Page 1

Technical System Catalogue

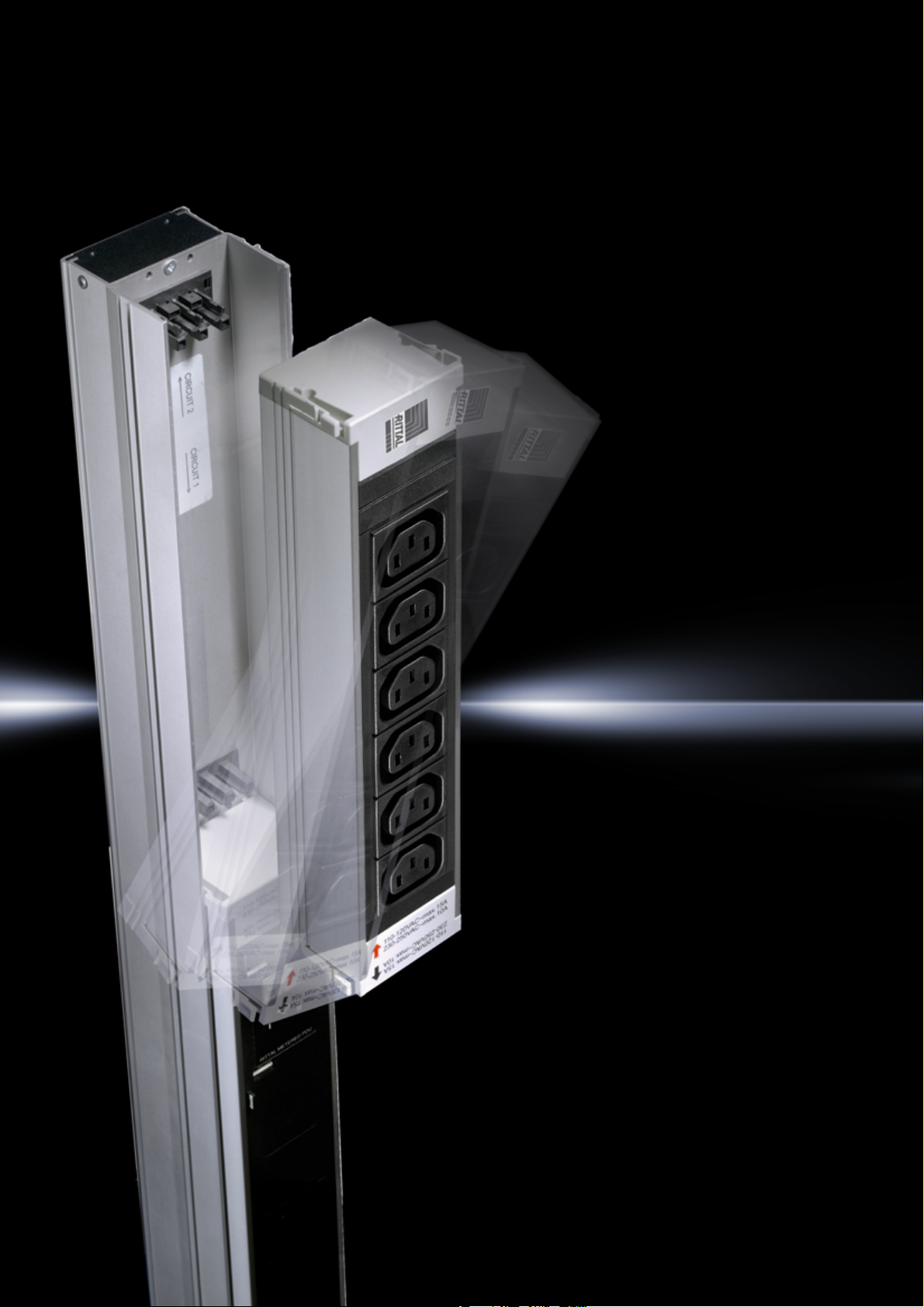

Modular PDU (PSM)

Page 2

Modular PDU (PSM)

Benefits of PSM busbars at a glance

◾ Modular configuration, flexibly extendible

◾ Redundant designs in busbars are supported

◾ Vertical mounting in the rack without loss

of U space

◾ Configuration changes are supported at any

time with the system operational by replacing

the module

◾ Shock-hazard-protected assembly of the

power distribution

◾ Choose from different connection types and

phase currents

◾ Extensive range of accessories for connection

cables and mounting kits

◾ Integral energy measurement and remote

monitoring via CMC III (with special PSM

measuring bars)

Technical System Catalogue/IT infrastructure2

Page 3

Modular PDU (PSM)

Modular PDU (PSM busbars)

The PSM system is a unique, modular power distributor for

integration into IT network and server racks. The configuration

(type and quantity of output slots) can be modified to accommodate altered requirements at any time, even whilst operational.

The modular PDU comprises a support rail which is fitted

vertically into the IT rack. This PSM busbar has individual

module slots into which various PSM plug-in modules may

be integrated.

These plug-in modules are available in a range of output pin

patterns and functions. Alongside purely passive distribution

modules, special active modules with switching and measuring

functions may also be integrated into the PSM busbar.

The electrical connection is made using the preassembled

plug&play connection cable available as an accessory, but also

can be made directly by a qualified electrician using the Wago

X-COM connector included in the supply pack.

Some versions of PSM busbars, including all 32 A versions,

have a fixed, prefitted connection cable with CEE connector

(to IEC/EN 60 309).

A range of mounting kits are available for flexible rack mounting,

so as to accommodate varying requirements such as vertically

hinged installation or quick installation in the TS IT rack.

A

B

Each plug-in module

picks off a phase on the

support rail, either from

infeed A or from the

redundant infeed B,

depending on the

direction of connection.

Criteria for selecting the correct PSM busbar

◾ Enclosure height

◾ No. of infeeds

◾ Type of infeed (e.g. fixed infeed)

◾ Phase current (16 A, 32 A)

◾ No. of phases (single or three-phase)

◾ No. of required PSM plug-in modules

◾ Additional measurement and management functions required

3Technical System Catalogue/IT infrastructure

Page 4

Modular PDU (PSM)

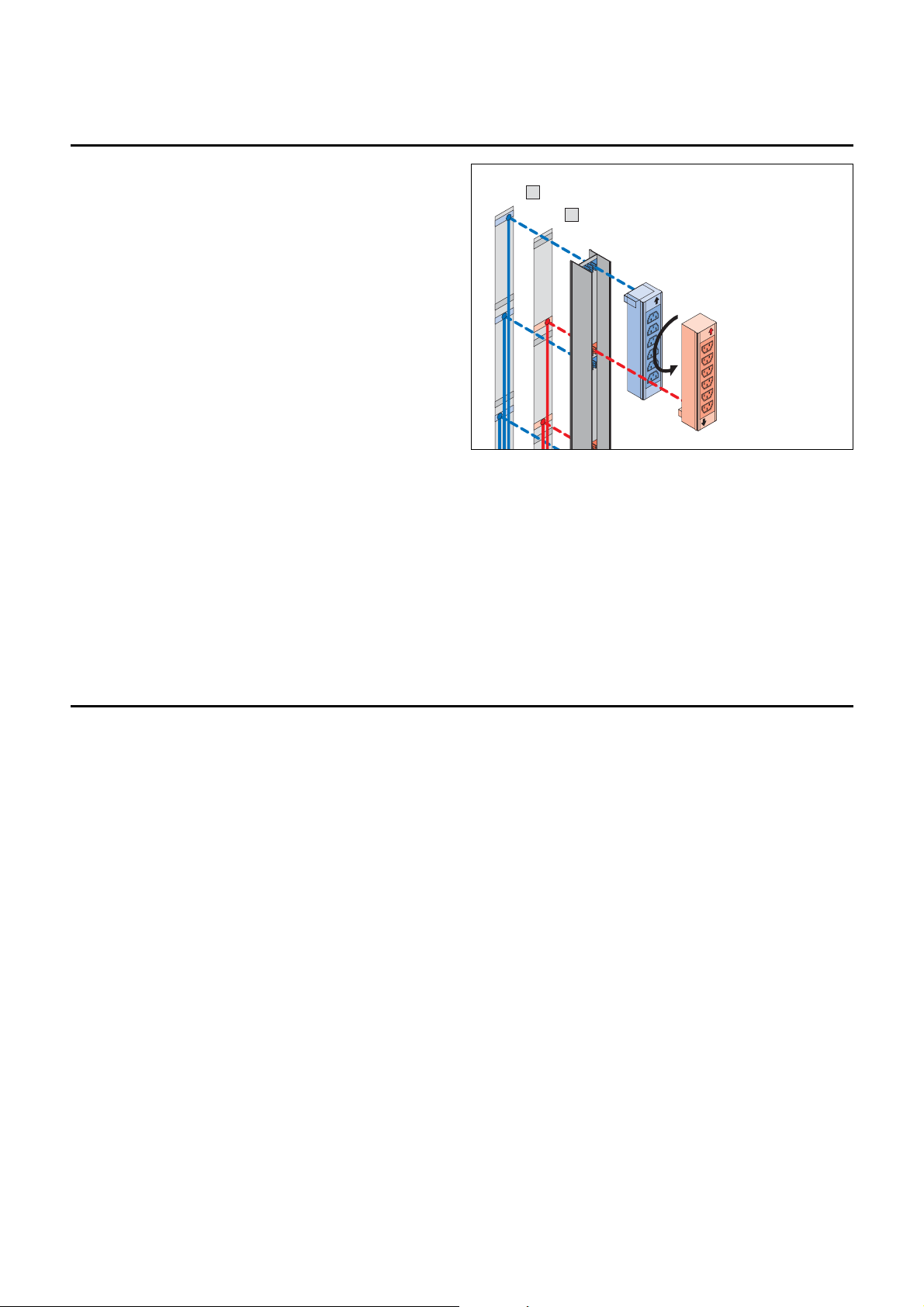

Function

Model No. 7856.005 7856.006 7856.008 7856.010 7856.020 7856.321 7856.323 7856.050 7856.053

Minimum height of rack (mm) 2000 2000 2200 1200 2000 2000 2000 2000 2000

Type of connection/length Fixed/3 m Fixed/3 m WAGO jack WAGO jack WAGO jack Fixed/3 m Fixed/3 m WAGO jack Fixed/3 m

Connector CEE CEE Various Various Various CEE CEE Various CEE

No. of infeeds 122221121

No. of phases 333331331

Phase current (A) 16 16 16 16 16 32 32 16 32

Various connection cables, also for single-phase

connection

––

◾◾◾––◾ –

No. of PSM module slots 778476666

Integral energy measurement of voltage, current,

active power, apparent power, active energy, power

factor, mains frequency

–––––––

◾◾

Measurement accuracy (U, l, f, P, S) –––––––2%2%

Measurement accuracy (E/kWh) –––––––1%1%

Graphic display for visualising the measurements

(24 V DC required)

–––––––

◾◾

CAN bus interface for connecting to CMC III system –––––––◾◾

Web server (IPv4, IPv6, SNMP, SSH) via CMC III

(PU III - 7030.000)

–––––––

◾◾

E-mail forwarding of exceeded limits and alarms

(CMC III required)

–––––––

◾◾

Operating temperature (°C) 5 – 45

Ambient humidity % (non-condensing) 10 – 90

Protection category IP (to IEC 60529) IP 20

Approvals CE CE CE CE/VDE CE/VDE CE CE CE CE

Technical System Catalogue/IT infrastructure4

Page 5

Modular PDU (PSM)

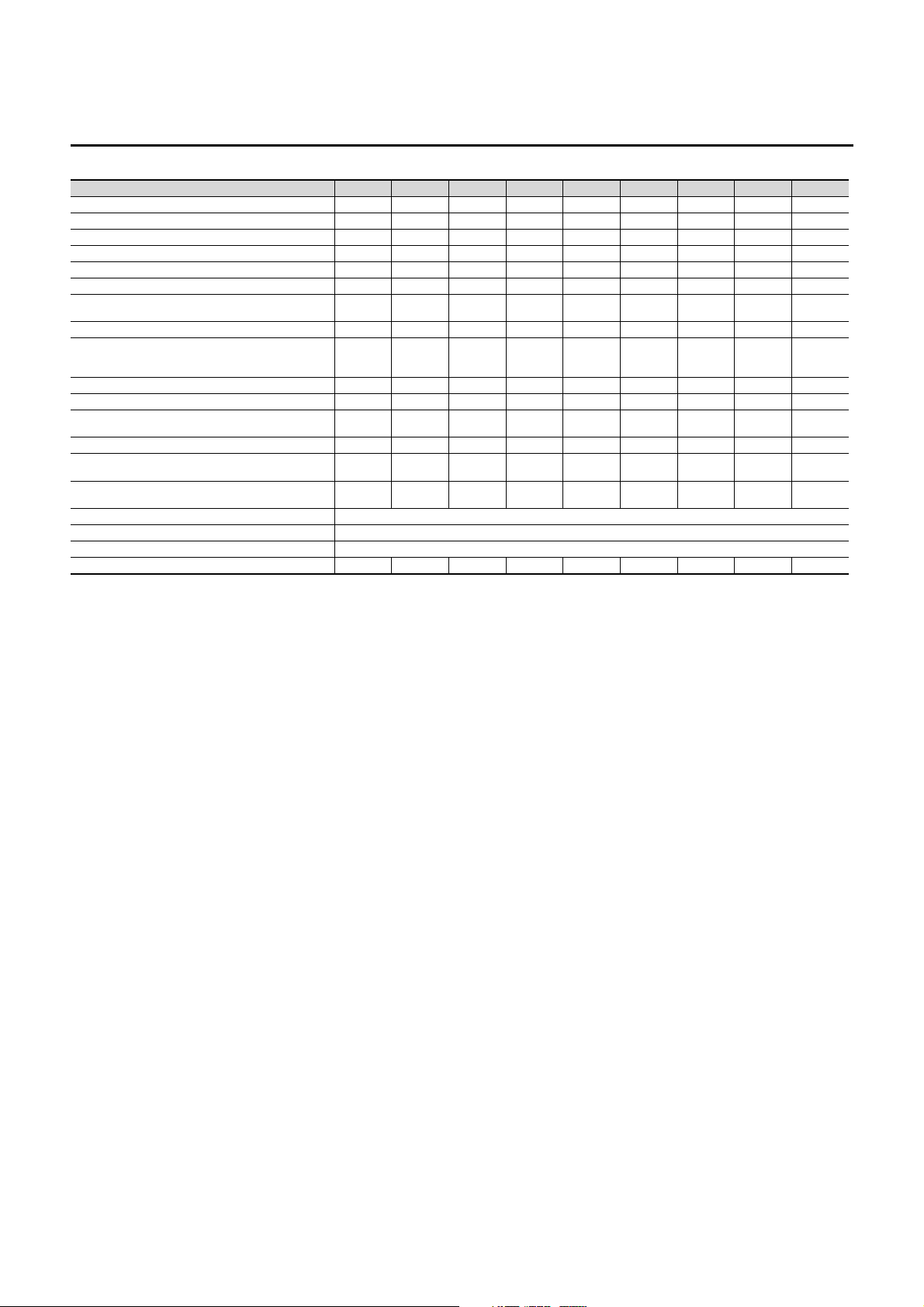

Modular PDU (PSM plug-in modules)

Choose from a wide range of PSM plug-in modules to configure

the PSM busbar with the required output slots. The modules

are snap-fastened into the PSM busbar without the use of

tools, and the slots are then available for the equipment.

It may be assembled while operational and connected to the

power supply (but only off-load). A range of different pin

patterns and functions are available (e.g. switching the outputs

and power measurement), so that every PSM busbar can be

configured individually depending on the preferred application.

Data communication and network connection occur via the

CMC III. Together with the CMC III and in conjunction with other

CMC III sensors e.g. for ambient parameters such as temperature and humidity, this creates a comprehensive monitoring

solution.

PSM plug-in modules (passive, distribution only)

Model No. 7856.080 7856.082 7856.100 7856.240 7856.230 7856.070 7856.220 7856.090 7856.120 7856.191 7859.120 7859.130

Occupied slots in PSM busbar 1

Pin pattern (type)

IEC

60320

C13

IEC

60320

C13

CEE 7/3

type F

CEE 7/3

type F

IEC

60320

C19

IEC

60320

C13

IEC

60320

C13

CEE 7/3

type F

CEE 7/5

type E

T 23

type J

IEC

60320

C13

IEC

60320

C19

Number of outputs 664446444464

Colour of slots black red black red black black black black black black black black

Lockable connectors (optional)

◾◾––––◾ –––––

Miniature fuse per output ––––––

◾ –––––

Thermal overload protection –––––

◾ – ◾ ––––

Optical LED current display

(total current)

––––––––––

◾◾

Switchable outputs

(via CMC III)

––––––––––––

Current measurement per

module/output

––––––––––––

Dimensions W x H x D mm 52 x 250 x 45

Operating temperature (°C) 5 – 45

Ambient humidity %

(non-condensing)

10 – 95

Material Extruded aluminium section/plastic

Approvals CE CE CE/VDE CE CE CE CE CE CE CE CE CE

5Technical System Catalogue/IT infrastructure

Page 6

Modular PDU (PSM)

PSM plug-in modules with power monitoring and output switching function

As well as passive PSM plug-in modules, which merely

distribute power via various types of output slots, there are

also smart PSM plug-in modules with additional functions.

These modules are ideally suited for retrofitting a power and

load management system and provides remote switching

functionality if the PSM busbar has already been installed and

commissioned. There is a choice of three modules with

identical functions but different slot configurations.

Data forwarding (or switching function) occurs with the aid of

a CMC III PU or PU compact. The modules have a CAN bus

interface for direct connection.

One LC display per module is available for local display in the

rack. The colour of the background lighting visualises the

various system states and exceeded limits clearly and

intelligibly. LEDs on the slots visualise the current switching

status.

Functions:

◾ Measurement of power consumption per module

◾ Output slots may be switched individually and in groups

◾ LEDs per slot to visually indicate the switching status

◾ LC display with multi-coloured backlight for local display

◾ Adjustable limits for voltage, current and active power

◾ Configurable overload detection per module

◾ High level of measurement accuracy

◾ Alarm signalling via the display

◾ Alarm management via CMC III (e.g. e-mail or text message)

◾ Visualisation of the switching status on the CMC III website

and RiZone

◾ Up to 16 PSM modules on one CMC III PU (per IP address)

◾ Rights management via CMC III (e.g. restriction of the

switching function)

◾ Facilitates the implementation of requirements

to EN 16001/ISO 50001 and EN 50600-2-2

◾ Stable aluminium section with plastic socket inserts

◾ Supports universal connector locking of the IEC 60320

C13 and C19 slots

◾ Supports the closure of unneeded IEC 60320

C13 and C19 slots

◾ PSM module is easily fitted into and removed from

the PSM busbar, for use at different locations

◾ Compatible with the European PSM busbar range

◾ Depending on the PSM busbar, up to four modules per

bar may be fitted

Technical System Catalogue/IT infrastructure6

Page 7

Modular PDU (PSM)

PSM plug-in modules with power monitoring and switching function

Product characteristics Unit PSM module type

Model No. 1 pc(s). 7859.410 7859.420 7859.430

No. of IEC 60320 C13 slots 822

No. of IEC 60320 C19 slots –4–

No. of earthing-pin slots (CEE 7/3 or type F) ––4

Total no. of all switchable outputs 866

No. of slots required in the PSM busbar 2

Module dimensions (W x H x D) mm 53 x 500 x 45

Section Aluminium, anodised

Plastic PA6 GF 30 V1

Electrics

No. of infeeds per module Qty. 1

Input voltage V AC 230

Input voltage, tolerance V AC 207–250

Rated current A16

Distribution output per module (at 230 V) W 3680

Power supply (via CMC III system, alternatively with power pack 7201.210) V DC 18-24

Functional overview

Measurement functions Per m odu le

Switching functions Per output slot

Relay type Dual coil/bistable

Relay switching load VA 4000

Display (LC matrix display with coloured backlight) Per m odu le

LEDs (blue) to indicate switching status Per output slot

Status LEDs - CAN bus communication 4 pc(s). Per module

Keys for operation & configuration 4 pc(s). Per module

Location sensor for correct display and Web view in 90° increments

Connector lock (optional, for C13 & C19 slots) 20 pc(s). 7955.020

Measurement functions

Voltage (V), current (A), frequency (Hz) ◾

Active power (kW), active energy (kWh) ◾

Reactive power (kVar), reactive energy (kVarh)

◾

Apparent power (kVA),

apparent energy (kVAh)

◾

Power factor (cos ?), crest factor (amplitude factor)

◾

Operating hours meter (d. h. min) ◾

Measurement accuracy %+/–1

Resettable measurement functions/reset via software/interval measurement

Active energy (kWh) ◾

Operating hours meter (h) ◾

Threshold values (warning/alarm), freely configurable

Voltage, current, power

Connectivity / management functions (in conjunction with CMC III)

Maximum no. of modules that may be used per CMC III Processing Unit Qty. 16

Maximum no. of modules that may be used per CMC III Processing Unit Compact Qty. 4

CAN bus for direct linking to CMC III system pc(s). 2 (RJ45)

Network functionality (only in conjunction with CMC III system) IPv4, IPv6, SNMPv3, Modbus/TCP, OPC-UA

Ambient conditions

Operating temperature

°C

+5…+50

Operating temperature (at max. 8 A per output slot)

°C

+5…+60

Storage temperature °C -20…+70

Ambient humidity (non-condensing) rel. humidity, % 10 – 90

Maximum installation height m 2000

Overvoltage category II

Contamination level 2

Protection class (IEC 60529) IP 20

Approvals and standards

Approval CE, RoHS II

Standards (excerpt)

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

EN 50600-2-2

EN 60 950

7Technical System Catalogue/IT infrastructure

Page 8

Modular PDU (PSM)

+ –

+

–

+ –

+ –

+ –

+ –

Control and monitoring with CMC III management system

The CAN bus connection with the CMC III monitoring system

is made for control and remote management of the PSM busbars, PSM measurement modules and MID measurement

modules (482.6 mm (19") inline meter). The CMC III provides

a connection to the outside world using a range of protocols

(IPv4, IPv6, SNMP, OPC-UA, Modbus/TCP, SSH etc.) In this

way, multiple busbars and PSM modules, even distributed

across several racks, can be combined and managed under

one IP address. Logical links with other CMC III sensors (e.g.

temperature, humidity, smoke alarm etc.) are also supported.

The benefits of PSM plug-in modules at a glance:

◾ May be installed and replaced at any time, even while live,

without specialist knowledge

◾ Various pin patterns for every application

◾ Modules with switching and measurement functions, also

suitable for retrofitting

◾ Versions with miniature fuses and load display via LED are

available

◾ VDE-tested (some versions)

◾ Compact design, despite modularity

PSM measurement modules, connection to CMC III

Max. 8 modules per CAN bus

Connection of PSM measurement modules to the CMC III PU and

network 230 V supply to the PSM modules via PSM busbar!

PSM measurement bars, connection to CMC III

Max. 4 PSM measurement bars per CAN bus

Connection of PSM measurement bars to the CMC III PU and

network

IP network

IP network

+ –

+ –

+ –

+ –

+ –

+

–

Type of cabling:

230 V/400 V mains

24 V DC, buffered

CMC III CAN bus

Network/IP/SNMP

Type of cabling:

230 V/400 V mains

24 V DC, buffered

CMC III CAN bus

Network/IP/SNMP

Technical System Catalogue/IT infrastructure8

Page 9

Modular PDU (PSM)

Visual load management with PSM

In many cases, fast identification of the module or phase load is

useful. However, companies often shy away from investing in

complex measurement technology. For such cases, special

PSM modules are available which visualise the current rating of

all connected equipment without the need for additional accessories. These modules can be integrated into any existing PSM

busbar, or replace existing PSM modules.

There are two versions available with 6 x IEC 60320 C13

(7859.120) or 4 x IEC 60320 C19 (7859.130) output slots.

Using these PSM modules with LED current display allows you

to visualise the load distribution in the PSM busbar. You can

see at a glance which PSM module can accommodate further

equipment without causing a phase overload.

Once the prescribed load limit of the module is reached, any

remaining slots may be sealed with optionally available

IEC 60320 C13 or C19 covers to prevent mistakes being made

in the hectic environment of data centre operation.

The limits are preset in the factory and cannot be altered.

Current limits:

0 – 7 A (green), 7 – 13 A (yellow) and >13 A (red)

These PSM plug-in modules with LED load display are ideally

suited for retrofitting to existing PSM installations to enhance

the reliability of the supply.

To match the LED modules with load display, IEC 60320

C13/C19 slot covers are also available, to prevent overloading

with additional equipment. The cover is easily removed with

a release tool if necessary.

Ingeniously simple: Optical load indicators

Phase loads are clearly visible at all times. No more worries

about unnoticed overloading or unbalanced power distribution

in the rack.

Covers for secure load management

PSM plug-in module with load display

9Technical System Catalogue/IT infrastructure

Page 10

Modular PDU (PSM)

PSM MID measurement module for

482.6 mm (19") installation

This measurement device is connected into the connection

cable (infeed) of the equipment or the power distributor, and

records the consumed active energy with 1% accuracy.

MID approval means that the module is licensed for use in the

European Union for energy billing purposes. As well as

measuring energy, it also measures other performance data

such as voltage, current, active and apparent power, power

factor, and neutral conductor current. Measurement of the

neutral conductor current aids the reliable detection of asymmetries (different phase utilisation levels) in power distribution.

The meter is fitted horizontally in the 482.6 mm (19") level.

There are two versions available, for 16 A and 32 A phased

current, which are connected using cable sets available as

accessories. A special preassembled connection cable set is

available for connecting to PSM busbars with Wago X-COM

connectors. In this way, a power distributor without measurement capabilities is quickly and easily extended.

Approval for energy billing purposes is valid for 8 years and can

be extended for a further 8 years by recalibrating.

IT network/server rack

IT rack with redundant power

supply (PSM or PDU basic )

Measurement via MID inline

meter

Type of cabling:

230 V/400 V mains

24 V DC, buffered

CMC III CAN bus

Network/IP/SNMP

Serial connection

CMC III power pack

(redundant design with

2 power packs optionally

supported)

CMC III PU/PU Compact

IP mains

Circuit A Circuit B

Max.

8 MID modules

What is MID?

MID stands for “Measurement Instruments Directive” and

regulates 10 types of measurement equipment based on

EU Directive 2004/22/EC.

The aim is to harmonise the approval of measurement

equipment in the Member States. However, country-specific

regulations (such as the Calibration Act in Germany) continue

to apply.

MID regulates the entire manufacturing process, from

development, to production, through to final testing of the

measurement equipment. General and device-specific

performance requirements are defined in the MID, which the

manufacturer must comply with. Following successful testing,

the MID-approved devices are labelled and may be sold

throughout the EU.

Benefits of the MID measurement module:

◾ Easy to install active energy meter based on the plug & play

system

◾ Variants for 16 A and 32 A phase current

◾ Two independent circuits in each case (3-phase)

◾ Pre-assembled connection cable with CEE connector /

coupling

◾ Simple, flexible assembly

◾ Billable MID measurement units

◾ CAN bus for connection to CMC III system

◾ Extensive monitoring functions (via CMC III)

◾ High-MTBF and measurement accuracy of 1%

◾ Energy-efficient electric design – minimal inherent power

consumption

◾ High-quality sheet steel enclosure

+ –

+ –

+

–

+ –

+ –

+

–

+ –

+ –

+ –

Technical System Catalogue/IT infrastructure10

Page 11

◾Enclosures

◾ Power Distribution

◾ Climate Control

◾ IT Infrastructure

◾ Software & Services

You can find the contact details of all

Rittal companies throughout the world here.

www.rittal.com/contact

XWW00090EN1603

Loading...

Loading...