Page 1

49-8104RK

Standby Battery

Operator’s Manual

Part Number: 71-0118RK

Revision: B

Released: 2/19/13

www.rkiinstruments.com

Page 2

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in

materials, workmanship, and performance for a period of one year fr o m date of shipment

from RKI Instruments, Inc. Any parts found defective withi n tha t period will be repaired

or replaced, at our option, free of charge. This warranty does not apply to those items

which by their nature are subject to deterioration or consumption in normal ser v ice, and

which must be cleaned, repaired, or replaced on a routine basis. Examples of such items

are:

W arranty is voided by abuse including mechanical damage, alteration, rough handling, or

repair procedures not in accordance with the operator’s manual. This warranty indicates

the full extent of our liability , a nd we are not r esponsible for removal or r eplacement costs,

local repair costs, transportation costs, or contingent expenses incurred without our prior

approval.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF

RKI INSTRUMENTS, INC., INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF

ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR

OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors,

dealers, and representatives as appointed by RKI Instruments, Inc.

We do not as su m e i ndemnification for any accident or damage caused b y t he op e ration of

this gas monitor, and our warranty is limited to the replacement of parts or our complete

goods.

2 • 49-8104RK Standby Batter y

Page 3

Overview

Note: Front

View Shown

Without Door

Wire (black) for negative c onnection

4X 1/4"

Screws

3/4" NPT

Conduit Hub

12 Am p Hour

Battery, 2X

Vent

User

Installed

Jumper

Wire nuts, 3

shipped with unit

(1 extra)

Wire (red)

for po sitive

connection

Battery Mounting Bracket

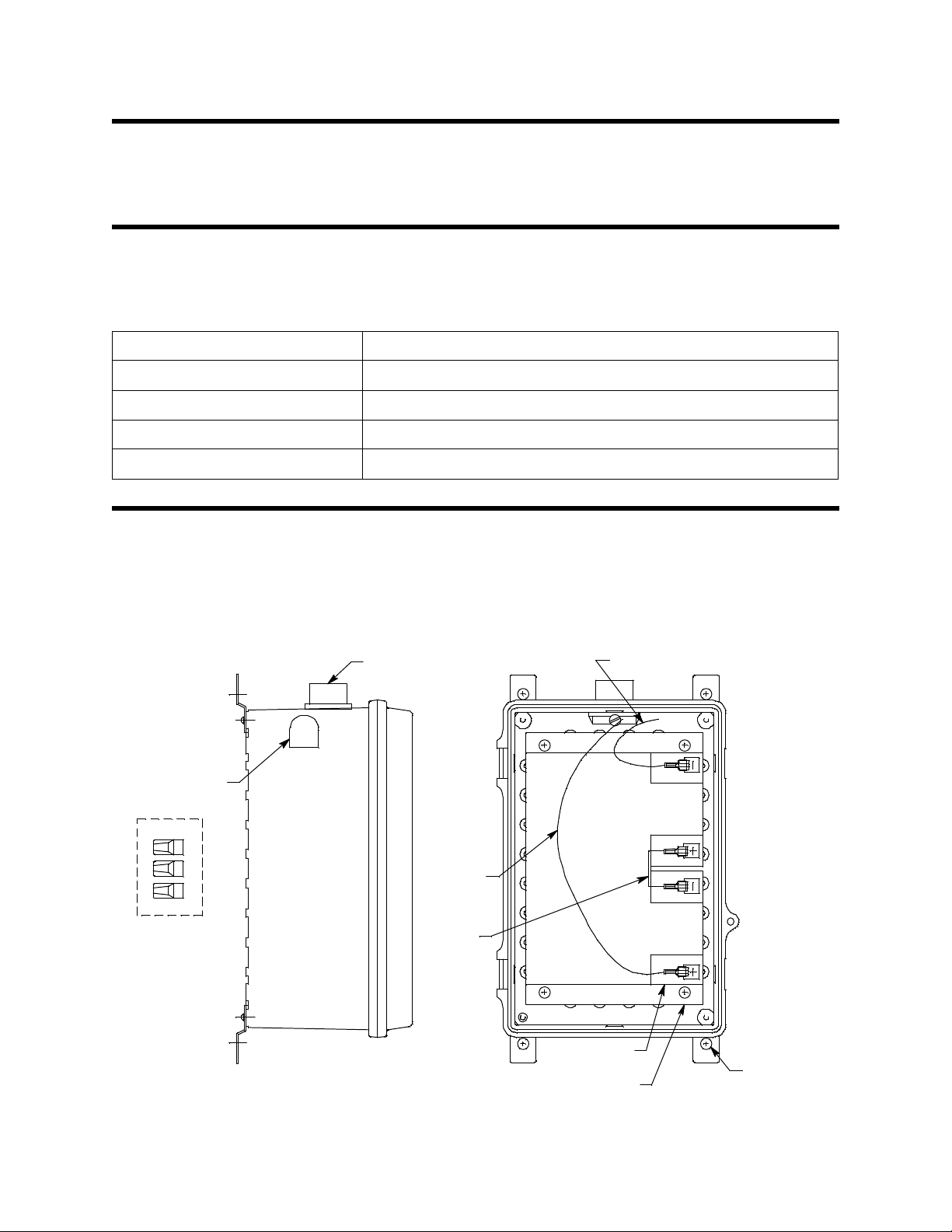

This manual describes the 49-8104RK standby battery. This manual also describes how to

install and maintain the stan d b y battery.

Specifications

Table 1 lists specifications for th e standby battery.

Table 1: Specifications

Construction (housing) Weatherproof ABS plastic

Power Rating 24 VDC, 12 AH (amp hour)

Operating Temperature 32° F to 104° F (0°C to 40°C)

Size 11.28” H x 7.48” W x 5.91” D (287 mm D x 190 mm W x 150 mm D)

Weight 22 lbs (10 kg)

Description

The 49-8104RK Standby Battery is designed for use with a gas monitoring controller

capable of running from 24 VDC such as the RKI Instruments, Inc. Beacon 200, Beacon

410, or Beacon 800 controller. It can provide temporary power to a controller if primary

AC power is lost. The standby battery consists of the ho using, two batteries (shipped

uninstalled), three connection wires (shipped in a small bag), and wire nuts for wiring

connections. The figure below shows the batteries and wires installed.

Figure 1: Standby Battery Component Location

49-8104RK Standby Battery • 3

Page 4

Housing

The standby battery’s fiberglass housing is weather- and corrosion-resistant. It is suitable

for installation where general purpose equipment is in use. The housing door is hinged on

the left side and is secured by two latches on the right side. Four mounting feet are

attached to the back of the housing (one at each corner). The mounting feet allow you to

install the housing to a vertical surface. A cond uit hub on the top of the housing is for

external wiring connections. A weathe r-resistant vent on the upper left side prevents

buildup of hydrogen in the housing if it is vented by the batteries.

Batteries

Two lead acid 12 VDC, 12 AH batteries are shipped with the housing but are not installed.

The batteries must be installed into the housing and connected with a wire jumper s o th at

they produce 24 VDC. T wo wires must be connected to the batteries to allow connection to

the positive and negative of the standby battery. The ends of these wires are covered with

insulating shrink tubing to prevent shorting during shipment. These pi eces of shrink

tubing will have to be removed during installation of the standby battery (see “Wiring the

Standby Battery to a Controller” on page 7 ).

Wire Nuts

Three wire nuts are provided with the standby battery for wiring connections. The wire

nuts are shipped in the standby battery packaged in a small plastic bag. Only two wiring

connections will have to be made to the standby battery (see “Wiring the Standby Battery

to a Controller” on page 7), so one of the wire nuts is provided as an extra in case one is

lost or damaged.

4 • 49-8104RK Standby Batter y

Page 5

Installation

Battery

Mounting

Bracket

Note: Front

View Shown

Without Door

Jumper Wire

12 Amp Hour

Battery, 2X

Wire (red)

for positive

connection

Wire (black) for

negative

connection

Wire nuts, 3

shipped with unit

(1 extra )

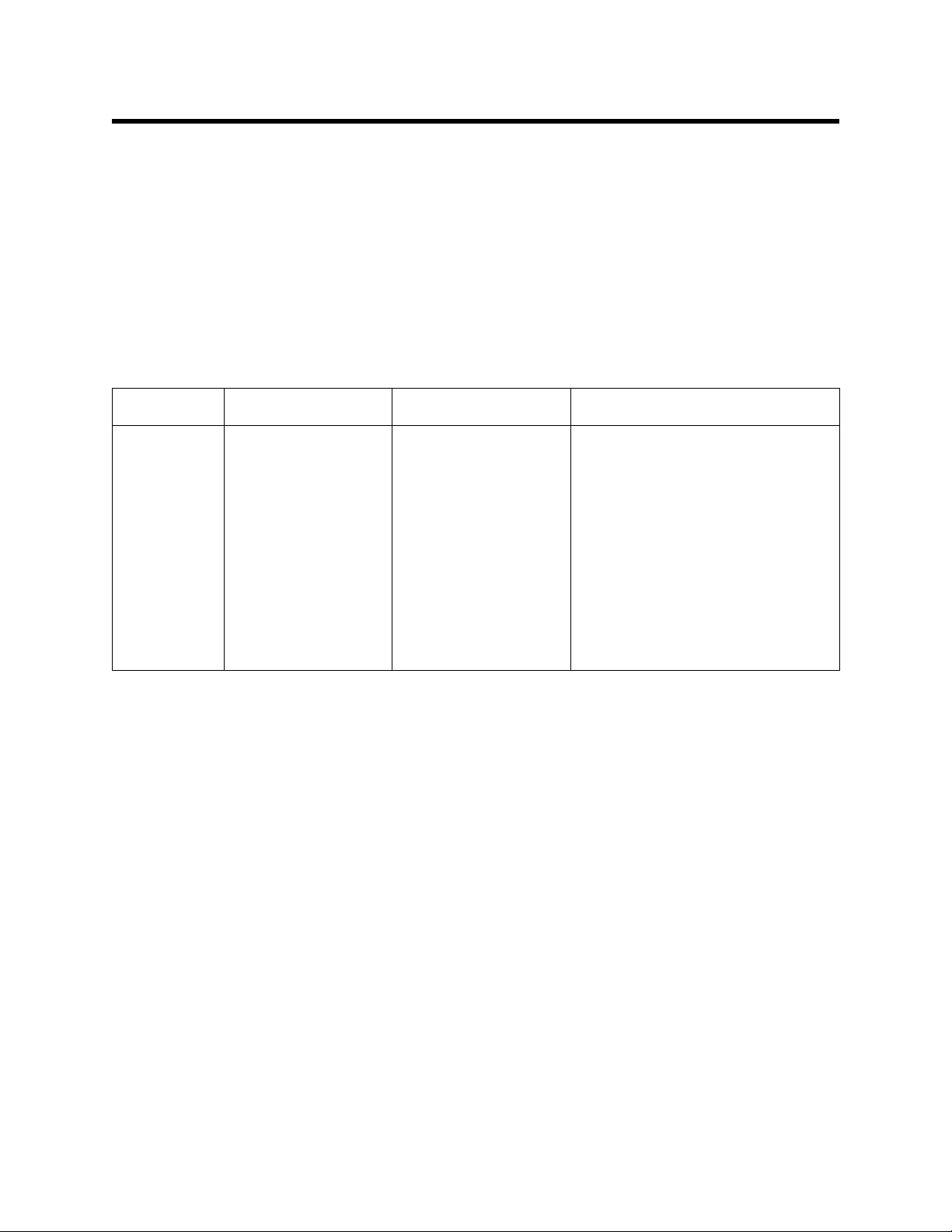

This section describes procedures to mount the standby battery and wire it to a controller.

Installing the Batteries

The batteries are shipped separately in order to prevent damage to the housing. Three

wires are provided in a bag in order to make connections to the batteries. The figure below

shows how the standby battery is shipped.

Figure 2: Standby Battery Components as Shipped

1. Place the enclosure on a table or bench top and open the door.

2. Unscrew the four screws retaining the battery mounting bracket to the case.

3. Carefully remove the battery mounting bracket from the case.

4. Place the batteries in the enclosure and arrange them so that all battery terminals are

on the right as shown in Figure 1 .

5. Place the battery bracket over the batteries and line up the mounting holes in the

bracket with the mounting holes in the case.

6. Install the four screws that retain the battery bracket and tighten firmly.

7. Install the positive (red) wire to the “+” connection on the bottom battery (see

Figure 1). This wire is one of three wires in a small bag included with the shipping

contents.

8. Install the negative (black) wire to the “-” connection of the top battery (see Figure 1).

This wire is one of three wires in a small bag included with the shipping co ntents.

49-8104RK Standby Battery • 5

Page 6

CAUTION: Before continuing, confirm that the positive wire (red) and the negative wire (black)

3.74

7.48

3/4" Conduit

Hub

6.15

3.07

5.91

11.88 Max

1/4" Screw, 4X,

User Supplied

13.00

11.28

11.38 Min

are not shorting to each other. Each wire has s hrink tubing on the end to prevent

shorting. Leave the shrink tubing on.

9. Install the wire jumper between the “+” connection of the top battery and the “-”

connection of the bottom battery (see Figure 1). This wire is one of three wires in a

small bag included with the shipping contents.

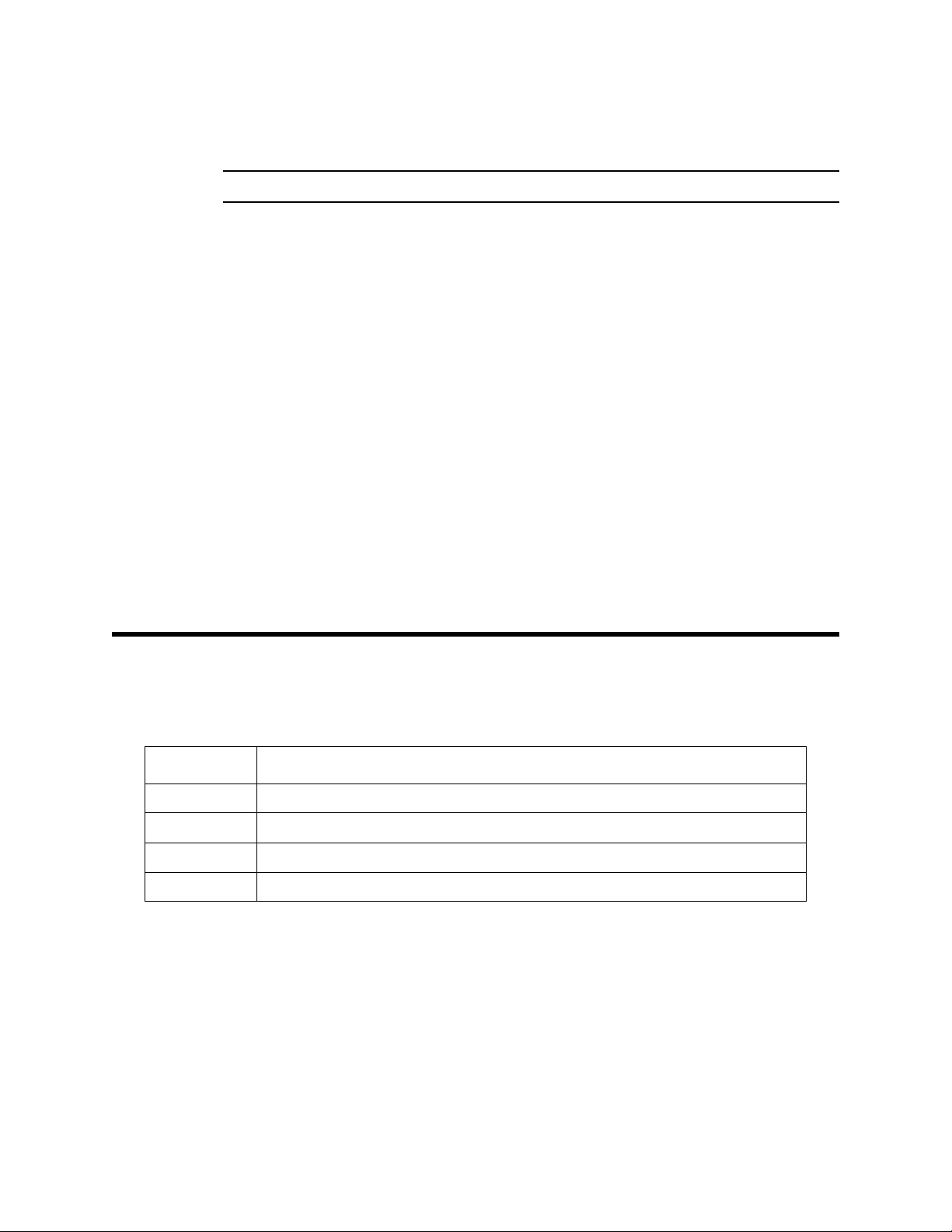

Mounting the Standby Battery

1. Select a mounting site close to the controller that requires standby power. Consider

the following when you select the mounting site.

• Select a site where the standby battery is not likely to be bumped or disturbed.

Make sure there is sufficient room to perform maintenance procedures.

• The conduit hub on the top of the standby battery housing makes wiring to a

controller convenient if the standby battery is mounted below a con troller.

2. Open the standby battery door and remove any packin g materials from the housing.

Be careful not to lose the three wire nuts that are provided for wiring connections.

3. Close and latch the standby battery housing door.

4. The standby battery is shipped with the mounting feet positi oned be hind the hou sing.

Loosen the screws that secure the feet to the housing, rotate the feet to their mounting

position as shown in Figure 3, th en tighten the screws.

Figure 3: Outline & Mounting Dimensions

5. Insert 1/4 inch screws through the slots in the mounting feet at each corner of the

housing to secure the housing to the mounting surface.

6 • 49-8104RK Standby Batter y

Page 7

Wiring the Standby Battery to a Controller

WARNING: Always verify that all power to the controller is OFF before you make

wiring connections.

1. Turn off the cont roller.

2. Turn off or unpl ug power to the controller.

3. Install an appropriately rat ed cable bushing or conduit to the conduit hub on the

controller that will be used for wires from the standby battery.

4. Open the standby battery housing door.

5. Install an appropriately rat ed cable bushing or conduit to the conduit hub on the

standby battery housing.

6. Route two wires in conduit or a two wire cable with wires from the controller conduit

hub to the standby battery conduit hub. 16 AWG wire is recommended, but the wire

nuts will accommodate wire up to 14 AWG wire.

7. Connect the two wires to the 24 VDC power input terminals at the controller. Note

which wire is positive and which wi re is nega tive.

8. A short factory installed jump er wire terminated with push-on lugs connects the two

batteries in the standby battery. Remove this wire from one of the battery terminals

and make sure it is not contacting the terminal.

9. When the standby battery is shipped from the factory, the ends of the two wires

provided for external wiring connections are covered with shrink tubing to prevent

shorting of the batteries during shipment. Remove the shrink tubing and strip the end

of each wire. Take care not to short the wires to the mounting bracket or to each other.

49-8104RK Standby Battery • 7

Page 8

10. Use the wire nuts provided with the standby battery to connect the positive and

Connections

Made With Wire

Nuts Provided

RESET

CH1

OUT

CH2

OUT

+

+

BAT

BUZ +

BAT +

Contr oll er Terminal Strip

Beacon 200 Housing

User

Installed

Jumper

Standby Battery Shown Without Door

RESET

BUZ

negative wires in the standby battery to the positive and negative wires coming from

the controller as shown in Figure 4, Figure 5, and Figure 6.

Figure 4: Wiring the Standby Battery to a Beacon 200

8 • 49-8104RK Standby Batter y

Page 9

Connections

Made With Wire

Nuts Prov ided

Controll er Ter minal Str ip

Beacon 410 Housing

User

Installed

Jumper

Standby Battery Shown Without Door

Figure 5: Wiring the Standby Battery to a Beacon 410

49-8104RK Standby Battery • 9

Page 10

Connections

Made With Wire

Nuts Pro vi ded

NC

NO

BAT+

ALM2

NO

C

C

NO

NC

RX

GND

+28V

TX

RESET

BUZ +

BUZ

RESET

BAT

FAIL ALM1

Beacon 800 Housing

User

Installed

Jumper

Cont rol ler Te rminal Str ip

24

VDC

Standby Battery Shown Without Door

C

NC

10 • 49-8104RK Standby Bat tery

Figure 6: Wiring the Standby Battery to a Beacon 800

11. Turn on power to the controller.

12. Turn on the controller.

13. When the controller has completed its startup sequence, re-connect the end of the

jumper wire to the battery terminal from which it was removed.

14. Close the standby battery ho using door.

15. The on/off switch in the Beacon 200, Beacon 410, and Beacon 800 controls AC power

to the instruments. Verify that the standby battery is installed properly by flipping the

on/off switch to the off position and observing that the controller continues to operate

powered by the standby battery.

16. Flip the controller power switch to the on position.

Page 11

Operation

When the standby battery is connected to an RKI Instruments, Inc. controller such as the

Beacon 200, Beacon 410 , o r th e Beacon 800, the controller m ai n tain s a t rick l e ch arge on the

battery to keep it fully charged. If primary AC power to the controller goes down, the

standby battery will power the controller for a limited amount of time until primary

power returns. When primary AC power returns, the controller will begin charging the

standby battery. Recharge time will vary depending on the controller and the level of

discharge, but a typical recharge time if the battery is completely discharged is about 4

days.

Runtime will vary depending on the con troller and config uration of the controller. The

table below shows typical controller runtimes for common configu rations.

Table 2: Typical Controller Runtimes on Standby Battery

Controller Controller Detector Configuration Runtime

Beacon 200 2 Channels LEL 40 hours

Beacon 200 2 Channels Toxic or Oxygen 90 hours

Beacon 200 2 Channels 35-3000RK Sample Draw 18 hours

Beacon 200 2 Channels GD-K7D2 Sampl e Draw 22 hours

Beacon 410 4 Channels LEL 40 hours

Beacon 410 4 Channels Toxic or Oxygen 96 hours

Beacon 410 4 Channels 35-3000RK Sample Draw 14 hours

Beacon 410 4 Channels GD-K7D2 Sampl e Draw 17 hours

Beacon 800 8 Channels LEL 18 hours

Beacon 800 8 Channels Toxic or Oxygen 60 hours

Beacon 800 8 Channels 35-3000RK Sample Draw 4 hours

Beacon 800 8 Channels GD-K7D2 Sample Draw 5 hours

49-8104RK Standby Battery • 11

Page 12

Maintenance

This section describes preventive maintenance and troubleshooting procedures. It also

includes component replacement procedures and a parts list.

Preventive Maintenance

Check the standby battery voltage with a volt meter on a quarterly basis and verify that it

is fully charged. A fully charged standby battery connected to a controller that trickle

charges it will typically measure between 28 volts and 29 volts.

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended

action for problems you may encounter with the standby battery.

Condition Symptom(s) Probable Causes Recommended Action

Low Battery

Voltage

•The standby battery

voltage measures

below 28VDC at t he

quarterly voltage

check.

• The wiring to the

controller is

disconnected or

misconnected.

•The wire nut

connections in the

standby battery are

not properly made.

• The wiring to the

battery terminals in

the standby battery is

disconnected.

• The controller is not

fully charging the

standby battery.

1. Verify that the wiring at the

controller is correct and secure.

2. Verify that the wire nut connections

in the standby battery are properly

made.

3. Verify that th e lugs that fit over the

battery terminals are securely and

correctly installed.

4. Check the DC fuse at the controller.

5. If the low voltage condition

continues, contact RKI for furth e r

instruction.

Replacing a Battery

If one of the 12 VDC batteries in the standby battery needs replacement, RKI Instruments,

Inc. recommends that both batteries be replaced. The part number for a replacement

battery is listed in the parts list at the end of this section. Follow the instructions below to

replace the batteries.

1. Turn off the cont roller.

2. Turn off power to the controller.

3. Open the standby battery housing door.

4. Remove the jumper wire that connects the two batteries. It connects to both batteries

with a push-on lug.

5. Remove the remaining two connections to the batteries, the positive and negative

connections, by removing the push-on lugs from each battery.

6. Fix the positive and negative wires out of the way.

7. Unscrew the top two screws retaining the battery bracket to the case. Hold the battery

bracket in place so that the batteries do not fall out of the case.

8. While holding the battery bracket in place, unscrew the bottom two screws retaining

the battery bracket in place. Be careful when the screws are removed as the batteries

are heavy and may fall out of the housing if the battery bracket is not held firmly

when the screws are removed.

12 • 49-8104RK Standby Bat tery

Page 13

9. Carefully remove the battery bracket and batteries from the case.

10. Replace the batteries in the bracket with the new batteries.

NOTE: Dispose of the old batteries properly.

11. Place the battery bracket with the batteries in the case and line up the mounting holes

in the bracket with the mounting holes in the case. Hold the bracket with the batteries

in place firmly.

12. Install the bottom screws that retain the battery bracket and tighten firmly.

13. Install the top screws that retain the battery bracket and tighten firmly.

14. Install the positive and negative connections to the appropriate battery terminals (see

Figure 4, Figure 6, and Figure 6).

15. Turn on power to the controller.

16. Turn on the controller.

17. When the controller has completed its warm-up sequence, install the jumper wire

between the two batteries (see Figure 4, Figure 6, and Figure 6).

18. Close the standby battery ho using door.

19. The on/off switch in the Beacon 200, Beacon 410, and Beacon 800 controls AC power

to the instruments. Verify that the standby battery is installed properly by flipping the

on/off switch to the off position and observing that the controller continues to operate

powered by the standby battery.

20. Flip the on/off switc h to the on position.

Parts List

Table 3 below list s sp are parts for the stan d b y b at tery.

Table 3: Standby Battery Spare Parts

Part Number Description

18-0107RK 3/4” NPT conduit hub

18-0112RK Vent

45-0600RK Wire nut, for 22 - 14 AWG wire

49-1552RK Battery , le ad acid, 12 V, 12 amp hour

49-8104RK Standby Battery • 13

Loading...

Loading...