.

17. Secure the M2 junction box cover to the junction box.

18. Make controller, device, and relay connections as appropriate. If shielded cable is

used for the PWR/SIG connections, connect the cable shield’s drain wire to an

available chassis ground at the gas mon itoring controller, recording device, or

program mable controller.

Introducing Incoming Power

1. Complete the installation procedures described earlier in this manual.

2. Verify that all wiring connections are correct and secure.

3. Turn on the incomi ng power.

4. If necessar y, turn on the contr ol l e r or ot h e r monitoring device that is connected to the

M2.

5. The LCD display will indicate the firmware version when the M2 is first powered up

and will then count down a o ne minute warm-up period b efore normal ope ration

begins. During normal operation, the display will indicate the target gas and current

gas reading. V erify that the display is indicating the target gas and current gas reading

after the warm-up period is complete and normal operation begins.

METHANE

0 %LEL

NOTE: Allow the M2’s detector to warm up for 15 minutes before you continue with

the next section, “Adjusting the Fresh Air Reading.”

Adjusting the Fresh Air Reading

When the M2 is shipped from RKI Instruments, Inc., it is factory calibrated. If a full

calibration is desired at startup, see “Calibration” on page 31.

Verify that the M2 is in a fresh air environment (environment known to be free of

combustible or toxic gas vapors and of normal oxygen content, 20.9%).

CAUTION: If you suspect the presence of combustible gas in the monit oring environment, use

the calibration kit and the zero air calibration cylinder to introduce “fresh air” to

the detector and verify an accurate fresh air setting. See the “Calibration” on

page 31 for instructions on how to use a zero air cylinder when performing a fresh

air adjustment.

Non-Intrusive Fresh Air Signal Adjustment

If the M2 is installed in a classified area and non-intrusive zero adjustment is required,

follow the instructions below, but do not remove the junction box cover. Use the

magnetic wand accessory to actuate the magnetic switches instead of pushing the control

switch buttons. To actuate a magnetic switch and perform the same operation as pressing

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 14

Page 20

a control switch button, touch the magnet in the end of the magnetic wa nd to the M2’s

glass cover directly over the magnetic switch you wish to actuate. Touching the glass and

removing the wand is the same as pressing and releasing a button. Touching the glass and

keeping the wand in place is the same as pressing and holding a button.

WARNING : The M2 i s not an active gas monitoring device dur in g the fresh air

adjustment procedure. The 4-20 mA output signal will “freeze” at 3.5 mA

and all relays will remain in their non-alarm state while the M2 is in

Calibration Mode. The output signal will not indicate current readings

and the relays will not resume operating normally until the M 2 is in

normal operation again.

NOTE: While in the calibration program, if there is no switch activity for the

calibration time-out period the unit will return to normal operation. The factory

set time-out is 15 minutes. If you want a different time-out period, see

“Viewing & Changing M2 Parameters” on page 21 for instructions to change

the calibration time-out.

1. While in normal operation, press and hold the UP/YES button for 5 seconds to enter

Calibration Mode. Release the button when the following screen appears.

Calib?

YES/NO

2. Press and release the UP/YES button to continue. The display will indicate the target

gas and CAL Mode for a few seconds before showing FreshAir Adjust?.

3. Press and release the UP/YES button. ENTER will alternate with FreshAir on the top

display line and the current gas reading will be on the bottom di splay line.

4. Press and release the ENTER button. The M2 will perform a zero operation and the

display will indicate SPAN w/Cal Gas?.

5. Press and release the DOWN/NO button. The display will indicate Leaving CAL

Mode and the M2 will return to normal operation.

15 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 21

Chapter 4: Operation

Overview

This chapter describes the M2 in normal operation. This chapter also describes the M2 in

alarm 1, alarm 2, and fail co nditions and suggests responses to these conditions.

Normal Operation

Normal operation is defined as follows:

• The start-up procedure is complete.

• The M2 is not indicating an alarm 1, alarm 2, or fail condition.

• The M2 is not in Calibration, Configuration, or Gas Type modes.

During normal operation, the M2 simultaneously displays the current gas reading, unit of

measure, and target gas.

Information Screen

The Information Screen displays the M2’s operating voltage and firmware and hardware

information. To display the Information Screen, do the following:

1. Press and hold the DOWN/NO button for 3 seconds. The Information Screen will

appear.

2. Continue holding the DOWN/NO button to keep the Information Screen on the

display. The top line indicates the operating voltage that is connected to the M2. The

second line indicates the firmware that is running, version 5.0 in this example, and the

M2’s hardware version, version 2A in this example. This information may be useful if

you need to contact the factory with question s about the M2.

3. Release the DOWN/NO button when you are done viewing the Information Screen.

The display will return to the normal operation screen within a couple of seconds.

METHANE

0 %LEL

24.2V

v5.0L 2A

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 16

Page 22

4 - 20 mA Signal Output Operation

The output at the S terminal of the power/signal terminal s t rip is a 4 - 20 mA signal t hat

corresponds to the detection range of the M2. During normal operation, this signal tracks

the gas concentration on the LCD.

There are several cir cumstances where th e signal output will not track the display reading

but will behave as follows:

• When the M2 is in its warm-up period, the signal output will be fixed at 3.5 mA (zero).

• When the M2’s gas type is changed, the M2 will enter Configuration Mode for you to

verify the parameter settings. When you exit Configuration Mode, the dis play will

indicate NEEDS CALIBRATION and will con tinue to indicate this until Calibration

Mode is entered and a calibration is performed. In this situation, the signal output will

be fixed at 3.5 mA from the time Gas Type Mode is entered until the M2 is calibrated

and returns to normal operat ion.

• If you enter Calibration Mode, Configuration Mode, Gas Type Mode, or Modbus

Mode, the signal output will be fixed at 3.5 mA until the M2 returns to normal

operation.

• If the M2’s input power decreases below 18.5 volts so that the M2 is in a low power

alarm, the signal output is fixed below 2.4 mA until the low power alarm is cleared.

• If the M2 goes into a fail condition, after a 30 second d e lay, the signal output is fixed

below 2.4 mA until the fail alarm is cleared.

Alarm Indications

NOTE: The M2 includes al arm o n an d a la rm off delay settings for alarm 1 an d alarm 2.

Condition Cause Visual Indication(s)

Alarm 1

Alarm 2

Fail • Disconnected or misconnected

1

1

The alarm indications described in this section operate according to the factory

set alarm settings. See Table 5 on page 22 for all the factory settings.

Table 4: Visual and Audible Alarm Indications

Increasing gas reading at or above the

alarm 1 setpoint

Increasing gas reading at or above the

alarm 2 setpoint

detector wiring

• Display reading at -10% of full

scale or lower

• Defective components

• A1 LED is on

• Gas reading alternates

with ALARM-1 message

• A2 LED is on

• Gas reading alternates

with ALARM-2 message

• F LED is on

• FAIL message replaces

gas reading

NOTE: There is a 30 second

delay on the fail condition.

17 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 23

Table 4: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

Low Power DC power source less than 18.5 volts. • F LED is on

• LowPower message and

actual voltage of

incoming DC power

*1If the M2 is in both an ala r m 1 and an a l arm 2 c ondition, both alarm LEDs are on an d t he

display alternates between the gas reading and the AL MS 1&2 message.

NOTE: You can select normally energized (N. EN) or normally de-energized (N. DE-

EN) alarm 1 and alarm 2 relay set tings in Configuration Mo d e. The following

sections describe the standard factory setting for these relays which is

N. DE-EN.

The fail relay is factory set as N. EN and is not user-adjustable.

Alarm 1 Condition

Alarm 1 Condition Indications

When the gas reading reaches the alarm 1 setpoint, the M2 senses an alarm 1 condition.

The M2 alerts you to an alarm 1 condition as follows:

• The A1 LED turns on.

• The gas reading alternates with the ALARM-1 messag e.

• The alarm 1 relay energizes.

Responding to an Alarm 1 Condition

1. Follow your established procedure for a low level combustible gas condition.

2. After the gas reading falls below the alarm 1 setpoint, press the ENTER button to reset

the alarm 1 circuit. Resetting the alarm 1 circuit turns off the A1 LED, resets the LCD,

and de-energizes the alarm 1 relay.

NOTE: If the ENTER button is pressed while the M2 is in an alarm 1 cond ition, the A1

LED will flash but all other indica tions will remain unchanged.

You cannot de-energize the al arm 1 relay until the gas reading falls below the

alarm 1 setpoint.

Alarm 2 Condition

Alarm 2 Condition Indications

When the gas reading reaches the alarm 2 setpoint, the M2 senses an alarm 2 condition.

The M2 alerts you to an alarm 2 condition as follows:

• The A2 LED turns on.

• The gas reading alternates with the ALARM-2 messag e.

• The alarm 2 relay energizes.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 18

Page 24

NOTE: If the M2 is in both an alar m 1 and al arm 2 cond ition , both the A1 and A2 LED s

will be on, the gas reading will alternate with the ALMS 1&2 message, and

both alarm relays will energize.

Responding to an Alarm 2 Condition

1. Follow your established procedure for a high level combustible gas condition.

2. After the gas reading falls below the alarm 2 setpoint, press the ENTER button to reset

the alarm circuit. Resetting the alarm circuit turns off the A2 light, resets the LCD, and

de-energizes the alarm 2 relay.

NOTE: If the ENTER button is pressed while the M2 is in an alarm 2 cond ition, the A2

LED will flash but all other indica tions will remain unchanged.

You cannot de-energize the al arm 2 relay until the gas reading falls below the

alarm 2 setpoint.

Fail Condition

Fail Condition Indications

The M2 indicates a fail condition for any of the following:

• The detector wiring is disconnected or incorrectly connected.

• The display reading is -10% of full scale or lower.

When the M2 senses a fail condition , it alerts you as follows:

• The F LED turns on.

• The gas reading is replaced by the FAIL message.

• The fail relay de-energizes.

NOTE: The fail alarm has a 30 second delay.

Responding to a Fail Condition

1. Verify that the detector wiring is correctly and securely connected.

Low Power Alarm

Low Power Alarm Indications

The M2 senses a low power condition when the DC power source is 18.5 volts or less.

WARNING: While in a low power condition, the M2 is not an active gas monitor.

When the M2 senses a low power condi tion, it alerts you as follows:

• The F LED turns on.

•The message LowPower is indicated on the top line of the LCD and the input voltage

is displayed on the bottom line of the LCD.

• The fail relay de-energizes.

19 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 25

NOTE: The low power alarm canno t be cl eared using the ENTER button.

When the voltage increases to 19.0 volts, the low power alarm is cleared and the M2 will

begin its warm-up sequence.

Responding to a Low Power Condition

1. Determine and correct the cause of the low power condition.

2. When the input power increases above 19.0 volts, the M2 will begin its warm-up

sequence.

3. Verify that the M2 enters normal operation after its warm-up sequence. If necessary,

perform a fresh air adjustment. See “Adjusting the Fresh Air Reading” on page 14.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 20

Page 26

Chapter 5: Configuration Mode

Overview

This chapter describes how to view and change M2 parameters using Configuration

Mode. It is accessed using the program buttons.

Configuration Mode includes a 5-minute time-out feature. If you do not press a control

button for 5 minutes, the M2 automatically returns to no rmal operation.

NOTE: If the M2 returns to normal operation because of a time-out, it enters a warm-

up period just as it does when it is first turned on.

If you are installing a new M2, it has been setup at the factory. Use

Configuration Mode only if you want to change the M2’s setup. If you want to

change the detector type see “Chapter 6: Gas Type Mode” on page 24.

Viewing & Changing M2 Parameters

1. While in normal operation , simultaneously press and hold the UP/YES and ENTER

buttons for 5 seconds to enter Configuration Mode. Release the buttons wh en the

following screen appears.

Enter

Config?

2. If you want to exi t Config uration M ode, pr ess and r eleas e the DOWN/N O button an d

the M2 will return to normal operation.

If you want to continue in Configuration Mode, press and release the UP/YES button.

The target gas and the full scale will be displayed for a few seconds b efo re the first

adjustable par ameter, the alarm 1 setpoint, is displayed.

3. If you want to change the currently displayed parameter, use the UP/YES and

DOWN/NO buttons to adjust it to the desired setting, then press ENTER to continue

to the next parameter.

If the currently displayed parameter is OK, press the ENTER button to proceed to the

next parameter.

Table 5 lists the M2 parameters you can set. Table 5 also lists the factory set value for

each parameter.

21 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 27

Table 5: Configuration Parameters

Parameter

(Factory Set Value)

ALARM-1 (level)

(10% LEL)

ALARM-1 (activation)

(Increase)

ALARM-1 (relay action)

(N. DE-EN)

ALARM-1 (relay reset)

(LA TCH)

A1 OnDy (alarm 1 on delay)

(1 secs)

A1 OffDy (alarm 1 off delay)

(0 sec.)

Description

The gas reading at which the M2 initiates an alarm 1 condition.

Indicates if the alarm 1 circuit is activated by gas readings increasing

(Increase) or decreasing (Decrease) to the ALARM-1 Level.

If set as N. DE-EN, the ala rm 1 relay is de-ene rgized in normal operatio n

and energizes when an alarm 1 condition is initiated.

If set as N. EN, the alarm 1 relay is energized in normal operation and

de-energizes when an alarm 1 cond ition is initiated.

If set as LATCH, you must press the ENTER button to reset the alarm 1

circuit after the alarm 1 condition passes.

If set as SELF-RST, the M2 automatically resets the alarm 1 circuit after

the alarm 1 condition passes.

The amount of time the M2 delays activation of the alarm 1 circuit once

an alarm 1 condition is initiated. It can be set in 1 second increments

from 0 - 60 seconds, in 1 minute increments from 1 - 15 minutes, and in

15 minute increments from 15 - 60 minutes.

The amount of time the M2 delays turning off the alarm 1 circuit once an

alarm 1 condition passes. This parameter appears only if the alarm 1

relay reset setting is set to SELF-RST. It can be set in 1 second

increments from 0 - 60 seconds, in 1 minute increments from 1 - 15

minutes, and in 15 minut e increments from 15 - 60 minutes.

ALARM-2 (level)

(50% LEL)

ALARM-2 (activation)

(Increase)

ALARM-2 (relay action)

(N. DE-EN)

ALARM-2 (relay reset)

(LA TCH)

A2 OnDy (alarm 2 on delay)

(1 secs)

A2 OffDy (alarm 2 off delay)

(0 sec.)

The gas reading at which the M2 initiates an alarm 2 condition.

Indicates if the alarm 2 circuit is activated by gas readings increasing

(Increase) or decreasing (Decrease) to the ALARM-1 Level.

If set as N. DE-EN, the ala rm 2 relay is de-ene rgized in normal operatio n

and energizes when an alarm 2 condition is initiated.

If set as N. EN, the alarm 2 relay is energized in normal operation and

de-energizes when an alarm 2 cond ition is initiated.

If set as LATCH, you must press the ENTER button to reset the alarm 2

circuit after the alarm 2 condition passes.

If set as SELF-RST, the M2 automatically resets the alarm 2 circuit after

the alarm 2 condition passes.

The amount of time the M2 delays activation of the alarm 2 circuit once

an alarm 2 condition is initiated. It can be set in 1 second increments

from 0 - 60 seconds, in 1 minute increments from 1 - 15 minutes, and in

15 minute increments from 15 - 60 minutes.

The amount of time the M2 delays turning off the alarm 2 circuit once an

alarm 2 condition passes. This parameter appears only if the alarm 2

relay reset setting is set to SELF-RST. It can be set in 1 second

increments from 0 - 60 seconds, in 1 minute increments from 1 - 15

minutes, and in 15 minut e increments from 15 - 60 minutes.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 22

Page 28

Table 5: Configuration Parameters (Continued)

ZeroSupp

(2% LEL)

FILTER

(5 secs)

CAL Time

(15 mins)

Auto Zero

(Enabled)

Parameter

(Factory Set Value)

Description

The zero suppression feature helps prevent “jumpy” readings near the

fresh air reading.

For example, if the zero suppression is 2.0% LEL, the M2 will display a

reading of 0% LEL for gas readings from -2% LEL to 2% LEL. It is

settable from 0 to 6% of the detection range.

The filter feature helps “smooth out” jumpy or noisy signals from the

detector. You can set the filter from 0 seconds to 60 seconds in 5

seconds increments.

The displayed gas reading is the average reading over the previous time

period defined by the filter setting. So if the filter is set to 5 seconds, the

displayed gas reading is the average over the past 5 seconds.

The calibration t ime-out s ets the amount of time af ter the l ast button push

while in Calibration Mo de th at the M2 will wait before returning to normal

operation. If the calibratio n time-o ut is set to 15 mins, then M2 will return

to normal operation automatically 15 minutes after the last button push.

If set to Enabled, the M2’s firmware will monitor the zero (fresh air)

reading and make automatic zero adjustments under precisely specified

conditions if it determine s that a reading change is due to normal sensor

drift.

If set to Disabled, the Auto Zero function is turned off.

4. When you have scrolled through all the adjustable parameters, SAVE IT? YES/NO

appears on th e display.

5. If you do not wish to save the adjustments and want to exit Configuration Mode,

press and release the DOWN/NO button. The DO OVER? YES/NO message will

display. Press and release the DOWN/NO button. The ABORT? YES/NO message

will display. Press the UP/YES button to return to normal operation.

If you wish to change some of the adjustments made, press and release the DOWN/

NO button. The DO OVER? YES/NO message will display. Press and release the UP/

YES button. The Re-do Config message will display and the M2 will return to the first

adjustable pa rameter. Go back to step 3 and continue.

If you wish to save the adjustments made, press and release the UP/YES button.

Config Saved is indicated on the display for a few seconds and the M2 returns to

normal operation.

23 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 29

Chapter 6: Gas Type Mode

Overview

This chapter describes how to use Gas T y pe Mode to select the M2’s gas type. The gas type

determines the target gas and detection range.

CAUTION: The 65-2619RK-CH4-4 M2 is factory setup for methane (CH4). Do not change the

Gas Type se tting.

Gas Type Mode includes a 5-minute time-out feature. If you do not press a button for 5

minutes, the M2 automatically returns to normal operation.

NOTE: If the M2 enters normal operation because of a program time-out, it enters a

warm-up period just as it does when it is first turned on.

Selecting the Gas Type

1. While in normal operation or d uring the warm-up sequence, press and hold the UP/

YES and DOWN/NO buttons for five seconds. Release them when the following

screen appears.

2. If you want to exit Gas Type Mode, press and release the DOWN/NO button. The

display will indicate NO CHANGE and the M2 will return to normal operation.

If you want to continue in Gas Type Mode, press and release the UP/YES button. The

top display line will indicate GasType? and the bottom display line will indicate the

target gas choice.

3. Use the UP/YES or DOWN/NO button to scroll through the choices of target gas.

Table 6 below lists the choices of target gas for the M2.

HC 0 - 100% LEL

iBUTANE 0 - 100% LEL

Table 6: Gas Types

Gas Type

Choices

Select

GasType?

Detection Range

PROPANE 0 - 100% LEL

HEXANE 0 - 100% LEL

HYDROGEN 0 - 100% LEL

METHANE 0 - 100% Volume

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 24

Page 30

Table 6: Gas Types

Gas Type

Choices

Detection Range

METHANE 0 - 100% LEL

CO2 0 - 5,000 ppm

CO2 0 - 2,000 ppm

CO2 0 - 100% volume

CO2 0 - 50.0% volume

CO2 0 - 5.00% volume

NH3 0 - 5.00% volume

NH3 0 - 2.00% volume

4. When the desired target gas is on the display, press and release the ENTER button.

The display will ask SAVE IT? YES/NO.

5. To discard the gas type change, press and r elease th e DOWN/NO button. The display

will ask DO OVER? YES/NO. Press the DOWN/NO button. The display will ask

ABOR T? YES/ NO . Pr ess the UP/YES button. The M2 will return to normal operation

without changing the gas type.

To save the gas type, press and release the UP/YES button. The display will indicate

Gas T ype Up dated, the display will indicate the target gas and the detection range for

a few seconds, and then the M2 will enter Configuration Mode automat ical ly so that

the parameter settings in Configuration Mode can be verified or changed.

6. While in Configuration Mode press and release the ENTER button to accept the

displayed parameter setting and move to the next one. Use the UP/YES and DOWN/

NO buttons to adjust a s et tin g. See “Chapter 5: Configuration Mode” on pag e 21 for a

complete description of Configuration Mode.

7. When you have reviewed and accepted the last item in Configuration Mode by

pressing the ENTER button, display will ask SAVE IT? YES/NO.

8. To save the configuration settin gs, press and release the UP/YES button.The display

will indicate Config Saved and the M2 will begin its warm- up sequence.

To discard the settings and review them again, press the DOW N/NO button. The

display will ask DO OVER? YES/NO. Press the UP/YES button and the display will

indicate Re-do Config, then display the target gas and the detection range for a few

seconds before returning to Configuration Mode. Repeat steps 6 - 8 until the settings

are as desired.

9. After the M2 completes its warm-up sequence, the display will indicate CAL

NEEDED. Since the gas type has been changed, a successful calibration must be

performed before the M2 can enter normal operation.

10. Press and release the UP/YES button to enter Calibration Mode. Normally, you must

hold the UP/YES button for 5 seconds to enter Calibration Mode, but since a

calibration is required, only a momentary push is needed to enter Calibration Mode

after changing the gas type.

11. See “Calibration” on page 31 for calibration instructions.

25 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 31

NOTE: When calibrating an M2 after changing the gas typ e, the M2 will not ask if you

want to calibrate, or whether you want to perform a fresh air adjustment, span

adjustment or zero adjustment. Since a complete calibratio n is required, the

calibration sequence will proceed without asking if you want to perform

certain operat ions.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 26

Page 32

Chapter 7: Maintenance

Overview

This chapter describes procedures for performing preventive maintenance,

troubleshooting, calibrating the M2, and replacing field replaceable parts.

Preventive Maintenance

This section describes a recommended preventive maintenance schedule to ensure the

optimum performance of the M2. It includes daily, monthly, and quarterly procedures.

Daily

Verify a display reading of 0% LEL. Investigate significant chang es in the reading.

Monthly

This procedure describes a test to verify that the M2 responds properly to the target gas.

NOTE: Performing a response test on the M2 may cause alarms. If you do not want

external alarms to act u ate, disable any external alarms duri ng the response test

to avoid unwanted external alarm indication s .

NOTE: The following procedure assumes the use of a calibration kit which includes a

calibration gas cylinder and a fixed flow regulator with an on/off knob.

1. Disable all external alarms if external alarm indications are not desired during the

response test.

2. Screw the calibration gas cylinder into the fixed flow regulator.

3. Use the flexible tubing coming from the calibration adapter/splash guard to connect

the regulator to the calibration adapter/splash guard.

4. Turn the regulator knob counterclockwise to open the regulator.

5. Allow calibration gas to flow for the length of time determined in “D et ermining

Response Time” on page 30.

6. Verify that the display reading is within ± 20% of the gas concentration .

NOTE: If the reading is not within ± 20% of the gas concentration, calibrate the M2 as

described in “Calibration” on page 31.

7. Turn the regulator knob clockw ise to close the regulator.

8. Unscrew the calibration gas cylinder from the fixed flow regulator.

9. Disconnect the calibration adapter/splash guard’s flexible tubing from the regulator.

NOTE: Do not disconnect the flexible tubing from the calibration adapter/splash guard.

27 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 33

10. If external alarms have been disabled, enable them when the display returns to a

normal fresh air reading.

11. Store the components of the calibration kit in a safe place.

Biannually

Calibrate the M2 as described in “Calibration” on page 31. See “Calibration Frequency”

on page 30 for a discussion of calibration frequency guidelines.

Troubleshoo ting

The troubleshooting guide describes symptoms, probable causes, and recommended

action for problems you may encounter with the M2.

NOTE: This troubleshooting guide describes M2 problems only . If the M2 is connected to

a controller, see the controller operator’s man ua l f or problems you may

encounter with the controller.

Table 7:Troubleshooting the Combustible Gas Detector

Condition Symptom(s) Probable Causes Recommended Action

No Power The display backlight

is off and the display

screen is blank.

Frequent or

Suspect

Alarms

The M2 alerts you to

frequent or suspect

alarms while th e

fresh air readings

remain on zero.

• The power wiring is

disconnected or

misconnected.

• The display cable is

disconnected or

misconnected.

•The M2 is

experiencing false

readings due to RFI

or EMI.

• The detector wiring

is disconnected,

misconnected, or

intermittent.

1. Verify that the wiring to the

power source or controller is

correct and secure.

2. Verify that the ribbon cable

connecting the terminal PCB to

the control PCB is securely

installed. This ribbon cable plugs

into a connector on the top edge

of the control PCB and on the

bottom of the terminal PC B.

3. If the power difficulties continue,

contact RKI for further

instruction.

1. Verify that the M2 wiring is

properly shielded. See “Wiring

the M2 Transmitter” on page 11.

2. Verify that the detector wiring is

correct and secure.

3. Increase the alarm on delay

setting in Configuration Mode.

4. If the frequent or suspect alarm

difficulties continue, contact RKI

for further instruction.

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 28

Page 34

Table 7:Troubleshooting the Combustible Gas Detector (Continued)

Condition Symptom(s) Probable Causes Recommended Action

Flickering

Display

Fail

Condition

The display reading

flickers often.

• M2 indicates a fail

condition.

• Controller

indicates a fail

condition

•The M2 is

experiencing false

readings due to RFI

or EMI.

•The noise filter

setting is too low.

•The zero

suppression setting

is too low.

• The display screen

is malfunctioning.

• The detector wiring

to the terminal PCB

is disconnected or

misconnected.

•The wiring from the

M2 to the controller

is disconnected or

misconnected.

• The detector fresh

air signal is low

enough to cause a

fail condition.

•The detector is

malfunctioning.

•The terminal or

display PCB is

malfunctioning.

1. Verify that the M2 wiring is

properly shielded. See “Wiring

the M2 Transmitter” on page 11.

2. Verify that the detector wiring is

correct and secure.

3. Increase the filter setting in

Configuration Mode.

4. Increase the zero suppression

setting in Configuration Mode.

5. If the display difficulties continue,

contact RKI for further

instruction.

1. Verify that the detector wiring is

correct and secure.

2. Verify that the wiring between the

M2 and the controller is correct

and secure.

3. Calibrate the M2.

4. If the fail condition continues,

replace the detector.

5. If the fail condition continues,

contact RKI for further

instruction.

Slow or No

Response/

Difficult or

Unable to

Calibrate

•M2 responds

slowly or does not

respond to

response test.

•Unable to

successfu l ly set

the fresh air or

span reading

during

calibration.

•M2 requires

frequent

calibration.

Note: See “Calibration

Frequency” o n page 30 for

calibration frequenc y

guidelines.

• The calibration

cylinder is low, outdated, or defective.

• The calibration gas

flow rate is too low.

• The calibration gas

is not an

appropriate

concentration.

•The detector is

malfunctioning.

• The terminal PCB is

malfunctioning.

• The flexible tubing

to the calibration

adapter/splash

guard has become

kinked, blocked, or

disconnected.

1. V erify that the calibration cylinder

contains an adequate supply of a

fresh test sample.

2. Verify that the regulator used for

calibration is a 0.5 LPM regulator.

3. Verify that the calibration gas

concentration is appropriate for

the transmitter. The concentration

should be in the detection range,

preferably about half of the

detection range.

4. Verify that the flexible tubing to

the calibration adapter/splash

guard is clear and connected to

the calibration adapter/splash

guard.

5. If the calibration/response

difficulties continue, replace the

detector.

6. If the calibration/response

difficulties continue, contact RKI

for further instruction.

29 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 35

Calibration Frequency

Although there is no particular calibration frequency that is correct for all applications, a

calibration frequency of every 6 months is adequate for most infrared combustible gas

transmitter applications. Unless experience in a particular application dictates otherwise,

RKI Instruments, Inc. recommends a calibration frequency of every 6 months.

If an application is not very demanding, for example detection in a clean, temperature

controlled environment where calibration adjustments are minimal at calibration, then a

calibration frequency of every 9 to 12 months is adequate.

If an application is very demanding, for example if the environment is not well controlled,

then more frequent calibration than every 6 months may be necessary.

Determining Response Time

Since the detector junction box is installed remotely from the M2, the response time of the

detector will depend on the length of flexible tubing tha t is attached to the calibration

adapter/splash guard. To determine the response time based on the length of tubing

connected:

1. Place the M2 into its calibration mode or disable external alarms.

2. Note the current gas reading displayed at the M2.

3. Screw the regulator into the calibration cylinder. Do not use a zero air cylinder for this

operation.

4. Use the flexible tubing coming from the calibration adapter/splash guard to connect

the regulator to the calibration adapter/splash guard.

5. Turn the regulator’s on/off knob counterclockwise to open the regulator. Gas will

begin to flow. Take note of the time or start a stopwatch.

6. When you first start to notice an increase in the gas reading, note how much time

passed between starting the gas flow and noticing a reading response.

7. Turn the regulator’s on/off knob clockwise to close the regulator.

8. Unscrew the regulator from the calibration cylind er.

9. Disconnect the calibration adapter/splash guard’s flexible tubing from the regulator.

NOTE: Do not disconnect the flexible tubing from the calibration adapter/splash guard.

10. Add 1 minute to the length of time determined in step 6. This is the response time for

the detector. When performing a response test, zero adjustment, or span adjustment,

gas must be applied for this length of tim e .

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 30

Page 36

Calibration

This section describes how to calibrate the M2 transmitter. It includes procedures to

prepare for calibration, enter Calibration Mode, adjust the fresh air (zero) setting, adjust

the span setting, and return to normal operation.

WARNING : The M2 i s not an active gas monitoring device dur ing the calibration

procedure. The 4-20 mA output signal will “freeze” at 3.5 mA and all

relays will remain in their non-alarm state while the M2 is in Calibration

Mode. The output signal will not indicate current readings and the relays

will not resume operating normally until the M2 is in normal operation

again.

NOTE: The following procedure assumes the use of a calibration kit which includes a

calibration gas cylinder, a zero air cylinder and a fixed flow regulator with an

on/off knob.

NOTE: While in the calibration program, if there is no switch activity for the

calibration time-out period the unit will return to normal operation. See

“Viewing & Changing M2 Parameters” on page 21 for instructions to set the

calibration time-out.

NOTE: The following procedure assumes that the target gas is present in a high

enough concentration to affect the fresh air (zero) reading. If a fresh air

environment can be verified, applying zero air to the detector is not necessary

when setting the zero (span for oxygen) reading.

Non-Intrusive Calibration

If the M2 is installed in a classified area and non-intrusive calibration is required, follow

the instructions below, but do not remove the junction box cover. Use the magnetic wand

accessory to actuate the magnetic switches instead of pushing the control switch buttons.

To actuate a magnetic switch and perform th e same operat ion as pres sing a contr ol s witch

button, touch the magnet in the end of the magnetic wand to the M2’s glass cover directly

above the magnetic switch you wish to actuate. Touching the glass and removing the

wand is the same as pressing and releasing a button. Touching the glass and keeping the

wand in place is the same as pressing and holding a button.

Calibration Gas Response Memory Feature

The M2 has the capability to “remember” the detector’s response to the calibration gas

after the gas is removed from the detector during the fresh air and span adjustment

procedure. This feature enables one person to perform calibration if the detector is

mounted remotely from the M2. When zero air is applied to the M2 during a fresh air

adjustment, the M2 will freeze the display reading at the lowest response and the M2 will

continue to display this reading and retain it in its mem ory until the fresh air adjustment

procedure is completed. When calibration gas is applied to the M2 during a span

adjustment, the M2 will freeze the display reading at the highest response to the

calibration gas. The calibration gas can then be removed and the M2 will continue to

display this reading and retain it in its memory until the spa n a d justment procedure is

completed.

31 65-2619RK-CH4-4 M2 Transmitter Operator’s Manual

Page 37

Adjusting the Fresh Air Reading

1. While in normal operation, press and hold the UP/YES button for 5 seconds to enter

Calibration Mode. Release the button when the following screen appears.

Calib?

YES/NO

2. If you want to continue with calibration, press and release the UP/YES button. The

display will indicate the target gas and CAL Mode for a few seconds before showing

FreshAir Adjust?.

If you want to exit Calibration Mode, press and release the DOWN/NO button. The

M2 will indicate Leaving CAL Mode and the M2 will return to normal operation.

3. T o continue with adjusting the fresh air reading, press and release the UP/YES button.

ENTER will alternate with FreshAir on the top display line and the current gas

reading will be on the bottom display lin e.

To skip adjusting the fresh air reading, press and release the DOWN/NO button. The

display will indicate SP A N w/ C a l Gas?. Skip to the next section, “Adjusting the Span

Setting”.

4. Screw the zero air cylinder into the fixed flow regulator.

5. Use the flexible tubing coming from the calibration adapter/splash guard to connect

the regulator to the calibration adapter.

6. Turn the regulator knob counterclockwise to open the regulator.

7. Allow zero air to flow for the length of time determined in “Determining Response

Tim e” on page 30.

8. Turn the regulator knob clockw ise to close the regulator.

9. Unscrew the zero air cylinder from the fixed flow regulator. Leave the calibration

adapter/splash guard’s flexible tubing connected to the regulator. The M2 will

continue to display the minimum gas response on the display and retain the response

level in its memory.

10. Press and release the ENTER button. The M2 will perform a fresh air adjustment and

the display will indicate SPAN w/Cal Gas?.

NOTE: If the fresh air adjustment fai ls, see “Troubleshoot ing ” on page 28 for

recommended actions.

Adjusting the Span Setting

1. If you want t o con tin ue w ith adj usti ng t he sp an se ttin g, pr es s an d r ele ase the UP/YE S

button. APPLY will alternate with SPAN Gas on the top display line and the current

gas reading will be on the bottom display line.

If you want to skip adjusting the span reading, press and release the DOWN/NO

button. The display will indicate Leaving Cal Mode and the M2 will return to normal

operation.

2. Screw the calibration gas cylinder into the fixed flow regulator.

3. Turn the regulator knob counterclockwise to open the regulator.

4. Allow calibration gas to flow for the length of time determined in “D et ermining

65-2619RK-CH4-4 M2 Transmitter Operator’s Manual 32

Page 38

Response Time” on page 30.

5. Turn the regulator knob clockwise to close it.

6. Unscrew the calibration gas cylinder from the fixed flow regulator. The M2 will

continue to display the maximum gas response on the display and retain the response

level in its memory.

7. Adjust the gas reading up or down to match the calibration gas cylinder concentration

by using the UP/YES and DOWN/NO buttons, then press and release the ENTER

button.

8. The M2 will perform a span operation. The display will indicate SPAN Gas PASS for

a few second s, then in dicat e SPAN Gas SAVED before indicating Leaving CAL Mode

for a few seconds.

NOTE: If the span adjustment fails, see “Troubleshooting” on page 28 for

recommended actions.