Rittal 3311.700, 3311.710, 3311.600,3311.800,3311.610,3311.810,3311.700,3311.900,3311.710,3311.910, 3311.600, 3311.900 Assembly And Operating Instructions Manual

...Page 1

TopTherm LCP Hybrid

3311.600 3311.800

3311.610 3311.810

3311.700 3311.900

3311.710 3311.910

Montage-, Installations- und Bedienungsanleitung

Assembly and operating instructions

Page 2

EN

Foreword

Foreword

Dear Customer!

Thank you for choosing a Rittal Liquid Cooling Package

(also referred to hereafter as "LCP").

This documentation applies to the LCP Hybrid unit.

Take time to read this documentation carefully.

Pay particular attention to the safety instructions in the

text and to section 2 "Safety instructions".

This is essential for:

– secure assembly of the Liquid Cooling Package

– safe handling and

– trouble-free operation.

Please keep the complete documentation readily available so that it is always on hand when needed.

We wish you every success!

Yours

Rittal GmbH & Co. KG

Rittal GmbH & Co. KG

Auf dem Stützelberg

35745 Herborn

Germany

Tel.: +49(0)2772 505-0

Fax: +49(0)2772 505-2319

E-mail: info@rittal.de

www.rimatrix5.com

www.rimatrix5.de

We are always happy to answer any technical questions

regarding our entire range of products.

2 Rittal Liquid Cooling Package

Page 3

Table of contents

Table of contents

1 Notes on documentation .................. 4

1.1 Storing the documents.................................. 4

1.2 Symbols used in these operating instructions 4

1.3 Associated documents ................................. 4

1.4 Normative instructions .................................. 4

1.4.1 Legal information concerning the operating instruc-

tions ..................................................................... 4

1.4.2 Copyright ............................................................. 4

1.4.3 Revision ................................................................ 4

2 Safety instructions ............................ 5

2.1 Important safety instructions ......................... 5

2.2 Service and technical staff ............................ 5

2.3 RoHS compliance ......................................... 5

3 Device description ............................ 6

3.1 General functional description ....................... 6

3.2 Air routing ..................................................... 8

3.3 Equipment assembly..................................... 9

3.3.1 Unit components .................................................. 9

3.3.2 Air/water heat exchanger with cold water

connection ......................................................... 10

3.4 Proper and improper usage ........................ 10

3.5 Supply scope of a Liquid Cooling Package . 11

12 Accessories .................................... 29

EN

13 Further technical information ........... 30

13.1 Hydrological information............................. 30

13.2 Characteristic curves and tables................. 30

13.2.1 General .............................................................. 30

13.2.2 Determination of the dew point ........................... 30

13.2.3 Pressure loss ...................................................... 31

13.2.4 Cooling output at a room temperature of 21°C ... 33

13.2.5 Cooling output at a room temperature of 22°C ... 35

13.2.6 Cooling output at a room temperature of 23°C ... 37

13.2.7 Cooling output at a room temperature of 24°C ... 39

13.2.8 Cooling output at a room temperature of 25°C ... 42

13.3 Overview drawing....................................... 45

14 Preparation and maintenance of the

cooling medium .............................. 49

15 List of spare parts ........................... 50

16 Glossary ......................................... 51

4 Transportation and handling ........... 12

4.1 Transportation ............................................ 12

4.2 Unpacking .................................................. 12

5 Assembly and siting ....................... 13

5.1 General....................................................... 13

5.1.1 Installation site requirements ............................... 13

5.1.2 Installation guidelines .......................................... 13

5.2 Assembly procedure ................................... 14

5.2.1 General .............................................................. 14

5.2.2 Seal the server enclosure .................................... 14

5.2.3 Dismantle the rear server enclosure door ............ 14

5.2.4 Fit the door latch mechanisms ............................ 15

5.2.5 Fit the LCP Hybrid .............................................. 15

5.2.6 Fitting the potential equalisation .......................... 16

5.2.7 Install the air routing kit (optional) ........................ 16

5.2.8 Remove the mounting aid ................................... 16

6 Installation ...................................... 18

6.1 Cooling water connection ........................... 18

6.2 Bleeding the air from the heat exchanger .... 19

6.3 Installing the cover ...................................... 20

7 Commissioning checklist ................ 22

8 Troubleshooting ............................. 24

9 Inspection and maintenance .......... 25

10 Storage and disposal ..................... 26

11 Technical specifications ................. 27

11.1 10 kW versions ........................................... 27

11.2 20 kW versions ........................................... 28

Rittal Liquid Cooling Package 3

Page 4

1 Notes on documentation

EN

1 Notes on documentation

1.1 Storing the documents

The assembly, installation and operating instructions as

well as all applicable documents are an integral part of

the product. They must be passed to those persons

who are engaged with the unit and must always be available and on hand for the operating and maintenance

personnel.

1.2 Symbols used in these operating instructions

The following symbols are used in this documentation:

Danger!

Hazardous situation which may lead to

death or serious injury if the instructions

are not followed.

Warning!

Hazardous situation which may lead to

death or severe injury if the instructions

are not followed.

in this documentation. Liability for indirect damages associated with the supply or use of this documentation is

excluded to the extent allowable by law.

1.4.2 Copyright

The distribution and duplication of this document and

the disclosure and use of its contents are prohibited unless expressly authorised.

Offenders will be liable for damages. All rights created by

a patent grant or registration of a utility model or design

are reserved.

1.4.3 Revision

Rev. 1A of 08/10/2014

Caution!

Hazardous situation which may lead to

(minor) injuries if the instructions are not

followed.

Note:

Information concerning individual proce-

dures, explanations, or tips for simplified approaches. It also indicates situations which

may result in material damage.

This symbol indicates an "Action Point" and shows

that you should perform an operation/procedure.

1.3 Associated documents

In conjunction with these assembly, installation and operating instructions, the superordinate system documentation (if available) also applies.

Rittal GmbH & Co. KG is not responsible for any damage

which may result from failure to comply with these assembly, installation and operating instructions. The

same applies to failure to comply with the valid documentation for the accessories used.

1.4 Normative instructions

1.4.1 Legal information concerning the operating

instructions

We reserve the right to make changes in content. Rittal

GmbH & Co. KG will not be held liable for any mistakes

4 Rittal Liquid Cooling Package

Page 5

2 Safety instructions

2 Safety instructions

The Liquid Cooling Packages produced by Rittal GmbH

& Co. KG are developed and produced with due regard

to all safety precautions. Nevertheless, the unit still poses a number of unavoidable dangers and risks. The

safety instructions provide you with an overview of these

dangers and the necessary safety precautions.

In the interests of your own safety and the safety of others, please read these safety instructions carefully before assembly and commissioning of the Liquid Cooling

Package.

Follow the user information found in these instructions

and on the unit carefully.

2.1 Important safety instructions

Danger! Injury due to falling loads!

Do not stand under suspended loads

when transporting the unit with a hoist

trolley, a forklift, or a crane.

Warning! Danger of cut wounds, especially from the sharp edges of the heat

exchanger module!

Put on protective gloves before beginning assembly or cleaning work!

Warning! Injury due to falling loads!

If the server rack is not fully populated,

there is a risk of it tipping over when the

Liquid Cooling Package is swung away.

Heavy equipment should be installed in

the bottom part of the server enclosure.

Where necessary, secure the server enclosure to the floor to prevent it tipping

over.

Caution! Risk of malfunction or damage!

The medium necessary for the control

system, i.e. cooling water, must be available throughout the entire operating

time.

Caution! Risk of malfunction or damage!

It is vital that the manufacturer's consent is obtained before adding antifreeze!

Caution! Risk of malfunction or damage!

During storage and transportation below

freezing point, the water circuit should

be drained completely using compressed air!

2.2 Service and technical staff

The installation, commissioning, maintenance and repair

of this unit may only be carried out by qualified, trained

mechanics.

Only properly instructed personnel may work on a unit

while in operation.

2.3 RoHS compliance

The Liquid Cooling Package fulfils the requirements of

EU Directive 2011/65/EC on the Restriction of Use of

Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS) of 1 July 2011.

Note:

The corresponding information about the

RoHS Directive can be found on our website

at www.rittal.com.

EN

Caution! Risk of malfunction or damage!

Do not modify the unit! Use only original

spare parts!

Caution! Risk of malfunction or damage!

Proper operation can only be ensured if

the unit is operated under the intended

ambient conditions. As far as possible,

be sure that the ambient conditions for

which the unit is designed are complied

with, e.g. temperature, humidity, air purity.

Rittal Liquid Cooling Package 5

Page 6

3 Device description

bene

Server

erver

r

HD

t

t

t

LCP Hybrid

Server rack

12 345

EN

3 Device description

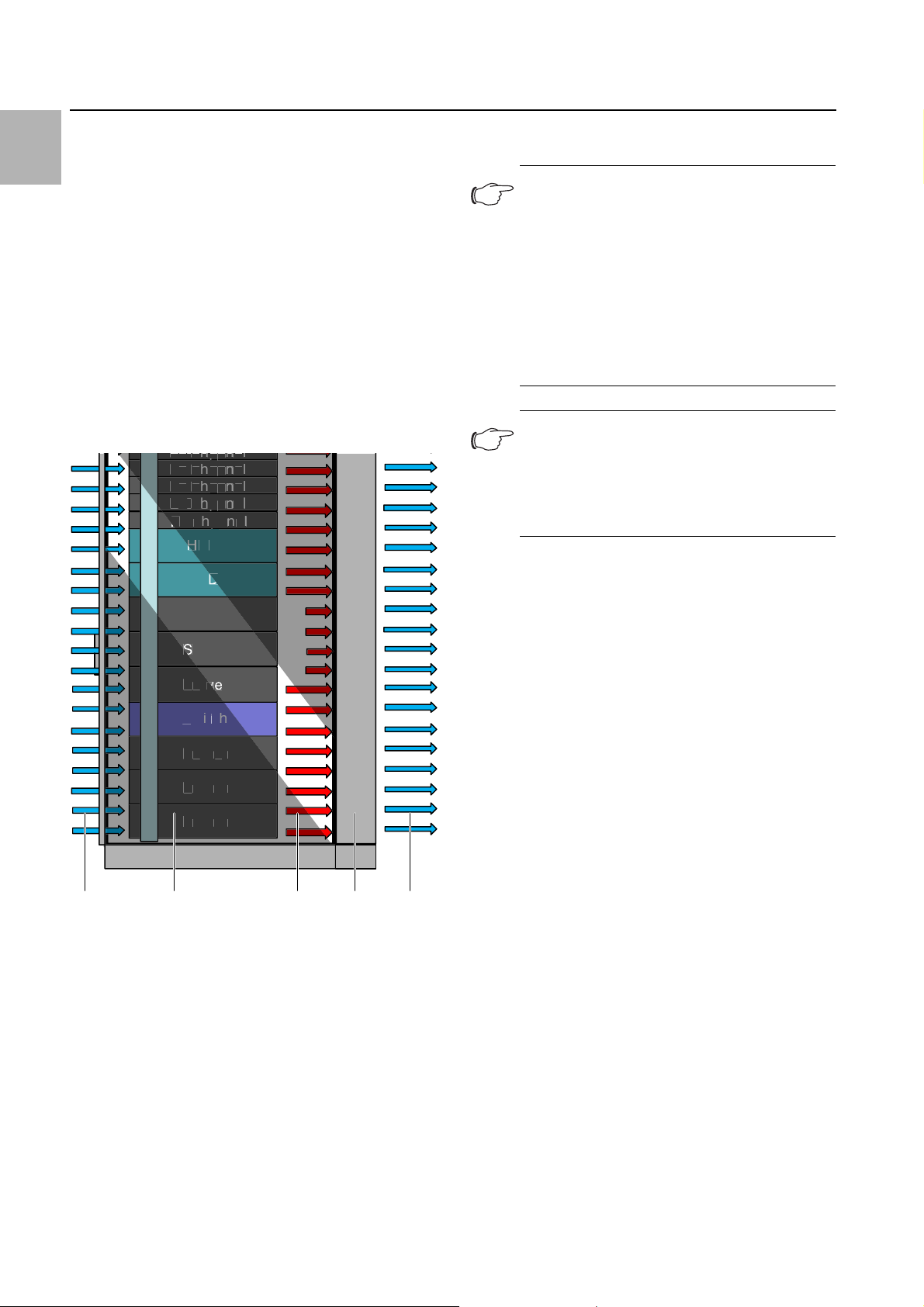

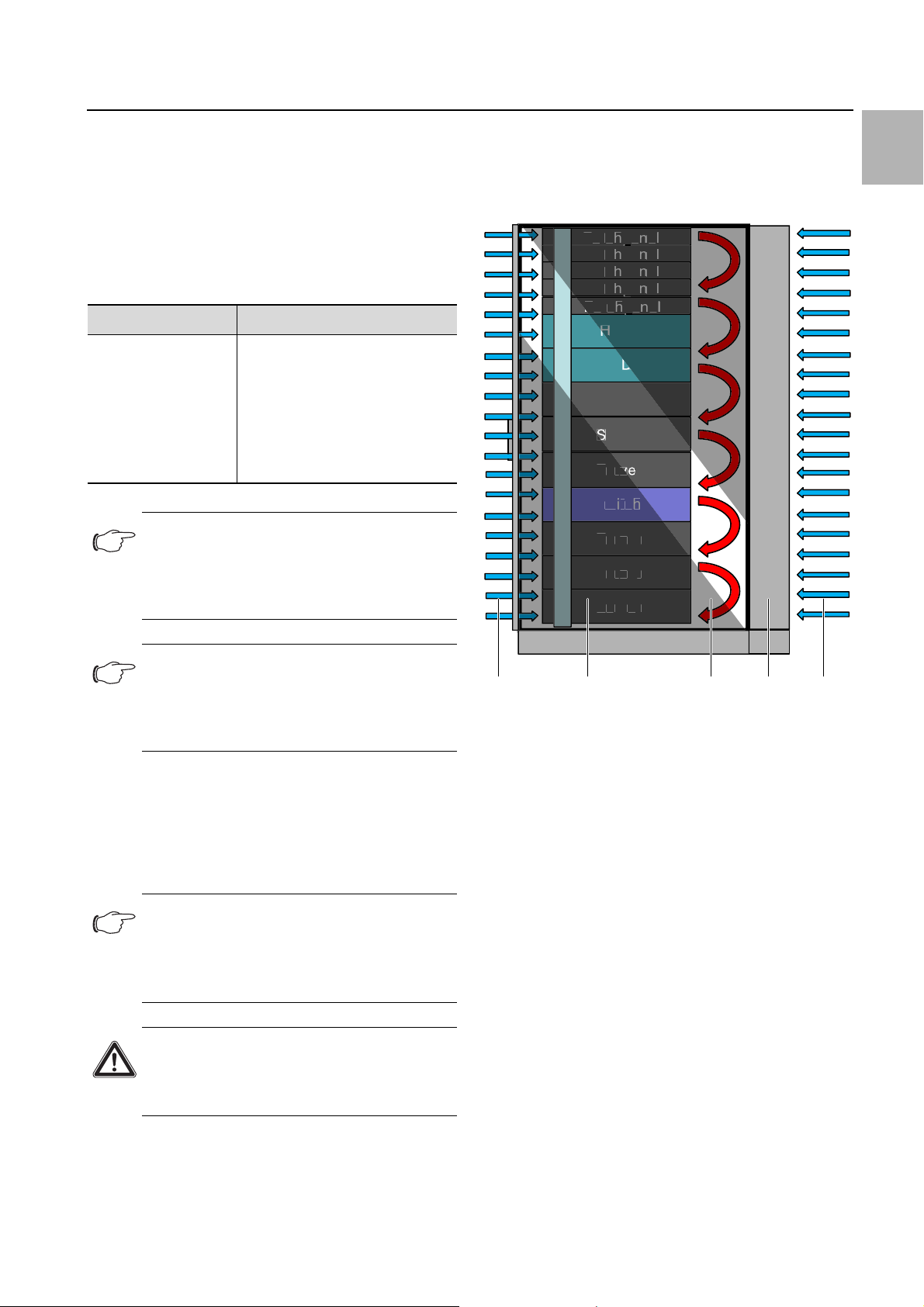

3.1 General functional description

The LCP Hybrid is essentially an air/water heat exchanger. It cools the room by cooling the hot air from devices

in a server enclosure to the ambient temperature. This

prevents the temperature at the installation site from rising as a result of heat loss from the IT components. To

this end, the device is fitted to the rear of a server enclosure.

Air routing follows the "front to back" cooling principle,

and is effected by the device fans built into the server enclosure. The expelled warm air is routed through the air/

water heat exchanger of the Liquid Cooling Package. To

this end, the fans of the built-in 482.6 mm (19") equipment must be capable of overcoming the airside pressure loss from the LCP Hybrid.

There, the air is cooled and then flows out into the ambient air at the rear.

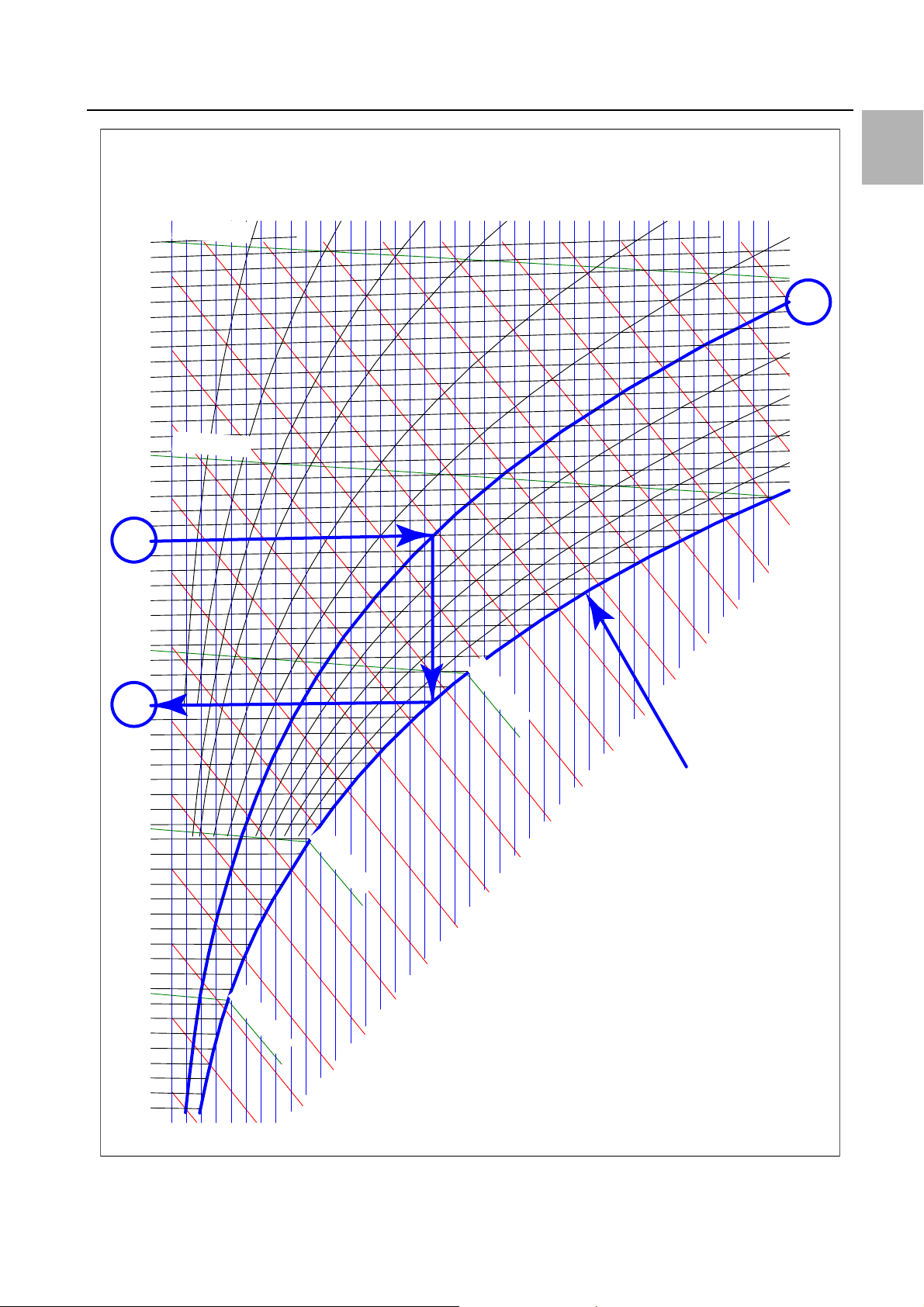

Note:

The water inlet temperature must always be

selected (controlled) to be above the dew

point for the existing ambient temperature

and humidity in the data centre. The dew

point can be found in the Mollier h-x diagram

(fig. 2).

Furthermore, we advise compliance with the

ASHRAE standard "ASHRAE TC 9.9, 2011

Thermal Guidelines for Data Processing Environments".

Note:

As an alternative to use of the h-x diagram, in

section 13.2.2 "Determination of the dew

point", you will find tables showing the dew

point for selected temperatures and air humidity levels.

Fig. 1: Air routing on the LCP Hybrid – Side view

Key

1 Cold ambient air

2 Server rack with installed equipment

"

3 Hot airflow from 482.6 mm (19

4 LCP Hybrid with air/water heat exchanger

5Cooled air

Immediately in front of the heat exchanger is a row of

heat pipes. These heat pipes support even distribution

of the thermal load over the entire height of the heat exchanger.

In the heat exchanger, the thermal energy (heat loss

from the devices) is transferred to a cold water system.

6 Rittal Liquid Cooling Package

) equipment

Page 7

3 Device description

0 g/kg

Temperature

1.05 kg/m3

40˚

35˚

30˚

1.10 kg/m3

25˚

22˚

20˚

2 g/kg

4 g/kg

6 g/kg

8 g/kg

10 g/kg

12 g/kg

14 g/kg

16 g/kg

30% 20% 15% 10% 5%

18 g/kg

Water

20 g/kg

40%

50%

60%

70%

80%

90%

100%

EN

Rel. Humidity

15˚

11˚

10˚

-5˚

-10˚

-15˚

60 kJ/kg

1.15 kg/m3

5˚

1.20 kg/m3

0˚

20 kJ/kg

1.25 kg/m3

0

kJ/kg

40 kJ/kg

Dew point curve

Enthalpy

Mollier h-x diagram for humid air – pressure 0.950 bar (537.000 m / 10.000˚C / 80.000% rF)

Fig. 2: Mollier h-x diagram for humid air

Rittal Liquid Cooling Package 7

Page 8

3 Device description

EN

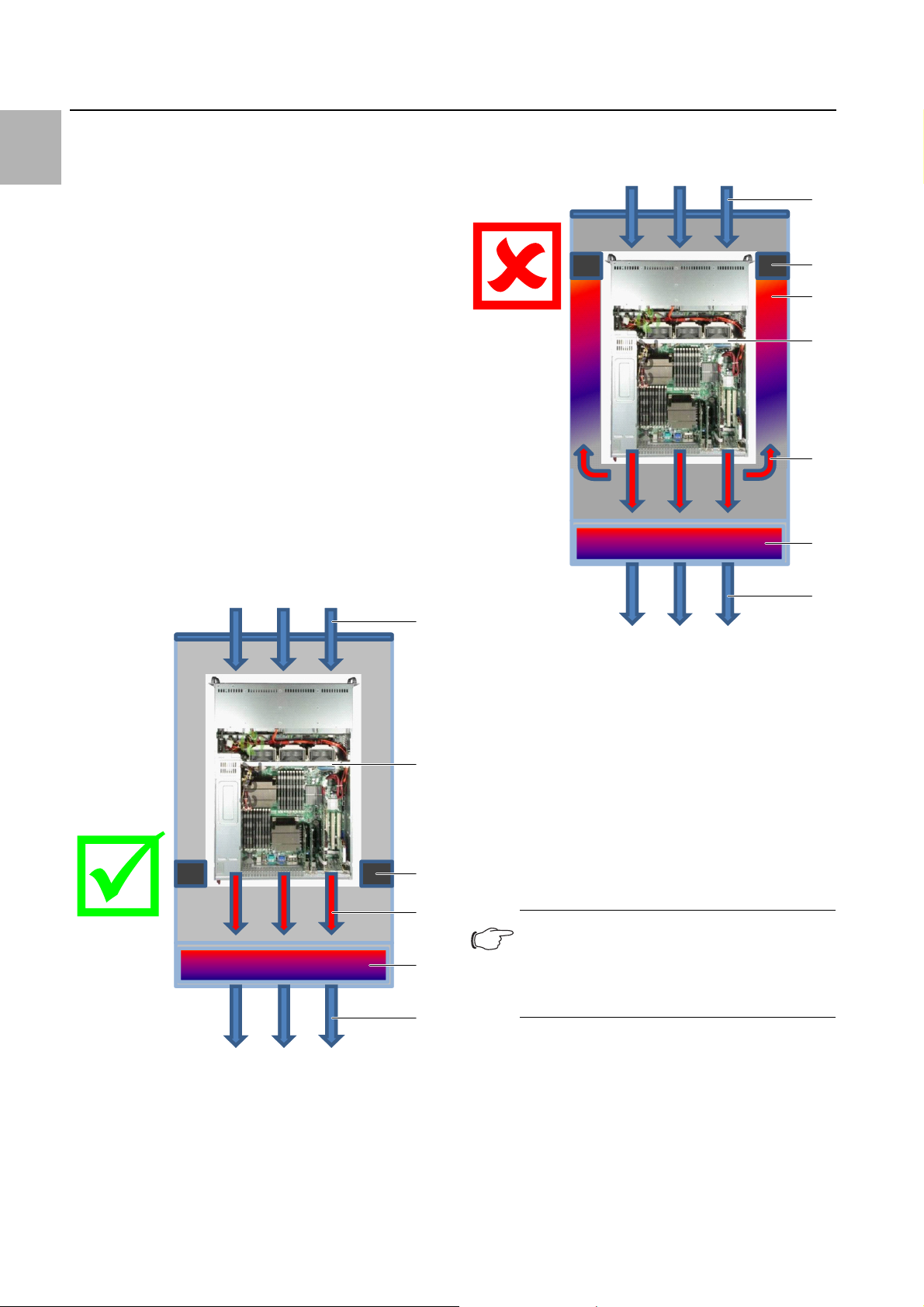

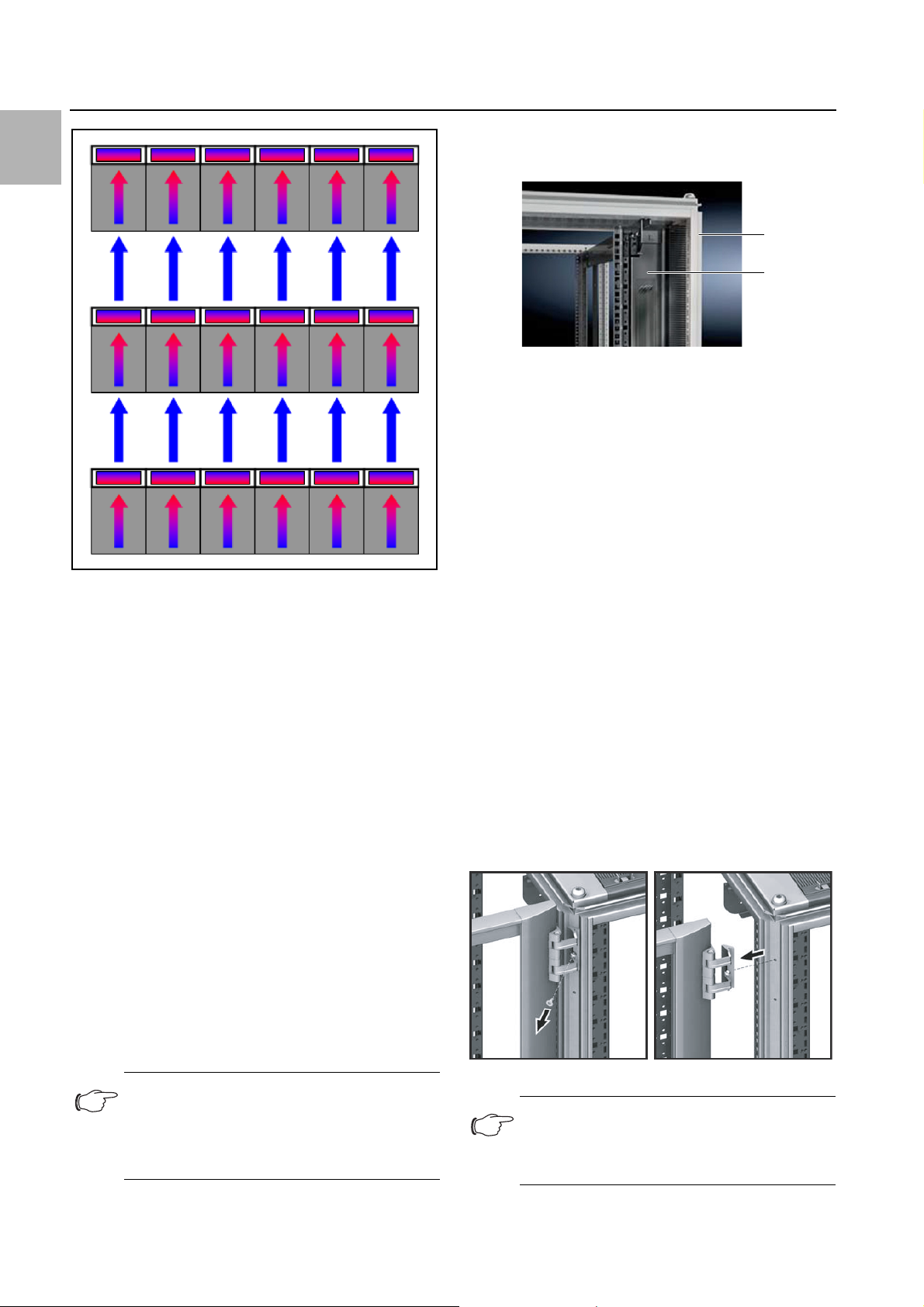

3.2 Air routing

In order to ensure adequate cooling in the server enclosure, it is important to ensure that the hot air from the

fans of the installed equipment is routed directly via the

LCP Hybrid and is prevented from accumulating inside

the server enclosure.

Targeted air routing in the server enclosure has a major

effect on the heat loss to be dissipated. It is therefore important to assemble the device and the additional installed equipment in the server enclosure as described

in section 5.2 "Assembly procedure".

In order to ensure targeted air routing in the system, the

server enclosure should be divided vertically into warm

air and cold air sections. The division is accomplished in

the rear section of the server assembly to the left and

right of the 482.6 mm (19") level using air baffle plates,

which, depending on the enclosure width and the number of server enclosures to be cooled, can be ordered as

accessories (see section 12 "Accessories").

This prevents the hot air from flowing back at the sides

adjacent to the server installations and forming hot spots

(fig. 3).

1

2

If the air baffle plates remain in the front section of the

server enclosure, hot spots may form in the server enclosure (fig. 4).

1

2

3

4

5

6

7

Fig. 4: Incorrect arrangement of the partitioning plates (air baf-

fle plates)

Key

1 Cold ambient air

2 Partitioning plates in the front section

3 Formation of a hot spot

4 Installed devices

5 Misdirected hot airflow

6 LCP Hybrid with air/water heat exchanger

7Cooled air

If devices which require sideways air throughput are built

into the server enclosure (e.g. switches, router, etc.),

these may be cooled via targeted repositioning of the air

3

baffle plates.

4

Note:

When using devices which require sideways

5

air throughput, repositioning of the air baffle

plates means that the entire width of the heat

exchanger is not used to optimum effect.

6

Fig. 3: Correct arrangement of the partitioning plates (air baffle

plates)

Key

1 Cold ambient air

2 Installed devices

3 Partitioning plates in the rear section

4Hot airflow

5 LCP Hybrid with air/water heat exchanger

6Cooled air

8 Rittal Liquid Cooling Package

Page 9

3 Device description

1

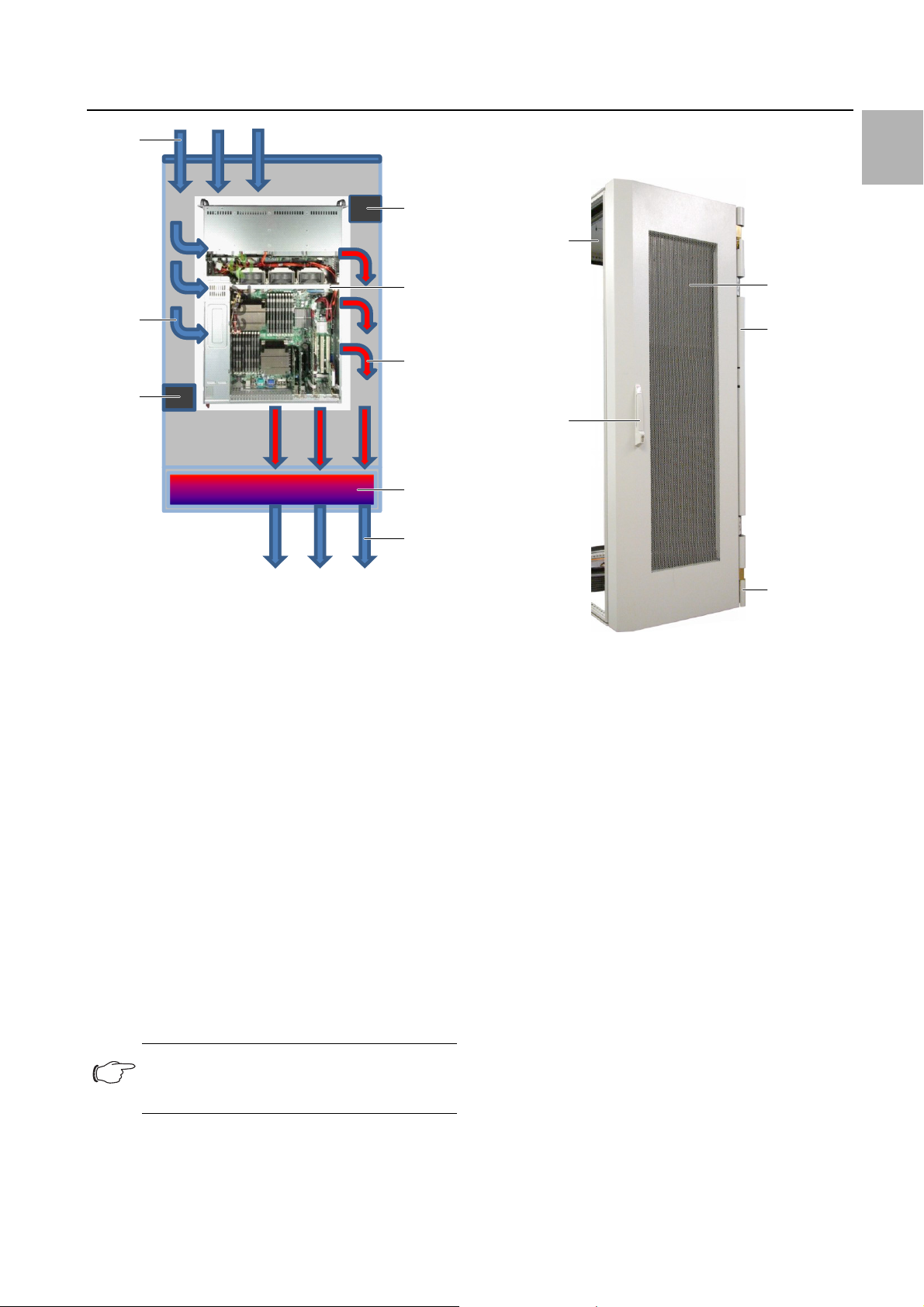

3.3 Equipment assembly

EN

3.3.1 Unit components

2

5

3

4

5

6

4

7

8

1

2

Fig. 5: Arrangement of the partitioning plates (air baffle plates)

for devices with sideways air throughput

Key

1 Cold ambient air

2 Partitioning plate in the front section

3 Installed devices

4 Cold airflow in the server enclosure

5 Hot airflow in the server enclosure

6 Partitioning plate in the rear section

7 LCP Hybrid with air/water heat exchanger

8Cooled air

Additionally, please observe the following regarding installed equipment in the server enclosure:

Ensure that the 482.6 mm (19") equipment is distributed as evenly as possible inside the server enclosure.

This prevents selective loading of the heat exchanger.

Install heavy equipment with high heat generation at

the bottom of the server enclosure, and passive components with low heat generation at the top.

If the server enclosure is not fully populated, seal the

open height units (U) in the 482.6 mm (19") level with

blanking plates, available as Rittal accessories (see

section 12 "Accessories").

3

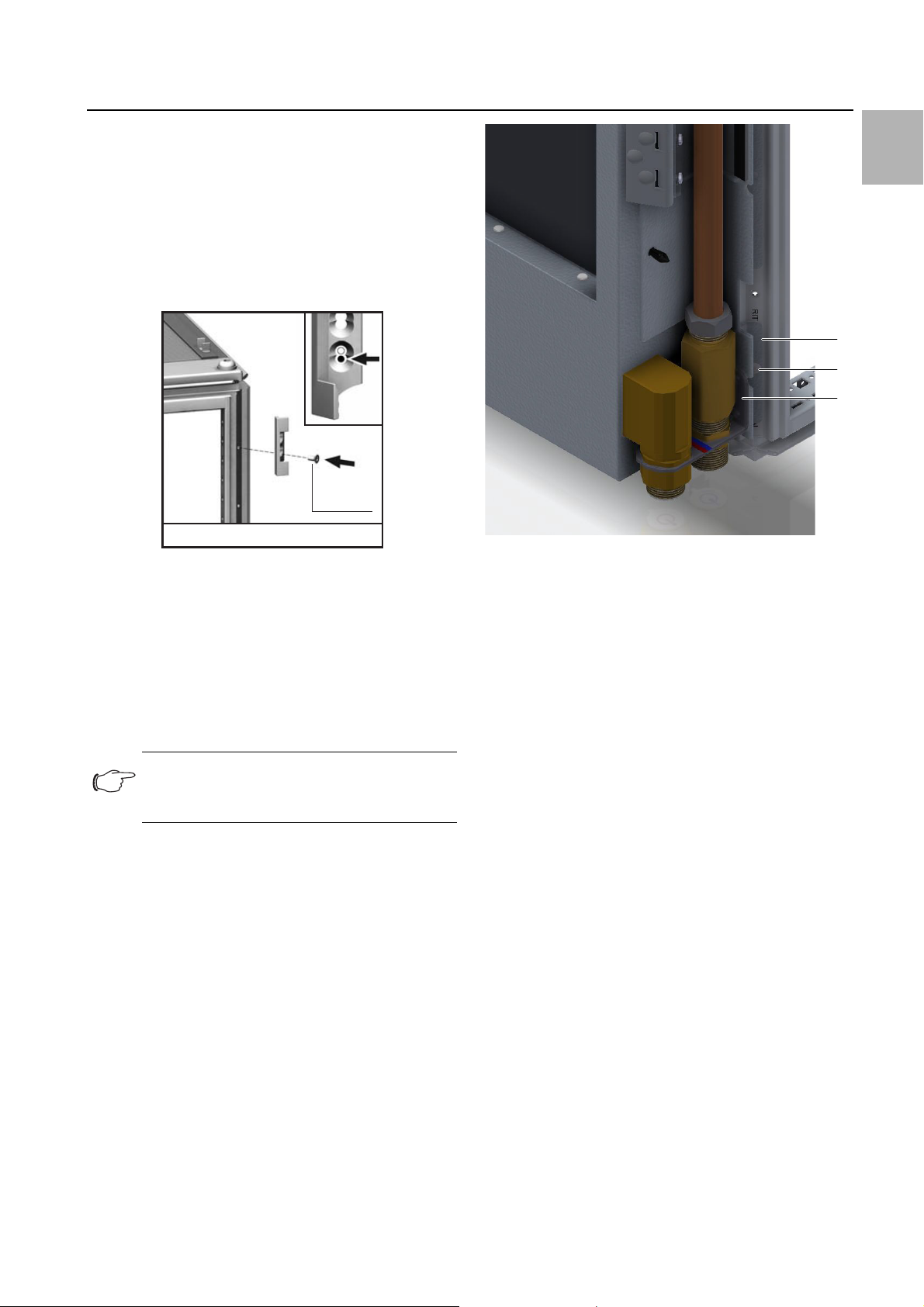

Fig. 6: LCP Hybrid – Door closed

Key

1 LCP door with air/water heat exchanger

2Door bracket

3Cooling water connection

4 Door handle

5 Server enclosure

The Liquid Cooling Package is comprised of a rear door

with heat exchanger and a side frame.

The door is fitted with a special door bracket at the rear

of the server enclosure, and seals the server enclosure

with 4-point locking.

There is a maintenance door fitted on the inside of the

Liquid Cooling Package. Whilst closed, this provides access protection for the heat exchanger.

Note:

Foam strips may also be used as an alterna-

tive to air baffle plates.

Rittal Liquid Cooling Package 9

Page 10

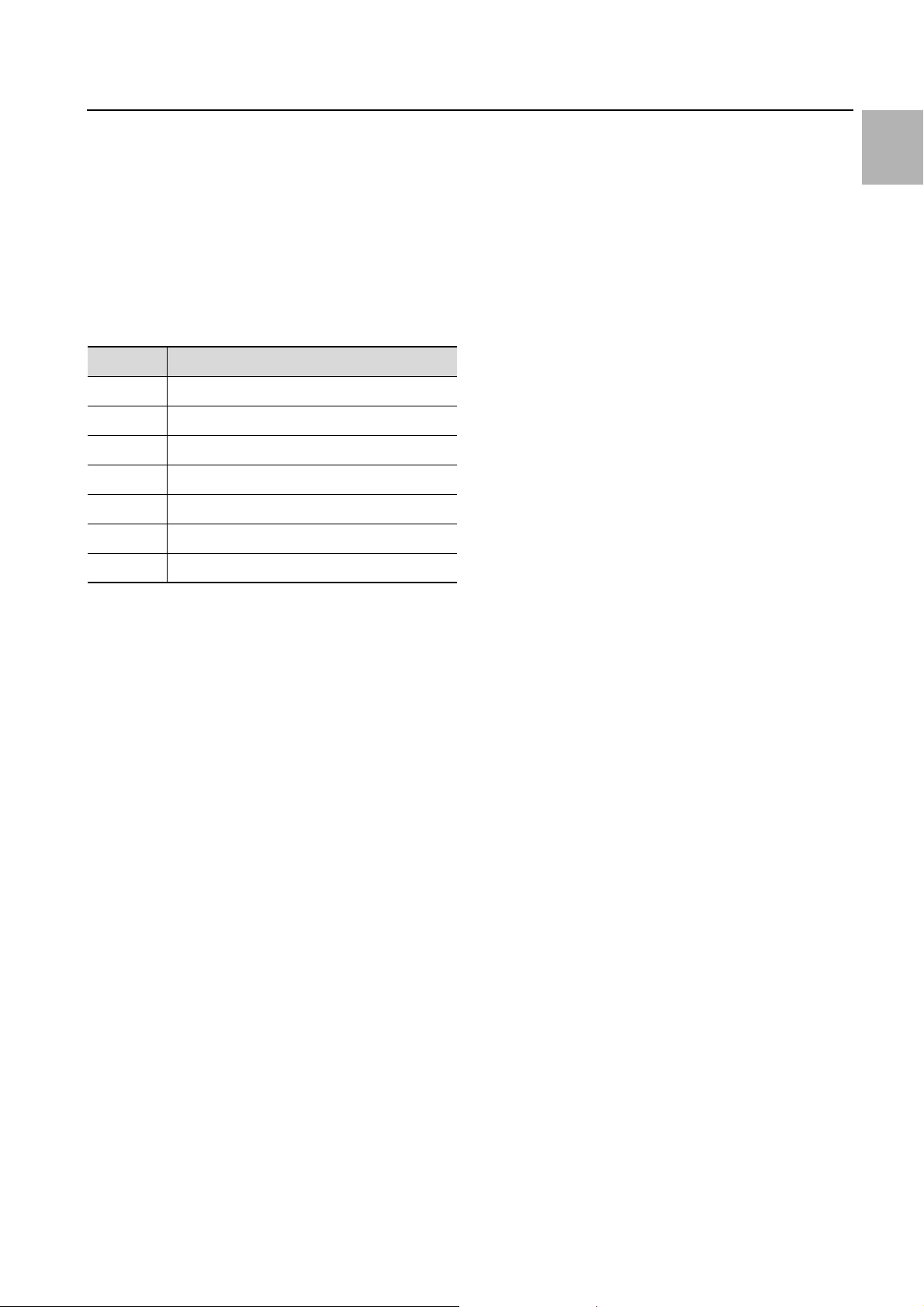

3 Device description

EN

1

4

2

3

Fig. 7: LCP Hybrid – Maintenance door open

Key

1 Vent valves

2 Air/water heat exchanger with heat pipes

3Ventilation hose

4 Maintenance door

3.3.2 Air/water heat exchanger with cold water

connection

The air/water heat exchanger is fitted as a rear door in

the Liquid Cooling Package. The cooling water connection is connected to the main inlet and return connections by two DN 25 (G1") externally threaded pipes. The

connection nozzles are positioned vertically downwards.

1

2

3

4

5

Fig. 8: Connection nozzles at the bottom of the LCP Hybrid

Key

1 Door bracket hinge

2LCPHybrid

3 Server enclosure

4 Cooling water connection, inlet

5Cooling water connection, return

The cooling water is generally connected to the cold water system using an optional connection hose. Alternatively, the LCP Hybrid may also be connected on-site

with the installed pipework.

3.4 Proper and improper usage

The Liquid Cooling Package is used to dissipate high

heat losses and for the effective cooling of the waste air

from IT components built into a server enclosure.

The unit is state of the art and built according to recognised safety regulations. Nevertheless, improper use

can pose a threat to the life and limb of the user or third

parties, or result in possible damage to the system and

other property.

Consequently, the unit must only be used properly and

in a technically sound condition! Any malfunctions which

impair safety should be rectified immediately. Follow the

operating instructions!

Proper use also includes following the operating instructions and fulfilling the inspection and maintenance conditions.

10 Rittal Liquid Cooling Package

Page 11

Inappropriate use can be dangerous. Examples of inappropriate use include:

– Use of impermissible tools.

– Improper operation.

– Improper rectification of malfunctions

– Use of replacement parts which are not authorised by

Rittal GmbH & Co. KG.

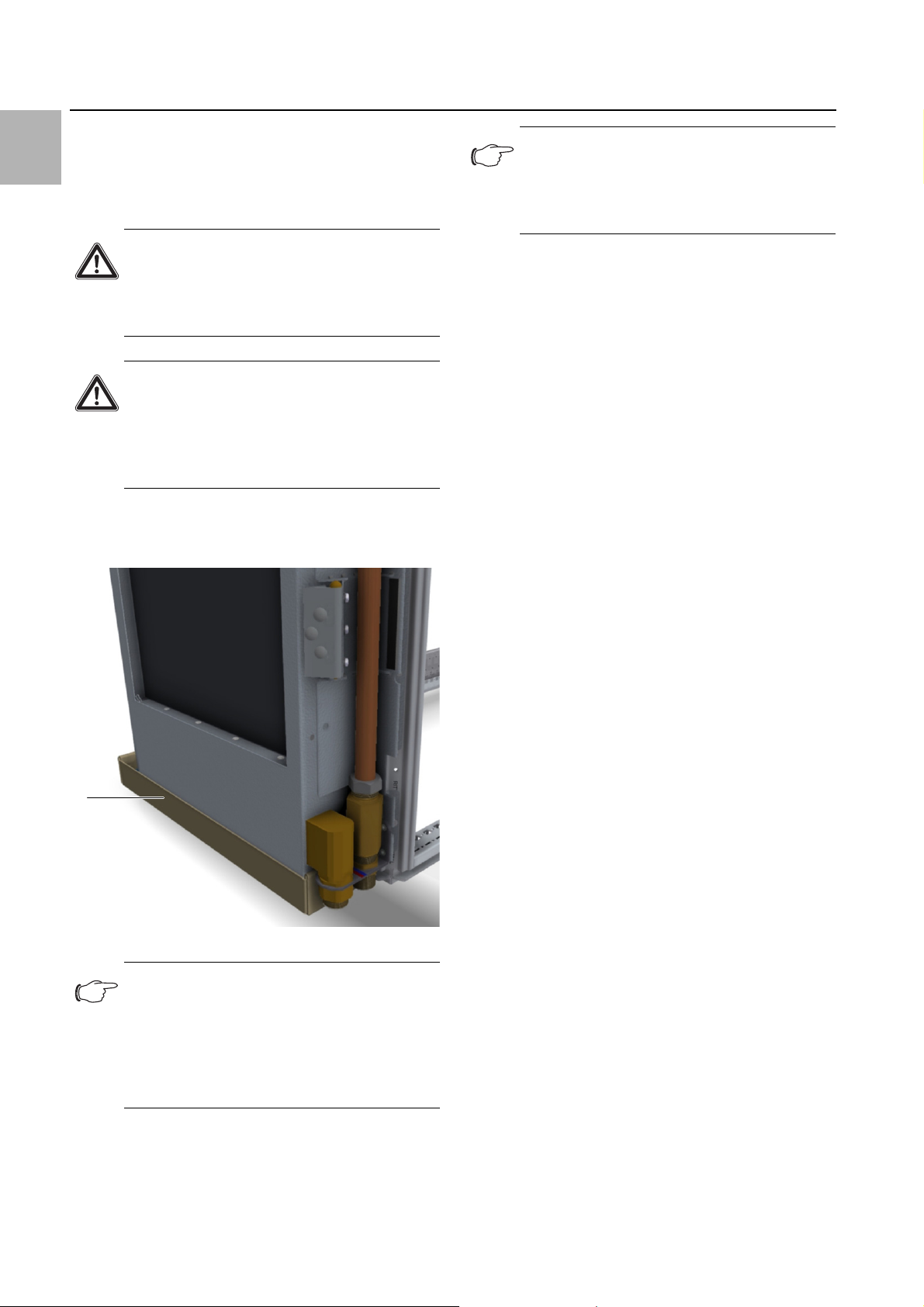

3.5 Supply scope of a Liquid Cooling Package

The Liquid Cooling Package supply includes:

Qty. Parts

1 Liquid Cooling Package, ready for connection

1Cover

1 Assembly instructions

5 Posidrive raised countersunk screw

3 Contact washer

7 Screw

3 Device description

EN

1Bleed tool

Tab. 1: Supply scope of an LCP Hybrid

Rittal Liquid Cooling Package 11

Page 12

4 Transportation and handling

EN

4 Transportation and handling

4.1 Transportation

The Liquid Cooling Package is delivered on a pallet in a

protective box.

Caution!

Because of its height and narrow base,

the Liquid Cooling Package is subject to

tipping. Risk of toppling, especially after

the unit is removed from the pallet!

Caution!

Transportation of the Liquid Cooling

Package without a pallet:

Use only suitable and technically sound

lifting gear and load-bearing devices

with sufficient load capacity.

4.2 Unpacking

Remove the unit's packaging materials but not the

mounting aid.

Note:

Damage and other faults, e.g. incomplete delivery, should be reported immediately, in

writing, to the shipping company and to Rittal

GmbH & Co. KG.

Place the unit in its intended location.

1

Fig. 9: Mounting aid

Note:

After unpacking, the packaging materials

must be disposed of in an environmentally

friendly way. They consist of the following

materials:

Wood, polythene, polypropylene, corrugated

cardboard, steel.

Check the unit for any damage that may have occurred during transport.

12 Rittal Liquid Cooling Package

Page 13

5 Assembly and siting

t

t

t

5 Assembly and siting

5.1 General

5.1.1 Installation site requirements

In order to ensure problem-free operation of the Liquid

Cooling Package, the following conditions for the installation location should be observed:

Supply connections required at the installation site

Type of connection Connection description:

Cooling water connection:

Tab. 2: Supply connections required at the installation site

Note:

Please also observe the instructions and data

relating to the cold water connection as outlined in section 6.1 "Cooling water connection".

15°C inlet temperature (depending on relative humidity)

Max. 6 bar permissible operating

pressure

Volumetric flow: depending on

design (see section 13.2 "Characteristic curves and tables")

DN 25 (G1") external pipe thread

taken to ensure that external air streams are not pointing

directly at the rear of the LCP Hybrid. Such counterflows

prevent hot air from being expelled by the LCP Hybrid,

leading to the formation of a hot spot inside the server

enclosure.

HD

bene

Server rack

Server

erver

r

LCP Hybrid

EN

Recommendation:

To facilitate easy servicing of the Liquid

Cooling Package, maintain a distance of at

least 1 m between the rear of the device and

the nearest wall.

Floor conditions

– The floor of the installation space should be rigid and

level.

– Choose the installation site so that the unit is not situ-

ated on a step or uneven surface, etc.

Recommendation:

Room temperature +22°C at 47% relative air

humidity, according to ASHRAE guidelines.

The room temperature must correspond to

the required air intake temperature.

Caution! Risk of tipping over!

Stand-alone enclosures should be se-

cured to the floor to prevent them tipping over.

12 345

Fig. 10: Incorrect external air stream

Key

1 Cold ambient air

2 Server rack with installed equipment

3 Hot spot caused by failure to expel hot air

4 LCP Hybrid with air/water heat exchanger

5 External air stream onto the LCP Hybrid

A serial layout is the best option. This means that cold air

produced by the LCP Hybrid is drawn in by a server enclosure positioned behind it. The LCP Hybrid installed

there cools the air from this enclosure, and so on.

If several server enclosures are positioned adjacent to

one another, each enclosure must be partitioned separately. To this end, we recommend using a partition between two enclosures, and a corresponding side panel

as the termination.

5.1.2 Installation guidelines

The positioning in the rack aisles must be considered

when planning the layout. In particular, care should be

Rittal Liquid Cooling Package 13

Page 14

EN

5 Assembly and siting

Fig. 11: Serial layout

Secure one air baffle plate from the LCP Hybrid accessories to one of the rear supports in the server rack

(fig. 12).

1

2

Fig. 12: Air baffle plate in the server rack

Key

1 Server rack

2 Air baffle plate

If devices which require cooling via sideways air

throughput (e.g. switches, router, etc.) are built into the

server enclosure, the air baffle plates will need to be

repositioned to allow for cooling (fig. 5):

Attach the air baffle plate in the front section on one

side of the server rack.

Attach the air baffle plate in a suitable place in the rear

section on the other side of the server rack.

5.2 Assembly procedure

5.2.1 General

Before the Liquid Cooling Package can be bayed onto a

server enclosure, the following work should be carried

out:

– Seal the server enclosure,

– Dismantle the rear server enclosure door, if available

– Remove the lock pieces with the divided rear door and

– Fit the side panels.

After baying the Liquid Cooling Package, the optional air

routing kit may be installed.

5.2.2 Seal the server enclosure

In order to ensure targeted air routing in the system, the

server enclosure is vertically divided into hot air and cold

air zones by sealing the 482.6 mm (19") level.

Proceed as follows to seal the 482.6 mm (19") level:

If the server enclosure is only partially configured, seal

the open sections of the 482.6 mm (19") level using

blanking plates. Screw these tightly into the server

rack from the rear.

5.2.3 Dismantle the rear server enclosure door

For baying the LCP Hybrid, the rear door of the server

enclosure (if available) will need to be removed. The

frame of the LCP Hybrid is bayed to the server enclosure

frame in place of the existing server door.

Proceed as follows to dismantle the server enclosure

door:

Remove the sealing bungs from the four door hinges

using an appropriate tool (e.g. screwdriver).

Release and open the server enclosure door.

On each hinge, loosen the locking screw used to secure it to the server enclosure.

Note:

Fig. 13: Removing a door hinge

Blanking plates in the various height units (U)

and narrow air baffle plates are available as

Rittal accessories (see section 12 "Accessories").

14 Rittal Liquid Cooling Package

Note:

Support the server enclosure door so that it

will not fall as the hinges are loosened. If necessary, work with a second person.

Page 15

Remove the server enclosure door from the enclosure,

including the hinges, to the rear.

If divided rear doors were fitted to the server enclosure, the lock pieces in the centre will additionally need

to be removed.

5.2.4 Fit the door latch mechanisms

To lock the LCP Hybrid with the server enclosure, the

four lock pieces included with the supply are mounted

on the handle side.

4 x

M6 x 12

5 Assembly and siting

EN

1

2

3

MD= 9 Nm

Fig. 14: Lock piece

Rotate the first lock piece so that the "L" marking is

legible.

Screw the lock piece through the bottom opening on

one of the four mounting positions in the server enclosure.

In the same way, attach the three other lock pieces to

the lock side of the server enclosure.

5.2.5 Fit the LCP Hybrid

Note:

At least two people must work together to in-

stall the LCP Hybrid.

Leaving the LCP Hybrid in its packaging, position it behind the server enclosure on which it is to be fitted.

Open the packaging.

With at least two people, lift the LCP Hybrid out of the

packaging and set it upright.

Rotate the LCP Hybrid on the mounting aid, in such a

way that the mounting points and the cooling water

connections are on the right-hand side.

Push the LCP Hybrid against the server enclosure on

the mounting aid, and align it in such a way that the

mounting points in the door hinge of the LCP Hybrid

are aligned with the corresponding openings in the

server enclosure.

Fig. 15: Mounting the LCP Hybrid – Exterior

Key

1 Server enclosure

2 Mounting point

3 Door hinge

Screw the LCP Hybrid onto the four mounting points

to which standard server enclosure door hinges are

attached.

The LCP Hybrid is additionally screw-fastened to the inside of the server enclosure at the top and bottom.

Swing the LCP Hybrid away from the server enclosure

to give you access to the rear of the server enclosure.

Secure the LCP Hybrid on the inside top using two

screws included with the supply.

Rittal Liquid Cooling Package 15

Page 16

EN

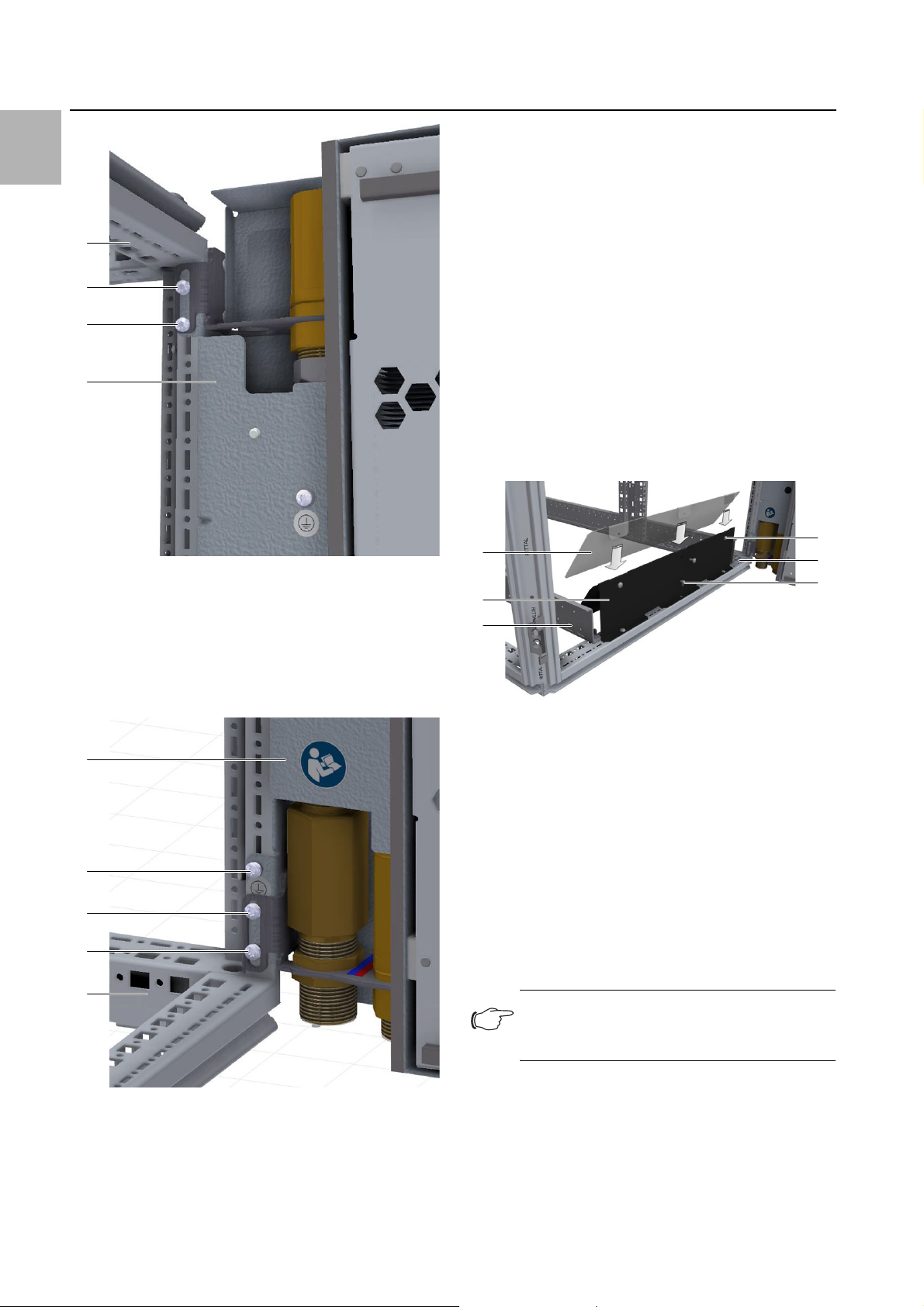

5 Assembly and siting

1

2

2

3

5.2.6 Fitting the potential equalisation

In order to ensure reliable potential equalisation between

the server enclosure and the LCP Hybrid, it is additionally necessary to fit the special potential equalisation

screw.

Screw the potential equalisation screw and contact

washer included with the supply into the point marked

with an earth symbol above the bottom two assembly

screws, as far as they will go (fig. 17, item 2).

5.2.7 Install the air routing kit (optional)

It is also important to ensure correct routing of the heated air through the LCP Hybrid for the devices installed at

the top and bottom of the server enclosure. To this end,

the air routing kit (3311.160) available as an accessory

should be mounted at the rear on the inside of the server

enclosure frame.

First, insert one air baffle plate each from above into

the corresponding fastening plate.

Fig. 16: Mounting the LCP Hybrid – Inside top

Key

1 Server enclosure

2 Assembly screws (2x)

3LCPHybrid

Secure the LCP Hybrid at the inside bottom using two

screws included with the supply.

1

2

3

3

4

6

5

4

Fig. 18: Air routing kit at the bottom of the server enclosure

Key

1 Assembly screw, air baffle plate – fastening plate (3x)

2 Server enclosure

3 Assembly screw, fastening plate – server enclosure (3x)

4 482.6 mm (19") level

5 Fastening plate

6 Air baffle plate

Secure the air baffle plate in this position using a total

of three assembly screws.

Mount the fastening plate, including the air baffle plate,

at the bottom rear of the server enclosure frame, and

secure it in this position, likewise with three assembly

screws.

Note:

The side position of the air baffle plate is de-

termined by the 482.6 mm (19") chassis.

1

2

3

Fig. 17: Mounting the LCP Hybrid – Inside bottom

Key

1LCPHybrid

2 Position for potential equalisation

3 Assembly screws (2x)

4 Server enclosure

16 Rittal Liquid Cooling Package

Fit the second air baffle plate in the server enclosure as

outlined above.

5.2.8 Remove the mounting aid

Finally, remove the mounting aid beneath the Liquid

Cooling Package.

Page 17

Fig. 19: Mounting aid on the LCP Hybrid

5 Assembly and siting

EN

Rittal Liquid Cooling Package 17

Page 18

6 Installation

EN

6 Installation

6.1 Cooling water connection

The Liquid Cooling Package is connected to the cold

water network via two DN 25 (G1") threaded pipe connections (external thread) on the inlet and return (on the

underside of the unit). The connection nozzles are positioned vertically downwards. If there is a raised floor

present, connection to the on-site cold water network is

made in a downward direction.

1

2

3

Recommendation:

Ideally, Liquid Cooling Packages should be

connected to the cooling water circuit via a

water/water heat exchanger when using a

water/glycol mixture.

Benefit:

– Reduction of water volumes in the second-

ary circuit,

– Setting of a defined water quality,

– Setting of a defined inlet temperature and

– Setting of a defined volumetric flow.

Tichelmann principle and hydraulic balancing

For an efficient cold water supply to the Liquid Cooling

Package, the cold water system must be hydraulically

balanced. If the hydraulics are not balanced, the LCP

systems will not be supplied homogeneously with the required volume of cold water. This will adversely affect efficient operation.

4

5

Fig. 20: Cold water network connection

Key

1Door bracket hinge

2LCPHybrid

3 Server enclosure

4 Cooling water connection, inlet

5 Cooling water connection, return

Caution!

When installing, observe the applicable

specifications concerning water quality

and water pressure.

Caution!

Connection of the LCP Hybrid to the

cooling water supply may only be carried

out by properly trained staff.

Fig. 21: Cooling distribution without hydraulic balancing

Key

1 Circulating pump

2 Shut-off valve

3 Fine filter

4Return

5 Supply

6 Pump pressure

7 Appliance to be cooled (LCP Hybrid)

8 Pipe friction pressure factor

9 Opening of control valve

10 Control valve

Here, hydraulic balancing can be achieved via balancing

valves.

18 Rittal Liquid Cooling Package

Page 19

Fig. 22: Cooling distribution with hydraulic balancing

However, if the individual connection lines for the LCP

systems are laid according to the "Tichelmann" connection principle, hydraulic balancing is not necessary. With

this connection variant, all individual connection lines

have the same pressure loss.

6 Installation

closed, but they must be opened prior to commissioning.

Warning! Danger of cut wounds, especially from the sharp edges of the heat

exchanger module!

Put on protective gloves before beginning assembly or cleaning work!

Proceed as follows to bleed the device:

Swing the LCP Hybrid away from the server enclosure.

Remove the three assembly components from the inner maintenance door of the LCP Hybrid and open the

maintenance door.

Remove the vent hose included with the supply from

the inside of the maintenance door.

EN

Fig. 23: Cooling distribution with Tichelmann principle

Notes on water quality

For safe operation, it is vital that the requirements of Directive VDI 2035-2 are observed.

Note:

The maximum permissible working pressure

(PS1) of the LCP Hybrid is 6 bar. Membrane

expansion tanks and safety valves must be

used to ensure that this pressure is not exceeded.

Note:

Before commencing operation with water, all

supply lines must be adequately flushed.

1

2

Fig. 24: Vent hose on the LCP Hybrid

Key

1Vent hose

2 Maintenance door

Connect the vent hose to the collective vent of the

heat exchanger from below.

1

2

3

4

Detailed diagrams and tables showing cooling output

and pressure loss can be found in section 13.2 "Characteristic curves and tables".

6.2 Bleeding the air from the heat exchanger

Two vent valves are installed at the uppermost point of

the heat exchanger package in the Liquid Cooling

Package. The unit is delivered with these valves fully

Rittal Liquid Cooling Package 19

Fig. 25: Vent valves on the LCP Hybrid

Key

1Vent valve 1

2Vent valve 2

3Collective vent

4Vent hose

Page 20

EN

6 Installation

Position a collecting vessel underneath the open end

of the vent hose to collect any escaping water.

Open the two vent valves using the supplied bleed tool

until you hear the hiss of escaping air.

Wait until water escapes from the vent hoses, then

close the valves again completely.

Next, open both vent valves again slightly and check

whether any more air escapes.

If so, hold the vent valves open until water escapes

again.

Repeat this process until there are no bubbles visible

in the vent hose for a significant period of time, ensuring that there is no air left in the system.

Once you have finished the vent process, remove the

vent hose again, and secure it to the inside of the

maintenance door.

Close the inner maintenance door of the Liquid

Cooling Package.

Swing the LCP Hybrid towards the server enclosure

and close the door.

Note:

The system is usually bled during the course

of commissioning. This process may need to

be repeated if the device is failing to supply

the desired cooling output (see section 8

"Troubleshooting").

6.3 Installing the cover

Once all the installation work is complete, the cover is fitted over the door hinge.

1

Fig. 26: Cover on the LCP Hybrid

Key

1Cover

Position the cover over the entire height of the door

hinge at the side.

Secure the cover with the screws supplied loose.

Create potential equalisation using the screw and contact washer supplied loose.

20 Rittal Liquid Cooling Package

Page 21

1

Fig. 27: Cover on the LCP Hybrid

Key

1 Screw and contact washer for potential equalisation

6 Installation

EN

Rittal Liquid Cooling Package 21

Page 22

7 Commissioning checklist

Photo: Amacell

Photo: Honeywell

EN

7 Commissioning checklist

Rittal GmbH & Co. KG hopes that this checklist will help

its customers and cooperation partners install and operate the products of the Liquid Cooling Package family

successfully.

Before the installation:

Are shut-off valves installed in the flow and return?

These valves make it easier to replace or repair the

Liquid Cooling Package without the need to shut off

the entire cold water supply.

Is there a taco-setter installed in the return of each Liquid

Cooling Package?

The taco-setter ensures a constant volumetric flow

and helps to maintain the hydraulic balance of the system, especially when operating with other types of

units, such as convectors.

Note:

If the pipework for the Liquid Cooling

Package is laid according to the Tichelmann

principle, a taco-setter is not necessary.

Is the water supply properly insulated?

Proper insulation protects against condensate formation, especially on the cooling water inlet components.

Is there a good water supply available which meets the

quality requirements?

Water quality determines the lasting reliability of the

system. It ensures that no undesirable corrosion or

harmful deposits will occur. The exact manufacturer's

recommendations regarding water quality can be

found in section 13.1 "Hydrological information" of the

assembly and operating instructions of your Liquid

Cooling Package. It is important to ensure that the

recommended water quality is maintained even after

installation.

Was the pipework sufficiently flushed before the Liquid

Cooling Package was connected?

It is important to clean or flush the water circuits appropriately, especially for new installations. Experience

has shown that there are often remnants of sealants,

lubricants, and even metal chips in new systems,

which may lead to a premature failure of the Liquid

Cooling Package. Cleaning the cold water system

carefully before connecting the Liquid Cooling

Package ensures reliable operation later.

Are the permissible bending radii of the hoses adhered

to?

The hoses must not be kinked too tightly, otherwise

the flow volume may be impaired and the materials

may fatigue prematurely.

22 Rittal Liquid Cooling Package

If the water quality of the primary cold water supply is inadequate, was a separate water circuit with a water/water heat exchanger installed?

If the cold water supply is strongly contaminated, it

may make sense to install a second, high quality cold

water circuit which is connected to the primary circuit

via a water/water heat exchanger. Even in this case,

the water circuit on the Liquid Cooling Package side

must be carefully cleaned before connecting the device. Our recommendations regarding water quality in

section 13.1 "Hydrological information" of the assembly and operating instructions of your Liquid Cooling

Package apply to this procedure as well.

Page 23

7 Commissioning checklist

Photo: Clariant

Was the water prepared/treated with the appropriate

additives?

In addition to our recommendations regarding water

quality, we recommend that the water be enriched

with corrosion inhibitor and/or antifreeze. Also, a treatment to prevent algae and biofilms may be expedient

in some cases.

Are unused height units in the bayed server enclosures

sealed with vertical blanking plates, and are the side vertical air baffle plates installed?

In order to prevent undesired air short circuits and circulation patterns inside the server enclosure, all unused height units of the 482.6 mm (19") level should

be closed off with blanking plates. This prevents the

warm air from being routed back in front of the installed equipment. The blanking plates are available in

various heights. The vertical air baffle plates installed

on each side of the server enclosure ensure that the

warm air cannot collect at the sides of the 482.6 mm

(19") level. Air baffle plates are available for 2 applications and 2 enclosure widths.

Venting of the Liquid Cooling Package

In order to ensure even water circulation through the

circuit and effective heat transfer, the Liquid Cooling

Package must be vented during commissioning.

Please feel free to contact Rittal if you have any questions or problems:

For malfunctions and repairs

Rittal Service Department

Tel.: +49(0)2772 505-1855

E-mail: RSI@Rittal-Service.com

EN

Are all water connections correctly made?

Before water is admitted, and, ideally before the ball

valves are opened, be sure to check that all connections are properly made.

Is the server enclosure equipped with suitable doors?

The front side/front door of the server enclosure must

have unrestricted air permeability, so that the servers

can draw in the cool ambient air at the front.

After admitting cold water:

Are all parts and connections watertight?

Please check to be sure that all parts and connections

which carry water are watertight. The Liquid Cooling

Package is subject to an individual, comprehensive

factory test, which also includes checking for leaks.

This additional check serves to locate problems, such

as possible transport damage, and to prevent greater

damage.

Rittal Liquid Cooling Package 23

Page 24

EN

8 Troubleshooting

8 Troubleshooting

Malfunction location

Malfunction Cause of malfunction Effect Remedy

Liquid Cooling Package

The unit is not

supplying the

required

cooling output

Air in the system If there is air in the system,

Increased pressure loss on

the piping network side, e.g.

through a clogged filter or incorrectly set flow limiter

Air routing not correct The cooled air passes

In order to prevent malfunctions caused by the cold water system, the following remedies should be implemented.

Malfunction location

Malfunction Cause of malfunction Effect Remedy

the water cannot circulate

properly in the heat exchanger. Thus, it cannot remove heat.

The external pumps are not

able to pump enough cold

water through the Liquid

Cooling Package.

through unsealed openings

past the equipment to the

front of the enclosure.

Bleed the air from the heat

exchanger.

Clean the filter, set the flow

limiter correctly.

Unused height units in the

482.6 mm (19") level as well

as side slots and openings

must be sealed using blanking plates or air baffle plates.

Both are available as accessories.

Cold water

system

Corrosion

and contaminants in the

cold water

system

Insufficient cleaning after a

new installation

Improper treatment of the

water with corrosion protection additives

Older systems with existing

contaminants

Unclean and aggressive water leads to a weakening of

the material and to improper

function.

During initial installation, the

pipe network and the system

parts should be flushed out

before installing the Liquid

Cooling Package.

Rittal GmbH & Co. KG recommends the installation of

filters and the treatment of

the water with appropriate

corrosion and, if needed, antifreeze additives. The recommended notes regarding

water quality are found in

section 13.1 "Hydrological

information".

When integrating into existing cold water networks, the

use of a water/water heat

exchanger is recommended.

This forms a second water

circuit.

24 Rittal Liquid Cooling Package

Page 25

9 Inspection and maintenance

The Liquid Cooling Package is largely maintenance-free.

An additional external strainer with fine-mesh sieve

(0.25 mm) is required if the cooling water is contaminated. This should be cleaned regularly.

Visually inspect for leaks regularly (annual cycle).

The maintenance door to the Liquid Cooling Package

should be opened at regular intervals and the heat exchanger vacuumed clean.

9 Inspection and maintenance

EN

Rittal Liquid Cooling Package 25

Page 26

EN

10 Storage and disposal

10 Storage and disposal

Caution! Risk of damage!

The air/water heat exchanger must not

be subjected to temperatures above

+70°C during storage.

During storage, the air/water heat exchanger must be

laid on its side.

Disposal can be performed at the Rittal plant.

Please contact us for advice.

Emptying:

During storage and transportation below freezing point,

the air/water heat exchanger should be drained completely.

To this end, attach two vent hoses to the vent valves of

the Liquid Cooling Package and open the valves so that

the cooling fluid can run out (see section 6.2 "Bleeding

the air from the heat exchanger").

Caution! Risk of environmental contamination!

Refrigerant must not be released from

the heat pipes. It must be properly disposed of in accordance with the valid regional regulations.

26 Rittal Liquid Cooling Package

Page 27

11 Technical specifications

11 Technical specifications

EN

11.1 10 kW versions

Technical specifications

Description/Model No. TopTherm LCP Hybrid / 3311.610 (2000 mm high, 600 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.710 (2200 mm high, 600 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.810 (2000 mm high, 800 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.910 (2200 mm high, 800 mm wide)

Dimensions and weight 3311.610 3311.710 3311.810 3311.910

(Width x height x depth [mm]) 600 x 2000 x 105 600 x 2200 x 105 800 x 2000 x 105 800 x 2200 x 105

Usable U 42474247

Opening angle of door 135° 135° 135° 135°

Weight [kg] 76 78 78 81

Cooling circuit

Cooling medium Water (see Internet for specifications)

Cold water inlet temperature [°C] +7…+30 and at least 3 K above the dew points of the ambient and flowing air

Permissible operating pressure PS1

[bar]

Fill quantity of heat exchanger [l] 8

Max. volumetric flow of water [l/min] 70

Fill quantity of heat pipe with R134a

[kg]

Water connection DN 25 (G1")

Rated cooling output

Cooling output, sensible [kW] 10

Volumetric flow of cooling water

[l/min]

Cold water inlet temperature [°C] +15

Volumetric flow of air [m

Room air temperature [°C] +24 (air outlet temperature from LCP Hybrid)

Relative humidity [%] 43

Other information

3

/h] 2700 (air from IT equipment)

6

0.65

30

Noise level Depends on the configuration of the IT rack with equipment

Colour RAL 7035

Tab. 3: Technical specifications for 10 kW versions

Rittal Liquid Cooling Package 27

Page 28

EN

11 Technical specifications

11.2 20 kW versions

Technical specifications

Description/Model No. TopTherm LCP Hybrid / 3311.600 (2000 mm high, 600 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.700 (2200 mm high, 600 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.800 (2000 mm high, 800 mm wide)

Description/Model No. TopTherm LCP Hybrid / 3311.900 (2200 mm high, 800 mm wide)

Dimensions and weight 3311.600 3311.700 3311.800 3311.900

(Width x height x depth [mm]) 600 x 2000 x 105 600 x 2200 x 105 800 x 2000 x 105 800 x 2200 x 105

Usable U 42474247

Opening angle of door 135° 135° 135° 135°

Weight [kg] 76 81 81 84

Cooling circuit

Cooling medium Water (see Internet for specifications)

Cold water inlet temperature [°C] +7…+30 and at least 3 K above the dew points of the ambient and flowing air

Permissible operating pressure PS1

[bar]

Fill quantity of heat exchanger [l] 8

Max. volumetric flow of water [l/min] 70

Fill quantity of heat pipe with R134a

[kg]

Water connection DN 25 (G1")

Rated cooling output

Cooling output, sensible [kW] 20

Volumetric flow of cooling water

[l/min]

Cold water inlet temperature [°C] +15

Volumetric flow of air [m

Room air temperature [°C] +24 (air outlet temperature from LCP Hybrid)

Relative humidity [%] 43

Other information

Noise level Depends on the configuration of the IT rack with equipment

3

/h] 4000 (air from IT equipment)

6

0.65

58

Colour RAL 7035

Tab. 4: Technical specifications for 20 kW versions

28 Rittal Liquid Cooling Package

Page 29

12 Accessories

12 Accessories

Item Model No. Qty./Packs of Remarks

Air baffle plate for TS IT 5501.805 1 Width x height: 600 mm x 2000 mm

Air baffle plate for TS IT 5501.815 1 Width x height: 800 mm x 2000 mm

Air baffle plate for TS IT 5501.825 1 Width x height: 600 mm x 2200 mm

Air baffle plate for TS IT 5501.835 1 Width x height: 800 mm x 2200 mm

Connection hose 3301.351 2 Length 1 m, may be cut to required

length.

Air routing kit 3311.160 2

Tab. 5: Accessories list – Liquid Cooling Package

EN

Rittal Liquid Cooling Package 29

Page 30

13 Further technical information

EN

13 Further technical information

13.1 Hydrological information

To avoid damages to the system and ensure reliable operation, the provisions of VDI 2035 should be observed

for filling and top-up water.

Admissible cooling media

– Saline and low-salinity water based on VDI 2035 plus

max. 50 volume percent Antifrogen-N (see table 6).

Recommended cooling medium

– Low-salinity water (demineralised water) based on VDI

2035. Up to a maximum of 50 volume percent Antifrogen-N may be added (see table 6).

Low-salinity Saline

Electrical conductivity at 25°C [μS/cm]

Appearance Free from sedimenting substances

pH value at 25°C 8.2…10.0

Oxygen [mg/l] < 0.1 < 0.02

Tab. 6: Water specifications

13.2 Characteristic curves and tables

13.2.1 General

All information in the following tables refers to the use of

pure water as a cooling medium. The cooling performance data when using a water-glycol mixture is available on request from Rittal.

Proceed as follows to determine the required cooling

water temperature:

Determine the dew point for the room temperature

and relative humidity in the room (see section 13.2.2

"Determination of the dew point"). Alternatively, you

can use the h-x diagram (fig. 2).

Determine the minimum admissible cooling water

temperature by adding a safety margin of 3°C to this

figure.

Determine the required water throughput and

achieved cooling efficiency for the required airside

temperature difference T.

If the cooling efficiency determined in this way is 100%,

then the air outlet temperature from the LCP Hybrid will

be less than, or at the most, equal to the air inlet temperature into the server enclosure.

If the cooling efficiency determined in this way is less

than 100%, then the air outlet temperature from the LCP

Hybrid will be greater than the air inlet temperature into

< 100 100…1,500

the server enclosure. The room temperature will rise accordingly over time.

13.2.2 Determination of the dew point

Determination of the dew point for room temperature

20°C

Room temperature [°C/°F]

20 / 68.0 40 6 / 42.8

20 / 68.0 45 7.7 / 45.9

20 / 68.0 50 9.3 / 48.7

20 / 68.0 55 10.7 / 51.3

20 / 68.0 60 12 / 53.6

Tab. 7: Determination of the dew point for room temperature

20°C

Determination of the dew point for room temperature

21°C

Room temperature [°C/°F]

21 / 69.8 40 6.9 / 44.4

21 / 69.8 45 8.6 / 47.5

21 / 69.8 50 10.2 / 50.4

21 / 69.8 55 11.6 / 52.9

21 / 69.8 60 12.9 / 55.2

Tab. 8: Determination of the dew point for room temperature

21°C

Determination of the dew point for room temperature

22°C

Room temperature [°C/°F]

22 / 71.6 40 7.8 / 46

22 / 71.6 45 9.5 / 49.1

22 / 71.6 50 11.1 / 52

22 / 71.6 55 12.5 / 54.5

22 / 71.6 60 13.9 / 57

Tab. 9: Determination of the dew point for room temperature

22°C

Rel. humidity

[%]

Rel. humidity

[%]

Rel. humidity

[%]

Dew point

[°C/°F]

Dew point

[°C/°F]

Dew point

[°C/°F]

30 Rittal Liquid Cooling Package

Page 31

Determination of the dew point for room temperature

23°C

13 Further technical information

EN

Room temperature [°C/°F]

23 / 73.4 40 8.7 / 47.7

23 / 73.4 45 10.4 / 50.7

23 / 73.4 50 12 / 53.6

23 / 73.4 55 13.5 / 56.3

23 / 73.4 60 14.8 / 58.6

Tab. 10: Determination of the dew point for room temperature

23°C

Determination of the dew point for room temperature

24°C

Room temperature [°C/°F]

24 / 75.2 40 9.6 / 49.3

24 / 75.2 45 11.3 / 52.3

24 / 75.2 50 12.9 / 55.2

24 / 75.2 55 14.4 / 57.9

Rel. humidity

[%]

Rel. humidity

[%]

Dew point

[°C/°F]

Dew point

[°C/°F]

Fig. 28: Airside pressure loss in the "10 kW" version

Tab. 11: Determination of the dew point for room temperature

24°C

Determination of the dew point for room temperature

25°C

Room temperature [°C/°F]

25 / 77 40 10.5 / 50.9

25 / 77 45 12.2 / 54

25 / 77 50 13.8 / 56.8

Tab. 12: Determination of the dew point for room temperature

25°C

Rel. humidity

[%]

Dew point

[°C/°F]

13.2.3 Pressure loss

Note:

When using a water/glycol mixture (67% water, 33% glycol), the waterside pressure loss

must be multiplied by a factor of 1.2.

Fig. 29: Airside pressure loss in the "20 kW" version

Fig. 30: Upstream pressure loss in the "10 kW" version

Rittal Liquid Cooling Package 31

Page 32

EN

13 Further technical information

Fig. 31: Upstream pressure loss in the "20 kW" version

32 Rittal Liquid Cooling Package

Page 33

13 Further technical information

13.2.4 Cooling output at a room temperature of 21°C

10 kW devices 3311.610/710/810/910

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 19 19 19 19 19.5 19.5 20

Water volume [l/min] 10111419212840

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 33 33 33 33 33 33 33

T air [K] 12121212121212

Tab. 13: Cooling output at partial load and a T air of 12 K

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

3

/h] 1200 1200 1200 1300 1300 1300 1300

EN

Return temperature [°C] 19 19.5 19 19 19.5 20 20

Water volume [l/min] 10111419212840

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 36 36 36 36 36 36 36

T air [K] 15151515151515

Tab. 14: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 17.5 17.5 18 18 18

Water volume [l/min] 2630304658

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 33 33 33 33 33

T air [K] 1212121212

3

/h] 1000 1000 1000 1100 1100 1100 1100

3

/h] 2400 2500 2500 2600 2400

Tab. 15: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 17.5 18 18 18 19

Water volume [l/min] 2630354658

Volumetric airflow [m

Tab. 16: Cooling output at full load and a T air of 15 K

Rittal Liquid Cooling Package 33

3

/h] 2000 2100 2100 2100 2100

Page 34

13 Further technical information

EN

Cooling output, sensible [kW] 10 10 10 10 10

Air outlet from LCP Hybrid [°C] 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 36 36 36 36 36

T air [K] 1515151515

Tab. 16: Cooling output at full load and a T air of 15 K

20 kW devices 3311.600/700/800/900

Cooling output, sensible [kW] 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 18.5 19 19 19 20

Water volume [l/min] 3236425060

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 33 33 33 33 33

T air [K] 1212121212

Tab. 17: Cooling output at partial load and a T air of 12 K

3

/h] 3600 3600 3800 3800 3800

Cooling output, sensible [kW] 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 19 19 19 20 20

Water volume [l/min] 3236434860

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21 21

Air inlet to LCP Hybrid [°C] 36 36 36 36 36

T air [K] 1515151515

Tab. 18: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 20 20 20 20

Inlet temperature [°C] 12 13 14 15

Return temperature [°C] 17.5 18 18 19

Water volume [l/min] 50556075

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21

3

/h] 3200 3200 3200 3200 3200

3

/h] 4500 4800 4800 4800

Air inlet to LCP Hybrid [°C] 33 33 33 33

T air [K] 12121212

Tab. 19: Cooling output at full load and a T air of 12 K

34 Rittal Liquid Cooling Package

Page 35

13 Further technical information

Cooling output, sensible [kW] 20 20 20 20

Inlet temperature [°C] 12 13 14 15

Return temperature [°C] 18 18.5 18 19

Water volume [l/min] 48526875

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 21 21 21 21

Air inlet to LCP Hybrid [°C] 36 36 36 36

T air [K] 15151515

Tab. 20: Cooling output at full load and a T air of 15 K

3

/h] 4000 4000 4000 4000

13.2.5 Cooling output at a room temperature of 22°C

10 kW devices 3311.610/710/810/910

Cooling output, sensible [kW] 5 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18 19

Return temperature [°C] 20 20 20 20 20 20 21 21

Water volume [l/min] 9 11 13 15 19 22 28 40

Volumetric airflow [m

3

/h] 1300 1300 1300 1300 1300 1300 1300 1300

EN

Air outlet from LCP Hybrid [°C] 22 22 22 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 34 34 34 34 34 34 34 34

T air [K] 1212121212121212

Tab. 21: Cooling output at partial load and a T air of 12 K

Cooling output, sensible [kW] 5 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18 19

Return temperature [°C] 20.5 20 20 20 20 20.5 21 21

Water volume [l/min] 9 11 13 15 19 22 28 40

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 22 22 22 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 37 37 37 37 37 37 37 37

T air [K] 1515151515151515

Tab. 22: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

3

/h] 1100 1100 1100 1100 1100 1100 1100 1100

Return temperature [°C] 18 18 19 19 19

Water volume [l/min] 2428303745

Tab. 23: Cooling output at full load and a T air of 12 K

Rittal Liquid Cooling Package 35

Page 36

13 Further technical information

EN

Cooling output, sensible [kW] 10 10 10 10 10

Volumetric airflow [m3/h] 2400 2500 2500 2500 2500

Air outlet from LCP Hybrid [°C] 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 34 34 34 34 34

T air [K] 1212121212

Tab. 23: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 18 18.5 19 19 19

Water volume [l/min] 2428303745

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 37 37 37 37 37

T air [K] 1515151515

Tab. 24: Cooling output at full load and a T air of 15 K

3

/h] 2000 2100 2100 2100 2100

20 kW devices 3311.600/700/800/900

Cooling output, sensible [kW] 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 19 19 20 20 20 20.5

Water volume [l/min] 323638404860

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 22 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 34 34 34 34 34 34

T air [K] 121212121212

Tab. 25: Cooling output at partial load and a T air of 12 K

Cooling output, sensible [kW] 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 20 20 20 21 21 21

Water volume [l/min] 283236384654

Volumetric airflow [m

3

/h] 3600 3600 3600 3600 3600 3600

3

/h] 3100 3100 3100 3100 3100 3100

Air outlet from LCP Hybrid [°C] 22 22 22 22 22 22

Air inlet to LCP Hybrid [°C] 37 37 37 37 37 37

T air [K] 151515151515

Tab. 26: Cooling output at partial load and a T air of 15 K

36 Rittal Liquid Cooling Package

Page 37

13 Further technical information

Cooling output, sensible [kW] 20 20 20 20

Inlet temperature [°C] 12 13 14 15

Return temperature [°C] 18 19 19 19

Water volume [l/min] 48485462

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 22 22 22 22

Air inlet to LCP Hybrid [°C] 34 34 34 34

T air [K] 12121212

Tab. 27: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 20 20 20 20

Inlet temperature [°C] 12 13 14 15

Return temperature [°C] 19 19 19.5 20

Water volume [l/min] 44485262

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 22 22 22 22

3

/h] 4500 4500 4500 4500

3

/h] 4100 4100 4100 4100

EN

Air inlet to LCP Hybrid [°C] 37 37 37 37

T air [K] 15151515

Tab. 28: Cooling output at full load and a T air of 15 K

13.2.6 Cooling output at a room temperature of 23°C

10 kW devices 3311.610/710/810/910

Cooling output, sensible [kW] 5 5 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18 19 20

Return temperature [°C] 22 22 21 21 21 21 21.5 22 22

Water volume [l/min] 7 8 10121417202638

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 35 35 35 35 35 35 35 35 35

T air [K] 121212121212121212

Tab. 29: Cooling output at partial load and a T air of 12 K

3

/h] 1200 1200 1200 1200 1200 1200 1200 1200 1200

Cooling output, sensible [kW] 5 5 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18 19 20

Return temperature [°C] 22.5 19.5 21 21 21 21 22 22 22

Water volume [l/min] 7 11 10 12 14 17 20 26 38

Tab. 30: Cooling output at partial load and a T air of 15 K

Rittal Liquid Cooling Package 37

Page 38

13 Further technical information

EN

Cooling output, sensible [kW] 5 5 5 5 5 5 5 5 5

Volumetric airflow [m3/h] 1000 1000 1000 1000 1000 1000 1000 1000 1000

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 38 38 38 38 38 38 38 38 38

T air [K] 151515151515151515

Tab. 30: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 18.5 19 19.5 19 19

Water volume [l/min] 2123254647

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 35 35 35 35 35

T air [K] 1212121212

Tab. 31: Cooling output at full load and a T air of 12 K

3

/h] 2400 2400 2400 2900 2900

Cooling output, sensible [kW] 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16

Return temperature [°C] 19 19 20 19 20

Water volume [l/min] 2123254650

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 38 38 38 38 38

T air [K] 1515151515

Tab. 32: Cooling output at full load and a T air of 15 K

3

/h] 2000 2000 2000 2600 2600

20 kW devices 3311.600/700/800/900

Cooling output, sensible [kW] 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 19 19.5 20 20 20.5 21

Water volume [l/min] 303234384658

Volumetric airflow [m

3

/h] 3700 3700 3700 3700 3700 3700

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 35 35 35 35 35 35

T air [K] 121212121212

Tab. 33: Cooling output at partial load and a T air of 12 K

38 Rittal Liquid Cooling Package

Page 39

13 Further technical information

Cooling output, sensible [kW] 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 20 20 21 21 22 22

Water volume [l/min] 283234364050

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 38 38 38 38 38 38

T air [K] 151515151515

Tab. 34: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 18 18 18 18 18 18

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 19 19 20 20 20 21

Water volume [l/min] 404550556575

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23

3

/h] 3200 3200 3200 3200 3200 3200

3

/h] 4500 4500 4500 4500 4500 4500

EN

Air inlet to LCP Hybrid [°C] 35 35 35 35 35 35

T air [K] 121212121212

Tab. 35: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 20 20 20 20 20 20

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 20 20 20 20 20 21

Water volume [l/min] 374045557575

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 23 23 23 23 23 23

Air inlet to LCP Hybrid [°C] 38 38 38 38 38 38

T air [K] 151515151515

Tab. 36: Cooling output at full load and a T air of 15 K

3

/h] 4000 4000 4000 4000 4000 4000

13.2.7 Cooling output at a room temperature of 24°C

10 kW devices 3311.610/710/810/910

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 24 23 23 22 22 22 22

Water volume [l/min] 7 8 8 11 13 16 18

Tab. 37: Cooling output at partial load and a T air of 12 K

Rittal Liquid Cooling Package 39

Page 40

13 Further technical information

EN

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Volumetric airflow [m3/h] 1200 1300 1300 1300 1300 1300 1300

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 36 36 36 36 36 36 36

T air [K] 12121212121212

Tab. 37: Cooling output at partial load and a T air of 12 K

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 24 23 23 22 22 22 22

Water volume [l/min] 6 8 9 11 13 16 20

3

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 39 39 39 39 39 39 39

T air [K] 15151515151515

Tab. 38: Cooling output at partial load and a T air of 15 K

/h] 1000 1100 1100 1100 1100 1100 1100

Cooling output, sensible [kW] 10 10 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 19 19.5 20 20 21 21 21.5

Water volume [l/min] 20222426303440

Volumetric airflow [m3/h] 2400 2400 2400 2400 2500 2500 2500

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 36 36 36 36 36 36 36

T air [K] 12121212121212

Tab. 39: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 10 10 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 20 20 20 20 21 21 21

Water volume [l/min] 20222426303846

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

3

/h] 2100 2100 2100 2100 2200 2200 2200

Air inlet to LCP Hybrid [°C] 39 39 39 39 39 39 39

T air [K] 15151515151515

Tab. 40: Cooling output at full load and a T air of 15 K

40 Rittal Liquid Cooling Package

Page 41

13 Further technical information

20 kW devices 3311.600/700/800/900

Cooling output, sensible [kW] 15 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 20 21 21.5 22 22 22.5 23

Water volume [l/min] 23252830333842

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 36 36 36 36 36 36 36

T air [K] 12121212121212

Tab. 41: Cooling output at partial load and a T air of 12 K

Cooling output, sensible [kW] 15 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 21 21.5 22 22 22 23 23.5

Water volume [l/min] 24262830343838

Volumetric airflow [m

3

/h] 3500 3500 3500 3500 3500 3500 3500

3

/h] 3000 3000 3000 3000 3000 3000 3000

EN

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 39 39 39 39 39 39 39

T air [K] 15151515151515

Tab. 42: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 18 18 18 18 18 18

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 20 20 20 21 21 22

Water volume [l/min] 303436404655

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24

Air inlet to LCP Hybrid [°C] 36 36 36 36 36 36

T air [K] 121212121212

Tab. 43: Cooling output at full load and a T air of 12 K

Cooling output, sensible [kW] 20 20 20 20 20 20

Inlet temperature [°C] 12 13 14 15 16 17

3

/h] 4200 4200 4200 4200 4200 4200

Return temperature [°C] 20 20 21 21 21 18

Water volume [l/min] 404446546075

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 24 24 24 24 24 24

Tab. 44: Cooling output at full load and a T air of 15 K

Rittal Liquid Cooling Package 41

3

/h] 4500 4500 4500 4500 4500 4500

Page 42

13 Further technical information

EN

Cooling output, sensible [kW] 20 20 20 20 20 20

Air inlet to LCP Hybrid [°C] 39 39 39 39 39 39

T air [K] 151515151515

Tab. 44: Cooling output at full load and a T air of 15 K

13.2.8 Cooling output at a room temperature of 25°C

10 kW devices 3311.610/710/810/910

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 26 25 24 24 23 23 23

Water volume [l/min] 5678101214

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 25 25 25 25 25 25 25

Air inlet to LCP Hybrid [°C] 37 37 37 37 37 37 37

T air [K] 12121212121212

Tab. 45: Cooling output at partial load and a T air of 12 K

3

/h] 1200 1200 1200 1300 1300 1300 1300

Cooling output, sensible [kW] 5 5 5 5 5 5 5

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 26 25 25 25 24 24.5 23.5

Water volume [l/min] 5678101214

Volumetric airflow [m

Air outlet from LCP Hybrid [°C] 25 25 25 25 25 25 25

Air inlet to LCP Hybrid [°C] 40 40 40 40 40 40 40

T air [K] 15151515151515

Tab. 46: Cooling output at partial load and a T air of 15 K

Cooling output, sensible [kW] 10 10 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16 17 18

Return temperature [°C] 20 20 21 21 21.5 22 22

Water volume [l/min] 18202224263034

Volumetric airflow [m3/h] 2400 2500 2500 2500 2500 2500 2500

Air outlet from LCP Hybrid [°C] 25 25 25 25 25 25 25

3

/h] 1000 1000 1000 1100 1100 1100 1100

Air inlet to LCP Hybrid [°C] 37 37 37 37 37 37 37

T air [K] 12121212121212

Tab. 47: Cooling output at full load and a T air of 12 K

42 Rittal Liquid Cooling Package

Page 43

13 Further technical information

Cooling output, sensible [kW] 10 10 10 10 10 10 10

Inlet temperature [°C] 12 13 14 15 16 17 16

Return temperature [°C] 20 20.5 21 21 22 22 22

Water volume [l/min] 20222426283238

Volumetric airflow [m3/h] 2200 2200 2200 2300 2300 2300 2300

Air outlet from LCP Hybrid [°C] 25 25 25 25 25 25 25

Air inlet to LCP Hybrid [°C] 40 40 40 40 40 40 40

T air [K] 15151515151515

Tab. 48: Cooling output at full load and a T air of 15 K

20 kW devices 3311.600/700/800/900

Cooling output, sensible [kW] 15 15 15 15 15 15

Inlet temperature [°C] 12 13 14 15 16 17

Return temperature [°C] 21.5 22 22 23 23 23

Water volume [l/min] 232526283235

Volumetric airflow [m

3

/h] 3700 3700 3700 3700 3700 3700