RJ MOBILITY LTD.

METEOR & MINI-METEOR

TECHNICAL MANUAL

PROVIDING

ACTIVE USER

INDEPENDENCE

This Technical Manual will ensure that

the wheelchair is maintained to the

required standard and is for use by

trained personnel only.

This Technical Manual contains important information regarding maintenance of the Meteor

and Mini-Meteor wheelchairs thus ensuring their safe operation. Please make sure that y ou

understand all instructions thoroughly.

It is recommended that maintenance is undertaken at six monthly intervals for a wheelchair

that is in constant daily use.

The safety of the wheelchair user is paramount. If there is any doubt as to the

suitability of re-using existing parts they should be discarded and replaced with

manufacturer approved parts.

User Manuals should be stamped at correct intervals following completion of maintenance

work.

This product is manufactured to comply with the essential

requirements of the Medical Devices Directive 93/42 EEC.

If you fail to understand anything or have any questions concerning maintenance and

operating instructions please contact:

RJ MOBILITY LTD.

Boy Lane, Wheatley

Halifax HX3 5AF

England

Tel: +44(0) 1422 358888

Fax: +44(0) 1422 355924

-1-

CONTENTS

Section

1 USER CATEGORIES

2 SPECIFICATIONS

3 WHEELCHAIR DIAGRAM

4 MAINTENANCE CHECKS

5 TOOL REQUIREMENTS

6 UPHOLSTERY

7 ARMRESTS

8 FOOTRESTS

9 BRAKES

10 BACKREST AND PUSH HANDLES

11 FRAME AND CROSS BRACES

12 CASTORS

13 QUICK RELEASE WHEEL

-2- MMMTECHA.

SECTION 1. USER CATEGORIES

1.1 USER CATEGORIES FOR THE

METEOR AND MINI-METEOR

LIGHTWEIGHT ACTIVE USER WHEELCHAIR

A1 Occupant with all limbs intact and having the ability to co-ordinate both arms and

hands with sufficient strength to self-propel and control the wheelchair safely and

maintain an upright seating position.

A3 Occupant with sufficient upper body control who can maintain an upright seating

position.

-3-

SECTION 2. SPECIFICATIONS

Meteor Mini-Meteor

40cm (16inch) Seat Width 25cm (10inch) Seat Width

1 Overall length 97cm (38inch) 74cm (29inch)

2 Overall width 64cm (25inch) 47cm (18.5inch)

3 Folded length 68cm (27inch) 68cm (27inch)

4 Folded width 23cm (9inch) 23cm (9inch)

5 Folded height 71cm (28inch) 56cm (22inch)

6 Maximum weight 15.61kg (31.5 lb) 13.9kg (30.5 lb)

7 Weight less wheels, 8.3kg (18 lb) 7.5kg (16.5 lb)

footrests and backrest

8 Seat plane angle 5 degrees 5 degrees

9 Seat widths available 36-46cm (14-18inch) 25-33cm (10-13inch)

10 Seat depths available 33, 36, 38, 40, 43, 46cm 28, 33, 36, 38cm

(13, 14, 15, 16, 17, 18inch) (11,13,14, 15inch)

11 Seat height at front 47cm (18.5inch) 43cm (17inch)

12 Backrest angle 5 degrees from vertical 5 degrees from vertical

13 Backrest height 26cm (10inch) 28cm (11inch)

14 Footrest to seat 33-43cm (13-17inch) 32-37cm (12

1

/2-14inch)

15 Leg to seat angle 90 degrees 90 degrees

16 Armrest to seat 25cm (10inch) 25cm (10inch)

17 Front of armrest to backrest 28cm (11inch) 28cm (11inch)

18 Rear wheel diameter 61cm (24inch) 51cm (20inch)

19 Tyre pressures 50psi/340KPA 50psi/340KPA

20 Maximum user weight 102kg (16 stone/224 lbs) 75kg (12 stone/165 lbs)

21 Minimum turning radius 75cm (30inch) 55cm (22inch)

-4-

SECTION 3. WHEELCHAIR DIAGRAM

3.1 METEOR LIGHTWEIGHT ACTIVE USER ADULT WHEELCHAIR

3.2 MINI-METEOR LIGHTWEIGHT ACTIVE USER

CHILD'S WHEELCHAIR

-5-

1 REMOVABLE BACKREST

2 SKIRT GUARD

3 FOOTREST RELEASE

LEVER

4 BRAKE LEVER

5 FOOTREST HEIGHT

ADJUSTER

6 FLIP-UP FOOTREST

7 FRONT CASTOR

8 ANTI-TIP ROLLER

9 TIPPING LEVER

10 BACKREST LOCK

LEVER

11 QUICK RELEASE REAR

WHEEL

1 REMOVABLE BACKREST

2 SKIRT GUARD

3 FOOTREST RELEASE

LEVER

4 BRAKE LEVER

5 FOOTPLATE HEIGHT

ADJUSTER

6 FLIP-UP FOOTPLATE

7 FRONT CASTOR

8 ANTI-TIP ROLLER

9 TIPPING LEVER

10 BACKREST LOCK

LEVER

11 QUICK RELEASE REAR

WHEEL

SECTION 4. MAINTENANCE CHECKS

4.1 Open the wheelchair, all movements should be free throughout the folding range.

4.1.1 Examine the seat and backrest fabrics for wear, damage or staining.

Examine retaining screws for tightness and general condition. (See Section 6)

4.1.2 Examine armrest attachment blocks for security, if fitted. (See Section 7)

4.1.3 Examine footrest hanger for effective locking. Check that footrests remain vertical

when raised. (See Section 8)

4.1.4 Examine brake assemblies for wear, damage or misalignment. (See Section 9)

4.1.5 Check security of push handle assembly if fitted. Check that hand grips are not

damaged and are securely fitted to the push handle. (See Section 10)

4.1.6 Ensure that tube plugs and ends are fitted to the front of the seat tubes, armrest front,

tipping levers and top of footrest hanger.

4.1.7 Ensure that seat tube cradles are secure in the wheelchair frame.

4.2 Lift the front of the wheelchair and rest the backrest frame on the floor.

4.2.1 Examine the structure of the frame for damage. (See Section 11)

4.2.2 Check the pivot points for undue slackness, caused by loose nuts and bolts, or worn

parts. (See Section 11)

4.2.3 Check castors for free rotation of the wheel and the complete assembly.

Examine castors for wear in the bearings.

Examine locating spindle for signs of bending, at the point where it is attached to the

frame. (See Section 12)

4.2.4 Check rear wheels for free rotation.

Examine wheels for wear in the bearings.

Examine wheels for loose spokes, buckled or damaged rims and handrims.

Check for ease of wheel removal and replacement. (See Section 13)

-6-

-7-

SECTION 5. TOOL REQUIREMENTS

Spanners:15/16 inch or 24mm AF Castors (See Section 12)

5/16 inch AF Cross Brace (See Section 11)

10mm AF Wheels (See Section 13)

19mm AF Wheels (See Section 13)

22mm AF Socket and Driver Wheels (See Section 13)

22mm AF Open Ended Wheels (See Section 13)

7/16 inch AF General

7/16 inch AF Socket and Driver General

Torque wrench (minimum operating range

10 lbs/ft (13 Nm) General

Allen key: 5mm Brakes (See Section 9)

6mm Brakes (See Section 9)

Pozidrive Screwdriver Upholstery (See Section 6)

Flat Blade Screwdriver Pump Clip

Avdel Nutsert rivet tool Upholstery (See Section 6)

Avdel Nutsert rivet tool heavy duty Ar mrest (See Section 7)

Loctite thread locking compound - Grade 241 Brakes, Castors (See Section 9/12/13)

& Wheels

Light/Soft Head Hammer General

Light oil - eg 3 in 1 General

-8-

SECTION 6: UPHOLSTERY

6.1 Diagram

6.2 Parts Lists

GZF No RJ No

Backrest Fabric Black Nylon 137 to 140 295/17/SIZE

Seat Fabric Black Nylon 133 to 136 295/12/SIZE

Skirt Guard Fabric Left Black Nylon 295/19/L

Skirt Guard Fabric Right Black Nylon 295/19/R

Reinforcing Bar TSD8074

No. 10 UNF 3/4 inch long raised countersunk screw zinc plated F15

NO. 10 Flanged screw cup F38

No. 10 Avdel UNF Nutser t

09657/01014

Page 1 of 2

BACKREST FABRIC 295/17

LEFT SIDE PANELS 295/19/L

RIGHT SIDE PANEL 295/19/R

REINFORCING BAR TSD 8074

SEAT FABRIC 295/12

No.10 UNF x 3/4" RAISED

COUNTERSUNK SCREW F15

No.10 UNF FLANGED SCREW CUP F38

No.10 AVDEL UNF NUTSERT

09657/01014

No.10 UNF x 3/4" RAISED

COUNTERSUNK SCREW F15

No.10 UNF FLANGED SCREW CUP

F38

No.10 AVDEL UNF NUTSERT

09657/01014

-9-

6.3 Inspection

Check for staining, wear, tear and stitching.

Check nut inserts in frame for security and stripped threads.

Check securing screws for bending and stripped threads and burrs.

Cushions (if fitted);

Check cushions for staining, wear, tear and stitching.

6.4 Fabric Removal

If the Nutserts need replacement, use Avdel recommended tooling.

6.5 Fabric Fitting

Punch holes in seat fabric using holes in the reinforcing bar as a template.

Punch holes in skirt guard fabric commencing from rear of seat tube using holes in seat

tube as a template.

Slide the reinforcing bar into the stitched section on each side of the seat fabr ic.

Fit the countersunk screws through the flange cups and fit through holes in the side skirt,

seat fabric and reinforcing bars.

Place the fabric on the seat and tighten screws taking care not to exert excessive force to

flatten the flange cup or cut into the fabric.

Section 6 Page 2 of 2

REINFORCING BAR

No.10 UNF x 3/4"

COUNTERSUNK SCREW

FLANGED SCREW CUP

No.10 UNF AVDEL NUTSERT

SECTION 7: ARMRESTS

7.1 Diagram

7.2 Parts Lists

GZF No RJ No

Armrest Assembly complete Left 295/32/L

complete Right 295/32/R

Armrest Tube Left 295/29/L

Right 295/29/R

Armrest Pad 295/32/3

Armrest Socket 295/33

Tube Plug 2460

M5 x 20 Button head screw zinc plated F200

1 1/2 inch x 1/4 inch UNF Hex head bolt zinc plated F9

1/4 inch UNF Self locking thin nut zinc plated P92

M5 Nutsert L Flange steel zinc plated 09418/02517

7.3 Inspection

Check armrest pads for excess wear or damage.

Ensure armrest sockets are secure to backrest tube.

Ensure armrest assembly locates in socket without excessive movement.

Check nut inserts in frame for security and stripped threads.

7.4 Armrest Replacement

If the armrest pad is worn or becomes damaged a replacement ar mrest tube with pad

should be fitted.

-10-

ARMREST TUBE

295/29/L

295/29/R

1 1/2 x 1/4" UNF HEX HEAD BOLT

ZINC PLATED F9

M5 x 20 BUTTON HEAD SCREW

ZINC PLATED F200

M5 FLANGED STEEL NUTSERT

ZINC PLATED 09418/02517

1/4" UNF THIN NYLOC NUT ZINC

PLATED P92

ARMREST SOCKET 295/33

TUBE PLUG

2460

ARMREST PAD

295/32/3

-11-

SECTION 8: METEOR FOOTREST ASSEMBLY

8.1 Diagram

Page 1 of 5

22

LEFT

RIGHT

295/62

RH FOOTREST HANGER

ASSEMBLY COMPLETE

COMPRISING ITEMS 1 TO 6

INCLUSIVE 22 AND 23

295/63

RH FOOTREST SUPPORT

ASSEMBLY COMPLETE

COMPRISING ITEMS 7 TO 18

INCLUSIVE

295/64

LH FOOTREST SUPPORT

ASSEMBLY COMPLETE

COMPRISING ITEMS 7 TO 11

INCLUSIVE AND 19 TO 21

INCLUSIVE

295/61

LH FOOTREST HANGER

ASSEMBLY COMPLETE

COMPRISING ITEMS 1 TO 6

INCLUSIVE 22 AND 23

22

5

4

3

1

8

7

10

10

19

18

17

14

13

12

9

10

11

10

7

8

1

2

3

4

5

16

15

11

21

20

9

2

6

6

23

23

-12-

8.2 Parts List

GZF No RJ No

Footrest Hanger Assembly complete LH

comprising items 1-6 inclusive, 22 and 23 295/61

Footrest Hanger Assembly complete RH

comprising items 1-6 inclusive, 22 and 23 295/62

1 Footrest Hanger 295/3

2 Spring Pin F42

3 Sliding Peg Plunger SF194

4 Plunger Spring SF71

5 Sliding Peg SF163

6 Sliding Peg Handle SF614

22 Spring Pin F43

23 Plastic Cap 16313

Footrest Support Assembly complete RH

comprising items 7-18 inclusive 295/63

Footrest Support Assembly complete LH

comprising items 7-11 inclusive and 19-21 inclusive 295/64

7 Footrest Stem 295/11

8 Spring Catch MP222/M

9 1/4 inch UNF x 1 1/2 inch Bolt zinc plated F9

10 6mm Washer zinc plated Q79

11 1/4 inch UNF Nyloc Nut zinc plated P90

12 Footplate Hinge 295/14

13 Footrest Tube 295/13A

14 Footrest Bar 295/13B

15 1/4 inch UNF x 1 1/2 HT Hex Head Bolt zinc plated F9

16 6mm Washer zinc plated Q79

17 Location Tube 295/16

18 Spring Latch SC02108

19 Ball Stud SBV2141

20 4BA x 3/8 inch Cap Head Screw zinc plated SCR0760

21 Footplate Location 295/15

8.3 Inspection

Ensure that all moving parts of the footrest hanger (1), spring pins (22) and sliding pegs (5)

do not bind and are easy to operate.

Check that the sliding peg (5) locates into its hole on the wheelchair frame.

Check that all bolts, both locking (15) and pivotal (9) are secure.

Check that there is not excessive play in the footplate hinge (12) or footplate location (21).

Check that the paintwork is not scratched or chipped.

Section 8 Page 2 of 5

8.4 Footrest Dismantling

Unclip the footrest bar (14) from the footplate location ball stud (19).

Remove each footrest hanger from the frame by sliding the peg handle (6) forward.

Rotate the footrest hanger away from the wheelchair frame and at the same time lift the

hanger upwards to remove.

8.5 Left Hand Footrest Hanger Assembly Dismantling

Depress the spring catch (8) and remove the footrest stem (7) from the footrest hanger (1).

Hook the spring catch (8) and withdraw from the footrest stem (7).

Release the pivot bolt (9) and withdrawn to release the footplate location (21) from the

footrest stem (7).

Release the cap head screw (20) to remove the ball stud (19).

8.6 Right Hand Footrest Hanger Assembly Dismantling

Depress the spring catch (8) and remove the footrest stem (7) from the footrest hanger (1).

Hook the spring catch (8) and withdraw from the footrest stem (7).

Release the pivot bolt (9) and withdraw to release footplate hinge (12) from the footrest

stem (7).

Release the two mounting bolts (15) and separate the footrest bar (14) from the footplate

hinge (12), footrest tube (13) and location tub e (17). The spring latch (18) can then be

removed from the location tube (17).

8.7 Footrest Assembly

To reassemble reverse 8.4, 8.5 and 8.6 procedures.

The mounting bolts (15) should be inserted using thread locking compound grade 241.

Ensure that all washers are inserted correctly in accordance with diagram 8.1.

All 1.4 inch bolts are to be torqued to 10 lbs/ft (13 Nm).

-13-

Section 8 Page 3 of 5

8.8 MINI-METEOR FOOTREST ASSEMBLY

8.8.1 Diagram

8.9 Parts List

GZF No RJ No

Footrest Hanger Assembly complete RH

comprising all items listed below 302/12

Footrest Hanger Assembly complete LH

comprising all items listed below 302/13

Footrest Hanger Assembly excluding Footplate Assembly 302/3

Footplate RH 300/8/17-10R

LH 300/8/17-10L

Footplate Support 300/8/16

1/4 inch UNF x 1 1/2 inch Hexagon Head Bolt zinc plated F9

M6 Washer Q79

1/4 inch UNF Locknut zinc plated F25

Spring Pin F42

Sliding Peg Plunger SF194

Plunger Compression Spring SF71

Sliding Peg SF163

Sliding Peg Handle SF164

Plastic Cap 161313

-14-

Section 8 Page 4 of 5

SLIDING PEG HANDLE

SF164

SLIDING PEG

PLUNGER SF194

FOOTREST HANGER

ASSY 302/3

1/4" UNF LOCKNUT ZINC PLATED F25

M6 WASHER Q79

FOOTPLATE SUPPORT 300/8/16

1/4" UNF x 1 1/2" HEX HEAD

BOLT ZINC PLATED F9

FOOTPLATE 300/8/17-10R

FOOTPLATE 300/8/17-10L

FOOTREST HANGER ASSEMBLY

RH 302/12

LH 302/13

SLIDING PEG SF163

PLUNGER COMPRESSION

SPRING SF71

PLASTIC CAP 161313

SPRING PIN F42

SPRING PIN F42

-15-

8.10 Inspection

Ensure that all moving parts of the footrest hanger assembly do not bind and are easy to

operate.

Check that the sliding peg locates into its hole on the wheelchair frame.

Check that all bolts are secure.

Check that the paintwork is not scratched or chipped.

8.11 Footrest Dismantling

Remove each footrest hanger from the wheelchair frame by sliding the peg handle forward.

Rotate the footrest hanger away from the wheelchair frame and at the same time lift

upwards to remove.

Release the 1/4 inch UNF bolts to remove the f ootplates from the f ootrest hanger assemb ly.

8.12 Footrest Assembly

To reassemble, reverse 8.11 procedure.

Ensure that all washers are inserted correctly in accordance with diagram 8.8.1.

All 1/4 inch bolts are to be torqued to l0 lbs/ft (13 Nm).

Section 8 Page 5 of 5

-16-

SECTION 9: METEOR BRAKE ASSEMBLY

9.1 Diagram

9.2 Parts List

GZF No RJ No

Brake Assembly complete RH 26085

LH 26086

Comprising:

1 Lever 295/59

2 Brake Shoe Bar

3 M6 x 26mm Button Head Screw

4 Handle Assembly

5 Brake Knob

6 No.10 x 5/8 inch long Screws

7 Small Link

8 Disc Springs

9 M5 Self-locking Nuts

10 Large Brake Block Clamp

11 4mm x 20mm Spiral Pin

12 M6 x 25mm Socket Head Cap Screws

13 Small Brake Block Clamp

14 M6 x 30mm Socket Head Cap Screws

Page 1 of 4

5

BRAKE ASSEMBLY

RH 26085

LH 26086

9 11 124876

2 1 1 10 13 14

9.3 Inspection

The Brake Assembly must be fir mly attached to the wheelchair frame and easily operable.

The force required to apply the brake is min/max: 5 lbs (22N)/10 lbs (44N).

If the brake is difficult to apply it must be replaced.

The force required to revolve the wheel against the brake must exceed 30 lbs(132N) at the

wheel rim. If it does not, check that the tyre pressure is correct as 50psi (340 Kilopascals).

9.4 Brake Assembly Removal

Release the two socket head cap scre ws in the br ak e clamp to remo ve the brake assembly.

9.5 Brake Assembly Fitting

Position the br ake assemb ly on the wheelchair frame bef ore finally tightening the two sock et

head cap screws ensuring that the brake is effective. Apply Loctite thread locking

compound and tighten the two socket head cap screws in the clamp to 10-12 lbs/ft (13.55-

16.26 Nm).

-17-

Section 9 Page 2 of 4

SECTION 9.6: MINI-METEOR BRAKE ASSEMBLY

9.6.1 Diagram

9.7 Parts List

GZF No RJ No

Brake Assembly complete RH 302/46R

LH 302/46L

Brake Handle 302/48

Red Vinyl Sleeve F3-2-S14R

Hinge Block 287/100D

Brake Pin 287/100G

Link Assembly 287/100J

1/4 inch UNF Locknut zinc plated P92

M6 Nylon Washer F86

1/4 inch UNF x 1 1/4 inch Hex Head Bolt zinc plated F6

1/4 inch UNF Nyloc Nut zinc plated P96

1/4 inch Shakeproof Washer zinc plated F98

-18-

Section 9 Page 3 of 4

RED VINYL SLEEVE F3-2-S14R

MINI-METEOR BRAKE ASSEMBLY

LH 302/46L

RH 302/46R

BRAKE HANDLE 302/48

BRAKE PIN 287/100G

1/4" UNF LOCKNUT

ZINC PLATED P92

1/4" UNF LOCKNUT P92

1/4" UNF NYLOC NUT

ZINC PLATED P96

1/4" UNF x 1 1/4 HEX HEAD

BOLT ZINC PLATED F6

M6 NYLON WASHER F86

M6 NYLON WASHER F86

M6 NYLON WASHER F86

M6 NYLON WASHER F86

1/4" SHAKEPROOF WASHER ZINC

PLATED F98

LINK ASSEMBLY 287/100J

HINGE BLOCK 287/100D

-19-

9.8 Inspection

The Brake Assembly must be fir mly attached to the wheelchair frame and easily operable.

The force required to apply the brake is min/max: 5 lbs (22N)10 lbs (44N).

If the brake is difficult to apply it must be replaced.

The force required to re volve the wheel against the brake must exceed 30 lbs (132N) at the

wheel rim. If it does not, check that the tyre pressure is correct as 50psi (340 Kilopascals).

9.9 Brake Assembly Removal

Release the two hex head bolts to remove the brake assembly.

9.10 Brake Assembly Fitting

Position the brake assembly on the wheelchair frame.

Locate the two bolts through the recess, fit washers and nyloc nuts.

Before tightening the two bolts ensure that the brake is effective.

Tighten the two bolts to 10-12 lbs/ft (13.55-16.26 Nm).

Section 9 Page 4 of 4

SECTION 10: BACKREST ASSEMBLY

10.1 Diagram

10.2 Parts List

GZF No RJ No

Backrest Assembly 295/9

Backrest Fabric 295/17

End Cap 2460

Tapered Plug WS511

No. 10 Avdel UNF Nutser t 09657/01014

No. 10 Flanged Screw Cup F38

2 BA x 3/4 inch raised head

Pozidrive CSK Screw black zinc plated F102

-20-

Page 1 of 2

HAND GRIP M57

PUSH HANDLE 295/10

1/4 UNFx1 1/8" HEX HD BOLT

ZINC PLATED F6

No.10 UNF AVDEL NUTSERT 09657/01014

No.10 FLANGED SCREW CUP F38

2 BA x 3/4" RAISED HEAD POZI DRIVE

CSK SCREW BLACK ZINC PLATED F102

M5 FLANGED STEEL NUTSERT ZINC

PLATED 09418/02517

SAME FOR LEFT & RIGHT

BACKREST TUBE

BACKREST ASSEMBLY 295/9

BACKREST 295/17

TAPERED PLUG WS511

END CAP 2460

1/4 UNF THIN LOCKNUT

ZINC PLATED P90

10.2 Parts List (Continued)

GZF No RJ No

Push Handle 295/10

Hand Grip M57

1/4 inch UNF x 1 1/8 inch Hexagon Head

Set Screw zinc plated F6

1/4 inch UNF Thin Nyloc Nut P90

M5 Nutsert L Flange Steel zinc plated 09418/02517

10.3 Inspection

Check fabric for staining, stretching, wear, tear and stitching.

Check nut inserts in frame for security and stripped threads.

Check securing screws for bending, any stripped threads and burrs.

Check that all end caps and tapered plugs are fitted.

Ensure that the hand grips are firmly attached to the push handles, if fitted.

Check that the Velcro retains skirtguards in position.

10.4 Fabric Removal

Release the four countersunk fixing screws and flanged cup washers.

Slide the fabric downwards to remove from the backrest assembly.

If the nutserts need replacement use Avdel recommended tooling.

10.5 Fabric Fitting

Slide the backrest fabric onto the ver tical backrest tubes.

Fit the countersunk fixing screws through the flanged cup washers and pass through the

holes in the fabric.

Tighten the screws taking care not to exer t excessive force to flatten the flange cup washer

or cut into the fabric.

10.6 Push Handle Fitting

Remove the end caps from the backrest tubes, and inser t the push handles.

Pass the setscrew through the backrest tube and push handle.

Attach the nut and tighten until it is a snug fit against the backrest tube.

10.7 Push Handle Removal

Reverse 10.6 procedure.

-21-

Section 10 Page 2 of 2

SECTION 11: FRAME AND CROSS BRACE ASSEMBLY

11.1 Diagram

-22-

Page 1 of 4

3

5

10

12

13

14

6

1

21

10

18

20

19

17

22

10

9

15

16

8

11

2

10

11,1

4

7

11.2 Parts List

GZF No RJ No

1 Side Frame Assembly 295/2L

2 Side Frame Assembly 295/2R

3 RH Seat Tube & Cross Brace Assembly 295/4

4 LH Seat Tube & Cross Brace Assembly 295/5

5 Cross Brace Stay Assembly 295/6

6 Side Frame Pivot Bush 295/23

7 Seat Tube Plug 5520

8 Tube Plug 2460

9 Seat Location WS151

10 1/4 inch Plain Washer Q79

11 1/4 inch Nyloc Nut P90

12 1/4 inch UNF x 1 3/4 inch Hexagon Head

Bolt, zinc plated F11

13 8mm Form B Plain Washer, zinc plated F141

14 5/16 inch UNF x 2 1/2 inch HT Hexagon Head

Bolt, zinc plated Q707

15 5/16 inch UNF Nyloc Nut, zinc plated P113

16 Spring Catch MP222/M

17 Wheel Mounting Block 295/7

18 1/4 inch UNF x 2 1/4 inch HT Hexagon Head

Bolt, zinc plated Q704

19 Wheel Insert Bush complete with wheel assembly )

20 Washer 16mm ) WHLQRB12

21 Nut 16mm x 1mm )

22 Anti-tipping Assembly 295/8

-23-

Section 11 Page 2 of 4

11.3 BACKREST LOCKING ASSEMBLY

11.3 Diagram

11.4 Parts List

GZF No RJ No

1 Lock Pin TSD1306

2 Plunger Spring TSD1269

3 Lock Lever TSD1323

4 Plain Washer Q5

5 3/16 Star Lock Washer F37

11.5 Inspection

Examine the structure of the frame for damage.

Check pivot points for undue slackness due to loose nuts and bolts or worn parts.

Check that the cross braces fold with ease without binding.

Check all joints for fractures.

Check that there is no misalignment of the castor mounting tubes or thread bushes.

Check all tube plugs, side frame pivot bushes and seat location mouldings for integrity,

replace if missing or broken.

Check that the lock lever rotates easily and that the lock pin moves in and out of the side

frame rear tube.

11.6 Frame Dismantling

Remove the upholstery as described in Section 6.

Remove the castors as described in Section 12.

Remove the wheels as described in Section 13.

Release the cross brace stay pivot bolts (12) and withdraw.

Release the main cross brace pivot bolt (14) and withdraw from cross brace assemblies.

Remove the brake assemblies as described in Section 9.

Release the wheel mounting block bolts (18) and remove the wheel mounting blocks (17).

Squeeze the spring catch (16) to remove the anti-tipping rollers (22) and then withdraw

the catch using a hook.

-24-

Section 11 Page 3 of 4

2

1

3

4

5

-25-

11.7 Frame Assembly

Reverse 11.6 procedure.

All bolts are to be tightened to the following values:

1/4 inch UNF 10 lbs/ft (13 Nm)

5/16 inch UNF 25 lbs/ft (33 Nm)

The mounting bolts (15) and wheel insert bush (19) should be inserted using thread locking

compound grade 241.

Ensure that all plastic bushes and mouldings are fitted and that the wheelchair frame folds

with ease on completion of assembly.

Section 11 Page 4 of 4

-26-

SECTION 12: CASTORS

12.1 Diagram 12.2. Diagram

12.3 Parts List

GZF No RJ No

125mm Wide Profile MCP M142

125mm Narrow Profile MCP M78

12.4 Inspection

Check for excessive wear in crown bearings and wheel spindle. Replace castor if

necessary.

Check condition of stud which screws into frame.

View frame and check both castor mounting tubes are at the same angle, checking for

frame distortion due to impact damage, replace if necessary.

Check tyre security to rim and for splits, cracking or damage.

Check security of castor.

Page 1 of 2

23.95mm

HEXAGON

23.95mm

HEXAGON

125

91

45

29

175 EFFECTIVE HEIGHT

PIN DIMENSIONS

M14 x 22 LONG

PIN DIMENSIONS

M14 x 22 LONG

125mm WIDE PROFILE

METEOR M142

125mm NARROW PROFILE

MINI-METEOR M78

108 SWIVEL

RADIUS

10

203 EFFECTIVE HEIGHT

105 SWIVEL RADUIS

12.5 Castor Removal

Unscrew the hexagon at the top of the castor s wivel using a 24mm (15/16 inch) AF spanner

until the castor is removed.

12.6 Castor Fitting

Apply Loctite thread locking compound Grade 241, or equivalent, to the thread and tighten

to 30-35 lbs/ft (40-47 Nm).

-27-

Section 12 Page 2 of 2

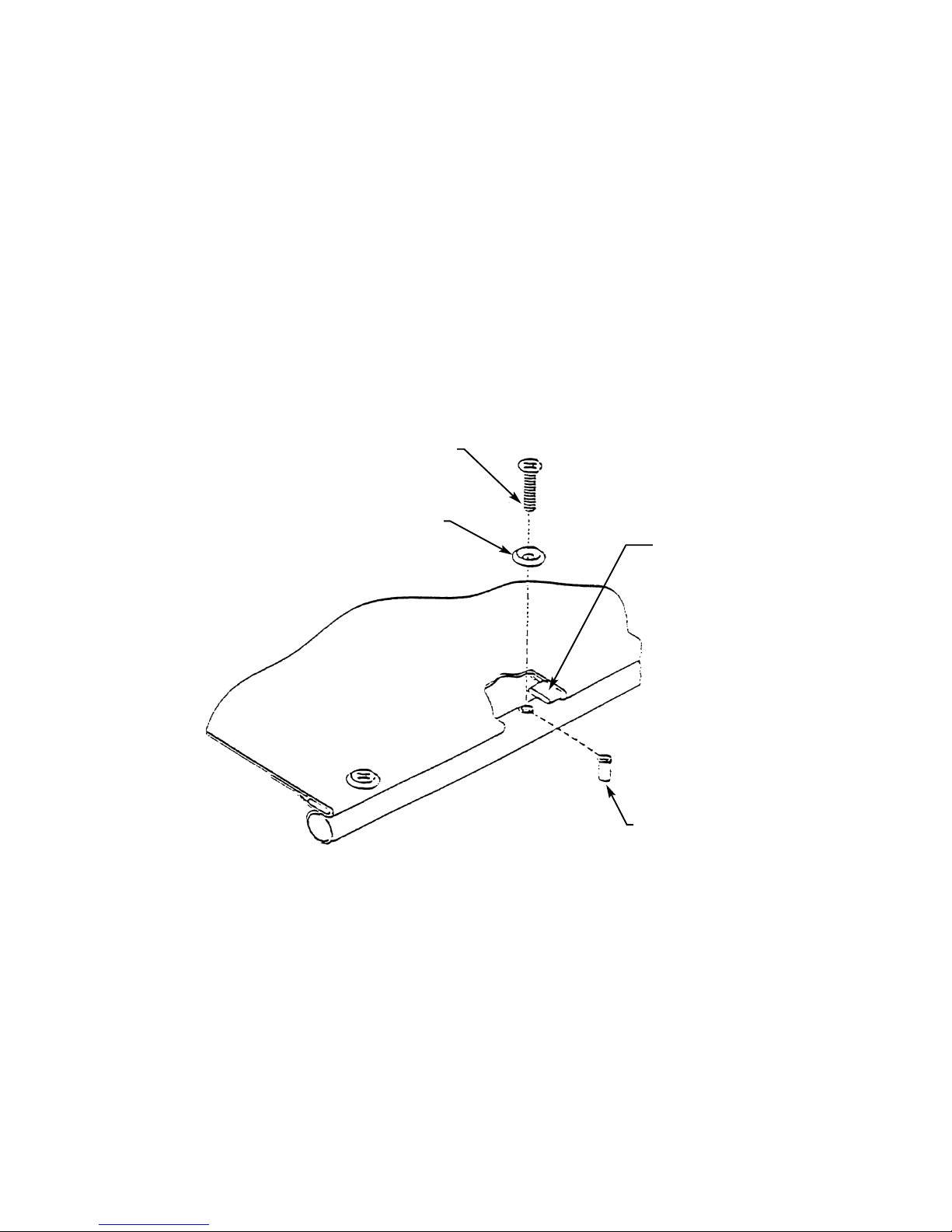

SECTION 13: QUICK RELEASE WHEEL

13.1 Diagram

13.2 Parts List

GZF No RJ No

Mini-Meteor

50cm (20") diameter detachable

wheel with spindle WH20BKALTTT

50cm (20") diameter pneumatic tyre 20TYR

50cm (20") diameter pneumatic tube 20TUB

50cm (20") diameter rim band tape 20TAP

Handrim suitable for 50cm (20") diameter wheel M190

12mm Quick Release Axle )

) complete with nut and washers WHLQRB12

12mm Quick Release Bush )

Meteor

61cm (24") diameter detachable

wheel with spindle WHL24BKALTTT

61cm (24") diameter pneumatic tyre 24TYR

61cm (24") diameter pneumatic tube 24TUB

61cm (24") diameter rim band tape 24TAP

Handrim suitable for 61cm (24") diameter wheel M191

12mm Quick Release Axle )

) complete with nut and washers WHLQRB12

12mm Quick Release Bush )

-28-

Page 1 of 3

16mm x 1mm THIN NUT ZINC PLATED

16mm WASHER

12mm QUICK RELEASE BUSH

WHLQRB12

12mm QUICK RELEASE AXLE

WHLQRAX12

-29-

Section 13 Page 2 of 3

13.3 Inspection

Check tyre for excess wear, splits, cracking and punctures.

(Puncture proof is available as an option).

Check for loose spokes and wheel to be true.

Check handrim for security and damage. ANY SHARP EDGES ARE DANGEROUS TO

THE USER.

Check axle for distortion.

Check that spindle plunger ends are screwed securely by gripping the ends lightly with

pliers and twisting in opposite directions.

Check that wheel insert bush is secure in the wheelchair frame by gripping ends lightly with

pliers and tightening to remove excessive play. If replacing apply Loctite thread locking

compound grade 241 or equivalent to the wheel insert bush thread.

Check for ease of wheel removal and replacement.

13.4 Wheel Removal

To remove the wheels, enure the brakes are not applied. With one hand hold the frame of

the wheelchair and with the other hand hold the spokes surrounding the hub and fully

depress the centre button. Pull the wheel away from the wheelchair and wheel insert bush.

Finally release the centre button.

13.5 Wheel Fitment

Lift the frame with one hand and the wheel in the other hand. Hold the spokes surrounding

the hub and fully depress the centre button. Insert the axle fully into the axle bush and

release the centre button. Ensure that the wheel is fully locked. Pull wheel outwards

without depressing the centre button. If located correctly, the wheel will not come off. If a

new axle has been fitted, length adjustment may be necessary.

QUICK RELEASE WHEEL BUSH

QUICK RELEASE WHEEL

PRESS

ANTI-TIP WHEELS

QUICK RELEASE SPINDLE

WHEEL HUB

SPOKES OMITTED FOR CLARITY

-30-

13.6 Adjustment

Assemble the wheel and spindle to the wheelchair. Opposing ball bearings on the spindle

must fully protrude past the inner face of the wheel bush. If they do not, slacken the nyloc

nut on the outer end of the spindle until this is achiev ed. Adjust the nyloc n ut until 1mm end

float (maximum). Excessive end float will cause the quick release spindle to bend. lack of

float may cause incorrect fitting of the wheel to the wheelchair.

13.7 Tyre Fitting

Fit a strong rim tape and check that the inside of the tyre and the rim well are clean. Put

one side of tyre onto rim, pass the valve of the tube through the rim and partially inflate the

tube until round in shape. Fit the remainder of the tube into the tyre.

Starting at the valve fit the other bead of the tyre into the rim working outwards with the

thumbs ensuring the tube is not pinched between the tyre and the rim.

Before inflating to the correct pressure, centre the tyre on the rim by lining up the bead line

on the tyre sidewalls with the edge of the rim. Spin the wheel and check that the tyre rides

evenly. If not then adjust the tyre again and recheck. When running centrally, inflate the

tyre to the correct pressure.

MAINTENANCE

It is essential that the quick release axle and bush are kept lightly lubr icated at all times to

ensure ease of action and it is recommended that a graphite-based lubricant is used for this

application.

Section 13 Page 3 of 3

TECHNICAL MANUAL

AMENDMENT RECORD

ISSUE SECTION DATE COMMENTS

AMENDED

-31-

Loading...

Loading...