Page 1

Digital Controller

CB103/CB403/CB903

INSTRUCTION MANUAL

Thank you for purchasing this RKC product. In order to achieve maximum performance

and ensure proper operation of your new instrument, carefully read all the instructions in

this manual. Please place the manual in a convenient location for easy reference.

• An external protection device must be installed if failure of this

instrument could result in damage to the instrument, equipment or

WARNING

injury to personnel.

• All wiring must be completed before power is turned on to prevent

electric shock, fire or damage to instrument and equipment.

• This instrument must be used in accordance with the specifications

to prevent fire or damage to instrument and equipment.

• This instrument is not intended for use in locations subject to

flammable or explosive gases.

• Do not touch high-voltage connections such as power supply

terminals, etc. to avoid electric shock.

• RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel.

Malfunction can occur and warranty is void under these conditions.

• This product is intended for use with industrial machines, test and

measuring equipment. (It is not designed for use with medical

equipment and nuclear energy.)

• This is a Class A instrument. In a domestic environment, this instrument

may cause radio interference, in which case the user may be required

to take additional measures.

• This instrument is protected from electric shock by reinforced insulation.

Provide reinforced insulation between the wire for the input signal and

the wires for instrument power supply, source of power and loads.

• Be sure to provide an appropriate surge control circuit respectively for

the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

• This instrument is designed for installation in an enclosed

instrumentation panel. All high-voltage connections such as power

supply terminals must be enclosed in the instrumentation panel to avoid

electric shock by operating personnel.

• All precautions described in this manual should be taken to avoid

damage to the instrument or equipment.

• All wiring must be in accordance with local codes and regulations.

• All wiring must be completed before power is turned on to prevent

electric shock, instrument failure, or incorrect action. The power must

be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must

be completed before power is turned on again.

• To prevent instrument damage of failure, protect the power line and the

input/output lines from high currents with a protection device such as

fuse, circuit breaker, etc.

• Prevent metal fragments or lead wire scraps from falling inside

instrument case to avoid electric shock, fire or malfunction.

• Tighten each terminal screw to the specified torque found in the manual

to avoid electric shock, fire or malfunction.

• For proper operation of this instrument, provide adequate ventilation for

heat dispensation.

• Do not connect wires to unused terminals as this will interfere with

proper operation of the instrument.

• Turn off the power supply before cleaning the instrument.

• Do not use a volatile solvent such as paint thinner to clean the

instrument. Deformation or discoloration will occur. Use a soft, dry cloth

to remove stains from the instrument.

• To avoid damage to instrument display, do not rub with an abrasive

material or push front panel with a hard object.

• When high alarm with hold action is used for Alarm function, alarm does

not turn on while hold action is in operation. Take measures to prevent

overheating which may occur if the control device fails.

CAUTION

NOTICE

• This manual assumes that the reader has a fundamental

knowledge of the principles of electricity, process control, computer

technology and communications.

• The figures, diagrams and numeric values used in this manual are

only for purpose of illustration.

• RKC is not responsible for any damage or injury that is caused as a

result of using this instrument, instrument failure or indirect damage.

• RKC is not responsible for any damage and/or injury resulting from

the use of instruments made by imitating this instrument.

• Periodic maintenance is required for safe and proper operation of

this instrument. Some components have a limited service life, or

characteristics that change over time.

• Every effort has been made to ensure accuracy of all information

contained herein. RKC makes no warranty expressed or implied,

with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

• No portion of this document may be reprinted, modified, copied, transmitted,

digitized, stored, processed or retrieved through any mechanical,

electronic, optical or other means without prior written approval from RKC.

All Rights Reserved, Copyright © 1999, RKC INSTRUMENT INC.

IMCB11-E7

RKC INSTRUMENT INC.

®

1. PRODUCT CHECK

CB103

CB403

CB903

-* - //Y

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

(1) Control action

F: PID action with autotuning (Reverse action)

D: PID action with autotuning (Direct action)

(2) Input type, (3) Range code: Refer to 9. INPUT RANGE TABLE.

(4) Control output [OUT1]

M: Relay contact T: Triac V: Voltage pulse

8: Current (4 to 20 mA DC) G: Trigger (for triac driving)

(5) Alarm 1 [ALM1], (6) Alarm 2 [ALM2]

N: No alarm H: Process high alarm

A: Deviation high alarm J: Process low alarm

B: Deviation low alarm K: Process high alarm with hold action

C: Deviation high/low alarm L: Process low alarm with hold action

D: Band alarm P: Heater break alarm (CTL-6

E: Deviation high alarm S: Heater break alarm (CTL-12

with hold action R: Control loop break alarm

F: Deviation low alarm V: SV high alarm

with hold action W: SV low alarm

G: Deviation high/low alarm with hold action

(7) Auxiliary output [DO]

N: No auxiliary output 7: Current (0 to 20 mA DC)

A to L: Temperature alarm output 8: Current (4 to 20 mA DC)

(Refer to the above alarm code) Y: RUN/STOP status output

3

1

)

1

)

2

(8) Contact input

N: No contact input 2: RUN/STOP

1: STEP function (SV1/SV2 switching)

(9) Waterproof/Dustproof

N: No waterproof/Dustproof 1: Waterproof/Dustproof

(10) Case color

N: White A: Black

1

Heater break alarm can not be specified in case of ALM1. Also, it isn’t possible to

specify when control output is current output.

2

As control loop break alarm, only either the alarm 1 or alarm 2 is selected.

3

No auxiliary output is provided when control output is trigger output.

Check that power supply voltage is also the same as that specified

when ordering.

<Accessories>

z Mounting frame (CB103): 1 (KCA100-526)

z Mounting brackets (CB403/CB903): 2 * (KCA400-532)

z Instruction manual (IMCB11-E7): 1

*CB903 waterproof/dustproof option: 4 pieces

2. MOUNTING

2.1 Mounting Cautions

(1) This instrument is intended to be used under the following environmental

conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

• Allowable ambient temperature: 0 to 50 °C

• Allowable ambient humidity: 5 to 95 %RH

(Absolute humidity: MAX. W. C 29.3 g/m

• Installation environment conditions: Indoor use, Altitude up to 2000 m

(3) Avoid the following conditions when selecting the mounting location:

• Rapid changes in ambient temperature which may cause condensation.

• Corrosive or inflammable gases.

• Direct vibration or shock to the mainframe.

• Water, oil, chemicals, vapor or steam splashes.

• Excessive dust, salt or iron particles.

• Excessive induction noise, static electricity, magnetic fields or noise.

• Direct air flow from an air conditioner.

• Exposure to direct sunlight.

• Excessive heat accumulation.

(4) Mount this instrument in the panel considering the following conditions:

• Provide adequate ventilation space so that heat does not build up.

• Do not mount this instrument directly above equipment that generates large

amount of heat (heaters, transformers, semi-conductor functional devices,

large-wattage resistors.)

• If the ambient temperature rises above 50 °C, cool this instrument with a forced

air fan, cooler, etc. Cooled air should not blow directly on this instrument.

• In order to improve safety and the immunity to withstand noise, mount this

instrument as far away as possible from high voltage equipment, power lines,

and rotating machinery.

High voltage equipment: Do not mount within the same panel.

Power lines: Separate at least 200 mm.

Rotating machinery: Separate as far as possible.

• Mount this instrument in the horizontal direction for panel. If you did installation

except a horizontal direction, this causes malfunction.

(5) If this instrument is permanently connected to equipment, it is important to

include a switch or circuit-breaker into the installation. This should be in close

proximity to the equipment and within easy reach of the operator. It should be

marked as the disconnecting device for the equipment.

3

dry air at 101.3 kPa)

Page 2

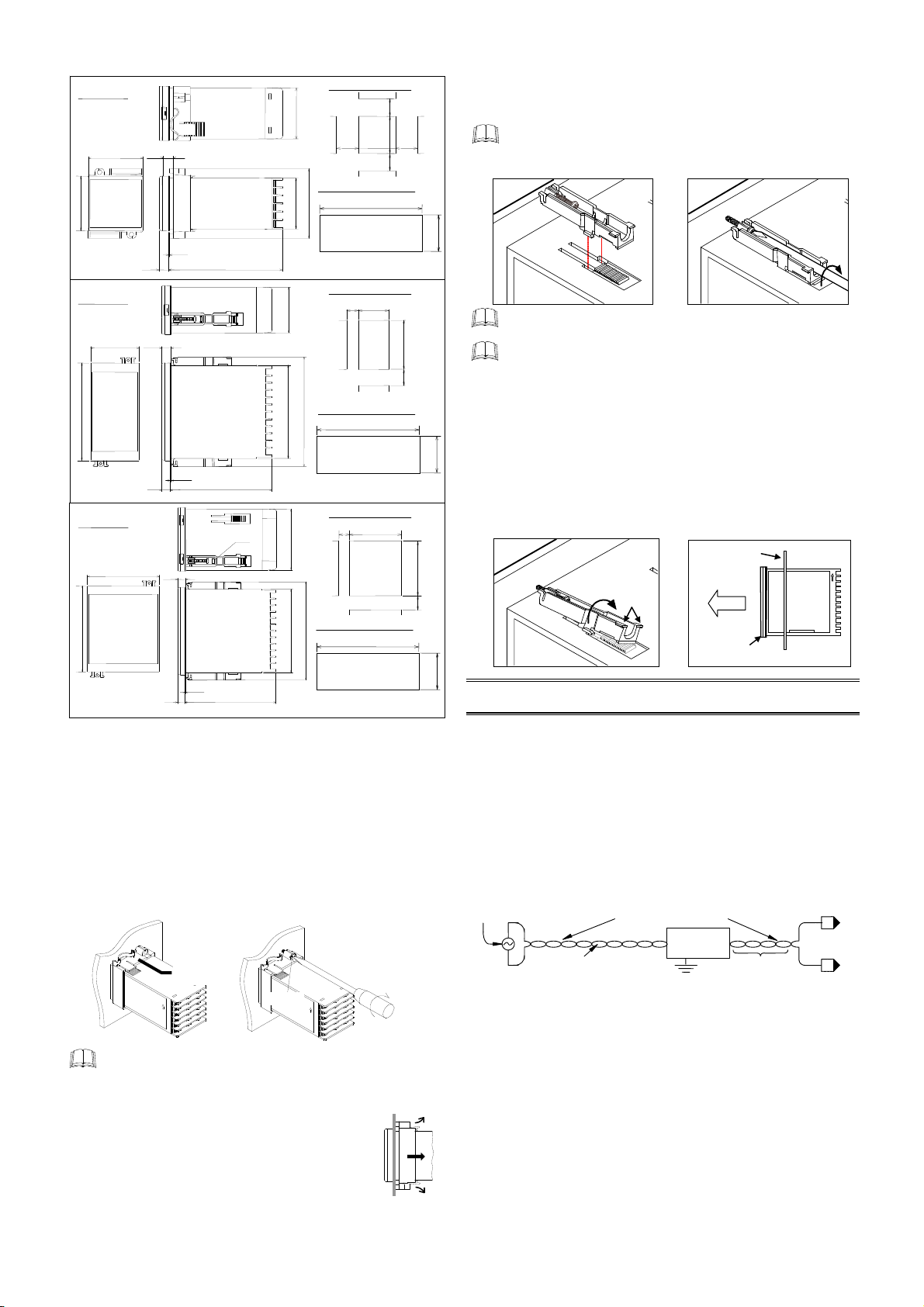

2.2 Dimensions

r

91.8

CB103

(Unit: mm)

48

9.2

48

CB403

(Unit: mm)

48

(*1)

1

8.2 100

9.2

96

8.2

(*1)

1

100

CB903

(Unit: mm)

96

9.2

*2

96

*1 Rubber (option)

*2 Up to four mounting brackets can be used.

z For mounting of the instrument, panel thickness must be between 1 to 10 mm.

(When mounting multiple instruments close together, the panel strength should be

checked to ensure proper support.)

z Waterproof and dustproof are not effective when instruments are closely spaced.

(*1)

1

8.2 100

Individual Mounting

44.8

25

Close vertical mounting

61.6

44.8

L1=48×n−3

n: Number of controllers (2 to 6)

Individual Mounting

44.8

91.8

91.8

25

Close vertical mounting

107.4

L1=48×n−3

n: Number of controllers (2 to 6)

Individual Mounting

25

Close vertical mounting

107.4

L1=96×n−4

n: Number of controllers (2 to 6)

0

+0.6

45

+0.6

0

25

45

25 25

+0.6

L1

0

+0.6

45

0

0

+0.8

92

30

+0.6

0

L1

+0.8

0

92

0

+0.8

92

30

+0.8

0

L1

2.3 Mounting Procedures

CB103

<Mounting Procedures>

1. Prepare the panel cutout as specified in 2.2 Dimensions.

2. Insert the instrument through the panel cutout.

3. Insert the mounting frame into the mounting from the rear of the instrument.

4. Push the mounting frame forward until the frame is firmly secured to the

panel. (Fig.1)

5. Fix the instrument to the panel by using the two screws. (Fig.2)

Fig.1

Mounting

frame

The waterproof/dustproof option on the front of the instrument conforms

to IP66 when mounted on the panel. For effective waterproof/dustproof,

the gasket must be securely placed between instrument and panel

without any gap. If the gasket is damaged, please contact RKC sales

office or the agent.

<Removal Procedures>

1. Turn the power OFF.

2. Remove the wiring.

3. Loosen the screw of the mounting frame.

4. Remove the mounting frame from the case. (Fig.3)

CB403/CB903

<Mounting Procedures>

1. Prepare the panel cutout as specified in 2.2 Dimensions.

2. Insert the instrument through the panel cutout.

Fig.2

Screw

When using the mounting

screws, only turn one full

revolution after the screw

touches the panel.

Fig.3

d

3. Insert the mounting bracket into the mounting groove of the instrument. Do not

push the mounting bracket forward. (Fig. 1)

4. Secure the bracket to the instrument by tightening the screw. Take care to

refrain from moving the bracket forward.

5. Only turn about one full revolution after the screw touches the panel. (Fig. 2)

If the screw has been rotated too tight, the screw may turn idle. In such a case,

loosen the screw once and tighten it again until the instrument is firmly fixed.

6. The other mounting bracket should be installed in the same way as described

in 3. to 5.

0

+0.6

45

When the instrument is mounted, always secure with two mounting brackets

so that upper and lower mounting brackets are positioned diagonally.

The waterproof/dustproof option (CB903: mounting bracket 4 pieces) on

the front of the instrument conforms to IP65 when mounted on the panel.

For effective waterproof/dustproof, the gasket must be securely placed

between instrument and panel without any gap. If gasket is damaged,

please contact RKC sales office or the agent.

<Removal Procedures>

1. Turn the power OFF.

2. Remove the wiring.

0

+0.8

3. Loosen the screw of the mounting bracket.

92

4. Hold the mounting bracket by the edge (c) and tilt it (d) to remove from the

case. (Fig. 3)

5. The other mounting bracket should be removed in the same way as described

in 3. and 4.

6. Pull out the instrument from the mounting cutout while holding the front panel

frame of this instrument. (Fig. 4)

Fig. 3

d

c

Panel

Pull out

0

+0.8

92

Front panel

frame

3. WIRING

3.1 Wiring Cautions

• For thermocouple input, use the appropriate compensation wire.

• For RTD input, use low resistance lead wire with no difference in resistance

between the three lead wires.

• To avoid noise induction, keep input signal wire away from instrument power

line, load lines and power lines of other electric equipment.

• If there is electrical noise in the vicinity of the instrument that could affect

operation, use a noise filter.

- Shorten the distance between the twisted power supply wire pitches to

achieve the most effective noise reduction.

- Always install the noise filter on a grounded panel. Minimize the wiring

distance between the noise filter output and the instrument power supply

terminals to achieve the most effective noise reduction.

- Do not connect fuses or switches to the noise filter output wiring as this

will reduce the effectiveness of the noise filter.

Instrument power

• Allow approximately 4 seconds for contact output when the instrument is

turned on. Use a delay relay when the output line is used for an external

interlock circuit.

• Power supply wiring must be twisted and have a low voltage drop.

• This instrument is not furnished with a power supply switch or fuses. If a fuse or

power supply switch is required, install close to the instrument.

- Fuse type: Time-lag fuse

- Recommended fuse rating: Rated voltage 250 V

Rated current: 1 A

• For the current input specification, an external resistor (250 Ω ±0.02 %, 0.25 W

or more, ±10 ppm/°C) must be connected between the input terminals. For

c

c

external resistor (shunt resistor), use the KD100-55: sold separately (RKC

product). If this resistor is installed, close horizontal mounting is not possible.

• For an instrument with 24 V power supply, supply power from a SELV circuit.

• A suitable power supply should be considered in end-use equipment. The

power supply must be in compliance with a limited-energy circuits (maximum

available current of 8 A).

• Use the solderless terminal appropriate to the screw size.

- Screw size: M3 x 6

- Recommended tightening torque: 0.4 Nxm [4 kgfxcm]

- Specified solderless terminals: With isolation

• Make sure that the any wiring such as solderless terminal is not in contact

with the adjoining terminals.

ten distance between

Sho

pitches

Twist these leadwires

IN

Noise filter

OUT

Minimize

distance

Fig.2Fig.1

Fig. 4

Instrument

power

terminals

2 IMCB11-E7

Page 3

3.2 Terminal Configuration

A

/

V

V

/

V

A

A

A

/

r

A

A

y

CB103

1

13

7

2

14

8

3

15

9

4

16

10

5

17

11

6

12

18

NO: Normally open

Power terminals

L

C

1

24 V

2

N

CB403

1

2

3

4

5

6

7

8

9

10

11

12

CB903

13

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

NC: Normally closed

DC

+

1

24 V

2

-

C

L

100 - 240 V

N

13

14

15

16

17

18

19

20

21

22

23

24

1

2

Auxiliary output terminals (optional)*

Relay contact

DO

3

NO

4

Alarm output (ALM3)

RUN/STOP state output

No auxiliary output is provided when control output is

trigger output.

Specifications

Input:

Input type:

Thermocouple:

K, J, R, S, B, E, T, N, PLII, W5Re/W26Re, U, L

Input impedance: Approx. 1 MΩ

RTD:

Pt100, JPt100

Voltage:

0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC (Z-1010)

Current:

0 to 20 mA DC, 4 to 20 mA DC

Sampling cycle: 0.5 seconds

Input range: Refer to Input range table

Control method: PID control, ON/OFF, P, PI,

or PD actions is available

Control output:

Relay contact output:

250 V AC, 3A (Resistive load), 1a contact

Electrical life: 300,000 times or more (Rated load)

Voltage pulse output:

0/12 V DC (Load resistance 600 Ω or more)

Current output:

4 to 20 mA DC (Load resistance 600 Ω or less)

Trigger output (for triac driving):

Zero cross method for medium capacity triac

driving (100 A or less)

Load voltage used: 100 V AC line, 200 V AC line

Load used: Resistive load

Current

AO

+

3

0 to 20 mA DC

4 to 20 mA DC

4

-

Analog output

or

Control output terminals

Trigge

T2

T1

G

OUT1

Triac

Voltage pulse

Current

4

OUT1

5

Triac out

6

+

5

OUT1

6

-

Rela

contact

OUT1

5

6

5

NO

6

Alarm output terminals (optional)

7

Alarm 2

Alarm 1

NO

ALM 2

8

NO

ALM 1

9

Input terminals

Voltage

+

11

0 to 5 V DC

or

IN

1 to 5 V DC

12

-

Triac output:

0.5 A (Ambient temperature: 40 °C or less)

RTD

10

A

RTD

B

11

B

12

Alarm output (option):

Relay contact output:

250 V AC, 1A (Resistive load), 1a contact

Electrical life: 50,000 times or more (Rated load)

Auxiliary out put (option)

Relay contact output rated:

250 V AC, 3 A (Resistive load), 1a contact

Current output rated:

0 to 20 mA DC or 4 to 20 mA DC

(Load resistance 600 Ω or less)

Contact input (option):

Dry contact input rated

At open 500 kΩ or more

At close 10 Ω or less

Performance:

Display accuracy

(at the ambient temperature 23 °C ± 2 °C):

Thermocouple:

± (0.3 % of display value + 1 digit) or

± 2 °C [4 °F] Whichever is greater

R, S and B input:

0 to 399 °C [0 to 799 °F]

Accuracy is not guaranteed.

T and U input:

−199.9 to −100.0 °C [−199.9 to −158.0 °F]

Accuracy is not guaranteed.

Contact input terminals (optional)

-

13

DI

15

+

Current transformer input terminals (optional)

CB103

17

CT1

18

Thermocouple

+

11

TC

12

-

RTD:

± (0.3 % of display value + 1 digit) or

± 0.8 °C [1.6 °F] Whichever is greater

Voltage/Current:

± (0.3 % of span + 1 digit)

CB403/CB903

23

CT1

24

Current

+

11

0 to 20 mA DC

4 to 20 mA DC

12

-

External resistor

or

Memory backup:

Backed up by Nonvolatile Memory

Number of write times: Approx. 1,000,000 times

Data storage period: Approx. 10 years

Power:

Power supply voltage:

85 to 264 V AC (Power supply voltage range), 50/60 Hz

Rating: 100 to 240 V AC

21.6 to 26.4 V AC (Power supply voltage range), 50/60 Hz

Rating: 24 V AC

21.6 to 26.4 V DC (Power supply voltage range)

Rating: 24 V DC

Power consumption:

7 VA max. (at 100 V AC), 10 VA max. (at 240 V AC)

5 VA max. (at 24 V AC), 160 mA max. (at 24 V DC)

Weight:

CB103: Approx. 170 g

CB403: Approx. 250 g

CB903: Approx. 340 g

4. PARTS DESCRIPTION

Measured value (PV) display [Green]

P

S

T

OUT1

SET

R

S

CB100

5

4

6

PV

S

T

OUT1

SET

R

S

CB900

5 4

1

STEP

2

ALM1

DO

ALM2

3

7

STEP

ALM1

ALM2

DO

PV

STEP

SV

T

SET

CB400

1

2

5 4

OUT1

DO

LM2

ALM1

R

S

6

7

3

7 6

c

Displays PV or various parameter symbols. The

decimal point at the least significant digit lights in

1

the step state (while the contact input closed).

d Set value (SV) display [Orange]

2

Displays SV, STEP set value (SV2), or various

parameter set values (or CT input value).

3

Indication lamps

e

Alarm output lamps (ALM1, ALM2) [Red]

ALM1: Lights when alarm 1 output is turned on.

ALM2: Lights when alarm 2 output is turned on.

Autotuning (AT) lamp [Green]

Flashes when autotuning is activated. (After

autotuning is completed: AT lamp will go out)

Control output lamps (OUT1) [Green]

OUT1: Lights when control output is turned on.*

* Lamp indication becomes as follows for current

output.

For an output of less than 0 %: Extinguished

For an output of more than 100 %: Lit

For an output of more than 0 % but less than

100 %: Dimly lit.

IMCB11-E7 3

Auxiliary output lamp (DO) [Green]

DO: Lights when first auxiliary output (alarm 3

[ALM3], RUN/STOP state output) is turned

on. When the analog output is selected as an

auxiliary output, the DO lamp does not light.

f

g

(Set key)

SET

Used for parameter calling up and set value

registration.

R/S

(Shift & R/S key)

Shift digits when settings are changed.

Select the RUN/STOP function.

(DOWN key)

h

Decrease numerals.

(UP key)

i

Increase numerals.

To avoid damage to the instrument,

never use a sharp object to press keys.

Page 4

5. SETTING

JPt

t

t

Set Val

(SV1)

Set Val

(SV2)

5.1 Operation Menu

Input type and Input range Display

The controller will display the M easured value (PV) and

the Set value (SV). The controller will displa y the Measured

value (PV) and the Set value (SV). If the ST EP function is

provided, the SV display will shows the Set value (SV1) or

STEP set value (SV2) depending on whether the contact

input is opened or closed.

Display in STEP State:

PV

SV

PV/SV monitor

(RUN mode)

Press and hold the

<R/S key for 1 second.

SV

Factory set value: RUN

Input type and input range display

When the instrument is powered on, it immediately confirms the input type and input range

Example: When sensor type of input is K thermocouple.

PV

SV

Power ON

SV Setting Mode

Automatically (in 4 sec)

PV/SV Display Mode

Digital poin

:

ON

This decimal point indicates that the

instrument is in the STEP state. It also

lights in the STEP state while Parameter

setting mode are being displayed.

Press the SET key

STOP character display

(STOP mode)

Display returns to the PV/SV display mode if no key operation is

performed within 1 minute.

Symbol

Automatically

Input type symbol *

Unit for input and SV display

(Celsius: °C, Fahrenheit: °F, Voltage/Current inputs: no character shown)

PV

SV

Input range high

Input range low

This is the mode used to set the Set v alue (SV).

Without STEP function:

Press the

SET key

Press the

SET key

Press and hold the SET key for 2 seconds.

PV

Factory Set Value: 0 °C [°F] or 0.0 °C [°F]

With STEP function:

If the STEP function is provided, th e following

parameter symbols are d isplayed on the PV display.

SV

ue

SV

Press the SET key

ue

SV

SV1 Setting

SV2 Setting

SV Setting

* Input Type Symbol Table

Symbol

Input type

K J R S B E T N PL II

This mode is used to set the parameters such as alarms, PID constants, etc. (Refer to page 6.)

The following parameter symbols are displayed as the SET key is pressed.

(CT1)

(AL1)

(AL2)

(AL2)

(HbA1)

(LbA)

(Lbd)

(ATU)

(STU)

(P)

Current transformer

monitor

Press the SET key

Alarm 1 set value (ALM1)

Press the SET key

Alarm 2 set value (ALM2)

Press the SET key

Alarm 3 set value (ALM3)

Press the SET key

Heater break alarm 1

set value (HBA)

Press the SET key

Control loop break

alarm (LBA) time

Press the SET key

LBA deadband

Press the SET key

Autotuning (AT)

Press the SET key

Self-tuning (ST)

Press the SET key

Proportional band

Parameters which are not related to existing functions on the controller are not displayed.

Thermocouple (TC)

Parameter Setting Mode

Press the SET key

W5Re/

U L

W26Re

Integral time

(I)

Press the SET key

Derivative time

Press the SET key

(D)

(Ar)

(Pb) Press the SET key

(Ao)

(AHS)

(ALS)

(LCK)

Return to the first parameter

100

Anti-reset windup

Press the SET key

Proportioning cycle

Press the SET key(T)

PV bias

Analog Output (Ao) Selection

Press the SET key

Analog output scale high (AHS)

Press the SET key

Analog output scale low (ALS)

Press the SET key

Set data lock

Press the SET key

RTD

P

(Current)

100

Voltage

5.2 Parameter List

Parameter symbols which are not related to existing functions on the controller are not displayed.

Symbol Name Setting range Description Factory set value

Current transformer

input 1

Alarm 1 set value

(ALM1)

Alarm 2 set value

(ALM2)

Alarm 3 set value

(ALM3)

Heater break

alarm 1 set value

1

(HBA)

Control loop break

alarm (LBA) time

LBA deadband 3 TC/RTD inputs:

Autotuning (AT) 0: AT end or cancel

Self-tuning (ST) 0: Self-tuning OFF

Proportional band

(P)

Integral time (I)

Derivative time (D)

Anti-reset windup

(ARW)

Proportioning cycle

(T)

PV bias (Pb) TC/RTD inputs:

0.0 to 100.0 A

[Display only]

TC/RTD inputs:

Deviation alarm, Process alarm, SV alarm:

−1999 to +9999 °C [°F] or

−199.9 to +999.9 ° C [°F]

Voltage/Current inputs:

Deviation alarm:

−span to +span (Within 9999)

Process alarm, SV alarm:

Same as input range

0.0 to 100.0 A

See *1.

0.1 to 200.0 minutes

2

See *2.

0 to 9999 °C [°F]

Voltage/Current inputs:

0 to 100 % of span

1: AT start or execution

1: Self-tuning ON

TC/RTD inputs:

1 (0.1) to

span or 9999 (999.9) °C [°F]

Voltage/Current inputs:

0.1 to 100.0 % of span

1 to 3600 seconds

(0 second: PD action)

1 to 3600 seconds

(0 second: PI action)

1 to 100 % of proportional band

(0 %: Integral action OFF)

1 to 100 seconds

(Not displayed if the control output is

current output.)

−1999 to +9999 °C [°F] or

−199.9 to +999.9 °C [°F]

Voltage/Current inputs:

−span to +span

Display input value from the current transformer.

[Displayed only when the instrument has the Heater break

alarm]

Set the ALM1 set value, ALM2 set value,.and ALM3 set

value.

For the alarm action type, refer to page 7.

Alarm differential gap:

TC/RTD inputs: 2 or 2.0 °C [°F]

Voltage/Current inputs: 0.2 % of span

SV alarm can not be specified in case of ALM3.

ALM3 is auxiliary output.

Alarm value is set by referring to input value from the

Current transformer (CT).

Used only for single-phase.

Set control loop break alarm set value.

Set the area of not outputting LBA.

No LBA deadband functions with 0 set.

Differential gap :

TC/RTD inputs: 0.8 °C [°F ]

Voltage/Current inputs: 0.8 % of span

Turns the autotuning ON/OFF.

Turns the self-tuning ON/OFF.

Set when PI, PD or PID control is performed.

ON/OFF action control when set to 0 (0.0).

ON/OFF action differential gap:

TC/RTD inputs: 2 (0.2) °C [°F ]

Voltage/Current inputs: 0.2 % of span

Set the time of integral act ion to eliminate the offset

occurring in proportional control.

Set the time of derivative action to improve control

stability by preparing for output changes.

Overshooting and undershooting are restricted by the

integral effect.

Set control output cycle.

Sensor correction is made by adding bias value to

Measured value (PV).

TC/RTD inputs:

50 (50.0)

Voltage/Current inputs:

5.0

0.0

8.0

0

0

0

TC/RTD inputs:

30 (30.0)

Voltage/Current inputs:

3.0

240

60

100

Relay contact output: 20

Voltage pulse output/

Trigger output for triac

driving/Triac output: 2

0 or 0.0

4 IMCB11-E7

Page 5

(

)

y

(

)

Symbol Name Setting range Description Factory set value

1

Heater Break Alarm (HBA) function

The HBA function monitors the current flowing through the load by a dedicated

Current transformer (CT), compares the measured value with the HBA set value,

and detects a fault in the heating circuit.

Low or No current flow (Heater break, malfunction of the control device, etc.):

When the control output is ON and the current transformer input value is equal

to or less than the heater break determination point for the preset number of

consecutive sampling cycle, an alarm is activated.

Over current or short-circuit:

When the control output is OFF and the current transformer input value is equal

to or greater than the heater break determination point for the preset number of

consecutive sampling cycle, an alarm is activated.

Precaution for HBA setting:

• Displayed only for when HBA is selected as Alarm 2.

• HBA is not available on a current output.

• Set the set value to approximately 85 % of the maximum reading of the CT

input.

• Set the set value to a slightly smaller value to prevent a false alarm if the

power supply may become unstable.

• When more than one heater is connected in parallel, it may be necessary to

increase the HBA set value to detect a single heater failure.

• When the current transformer is not connected, the HBA is turned on.

2

Control Loop Break Alarm (LBA) function

The LBA function is used to detect a load (heater) break or a failure in the

external actuator (power controller, magnet relay, etc.), or a failure in the control

loop caused by an input (sensor) break. The LBA function is activated when

control output reaches 0 % (low limit with output limit function) or 100 % (high

limit with output limit function). LBA monitors variation of the measured value

(PV) for the length of LBA time. When the LBA time has elapsed and the PV is

still within the alarm determination range, the LBA will be ON.

Precaution for LBA setting:

• Displayed only for when LBA is selected as Alarm 1 or Alarm 2.

• The LBA function can not be activated when AT function is turned on.

• The LBA function is activated when control output reaches 0 % or 100 %.

The time required for the LBA output to turn on includes both the time from

the initial occurrence of loop failure and the LBA setting time. Recommended

setting for LBA is for the set value of the LBA to be twice the value of the

Integral time (I).

• If LBA setting time does not match the controlled object requirements, the

LBA selling time should be lengthened.

If setting time is not correct, the LBA will malfunction by turning on or off at

inappropriate times or not turning on at all.

3

LBA Deadband function

The LBA may malfunction due to external disturbances. To prevent

malfunctioning due to external disturbance, LBA deadband (LBD) sets a neutral

zone in which LBA is not activated. When the Measured value (PV) is within the

LBD area, LBA will not be activated. If the LBD setting is not correct, the LBA

will not work correctly.

Alarm area Alarm area

Low High

A: During temperature rise: Alarm area

During temperature fall: Non- alarm area

* TC/RTD inputs: 0.8 °C [°F] (fixed) Voltag e/Current inputs: 0.8 % of span (fixed)

5.3 Changing Parameter Settings

Procedures to change parameter settings are shown below.

To store a new value for the parameter, always press the SET key. The

display changes to the next parameter and the new value will be stored.

− A new value will not be stored without pressing SET key after the new

value is displayed on the display.

− After a new value has been displayed by using the UP and DOWN keys,

the SET key must be pressed within 1 minute, or the new value is not

stored and the display will return to the PV/SV monitor screen.

Analog output

(Ao) selection

Analog output

scale high (AHS)

Analog output

scale low (ALS)

Set data lock

(LCK)

0: Measured value (PV)

1: Set value (SV)

2: Deviation value (DEV)

3: Manipulated output value (MV)

PV,SV: ALS to Setting limiter high (SLH)

DEV: ALS to +span (within 9999)

MV: ALS to 100.0

PV,SV: Setting limiter low (SLL) to AHS

DEV: −span (within −9999) to AHS

MV: 0.0 to AHS

Parameters other than SV and Alarms

0: Unlock 1: Lock

Alarms 0: Unlock 1: Lock

SV 0: Unlock 1: Lock

Initialization mode

0: Lock 1: Unlock

LBD differential gap*

Non-alarm area

A B

Set value (SV) LBD set value

B: During temperature rise: Non-alarm area

-

During temperature fall: Alarm area

Select the analog output type.

Analog output is auxiliary output.

Set the analog output scale high.

Set the analog output scale low.

Performs set data change enable/disable.

0

Input range

(high limit)

Input range

(low limit)

0000

z Change the Set value (SV)

Change the Set value (SV) from 0 °C to 200 °C (No step function)

1. Select the SV setting mode

Press the SET key at PV/SV monitor

screen until SV setting screen is

displayed.

2. Shift the high-lighted digit

Press the <R/S key to high-light the

hundreds digit.

The high-lighted digit indicates which

digit can be set.

3. Change the set value

Press the UP key to change the

number to 2.

4. Store the set value

Press the SET key to store the new

set value. The display returns to the

PV/SV monitor screen.

z Change parameters other than the Set value (SV)

The changing procedures are the same as those of example 2 to 4 in the above

"z Change the Set value (SV)". Pressing the SET key after the setting end

shifts to the next parameter. When no parameter setting is required, return the

instrument to the PV/SV display mode.

PV

SV

PV/SV monitor display

(PV/SV display mode)

PV

SV

PV

SV

PV

SV

PV

STEP STEP

SV

SV setting display

SV setting mode

PV

STEP STEP

SV

PV

STEP STEP

SV

PV

STEP STEP

SV

PV/SV monitor displa

PV/SV display mode

6. OPERATIONS

z All mounting and wiring must be completed before the power is turned on.

If the input signal wiring is disconnected or short-circuited (RTD input only),

the instrument determines that burnout has occurred.

− Displays:

• Upscale: Thermocouple input, RTD input (when input break)

• Downscale: Thermocouple input (specify when ordering),

RTD input (when short-circuited),

Voltage input (1 to 5 V DC), Current input (4 to 20 mA DC)

• For the voltage (0 to 5 V DC, 0 to 10 V DC*) or current (0 to 20 mA DC)

input, the display becomes indefinite (display of about zero value).

* Z-1010 specification

− Outputs

• Control output: OFF

• Auxiliary output: Analog output:

RUN/STOP status output:

Alarm 3 output:

• Alarm outp ut: Both of the Alarm 1 and Alarm 2 outputs of this instrument

z A power failure of 20 ms or less will not affect the control action.

When a power failure of more than 20 ms occurs, the instrument

assumes that the power has been turned off.

When power returns, the controller will retain the conditions that

existed prior to shut down.

z The alarm hold action is activated when not only the power is turned

on or the SV is changed, including an SV change made with the

STEP function.

6.1 Operation Procedures

1. Prior to starting operation, check that the mounting and wiring have been

finished, and that the SV and various parameters have been set.

2. A power supply switch is not furnished with this instrument. It is ready to

operate as soon as the power is turned on. (Factory set value: RUN).

This instrument holds the conditions that exist just before the power is

turned on. For example, if the power is turned off in STOP mode, the

instrument starts in STOP mode when the power is turned on again.

CAUTIONS

For 4 to 20 mA DC, a current of 4 mA is output

and for 0 to 20 mA, the output becomes indefinite

(output of about 0 mA).

Outputs the STOP state (OPEN).

Becomes the same as the following alarm output.

are turned on when burnout occurs regardless of any of

the following actions taken. (High alarm, low alarm, etc.) In

addition, when used for any purposes other than these

alarms (event, etc.), specify the Z-124 specification (not to

be forcibly turned on).

IMCB11-E7 5

Page 6

6.2 RUN/STOP

RUN/STOP can be selected by contact input (optional) other than the key

operation. In addition, at STOP the key operation and contact state are

displayed on the PV display. Relationships between key operation, RUN/STOP

and the characters to indicate the STOP state are shown in the following.

RUN/STOP

RUN

with Key

Operation

1

Contact input: Terminal No.13, 15

2

Characters in parentheses are those shown on the PV display:

• Control, Alarm: Control OFF, Alarm OFF

• Output: OUT1 output OFF

• Autotuning (AT): AT canceled (The PID constants are not updated)

When operation is changed to the STOP mode by RUN/STOP selection, a

parameter symbol to indicate the STOP mode is displayed on the SV display.

Pressing the SET key with the STOP mode displayed can also check and

change the Set value (SV).

STOP

(KSTP)

: Only contact input is in the STOP mode

: Only key operation is in the STOP mode

: Both key operation and contact inputs are in the STOP mode

Conditions when changed to STOP mode:

RUN/STOP display (Z-1018 specification):

RUN/STOP with Contact Input 1

RUN (Contact closed) STOP (Contact open)

RUN STOP

STOP is not displayed (dSTP)

STOP STOP

2

(SToP)

2

2

6.3 STEP Function (optional)

The controller has two Set value (SV). This STEP function selects these two Set

values (SV) by contact input (terminal No.13, 15).

Contact open: Set value (SV1)

Contact closed: STEP set value (SV2)

6.4 Auxiliary Output Function (optional)

One auxiliary output can be selected form among ALM3, analog output, and

RUN/STOP mode output (RUN: contact closed, STOP: contact open).

6.5 Set Data Lock (LCK) Function

The set data lock restricts parameter setting changes by key operation. This

function prevents the operator from making errors during operation. There are 8

set data lock levels. (refer to below)

Set value Parameters which can be changed

0000 All parameters [Factory set value]

0001 SV, Alarms (ALM1, ALM2, ALM3)

0010 All parameters except for Alarms (ALM1, ALM2, ALM3)

0011 SV

0100 All parameters except for SV

0101 Alarms (ALM1, ALM2, ALM3)

0110 All parameters except for SV and Alarms (ALM1, ALM2, ALM3)

0111 No parameters (All Locked)

HBA, LBA and LBD can be locked when any of 0001, 0011, 0101 and 0111 is set.

Set data lock can be changed in both RUN and STOP mode.

Parameters protected by Set data lock function are still displayed for

monitoring.

6.6 Autotuning (AT) Function

Autotuning (AT) automatically measures, computes and sets the optimum PID

and LBA constants. The following conditions are necessary to carry out

autotuning and the conditions which will cause the autotuning to stop.

Caution for using the Autotuning (AT)

When a temperature change (UP and/or Down) is 1 °C or less per

minute during AT, AT may not be finished normally. In that case,

adjust the PID values manually. Manual setting of PID values may

also be necessary if the set value is around the ambient temperature

or is close to the maximum temperature achieved by the load.

Requirements for AT start

Start the autotuning when all following conditions are satisfied:

• Prior to starting the AT function, end all the parameter settings other than PID

and LBA.

• Confirm the LCK function has not been engaged.

When the autotuning is finished, the controller will automatically returns

to PID control.

Requirements for AT cancellation

The autotuning is canceled if any of the following conditions exist.

• When the Set value (SV) is changed.

• When the PV bias value is changed.

• When the RUN/STOP mode is changed to the STOP mode.

• When the PV becomes abnormal due to burnout.

• When the power is turned off.

• When power failure longer than 20 ms occurs.

• When the AT does not end in 9 hours after autotuning started.

If the AT is canceled, the controller immediately changes to PID control.

The PID values will be the same as before AT was activated.

When AT is completed, the controller immediately changes to PID

control. If the control system does not allow the AT cycling process, set

each PID constant manually to meet the needs of the application.

6.7 Self-tuning (ST) Function

The ST function is used to automatically calculate and set adaptive PID

constants anytime the power is turned on, the SV is changed or the controller

detects unstable control conditions.

The ST function should be turned off when the controlled system is

affected by rippling that occurs due to periodic external disturbances.

The power to the controlled system must be turned on before the

power to the instrument is turned on or SV is changed. This is

required when ST function is on.

To activate the ST function, the following parameters must not be

set to zero: P≠0, I≠0, D≠0, ARW≠0.

When the AT function is activated, the ST function can not be turned on.

When the ST function is activated, the PID and ARW settings can be

monitored, but not changed.

7. INITIAL SETTING

Parameters in the Initialization mode should be set according to the

application before setting any parameter related to operation. Once

the Parameters in the Initialization mode are set correctly, no further

changes need to be made to parameters for the same application

under normal conditions. If they are changed unnecessarily, it may

result in malfunction or failure of the instrument. RKC will not bear

any responsibility for malfunction or failure as a result of improper

changes in the Initialization mode.

7.1 Go to Initialization Mode

1. Turn on the power to this controller. The instrument goes to the PV/SV

display after confirming input type symbol and input range.

2. Press and hold the SET key for 2 seconds to go to the Parameter setting

mode from the PV/SV display.

3. Press the SET key until “LCK” (Set data lock display) will be displayed.

4. The high-lighted digit indicates which digit can be

set. Press <R/S key to high-light the thousands

digit. (The section in each image of the

controller shows the digits which are not

high-lighted.)

5. Press the UP key to change 0 to 1.

Set value 0: Initialization mode locked

1: Initialization mode unlocked

6. Press the SET key to store the new set value.

The display goes to the next parameter, and the

Initialization mode is unlocked. (The parameter

displayed varies on the instrument specification.)

7. Press the <R/S key for 2 seconds while pressing the SET key to go to

the Initialization mode.

When the controller goes

to the Initialization mode,

“Cod” will be displayed.

7.2 Exit Initialization Mode

When any parameter setting is changed in the Initialization mode,

check all parameter set values in SV setting mode and Parameter

setting mode.

1. Press the <R/S key for 2 seconds while pressing the SET key from any

display in the Initialization mode. The controller goes back to the operation

mode and the PV/SV display will be displayed.

2. Press and hold the SET key for 2 seconds in the PV/SV display.

3. Press the SET key until “LCK” (Set data lock display) will be displayed.

4. The high-lighted digit indicates which digit can be set. Press <R/S key to

high-light the thousands digit. (The section in each image of the

controller shows the digits which are not high-lighted.)

5. Press the DOWN key to change 1 to 0.

Set value 0: Initialization mode locked

1: Initialization mode unlocked

6. Press the SET key to store the new set value.

The display goes to the next parameter, and the

Initialization mode is locked. (The parameter

displayed varies on the instrument specification.)

WARNING

PV

SV

CT1 input value display

STEP

PV

SV

Set data lock function dis play

PV

SV

PV

SV

CT1 input value display

PV

SV

Initialize code selection display

of initialization mode

PV

SV

Set data lock function display

PV

SV

CT1 input value display

STEP

STEP

STEP

STEP

STEP

STEP

6 IMCB11-E7

Page 7

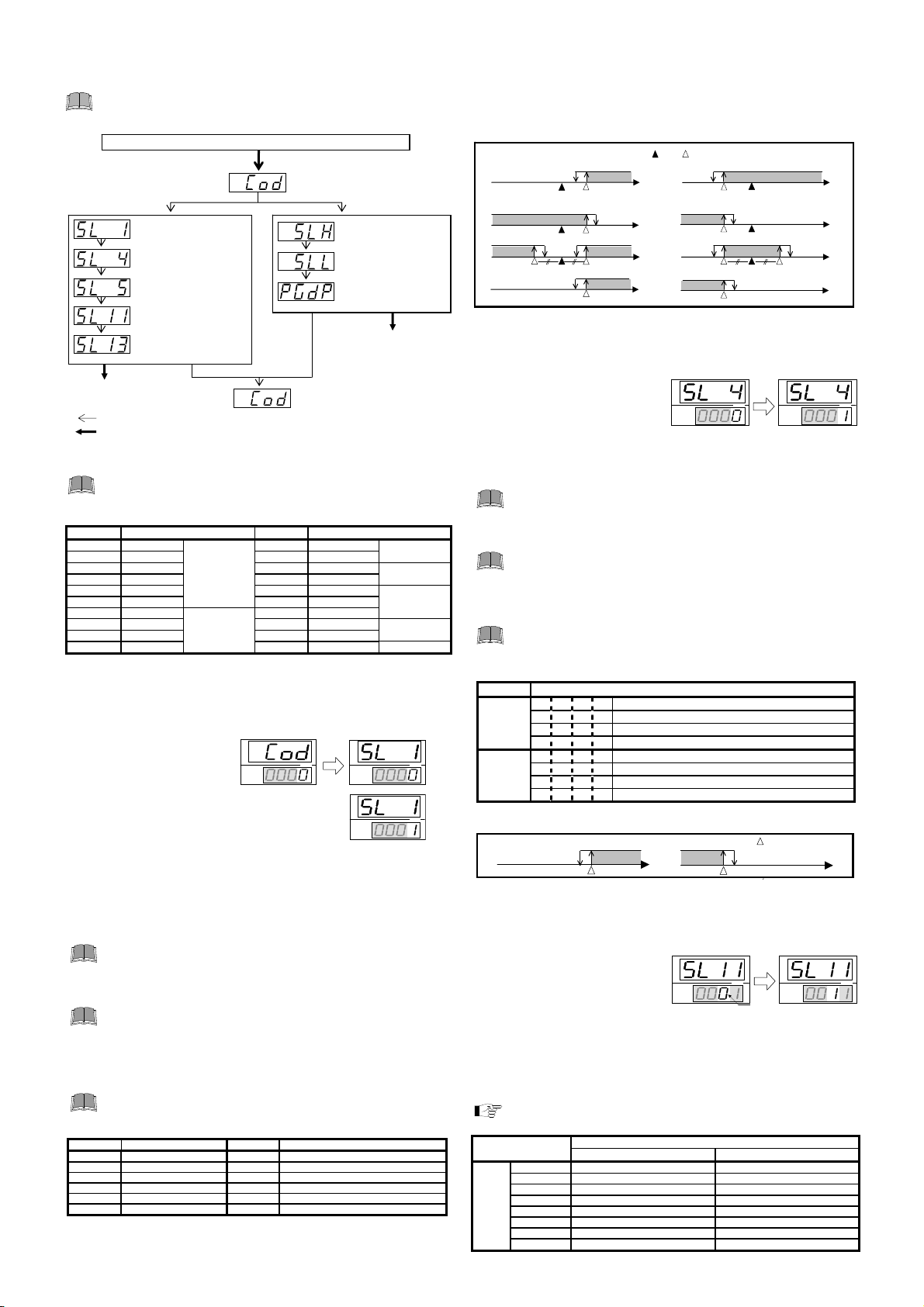

7.3 Initial Setting Menu

g

)

g

g

The “Cod” display will be displayed when the controller goes to the Initialization mode.

Do not change to any parameter in the Initialization mode which is

not described in the initial setting menu above.

It may result in malfunction or failure of the instrument.

Press the <R/S key while pressing th e SET key

for 2 seconds with the unlocked.

Set Cod to 0000.

PV/SV display mode or Parameter setting mode

(Cod)

Input type selection

(SL1)

Alarm1 type selection

(SL4)

Alarm2 type selection

(SL5)

SV alarm type selection

(SL11)

Alarm3 type selection

(SL13)

Initialization code selection

Set Cod to 0001.

Setting limiter [high]

(SLH)

Setting limiter [low]

(SLL)

Decimal point position

(PGdP)

To PV/SV display mode

To PV/SV display mode

: Press the SET key, or press the SET key several times.

: Press the <R/S key while pressing the SET key for 2 seconds.

7.4 Input Type Selection (SL1)

When any parameter setting is changed in the Initialization mode,

check all parameter set values in SV setting mode and Parameter

setting mode.

Set value Input type Set value Input type

0000 K 0101 T

0001 J 0110 U

0010 L 1100 Pt100 Ω (JIS/IEC)

0011 E 1101 JPt100 Ω (JIS)

0100 N 1110 0 to 5 V DC

0111 R

1000 S 1111 1 to 5 V DC

1001 B 1110 0 to 20 mA DC

1010 W5Re/W26Re 1111 4 to 2 0 mA DC

1011 PL II

1

Any input change in TC&RT D group is possible. Any input change in Voltag e & Current group except for 0 to

10 V DC input is possible. No input change between TC&RTD group and Voltage & Current group is possible.

2

The input type of Z- 1010 specification is fixed to 0 to 10 V D C due to the hardware difference.

3

For the current input sp ecification, a resistor of 250 Ω m ust be connected between the input terminals .

Factory set value varies depending on the input type.

Thermocouple

1

(TC)

Initialization code selection

Thermocouple

1110 0 to 10 V DC 2

⎯ ⎯ ⎯

Voltage

Current

(TC)

RTD

1

1, 3

Change Settings

Example: Change the input type from “K” to “J”

1. Set “Cod” to 0000, and

press the SET key. The

display will go to SL1.

2. Press the UP key to change the number to 1.

3. Press the SET key to store the new set value.

The display goes to the next parameter.

PV

SV

Initialize code selection display

PV

STEP

SV

PV

SV

Input type selection

STEP

STEP

7.5 Alarm 1 [ALM1] Type Selection (SL4)

Alarm 2 [ALM2] Type Selection (SL5)

Alarm 3 [ALM3] Type Selection (SL13)

If the alarm function is not provided with the instrument when shipped from the

factory, no alarm output is available by changing SL4 and/or SL5.

SL4 is set to 0000 in the following cases.

• When the instrument does not have ALM1 output

• When Control Loop Break Alarm (LBA) is provided and assigned

to ALM1

• When the SV alarm is provided and assigned to ALM1

SL5 is set to 0000 in the following cases.

• When the instrument does not have ALM2 output

• When Control Loop Break Alarm (LBA) is provided and assigned

to ALM2

• When the SV alarm is provided and assigned to ALM2

• When the Heater Break Alarm (HBA) is provided

• When the instrument has Z-168 specification

SL13 is set to 0000 in the following cases.

• When the instrument does not have ALM3 output

Set value Details of setting Set value Details of setting

* Hold action:

When Hold action is ON, the alarm action is suppressed at start-up or the

control set value change until the measured value enters the non-alarm range.

Factory set value varies depending on the instrument specification.

0000 No alarm 0111 Process low alarm

0001 Deviation high alarm 1001 Deviation high alarm with hold action *

0010 Deviation high/low alarm 1010 Deviation high/low alarm with hold action *

0011 Process high alarm 1011 Process high alarm with hold action *

0101 Deviation low alarm 1101 Deviation low alarm with hold action *

0110 Band alarm 1111 Process low alarm with hold action *

z Alarm action type

The Alarm 1, Alarm 2 and Alarm 3 outputs of this instrument are turned on

when burnout occurs regardless of any of the following actions taken (High

alarm, low alarm, etc.). In addition, when used for any purposes other than

these alarms (event, etc.), specify the Z-124 specification (not to be

forcibly turned on).

Deviation high alarm

(Alarm set value is greater than 0)

OFF

Low

Deviation low alarm

(Alarm set value is greater than 0)

ON

Low

Deviation high/low alarm

Low High

Process high alarm

Low

OFF ONON

OFF

ON

☆

High

☆

OFF

High

☆☆

☆

ON

Hi

h

: Alarm set value ☆: Alarm differential gap)

( : SV

(Alarm set value is less than 0)

☆

PV

PV

PV

PV

OFF

Low

(Alarm set value is less than 0)

ON

☆

Low

Band alarm

OFF

☆ ☆

Low

Process low alarm

ON

☆

Low Hi

Change Settings

Example: Change the ALM1 type from “No alarm (0000)” to

“Deviation high alarm (0001)”

1. Press the SET key several times at SL1 until SL4 is displayed.

2. Press the UP key to change

the number to 1.

3. Press the SET key to store the new set value. The display goes to the next

parameter.

7.6 SV Alarm Type Selection (SL11)

For ALM1 setting, the first digit from the right is set to “0” in the

following cases.

• When the instrument does not have ALM1 output.

1

1

• When the ALM1 output is used for Process/Deviation/Band alarm

z SV alarm action type

or Loop break alarm (LBA).

For ALM2 setting, the third digit from the right is set to “0” in the

following cases.

• When the instrument does not have ALM2 output.

• When the ALM1 output is used for Process/Deviation/Band alarm,

Heater break alarm (HBA) or Loop break alarm (LBA).

• When Z-168 is specified.

To make SV alarm setting effective, set SL4 to “0000” when using

ALM1 for SV alarm, or set SL5 to “0000” when using ALM2 for SV

alarm. SL4 and SL5 have priority to SL11 setting.

Factory set value varies depending on the instrument specification.

Alarm Details of setting

0 SV alarm not provided

Alarm 1 1 SV alarm provided

[ALM1] 0 SV high alarm

1 SV low alarm

0 SV alarm not provided

Alarm 2 1 SV alar m provided

[ALM2] 0 SV high alarm

1 SV low alarm

SV high alarm

Low

☆

OFF ON

High

PV

SV

SV low alarm

SV

Low

ON

STEP

( : Alarm set value

☆

☆

Change Settings

Example: Change the SV alarm type of the ALM1 from “SV high

alarm (0001)” to “SV low alarm (0011)”

1. Press the SET key several times at SL1 until SL11 is displayed.

2. Press the <R/S key to high-light

the tens digit. Next, press the UP

key to change the number to 1.

3. Press the SET key to store the new set value. The display goes to the

initialize code parameter.

PV

SV

STEP

High-light

7.7 Setting Limiter [High] (SLH)

Setting Limiter [Low] (SLL)

For voltage or current input, set scaling within the input range.

Refer to 9. INPUT RANGE TABLE.

K SLL to 1372 °C SLL to 2502 °F 0 to SLH °C 0 to SLH °F

J SLL to 1200 °C SLL to 2192 °F 0 to SLH °C 0 to SLH °F

R SLL to 1 769 °C SLL to 3216 °F 0 to SLH °C 0 to SLH °F

TC S SLL to 1769 °C SLL to 3216 °F 0 to SLH °C 0 to SLH °F

B SLL to 1820 °C SLL to 3308 °F 0 to SLH °C 0 to SLH °F

E SLL to 1000 °C SLL to 1832 °F 0 to SLH °C 0 to SLH °F

N SLL to 1 300 °C SLL to 2372 °F 0 to SLH °C 0 to SLH °F

T SLL to 400.0 °C SLL to 752.0 °F −199.9 to SLH °C −199.9 to SLH °F

Factory set value varies depending on the instrument specification.

Input type

Setting limiter [high] Setting limiter [low]

Setting range

ON

High

OFF

High

OFFON

High

OFF

: Alarm differential

PV

SV

OFF

h

High

PV

SV

PV

PV

PV

PV

STEP

ap

SV

STEP

IMCB11-E7 7

Page 8

TC W5Re/W26Re SLL to 2 320 °C SLL to 4208 °F 0 to SLH °C 0 to SLH °F

PLII SLL to 1390 °C SLL to 2 534 °F 0 to SLH °C 0 to SLH °F

U SLL to 600.0 °C SLL to 999. 9 °F −199.9 to SLH °C −199.9 to SLH °F

L SLL to 900 °C SLL to 1652 °F 0 to SLH °C 0 to SLH °F

RTD Pt100

JPt100

Voltage 0 to 5 V DC

0 to 10 V DC *

1 to 5 V DC

Current 0 to 20 mA DC

4 to 20 mA DC

* Z-1010 specification

Change Settings

Example: When the display range is scaled to 0.0 to 400.0 for

a voltage input of 1 to 5 V DC.

1V 5 V

1. Set Cod to 0001, and

2. The high-lighted digit indicates which digit can be

3. Press the UP key to change the number to 4.

4. Press the SET key to store the new set value. The display goes to SLL.

5. Set SLL to 0.0.

6. Press the SET key to store the new set value. The display goes to the next

7.8 Decimal Point Position (PGdP)

Use to select a Decimal point position of the input range (voltage input and

current input). PGdP is displayed only for voltage or current input.

Set value Description

Factory set value varies depending on the instrument specification.

Input type

Factory set value → 0.0 100.0

Scaling → 0.0 400.0

press the SET key. The

display will go to SLH.

set. Press <R/S key to high-light the first digit

from the left. (The **** section in each image of

the controller shows the digits which are not

high-lighted.)

Setting limiter [high] Setting limiter [low]

SLL to 649.0 °C SLL to 9 99.9 °F −199.9 to SLH °C −199.9 to SLH °F

SLL to 9999

(Programmable scale)

Setting range

PV

SV

Initialize code selection display

STEP

−1999 to SLH

(Programmable scale)

PV

SV

Setting limiter [high ] display

PV

SV

PV

SV

parameter.

Inappropriate settings may result in malfunction.

0000 No decimal place ()

0001 One decimal place (.) [Factory set value]

0002 Two decimal places (.)

0003 Three decimal places (.)

9. INPUT RANGE TABLE

zTC/RTD inputs

Input type Range Code Range Code Range Code

K 0 to 200 °C K 01 0 to 400 °C K 02 0 to 600 °C K 03

TC

STEP

STEP

STEP

W5Re/W26Re

RTD

1

Accuracy is not guaranteed between 0 to 399 °C (0 to 751 °F).

2

Accuracy is not guaranteed between −199.9 to −100.0 °C (−199.9 to −148 °F).

0 to 800 °C K 04 0 to 1000 °C K 05 0 to 1200 °C K 06

0 to 1372 °C K 07 0 to 100 °C K 13 0 to 300 °C K 14

0 to 450 °C K 17 0 to 500 °C K 20 0 to 800 °F K A1

0 to 1600 °F K A2 0 to 2502 °F K A3 20 to 70 °F K A9

J 0 to 200 °C J 01 0 to 400 °C J 02 0 to 600 °C J 03

0 to 800 °C J 04 0 to 1000 °C J 05 0 to 1200 °C J 06

0 to 450 °C J 10 0 to 800 °F J A1 0 to 1600 °F J A2

0 to 2192 °F J A3 0 to 4 00 °F J A6 0 to 300 °F J A7

1

0 to 1600 °C R 01 0 to 1769 °C R 02 0 to 1350 °C R 04

R

0 to 3200 °F R A1 0 to 3216 °F R A2 ⎯ ⎯ ⎯

1

0 to 1 600 °C S 01 0 to 1769 °C S 02 0 to 3200 °F S A1

S

0 to 3216 °F S A2 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

1

400 to 1800 °C B 01 0 to 1820 °C B 02 800 to 3200 °F B A1

B

0 to 3308 °F B A2 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

E 0 to 800 °C E 01 0 to 1 000 °C E 02 0 to 1600 °F E A1

0 to 1832 °F E A2 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

N 0 to 1200 °C N 01 0 to 1300 °C N 02 0 to 2300 °F N A1

0 to 2372 °F N A2 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

2

−199.9 to +400.0 °C T 01 −199.9 to +100.0 °C T 02 −100.0 to +200.0 °CT03

T

0.0 to 350.0 °C T 04 −199.9 to +752.0 °F T A1 −100.0 to +200.0 °FTA2

−100.0 to +400.0 °F T A3 0.0 to 450.0 °F T A4 0.0 to 752.0 °FTA5

0 to 2000 °C W 01 0 to 2320 °C W 02 0 to 4000 °F W A1

0 to 1300 °C A 01 0 to 1 390 °C A 02 0 to 1200 °C A 03

PLII

0 to 2400 °F A A1 0 to 2534 °F A A2 ⎯ ⎯ ⎯

2

−199.9 to +600.0 °C U 01 −199.9 to +100.0 °C U 02 0.0 to 400.0 °CU03

U

−199.9 to +999.9 °FUA1 −100.0 to +200.0 °F U A2 0.0 to 999.9 °FUA3

L 0 to 400 °C L 01 0 to 800 °C L 02 0 to 800 °F L A1

0 to 1600 °F L A2 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

Pt100 −199.9 to +649.0 °C D 01 −199.9 to +200.0 °C D 02 −100.0 to +50.0 °CD03

−100.0 to +100.0 °C D 04 −100.0 to +200.0 °C D 05 0.0 to 50. 0 °C D 06

0.0 to 100.0 °C D 07 0.0 to 200.0 °C D 08 0.0 to 300.0 °CD09

0.0 to 500.0 °C D 10 −199.9 to +999.9 °F D A1 −199.9 to +400.0 °FDA2

−199.9 to +200.0 °FDA3 −100.0 to +100.0 °F D A4 −100.0 to +300.0 °FDA5

0.0 to 100.0 °F D A6 0.0 to 200.0 °F D A7 0.0 to 400.0 °FDA8

0.0 to 500.0 °FDA9 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

−199.9 to +649.0 °C P 01 −199.9 to +200.0 °C P 02 − 100.0 to +50.0 °CP03

JPt100

−100.0 to +100.0 °C P 04 −100.0 to +200.0 °C P 05 0.0 to 50.0 °C P 06

0.0 to 100.0 °C P 07 0.0 to 200.0 °C P 08 0.0 to 300.0 °CP09

0.0 to 500.0 °C P 10 ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

zVoltage/current inputs

Type Range Code Type Range Code

0 to 5 V DC 0.0 to 100.0 % 4 01 0 to 20 mA DC 0.0 to 100.0 % 7 01

0 to 10 V DC 1 0.0 to 100.0 % 5 01 4 to 20 mA DC 0.0 to 100.0 % 8 01

1 to 5 V DC 0.0 to 100.0 % 6 01 ⎯ ⎯ ⎯ ⎯

1

Z-1010 specification.

10. REMOVING THE INTERNAL ASSEMBLY

Change Settings

Example: Change the Decimal point position from “One

decimal place (0001)” to “No decimal place (0000)”

1. Press the SET key two times at SLH until PGdP is displayed.

2. Press the UP key to

change the number to 0.

PV

SV

PV

STEP

SV

STEP

3. Press the SET key to store the new set value. The display goes to the next

parameter.

8. ERROR DISPLAYS

Error display

Over-scale and Underscale

Measured value (PV)

[Flashing]

[Fashing]

[Fashing]

RAM failure

(Incorrect set data

write, etc.)

PV is outside of input

range.

Over-scale: PV is above

the high input display

range limit.

Underscale: PV is below

the low input display range

limit.

Turn off the power at once. If an error occurs

after the power is turned on again, please

contact RKC sales office or the agent.

Check Input type, Input range and

connecting state of sensor. Confirm

that the sensor or wire is not broken.

WARNING

!

To prevent electric shock,

always turn off the power

before replacing the sens or.

Usually, this instrument is not necessary to remove the internal assembly from

the case. When removing the internal assembly without disconnecting the

external wiring, take the following steps.

z To prevent electric shock or instrument failure, only qualified

personnel should be allowed to pull out the internal assembly.

z To prevent electric shock or instrument failure, always turn off the

power before pulling out the internal assembly.

z To prevent injury or instrument failure, do not touch the internal

printed wiring board.

Lock (upper)

Recommended tool:

Blade screwdriver

Lock (lower)

Unlock using such a blade screwdriver.

Gently press down on handle for the upper lock

and lift up for the lower lock.

Apply pressure very carefully when removing internal assembly

to avoid damage to the frame.

To conform to IEC61010-1 requirements for protection from electric

shock, the internal assembly of this instrument can only be removed

with an appropriate tool.

(Blade width: 6 mm or less)

WARNING

Unlocking points (marked with

“{”) depend on the model as

follows:

The first edition:

The seventh edition: NOV. 2009 [IMQ00]

CB403

CB103

APR. 1999 [IMQ00]

CB903

RKC INSTRUMENT INC.

®

IMCB11-E7 NOV. 2009

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OHTA-KU TOKYO 146-8515 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799) E-mail: info@rkcinst.co.jp

FAX: 03-3751-8585 (+81 3 3751 8585)

Loading...

Loading...