Page 1

35-3010RKA-06 Sample-Draw

Part Number: 71-0207RK

Revision: D

Released: 9/24/13

Detector

rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before operating

detector . Improper use of the dete ctor could result in bodily harm

or death.

Periodic calibration and maintenance of the detector is essential

for proper operation and correct readings. Please calibrate and

maintain this detector regularly! Frequency of calibration

depends upon the type of use you have and the sensor types.

T ypical calibration frequencies for most applications a re between

3 and 6 months, but can be required more often or less often

based on your usage.

35-3010RKA-06 Sample-Draw Detector

Page 3

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free fro m defects in

materials, workmanship, and performance for a period of one year fr o m date of shipment

from RKI Instruments, Inc. Any parts found defective withi n tha t period will be repaired

or replaced, at our option, free of charge. This warranty does not apply to those items

which by their nature are subject to deterioration or consumption in normal service, and

which must be cleaned, repaired, or replaced on a routine basis. Examples of such items

are:

W arranty is voided by abuse including mechanical damage, alteration, rough handling, or

repair procedures not in accordance with the operator’s manual. This warranty indicates

the full extent of our liability , a nd we are not r esponsible for removal or r eplacement costs,

local repair costs, transportation costs, or contingent expenses incurred without our prior

approval.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF

RKI INSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF

ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR

OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors,

dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification fo r any accident or dama g e ca u s e d by the operation of

this gas monitor, and our warranty is limited to the replacement of parts or our complete

goods.

35-3010RKA-06 Sample-Draw Detector

Page 4

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Flow System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Detection System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Sample-Draw Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting the Sample Lines to the Sample-Draw Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring the Sample-Draw Detector to a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introducing Incoming Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the Zero Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Low Flow Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacing Components of the Sample-Draw Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting the Low Flow Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibration Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preparing for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Zero Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Response Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Returning to Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

35-3010RKA-06 Sample-Draw Detector

Page 5

Overview

This manual describes the 35-3010RKA-06 sample-draw detector. This manual also

describes how to install, start up, maintain, and calibrate the dete ctor. A parts list at the

end of this manual lists replacement parts and accessories for the sample-draw detector.

Specifications

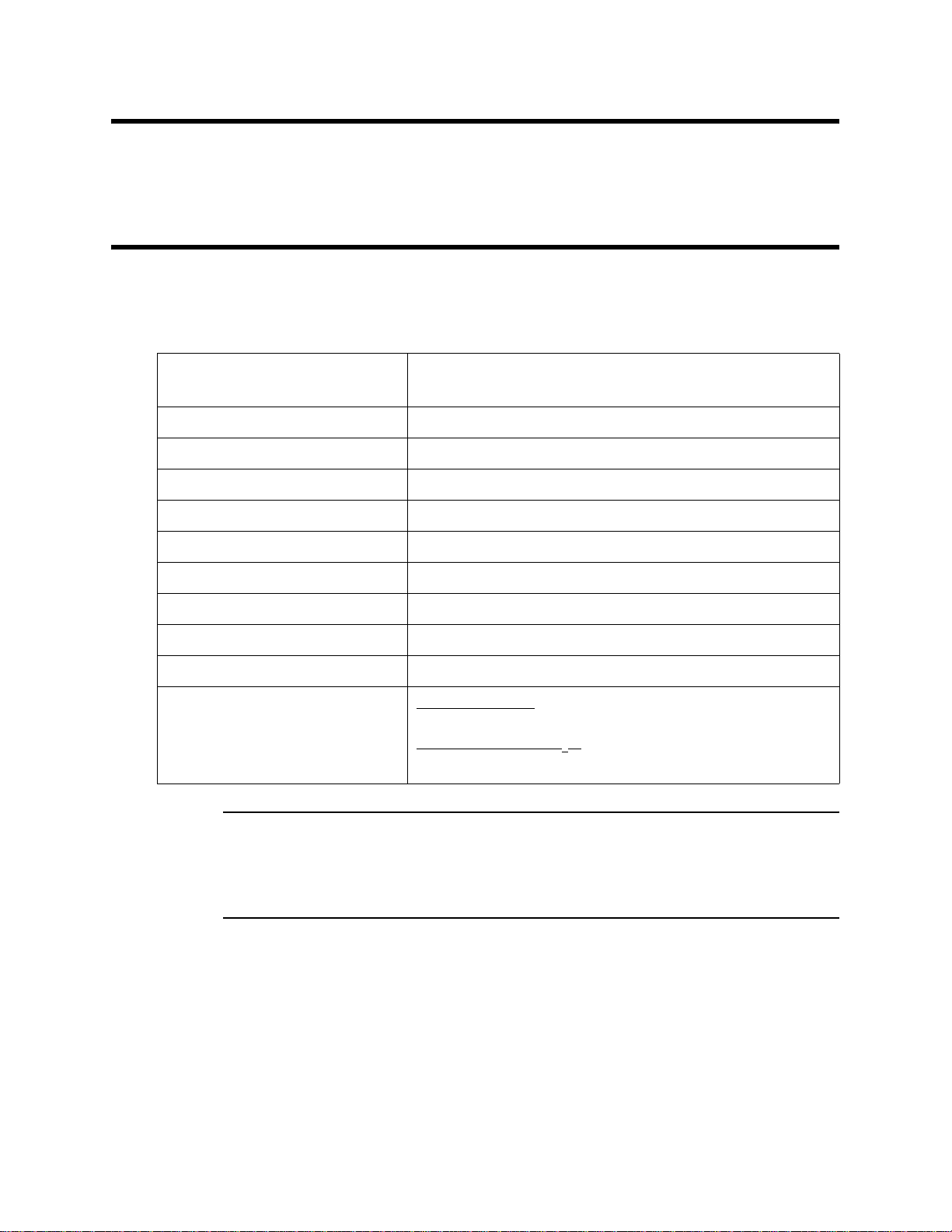

Table 1 lists specifications for the 35-3010RKA-06.

Target Gases & Detection Ranges Combustible Gas: 0 - 100% LEL

Input Power 24 VDC

Current Draw 240 mA

Output Signals 4-20 mA each channel

Table 1: Specifications

Hydrogen Sulfide (H

S): 0 - 100 ppm

2

Construction (housing) Fiberglass/polyester (NEMA 4X)

Dimensions 15.44 in. H x 12.55 in. W x 8.31 in. D

Weight 14 lbs.

Sampling Method Sample-draw

Sample Flow 1.2 SCFH (nominal)

Response Time 90% in 30 se conds

Accuracy Combustible Gas

± 5% of reading or ± 2% LEL (whichever is greater)

Hydrogen Sulfide (H

± 5% of reading or ± 2 ppm H

WARNING: When using the 35-3010RKA-06, you must follow the instructions and

warnings in this manual to assure proper and safe opera tion of the

35-3010RKA-06 an d to minimize the ris k of personal injury. Be sure to

maintain and periodically calibrate the 35-3010RKA-06 as described in this

manual.

:

S):

2

S (whichever is greater)

2

35-3010RKA-06 Sample-Draw Detector • 1

Page 6

Description

Hydrophobic

Filter (AcroPak)

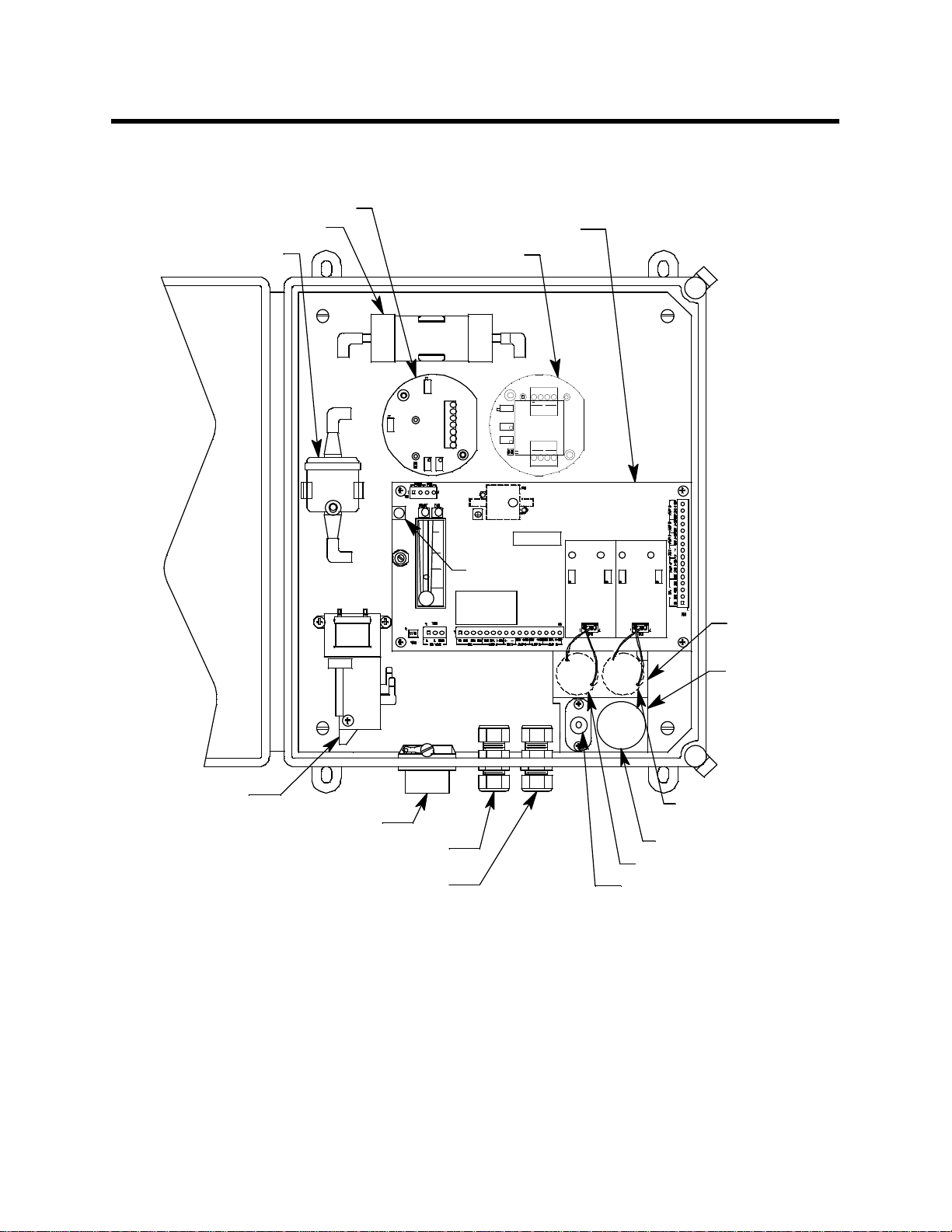

This section describes the components of the 35-3010RKA-06 sample-draw detector. The

sample-draw detector consists of the housing, flow system, and detection system.

LEL Transmitter

Charcoal Filter

MainCircuit Board

Oxygen Transmitter

+

+

FB

24VBATT

4/20

TP -

TP +

ZERO

SPAN

OXY

TOXIC

OXY

G

BKRD

W

TOXIC

Reset Switch

Amp 1

Pump

3/4Conduit Hub, 2X

Exhaust Fitting For 1/4"

OD Rigid Tubing

Inlet FittingFor 1/4" OD

Rigid Tubing

Amp 2

Preamp

Circuit

Board

Flow

Block

H2SSensor

Dummy Plug

OxygenSensor

CO Sensor

Combustible

Sensor

Figure 1: Sample-Draw Detector Component Location

Housing

The sample-draw detector’s fiberglass housing is weather- and corrosion-resistant. It is

suitable for installation where general purpose equipment is in use. The housing door is

hinged on the left side and is secured by two latches on the right side.

Four mounting feet are attached to the back of the housing (one at each corner). Use the

mounting feet to install the housing to a vertical surface. Use the two conduit hubs on the

bottom of the housing to make wiring connections.

2 • 35 -3010RKA-06 Sample-Draw Detec tor

Page 7

Filter

Exhaust

An aluminum subpanel is mounted to th e interior of the housing. The sample-draw

detector’s internal components are mounted to the subpanel.

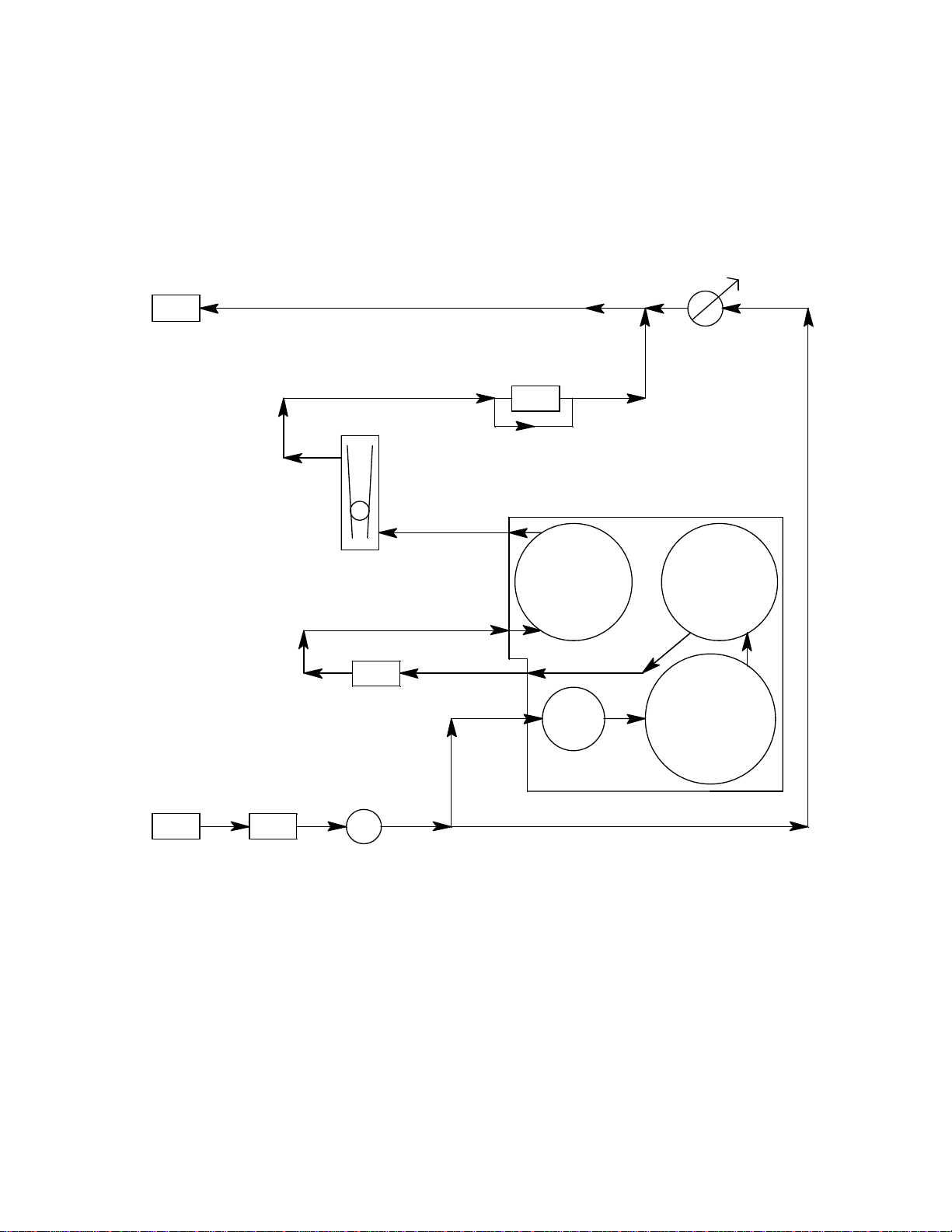

Flow System

The sample-draw detector’s flow system consists of the INLET fitting, hydrophobic filter,

charcoal filter, pump, flowmeter, bypass valve, status lights, pressure switch, flow block,

and EXHAUST fitting (see Figure 1). Figure 2 illustrates how the gas sample moves

through the flow system.

Bypass

Valve

Pressure Switch

Flow meter

Fl ow Block

Inle t

CO

Hydrophobic

Charcoal

Filter

Pump

Dummy

Plug

LEL

H2S

Oxygen

Dummy

Plug

Figure 2: Sample-Draw Detector Flow Diagram

INLET Fitt i n g

The INLET fitting on the bottom of the housing allows the gas sample to enter the sampledraw detector. The INLET fitting accepts 1/4 in. rigid tubing. See “Installation” on page 9

for instructions to connect tubing to the INLET fitting.

Hydrophobic Filter

The hydrophobic filter is to the left of the main circuit board. It is held in place by a metal

clip. It prevents water and other liquids from contaminating the flow system. Replace the

filter when it appears dirty, discolored, or clogged. If a liquid other than water is drawn

into the filter, repl ace the filter as soon as possible.

35-3010RKA-06 Sample-Draw Detector • 3

Page 8

Charcoal Filter

The charcoal filter is located in the top left corner of the enclosure. It is held in place by a

metal clip. The charcoal filter is placed after the H

S sensor and before the CO sensor (if

2

one is installed) in the flow system. It scrubs out interfering gases w hich may cause the

CO sensor to respond, such as H

S or certain hydrocarbons. It is included in this version

2

of the sample draw detector in case a CO sensor is added in the field. If a CO sensor is

added in the field, a new charcoal filter should also be installed.

Pump

The pump is located to the left of the main circuit board near the bottom left of the

sample-draw detector. The pump pulls the gas sample into the sample-draw detector. The

pump operates on 24 VAC, which is generated from the 24 VDC supplie d to the sample

draw detector.

Flowmeter

The flowmeter is attached to the main circuit board near the top left corner (see Figure 4).

A ball in the flowmeter column indicates the flow rate to the sensors. The flowmeter

measures the flow in the range 0.2 to 2.0 SCFH (Standard Cubic Feet per Hour). Although

the sample-draw detector will operate down to a flow of 0.6 SCFH, the optimum flow rate

is 1.2 SCFH.

Bypass Valve

The bypass valve is to the left of the flowmeter. The bypass valve adjusts the flow rate to

the sensors. Use a flat-blade screwdrive r to adjust the bypass valve.

NOTE: The bypass valve allows fine adjustments of the flow rate. For a wider range of

adjustment, use the flow adjust potentiometer (see Figure 4).

Status Lights

Two status lights are above the flowmeter.

Pilot Light

The green Pilot light is on when the sample-draw detector is receiving power.

Fail Light

The red Fail light is on when the sample flow rate is below the low flow level.

NOTE: The factory set low flow level is 0.6 SCFH (±0.2). See “Adj usting the Low Flow

Setting” on page 18 for instructions to adjust this setting.

Pressure Switch

The pressure switch is mounted to the opposite side of the main circuit board. The

pressure switch monitors the flow rate to the sensors.

If the flow rate falls below the preset low flow level, the pressure switch causes the fail

relay to interrupt the signal in the 4-20 mA line for the H

downscale reading at the monitor on this channel. The low flow level is factory-set at 0.6

SCFH (±0.2 SCFH).

NOTE: There is no low flow indication for the LEL channel.

4 • 35 -3010RKA-06 Sample-Draw Detec tor

S channel. This causes a

2

Page 9

Flow Block

The flow block is located in the lower right corner of the sample-draw detector. All the

sensors are installed in the flow block. The flow block routes the sampled air to each

sensor.

EXHAUST Fitting

The EXHAUST fitting on the bottom of the housin g allows the gas sample to exit the

sample-draw detector. The EXHAUST fitting accepts 1/4 in. rigid tubing. See

“Installation” on page 9 for instructions to connect tubing to the EXHAUST fitting.

Detection System

The detection system consists of the gas sensors, LEL tran smitter, preamp circuit board,

and the main circuit board.

Combustible Gas Sensor

The combustible gas sensor is installed in the lower left of the flow block. The combustible

gas sensor includes the sensing elements, flame arrestor, connector, and sensor leads.

Sensing Elements

Two sensing elements are protected within the sensor assembly. Through a series of

thermal and electronic reactions, these elements produce an output that is pr o portional to

the detection range of the sample draw detector. The LEL transmitter converts the output

to a 4 - 20 mA signal which can be us ed by a recording or monitoring device.

The porous flame arrestor allows the gas sample to enter the sensor assembly and contact

the sensing element. The flame arrestor also contains sparks within the sensor.

Connector

The top of the sensor includes five pins that plug into the socket connector. This connector

allows you to replace the sensor without disconnecting the wiring. The sensor leads are

soldered to the connector.

Sensor Leads

Four color-coded leads extend from the connector. The leads allow you to connect the

combustible gas sensor to the main circuit board.

Oxygen Sensor

The oxygen sensor is installed in the lower right of the flow block. In the 35-3010RKA-06,

the oxygen sensor position in the flow block is occupi ed by a dummy sensor.

Carbon Monoxide Sensor

The carbon monoxide gas sensor is installed in the upper left side of the flow block. In t h e

35-3010RKA-06, the carbon monoxide sensor position in the flow block is occupied by a

dummy sensor.

Hydrogen Sulfide Gas Sensor

The hydrogen sulfide gas sensor position is located in the upper right side of the flow

block.

35-3010RKA-06 Sample-Draw Detector • 5

Page 10

LEL Transm itt er

Test Point TP+

Test Point TP-

Interconnect

Terminal Strip

Span Pot

Zero Pot

Figure 3: LEL Transmitter

LEL Transmitter

The LEL transmitter is mounted above the main circuit board. It consists of the span pot,

zero pot, one internally wired terminal strip, and the test points.

Span/Zero Pots

The span and zero pots are located at the bottom edge of the transmitter and are used for

calibration. Use the span pot to make adjustments to gas response readings and the zero

pot to make adjustments to the zero reading.

Transmitter Interconnect Terminal Strip

The transmitter interconnect terminal strip is the seven-point terminal strip near the right

edge of the transmitter. The transmitter is factory wired to the sensor and main circuit

board.

T est Points

The test points are located on the left side of the transmitter and are labeled TP+ and TP-.

A 100 mV - 500 mV outpu t is available at these test points for use during calibration.

Preamp Circuit Board

The preamp circuit is used to connect the H

S sensor to the main circuit board and to

2

secure the sensor in the flow block. Two cables mate to the main circuit board: the one on

the left is for the CO sensor signal and the one of the right is for the H

S sensor signal.

2

Since there is no CO channel, the cable on the left is not used.

6 • 35 -3010RKA-06 Sample-Draw Detec tor

Page 11

2

Reset

Switch

Pilot LED

Main Circuit Board

Pum p Termin al St ip

Pressure Switch

Fail LED

Flowmeter

Flow Adjust Pot

Low Flow Adjust

Relay

Test Point CAL - 1

Test Point CAL + 1

Test Point CAL - 2

Test Point CAL +

Interconnect Terminal

Strip

AC T erminal

Strip Not Used

Zero Span Zero

Amp 1

(CO)

Sensor/Transmitter

Terminal Strip

Span

Amp 2

(H2S)

Figure 4: Main Circuit Board

The main circuit board includes the interconnect terminal strip, sensor/transmitter

terminal strip, amp 1 circuit, amp 2 circuit, pump terminal strip, relay, and reset switch.

NOTE: The flowmeter and status lights are mounted to the main circuit board but are

considered part of the flow system.

Interconnect Terminal Strip

The interconnect terminal strip is the sixteen-point terminal strip near the bottom edge of

the main circuit board. Use the interconnect terminal strip to connect the sample-draw

detector to a controller.

Sensor/Transmitter Terminal Strip

The sensor/transmitter terminal strip is the sixteen-point terminal strip near the right

edge of the circuit board. Use the transmitter terminal strip to connect sensors or

transmitters to the main circuit board.

NOTE: The sensors and transmitters are factory wired to the sensor/transmitter

terminal strip. See “Wiring the Sample-Draw Detector” on page 10 for all wiring

procedures related to the sample-draw detector.

35-3010RKA-06 Sample-Draw Detector • 7

Page 12

Amp 1 and Amp 2 Circuits

These circuits are located to the left of the sensor/transmitter terminal strip. They each

include test points, a zero pot, and a span pot. Amp 1 is on the left and is for the CO

channel. Amp 2 is on the right and is for the H

S channel. Since there is no CO channel,

2

Amp 1 is not used.

The zero and span po ts are used during calibration. Use th e span pot t o mak e adj ustment s

to gas response readings and the zero pot to make adjustments to the zero reading.

The test points are labeled CAL-1 and CAL+1 for the CO channel and CAL-2 and CAL+2

for the H

S channel. A 10 0 mV - 500 mV out put is available at the H2S test points for use

2

during calibration. No output is ava ilable at the CO test points.

Pump Terminal Strip

The pump terminal strip is the four-point terminal in the top left corner of the circuit

board. Use the pump terminal strip to connect the pump and pressure switch to the main

circuit board.

NOTE: The pump and pressure switch are factory-wired to the circuit board. See

“Wiring the Sample-Draw Detector” on page 10 for all wiring procedures related

to the sample-draw detector.

Relay

The relay is approximately in the middle of the circuit board. The relay is a four pole,

double-throw (4PDT) relay and is rated for 2 amps at 25 VDC (resistive). If the pressure

switch senses a low flow condition, the relay interrupts the 4-20 mA signal from the H

S

2

channel which will cause a downscale reading at the controller or recording device.

NOTE: There is no flow fail indication for the LEL chan nel on the 35-3010RKA-06

Sample Draw Detector.

Reset Switch

A small reset button is located in the upper left corner of the main PCB. When a low flow

condition occurs, the pump will be shut off. To reset the low flow condition and sta r t the

pump again, press and hold the reset sw itch for about 2 seconds, the n release.

8 • 35 -3010RKA-06 Sample-Draw Detec tor

Page 13

Installation

12.55

This section describes procedures to mount the sample-draw gas detector in the

monitoring environment and wire the sample-draw detector to power and an external

device.

Mounting the Sample-Draw Detector

1. Select the mounting site. Consider the following when you select the mounting site.

• Is there enough room to open the housing door and make wiring connections at

the bottom of the housing and tubing connections at the right of the housing?

• Make sure there is sufficient room to perform start-up, maintenance, and

calibration procedures.

14.94

15.44

3/4" Conduit Hub, 2X

14.55

10.00

Door Latch

Ø .31 x .50 slot, 4X

.18

8.31

Tube Fitting for 1/4"

OD tube, 2X

Figure 5: Mounting the Sample-Draw De tect or

2. Clos e and latch the housing door.

NOTE: The sample-draw detector is shipped with the mounting feet “tucked under” the

housing to protect the mounting feet during shipment.

3. Slightly loo sen the screw that secures one of the mounting feet to the housing, then

rotate the mounting foot 180 degrees.

4. Tighten the screw that secures the mounting foot to the housing.

35-3010RKA-06 Sample-Draw Detector • 9

Page 14

5. Repeat steps 3 and 4 for the remaining three mounting feet.

6. Position the sample-d raw housing on a vertical surface at eye level (4 1/2 to 5 feet

from the floor).

7. Ins ert 1/4 in. or 5/16 in. screws through the slot s in the mounting feet t o secure the

housing to the mounting surface.

Connecting the Sample Lines to the Sample-Draw Detector

1. Attach 1/4 in. O.D. rigid polypropylene or rigid Teflon sample tubing to the INLET

fitting.

CAUTION: If you use flexible sample tubing (polyurethane is acceptable), use an appropriate

insert to seal the connection between the tubing and the INLET fitting.

2. Place the opposite end of the tubing at the sampling area.

CAUTION: Avoid loops or slumps in the incoming sample line. T o r educe response time, keep the

incoming sample line as short as possibl e.

3. Attach rigid sample tubing to the EXHAUST fitting.

4. Route the opposite end of the tubing to an open area where the sample can safely

disperse.

Wiring the Sample-Draw Detector

WARNING: Always verify that the power source is OFF before you make wiring

connections.

1. Turn off the controller.

2. Turn off or unplug incoming power to the controller.

3. Unlatch and op en the housing door of the sample-draw detector.

4. Guide a five-conductor 18 gauge, shielded cable or five 18 gauge wires in conduit

through one of the conduit hubs at the bottom of the sample-draw housin g. If

necessary, use both hubs to bring the wires in making sure that all the wires for a

particular channel go through the same hub.

5. Connect the cable to the sample-draw detector’s interconnect terminal strip as shown

in Figure 6.

6. Close and latch the housing door of the sample-draw detector.

CAUTION: Leave the cable shield drain wire insulated and disconnected at the sample-draw

detector. You will connect the op posite end of the drain wire at the controller.

7. Route the cable or wires in conduit leadin g from the sample-draw detector to the

controller.

8. Connect the drain wire to an available chassis ground at the controller end. RKI

controllers typically have a ground stud that can be used to ground the cable’s drain

wire.

10 • 35-3010RKA-06 Sample-Draw Detector

Page 15

Sa mpleDrawHousing

Main Circuit Board

Interconnect Terminal Strip

(C ontroller Transm itter

Oxyge n

Terminals)

(ControllerTransmitter

4/20 (Feedback)

+

24 VDC

4/20 (Feedback)

CO

Terminals)

24 VDC

+

24 VDC +

4/20 (Feedback)

Figure 6: External (Field) Wiring, S ample-Draw Detector

LEL

(Controller Transm itter

Terminals)

35-3010RKA-06 Sample-Draw Detector • 11

Page 16

Pump

Factory

Wired

LEL Sensor

Connector

Black

Green

White

Red

P/N 57 -1 05 0 R K

REV. 0

TP+

SPAN Z ER O

TP-

GND

24V

4-20

POWER/SIG

RED

WHT

INSTRUMEN TS

GRN

SENSOR

BLK

Pressure Swi tch

Factory W ire d

ZERO

SPAN

OXY

TOXIC

+

+

24V4/20

BATT

TP -

TOXIC

TP +

OXY

GFBBK WRD

Green

White

LEL

Detector

Oxygen Sensor

CO Sensor Plugs Into

FarSide of Pr eamp

Circuit Board

CO

H2S

(Not

Used)

Figure 7: Internal (Factory) Wiring, Sample-Draw Detector

12 • 35-3010RKA-06 Sample-Draw Detector

Page 17

Start Up

This section describes procedures to start up the sample-draw detector and place t he

sample-draw detector into normal operation.

Introducing Incoming Power

1. Complete the installation procedures described earlier in this manual.

2. Verify that the power wiring to the controller is correct and secure. See the controller

operator’s ma nual.

3. Turn on or plug in the incoming power at the controller, then turn on the controller.

4. Verify that the controller is on and operating properly.

5. Verify that the Pilot light is on at the sample draw detector.

6. Verify tha t the flowmeter indicates a flow rate of approximately 1.2 SCFH. If

necessary, use the bypass valve or flow adjust potentiometer to adjust the flow rate.

NOTE: The following step tests for leaks in the sample lin e. T his test may cause a low

flow condition at the sample-draw detector.

7. Verify that the incoming sample line is not leaking. To test the sample line, plug the

open end of the sample line with your thumb. If the flowmeter ball drops to the

bottom of the flowmeter, the incoming sample line is not leaking.

8. Remove your thumb from the sample line, press the pump reset switch, and verify the

flowmeter returns to a normal flow rate.

Setting the Zero Reading

CAUTION: If you suspect the presence of combustible gas, hydrogen sulfide, or an abnormal

oxygen condi tion (no t 20.9% ) in the monitori ng env iro nment, u se the c alib ration k it

and the zero air calibration cylinder to introduce “fresh air” to the sam ple draw

adapter and verify an accurate zero setting.

1. Verify that the sample-draw detector is sampling a fresh air environment

(environment known to be free of combustible gas, H

content, 20.9%).

2. Open the housing door.

3. Set a voltmeter to measure in the millivolt (mV) range.

4. Check the zero reading for each channel.

For the LEL channel, plug the voltmeter leads into the test points on the LEL

transmitter. Plug the positive lead into the test point labeled TP+; plug the negative

lead into the test point labeled TP-.

For the H

main circuit board. Plug the positive lead into the test point labeled CAL+2; plug the

negative lead into the test point labeled CAL-2.

S channel, plug the voltmeter into the test points in the AMP 2 section of the

2

S and of normal oxygen

2

5. Verify a voltmeter reading of 100 mV (± 2 mV) .

6. If necessary, use a s ma ll flat-blade screwdriver to adjust the zero pot until the

voltmeter reading is 100 mV (± 2 mV).

7. Close the housing door.

35-3010RKA-06 Sample-Draw Detector • 13

Page 18

Operation

Normal Operation

During normal operation, the Pilot LED will be on and the flowmeter will indicate about

1.2 SCFH. The current gas readings will be indicated at the controller. See the controller’s

operator’s manual for a description of the reading indications.

Low Flow Alarm

If the flowrate falls below 0.6 SCFH (±0.2 SCFH), then the sample draw detector will

initiate a low flow alarm. In a low flow alarm the Fail LED will turn on and the pump will

shut off. In addition, the H

sample draw detector resulting in a failure indication for the H

If a low flow alarm occurs, press the pump reset switch fo r about 2 seconds to restart the

pump, turn off the Fail LED, and resume proper sensor signal transmission to the

controller. If the condition continues, find the cause of the reduced flow, correct it, and

restart the pump with the pump reset switch. A flow reduction can be caused by a flow

blockage, a leak in the flow system, a malfunctioning pressure switch, or a malfunctioning

pump.

S sensor signal to the controller will be interrupted by the

2

S channel at the controller.

2

NOTE: There is no flow fail indication for the LEL chan nel on the 35-3010RKA-06.

Maintenance

This section describes maintenance procedures. It includes preventive maintenance

procedures. This section also includes procedures to troubleshoot the sample-draw

detector, replace components of the sample-draw detector, and adjust the low flow

setting.

Preventive Maintenance

This section describes a preventive maintenance schedule to ensure the optimum

performance of the sample-draw detector. It includes daily, monthly, and quarterly

procedures.

Daily

1. Ve ri fy that the pilot light is on.

2. Verify that the flowmeter indicates a flow rate of approximately 1.2 SCFH.

3. V erify a r eading of 0%LEL fo r the combustible channel (100 mV at the LEL trans mitter

If necessary use the bypass valve or flow ad just potentiometer to adjust t he flow rate

to 1.2 SCFH.

test points) and 0 ppm for the H

Investigate significant changes in the reading.

S channel (100 mV at the amp 2 t est points).

2

14 • 35-3010RKA-06 Sample-Draw Detector

Page 19

Monthly

This pr oc edure describes a test to verify that the sample-draw detector responds properly

to the target gases.

Preparing for the response test

CAUTION: This procedure may cause alarms at the controller. Take appropriate action to avoid

this, such as entering the calibration mode at the controller or disabling external

alarms.

1. Verify tha t the controller is reading 0 for the combustible and H

If the reading is not 0 on the combustible or H

S channels, set the zero reading as

2

S channels.

2

described in “Start Up” on page 13, then continue this procedure.

2. Assemble the calibration kit as described in “Preparing for Calibratio n” on page 19 .

Use of a 4-gas cylinder is recommended so that all channels may be checked at once.

Performing the response test

NOTE: This procedure describes the RKI calibration kit that includes a demand flow

regulator. A calibration kit that uses a calibration bag is also available.

1. Screw the regulator into the calibration cylinder.

2. Connect the c ali brat io n tu bi ng fr om the r e gul ator to the inlet line at or near the INLET

fitting. Gas will begin to flow.

3. After approximately one minute, verify that the reading for each channel at the

controller stabilizes within ± 20% of the concentration of the test sa mple. If the

reading is not within ± 20% of the test sample, calibrate the sample-draw detecto r as

described in “Calibration” on page 19.

4. Remove the calibrati on tubing from the inlet line, then reconnect the inlet line.

5. Store the calibration kit in a safe place.

Quarterly

Calibrate the sample-draw detector as described in “Calibration” on page 19.

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended

action for problems you may encounter with the sample-draw gas detector.

NOTE: This troubleshooting guide describes sample-draw detector problems only. See

the instruction manual for the controller if it exhibits any problems.

Fail Condition

Symptoms

• The sample-draw detector’s Fail light is on.

• The controller is operating properly but indicates a reading well below zero on one or

more channels.

Probable Causes

• The sample-draw detector’s flow rate is too low because of an obstructed sample line,

35-3010RKA-06 Sample-Draw Detector • 15

Page 20

failed pump, etc.

• The sample-draw detector is malfunction ing.

• The sensor or transmitter wiring is disconnected or misco nnected.

Recommended Action

1. At the sample-draw detector, set the correct flow rate with the bypass valve or flow

adjust potentiometer.

2. If you cannot set the correct flow rate, check the sample lines for obstructions or kinks.

3. Verify that the sensor and transmitter wiring are correct and secure. “Installation” on

page 9 describes detector wiring connections.

4. Calibrate the problem channel or channels as described in “Calibration” on page 19.

5. If the fail condition continues, replace the sensor from the problem channel or

channels as described later in this section.

6. If the fail condition continues, contact RKI Instruments, Inc. for further instruction.

Slow or No Response/Difficult or Unable to Calibrate

Symptoms

• One or more of the sensors respond slowly or does not respond durin g the monthly

response test.

• Unable to accurately set the zero or response reading on one or more of the channels

during the calibration procedure.

• One or more of the sensors requires frequent calibration.

NOTE: Under “normal” circumstan ces, the sample-draw de tector requires calibration

once a quarter. Some applications may require a more frequent calibration

schedule.

Probable Causes

• The calibration cylinder is low, out-dated, or defective.

• The sample-draw detector’s flow rate is too low because of an obstructed sample line,

failed pump, etc.

• The sample-draw detector is malfunction ing.

Recommended Action

1. Verify that the calibration cylinder contains an adequate supply of a fresh test sample.

2. If necessary, set the co rrect flow rate with th e bypas s valve or flow adjust

potentiometer.

3. If you cannot set the correct flow rate, check the sample line for obstructions or kinks.

4. If the calibration/response difficulties continue, replace the sensor as described later

in this section.

5. If the calibration/response difficulties continue, contact RKI Instruments, Inc. for

further instruction.

16 • 35-3010RKA-06 Sample-Draw Detector

Page 21

Replacing Components of the Sample-Draw Detector

This section includes procedures to replace the sensors, the hydrop hobic filter, and the

charcoal filter.

Replacing the Combustible Sensor

1. Turn off incoming po wer.

2. Open the housing door of the sample-draw detector.

3. Unscrew and remove the two screws that secure the retaining plate, then lift the plate,

connector, and sensor out of the housing.

4. Unplug the connector from the sensor.

5. Verify that you are using the correct replacement sensor (NC-6245 is printed on the

sensor), then plug the sensor into the connector.

6. Place the sensor in the combustible gas sensor cavity, then position the retaining plate

on the two standoffs.

7. Secure the retaining plate to the standoffs with the two screws you removed in step 3.

8. Turn on incoming power.

9. Calibrate the replacement sensor as described in “Calibration” on page 19.

Replacing the Hydrogen Sulfide Sensor

1. Turn off incoming po wer.

2. Open the housing door of the sample-draw detector.

3. Unscrew the 5 screws that retain the preamp circuit board.

4. Lift the preamp circuit board away from the flow block.

Be careful not to pull on the cables that connect the preamp circuit to the main circuit

board.

There is a foam gasket in the bottom of each flow cavity beneath the circuit board.

Make sure the gaskets stay in place.

5. Pull the H

S sensor off the preamp circuit board. It is located in the amp 2 position

2

(right side) of the preamp circuit board.

6. Plug the new sensor into the preamp board.

7. Reinstall the preamp circuit board with the sensors onto the flow block.

8. Turn on incoming power.

9. Calibrate the replacement sensor as described in “Calibration” on page 19.

Replacing the Hydrophobic Filter

1. Turn off or unplu g power to the controller.

2. Locate the hydrophobic filter. It is just to the left of the main circuit board.

3. Grasp the hydrophobic filter and pull it out of its metal clamp.

4. Remove the rubber seals from each end of the hydrophobic filter and remove the

filter.

5. Place the new hydrophobic filter in the same orientation as the one that was removed.

6. Place the new hydrophobic filter back into the metal clamp.

35-3010RKA-06 Sample-Draw Detector • 17

Page 22

Replacing the Charcoal Filter

NOTE: The charcoal filter does not normally need to be replaced in the 35-3010RKA-06

because it does not include a CO sensor.

1. Turn off or unplu g power to the controller.

2. Locate the charcoal filter. It is located along the upper edge of the detector housing.

3. Grasp the charcoal filter and pull it out of its metal clamp.

4. Remove the rubber seals from each end of the charcoal filter and remove the filter.

5. Place the new charcoal filter in the same orientation as the one that was removed.

6. Place the new charcoal filter back into the metal clamp.

Adjusting the Low Flow Setting

The factory-set low flow setting is 0.6 SCFH (±0.2). To adjust the low flow setting:

1. Use the flow adjust potenti om e ter (VR1 ) to set the flow to 0.6 SCFH.

If the sample-draw detector goes into low flow alarm before you can adjust the flow

down to 0.6 SCFH, adjust the low flow potentiometer 1/4 turn clockwise, then

attempt to set the flow again. Repeat this step until you are able to adjust the flow to

0.6 SCFH.

2. Slowly turn the low flow potentiometer counterclockwise just until the sa mple-draw

detector goes into low flow alarm.

NOTE: The low flow potentiometer is accessible through a circular cutout in the main

circuit board. The cutout is labeled PS1.

3. Verify that the low flow alarm is 0.6 SCFH (±0.2). Repeat steps 3 and 4 if necessary.

4. Use the flow adjust potenti om e ter (VR1 ) to set the flow to 1.2 SCFH.

5. Make sure the sample-draw detector’s Fail light is off.

Calibration Frequency

Although there is no particular calibration frequency that is correct for all applications, a

calibration frequency of every 3 months is adequate for most sample-draw detector

applications. Unless experience in a particular application dictates otherwise, RKI

Instruments, Inc. recommends a calibration frequency of every 3 months for the sampledraw detector.

If an application is not very demanding, for example detection in a clean, temperature

controlled environment, and calibration adjustments a re minima l at calibration, then a

calibration frequency of every 6 months is adequate.

If the application is very demanding, for example if the environment is not well

controlled, then more frequent calibration than every 3 months may be necessary.

18 • 35-3010RKA-06 Sample-Draw Detector

Page 23

Calibration

This secti on des cribe s how t o cali brat e the sa mple-draw adapter. It includes procedures to

prepare for calibration, set the zero reading for each channel, set the response reading for

each channel, and return to normal operation.

NOTE: This procedure describes calibration using a demand flow regulator, a zero air

calibration cylinder, and a 4-gas calibration cylinder.

Prepari ng for Ca libration

CAUTION: This procedure may cause alarms at the controller. Take appropriate action to avoid

this, such as entering the calibration mode at the controller.

1. Open the housing door.

2. Set a voltmeter to measure in the millivolt (mV) range.

3. When checking the mV output of each channel, plug the voltmeter leads in to the

appropriate test points.

For the LEL channel, plug the voltmeter leads into the test points on the LEL

transmitter. Plug the positive lead into the test point labeled TP+; plug the negative

lead into the test point labeled TP-.

For the H

main circuit board. Plug the positive lead into the test point labeled CAL+2; plug the

negative lead into the test point labeled CAL-2.

4. Use the following formula to determine the correct test points output for the

calibrating sample.

For example, with a calibrating sample of 50 %LEL methane and a fullscale setting of

100%LEL, the correct output for the LEL test points is 300 mV.

S channel, plug the voltmeter into the test points in the AMP 2 section of the

2

Output (mV) = (calibrating sample/fullscale) X 400 + 100

300 (mV) = (50/100) X 400 +100

Setting the Zero Reading

NOTE: If you can verify a fresh air environment, it is not necessary to use the zero air

calibration cylinder to set the zero reading.

1. Screw the regulator into the zero air calibration cyli nd er.

2. Connect the calibration kit sample tubing to the regulator.

3. Connect the sample tubing from the regulator to the inlet line at or near the INLET

fitting.

4. Allow the gas to fl ow for one minute.

5. Verify a voltmeter reading of 100 mV ± 2 mV at the test points for each channel as

described in the Preparing for Calibration section above.

6. If necessary, use a small flat-blade screwdriver to adjust the zero pot for the

appropriate channel until the voltmeter reading is 100 mV ± 2 mV.

35-3010RKA-06 Sample-Draw Detector • 19

Page 24

7. Disconnect the sample tubing from the inlet line.

8. Unscrew the regulator from the zero air calibration cylinder. Leave the sample tubing

connected to the regulator.

Setting the Response Reading

1. Screw the regulator into the 4-gas calibration cylinder.

2. Connect the sample tubing from the regulator to the inlet line at or near the sa mpledraw detector’s INLET fitting.

3. Allow the calibra tion gas to flow for one minute.

4. Check the mV output on the LEL transmitter test points and verify that the reading

matches the response reading (±2 mV) you determined earlier.

5. If necessary, use the span pot on the LEL transmitter to adjust the reading to match the

correct response reading.

6. Repeat steps 3 and 4 for the H

the Preparing For Calibration section above and the appropriate span pot.

7. Disconnect the sample tubi ng from the sample-draw detector’s inlet line.

8. Unscrew the regulator from the calibration cylinder.

NOTE: For convenience, leave the regulator connected to the sample tubing.

S channel using the appropriate test points described in

2

Returning to Normal Operation

1. Remove the voltmeter leads from the test points.

2. Reconnect the in coming sample line.

3. Wait 1 to 2 minutes to allow the calibration gas to be drawn out and the readings to

stabilize.

4. Close the housing door.

5. Store the components of the calibration kit in a safe and convenient place.

20 • 35-3010RKA-06 Sample-Draw Detector

Page 25

Parts List

Table 2 lists replacement parts and accessories for the sample-draw gas detector.

Table 2: Parts List

Part Number Description

06-1248RK Sample tubing, 3/16 x 5/16, specify length, (for calibration kit)

07-0034RK Sealing gasket, for CO and H

S flow block cavities

2

30-0610RK Pump

33-0171RK Hydrophobic filter (AcroPak)

33-6095RK Charcoal filter, CF-188

81-0076RK-01 Zero air calibration cylinder (34 liter)

81-0154RK-04 4-gas calibration gas cylinder, 50% LEL methane/12% oxygen/50

ppm CO/25 ppm H2S, 34 liter

81-1055RK Regulator, demand flow, for 17 and 34 liter steel cylinders

ES-1537-H2S H

S sensor

2

NC-6245 Combustible sensor

35-3010RKA-06 Sample-Draw Detector • 21

Loading...

Loading...