Rittal SK 3382.xxx, SK 3359.xxx, SK 3383.xxx, SK 3384.xxx, SK 3385.xxx Assembly Instructions Manual

...

SchaltschrankKühlgerät

Cooling unit

Climatiseur

Koelaggregaat

Kylaggregat

Condizionatore

per armadi

Refrigerador

para armarios

Montageanleitung

Assembly instructions

Notice de montage

Montage-instructie

Montageanvisning

Istruzioni di montaggio

Instrucciones de montaje

Umschalten auf Perfektion

SK 3382.xxx

SK 3359.xxx

SK 3383.xxx

SK 3384.xxx

SK 3385.xxx

SK 3386.xxx

SK 3387.xxx

00_Umsch_Ti_SK3382.fm Seite 1 Freitag, 5. März 2004 4:24 16

2

375

415

326

170

597

415

365

Ø 80

30

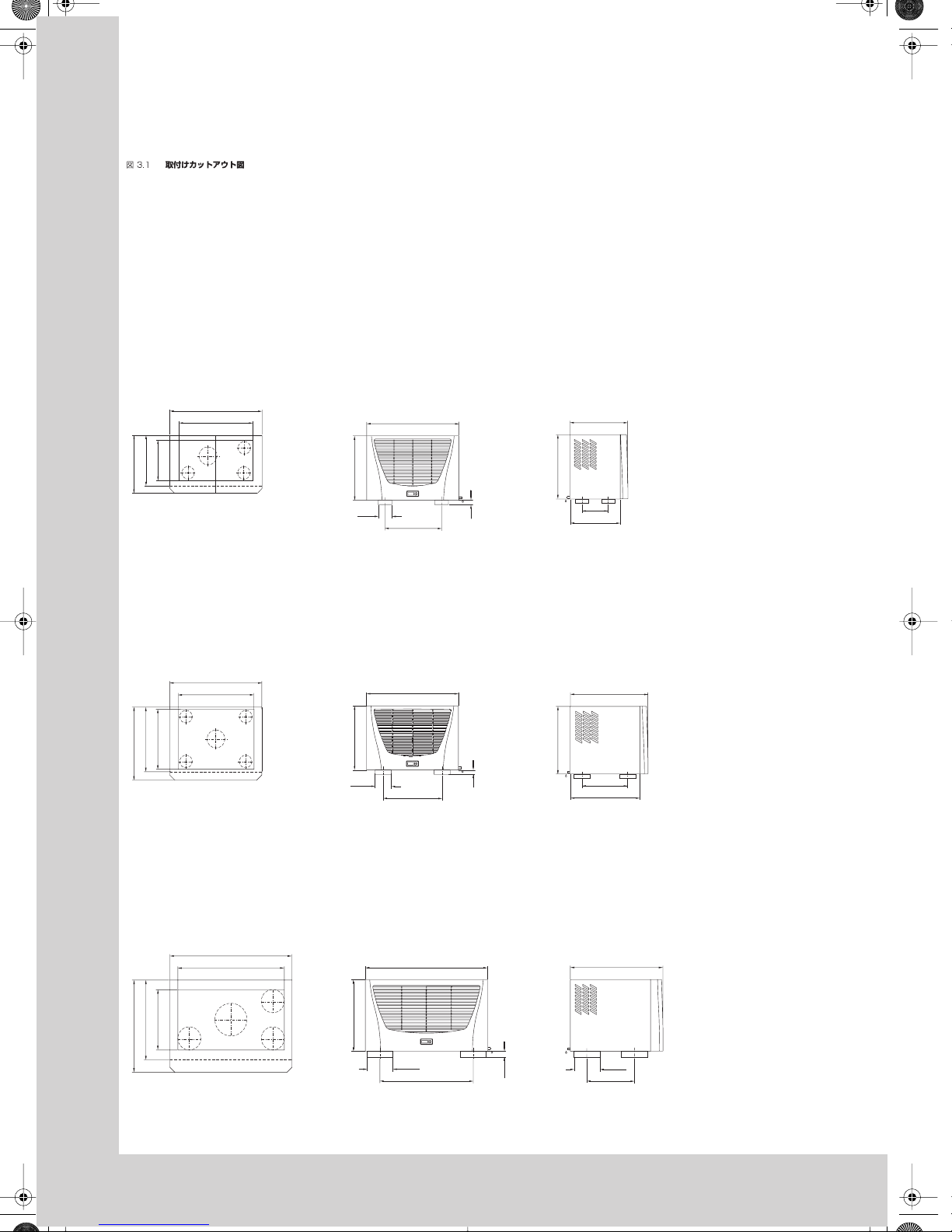

Abb. 3.1

Montageausschnitte

Fig. 3.1

Mounting cutouts

Fig. 3.1

Découpes de montage

Afb. 3.1

Montage-uitsparingen

Bild 3.1

Håltagning

Fig. 3.1

Dime di foratura

Fig. 3.1

Recorte del montaje

Montageausschnitt

SK 3359.... / SK 3382....

Montageausschnitt

SK 3383.... / SK 3384.... / SK 3385....

Montageausschnitt

SK 3386.... / SK 3387....

475

260

326

375

597

475

415

420

280

597

415

380

Ø 100

27

490

597

420

390

475

580

520

392

796

692

470

796

538

Ø 150

38.5

580

238

Ø 150

01_SK3382_2_3.fm Seite 2 Freitag, 5. März 2004 4:27 16

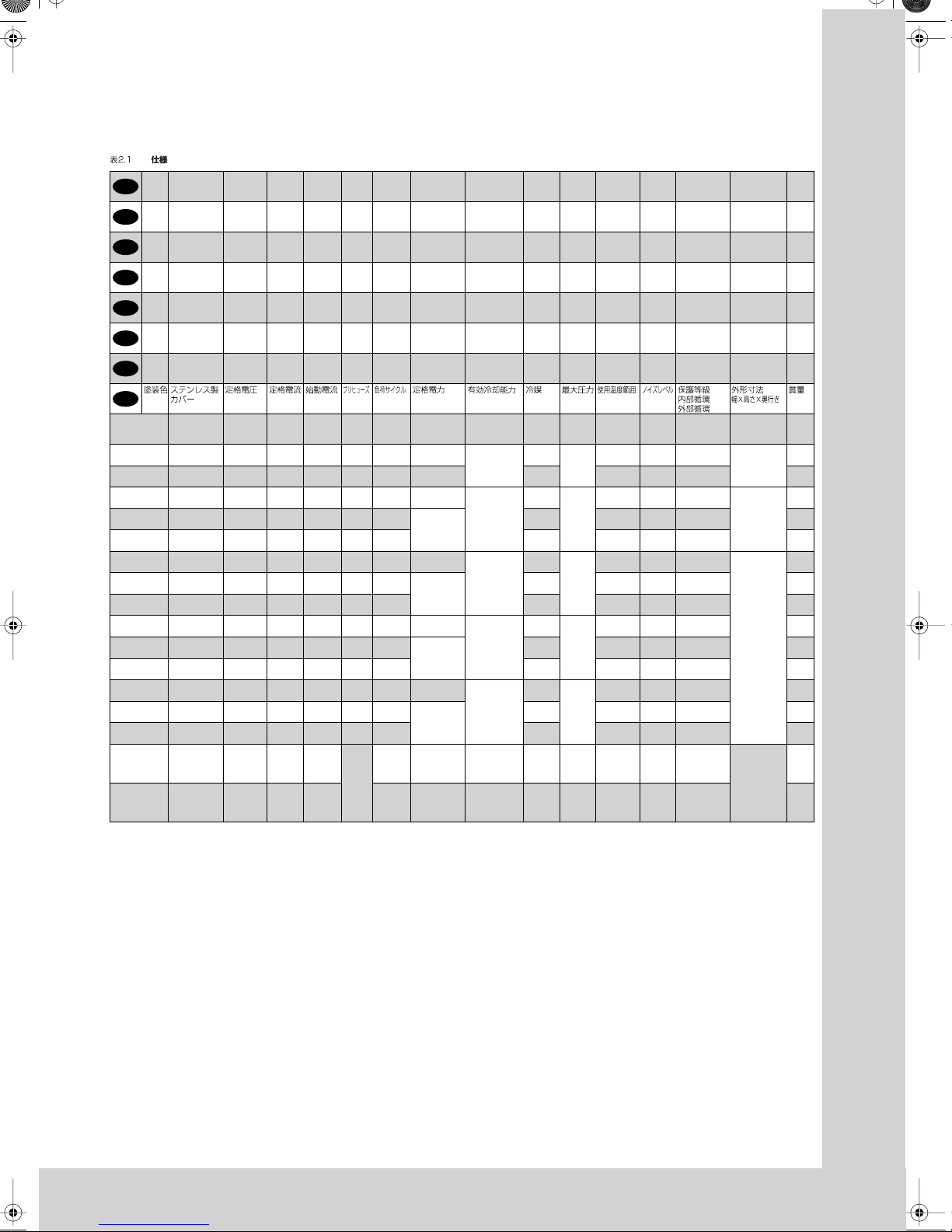

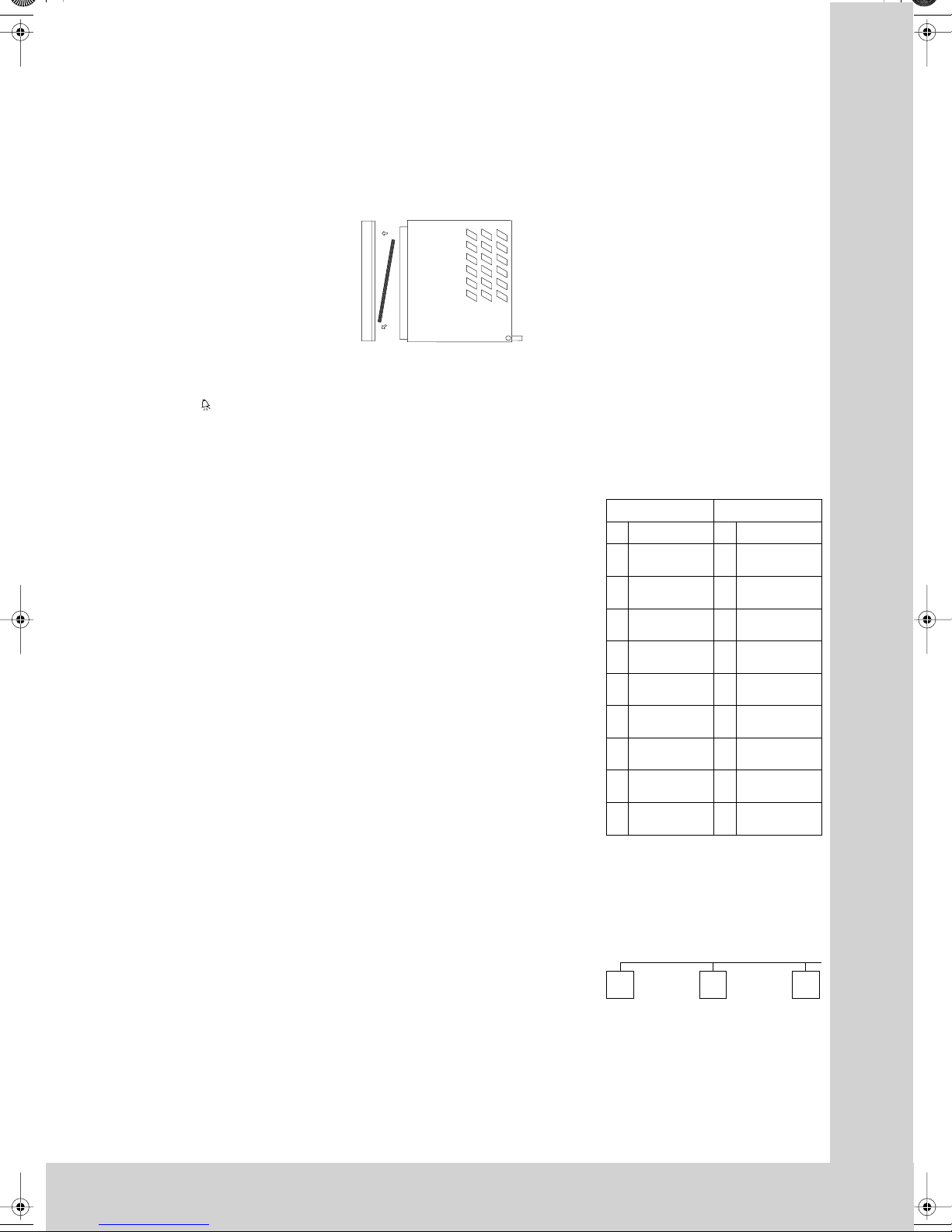

Tab. 2.1

Tec hnische Daten

Tab. 2.1

Tec hnical data

Tab. 2.1

Données techniques

Tab. 2.1

Tec hnische gegevens

Tab. 2.1

Tekniska data

Tab. 2.1

Caratteristiche tecniche

Tab. 2.1

Datos técnicos

Farbton

RAL

7035

Edelstahlhaube

1.4301

Bemessungsspannung

Bemessungsstrom

Anlaufstrom

Vorsicherung T

Einschaltdauer

Bemessungsleistung

Nutzkühlleistung Kältemittel zul.

Druck

PS

Temperaturbereich

Geräuschpegel

Schutzart

Innenkreislauf

Außenkreislauf

Abmessungen

(B x H x T)

mm

Gewicht

Colour

RAL

7035

Stainless

steel cover

1.4301

Operating

voltage

Rated

current

Starting

current

Pre-fuse TDuty cycle Nom.

refrigeration

Useful cooling

output

Refrigerant Permis-

sible

pressure

Temperature

range

Noise

level

Protection categ.

Internal circuit

External circuit

Dimensions

(W x H x D)

mm

Weight

Coloris

RAL

7035

Capot en acier

inoxydable

1.4301

Tension

nominale

Courant

nominal

Courant de

démarrage

Dispositif

de

sécurité T

Durée de

mise en

circuit

Puissance

nominale

Puissance

frigorifique

de régime

Fluide

frigorigène

Pression

de régime

autor.

Plage de

température

Niveau

sonore

Degré de protect.

Circuit intérieur

Circuit extérieur

Dimensions

(L x H x P)

mm

Poids

Kleur

RAL

7035

RVS mantel

1.4301

Bedrijfsspanning

Nominale

stroom

Aanloopstroom

Primaire

zekering

T

Inschakelduur

Nominaal

vermogen

Nuttig

koelvermogen

Koelmiddel

p. max. Temperatuur-

bereik

Geluidsnivo

Beschermklasse

Inwendig circuit

Uitwend. circuit

Afmetingen

(B x H x D)

mm

Gewicht

Färgton

RAL

7035

Huv i rostfritt

stål 1.4301

Anslutningsspänning

Märkström

Startström För-

säkring

gL

Inkopplingstid

Märkeffekt Effektiv

kyleffekt

Kylmedel Tillåtet

driftsövertryck

Temperaturområde

Ljudnivå Kapslingsklass

Inre kretslopp

Yttre kretslopp

Mått

(B x H x D)

mm

Vikt

Colore

RAL

7035

Cover in acciaio

inox 1.4301

Tensione

nominale

Corrente

nominale

Corrente

di spunto

Fusibili T Ciclo d’in-

serzione

Potenza

nominale

Potenza

frigorifera utile

Fluido

frigorigeno

Pressione

max.

Campo di

temperatura

Livello

di rumore

Grado di protez.

Circuito interno

Circuito esterno

Dimensioni

(L x A x P)

mm

Peso

Color

RAL

7035

Cubierta de acero

inoxidable

1.4301

Tensión

de

servicio

Intensidad

nominal

Intensidad

de

arranque

Fusible T Duración

de

conexión

Potencia

nominal

Potencia

frigorífica útil

Fluido

frigorífico

Presión

máxima

admis.

Campo de

temperaturas

Nivel

de ruido

Protección

Circuito interior

Circuito exterior

Dimensiones

(anch. x alt.

x prof.) mm

Peso

RAL

7035

1.4301

L35 L 35

L35 L 50

DIN 3168/EN 814

L35 L 35

L35 L 50

EN 60529

SK 3382.100

SK 3382.500

SK 3382.200

SK 3382.600

230 V,

50/ 60 Hz

2.7 A/

2.9 A

9.2 A/

10.2 A

10.0 A/

10.0 A

100 %

360 W/410 W

410 W/450 W

500 W/510 W

270 W/370 W

R134a,

250 g

25 bar

+20 –

+55°C

<64dB(A)

IP 54

IP 34

597 x 415 x 375

30 kg

SK 3382.110

SK 3382.510

SK 3382.210

SK 3382.610

115 V,

50/ 60 Hz

5.5 A/

6.0 A

18.4 A/

18.4 A

10.0 A/

10.0 A

100 %

370 W/420 W

420 W/470 W

R134a,

250 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

35 kg

SK 3359.100

SK 3359.500

SK 3359.200

SK 3359.600

230 V,

50/ 60 Hz

3.0 A/

3.9 A

10.0 A/

10.7 A

10.0 A/

10.0 A

100 %

410 W/520 W

490 W/600 W

750 W/810 W

545 W/590 W

R134a,

300 g

25 bar

+20 –

+55°C

<64dB(A)

IP 54

IP 34

596 x 415 x 375

32 kg

SK 3359.110

SK 3359.510

SK 3359.210

SK 3359.610

115 V,

50/ 60 Hz

6.0 A/

7.8 A

20.0 A/

21.4 A

16.0 A/

16.0 A

100 %

420 W/535 W

500 W/615 W

R134a,

300 g

+20 –

+55°C

<64dB(A)

IP 54

IP 44

34 kg

SK 3359.140

SK 3359.540

SK 3359.240

SK 3359.640

400 V, 2 ~,

50/60 Hz

1.7 A/

2.2 A

5.8 A/

6.2 A

10.0 A/

10.0 A

100 %

R134a,

300 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

34 kg

SK 3383.100

SK 3383.500

SK 3383.200

SK 3383.600

230 V,

50/ 60 Hz

4.3 A/

4.5 A

15.5 A/

15.5 A

10.0 A/

10.0 A

100 %

550 W/650 W

660 W/750 W

1000 W/1080 W

760 W/ 820 W

R134a,

500 g

25 bar

+20 –

+55°C

<64dB(A)

IP 54

IP 34

597 x 415 x 475

40 kg

SK 3383.110

SK 3383.510

SK 3383.210

SK 3383.610

115 V,

50/ 60 Hz

8.3 A/

8.7 A

25.3 A/

24.3 A

16.0 A/

16.0 A

100 %

580 W/660 W

670 W/755 W

R134a,

500 g

+20 –

+55°C

<64dB(A)

IP 54

IP 44

46 kg

SK 3383.140

SK 3383.540

SK 3383.240

SK 3383.640

400 V, 2 ~,

50/60 Hz

2.4 A/

2.4 A

8.0 A/

8.8 A

10.0 A/

10.0 A

100%

R134a,

500 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

46 kg

SK 3384.100

SK 3384.500

SK 3384.200

SK 3384.600

230 V,

50/ 60 Hz

5.7 A/

6.8 A

16.6 A/

17.1 A

10.0 A/

10.0 A

100%

815 W/ 930 W

950 W/1090 W

1500 W/1520 W

1100 W/1210 W

R134a,

500 g

25 bar

+20 –

+55°C

<64dB(A)

IP 54

IP 34

41 kg

SK 3384.110

SK 3384.510

SK 3384.210

SK 3384.610

115 V,

50/ 60 Hz

12.5 A/

14.1 A

30.7 A/

29.1 A

20.0 A/

20.0 A

100%

850 W/ 950 W

1000 W/1150 W

R134a,

500 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

47 kg

SK 3384.140

SK 3384.540

SK 3384.240

SK 3384.640

400 V, 2 ~,

50/60 Hz

3.4 A/

4.0 A

9.8 A/

9.6 A

10.0 A/

10.0 A

100%

R134a,

500 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

47 kg

SK 3385.100

SK 3385.500

SK 3385.200

SK 3385.600

230 V,

50/ 60 Hz

5.7 A/

6.6 A

16.8 A/

18.4 A

10.0 A/

10.0 A

100 %

1000 W/1175 W

1100 W/1310 W

2000 W/2130 W

1570 W/1670 W

R134a,

950 g

25 bar

+20 –

+55°C

<64dB(A)

IP 54

IP 34

42 kg

SK 3385.110

SK 3385.510

SK 3385.210

SK 3385.610

115 V,

50/ 60 Hz

13.0 A/

14.2 A

36.0 A/

32.0 A

20.0 A/

20.0 A

100 %

1050 W/1250 W

1160 W/1380 W

R134a,

950 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

48 kg

SK 3385.140

SK 3385.540

SK 3385.240

SK 3385.640

400 V, 2 ~,

50/60 Hz

3.3 A/

3.8 A

10.0 A/

12.0 A

10.0 A/

10.0 A

100%

R134a,

950 g

+20 –

+55°C

<64dB(A)

IP 54

IP 34

48 kg

SK 3386.140

SK 3386.540

SK 3386.240

SK 3386.640

400 V, 3 ~,

50 Hz,

460 V, 3 ~,

60 Hz

3.0 A/

3.1 A

8.0 A/

9.0 A

10.0 A*/

10.0 A*

100%

1180 W/1490 W

1430 W/1770 W

3000 W/3300 W

2460 W/2750 W

R134a,

1600 g

25 bar

+20 –

+55°C

<67dB(A)

IP 54

IP 34

796 x 470 x 580

70 kg

SK 3387.140

SK 3387.540

SK 3387.240

SK 3387.640

400 V, 3 ~,

50 Hz

460 V, 3 ~,

60 Hz

3.5 A/

3.6 A

17.0 A/

19.0 A

100%

1620 W/2060 W

1870 W/2340 W

4000 W/4200 W

3250 W/3490 W

R134a,

1800 g

25 bar

+20 –

+55°C

<67dB(A)

IP 54

IP 34

77 kg

Technische Änderungen vorbehalten.

Technical modifications reserved.

Sous réserve de modifications techniques.

Technische wijzigingen voorbehouden.

Tekniska ändringar förbehålles.

Rittal si riserva di apportare eventuali modifiche tecniche.

Se reserva el derecho a realizar cambios técnicos.

* Motorschutzschalter, motor circuit breaker, disjoncteur-protecteur, motorbeveiligingsschakelaar, motorskyddsbrytare, salvamotore, guardamotor.

D

GB

F

NL

S

I

E

J

3

01_SK3382_2_3.fm Seite 3 Freitag, 5. März 2004 4:27 16

8

Contents

1. Application

2. Technical data

3. Assembly of roof-mounted units

4. Safety notices

5. Electrical connection

6. Commencing operation and control

behaviour

7. Supplementary functions

8. BUS system

9. Technical information

10. Handling Instructions

11. Scope of supply and guarantee

12. Display screen and system analysis

13. Comfort control programming

1. Application

Enclosure cooling units are designed and built

to dissipate heat from enclosures by cooling the

air inside the enclosure and protecting temperature-sensitive components. Enclosure cooling

units are particularly suitable for a temperature

range of +40°C to +55°C.

2. Technical data

(see table 2.1)

3. Assembly of

roof-mounted units

The roof-mounted unit can be assembled as

standard. Make the cutout at the mounting place

as shown in Fig. 3.1. Attach the enclosed sealing

plate under the plastic base of the cooling unit

and the enclosed sealing frame to the cut out roof

plate. After the assembly of the unit, screw

double-threaded bolts in the holes of the plastic

base at the bottom side of the unit. After this,

insert the sliding part, slide it over the cutout

and fasten it by means of washers and nuts.

4. Safety notices

The following safety notices are to be observed

in their entirety for the correct use of the

equipment:

Prior to mounting, ensure that:

the site for the enclosure, and hence the

arrangement of the cooling unit, is selected

so as to ensure good ventilation;

the location is free from excessive dirt and

moisture;

the cutout for air extraction is located in the

upper area of the enclosure;

the mains connection ratings, as stated on

the rating plate, are available;

the ambient temperature does not exceed

+55°C;

the packaging shows no signs of damage.

Traces of oil on damaged packaging are an

indication of refrigerant loss and of leakage in

the unit system. Any damage to the packaging

may be the cause of subsequent malfunctions;

the enclosure is sealed on all sides (IP 54).

Condensation will occur if the enclosure is

leaky;

the distance of the units from the wall should

not be less than 200 mm;

air inlet and outlet are not obstructed on the

inside of the enclosure;

units are only fitted horizontally in the specified position.

Max. deviation from the true horizontal: 2°;

condensate drainage is provided

(see 9.3);

electrical connection and repair are carried

out only by authorised personnel. Use only

original replacement parts!

to avoid an increase in condensation, a dooroperated switch (e.g. PS 4127.000) should be

used which will switch the cooling unit off

when the enclosure door is opened (see 7.3);

losses from the components installed in

the enclosure must not exceed the specific

refrigeration capacity of the cooling unit itself;

the customer must not modify the cooling unit

in any way.

Important note:

In order to achieve a permanent seal between

cooling unit and enclosure, the mounting surface

should be reinforced or supported where necessary (see example fig. 3.2), especially in case of

larger roof surfaces. Observe assembly instruction under heading 3.

Fig. 3.2

Roof plate reinforcement

with TS 8 enclosure

Accessory for roof plate reinforcement with TS:

Mounting rail

Sliding nut

Mounting bracket

Threaded block

(see Accessories in the Rittal Catalogue)

Transportation by means of a crane:

Remove blanking plug in the cover and

screw in eyebolt M12.

5. Electrical connection

The connected voltage and frequency must

correspond to the values stated on the rating

plate. During commissioning, the data on the

rating plate of the device shall apply. The cooling

unit must be connected to the mains via an all-pin

isolating device, which ensures at least 3 mm

contact opening when switched off. The unit must

not have any additional temperature control

connected up-stream at the supply end. The fans

and compressors built into single and threephase devices are intrinsically safe (thermal

winding protection).

This also applies to SK 3382...., SK 3359....,

SK 3383...., SK 3384...., SK 3385....

transformer types, and to specially rated units

which are also fitted with a transformer.

Line protection should be provided by means of

the pre-fuse specified on the rating plate. Only

one automatic cutout should be connected between the cooling unit and the power supply. A

time-lag backup-fuse as specified on the rating

plate (safety cutout K-characteristic or time-lag

lead fuse) is mandatory.

The three phase supplies for the SK 3386.... /

SK 3387.... must be connected via a motor

safety switch to a TN grid with grounded star

point. Summation current as specified on the

rating plate. Specially rated three-phase units

must be protected by means of transformer safety

switches (category AC-6A) specified on the rating

plate.

For units designed for three phase 400/460 V,

the rotary field or the absence of a phase is also

monitored. If the rotary field is incorrect or a phase

is absent, the unit will not run. Observe the

relevant regulations during installation!

6.Commencing operation

and control behaviour

Following the completion of mounting and a

waiting period of approximately 30 minutes

(to allow oil to collect in the compressor in order

to ensure lubrication and cooling).

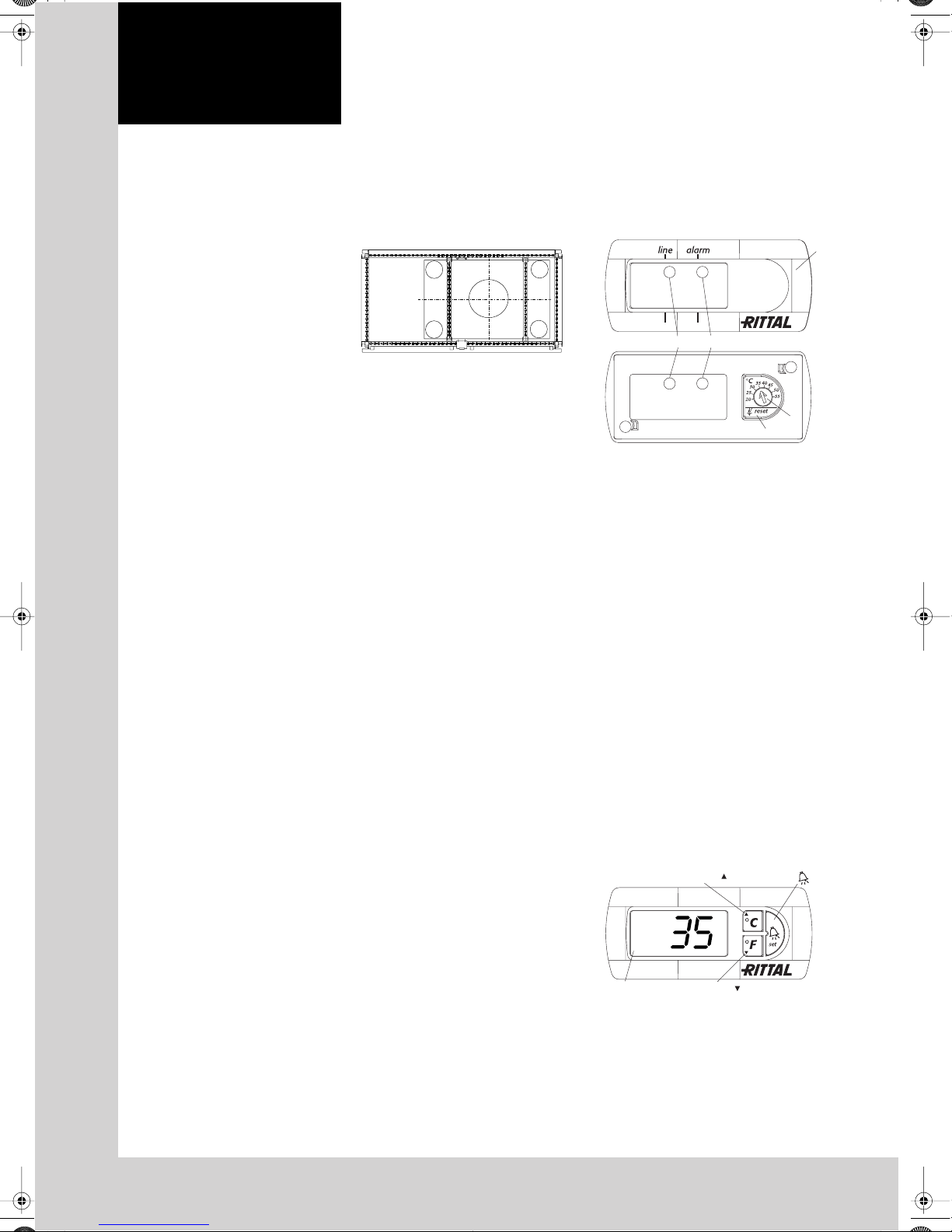

6.1 Basic control system

Version .....100 / .110 / .140

The cooling unit operates automatically, i.e. after

electrical connection, the evaporator fan will run

continuously to circulate the air inside the enclosure. The installed basic controller (setting the

desired internal temperature; factory setting

+35°C) provides automatic control switch-off of

the cooling unit by the set value of the fixed

switching difference of 5 K.

English

6.1.1 Temperature setting at the basic

controller

First of all, the louvred grille with the incorporated

display is to be removed from the unit. The display

lock is then to be slackened and this is to be

pushed forward off the louvred grille. Finally, the

display screen (1) is carefully removed, e.g. with a

screwdriver. The desired nominal temperature can

be set on the potentiometer (2) which is now

accessible. After the temperature has been set,

the display of all screens in the louvred grille is to

be locked once more. The louvred grille is to be

fastened to the unit again.

Fig. 6.1

Basic controller

6.1.2 Operation of the basic controller

The basic controller monitors and controls the

cooling unit. After the supply voltage has been

connected, the green LED (3) lights to indicate

readiness for operation. The green LED is

connected in series with a door limit switch, and

flashes if the enclosure door is opened. The red

LED (4) signals too high a temperature inside the

enclosure; at 5 K above the set value, the red LED

comes on permanently. In addition, the excess

temperature message can still be queried via an

integrated potential-free contact in the cooling

unit connection terminal.

K1 fault signal relay with changeover contact

Te rminal 3: NC (normally closed)

Te rminal 4: C (connection between voltage

supply and fault signal relay)

Te rminal 5: NO (normally open)

The definitions NC and NO refer to the deenergised state. As soon as voltage is applied to

the cooling unit, the fault signal relay picks up.

As a result, the relay contacts change their state

(contact 3 – 4 open; contact 4 – 5 closed),

representing the normal operating status of the

cooling unit. As soon as a system message

occurs or the voltage supply is interrupted, the

relay drops out. (see circuit diagrams on

page 37).

The high pressure alarm in the cooling circuit is

indicated by the red LED flashing. In this case,

the unit is to be reset manually, by pressing the

rubberized potentiometer display (5) for

3 seconds (see 6.1.1).

6.2 Comfort controller control

Version .....500 / .510 / .540

Fig. 6.2

Comfort controller

34

1

2

5

H2 = Button

H4 = Button

/set

°C

H3 = Button

°F

H1 = Display terminal

After electrical connection the internal fan turns on

and circulates the enclosure air. This helps assure

even temperature distribution within the enclosure.

The condenser fan and compressor are controlled

by the Comfort controller. The minimum break time

is 3 min. The switching difference is 5 K, but

can be set in the range 2 – 10 K. To avoid short

switching cycles and hence the danger of

inadequate or only partial cooling in some

sections of the enclosure, the switching difference

should be set to be only as low as necessary.

For economic reasons (energy saving), the

nominal value of the internal enclosure

temperature T

as low as necessary.

6.2.1 Operation of the Comfort controller

The display terminal H1 consists of a 3 position

7-segment display which indicates the enclosure

internal temperature in °C or °F (changeable) as

well as any fault codes. The actual enclosure

internal temperature is constantly displayed on

H1. When a system message is generated, this

alternates in the display with the current internal

enclosure temperature. While programming the

unit, the programming level and prescribed value

are also displayed.

Test mode

By simultaneously holding down keys H2

°C key) and H4 ( /set key) for 5 seconds, the

(

cooling unit will commence cooling operation,

irrespective of the setpoint. The door limit switch

function is disregarded in such cases. After

approximately 5 minutes or upon reaching 15°C,

the device deactivates cooling operation once

again.

6.2.2

In the EEPROM of the Comfort controller various

parameters are stored which can be changed by

using the buttons H2, H3 and H4. 24 changeable

parameters can be set via 24 programme levels in

the stated ranges (max. and min. values).

To this end, input code “22” is required

(see diagram 13.1).

The H2, H3 and H4 keys are multiple occupancy.

To access programming mode, set 5 sec is to be

pressed and held down.

Primary occupancy (only diode displays):

H2: °C, H3: °F, H4: Alarm

Secondary occupancy (for programming):

H2: Arrow upwards, H3: Arrow downwards,

H4: set

Programming via diagnostic software (order no.

SK 3159.100) is also an option. The programming

cable interface is the connecting cable plug,

located on the rear of the Comfort controller. To do

this, the louvred grille also is to be removed if

necessary.

6.2.3 System messaging equipment

All system messages at the cooling unit are

recorded and displayed as an error number

by H1. System messages alternate in the display

with the current internal enclosure temperature.

(see 12. Comfort control fault display and error

analysis).

6.2.3.1 System message contacts

Both relays are normally closed.

All system messages assigned to an individual

relay result in it opening. If the control voltage

fails, this also results in the relay opening and can

hence be captured and documented in the log

file. According to individual weighting, all system

messages can be assigned to both relays or

suppressed. Terminal strip X3 provides the

connection. See the wiring diagram for contact

data and occupancy.

K1/K2 fault signal relay (normally open contact):

Te rminal 3: Fault signal relay 1

Te rminal 4: Voltage supply connection for both

Te rminal 5: Fault signal relay 2

(see the circuit diagrams on page 37).

should also be set to be only

i

(see diagram 13.1 Programming)

Programming

(see 13.1 Comfort controller

programming)

(K1 and K2; potential free)

fault signal relays

7. Supplementary functions

7.1 Filter mat use and changing

The PU foam filter mat available as an accessory

is coarse and filters large dust particles or fluff

from the air. Metallic filter mats are used to trap

oil condensate. These are also available as an

accessory. Subject to the suction of the blower

being high enough, fine dust is blown through

the filter mat and the external circuit of the unit.

This does not affect the unit's operation.

Fig.7.1

Filter mat replacement

2.

1.

7.2 Filter mat monitoring

Function of the filter mat monitor:

The filter mat is monitored for soiling by measuring the temperature difference in the external circulation of the cooling unit (see diagram 13.1:

Programming on page 45). In the event of any

filter mat soiling, the temperature difference will

increase. The nominal value of the temperature

difference in the external circuit is matched to the

relevant operating points in the characteristic

fields. Hence there is no requirement to adjust the

nominal value for different unit operating points.

7.3 Door limit switch S1

(supplied by customer)

Where a door limit switch is used and the enclosure door is open (contact is closed when door is

open), the cooling unit (fans and condenser) will

switch off after approx. 15 s. This only applies to

devices with a Comfort controller and devices

with a three-phase connection to the basic controller. For devices with a basic controller (115 V,

230 V and 400 V, 2~), the internal fan is not

switched off when using a door limit switch.

Thereby avoiding an increase in condensation

while the door is open. To avoid cyclic operation,

switch-on of condenser and external fan is

delayed by about 3 minutes after the cooling unit

has been switched off.

The internal fan will start up after about 15 s on

closure of the door. Connection is made at the

terminals 1 and 2. The extra low voltage is

supplied by the internal power pack, current is

approx. 30 mA DC. Each door limit switch must

only be assigned to one cooling unit. Several door

limit switches may be operated on one cooling

unit (parallel connection). The minimum crosssection of the connection cable is 0.3 mm

cable length of 2 m. The resistance of the door

limit switch contact must not exceed a maximum

of 50Ω.

Only connect the door limit switch to the

cooling unit’s own DC supply!

7.4 Interface X3 (option)

(Connector X3)

Note!

The electrical signals at the interface are of an

extra-low voltage (not extra-low safety voltages

to EN 60 335).

The 9-pin SUB-D socket X3 can be used to

connect additional interface cards for integrating

cooling units with higher level monitoring systems.

These cards are also available as an accessory.

(Interface card: Model No. SK 3124.200).

2

for a

8. BUS system

(Model No.: Master-slave cable SK 3124.100)

8.1 General

The BUS system allows a maximum of 10 cooling units to be interconnected.

As a result, the following functions are available

to the operator:

Parallel unit control (the cooling units in the

network can be simultaneously switched

on and off)

Parallel door status messages (“door open”)

Parallel collective fault message

The data exchange is carried out using masterslave cables (shielded, two-wire leads). All units

are assigned an address. This address also

includes the ID for “master” or “slave”.

8.2 Installation notices for the X2 interface

(Jack X2)

Note!

The electrical signals at the interface are of an

extra-low voltage (not extra-low safety voltages

to EN 60 335). Always heed the following notes!

De-energise the cooling units to be

connected.

Ensure proper electrical insulation.

Make sure the cables are not laid in parallel

to power lines.

Make sure that the lines are short.

8.3 Programming the cooling unit

See diagram 13.1 for details on programming.

ID’s:

Master cooling unit Slave cooling unit

00 Basic state 00 Basic state

Master

01

with 1 slave

Master

02

with 2 slaves

Master

03

with 3 slaves

Master

04

with 4 slaves

Master

05

with 5 slaves

Master

06

with 6 slaves

Master

07

with 7 slaves

Master

08

with 8 slaves

Master

09

with 9 slaves

Note

Only one unit may be configured as master; the

address ID must match the number of slave

units.

The individual slave units must have different

addresses; the addresses must be in ascending

order (without gaps in between).

Example:

1 master cooling unit with 2 slave cooling units

Master

02

(see wiring example of master/slave and door

limit function, page 42/43).

Slave

11

11

12

13

14

15

16

17

18

19

Slave

with address 1

Slave

with address 2

Slave

with address 3

Slave

with address 4

Slave

with address 5

Slave

with address 6

Slave

with address 7

Slave

with address 8

Slave

with address 9

Slave

12

9

Fig. 9.3

Condensate discharge

English

9.Technical information

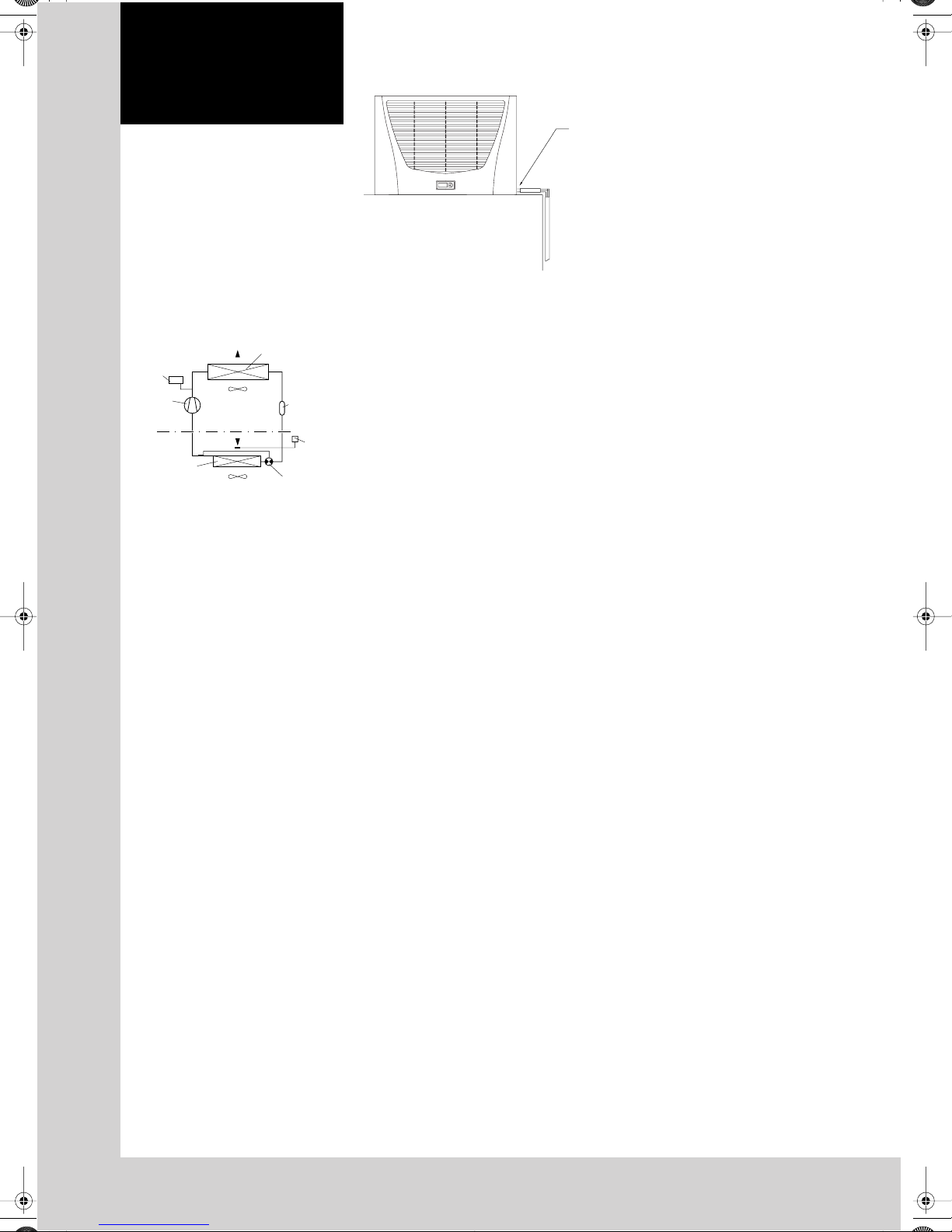

The cooling unit (compressor refrigeration unit)

consists of four main components: the coolant

compressor, evaporator, condenser, and the

control or expansion valve, which are connected

by suitable pipework. This circuit is filled with

a readily boiling substance, the refrigerant. The

R134a (CH

rine. It has an ozone destroying potential (ODP)

of 0 and is therefore environmentally friendly. A

filter dryer which is integrated in the hermetically

sealed cooling circuit, provides effective protection against moisture, acid, dirt particles, and

foreign bodies within the cooling circuit.

9.1 Operation of the cooling unit

Fig. 9.1

Compressor

External circuit

Internal circuit

The compressor takes the gaseous refrigerant

from the evaporator and compresses it to a

higher pressure in the condenser. During this

process the temperature of the refrigerant rises

above the ambient temperature and heat can be

dissipated to the environment via the surface of

the condenser. Then the refrigerant is liquefied

and, by means of a thermostatically controlled

expansion valve, returned to the evaporator,

where it evaporates at low pressure. The heat

required for complete evaporation is drawn from

the enclosure interior causing it to cool down.

The cooling cycle is thus completed, the aforementioned process of the heat transfer starts

afresh.

9.2 Safety equipment

The cooling circuit of the cooling unit has a

component-tested, high-pressure monitor to

EN 12 263, which is set to maximum PS (allowed

pressure) and operates via an automatic reset

device in case of recurring pressure drop. Temperature monitoring will prevent the evaporator

from icing up. If there is a risk of icing up, the

compressor is switched off and automatically

switched on again at higher temperatures.

The refrigerant compressor and the fans are

equipped with thermal winding protection

switches against excess current and excess

temperatures.

9.3 Condensate discharge

A cast gutter in the evaporator tray ensures that

any condesate which may form on the evaporator (at high air humidity, low temperatures inside

the enclosure), is drained away to the right or

rear of the unit. For this purpose, a length of

hose should be fitted to one of the two condensate pipe connection pieces (see fig. 9.3). The

other drain that is not used has to be sealed

accordingly. The condensate must be able to

run off freely. If the condensate is to be drained

off over a greater distance, then care must be

taken that the hose is free from kinks and a

check for correct drainage made. Units with a

comfort controller have an additional condensate alarm.

FCF3) refrigerant is free from chlo-

2

Operation of the cooling unit

H

PSA

monitor

Fan 2

Evaporator

Fan 1

Liquefier

Filter

dryer

Thermostat

Expansion valve

1

′′

/

2

10. Handling Instructions

Storage, maintenance, transport and disposal

As a maintenance-free, hermetically sealed

system, the cooling circuit has been filled in the

factory with the required amount of refrigerant,

and tested for leaks and subjected to a function

trial run.

The installed maintenance-free fans use ball

bearings, they are protected against moisture and

dust, and are fitted with a temperature monitor.

The life expectancy is at least 30,000 operating

hours. The cooling unit is thus largely maintenance free. All that may be required from time to

time is that the components of the external air

circuit are cleaned by compressed air. The use of

a filter mat is recommended only if large particles

of lint are present in the air, so that blockage of the

condenser is prevented. (Filter mat replacement,

fig. 7.1). Note: Prior to any maintenance work, the

power to the cooling unit must be disconnected.

Storage temperature: The cooling units must not

be exposed to temperatures above +70°C.

Transport position: The cooling units must always

be transported upright.

Waste disposal: The closed cooling circuit

contains refrigerant and oil which must be

correctly disposed of for the protection of the

environment. Disposal can be carried out at

Rittal.

We reserve the right to make technical

modifications.

11. Scope of supply and

guarantee

1 cooling unit, ready for connection

1 drilling template

1 sealing plate

1 sealing frame

1 set of mounting and operating instructions

1 plug-in terminal strip

Guarantee:

This unit is covered by a 1-year guarantee from the

date of supply, subject to correct usage (see also

Safety notices under heading 4.). Within this period,

the returned unit will be repaired in the factory or

replaced free of charge. The cooling unit is to be

used for the cooling of enclosures only. If it is connected or handled improperly the manufacturer’s

guarantee does not apply and in this case we are

not liable for any damage caused.

10

Loading...

Loading...