Page 1

Sample-Draw Hydrogen Sulfide Gas Detector for Use

With Generic Device

Specifications

Table 1 lists specifications for the sample-draw hydrogen sulfide detector. .

Table 1: Specifications

Target Gas Hydrogen Sulfide

Input Power 24 VDC

Output Signal 4-20 mA

Construction (housing) Fiberglass/polyester (NEMA 4X)

Dimensions 8.5 in. H x 6.5 in. W x 4.25 in. D

Weight 4.5 lbs.

Sampling Method Sample-draw

Sample Flow 1.5 SCFH (nominal)

Detection Range 0 to 100 ppm

Response Time 90% in 30 seconds

Accuracy ±5% of detection range

Repeatability ±2% of detection range

Sample-Draw Hydrogen Sulfide Gas Detection • 1

Page 2

Description

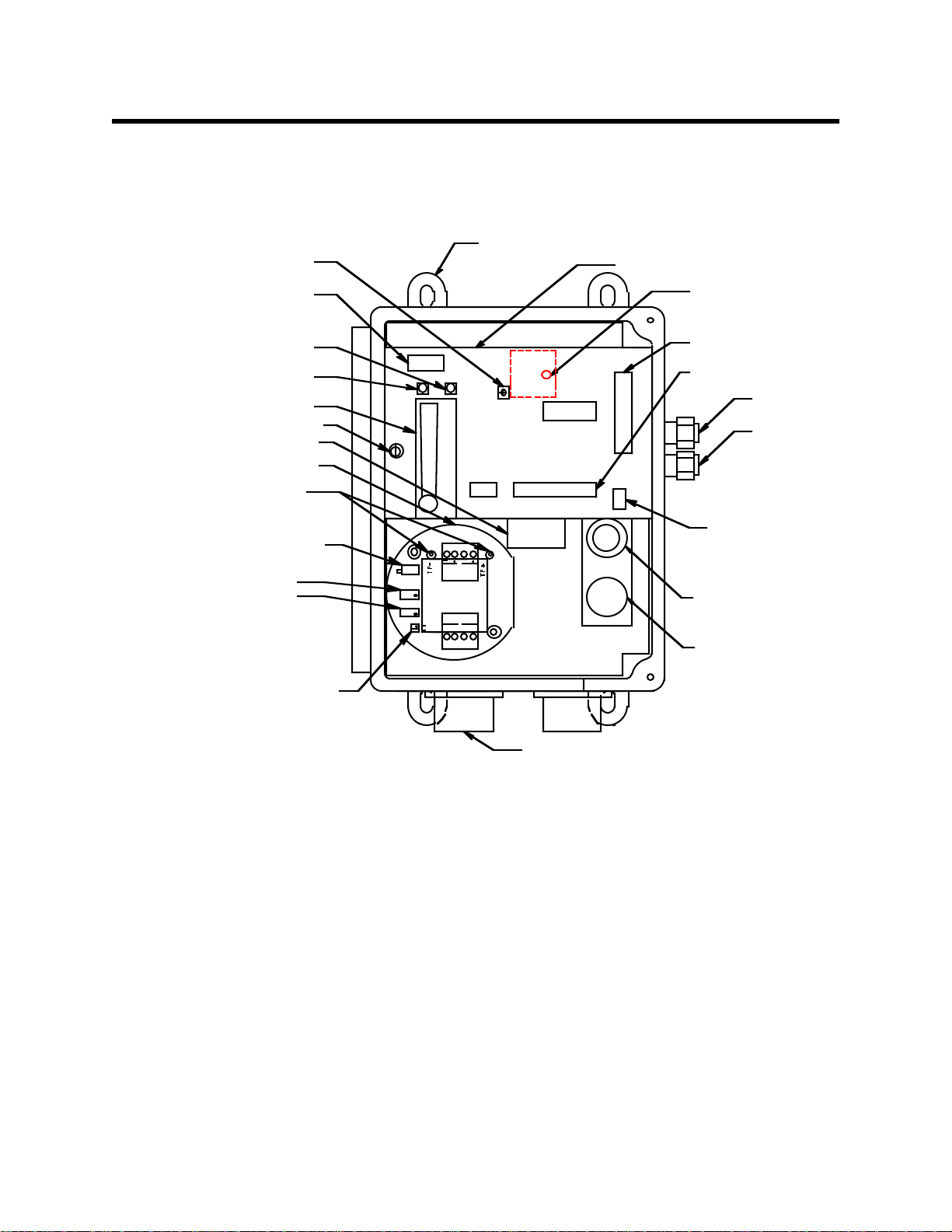

This section describes the components of the sample-draw hydrogen sulfide gas detector.

The sample-draw detector consists of the housing, flow system, and detection system.

Mounting Foot,

Flow Adjust

Potentiometer

Pump/flow switch

terminal block

4X

Main Circuit Board

Flow Alarm Setpoint

Adjustment

Potentiometer

Fail LED

Pilot LED

Flowmeter

Bypass valve

Particle filter

Transmitter

Test Points

100 - 500 mV range

Factory Set Pot

Zero Pot

Span Pot

JUMPER PINS FOR

FACTORY USE

ONLY

ZERO

SPAN

TOXIC

Transmitter

Te rminal Strip

Interconnect Terminal

Strip

Exhaust

Inlet

Sensor

Connector

24VFB4/20BATT

Hydrogen Sulfide Sensor

OXY

TOXIC

OXY

G

BKRD W

Not Used

3/4" Conduit

Hub , 2X

Figure 1: Sample-draw Hydrogen Sulfide Gas Detector Component Location

Housing

The sample-draw detector’s fiberglass housing is weather- and corrosion-resistant. It is

suitable for installation where general purpose equipment is in use.

The housing door is hinged on the left side and is secured by two latches on the right side.

The flowmeter and status lights are visible through a window in the housing door.

Four mounting feet are attached to the back of the housing (one at each corner). Use the

mounting feet to install the housing to a vertical surface. Use the two conduit hubs on the

bottom of the housing to make wiring connections.

An aluminum subpanel is mounted to the interior of the housing. The sample-draw

detector’s internal components are mounted to the subpanel.

2 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 3

Flow System

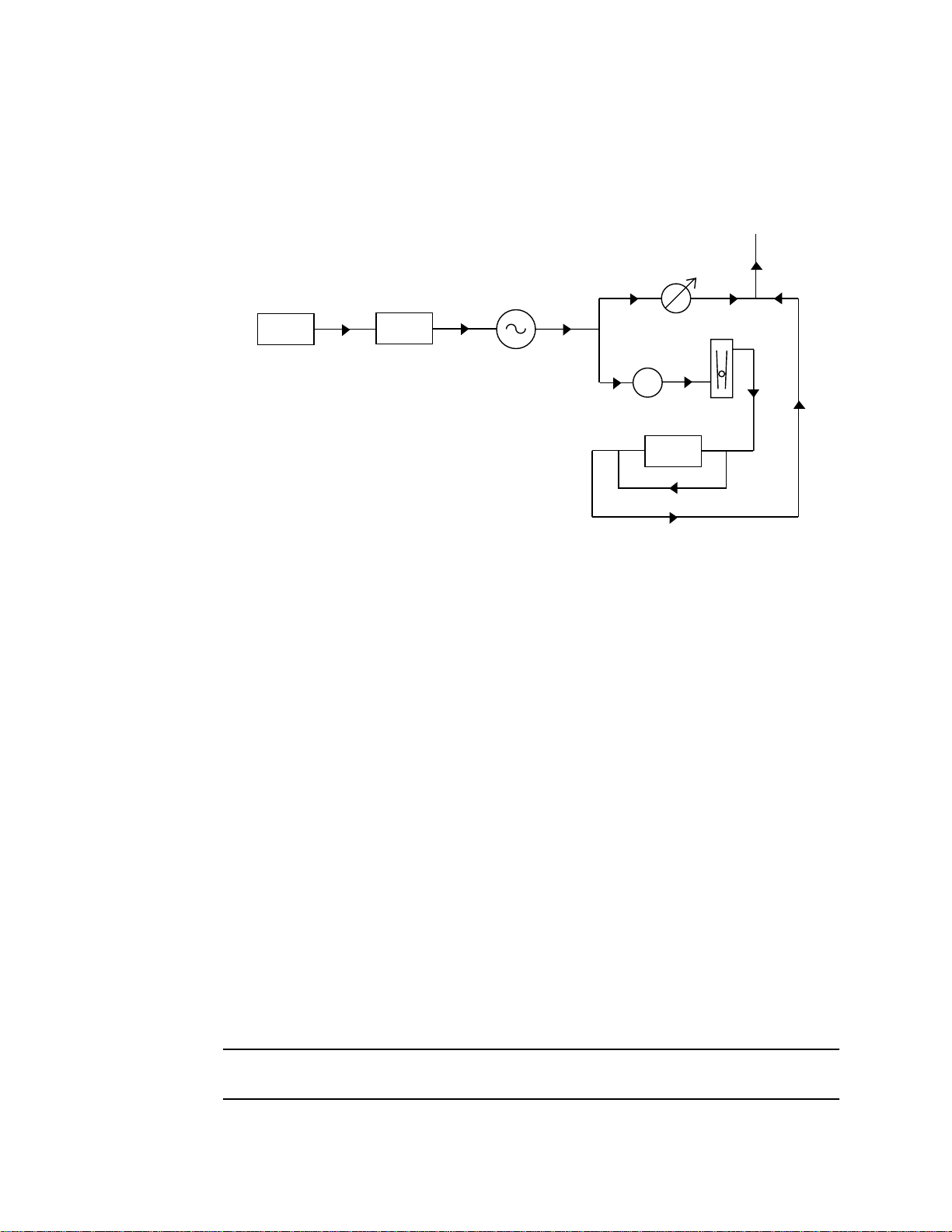

The sample-draw detector’s flow system consists of the INLET fitting, filter, pump,

flowmeter, bypass valve, status lights, pressure switch, and EXHAUST fitting (see

Figure 1). Figure 2 illustrates how the gas sample moves through the flow system.

To

Exhaust

Bypass

Valve

Flowmeter

Inlet Filter Pump Sensor

Pressure Switch

Figure 2: Sample-draw Hydrogen Sulfide Gas Detector Flow Diagram

INLET fitting

The INLET fitting on the right side of the housing allows the gas sample to enter the

sample-draw detector. The INLET fitting accepts 1/4 in. rigid tubing. See the Installation

section on page 6 to connect tubing to the INLET fitting.

Filter

The dust filter is below the main circuit board. The filter prevents particulates in the

incoming gas sample from damaging the flow and detection systems. Replace the filter

when it appears dirty, discolored, or clogged.

Pump

The pump is behind the main circuit board near the top of the sample-draw detector.

The pump pulls the gas sample into the sample-draw detector. The pump operates on

24 VAC, which is generated from the 24 VDC supplied to the sample draw detector.

Flowmeter

The flowmeter is attached to the main circuit board near the top left corner (see Figure 1.)

You can see it through the window in the door. A ball in the flowmeter column indicates

the flow rate of the sample-draw detector. The flowmeter measures the flow in the range

0.2 to 2.0 SCFH (Standard Cubic Feet per Hour). The optimum flow rate is 1.5 SCFH.

Bypass valve

The bypass valve is to the left of the flowmeter. The bypass valve adjusts the flow rate to

the sensor. Use a flat-blade screwdriver to adjust the bypass valve.

NOTE: The bypass valve allows fine adjustments of the flow rate. For a wider range of

adjustment, use the flow adjust potentiometer (see Figure 1.)

Sample-Draw Hydrogen Sulfide Gas Detection • 3

Page 4

Status lights

Two status lights are above the flowmeter. They are also visible through the window in

the housing door.

Pilot light

The green Pilot light is on when the sample-draw detector is receiving power from the

Pioneer.

Fail light

The red Fail light is on when the sample flow rate is below the low flow level.

NOTE: The default low flow level is 0.6 SCFH (±0.2). See “Adjusting the Low Flow

Setting” on page 13 to adjust this setting.

Pressure switch

The pressure switch is mounted to the opposite side of the main circuit board. The

pressure switch monitors the flow rate of the incoming gas sample.

If the flow rate falls below the preset low flow level, the pressure switch causes the fail

relay to interrupt the signal in the 4-20 mA line. This causes a downscale reading at the

monitor. The low flow level is factory-set at 0.6 SCFH (±0.2 SCFH).

EXHAUST fitting

The EXHAUST fitting on the right side of the housing allows the gas sample to exit the

sample-draw detector. The EXHAUST fitting accepts 1/4 in. rigid tubing. See the

Installation section on page 6 to connect tubing to the EXHAUST fitting.

Detection System

The detection system consists of the hydrogen sulfide gas sensor, the hydrogen sulfide

transmitter, and the main circuit board.

Hydrogen sulfide gas sensor

The hydrogen sulfide gas sensor is installed in a cavity block. The cavity block is mounted

to the aluminum subpanel on the right of the sample-draw detector. The hydrogen

sulfide gas sensor includes the sensor and the cable with connector.

NOTE: The cavity block includes a cavity for a second hydrogen sulfide or a carbon

monoxide sensor. This version of the sample-draw detector does not include the

second sensor.

Sensor

The sensor is pushed into the cavity block and held in place by two o-rings. Through a

series of chemical and electrical reactions, the sensor produces an electrical output that is

proportional to the detector range of the transmitter.

Cable w/Connector

The sensor has a two wire cable with a 4-pin connector soldered to it. The connector is

plugged into the sensor connector in the lower right of the Main Circuit Board.

4 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 5

Hydrogen Sulfide Transmitter

The hydrogen sulfide transmitter is mounted to the left of the hydrogen sensor. It consists

of the span pot, zero pot, two internally wired terminal strips, and the test points.

Span/zero pots

The span and zero pots are located at the left edge of the transmitter and are used for calibration. Use the span pot to make adjustments to gas response readings and the zero pot

to make adjustments to the zero reading

Termainal Strips

There are two terminal strips which are used for internal factory wiring.

Test points

The test points are located at the top of the transmitter and are labeled TP+ and TP- . A

100 mV - 500 mV output is available at these testpoints for use during calibration.

Main Circuit Board

The main circuit board includes the interconnect terminal strip, transmitter terminal strip,

pump terminal strip, and relay (see Figure 1).

NOTE: The flowmeter and status lights are mounted to the main circuit board but are

considered part of the flow system.

Interconnect terminal strip

The interconnect terminal strip is the nine-point terminal strip near the bottom edge of the

main circuit board. Use the interconnect terminal strip to connect the sample-draw

detector to power and an external device.

Transmitter terminal strip

The transmitter terminal strip is the nine-point terminal strip near the right edge of the

circuit board. Use the transmitter terminal strip to connect the transmitter to the main

circuit board.

NOTE: The transmitter is factory-wired to the circuit board. See the “Installation” section

on page 6 for all wiring procedures related to the sample-draw detector.

Pump terminal strip

The pump terminal strip is the four-point terminal strip near the top edge of the circuit

board. Use the pump terminal strip to connect the pump and pressure switch to the main

circuit board.

NOTE: The pump and pressure switch are factory-wired to the circuit board. See the

“Installation” on page 6 for all wiring procedures related to the sample-draw

detector.

Relay

The relay is to the left of the detector terminal strip. The relay is double pole, doublethrow (DPDT) and is rated for 2 amps at 25 VDC (resistive). If the pressur e switch senses a

low flow condition, the relay interrupts the signal from the sensor. The interrupted sensor

signal causes a fail condition at the Pioneer.

Sample-Draw Hydrogen Sulfide Gas Detection • 5

Page 6

Installation

This section describes procedures to mount the sample-draw hydrogen sulfide gas

detector in the monitoring environment and wire the sample-draw detector to power and

an external device.

Mounting the Sample-Draw Combustible Gas Detector

1. Select the mounting site. Consider the following when you select the mounting site.

• Is there enough room to open the housing door and make wiring connections at

the bottom of the housing and tubing connections at the right of the housing?

Make sure there is sufficient room to perform start-up, maintenance, and

calibration procedures.

• Are the flowmeter and status lights visible?

7.3 in.

6.5 in.

4.0 in.

8.5

in.

8.9

in.

9.3

in.

3/4 in. conduit hub

Note: The housing is 4.25 in. deep.

Figure 3: Mounting the Sample-Draw Hydrogen Sulfide Gas Detector

(total of 2 hubs)

6 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 7

2. Close and latch the housing door.

NOTE: The sample-draw detector is shipped with the mounting feet “tucked under” the

housing to protect the mounting feet during shipment.

3. Slightly loosen the screw that secures the mounting foot to the housing, then rotate

the mounting foot 180 degrees (see Figure 3).

4. Tighten the screw that secures the mounting foot to the housing.

5. Repeat steps 3 and 4 for the remaining three mounting feet.

6. Position the sample-draw housing on a vertical surface at eye level (4 1/2 to 5 feet

from the floor).

7. Insert 1/4 in. or 5/16 screws through the slots in the mounting feet to secure the

housing to the mounting surface.

Connecting the Sample Lines to the Sample-Draw

Hydrogen Sulfide Gas Detector

1. Attach 1/4 in. O.D. stainless steel, rigid teflon, or rigid polypropylene sample tubing

to the INLET fitting.

CAUTION: If you use flexible sample tubing (polyurethane is acceptable), use an appropriate

metal insert to seal the connection between the tubing and the INLET fitting. See

Appendix A, Parts List, for an example of an appropriate metal insert.

2. Place the opposite end of the tubing at the sampling area.

CAUTION: Avoid loops or slumps in the incoming sample line. To r educe r esponse time, keep the

incoming sample line as short as possible.

3. Attach rigid sample tubing to the EXHAUST fitting.

4. Route the opposite end of the tubing to an open area where the sample can safely

disperse.

Wiring the Sample-Draw Hydrogen Sulfide Gas Detector

WARNING: Always verify that the power source is OFF before you make wiring

connections.

1. Unlatch and open the housing door of the sample-draw detector.

2. Guide a three-conductor, shielded cable or three wires in conduit through one of the

conduit hubs at the bottom of the sample-draw housing.

3. Connect the cable to the sample-draw detector’s interconnect terminal strip as shown

in Figure 4.

4. Close and latch the housing door of the sample-draw detector.

CAUTION: Leave the shield cable insulated and disconnected at the sample-draw detector.

You will connect the opposite end of the shield cable at the device.

Sample-Draw Hydrogen Sulfide Gas Detection • 7

Page 8

5. Route the cable or wires in conduit leading from the sample-draw detector to the

monitoring device and power.

6. Connect the cable shield to an available chassis ground at the device end.

H2S Sample Draw Housing

PUMP ASSY

INTERNALLY

WIRED.

ZERO

SPAN

PUMP

OXY

TOXIC

Not

Used

BATT 4/20

TOXIC

PSW

FB

24V

OXY

WBKRD G

PRESSURE SWITCH

INTERNALLY

WIRED.

PCBIN SINGLE

POINT SAMPLE

DRAWING

DETECTOR ASSY

Transmitter,

Internally

wired

H2S Sensor,

Internally Connected

NOT USED

ONTHIS

VERSION

115VAC

RDHN

CGND

LEL/O2 AMPP-AMP

_

4/20 +GND 24VWHT GRN BLK

4/20 (Feedback)

+

24VDC

-

Figure 4: Wiring the Sample-Draw Hydrogen Sulfide Gas Detector

8 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 9

Start Up

This section describes procedures to start up the sample-draw hydrogen sulfide gas

detector and place the sample-draw detector into normal operation.

Introducing Incoming Power

1. Complete the installation procedures described earlier in this manual.

2. Verify that the power /device wiring is correct and secure.

3. Turn on or plug in the incoming power at the power source end.

4. Verify that the Pilot light is on.

5. Verify that the flowmeter indicates a flow rate of approximately 1.5 SCFH. If

necessary, use the bypass valve or flow adjust potentiometer to adjust the flow rate.

NOTE: The following step tests for leaks in the sample line. This test may cause a low

flow condition at the sample-draw detector.

6. Verify that the incoming sample line is not leaking. To test the sample line, plug the

open end of the sample line with your thumb. If the flowmeter ball drops to the

bottom of the flowmeter, the incoming sample line is not leaking.

7. Remove your thumb from the sample line, verify the flowmeter returns to a normal

flow rate.

Setting the Zero Reading

CAUTION: If you suspect the presence of hydrogen sulfide gas in the monitoring environment,

use the calibration kit and the zero air calibration cylinder to introduce “fresh air” to

the sensor and verify an accurate zero setting.

1. Verify that the sample-draw detector is sampling a fresh air environment

(environment known to be free of combustible gas).

2. Open the housing door.

3. Set a voltmeter to measure in the milivolt (mV) range.

4. Plug the voltmeter leads into the test points on the amplifier. Plug the positive lead

into the test point labeled TP+ ; plug the negative lead into the test point labeled TP- .

5. Verify a voltmeter reading of 100 mV (± 2 mV).

6. If necessary, use a small flat-blade screwdriver to adjust the zero potentiometer until

the voltmeter reading is 100 mV (± 2 mV).

7. Close the housing door.

Sample-Draw Hydrogen Sulfide Gas Detection • 9

Page 10

Maintenance

This section describes maintenance procedures. It includes preventive maintenance

procedures. This section also includes procedures to troubleshoot the sample-draw

detector, replace components of the sample-draw hydrogen sulfide gas detector, and

adjust the low flow setting.

Preventive Maintenance

This section describes a preventive maintenance schedule to ensure the optimum

performance of the sample-draw detector. It includes daily, monthly, and quarterly

procedures.

Daily

1. Verify that the pilot light is on.

2. Verify that the flowmeter indicates a flow rate of approximately 1.5 SCFH.

3. Verify a reading of 0 ppm (4 mA) at the monitoring device or a reading of 100 mV at

Monthly

If necessary use the bypass valve or flow adjust potentiometer to adjust the flow rate

to 1.5 SCFH.

the transmitter test points. Investigate significant changes in the reading.

This procedure describes a test to verify that the sample-draw hydrogen sulfide gas

detector responds properly to the target gas.

Preparing for the response test

1. Verify that the monitoring device is reading 0 ppm (4 mA).

If the reading is not 0, set the zero reading as described in the “Start Up” section on

page 9, then continue this procedure.

2. Assemble the calibration kit as described in the Calibration section of this insert.

Performing the response test

NOTE: This procedure describes the RKI calibration kit that includes a gas collection

bag. A calibration kit that uses a demand flow regulator is also available.

1. Connect the calibration tubing from the gas collection bag to the inlet line at or near

the INLET fitting.

The sample-draw detector’s pump automatically begins pulling the test sample from

the gas collection bag when you connect the tubing to the inlet line.

2. After approximately one minute, verify that the reading at the monitoring device

stabalizes within ± 10% of the concentration of the test sample. If the reading is not

within ± 10% of the test sample, calibrate the sample-draw detector as described in the

Calibration section of this manual.

3. Remove the calibration tubing from the inlet line, then reconnect the inlet line.

Quarterly

Calibrate the sample-draw detector as described in the “Calibration” section on page 14 .

10 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 11

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended

action for problems you may encounter with the sample-draw hydrogen sulfide gas

detector.

NOTE: This troubleshooting guide describes sample-draw detector problems only. See

the instruction manual for the monitoring device if it exhibits any problems.

Fail condition

Symptoms

• The sample-draw detector’s Fail light is on.

• The monitoring device is operating properly but indicates a reading well below zero.

Probable causes

• The sample-draw detector’s flow rate is too low because of an obstructed sample line,

failed pump, etc.

• The sample-draw detector is malfunctioning.

• The sensor or transmitter wiring is disconnected or misconnected.

Recommended action

1. At the sample-draw detector, set the correct flow rate with the bypass valve or flow

adjust potentiometer.

2. If you cannot set the correct flow rate, check the sample lines for obstructions or kinks.

3. Verify that the detector and transmitter wiring are correct and secure. The Installation

section on page 6 describes detector wiring connections.

4. Calibrate the sample-draw detector as described in the Calibration section on page 14.

5. If the fail condition continues, replace the sensor as described later in this section.

6. If the fail condition continues, contact RKI Instruments, Inc., for further instruction.

Slow or no response/difficult or unable to calibrate

Symptoms

• The detector responds slowly or does not respond during the monthly response test.

• Unable to accurately set the zero or response reading during the calibration

procedure.

• The detector requires frequent calibration.

NOTE: Under “normal” circumstances, the detector requires calibration once a quarter.

Some applications may require a more frequent calibration schedule.

Probable causes

• The calibration cylinder is low, out-dated, or defective.

• The sample-draw detector’s flow rate is too low because of an obstructed sample line,

failed pump, etc.

• The sample-draw detector is malfunctioning.

Sample-Draw Hydrogen Sulfide Gas Detection • 11

Page 12

Recommended action

1. Verify that the calibration cylinder contains an adequate supply of a fresh test sample.

2. If necessary, set the correct flow rate with the bypass valve or flow adjust

potentiometer.

3. If you cannot set the correct flow rate, check the sample line for obstructions or kinks.

4. If the calibration/response difficulties continue, replace the sensor as described later

in this section.

5. If the calibration/response difficulties continue, contact RKI Instruments, Inc., for

further instruction.

Replacing Components of the Hydrogen Sulfide Gas

Sample-draw Detector

This section includes procedures to replace the sensor, filter, and ferrules.

Replacing the hydrogen sulfide gas sensor

1. Turn off incomming power.

2. Open the housing door of the sample-draw detector.

3. Unplug the sensor connector from the main circuit board.

4. Grasp the sensor firmly and pull it out of the flow chamber.

5. Install the new sensor in the flow chamber. Make sure it is pushed all the way down.

6. Connect the sensor connector to the main circuit board.

7. Turn on incomming power.

CAUTION: Allow the replacement sensor to warm up for 15 minutes before you continue.

8. Calibrate the replacement sensor as described in the “Calibration” section on page 14.

Replacing the filter

1. Open the housing door of the sample-draw detector.

2. Note the direction of the arrow on the filter. The arrow indicates the direction of the

sample flow.

3. Disconnect the filter from the elbows on each end of the filter, then remove the filter

from the sample-draw detector.

4. Make sure the arrow is pointing in the same direction as the arrow on the filter you

removed, then connect each end of the replacement filter to the elbows.

5. Verify that the flow rate is approximately 1.5 SCFH, then close the housing door.

Replacing the ferrules

The INLET and EXHAUST fittings each includes two ferrules that seal the incoming or

exhaust tubing to the fitting. Replace the ferrules if the seal is bad or if you replace the

sample tubing. Always replace the ferrules as a pair.

1. Disconnect the sample tubing from the fitting, then unscrew the nut from the fitting.

2. Verify that the ferrules did not remain in the nut. If necessary, remove the ferrules

from the nut.

3. Position the nut so the threaded end is facing you, then insert the back (smaller)

12 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 13

ferrule into the nut. Insert the ferrule so the flat side is facing down.

NOTE: Make sure the bottom ferrule is laying flat in the nut.

4. Insert the cone-shaped front ferrule on top of the bottom ferrule. Insert the ferrule so

the smaller end of the cone is facing up.

5. Screw the nut onto the fitting, then connect the sample tubing to the fitting. Make sure

you firmly tighten the tubing to the fitting.

Adjusting the Low Flow Setting

The factory-set low flow setting is 0.6 SCFH (±0.2). To adjust the low flow setting:

1. Use the flow adjust potentiometer (VR1) to set the flow to 0.6 SCFH.

If the sample-draw detector goes into low flow alarm before you can adjust the flow

down to 0.6 SCFH, adjust the low flow potentiometer 1/4 turn clockwise, then

attempt to set the flow again. Repeat this step until you are able to adjust the flow to

0.6 SCFH.

2. Slowly turn the low flow potentiometer counterclockwise just until the sample-draw

detector goes into low flow alarm.

NOTE: The low flow potentiometer is accessible through a circular cutout in the main

circuit board. The cutout is labeled PS1.

3. Increase the flow using VR1 until the unit is out of low flow alarm.

4. Decrease the flow very slowly and verify that the low flow alarm is 0.6 SCFH (±0.2).

If the low flow alarm is set too low, turn the low flow potentiometer slightly

clockwise. Repeat steps 3 and 4 if necessary.

5. Use the flow adjust potentiometer (VR1) to set the flow to 1.5 SCFH.

6. Make sure the sample draw detector’s Fail light is off.

Sample-Draw Hydrogen Sulfide Gas Detection • 13

Page 14

Calibration

This section describes how to calibrate the sample-draw combustible gas detector. It

includes procedures to assemble the calibration kit, set the zero reading, set the response

reading, and return to normal operation.

NOTE: This procedure describes calibration using a gas collection bag. A demand-flow

calibration kit is also available for calibrating the hydrogen sulfide gas sampledraw detector.

Preparing for Calibration

1. Open the housing door.

2. Set a voltmeter to measure in the millivolt (mV) range.

3. Plug the positive lead into the transmitter test point labeled TP+; plug the negative

lead into the transmitter test point labeled TP-.

4. Use the following formula to determine the correct test points output for the

calibrating sample.

Output (mV) = (calibrating sample/fullscale) X 400 + 100

For example, with a calibrating sample of 25 ppm hydrogen and a fullscale setting of

100 ppm hydrogen, the correct output is 200 mV.

200 (mV) = (25/100) X 400 +100

Assembling the Calibration Kit

NOTE: If you can verify a fresh air environment, it is not necessary to use a zero air

calibration cylinder to set the zero reading. Go to the next section, “Setting the

Zero Reading.”

1. Connect the calibration kit sample tubing to the fitting on the gas collection bag.

2. Connect the sample tubing from the gas collection bag to the inlet line at or near the

INLET fitting.

Allow the sample-draw pump to draw out any residual gas in the gas collection bag.

3. Disconnect the calibration kit sample tubing from the inlet line.

4. Close the clamp right away. The clamp is attached to the calibration kit sample

tubing.

5. Connect the tubing from the gas collection bag to the fixed flow regulator, then open

the clamp.

6. Screw the fixed flow regulator onto the zero air calibration cylinder. The gas

collection bag begins to fill.

7. When the bag is full, unscrew the fixed flow regulator form the cylinder.

8. Close the clamp, then disconnect the sample tubing from the fixed flow regulator.

14 • Sample-Draw Hydrogen Sulfide Gas Detection

Page 15

Setting the Zero Reading

1. Open the clamp, then connect the sample tubing from the gas collection bag to the

sample-draw detector’s inlet line. This step is not necessary if you verified a fresh

air environment earlier in this procedure.

2. Allow the reading to stabilize for approximately 1 minute.

3. Verify a voltmeter reading of 100 mV (± 2 mV).

4. If necessary, use a small flat-blade screwdriver to adjust the zero potentiometer until

the voltmeter reading is 100 mV (± 2 mV).

5. Allow the sample-draw pump to draw out any residual gas in the gas collection bag.

Steps 6 through 8 are not necessary if you verified a fresh air environment earlier in

this procedure. Go to step 9.

6. Disconnect the sample tubing from the inlet line, then close the clamp.

7. Connect the sample tubing from the gas collection bag to the fixed flow regulator,

then open the clamp.

8. Screw the fixed flow regulator onto the calibration gas cylinder. The gas collection

bag begins to fill.

9. Unscrew the fixed flow regulator from the cylinder when the gas collection bag

appears full.

10. Close the clamp, then disconnect the sample tubing from the fixed flow regulator.

Setting the Response Reading

1. Open the clamp, then connect the sample tubing from the gas collection bag to the

inlet line at or near the sample-draw detector’s INLET fitting.

2. Allow the sample-draw detector to respond to the calibrating sample for

approximately 1 minute.

3. When the reading on the voltmeter stabilizes, verify that the reading matches the

response reading (±2 mV) you determined earlier.

4. If necessary, use the span potentiometer on the amplifier to adjust the reading to

match the correct response reading.

5. Allow the sample-draw pump to draw out any residual gas in the gas collection bag.

6. Disconnect the sample tubing from the sample-draw detector’s inlet line, then close

the clamp.

7. Reconnect the incoming sample line.

8. Wait 1 to 2 minutes to allow the hydrogen gas reading to decrease and stabilize.

9. Store the components of the calibration kit in a safe and convenient place.

Sample-Draw Hydrogen Sulfide Gas Detection • 15

Page 16

Parts List

Table 4 lists replacement parts and accessories for the sample-draw hydrogen sulfide gas

detector.

Table 2: Parts List

Part Number Description

06-1248RK Sample tubing, 3/16 x 5/16, specify length, (for calibration kit)

17-2593RK Brass insert (for INLET and EXHAUST fittings)

17-2683RK Front ferrule (for INLET and EXHAUST fittings)

17-2688RK Back ferrule (for INLET and EXHAUST fittings)

30-0610RK Pump

33-0163RK Filter (Boston DFU9933-05-DQ)

65-2037RK Hydrogen sulfide sensor w/cable and 4-pin connector

81-0151RK-02 Calibration cylinder, 25 ppm H2S in nitrogen, 58 liters

81-0076RK-03 Zero air calibration cylinder (103 liter)

81-1005RK Regulator, fixed flow, 6 LPM

81-1126RK Gas collection bag (2 liter)

16 • Sample-Draw Hydrogen Sulfide Gas Detection

Loading...

Loading...