Rittal SK 3293.540, SK 3293.140, SK 3393.100, SK 3393.140, SK 3381.100 Assembly Instructions Manual

...

Rittal

SK

Umweltorientierte

Kühltechnik

Schaltschrank-

SK 3293.100

SK 3293.140

SK 3281.100

SK 3293.500

SK 3293.540

SK 3393.100

SK 3393.140

SK 3381.100

393.5

SK 3

00

SK 3393.540

3279.100

SK

SK

3298.100

SK

3298.500

SK

3260.500

SK

3260.140

Kühlgerät

Cooling Unit

Climatiseur

Koelaggregaat

Kylaggregat

Condizionatore

per armadi

Refrigerador

para armarios

Montageanleitung

Assembly Instructions

Notice de montage

Montage-instructie

Montageanvisning

Istruzioni di montaggio

Instrucciones de montaje

Umschalten auf PerfektionUmschalten auf Perfektion

D

ACHTUNG!

Montage von

Schaltschrank-Kühlgeräten

Bei der Montage ist zu beachten, daß

Warmluftein- und Kaltluftaustritt nicht zu

verbauen sind. Eine ungehinderte Luftzirkulation im Innenkreislauf ist zu gewährleisten. Ein Abstand zu den Luftaus- und -eintrittsöffnungen von 200 mm

bis zur Installation ist einzuhalten. Wird

das Gerät vom Netz getrennt, darf ein

erneutes Einschalten erst nach einer

Wartezeit von > 5 min. erfolgen.

Einsatz von Türpositionsschaltern

bei Kühlgeräten

Serie .100 / .140: Die o.g. Wartezeit muß

z.B. durch die Verwendung eines

Zeitrelais sichergestellt werden.

Serie .500 / .540: Die o.g. Wartezeit wird

durch den integrierten Microcontroller

sichergestellt. Pro Gerät ist ein

potentialfreier Türpositionskontakt zu

verwenden; es dürfen auf keinen Fall

mehrere Geräte über einen Türendschalter betrieben werden.

In Umgebungen mit erhöhter elektromagnetischer Störung muß eine

geschirmte Leitung verwendet werden.

Der Türkontakt ist über zusätzliches

Relais, das in der Nähe des Gerätes plaziert ist, zu schalten. Die Leitungen sind

getrennt von den Netzleitungen zu verlegen. Auf kurze Leitungswege achten!

Einsatz von Motor- bzw.

Trafoschutzschaltern bei Kühlgeräten

Drehstromgeräte sind über einen

Motorschutzschalter an ein TN-Netz mit

geerdetem Sternpunkt anzuschließen.

Beim Einsatz von Schaltschrank-Kühlgeräten der Serie .140 / .540 mit

Transformatoren und Geräten in Sonderspannung, die ebenfalls mit Trafo

ausgerüstet sind, sind normale Motorschutzschalter von ihrer Einschaltcharakteristik nicht mehr ausreichend.

Deshalb müssen kundenseitig Trafoschutzschalter installiert werden. Diese

sind auf den auf dem Typenschild

angegebenen Nennstrom einzustellen.

GB

ATTENTION!

Installation of cooling units

Please make sure during installation that

warm air inlet and cold air outlet are not

obstructed. An unobstructed air circulation in the inside circuit has to be

ensured. A distance of 200 mm from air

inlet and air outlet openings to the

installed equipment should be

respected. After disconnection of the

cooling unit, waiting period of > 5 min.

before reactivation.

Use of door operated switch with

cooling units

Series .100 / .140: The mentioned above

waiting period has to be ensured by

using a time relay.

Series .500 / .540: One potential-free

door operated contact has to be used

per unit, never operate more than one

unit via one door operated switch. In

environments with high electromagnetic

interference a shielded cable has to

be used. The door contact is to be

connected via an additional relay, which

is placed near the unit. The cables and

the supply line are to be laid separately.

Please ensure that the cables are as

short as possible.

Use of motor or transformer

protection switch with cooling units

Three-phase devices are to be

connected via a motor protection switch

to a TN network with earthed neutral. If

units of series .140 / .540 are used with

transformers and units with special

voltage, also equipped with transformer,

standard motor protection switches are

not sufficient due to their closed cricuit

condition. That is why transformer

protection switches have to be installed

by the customer, and have to be

adjusted to the rated current on the type

plate.

F

ATTENTION!

Montage des climatiseurs

d’armoires électriques

Veiller lors du montage à n’obstruer ou

gêner ni l’entrée de l’air chaud ni la

sortie de l’air froid. L’air doit pouvoir

circuler librement dans le circuit

intérieur. Respecter un écartement de

200 mm entre l’appareil installé et les

ouvertures d’entrée et de sortie d’air.

Lorsque l’appareil a été coupé du

secteur, attendre au moins 5 minutes

avant de le remettre en circuit.

Utilisation d’un interrupteur de porte

avec les climatiseur

Séries .100 / .140: La durée d’attente

mentionnée plus haut sera assurée en

installant un relais retardeur.

Séries .500 / .540: Utiliser un interrupteur

de porte sans potentiel pour chaque

appareil. Ne jamais faire fonctionner

plusieurs appareils avec un seul

interrupteur de porte.

Lorsque le milieu ambiant est soumis à

d’importantes interférences électromagnétiques, utiliser un câble avec

contacteur de protection. Monter le

contact de la porte avec un relais

supplémentaire placé à proximité de

l’appareil. Lors de la pose des conducteurs, veiller à les séparer des lignes

d’alimentation et choisir la voie la plus

courte.

Utilisation d’un contacteur-disjoncteur

ou disjoncteur de protection pour

transformateur dans les climatiseurs

d’armoires électriques

Les appareils à courant triphasé doivent

être connectés par un contacteurdisjoncteur au réseau TN avec neutre

mis à la terre. Dans le cas des climatiseurs d’armoires électriques des séries

.140 / 540, équipés de transformateurs et

dans le cas des appareils avec tensions

spéciales également équipés de transformateurs, les propriétés d’enclenchement des disjoncteurs standard ne sont

pas suffisantes. Le client devra alors

prévoir des disjoncteurs de protection

pour transformateurs et les régler sur la

valeur du courant nominal indiquée sur

la plaque signalétique.

NL

LET OP!

Montage van schakelkastkoelaggregaten

Bij de montage dient erop te worden

gelet dat de aanzuigopeningen van de

warme lucht en de inblaasopeningen

van de koude lucht niet mogen worden

gemodificeerd. Anders kan geen

ongehinderde luchtcirculatie in het

binnencircuit worden gegarandeerd.

Tussen de luchtaanzuig-, luchtinblaasopeningen en de installatie dient een

afstand van minimaal 200 mm te worden

aangehouden. Wordt het aggregaat van

het net gescheiden, dan mag het pas na

een wachttijd van tenminste 5 minuten

opnieuw worden ingeschakeld.

Toepassing van deurschakelaars bij

koelaggregaten

Serie .100 / .140: De hierboven genoemde wachttijd dient door toepassing van

bijv. een tijdrelais te worden zekergesteld. Serie .500 / .540: Per aggregaat

dient één potentiaalvrij deurcontact te

worden toegepast; er mogen in geen

geval meerdere aggregaten op één

deurschakelaar worden aangesloten. In

omgevingen waar verhoogde elektromagnetische storingen voorkomen, dient

een afgeschermde kabel te worden

toegepast. Het deurcontact kan via een

extra relais, dat in de buurt van het

aggregaat is aangebracht, worden

geschakeld. De kabels diene gescheiden van de netvoedingskabels te

worden gelegd. Let erop dat zo kort

mogelijke kabels worden gebruikt!

Inzet van motor respectievelijk

transformatorbeveiligingsschakelaar

bij koelaggregaten

Draaistroomaggregaten zijn via een

motorbeveiligingsschakelaar aan een

TN-stelsel met geaard sterpunt ann te

sluiten. Bij de toepassing van schakelkast-koelaggregaten van de serie .140 /

.540 met transformatoren en aggregaten

met afwijkende spanningen die ook

zijn voorzien van een transformator zijn

standaard motorbeveiligingsautomaten niet voldoende als gevolg van hun

inschakelkarakteristiek. Daarom dienen

trafobeveiligingsschakelaars door de

klant zelf te worden geïnstalleerd en te

worden ingesteld volgens de op het typeplaatje aangegeven nominale stroom.

S

VARNING!

Montering av

apparatskåpskylaggregat

Vid montering måste beaktas att

varmluftsintag och kalluftsutblås inte är

spärrade. En fri luftcirkulation inuti

skåpet måste garanteras. Utrymmet

mellan luftintag, utblåsöppningar och

installationerna måste vara 200 mm.

Efter att kylaggregatet stängts av kan

det startas först efter 5 minuter.

Användning av dörrkontakt med

kylaggregat

Vid serierna .100 / .140 måste den ovan

nämnda väntetiden åstadkommas

genom ett tidrelä.

Vid serierna .500 / .540 måste en

potentialfri dörrkontakt användas per

enhet, det får heller aldrig användas mer

än en enhet per dörrkontakt. I miljöer

med hög elektromagnetisk påverkan

måste en skärmad kabel användas.

Dörrkontakten ska kopplas via ytterligare

ett relö, vilket placeras nära enheten.

Kablage dras skiljt från nätledningen. Se

till att kablarna är så korta som möjligt!

Användning av motor- resp transformatorskyddsbrytare med kylaggregat

Trefasaggregat ansluts via en

motorskyddsbrytare till ett TN-nät med

jordad nollpunkt. Om kylaggregat ur

serierna .140 / .540 används med

transformatorer och enheter med

specialspänning, även de utrustade

med transformatorer, räcker inte

standard motorskyddsbrytare beroende

på deras slutna kretsar. Därför måste

transformatorskyddsbrytare installeras,

Dessa ska ställas in på den på

typskylten angivna nätströmmen.

I E

ATTENZIONE!

Installazione di condizionatori

Durante il montaggio accertarsi che

l’entrata aria calda e l’uscita aria fredda

non siano ostruite. Occorre assicurare la

libera circolazione dell’aria nel circuito

interno, nonchè rispettare una distanza

di 200 mm dalle aperture di entrata e

scarico aria al luogo di installazione.

Una volta disinserito l’apparecchio è

possibile riavviarlo soltanto dopo

> 5 min. di attesa.

Impiego di interruttori di posizionamento porta nei condizionatori

Serie .100 / .140: il suddetto tempo di

attesa prima di riavviare l’apparecchio

deve essere rispettato utilizzando ad es.

un relais a tempo.

Serie .500 / .540: il tempo di attesa

sopra indicato viene assicurato dal

microcontroller integrato. Si deve

utilizzare un interruttore di posizionamento porta per ogni apparecchio; non

è possibile in nessun caso azionare più

apparecchi con un interruttore.

In ambienti particolarmente soggetti ad

interferenze elettromagnetiche occorre

utilizzare un cavo schermato.

L’interruttore per la porta dovrà essere

collegato ad un ulteriore relais, situato

vicino all’apparecchio. I cavi e le linee

elettriche devono essere posati in sede

separata. Prevedere linee di connessione con lunghezza limitata.

Impiego di interruttori di protezione

trasformatore nei condizionatori

I normalli interruttori di protezione dei

motori, per le loro caratteristiche, non

sono più sufficienti per essere impiegati

su condizionatori della serie .140 / .540

con trasformatori e apparecchiature a

tensione speciale, dotate anch’esse di

trasformatore: Il cliente dovrà quindi

installare interruttori di protezione del

trasformatore, da tarare in base al valore

della corrente nominale indicato sulla

targhetta.

¡

ATENCION!

Montaje de refrigeradores

En el montaje debe tenerse en cuenta

que la entrada de aire caliente y la

salida de aire frío no se encuentren

obstruidas. Debe garantizarse una

circulación adecuada del aire en el

circuito interior. Debe mantenerse una

distancia de 200 mm entre las escotaduras de salida y de entrada de aire

hasta el punto de instalación. Tras la

desconexión del aparato deben transcurrir >5min. hasta la próxima conexión.

Uso de interruptores de posición de

puerta en refrigeradores

Serie .100 / .140: El tiempo de reposo

mencionado arriba debe garantizarse

mediante el montaje de un relé de

tiempo.

Serie .500 / .540: Debe utilizarse un

contacto libre de potencial de posición

de puerta por aparato; en ningún caso

deberá utilizarse un sólo interruptor final

para más de un aparato.

En entornos con elevada perturbación

electromagnética debe utilizarse un

cable apantallado. El contacto de

puerta debe conectarse a través de un

relé adicional situado cerca del aparato.

Los cables deben tenderse separados

de los cables de red. Procure que los

cables sean lo más cortos posibles.

Uso de interruptores de protección

de motores o de transformadores en

refrigeradores

Los aparatos de corriente trifásica

deben conectarse mediante un interruptor de protección de motores a una

red TN con toma de tierra en forma de

estrella. Con la aplicación de los refrigeradores para armarios de las series

.140 / .540 con transformadores y aparatos con tensión especial, equipados

también con transformadores, los

interruptores de protección de motor

normales son insuficientes a causa de

sus características de conexión. Por tal

motivo el cliente deberá instalar un

interruptor de protección de transformador. Estos deben ajustarse en función

de la corriente nominal indicada en la

placa de características.

J

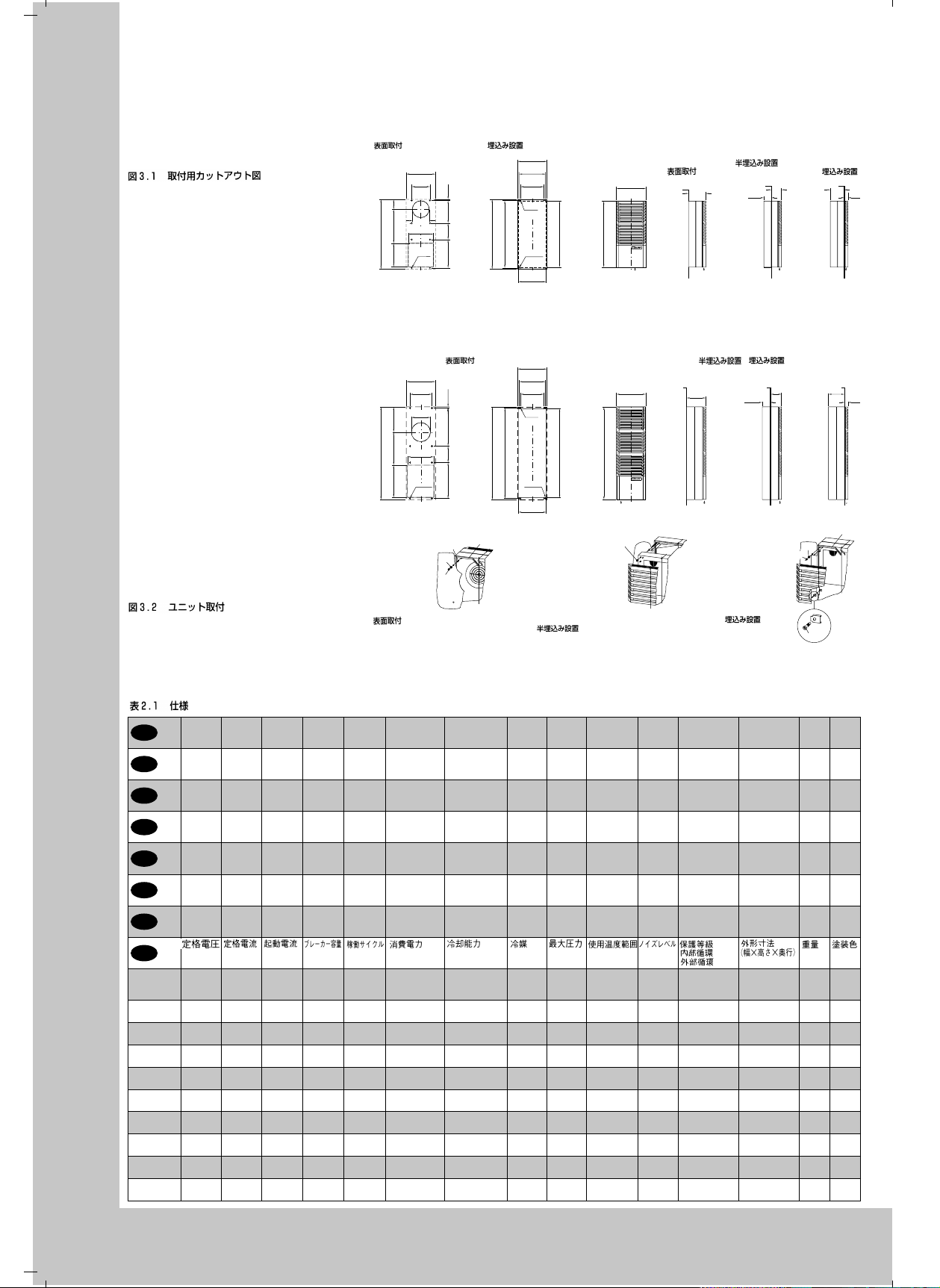

SK 3293.... / 3281.100 / 3393.... / 3381.100*

Abb. 3.1 Montageausschnitte

Fig. 3.1 Mounting Cut-out

Fig. 3.1 Découpe de montage

Afb. 3.1 Montage-uitsparingen

Bild 3.1 Håltagning

Fig. 3.1 Dime di foratura

Fig. 3.1 Recorte del montaje

SK 3298.... / 3279.100 / 3260.500

Abb. 3.2 Gerätemontage

Fig. 3.2 Mounting

Fig. 3.2 Montage de l’appareil

Afb. 3.2 Apparaatmontage

Bild 3.2 Aggregatmontage

Fig. 3.2 Montaggio dell’apparecchio

Fig. 3.2 Montaje del aparato

Tab. 2.1 T ec hnisc he Daten

Tab. 2.1 T ec hnical Data

Tab. 2.1 Données techniques

Tab. 2.1 T ec hnisc he gegevens

Tab. 2.1 T ekniska data

Tab. 2.1 Caratteristiche tecniche

Tab. 2.1 Datos técnicos

Betriebs-

Nenn-

Anlauf-

D

GB

F

NL

S

I

E

J

SK 3293.100

SK 3293.500

SK 3293.140

SK 3293.540

SK 3281.100

SK 3393.100

SK 3393.500

SK 3393.140

SK 3393.540

SK 3381.100

SK 3298.100

SK 3298.500

SK 3279.100

SK 3260.500

SK 3260.140

spannung

Operating

voltage

Tension

nominale

Bedrijfs-

spanning

Anslut-

ningsspänning

Tensione

nominale

Tensión

de

servicio

230 V,

50/60 Hz

400 V,

50/60 Hz

115 V,

50/60 Hz

230 V,

50/60 Hz

400 V,

50/60 Hz

115 V,

50/60 Hz

230 V,

50/60 Hz

115 V,

50/60 Hz

400 V– 3~

50/60 Hz

strom

Rated

current

Courant

nominal

Nominale

stroom

Märk-

ström

Corrente

nominale

Intensidad

nominal

3.1 A/

3.6 A

1.8 A/

2.1 A

6.5 A/

7.6 A

4.2 A/

4.4 A

2.5 A/

2.6 A

8.6 A/

9.2 A

5.5 A/

5.7 A

11.5 A/

12.0 A

2.3 A/

2.6 A

Vorsiche-

strom

rung T

Starting

Pre-fuse TDuty cycle Power

current

Courant de

Dispositif

démarrage

de sécurité

T

Aanloop-

Primaire

stroom

zekering T

Startström Försäkring gLInkopp-

Corrente

Fusibili T Ciclo d’in-

di spunto

Intensidad

Fusible T Duración

de

arranque

8.5 A/

6 A/

10.0 A

6 A

4.6 A/

4 A/

5.8 A

4 A

16.4 A/

10 A/

20.1 A

10 A

9.8 A/

6 A/

11.4 A

6 A

5.7 A/

6 A/

6.6 A

6 A

19.8 A/

10 A/

23.1 A

10 A

17.5 A/

10 A/

16.5 A

10 A

36.0 A/

16 A/

37.0 A

16 A

9.5 A/

6 A/

9.5 A

6 A

Anbau Einbau

External Installation Internal Installation

Implanté Intégré

Aanbouw Inbouw

Utanpå Inbyggnad

Montaggio sporgente Montaggio incassato

Montaje exterior Montaje interior

920

950

1265

1235

Refrigerant Permis-

Fluide

frigorigène

Koelmiddel

Kylmedel Tillåtet

Fluido

frigorigeno

Fluido

frigorífico

R134 a,

525 g

R134 a,

525 g

R134 a,

525 g

R134 a,

550 g

R134 a,

550 g

R134 a,

550 g

R134 a,

525 g

R134 a,

525 g

R134 a,

525 g

400

360

320

Ø 7

(4 x)

900

Ø 9.5

(4 x)

380

400

360

320

Ø 7

(4 x)

1215

Ø 9.5

(4 x)

380

Teileinbau

Partially Internal

Installation

Partiellement

intégré

Gedeeltelijke

inbouw

Delvis inbyggnad

Montaggio

semincassato

Montaje parcial

Betriebsüberdruck

sible

pressure

Pression

de régime

autor.

p. max. Temperatuur-

driftsövertryck

Pressione

max.

Presión

máxima

admis.

25 bar

25 bar

25 bar

24 bar

24 bar

24 bar

25 bar

25 bar

24 bar

950

1265

M 8

SW 13

Temperaturbereich

Temperature

range

Plage de

température

bereik

Temperatur-

område

Campo di

temperatura

Campo de

temperaturas

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

+ 20 –

+ 55°C

400

A

15

135

465

950

320

345

450440

1265

Anbau

External

Installation

Implanté

Aanbouw

Utanpå

Montaggio

sporgente

Montaje

exterior

* Nur für 400 mm tiefe PS/ES Schränke SK 3393.... / 338.1100, A = 250 mm, B = 300 mm

Nur für Schränke über 400 mm Tiefe SK 3393.... / 338.1100 A = 250 mm, B = 340 mm

Nur für Schränke über 400 mm Tiefe SK 3293.... / 328.1100 A = 300 mm, B = 340 mm

Einschalt-

Nennleistung Nutzkühlleistung Kältemittel zul.

dauer

consumption

Durée de

Puissance

mise en

nominale

circuit

Inschakel-

Nominaal

duur

vermogen

Märkeffekt Effektiv

lingstid

Potenza

serzione

nominale

Potencia

de

nominal

conexión

L35 L35

L35 L50

450 W/500 W

100 %

500 W/580 W

470 W/520 W

100 %

520 W/605 W

470 W/520 W

100 %

520 W/605 W

590 W/660 W

100 %

670 W/750 W

610 W/680 W

100 %

690 W/780 W

610 W/680 W

100 %

690 W/780 W

830W/1040W

100 %

940W/1170W

860W/1080 W

100 %

975W/1210W

900W/750W

100 %

1060W/920W

310225385

230

B

Ø 9.5

(4 x)

Anbau

External Installation

Implanté

Aanbouw

Utanpå

Montaggio sporgente

Montaje exterior

400

300

15520225490

260

360

Ø 9.5

(8 x)

A 8.4

M 8

SW 13

Useful cooling

output

Puissance

frigorifique

de rég.

Nuttig

koelvermogen

10 x 8

M 8 x 30

kyleffekt

Potenza

frigorifera utile

Potencia

frigorífica útil

DIN 3168/EN 814

L35 L35

L35 L50

825 W/960 W

680 W/720 W

825 W/960 W

680 W/720 W

825 W/960 W

680 W/720 W

1100W/1150 W

830W/850W

1100W/1150W

830W/850W

1100W/1150W

830W/850W

1400W/1450W

1100W/1150W

1400W/1450W

1100W/1150W

1740W/1630W

1340W/1220W

Anbau

External

Installation

Implanté

Aanbouw

Utanpå

Montaggio

sporgente

Montaje

exterior

400

Internal or Partially Internal Installation

Montaggio semincassato o incassato

400

Geräuschpegel

Noise

level

Niveau

sonore

Geluidsnivo

Ljudnivå Kapslingsklass

Livello

di rumore

Nivel

de ruido

62 dB (A)

62 dB (A)

62 dB (A)

62 dB (A)

62 dB (A)

62 dB (A)

62 dB (A)

62 dB (A)

65 dB (A)

Teileinbau

Partially

Installation

Partiellement Intégré

Gedeeltelijke inbouw

Delvis inbyggnad

Montaggio

semincass.

Montaje parcial

230

Teileinbau, Einbau

Partiellement intégré, intégré

Delvis inbyggnad, inbyggnad

Montaje parcial, montaje interior

260

Einbau

Internal

Installation

Intégré

Inbouw

Inbyggnad

Montaggio

incassato

Montaje

interior

Schutzart

Innenkreislauf

Außenkreislauf

Protection categ.

Internal circuit

External circuit

Degré de protect.

Circuit intérieur

Circuit extérieur

Beschermklasse

Inwendig circuit

Uitwend. circuit

Inre kretslopp

Yttre kretslopp

Grado di protez.

Circuito interno

Circuito esterno

Protección

Circuito interior

Circuito exterior

100

Inbouw

,

100

Abmessungen

(B x H x T)

mm

Dimensions

(W x H x D)

mm

Dimensions

(L x H x P)

mm

Afmetingen

(B x H x D)

mm

Mått

(B x H x D)

mm

Dimensioni

(L x A x P)

mm

Dimensiones

(anch. x alt.

x prof.) mm

130

160

M 6

SW 13

EN 60 529

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

IP 54

IP 34

400 x 950 x 230 35 kg

400 x 950 x 230 38 kg

400 x 950 x 230 38 kg

400 x 950 x 230 38 kg

400 x 950 x 230 41 kg

400 x 950 x 230 41 kg

400 x 1265 x 260 48 kg

400 x 1265 x 260 51 kg

400 x 1265 x 260 60 kg

Einbau

Internal

Installation

Intégre

Inbouw

Inbyggnad

Montaggio

incassato

Montaje

interior

185

215

A 8.4

B 4.8 x 13

Gewicht Farbton

Weight Colour

Poids Coloris

Gewicht Kleur

Vikt Färgton

Peso Colore

Peso Color

RAL

7032

RAL

7032

RAL

7032

RAL

7032

RAL

7032

RAL

7032

RAL

7032

RAL

7032

RAL

7032

45

45

10 x 4

English

Contents

1. Application

2. Technical data

3. Assembly

4. Electrical connection

5. Commencing operation and control

behaviour

6. BUS System (Model No. SK 3124.000)

7. Technical information

8. Maintenance

9. Scope of supply and guarantee

10. Fault indication and fault analysis

11. Programming

1. Application

Enclosure cooling units are designed and built

to dissipate heat from enclosures, by cooling

the air inside the enclosure and protecting temperature sensitive components. Enclosure cooling units are particularly suitable for the

temperature range of + 40 ° C to + 55 ° C.

2.Technical Data

(see table 2.1)

3. Assembly

The cooling unit can be mounted either internally, partially internally or externally.

Make cutouts and drill holes at the mounting

position (see fig. 3.1). Cut the enclosed seal to

the required length and attach it to the unit (see

fig. 3.2). In the case of external mounting screw

set-screws M8 x 30 into the blind nuts at the

rear face of the unit and fix them by means of

washers A 8.4 and nuts M8. In the case of partially internal mounting the unit has to be divided

by removing the lamella grille and unscrewing

the nuts M8. For external, partially internal and

internal mounting see fig. 3.2.

Prior to mounting, ensure that:

v

the site for the enclosure, and hence the

arrangement of the cooling unit, is selected

so as to ensure good ventilation;

v

the location is free from excessive dirt and

moisture;

v

the round cut-out for air extraction is located

in the upper area of the enclosure;

v

the mains connection ratings, as stated on

the name plate, are available;

v

the ambient temperature is no higher than

+55 ° C;

v

the packaging shows no signs of damage;

v

the enclosure is sealed on all sides.

Condensation will occur if the enclosure is

leaky;

v

the separation of the units from one another

and from the wall should not be less than

200 mm;

v

air inlet and outlet are not obstructed on the

inside of the enclosure;

v

units are only fitted vertically in the specified

position. Max. deviation from true vertical: 2 ° ;

v

condensate discharge must be made up by

means of the material provided in the dispatch bag. The discharge tube must be free

from kinks and must be arranged sloping

away from the unit;

v

electrical connection and repair are carried

out only by authorized specialist personnel.

Use only original replacement parts!

v

To avoid an increase in condensation, a door

operated switch (e.g. PS 4127.000) should

be used which will switch the cooling unit off

when the enclosure door is opened (see

5.2.3.3).

4.Electrical Connection

The connected voltage and frequency must correspond to the values stated on the name plate. The

cooling unit must be connected to the mains via

an isolating device, which ensures at least 3 mm

contact opening when switched off. The unit must

not have any additional temperature control connected before it. Line protection should be provided by means of the pre-fuse specified on the

name plate. Observe the relevant regulations

during installation!

Connect the mains connection to the plug-in terminal strip X10, see page 35.

Version .....500 / .540

Door limit switch, see 5.2.3.3

v

Collective fault signal connection, see 5.2.3.1

v

Note the designations on the terminal strip (see

wiring diagram).

v

The unit must be disconnected prior to

checking the protective earth conductor, high

voltage and the insulation in the enclosure.

5. Commencing Operation

and Control Behaviour

Following the completion of mounting and a

waiting period of approximately 30 minutes (to

allow oil to collect in the compressor in order to

ensure lubrication and cooling) electrical connection can be made.

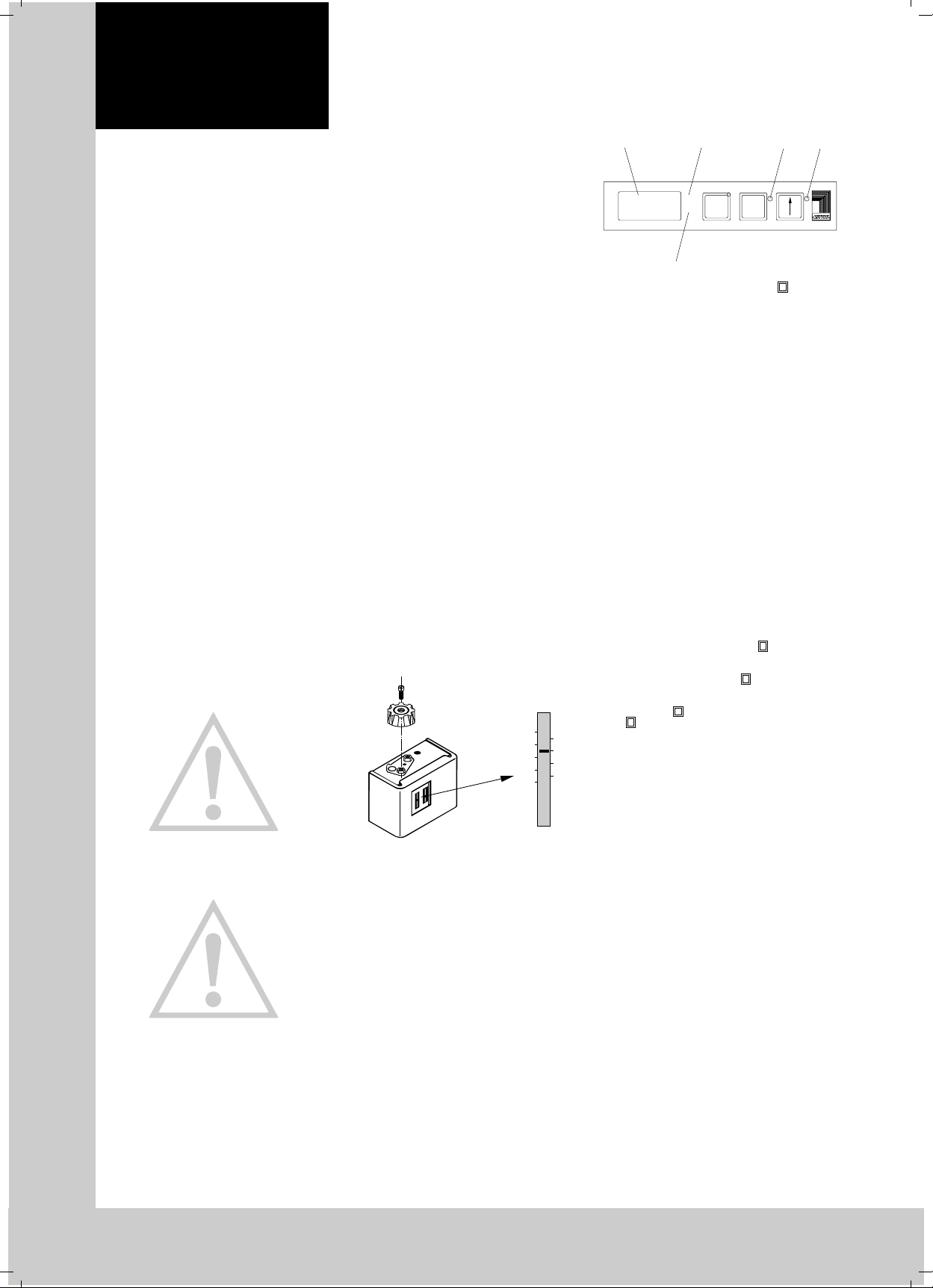

5.1 Control by Thermostat

Version .....100 / .140

The cooling unit operates automatically, i.e. following the electrical connection, the evaporator fan

will run continuously to circulate the air inside the

enclosure. This provides a uniform temperature

distribution in the enclosure. The built-in temperature controller (setting the desired internal temperature) effects automatically controlled switch-off

of the cooling unit by the value of the fixed

switching difference setting of 5 K. This is set at

the factory to + 35 ° C.

5.1.1 Temperature Setting at the Controller

Fig.5.1 Thermostat

20

25

30

35

40

45

50

55

60

°C °C

1. Remove the setting knob after slackening the

screw.

2. Remove locking plate.

3. Replace the setting knob and set the desired

temperature. Setting range + 20 ° C to + 55 ° C.

4. Replace the locking plate and fix the setting

knob by tightening the screw.

5.2 Control by Microcontroller

Version .....500 / .540

Fig. 5.2 Microcontroller

H2H1

°C

°F

H3

After electrical connection the internal fan turns on

and circulates the enclosure air. This helps assure

even temperature distribution within the enclosure.

The condensor fan and compressor are controlled

by the microcontroller. The minimum run time is

90 seconds. The switching difference is 5 – 10 K

and is set at the factory. In order to maximize

energy efficiency the thermostat should be set to

the highest enclosure temperature as allowed by

the electronics.

5.2.1 Operation of the Microcontroller

The display terminal H1 consists of a 3 position

7-segment display which indicates the enclosure

internal temperature in ° C or ° F (changeable, see

section 5.2.2) as well as any fault codes. The

actual enclosure internal temperature is constantly displayed. If a fault occurs then the fault

number is indicated in the left position. When programming the microcontroller the program level

and parameter value is indicated on the display.

When the “TEST” button is pushed the compressor and the fans will run for 5 minutes regardless

of the internal temperature or door limit switch.

This allows for a system test after an extended

shutdown period (e.g. after the winter).

5.2.2 Programming

(see diagram 5.1 page 39)

In the EEPROM of the microcontroller various

parameters are stored which can be changed

through using the “ENTER” and “ ” buttons,

9 different parameters are changeable as outlined

in table 5.1. To access the programming mode

push both the “ENTER” and “ ” buttons simultaneously for 10 seconds. The left digit will then

indicate the program level and the LED for the

“ENTER” and “ ” buttons will blink. By pushing

°C

the “ ” button the program level can be advan-

➡

ced to the next level. In order to access levels

10

5 through 9 a security code must be entered. If no

8

buttons are pushed for 60 seconds the display will

6

return to the standard mode which displays the

4

enclosure temperature. Programming of the para-

3

meters is made easy with diagram 5.1 on page

39. A description of the parameters to be pro-

grammed can be found in table 5.1. All parameters are stored in the EEPROM and are retained

when power is shut off to the air conditioner.

➡

ENTER

TEST

H1 = Display Terminal

H2 = LED °C

H3 = LED °F

H4 = LED ENTER

H5 = LED

➡

H5

H4

➡

➡

6

Loading...

Loading...