Page 1

M

-

G

r

RKC INSTRUMENT INC.

®

PROFIBUS Communication

Converte

CO

J

[For SRZ]

Instruction Manual

IMR01Y35-E3

Page 2

SIMATIC® is registered trademarks of SIEMENS AG.

Modbus is a registered trademark of Schneider Electric.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright © 2006, RKC INSTRUMENT INC.

Page 3

t

Thank you for purchasing this RKC product. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place the manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMS01Y35-E3

i-1

Page 4

CAUTION

This product is intended for use with industrial machines, test and measuring equipment.

(It is not designed for use with medical equipment and nuclear energy.)

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take additional measures.

This instrument is protected from electric shock by reinforced insulation. Provide reinforced

insulation between the wire for the input signal and the wires for instrument power supply,

source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the instrument or

equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock, instrument

failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure including

replacement of sensor, contactor or SSR, and all wiring must be completed before power is

turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines from

high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric shock,

fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

When high alarm with hold action/re-hold action is used for Event function, alarm does not turn

on while hold action is in operation. Take measures to prevent overheating which may occur if

the control device fails.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some components

have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in this

manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMS01Y35-E3

Page 5

CONTENTS

Page

1. OUTLINE ............................................................................ 1

1.1 Product Check ................................................................................................2

1.2 Model Code .................................................................................................... 2

1.3 Parts Description ............................................................................................3

2. HANDLING PROCEDURES............................................... 4

3. MOUNTING......................................................................... 5

3.1 Mounting Cautions..........................................................................................5

3.2 Dimensions.....................................................................................................6

3.3 DIN Rail Mounting ..........................................................................................6

3.4 Panel Mounting...............................................................................................7

4. WIRING............................................................................... 8

4.1 Wiring Cautions ..............................................................................................8

4.2 Terminal Configuration ...................................................................................9

4.3 Connection to PROFIBUS ............................................................................10

4.4 Connection to the Controllers .......................................................................12

4.5 Installation of Termination Resistor...............................................................13

5. SETTING........................................................................... 15

5.1 PROFIBUS Address Setting ......................................................................... 15

5.2 DIP Switch Setting ........................................................................................16

5.3 COM-JG Initial Setting .................................................................................. 17

5.4 Controller Address Auto Obtain Methods .....................................................19

6. PROFIBUS COMMUNICATION ....................................... 21

6.1 PROFIBUS System Configuration ................................................................21

6.2 PROFIBUS Communication Data .................................................................22

6.2.1 Data types and data length of communication data .......................................... 22

6.2.2 Static data request............................................................................................. 22

6.2.3 Dynamic data request .......................................................................................23

6.2.4 Registers assigned to PLC ................................................................................ 25

6.3 Processing of Numeric Data Values .............................................................27

IMS01Y35-E3 i-3

Page 6

Page

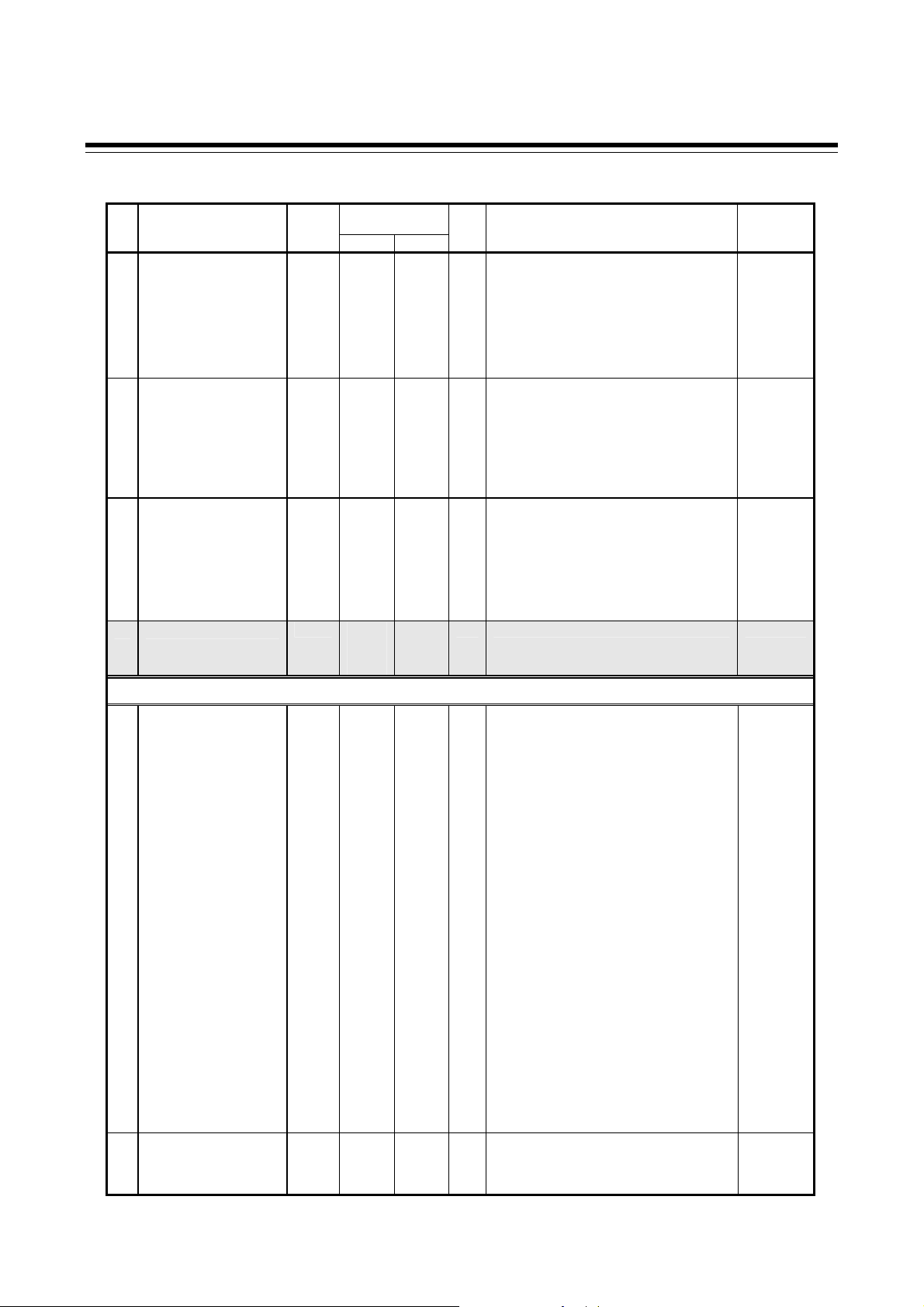

7. COMMUNICATION DATA MAP....................................... 28

7.1 Reference to Communication Data Map .......................................................28

7.2 Communication Data of Z-TIO Module .........................................................30

7.3 Memory Area Data of Z-TIO Module.............................................................51

7.4 Communication Data of Z-DIO Module......................................................... 53

7.5 COM-JG Initial Setting Items ........................................................................58

8. USAGE EXAMPLE........................................................... 60

8.1 Handling Procedures ....................................................................................60

8.2 System Configuration ...................................................................................61

8.3 Use Instruments Setting................................................................................62

8.4 Contents Check of COM-JG Initial Setting....................................................63

8.5 PLC Tool Setting...........................................................................................70

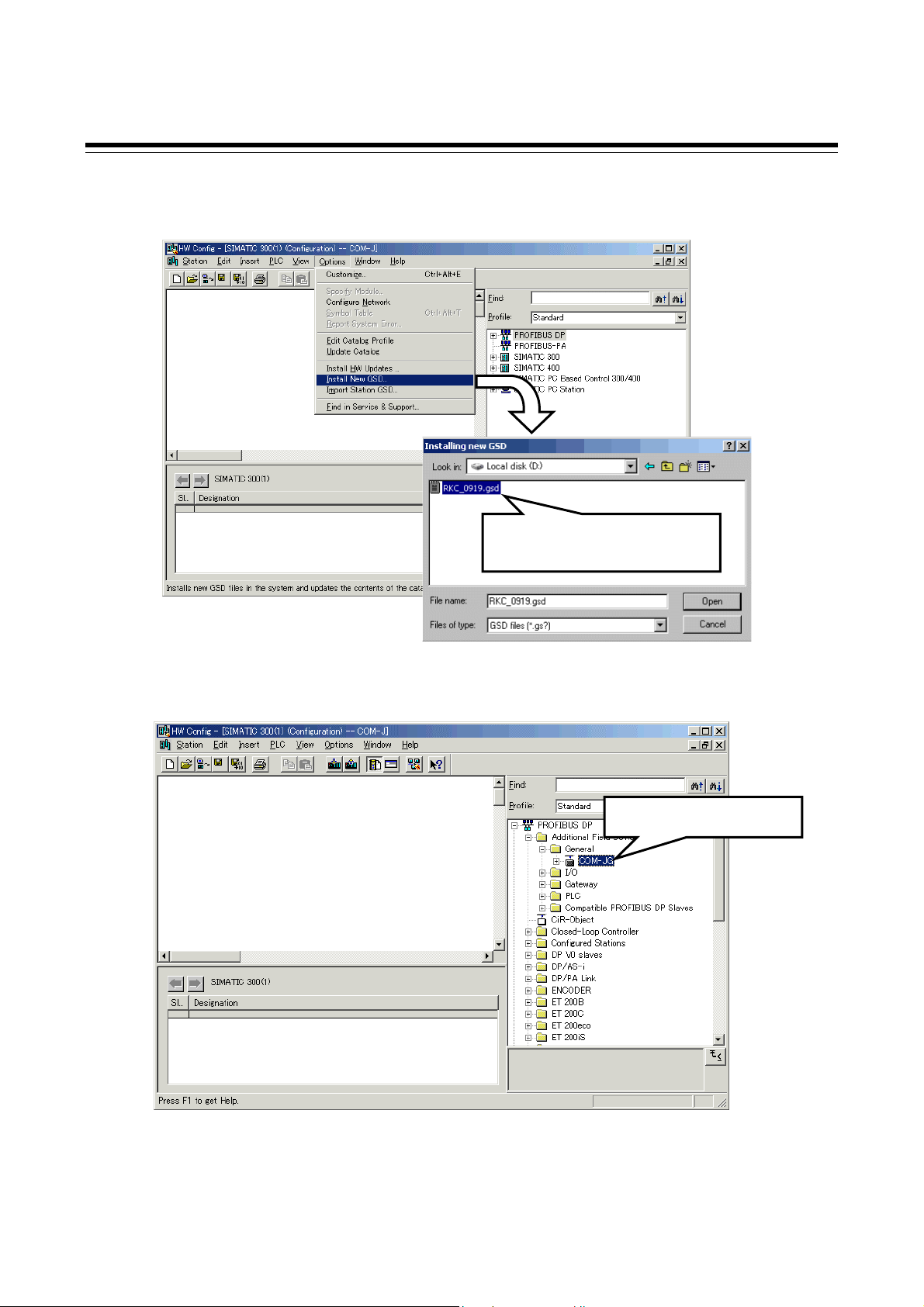

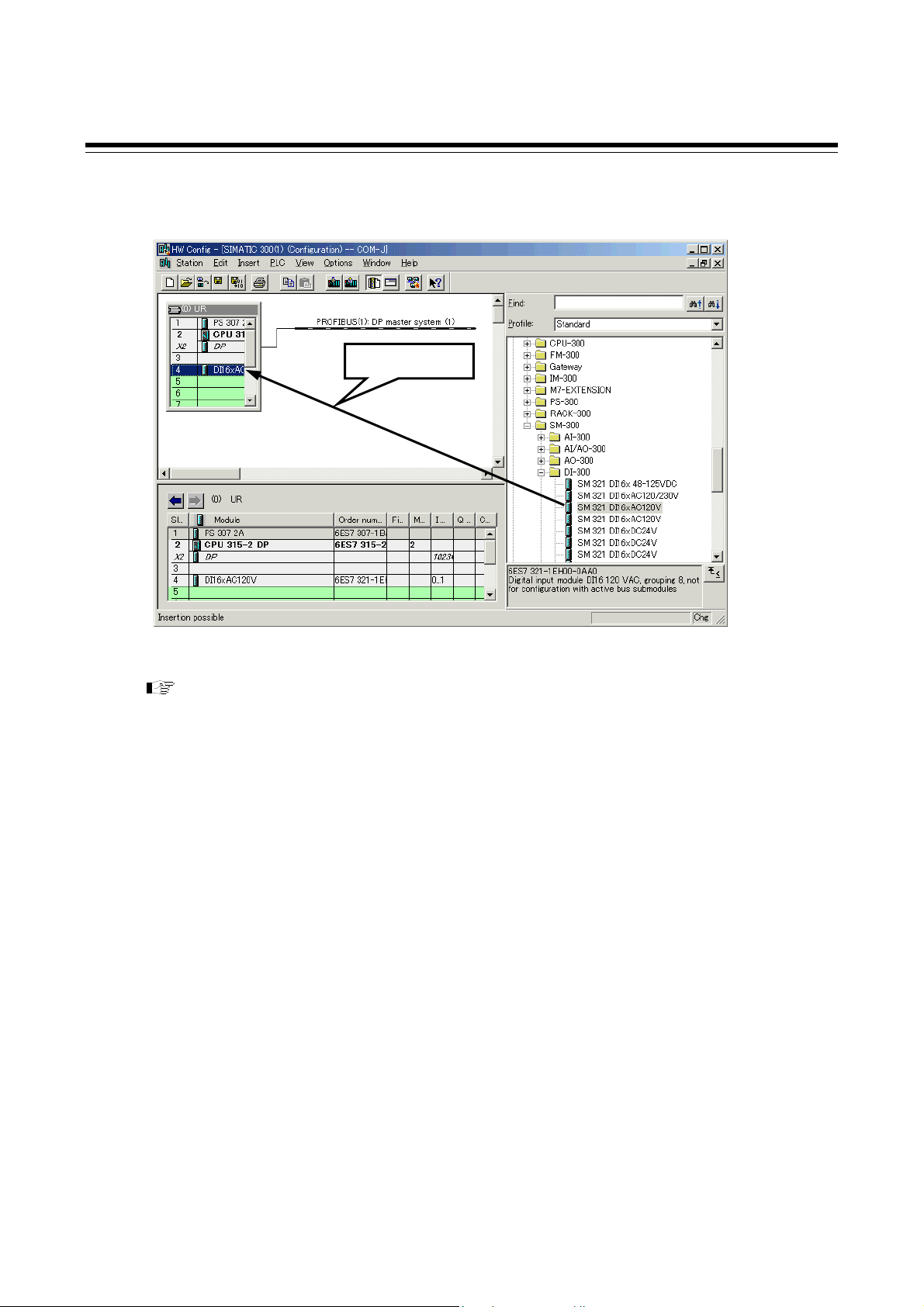

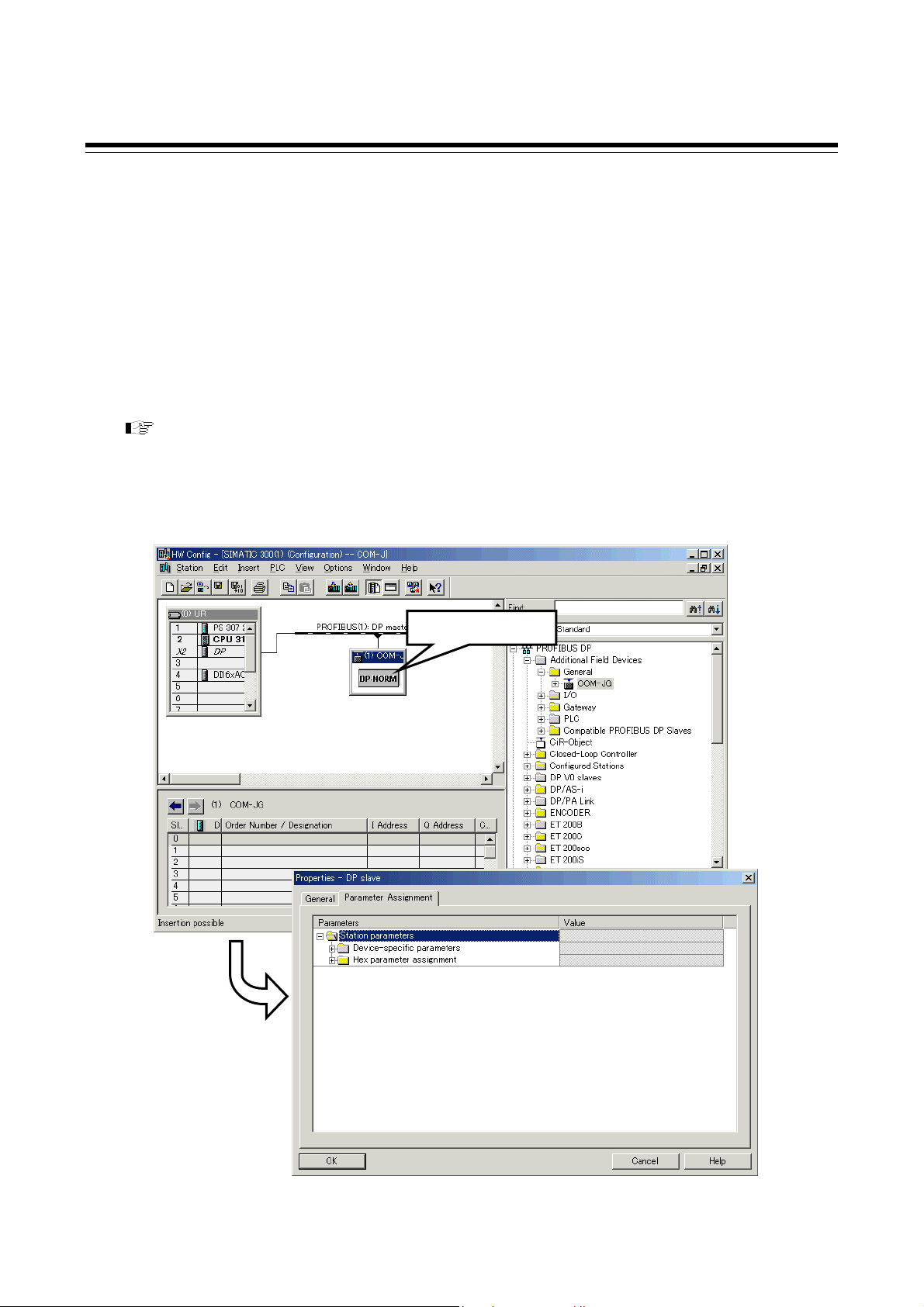

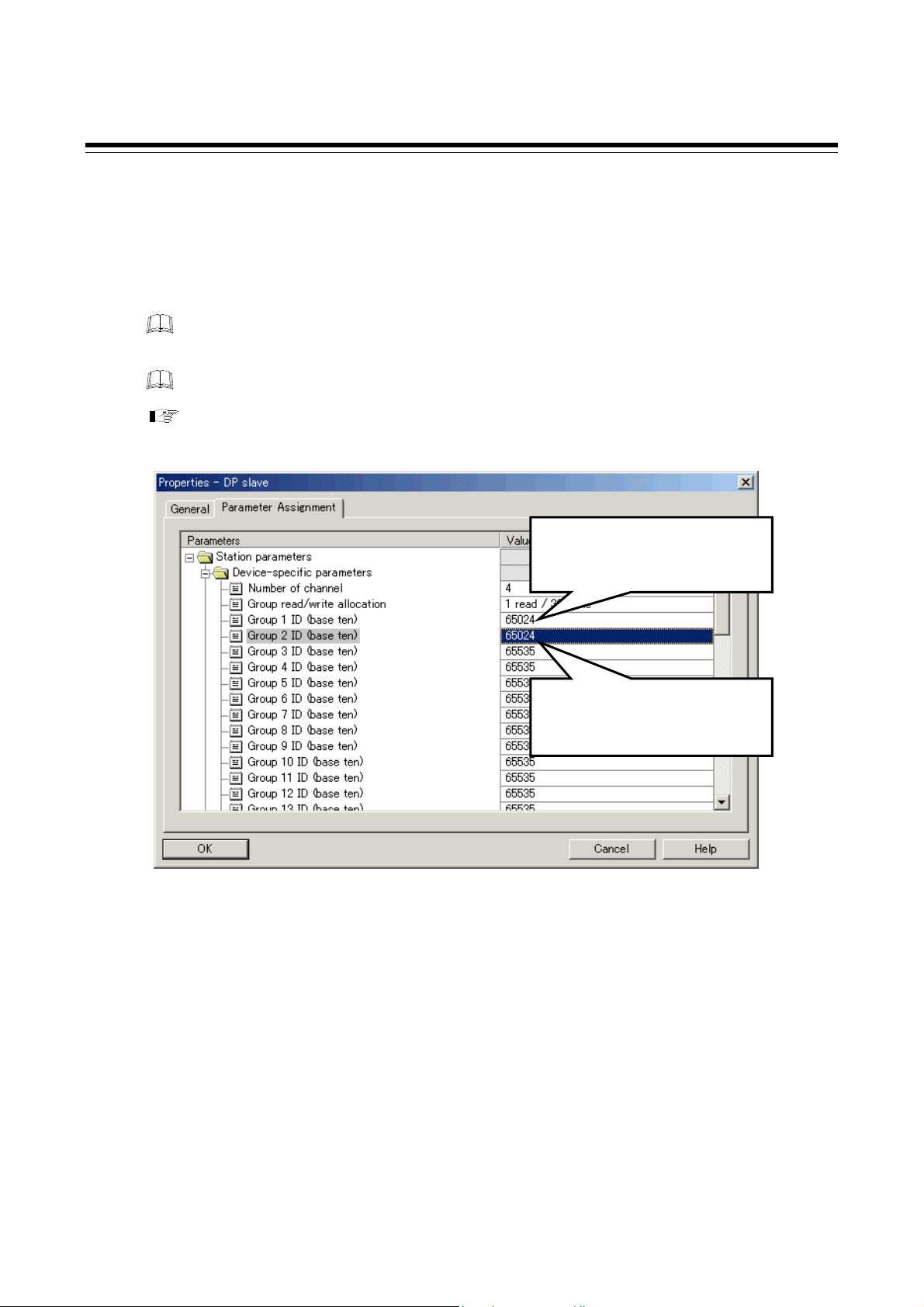

8.5.1 Setting procedures ............................................................................................ 70

8.5.2 General procedures........................................................................................... 73

8.5.3 COM-JG initial setting .......................................................................................83

8.5.4 Communication item setting ............................................................................ 102

9. TROUBLESHOOTING.................................................... 113

10. SPECIFICATIONS.......................................................... 116

i-4

IMS01Y35-E3

Page 7

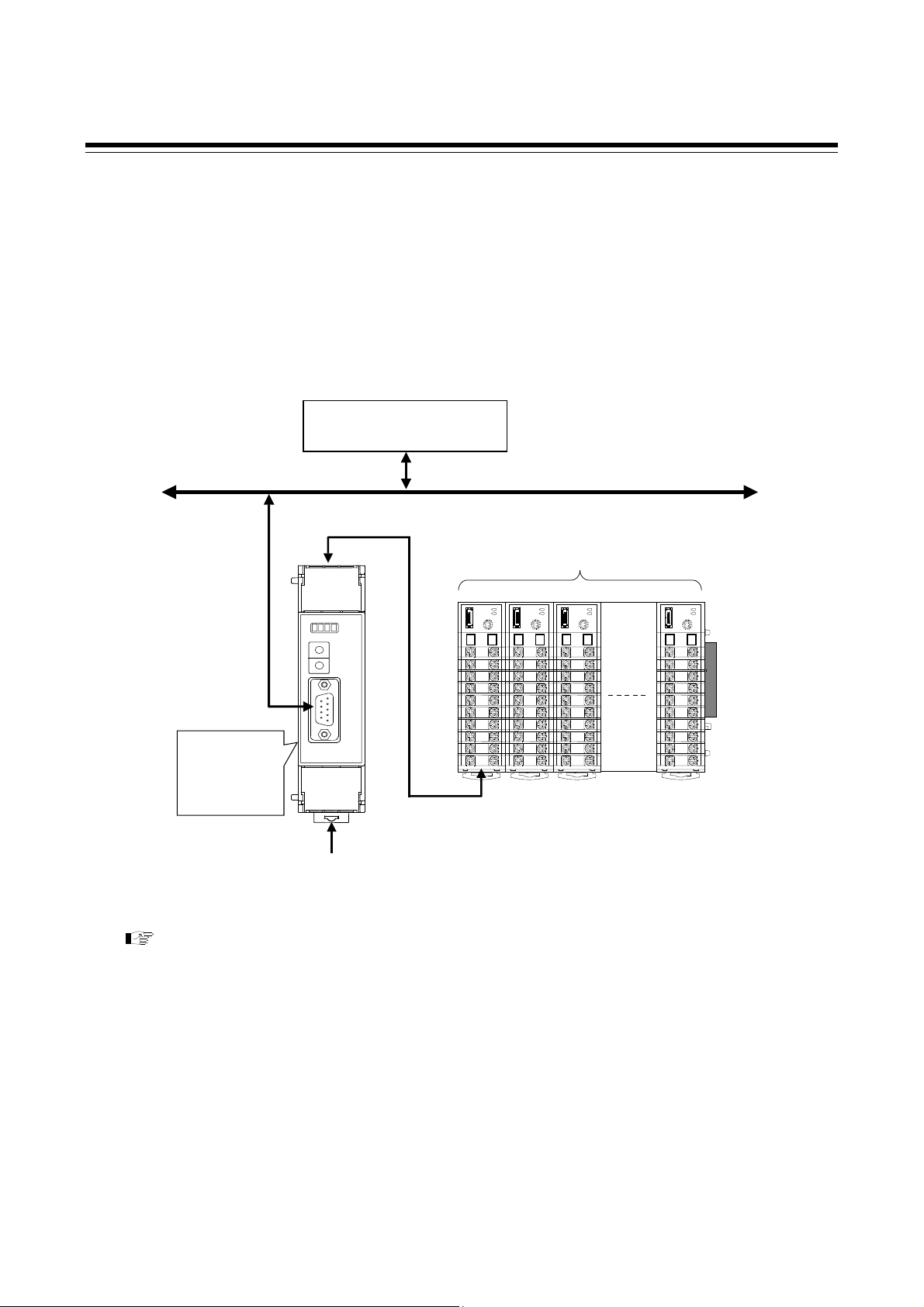

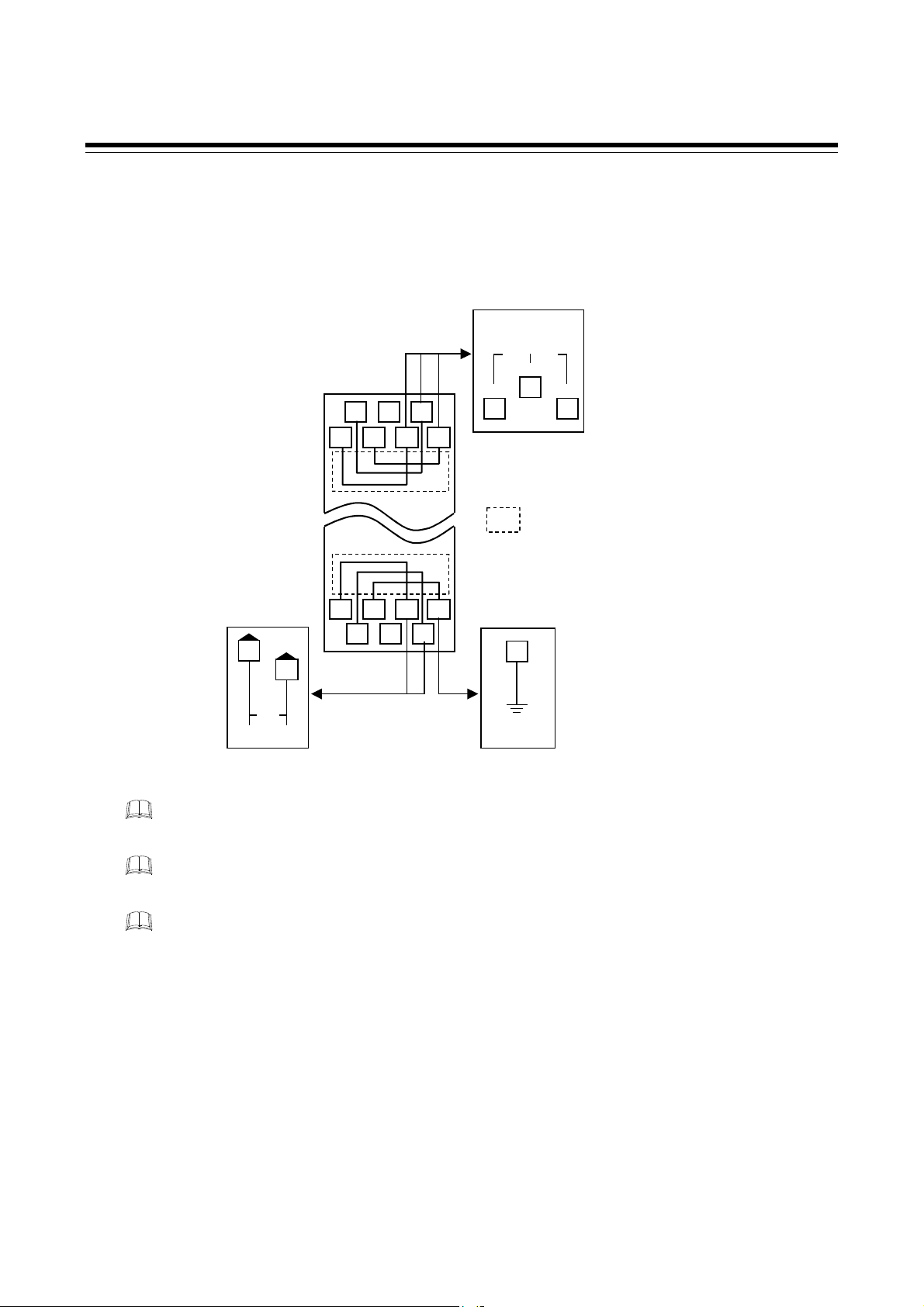

1. OUTLINE

This manual describes the communication specifications, mounting, wiring, setting and data

instructions for the PROFIBUS Communication Converter COM-JG [For SRZ].

PROFIBUS Communication Converter COM-JG [For SRZ] (hereafter called COM-JG) is

communication converter to connect the RKC module type controller SRZ to a programmable

controller (hereafter called PLC) for PROFIBUS.

The COM-JG supports PROFIBUS-DP protocol. This protocol includes master and slave. The PLC is

the master and the COM-JG is the slave.

Programmable controller

PLC (Master)

PROFIBUS-DP

SRZ unit

[Up to 31 modules]

PROFIBUS

communication

converter

COM-JG

(Slave)

Power supply (24 V DC)

(Z-TIO and Z-DIO module)

1 2 3 31

Controller communication

(RS-485: Modbus)

For PROFIBUS, refer to the website of PROFIBUS International.

URL: http://www.profibus.com/

IMR01Y35-E3 1

Page 8

1. OUTLINE

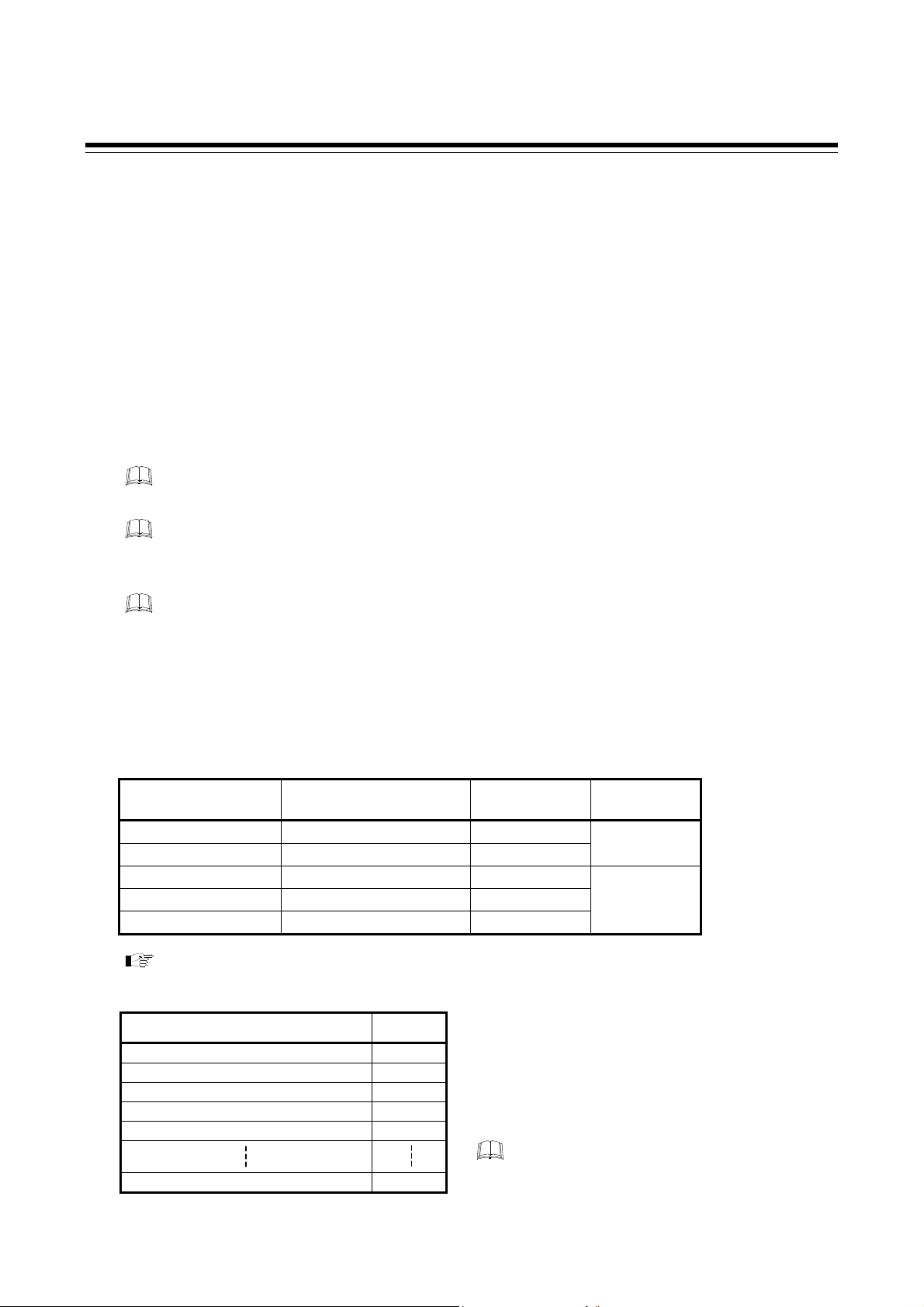

1.1 Product Check

Before using this product, check each of the following.

Model code

Check that there are no scratches or breakage in external appearance (case, front panel, terminal, etc).

Check that all of the accessories delivered are complete. (Refer to below)

COM-JG [For SRZ] Installation Manual

(IMR01Y23-E)

COM-JG [For SRZ] Quick Instruction Manual

(IMR01Y27-E)

COM-JG [For SRZ] Communication Data List

(IMR01Y31-E)

COM-JG [For SRZ] Instruction Manual

(IMR01Y35-E3)

Accessories Q’TY Remarks

1 Enclosed with instrument

1 Enclosed with instrument

1 Enclosed with instrument

This manual

1

(Download free or purchase hard copy)

GSD file * 1 Download free

If any of the products are missing, damaged, or if your manual is incomplete, please contact

RKC sales office or the agent.

* GSD file

The GSD file for COM-JG can be downloaded from the RKC official website.

(URL: http://www.rkcinst.com/english/download/field_network.htm)

1.2 Model Code

Check that the product received is correctly specified by referring to the following model code list:

If the product is not identical to the specifications, please contact RKC sales office or the agent.

COM- JG ∗ 02

Corresponding to the RKC controller

02: SRZ

2

IMR01Y35-E3

Page 9

r

t

X

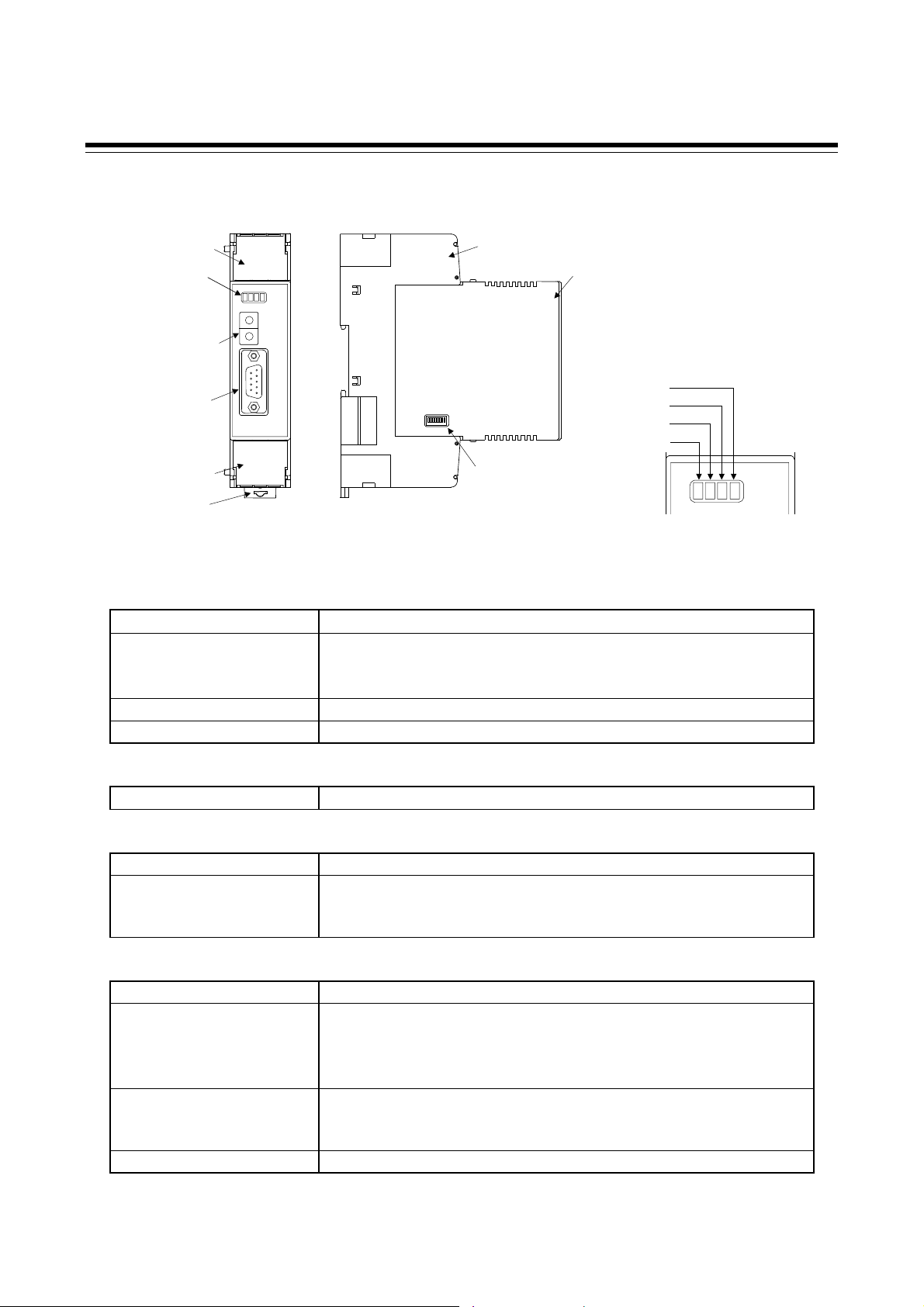

1.3 Parts Description

1. OUTLINE

Terminal cover

Indication

lamps

Address setting

switch

PROFIBUS

connector

(COM.PORT)

Terminal cove

Mounting

bracke

Front view

Indication lamps

FAIL [Red]

RUN [Green]

ONL [Green]

RX/TX [Green]

PROFIBUS connector

COM. PORT

Switches

Address setting switch

DIP switch

Others

Terminal cover

Mounting bracket

Terminal base

Mainframe

Terminal base

Mainframe

[Details of Indication lamps]

RX/T

ONL

RUN

FAIL

DIP switch

Left side view

• When instrument abnormally: Turns on

• When normally: Turns on

• Operation error: Flashes slowly

• During controller communication initialization: Flashes rapidly

During PROFIBUS connection establishment: Turns on

During PROFIBUS data send and receive: Flashes

Connector for PLC (Master) connection

Set the address for PROFIBUS

Set the communication speed for controller communication,

controller address auto obtain, and controller communication

enable/disable

Terminal covers above and below the COM-JG

• Used for the DIN rail mounting

• When panel mounted, two mounting brackets are required for the

upper and lower sides (one required for the upper side: separately

sold).

Part of the terminal and base of COM-JG

(There is the Termination resistor transfer switch in the inside of

terminal base)

Part of the mainframe of COM-JG

IMR01Y35-E3

3

Page 10

2. HANDLING PROCEDURES

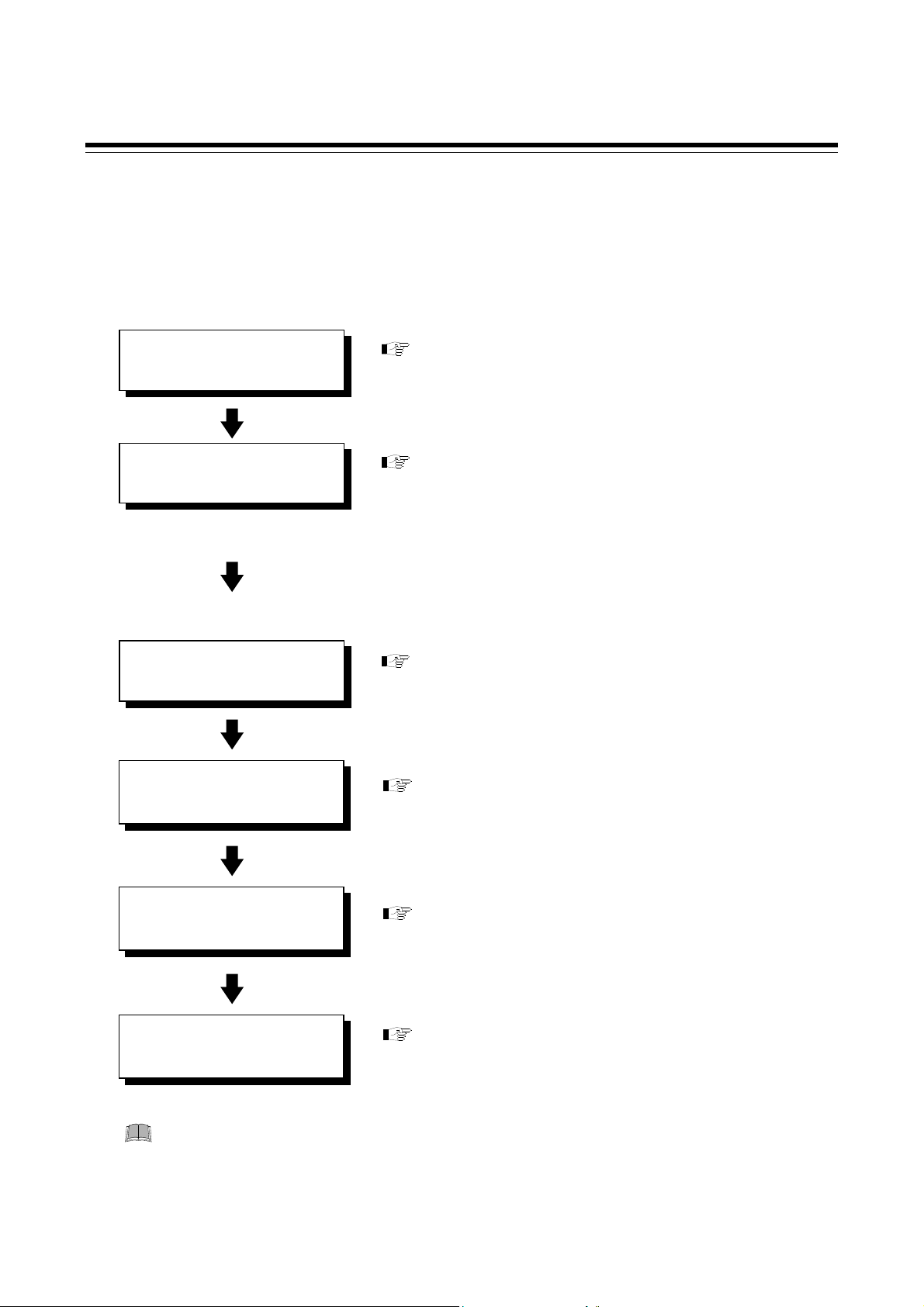

Conduct the setting necessary for performing communication in accordance with the following procedure.

COM-JG Setting

Mounting

Wiring

and

Connection

Controller (SRZ) Setting

COM-JG Initial Setting

Communication Data

Setting

To avoid error at operation start-up, COM-JG must be powered on LAST (after the

controller, PLC, etc.).

Set the PROFIBUS address and DIP switch setting of COM-JG.

Refer to 5. SETTING (P. 15)

Install the COM-JG.

• Refer to 3. MOUNTING (P. 5)

• For controller (SRZ), refer to Z-TIO INSTRUCTION

MANUAL (IMS01T01-E) or Z-DIO

INSTRUCTION MANUAL (IMS01T03-E)

Connect power supply wires to the COM-JG, and also connect

the COM-JG to the controller (SRZ) and the COM-JG to the

PLC, respectively.

• Refer to 4. WIRING (P. 8)

• For controller (SRZ), refer to Z-TIO INSTRUCTION

MANUAL (IMS01T01-E) or Z-DIO

INSTRUCTION MANUAL (IMS01T03-E)

Set communication parameters of controller (SRZ).

• Refer to 8.3 Use Instruments Setting (P. 62)

• Refer to Z-TIO Host Communication Quick Manual

(IMS01T02-E) or Z-DIO INSTRUCTION

MANUAL (IMS01T03-E)

Set initial setting of the COM-JG.

• Refer to 5.3 COM-JG Initial Setting (P. 17)

• Refer to 5.4 Controller Address Auto Obtain

Methods

• Refer to 8.4 Contents Check of COM-JG Initial

Setting (P. 63)

• Refer to 8.5 PLC Tool Setting (P. 70)

Set PLC programming software STEP7.

Refer to 8.5 PLC Tool Setting (P. 70)

(P. 19)

4 IMR01Y35-E3

Page 11

3. MOUNTING

This chapter describes installation environment, mounting cautions, dimensions and mounting

procedures.

To prevent electric shock or instrument failure, always turn off the power before

mounting or removing the instrument.

WARNING

!

3.1 Mounting Cautions

(1) This instrument is intended to be used under the following environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

• Allowable ambient temperature: −10 to +50 °C (14 to 122 °F)

• Allowable ambient humidity: 5 to 95 % RH

(Absolute humidity: MAX.W.C 29.3 g/m

• Installation environment conditions: Indoor use

Altitude up to 2000 m

(3) Avoid the following conditions when selecting the mounting location:

• Rapid changes in ambient temperature which may cause condensation.

• Corrosive or inflammable gases.

• Direct vibration or shock to the mainframe.

• Water, oil, chemicals, vapor or steam splashes.

• Excessive dust, salt or iron particles.

• Excessive induction noise, static electricity, magnetic fields or noise.

• Direct air flow from an air conditioner.

• Exposure to direct sunlight.

• Excessive heat accumulation.

(4) Mount this instrument in the panel considering the following conditions:

• Ensure at least 50 mm space on top and bottom of the instrument for maintenance and

environmental reasons.

• Do not mount this instrument directly above equipment that generates large amount of heat

(heaters, transformers, semi-conductor functional devices, large-wattage resistors).

• If the ambient temperature rises above 50 °C (122 °F), cool this instrument with a forced air fan,

cooler, etc. Cooled air should not blow directly on this instrument.

3

dry air at 101.3 kPa)

• In order to improve safety and the immunity to withstand noise, mount this instrument as far

away as possible from high voltage equipment, power lines, and rotating machinery.

High voltage equipment: Do not mount within the same panel.

Power lines: Separate at least 200 mm.

Rotating machinery: Separate as far as possible.

(5) If this instrument is permanently connected to equipment, it is important to include a switch or

circuit-breaker into the installation. This should be in close proximity to the equipment and within

easy reach of the operator. It should be marked as the disconnecting device for the equipment.

IMR01Y35-E3 5

Page 12

3. MOUNTING

t

3.2 Dimensions

109.5 3

6.5

30

(Unit: mm)

125

5

78

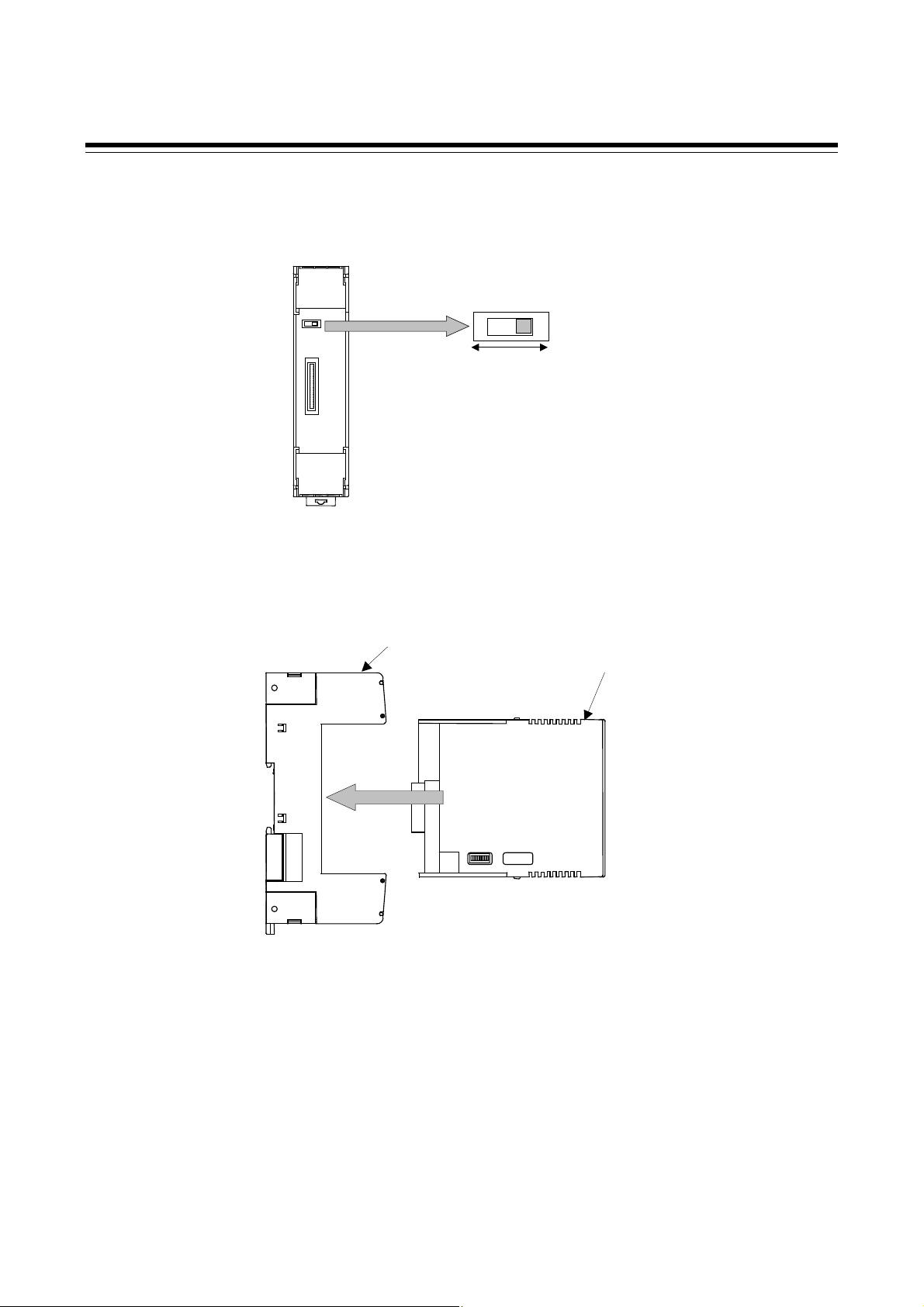

3.3 DIN Rail Mounting

Mounting procedures

1. Pull down the mounting bracket at the bottom of the instrument (A). Attach the hooks on the top

of the instrument to the DIN rail and push the lower section into place on the DIN rail (B).

2. Slide the mounting bracket up to secure the instrument to the DIN rail (C).

DIN rail

(B) Push

Mounting

bracke

6

(A) Pull down

(C) Locked

IMR01Y35-E3

Page 13

Removal procedures

1. Turn the power OFF.

2. Remove the wiring.

3. Pull down a mounting bracket with

a slotted screwdriver (A). Lift the

instrument from bottom, and take it

off (B).

3. MOUNTING

(B) Lift and take

off

(A) Pull down

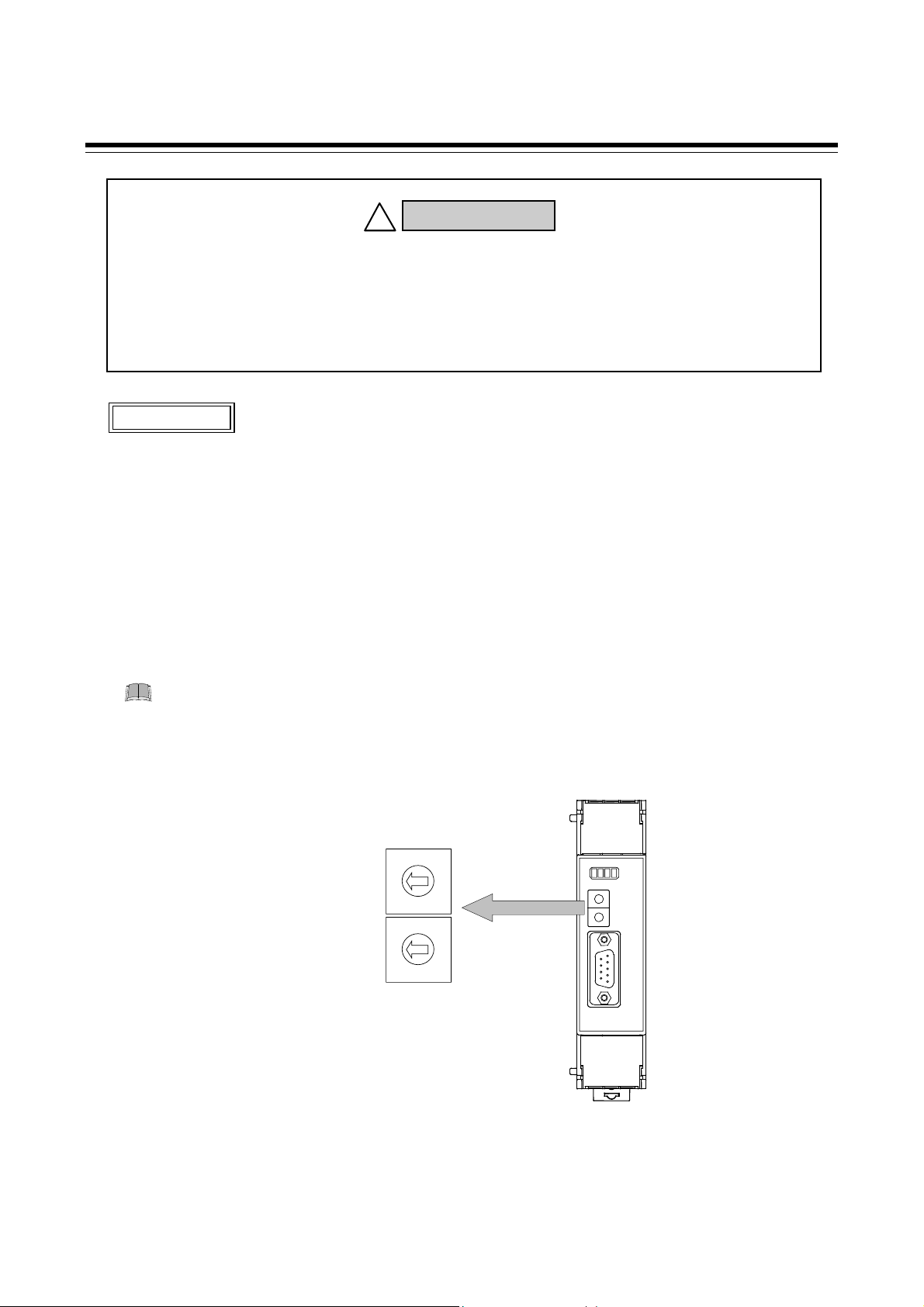

3.4 Panel Mounting

Mounting procedures

1. Pull down the mounting bracket (A) until locked and that a mounting hole appears.

2. Prepare one mounting bracket per instrument (B) sold separately (KSRX-55) and then insert it in

the rear of the terminal board at top of the instrument until locked but a mounting hole does not

disappear.

3. Mount each module directly on the panel with screws which are inserted in the mounting holes of

the top and bottom mounting brackets.

Recommended tightening torque: 0.3 N⋅m (3 kgf⋅cm)

The customer needs to provide the M3 size screws. Select the screw length that matches the

mounting panel.

(B) Insert

Mounting dimensions

(Unit: mm)

IMR01Y35-E3

Mounting bracket

(Sold separately)

(KSRX-55)

(A) Pull down

Mounting

holes

M3

130.5 ± 0.2

7

Page 14

4. WIRING

This chapter describes wiring cautions, terminal configuration and connections.

4.1 Wiring Cautions

To prevent electric shock or instrument failure, do not turn on the power until all

wiring is completed. Make sure that the wiring is correct before applying power

to the instrument.

• To avoid noise induction, keep communication signal wire away from instrument power line, load

lines and power lines of other electric equipment.

• If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise

filter.

− Shorten the distance between the twisted power supply wire pitches to achieve the most effective

noise reduction.

WARNING

!

− Always install the noise filter on a grounded panel. Minimize the wiring distance between the

noise filter output and the instrument power supply terminals to achieve the most effective noise

reduction.

− Do not connect fuses or switches to the noise filter output wiring as this will reduce the

effectiveness of the noise filter.

• Power supply wiring must be twisted and have a low voltage drop.

• For an instrument with 24 V power supply, supply power from a SELV circuit.

• A suitable power supply should be considered in end-use equipment. The power supply must be in

compliance with a limited-energy circuits (maximum available current of 8 A).

• Use the solderless terminal appropriate to the screw size (M3).

• Make sure that the any wiring such as solderless terminal is not in contact with the adjoining terminals.

5.9 mm or less

3.2 mm or more

Recommended tightening torque:

0.4 N⋅m (4 kgf⋅cm)

8 IMR01Y35-E3

Page 15

4.2 Terminal Configuration

The terminal layout is as follows.

Upper-side

terminal

3

7 6 5 4

2 1

Controller

communication

RS-485

T/R(A)

1

T/R(B)

5

SG

4

4. WIRING

: The part of internal wiring

Power supply

11 10 9 8

Ground

14 13 12

9

8

12

DC

−

+

24 V

Lower-side

terminal

FG

As controller communication terminal Nos. 1, 4 and 5 are internally connected to terminal Nos. 3,

6 and 7, any terminals can be used.

As ground and power supply terminal Nos. 8, 9 and 12 are internally connected to terminal Nos.

10, 11 and 14, any terminals can be used.

Terminal No. 2 and No. 13 is not used.

IMR01Y35-E3

9

Page 16

4. WIRING

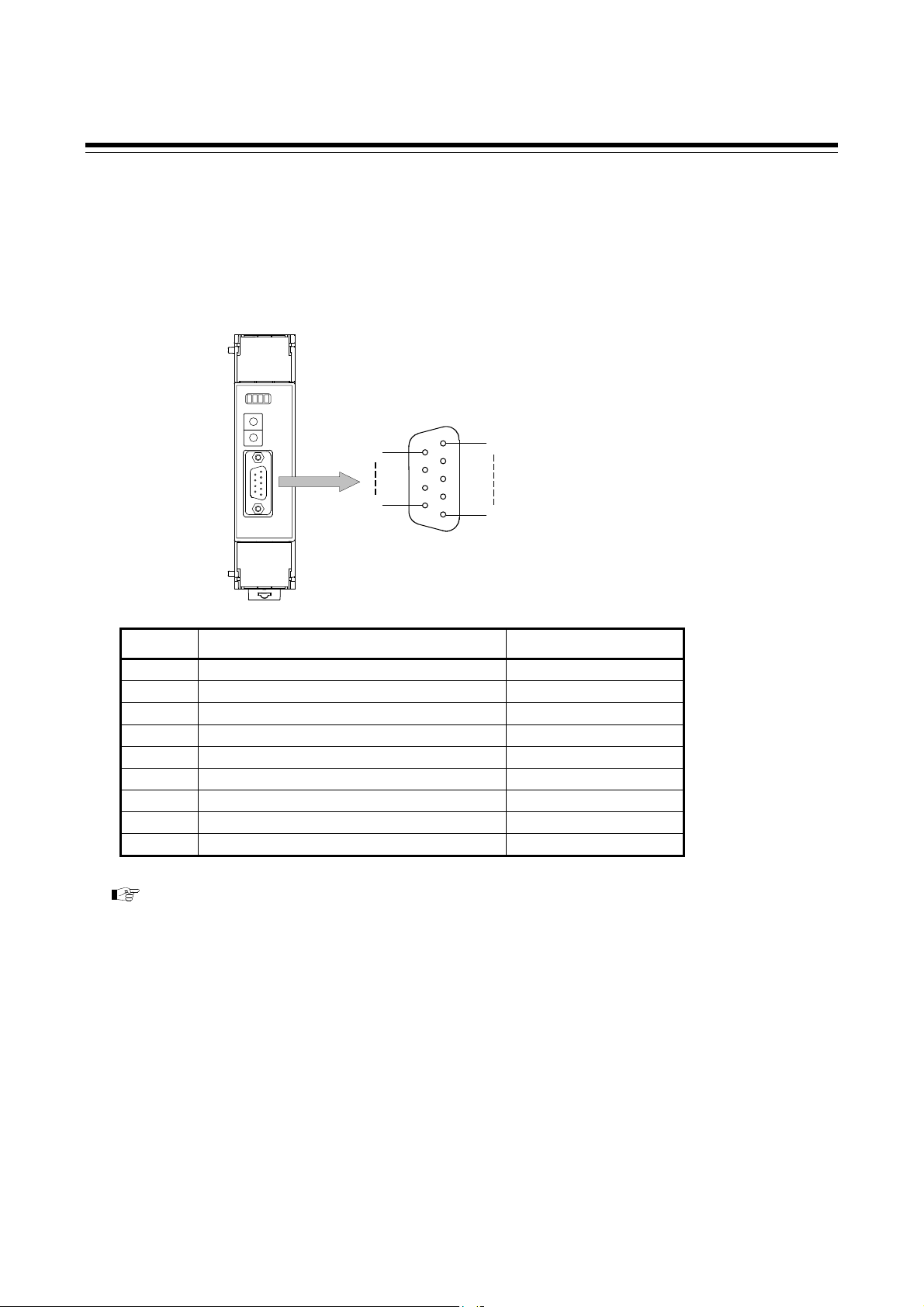

4.3 Connection to PROFIBUS

Connect COM-JG to PROFIBUS.

Pin layout of connector

COM-JG

PROFIBUS connector

(COM. PORT)

9

6

5

1

Pin No. Signal name Symbol

1

2

⎯

⎯

Unused

Unused

3 Receive data /Transmission data (plus) RxD/TxD-P

4

⎯

Unused

5 Signal ground DGND

6 Termination resistor supply voltage (5 V) VP

7

⎯

Unused

8 Receive data /Transmission data (negative) RxD/TxD-N

9

⎯

Unused

For the connectable connector of the PLC, refer to the instruction manual for the used PLC.

10

IMR01Y35-E3

Page 17

Ω

Ω

Ω

PROFIBUS cables

Use the PROFIBUS cable which fitted the following requirement.

• Use the shielded twisted pair wire

• Based on IEC61158, Standard (Recommend cable type A)

Cable type A specification

Impedance: 135 to 165 Ω

Capacitance: < 30 pF/m

Loop resistance: 110 Ω/km

Core diameter: 0.64 mm

Core cross section: > 0.34 mm

Maximum cable length by communication speed (For cable type A)

Communication speed (kbps)

Cable length (m)

2

9.6 19.2 93.75 187.5 500 1500 12000

1200 1200 1200 1000 400 200 100

4. WIRING

• Connect the termination resistor to the end of a bus (Refer to below)

Signal

RxD/TxD-P

RxD/TxD-N

DGND

VP

Termination resist or

390

220

390

Customer must provide the PROFIBUS cable (a connection cable of PLC and COM-JG).

As for the PROFIBUS cable, there is a case prepared by a PLC manufacturer.

The details except the above are connected to a website of PROFIBUS International, and

obtain necessary information.

URL: http://www.profibus.com/

IMR01Y35-E3

11

Page 18

4. WIRING

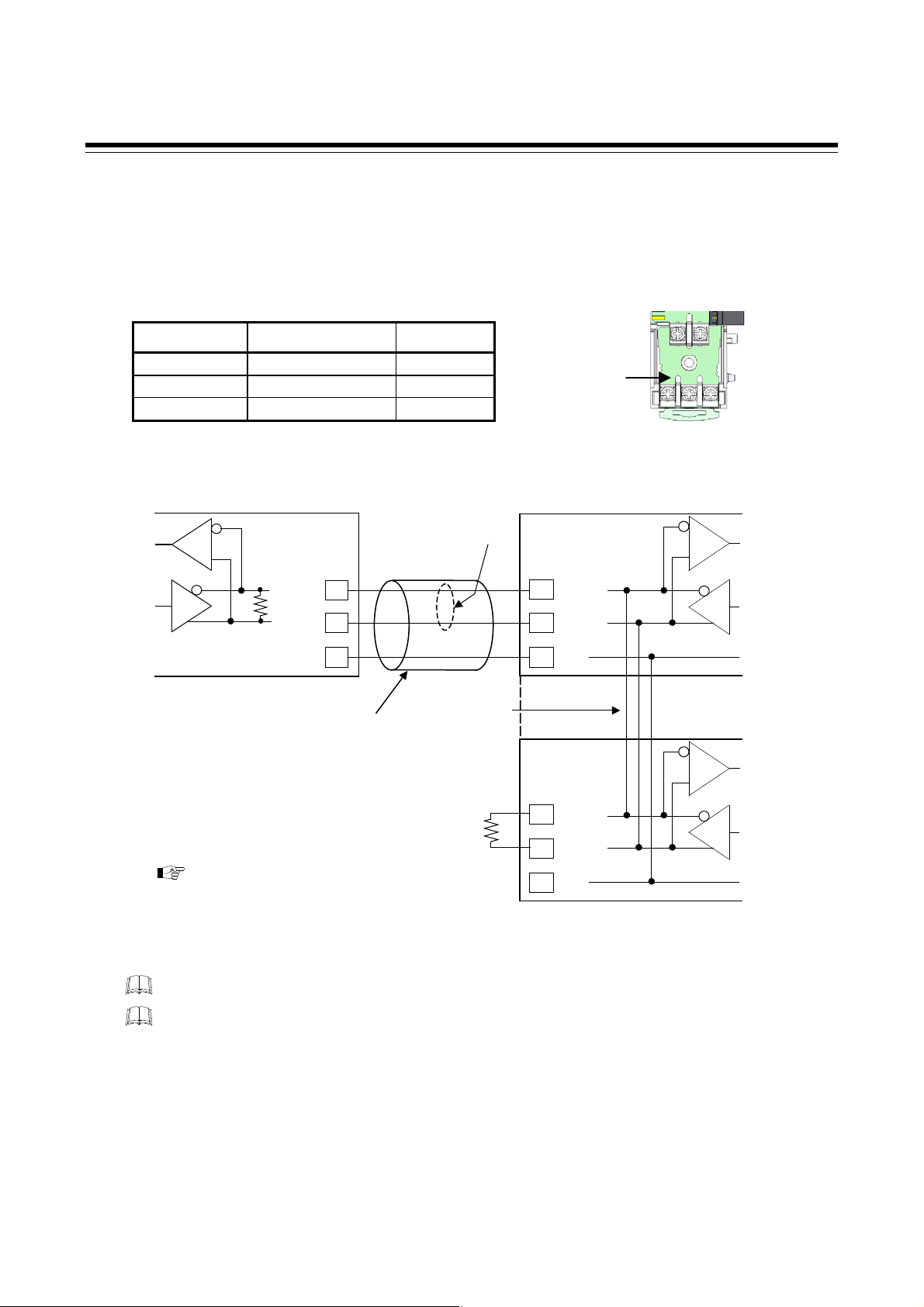

4.4 Connection to the Controllers

Conduct wiring between the COM-JG and controller (SRZ) as shown in the following.

SRZ (Z-TIO module/Z-DIO module) communication terminal number and

signal details

Terminal No. Signal name Symbol

3 Send/Receive data T/R (A)

4 Send/Receive data T/R (B)

5 Signal ground SG

Wiring

COM-JG

(−)

T/R (A)

RS-485

1

Paired

wire

Communication

terminal No.

Controller (SRZ)

Z-TIO module

3

T/R (A)

SRZ base section

2 1

3 4 5

(−)

(+)

R1: Internal termination resistor

(Example: 120 Ω 1/2 W)

R2: Termination resistor for external

connection (120 Ω 1/2 W)

T/R (B)

R1

Terminal block

Shielded twisted

5

SG

4

pair wire

For termination resistors, refer to

Connected by

the internal

communication

line

R2

4

T/R (B)

5

SG

Z-TIO module

3

T/R (A)

4

T/R (B)

5

SG

(+)

(−)

(+)

4.5 Installation of Termination

Resistor (P. 13)

Up to 16 Z-TIO modules can be connected.

The cable and termination resistor(s) must be provided by the customer.

A combined total of up to 31 Z-TIO and Z-DIO modules can be connected in the SRZ,

however, in some cases this may not be possible due to restrictions related to the number of

connected channels and communication items.

[ Refer to 6.2.1 Data type and data length of communication data (P. 22)]

12

IMR01Y35-E3

Page 19

4. WIRING

r

4.5 Installation of Termination Resistor

Procedure for setting a termination resistor to Controller communication (RS-485) and its setting

position are described in the following.

If communication errors occur frequently due to the operation environment or the

communication distance, connect termination resistors.

Termination resistor setting position

If the COM-JG is connected to the extreme end of the communication line, install one termination

resistor each to the COM-JG and the controller (module of the SRZ) located most distantly from the

COM-JG.

Termination

resistor ON

(Factory

set value)

COM-JG

Z-TIO or Z-DIO module

Internal communication line

Controller communication

(RS-485: Modbus)

Setting procedure of termination resistor (COM-JG)

SRZ unit

Connect a termination

resistor to the terminals

from exterior.

(RS-485)

Termination resisto

As the COM-JG is internally provided with a selector switch for choosing the ON/OFF of a

termination resistor, it is not required to externally install the termination resistor.

(Factory set value: Termination resistor connected)

1. Turn off the power supply of the COM-JG.

Do not separate the mainframe from terminal base with the power turned on. If so,

instrument failure may result.

2. Pull out the mainframe itself toward you while pushing the locks at its top and bottom (1), and

then separate it from the terminal base (2).

Upper-side

lock

Lower-side

lock

Top view

Bottom view

Terminal base

Removing the module mainframe

Mainframe

(1) Push

(2) Pull out

(1) Push

IMR01Y35-E3

13

Page 20

4. WIRING

3. Turn on the Termination resistor transfer switch in the terminal base.

The COM-JG is shipped from the factory with the selector switch set to “ON: Termination

resistor connected.”

Termination resistor

transfer switch

ON

OFF

Termination

resistor

OFF

Termination

resistor

ON

(120 Ω 1/2 W)

Factory set value

: ON

A terminal base of the state which removed module mainframe

4. Push the mainframe thus separated in the terminal base until firmly locked.

Terminal base

Mainframe

Push the module

mainframe until

firmly locked

14

Mounting the module mainframe

IMR01Y35-E3

Page 21

5. SETTING

WARNING

!

To prevent electric shock or instrument failure, always turn off the power

before setting the switch.

To prevent electric shock or instrument failure, never touch any section other

than those instructed in this manual.

CAUTION

Do not separate the mainframe from the terminal base with the power turned on.

If so, instrument failure may result.

5.1 PROFIBUS Address Setting

The master communicates with the selected slave by specifying that slave’s address number. Each

slave must have a unique address number for this data transmission. Set the slave address with the

address setting switch prior to operation.

With the tow rotary switch in the front of the COM-JG, set an address number on the PROFIBUS. For

this setting, use a small slotted screwdriver.

No communication with PROFIBUS can be conducted with each factory set value (00h)

left as it is. Set it to the same value as the PROFIBUS address set when system

configured.

High-order digit

setting

(Set value × 10h)

Low-order digit

setting

(Set value × 1h)

Address setting switch

4

5

6

3

7

2

8

1

9

0

A

F

B

E

D

C

4

5

6

3

7

2

8

1

9

0

A

F

B

E

D

C

COM-JG

Setting range:

1 to 125 [01h to 7Dh: hexadecimal]

(Factory set value: 00h)

IMR01Y35-E3 15

Page 22

5. SETTING

5.2 DIP Switch Setting

Configure settings for controller communication speed, controller address auto obtain, and controller

communication enable/disable using the DIP switches on the left side of the mainframe.

DIP switch

ON

12345678

12345678

ON

OFF

Left side view

1 2 Controller communication speed

OFF OFF 38400 bps

ON OFF 9600 bps

OFF ON 19200 bps

ON ON 38400 bps

Factory set value: 19200 bps

4 Controller address auto obtain

OFF

ON

Factory set value: Auto obtain off

(No controller address search when power is turned on)

(Controller address search and update when power is turned on)

Refer to 5.4 Controller Address Auto Obtain Methods (P. 19).

Auto obtain off

Auto obtain on

7 Controller communication enabled/disabled

OFF

ON

(When COM-JG initial settings are configured using PLC tool)

Controller communication enabled

Controller communication disabled

16

Factory set value: Controller communication enabled

Refer to 5.3 COM-JG Initial Setting (P. 17).

3 5 6 8

OFF OFF OFF OFF

(Do not change the factory set value)

Fixed

Dip switch No. 3, 5, 6 and 8 must be always OFF. Do not set to ON.

IMR01Y35-E3

Page 23

5. SETTING

5.3 COM-JG Initial Setting

To perform communication between a PLC and controller (SRZ), the following items must be set to

COM-JG. These settings are configured using the configuration tool of the PLC.

Preparations and an overview of the settings are explained below.

[COM-JG initial setting items]

• Controller address

• Number of continuous accesses

• Continuous accesses enable selection

• Static data read/write range

• Transmission wait time of controller communication

For the concrete setting method of using the PLC configuration tool, refer to 8.5 PLC Tool

Setting (P. 70).

Setting preparations

To configure the COM-JG initial setting items, controller communication must be disabled using the

DIP switches.

Change DIP switch No. 7 to ON (controller communication disabled) on the left side of the COM-JG.

DIP switch

ON

1234567 8

1234567 8

ON

OFF

ON: Controller communication

disabled

When you have completed the initial settings of the COM-JG, be sure to return DIP switch

No. 7 to OFF (controller communication enabled).

Setting overview

• Controller address (required setting)

This is required in order to make the COM-JG recognize the address of each controller (SRZ

module). Controller addresses can be obtained automatically by switching DIP switch No. 4.

For controller address auto obtain, refer to 5.4 Controller Address Auto Obtain

Methods (P. 19).

IMR01Y35-E3

17

Page 24

5. SETTING

• Number of continuous accesses (elective setting)

Each module in the controller (SRZ) has multiple channels, and thus in the case of a 4-channel

type Z-TIO module, four data areas (data parameters) must be retained for each communication

item. However, the number of continuous accesses setting can be configured to allow

communication with just one data area (data parameter) per communication item regardless of the

number of channel.

In a static data request, a combined total of up to 40 read and write items can be

communicated.

The factory set value for the number of continuous accesses is “4,” and thus when the

controller (SRZ) configuration consists only of 4-channel type Z-TIO modules, the

setting does not need to be configured.

For information on the number of continuous accesses, refer to also Number of

continuous accesses (P. 65) in 8.4 Contents Check of COM-JG Initial Setting.

• Continuous accesses enable selection (elective setting)

When the communication items of a static data request contain both channel-based data and

module-based data, the number of continuous accesses setting must be disabled for module-based

.

data

When only channel-based data is communicated, this setting is not necessary.

For information on the continuous accesses enable selection, refer to also Continuous

accesses enable selection (P. 66) in 8.4 Contents Check of COM-JG Initial Setting.

• Static data read range (elective setting)

When a communication item is specified in a static data request, a read or write request is

normally sent to the same Modbus register address of all connected controllers (each module of

the SRZ).

For example, when a Z-TIO module and a Z-DIO module of an SRZ are connected and a

communication item of the Z-TIO module is read, the data of the same Modbus register address

in the Z-DIO module as the communication item specified in the Z-TIO module is read. However,

because the contents of the Modbus register addresses of the Z-TIO module and the Z-DIO

module are different, different data is read from each.

To avoid having unnecessary data read, the range of data that can be communicated for the same

module type can be assigned.

This setting is not necessary when the controller consists only of modules that are the

same type.

For information on the static data read range, refer to also Static data read/write

range (P. 68) in 8.4 Contents Check of COM-JG Initial Setting.

• Static data write range (elective setting)

Same as the static data read range.

• Transmission wait time of controller communication (elective setting)

This setting is normally not necessary.

18

IMR01Y35-E3

Page 25

5. SETTING

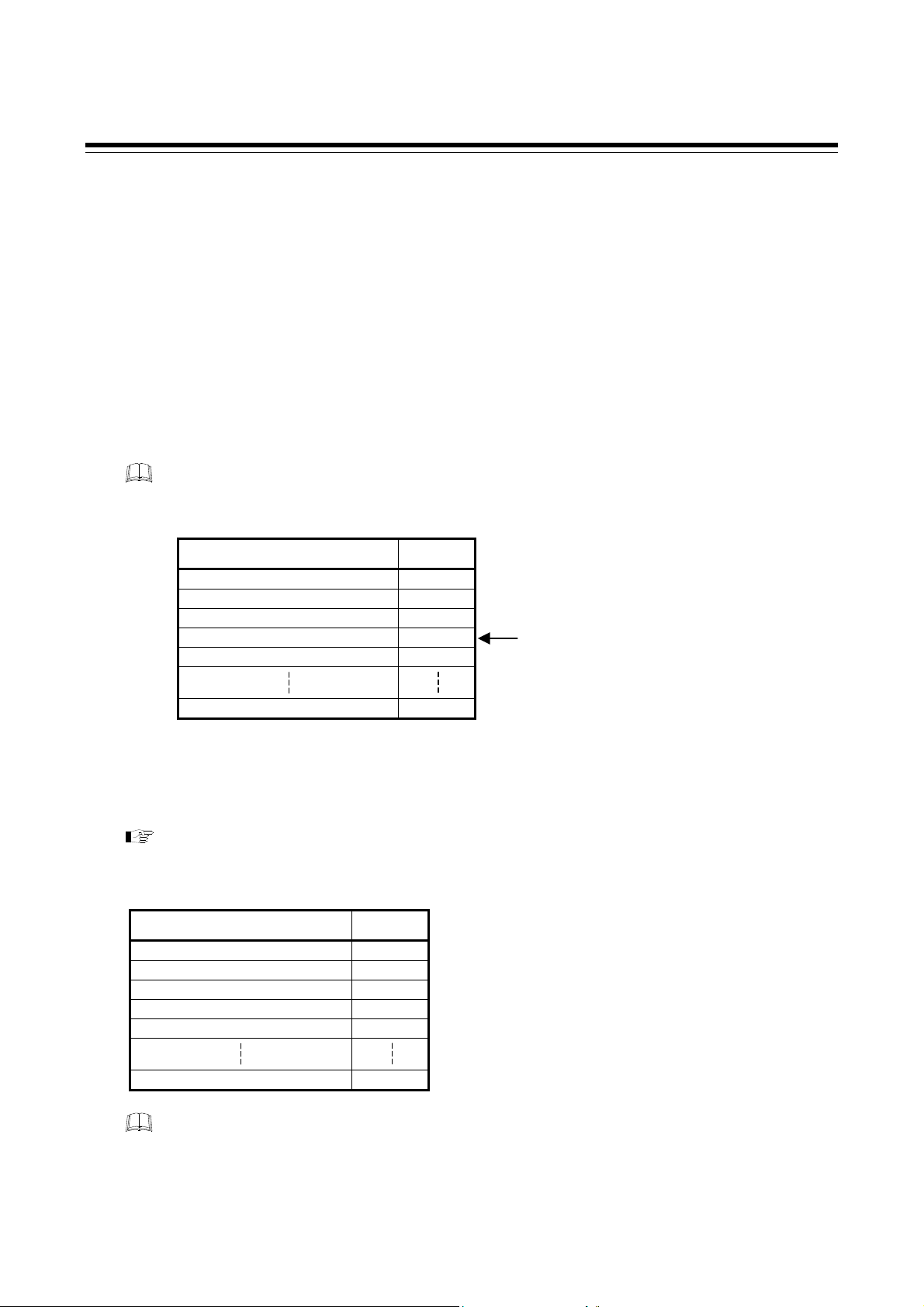

5.4 Controller Address Auto Obtain Methods

To allow the PLC and COM-JG to communicate, the COM-JG must be made to recognize the address

of each controller (the module addresses of the SRZ).

Although the PLC configuration tool can be used to configure settings to make the COM-G recognize

the controller addresses, the DIP switches can be set to have the settings configured automatically.

For setting method using the PLC configuration tool, refer to 5.3 COM-JG Initial Setting (P. 17),

8.4 Contents Check of COM-JG Initial Setting (P. 63) and 8.5 PLC Tool Setting (P. 70).

Procedure

This procedure assumes that the controller (SRZ) communication settings have been

completed.

To execute controller address auto obtain, DIP switch No. 7 on the left side of the COM-JG

must be set to OFF (controller communication enabled).

1. Set DIP switch No. 4 on the left side of the COM-JG to ON (auto obtain ON).

Set the controller communication speed with DIP switch Nos. 1 and 2.

Set the controller communication speed to the same value as the controller (SRZ) setting.

For the DIP switch setting, refer to 5.2 DIP Switch Setting (P. 16).

DIP switch

ON

12345678

12345678

ON

OFF

ON: Auto obtain ON

Controller communication

speed setting

(19200 bps)

2. Connect the power wiring and the wiring between the COM-JG and the controllers (SRZ).

There is no need for the COM-JG to be connected to the PROFIBUS when controller

address auto obtain is executed.

IMR01Y35-E3

19

Page 26

5. SETTING

3. When the power is turned on, controller address auto obtain starts.

While auto obtain is in progress, the RUN lamp of the COM-JG blinks.

The obtained addresses are stored in “Controller address” in the COM-JG initial setting items.

“Controller address” has 31 address spaces, Nos. 1 to 31 [equal to the maximum number of

controller (SRZ) connections], and the obtained addresses are stored in order from No. 1

beginning from the lowest-value address.

The COM-JG checks each controller (SRZ) address against addresses 1 to 99. For this

reason, a certain amount of time is required to complete auto obtain (up to about 90

seconds).

4. When controller address auto obtain is finished, the RUN lamp of the COM-JG stops blinking

and lights steadily.

5. Turn off the power and return DIP switch No. 4 on the left side of the COM-JG to OFF (auto

obtain OFF).

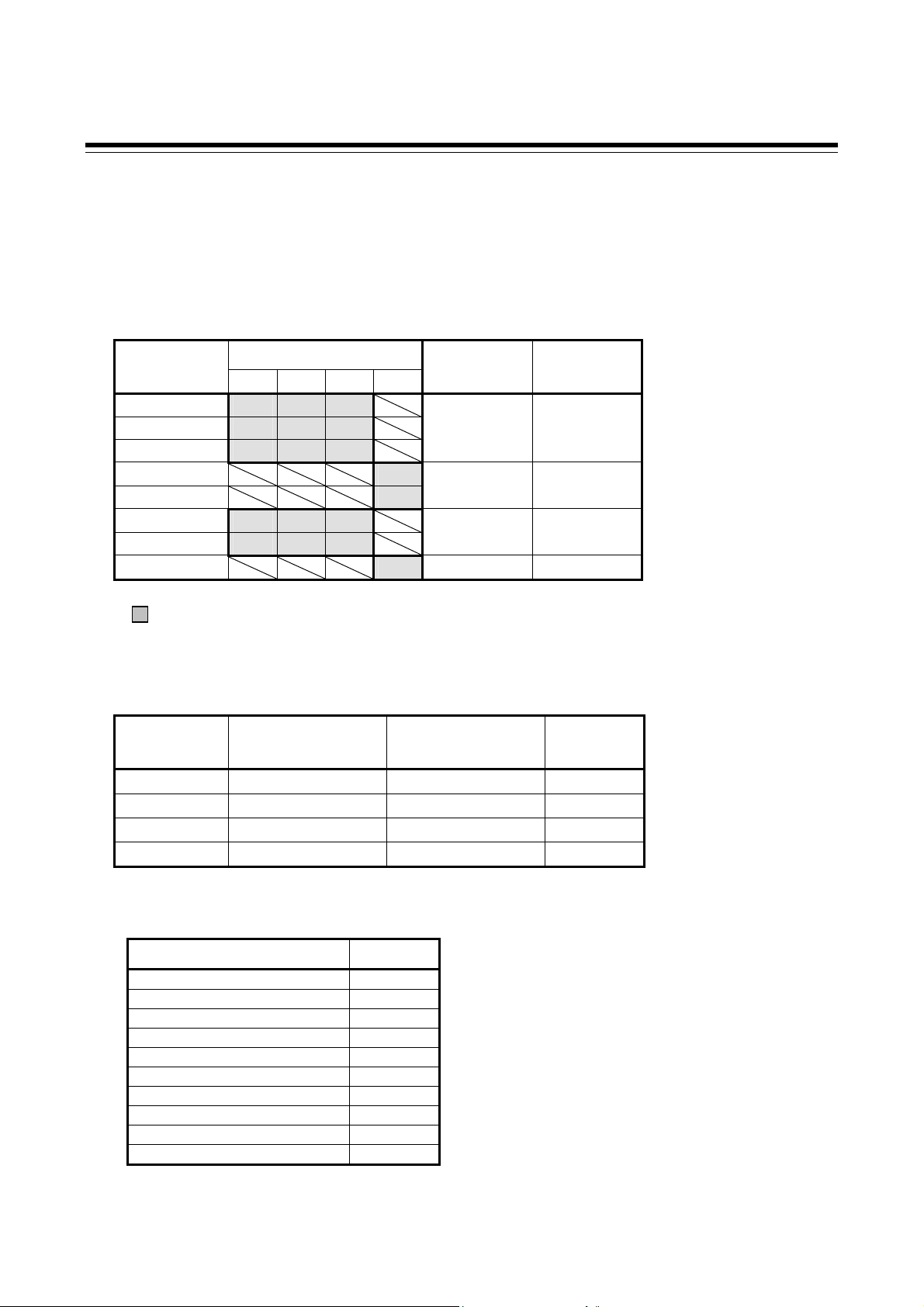

[Example] When the controller (SRZ) configuration is three Z-TIO modules and two Z-DIO modules

Obtained address

Z-TIO

module

Z-DIO

module

COM-JG

1 5 10 17 30

SRZ

Controller address

(Module address)

COM-JG initial setting item

No. 1 Controller address 1

No. 2 Controller address 5

No. 3 Controller address 10

No. 4 Controller address 17

No. 5 Controller address 30

No. 6 Controller address 0

No. 31 Controller address 0

Automatically obtained

controller addresses

Addresses are stored in

order from No. 1 from the

lowest address.

In this example there are

five modules, and thus the

automatically obtained

addresses are stored in Nos.

1 to 5.

The data in controller addresses 6 to 31 will be “0” (No controller connected).

20

The controller address of a Z-TIO module will be the value (decimal) set in the address

setting switch plus “1.” The controller address of a Z-DIO module will be the value

(decimal) set in the address setting switch plus “17.”

IMR01Y35-E3

Page 27

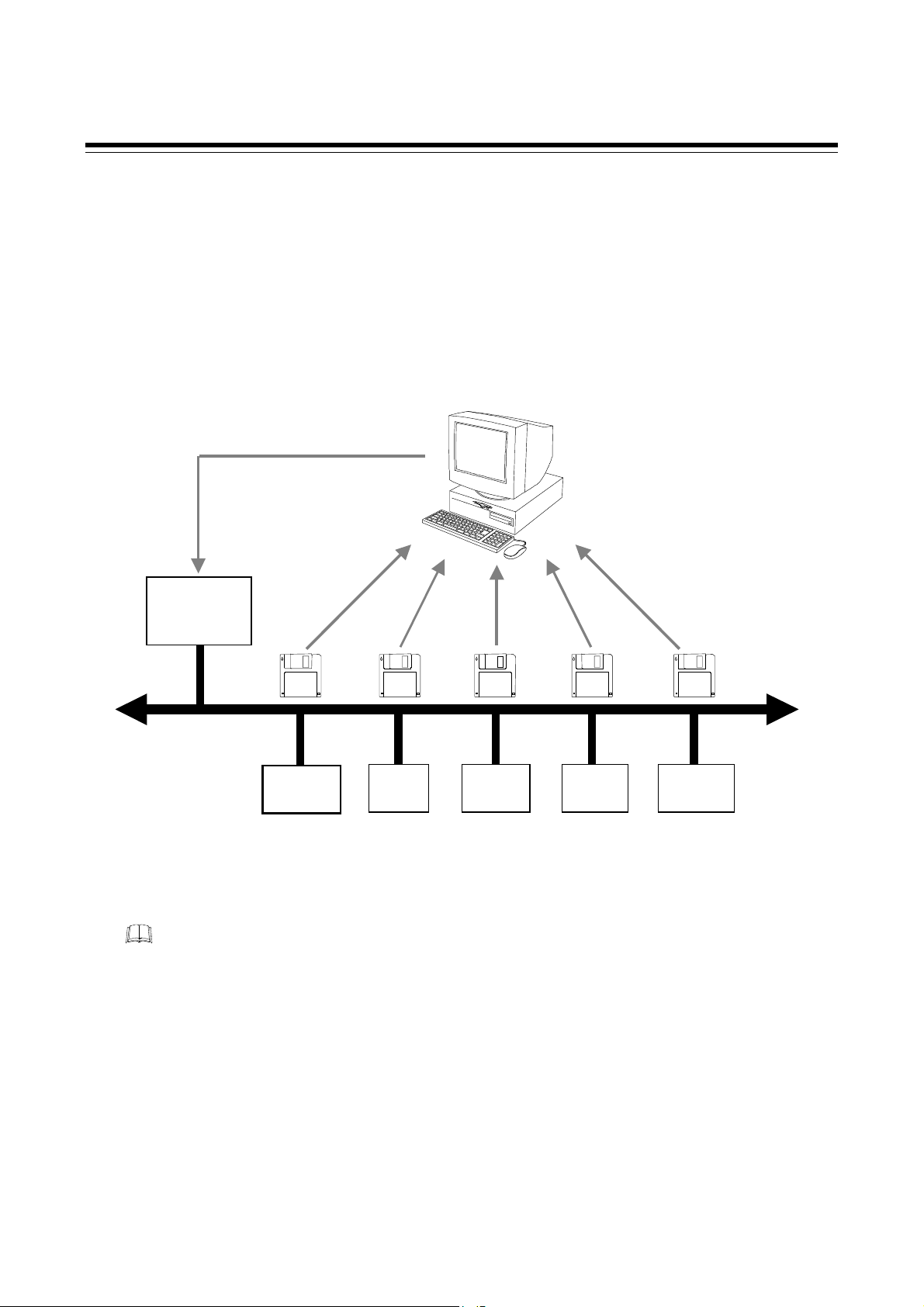

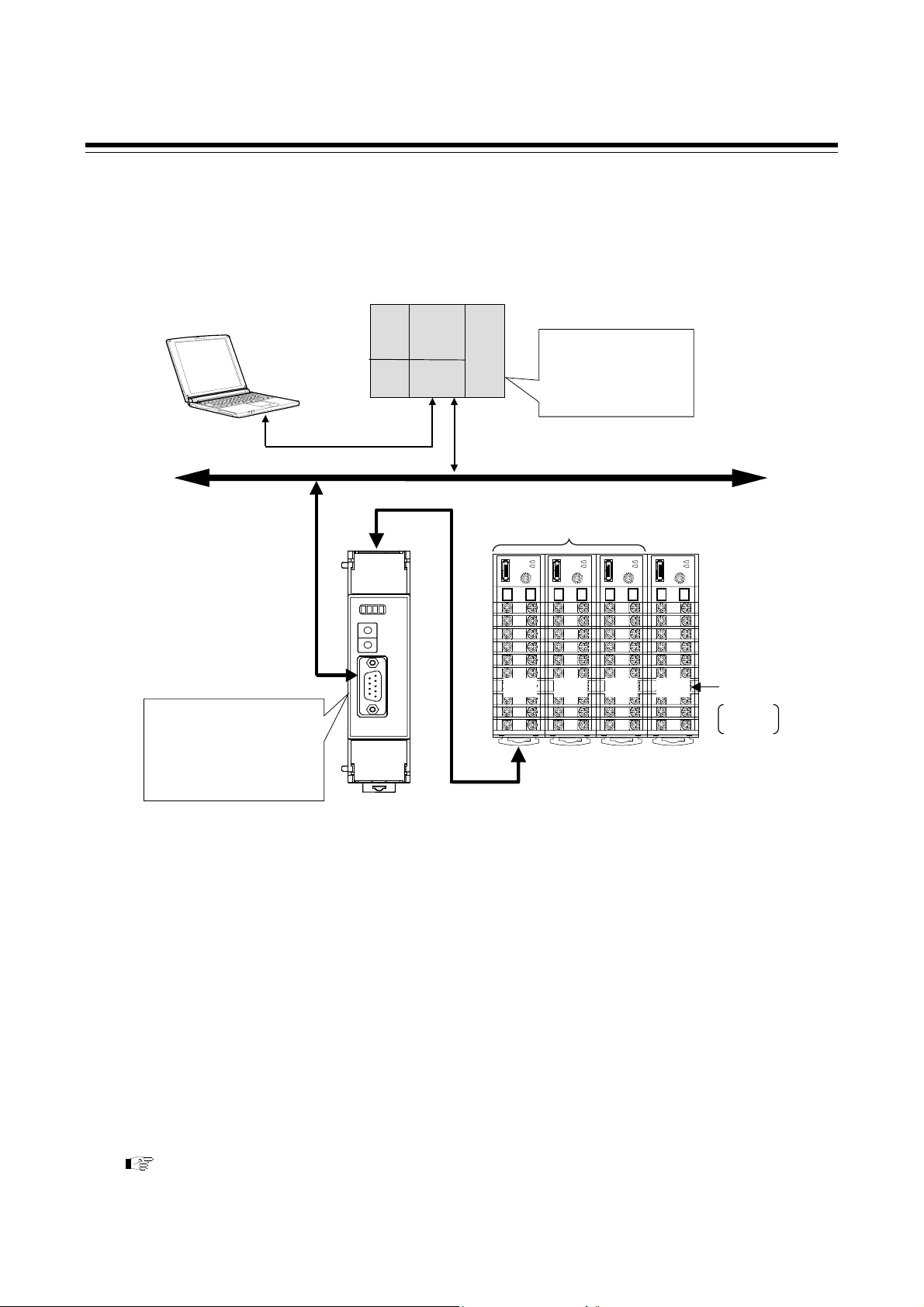

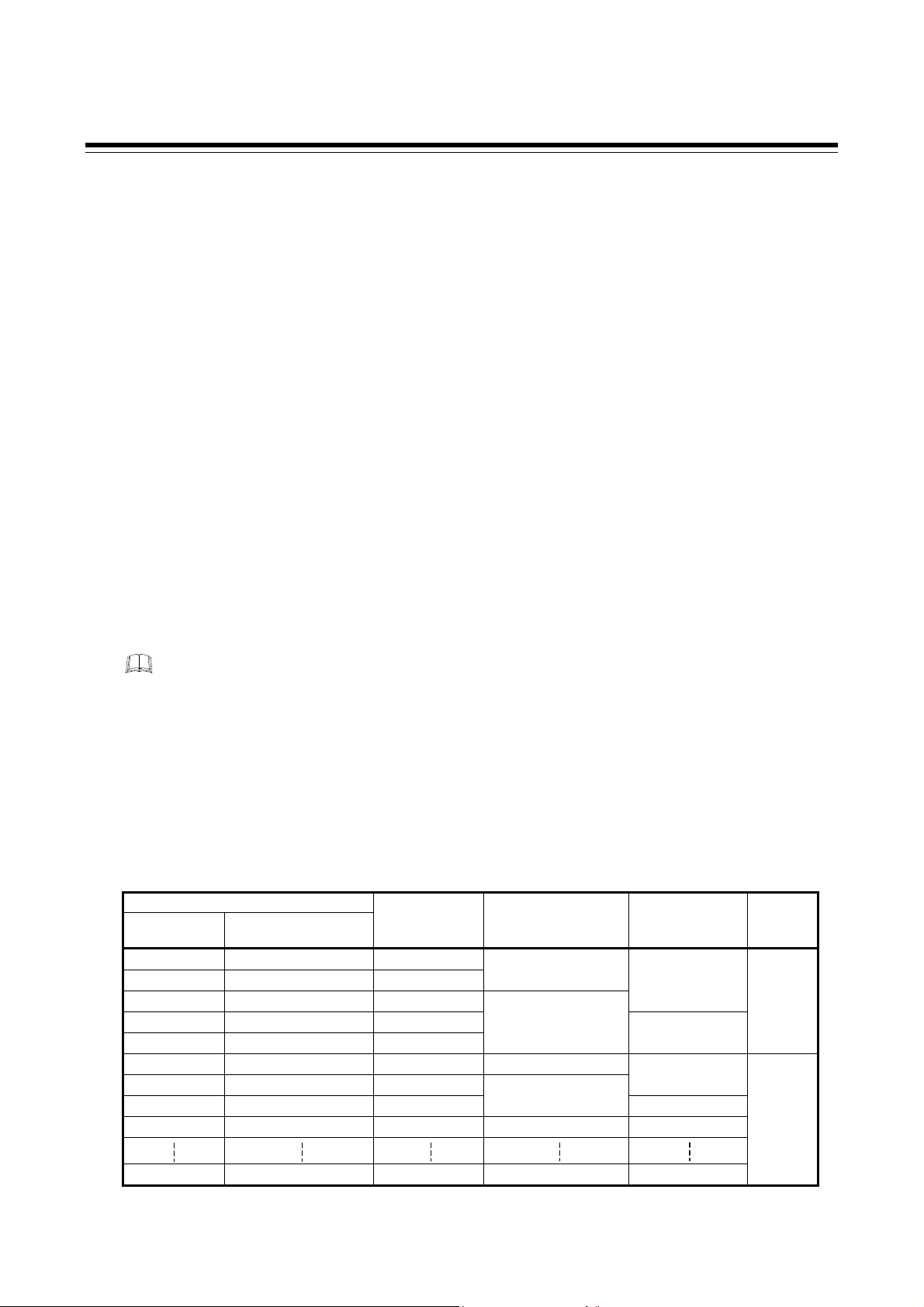

6. PROFIBUS COMMUNICATION

6.1 PROFIBUS System Configuration

For system configuration with PROFIBUS-DP protocol, have to offer the communication information

about each slave for a master in the form of electronic device data seat (GSD file).

A manufacturer of PLC (master) has prepared configuration tool for a system configuration of

PROFIBUS. By combining all GSD files of the slaves to be connected, the configuration tool creates a

master parameter record containing all pertinent data for the bus system. The configuration of a

PROFIBUS system is enabled by downloading these data to a master.

System configuration

PROFIBUS

configuration tool

PLC

(Master)

GSD file

PROFIBUS-DP

COM-JG

Overview of PROFIBUS system configuration

I/O

Sensor Drive

Slave

Field

device

About configuration tool, please ask a manufacturer of a master product.

IMR01Y35-E3 21

Page 28

6. PROFIBUS COMMUNICATION

6.2 PROFIBUS Communication Data

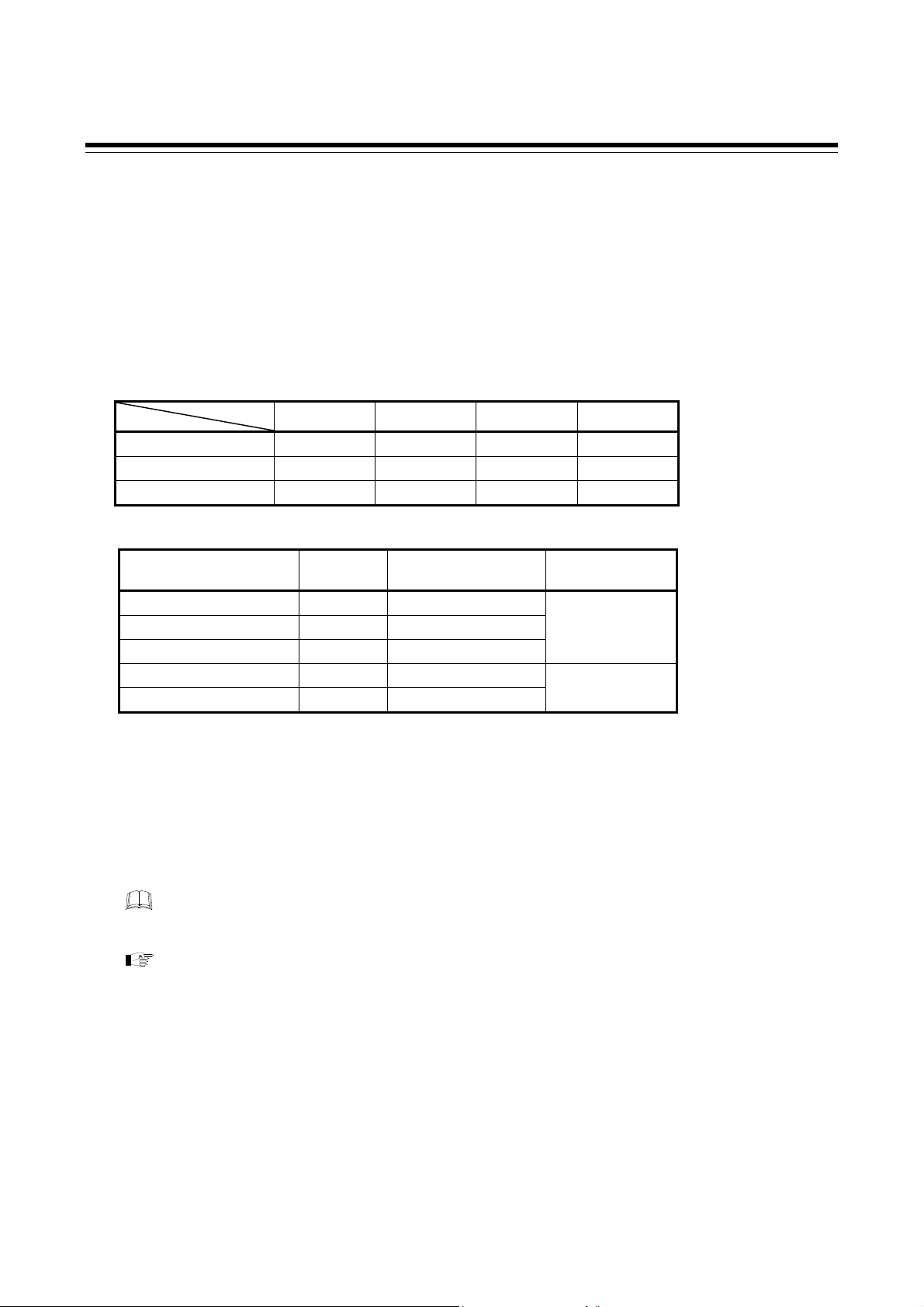

6.2.1 Data types and data length of communication data

Data access types

• Static data read/write

• Dynamic data read/write

• Error state register

• Write permission flag register

• Write control flag register

Communication data length

A maximum of 170 bytes can be read or written.

Static data request

The maximum number of communication items which can be specified:

40 items (Read items+Write items)

The communication items which can be specified:

Data of the 7. COMMUNICATION DATA MAP (P. 28)

Dynamic data request

The communication items which can be requested:

Data of the 7. COMMUNICATION DATA MAP (P. 28)

The number of communication items becomes as follows depending on the number of

connection channels.

[Read data] Number of static read data × Number of connection channel

Number of dynamic data × 6 + 12

[Write data] Number of static write data × Number of connection channel

Number of dynamic data × 6 + 11

a

Total number of continuous accesses

b

(Error state register: 1 byte)+(Write permission flag register: 1 byte)+(Write control flag register: 10 bytes) = 12

c

(Write permission flag register: 1 byte)+(Write control flag register: 10 bytes) = 11

b

≤ 170

c

≤ 170

Number of connection channels Number of static data *

1 channel Maximum of 40 items for both read and write.

16 channels Maximum of 5 items for both read and write.

31 channels Maximum of 2 items for both read and write.

* Calculated with the number of dynamic data equal to 0. The 10 bytes of the write control flag register

for read data and the 10 bytes of the write control flag register for write data can be omitted.

6.2.2 Static data request

a

× 2 +

a

× 2 +

• Static data is that which is always read/written from/to the PROFIBUS master such as the PLC. The

data item is selected by the configuration tool such as the PLC.

• As the Modbus register address is directly specified, data items of all the controllers connected to the

COM-JG can be selected.

• When static data is requested, 1-word (2-byte) data is used for both read and write.

As the static data register address is set when system configured, it is not required to create a

sequence program for static data assignment.

22

IMR01Y35-E3

Page 29

6. PROFIBUS COMMUNICATION

6.2.3 Dynamic data request

• Dynamic data is that which is freely read/written from/to the PROFIBUS master such as the PLC.

The data item is freely selected by the sequence program.

• As the Modbus register address is directly specified, data items of all the controllers connected to the

COM-JG can be selected.

• When dynamic data is requested, 3-word (6-byte) data is used for both read and write.

Send data from PLC to COM-JG

Register configuration

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Attribute

Device

address

Communication item

address

Byte 0: Specify an attribute of data. Only Bit 7 and Bit 6 are used.

Byte 0 (Attribute)

Communication item

data

Bit 7 Bit 6

Bit 0

Bit 6: Send data validate/invalidated discriminating bit

0: Send data is validated

1: Send data is invalidated

Bit 7: Read/Write discriminating bit

0: Data read

1: Data write

Unused (Any value, even if set, is ignored.)

Byte 1: Specify an accessing device address of controller.

Data range: 1 to 99 (“0” at Modbus is invalidated)

Byte 2, Byte 3: The communication item address of controller, to/from which data

is written/read is specified.

Z-TIO module Data address range: 0000H to 035BH

Z-TIO module Address range of memory area: 0500H to 0553H

Z-DIO module Data address range: 0000H to 00DBH

Byte 4, Byte 5: Write data of a communication item.

− If Bit 7 in Byte 0 is set to “1: Data write,” data in the address specified by

Bytes 1, 2, and 3 is written.

− If Bit 7 in Byte 0 is set to “0: Data read,” data in Byte 4 and 5 will be

ignored.

For communication item, refer to 7. COMMUNICATION DATA MAP (P. 28).

IMR01Y35-E3

23

Page 30

6. PROFIBUS COMMUNICATION

PLC received data from COM-JG

Register configuration

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Attribute

Byte 0: Echo back of Byte 0 of send data, and data updating state of

controller (Bit 5)

Device

address

Communication item

address

Communication item

data

The details of data in Byte 0 sent to the controller from the PLC and data

updating state of controller (Bit 5) are returned.

Byte 0 (Attribute)

Bit 7 Bit 6 Bit 5

Bit 0

Bit 6: Send data validate/invalidate discriminating bit

0: Send data is validated

1: Send data is invalidated

Bit 7: Read/Write discriminating bit

0: Data read

1: Data write

Unused (Any value, even if set, is ignored.)

Bit 5: Data updating state of controller

0: Data update

1: Data non-update

Byte 1: Echo back of Byte 1 of send data

The specified controller device address is returned. However, if there is no

specified device address, “FFH” is returned.

Byte 2, Byte 3: Echo back of Byte 2 and Byte 3 of send data

The communication item address of controller, to/from which data is

written/read is returned. However, if any communication item address out of the

data range or of unused item is specified, “FFFFH” is returned.

Z-TIO module Data address range: 0000H to 035BH

Z-TIO module Address range of memory area: 0500H to 0553H

Z-DIO module Data address range: 0000H to 00DBH

Byte 4, Byte 5: Data of communication item

− For data read, the current value of relevant communication item is stored.

− For data write, the current value of relevant communication item is stored.

If the written data is validated, the written value is returned.

If the written data is invalidated, the present (before data write) value is

returned.

When the data is written, there is a delay in rewriting the data in this

register as the COM-JG updates the register after rereading the data on

the controller.

24

IMR01Y35-E3

Page 31

6. PROFIBUS COMMUNICATION

6.2.4 Registers assigned to PLC

Set the register area after the GSD file is read to the configuration tool for the PLC.

The static data request read, static data request write and dynamic data request registers are set to the

register area.

In addition to the above register area setting, the following data is set at the beginning of the register.

• Read register: Error state (1-byte), Write permission flag (1-byte), Write control flag (10-byte)

• Write register: Write permission flag (1-byte), Write control flag (10-byte)

Error state register

The first read only 1-byte register consists of bits of error state.

Error state register

Bit 7 Bit 3 Bit 2 Bit 1 Bit 0

Unused

Bit 0: Instrument error

0: No instrument error

1: Instrument error

Bit 1: Time-out error

0: No time-out error

1: Time-out error

Bit 2: Controller communication validate/invalidate

0: Controller communication is validated

1: Controller communication is invalidated

Bit 3: Controller communication initialization

0: Completed initialization of controller communication

1: During initialization of controller communication

Instrument error

In case of the following either, become an error.

− None of the controllers is connected.

− COM-JG is hardware abnormally.

If an instrument error occurs, the RUN lamp at the front of COM-JG flashes (flashes slowly).

Time-out error

Successive communication time-out occurring twice in the same controller after PROFIBUS is

initialized causes a time-out error. Communication continues even during the time-out error and

recovers with no time-out error when the communication returns to normal.

Time-out time: 3 seconds

IMR01Y35-E3

25

Page 32

6. PROFIBUS COMMUNICATION

Controller communication validate/invalidate

Interlocked with dip switch No. 7 at the side of the COM-JG.

Factory set value of dip switch No. 7: OFF (0: Controller communication validate)

Controller communication initialization

Indicates the controller communication initialized state when the power is turned on and at this state

invalidates the data on each communication item.

Write permission flag register

Data may be written by static data request depending on the PLC even if the PLC is not in the RUN

state. In order to prevent this, the COM-JG is provided with the 1-byte flag register.

Only when the flag value in this one byte corresponds to “0FH” (hexadecimal), data is written to each

controller.

The operation of writing a hexadecimal value of “0FH” to the write permission flag

register is necessary for both static and dynamic data requests.

Write control flag register

This register controls whether data writing is “permitted” or “not permitted” for each requested word.

Permitted or not permitted is set by bit for each requested word of a static data write request.

0: Not permitted

1: Permitted

The write control flag register allocates a static data write request for 10 bytes of data with each byte

containing 8 words, and sets the bit for each word to “permitted” or “not permitted.”

[Example] Write “permitted” or “not permitted” state when the value of the first byte of the write

control flag register is A5H (hexadecimal)

A5H (hexadecimal) = 10100101 (binary)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte 9th byte 10th byte

1 to 8

words

9 to 16

words

17 to 24

words

25 to 32

words

33 to 40

words

41 to 48

words

49 to 56

words

57 to 64

words

65 to 72

words

73 to 80

words

8th word 7th word 6th word 5th word 4th word 3rd word 2nd word 1st word

1 0 1 0 0 1 0 1

The write control flag register is only effective for writing of static data requests.

26

If you do not need to set write “permitted” or “not permitted” for each word, this setting can

be omitted.

IMR01Y35-E3

Page 33

6. PROFIBUS COMMUNICATION

6.3 Processing of Numeric Data Values

Numeric data values used via communication with the PLC and processed by COM-JG include those

with and without decimal points and also those with minus signs.

For numeric data value without decimal point

If there is no decimal point, the value is processed as it is.

In parameters which only have ON or OFF status, 1 = ON, 0 = OFF.

[Example]

A signal wire for temperature input is disconnected and the burnout state occurs.

→ Read value corresponding to communication item address 0021 (Burnout state monitor):

1 (Hexadecimal number: 0001H)

For numeric data value with decimal point

The decimal point is omitted.

[Example 1]

When temperature measured value of controller is 120.5 °C

→ Read value corresponding to communication item address 0000 [Measured value (PV)]:

1205 (Hexadecimal number: 04B5H)

[Example 2]

When temperature measured value of controller is 130 °C

→ Read value corresponding to communication item address 0000 [Measured value (PV)]:

130 (Hexadecimal number: 0082H)

For numeric data value with minus sign

The value is expressed as a 2’s complement value which is obtained by subtracting the minus value

from the hexadecimal number 10000H.

[Example 1]

When temperature measured value of controller is −1 °C

→ Read value corresponding to communication item address 0000 [Measured value (PV)]:

Hexadecimal number: FFFFH

(10000H − 1 = FFFFH)

[Example 2]

When temperature measured value of controller is −2.5 °C

→ Read value corresponding to communication item address 0000 [Measured value (PV)]:

Hexadecimal number: FFE7H

(10000H − 25 = 10000H − 19H = FFE7H)

The original minus value can be found by revising the WORD value to the INT value on the

sequence program side.

IMR01Y35-E3

27

Page 34

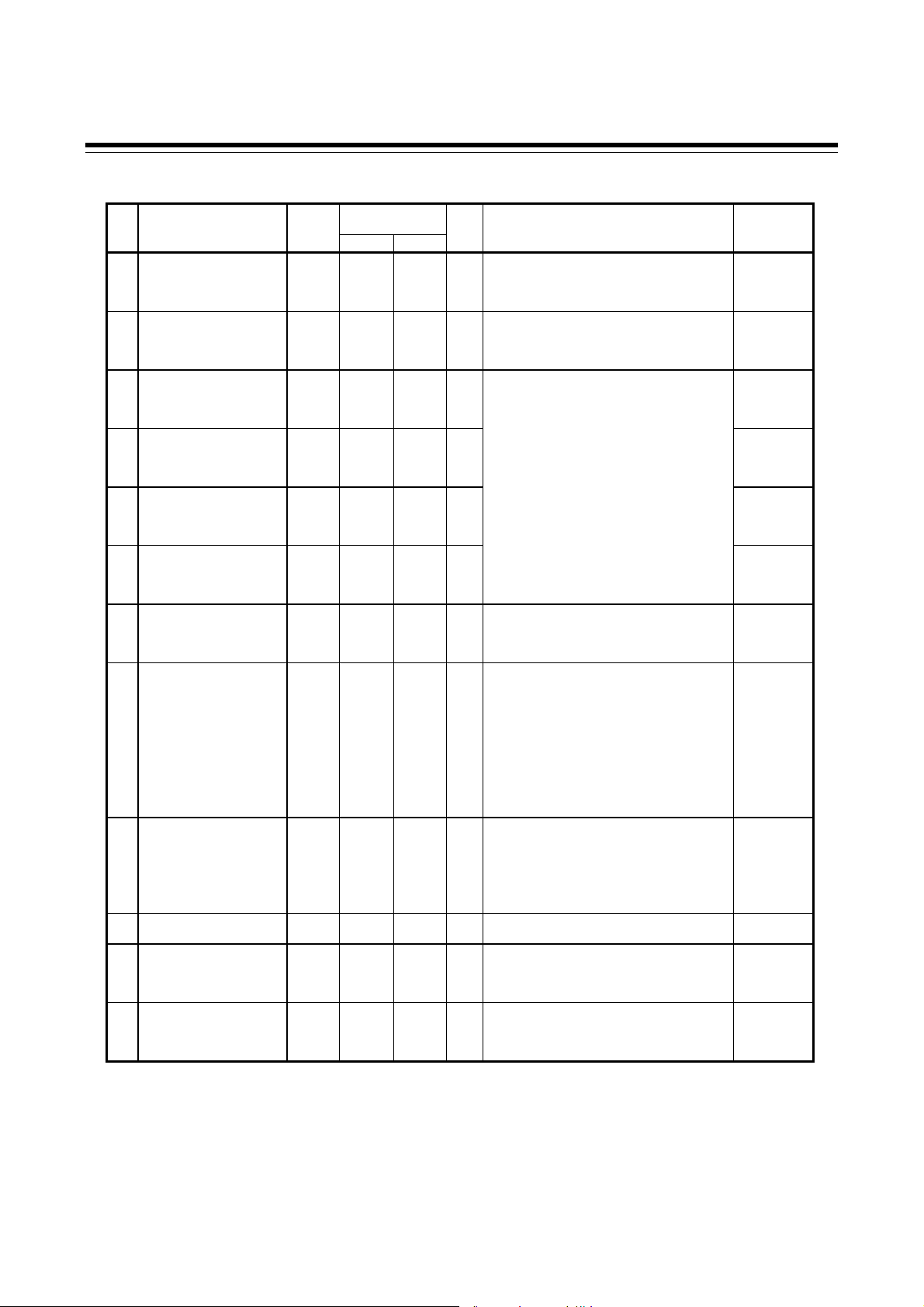

7. COMMUNICATION DATA MAP

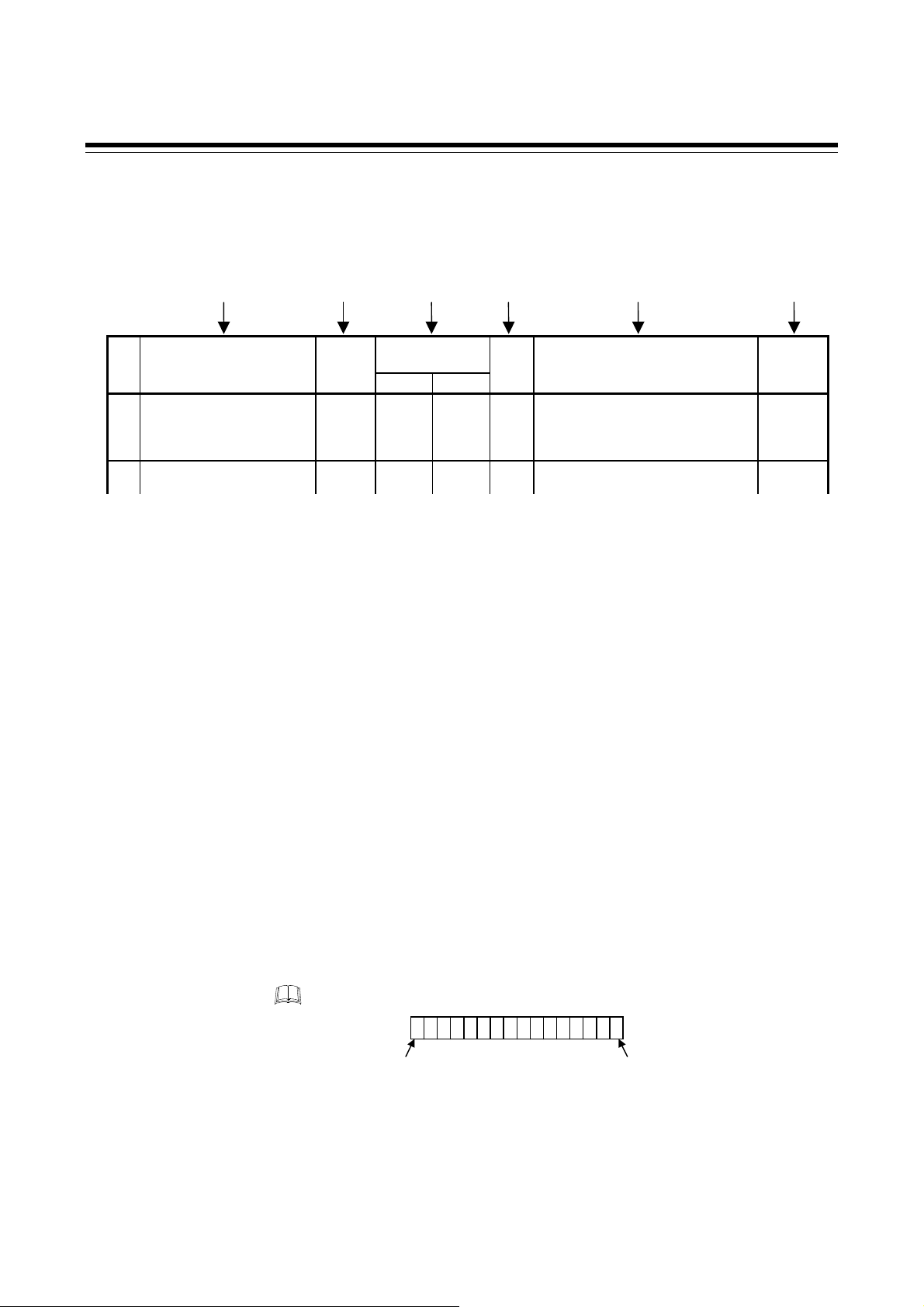

7.1 Reference to Communication Data Map

A data map of communication items shows data on controller (SRZ) which can make communication

via PROFIBUS.

(1)

(2)

No. Name Channel

1 Measured value (PV)

2 Comprehensive event state

CH1

CH2

CH3

CH4

CH1 0004 4

(3)

Modbus

register address

HEX DEC

0000

0001

0002

0003

0

1

2

3

(4)

Attri-

bute

RO Input scale low to Input scale high

RO Bit data

(5)

Data range

(6)

Factory

set value

⎯

⎯

(1) Name: Communication item name

(2) Channel: Channel numbers of each function module (Z-TIO, Z-DIO)

(3) Modbus register address:

The communication item address is the address number to specify with

configuration tool when carry out read/write of data.

HEX: Hexadecimal

DEC: Decimal

With respect to the following communication data of the Z-TIO module, the

register addresses of the indicated channels are non-used areas.

• 2-channel type module: Register addresses of the 3rd and 4th channels

• Heat/Cool control and Position proportioning control:

Register addresses of the 2nd and 4th channels *

• Cool-only communication data of Heat/Cool control:

Register addresses of the 2nd and 4th channels *

* Communication data with a ♣ mark in the name column

(4) Attribute: RO: Read only data

Data direction: Master (PLC) → Slave (COM-JG)

R/W: Read and Write data

Data direction: Master (PLC) ↔ Slave (COM-JG)

(5) Data range: Read or write range of communication data

Bit image of bit data is as follows.

16-bit data

…………….……………………

Bit 15

Bit 0

(6) Factory set value: Factory set value of communication data

28 IMR01Y35-E3

Page 35

7. COMMUNICATION DATA MAP

Communication includes both Normal setting data and Engineering setting data.

During RUN (control), the attribute of Engineering setting data is RO. To configure

Engineering setting data, the RUN/STOP switch must be set to STOP (control stopped).

Z-TIO module: Normal setting data No. 1 to 83,

Engineering setting data No. 85 to 207

Z-DIO module: Normal setting data No. 1 to 13,

Engineering setting data No. 15 to 28

The Engineering setting data should be set according to the application before setting any

parameter related to operation. Once the Engineering setting data are set correctly, no

further changes need to be made to datas for the same application under normal conditions.

If they are changed unnecessarily, it may result in malfunction or failure of the instrument.

RKC will not bear any responsibility for malfunction or failure as a result of improper changes

in the Engineering setting.

IMR01Y35-E3 29

Page 36

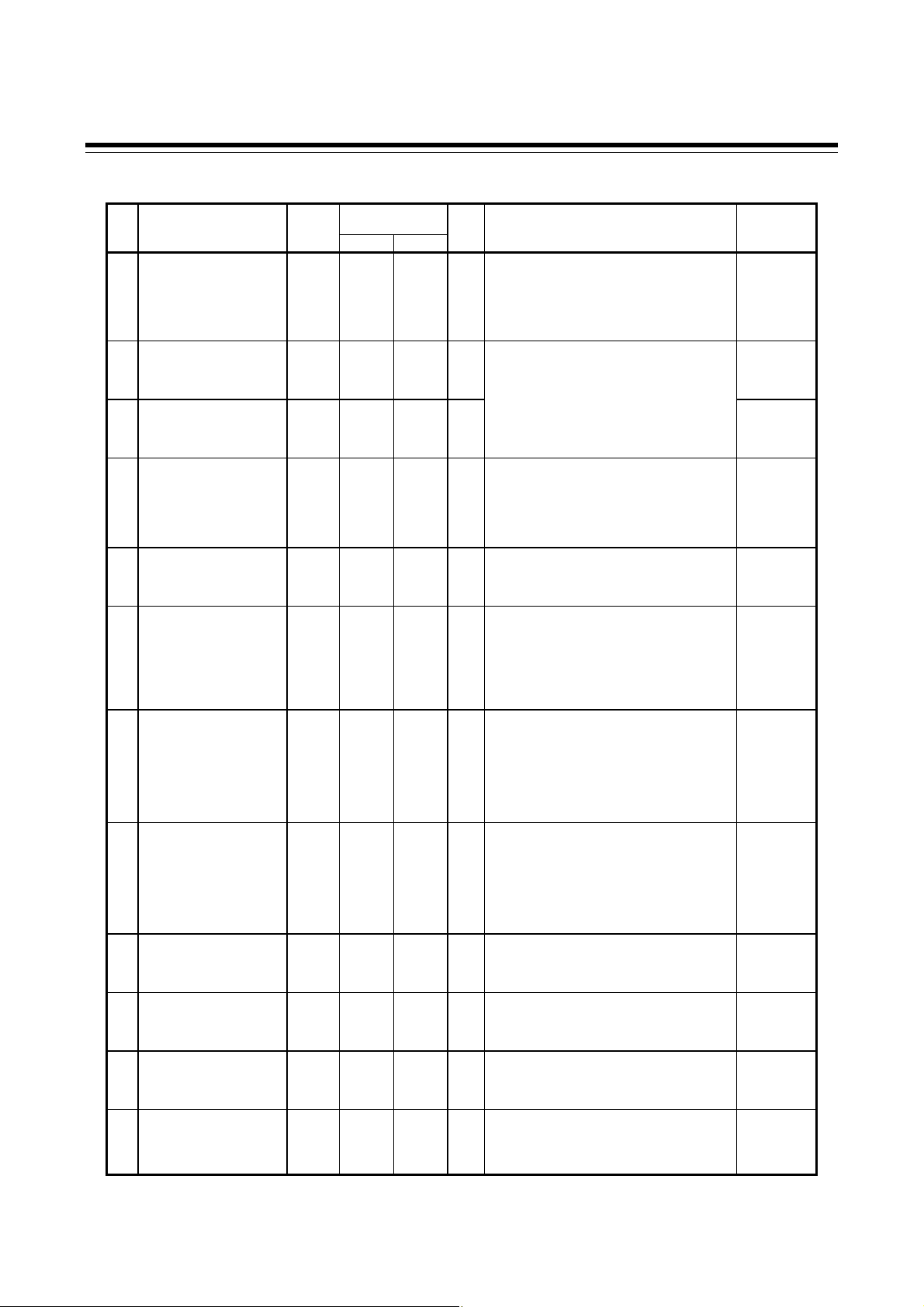

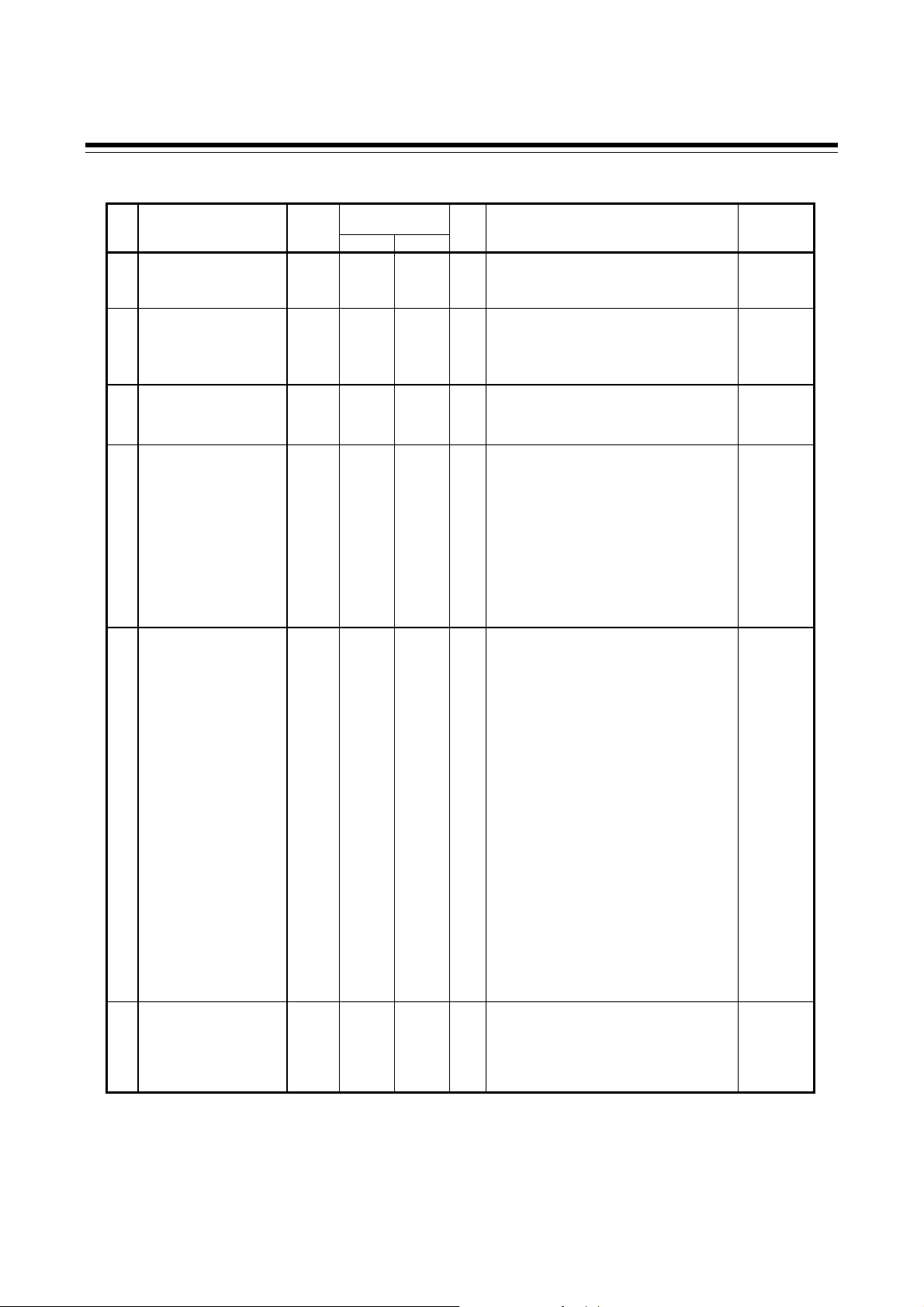

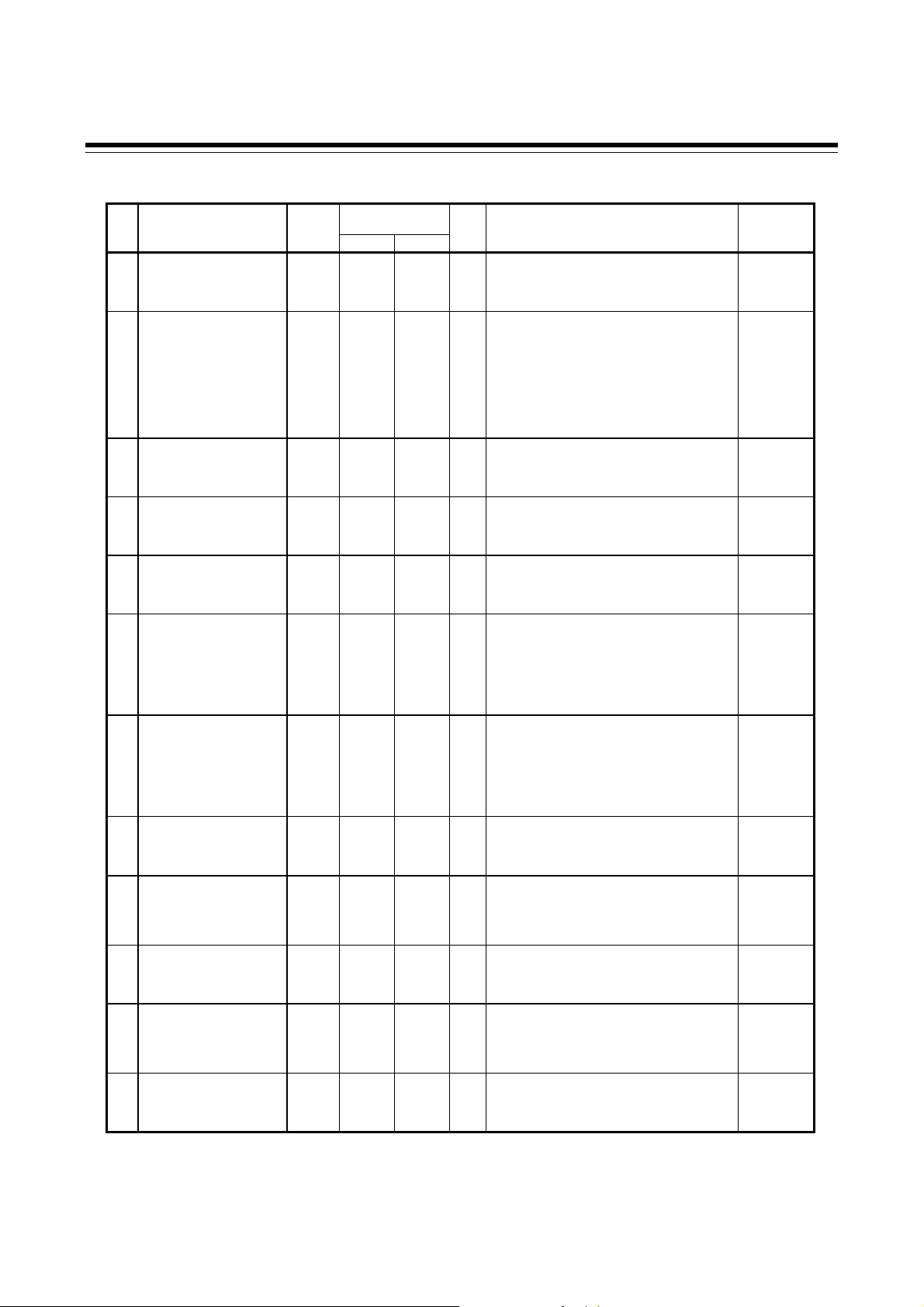

7. COMMUNICATION DATA MAP

7.2 Communication Data of Z-TIO Module

Modbus

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH3

CH1

CH2

CH3

CH4

CH2

CH3

CH4

register address

HEX DEC

0000

0001

0002

0003

0004

0005

0006

0007

0008

0009

000A

000B

000D

000E

000F

0010

0011

Unused

0012

Unused

0015

0016

0017

0018

0019

001A

001B

001C

No. Name Channel

1 Measured value (PV) CH1

2 Comprehensive event

state

3 Operation mode state

monitor

4 Error code ⎯ 000C 12 RO Bit data

5 Manipulated output value

(MV) monitor [heat-side]

♣

6 Manipulated output value

(MV) monitor [cool-side]

♣

7 Current transformer (CT)

input value monitor

8 Set value (SV) monitor CH1

Unused

Unused

0

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

Unused

19

Unused

21

22

23

24

25

26

27

28

Attri-

bute

RO Input scale low to Input scale high ⎯

RO Bit data

Bit 0: Event 1 state

Bit 1: Event 2 state

Bit 2: Event 3 state

Bit 3: Event 4 state

Bit 4: Heater break alarm state

Bit 5: Temperature rise completion

Bit 6: Burnout

Bit 7 to Bit 15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 127]

RO Bit data

Bit 0: Control STOP

Bit 1: Control RUN

Bit 2: Manual mode *

Bit 3: Remote mode *

Bit 4 to Bit 15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

* During operation in manual mode, the manual

mode of the operation mode state monitor is

set to the “1: ON” state and the remote mode

of the same monitor is se to the “0: OFF”

state even if the parameter, “Remote/Local

transfer” is set to “1: Remote mode.”

Bit 0: Adjustment data error

Bit 1: Data back-up error

Bit 2: A/D conversion error

Bit 3: Unused

Bit 4: Unused

Bit 5: Logic output data error

Bit 6 to Bit 15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 63]

If two or more errors occur simultaneously, the

total summation of these error codes is displayed.

RO PID control or Heat/Cool PID control:

−5.0 to +105.0 %

Position proportioning control with feedback

resistance (FBR) input:

0.0 to 100.0 %

RO −5.0 to +105.0 % ⎯

RO CTL-6-P-N: 0.0 to 30.0A

CTL-12-S56-10L-N: 0.0 to 100.0 A

RO Setting limiter low to Setting limiter high

Data range

⎯

Factory

set value

⎯

⎯

⎯

⎯

⎯

♣ Parameters only used for Heat/Cool PID control or Position proportioning control, therefore data for CH2 and CH4 of

Z-TIO modules are unused.

Continued on the next page.

30 IMR01Y35-E3

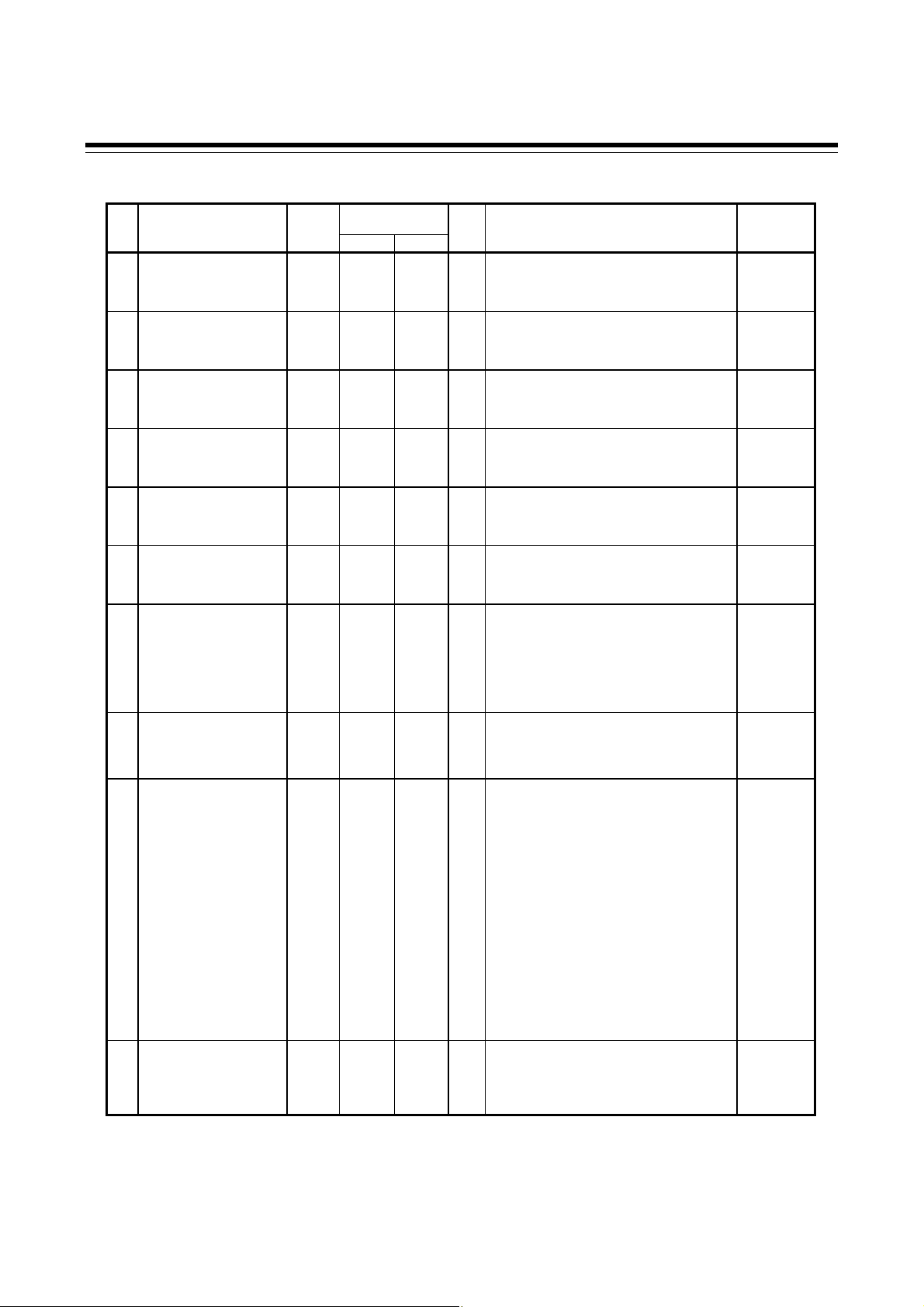

Page 37

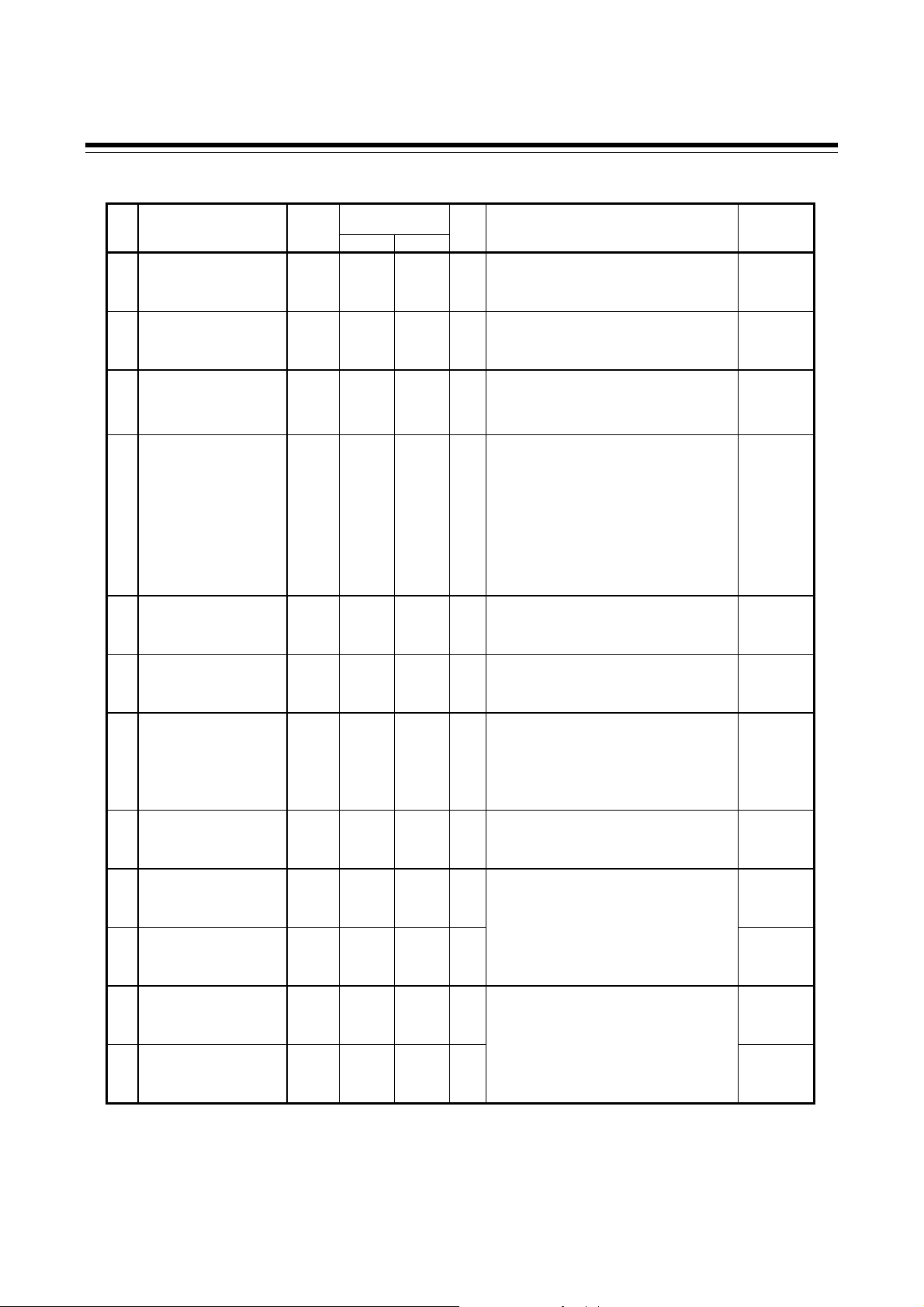

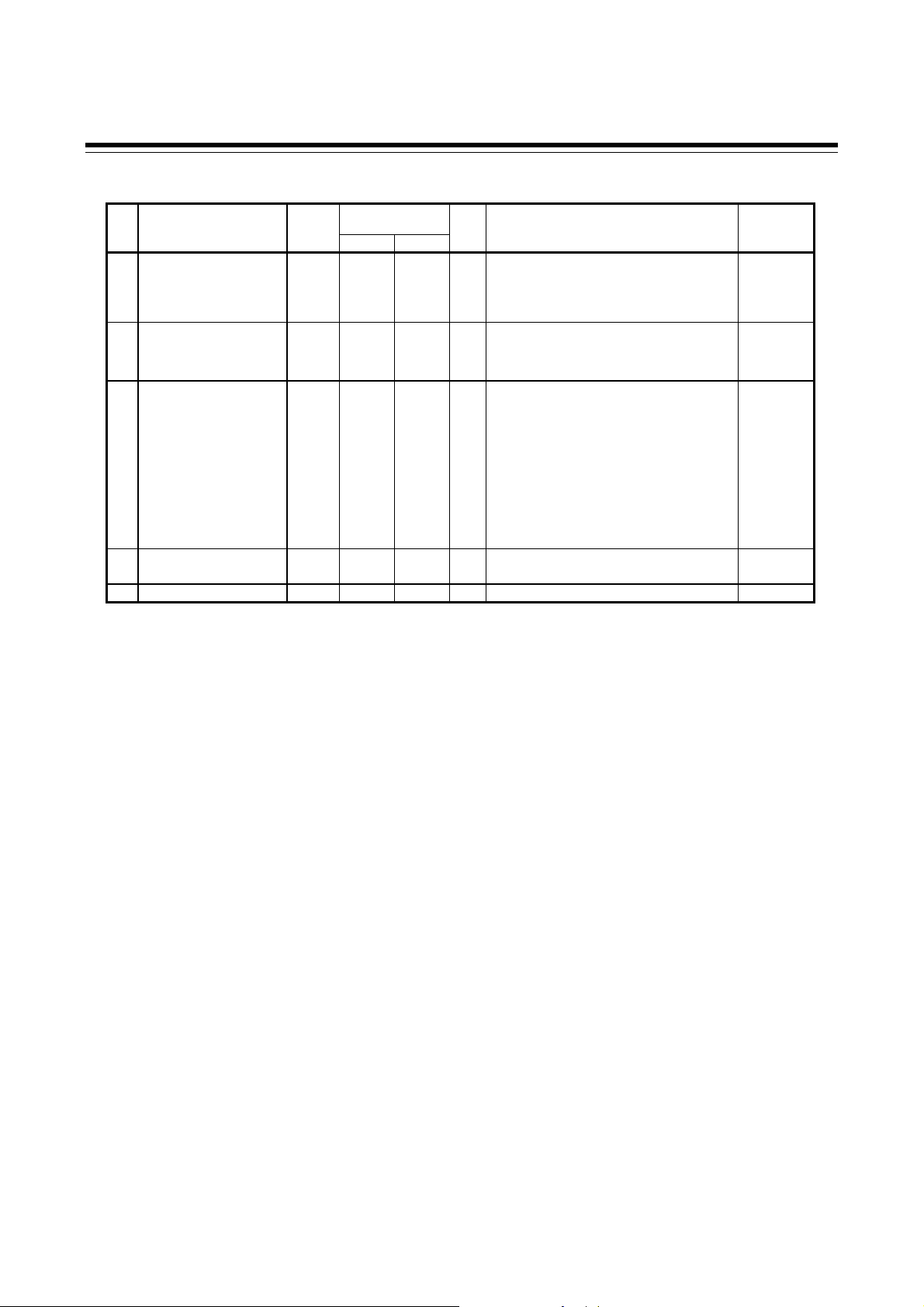

Continued from the previous page.

Modbus

No. Name Channel

9 Remote setting (RS) input

value monitor

10 Burnout state monitor CH1

11 Event 1 state monitor CH1

12 Event 2 state monitor CH1

13 Event 3 state monitor CH1

14 Event 4 state monitor CH1

15 Heater break alarm (HBA)

state monitor

16 Output state monitor ⎯ 0039 57 RO Bit data

17 Memory area soak time

monitor

18 Integrated operating time

monitor

19 Holding peak value ambient

temperature monitor

20 Backup memory state

monitor

register address

HEX DEC

CH1

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

001D

001E

001F

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

002A

002B

002C

002D

002E

002F

0030

0031

0032

0033

0034

0035

0036

0037

0038

003A

003B

003C

003D

⎯ 003E 62 RO 0 to 19999 hours ⎯

003F

0040

0041

0042

⎯ 0043 67 RO 0: The content of the backup memory does

Attri-

bute

RO Setting limiter low to Setting limiter high

29

30

31

32

RO 0: OFF

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

58

59

60

61

63

64

65

66

1: ON

0: OFF

RO ⎯

1: ON

RO ⎯

RO ⎯

RO

RO 0: OFF

1: ON

Bit 0: OUT1

Bit 1: OUT2

Bit 2: OUT3

Bit 3: OUT4

Bit 4 to Bit 15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

When control output is specified, this function

is available only for a proportioning control.

RO 0 minutes 00 seconds to 199 minutes 59 seconds:

0 to 11999 seconds

0 hours 00 minutes to 99 hours 59 minutes:

0 to 5999 minutes

Data range of Area soak time can be selected

on the Soak time unit.

RO −10.0 to +100.0 °C (14.0 to 212.0 °F) ⎯

1: The content of the backup memory

7. COMMUNICATION DATA MAP

Data range

not coincide with that of the RAM.

coincides with that of the RAM.

Continued on the next page.

Factory

set value

⎯

⎯

⎯

⎯

⎯

⎯

IMR01Y35-E3 31

Page 38

7. COMMUNICATION DATA MAP

Continued from the previous page.

Modbus

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH2

CH3

CH4

register address

HEX DEC

・

・

・

0060

0061

0062

0063

0064

0065

0066

0067

0068

0069

006A

006B

006C

006E

006F

0070

0071

0072

0073

0074

0075

0076

0077

0078

0079

007A

007B

007C

007D

007E

007F

0080

0081

0082

0083

0084

0085

0086

0087

0088

0089

008A

008B

008C

008D

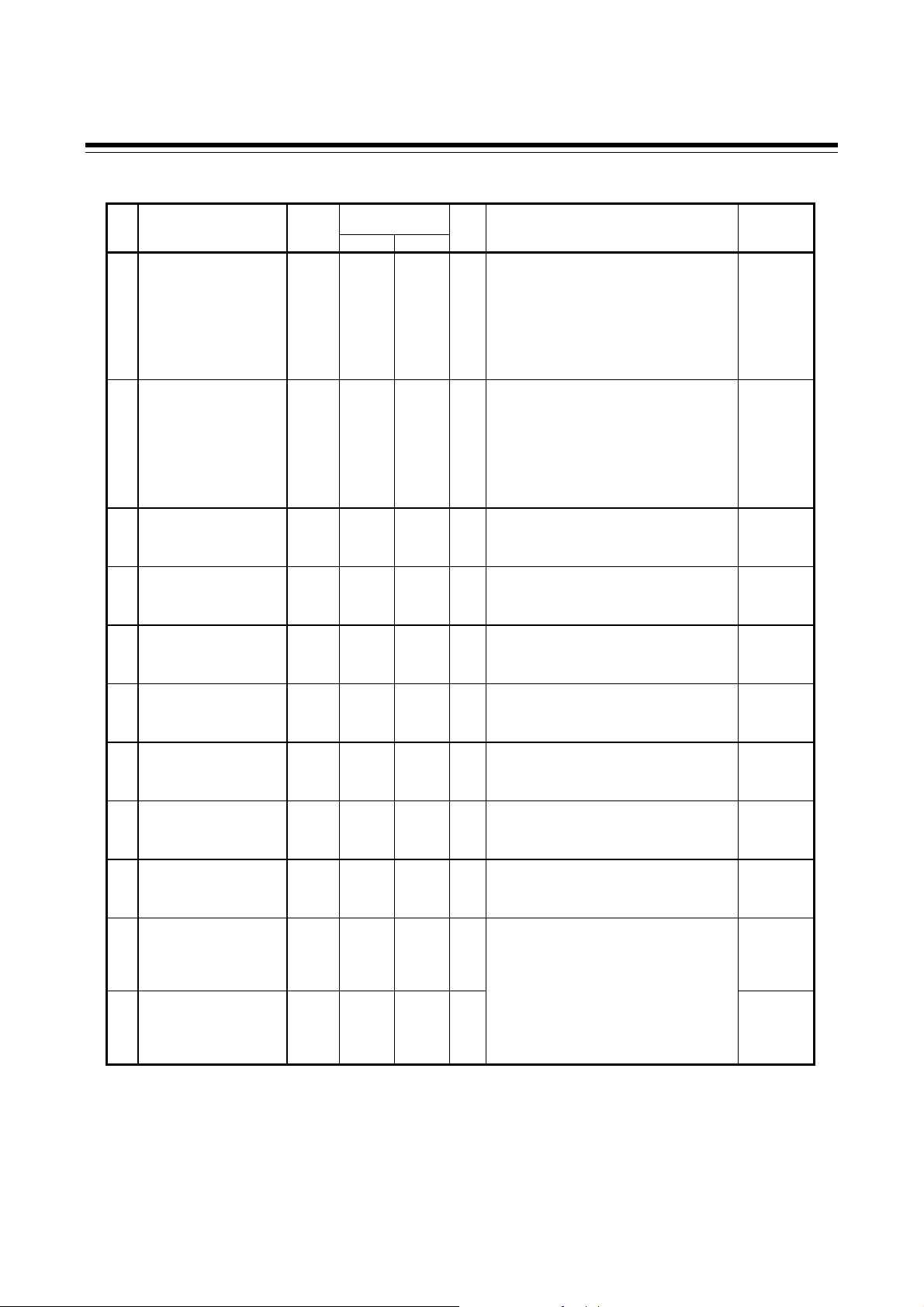

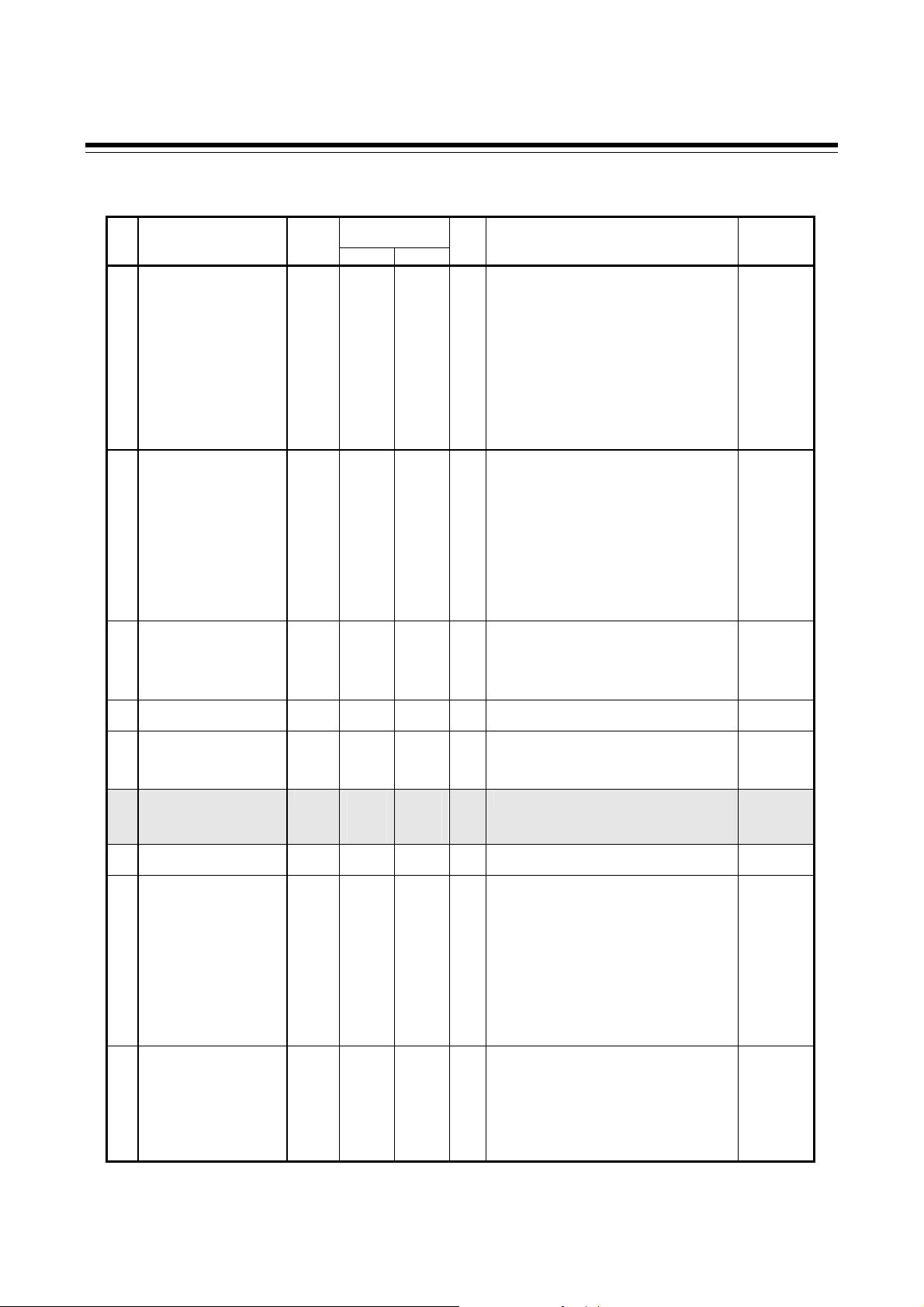

No. Name Channel

21 Logic output monitor ⎯ 0044 68 RO Bit data

22 Unused ⎯ 0045

23 PID/AT transfer CH1

24 Auto/Manual transfer CH1

25 Remote/Local transfer CH1

26 RUN/STOP transfer ⎯ 006D 109 R/W 0: STOP (Control stop)

27 Memory area transfer CH1

28 Interlock release CH1

29 Event 1 set value (EV1)

★

30 Event 2 set value (EV2)

★

31 Event 3 set value (EV3)

★

32 Event 4 set value (EV4)

★

33 Control loop break alarm

(LBA) time ★

34 LBA deadband ★ CH1

★: Parameters which can be used in Multi-memory area function.

Attri-

bute

Bit 0: Logic output 1

Bit 1: Logic output 2

Bit 2: Logic output 3

Bit 3: Logic output 4

Bit 4: Logic output 5

Bit 5: Logic output 6

Bit 6: Logic output 7

Bit 7: Logic output 8

Bit 8 to Bit 15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 255]

69

⎯ ⎯ ⎯

・

・

・

96

R/W 0: PID control

97

98

99

100

101

102

103

104

105

106

107

108

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

1: Autotuning (AT)

R/W

0: Auto mode

1: Manual mode

R/W 0: Local mode

1: Remote mode

When performing remote control by remote

setting input and also performing cascade control

and ratio setting, transfer to the Remote mode.

1: RUN (Control start)

R/W 1 to 8 1

R/W 0: Normal state

1: Interlock release execution

R/W 50

Deviation action, Deviation action between

channels, Temperature rise completion range:

−Input span to +Input span

Process action, SV action:

R/W 50

Input scale low to Input scale high

MV action:

−5.0 to +105.0 %

If the Event type corresponds to “0: None,” set

R/W 50

to RO (Only reading data is possible).

When temperature rise completion is selected

at Event 3 action type.

If Event 4 corresponds to “9: Control loop

R/W

break alarm (LBA),” the Event 4 set value

becomes RO (Only reading data is possible).

R/W 0 to 7200 seconds (0: Unused)

R/W 0 (0.0) to Input span

Data range

Factory

set value

⎯

0

0

0

0

0

50

480

0 (0.0)

Continued on the next page.

32 IMR01Y35-E3

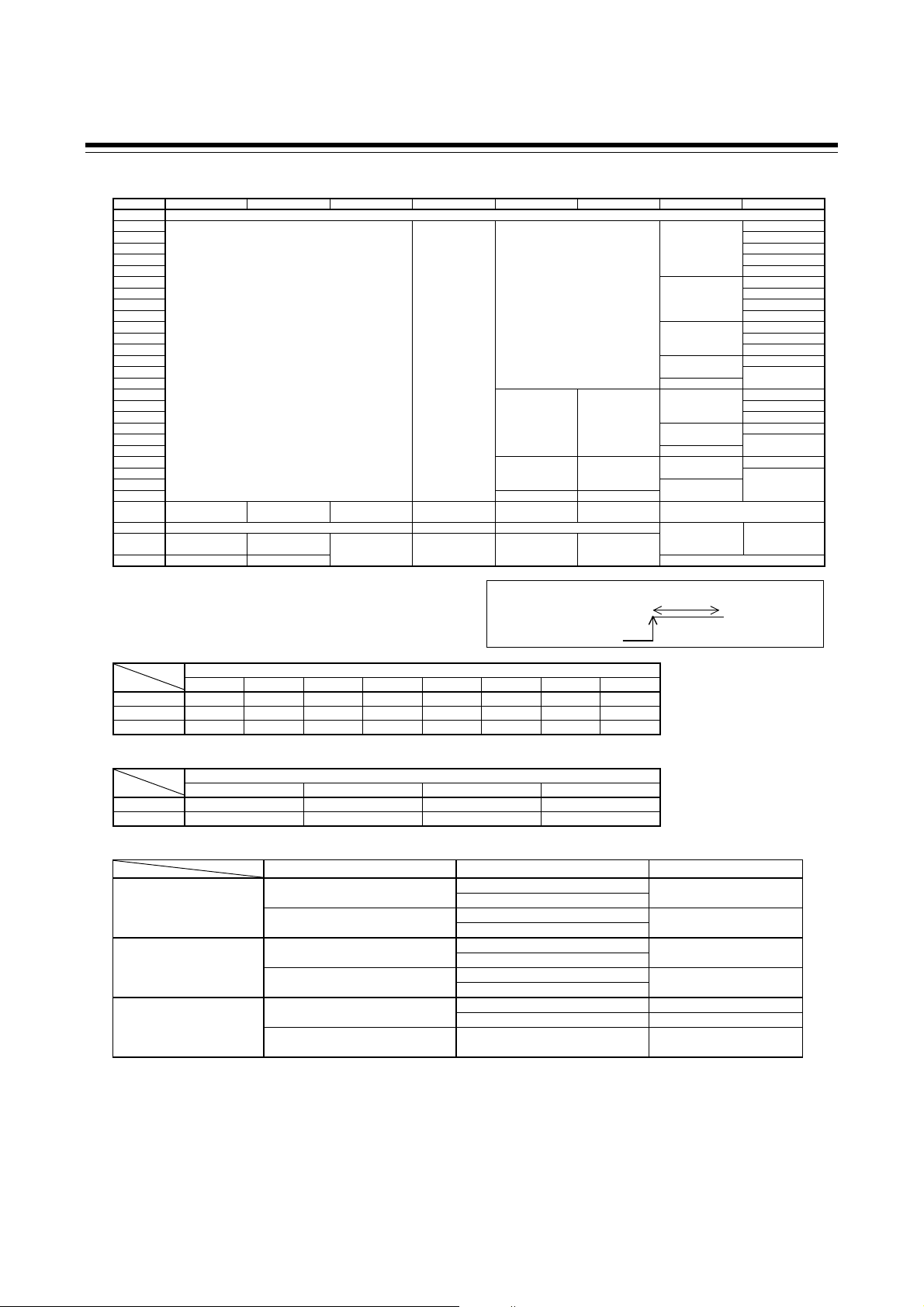

Page 39

7. COMMUNICATION DATA MAP

Continued from the previous page.

Modbus

No. Name Channel

register address

HEX DEC

35 Set value (SV) ★ CH1

CH2

CH3

CH4

36 Proportional band

[heat-side] ★ ♣

CH1

CH2

CH3

CH4

37 Integral time

[heat-side]

★ ♣

CH1

CH2

CH3

CH4

38 Derivative time

[heat-side]

★ ♣

CH1

CH2

CH3

CH4

39 Control response

parameter

★ ♣

CH1

CH2

CH3

CH4

40 Proportional band

[cool-side] ★ ♣

CH1

Unused

CH3

Unused

41 Integral time [cool-side]

★ ♣

CH1

Unused

CH3

Unused

42 Derivative time

[cool-side]

★ ♣

CH1

Unused

CH3

Unused

43 Overlap/Deadband ★ ♣ CH1

CH2

CH3

CH4

008E

008F

0090

0091

0092

0093

0094

0095

0096

0097

0098

0099

009A

009B

009C

009D

009E

009F

00A0

00A1

00A2

Unused

00A4

Unused

00A6

Unused

00A8

Unused

00AA

Unused

00AC

Unused

00AE

00AF

00B0

00B1

★ Parameters which can be used in Multi-memory area function.

♣

Parameters only used for Heat/Cool PID control or Position proportioning control, therefore data for CH2 and CH4 of

Z-TIO modules are unused.

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

Unused

164

Unused

166

Unused

168

Unused

170

Unused

172

Unused

174

175

176

177

Attri-

bute

Data range

R/W Setting limiter low to Setting limiter high

TC/RTD inputs:

R/W

0 (0.0) to Input span (Unit: °C [°F])

Varies with the setting of the decimal point position

selection.

Voltage (V)/Current (I) inputs:

0.0 to 1000.0 % of Input span

0 (0.0): ON/OFF action

(ON/OFF action for both heat and cool actions

in case of a Heat/Cool PID control type

PID control or Heat/Cool PID control:

R/W

0 to 3600 seconds or 0.0 to 1999.9 seconds

(0, 0.0: PD action)

Position proportioning control:

1 to 3600 seconds or 0.1 to 1999.9 seconds

Varies with the setting of the Integral/Derivative

time decimal point position selection.

R/W

0 to 3600 seconds or 0.0 to 1999.9 seconds

(0, 0.0: PI action)

Varies with the setting of the Integral/Derivative

time decimal point position selection.

R/W 0: Slow

1: Medium

2: Fast

When the P or PD action is selected, this

setting becomes invalidate.

TC/RTD inputs:

R/W

1 (0.1) to Input span (Unit: °C [°F])

Varies with the setting of the Decimal point

position selection.

Voltage (V)/Current (I) inputs:

0.1 to 1000.0 % of Input span

If control is other than Heat/Cool PID control,

set to RO (Only reading data is possible).

0 to 3600 seconds or 0.0 to 1999.9 seconds

R/W

(0, 0.0: PD action)

Varies with the setting of the Integral/Derivative

time decimal point position selection.

If control is other than Heat/Cool PID control,

set to RO (Only reading data is possible).

0 to 3600 seconds or 0.0 to 1999.9 seconds

R/W

(0, 0.0: PI action)

Varies with the setting of the Integral/Derivative

time decimal point position selection.

If control is other than Heat/Cool PID control,

set to RO (Only reading data is possible).

TC/RTD inputs:

R/W

−Input span to +Input span (Unit:°C [°F])

Voltage (V)/Current (I) inputs:

−100.0 to +100.0 % of Input span

Minus (−) setting results in overlap.

However, the overlapping range is within the

proportional range.

If control is other than Heat/Cool PID control,

set to RO (Only reading data is possible).

Continued on the next page.

Factory

set value

TC/RTD: 0

V/I: 0.0

TC/RTD: 30

V/I: 30.0

240

60

PID control,

Position

proportioning

control: 0

Heat/Cool

PID control: 2

TC/RTD: 30

V/I: 30.0

240

60

0

IMR01Y35-E3 33

Page 40

7. COMMUNICATION DATA MAP

Continued from the previous page.

Modbus

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

CH2

CH3

CH4

register address

HEX DEC

00B2

00B3

00B4

00B5

00B6

00B7

00B8

00B9

00BA

00BB

00BC

00BD

00BE

00BF

00C0

00C1

00C2

00C3

00C4

00C5

00C6

00C7

00C8

00C9

00CA

00CB

00CC

00CD

00CE

00CF

00D0

00D1

00D2

00D3

00D4

00D5

00D6

00D7

00D8

00D9

00DA

00DB

00DC

00DD

00DE

00DF

00E0

00E1

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

No. Name Channel

44 Manual reset ★

45 Setting change rate limiter

(up) ★

46 Setting change rate limiter

(down) ★

47 Area soak time ★ CH1

48 Link area number ★ CH1

49 Heater break alarm (HBA)

set value

50 Heater break

determination point

51 Heater melting

determination point

52 PV bias CH1

53 PV digital filter CH1

54 PV ratio CH1

55 PV low input cut-off CH1

★ Parameters which can be used in Multi-memory area function.

Attri-

bute

−100.0 to +100.0 %

R/W

If the Integral function is validated, set to RO

(Only reading data is possible).

When integral action (heating or cooling side)

is zero, manual reset value is added to the

control output.

R/W 0 (0.0) to Input span/unit time *

0 (0.0): Unused

R/W

* Unit time: 60 seconds (factory set value)

R/W 0 minutes 00 seconds to 199 minutes 59 seconds:

0 to 11999 seconds

0 hours 00 minutes to 99 hours 59 minutes:

0 to 5999 minuts

Data range of Area soak time can be selected

on the Soak time unit.

R/W 0 to 8

(0: No link)

R/W

When CT is CTL-6-P-N:

0.0 to 30.0 A (0.0: Not used)

When CT is CTL-12-S56-10L-N:

0.0 to 100.0 A (0.0: Not used)

If there is no Current transformer (CT) or CT is

assigned to “0: None,” set to RO (Only reading

data is possible).

R/W

0.0 to 100.0 % of HBA set value

(0.0: Heater break determination is invalidated)

If there is no Current transformer (CT) or CT is

assigned to “0: None,” set to RO (Only reading

data is possible).

If Heater break alarm (HBA) corresponds to

“0: Type A,” set to RO (Only reading data is

possible).

0.0 to 100.0 % of HBA set value

R/W

(0.0: Heater melting determination is invalidated)

If there is no Current transformer (CT) or CT is

assigned to “0: None,” set to RO (Only reading

data is possible).

If Heater break alarm (HBA) corresponds to “0:

Type A,” set to RO (Only reading data is

possible).

R/W −Input span to +Input span 0

R/W 0.0 to 100.0 seconds

(0.0: Unused)

R/W 0.500 to 1.500 1.000

R/W

0.00 to 25.00 % of input span

If the Square root extraction corresponds to “0:

Unused,” set to RO (Only reading data is

possible).

Data range

Factory

set value

0.0

0 (0.0)

0 (0.0)

0

0

0.0

30.0

30.0

0.0

0.00

Continued on the next page.

34 IMR01Y35-E3

Page 41

7. COMMUNICATION DATA MAP

Continued from the previous page.

Modbus

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

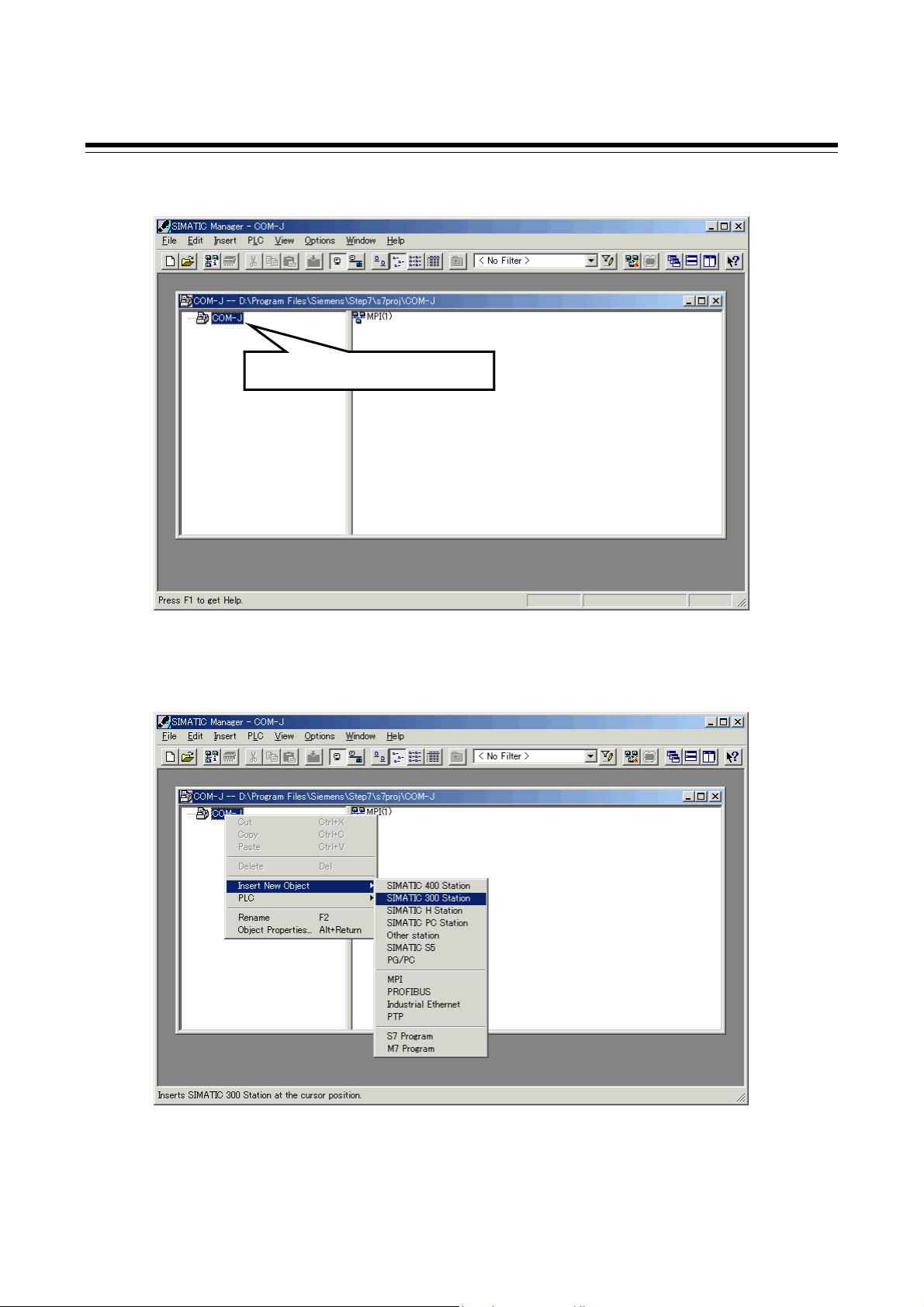

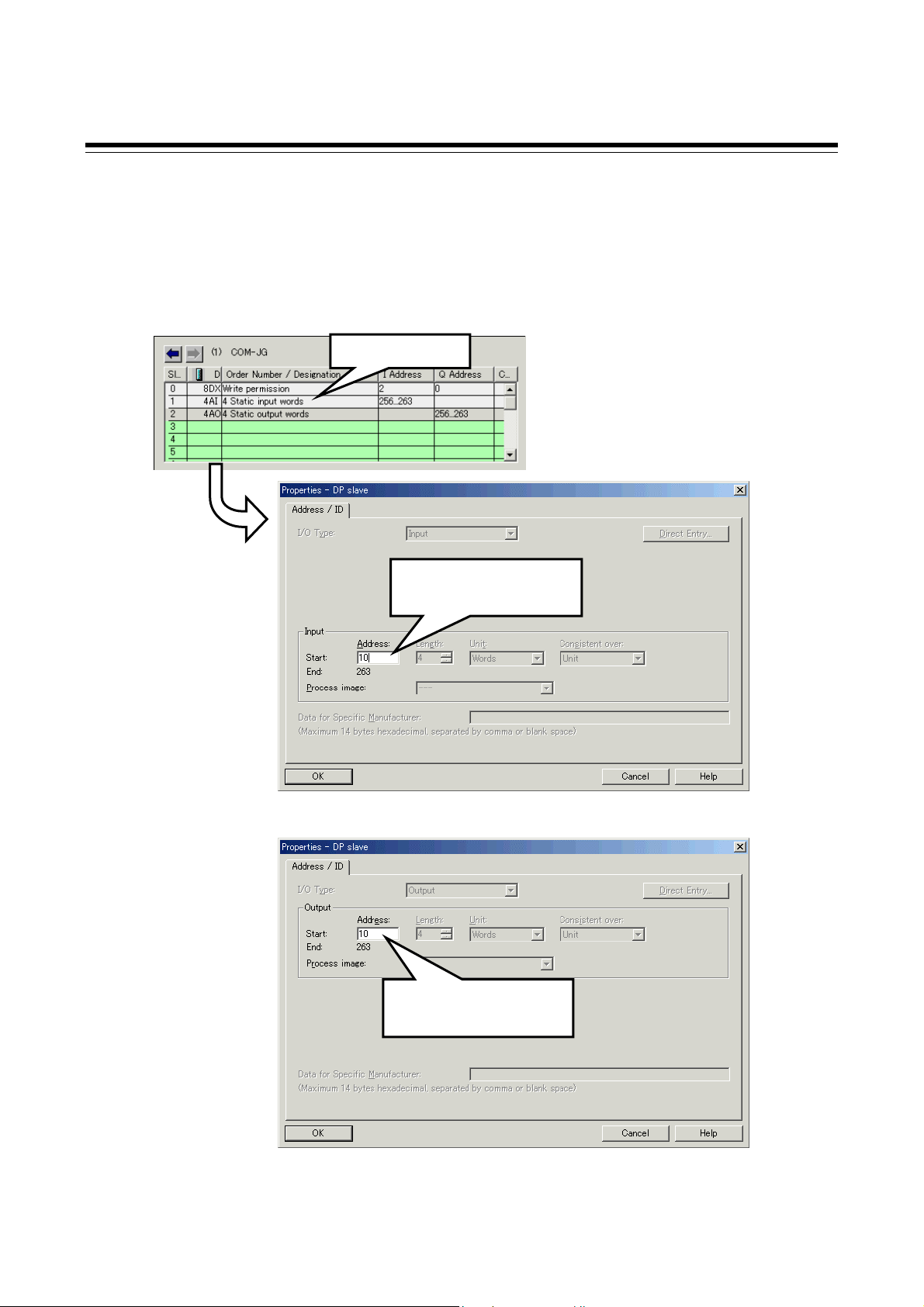

CH2