Page 1

30-0951RK-H2S Sample Draw

Aspirator Adapter

Operator’s Manual

Part Number: 71-0125RK

Revision: A

Released: 6/2/10

www.rkiinstruments.com

Page 2

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in

materials, workmanship, and performance for a period of one year from the date of

shipment from RKI Instruments, Inc. Any parts found defective within that period will be

repaired or replaced, at our option, free of charge. Parts must be returned to RKI

Instruments, Inc. for repair or replacement. This warranty does not apply to those items

which by their nature are subject to deterioration or consumption in normal ser v ice, and

which must be cleaned, repaired or replaced on a routine basis. Examples of such items

are:

a) Pump diaphragms and valves c) Batteries

b) Fuses d) Filter elements

W arranty is voided by abuse including mechanical damage, alteration, rough handling, or

repair procedures not in accordance with instruction manual. This warranty indicates the

full extend of our liability, and we are not responsible for removal or replacement costs,

local repair costs, transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO, THE WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty cover s i nstruments and part s sold to users only by authorized distributors,

dealers and representatives as appointed by RKI Instruments, Inc.

We do no t as su me indemnif ic a t ion for any accident or d amage caused b y t he op e r a t ion of

this gas monitor and our warranty is lim ited to the replacement of parts or our complete

goods. W arranty covers parts and labor performed at RKI Instruments, Inc. only, and does

not cover field labor or shipment of parts back to RKI Instruments, Inc.

2 • 30-0951RK-H2S Samp le Draw Aspirator Adapter

Page 3

Overview

This manual describes the 30-0951RK-H2S sample draw aspirator adapter. It also

describes how to install and use the adapter. A spare parts list at the end of this manual

lists replacement parts.

Specifications

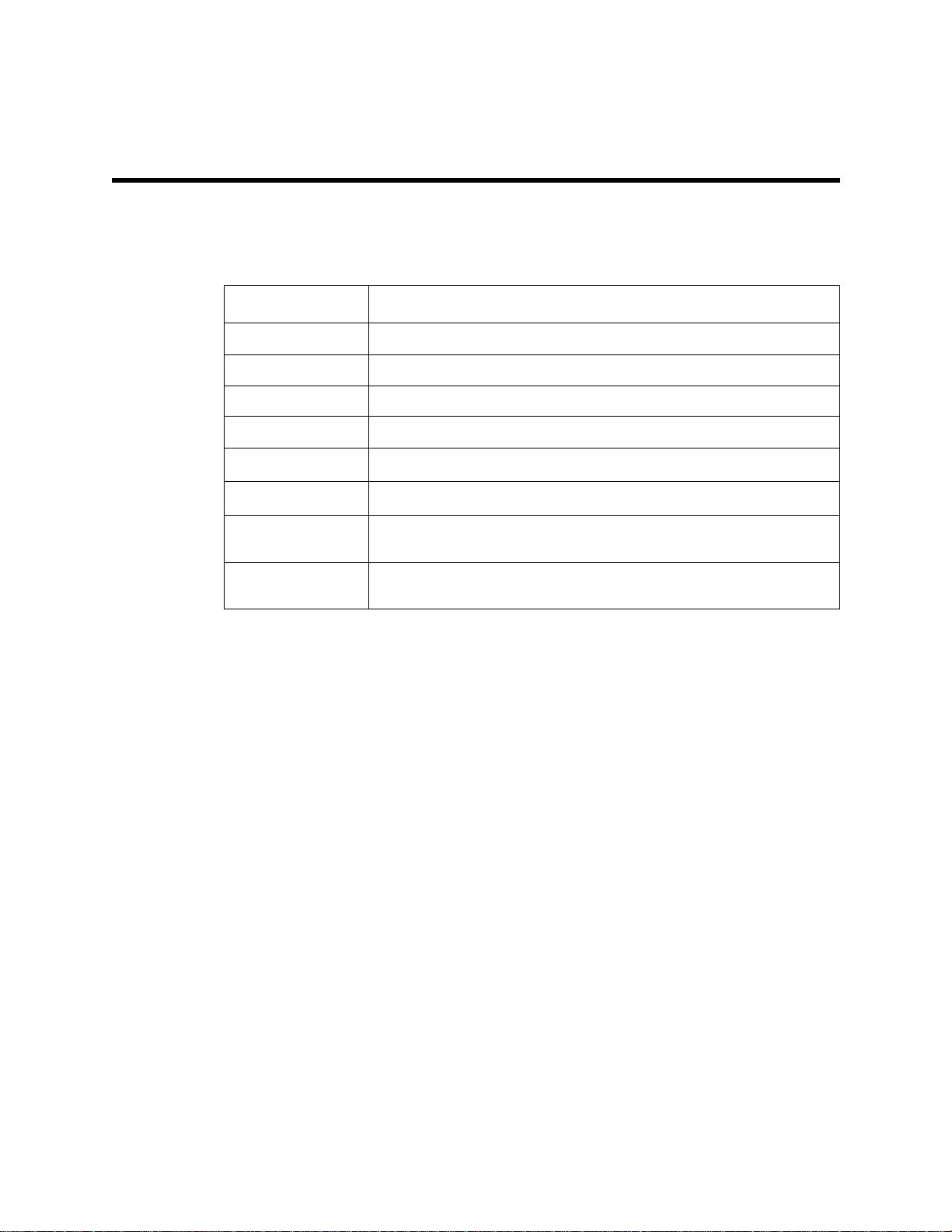

Table 1 lists specifications for the Sample Draw Aspirator Adapter.

Table 1: Specifications

Applicable Detec t ors • 65-2423RK-0 5, H

• Consult RKI Instruments, Inc. for othe r detectors

Maximum Inlet Pressure 300 psi

Outlet Pressure to Aspirator 5 - 50 psi adjustable (determined by required flow rate)

Recommended Flow Rate 3 SCFH (standard cubic feet per hour)

S detector

2

30-0951RK-H2S Sample Draw Aspirato r Adapter • 3

Page 4

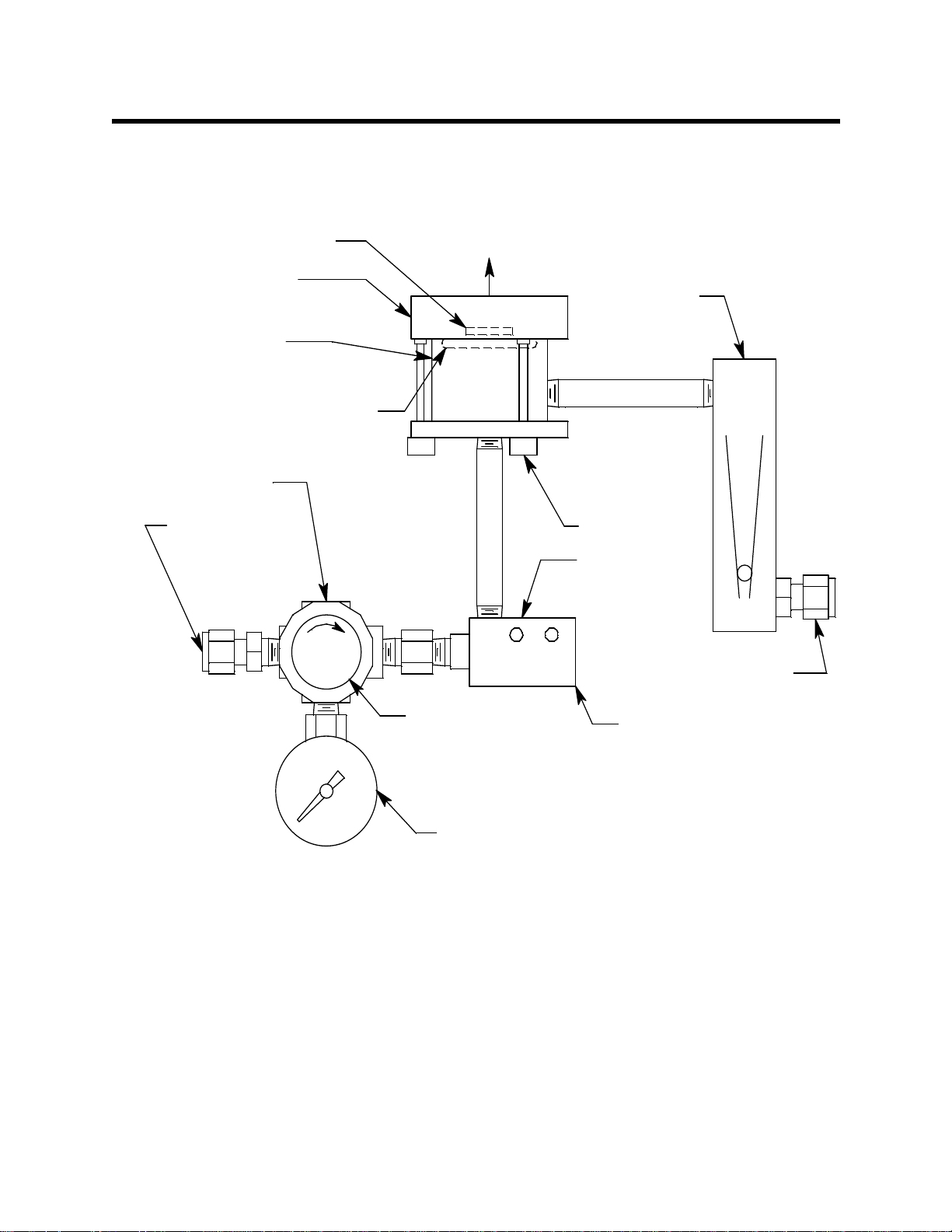

Description

Adapter Gasket (in

bottom of ad apter)

Sensor Adapter

Sensor Chamber

Pressure Regul ator

The sample draw aspirator adapter uses compressed air flowing through a venturi to

draw air into a sa mple chamber. The sample draw adapter screws directly onto the gas

detector.

Screw Onto Combustible

Sensor

Flowmeter

Chamber O-ring (in top of

chamber)

1/4 O.D. Tube

Compr essed Ai r

Inle t Fitting

The sample draw adapter consists of four major components (see Figure 1): the regulator,

aspirator, detector adapter, detector chamber, and flowmeter.

Regulator

Thumbscrew(3X)

As pi r ator

+

-

Pressure Adj ustment

Knob

Pressue Gauge

1/4 O.D. Tube Sample

Aspirator/Sa mple

Exhaust

(1/8 NPT female)

Inle t Fitting

Figure 1: Component Location

The regulator has an inlet port on its left side with a 1/4” tube fitting. The maximum

allowable inlet pressure is 300 psi. A gauge at the bottom of the regulator indicates the

output pressure. The output pressure, and detector flow, can be adjusted using the knob

on the front of the regulator. The detector flow rise s or fal ls a s the o utput pressure is

increased or decreased.

4 • 30-0951RK-H2S Samp le Draw Aspirator Adapter

Page 5

Aspirator

The aspirator inlet is connected to the output port on the right side of the regulator and

the vacuum port on top is connected to the detector chamber. It has a venturi tube inside

it which generates a vacuum at its top port when compressed air flows through it. The

compressed air and the air drawn from the detector chamber into the top port of the

aspirator both exhaust at the right side of the aspirator.

Detector Adapter

The detector adapter screws directly onto the H2S detector. It is inst alle d han d ti ght . I t ha s

an o-ring inside it which seals against the detector. When removing this adapter to change

the detector, be sure not to lose this o-ring.

Detector Chamber

The chamber has three thumbscrews which fasten it to the detector adapter. An o-ring at

the top of the chamber seals the chamber/adapter interface. The inlet of the chamber is on

the right side and is connected to the exhaust of the flowmeter. The exhaust of the

chamber is at the bottom and is connected to the vacuum port of the aspirator.

Flowmeter

The flowmeter indicates the flow to the detector. It has a 1/4” tube fitting at its inlet port

and its exhaust port is connected to the detector chamber. The flowmeter’s indication

range is 1 - 10 SCF H. I t has no flow adj ustm ent v alv e bec ause the fl owra te is con tr o lle d by

the regulator.

Installation

8.20 max

9.50 max

Scre wOntoCombustibleSensor

+

-

1/4O.D.TubeCom pressedAir Inlet

Fitting

1/4 O.D.Tube Sample

Inlet Fitting

Aspirator/Sampl e

Exhaust

(1/8 NPTfemale)

4.00 max

1.25

Figure 2: Outline & Mounting Dimensions

30-0951RK-H2S Sample Draw Aspirato r Adapter • 5

Page 6

1. Install and startup the detector head as described in the detector head operator’s

manual. Make sure there is sufficient room between the detector and the mounting

surface to install the sample draw adapter.

2. The sample draw adapter is no rmally shipped installed to the detector. If not, screw

the detector adapter onto the detector tightening firmly by hand and then attach the

chamber (with the regulator, aspirator and flowmeter attached) onto the detector

adapter with the three captive thumbscrews.

CAUTION: Make sure the detector adapter is installed tightly and after installation is complete

verify that the detector adapter is still tightened firmly onto the d etect or t o avoid

possible leaks.

3. Connect a sample line from the area to be sampled to the inlet fitting on the

flowmeter. The fitting accepts 1/4” OD rigid metal tubing. Stainless steel tubing is

recommended for the inlet line on the H

4. The aspirator exhaust includes the sample air. It m ay be routed to a different area

where it can be exhausted safely by installing a tube fitting in the exhaust port of the

aspirator and running tubing to the “safe” area from this port. The port has 1/8 NPT

female threads.

5. T urn the r egulator adjustment knob completely counterclockwise and then turn it one

turn clockwise so that the flow will start out at a low level when the compressed air is

connected and turned on.

S sample draw adapter

2

Calibration

6. Connect a compressed air source up to a maximum of 300 psi to the inlet of the

regulator . The r egulator is only rated up to 300 PSI inlet pressure. Adjust the regulator

adjustment knob so that the f lowmeter indicates 3 SCFH. The regulator exhaust

pressure indicated by the regulator gauge will vary for a particular flow depending

on the length of the sample line and other restrictions such as filters. Typically the

pressure will be between 5 and 10 psi for short sample runs. It will be higher for

longer sample runs and if filters are used.

7. Calibrate the detector head as described below.

NOTE: Calibrate the detector head with the sample draw adapter installed to insure an

accurate reading.

1. Follow the instructions in the detector head operato r’s manual for setting the zero

reading and making span adjustments.

2. When introducing gas to the detector, fill a gas sample bag with a regulator or

dispensing valve. See “Parts List” on page 7 for available parts.

NOTE: A gas bag is recommended for calibration instead of a demand flow regulator because a

demand flow regulator introduces enough flow restriction to significantly reduce the

flow. If a demand flow regulator is used, the flow will have to be adjusted up to 3 SCFH

while the regulator is connected during calibration and down to 3 SCFH after calibration.

3. Connect the sample bag tubing to the inlet of the flowmete r.

4. Allow the sample draw adapter to draw sample for 2 minutes and then make any

6 • 30-0951RK-H2S Samp le Draw Aspirator Adapter

Page 7

Parts List

calibration adjustments necessary.

5. Disconnect the sample bag from the flowmet e r inlet.

Table 2 lists replacement parts and accessories for the sample draw adapter.

Table 2: Parts List

Part Number Description

06-1248RK Tubing, 3/16 x 5/16, polyuret hane, for calibration kit

07-7218RK O-ring, 0.987 ID x .103, buna, for detector adapter

07-7225RK O-ring, 1.243 ID x .139, buna, for detector chamber

13-1070RK Captive panel screw, 10-32 x 1.75

81-0151RK-02 Gas cylinder, 25 PPM H

81-0151RK-04 Gas cylinder, 25 PPM H

S in nitrogen, 58 liter, aluminum

2

S in nitrogen, 34 liter, aluminum

2

81-1051RK-60 Regulator with gauge and knob, 6 LPM, for 34 liter and 58 liter

aluminum cylinders

81-1127RK Gas bag with fittings and hosebarb, 12 inches x 12 inches, 5 liters,

tedlar

30-0951RK-H2S Sample Draw Aspirato r Adapter • 7

Loading...

Loading...