Page 1

Enclosure cooling unit

SK 3186930

SK 3187930

SK 3188940

SK 3189940

Assembly and operating instructions

Page 2

EN

Preface

Preface

Dear Customer!

Thank you for choosing a "Blue e+" enclosure cooling

unit (referred to hereafter as "cooling unit") from Rittal.

Yours

Rittal GmbH & Co. KG

Rittal GmbH & Co. KG

Auf dem Stützelberg

35745 Herborn

Germany

Phone: +49(0)2772 505-0

Fax: +49(0)2772 505-2319

E-mail: info@rittal.com

www.rittal.com

www.rittal.de

We are always happy to answer any technical questions

regarding our entire range of products.

2 Rittal enclosure cooling unit

Page 3

Contents

Contents

1 Notes on documentation .................. 4

1.1 CE labelling................................................... 4

1.2 Storing the documents.................................. 4

1.3 Symbols used in these operating instructions 4

1.4 Other applicable documents ......................... 4

2 Safety notes ..................................... 5

2.1 General safety instructions ............................ 5

2.2 Operating and technical staff......................... 5

2.3 Other dangers when using the cooling unit ... 5

3 Product description .......................... 6

3.1 Functional description and components........ 6

3.1.1 Function ............................................................... 6

3.1.2 Components ........................................................ 7

3.1.3 Control ................................................................. 7

3.1.4 Safety devices ...................................................... 7

3.1.5 Condensation ....................................................... 7

3.1.6 Filter mats ............................................................ 7

3.1.7 Door limit switch ................................................... 8

3.2 Proper use, foreseeable misuse .................... 8

3.3 Supply includes............................................. 8

4 Transport and handling .................... 9

4.1 Delivery ......................................................... 9

4.2 Unpacking .................................................... 9

4.3 Transport ...................................................... 9

5 Installation ...................................... 10

5.1 Safety instructions....................................... 10

5.2 Siting location requirements ........................ 10

5.3 Assembly procedure ................................... 10

5.3.1 Assembly instructions ......................................... 10

5.3.2 Mounting options ............................................... 11

5.3.3 Make a mounting cut-out in the enclosure .......... 12

5.3.4 External mounting of the cooling unit .................. 12

5.3.5 Mounting the cooling unit externally on a 500 mm

deep enclosure ................................................... 14

5.3.6 Partial internal mounting of the cooling unit ......... 14

5.3.7 Full internal mounting of the cooling unit ............. 18

5.3.8 Connect the condensate water discharge .......... 19

5.4 Electrical connection ................................... 20

5.4.1 Notes on electrical installation ............................. 20

5.4.2 Install the power supply ...................................... 21

5.4.3 Connect the alarm relays .................................... 22

5.4.4 Interfaces ........................................................... 22

7.4 Configuration menu.................................... 26

7.4.1 Temperature ....................................................... 26

7.4.2 Alarm relays ....................................................... 27

7.4.3 Language settings .............................................. 27

7.4.4 Self-test .............................................................. 27

7.5 System messages...................................... 28

7.5.1 Occurrence of a malfunction ............................... 28

7.5.2 Display in case of errors ..................................... 28

7.6 List of system messages ............................ 29

8 Inspection and maintenance ........... 32

8.1 Safety instructions for maintenance work ... 32

8.2 Notes on the refrigerant circuit ................... 32

8.3 Maintenance work on the cooling unit ........ 32

8.4 Compressed air cleaning............................ 32

8.4.1 Dismantling a unit with full internal mounting ....... 32

8.4.2 Dismantling the unit ............................................ 32

8.4.3 Cleaning the components with compressed air .. 35

8.4.4 Re-assembling the cooling unit ........................... 35

9 Storage and disposal ...................... 36

10 Technical specifications .................. 37

11 List of spare parts ........................... 39

12 Drawings ........................................ 40

12.1 Representation of mounting cut-outs ......... 40

12.2 Dimensions and installation depths ............ 41

13 Accessories .................................... 43

14 Customer service addresses .......... 44

15 Compact service information .......... 48

EN

6 Commissioning .............................. 23

7 Operation ....................................... 24

7.1 General....................................................... 24

7.2 Layout of the display ................................... 24

7.2.1 Start screen ........................................................ 24

7.2.2 Changing a parameter value ............................... 24

7.3 Information menu ........................................ 25

7.3.1 Temperature information .................................... 25

7.3.2 Device information .............................................. 25

7.3.3 Efficiency information .......................................... 26

Rittal enclosure cooling unit 3

Page 4

EN

1 Notes on documentation

1 Notes on documentation

1.1 CE labelling

Rittal GmbH & Co. KG confirms the conformity of the

cooling unit with the European Union's Machinery Directive 2006/42/EC and EMC Directive 2004/108/EC.

A corresponding declaration of conformity has been issued and enclosed with the unit.

1.2 Storing the documents

The assembly and operating instructions as well as all

other applicable documents are an integral part of the

product. They must be issued to everyone who works

with the unit and must always be available and on hand

for operating and maintenance personnel.

1.3 Symbols used in these operating instructions

The following symbols are used in this documentation:

Danger!

A dangerous situation in which failure to

comply with the instructions will result in

death or severe injury.

Warning!

A dangerous situation which may cause

death or serious injury if the instructions

are not followed.

Caution!

A dangerous situation which may lead to

(minor) injuries if the instructions are not

followed.

Note:

Important notices and indication of situations

which may result in material damage.

This symbol indicates an "action point" and shows that

you should perform an operation or procedure.

1.4 Other applicable documents

Assembly and operating instructions exist as paper documents and/or digital data carriers for the unit types described here and are enclosed with the equipment.

We cannot accept any liability for damage associated

with failure to observe these instructions. Where applicable, the instructions for any accessories used also apply.

4 Rittal enclosure cooling unit

Page 5

2 Safety notes

2.1 General safety instructions

Please observe the following general safety instructions

for the installation and operation of the system:

– Please be sure to observe the applicable regulations

governing electrical installations of the country in

which the device is installed and operated as well as

national regulations for accident prevention. Please

also observe any internal company regulations, such

as work, operating and safety regulations.

– Use only original Rittal products or products recom-

mended by Rittal in conjunction with the cooling unit.

– Please do not make any changes to the cooling unit

that are not described in these operating instructions

or other applicable assembly and operating instructions.

– The operational safety of the cooling unit is only war-

ranted if used as intended. The technical specifications and limit values stated must not be exceeded under any circumstances. In particular, this applies to the

specified ambient temperature range and IP protection category.

– Operating the cooling unit in direct contact with water,

aggressive materials or inflammable gases and vapours is prohibited.

– Other than these general safety instructions, it is also

vital to observe the specific safety instructions when

carrying out the tasks described in the following chapters.

– Please note the maximum weights that may be lifted

by individuals. It may be necessary to use lifting gear.

2 Safety notes

Where applicable, use suitable components to divert

the air.

Please observe the prescribed minimum distances at

the installation site as outlined in section 5.3.1 "Assembly instructions".

EN

2.2 Operating and technical staff

– The assembly, installation, commissioning, mainte-

nance and repair of this cooling unit may only be performed by qualified, trained personnel.

– Only properly instructed personnel may operate a

cooling unit with the system operational.

– Children and persons with limited cognitive/coordina-

tive abilities must not operate, maintain or clean the

unit or be allowed to use it as a toy.

2.3 Other dangers when using the cooling unit

Particularly when the cooling unit is externally mounted

(see section 5 "Installation"), there is a risk that the enclosure could become unbalanced and tip over.

In such cases, the enclosure should be bolted to the

floor as a precaution.

If the air inlet or outlet of the cooling unit is obstructed,

there is a risk of air short-circuits, resulting in inadequate

climate control.

Please ensure that the electronic assemblies in the enclosure are installed in accordance with section 5.3.1

"Assembly instructions".

Rittal enclosure cooling unit 5

Page 6

3 Product description

EN

3 Product description

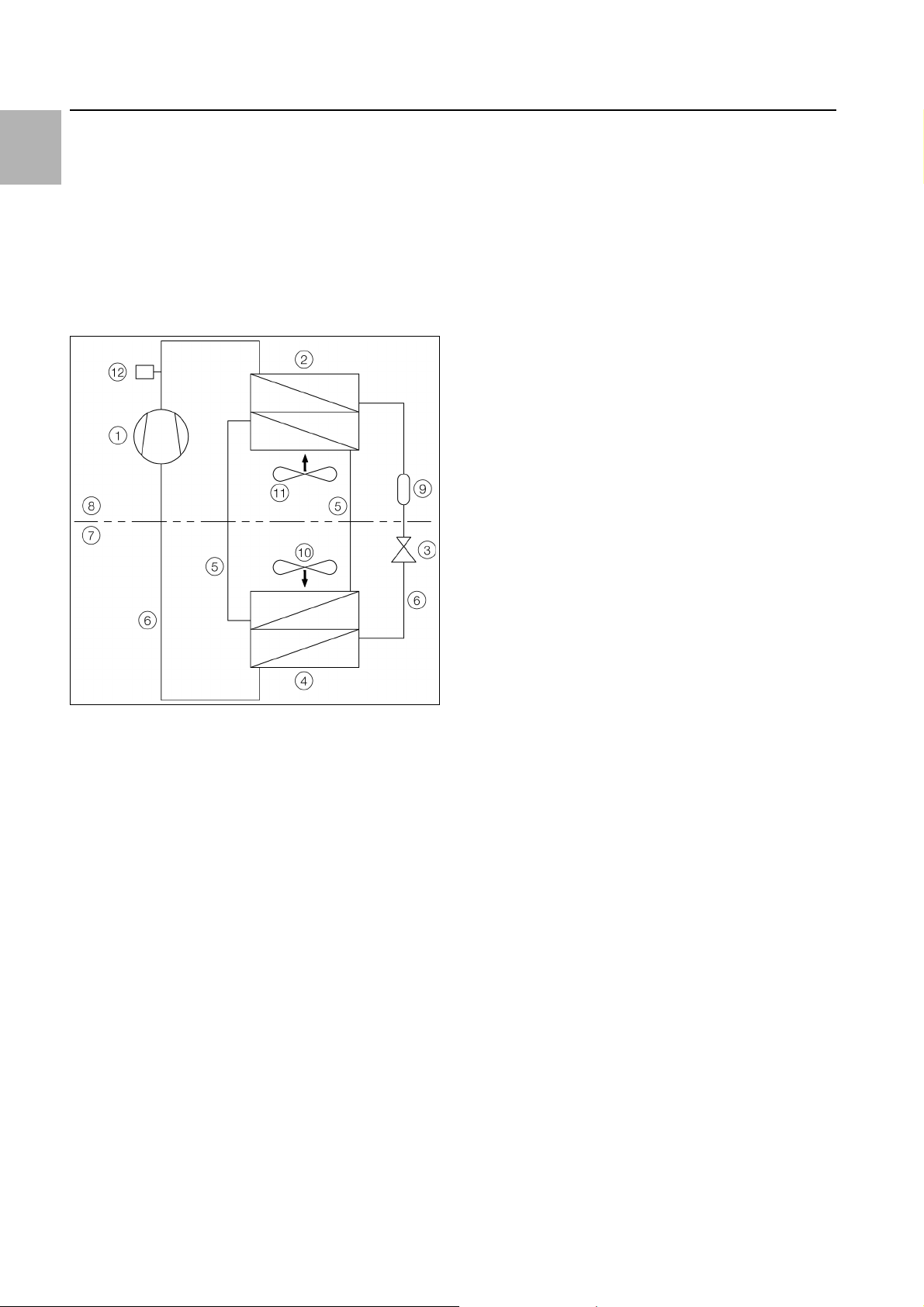

3.1 Functional description and components

3.1.1 Function

There are two separate cooling circuits installed in the

cooling unit.

– One conventional refrigerant circuit (compression sys-

tem), and

– One heat pipe integrated into the condenser and

evaporator coil.

Refrigerant circuit with compression system

The refrigerant circuit with compression system is comprised of the following four main components:

1. Evaporator coil

2. Compressor

3. Condenser

4. Expansion valve

The evaporator coil fan draws hot air from the enclosure

in the internal circuit of the cooling unit and passes it

over the evaporator coil. After the evaporator coil, the

cooled air is fed back into the enclosure via the outlet

opening.

The air is cooled down by evaporating the refrigerant in

the evaporator coil. The refrigerant vapour is transported

by the compressor in the external circuit of the cooling

unit to the condenser. There, the refrigerant condenses

and becomes a liquid. The heat produced is dissipated

by the condenser fan. The downstream electronic expansion valve reduces the high pressure of the refrigerant, and the refrigerant is then fed back into the evaporator coil.

Both the compressor and the two fans in the cooling unit

are activated via an inverter. This makes it possible to

control these components, so that the fan and compressor may be activated for a longer time but at a lower output and improved efficiency.

Fig. 1: Cooling circuit

Key

1 Compressor

2 Condenser (dual version) with fan

3Expansion valve

4 Evaporator coil (dual version) with fan

5 Refrigerant circuit with heat pipe

6 Refrigerant circuit with compression system

7 Internal circuit

8 External circuit

9 Dryer/collector

10 Internal fan

11 External fan

12 PSA

H

pressure monitor

In both cooling circuits, the individual components are

connected with pipes in which the refrigerant R134a is

circulating. This refrigerant is very environmentally friendly, thanks to the following properties:

–Chlorine-free

– Does not deplete the ozone layer (ozone destruction

potential ODP = 0)

Refrigerant circuit with heat pipe

The additional second refrigerant circuit operates without a compressor, expansion valve or other control elements, and is integrated into the evaporator coil and

condenser as a heat pipe.

The refrigerant inside the heat pipe (R134a) absorbs

thermal energy from the intake of enclosure air and

evaporates. The gaseous refrigerant then rises through

the pipeline until it reaches the condenser. The refrigerant is cooled down again in the condenser (provided Tu

< Ti), and the heat released is emitted into the environment. Gravity then causes the liquid refrigerant to flow

back down the pipelines. The whole cycle begins again.

6 Rittal enclosure cooling unit

Page 7

3 Product description

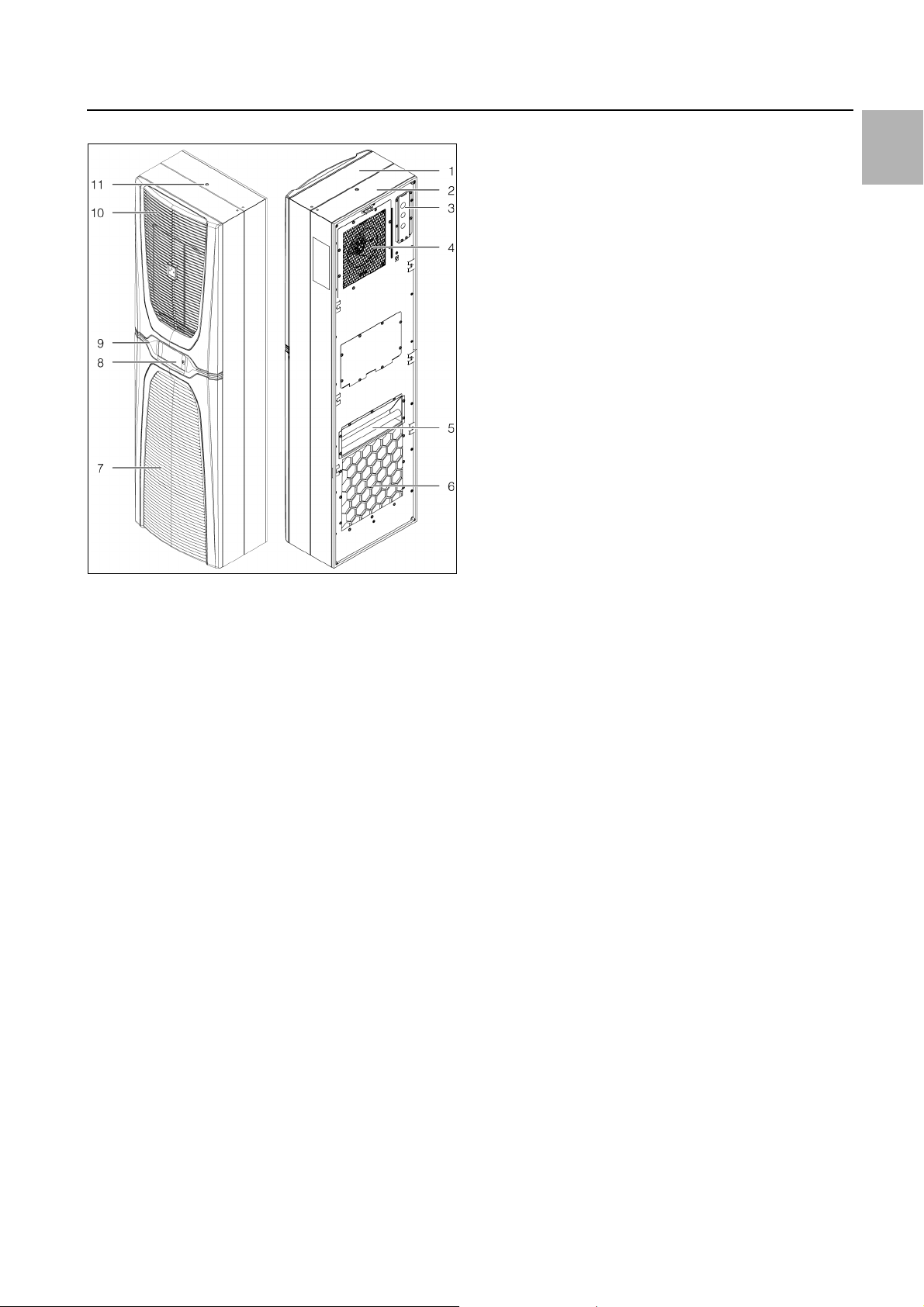

3.1.2 Components

Fig. 2: Main components of cooling unit

Key

1Cover

2 Chassis

3 Connection box

4Evaporator fan

5Handle

6 Air outlet opening

7 Lower louvred grille for air inlet

8Display

9 Infill panel

10 Upper louvred grille for air outlet

11 Thread for eyebolt

3.1.3 Control

Rittal enclosure cooling units are fitted with a controller

for setting the functions of the cooling unit.

Operation using this controller is described in section 7

"Operation".

3.1.4 Safety devices

– In the refrigerant circuit, the cooling units have a type-

tested pressure monitor (to EN 12263) which switches

off the cooling unit if the maximum admissible pressure is exceeded. Once the pressure drops back below the admissible pressure, the unit will automatically

resume operation.

– Temperature monitoring prevents the evaporator coil

from icing over. If there is a risk of icing, the compressor switches itself off and automatically switches itself

back on again at higher temperatures.

– The compressor is monitored and protected by the in-

verter to prevent overloading.

– The fans have a built-in overload protection with auto-

matic reset.

– In order to allow a reduction of pressure inside the

compressor and hence a safe restart, once it has been

switched off (e.g. upon reaching the set temperature

via the door limit switch function or via de-energising),

the device will switch back on with a delay of 180 seconds.

– The device has floating contacts on the connection

pins on terminals 1 and 3 of the signal connector (X2),

via which system messages from the device may be

polled, e.g. using a PLC (2 x normally closed or normally open contacts).

3.1.5 Condensation

At high levels of humidity and low temperatures inside

the enclosure, condensate water may form on the evaporator coil.

The cooling units have an automatic electrical condensate water evaporator. The thermal component used for

this purpose is based on self-regulating PTC technology. Condensate water arising on the evaporator coil is

collected in a tank in the external circuit of the cooling

unit, and partially evaporated via the airflow. When the

water level rises, the water enters the PTC thermal component and is evaporated (through-flow heater principle). The water vapour streams out of the cooling unit

with the airflow from the external fan.

The PTC thermal component is activated automatically

when the compressor is running, and continues to run

for around 15 minutes after the compressor has been

switched off. During the after-run phase, the condenser

fan will likewise continue to run at low speed.

In the event of a short-circuit in the PTC component or if

there is a risk of inverter overload (possible at high ambient temperatures), the PTC component will be deactivated. This means that any condensate water arising

can be discharged via the safety overflow.

If the fuse has tripped, any condensate water is drained

off via the safety overflow. The condensation is routed

downwards out of the unit via a drain pipe on the evaporator coil divider panel. For this purpose, a hose may be

connected to the condensate water nozzle (see section

5.3.8 "Connect the condensate water discharge").

3.1.6 Filter mats

The entire cooling unit condenser is covered with a dirtrepelling, easy-to-clean RiNano coating. In many applications, therefore, the use of filter media is unnecessary,

particularly with dry dusts.

For dry, coarse dust and lint in the ambient air, we recommend installing an additional PU foam filter mat (available as an accessory) in the cooling unit. Depending on

the incidence of dust, you will need to replace the filter

mat from time to time (see section 8 "Inspection and

maintenance").

For oily ambient air, we recommend the use of metal filters (also available as an accessory). These may be

cleaned with suitable detergents and reused.

EN

Rittal enclosure cooling unit 7

Page 8

3 Product description

EN

3.1.7 Door limit switch

The cooling unit may be operated with a floating door

limit switch connected. The door limit switch is available

as accessory from Rittal.

The door limit switch function causes the fans and the

compressor in the cooling unit to gradually slow down

and then switch off after approximately 15 seconds

when the enclosure door is opened (contacts 1 and 2

closed). This prevents the formation of condensate water inside the enclosure while the enclosure door is

open. In order to prevent damage to the unit, it is

equipped with an ON delay: The evaporator fan will cut

in again after a delay of a few seconds on closure of the

door.

Please note that no external voltage may be applied to

the door contacts (terminals 1 and 2)

3.2 Proper use, foreseeable misuse

The cooling unit is only intended for cooling connected

enclosures. Any other use is not permitted.

– The unit must not be installed and operated in loca-

tions which are accessible to the general public (see

DIN EN 60335-2-40, paragraph 3.119).

– The unit is designed solely for stationary use.

– The manufacturer's consent must be obtained in ad-

vance for mobile applications, e.g. on cranes.

The cooling unit is state of the art and built according to

recognised safety regulations. Nevertheless, improper

use can pose a threat to the life and limb of the user or

third parties, or result in possible damage to the system

and other property.

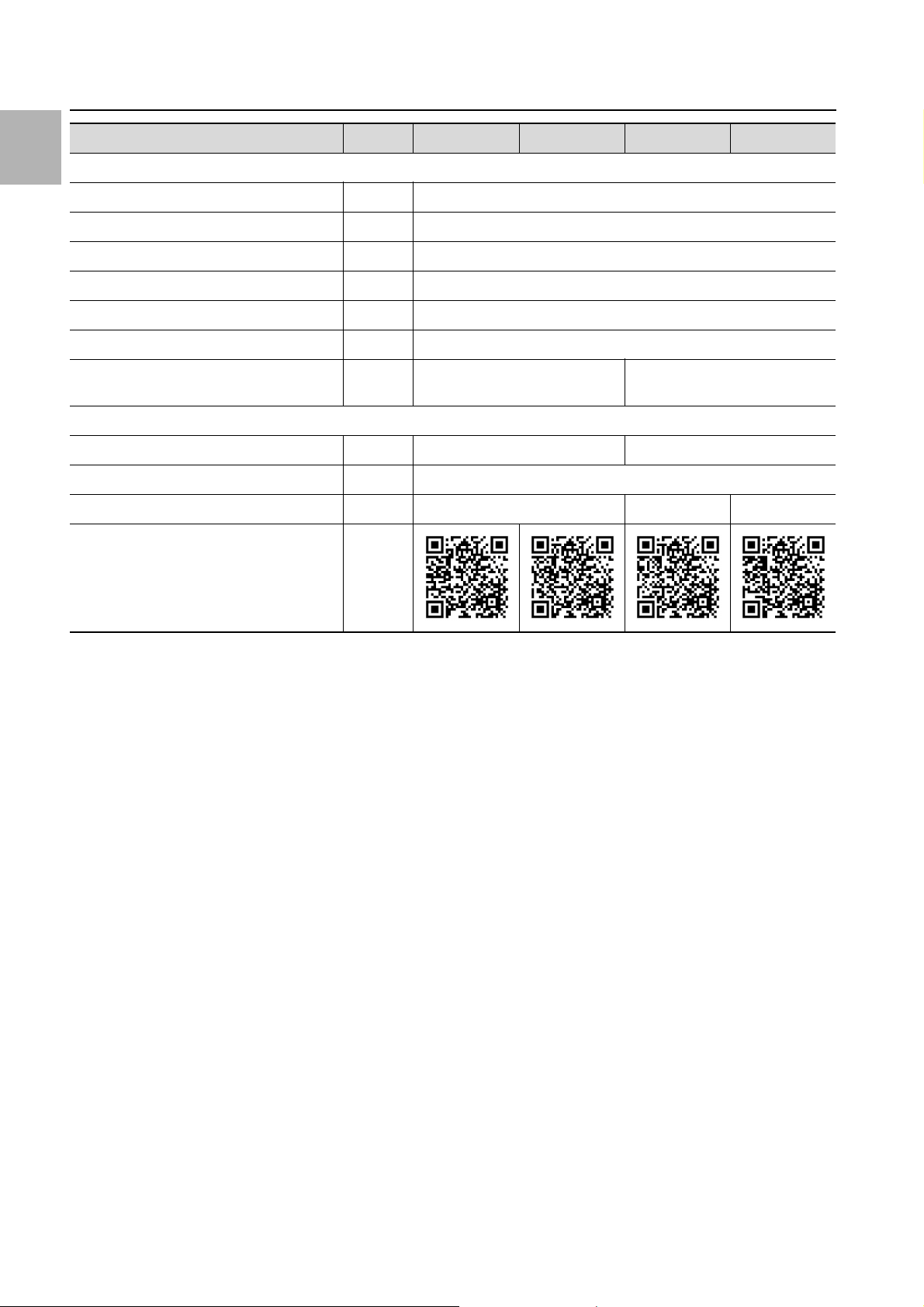

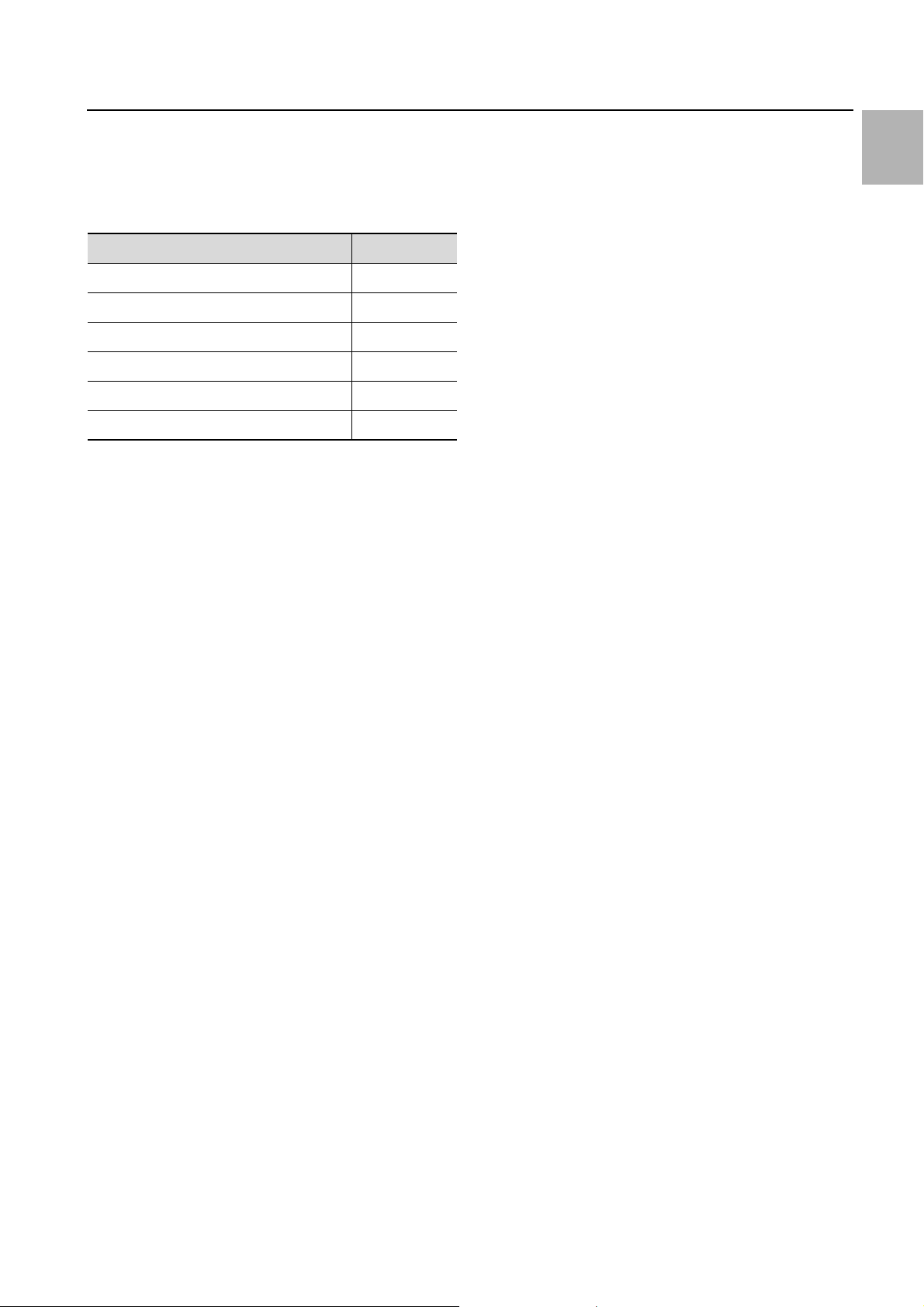

3.3 Supply includes

Qty. Description

1 Enclosure cooling unit

1 Shipping bag with

1 – Declaration of conformity

1 – Assembly and installation instructions

1 – Assembly, installation and operating in-

structions on digital data carrier

1 – Warning and safety notes

6 – Grub screws M8 x 40 mm

6 – Nut-and-washer assembly M8

1 – Sealing tape 10 x 10 mm, L = 4.1 m

1 – Signal connector X2

1–Connector X1

1 – Cover for connection unit

1 – Membrane entry grommet

1 – Clip

1 – Wedge element

6 – Fixing clamps

4 – Corner bracket for internal/external

mounting

2 – L-shaped brackets

Consequently, the cooling unit must only be used properly and in a technically sound condition! Any malfunctions which impair safety should be rectified immediately.

Proper use also includes the observance of the documentation provided, and compliance with the inspection

and maintenance conditions.

Rittal GmbH & Co. KG is not liable for any damage which

may result from failure to comply with the documentation provided. The same applies to failure to comply with

the valid documentation for any accessories used.

Inappropriate use may be dangerous. Examples of inappropriate include:

– Use of the cooling unit over long periods with the en-

closure open.

– Use of impermissible tools.

– Improper operation.

– Improper rectification of malfunctions.

– Use of accessories not approved by Rittal GmbH &

Co. KG.

1–Earth clamp 4 NS

1–Earth clamp 5 NS

1 – Washer for attaching the earth clamp

1 – Contact washer for attaching the earth

clamp

1 – M4 nut for attaching the earth clamp

1 – Cable gland M20 x 1.5 mm

1 – EMC cable gland M20 x 1.5 mm

1 – Strain relief

Tab. 1: Supply includes

8 Rittal enclosure cooling unit

Page 9

4 Transport and handling

4.1 Delivery

The cooling unit is supplied in one packaging unit.

Check the packaging carefully for signs of damage.

Traces of oil on damaged packaging indicate a loss of

refrigerant and/or a leak in the cooling unit. Any packaging damage may be the cause of a subsequent

functional failure.

4.2 Unpacking

Remove the packaging materials from the cooling unit.

Note:

After unpacking, the packaging materials

must be disposed of in an environmentally

friendly way.

Check the cooling unit for any damage that may have

occurred during transport.

Note:

Damage and other faults, e.g. incomplete delivery, should be reported immediately, in

writing, to the shipping company and to Rittal

GmbH & Co. KG.

4 Transport and handling

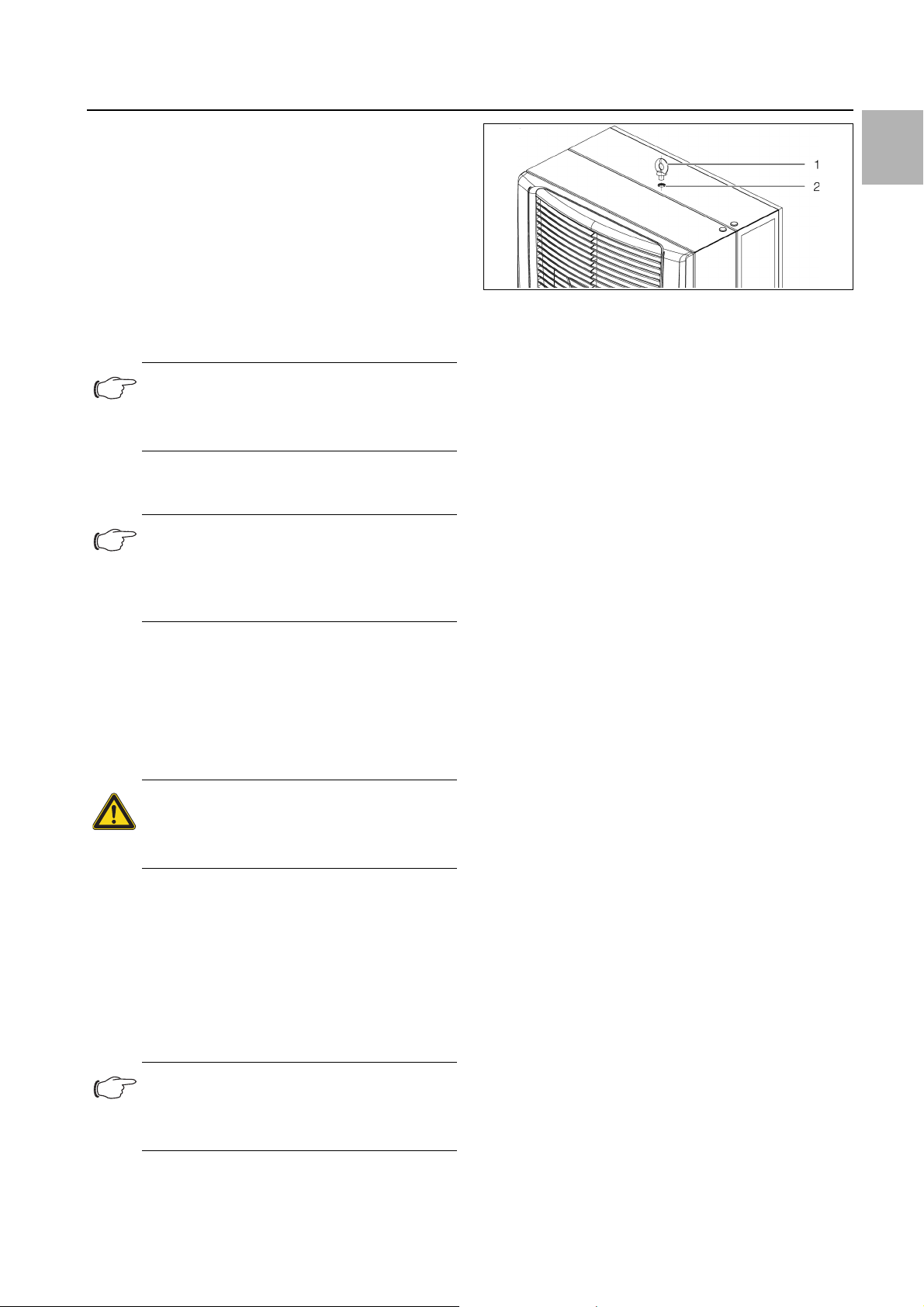

Fig. 3: Thread and eyebolt on top of the chassis

Key

1Eyebolt

2 M12 thread

Before transporting by crane, please ensure that the

lifting gear and crane have sufficient load capacity to

transport the cooling unit safely.

Never allow anyone to stand beneath a suspended

load, even for a short time, during transportation by

crane.

Protect the lifting gear on the crane hook from load deflection, because the load's centre of gravity may be

off-centre.

First position the cooling unit close to the installation

site and protect from accidentally being knocked over.

EN

Check the supply contents for completeness (see section 3.3 "Supply includes").

4.3 Transport

Depending on the chosen version, the cooling unit may

weigh up to 85 kg. The components in the cooling unit

chassis account for the bulk of the weight.

Warning!

Please note the maximum weights that

may be lifted by individuals. It may be

necessary to use lifting gear.

At the rear of the cooling unit is a handle which can be

used to briefly lift the cooling unit when inserting into the

mounting cut-out.

There is also an M12 thread at the top of the chassis,

into which a Rittal eyebolt (e.g. belonging to an enclosure) may be screw-fastened. The cooling unit is readily

transported with the aid of lifting gear and an indoor

crane.

Note:

An eyebolt with M12 thread may be ordered

as an accessory from Rittal (see section 13

"Accessories").

Rittal enclosure cooling unit 9

Page 10

5 Installation

EN

5 Installation

5.1 Safety instructions

Warning!

Please note the maximum weights that

may be lifted by individuals. It may be

necessary to use lifting gear.

Warning!

Work on electrical systems or equipment may only be carried out by an electrician or by trained personnel under the

guidance and supervision of an electrician. All work must be carried out in accordance with electrical engineering

regulations.

The cooling unit may only be connected

after the aforementioned personnel have

read this information!

Use only insulated tools.

Follow the connection regulations of the

appropriate electrical supply company.

The cooling unit must be connected to

the mains via an all-pin isolating device

to overvoltage category III (IEC 61058).

The cooling unit is not de-energised until

all of the voltage sources have been disconnected!

– The installation site must be free from excessive dirt,

aggressive ambient conditions and moisture.

– The ambient temperature must not exceed 60°C.

– It must be possible to fit a condensate water discharge

(see section 5.3.8 "Connect the condensate water

discharge").

– The mains connection data as stated on the rating

plate of the cooling unit must be guaranteed.

Size of installation room

– Units SK 3186930 and SK 3187930 must not be in-

stalled in rooms of less than 6 m³.

– Units SK 3188940 and SK 3189940 must not be in-

stalled in rooms of less than 12 m³.

Electromagnetic interference (EMI)

– Interfering electrical installations (high frequency) must

be avoided.

5.3 Assembly procedure

5.3.1 Assembly instructions

Before assembling, please ensure that the enclosure

is sealed on all sides (IP 54). Increased condensation

will occur later during operation if the enclosure is not

airtight.

If applicable, additionally fit a door limit switch (such as

4127.010) to the enclosure which switches off the

cooling unit when the enclosure door is opened to pre-

vent excessive condensation (see section 3.1.7 "Door

limit switch").

Please ensure that the electronic assemblies in the en-

closure allow the even circulation of air.

Please be sure to observe the applicable regulations

governing electrical installations of the country in

which the device is installed and operated, as well as

national regulations for accident prevention. Please

also observe any internal company regulations, such

as work, operating and safety regulations.

The technical specifications and limit values stated

must not be exceeded under any circumstances. In

particular, this applies to the specified ambient temperature range and IP protection category.

5.2 Siting location requirements

When choosing the installation site for the enclosure,

please observe the following:

– The site for the enclosure, and hence the positioning

of the cooling unit, must be carefully selected so as to

ensure good ventilation (clearance between cooling

units and clearance between a cooling unit and the

wall must be at least 200 mm in each case).

– The cooling unit must be installed and operated with a

maximum deviation of 2° from the vertical.

10 Rittal enclosure cooling unit

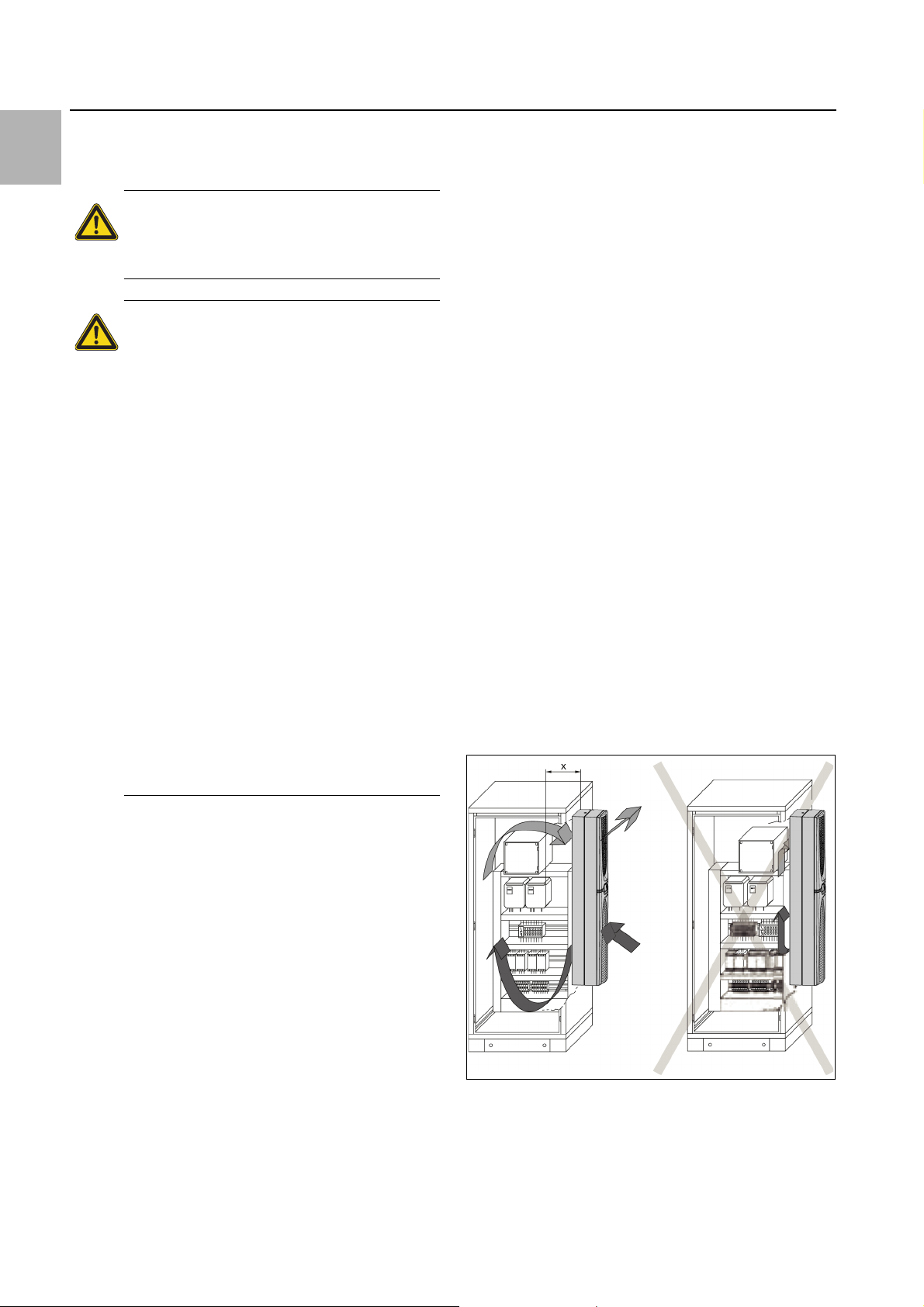

Fig. 4: Never direct the cold airflow at active components

Page 11

Under no circumstances should the air inlet and outlet

openings of the cooling unit be obstructed. Only in this

way is it possible to ensure that the maximum cooling

output is available.

Please ensure that the cold airflow from the cooling

unit is not directed at active components.

Fig. 5: Never direct the cold airflow at active components

If appropriate, install components to divert the air.

When installing in a dismantled door or side panel,

please ensure that it cannot fall over when installing

the cooling unit in the mounting cut-out.

Note:

The pictures in this chapter illustrate the in-

stallation of the cooling unit in an enclosure

door. Installation in a side panel is carried out

in the same way.

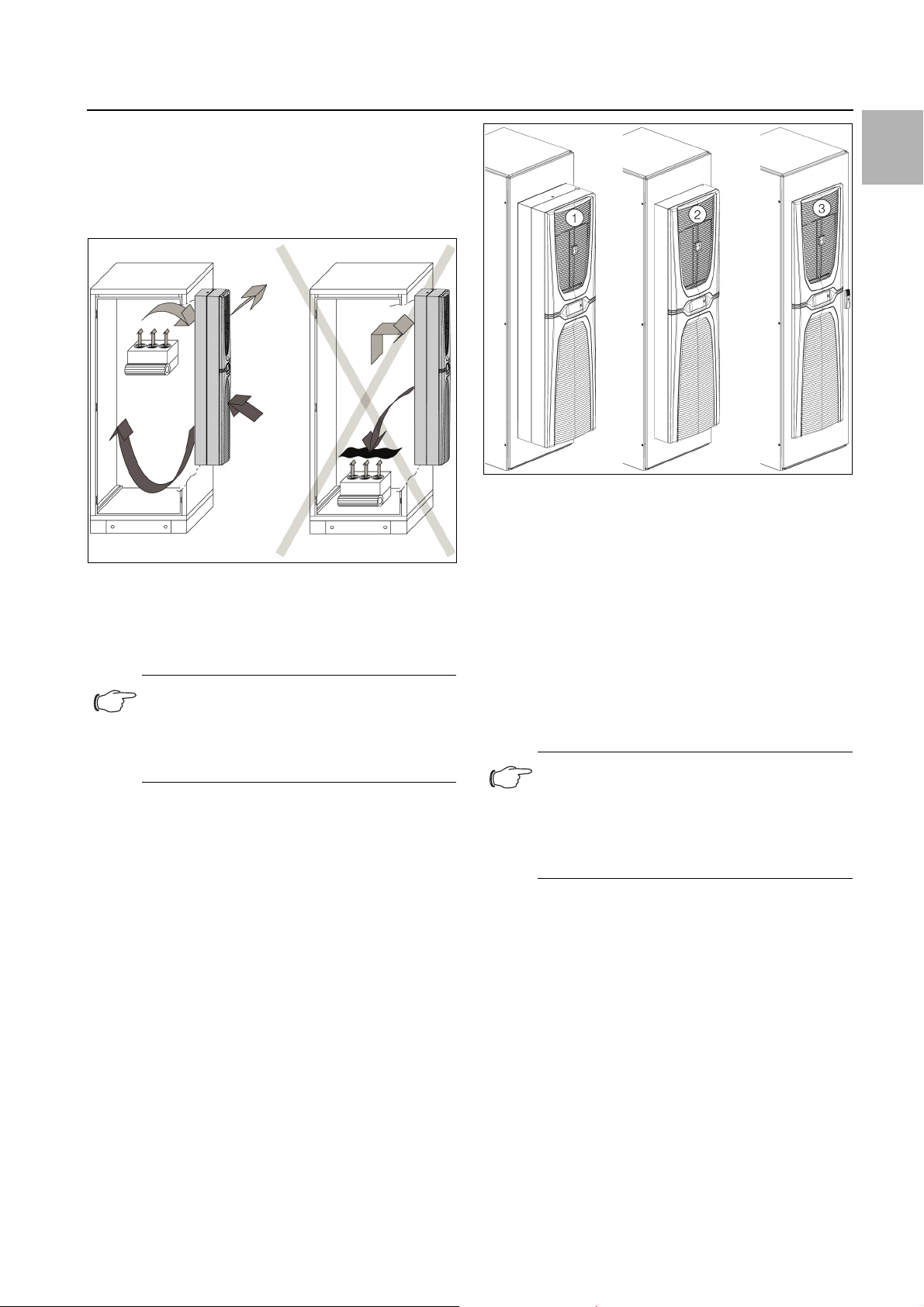

5.3.2 Mounting options

In principle, there are three different options for installing

the cooling unit on an enclosure door or side panel.

5 Installation

EN

Fig. 6: Mounting options

Key

1 External mounting

2 Partial internal mounting

3 Full internal mounting

– External mounting: All of the cooling unit is outside the

enclosure.

– Partial internal mounting The cooling unit chassis is in-

side the enclosure, while the cover and the louvred

grilles are outside.

– Full internal mounting: All of the cooling unit is inside

the enclosure. Only the louvred grilles project on the

outside.

Note:

– Full installation of the 6 kW cooling unit is

not possible.

– On an enclosure with 500 mm depth, the

unit may only be externally mounted on the

side panel.

Your chosen installation option will ultimately depend on

how much space you require inside and outside of the

enclosure. The various mounting options have no influence on the cooling output of the cooling unit, which remains the same in all cases.

– If there are a large number of components installed in-

side the enclosure, external mounting or partial internal mounting of the cooling unit may be appropriate. In such cases, the space inside the enclosure may

be insufficient for full internal mounting, or it may not

be possible to guarantee adequate cooling of all components inside the enclosure.

– If the space surrounding the enclosure is limited,

full internal mounting may be suitable, so as to keep

essential escape routes clear.

Rittal enclosure cooling unit 11

Page 12

EN

5 Installation

5.3.3 Make a mounting cut-out in the enclosure

In order to mount the cooling unit on the enclosure, a

suitable mounting cut-out must be made in the door or

side panel of the enclosure. In principle, the mounting

cut-out is identical for all three mounting options. A special mounting cut-out is only required for external mounting on the side panel of a 500 mm deep enclosure.

Note:

The dimensions of the mounting cut-outs

can be found in section 12.1 "Representation

of mounting cut-outs".

Using the diagrams in section 12.1 "Representation of

mounting cut-outs", calculate the required dimensions

for your mounting cut-out .

Drill all the required holes and make the mounting cutout.

Carefully deburr all drilled holes and the cut-out to prevent injuries caused by sharp edges.

Caution!

Drilled holes and cut-outs that have not

been fully deburred may cause cut injuries, particularly when assembling the

cooling unit.

5.3.4 External mounting of the cooling unit

Note:

The description in this section does not ap-

ply to external mounting of the cooling unit on

the side panel of a 500 mm deep enclosure.

This is described in section 5.3.5 "Mounting

the cooling unit externally on a 500 mm deep

enclosure".

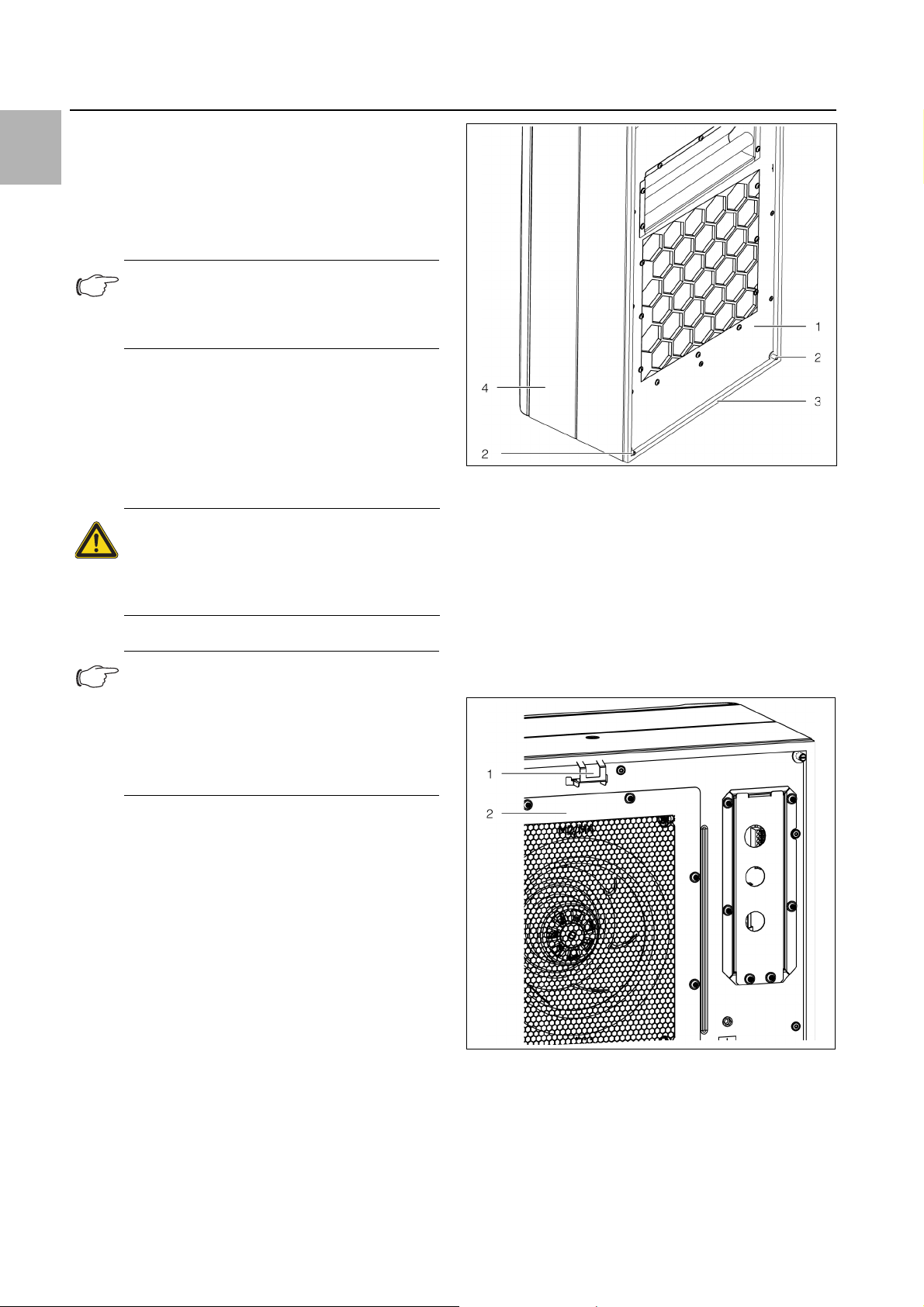

Fig. 7: Threaded bolts at the rear of the cooling unit

Key

1 Rear of cooling unit

2 Lower threaded bolt

3 Joint of sealing tape

4Cover

Push the clip included with the supply into the relevant

hole at the top edge of the cooling unit at the rear.

This clip will prevent the cooling unit from falling out of

the mounting cut-out later on if it is not yet adequately

secured with the threaded bolt.

Cut the sealing tape in the dispatch bag to the required length so that it can be placed all the way round

the rear of the cooling unit once.

Start by positioning the sealing tape on the bottom

edge, so that the joint between the two ends of the

sealing tape is likewise on the lower edge of the unit.

Carefully stick the sealing tape as close to the edge as

possible on the rear of the cooling unit.

Screw the four threaded bolts into the blind nuts in the

corners at the rear of the cooling unit.

Fig. 8: Clip at the rear of the cooling unit

Key

1 Clip

2 Rear of cooling unit

12 Rittal enclosure cooling unit

Page 13

Lift up the cooling unit, preferably from a lifting eye using suitable lifting gear, and initially set the cooling unit

down with the two bottom threaded bolts on the door

or side panel of the enclosure.

If transportation by crane is not possible, lift the cooling unit into the mounting cut-out in the same way using the handle.

Fig. 9: Threaded bolt in door cut-out

Key

1 Inside of enclosure door

2 Threaded bolts at bottom (2x)

3 Cooling unit on the outside of the enclosure door

5 Installation

Fig. 11: Corner brackets on the threaded bolts

Key

1Corner bracket

2 Threaded bolt

Next, attach the two corner brackets to the threaded

bolts at the bottom and secure with the corresponding

nuts.

EN

Slide the cooling unit into the mounting cut-out at the

top until the clip behind the cut-out latches home.

Fig. 10: Clip in mounting cut-out

Key

1 Inside of enclosure door

2 Clip

Attach the two corner brackets to the threaded bolts

at the top and secure with the corresponding nuts.

Fig. 12: Threaded bolts at rear

Key

1 Threaded bolts (4x)

2 Fastening clamps (6x)

3 Rear of cooling unit

4 Cooling unit in front of enclosure door

Insert the six fastening clamps into the rear of the cool-

ing unit.

Rittal enclosure cooling unit 13

Page 14

5 Installation

EN

These fastening clamps ensure that the cooling unit is

directly in contact with the mounting cut-out of the enclosure door over the entire height.

If applicable, re-attach the door or side panel including

cooling unit to the enclosure, if not mounted directly

on the enclosure.

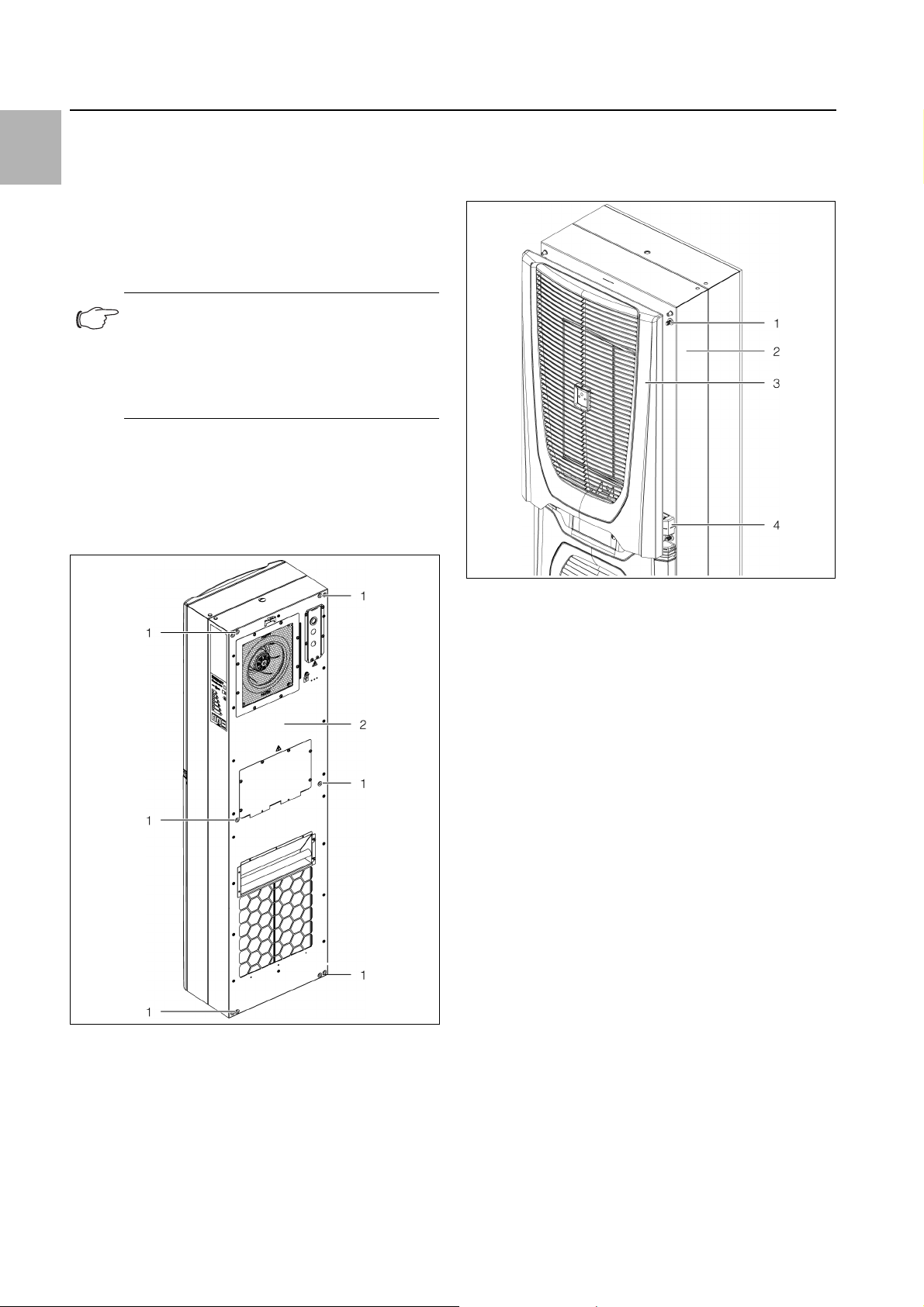

5.3.5 Mounting the cooling unit externally on a 500 mm deep enclosure

Note:

The description in this section applies to ex-

ternal mounting of the cooling unit on the

side panel of a 500 mm deep enclosure. External mounting on deeper enclosures is also

possible with this type of installation.

In principle, external mounting on the side panel is carried out in the same way as described in section 5.3.4

"External mounting of the cooling unit". However, please

note the following differences:

– Six threaded bolts are required for installation, rather

than four.

5.3.6 Partial internal mounting of the cooling unit

At the front of the cooling unit, pull the top louvred

grille away from the mounting clips on the cover, and

place or lay it down somewhere safe.

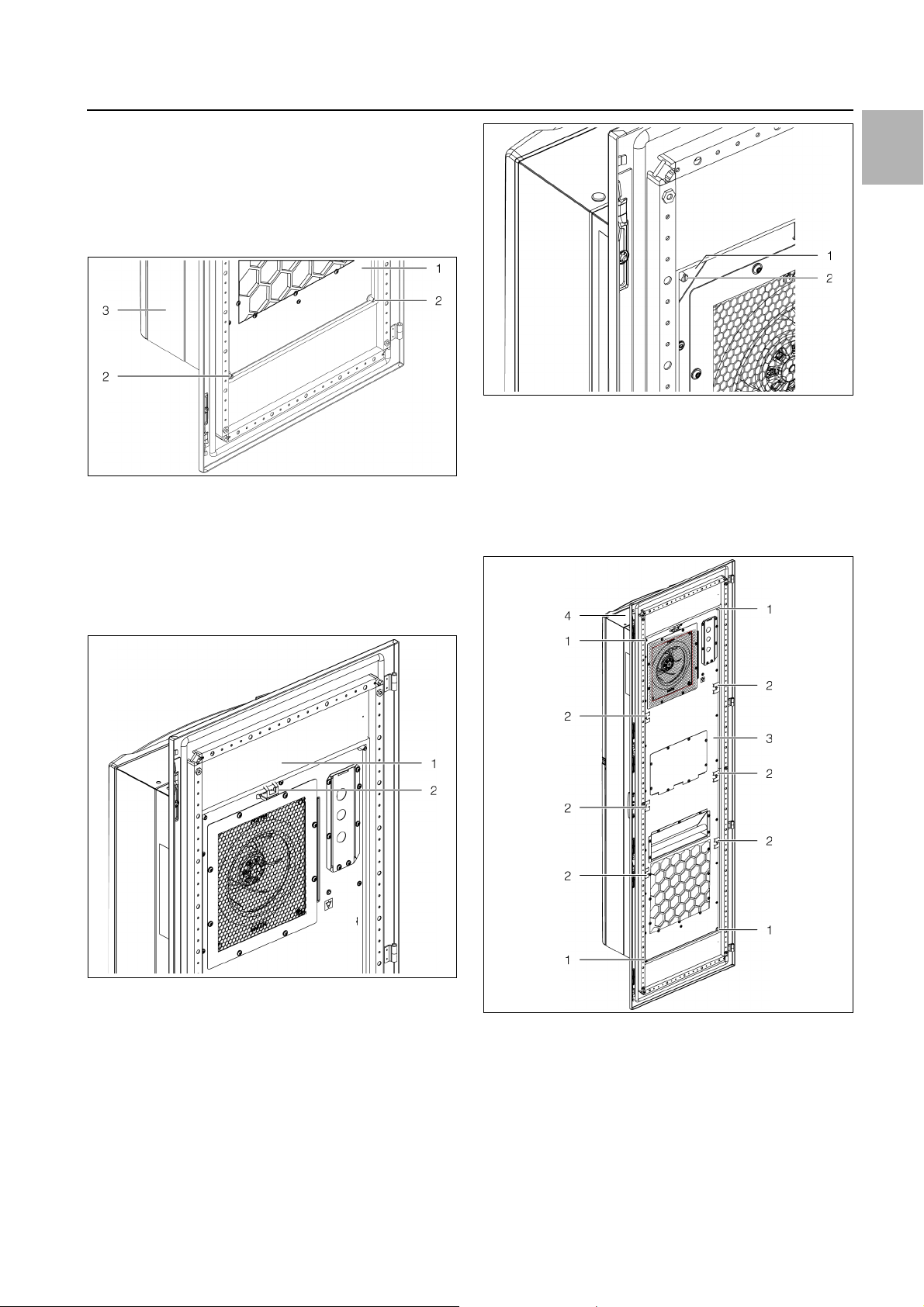

Fig. 13: Threaded bolts at rear

Key

1 Threaded bolts (6x)

2 Rear of cooling unit

Fig. 14: Remove the top louvred grille

Key

1Mounting clip

2Cover

3 Top louvred grille

4 Infill panel on cooling unit

Flip open the bottom louvred grille below the infill pan-

el.

Release the two stays in the hinge mechanism at the

top from the brackets attached to the cover of the

cooling unit.

– The unit with the threaded bolts is lowered into the rel-

evant holes, rather than on the mounting cut-out.

– No fastening clamps are fitted into the rear of the unit.

14 Rittal enclosure cooling unit

Page 15

Fig. 15: Attachments on hinge mechanism

Key

1Cover

2 Stays in hinge mechanism

3 Bracket

4 Bottom louvred grille

5 Installation

Fig. 17: Remove the infill panel

Key

1 Mounting clips

2Cover

3 Infill panel

On the rear of the display, disconnect both of the con-

nectors (PE conductor and connection) and remove

the infill panel completely from the cooling unit.

EN

Pull the bottom louvred grille forwards out of its hold-

ers, and place or lay it down somewhere safe.

Fig. 16: Bottom holders of louvred grille

Key

1 Bottom louvred grille

2Holders

Gently pull the infill panel including display forwards to

release it from the mounting clips on the cover.

Fig. 18: Connection point on the rear of the cooling unit

Key

1 Connection point

Place the infill panel somewhere safe.

Carefully push the connector including connection cable inwards through the cable gland in the cover.

Fig. 19: Cable gland in the cover

Key

1Cover

2 Cable gland

Rittal enclosure cooling unit 15

Page 16

5 Installation

EN

Caution!

The cooling unit will only be stable as

long as the cover and chassis are connected. For this reason, be sure to brace

the chassis, in particular, to prevent it

from falling over before removing the

cover.

Loosen the four threaded bolts in the corners of the

cover which connect the cover to the chassis.

Carefully pull the cover forwards (approx. 5 cm) from

the chassis.

The PE conductor connection between the cover and

the chassis is located on the right-hand side, approximately halfway up.

Fig. 21: Clip on the top edge of the chassis

Key

1Chassis

2 Clip in chassis

3 Seal

Lift up the chassis, preferably with a lifting eye using

suitable lifting gear, and insert it into the mounting cutout in the door or side panel of the enclosure from the

inside with the edge fold at the bottom of the chassis.

If transportation by crane is not possible, lift the chassis into the mounting cut-out in the same way using

the handle.

Fig. 20: PE conductor connection (viewed from behind)

Key

1 PE conductor connection, cover

2 PE conductor connection, chassis

Pull the flat-pin connector of the PE conductor off in-

wards, preferable on the chassis.

Remove the cover completely from the chassis, and

place or lay it down somewhere safe.

There is a clip prefitted to the top edge of the chassis

on the front. This clip will later prevent the chassis from

falling out of the mounting cut-out before it is properly

secured with the threaded bolt.

Fig. 22: Edge fold at bottom of chassis

Key

1 Edge fold on chassis (towards cover)

2 Outside of enclosure door

Push the chassis into the mounting cut-out at the top

until the clip behind the cut-out latches home.

16 Rittal enclosure cooling unit

Page 17

Fig. 23: Clip on the top edge of the chassis

Key

1 Outside of enclosure door

2 Clip in chassis

Make sure that the clip behind the cut-out is fully

snapped in towards the top.

5 Installation

Slide the flat-pin connector of the PE conductor into

place, and ensure that the cover and chassis are connected.

Warning!

The PE conductor which connects the

cover and the chassis must be connected to both connectors in all cases. Otherwise, there is a risk of injury from

electric shock if the unit connection was

faulty or defective.

Place the cover fully over the chassis, and connect the

cover and the chassis using the four threaded bolts in

the corners of the cover.

EN

Fig. 24: Mounting of the wedge element

Key

1 Outside of enclosure door

2 Clip in chassis

3 Wedge element

Please also insert the wedge element from the exterior

up to the stop in order to fasten the clip in the upper

position.

Fig. 25: Fully inserted wedge element

Set the cover down at the front near the chassis, and

thread the connection cable of the display outwards

through the cable gland in the cover.

Fig. 26: Cover on the chassis

Key

1 Threaded bolts (4x)

2 Outside of enclosure door

3Chassis

4Cover

Connect the display to the connector and insert the

entire infill panel on the cooling unit.

Place the bottom louvred grille onto the holders and

secure the two stays at the top of the hinge mechanism into the brackets attached to the cover of the

cooling unit.

Finally, replace the top louvred grille onto the cover.

If applicable, re-attach the door or side panel including

cooling unit to the enclosure, if not assembled directly

on the enclosure.

Rittal enclosure cooling unit 17

Page 18

EN

5 Installation

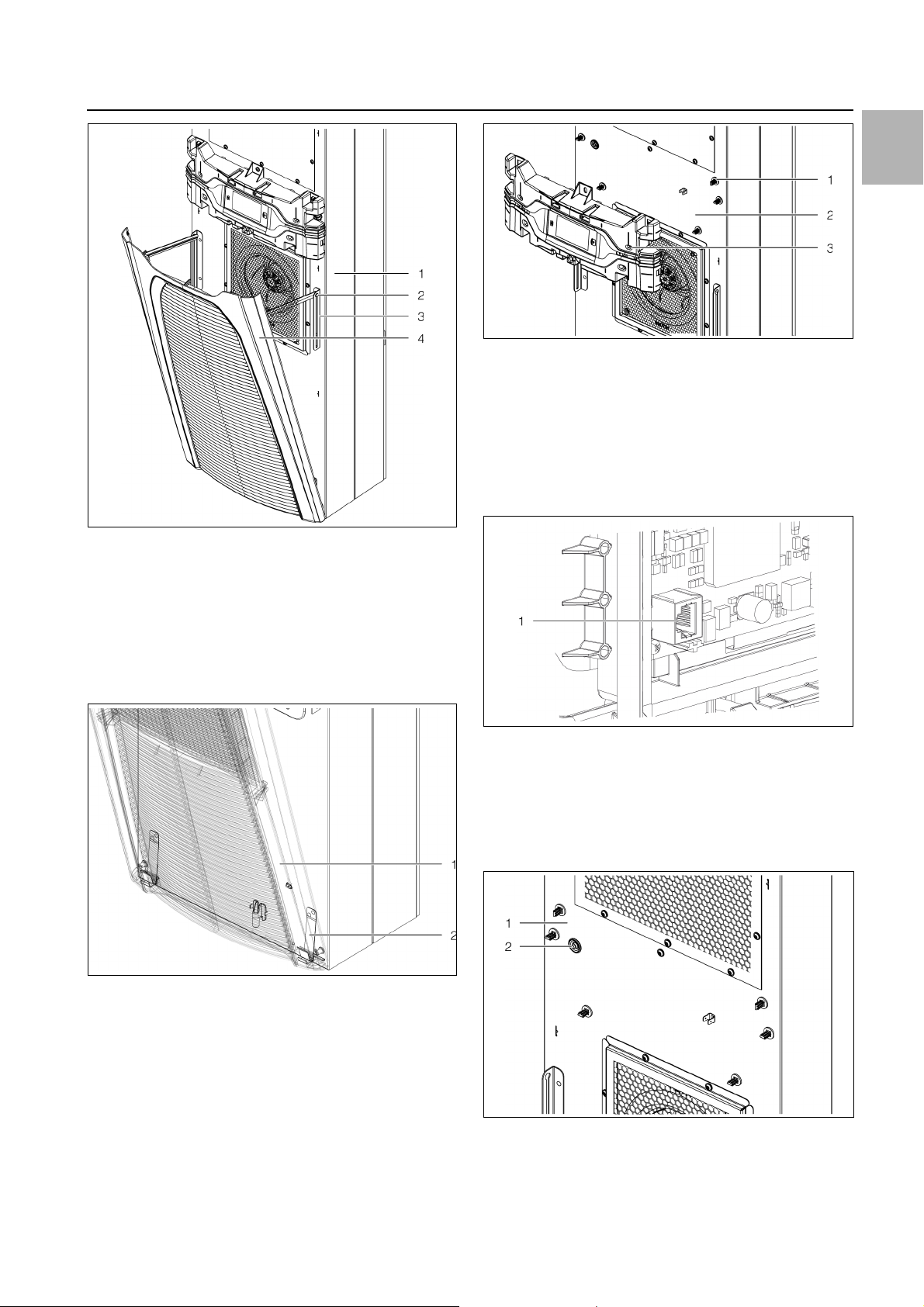

5.3.7 Full internal mounting of the cooling unit

First, dismantle the top and bottom louvred grilles as

well as the infill panel and the display in the same way

as for partial internal mounting (see section 5.3.6 "Partial internal mounting of the cooling unit").

Cut the sealing tape in the dispatch bag to the required length so that it can be placed all the way round

the cover once.

Start sticking the sealing tape at the bottom edge, so

that the joint between the two ends of the sealing tape

is likewise on the bottom edge of the unit.

Carefully stick the sealing tape as close as possible to

the edge of the cover.

On the front top edge of the cover, push the clip included with the supply into the relevant hole.

This clip will prevent the cooling unit from falling out of

the mounting cut-out later on before it is properly secured with the threaded bolt.

Fig. 28: Bracket at the bottom of the cover

Key

1 Bracket in mounting cut-out

2 Outside of door

Push the cooling unit into the mounting cut-out at the

top until the clip behind the cut-out latches home.

Fig. 27: Clip at top edge of cover

Key

1Cover

2 Clip on the cover

Lift up the cooling unit, preferably with a lifting eye us-

ing suitable lifting gear, and insert it into the mounting

cut-out in the door or side panel of the enclosure with

the two brackets at the bottom of the cover.

If transportation by crane is not possible, lift the cooling unit into the mounting cut-out in the same way using the handle.

Fig. 29: Clip at top edge of cooling unit

Key

1 Outside of enclosure door

2 Clip in mounting cut-out

Mount the corner brackets onto the top two threaded

bolts from the outside.

18 Rittal enclosure cooling unit

Page 19

Fig. 30: Corner brackets on top threaded bolts

Key

1 Threaded bolt

2Corner bracket

Mount the L-shaped brackets onto the bottom two

threaded bolts from the outside.

5 Installation

EN

Fig. 31: L-shaped brackets on bottom threaded bolts

Key

1 L-shaped bracket

2 Threaded bolt

Next, working from the outside of the enclosure, se-

cure the four threaded bolts in the corners of the cover

using the corresponding nuts from the dispatch bag.

Fig. 32: Mounting points on cooling unit

Key

1 Threaded bolts with nuts (4x)

2 Fastening clamps

3 Cooling unit behind enclosure door

4 Front of cooling unit (without louvred grille)

Insert the six fastening clamps into the cover of the

cooling unit.

These fastening clamps ensure that the cooling unit is

directly in contact with the mounting cut-out of the enclosure door over the entire height.

Connect the display to the connector and fit the entire

infill panel to the cooling unit.

Place the bottom louvred grilles onto the holders and

secure the two stays of the top hinge mechanism into

the brackets attached to the cooling unit cover.

Finally, replace the top louvred grille onto the cover.

If applicable, re-attach the door or side panel including

cooling unit to the enclosure if not mounting directly on

the enclosure.

5.3.8 Connect the condensate water discharge

There is a condensate water evaporator fitted in the external circuit of the cooling unit. With an enclosure connected, this condensate water evaporator may typically

evaporate condensate water volumes of up to 100 ml/h.

If larger quantities of condensate water are produced, a

condensate water discharge hose may additionally be

fitted. This hose allows condensate water to be routed

out of the cooling unit pressurelessly. A suitable hose is

available as an accessory from Rittal (see section 13

"Accessories").

Please follow the instructions given below:

Rittal enclosure cooling unit 19

Page 20

5 Installation

EN

– The hose must be laid with an adequate and constant

gradient to prevent siphoning.

– The hose must be laid without any kinks.

– If extended, the cross-section of the hose must not be

reduced.

– The hose should be routed to a drain or external con-

densate water evaporator by the customer.

Fig. 33: Connection for condensate water discharge hose

Key

1 Connection point

2 Hole in enclosure for hose

rated values may be taken from section 10 "Technical

specifications" below.

– Low-noise potential equalisation must be guaranteed

with the mains connection.

– In order to prevent EMC interference, the unit should

be incorporated into the existing potential equalisation

system with a larger cable cross-section (10 mm²).

Overvoltage protection and supply line load

– The unit does not have its own overvoltage protection.

Measures must be taken at the supply end by the

switchgear manufacturer or operator to ensure effective protection against lightning and overvoltage. The

limits specified in standard UL/IEC/EN 60335-2-40

must be observed.

– The units are classified as overvoltage category III. The

mains voltage must not deviate by more than the tolerance specified in section 10 "Technical specifica-

tions".

– The discharge current may exceed 3.5 mA.

– The units are high-voltage tested ex works. An addi-

tional high voltage test must only be carried out with a

DC voltage supply source (1500 VDC max.).

Connect a suitable hose to the condensate water discharge nozzle and secure using a hose clip.

Lay the hose as per the instructions above.

5.4 Electrical connection

5.4.1 Notes on electrical installation

When carrying out the electrical installation, it is important to observe all valid national and regional regulations as well as the provisions of the responsible

power supply company.

– Electrical installation must only be carried out by a

qualified electrician who is responsible for compliance

with the existing standards and regulations.

– The mains infeed and the signal cable must be of a

shielded design. The shielding can be connected to

the earth lug provided in the connection area of the

mains connector.

– All cables routed into the wiring compartment have to

be insulated for the maximum voltage of the power

supply.

Connection data

– The connected voltage and frequency must corre-

spond to the ranges stated on the rating plate. The

units support multiple voltages.

– The cooling unit must be connected to the mains via

an all-pole disconnect to overvoltage category III (IEC

61058-1).

– No additional temperature control may be connected

upstream of the unit at the supply end

– Install a pre-fuse to match the supply voltage used and

the specific electrical output of the cooling unit. The

Three-phase devices

– There is no need to observe a counterclockwise or

clockwise phase rotation when making the electrical

connection for inverter devices in the three-phase ver-

sion. The electronics incorporated into the devices au-

tomatically create the required phase rotation.

– In three-phase devices, the absence of a phase is de-

tected, and the device is switched off.

– Outgoing equipment is monitored by the inverter, and

deactivated in the event of a malfunction in the elec-

tricity supply.

Door limit switch

– Each door limit switch can only be assigned to one

cooling unit.

– Several door limit switches may be operated in parallel

with one cooling unit.

– The minimum cross-section for the connection cable

is 0.3 mm² for a cable length of 2 m.

– The line resistance to the door limit switch must not

exceed a maximum of 50 Ω.

– The maximum admissible line length is 10 m.

– The door limit switch only supports a floating connec-

tion; no external voltages.

– The contact of the door limit switch must be closed

when the door is open.

– The safety extra-low voltage for the door limit switch is

provided by the internal power pack: Current approx.

5mA DC.

Connect the door limit switch to terminals 5 and 6 of

the signal connector.

20 Rittal enclosure cooling unit

Page 21

Fig. 34: Connections at rear

Key

1 Connection for communication module (X3)

2 Connection for signal connector (X2)

3 Connection for mains connector (X1)

4 Bolt (here with fitted earth clamp)

Potential equalisation

If the unit is to be integrated into the customer's existing

potential equalisation system for EMC reasons, a conductor with a larger nominal cross-section of at least

10 mm² can be connected to the potential equalisation

connection point (attachment points) on wall-mounted

cooling units. The connection point is labelled with the

required switch symbol.

5 Installation

Fig. 36: Potential equalisation arrangement

Key

1 Ring terminal with PE conductor

2 Contact washer

3Washer

4 Screw

Note:

According to the standard, the PE conductor

in the mains connection cable is not classed

as an equipotential bonding conductor.

5.4.2 Install the power supply

Note:

– The mains supply must be of a shielded

design with preferred EMC types in order

to achieve the values required by the

standard.

– The earth clamp may be used to contact

the cable shielding with the enclosure inside the connection box (fig. 34, item 4).

Remove the mains connector from the dispatch bag

and connect to the mains as shown on the connection

diagram (fig. 37 or fig. 38).

EN

Fig. 37: Circuit diagram SK 3186930 and SK 3187930

Fig. 35: Connection point for potential equalisation

Key

1 Connection point

Attach the potential equalisation to the unit's connec-

tion point using the screw, washer and contact washer.

Rittal enclosure cooling unit 21

Page 22

EN

5 Installation

Fig. 38: Circuit diagram SK 3188940 and SK 3189940

There is also a cover for the connection box included in

the dispatch bag.

Insert the EMC cable gland included with the supply

into the openings in the cover to ensure adequate

strain relief for the connection cable.

Close the connection box with the cover.

Cover any unused openings in the cover with sealing

bungs.

When connecting the cooling unit in accordance with

NFPA 70 (NEC):

Use a conduit fitting instead of the cable gland.

Use copper conductors only to connect the supply cable to the mains connector.

Micro-USB interface

A micro-USB interface is located on the front, to the right

of the display. A tablet or laptop may be connected here

for easy configuration of the unit.

Connect a tablet or laptop with installed RiDiag soft-

ware to the micro-USB interface.

No other USB devices will be detected on this connec-

tion.

RS 485 interface

An RS 485 interface is located on the rear of the connection box. The communication module with which you

can connect the cooling unit to a monitoring system

(Rittal CMC), may be connected here.

Connect the communication module (available as an

accessory) to the RS 485 interface.

Note:

A direct connection to the cooling unit via the

RS 485 interface is not possible.

NFC interface

The cooling unit may be accessed with a smartphone

app via the integral NFC interface. Access is only possible with the app supplied by Rittal.

5.4.3 Connect the alarm relays

System messages from the cooling unit may be output

to an external signal source via two floating relay outputs.

Note:

The factory setting of the relay outputs in their

de-energised state is NO (Normally Open).

Connect a suitable connection cable to the connection terminals 1 (Alarm K1) and/or 3 (Alarm K2) of the

signal connector (X2).

Configure the alarm relays you wish to use to output

error messages (see section 7.4.2 "Alarm relays").

AC

cos φ = 1

I max. = 2 A

U max. = 250 V

Tab. 2: Contact data

5.4.4 Interfaces

The cooling unit has the following interfaces for communicating with external systems:

– Micro-USB interface on the front

– RS 485 interface on the rear

–NFC interface

22 Rittal enclosure cooling unit

Page 23

6 Commissioning

Note:

The oil must collect in the compressor in or-

der to ensure adequate lubrication and cooling. For this reason, do not operate the

cooling unit for at least 30 minutes after assembling the equipment.

Observe the aforementioned waiting period of at least

30 minutes before commissioning the unit after assembly.

Next, switch on the voltage supply to the cooling unit.

The Rittal logo will initially appear on the display, followed a short time later by the start screen.

You can now make your individual settings on the unit,

e.g. set the temperature or assign the network identifier, etc. (refer to chapter 7 "Operation").

Note:

It is not necessary to carry out leak or pressure tests on the cooling unit prior to commissioning. Rittal has already done this in the

factory.

6 Commissioning

EN

Rittal enclosure cooling unit 23

Page 24

7 Operation

EN

7Operation

7.1 General

The cooling unit is equipped with a touch function display for making basic settings and displaying error messages. This is an industrial-grade touch display which is

pressure-sensitive and may therefore be operated with

gloves.

As well as operating directly on the cooling unit itself,

there is also a smartphone app available. This offers almost the same functions as the actual display, and additionally provides extended explanations of error messages, as well as the option of contacting the Rittal Service team directly.

7.2 Layout of the display

The display is divided into a top section on a dark background, and a bottom section with the menu bar. This

layout is always identical, but the content of the two sections will vary according to the menu selected.

7.2.1 Start screen

The start screen is always displayed while the cooling

unit is in normal operation, provided there are no error

messages.

Item Description Possible icons

5 USB connection (if

connected)

6 Self-test (if initiated)

7 NFC connection (max.

120 seconds after connecting)

8 Type of cooling

9 Control based on ...

10 External sensor

11 Information menu

12 System messages

(where applicable)

13 Service icon (if re-

quired)

Fig. 39: Layout of the start screen

Key

Item Description Possible icons

1 Internal temperature

display (2-digit °C/3digit °F)

2 EER scale: Range

0...20 / current average

EER value of the last 24

hours

3 Ti scale: Range 20 ...60

/ value: Average enclosure internal temperature of the last 24 hours

4 Display temperature

unit

Numbers from 0-9

14 Configuration

Tab. 3: List of all icons with descriptions

Type of cooling

The current form of cooling is indicated by one of the following four icons.

Symbol Parameters

Cooling in compressor mode without support

from the heat pipe

Cooling in compressor mode with support

from the heat pipe

Cooling via the heat pipe only

No cooling

Tab. 4: Possible icons for the current type of cooling

7.2.2 Changing a parameter value

If a parameter value is changed, the display including the

menu bar will also change.

Tab. 3: List of all icons with descriptions

24 Rittal enclosure cooling unit

Page 25

Fig. 40: Screen for changing a parameter value

Key

1Main screen

2Control bar

The currently selected parameter value is displayed in

the centre of the main screen. To change this value, you

always proceed in the same way, as described below

with the example of adjusting the set temperature:

On the start screen, click on the "Configuration" button.

Enter the PIN to gain access to the lower-level screen

pages of the "Configuration" zone.

"22" is the default PIN.

Click on the "Temperature" symbol.

Click on the "Control mode" symbol.

Select your preferred control mode from the display.

Change the setting to the required temperature using

the "Up" and "Down" arrows.

Alternatively, you can also select the one of the displayed higher or lower values directly.

Finally, confirm the set value with "OK".

Exit this screen page with the "Back" button.

7.3 Information menu

Click on the "Information" symbol to display a list of

lower-level screen pages.

Symbol Parameters

7 Operation

7.3.1 Temperature information

Click on the "Temperature information" symbol.

The ambient temperature and internal temperature are

displayed, in each case as an average for the last 24

hours of operation.

Symbol Parameter

Ambient temperature

Average ambient temperature (external temperature) over the last 24 hours of operation.

Internal temperature

Average internal temperature over the last 24

hours of operation.

Tab. 6: "Temperature information" zone

7.3.2 Device information

Click on the "Device information" symbol.

A list of general information about the device will be

displayed.

Page through the list using the "Up" and "Down" arrows.

Symbol Parameter

Serial number

Production date YYYY-MM-DD

Hardware Release x.xx.xx

Firmware Release x.xx.xx

Software Release x.xx.xx

EN

Temperature information

Device information

Efficiency information

Tab. 5: "Information" zone

Tab. 7: "Device information" zone

Rittal enclosure cooling unit 25

Last updated YYYY-MM-DD

Last serviced YYYY-MM-DD

Customer device name

Name assigned to the cooling unit by the customer. This title can be assigned using the

RiDiag software or the Blue e+ app to distinguish between individual units.

Current control mode

Page 26

7 Operation

EN

Symbol Parameter

If the unit is configured as a "slave": Slave number.

Tab. 7: "Device information" zone

7.3.3 Efficiency information

Click on the "Efficiency information" symbol.

The average energy efficiency ratio (EER) for the last

24 hours of operation will be displayed. The energy efficiency ratio is the ratio of the cooling output generated to the electrical power used.

Symbol Parameter

Efficiency information

Average energy efficiency ratio (EER) of the last

24 hours of operation.

Tab. 8: "Efficiency information" zone

7.4 Configuration menu

Click on the "Configuration" symbol.

A screen page will appear asking you to enter the PIN

in order to access the lower-level screen pages.

7.4.1 Temperature

Click on the "Temperature" symbol to display a list of

lower-level screen pages.

Symbol Parameter

Change unit

Set the unit "°C" or "°F"

Control mode

Alarm limit

Temperature limit which will trigger an alarm

message if exceeded.

Tab. 10: "Temperature" zone

Unit

All temperature values for the unit may be displayed either in degrees Celsius "°C" or degrees Fahrenheit "°F".

Click on the "Change unit" symbol.

Change the required unit ("°C" or "°F") using the "Up"

or "Down" arrows.

Confirm your entry with "OK".

Note:

"22" is preset in the factory as the default

PIN.

For the first digit, page through the digits "0" to "9" using the "Up" and "Down" arrows until the required digit

appears in the box.

Confirm your selection with "OK".

For the second digit, once again page through the digits "0" to "9" using the "Up" and "Down" arrows until

the required digit appears in the box.

Confirm your selection with "OK".

A list of lower-level screen pages will be displayed.

Symbol Parameter

Temperature

Settings for set temperature and control mode

Alarm relay

Settings for the alarm relays.

Display language

Choice of language for display texts.

Self-test

Perform a self-test.

Tab. 9: "Configuration" zone

Control mode

The cooling unit is able to control cooling output according to one of the following two temperature values:

– Internal temperature: The temperature at which air

is drawn out of the enclosure into the cooling unit.

– External sensor: The temperature measured with an

external temperature sensor at a so-called hot spot in

the enclosure.

Click on the "Control mode" symbol.

The setpoint for the currently set control mode is dis-

played.

Choose your preferred control mode by selecting it

from the display:

Symbol Parameter

Internal temperature

External sensor

Tab. 11: "Control mode" zone

The corresponding symbol for the chosen control mode

is likewise displayed on the overview page.

Note:

The external temperature sensor is available

as accessory from Rittal.

26 Rittal enclosure cooling unit

Page 27

Change the setpoint using the "Up" and "Down" arrows or select the required temperature directly.

Setting range: 20°C (68°F)…50°C (122°F)

Factory setting: 35°C (95°F)

Confirm your entry with "OK".

Symbol Parameters

Normally Open

Switch the alarm relay as a normally open contact.

7 Operation

EN

Alarm limit

This limit is used for an alarm message. The set value

must therefore be at least 3 K and up to a maximum of

15 K above the actual setpoint to which the cooling unit

is set.

For example:

– Setpoint: 35°C (95°F)

– Alarm limit min.: 38°C (100°F)

– Alarm limit max.: 50°C (122°F)

The setpoint must likewise be modified accordingly if the

control mode is changed.

Click on the "Alarm limit" symbol.

Change the setpoint using the "Up" and "Down" arrows or select the required temperature directly (Factory setting: 38°C (100°F)).

Confirm your entry with "OK".

7.4.2 Alarm relays

There are two floating relay outputs in the connection

box on the rear of the unit, which may be used to output

system messages from the cooling unit to an external

signal source (see section 5.4.3 "Connect the alarm relays"). The relay outputs may be configured here.

Click on the "Alarm relay" symbol to display a list of

lower-level screen pages.

Symbol Parameter

Normally Closed

Switch the alarm relay as a normally closed

contact.

Tab. 13: Switch logic of the alarm relay

Note:

The factory setting of the relay outputs in their

de-energised state is NO (Normally Open).

List of functions

This is where you specify which error messages should

lead to switching of the respective relay output.

Click on the "Relay 1" or "Relay 2" symbol, and select

the alarm relay to which you wish to assign a function.

From the list of errors, select the function which should

cause the previously selected relay output to switch.

If applicable, assign further functions to the relay output, and the output will then be switch if at least one

of the assigned functions leads to an error message.

Confirm your entry with "OK".

If applicable, configure the other relay output with other functions.

Symbol Parameter

Assign relay 1

Change NO/NC

Switch the alarm relay as a normally closed or

normally open contact.

List of functions

Allocation of a function to the respective alarm

relay.

Tab. 12: "Alarm relay" zone

Note:

For the factory setting of alarm relay alloca-

tion see section 7.6 "List of system messages" (Tab. 15).

Change NO/NC

The switch logic of the relay output, i.e. whether it is to

be used as a normally closed or normally open contact,

may be set here.

Click on the "Change NO/NC" symbol.

Choose your preferred switch logic by selecting it from

the display.

Confirm your entry with "OK".

Assign relay 2

Tab. 14: List of functions

7.4.3 Language settings

All the unit's displays may be shown in different languages. The languages "English" and "German" are available

as standard on the unit. Other languages may be installed using the RiDiag software or with the aid of an online tool available on the Rittal website.

Click on the "Display language" symbol.

Page through to the required language using the "Up"

and "Down" arrows.

Confirm the chosen language with "OK".

The language will change over immediately, and all

menu displays will appear in the chosen language.

7.4.4 Self-test

In the event of a malfunction in the unit which fails to produce an error message, it may be useful to check the

key functions of all components with a self-test. You

Rittal enclosure cooling unit 27

Page 28

7 Operation

EN

may continue to operate the unit as normal while the

self-test is being carried out.

Click on the "Self-test" symbol.

Confirm the start of the self-test with "OK".

While the self-test is being carried out, a progress indicator will appear on the display. Once the test is complete, either the message "Unit OK" or "Check error" will

be displayed.

If applicable, use the error list to determine which malfunction applies.

7.5 System messages

We distinguish between three different types of system

messages on the unit:

– Malfunctions

–Errors

– Servicing

If a corresponding message applies, the "System messages" symbol is displayed in the menu bar (fig. 39,

item 13). A list of all possible system messages may be

found in section 7.6 "List of system messages".

Click on the "System messages" symbol.

A list of all active system messages will be displayed.

The individual messages are arranged in ascending order as they occur according to the above three categories.

If an error message can only be resolved by the Rittal

Service team, the "Service" symbol will additionally

appear after the error message.

In such cases, please contact Rittal Service (see section 14 "Customer service addresses").

7.5.1 Occurrence of a malfunction

In the event of a malfunction, the start screen will be superimposed with an error message.

If the malfunctions cannot be resolved by the operator

himself, the Service symbol will additionally be displayed

(Fig. 39, item 14).

Contact the Rittal Service team if you are unable to re-

solve the malfunction yourself (see section 14 "Cus-

tomer service addresses").

7.5.2 Display in case of errors

If errors have occurred or servicing is required, the "System messages" symbol will appear in the menu bar (see

section 7.5 "System messages").

Most system messages are reset automatically once the

fault has been resolved.

Fig. 42: Screen showing error messages

Key

1 "Errors" menu

2 Error message

If an error message applies that cannot be resolved by

the operator himself and which is not reset automatically, the "Service" symbol will appear after the error message and in the control bar next to the symbol for system

messages (fig. 43, item 2).

Fig. 43: Screen showing error messages

Fig. 41: Screen in the event of a malfunction

Key

1Superimposed

2 Menu bar in red

The start screen is superimposed with a message in the

following three cases:

1. There is a malfunction on the unit itself.

Key

1 "Errors" menu

2 Error message

3 "Return" button

Contact Rittal Service (see section 14 "Customer ser-

vice addresses").

Acknowledge the error message by pressing the "Re-

turn" button.

2. There is a malfunction on one of the units in the master-slave combination.

3. The enclosure door is open and a connected door

contact is emitting a corresponding message.

28 Rittal enclosure cooling unit

Page 29

7 Operation

7.6 List of system messages

The applicable error messages are displayed with the

Contact details for the Rittal Service team can be found

in section 14 "Customer service addresses".

corresponding symbol in the Errors list (see section 7.5

"System messages"). Extended information for resolving individual faults may be found in this section.

System message Alarm relay output

(factory setting)

Door open – Please close the enclosure door and check the door contact switch.

Interior temperature too

high

Change filter – The filter mat in your cooling unit is dirty. Please replace or clean the filter

Clean condenser – The condenser in your cooling unit is dirty. Please remove the top lou-

– The measured interior temperature exceeds the set alarm limit for your

Troubleshooting measures/solutions

The error message will terminate automatically approximately 30 seconds after it has been resolved.

cooling unit.

Please check any maintenance and error messages, and check the rating of your cooling unit. For any further questions, please contact Rittal

Service directly.

mat and confirm this by pressing reset in the list of system messages on

the cooling unit display.

vred grille and clean the heat exchanger, e.g. using compressed air.

The error message will terminate automatically approximately 30 seconds after it has been resolved.

EN

Air routing EC 1 The air inlet or outlet in the external circuit is blocked. Please remove the

blockage and ensure that minimum distances from the air inlet or outlet

are observed.

Air routing IC – The air inlet or outlet in the internal circuit is blocked. Please remove the

blockage and ensure that minimum distances from the air inlet or outlet

to components inside the enclosure are observed.

EEV defective – A malfunction has been detected in the electronic expansion valve.

Please contact your Rittal Service.

External temperature too

high

Refrigerant shortage 2 Your cooling unit is reporting a lack of cooling in the active refrigerant cy-

Condensate warning 1 Please check whether the condensate water drain of your cooling unit is

– Your cooling unit is being operated outside of the admissible ambient

temperature. Please ensure that the ambient temperature does not exceed the admissible range (-20°C…+60°C).

cle. Please contact the Rittal Service team immediately. The system message will need to be acknowledged manually once the cause has been

rectified.

blocked, and remove the blockage. If you are unable to resolve the fault,

please contact your Rittal Service team.

Tab. 15: Error messages

Rittal enclosure cooling unit 29

Page 30

7 Operation

EN

System message Alarm relay output

(factory setting)

Internal fan Alarm 1 1 The fan in the internal circuit of your cooling unit is blocked. Please check

Internal fan Alarm 2 1 The fan in the internal circuit of your cooling unit is defective. Please re-

External fan Alarm 1 1 The fan in the external circuit of your cooling unit is blocked. Please check

External fan Alarm 2 1 The fan in the external circuit of your cooling unit is defective. Please re-

Inverter cooler – The cooling body of the inverter in your cooling unit is dirty. Please re-

Troubleshooting measures/solutions

if you can see a blockage and remove it. If no blockage is visible, please

replace the fan in the internal circuit. The required spare part may be ordered directly from Rittal using the Blue e+ app. Please use the contact

form "Generate service order".

place the fan in the internal circuit. The required spare part may be ordered directly from Rittal using the Blue e+ app. Please use the contact

form "Generate malfunction report".

if you can see a blockage and remove it. If no blockage is visible, please

replace the fan in the external circuit. The required spare part may be ordered directly from Rittal using the Blue e+ app. Please use the contact

form "Generate service order".

place the fan in the external circuit. The required spare part may be ordered directly from Rittal using the Blue e+ app. Please use the contact

form "Prepare malfunction report".

move the filter grille and the cover at the front and clean the cooling body,

e.g. using compressed air.

The error message will terminate automatically approximately 30 seconds after it has been resolved.

Compressor defective 2 The compressor in your cooling unit is reporting a malfunction. Please

contact the Rittal Service team immediately.

Sensor xx defective 1 Sensor xx in your cooling unit is reporting a sensor failure. Please contact

the Rittal Service team.

Ext. sensor missing 1 The external sensor is not connected or has a malfunction. Please check

the connection or select another control mode.

Check voltage 1 You are operating your cooling unit outside of the admissible voltage

ranges. Please check the power supply to the cooling unit and observe

the specifications on the rating plate. With a three-phase infeed, please

also check that all three phases are correctly connected.

Electronic fault 2 The electronics in your cooling unit are reporting an electronic fault.

Please contact the Rittal Service team.

Check parameters – Due to an error, the cooling unit has been reset to the factory defaults.

Please check the current messages or contact your Rittal Service team.

Inverter fault 2 The inverter in your cooling unit is reporting a malfunction. Please contact

the Rittal Service team.

Tab. 15: Error messages

30 Rittal enclosure cooling unit

Page 31

7 Operation

System message Alarm relay output

(factory setting)

Emergency operation active

Compressor phase 2 The compressor in your cooling unit is reporting a malfunction. Please

Overload 1 Please check the rating of your cooling unit. For any further questions,

Alarm active cooling – The active cooling function of your unit is defective. Please contact the

Tab. 15: Error messages

– Due to a previous error your cooling unit is only operating with a perfor-

Troubleshooting measures/solutions

mance of 50%. Please remedy this error and/or contact your Rittal Service team.

contact your Rittal Service team.

please contact your Rittal Service team directly.

Rittal Service team immediately, and/or check the rating of your cooling

unit.

EN

Rittal enclosure cooling unit 31

Page 32

EN

8 Inspection and maintenance

8 Inspection and maintenance

8.1 Safety instructions for maintenance

work

The unit must be opened in order to carry out maintenance work. There is a risk of injury from electric shock.

Switch off the power supply before carrying out maintenance work.

Secure the power supply to prevent it being switched

back on accidentally.

Disconnect the electrical connection cable of the cooling unit from the power supply at the connection box.

Wait at least five minutes before handling the unit. Only

then will the capacitors built into the unit have discharged themselves.

When handling the enclosure, be aware of any exposed power sources, where applicable.

If possible, disconnect the entire enclosure from the

power.

There is also a risk of injury from sharp edges, such as

the louvres of the heat exchanger.