Page 1

35-3001A-11

Hydrogen Sample-Draw Detector

Operator’s Manual

Part Number: 71-0334

Revision: P2

Released: 9/17/14

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before operating

detector . Improper use of the dete ctor could result in bodily harm

or death.

Periodic calibration and maintenance of the detector is essential

for proper operation and correct readings. Please calibrate and

maintain this detector regularly! Frequency of calibration

depends upon the type of use you have and the sensor types.

T ypical calibration frequencies for most applications a re between

9 and 12 months, but can be required more often or less often

based on your usage.

35-3001A-11 Hydrogen Sample-Draw Detector

Page 3

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment s old by us t o be free from def ects in material s,

workmanship, and performance for a period of one year from date of shipment from RKI

Instruments, Inc. Any parts found defective within that period will be repaired or replaced, at our

option, free of charge. This warrant y does not apply to those items which by their nature are subject

to deterioration or consumption in normal service, and which must b e cleaned, repaired, o r replaced

on a routine basis. Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repair

procedures not in accordance with the operator’s manual. This warranty indicates the full extent of

our liability, and we are not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC. INCLUDING BUT N OT LIMITED T O, THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and

representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor, and our warranty is limited to the replacement of parts or our complete goods.

35-3001A-11 Hydrogen Sample-Draw Detector

Page 4

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

External Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting the Hydrogen Sample-Draw Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the Inlet Fitting Tubing Stub, if Necessary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting the Sample Lines to the Sample-Draw Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the Hydrogen Sample-Draw Detector to a Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Introducing Incoming Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the Zero Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing Components of the Hydrogen Sample-Draw Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjusting the Low Flow Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Calibration Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Preparing for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Zero Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Response Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Returning to Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

35-3001A-11 Hydrogen Sample-Draw Detector

Page 5

Overview

This operator’s manual describes the 35-3001A-11 hydrogen sample-draw detector. This manual

also describes how to install, start up, maintain, and calibrate the sample-draw detector when using

it with a gas monitoring controller. A parts list at the end of this manual lists replacement parts and

accessories for the sample-draw detector.

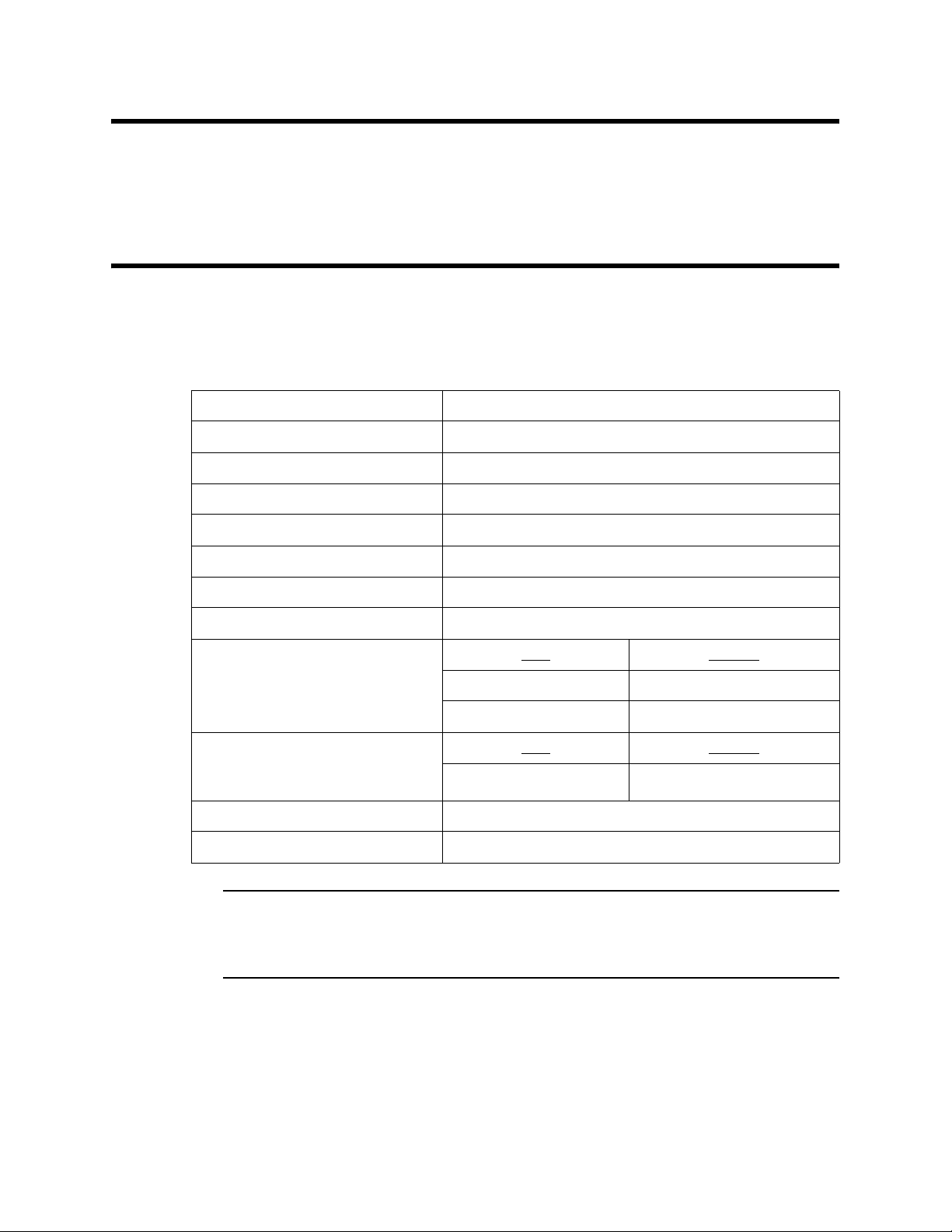

Specifications

Table 1 lists specifications for the hydrogen sample-draw detector. See the controller Operator’s

Manual for information specific to the controller.

Target Gas and Detection Range Hydrogen: 0 - 10% volume

Input Power 24 VDC Nominal (18.5 VDC - 30 VDC)

Construction (housing) Fiberglass/polyester (NEMA 4X)

Dimensions 8.5 in. H x 6.5 in. W x 4.25 in. D

Table 1: Specifications

W eight 4.5 lbs.

Sampling Method Sample-draw

Sample Flow 3.0 SCFH typical, with no inlet or exhaust line

Flow to Sensor 1.0 SCFH (nominal)

Maximum Recommended Inlet/

Exhaust Line Length for

1/4” O.D. x 1/8” I.D. Tubing

Maximum Recommended Inlet/

Exhaust Line Length for

1/4” O.D. x 0.170” I.D. Tubing

Response Time 90% in 30 seconds

Accuracy ± 5% of reading or ± 2% of full scale (whichever is greater)

WARNING: When using the 35-3001A-11, you must follow the instructions and warnings in

this manual to assure proper and safe operation of the 35-3001A-11 and to

minimize the risk of personal injury. Be sure to maintain and periodically

calibrate t h e 35-3001A- 11 as descri bed in this manual.

Inlet

100 feet 0 feet

50 feet 50 feet

Inlet

100 feet 100 feet

Exhaust

Exhaust

35-3001A-11 Hydrogen Sample- Draw Detector • 1

Page 6

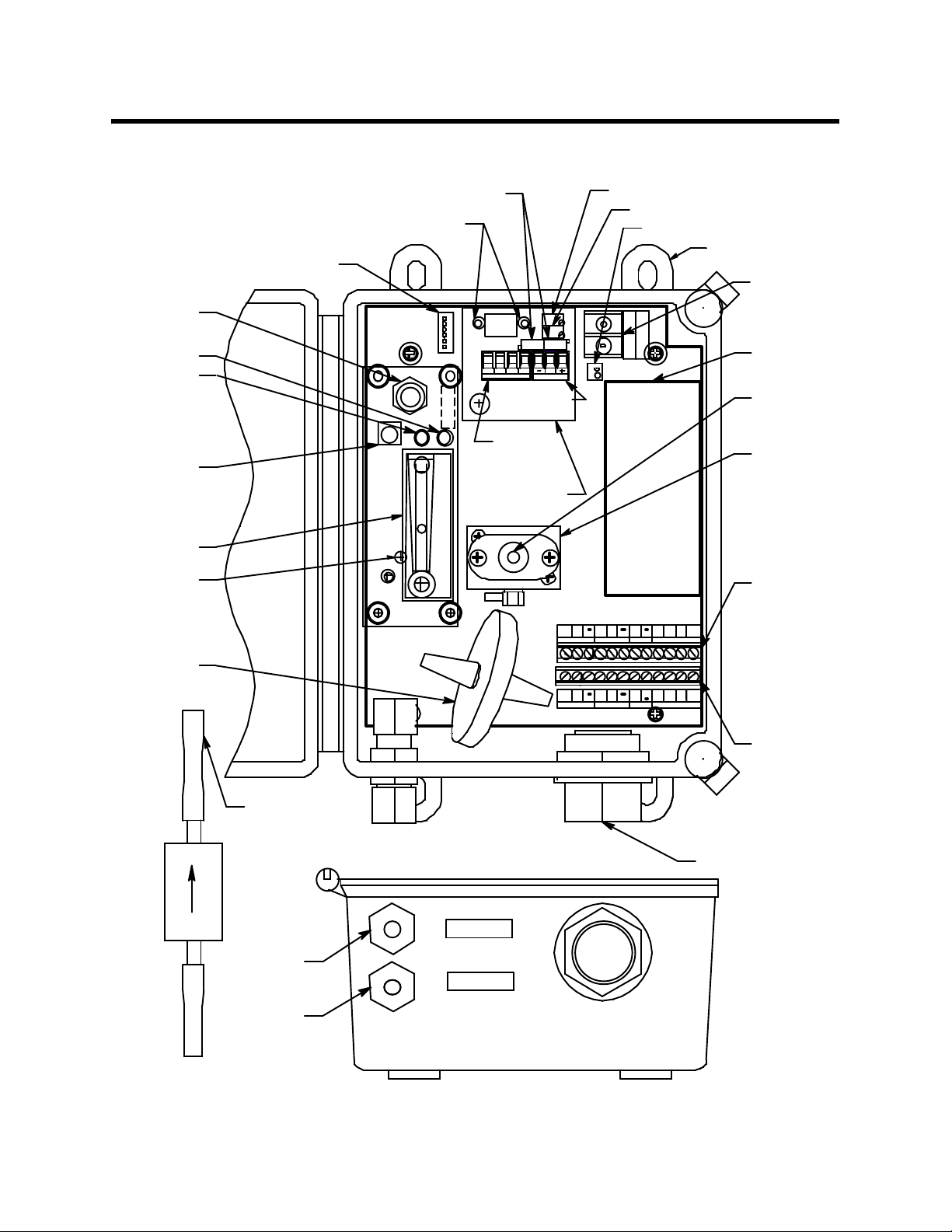

Description

p

p

Sensor Flow

Con trol Valve

Fail LE D

Pilot LED

This section describes th e components of the hydrogen sample-draw detector.

Zero Pot

Span Pot

Pump C onnector

O

W

X

+

Y

G

B

E

_

N

Flowmeter Circuit

Board Connector

Factory Set Pots

Test P oints

100-500mV Range

Sensor

Cur r ent

148mA

GBR

W

S

LEL

PWR / SIG

Con tro l l er

Termin al S trip

Mounting

Foot, 4X

Oxygen

Sensor

Termina l

Strip

Pum p

Hydrogen

Sensor

Pum p Reset

Switch

Flo wmeter

Pressure

Switch

Adjustment

Screw

(behind P CB)

Hydrophobi c

Filter

This End

To Inlet

Fitting

Particle

Filte r

Detector

Termina l

Strip

Hydrogen

Amp lifier

+

S

+

AMP2AMP

+

S S R

+

AMP1

AMP 2

+

W B

OXY

LEL/IR

W

WG

+

OXYGLEL/IR

GS R

B

3/4" Conduit Hub

Hydrogen

Flo w

Block

Detector/Am

Terminal Stri

(Factory

W ired)

Int erconnect

Termina l

Strip

INLET

Inlet

Fitting

EXHAUST

Exhaust

Fitting

Figure 1: Hy drogen Sampl e-Draw Detector Component Location

2 • 35-3001A-11 Hydrogen S ample-Draw Detector

Page 7

External Components

This section describes the sample-draw detector’s external components.

Housing

The sample-draw detector’s fiberglass housing is weather- and corrosion-resistant. It is suitable fo r

installation where general purpose equipment is in use.

The housing door is hinged on the left side and is secured by two latches on the right side. The

flowmeter and status LEDs are visible through a window in the housing door.

Four mounting feet are attached to the back of the housing (one at each corner). Use the mounting

feet to install the housing to a vertical surface.

Sample Fittings

The sample fittings are located on the left side of the bottom of the housing. The inlet fitting is near

the front of the housing and the exhaust fitting is near the back of the housing. The inlet fitting has

a short factory installed tubing stub for use with the particle filter. The sample fittings accept 1/4 in.

rigid tubing. See the Installation section on page 7 to connect tubing to the sample fittings.

Inlet Fitting Tubing Stub

A short tubing stub comes factory installed in the inlet fittin g. It is used for connecting the particle

filter. If the particle filter is not used, or if you install the particle filter in a different location, the

tubing stub needs to be removed and replaced with tubing.

Conduit Hub

One 3/4” conduit hub is located on the right sid e of the bottom of the hous ing. It is used fo r routing

wiring into the housing by using conduit or an appropriate cable bushing.

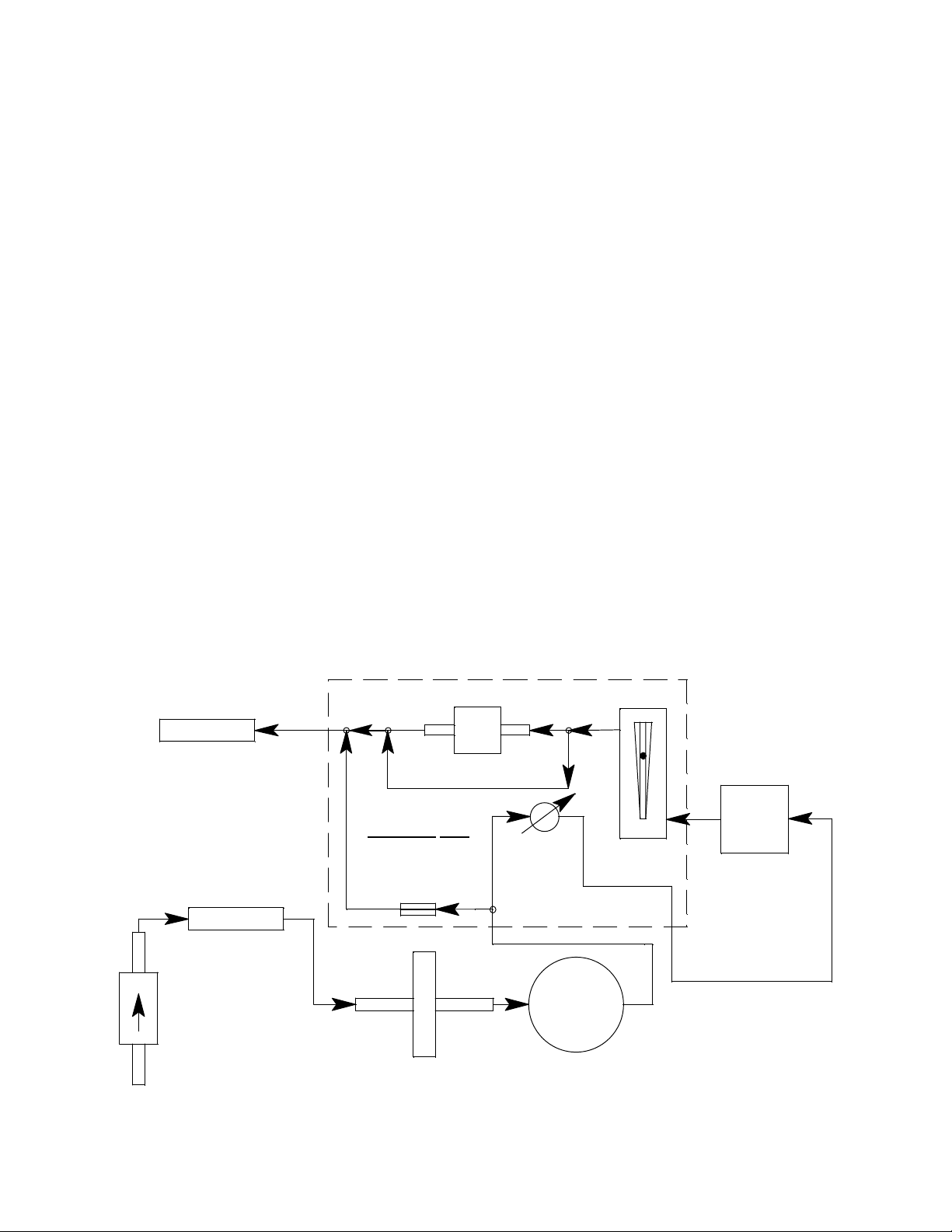

Internal Components

This section describes the sample-draw detector’s internal components (see Figure 1). Figure 2

illustrates how the gas sample moves through the flow system.

Exhaust

Inlet

Pressure Switch

Flowmeter PCB

Restrictor

Sensor

Flow

Control

Valve

Flowmeter

Hydrogen

Sensor

ParticleFilter

Pump

HydrophobicFilter

Figure 2: Hydrogen Sample-Draw Detector Flow Diagram

35-3001A-11 Hydrogen Sample- Draw Detector • 3

Page 8

Main Circuit Board

The main circuit board includes the detect or/amp terminal strip, intercon nect terminal st rip, oxygen

sensor terminal strip, pump connector, and flowmet er circuit board connector (see Figure 1).

Detector/Amp Terminal Strip

The detector/amp terminal strip is the upper twelve-point terminal strip in the bot tom right corner

of the main circuit board. Use the detector/amp terminal strip to connect the amplifier to the main

circuit board.

NOTE: The amplifier is factory-wired to the main circuit board. See the “Installation” section on

page 7 for all wiring procedures related to the sample-draw detector.

Interconnect Terminal Strip

The interconnect terminal strip is the lower twelve-point terminal strip in the bottom right corner of

the main circuit board. Use the interconnect termin al stri p to con n ect the sam ple-draw detector to a

controller.

Oxygen Sensor Terminal Strip

The oxygen sensor terminal strip is a two-point terminal strip in the upper right corner of the main

circuit board. This terminal strip is not used in this version of the sample-draw detector.

Pump Connector

The pump connector is the two-point connector below the oxygen terminal strip in the upper right

corner of the main circuit board. Use the pump co nnector to connect the pump to the main circuit

board.

NOTE: The pump is factory-wired to the main circuit board. See “Installation” on page 7 for all

wiring procedures related to the sample-draw detector.

Flowmeter Circuit Board Co nnector

The flowmeter circuit board connector is a six-position connector in the upper left corner of the

main circuit board. Use the flowmeter circuit board connector to connect the flowmeter circuit

board to the main circuit board.

NOTE: The flowmeter circuit board is factory wired to the main circuit board. See “Installation”

on page 7 for all wiring procedures related to the sample-d raw detector.

Flowmeter Circuit Board

The flowmeter circuit board is mounted to the left side of the main circuit board using standoffs. It

includes the flowmeter, sensor flow control valve, status LEDs, pressure switch, and pump reset

switch.

Flowmeter

The flowmeter is mounted to the right side of the flowmeter circuit board. You can see it through

the window in the door. A ball in the flowmeter column indicates the flow rate to the sensor. The

flowmeter measures the flow in the range 0.2 to 2.0 SCFH (Standard Cubic Feet per Hour). The

optimum flow rate is 1.0 SCFH.

Sensor Flow Control Valve

The sensor flow control valve is mounted to the flowmeter circuit board above the flowmeter. The

sensor flow control valve adjusts the flow rate to the detector. Turn the valve’s knob

4 • 35-3001A-11 Hydrogen S ample-Draw Detector

Page 9

counterclockwise to increase the flow and clockwise to decrease the flow.

Status LEDs

T wo status LEDs are abov e the flowmeter. They are also visible through the wi ndow in t he hou sin g

door. The green Pilot LED is on when the sample-draw detector is receiving power from the

controller. The red Fail LED is on when the sample flow rate is below the low flow level.

Pressure Switch

The pressure switch is mounted to the back of the flowmeter circuit board. The pressure switch

monitors the flow rate of the incoming gas sample.

If the flow rate falls below the preset low flow level, the pressure switch causes the Fail LED to

turn on and interrupts the signal from the detector. The interrupted detector signal causes a fail

condition at the controller. The low flow level is factory-set at 0.6 SCFH (±0.1 SCFH). See

“Adjusting the Low Flow Setting” on page 17 to adjust this setting.

Pump Reset Switch

The pump reset switch is located to the left of the status LEDs. When a low flow condition occurs,

the pump will be shut off. To reset the low flow condition and start the pump again, press and hold

the pump reset switch for about 2 seconds, then release.

Hydrophobic Filter

The hydrophobic filter is located toward the bottom left of the main circuit board. The filter

prevents particulates and water in the incoming gas sample from damaging the flow and detection

systems. Replace the filter when it appears dirty, discolored, or clogged.

Pump

The pump is mounted to the right side of the main circuit board. The pump pulls the gas sample

into the sample-draw detector. The pump operates on 24 VAC, which is generated from the 24

VDC supplied by the controller.

Hydrogen Sensor

The hydrogen sensor detects hydrogen in the %vol range. Two sensing elements are protected

within the detector. Through a series of thermal and electronic reactions, these elements

produce an electrical output that is proportional to the detection range of the sampledraw detector.

The hydrogen sensor is installed in the flow block and the flow block i s mounted to the middle of

the main circuit board. The sensor housing i nclud es a sintere d metal flame arrestor on one end that

allows gas to diffuse into the sensor. On the other end, five pins extend from the sensor and plug

into the socket connector . The connector allows you to replace the sensor without disconnecting the

wiring. Four leads extending from the connector are factory wired to the amplifier.

Amplifier

The amplifier converts the electrical output from the detector to a 4 to 20 mA signal that

corresponds to the detection range and transmits the signal to a gas monitoring controller. A label

on the amplifier indicates the detector drive current. This d rive cu rrent is factory s et and is dictated

by the combustible gas to which the detector is calibrated. Consult RKI Instruments, I nc. if you

plan to change the calibration gas for the sample-draw detector, for example from a hydrogen

calibration to a methane calibration. The amplifier is mounted on the top middle edge of the main

circuit board. It consists of the zero pot, span pot, controller terminal strip, detector terminal strip,

and test points.

35-3001A-11 Hydrogen Sample- Draw Detector • 5

Page 10

Zero Pot

The zero pot is located in the upper right corner of the amplifier (see Figure 1). Use a small flat

blade screwdriver to turn the zero pot’s adjustment screw and adjust the amplifier’s zero (f res h air)

output during the star t-up and cali bration procedures. Turn the adjustment screw clockwise to

increase the fresh air output and counterclockwis e to decrease the fresh air output.

Span Pot

The span pot is located below the zero pot (see Figure 1). Use a small flat blade screwdriver to turn

the span pot’s adjustment screw and adjust the amplifier’s gas response output during the

calibration procedure. Turn the adjustment screw clockwise to increase the span output and

counterclockwise to decrease the span output.

CAUTION: The amplifier includes additional pots. They are factory-set. Do not adjust them.

Controller and Detector Terminal Strips

The controller terminal strip and detector terminal strip are three- and four-position plug-in style

terminal strips, respectively. The controller terminal strip is located on the right side of the

amplifier and the detector terminal strip is to the left of it. Both terminal strips are factory wired to

the sensor and main circuit board.

T est Points

The test points are on the left side of the amplifier (see Figure 1). The test points produce a 100 mV

to 500 mV output that corresponds to the sample-draw detector’s 4 to 20 mA output. Use the test

points and a voltmeter to measure the amplifier’s output during the start-up and calibration

procedures. The black test point in the upper left corner is the negative (-) test point and the red test

point to the left of the zero and span pots is the positive (+) test point.

6 • 35-3001A-11 Hydrogen S ample-Draw Detector

Page 11

Installation

This section describes procedures to mount the sample-draw detector in the monitoring

environment and wire the sample-draw detector to a controller.

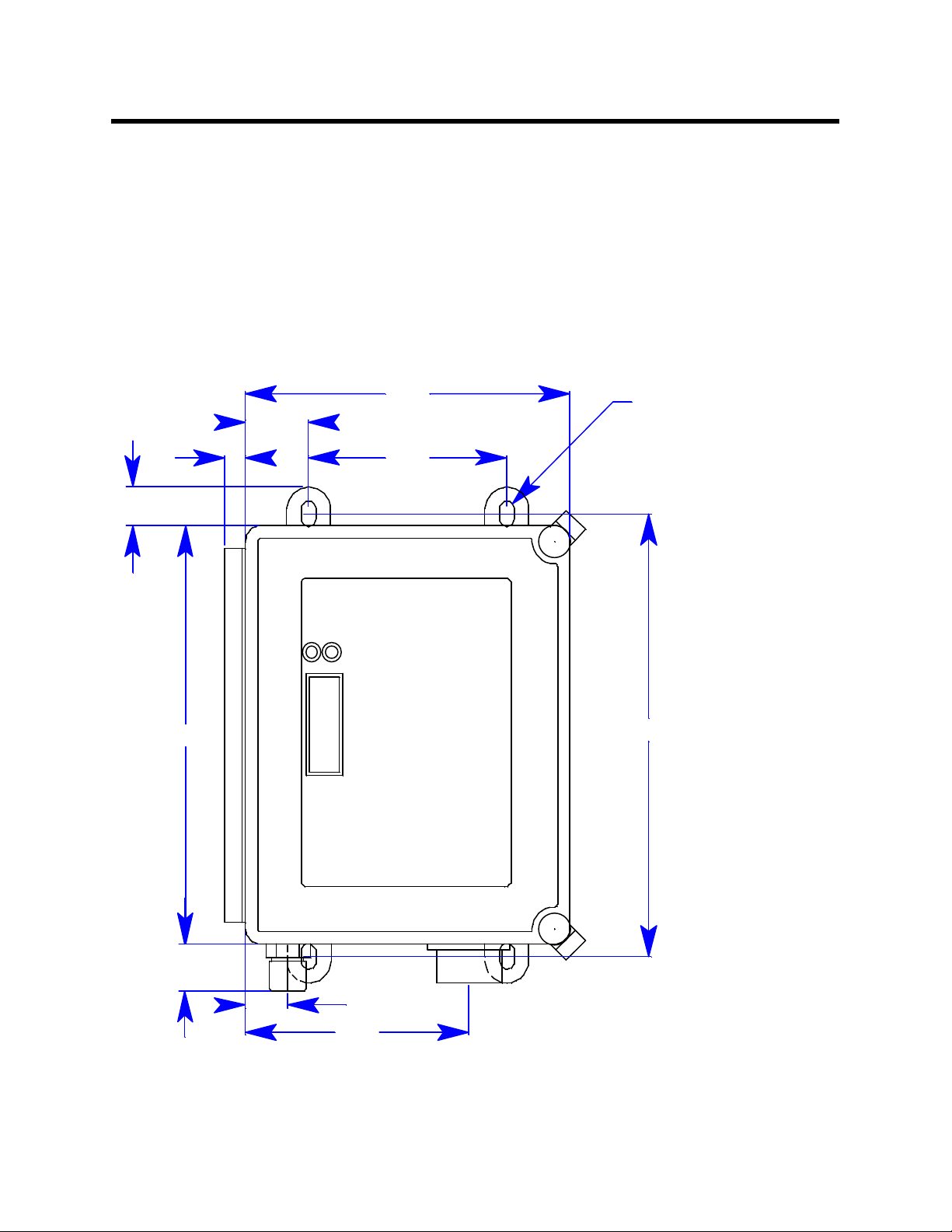

Mounting the Sample-Draw Hydrogen Detector

1. Select the mounting site. Consider the following when you select the mounting site:

• Is there enough room to open the housing door and make wi ring and tubi ng connect io ns at

the bottom of the housing?

• Make sure there is sufficient room to perform start-up, maintenance, and calibration

procedures.

• Are the flowmeter and status LEDs visible?

6.50

1.13

Ø.30x.50(4X)MOUNTING

.78

.40

8.50

Pil o t Fail

Sa mple Drawing

Gas Dete ctor

ww w.rkiinstruments.com

4.00

35-3001

8.88

.80

.85

4.50

NOTE: Housing is4.3 inchesdeep

Figure 3: Outline and Mounting Dimensions

35-3001A-11 Hydrogen Sample- Draw Detector • 7

Page 12

2. Close and latch the housing door.

NOTE: The sample-draw detector is shipped with the mounting feet “tucked under” the housing

to protect the mounting feet during shipment.

3. Slightly loosen the screw that secures the mounting foot to the housing, then rotate the

mounting foot 180 degrees (see Figure 3).

4. Tighten the screw that secures the mounting foot to the housing.

5. Repeat steps 3 and 4 for the remaining three mounting feet.

6. Position the sample-draw housing on a verti cal surface at eye level (4 1/2 to 5 feet from the

floor).

7. Insert 1/4 inch screws through the slots in the mounting feet to secure the housing to the

mounting surface.

Removing the Inlet Fitting Tubing Stub, if Necessary

A short tubing stub comes factory installed in the inlet fittin g. It is used for connecting the particle

filter. If the particle filter is not used, or if you install the particle filter in a different location, the

tubing stub needs to be removed and replaced with tubing.

O-ring

Tube Nut

1/4 " Tube

Inside of Case

Outsideof Case

Fitting Body

Back Ferrule

Front Ferrule

1/4 " Tube

Figure 4: Inlet Fitting with Tubing Stub

CAUTION: Do not pull the tubing stub downward to remove it.

1. Unscrew the outside inlet fitting tube nut from the fitting body. The tubing stub should come

out with the tube nut. Be careful not to lose the O-ring that may come out with the tubing stub.

2. Push the tubing stub up and out of the front ferrule being careful not to lose the ferrule set.

3. Push the new tubing up through the inlet fitting tube nut and replace the ferrule set and the O-

8 • 35-3001A-11 Hydrogen S ample-Draw Detector

Page 13

ring, if it came out, in the orientation shown in Figure 4.

4. Screw the inlet fitting tube nut back onto the fitting body. See the next section for instructions

to install a new piece of tubing into the fitting.

Connecting the Sample Lines to the Sample-Draw Detector

See Figure 4 for the fitting layout.

Installing the Inlet Line with Particle Filter

1. Connect the particle filter to the tubing stub on the inlet by pushing the flexible tubing on the

filter onto the stub. Be sure the arrow on the particle filter is pointing toward the inlet fitting.

2. Connect a length of sample tubing to the other side of the particle filter and route it to the

sampling area. 1/4” O.D. rigid polypropylene, Teflon, or flexible polyurethane tubing may be

used. RKI Instruments , Inc. recomm ends using either 1/4” O.D. x 1/8” I.D. or 1/4” O.D. x

0.170” I.D. tubing based on your length requirements. See “Specifications” on page 1 for

maximum tubing lengths based on tubing size.

CAUTION: If you use flexible sample tubing (polyurethane is acceptable), use an appropriate

insert if necessary to provide support to the tubing and ensure a good s eal when

connecting to the flexible stub on the filter.

CAUTION: Avoid lo ops or slumps in the incoming sample lin e. To reduce r esponse time, keep the

incoming sample line as short as possib le.

Installing the Inlet Line without Particle Filter

1. Remove the tubing stub as described in “Removing the Inlet Fitting Tubing Stub, if Necessary”

on page 8.

2. Loosen the nut on the inlet fitting until 3 threads are visible.

3. Push 1/4” O.D. rigid polypropylene or rigid Teflon sample tubing into the fitting until it stops.

Flexible polyurethane tubing may be used with an appropriate insert. RKI Instruments, Inc.

recommends using either 1/4” O.D. x 1/8” I.D . or 1/4” O.D. x 0. 170” I.D. t ubing based o n your

length requirements. See “Specifications” on page 1 for maximum tubing lengths based on

tubing size.

CAUTION: If you use flexible sample tubing (polyurethane is acceptable), use an appropriate

insert to seal the connection between the tubing and the inlet fitting.

4. Hand tighten the nut on the inlet fitting so the ferrules clamp on the tubing. If the tube nut is

removed, see Figure 4 for the arrangement of the fitting components.

5. Route tubing from the inlet fitting to the sample area. S ee “Specifications” on page 1 for

maximum tubing lengths based on tubing size.

CAUTION: Avoid lo ops or slumps in the incoming sample lin e. To reduce r esponse time, keep the

incoming sample line as short as possib le.

35-3001A-11 Hydrogen Sample- Draw Detector • 9

Page 14

Installing the Exhaust Line

1. Loosen the nut on the exhaust fitting until 3 threads are visible.

2. Push 1/4” O.D. rigid polypropylene or rigid Teflon sample tubing into the fitting until it stops.

Flexible polyurethane tubing may be used with an appropriate insert. RKI Instruments, Inc.

recommends using either 1/4” O.D. x 1/8” I.D . or 1/4” O.D. x 0. 170” I.D. t ubing based o n your

length requirements. See “Specifications” on page 1 for maximum tubing lengths based on

tubing size.

CAUTION: If you use flexible sample tubing (polyurethane is acceptable), use an appropriate

insert to seal the connection between the tubing and the inlet fitting.

3. Hand tighten the nut on the exhaust fitting so the ferrules clamp on the tubing. If the tube nut is

removed, see Figure 4 for the arrangement of the fitting components.

4. Route the opposite end of the tu bing t o an op en area where the sample can safely disp erse or to

an exhaust duct. See “Specifications ” on page 1 for maximum tubing lengths based on tubing

size.

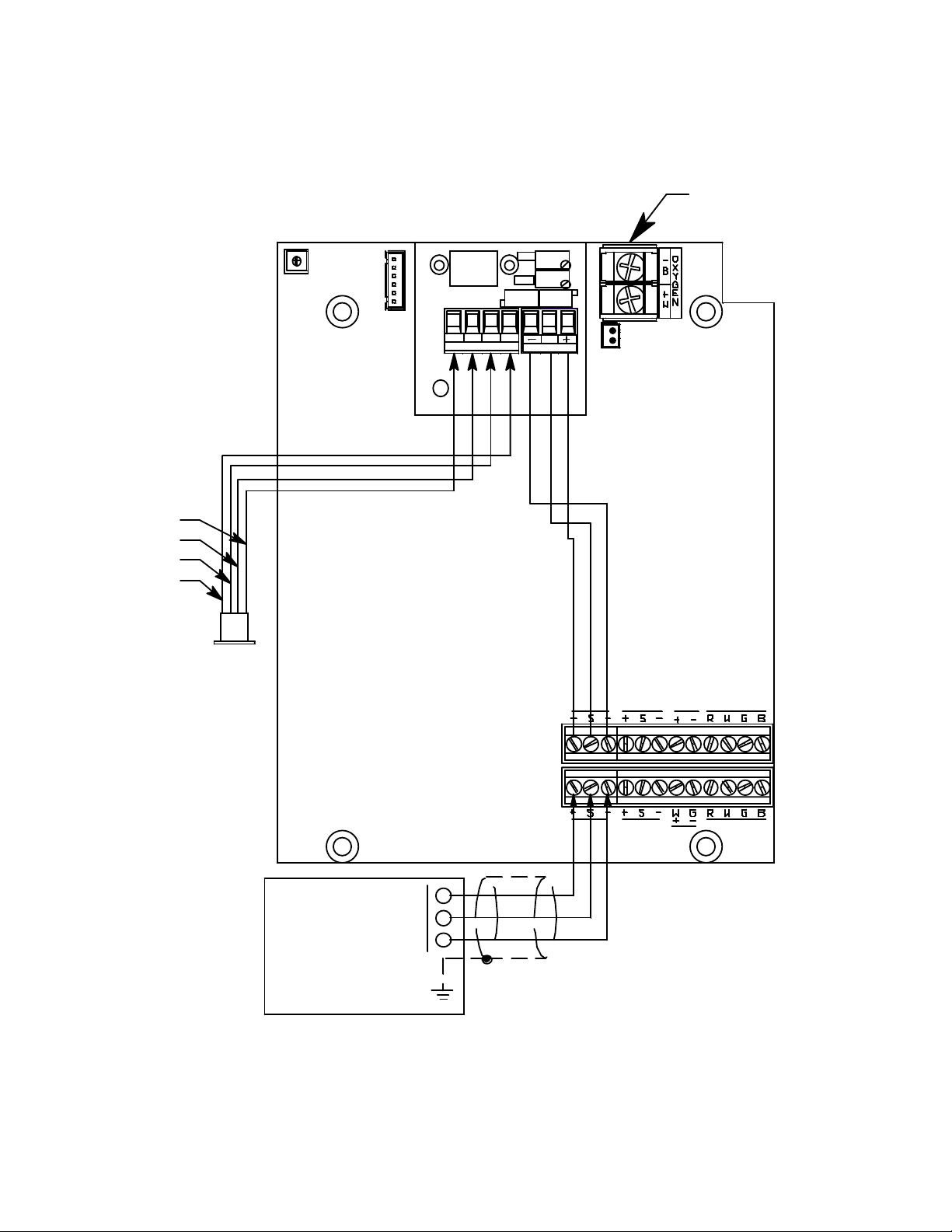

Wiring the Sample-Draw Hydrogen Detector to a Controller

WARNING: Always verify that the controller is off and that power to the controller is off

before you make wiring connections.

1. Turn off the controller.

2. Turn off power to the controller.

3. Unlatch and open the housing door of the sample-draw detector.

4. Guide a three-conductor , shielded cabl e or thr ee wires in co nduit thro ugh the cond uit hub at the

bottom of the sample-d raw housing. A minimum of 18 AWG wire is recommen ded.

5. Connect the cable to the sample-draw detector’s interconnect terminal strip as shown in Figure

5.

6. Close and latch the housing door of the sample-draw detector.

CAUTION: If using shielded cable, leave the cable shield’s drain wire insulated and

disconnected at the sample-draw detector. You will connect the opposite end of the

drain wire at the controller.

7. Route the cable or wires in conduit leading from the sample-draw detector through one of the

conduit hubs at the controller.

10 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Page 15

8. Connect the wires to the applicable detector/transmitter terminal strip at th e contr oller as

shown in Figure 5. Refer to the controller operator’s manual and the controller detector head

specification sheet for the 35-3001A-11 for detector/terminal strip connections specific to the

controller.

Not Used on

This Version

Red

White

Green

Black

To

Hydrogen

Sensor

Sensor

Current

148mA

W

LEL

ZE RO

SP AN

GBR

S

PWR / SIG

AMP 1

AMP 2

OXY LEL/IR

PATS201PATS201

Controller or

Recording

Dev ice

9. If shielded cable is used, connect the cable’s drain wire to an available chassis (earth) ground at

PATS101PATS101

AMP 2

OXY

LEL/IRAMP 1

+24VDC

4/20 Signal

- (DCG round)

Figure 5: Wiring the Sample-Draw Detector to a Controller

the controller. RKI controllers typically have a ground stud that can be used to ground the

cable’s drain wire.

35-3001A-11 Hydrogen Sample-Draw Detector • 11

Page 16

Start Up

This section describes procedures to start up the sample-draw detector and place the sample-draw

detector into normal operation.

Introducing Incoming Power

1. Complete the installation procedures described earlier in this m anual.

2. Verify that the wiring is correct and secure. Refer to the controller operator’s manual for

connections at the controller.

3. Turn on or plug in the power to the controller, then turn on the controll er.

4. Verify that the sample-draw detector’s Pilot LED is on.

5. Verify that the controller is on and operating properly. Refer to the controller operator’s

manual.

6. Verify that the flowmeter indicates a flow rate of approximately 1.0 SCFH. If neces sary, use

the sensor flow control valve to adjust the flow rate. Turn the valve’s knob counterclockwise to

increase the flow and clockwise to decrease the flow.

NOTE: The following step tests for leaks in the sample line. This test will cause a low flow

condition at the sample-draw detector and a fail condition at the controller. Be sure to put

the controller into its calibration program or disable external alarms before performing

this test.

7. Verify that the incoming sample line is not leaking. To test the sample line, press and hold the

reset switch and plug the open end of the sample line with your thumb. If the flowmeter ball

drops to the bottom of the flowmeter, the incoming sample line is not leaking.

8. Remove your thumb from the sample line, release the reset switch, and verify the flowmeter

returns to a normal flow rate.

9. Enable alarms or place the controller in normal operation.

CAUTION: Allow the sample-draw detector to warm up for 5 minutes before you continue with

the next section, “Setting the Zero Reading.”

Setting the Zero Reading

CAUTION: If you suspect the presence of hydrogen in the monitoring environment, use the

calibration kit and the zero air calibration cylinder to introduce “fresh air” to the

sensor and verify an accurate zero setting. See “Calibration” on page 18 for

instructions on using a zero air calibration cylinder for setting the zero reading.

1. Verify that the sample-draw detector is sampling a fresh air enviro nmen t (envi ron ment known

to be free of hydrogen).

2. Open the housing door.

3. Set a voltmeter to measure in the millivolt (mV) range.

4. Plug the voltmeter leads into the test points on the amplifier. Plug the positive lead into the red

(+) test point; plug the negative lead into the black (-) test point.

5. Verify a voltmeter reading of 100 mV (± 2 mV).

12 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Page 17

6. If necessary, use a small flat-blade screwdriver to adjust the zero potentiometer until the

7. Remove the voltmeter leads from the test points.

8. Close the housing door.

Maintenance

This section describes maintenance procedures. It includes preventive maintenance procedures.

This section also includes procedures to troubleshoot the sample-draw detector, replace

components of the sample-draw detector, and adjust the low flow setting.

Preventive Maintenance

This section describes a preventive maintenance schedule to ensure the optimum performance of

the sample-draw detector. It includes daily, monthly, and annual procedures.

Daily Visual Checks

1. Verify that the Pilot LED is on.

2. Verify that the flowmeter indicates a flow rate of approximately 1.0 SCFH. If necessary use the

voltmeter reading is 100 mV (± 2 mV).

sensor flow control valve to adjust the flow rate to 1.0 SCFH. Turn the valve’s knob

counterclockwise to increase the flow and clockwise to decrease the flow.

3. Verify a display reading of 0% vol at the controller or a reading of 100 mV at the amplifier test

points. Investigate significant changes in the display reading.

Monthly Response Test

This procedure describes a test to verify that the sample-draw detector responds properly to the

target gas.

NOTE: To reduce the response time of this test, use a short incoming sample line. If the sample-

draw detector’s sample line is long, connect a shorter line for this test. Make sure you

reconnect the sample line after you complete this procedure.

NOTE: Performing a response test on the sample-draw detector may cause alarms. Be sure to put

the controller into its calibration program or disable external alarms before performing

this test.

Preparing for the response test

NOTE: This procedure describes the RKI calibration kit that includes a demand flow re gulator.

1. Verify that the display reading at the controller is 0% vol.

If the display reading is not 0% vol, set the zero reading as described in “Calibration” on

page 18, then continue this procedure.

2. Set a voltmeter to measure in the millivolt (mV) range.

3. Open the housing door, then plug the voltmeter leads into the test points on the amplifier.

Plug the positive lead into the red (+) test point; plug the negative lead into the black (-) test

point.

35-3001A-11 Hydrogen Sample-Draw Detector • 13

Page 18

4. Use the following formula to determine the correct test points output for the test sample.

Output (mV) = (calibrating sample/fullscale) X 400 + 100

For example, with a test sample of 4% vol and a fullscale setting of 10% vol, the correct output

is 260 mV.

260 (mV) = (4/10) X 400 +100

Performing the response test

1. Screw the demand flow regulator into the calibration cylinder.

2. Connect the calibration tubing from the demand flow regulator to the inlet fi tting. Gas will

begin to flow.

3. After approximately one minute, verify that the reading at the controller stabilizes within

± 20% of the concentration of the test sample. If the reading is not within ± 20% of the test

sample, calibrate the sample-draw detector as described in “Calibration” on page 18.

4. Remove the calibration tubing from the inlet fitting, then reconnect the sample tubing to th e

inlet fitting.

5. Remove the voltmeter leads from the amplifier test points.

6. Close the housing door.

7. Store the calibration kit in a safe place.

Annual Calibration

Calibrate the sample-draw detector as described in “Calibration” on page 18.

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended action for

problems you may encounter with the sample-draw detector.

NOTE: This troubleshooting guide describes sample-draw detector problems only. See the

controller Operator’s Manual if the control ler exhibits any problems.

Fail Condition

Symptoms

• The sample-draw detector’s Fail LED is on.

• The monitoring device is operating properly but indicates a reading well below zero or a

failure alarm.

Probable causes

• The sample-draw detector’s flow rate is too low because of an obstructed sample line, failed

pump, etc.

• The sample-draw detector is malfunctioning.

• The sensor and/or amplifier wiring is disconnected or misconnected.

Recommended action

1. At the sample-draw detector, set the correct flow rate with the sensor flow control val ve.

2. If you cannot set the correct flow rate, check the sample lines for obstructions or kinks.

3. Verify that the sensor wiring and amplifier wiring is correct and secure. “Wiring the SampleDraw Hydrogen Detector to a Cont roller” on page 10 describes sensor and amplifier wiring

connections.

14 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Page 19

4. Calibrate the sample-draw detector as described in “Calibration” on page 18.

5. If the fail condition continues, replace the sensor as described in “Replacing the Hydrogen

Sensor” on page 15.

6. If the fail condition continues, contact RKI Instrument s, Inc. for further instruction.

Slow or No Response/Difficult or Unable to Calibrate

Symptoms

• The sensor responds slowly or does not respond during the monthly response test.

• Unable to accurately set the zero or response reading during the calibration procedure.

• The sensor requires fre quent calibration.

Probable causes

• The calibration cylinder is low, out-dated, or defective.

• If a demand flow regulator cal ibra tion kit i s used, t he deman d flow r egulator is not functi oning

properly.

• The sample-draw detector’s flow rate is too low because of an obstructed sample line, failed

pump, etc.

• The sample-draw detector is malfunctioning.

Recommended action

1. Verify that the calibration cylinder contains an adequate supply of a fresh test sample.

2. If a demand flow regulator calibration kit is used, use a different demand flow regulator to

determine if the original one is functioning properly.

3. If necessary, set the correct flow rate with the sensor flow control valve.

4. If you cannot set the correct flow rate, check the sample line for obstructions or kinks.

5. If the calibration/response difficulties continue, replace the sensor as described later in this

section.

6. If the calibration/response difficulties continue, contact RKI Instruments, Inc. for further

instruction.

Replacing Components of the Hydrogen

Sample-Draw Detector

This section includes procedures to replace the sensor, hydrophobic filter, and particle filter.

Replacing the Hydrogen Sensor

1. Turn off the controller.

2. Turn off power to the controller.

3. Open the housing door of the sample-draw detector.

4. Unscrew and remove the two screws that secure t he sensor retaining plate, then lift the plate,

connector, and sensor out of the housing.

5. Unplug the connector from the sensor.

6. Verify that you are using the correct replacement sensor (TE-7560 is printed on the sensor),

then plug the sensor into the connector.

7. Place the sensor in the hydrogen sensor cavity, then position the retaining plate on the two

standoffs.

8. Secure the retaining plate to the standoffs with the two screws you removed in step 4.

35-3001A-11 Hydrogen Sample-Draw Detector • 15

Page 20

9. Turn on power to the controller and place it into normal operation.

10. Turn on the contr ol ler.

CAUTION: Allow the replacement sensor to warm up for 5 minutes before you continue.

11. Calibrate the replacement sensor as described in “Calibration” on page 18.

Replacing the Amplifier

1. Turn off the controller.

2. Turn off power to the controller.

3. Open the housing door of the sample-draw detector.

4. Remove the detector and controller plug-in terminal strips by grasping t he sides of the strips

with your fingers. Let the terminal strips hang by their connected wires while you replace the

amplifier.

5. Unscrew the screw in the lower left corner of the amplifier and remove the screw , lock washer ,

and flat washer. Be careful not to lose any of these parts.

6. Remove th e old amplifier from the main circu it board.

7. Install the new amplifier in the same orientation as the old amplifier. See Figure 1.

8. Reinstall the screw, lock washer, and flat washer you removed in step 5.

9. Install the detector and controller plug-in terminals strips into their sockets on the new

amplifier. If controller leads or detector cable leads were removed from the plug-in terminal

strips during this procedure, refer to Table 2 and Table 3 below.

Table 2:Reconnecting the Amplifier

to the Detector/Amp Terminal Strip

Amplifier Controller

Terminal Strip

PWR/SIG “-” PWR/SIG “S” S

PWR/SIG “+” +

Table 3:Reconnecting the Hydrogen

Detector to the Amplifier

Amplifier Detector

T erminal Strip

DETECTOR “R” RED

DETECTOR “W” WHT

Detector/Amp Terminal

Strip on Main PCB

Detector Lead

DETECTOR “G” GREEN

DETECTOR “B” BLK

16 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Page 21

NOTE: When the sample-draw detector is first powered up with a new amplifier, the initial

output may be either hi g h o r b elo w zero depending on the setting of the zero pot. Be s ur e

to make arrangements so that this does not cause unwanted alarms.

10. Turn on power to the controll er.

11. Tur n on the controller and place it into normal operation.

12. Allow the sample-draw detector to warmup for 5 minutes.

13. Calibrate the sample-draw detector as described in “Calibration” on page 18 of this manual.

Replacing the Hydrophobic Filter

1. Open the housing door of the sample-draw detector.

2. Disconnect the filter from the rubber elbows on each end of the filter, then remove the filter

from the sample-draw detector.

3. Install the new filter. Be sure the side of the filter marked “INLET” is connected to the elbow

that is connected to the inlet fitting.

4. Verify that the flow rate is approximately 1.0 SCFH, then close the housing door.

Replacing the Particle Filter

1. Disconnect the tubing routed to the sampling area, if installed, from the particle filter.

2. Disconnect the particle filter from the inlet fitting’s tubing stub.

3. Install the new particle filter onto the inlet fitting’s tubing stub. Be sure the arrow on the

particle filter is pointing toward the inlet fitting.

4. Reinstall the tubing routed to the sampling area.

Adjusting the Low Flow Setting

NOTE: Adjusting the low flow setting will cause a low flow alarm at the sample-draw detector

and a fail alarm at the controller. Be sure to put the controller into its calibration program

or disable external alarms before performing this test.

The factory-set low flow setting is 0.6 SCFH (±0.1). To adjust the low flow setting:

1. Use the sensor flow control valve to set the flow to 0.6 SCFH. Turn the valve’s knob

counterclockwise to increase the flow and clockwise to decrease the flow.

If the sample-draw detector goes into low flow alarm before you can adjust the flow down to

0.6 SCFH, adjust the pressure switch adjustment screw 1/4 turn clockwise, then attempt to set

the flow again. Repeat this step until you are able to adjust the flow to 0.6 SCFH.

NOTE: The pressure switch adjustment screw is accessible through a circular cutout in the

flowmeter circuit board.

2. Slowly turn the pressure switch adjustment screw counterclockwise just until the sample-draw

detector goes into low flow alarm.

3. Turn the sensor flow control valve’s knob counterclockwise to increase the flow until the unit

is out of low flow alarm.

4. Decrease the flow very slowly by turning the sensor flow control valve’s knob clockwise and

verify that the low flow alarm is 0.6 SCFH (±0.1).

35-3001A-11 Hydrogen Sample-Draw Detector • 17

Page 22

If the low flow alarm is set too low, turn the pressure switch adjustment screw slightly

clockwise. Repeat steps 3 and 4 if necessary.

5. Use the sensor flow control valve to set the flow to 1.0 SCFH.

6. Make sure the sample-draw detector’s Fail LED is off.

Calibration Frequency

Although there is no particular calibration frequency that is correct for all sample draw detector

applications, a calibration frequency of every 9 to 12 months is adequate for most applications.

Unless experience in a particular application dictates otherwis e, RKI Instruments , Inc. recommends

a calibration frequency of every 9 months.

If an application is not very demanding, for example detection in a clean, temperature controlled

environment where hydrogen is not normally pr esent and calibration adjustments are minimal at

calibration, then a calibration frequency of every 12 months is adequate.

If an application is very demanding, for example if hydrogen is present often and in significant

concentrations or the environment is not well controlled, then more frequent calibration than every

9 months may be necessary.

Calibration

This section describes how to calibrate the hydrogen sample-draw detector. It includes procedures

to prepare for calibration, set the zero reading, set the response reading, and return to normal

operation.

NOTE: This procedure describes calibration using a demand flow regulator.

Prepari ng for Ca libration

1. Follow the instructions in the controller’s operator’s manual for entering calibration mode.

NOTE: If you can verify a fresh air environment, it is not necessary to us e the zero air calib ration

cylinder to set the zero reading.

2. Screw the regulator into a zero air calibration cylinder.

3. Open the housing door.

4. Set a voltmeter to measure in the millivolt (mV) range.

5. Plug the positive lead into the red (+) amplifier test point; plug the negative lead into the black

(-) amplifier test point.

6. Use the following formula to determine the correct test points output for the calibrating

sample.

Output (mV) = (calibrating sample/fullscale) X 400 + 100

For example, with a calibrating sample of 4% vol and a fullscale setting of 10% vol, the correct

output is 260 mV.

260 (mV) = (4/10) X 400 +100

18 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Page 23

Setting the Zero Reading

1. Connect the sample tubing from the demand flow regulator to the sample-draw detector’s inlet

line. This step is not necessary if you verified a fresh air environment earlier in this

procedure.

2. Allow the sample-draw detector to draw sample for one minute.

3. Verify a voltmeter reading of 100 mV (± 2 mV).

4. If necessary, use a small flat-blade screwdriver to adjust the zero potentiometer until the

voltmeter reading is 100 mV (± 2 mV). If you used a zero air calibration cylinder to set the

zero reading, proceed to step 5. If you verified a fresh air environment, proceed to the next

section, Setting the Response Reading.

5. Disconnect the sample tubing from the inlet line.

6. Unscrew the regulator from the zero air calibration cylinder.

Setting the Response Reading

1. Screw the regulator into the hydrogen calibration cylinder.

2. Connect the sample tubing from the demand flow regulator to the sample-draw detector’s inlet

line.

3. Allow the sample-draw detector to draw sample for one minute.

4. When the reading on the voltmeter stabilizes, verify that the reading matches the response

reading (±2 mV) you determined earlier.

5. If necessary, use the span potentiometer on the amplifier to adjust the reading to match the

correct response reading.

6. Disconnect the sample tubing from the inlet line.

7. Unscrew the regulator from the hydrogen calibration cylinder.

Returning to Normal Operation

1. Wait appro ximately one minute to allow the hydrogen reading to stabilize.

2. Remove the voltmeter leads from the amplifier test points.

3. Close the housing door.

4. Follow the instructions in the controller’s operator’s manual to exit the calibration mode.

5. Store the components of the calibration kit in a safe and convenient place.

35-3001A-11 Hydrogen Sample-Draw Detector • 19

Page 24

Parts List

Table 2 lists replacement parts and accessories for the sample-draw hydrogen detector.

Table 4: Parts List

Part Number Description

06-1248RK Sample tubing, 3/16 in. x 5/16 in., specify length

06-1248RK-03 Sample tubing, 3/16 in. x 5/16 in., 3 feet (for calibration ki t)

30-1016RK Pump

33-0165RK Hydrophobic filter

33-0167RK Particle filter

57-1053RK-01 Amplifier (specify target gas when ordering)

71-0334 Operator’s Manual, 35-3001A-11 Sample-Draw Detector

81-0022RK-01 Calibration cylinder, 4% volume hydrogen in nitrogen, 34 liter

81-0076RK-01 Zero air calibration cylinder, 34 liter

81-0076RK-03 Zero air calibration cylinder, 103 liter

81-1054RK Regulator, demand flow, for 58- and 103-liter cylinders

81-1055RK Regulator, demand flow, for 17- and 34-liter steel cylinders

TE-7560 Hydrogen sensor, plug-in type, volume range

20 • 35-3001A-11 Hydrogen S ample-Draw Detecto r

Loading...

Loading...