Page 1

Montage-, Installations- und Bedienungsanleitung

Assembly and operating instructions

Manuel d’installation et de maintenance

R

RITTAL

TOP

THERM

Rittal

Thermoelectric Cooler

SK 3201.200

SK 3201.300

Montage- en bedieningshandleiding

Montage- och hanteringsanvisning

Istruzioni di montaggio e funzionamento

Instrucciones de montaje

SchaltschrankKühlgerät

Cooling unit

Climatiseur

Koelaggregaat

Kylaggregat

Condizionatore

per armadi

Refrigerador

para armarios

Page 2

2 Rittal Thermoelectric Cooler assembly and operating instructions

GB

Before installation of the cooling unit,

please read this manual completely and carefully.

The manual is a permanent part of the supplied system

and must be retained until the device is decommissioned.

We thank you for deciding to purchase a Rittal product!

The Rittal Thermoelectric Cooler is a high-performance thermoelectric light-weight cooling unit with

the highest efficiency (COP > 1) of its class!

The cooling unit is particularly suitable for the climate

control of operating housings and small enclosures!

Before using the cooling unit, read this manual carefully in order to make full use of the excellent performance characteristics of the product.

Rittal GmbH & Co. KG products are continually

adapted to the requirements and needs of our customers. This means the information concerning the

product characteristics and functions contained in

this manual can be changed without notice in the

case of product improvements.

Page 3

Rittal Thermoelectric Cooler assembly and operating instructions 3

GB

Contents

1 Unpacking and checking. . . . . . . . . . 4

2 Notes on documentation. . . . . . . . . . 4

2.1 Retention of the manual . . . . . . . . . . . . . . . . 4

3 Safety notes . . . . . . . . . . . . . . . . . . . . 5

3.1 Proper usage . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Standards, guidelines. . . . . . . . . . . . . . . . . . 5

4 How it works. . . . . . . . . . . . . . . . . . . . 6

5 Control . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Device description . . . . . . . . . . . . . . . 8

7 Device mounting . . . . . . . . . . . . . . . . 9

7.1 External mounting. . . . . . . . . . . . . . . . . . . . 10

7.2 Internal mounting . . . . . . . . . . . . . . . . . . . . 10

8 Filter mounting. . . . . . . . . . . . . . . . . 11

9 Mounting of the

condensate discharge . . . . . . . . . . . 11

10 Electrical connection. . . . . . . . . . . . 12

10.1 Connection data . . . . . . . . . . . . . . . . . . . . . 12

11 Interfaces . . . . . . . . . . . . . . . . . . . . . 13

11.1 Interface X1 –

power supply and alarm output. . . . . . . . . 13

11.2 Interface X2 –

device programming. . . . . . . . . . . . . . . . . . 13

11.3 Interface X3 –

integration in a higher-level

monitoring system . . . . . . . . . . . . . . . . . . . 13

12 Earth connection . . . . . . . . . . . . . . . 13

13 Commissioning . . . . . . . . . . . . . . . . 14

14 Status and function displays . . . . . 14

15 Technical specifications . . . . . . . . . 15

16 Maintenance and cleaning . . . . . . . 16

16.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 16

16.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

17 Fault correction . . . . . . . . . . . . . . . . 17

18 Disposal . . . . . . . . . . . . . . . . . . . . . . 18

19 Guarantee . . . . . . . . . . . . . . . . . . . . . 18

Page 4

4 Rittal Thermoelectric Cooler assembly and operating instructions

1 Unpacking and checking

GB

1 Unpacking and checking

The Rittal Thermoelectric Cooler is delivered in transport packaging.

The supplied system consists of:

1 x cooling unit

1 x assembly and operating instructions

1 x accessories bag

Shipping bag content:

1 x assembly and operating instructions

1 x self-adhesive sealing tape

1 x filter mat

1 x drilling template

1 x connector plug (power supply and alarm output)

Assembly parts

Check that the delivered system is complete and undamaged. Any obvious transport damage must be

reported without delay to the responsible transport

company.

The latest version of the “General conditions for

deliveries and services” of the ZVEI (Central Association of the German Electrotechnical Industry)

applies.

Prior to disposal, check the packaging material for

any loose function parts!

2 Notes on documentation

Assembly and operating instructions are available in

printed form (provided with the supplied system) and

as a PDF file for the

Rittal Thermoelectric Cooler.

A PDF file is available as free download from

www.rittal.com. ACROBAT READER® is required

to view the file.

The accompanying documentation must be observed for the assembly, installation and operation of

the cooling unit. Rittal cannot accept any liability for

damage associated with the failure to observe these

instructions.

The information and safety notes in this manual

follow the following structure:

Safety and other instructions:

2.1 Retention of the manual

The operating company is responsible for retaining

the manual.

No part of the manual may be reproduced or

processed, copied or distributed using electronic

systems in any form (printed, microfilm or any

other form) without the written approval of Rittal

GmbH & Co. KG. No liability can be assumed for

any damage resulting from the non-observance

of the information contained in this manual.

Danger!

Warning of a potential danger source.

Danger to life and health in case of

non-observance!

Danger!

Warning of a dangerous electrical

voltage.

Danger to life and health in case of

non-observance!

Danger!

Warning of slippery surface.

Danger to life and health in case of

non-observance!

Note:

Useful information and special features.

Page 5

3 Safety notes

Rittal Thermoelectric Cooler assembly and operating instructions 5

GB

3 Safety notes

The following general safety notes must be observed

for the assembly, installation and operation of the

cooling unit:

– The assembly, installation and servicing of the

cooling unit may only be performed by properly

trained specialists.

– The mains connector of the cooling unit must only

be connected and disconnected with the system

de-energised. The device must be protected with

a pre-fuse.

– No changes may be made to the cooling unit.

– Only the customer service or authorised personnel

may open the device. The opening of the device by

the user or unauthorised persons is not permitted

and will void any warranty claim.

– The cooling unit is intended only for the climate

control of enclosures and housings. Any other use

shall be deemed improper. The manufacturer is

not liable for any resulting damage! Proper usage

also includes the observance of all valid docu-

ments and compliance with the inspection and

servicing conditions.

– The air inlet and outlet openings on the cooling unit

must not be covered.

– Use only original spare parts and accessories

expressly approved for the Rittal Thermoelectric

Cooler. Otherwise malfunctions or damage can

occur. Warranty claims cannot be accepted for

such damage.

3.1 Proper usage

The Rittal Thermoelectric Cooler conforms to the

current state-of-the-art.

The cooling unit is intended only for cooling enclosures and operating housings. Any other use shall

be deemed improper.

Proper usage is possible only when all associated

documents, and the device-specific assembly and

operating instructions are observed.

The manufacturer is not liable for any damage resulting from improper use.

3.2 Standards, guidelines

The Rittal Thermoelectric Cooler meets the requirements of the following guidelines and standards:

– DIN 3168 Section 4.5 (enclosure cooling units)

– Machine directive 98/37/EC

– Low-voltage directive 2006/95/EC

– Electromagnetic compatibility 2004/108/EC

– EN 378-1 to -4 (cooling systems and heat pumps)

– EN ISO 12100-1 and -2 (machine safety)

– EN 294 (safety distances for contact)

– EN 60 204-1 (machine electrical equipment)

– EN 60 529 (degrees of protection provided by the

housing IP rating)

– EN 60 335-1 and -2-40

(safety of electrical devices)

– EN 55 011 Kl B (radio disturbances)

– EN 61 000-3-11 (electromagnetic compatibility)

– ISO 9001/14001

– RoHs COMPLIANT 2002/95/EC

Page 6

6 Rittal Thermoelectric Cooler assembly and operating instructions

4 How it works

GB

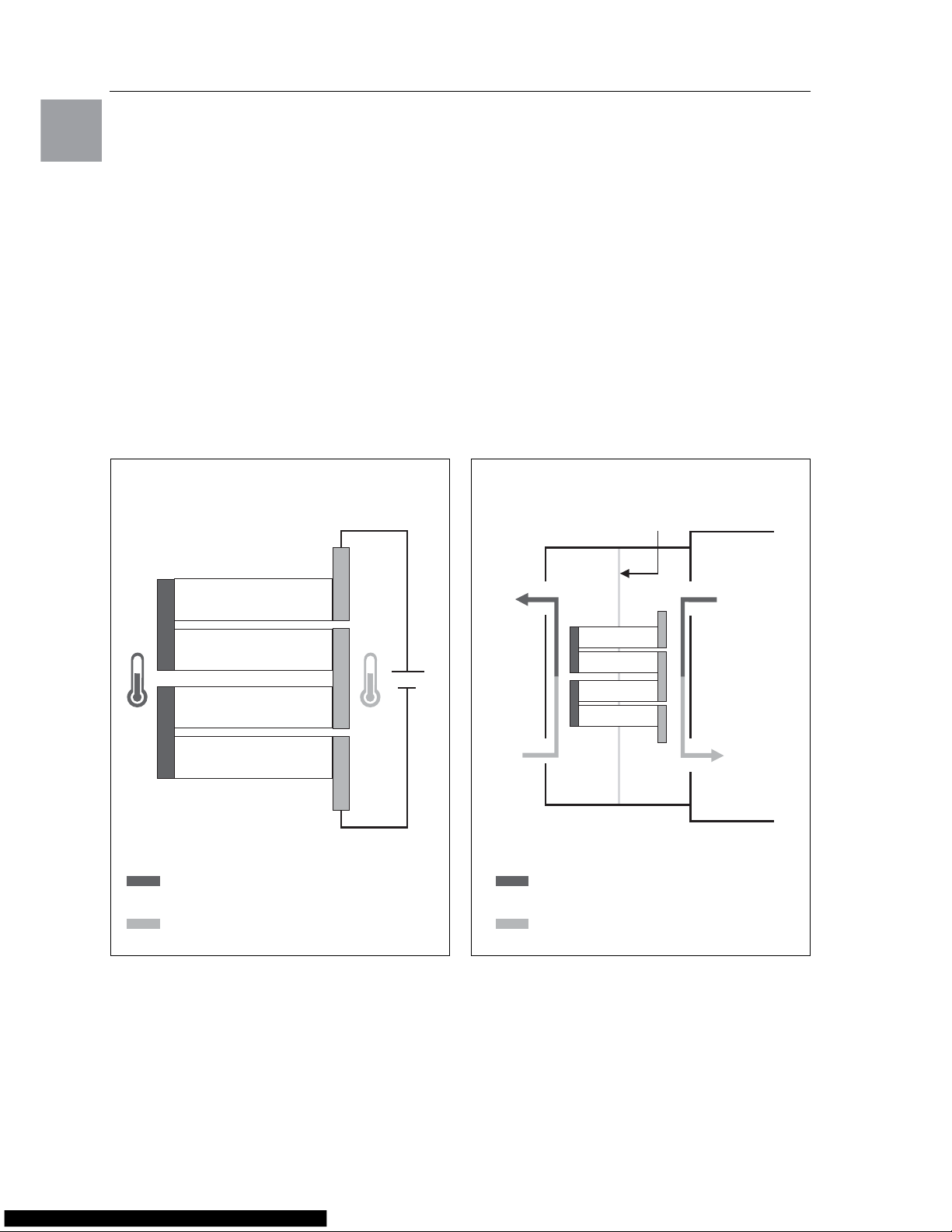

4 How it works

The Rittal Thermoelectric Cooler uses the Peltier effect for cooling. This effect is based on the principle

that an electric direct-current flowing through a circuit consisting of two different metals causes the

cooling of one contact point and the heating of the

other contact points. An appropriate layout for the

cooling production is designated as Peltier element.

When the Peltier effect is used for enclosure climate

control, an air flow is fed over the upper and lower

connection point. The heat energy is released or

accepted from the air flow to the Peltier element.

The air flow that releases the heat energy to the element is introduced as cooling air flow in the enclosure or the operating housing. After

the heating of the

cooling air flow by the active installed equipemt

, it is

returned to the cooling unit and fed for renewed cooling over the “cold” side of the Peltier element. This

produces an air circulation that causes the cooling of

the enclosure or the operating housing.

The air flow that accepts the heat energy from the

“warm” side of the Peltier element is released as

warm air flow to the external air circuit of the cooling

unit. This means the heat produced by the components in the enclosure is dissipated to the ambient air

surrounding the cooling unit.

Fig. 1: Peltier element Fig. 2: Peltier cooling unit

n-doped

n-doped

p-doped

p-doped

Warm area

Cold area

+

–

Divider panel

Environment

Enclosure/operating housing

Warm area

Cold area

Page 7

5 Control

Rittal Thermoelectric Cooler assembly and operating instructions 7

GB

5 Control

The Rittal Thermoelectric Cooler controls the cooling

capacity of the Peltier elements and the air throughput of the integrated fans so that the required internal

temperature of the enclosure or the operating housing is set with high accuracy. For this purpose, the

device permanently monitors the air entry temperature at the warm air entry (internal circulation). If this

temperature exceeds a parameterised temperature

value (factory setting: 35°C), the device starts cooling operation. To do this, the trigger voltages of the

Peltier elements and fans are corrected by a PID

control so that the cooling capacity required for the

cooling is always available and the cooling operation

is provided with the least possible power. The redundant fans in the external air circuit of the Rittal Thermoelectric Cooler have variable air delivery rates

(and consequently variable speeds) appropriate for

the required cooling capacity. If only limited or indeed no cooling capacity is required, this control behaviour can lead to a temporary inactivity of the fans

in the external air circuit. This does not constitute

a malfunction of the device, but rather an extreme

power-saving operating state that also increases the

service life of the used fans.

Note:

The fan speed in the external air circuit of

the cooling unit is matched to the current

cooling capacity requirement.

Consequently, a stoppage of the fans –

interrupted by periodic, short-term fan

starts – is not a malfunction of the device,

but rather represents an extreme powersaving operating state!

Fig. 3: Control behaviour of the fans in the external air circuit

max.

Cooling capacity requirement

Fan speed in the external air circuit

Fan off

min.

Page 8

8 Rittal Thermoelectric Cooler assembly and operating instructions

6 Device description

GB

6 Device description

Fig. 4: Device front Fig. 5: Device rear

1 2 3

4

5

7

6

1098

11

12

13

14

16

15

Legend

1 Status display

2 Function display

3 Housing

4 Louvred grille

5 Warm air outlet opening – external air circuit

6 Cold air inlet opening with filter element

(optional) – external air circuit

7 Condensate discharge

8 Interface X1: supply voltage and alarm output

9 Interface X2: USB 2.0, type B

10 Interface X3: RJ 45

11 Connection diagram

12 Warm air inlet opening – air internal circuit

13 Earth connection

14 Cold air outlet opening – air internal circuit

15 Blind nut

16 Rating plate (on the device lower side)

Page 9

7 Device mounting

Rittal Thermoelectric Cooler assembly and operating instructions 9

GB

7 Device mounting

The following principles must be observed for determining the mounting position on the enclosure or operating housing:

The Rittal Thermoelectric Cooler is mounted as external or full internal mounting.

The supplied drilling template must be used to fasten

the cooling unit on the enclosure or the operating

housing.

The drilling template provides dimension lines for the

various installation options of the cooling unit.

Identify appropriate lines and dimensions on the

drilling template for the required mounting type

(external or full internal mounting) using figures 6

and 7.

Drill the required holes for fastening the cooling unit

and then cut the required cut-out, including the line

width, in accordance with the drilling template.

The direct incidence of cold air on temperature-sensitive components must be

avoided!

Components with integrated fans

determine the cooling air routing in the

enclosure or operating housing.

The mounting position of the cooling unit

must be chosen so that the cooling air flow

supports the heat dissipation of these components.

A free space of at least 100 mm is required

in front of the air inlet and outlet openings of

the cooling unit in the internal and external

circuit.

The cooling unit must be positioned on

the enclosure so that the condensate discharge opening is located at the lowest

point of the cooling unit.

Risk of injury!

Wear protective gear (safety glasses,

protective gloves) when cutting the

mounting cut-out and drilling the

fastening holes.

Carefully deburr all drilled holes and

cut-outs to prevent injuries caused by

sharp edges.

Fig. 6: Mounting cut-out and hole sizes

for external mounting

Fig. 7: Mounting cut-out and hole sizes

for internal mounting (full internal mounting)

377

366

400

25

25

11.5

15

Ø 6.5

10012.5

8.5

108

125

Climate control unit external contour

386

400

25

15

100

15

25

40

377

25

18

Ø 6.5 Ø 12

10

7

11.5

85

11

12.5

8.5

108

125

12

Climate control unit external contour

Page 10

10 Rittal Thermoelectric Cooler assembly and operating instructions

7 Device mounting

GB

7.1 External mounting

When the cooling unit is mounted as externallymounted variant, the supplied self-adhesive sealing

tape must be fastened on the device rear wall of the

cooling unit so that no gaps result at the joint edges.

Then screw the supplied studs into the blind nuts at

the rear of the unit. Secure the cooling unit using the

supplied washers and nuts.

Fig. 8: Position of the sealing tape

Fig. 9: Fastening the cooling unit

Fig. 10: External and internal mounting

Fig. 11: Permissible mounting positions

7.2 Internal mounting

For the full internal mounting of the cooling unit, the

louvred grille must be carefully removed from the device. The self-adhesive sealing tape supplied must

be placed on the front of the cooling unit (the device

face from which the louvred grille has been removed) so that no gaps result at the joints. Then

screw the supplied studs into the blind nuts at the

front of the unit. Secure the cooling unit using the

supplied washers and nuts. To complete the mounting, the louvred grille must be re-attached.

Fig. 12: Position of the sealing tape

Fig. 13: Fastening the cooling unit

125

400

400

155

55100

10055

Internal mountingExternal mounting

External

mounting,

vertical

External

mounting,

horizontal

Internal

mounting,

horizontal

Internal

mounting,

vertical

max. 45°

max. 45°

max. 45°

max. 45°

Page 11

8 Filter mounting

Rittal Thermoelectric Cooler assembly and operating instructions 11

GB

8 Filter mounting

The Rittal Thermoelectric Cooler can be equipped

with a device filter (supplied).

An appropriate filter unit is recommended when the

cooling unit is used in ambient air subject to dust.

When a filter is installed, the lower louvred grille in

the air inlet of the cooling unit must be removed. To

do this, raise the louvred grille with a light tug at the

marked position (see Figure 14) and withdraw it at

the front. Then place the filter mat in the filter holder

of the device. The colour-marked side of the filter mat

must face the device. Then re-mount the louvred

grille and snap it into position by applying light pressure.

Fig. 14: Removable louvred grille

9 Mounting the

condensate discharge

The Rittal Thermoelectric Cooler is equipped with

a condensate discharge.

Fig. 15: Condensate discharge

The controlled condensate discharge requires a

condensate discharge hose be connected to the

cooling unit’s condensate discharge supports.

The condensate hose is available as accessory.

The installation of the condensate hose requires

that it

– is laid with a gradient (no siphon formation),

– does not have any kinks,

– must not have a reduced cross-section if extended.

Note:

When a filter unit is used, it must be cleaned

regularly or, if necessary, replaced.

Risk of injury!

The operation of the cooling unit without

controlled condensate discharge can

cause liquid to accumulate below the

device.

Condensate

discharge

Page 12

12 Rittal Thermoelectric Cooler assembly and operating instructions

10 Electrical connection

GB

10 Electrical connection

10.1 Connection data

– The mains voltage and frequency must corres-

pond to the values stated on the rating plate.

– An all-range fuse specified on the rating plate must

be connected upstream as line and device protection.

– No additional temperature control is allowed to be

connected upstream of the cooling unit on the

supply side.

– An isolating device that ensures a contact opening

of at least 3 mm in switched-off state must be

connected upstream of the cooling unit.

– The mains connection must ensure low-noise

potential equalisation.

Fig. 16: Rating plate

The Rittal Thermoelectric Cooler is available as

version with integrated multi-range power pack

(100 – 240 V) and as 24 V variant (without integrated

power pack).

Fig. 17: SK 3201.200 connection diagram,

with integrated power pack

Fig. 18: SK 3201.300 connection diagram,

without integrated power pack

Legend

A1 Power PCB

A2 Power pack

B1 Temperature sensor, internal temperature

B2 Ambient temperature sensor

B3 Temperature sensor, power pack

H1/H2 Status and function display

M2.1 Condenser fan 1

M2.2 Condenser fan 2

M4 Evaporator fan

TE Thermoelectric elements

X1 Terminal strip

X2 USB connection

X3 Optional interface

Danger!

Warning of a dangerous electrical

voltage.

Danger to life and health in case of

non-observance!

M M M

M4

MS1

3

2

1

213

Ser ial

A1

TE

1

2

Power

PE

+

–

M2.2

1

3

2

M4

3

2

1

X1

1PE2

3

M2.2

4

M2.1

1

3

2

M2.1

4 4

L1

N

PE

TE

~

–

A2

PE

Mains

X2

X3

Alarm

NTC_O YELLOW

NTC_I RED

2

B2

2

B1

2

B3

NTC_N WHITE

H1 H2

M4

NTC_O YELLOW

NTC_I RED

MS1

3

2

1

2

1

3

Ser ial

A1

TE

1

2

Power

PE

+

–

M2.2

1

3

2

M4

3

2

1

PE

X1

Mains

1PE23

X2

X3

2

B2

2

B1

M2.2

4

M2.1

1

3

2

M2.1

M

4

M M

4

+ –

PE

TE

Alarm

H1 H2

Page 13

11 Interfaces

Rittal Thermoelectric Cooler assembly and operating instructions 13

GB

11 Interfaces

Fig. 19: Designations of the device interfaces

11.1 Interface X1 –

power supply and alarm output

– Power supply

SK 3201.200: AC: 100 – 240 V, 50/60 Hz

SK 3201.300: DC: 24 V (SELV)

– Change-over contact/alarm output (floating

connection)

Switching load: AC: 250 V/2 A, DC: 6...30 V/2 A

The signal relay releases for overtemperature,

sensor break and fan failures.

Fig. 20: Change-over contact assignment

11.2 Interface X2 –

device programming

– USB 2.0

11.3 Interface X3 –

integration in a higher-level

monitoring system

– RJ 45

The interface X3 permits the connection of the cooling unit in higher-level monitoring systems.

12 Earth connection

The Rittal Thermoelectric Cooler is equipped with a

potential equalisation connection point. A conductor

with a nominal cross-section of at least 6 mm2 must

be connected to this connection point and included

in the provided potential equalisation.

Fig. 21: Contact point for potential equalisation

X2X1 X3

PE

1+

–

23

24 V DC

0322231

X2X1 X3

PEL1

L2

N

123

0322416

Connection terminal designation SK 3201.300

Connection terminal designation SK 3201.200

Interface X3Interface X2Interface X1

Interface X3Interface X2Interface X1

Pin 1 Pin 2 Pin 3

Note:

The electrical signals at the interface X3

are extra-low voltages (not extra-low safety

voltages in accordance with EN 60 335).

Note:

According to the standard, the PE conductor in the mains connection cable is not

classified as an equipotential bonding conductor.

X2X1 X3

PE

123

24 V DC

0322231

Contact point for

the potential equalisation

Page 14

14 Rittal Thermoelectric Cooler assembly and operating instructions

13 Commissioning

GB

13 Commissioning

The Rittal Thermoelectric Cooler is operational immediately after connection of the power supply. If the

factory setting is unchanged, the temperature control of the enclosure or operating housing uses the

following parameters:

Set enclosure interior temperature: +35°C

Start temperature for cooling operation: +35°C

Overtemperature alarm message: +45°C

Under normal operating conditions, device operation with unchanged factory setting should ensure a

problem-free enclosure climate control. If it would

appear to be useful to change the predefined parameters for special climate control requirements,

this can be realised with programming software. In

this case, please contact the device manufacturer.

14 Status and function displays

The Rittal Thermoelectric Cooler is equipped with

a status and function display. Two coloured LEDs

show the status, alarm and error messages that indicate the operating state of the cooling unit.

Fig. 22: Status and function displays on the cooling unit

Tab. 1: Function display

Tab. 2: Status display

Function LED

Description

Off Unit OFF or Cooling OFF

Green Cooling operation ON

Red Error – unit

Status LED

Description

Off Unit OFF

Green Unit OK

Orange Warning (temperature alarm,

temperature > alarm value)

Red Error (sensor defective, fan

defective, thermoelectric module

defective)

Function

display

Status

display

Page 15

15 Technical specifications

Rittal Thermoelectric Cooler assembly and operating instructions 15

GB

15 Technical specifications

Tab. 3: Technical specifications

Tab. 4: Setting ranges

Fig. 23:

Cooling output characteristic curve for full internal mounting and an enclosure internal temperature T

i

of 35°C

Model No. SK

3201.200 3201.300

Dimensions in mm

W

H

D

125

400

155

Operating voltage in volts, Hz 100 – 240 V AC, 50/60 Hz 24 V DC

Useful cooling output

Q

k

in accordance with DIN 3168

L 35

L 35

100 W

Power consumption P

el

in accordance with DIN 3168

L 35

L 35

Max. 100 W

Refrigeration factor (max.)/COP

L 35

L 35

1.0 1.2

Power pack Integral –

Housing colour RAL 7024/anodised aluminium

Protection category

according to EN 60 529

Internal circuit

External circuit

IP 54

IP 34

Weight 3.0 kg 2.4 kg

Noise level Max. 63 dB(A)

Operating temperature +5°C to +55°C

Storage temperature –20°C to +70°C

Installation position Horizontal or vertical

Air throughput, unimpeded air flow

Internal circuit

External circuit

132 m

3

/h

132 m

3

/h

Temperature setting range +20°C to +55°C

Cooling activation temperature +35°C (factory setting)

Type of connection Plug-in terminal strip

Pre-fuse gG 2 A 10 A

Floating change-over contact;

contact loading

DC: 6...30 V / 0.1...2 A

AC: 250 V / 2 A

Technical modifications reserved.

.

Variable Range Default value EEPROM

Temperature conversion °C/°F 0...1 0 (°C) Yes

Cooling setpoint +20 to +55°C 35°C Yes

Overtemperature alarm message (0)2...15 K (0 = off) 10 K Yes

Internal fan deactivation (during cooling pauses) 0...1 0 (no deactivation) Yes

2520 30 35 40 45

0

140

160

120

100

80

60

40

20

Cooling output in W

T

i

Ambient temperature in °C

Ti = Enclosure internal temperature (°C)

Room temperature

Page 16

16 Rittal Thermoelectric Cooler assembly and operating instructions

16 Maintenance and cleaning

GB

16 Maintenance and cleaning

16.1 Maintenance

The Rittal Thermoelectric Cooler is low-maintenance.

16.2 Cleaning

If the Rittal Thermoelectric Cooler is used in ambient

air subject to dust, dust can accumulate in the area

of the air inlet and outlet openings and on the heat

transferring surfaces of the Peltier element. This can

cause a reduction of the air flow in the device and

thus a gradually reducing cooling capacity. To remove the dust, withdraw the louvred grille at the device front side. Blow compressed air through the air

inlet and outlet openings of the cooling unit.

If the Peltier cooling unit is equipped with a device

filter, it must be cleaned or replaced regularly. The

filter mat can be cleaned by washing, dusting or

blowing with compressed air. The high-quality filter

material used for the mat means the cleaning does

not impair the filter-technical properties and the form

stability. The fire class remains unchanged!

Danger!

Prior to any cleaning or maintenance

work, the power to the cooling unit must

be disconnected!

Note:

When the filter is replaced, use only filter

materials approved for the Rittal Thermoelectric Cooler.

The dust collecting efficiency and dust

storage capacity of the filter equipment

chosen is matched to the rated flow speed

of the cooling unit in the external air circuit

and so guarantees an excellent dust

filtering for a high useful cooling output.

Page 17

17 Fault correction

Rittal Thermoelectric Cooler assembly and operating instructions 17

GB

17 Fault correction

Tab. 5: Fault correction

Fault description Possible cause Correction

The unit does not switch on. No power supply. Check the mains connection and the

pre-fuse.

The unit does not cool adequately. The air circulation in the enclosure is

impaired.

Check the air circulation inside the

enclosure. Check, in particular, those

components equipped with a fan.

Check the free spaces above and

below the main heat dissipation

sources.

Ambient temperature too high. Reduce the ambient temperature.

Protect the unit from radiation heat

caused by direct sunshine and hot

surfaces.

Filter equipment contaminated. Check the filter and, if necessary,

clean or replace.

Internal fan defective.

Replace (Rittal Service).

External fan defective. Replace (Rittal Service).

The heat produced in the enclosure

exceeds the cooling capacity of the

Peltier cooling unit.

Reduce the heat loss.

Condensation. Enclosure leakages. Check the enclosure for leaks (IP 54).

Check, in particular, the cable entry

points for leaks.

Internal temperature of enclosure set

too low.

Check the set enclosure internal

temperature (factory setting: +35°C).

Page 18

18 Rittal Thermoelectric Cooler assembly and operating instructions

18 Disposal

GB

18 Disposal

To ensure the material reuse of the recyclable packaging materials, they must be delivered to the local

collection sites.

The cooling unit must be delivered to a waste management service provider that ensures the correct

reuse of the recyclable parts and the proper disposal

of the rest.

19 Guarantee

Provided the unit is used correctly (refer to the

operating instructions), Rittal gives its customers

a 24-month “Rittal manufacturer’s guarantee”

starting with date of manufacture.

If, within the guarantee period, during the 24 months

after manufacture, a malfunction occurs on the product that substantially adversely affects its functionality, Rittal will, within a reasonable period of time, rectify the malfunction by telephone service or, if necessary, by replacement, repair or other measures, at its

option. If this is inappropriate for the customer, Rittal

also has the possibility to provide the customer with

the replacement parts required to correct the malfunction.

Within the scope of its guarantee, Rittal will bear all

costs concerning the dispatching, deployment and

accommodation of its staff and with replacing or repairing any parts, provided the malfunction occurred

during the proper usage of the products and provided the costs are not increased by the movement of

the products to a place other than that where they

were originally delivered. In addition, Rittal will bear

the necessary costs for procuring and delivering the

replacement parts to the place where the products

were originally delivered.

Any parts delivered for or in replacement will be new

or in mint condition and in a fully functional state free

of faults; the replaced parts will become Rittal’s

property; the customer warrants that no rights of any

third parties will obstruct that exchange and transfer

of title.

Any claims based on this guarantee are to be submitted to Rittal in writing within one month after the

occurrence of the malfunction.

Any further claims, in particular claims for damages

,

are not covered by the guarantee. The statutory liability for defects is not affected by the guarantee.

Page 19

Switch to perfection

R

Power Distribution

Stromverteilung

Distribution de courant

Stroomverdeling

Strömfördelning

Distribuzione di corrente

Distribución de corriente

IT Solutions

IT-Solutions

Solutions IT

IT-Solutions

IT-lösningar

Soluzioni per IT

Soluciones TI

System-Klimatisierung

System Climate Control

Climatisation

Systeemklimatisering

Systemklimatisering

Soluzioni di climatizzazione

Climatización de sistemas

Schaltschrank-Systeme

Industrial Enclosures

Coffrets et armoires électriques

Kastsystemen

Apparatskåpssystem

Armadi per quadri di comando

Sistemas de armarios

Elektronik-Aufbau-Systeme

Electronic Packaging

Electronique

Electronic Packaging Systems

Electronic Packaging

Contenitori per elettronica

Sistemas de montaje para la electrónica

Communication Systems

Communication Systems

Armoires outdoor

Outdoor-behuizingen

Communication Systems

Soluzioni outdoor

Sistemas de comunicación

Rittal GmbH & Co. KG · Postfach 1662 · D-35726 Herborn

Tel.: +49 (0) 2772 505-0 · Fax: +49 (0) 2772 505-2319 · eMail: info@rittal.de · www.rittal.com

322 194

Loading...

Loading...