Rittal SK 3359.xxx, SK 3382.xxx, SK 3273.xxx, SK 3385.xxx, SK 3386.xxx Assembly And Operating Instructions Manual

...

Schaltschrank-Kühlgerät

Cooling unit

Climatiseur

Koelaggregaat

Kylaggregat

Condizionatore per armadi

Refrigerador para armarios

SK 3359.xxx

SK 3273.xxx

SK 3382.xxx

SK 3383.xxx

SK 3384.xxx

SK 3385.xxx

SK 3386.xxx

SK 3387.xxx

Montage-, Installations- und Bedienungsanleitung

Assembly and operating instructions

Manuel d’installation et de maintenance

Montage- en bedieningshandleiding

Montage- och hanteringsanvisning

Istruzioni di montaggio e funzionamento

Instrucciones de montaje

Rittal cooling unit assembly and operating instructions 3

EN

Contents

1 Notes on documentation. . . . . . . . . . 4

1.1 Associated documents. . . . . . . . . . . . . . . . 4

1.2 CE labelling . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Retention of documents. . . . . . . . . . . . . . . 4

1.4 Symbols used . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety notes . . . . . . . . . . . . . . . . . . . . 4

3 Device description . . . . . . . . . . . . . . . 5

3.1 Functional description . . . . . . . . . . . . . . . . 5

3.1.1 How it works . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1.2 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1.3 Bus mode (e-Comfort controller only). . . . . . 5

3.1.4 Safety equipment . . . . . . . . . . . . . . . . . . . . . 6

3.1.5 Condensation . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.6 Filter mats . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.7 Door limit switch . . . . . . . . . . . . . . . . . . . . . . 6

3.1.8 Additional interface X3 . . . . . . . . . . . . . . . . . 7

3.2 Proper usage. . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Scope of supply . . . . . . . . . . . . . . . . . . . . . 7

4 Assembly and connection . . . . . . . . 7

4.1 Choosing the installation site . . . . . . . . . . 7

4.2 Assembly instructions . . . . . . . . . . . . . . . . 7

4.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2.2 Layout of the electronic components

in the enclosure . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Fitting the cooling unit . . . . . . . . . . . . . . . . 8

4.3.1 Cutting out on the enclosure. . . . . . . . . . . . . 9

4.3.2 Top mounting of the cooling unit . . . . . . . . . 9

4.4 Connecting the condensate discharge. . 10

4.5 Notes on electrical installation . . . . . . . . 10

4.5.1 Connection data . . . . . . . . . . . . . . . . . . . . . 10

4.5.2

Overvoltage protection

and supply line load

. . . . . . . . . . . . . . . . . . 10

4.5.3 Three-phase devices . . . . . . . . . . . . . . . . . 11

4.5.4 Door limit switch . . . . . . . . . . . . . . . . . . . . . 11

4.5.5 Notes on the flicker standard . . . . . . . . . . . 11

4.5.6 Potential equalisation . . . . . . . . . . . . . . . . . 11

4.6 Carrying out the electrical installation . . 11

4.6.1 Bus connection

(only in conjunction with several units

with an e-Comfort controller) . . . . . . . . . . . 11

4.6.2 Connection X3 for serial interface. . . . . . . . 11

4.6.3 Installing the power supply. . . . . . . . . . . . . 13

4.7 Finalising assembly . . . . . . . . . . . . . . . . . 15

4.7.1 Installing the filter media . . . . . . . . . . . . . . . 15

4.7.2 Fitting the cooling unit. . . . . . . . . . . . . . . . . 15

4.7.3 Setting the filter mat monitor. . . . . . . . . . . . 15

5 Commissioning . . . . . . . . . . . . . . . . 15

6 Operation . . . . . . . . . . . . . . . . . . . . . 16

6.1 Control using the e-Comfort controller . 16

6.1.1 Properties. . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.2 Eco-mode. . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.3 Launching test mode . . . . . . . . . . . . . . . . . 17

6.1.4 General programming information . . . . . . . 17

6.1.5 Variable parameters. . . . . . . . . . . . . . . . . . 18

6.1.6 Programming overview . . . . . . . . . . . . . . . 19

6.1.7 Defining system messages

for evaluation . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.8 Setting the master-slave identifier . . . . . . . 21

6.1.9 Evaluating system messages. . . . . . . . . . . 21

6.1.10 Resetting the e-Comfort controller . . . . . . . 23

7 Inspection and maintenance. . . . . . 23

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.1 Compressed air cleaning. . . . . . . . . . . . . . 23

8 Storage and disposal. . . . . . . . . . . . 25

9 Technical specifications . . . . . . . . . 26

10 List of spare parts . . . . . . . . . . . . . . 29

11 Appendix:

Cut-out and hole sizes. . . . . . . . . . . 31

11.1 Dimensions for assembly . . . . . . . . . . . . 31

4 Rittal cooling unit assembly and operating instructions

1 Notes on documentation

EN

1 Notes on documentation

These assembly instructions are aimed at tradespersons who are familiar with assembly and installation

of the cooling unit, and at trained specialists who are

familiar with operation of the cooling unit.

1.1 Associated documents

There are two sets of instructions for the unit types

described here:

– Assembly and installation instructions enclosed

with the unit in the form of a paper document

– Assembly, installation and operating instructions

enclosed with the unit in the form of a PDF file

(Adobe Acrobat) on CD-ROM.

We cannot accept any liability for damage associated with failure to observe these instructions.

Where applicable, the instructions for any accessories used also apply.

1.2 CE labelling

The declaration of conformity is supplied with the unit

as a separate document.

1.3 Retention of documents

These instructions and all associated documents

constitute an integral part of the product. They must

be given to the plant operator. The plant operator is

responsible for storage of the documents so they are

readily available when needed.

1.4 Symbols used

Please observe the following safety instructions and

other notes in this guide:

Symbol for an instructed action:

• The bullet point indicates that you should perform

an action.

Safety and other instructions:

2 Safety notes

Please observe the following general safety instructions when assembling and operating the unit:

– Assembly, installation and servicing may only be

performed by properly trained specialists.

– Do not obstruct the air inlet and air outlet of the

cooling unit inside and outside the enclosure

(see also section 4.2.2).

– The heat loss of the components installed in the

enclosure must not exceed the specific useful

cooling output of the cooling unit.

– The cooling unit must always be transported in a

vertical position.

– Use only original spare parts and accessories.

– Do not make any changes to the cooling unit other

than those described in these instructions or asso-

ciated instructions.

– Risk of burn injuries! For cooling units with auto-

matic condensate evaporation, the surface of the

thermal element will get very hot during operation,

and will remain so for some time afterwards.

– The mains connector of the cooling unit must only

be connected and disconnected with the system

de-energised. Connect the pre-fuse specified on

the rating plate.

Danger!

Immediate danger to life and limb!

Caution!

Potential threat to the product

and its environment.

Note:

Useful information

and special features.

3 Device description

Rittal cooling unit assembly and operating instructions 5

EN

3 Device description

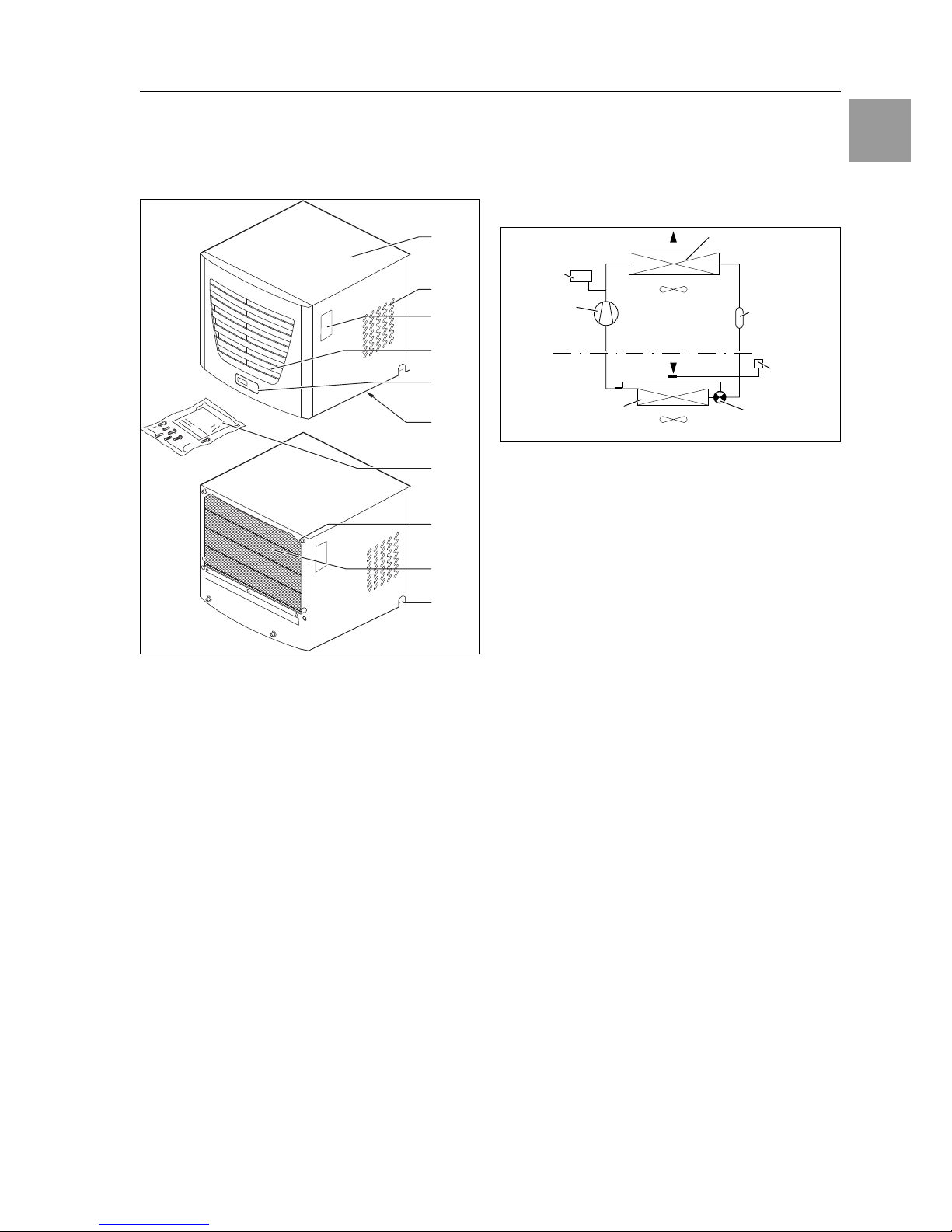

Depending on the model chosen, your cooling unit

may vary in appearance from the illustrations contained in these instructions. However, the functions

are identical in principle.

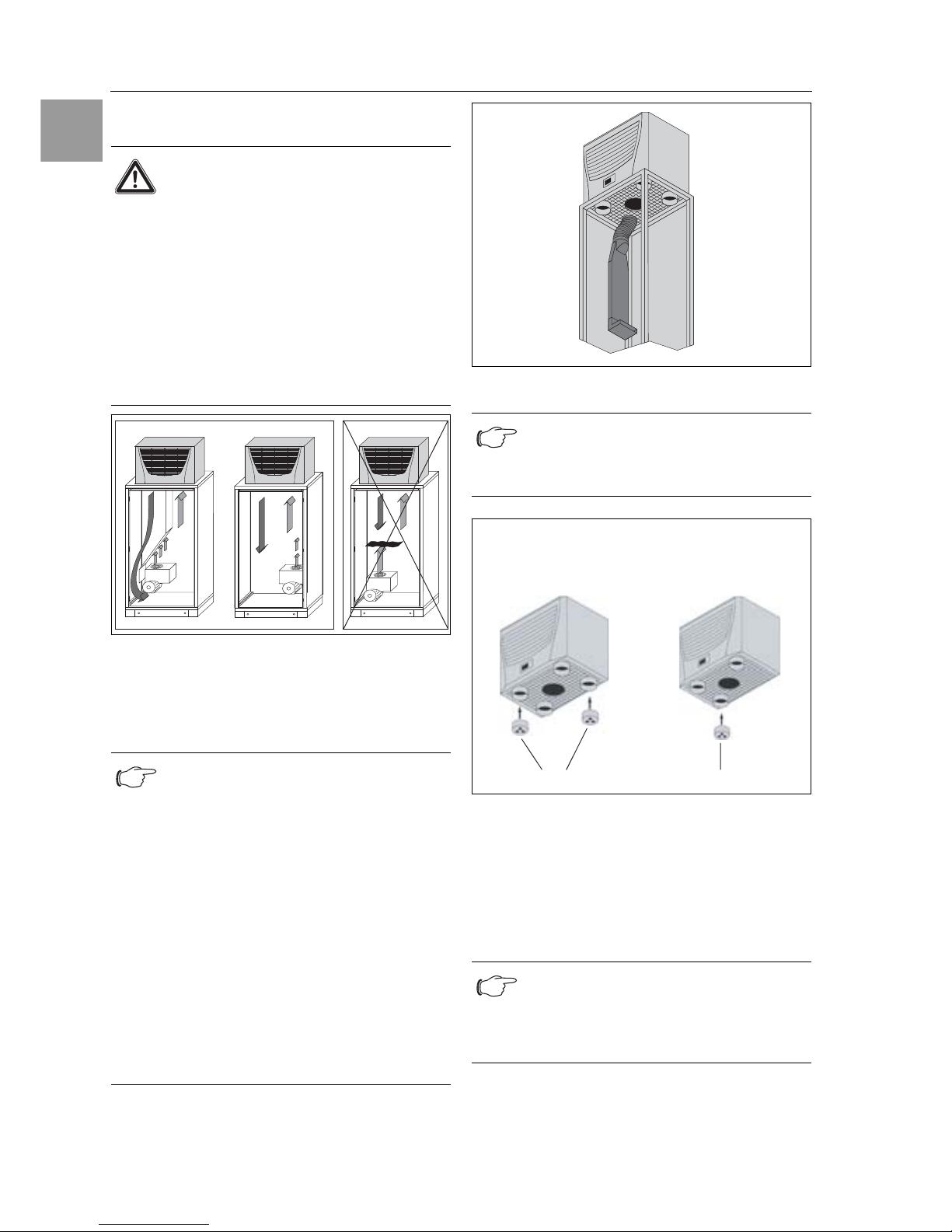

Fig. 1: Unit description

Legend

1Enclosure

2 Air outlet holes

3 Rating plate

4 Louvred grille for air inlet

5 Display

6 X2 master-slave connection (underside of the unit)

7 X1 terminal strip (underside of the unit)

8 X3 optional serial interface (underside of the unit)

9 Dispatch bag

10 Twin-threaded bolt

11 Condenser

12 Condensate discharge

3.1 Functional description

Enclosure cooling units are designed to dissipate

heat from enclosures by cooling the air inside the

enclosure and so protect the temperature-sensitive

components. It is mounted on the roof of an enclosure.

3.1.1 How it works

The cooling unit (compression refrigeration system)

is comprised of four main components (cf. Fig. 2):

the evaporator (1), the coolant compressor (2), the

condenser (3), and the control or expansion valve

(4), which are connected by suitable pipework.

This circuit is filled with a readily boiling substance,

the refrigerant. Coolant R134a (CH

2

FCF3) is chlorinefree. Its ozone destruction potential is 0, making it

very eco-friendly. A filter dryer (5) which is integrated

into the hermetically sealed cooling circuit provides

effective protection against moisture, acid, dirt particles, and foreign bodies within the cooling circuit.

Fig. 2: Cooling circuit

In the evaporator coil (1), the liquid coolant is converted to a gaseous state. The energy needed for

this purpose is taken from the enclosure air in the

form of heat, which has the effect of cooling the

enclosure air. In the compressor (2), the coolant is

heavily compressed, so that it achieves a higher

temperature inside the condenser (3) than the ambient air. This means that excess heat may be emitted

to the ambient air via the surface of the condenser,

as a result of which the temperature of the coolant

drops and it is converted back into liquid. It is

re-injected into the evaporator coil via a thermostatic

expansion valve (4), which causes it to cool down

further, and is then once again able to absorb the

energy from the enclosure air in the evaporator coil.

The whole cycle begins again.

3.1.2 Controller

Rittal enclosure cooling units are fitted with a controller for setting the functions of the cooling unit

(display plus extended functions, see chapter

“6 Operation”, page 16).

3.1.3 Bus mode (e-Comfort controller only)

The serial unit interface X2 allows you to create a bus

connection with up to ten cooling units using the

master-slave cable (shielded, four-wire cable, Model

No. SK 3124.100). This allows you to implement the

following functions:

– Parallel unit control (the cooling units in the network

can be switched on and off simultaneously)

– Parallel door status message (“door open”)

– Parallel collective fault message

3

6, 7, 8

12

4

11

10

9

5

2

1

PSA

H

pressure-

operated

switch

Condenser fan

Expansion valve (4)

Temperature

control

Filter dryer (5)

Internal circuit

Compressor

(2)

External circuit

Evaporator fan

Evaporator coil (1)

Condenser (3)

6 Rittal cooling unit assembly and operating instructions

3 Device description

EN

Data is exchanged via the master-slave connection.

During commissioning, assign an address to each

unit that also includes the identifier “master” or

“slave”.

3.1.4 Safety equipment

– In the cooling cycle, the cooling unit has a tested

pressure-operated switch to EN 12 263 which is

set to maximum PS (admissible pressure); this

operates via an automatic reset device whenever

the pressure drops again.

– Temperature monitoring prevents the evaporator

coil from icing over. If there is a risk of icing, the

compressor switches itself off and automatically

switches itself back on again at higher temperatures.

– The refrigerant compressor and the fans are

equipped with thermal winding shields to protect

against excess current and excess temperatures.

– In order to allow a reduction of pressure inside the

compressor and hence a safe restart, once it has

been switched off (e.g. upon reaching the set temperature via the door limit switch function or via

de-energising), the device will switch back on with

a delay of 180 seconds.

– The device has floating contacts on the connection

pins (terminals 3 – 5), via which system messages

from the device may be polled, e.g. using a PLC

(2x normally open contacts e-Comfort controller).

3.1.5 Condensation

At high levels of humidity and low temperatures inside the enclosure, condensation may form on the

evaporator coil.

The cooling units have an automatic electrical condensate evaporator. The thermal component used

for this purpose is based on self-regulating PTC

technology. Condensate arising on the evaporator

coil is collected in a tank in the internal circuit of the

cooling unit. When the water level rises, the water

enters the PTC thermal component and is evaporated (through-flow heater principle). The water

vapour streams out of the cooling unit with the airflow

from the external fan.

The PTC thermal component is permanently connected and has no switchpoint. It is protected

against short-circuits with miniature fuses (F1.1,

F1.2). If the fuse has tripped, any condensation is

drained off via the safety overflow.

In the case of a malfunction or a failure in the thermal

component, the condensation water is routed out of

the unit via a drain pipe at the side or rear for safety

reasons. For this purpose, a hose must be connected to the condensate nozzle (see “4.4 Connecting

the condensate discharge”, page 10). Condensate

hoses are available as accessories (refer also to the

accessories section in the Rittal Catalogue).

3.1.6 Filter mats

The cooling unit condenser is finished all over with a

dirt-repelling, easy-to-clean RiNano coating. In many

cases, therefore, the use of filter media is unnecessary, particularly in the case of dry dusts.

For coarse dust and lint in the enclosure air, we

recommend installing an additional PU foam filter

mat (available as an accessory) in the cooling unit.

Depending on the incidence of dust, you will need

to replace the filter from time to time.

For air containing oil condensation, we recommend

the use of metal filters (also available as an accessory). These may be cleaned with suitable detergents

and reused. When used in textile plants with heavy

lint contamination, lint screens should be used (available as an optional extra).

Function of the filter mat monitor:

Dirt on the filter mat is automatically determined by

measuring the temperature difference in the external

circuit of the cooling unit. As the level of filter mat

soiling rises, the temperature difference will increase.

The nominal value of the temperature difference in

the external circuit adapts automatically to the relevant operating points in the performance diagrams.

Hence there is no need to readjust the nominal value

for different operating points of the cooling unit.

3.1.7 Door limit switch

The cooling unit may be operated with a floating door

limit switch connected. The door limit switch is not included with the supply (available as an accessory,

Model No. PS 4127.0

10)

.

The

door limit switch function causes the fans and

the compressor in the cooling unit to be switched off

after approximately 15 seconds when the enclosure

door is opened (contacts 1 and 2 closed). This prevents the formation of condensation inside the enclosure while the enclosure door is open. In order to

prevent damage to the unit, it is equipped with an

ON delay: The evaporator fan cuts back in with a

delay of approximately 15 seconds after the door

has been closed, while the condenser fan and compressor switch on after approximately 3 minutes.

Note:

No external voltage must be applied to

the door contacts (terminals 1 and 2).

4 Assembly and connection

Rittal cooling unit assembly and operating instructions 7

EN

3.1.8 Additional interface X3

An additional interface card may be connected to

the 9-pole SUB-D connector X3 in order to incorporate the cooling unit into higher-level monitoring

systems (available as an accessory, interface card

Model No. SK 3124.200).

3.2 Proper usage

Rittal enclosure cooling units were developed and

designed in accordance with the state-of-the-art and

the recognised rules governing technical safety.

Nevertheless, if used improperly, they may pose a

threat to life and limb or cause damage to property.

The unit is only intended for cooling enclosures. Any

other use is deemed improper. The manufacturer will

not be liable for any damages caused as a result of

improper use, or for incorrect assembly, installation

or use. All risk is borne solely by the user.

Proper usage also includes the observation of all

valid documents and compliance with the inspection

and servicing conditions.

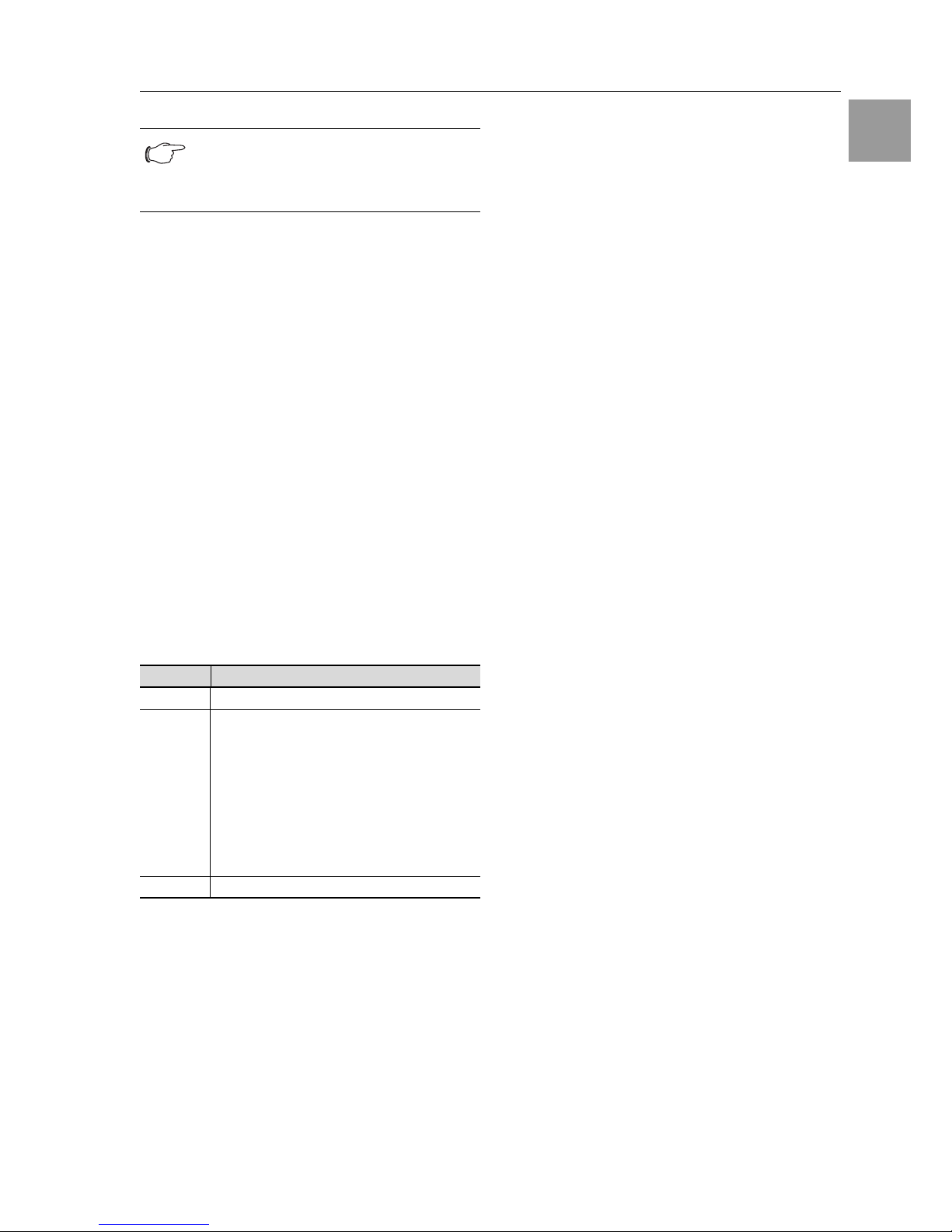

3.3 Scope of supply

The unit is supplied in a packaging unit in a fully

assembled state.

Please check the delivery for completeness:

Tab. 1: Scope of supply

4 Assembly and connection

4.1 Choosing the installation site

When choosing the installation site for the enclosure,

please observe the following:

– The site for the enclosure, and hence the arrange-

ment of the cooling unit, must be carefully selected

so as to ensure good ventilation. Depending on the

siting of the unit, if several units are installed direct-

ly adjacent to one another, the distance from the

wall must be at least 200 mm.

– The cooling unit must be installed and operated in

a vertical position (maximum deviation: 2°).

– The site must be free from excessive dirt and

moisture.

– The ambient temperature must not exceed 55°C.

– It must be possible to fit a condensate discharge

(see “4.4 Connecting the condensate discharge”,

page 10).

– The mains connection data as stated on the rating

plate of the unit must be guaranteed.

4.2 Assembly instructions

4.2.1 General

– Check the packaging carefully for signs of damage.

Traces of oil on damaged packaging are an indi-

cation of refrigerant loss and leakages. Packaging

damage may be the cause of a subsequent func-

tional failure.

– The enclosure must be sealed on all sides (IP 54).

Increased condensation will occur if the enclosure

is not airtight.

– In order to avoid excessive condensation inside

the enclosure, we recommend installing a door

limit switch (e.g. PS 4127.0

10) which deactivates

the cooling unit when the enclosure door is opened

(see “3.1.7 Door limit switch”, page 6).

Note:

The electrical signals at the interface are

of an extra-low voltage (not extra-low safety

voltages to EN 60 335).

Qty. Description

1 Enclosure cooling unit

1

1

1

1

1

1

1

1

Dispatch bag:

– Sealing plate (SK 3273.xxx, SK 3383.xxx

to SK 3387.xxx)

– Sealing frame

– Plug-in terminal strip

– Assembly and installation instructions

– Assembly, installation and operating

instructions on CD-ROM

– Declaration of conformity

– Safety notes

1 Drilling template

8 Rittal cooling unit assembly and operating instructions

4 Assembly and connection

EN

4.2.2 Layout of the electronic components

in the enclosure

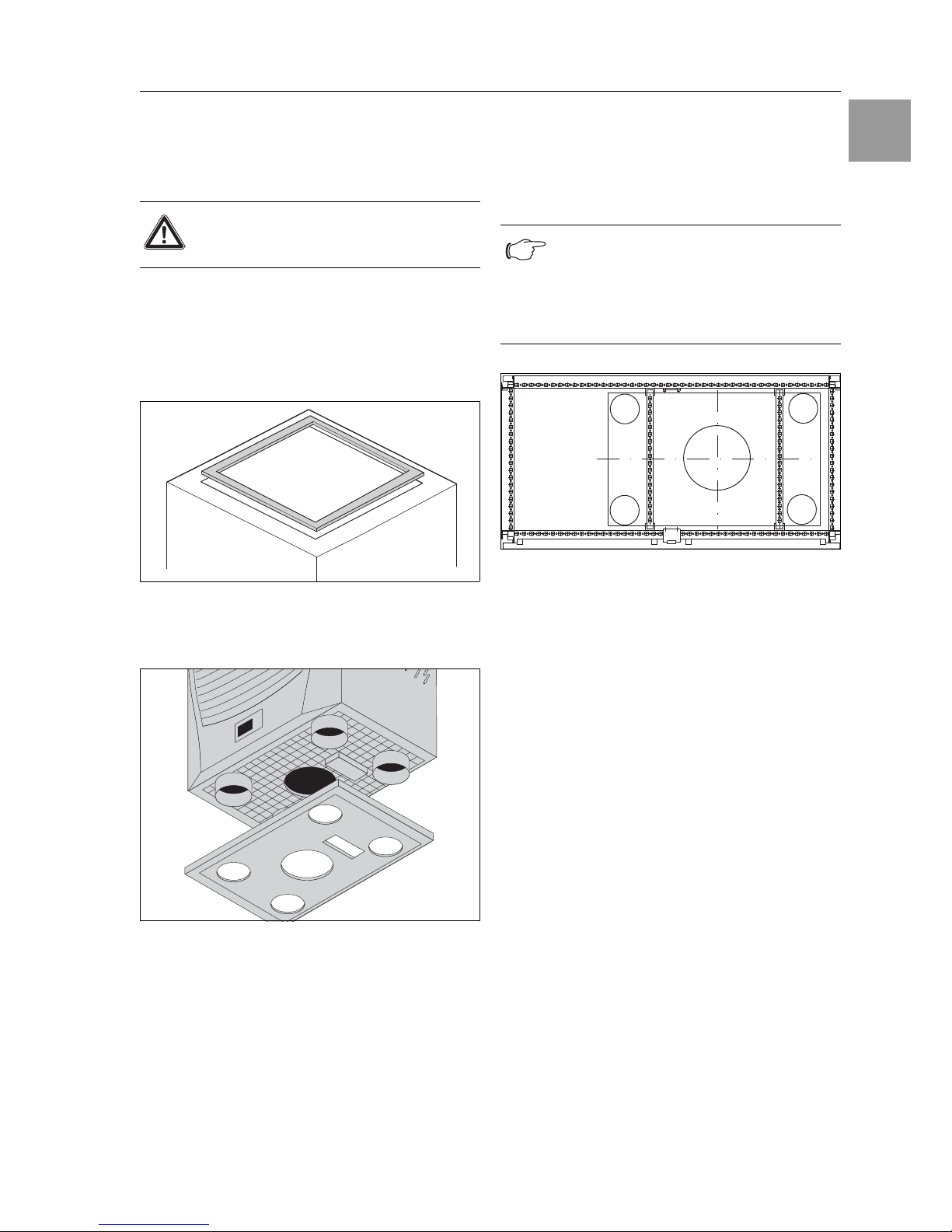

Fig. 3: Never direct the cold airflow at active components

Exercise particular caution with the airflow from the

blowers of built-in electronic components (cf. Fig. 3).

Components for targeted air routing are available as

accessories – please refer to the Rittal Catalogue.

Fig. 4: Targeted air routing inside the enclosure

Fig. 5: Cover bungs

4.3 Fitting the cooling unit

The enclosure cooling unit is mounted on top of the

enclosure roof:

To this end, the roof plate must be cut out as per the

drilling template included with the supply.

Caution!

Risk of condensation!

When arranging the components inside

the enclosure, please ensure that the

cold airflow from the cooling unit is not

directed at active components. Please

also ensure that the cold airflow is not

directed at the warm exhaust airflow

from active components such as converters. This may lead to an air shortcircuit and therefore prevent adequate

climate control, or may even cause the

cooling unit’s internal safety devices to

cease cooling operation.

Note:

When using an air duct system, care must

be taken to ensure that it is laid straight and

without kinks wherever possible. This minimises the resistance to the cold airflow.

It is important to ensure even air circulation

inside the enclosure. Under no circumstances should air inlet and outlet openings

be obstructed, otherwise the cooling performance of the unit will be reduced. Ensure

a suitable distance from electronic components and other installed enclosures so that

the required air circulation is not obstructed

and prevented.

One cold air outlet from the cooling unit

must be kept open at all times when

operating with the air duct, to prevent the

accumulation of cold air inside the unit.

Note:

When using the cover bungs, only a maximum of 1 or 2 cold air outlet openings may

be sealed, depending on the unit type.

Note:

Pre-configured, reinforced roof plates

with cut-outs to match your enclosure are

available as accessories; refer to the

Rittal Catalogue.

SK 3273.xxx

SK 3383.xxx

SK 3384.xxx

SK 3385.xxx

SK 3359.xxx

SK 3382.xxx

SK 3386.xxx

SK 3387.xxx

max. 2x max. 1x

4 Assembly and connection

Rittal cooling unit assembly and operating instructions 9

EN

4.3.1 Cutting out on the enclosure

• Stick the supplied drilling template onto the roof of

the enclosure using adhesive tape.

There are dimensioning lines on the drilling template

to suit the installation type for your cooling unit.

• Make the cut-outs including the line width as per

the drilling template.

Deburr the cut-outs.

4.3.2 Top mounting of the cooling unit

• Stick the supplied sealing frame onto the cut-out

roof plate.

Fig. 6: Sealing frame on roof plate

• Stick the supplied sealing plate underneath

the plastic base of the cooling unit (SK 3273.xxx,

SK 3383.xxx to SK 3387.xxx).

Fig. 7: Sealing plate underneath the plastic base

of the cooling unit

• Mount the cooling unit on the enclosure roof.

• Screw the supplied twin-threaded bolts into the

core holes in the plastic base on the underside

of the cooling unit with a maximum of 5 Nm.

• Secure the unit using the supplied washers and

nuts.

Fig. 8: Roof plate reinforcement for the TS 8 enclosure

Accessories for roof plate reinforcement with TS:

Punched rail

U nut

Fastening bracket

Threaded block

(refer also to Accessories in the Rittal Catalogue)

Risk of injury!

Carefully deburr all cut-outs to prevent

injuries caused by sharp edges.

Note:

In order to achieve a permanent seal between the cooling unit and the enclosure,

the mounting surface should be reinforced

or supported if necessary. This is particularly applicable with large roof areas.

10 Rittal cooling unit assembly and operating instructions

4 Assembly and connection

EN

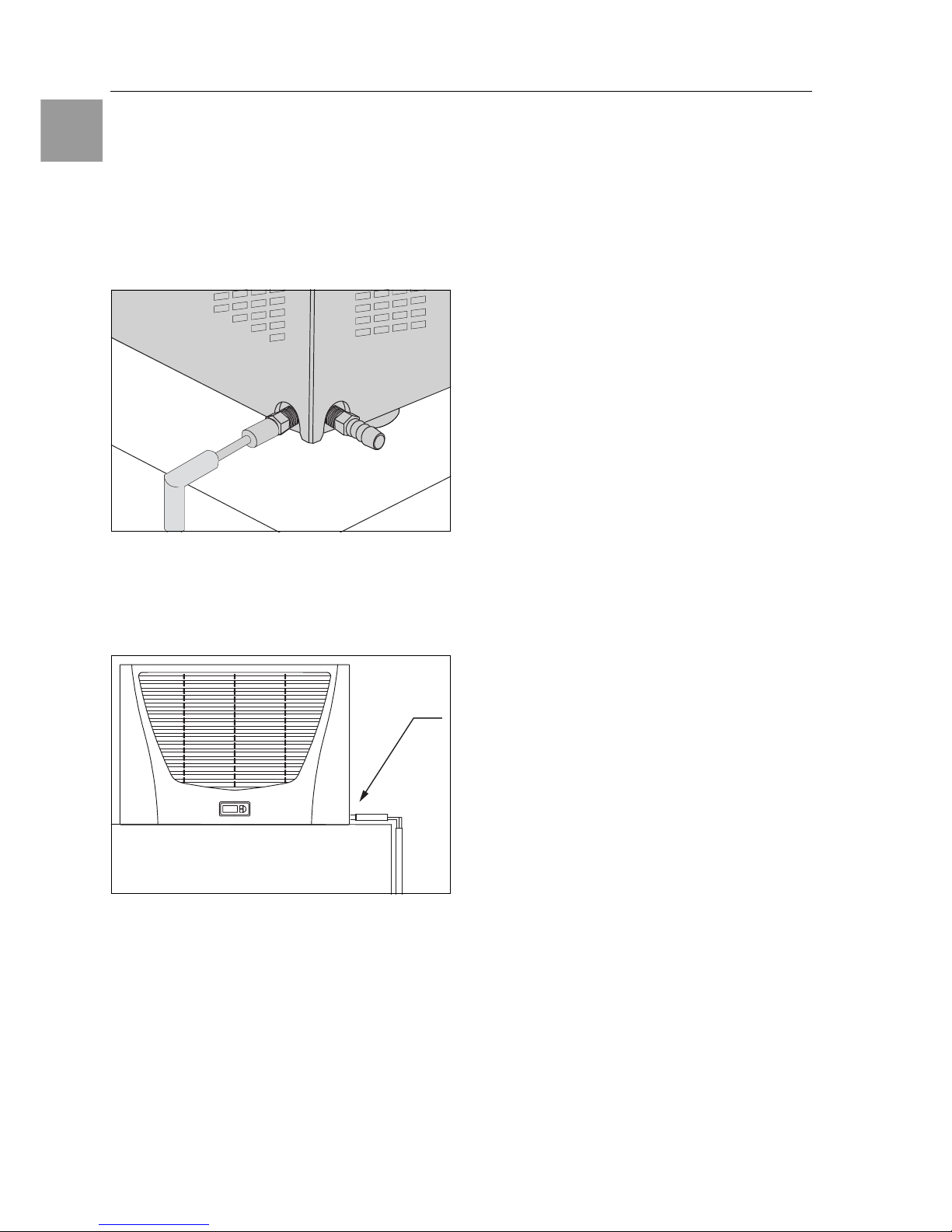

4.4 Connecting the condensate discharge

A condensate discharge hose (Ø1/2˝) may be fitted

onto the cooling unit.

The condensate discharge

– must be laid with a suitable and constant gradient

(no siphoning)

– must be laid without kinks

– must not have a reduced cross-section if extended.

The condensate hose is available as an accessory

(refer also to Accessories in the Rittal Catalogue).

Fig. 9: Connecting the condensate discharge

• Connect a suitable hose to one of the two conden-

sate nozzles and secure using a hose clip.

The unused condensate nozzle should be sealed

accordingly.

• Lay the condensate hose, e.g. into a drain.

Fig. 10: Lay the condensate discharge

4.5 Notes on electrical installation

When performing the electrical installation, it is important to observe all valid national and regional

regulations as well as the provisions of the responsible power supply company. Electrical installation

must only be carried out by a qualified electrician

who is responsible for compliance with the existing

standards and regulations.

4.5.1 Connection data

– The connected voltage and frequency must corre-

spond to the values stated on the rating plate.

– The cooling unit must be connected to the mains

via an all-pin isolating device, which ensures at

least 3 mm contact opening when switched off.

– No additional temperature control may be connec-

ted upstream of the unit at the supply end.

– Install the pre-fuse specified on the rating plate

to protect the cable and equipment from shortcircuits.

– The mains connection must ensure low-noise

potential equalisation.

4.5.2 Overvoltage protection

and supply line load

– The unit does not have its own overvoltage protec-

tion. Measures must be taken by the operator at

the supply end to ensure effective lightning and

overvoltage protection. The mains voltage must

not exceed a tolerance of ±10%.

– In accordance with IEC 61 000-3-11, the unit is

intended solely for use at sites with a continuous

current-carrying capacity (incoming mains power

supply) of more than 100 A per phase and with a

supply voltage of 400/230 V. If necessary, the

power supply company must be consulted to ensure that the continuous current-carrying capacity

at the point of connection to the public grid is

sufficient for connection of such a unit.

– The fans and compressors in single- and three-

phase units are intrinsically safe (thermal winding

protection). The same also applies to all transformer versions and to special-voltage units which are

likewise equipped with a transformer.

– Install the slow pre-fuse specified on the rating

plate (miniature circuit-breaker with appropriate

characteristic – e. g. K characteristic – or fuse gG

standard type, power circuit-breaker or transformer circuit-breaker) to protect the cable and

equipment from short-circuits. Select a suitable

motor circuit-breaker in accordance with the information specified on the rating plate: Set it to the

minimum specified value. This will achieve the best

short-circuit protection for cables and equipment.

Example: Specified setting range 6.3 – 10 A; set

to 6.3 A.

1

/2˝

Loading...

Loading...