RKI Instruments 35-3001A-07, 35-3001-06-01 Operator's Manual

35-3001A-07

Combustible Gas/Hydrogen Sulfide

Sample-Draw Detector

Operator’s Manual

Part Number: 71-0431

Revision: 0

Released: 8/7/17

www.rkiinstruments.com

WARNING

Read and understand this instruction manual before operating

detector. Improper use of the detector could result in bodily harm

or death.

Periodic calibration and maintenance of the detector is essential

for proper operation and correct readings. Please calibrate and

maintain this detector regularly! Frequency of calibration

depends upon the type of use you have and the sensor types.

Typical calibration frequencies for most applications are between

3 and 6 months, but can be required more often or less often

based on your usage.

35-3001A-07 Combustible Gas/Hydrogen Sulfide Sample-Draw Detector

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in materials,

workmanship, and performance for a period of one year from date of shipment from RKI

Instruments, Inc. Any parts found defective within that period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to those items which by their nature are subject

to deterioration or consumption in normal service, and which must be cleaned, repaired, or replaced

on a routine basis. Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repair

procedures not in accordance with the operator’s manual. This warranty indicates the full extent of

our liability, and we are not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior approval.

THIS W ARRAN T Y IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC. INCLUDING BUT N OT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and

representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor, and our warranty is limited to the replacement of parts or our complete goods.

35-3001A-07 Combustible Gas/Hydrogen Sulfide Sample-Draw Detector

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

External Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the Sample-Draw Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting the Sample Lines to the Sample-Draw Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the Sample-Draw Detector to a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Introducing Incoming Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the Zero Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacing Components of the Sample-Draw Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjusting the Low Flow Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Removing the Particle Filter’s Tubing Stub, if Necessary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Calibration Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Calibration, LEL Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Preparing for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Zero Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the Response Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Returning to Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Calibration, H2S Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Preparing for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the Zero Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the Response Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Returning to Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

35-3001A-07 Combustible Gas/Hydrogen Sulfide Sample-Draw Detector

Overview

This operator’s manual describes the 35-3001A-07 combustible gas/hydrogen sulfide sample-draw

detector. This manual also describes how to install, start up, maintain, and calibrate the sampledraw detector when using it with a gas monitoring controller. A parts list at the end of this manual

lists replacement parts and accessories for the sample-draw detector.

Specifications

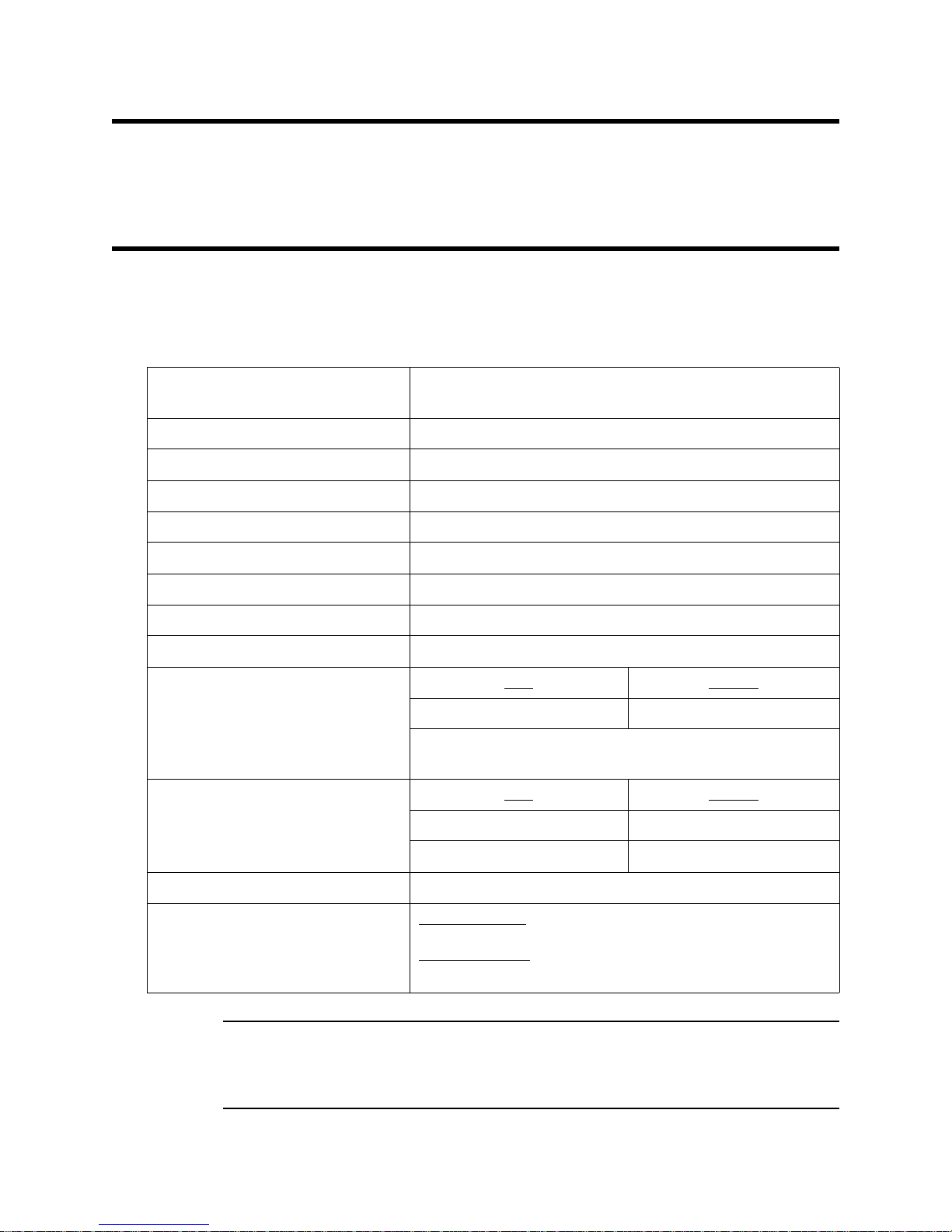

Table 1 lists specifications for the combustible gas/hydrogen sulfide sample-draw detector. See the

controller Operator’s Manual for information specific to the controller.

Table 1: Specifications

Target Gases and Detection Range Combustible Gas: 0 - 100% LEL

Hydrogen Sulfide: 0 - 100 ppm

Input Power 24 VDC Nominal (18.5 VDC - 30 VDC)

Construction (housing) Fiberglass/polyester (NEMA 4X)

Dimensions 8.5 in. H x 6.5 in. W x 4.25 in. D

Weight 4.5 lbs.

Sampling Method Sample-draw

Sample Flow 3.0 SCFH typical, with no inlet or exhaust line

Flow to Sensor 1.0 SCFH (nominal)

Low Flow Setpoint 0.6 ± 0.1 SCFH

Maximum Recommended Inlet/

Exhaust Line Length for

1/4” O.D. x 1/8” I.D. Tubing

* RKI Instruments, Inc. does not recommend installing this tubing

size on both the inlet and exhaust.

Maximum Recommended Inlet/

Exhaust Line Length for

1/4” O.D. x 0.170” I.D. Tubing

Response Time 90% in 30 seconds

Accuracy Combustible Gas

± 5% of reading or ± 2% LEL (whichever is greater)

Hydrogen Sulfide

± 5% of reading or ± 2 ppm H

Inlet

50 feet 0 feet

Inlet

50 feet 50 feet

75 feet 0 feet

:

:

S (whichever is greater)

2

Exhaust

Exhaust

WARNING: When using the 35-3001A-07, you must follow the instr uctions and warnings in

35-3001A-07 Com bustib le Gas /Hy drogen Sulfid e Sample-Draw Detec tor • 1

this manual to assure proper and safe operation of the 35-3001A-07 and to

minimize the risk of personal injury. Be sure to maintain and periodically

calibrate t he 35-3001A- 07 as describe d in this manual.

Description

Mounting

Foot, 4X

B

_

LEL Am plifier

Pump

H2S S ensor

(inside bl ock)

Pump Connector

W

LEL

GBR

W

+

O

X

Y

G

E

N

S

PWR/SIG

Flow B a ffle

LE L Flow

Block

LE L

Sensor

H2S Fl ow

Block

Se nsor

Current

148m A

Sensor Flow

Control Va lve

Pilot LED

Fail L ED

Flowmeter

Pum p Reset

Switch

S G B

AMP 1

+

AMP 2

+

WG

OXY

S

+

R

AMP OXY

AMP 2

Hydrophobic

Filter

This E n dTo

Inlet F itting

Particle Filter

Oxygen

Sensor

Terminal

Strip

Intercon nect

Terminal

Strip

LEL/ I R

FlowmeterCircui t

Board Connector

H2S

Amplifier

Inlet

Fitting

Exhaust

Fitting

LEL/ I R

W

3/4" Conduit Hu b

INLE T

EX HAUST

S

+

G B

Pressure Switch

Adjustm ent Screw

(be hind PCB)

Detector/A mp

Terminal Strip

(Factory Wired)

W

+

S R

+

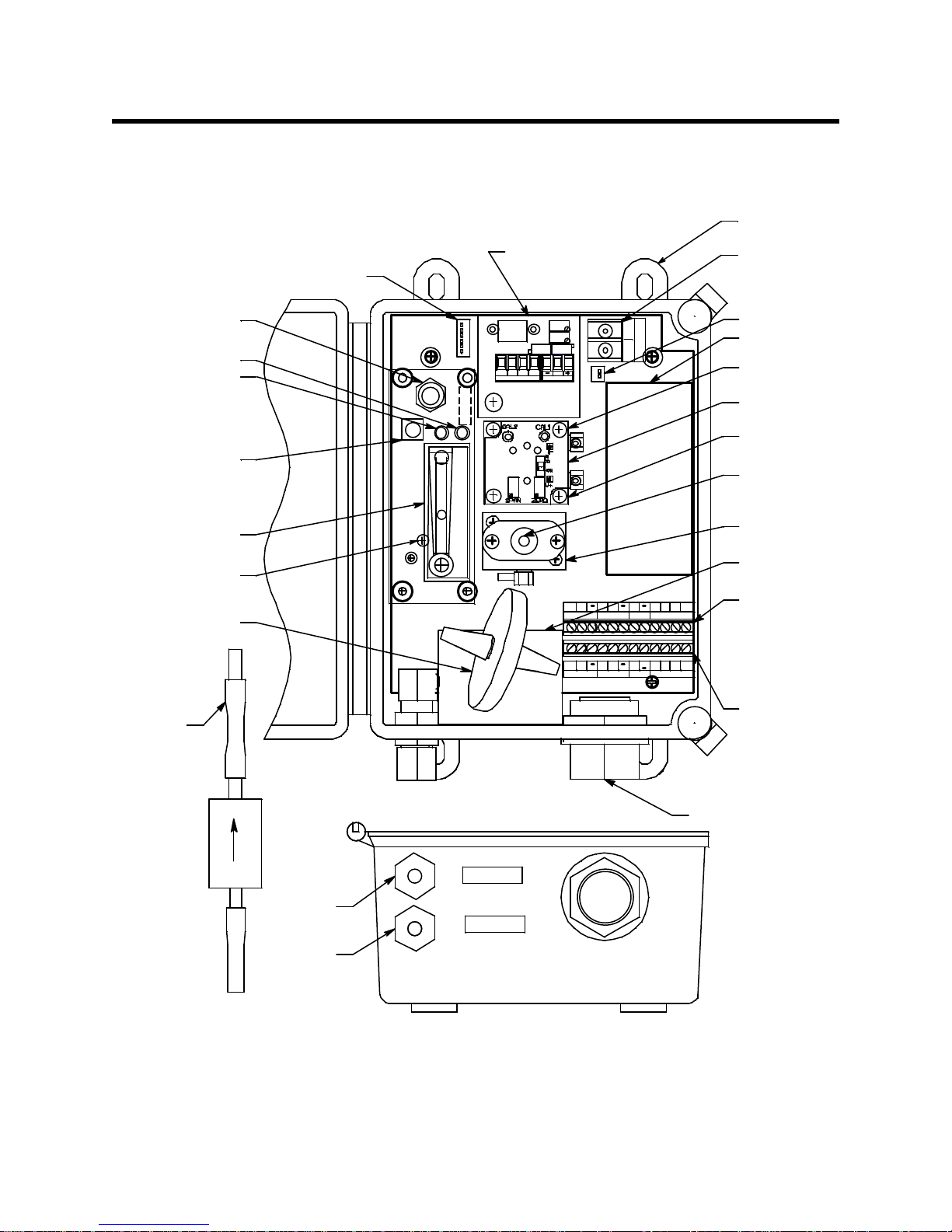

This section describes the components of the combustible gas/hydrogen sulfide sample-draw

detector.

Figure 1: Combustible Gas/Hydrogen Sulfide Sample-Draw Detector Component Location

2 • 35-3001A-07 Combustible Gas/Hydrogen Sulfide Sample-Draw Detector

External Components

Restrictor

Hydrogen

Sulfide

Sensor

LEL

Sensor

Pump

Flowmeter

Flow

Baffle

Particle Filter

Sensor Flow

Con tr o l Valve

Exhaust

Flowmeter PCB

Pressure Switch

Hydrophobic Filter

Inlet

This section describes the sample-draw detector’s external components.

Housing

The sample-draw detector’s fiberglass housing is weather- and corrosion-resistant. It is suitable for

installation where general purpose equipment is in use.

The housing door is hinged on the left side and is secured by two latches on the right side. The

flowmeter and status LEDs are visible through a window in the housing door.

Four mounting feet are attached to the back of the housing (one at each corner). Use the mounting

feet to install the housing to a vertical surface.

Sample Fittings

The sample fittings are located on the left side of the bottom of the housing. The inlet fitting is near

the front of the housing and the exhaust fitting is near the back of the housing. The sample fittings

accept 1/4 in. rigid tubing. See the Installation section on page 8 to connect tubing to the sample

fittings.

Particle Filter

A particle filter with a tubing stub on one end is shipped with the instrument but it is not factory

installed. If the particle filter is installed directly to the inlet fitting, the tubing stub must be used. If

the particle filter is installed somewhere else, like at the end of the inlet line, the tubing stub can be

used or removed.

Conduit Hub

One 3/4” conduit hub is located on the right side of the bottom of the housing. It is used for routing

wiring into the housing by using conduit or an appropriate cable bushing.

Internal Components

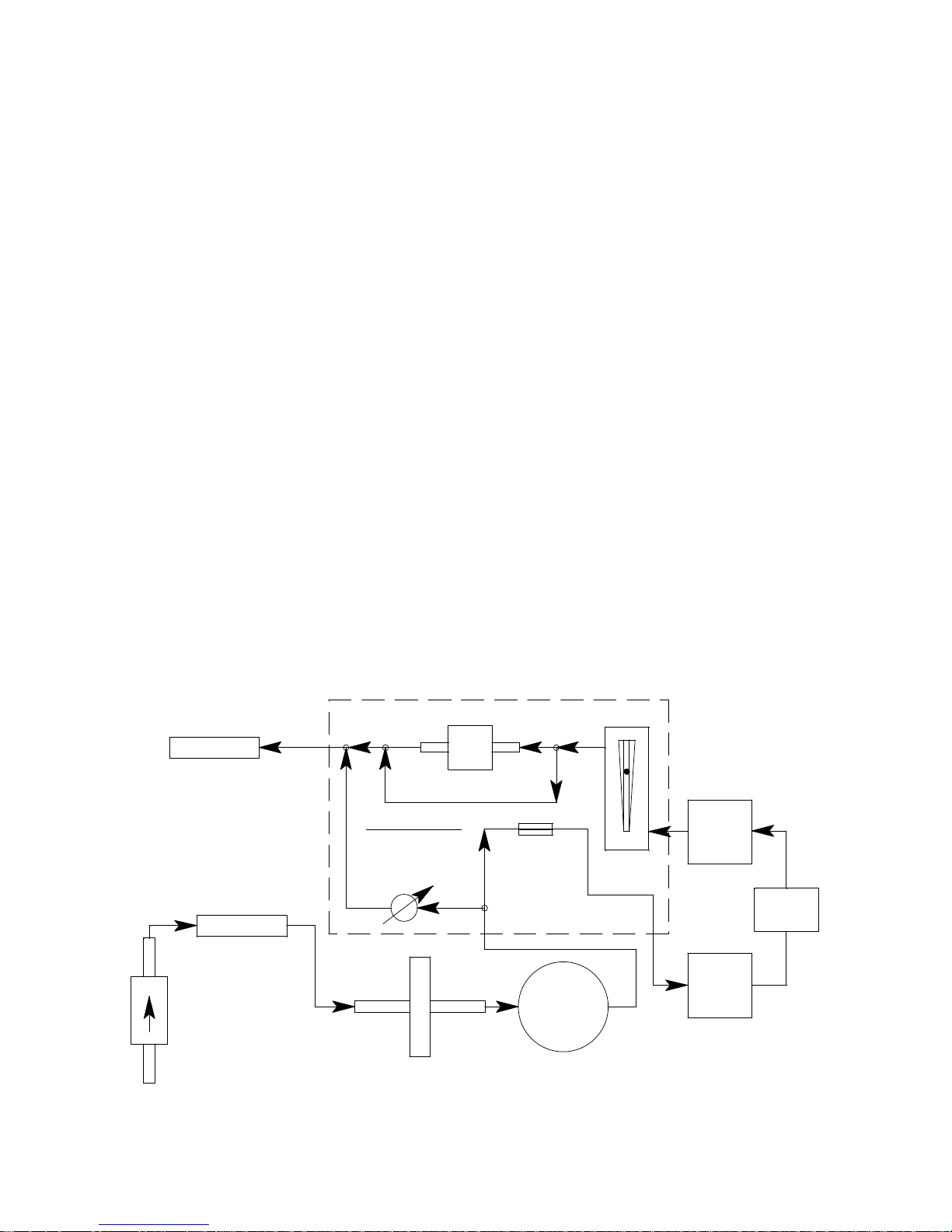

This section describes the sample-draw detector’s internal components (see Figure 1). Figure 2

illustrates how the gas sample moves through the flow system.

Figure 2: Combustible Gas/Hydrogen Sulfide Sample-Draw Detector Flow Diagram

35-3001A-07 Com bustib le Gas /Hy drogen Sulfid e Sample-Draw Detec tor • 3

Main Circuit Board

The main circuit board includes the detector/amp terminal strip, interconnect terminal strip, oxygen

sensor terminal strip, pump connector, and flowmeter circuit board connector (see Figure 1).

Detector/Amp Terminal Strip

The detector/amp terminal strip is the upper twelve-point terminal strip in the bottom right corner

of the main circuit board. Use the detector/amp terminal strip to connect the LEL amplifier and the

H

S amplifier to the main circuit board.

2

NOTE: The LEL amplifier and H2S amplifier are factory-wired to the main circuit board. See the

“Installation” section on page 8 for all wiring procedures related to the sample-draw

detector.

Interconnect Terminal Strip

The interconnect terminal strip is the lower twelve-point terminal strip in the bottom right corner of

the main circuit board. Use the interconnect terminal strip to connect the sample-draw detector to a

controller.

Oxygen Sensor Terminal Strip

The oxygen sensor terminal strip is a two-point terminal strip in the upper right corner of the main

circuit board. This terminal strip is not used in this version of the sample-draw detector.

Pump Connector

The pump connector is the two-point connector below the oxygen terminal strip in the upper right

corner of the main circuit board. Use the pump connector to connect the pump to the main circuit

board.

NOTE: The pump is factory-wired to the main circuit board. See “Installation” on page 8 for all

wiring procedures related to the sample-draw detector.

Flowmeter Circuit Board Co nnector

The flowmeter circuit board connector is a six-position connector in the upper left corner of the

main circuit board. Use the flowmeter circuit board connector to connect the flowmeter circuit

board to the main circuit board.

NOTE: The flowmeter circuit board is factory wired to the main circuit board. See “Installation”

on page 8 for all wiring procedures related to the sample-draw detector.

Flowmeter Circuit Board

The flowmeter circuit board is mounted to the left side of the main circuit board using standoffs. It

includes the flowmeter, sensor flow control valve, status LEDs, pressure switch, and pump reset

switch.

Flowmeter

The flowmeter is mounted to the right side of the flowmeter circuit board. You can see it through

the window in the door. A ball in the flowmeter column indicates the flow rate to the sensor. The

flowmeter measures the flow in the range 0.2 to 2.0 SCFH (Standard Cubic Feet per Hour). The

optimum flow rate is 1.0 SCFH.

4 • 35-3001A-07 Combustible Gas/Hydrogen Sulfide Sample-Draw Detector

Sensor Flow Control Valve

The sensor flow control valve is mounted to the flowmeter circuit board above the flowmeter. The

sensor flow control valve adjusts the flow rate to the detector. Turn the valve’s knob clockwise to

increase the flow and counterclockwise to decrease the flow.

Status LEDs

Two status LEDs are above the flowmeter. They are also visible through the window in the housing

door. The green Pilot LED is on when the sample-draw detector is receiving power from the

controller. The red Fail LED is on when the sample flow rate is below the low flow level.

Pressure Switch

The pressure switch is mounted to the back of the flowmeter circuit board. The pressure switch

monitors the flow rate of the incoming gas sample.

If the flow rate falls below the preset low flow level, the pressure switch causes the Fail LED to

turn on and interrupts the signal from the detector. The interrupted detector signal causes a fail

condition at the controller. The low flow level is factory-set at 0.6 SCFH (±0.1 SCFH). See

“Adjusting the Low Flow Setting” on page 19 to adjust this setting.

Pump Reset Switch

The pump reset switch is located to the left of the status LEDs. When a low flow condition occurs,

the pump will be shut off. To reset the low flow condition and start the pump again, press and hold

the pump reset switch for about 2 seconds, then release.

Hydrophobic Filter

The hydrophobic filter is located toward the bottom left of the main circuit board. The filter

prevents particulates and water in the incoming gas sample from damaging the flow and detection

systems. Replace the filter when it appears dirty, discolored, or clogged.

Pump

The pump is mounted to the right side of the main circuit board. The pump pulls the gas sample

into the sample-draw detector. The pump operates on 24 VAC, which is generated from the 24

VDC supplied by the controller.

Flow Baffle

A flow baffle is located at the bottom of the main circuit board, behind the hydrophobic filter. Its

function is to isolate the hydrogen sulfide sensor from vibrations in the flow line that are caused by

the pump.

Combustible Gas (LEL) Sensor

The catalytic combustible gas sensor detects combustible gas in the %LEL range. It uses a catalytic

element for detection. The reaction of gas with oxygen on the catalyst causes a change in the

resistance of the element which changes the current flowing through it. The current is proportional

to the detection range of the sample-draw detector.

The combustible gas sensor is installed in the flow block and the flow block is mounted to the

middle of the main circuit board. It is the lower of the two flow blocks mounted to the main circuit

board. The sensor housing includes a sintered metal flame arrestor on one end that allows gas to

diffuse into the sensor. On the other end, five pins extend from the sensor and plug into the socket

connector. The connector allows you to replace the sensor without disconnecting the wiring. Four

leads extending from the connector are factory wired to the amplifier.

35-3001A-07 Com bustib le Gas /Hy drogen Sulfid e Sample-Draw Detec tor • 5

Loading...

Loading...