Page 1

30-0951RK-01, 30-0951RK-HS-01,

30-0951RK-OC-01, and 30-0951RK-IR-01

Flow Through Adapters

Part Number: 71-0281RK

Revision: P1

Released: 6/3/13

www.rkiinstruments.com

Page 2

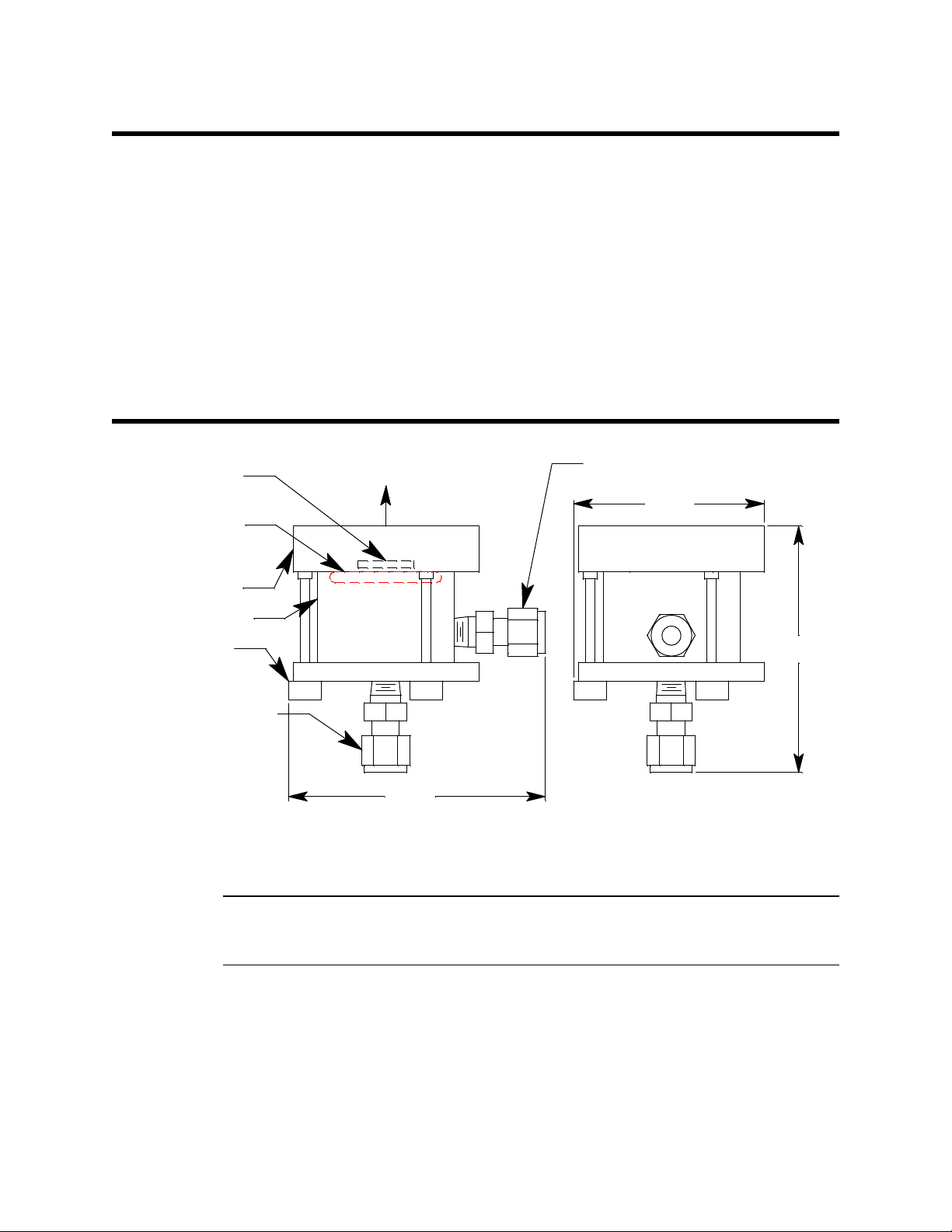

Description

1/4 inch OD Tube

Sample Exhaust

Fitting

Sensor Chamber

O-Ring

Sensor Adapter

Sens or Chamber

Thumbscrew,

3x

Sensor Adapter

O-Ring/Gasket

3.20 max

2.57

3.27

Screw Onto Sensor

1/4 inch OD Tube

Sample Inlet Fitting

Installation

The attached detector head operator’s manual can be used in conjunction with this

supplement for the 30-0951RK-01, 30-0951RK-HS-01, 30-0951RK-OC-01, or the

30-0951RK-IR-01 flow through adapter. The flow through adapter includes a sensor

adapter and a sensor chamber with two compression fittings. A sensor adapter gasket

seals to the 1/ 2” NPT combust ible sens or wh en i nstal led. A sens or ada pter O -ring seal s to

all other types of detectors when installed . This O-ring is different for different types of

detectors. A detector chamber O-ring seals the sensor chamber to the sensor adapter. This

O-ring is the same for all versions. Calibration instructions are the same as those outlined

in the attached detector head manual with the exception that the calibration ga s must be

connected either to the inlet fitting tubing or pump inlet as opposed to a calibration cup.

Installation instructions are slightly different and are outlined below.

1

Figure 1: Outline and Mounting Dimensions/Component Location

1. The flow through adapter is normally shipped in stalled to the detector. If it is not

installed, screw the flow through adapter onto the detector tightening firmly by hand.

CAUTION: Make sure the flow through adapter is installed tightly and after installation is

complete, verify that the flow through adapter is still tightened firmly onto the

detector to avoid possible leaks.

2. If necessary, re-orient the sensor chamber so the inlet fitting faces away from the

mounting surface by unscrewing the three thumbscrews, rotating the sensor chamber,

and tightening the three thumbscrews.

3. Install and startup the detector head as described in the detector head operator’s

manual. Make sure there is sufficient room between the detector and the mounting

surface for the flow through adapter.

4. The inlet and exhaust fittings accept 1/4” OD rigid metal tubing such as copper,

Page 3

Calibration

aluminum, or stainless steel. The inlet fitting is located on the side of the sensor

chamber and the exhaust fitting is located on the bottom. Insert the desired length of

tubing into each fitting and tighten the fittings so that the ferrules crimp onto the

tubing.

5. Install appropriate device(s) (pump, aspirator, etc.) to dra w sample to the detector.

NOTE: Be sure to use the inlet and exhaust ports as intended to ensure correct sensor

response and to allow any accumulated liquid to drain out the bottom of the flow

through adapter.

6. Calibrate the detector head as described in the attached manual and in the next

section.

NOTE: Calibrate the detector head with the flow through adapter installed to ensu re an

accurate reading.

A demand flow regulator should be used for calibration.

1. Follow the calibration instructions outlined in the attached detector head manual.

2. When the instructions call for applying gas, connect the cylinder.

• If you are drawing sample through the system, connect the cylinder to the inlet

fitting of the flow through adapter.

• If you are pushing sample through the system, connect the cylinder to the pump

inlet.

3. Perform a calibration as outlined in the attached detector head manual.

4. When the instructions call for removing the gas, disconnect the cylinder.

2

Page 4

Parts List

Part Number Description

See the table below for spare parts not listed in the attached detector manual.

Table 1: Parts List

07-0107RK Gasket, 0.75 OD x 0.58 ID x 0.093 thick, for 1/2” NPT combustible

sensor adapter

07-7120RK O-ring, 0.987 ID x .103, buna, for O

07-7218RK O-ring, 0.734 x .139, buna, for IR and H

/CO sensor adapter

2

S sensor adapters

2

07-7225RK O-ring, 1.243 ID x .139, buna, for sensor chamber

13-1070RK Captive panel screw, 10-32 x 1.75

81-1054RK R e gulator, demand flow, for 58- and 103-liter calibration cylinders

81-1055RK Re gulator, demand flow, for 17- and 34-liter calibration cylinders

3

Loading...

Loading...