Page 1

Blue e+ chiller

for cooling media

SK 3320200 SK 3334300 SK 3334400

Assembly and operating instructions

Page 2

Contents

EN

Contents

1 Notes on documentation .................. 4

1.1 General ........................................................ 4

1.2 CE conformity .............................................. 4

1.3 Storing the documents................................. 4

1.4 Symbols used in these operating instructions 4

1.5 Other applicable documents ........................ 4

2 Safety notes ..................................... 4

2.1 General ........................................................ 4

2.2 Risks in case of failure to observe the safety

instructions .................................................. 4

2.3 Safety instructions for assembly, inspection

and maintenance work ................................. 4

2.4 Unauthorised operation................................ 5

2.5 Health risks due to the refrigerant R134a and

the cooling medium ..................................... 5

2.6 First aid measures........................................ 5

2.7 Fire-fighting measures.................................. 5

2.8 Safety measures and equipment.................. 5

2.9 Potential hazards and how to avoid them..... 6

3 Device description ............................ 7

3.1 General ........................................................ 7

3.2 General functional description ...................... 8

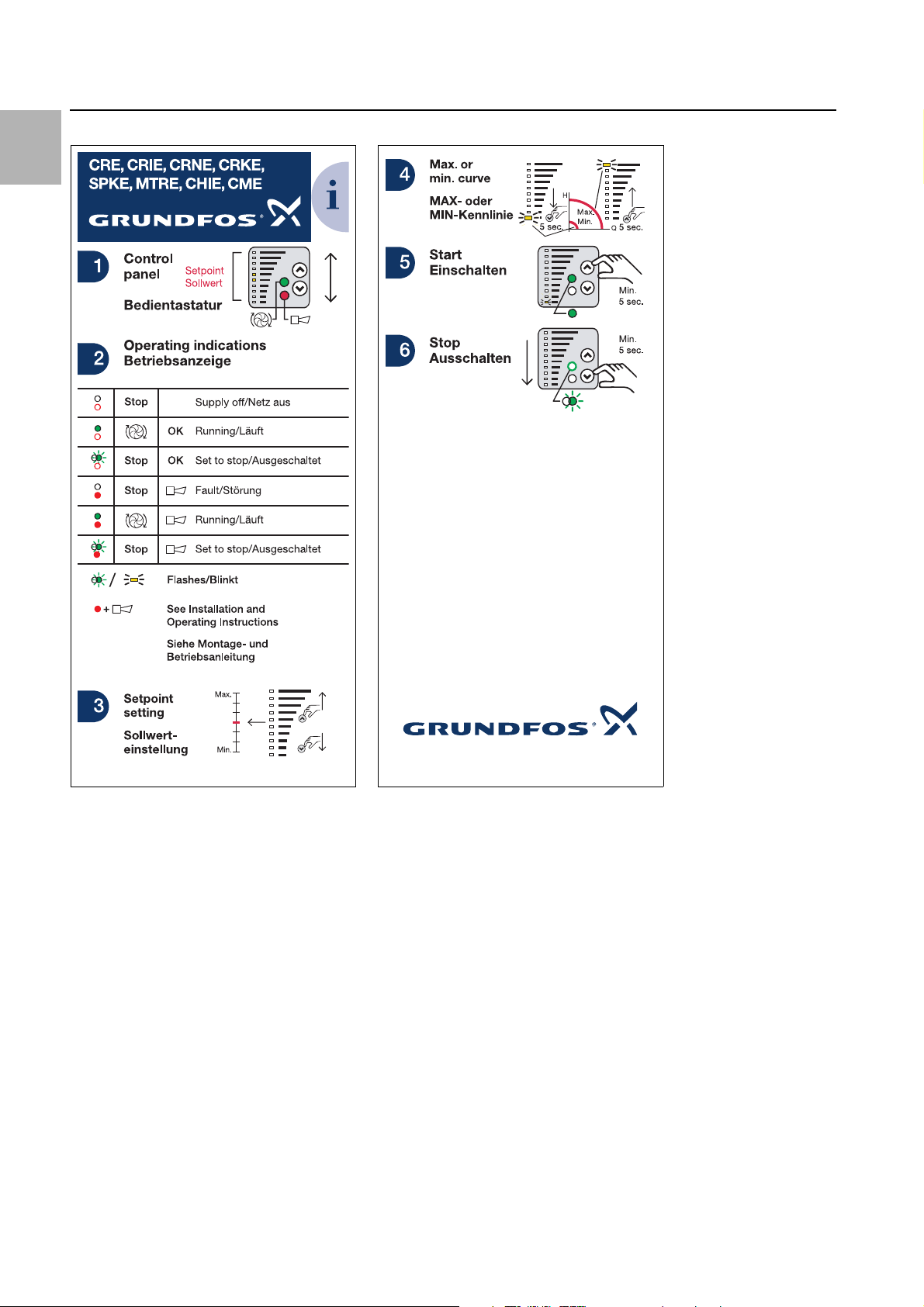

3.3 Control......................................................... 9

3.4 Characteristic curves.................................... 9

3.4.1 Characteristic curves of pump ............................... 9

3.4.2 Performance diagrams ........................................ 10

3.5 Safety devices............................................ 10

3.6 Options...................................................... 10

3.6.1 Inverter pump ..................................................... 10

3.6.2 Reinforced pump ................................................ 10

3.6.3 Outdoor .............................................................. 10

3.6.4 Oil/emulsion ........................................................ 10

3.6.5 Free Cooling ....................................................... 10

3.6.6 Water-cooled condenser ..................................... 10

3.6.7 Tank heating ....................................................... 10

3.7 Proper use, foreseeable misuse ................. 10

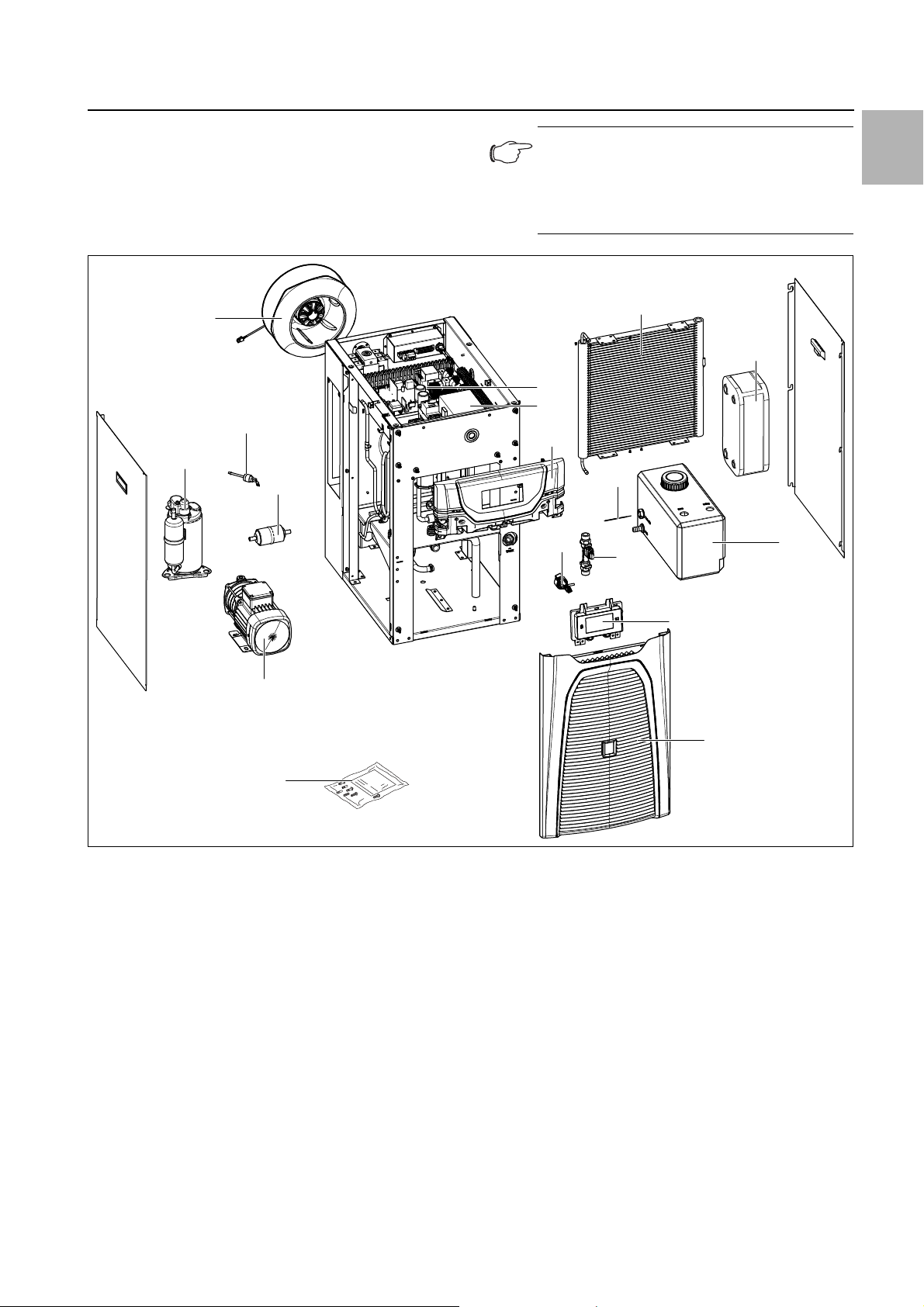

3.8 Supply includes.......................................... 11

4 Transport ....................................... 11

4.1 Delivery ...................................................... 11

4.2 Unpacking ................................................. 11

4.3 Transport ................................................... 11

6 Commissioning .............................. 18

6.1 Cooling medium water-glycol mixture......... 18

6.1.1 General remarks ................................................. 18

6.1.2 Cooling medium requirements ............................ 18

6.1.3 Preparation and care .......................................... 19

6.1.4 Recommended "Cooling medium for chillers" ..... 19

6.2 Filling the cooling medium .......................... 20

6.3 Bleeding the cooling medium pump ........... 20

6.4 Commissioning procedure ......................... 21

6.5 Adjusting the bypass valve ......................... 21

7 Operation ....................................... 21

7.1 General ...................................................... 21

7.2 Layout of the display .................................. 22

7.2.1 Start screen ........................................................ 22

7.2.2 Changing a parameter value ............................... 22

7.2.3 Help function ...................................................... 23

7.3 Info menu................................................... 23

7.3.1 Temperature info ................................................. 23

7.3.2 Device info .......................................................... 23

7.3.3 Efficiency info ...................................................... 24

7.3.4 Hydraulic info ...................................................... 24

7.4 Configuration menu.................................... 24

7.4.1 Control parameters ............................................. 25

7.4.2 Remote ............................................................... 28

7.4.3 Network .............................................................. 28

7.4.4 Alarm relays ........................................................ 29

7.4.5 Language settings .............................................. 29

7.4.6 Self-test .............................................................. 29

7.5 System messages...................................... 30

7.5.1 Occurrence of a malfunction ............................... 30

7.5.2 Display in case of errors ...................................... 30

8 Inspection and maintenance .......... 30

8.1 Maintaining the refrigerant circuit................ 31

8.2 Monitoring the cooling medium .................. 31

8.3 Cleaning the condenser ............................. 32

8.4 Cleaning the filter mat (accessories)............ 32

8.5 Draining the cooling medium tank .............. 32

9 Troubleshooting ............................. 33

9.1 List of system messages ............................ 34

10 Decommissioning and disposal ...... 36

10.1 Decommissioning....................................... 36

10.2 Disposal ..................................................... 36

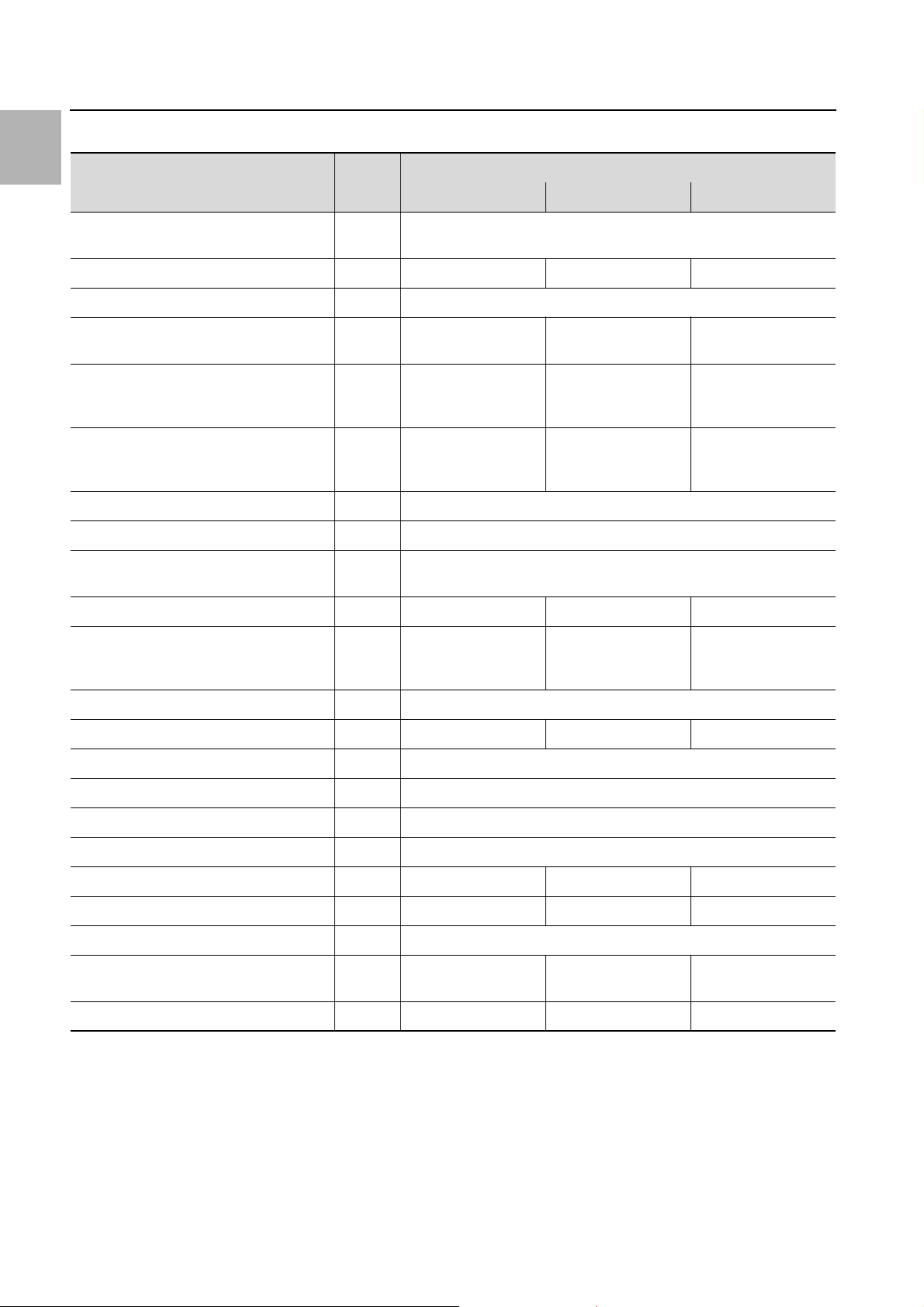

5 Assembly and connection .............. 13

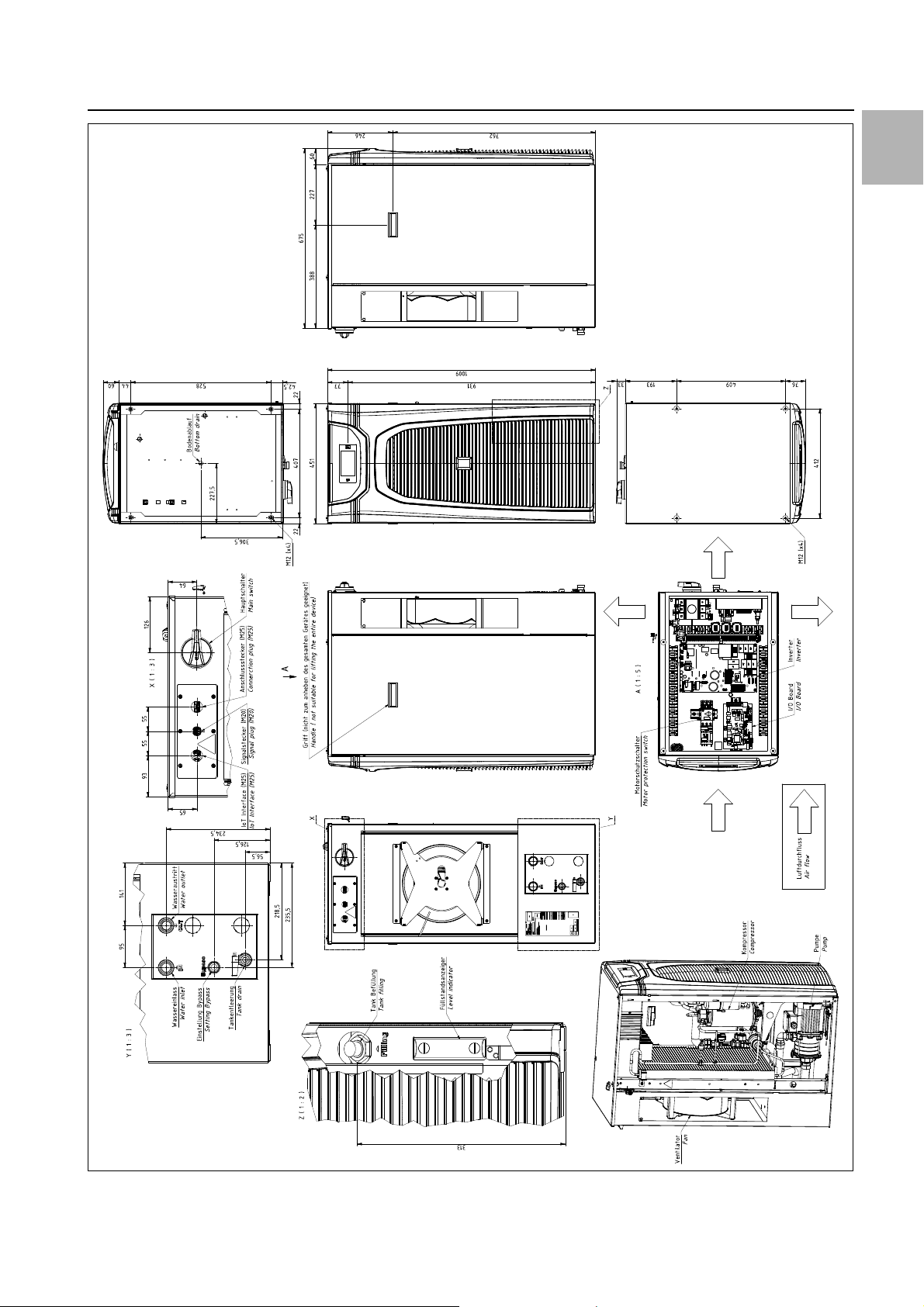

5.1 Dimensions ................................................ 13

5.2 Installation site requirements ...................... 13

5.3 Installing the chiller..................................... 14

5.4 Making the hydraulic connection................ 14

5.5 Connecting the cooling circuit (optional) ..... 15

5.6 Making electrical connection ...................... 15

5.6.1 Installing the power supply .................................. 16

5.6.2 Connecting the alarm relay query device ............. 16

5.6.3 External activation ............................................... 16

5.6.4 Room temperature sensor (accessories) ............. 16

5.7 Installing the filter mats (accessories).......... 16

2 Rittal Chiller Blue e+

11 Accessories ................................... 37

11.1 Connection set for air/water heat

exchangers ................................................ 37

11.2 Flow regulator valve.................................... 37

11.3 Textile filter mats ........................................ 37

11.4 Metal filter (aluminium filter)......................... 38

11.5 Cooling medium for chillers (ready-mix) ...... 38

11.6 Levelling feet .............................................. 38

11.7 Twin castors............................................... 38

11.8 Cross member ........................................... 38

11.9 External temperature sensor....................... 39

Page 3

12 Appendix ....................................... 40

12.1 Block diagram............................................. 40

12.2 Spare parts................................................. 41

12.3 Technical specifications .............................. 42

12.4 Device drawings ......................................... 43

12.5 Operation of inverter pump ......................... 46

12.6 Declaration of Conformity............................ 47

Contents

EN

Rittal Chiller Blue e+ 3

Page 4

1 Notes on documentation

EN

1 Notes on documentation

1.1 General

These instructions are aimed at installers and operators

who are familiar with the installation and the operation of

the chiller. It is very important to read and follow these

assembly and operating instructions prior to commissioning. These are the original operating instructions.

1.2 CE conformity

Rittal GmbH & Co. KG confirms the conformity of the

chiller with the European Union's Machinery Directive

2006/42/EC and EMC Directive 2004/108/EC. A corresponding declaration of conformity has been issued and

enclosed with the unit.

1.3 Storing the documents

The assembly and operating instructions as well as all

other applicable documents are an integral part of the

product. They must be issued to everyone who works

with the chiller and must always be available and on

hand for operating and maintenance personnel.

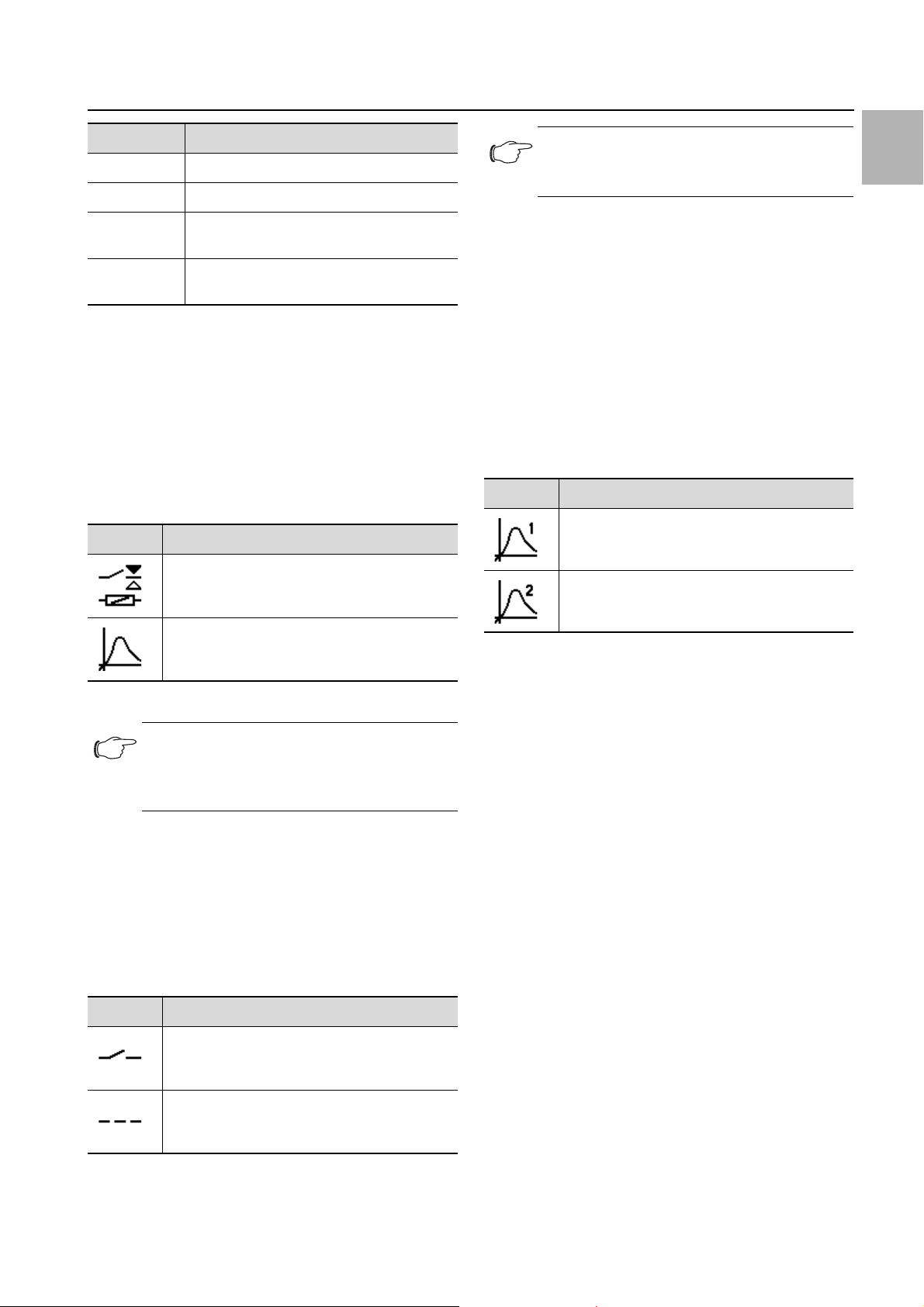

1.4 Symbols used in these operating instructions

The following symbols are used in this documentation:

Danger!

A dangerous situation in which failure to

comply with the instructions will result in

death or severe injury.

1.5 Other applicable documents

Assembly and operating instructions exist as paper documents and/or digital data carriers for the unit types described here and are enclosed with the equipment.

We cannot accept any liability for damage associated

with failure to observe these instructions. Where applicable, the instructions for any accessories used also apply.

2 Safety notes

2.1 General

Please observe the following general safety notes when

operating and installing the chiller:

Assembly, installation and maintenance must only be

carried out by qualified personnel.

Children and persons with limited cognitive/coordina-

tive abilities must not operate, maintain or clean the

unit or be allowed to use it as a toy.

Only use original spare parts and accessories author-

ised by the manufacturer to ensure the protection and

safety of the chiller. The usage of other parts will render any liability void.

Do not make any changes to the chiller that have not

been agreed with and approved by the manufacturer.

It is also imperative that you observe the special safety

instructions for the individual activities in the individual

chapters.

2.2 Risks in case of failure to observe the safety instructions

In case of failure to observe the safety notes, people, the

environment and the chiller may be placed at risk. Failure

to comply with the safety notes makes all claims for

compensation void.

Warning!

A dangerous situation which may cause

death or serious injury if the instructions

are not followed.

Caution!

A dangerous situation which may lead to

(minor) injuries if the instructions are not

followed.

Note:

Important notices and indication of situations

which may result in material damage.

This symbol indicates an "action point" and shows that

you should perform an operation or procedure.

4 Rittal Chiller Blue e+

2.3 Safety instructions for assembly, inspection and maintenance work

– The installation, commissioning and servicing of the

chiller must be carried out in strict compliance with the

technical documentation for the chiller and in such a

way that no potentially hazardous situations are allowed to occur.

– Cleaning and maintenance work on the chiller must

only be performed with the unit shut down. For this

purpose, it is vital to ensure that the chiller is disconnected from the power supply and is secured against

switching back on. It is imperative that you observe the

procedure for shutting down the chiller described in

the assembly and operating instructions.

– All safety devices and protective equipment must be

reattached or put in a functional condition immediately

after the work is complete.

– Modifications or changes to the chiller are not allowed.

– Only appropriately qualified personnel as defined by

BGR500 chap. 2.35 / EN 378 are allowed to work on

the refrigerant circuit.

Page 5

– Do not install the chiller without protection outside of

covered areas, or in an explosive or aggressive environment.

– Do not install the chiller on an unstable surface or a

surface that is not designed for the weight of the chiller.

– Do not bypass any electrical safety devices to make it

possible to operate the chiller.

2.4 Unauthorised operation

The safety of the chiller supplied is only ensured if it is

used properly (see section3.7 "Proper use, foreseeable

misuse"). Under no circumstances should the limit values specified in the technical data be exceeded.

The chiller is not allowed to be used for the direct cooling

of liquids that are used for foodstuffs (e.g. drinking water).

Any existing contact hazard protection for moving parts

must not be removed from chillers while operational.

Hazards due to electrical power, do not remove any

switch box cover!

2 Safety notes

EN

Explosion hazard!

The use of the chiller for cooling inflam-

mable or pyrophoric substances is prohibited.

2.5 Health risks due to the refrigerant R134a and the cooling medium

The refrigerant changes status during operation and becomes pressurised. The R134a safety data sheet must

be observed.

The cooling medium (additive) is a liquid. We suggest:

"Cooling medium for chillers" (see section6.1 "Cooling

medium water-glycol mixture"). The safety data sheet

"Cooling medium for chillers" must be observed.

2.6 First aid measures

Please refer to safety data sheets R134a and "Cooling

medium for chillers".

Note:

Safety data sheets are available for down-

loading at www.rittal.com.

2.7 Fire-fighting measures

Suitable extinguishing agent

All known extinguishing agents can be used.

2.8 Safety measures and equipment

Ensure adequate ventilation.

Hand protection: Safety gloves.

Eye protection: Safety goggles.

Body protection: Wear safety shoes when handling

pressurised gas bottles.

Rittal Chiller Blue e+ 5

Page 6

EN

2 Safety notes

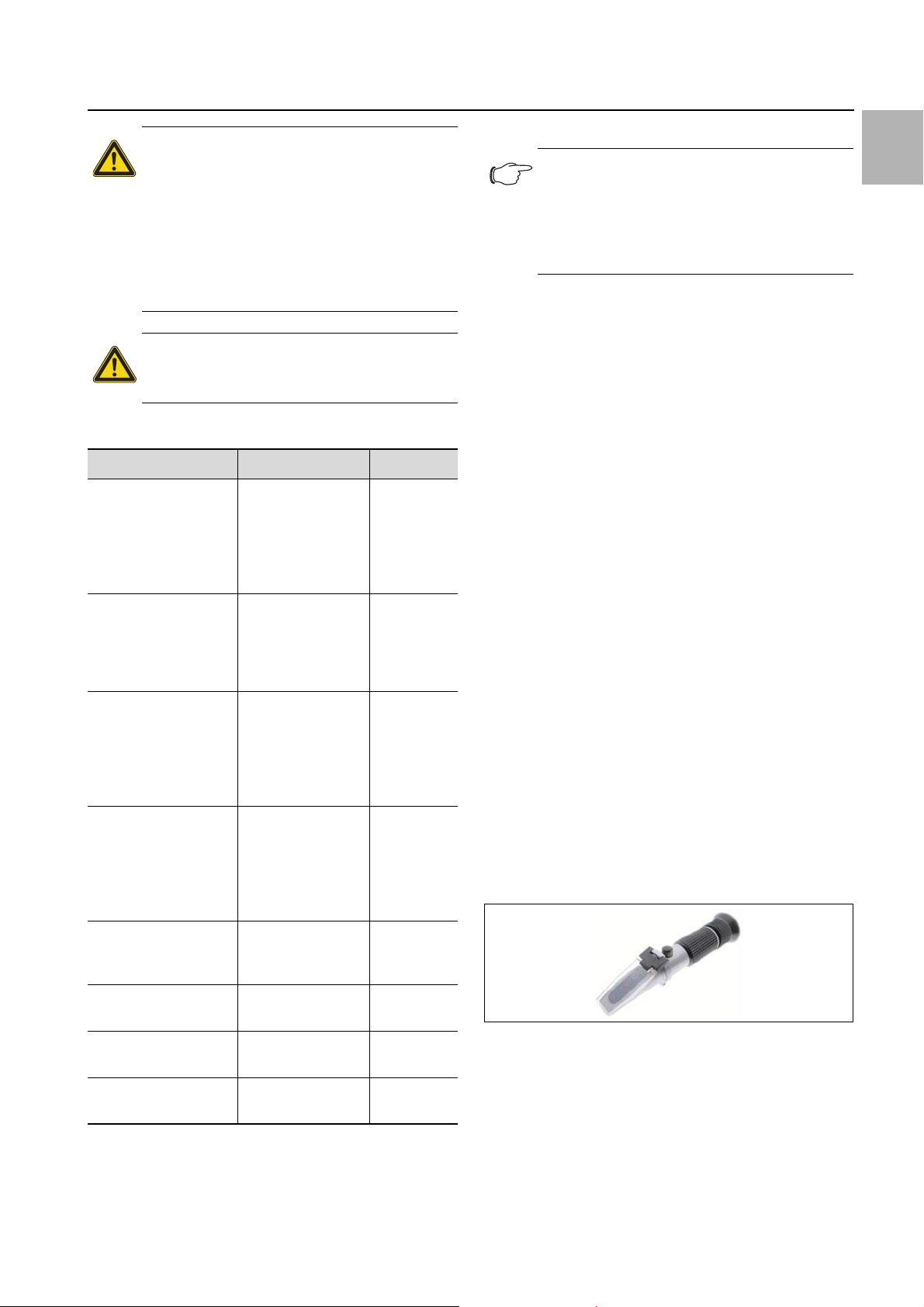

2.9 Potential hazards and how to avoid them

The following table provides an overview of other potential sources of danger and how to avoid them.

Location Hazard Cause Precautionary measures

Device interior Severe personal

injury or damage to

property

Device interior Personal injury or

damage to property

Device interior Inhalation of toxic

gases/materials

Device interior Risk for the prod-

uct

Device interior: Microchannel condenser

Device interior:

Hot or cold parts

Minor cuts Contact while cleaning the

Burns / frostbite Contact with parts with a

Hazard due to electrical

equipment of the chiller

Electrical hazard while

working on the chiller

Soldering work inside the

chiller may release toxic

gases due to the installed

cooling circuit.

Liquid level after transport

not in upright position

condenser (see section8.3 "Cleaning the

condenser")

high or low surface temperature.

Recurrent testing of electrical equipment

(Germany BGV A3)

The power to the chiller must be disconnected via the main switch.

Maintenance may only be carried out by specialist personnel. Before carrying out soldering work on the cooling circuit or in its

immediate vicinity, the refrigerant should be

drained from the chiller.

Only transport the chiller upright. Should the

chiller be tilted during transportation, please

wait some minutes before switching on

again.

Wear safety gloves.

The chiller may only be opened by trained,

qualified personnel.

Device interior:

Cooling medium circuit

Device exterior Severe personal

Device exterior Personal injury or

Device exterior Cuts Contact with fan wheel Do not remove the protective cover around

Device exterior:

Area around the chiller

Device exterior:

Chiller with wheels

Tab. 1: Hazards and precautionary measures

Fungus and algae

formation

injury or damage to

property

damage to property

Major burns Fire caused by short-cir-

Personal injury or

damage to property

Use of pure water as a

cooling medium or refrigerant.

The floor on which the

chiller is installed is unstable and unable to support

its weight. The chiller tips

over or the floor gives way.

Hazards when transporting or assembling the chiller

cuiting or overheating of

the electricity supply line to

the chiller

The chiller starts to move

due to unevenness of the

floor surface.

Use a water-glycol mixture as your cooling

medium. Rittal recommends the use of

"Cooling medium for chillers" (ready-mix).

The weight of the chiller can be found in section12.3 "Technical specifications". Additionally, please allow for the weight of the

liquid in the tank (the capacity of the tank can

likewise be found in section 12.3 "Technical

specifications") and make sure that the floor

is suitable for installation purposes.

Secure the chiller against any risk of tilting

(eyebolts) when transporting or assembling.

the fan wheel.

Ensure that the cable cross-section and electricity supply line comply with the valid regulations.

If the recooling system is equipped with

wheels (option), they must be locked with

brakes while operational.

6 Rittal Chiller Blue e+

Page 7

3 Device description

5

4

2

3

1

16

15

14

13

11

12

10

9

6

7

8

Note:

Specialist personnel are individuals who, by

virtue of their training, education, experience

and knowledge of the relevant provisions,

regulations and measures for accident prevention and relating to the operating conditions, have been authorised by the owner or

responsible individual to ensure the safety of

the system, carry out all essential tasks, and

are therefore in a position to identify and avert

all potential threats.

3 Device description

3.1 General

Chillers are used for the central and economical cooling

and supply of a cooling medium (water + glycol, see section6.1 "Cooling medium water-glycol mixture") in the

event of physical separation between the place where

cooling is required and the refrigeration. The cooling medium is supplied using a pipe system.

EN

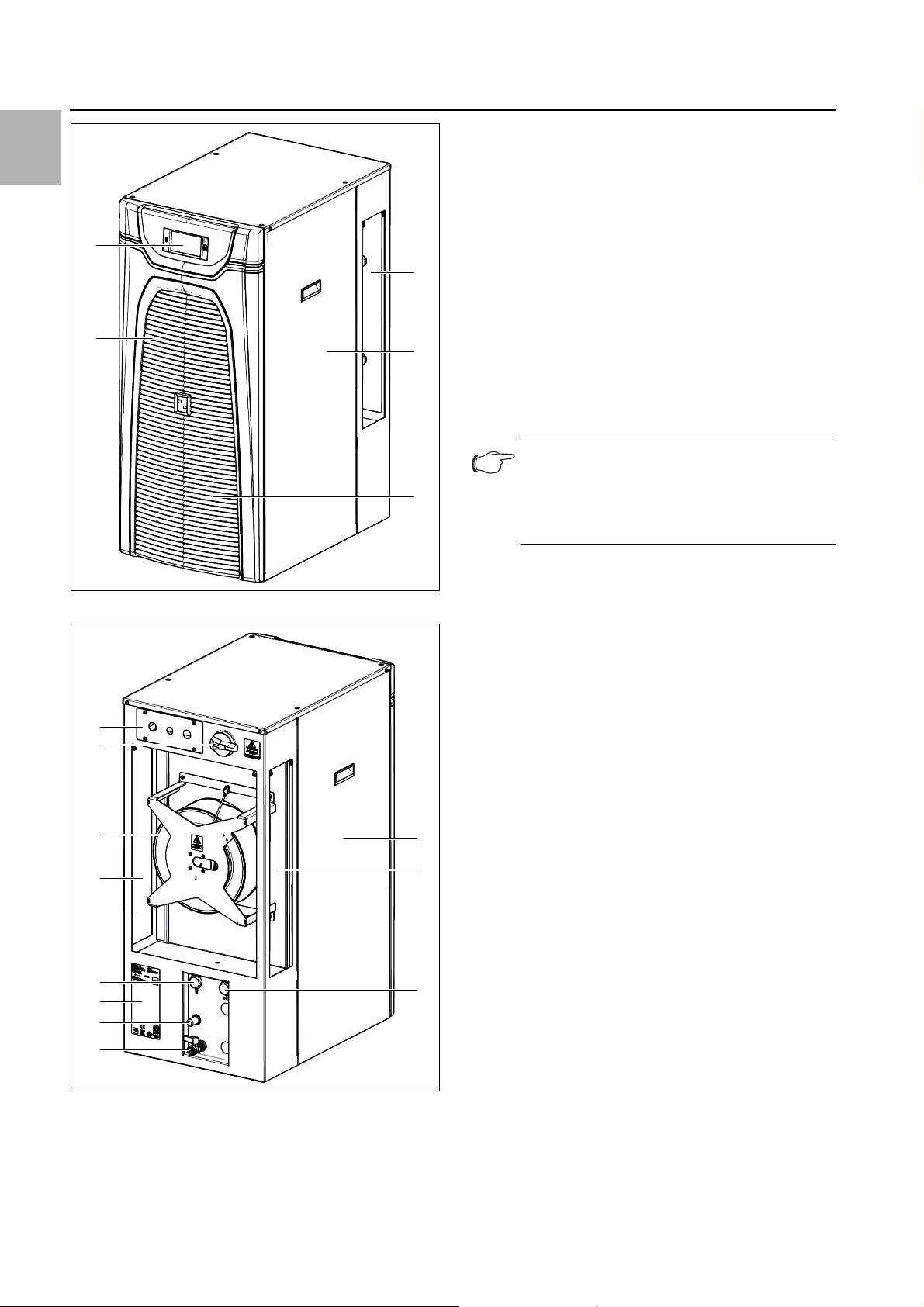

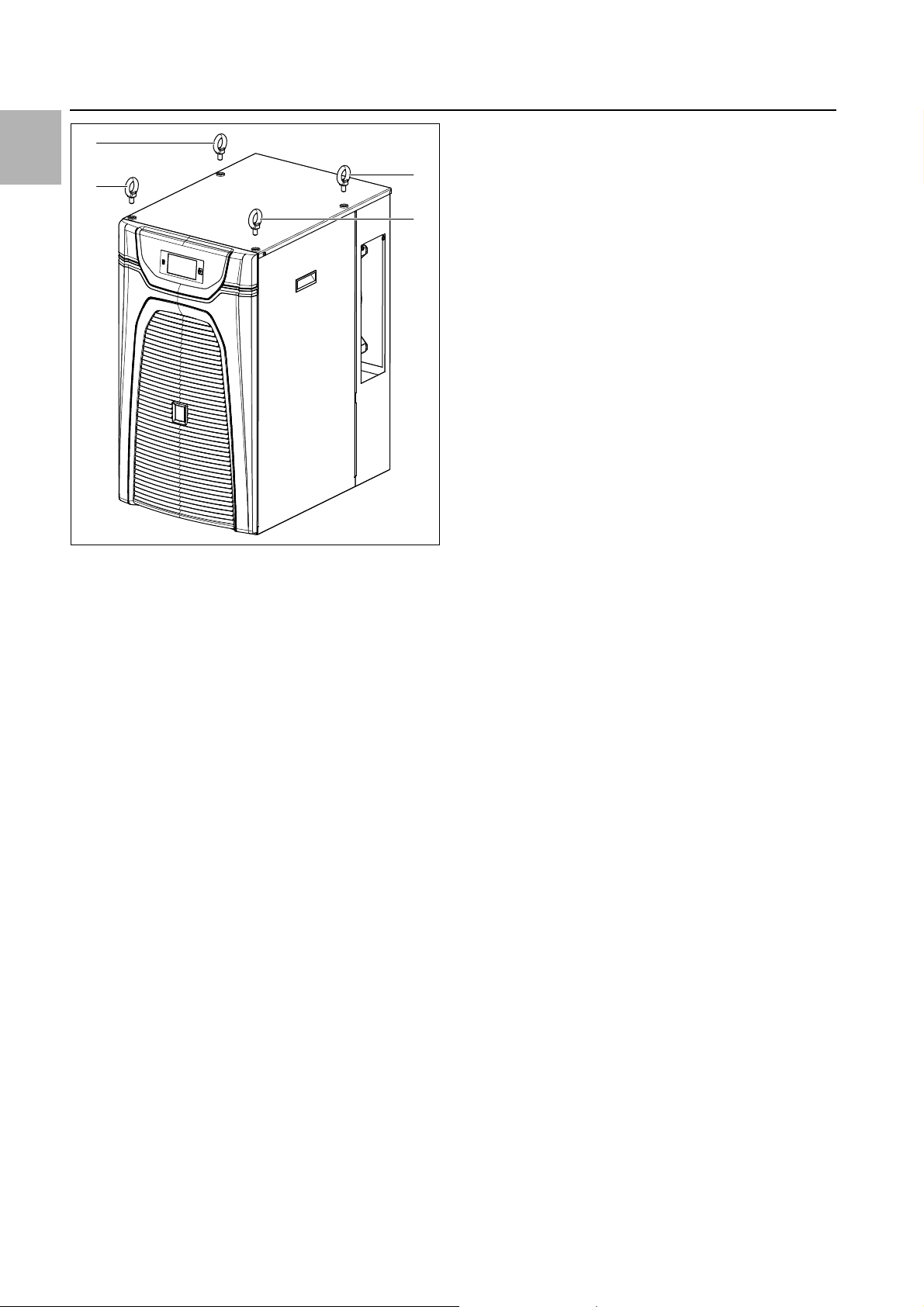

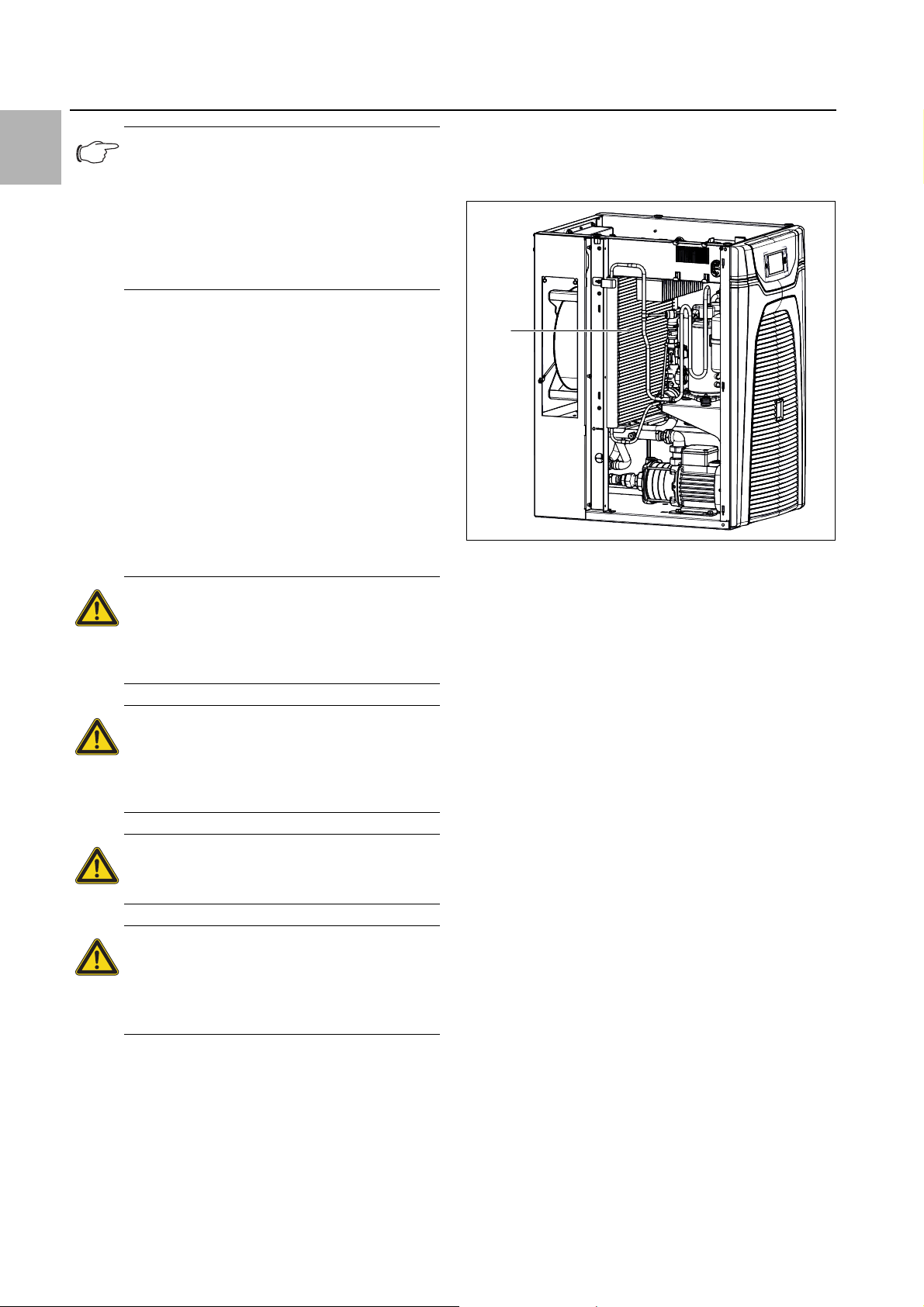

Fig. 2: View from rear (3320200 and 3334300)

Key fig. 1 and fig. 2

1 Side air outlet, right

2 Side cover, right

3 Filler nozzle for cooling medium (behind louvred grilles)

4 Louvred grille for air inlet

5Display

6 Side cover, left

7 Side air outlet, left

8 Cooling medium connection, inlet

9 Tank drain nozzle (stop valve)

10 Adjustable overflow valve (bypass)

11 Rating plate

12 Cooling medium connection, return

13 Air outlet, rear

14 Radial fan

15 Master switch

16 Electrical interfaces

Fig. 1: View from front (3320200 and 3334300)

Rittal Chiller Blue e+ 7

Page 8

EN

5

4

2

3

1

16

15

14

13

11

12

10

9

6

7

8

3 Device description

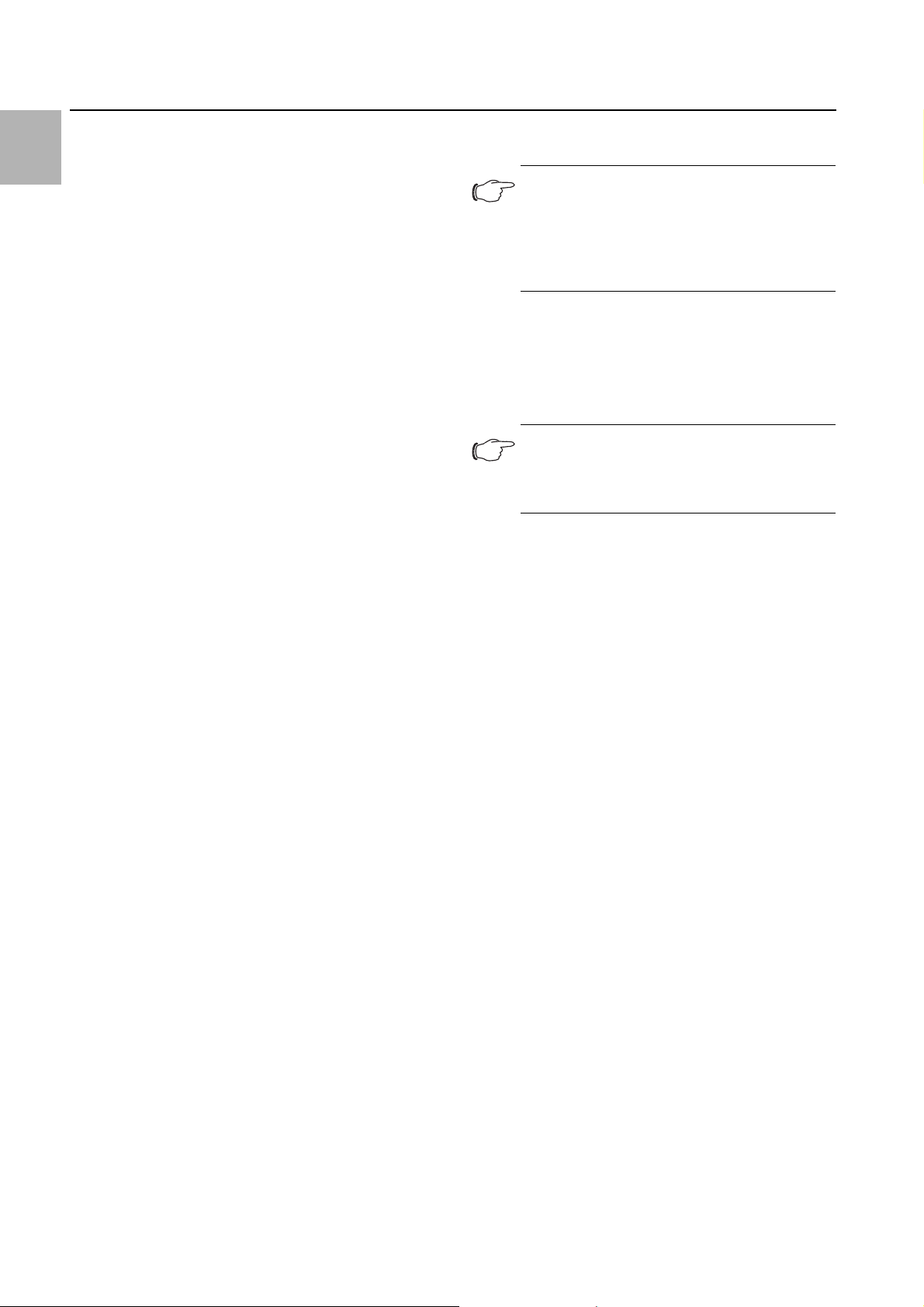

Key fig. 3 and fig. 4

1 Side air outlet, right

2 Side cover, right

3 Filler nozzle for cooling medium (behind louvred grilles)

4 Louvred grille for air inlet

5Display

6 Side cover, left

7 Side air outlet, left

8 Cooling medium connection, inlet

9 Tank drain nozzle (stop valve)

10 Adjustable overflow valve (bypass)

11 Rating plate

12 Cooling medium connection, return

13 Air outlet, rear

14 Radial fan

15 Master switch

16 Electrical interfaces

Note:

The motor circuit-breaker of the cooling me-

dium pump is accessed by opening the roof

plate. See also Q1 in section12.1 "Block diagram".

The chiller is equipped with an open reservoir for the

cooling medium.

Fig. 3: View from front (3334400)

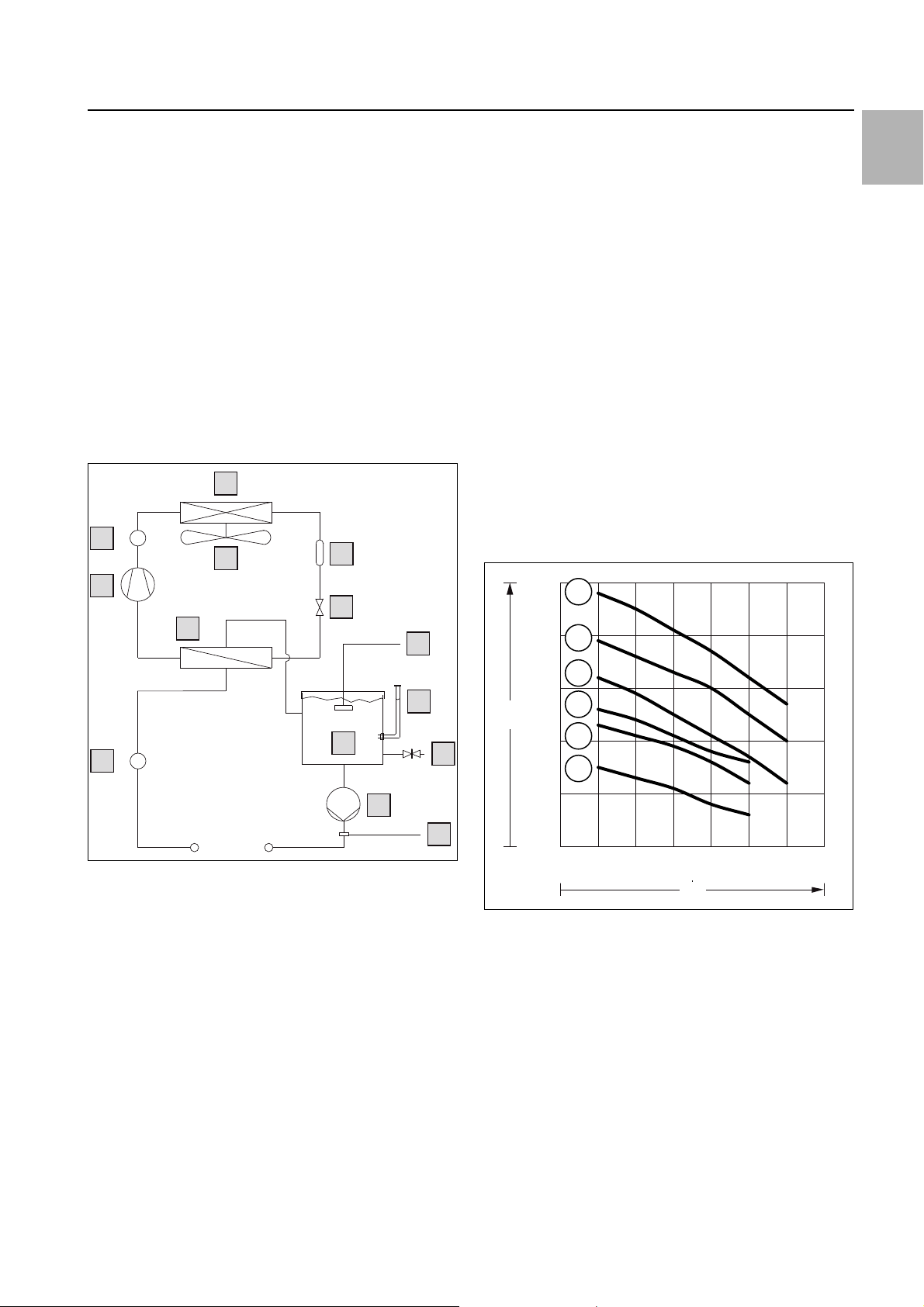

3.2 General functional description

The chiller comprises four main components (see fig. 5):

– Evaporator coil (item 12),

– refrigerant compressor (item 13),

– condenser (item 1) with fan (item 2),

– control or expansion valve (item 4),

which are connected together by pipes. A pressure

switch (item 14) limits the maximum pressure in the refrigerant circuit. The refrigerant R134a (CH2FCF3) is

chlorine-free. Its Ozone Depletion Potential (ODP) is 0.

A filter drier (item 3) which is integrated into the hermetically sealed refrigerant circuit provides effective protection against moisture, acid, dirt particles, and foreign

bodies. A temperature control with temperature probe

(item 6) ensures that the cooling medium is maintained

at a preset setpoint temperature.

In the evaporator coil (item 12), the liquid refrigerant is

converted to a gaseous state. The heat necessary for

this purpose is taken from the cooling medium in the

Fig. 4: View from rear (3334400)

8 Rittal Chiller Blue e+

plate heat exchanger, which has the effect of cooling the

cooling medium. The refrigerant is compressed in the

compressor (item 13). As a result the refrigerant has a

higher temperature than the ambient air. The DC inverter

technology enables load-specific speed control of the

compressor motor, so that only the power actually

needed is supplied.

This heat is dissipated to the ambient air over the surface

of the condenser (item 1), resulting in the refrigerant

liquefying again. A water-cooled condenser may optionally be used (see section3.6.6 "Water-cooled condenser").

Page 9

3 Device description

1

12

2

13

14

11

9

7

8

10

6

3

4

P

S

5

F

D

E

B

C

A

50 101520253035

6

5

4

3

2

1

P

Q

The refrigerant is injected into the evaporator (item 12)

via an electronic expansion valve (item 4), causing it to

expand and as a consequence is able to absorb the heat

from the cooling medium (water or water-glycol mixture).

The cooling medium is pumped to the equipment in an

additional circuit via the cooling medium tank (item 10)

and the cooling medium pump (item 9). The flow sensor

(item 11) ensures that the evaporator (item 12) is protected against freezing and running dry if the flow rate is

too low. The level switch (item 5) emits a warning if the

level in the cooling medium tank is too low. The inlet

temperature of the cooling medium (water or water-glycol mixture) is regulated using the temperature sensor

(item 6) on the water outlet. Optionally, an inverter pump

may also be used, so that the cooling medium pump is

also speed-controlled.

A layout drawing of the refrigerant circuit may be found

in fig. 5.

3.3 Control

The chillers are fitted with a controller for setting the

functions of the chiller.

Operation using this controller is described in section7

"Operation".

Within the compressor speed range from 25...100%, the

compressor is in continuous control mode. During continuous control mode, the control accuracy of the water

inlet temperature is ±0.5 K or better. At smaller loads requiring a speed of less than 25%, the compressor

switches to cycle mode, and the control accuracy of the

water inlet temperature is adjusted to ±2 K (refer to the

performance curves on the Rittal website).

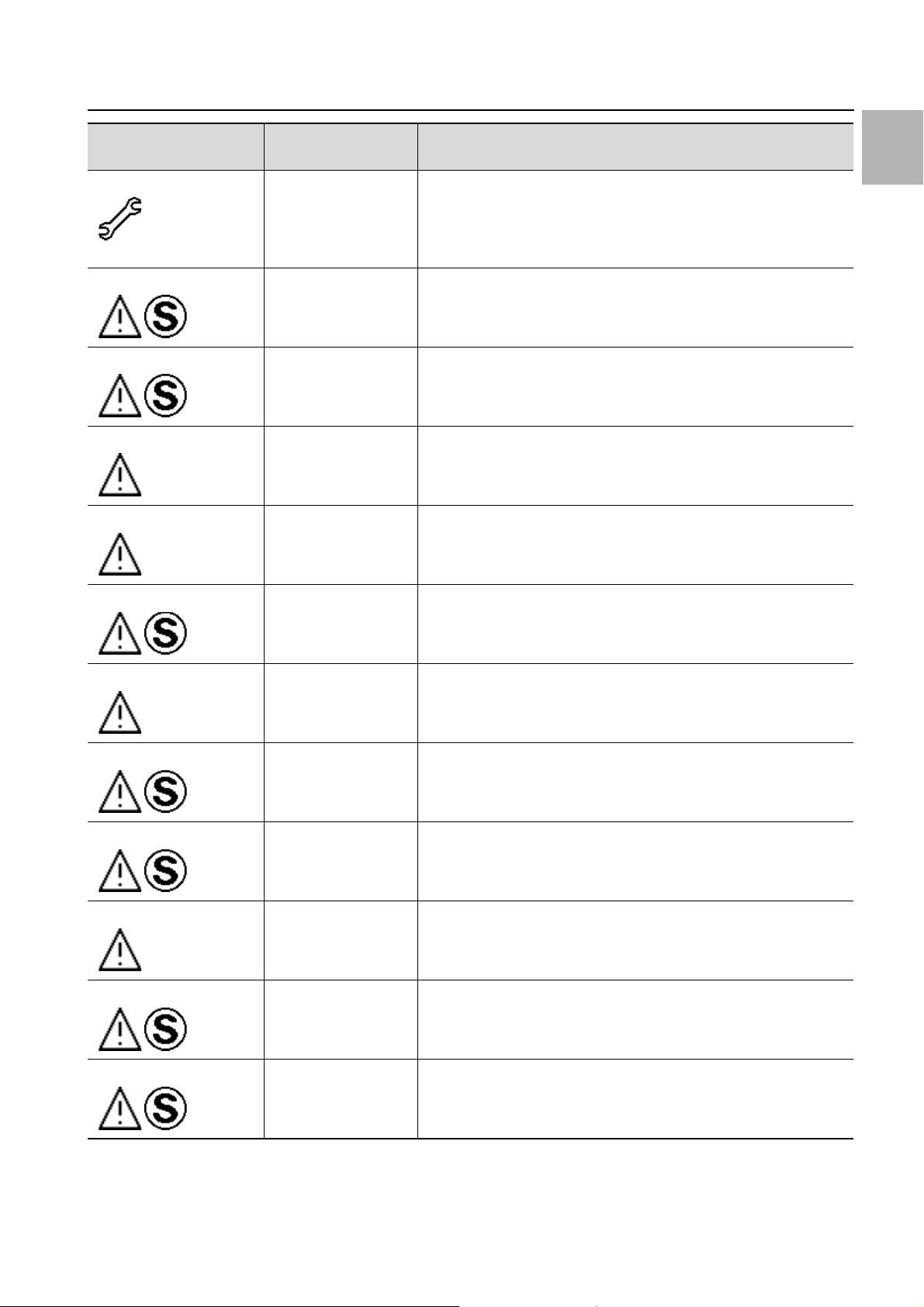

3.4 Characteristic curves

3.4.1 Characteristic curves of pump

Characteristic curves measured under the following

conditions:

– Ambient temperature (T

– Medium temperature (T

– Cooling medium "water"

) = 32°C

a

) = 18°C

w

EN

Fig. 5: Schematic diagram of refrigerant circuit

Key

1 Condenser, air-cooled

2 Condenser fan (radial fan)

3 Filter dryer

4Expansion valve

5 Fill level monitoring

6 Temperature sensor

7 Fill nozzle

8 Tank drain nozzle

9 Cooling medium pump

10 Cooling medium tank

11 Flow sensor

12 Evaporator (plate heat exchanger)

13 Compressor

14 Pressure-operated switch

Rittal Chiller Blue e+ 9

Fig. 6: Characteristic curves

Key fig. 6

A 3320200 standard pump 50 Hz

B 3320200 standard pump 60 Hz

C 3320200 reinforced pump 50 Hz (option) or

3334300 and 3334400 standard pump 50 Hz

D 3320200 reinforced pump 60 Hz (option) or

3334300 and 3334400 standard pump 60 Hz

E 3334300 and 3334400 reinforced pump 50 Hz (option)

F 3334300 and 3334400 reinforced pump 60 Hz (option)

P External static pressure [bar]

Q Delivery flow [l/min]

The flow speed of the circulating medium is monitored

with a flow sensor. The sensor has a preset alarm

threshold and a variable warning threshold that can be

Page 10

3 Device description

EN

set by the operator. When the warning threshold is

reached, a message is produced, and when the alarm

threshold is reached, a fault is generated.

If the flow rate of the circulating medium during operation drops below 4 l/min, the integrated flow sensor will

trip.

3.4.2 Performance diagrams

The performance diagrams can be found on the Rittal

website.

3.5 Safety devices

– In the cooling circuit, the chiller has a type-tested pres-

sure monitor (to EN 12263) which switches off the

chiller if the maximum admissible pressure is exceeded. Once the pressure drops back below the admissible pressure, the unit will automatically resume operation.

– Temperature monitoring prevents the evaporator coil

from icing over. The compressor gradually reduces the

output within the range 100...25%. If the risk of icing

persists for more than 2 minutes, the compressor will

switch off completely. At higher temperatures, the unit

automatically returns to control mode.

– The compressor motor and the fan motor are moni-

tored and protected by the inverter to prevent overloading.

– The cooling medium pump has a motor circuit-breaker

to prevent overcurrent and short-circuits.

– To ensure smooth-running and reliable operation (for

example after reaching the setpoint temperature or after a fault), the compressor automatically switches

back on after a delay.

– The chiller has floating contacts on terminals 8 to 10 of

the signal connector (X2), via which system messages

from the device may be polled, e.g. using a PLC (2 x

normally closed or normally open contacts).

3.6 Options

3.6.1 Inverter pump

The cooling medium pump can be designed as an inverter pump. In such cases, the pump is speed-controlled depending on the actual cooling medium demand

(see section12.5 "Operation of inverter pump").

3.6.2 Reinforced pump

For applications requiring a higher cooling medium

throughput or pressure, the cooling medium pump can

be designed in a higher output category.

3.6.3 Outdoor

The "Outdoor" option allows the chiller to be sited outside. To this end, the chiller is coated with a special

spray-finish. Outdoor siting means that the air at the system installation site is not additionally subject to waste

process heat.

For outdoor siting, a rain canopy should be provided by

the customer to protect the chiller from downpours.

Note:

With outdoor siting of the chiller, it is impor-

tant to ensure that a suitable cooling medium

is used (see section6.2 "Filling the cooling

medium"). This is the only scenario in which

operation to -20°C is admissible.

3.6.4 Oil/emulsion

Oil or an emulsion may also be used as a cooling medium, instead of the water/glycol mixture used as standard. In such cases, the components in the cooling circuit

are adapted accordingly, and the thermal capacity of the

cooling medium must be stored in the control system.

Note:

For the purpose of these instructions, we

have assumed that a water/glycol mixture is

used as the cooling medium.

3.6.5 Free Cooling

The "Free Cooling" option allows you to cool without the

refrigerant circuit in so-called hybrid mode. If this type of

cooling is preselected in the control system, with outdoor siting of the chiller, the system first attempts to use

only the (cold) ambient air to cool the cooling medium. If

this is no longer possible because the external temperatures are too high, it automatically activates the conventional cooling circuit to supply the required cooling medium temperature.

3.6.6 Water-cooled condenser

The condenser may be water-cooled. In such cases, a

separate cooling circuit must be connected to the condenser.

3.6.7 Tank heating

A tank heater may be installed to pre-heat the cooling

medium or for frost protection. A setting is made in the

control system to determine when the tank heater is

switched on and off.

3.7 Proper use, foreseeable misuse

The chiller is only used for cooling water-glycol mixtures.

Any other use is deemed improper. One exception to

this is operation with the "oil/emulsion" option (see section3.6.4 "Oil/emulsion").

When using other fluids, please refer to the technical

specifications in the appendix, or contact the manufacturer. Under no circumstances should the specified limits in the technical data be exceeded.

The chiller is state of the art and built according to recognised safety regulations. Nevertheless, improper use

can pose a threat to the life and limb of the user or third

10 Rittal Chiller Blue e+

Page 11

4 Transport

parties, or result in possible damage to the system and

other property.

Consequently, the chiller must only be used properly

and in a technically sound condition! Any malfunctions

which impair safety should be rectified immediately.

Proper use also includes the observance of the documentation provided and compliance with the inspection

and maintenance conditions, and strictly professional

use as defined in DIN EN 61000-3-2.

Rittal GmbH & Co. KG is not liable for any damage which

may result from failure to comply with the documentation provided. The same applies to failure to comply with

the valid documentation for any accessories used.

Inappropriate use may be dangerous. Examples of inappropriate include:

– Use of the chiller for cooling flammable or combustible

substances.

– The chiller must never be used for the direct cooling of

liquids used in the food industry (e.g. drinking water).

– Use of impermissible tools.

– Improper operation.

– Improper rectification of malfunctions.

– Use of accessories not approved by Rittal GmbH &

Co. KG.

3.8 Supply includes

Qty. Description

1Chiller

1 Shipping bag with

1 – Assembly and operating instructions

1 – Connector

1 – Signal connector

4 – Eyebolt and plastic washer

2 – M25 screw connection

1 – M20 screw connection

Tab. 2: Scope of supply

4.2 Unpacking

Only transport the chiller in its original packaging ma-

terial before commissioning for the first time.

Remove the packaging materials from the chiller.

Note:

After unpacking, the packaging materials

must be disposed of in an environmentally

friendly way.

Check the chiller for any damage that may have oc-

curred during transport.

Note:

Damage and other faults, e.g. incomplete de-

livery, should be reported immediately, in

writing, to the shipping company and to Rittal

GmbH & Co. KG.

Check the supply contents for completeness (see sec-

tion 3.8 "Supply includes").

4.3 Transport

If the chiller is stored or transported at temperatures below freezing, return to room temperature before commissioning. This instruction also applies to the external

condenser circuit for a water-cooled condenser (option).

When transporting the chiller, please make allowance

for the weight specified in section12.3 "Technical

specifications".

Use lifting gear with a suitable load capacity.

If it is necessary to move the chiller in the factory, you

must disconnect all connections on the chiller.

Before transporting, empty the water circuit and tank

(see section8 "Inspection and maintenance").

Prevent excessive vibration.

Only transport the chiller upright.

Only transport the chiller on the pallet supplied with the

chiller or with the eyebolt provided (fig. 7, item 1).

Serrated washers for earthing are fitted to the eyebolts

in the mounted state. After transportation, the eyebolts

are exchanged for the pan-head screws provided. Plastic washers are included in the bag of accessories to

protect the paint.

Protect the chiller from unintentional movement (e.g.

when being transported by vehicle).

EN

4Transport

4.1 Delivery

The chiller is supplied in a packaging unit in a fully assembled state.

Check the packaging carefully for signs of damage.

Traces of oil on damaged packaging indicate a loss of

refrigerant and/or a leak in the chiller. Any packaging

damage may be the cause of a subsequent functional

failure.

Rittal Chiller Blue e+ 11

Page 12

EN

1

1

1

1

4 Transport

Fig. 7: Eyebolt for transportation (3320200)

12 Rittal Chiller Blue e+

Page 13

5 Assembly and connection

710 mm450 mm

1020 mm

450 mm

710 mm

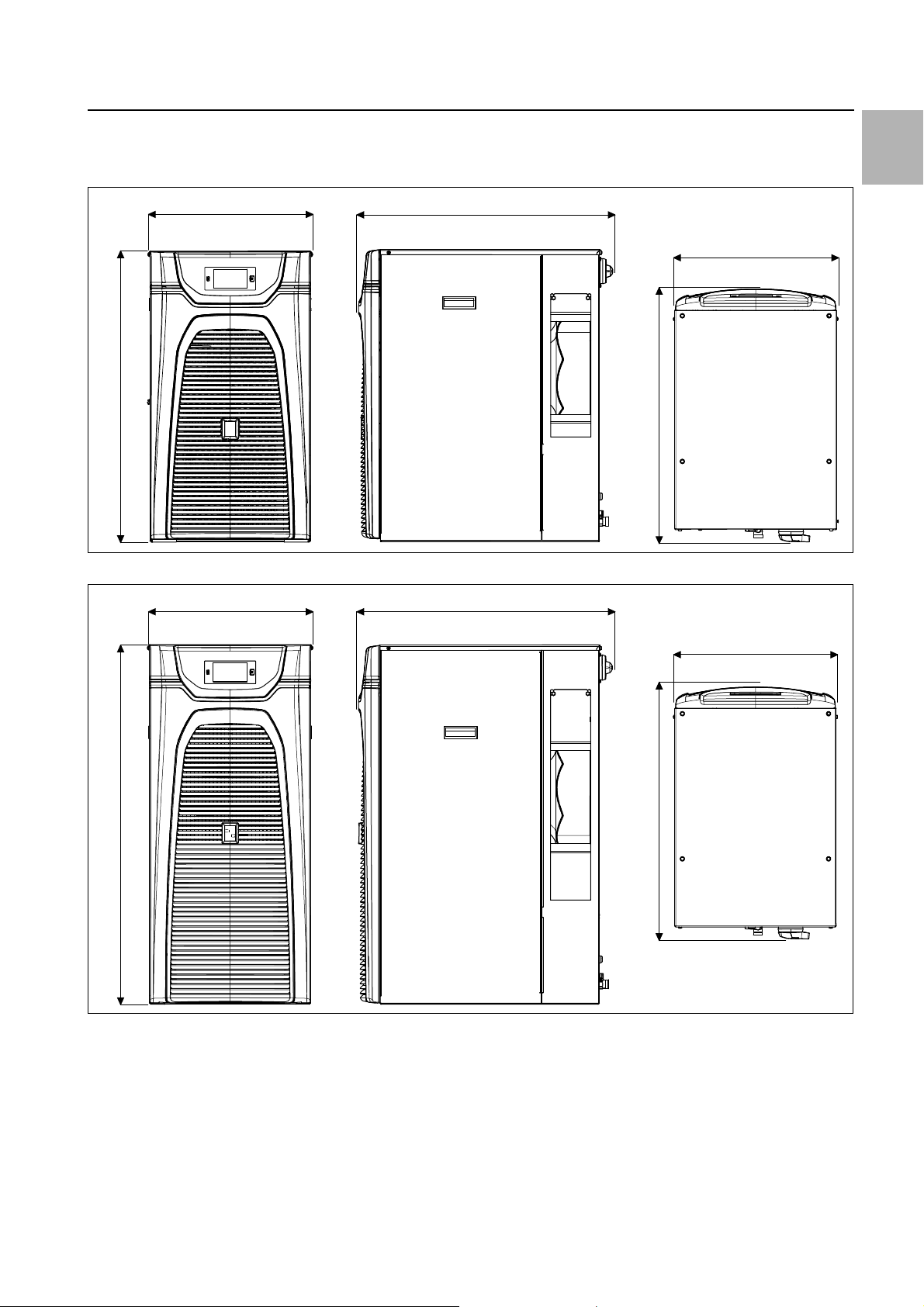

5.1 Dimensions

5 Assembly and connection

EN

450 mm

820 mm

Fig. 8: Dimensions 3320200 and 3334300

710 mm

450 mm

710 mm

Fig. 9: Dimensions 3334400

5.2 Installation site requirements

– The chiller must be adequately protected from external

weather conditions.

– If the ambient air contains a high concentration of dust

or oily substances, the chiller should be fitted with a

metal filter (see section11.4 "Metal filter (aluminium filter)").

Rittal Chiller Blue e+ 13

– The supporting surface should be flat and sufficiently

robust to hold the weight (see section12.3 "Technical

specifications") during operation.

– If the chiller is sited outdoors, the "Outdoor" option

must be used (see section3.6.3 "Outdoor").

– The ambient temperature must lie within the limit val-

ues indicated in the technical specifications (see sec-

tion12.3 "Technical specifications").

Page 14

5 Assembly and connection

300 mm

EN

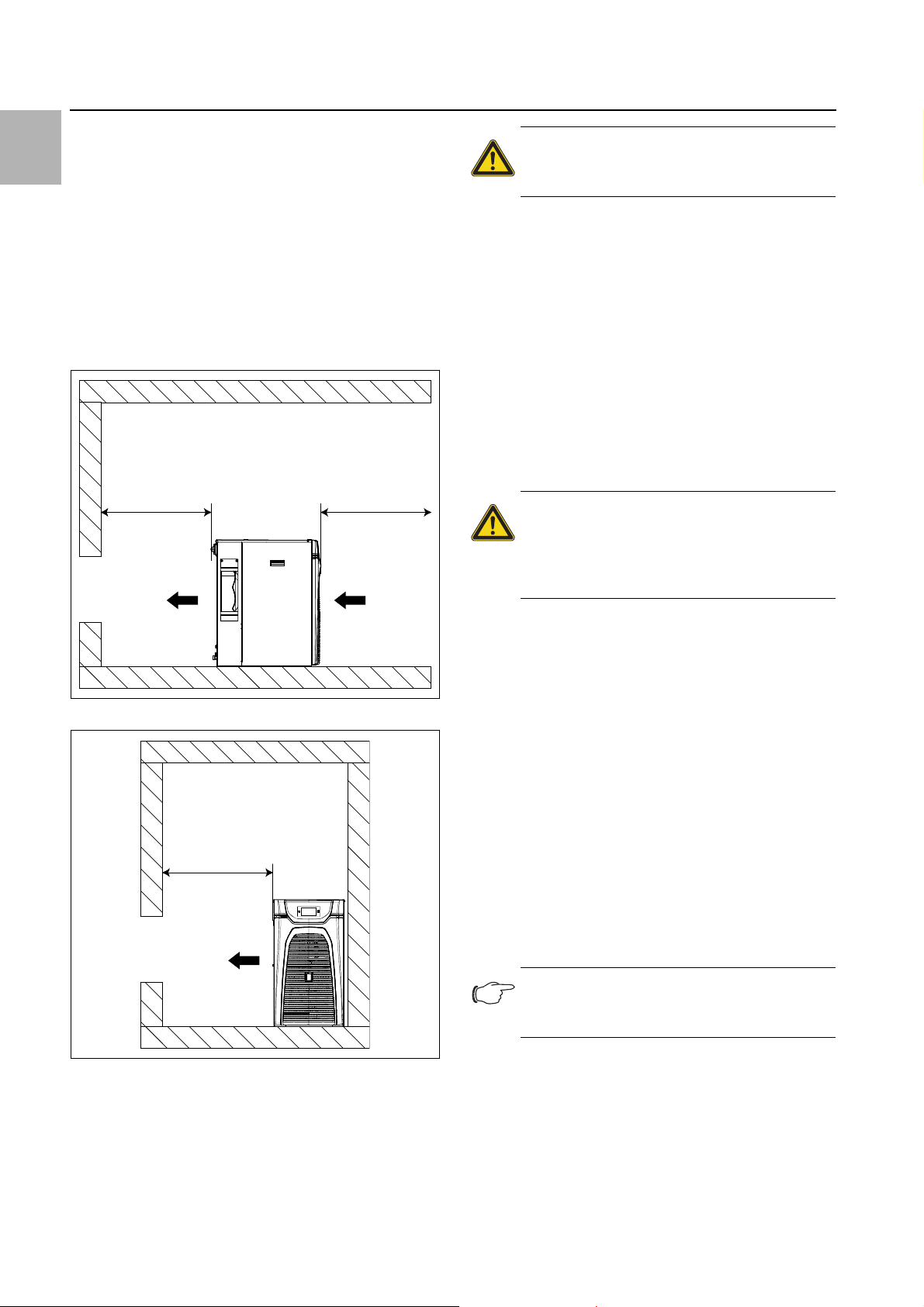

– In order to prevent performance losses caused by

pressure drops in the pipework, the chiller should be

sited as close as possible to the equipment.

– At least one of the openings (left or right) must be freely

accessible to enable the unhindered expulsion of hot

air (see fig. 11). To allow connection of the supply lines

and facilitate maintenance and repair work, the minimum distances shown under fig. 10 should be adhered to.

– In order to avoid an "air short-circuit" (mixing of air in-

take and waste air) and ensure full cooling performance, the minimum distances shown under fig. 10

should likewise be adhered to.

300 mm 800 mm

Caution!

The connection of an air intake / waste

air duct is inadmissible.

To prevent performance losses, do not install the chill-

er near any form of heating.

Outdoor siting

Chillers must be installed such that they cannot become

damaged by internal traffic and transport operations.

5.3 Installing the chiller

Install the chiller on an even, firm surface. The maxi-

mum permissible deviation from the vertical is 2°.

Avoid the production of noise due to vibration (vibra-

tion dampers, sheets of foam rubber).

5.4 Making the hydraulic connection

Caution!

Risk of damage to the cooling medium

pump due to soiling in the cooling medium circuit! Flush the cooling medium circuit prior to connecting the chiller.

Fig. 10: Minimum distances, front/rear

Fig. 11: Minimum distances, sides

Ensure the room is adequately ventilated by installing

the chiller such that the warm exhaust air does not

heat the room excessively.

In case of installation in a "small" room, it is imperative

that you provide forced ventilation, as otherwise the

heat dissipated will build up.

The cooling medium outlet (fig. 2 or fig. 4, item 8) on the

chiller must be connected to the cooling medium inlet on

the equipment to be cooled. At the same time, the cooling medium inlet (fig. 2 or fig. 4, item 12) on the chiller

must be connected to the cooling medium outlet on the

equipment to be cooled. Please observe the following:

– To avoid condensation, always connect the equip-

ment using insulated pipelines and/or hoses.

– The nominal width of the piping must correspond at

least to the nominal width of the media connections on

the chiller.

– The cooling medium infeed to the chiller must be pres-

sureless, because the tank used in the system is open

to the atmosphere.

– Never connect the chiller to the drinking water supply.

– The pipework must be approved for the maximum

pressure expected (see section12.3 "Technical spec-

ifications").

Note:

The use of steel pipes or galvanised steel

pipes is inadmissible.

Prior to commissioning, it is imperative that the cooling

medium pump is filled with cooling medium and bled

(see section6.3 "Bleeding the cooling medium pump").

14 Rittal Chiller Blue e+

Page 15

5 Assembly and connection

Caution!

An insufficient flow rate will trigger the

safety devices in the chiller. Pay attention to the minimum pressure required

and the minimum flow rate required (see

section12.3 "Technical specifications").

If the cooler on the equipment to be cooled is higher

than the chiller, we recommend installing a non-return

valve in the feed as well as a solenoid valve in the cooling

medium circuit return to prevent the tank from overflowing.

A bypass valve should be connected between the inlet

and return to protect the cooling medium pump. This

opens automatically, for example, if the equipment cycle

is shut off. Section6.5 "Adjusting the bypass valve" describes how to set the bypass valve.

5.5 Connecting the cooling circuit (optional)

If the chiller is equipped with the "water-cooled condenser" option (see section3.6.6 "Water-cooled condenser"), a cooling water supply must additionally be

connected to the condenser.

Additionally make the cooling water connections to

the condenser.

5.6 Making electrical connection

When carrying out the electrical installation, observe all

applicable national and regional regulations as well as

the regulations from the responsible utility company.

– Electrical installation must only be carried out by a

qualified electrician who is responsible for compliance

with the existing standards and regulations.

– All cables routed into the wiring compartment have to

be insulated for the maximum voltage of the power

supply.

Note:

The mains supply must be of a shielded de-

sign to guarantee the level of EMC protection.

– The cable shielding can contact the earth

terminal to the enclosure inside the connection box (fig.13, item 1).

– To ensure the proper functioning of internal presso-

stats in the event of a malfunction, a slow (time delay)

line fuse of no less than 15 A is required.

– Low-noise potential equalisation must be guaranteed

with the mains connection. As a general principal, the

chiller must be integrated into the building's potential

equalisation system.

– The conductor cross-sections of the power cable

must be selected according the rated current (see rating plate).

– The connection must be made with the field rotating

clockwise. The direction of rotation of the field can be

measured at the connection terminals L1, L2 and L3.

Connect with a clockwise rotating field to ensure that

the cooling medium pump motor rotates in the correct

direction.

Overvoltage protection and supply line load

– The chiller does not have its own overvoltage protec-

tion. Measures must be taken by the operator at the

supply end to ensure effective lightning and overvoltage protection.

– The mains voltage must not deviate by more than the

tolerance specified in section12.3 "Technical specifications".

– The chiller and its power electronics are designed in

accordance with overvoltage category III. If the combined output of the frequency converters, power converters or transformers in the network where the device is being operated is >70 kVA, the customer must

connect a Class II surge voltage protector in the mains

supply line upstream of the chiller. The surge voltage

protector must be designed to EN 61800 -1. The following values may be assumed as starting-points for

the design:

Transformers,

power electronics

70 kVA…100kVA 40J

100 kVA…200kVA 80J

200 kVA…400kVA 160J

400 kVA…800kVA 320J

Tab. 3: Design of the surge voltage protector

Assumed discharge

energy

EN

Connection data

– The connected voltage and frequency must corre-

spond to the ranges stated on the rating plate. The

units support multiple voltages.

– The chiller must be connected to the mains via an all-

pole isolating device.

– If a motor circuit-breaker or circuit-breaker is used, it

should be selected in accordance with EN 60898-1

(tripping characteristic type D).

Rittal Chiller Blue e+ 15

Interfaces

If you would like system messages from the chiller to be

evaluated via the alarm relay, you should also connect a

suitable low-voltage cable to the X2 signal connector

(see section5.6.2 "Connecting the alarm relay query device").

If you require remote activation of the chiller, this can

likewise be achieved via the X2 signal connector (see

section5.6.3 "External activation") and appropriate programming (see section7.4.2 "Remote").

Page 16

EN

3

4

1

2

5 Assembly and connection

5.6.1 Installing the power supply

Remove the mains connector from the dispatch bag

and connect to the mains as shown on the connection

diagram (fig. 12).

Fig. 12: Circuit diagram

Strain relief

Please provide suitable strain relief for the connection

cable.

When connecting the cooling unit in accordance with

NFPA 70 (NEC):

Use the cover for the connection unit and a conduit fit-

ting.

Use copper conductors only to connect the supply ca-

ble to the mains connector.

5.6.2 Connecting the alarm relay query device

System messages from the cooling unit may be output

to an external signal source via two floating relay outputs.

AC

cos φ = 1

I max. = 2 A

U max. = 250 V

Tab. 4: Contact data

5.6.3 External activation

The chiller has been prepared for control via an external

signal.

Connect a floating contact to terminals 5 and 6 of the

X2 signal connector.

Configure how you want the external enabling signal to

be evaluated (see section7.4.2 "Remote").

This function is deactivated by default, i.e. the chiller is

permanently in operational mode. With the function activated and the contact open, the cooling function and,

where applicable, the cooling medium pump are

switched off.

5.6.4 Room temperature sensor (accessories)

The chiller allows for room-temperature-based control.

This requires a room temperature sensor (see section11.9 "External temperature sensor"), available as an

optional accessory.

Connect the room temperature sensor to terminals 1

and 2 of the X2 signal connector.

Configure the chiller control mode so that the temper-

ature is regulated by the sensor measurement (see

section7.4.1 "Control parameters").

Fig. 13: Connection box

Key

1Earth tag

2 Connector connection (X1)

3 IoT interface connection 3124300 (X4)

4 Connection for signal connector (X2)

Note:

The factory setting of the relay outputs in their

de-energised state is NO (Normally Open).

Connect a suitable connection cable to the connec-

tion terminals 9 (Alarm K1) and/or 10 (Alarm K2) of the

signal connector (X2).

Configure the alarm relays you wish to use to output

error messages (see section 7.4.4 "Alarm relays").

5.7 Installing the filter mats (accessories)

For dry, coarse dust and lint in the ambient air, we recommend installing an additional PU foam filter mat (available as an accessory) in the chiller. Depending on the incidence of dust, you will need to replace the filter mat

from time to time (see section5.7 "Installing the filter

mats (accessories)").

For ambient air containing oil, we recommend the use of

metal filters (see section11.4 "Metal filter (aluminium filter)"). These may be cleaned with suitable detergents

and reused (see section8.4 "Cleaning the filter mat (accessories)").

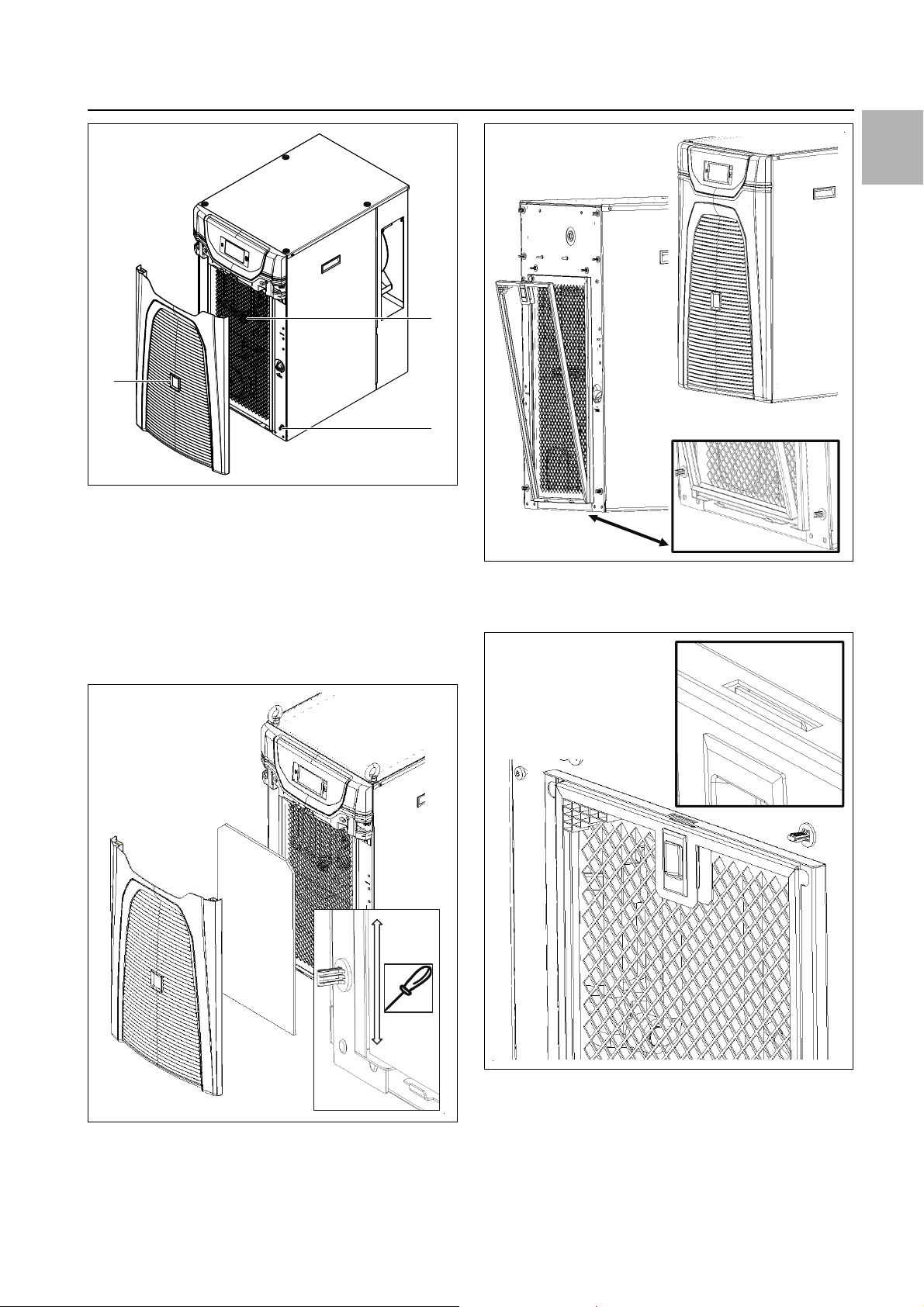

Types 3320200 and 3334300

At the front of the chiller, pull the louvred grille (fig. 14,

item 3) away from the mounting clips (fig. 14, item 2),

and place or lay it down somewhere safe.

16 Rittal Chiller Blue e+

Page 17

Fig. 14: Pull off the louvred grille 3320200 and 3334300

3

2

1

Key

1 Filter holder

2 Mounting clips (4x)

3 Louvred grille

Textile filter mat

Re-insert the filter mat into the frame at the front.

If necessary, use a tool, such as a screwdriver, to

press the filter into the U-section of the frame.

5 Assembly and connection

EN

Fig. 16: Insert the metal filter 3320200 and 3334300

Press in the filter at the top until the lug locks home

into the frame.

Fig. 17: Press in the metal filter 3320200 and 3334300

Textile filter mat and metal filter

Fig. 15: Insert the textile filter mat 3320200 and 3334300

Metal filter

Position the metal filter on the frame at the bottom.

Rittal Chiller Blue e+ 17

Press the louvred grilles back onto the mounting clips.

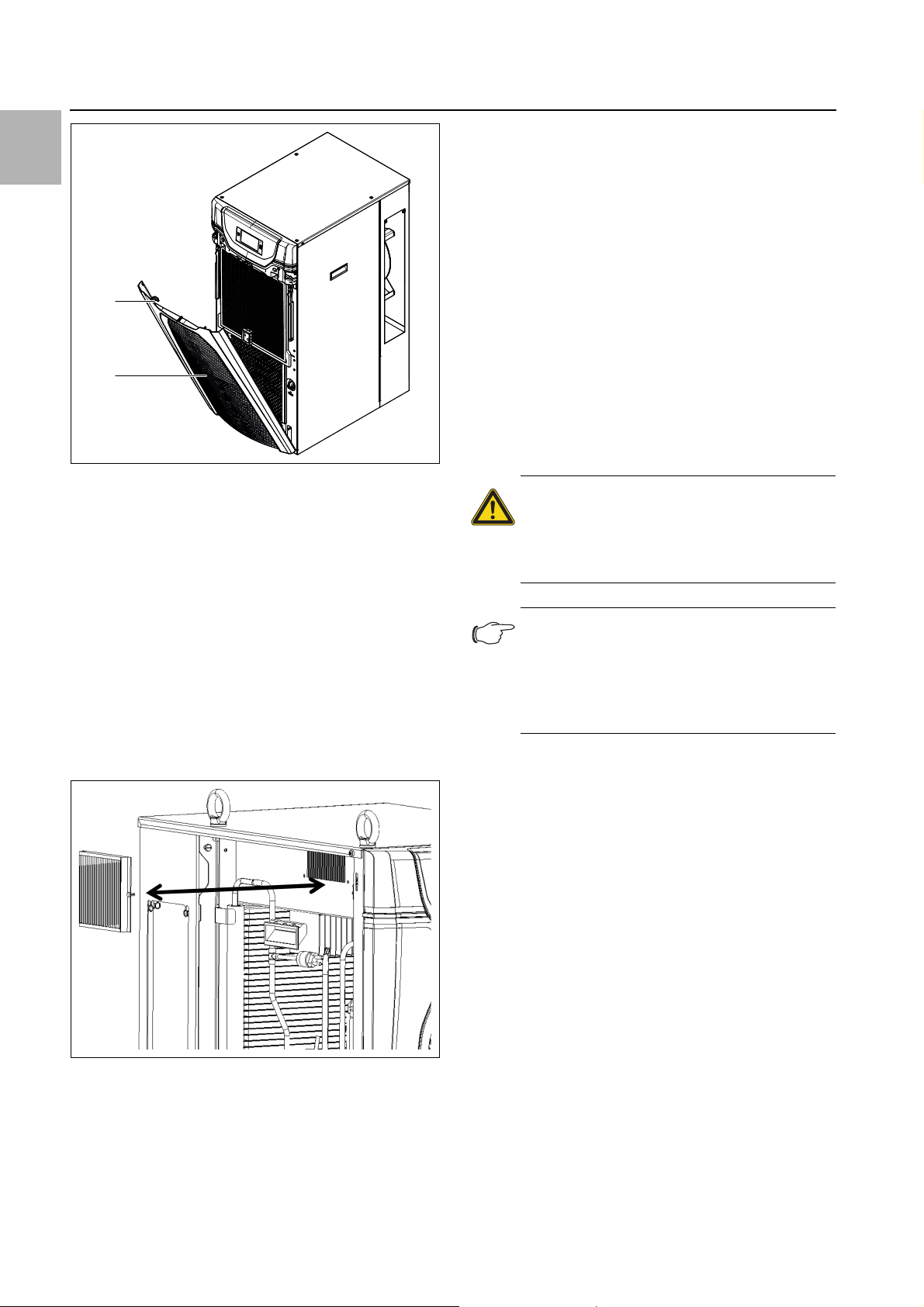

Type 3334400

Open the louvred grille below the infill panel by flipping

forwards (fig. 18, item 1).

Page 18

EN

1

2

6 Commissioning

Fig. 18: Flip open the louvred grille 3334400

Key

1 Louvred grille

2 Filter holder

Push the textile filter mat or metal filter into the back of

the filter holder on the rear of the louvred grille.

Push the louvred grille backwards so that it locks

home on the chiller.

Install the pleated filter for the inverter housing

Remove the left-hand side panel, and place or lay it

down somewhere safe.

If a pleated filter is already installed, loosen the split riv-

ets and remove the pleated filter from the inverter

housing.

6 Commissioning

The chiller has a master switch allowing it to be switched

off for maintenance work.

In day-to-day operation, it should be switched on and off

by the higher-level controller.

6.1 Cooling medium water-glycol mixture

As standard, the chiller is not suitable for operation below the specified minimum temperature (see section12.3 "Technical specifications").

Generally speaking, a water-glycol mixture with a maximum glycol proportion of between 20 and 34% by volume should be used as the cooling medium. We recommend our ready-mixed "Cooling medium for chillers"

(see section6.1.4 "Recommended "Cooling medium for

chillers""). Other water-glycol mixtures may be possible

in individual cases, but only in consultation with the manufacturer.

Caution!

Other additives may damage the pipes

and the seal on the cooling medium

pump, and are therefore only admissible

by arrangement with Rittal.

Note:

With the chiller sited outdoors ("Outdoor" option), it is important to adjust the glycol proportion accordingly. This can be ensured by

using the premixed outdoor medium "Cooling medium for chillers".

6.1.1 General remarks

When cooling the water-glycol mixture in an open circuit,

always remember that algae, deposits and corrosion

can damage the chiller. Residues will always impair the

performance of the chiller. Without water treatment it is

only seldom possible to achieve satisfactory conditions.

By means of regular monitoring of the quality of the cooling medium and cooling medium treatment, you must

ensure that deposits and corrosion are avoided, even

under extreme conditions.

6.1.2 Cooling medium requirements

The cooling medium must not cause any limescale deposits or loose debris. In other words, it should have a

low level of hardness, particularly a low level of calcium

hardness. In particular, the level of calcium hardness

should not be too high when using the equipment for re-

Fig. 19: Insert the pleated filter.

Insert a new pleated filter and secure with the split

rivet.

Close the side panel again.

circulated cooling. On the other hand, the cooling medium should not be so soft that it attacks the materials.

When recooling the cooling medium, the salt content

should not be allowed to increase excessively due to the

evaporation of large quantities of water, since the electrical conductivity will increase as the concentration of

dissolved substances rises, and the cooling medium will

become more corrosive. For this reason, not only is it al-

18 Rittal Chiller Blue e+

Page 19

6 Commissioning

ways necessary to add a corresponding quantity of fresh

water, but also to remove part of the enriched cooling

medium.

Furthermore, the properties of the water used must not

deviate from the following list of hydrological data:

Properties Value

p

value (7) 7.5 – 8.5

H

Electrical conductivity 200 – 1000 μS/cm

Residue on evaporation < 500 mg/dm³

Sedimentary substances < 3 mg/dm³

Hardness 3 – 8°dH (for German-

speaking regions)

Ca + Mg 0.5 – 2 mmol/l (for interna-

tional region)

Hydrogen carbonate 1 – 5 mmol/dm³

(60 – 300 mg/dm³)

Free CO

Sulphide < 0.01 mg/dm³

Chloride < 50 mg/dm³

Sulphate < 250 mg/dm³

Nitrate < 25 mg/dm³

Nitrite < 0.1 mg/m³

COD < 7 mg/dm³

NH

Fe < 0.1 mg/dm³

Mn < 0.1 mg/dm³

Cu < 0.1 mg/dm³

Tab. 5: Hydrological data

2

4

< 10 mg/dm³

< 0.05 mg/dm³

niques to eliminate them in industrial cooling are shown

in the following table:

Type of impurity Removal

Mechanical contamination Filtering of the cooling medi-

um via mesh filter, gravel filter, cartridge filter, or precoated filter

Excessive hardness: Softening of the cooling me-

dium using ion exchange

Moderate content of mechanical contaminants and

hardeners

Moderate levels of chemical

contaminants

Biological contaminants,

slime bacteria and algae

Tab. 6: Impurities and removal

Addition of stabilisers

and/or dispersing agents to

the water

Addition of passifiers and/or

inhibitors to the cooling medium

Addition of biocides to the

cooling medium

6.1.4 Recommended "Cooling medium for chillers"

Rittal recommends the use of "Cooling medium for chillers" (water-glycol mixture). This is a ready-mixed solution and is therefore suitable for immediate use (without

the need for mixing) (tab. 7).

Composition

Glycol (20-30% max.) + water (70-80% max.) = readymix ("Cooling medium for chillers")

Model No. Quantity [l] Application

3301950 10 Outdoor

3301960

3301955

10 Indoor

25 Outdoor

EN

Note:

The cooling medium thickens due to evaporation. You can return the values to within the

3301965 25 Indoor

Tab. 7: Model numbers – Cooling medium for chillers

usual ranges by completely replacing the

cooling medium (see section8.2 "Monitoring

the cooling medium").

Only use distilled or de-ionised water in chillers specified for such use (see data sheet in

Note:

When glycol is used, the cooling perfor-

mance is reduced, depending on the glycol

concentration (tab. 8).

section12.3 "Technical specifications").

6.1.3 Preparation and care

There are specific cooling medium requirements depending on the type of equipment being cooled. A suitable process must then be used to prepare and/or maintain the cooling medium to suit the level of contamination

and the size and design of the chiller. The most common

types of contamination and most frequently used tech-

Rittal Chiller Blue e+ 19

Page 20

EN

6 Commissioning

Cooling medium for

chillers

Standard

(20% glycol)

Antifreeze: -10°C

Outdoor

(30% glycol)

Antifreeze: -20°C

Tab. 8: Performance loss

To prevent problems in the cooling medium circuit (including water-cooled chillers), it is imperative that the

VGB Cooling Water Guidelines (VGB-R 455 P) are observed.

The correct glycol concentration proportions may be

read and determined using a refractometer.

6.2 Filling the cooling medium

The composition of the cooling medium is described in

section6.1 "Cooling medium water-glycol mixture".

For commissioning, proceed as follows:

Ensure that any shut-off valves installed in the cooling

medium circuit are open.

Temp.

[°C]

10 -6

15 -6

18 -6

10 -13

15 -13

18 -13

Loss of cooling performance compared

with pure water [%]

At the front of the chiller, pull the louvred grille away

from the mounting clips, and place or lay it down

somewhere safe.

Fill the chiller tank with cooling medium via the fill noz-

zle (fig. 20, item 2).

Check the fill level on the inspection glass (fig. 20,

item 4).

If the "Low fill level" warning appears, top up with ap-

proximately 7 litres of cooling medium.

If the tank is over-filled, or if a leak occurs, the cooling

medium will run off via a hole in the centre of the gland

plate.

Note:

Glycol poses a threat to groundwater. The

plant operator is obliged to observe the relevant requirements on groundwater protection in his country.

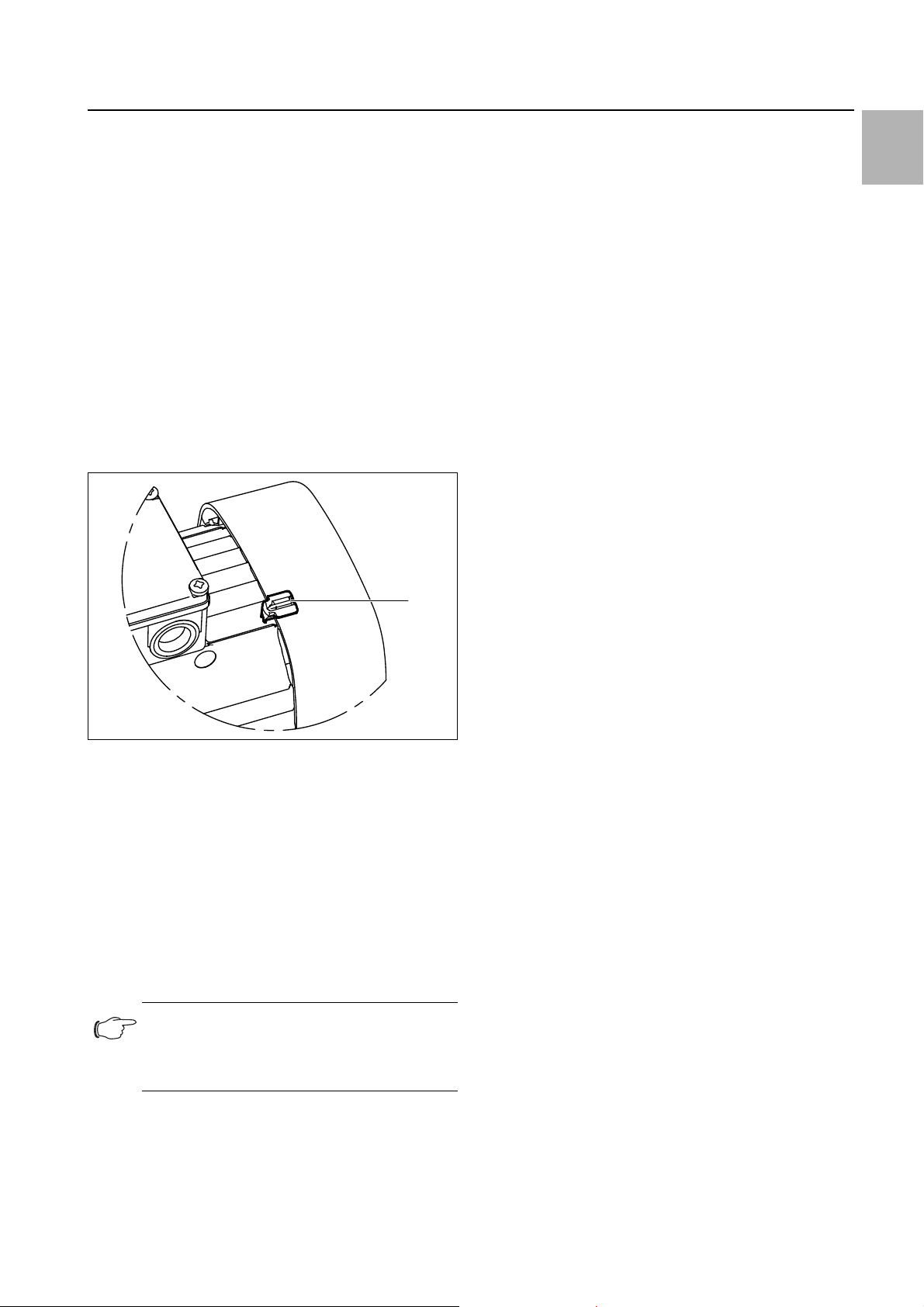

6.3 Bleeding the cooling medium pump

Bleed the pipes and top-up the cooling medium (see

section6.2 "Filling the cooling medium").

Bleed the cooling medium pump (with the system at a

standstill) by loosening the vent screw (fig. 21, item 1).

As soon as cooling medium escapes from the vent

screw, bleeding of the pump is complete.

1

1

2

3

4

Fig. 20: Filling the cooling medium

Key

1 Cooling medium pump

2 Fill nozzle for cooling medium

3 Supply tank

4 Inspection glass

Fig. 21: Bleeding the cooling medium pump

Key

1Vent screw

Re-tighten the vent screw.

Note:

With a water-cooled condenser (option), you

must activate the external condenser circuit

for the condenser.

Check the connection lines and pipe connections for

leaks during commissioning.

20 Rittal Chiller Blue e+

Page 21

7 Operation

1

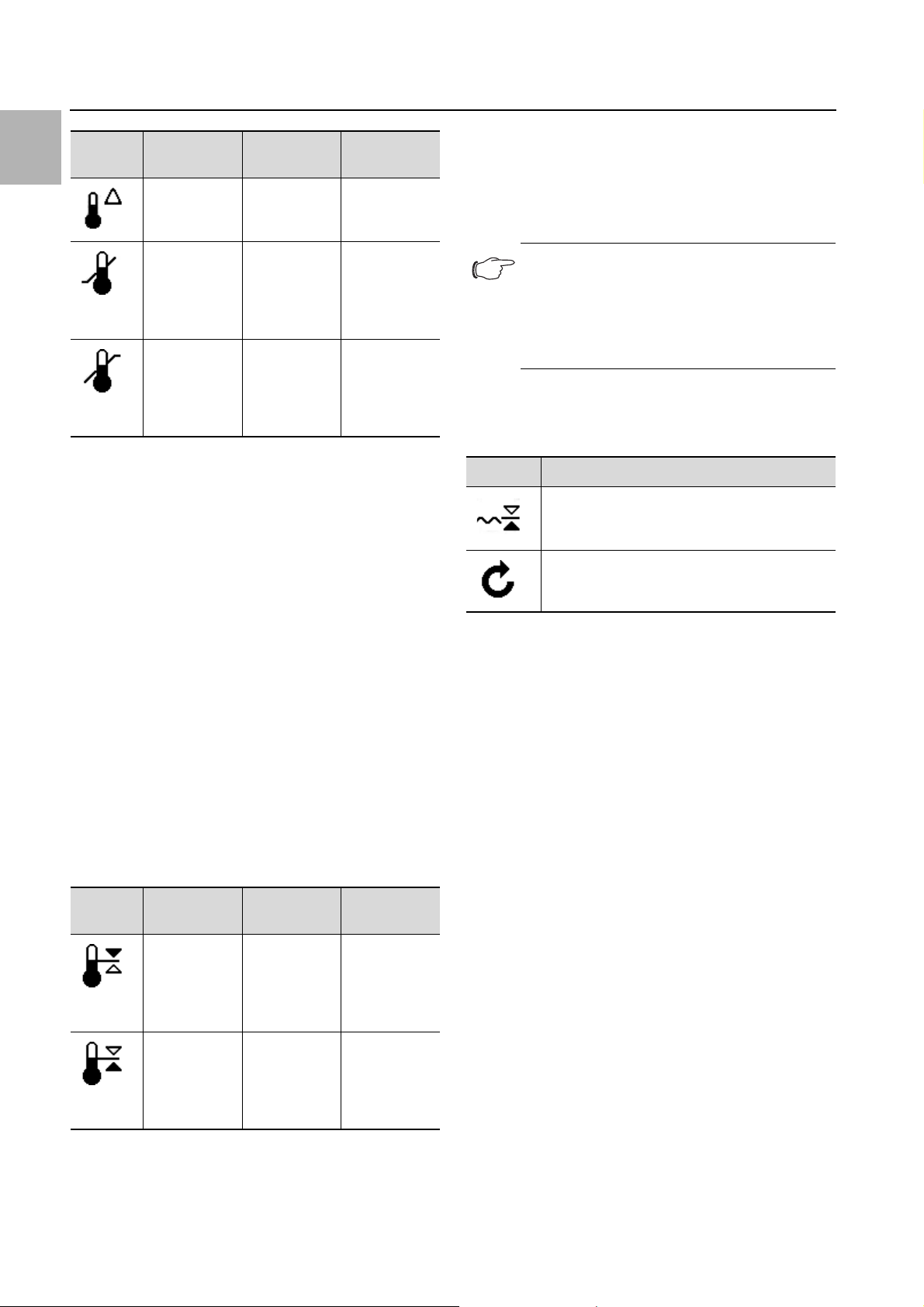

6.4 Commissioning procedure

Before switching on the motor for the first time, or if the

position of the display showing the direction of rotation

has been altered, check whether the display is working correctly, e.g. by moving the display panel with

your finger.

Switch on the power supply to the chiller via the super-

ordinate controller.

Switch the master switch into the "I" position.

The Rittal logo will initially appear on the display, followed a short time later by the start screen.

Check the direction of rotation of the motor in the cool-

ing medium pump.

The cover of the motor fan is equipped with a display

showing the direction of rotation (fig. 22). The motor

cooling air is used for the rotation direction display.

The correct direction of rotation is also indicated by arrows on the motor fan cover.

Fig. 22: Checking the direction of rotation

Key

1 Rotation direction display

If required, the condenser fan is activated by the temperature controller.

6.5 Adjusting the bypass valve

A bypass valve should be connected between the inlet

and return to protect the cooling medium pump (fig. 2 or

fig. 4, item 10). This opens automatically, for example, if

the equipment cycle is shut off. The bypass valve must

be adjusted to suit the requirements of the customer's

application.

Open the cover cap of the bypass valve by rotating in

a counter-clockwise direction.

Open the bypass valve by rotating in a counter-clock-

wise direction.

Vent the cooling medium pump (see section6.3

"Bleeding the cooling medium pump") and switch it

on.

Shut off the water flow to the customer application

completely using a customer-supplied shut-off valve in

the pipeline or in the end application.

On the chiller display, the current volumetric flow passing through the bypass is shown to the right of the

temperature reading (fig. 23, item 3).

Slowly close the bypass valve by rotating in a clock-

wise direction until the required flow rate is shown on

the display.

The factory setting is 5…6 l/min at 50 Hz. If a lower

value is set, the flow sensor will actuate an alarm message and the pump will stop.

If the pump stops due to an insufficient flow rate, open

the bypass valve by approximately another ¼ turn (approximately).

Close the cover cap of the bypass valve and open the

customer-supplied shut-off valve.

7 Operation

EN

To determine whether the motor’s direction of rotation is

correct, compare the display with the information in the

following list.

– Display panel "black": Direction of rotation correct

– Display panel "white/reflective": Direction of rotation

incorrect

If the direction of rotation is incorrect, you will need to

change over the connections for phases L1 and L2 on

the chiller's power supply connector.

Note:

If the compressor does not start up, the tem-

perature of the coolant added is lower than

the setpoint temperature.

7.1 General

The chiller is switched on and off by the higher-level control. It operates automatically, i.e. the cooling medium is

pumped continuously and heat extracted from it during

this process.

When switching on the unit, or following a malfunction,

the compressor has an ON delay of 3 minutes, and

starts with a reduced compressor output of 33% for 3

minutes. The compressor then enters control mode. If

there is a sudden cooling load demand, therefore, cooling medium temperatures may be increased during the

startup process.

The chiller is equipped with a touch function display for

making basic settings and displaying error messages.

This is an industrial-grade touch display which is pres-

If necessary, lower the setpoint temperature momen-

tarily (see section7.2.2 "Changing a parameter val-

ue").

The cooling air is drawn in from the front and expelled to

the rear.

Rittal Chiller Blue e+ 21

sure-sensitive and may therefore be operated with

gloves.

As well as operating directly on the chiller itself, there is

also a smartphone app available. This offers almost the

same functions as the actual display, and additionally

Page 22

7 Operation

EN

provides extended explanations of error messages, as

well as the option of contacting the Rittal Service team

directly.

Note:

Use the RiDiag software or an online tool,

available on the Rittal website, to check

whether the latest firmware version has

been installed.

7.2 Layout of the display

The display is divided into a top section on a dark background, and a bottom section with the menu bar. This

layout is always identical, but the content of the two sections will vary according to the menu selected.

7.2.1 Start screen

The start screen is always displayed while the cooling

unit is in normal operation, provided there are no error

messages.

Item Description Possible icons

8 Tank heater active (op-

tion)

9 Type of cooling: Active,

free cooling (option),

standby

10 Controlled by an inter-

nal or external sensor

11 External sensor (acces-

sory)

12 Info menu

13 System messages

(where applicable)

14 Service icon (if re-

quired)

15 Configuration

Fig. 23: Layout of the start screen

Key

Item Description Possible icons

1 Current medium tem-

perature (3-digit)

2EER value: Range

0…10

3 Water flow: Range

0…40 l/min

4 Display temperature

unit

5 USB connection (if

connected)

Numbers from 0-9

Tab. 9: List of all icons with descriptions

Type of cooling

The current form of cooling is indicated by one of the following four icons.

Symbol Parameter

Cooling active.

Cooling with the compressor switched off

("free cooling" option) or hybrid mode.

No cooling (standby).

Tab. 10: Possible icons for the current type of cooling

7.2.2 Changing a parameter value

If a parameter value is changed, the display including the

menu bar will also change.

6 Self-test (if initiated)

7 NFC connection (max.

120 seconds after connecting)

Tab. 9: List of all icons with descriptions

22 Rittal Chiller Blue e+

Page 23

Fig. 24: Screen for changing a parameter value

1

Key

1Main screen

2 Control bar

7 Operation

Exit the information screen by clicking on the "Back"

button.

7.3 Info menu

Click on the "Info" symbol to display a list of lower-level

screen pages.

Symbol Parameter

Temperature info

Device info

EN

The currently selected parameter value is displayed in

the centre of the main screen. To change this value, you

always proceed in the same way, as described below

with the example of adjusting the set temperature:

On the start screen, click on the "Configuration" but-

ton.

Enter the PIN to gain access to the lower-level screen

pages of the "Configuration" zone.

"22" is the default PIN.

Click on the "Temperature" symbol.

Click on the "Control mode" symbol.

Select your preferred control mode from the display.

Change the setting to the required temperature using

the "Up" and "Down" arrows.

Alternatively, you can also select the one of the dis-

played higher or lower values directly.

Finally, confirm the set value with "OK".

Exit this screen page with the "Back" button.

7.2.3 Help function

A help function is offered on selected screens. On these

pages, an "info symbol" is visible in the top right-hand

corner.

Efficiency info

Hydraulic info

Tab. 11: "Info" zone

7.3.1 Temperature info

Click on the "Temperature info" symbol.

A list of different temperature values will be displayed.

Page through the list using the "Up" and "Down" ar-

rows.

Symbol Parameter

Av. medium 24h

Average medium temperature over the last 24

hours of operation.

Av. ambient 24h

Average ambient temperature (external temperature) over the last 24 hours of operation.

Current setpoint

Current temperature setpoint, depending on

the chosen control mode.

Thresh. Overtemp.

Temperature limit which will trigger an alarm

message if exceeded.

Tab. 12: "Temperature info" zone

7.3.2 Device info

Click on the "Device info" symbol.

A list of general information about the device will be

Fig. 25: Screen with help function

Key

1Info symbol

Click on the info symbol at the top right of the page.

displayed.

Page through the list using the "Up" and "Down" ar-

rows.

An information screen showing further information

about the relevant parameters will be displayed.

Rittal Chiller Blue e+ 23

Page 24

7 Operation

EN

Symbol Parameter

Article number

Serial number

Manufacture date YYYY-MM-DD

Hardware release x.xx.xx

Firmware release x.xx.xx

Software release x.xx.xx

Last update YYYY-MM-DD

L. maintenance YYYY-MM-DD

User device name

Name assigned to the cooling unit by the customer. This title can be assigned using the

RiDiag software or the Blue e+ app to distinguish between individual units.

Act. control mode

Tab. 13: "Device info" zone

7.3.3 Efficiency info

Click on the "Efficiency info" symbol.

Click on the "Efficiency info" symbol.

The average energy efficiency ratio (EER) for the last

24 hours of operation will be displayed. The energy efficiency ratio is the ratio of the cooling output generated to the electrical power used.

Note:

The power consumption of the cooling medi-

um pump is not included in the calculation of

the EER value (see section12.3 "Technical

specifications").

Symbol Parameter

Efficiency info

Average energy efficiency ratio (EER) of the last

24 hours of operation.

Tab. 14: "Efficiency info" zone

7.3.4 Hydraulic info

Click on the "Hydraulic info" symbol.

A list of information about the cooling circuit will be displayed.

Page through the list using the "Up" and "Down" ar-

rows.

Symbol Parameter

Water flow

Current flow rate of the cooling medium in

l/min.

Tab. 15: "Hydraulic info" zone

7.4 Configuration menu

Click on the "Configuration" symbol.

A screen page will appear asking you to enter the PIN

in order to access the lower-level screen pages.

Note:

"22" is preset in the factory as the default

PIN.

For the first digit, page through the digits "0" to "9" us-

ing the "Up" and "Down" arrows until the required digit

appears in the box.

Confirm your selection with "OK".

For the second digit, once again page through the dig-

its "0" to "9" using the "Up" and "Down" arrows until

the required digit appears in the box.

Confirm your selection with "OK".

A list of lower-level screen pages will be displayed.

Symbol Parameter

Control param.

Settings for set temperature and control mode

Remote

Settings for evaluating the external enabling

signal

Network

Display of network information from the IoT interface (3124300)

Alarm relay

Settings for the alarm relays.

Tab. 16: "Configuration" zone

24 Rittal Chiller Blue e+

Page 25

7 Operation

Symbol Parameter

Filter mats

Display language

Choice of language for display texts.

Self-test

Perform a self-test.

Tab. 16: "Configuration" zone

7.4.1 Control parameters

Click on the "Control parameters" symbol to display a

list of lower-level screen pages.

Symbol Parameter

Temperature

Settings for set temperature and control mode

Water flow

Setting of alarm limits and start-up attempts.

Temperature > Control mode

The chiller can control cooling output according to one

of the following two temperature values:

– Cooling medium temperature (fixed value): Tem-

perature of the cooling medium.

– External temperature sensor: If the "External tem-

perature sensor" is installed as an accessory, temperature control of the cooling medium can also be based

on the temperature in the room where the chiller is located.

Note:

The external temperature sensor is available

as accessory from Rittal (see section 11 "Accessories").

Click on the "Control mode" symbol.

The setpoint for the currently set control mode is displayed.

Choose your preferred control mode by selecting it

from the display:

Symbol Parameter

Medium temp.

EN

Heating (optional)

If the "tank heater" option is installed, the relevant settings may be made here.

Cooling medium

Tab. 17: "Control parameters" zone

Temperature

Click on the "Temperature" symbol to display a list of

lower-level screen pages.

Symbol Parameter

Change unit

Set the unit "°C" or "°F"

Control mode

Alarm threshold

Temperature limit which will trigger an alarm

message if exceeded.

Tab. 18: "Temperature" zone

Temperature > Unit

All temperature values for the unit may be displayed either in degrees Celsius "°C" or degrees Fahrenheit "°F".

Click on the "Change unit" symbol.

Change the required unit ("°C" or "°F") using the "Up"

or "Down" arrows.

Confirm your entry with "OK".

External sensor (accessory)

Tab. 19: "Control mode" zone

The corresponding symbol for the chosen control mode

is likewise displayed on the overview page.

Temperature > Control mode > Medium temperature

Click on the "Medium temperature" symbol.

The currently set medium temperature is displayed.

Change the setpoint using the "Up" and "Down" ar-

rows or select the required medium temperature directly.

Confirm your selection with "OK".

Temperature > Control mode > External sensor

Please observe the following when selecting the sensor

position:

– Where possible, the temperature sensor should not be

placed in direct sunlight or in an air current.

Click on the "External sensor" symbol.

The prescribed temperature values for controlling the

cooling medium temperature are displayed with the

aid of the external temperature sensor.

Choose the required parameter by selecting it from the

display:

Rittal Chiller Blue e+ 25

Page 26

EN

7 Operation

Symbol Parameter Setpoint Factory

setting

Diff. to ext.

temp.

-10 K

…

10 K

5K

Choose your preferred type of alarm threshold (over-

temperaure or undertemperature) by selecting it from

the display.

Change the setpoint using the "Up" and "Down" ar-

rows or select the required temperature directly.

Confirm your entry with "OK".

5°C (41°F)

Min.

temperature

Max.

temperature

Tab. 20: "External temperature sensor" zone

Change the setpoint using the "Up" and "Down" ar-

…

current

maximum

temperature

Current

minimum

temperature

…

35°C (95°F)

10°C (50°F)

28°C (82°F)

rows or select the required temperature directly.

Confirm your entry with "OK".

With the factory settings, the cooling medium temperature is controlled depending on the value measured by

the external temperature sensor, within the following limits:

1. The temperature of the cooling medium is 5 K above

the measured temperature value.

2. However, if the measured temperature value drops

below 5°C (41°F), the temperature of the cooling

medium will remain at 10°C (50°F).

3. However, if the measured temperature value rises

above 23°C (73°F), the temperature of the cooling

medium will remain at 28°C (82°F).

Temperature > Alarm threshold

This threshold value is used for an alarm message (overtemperature or undertemperature). The set value must

therefore be above or below the actual setpoint to which

the cooling unit has been set.

Symbol Parameter Alarm

threshold

Factory

setting

Note:

At a water temperature of +2°C, the pump is

automatically switched on, and switched off

again at +5°C. This frost protection function

is always active, regardless of whether or not

it has been enabled externally.

Water flow

Click on the "Water flow" symbol to display a list of

lower-level screen pages.

Symbol Parameter

Alarm threshold

Lower flow rate threshold, below which a message is emitted.

Reset flow sensor

Tab. 22: "Water flow" zone

Water flow > Alarm threshold

This threshold value is used for a message (insufficient

flow rate).

Standard value: 5 l/min for all output categories.

Click on the "Alarm threshold" symbol.

Change the setpoint using the "Up" and "Down" but-

tons or select the required flow rate (5…15 l/min) directly.

Confirm your entry with "OK".

Water flow > Alarm threshold

Below a fixed limit of 4 l/min, the cooling function and the

pump are switched off. An alarm is set.

Reset the error as described in the following section.

+2 K

Over-

temperature

Subnormal

temperature

Tab. 21: "Alarm limit“ zone

Click on the "Alarm threshold" symbol.

26 Rittal Chiller Blue e+

(+3.6°F)

…

+15 K

(+27°F)

-2 K

(-3.6°F)

…

-15 K

(-27°F)

5K

(9°F)

Off

Water flow > Reset flow sensor

If the flow rate is too low (≤ 4 l/min), a corresponding

alarm message will appear on the display. In "Manual reset" mode, this message must be manually reset before

the pump will restart. In "Automatic reset" mode, a preset number of automatic restarts will occur.

Click on the "Reset flow sensor" symbol.

Choose the required mode by selecting it from the dis-

play.

Page 27

Symbol Parameter

Manual reset

Automatic reset

Tab. 23: "Reset flow sensor" zone

If "Automatic reset" mo de is activated, you will also need

to set the number of possible restarts.

For "Automatic reset" mode, indicate how often the er-

ror message should be automatically reset (between

once and five times).

"2 restarts" is preselected here as the default.

Heating (optional)

If the tank heater (optional) is installed for frost protection

or to preheat the cooling medium, this can be activated

or deactivated here.

Click on the "Heating" symbol.

Activate the heater by selecting "On", or deactivate the

heater by selecting "Off" (default setting).

7 Operation

The heater therefore cuts in and out at the following temperatures:

– Switching on: Setpoint temperature of cooling

medium - switch-on hysteresis

– Switching off: Activation temperature of heater +

switch-off hysteresis

Example:

– Setpoint temperature: 38°C

– Switch-on hysteresis: 3.0 K

– Switch-off hysteresis: 2.0 K

In this case, the heater is switched on and off at the fol-

lowing temperatures:

– Switch-on temperature: 38°C-3.0 K = 35°C

– Switch-off temperature: 35°C+2.0 K = 37°C

Cooling medium

Click on the "Cooling medium" symbol to display a list

of lower-level screen pages.

Symbol Parameter

Water/demi water (option)

EN

Heating > Heating control

If you have activated the heater, the screen page "heating control" will appear.

Select the desired parameter.

A screen page similar to the one requesting the PIN for

access to the lower-level screen pages of the configuration menu will appear.