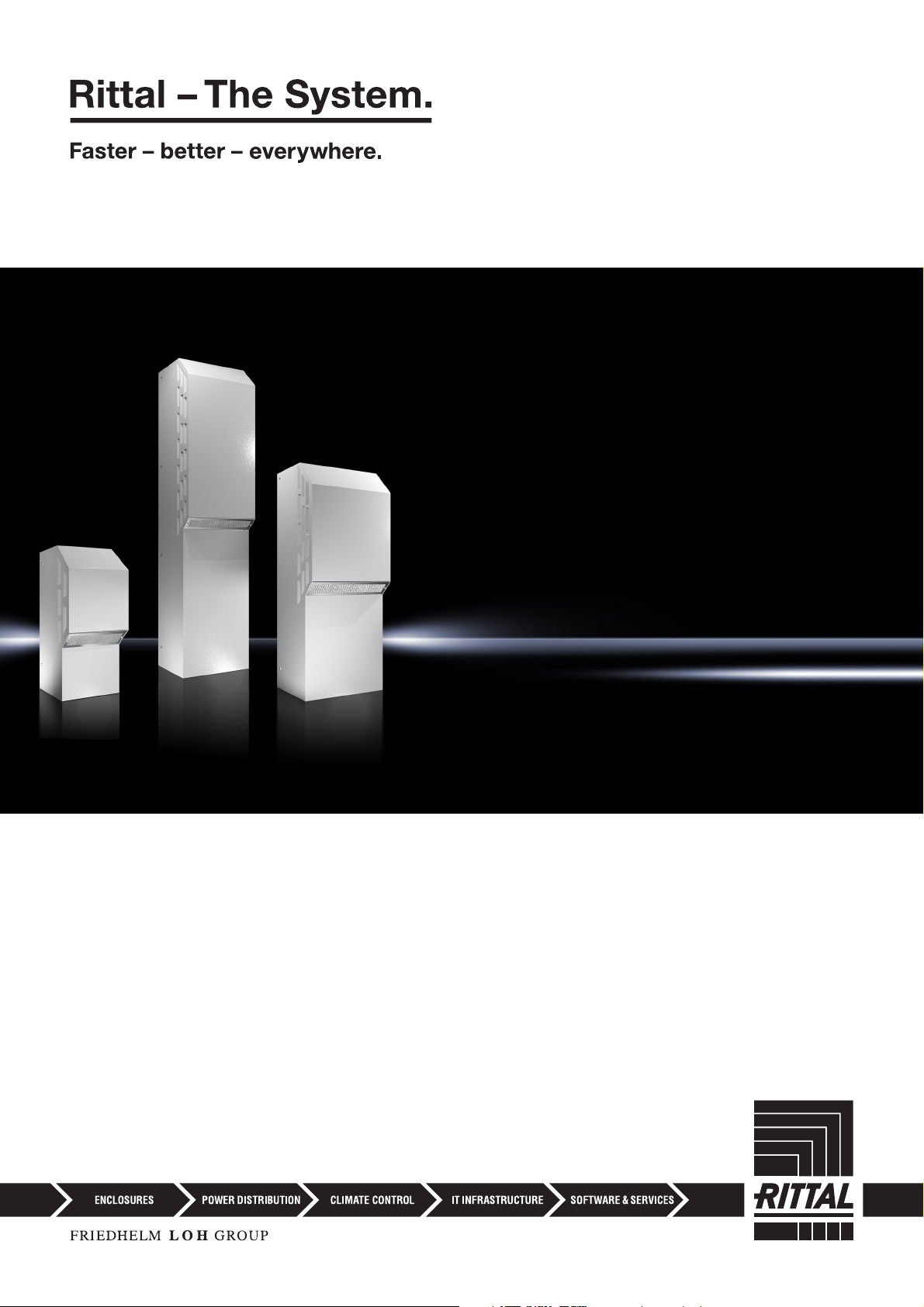

Rittal 3304.518, 3303.518, 3304.508, 3303.508,3303.518,3304.508,3304.518,3304.548,3305.508,3305.518,3305.548,3329.508,3329.518,3329.548, 3304.548 Assembly And Operating Instructions Manual

...Page 1

UL Type 12/3R/4

Cooling unit

3303.5x8

3304.5x8

3305.5x8

3329.5x8

Assembly and operating instructions

Page 2

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

Warn- und Sicherheitshinweise / Safety instru ctions and warnings / Consignes de sécurité

Warn- und Sicherheitshinweise / Safety instru ctions and warnings / Consignes de sécurité

DE Die Anschlussvorschriften des zuständigen Stromversorgungsunternehmens sind zu beachten. Der Schutzleiter, der Haube und

Chassis verbindet, muss in jedem Fall an beiden Steckern angeschlossen werden. Ansonsten besteht bei einem fehlerhaftem oder defekten Anschluss des Geräts Verletzungsgefahr durch Stromschlag.

EN The connection regulations of the appropriate power supply company are to be followed. The protective conductor between the

hood and the frame must always be attached to both plug connectors. Otherwise, there is risk of injury from electric shock if the connection to the unit is defective or connected incorrectly in any way.

FR Respecter les directives de raccordement du fournisseur d’électricité compétent. La tresse de mise à la masse qui relie le capot au

châssis doit dans tous les cas être raccordée aux deux fiches. Sinon il y a risque de blessure par électrocution en cas de raccordement

erroné ou défectueux de l’appareil.

NL Neem de aansluitvoorschriften van het desbetreffende energiebedrijf in acht. De beschermingsgeleiding, die de kap en het chassis

verbindt, dient in elk geval op beide connectoren te worden aangesloten. Anders bestaat bij een onjuiste of defecte aansluiting van het

apparaat een risico op letsel door een elektrische schok.

SE Anslutningsföreskrifterna från det ansvariga elförsörjningsföretaget måste följas. Skyddsledaren som förbinder huven och chassit

måste alltid vara ansluten till båda kontakterna. Annars finns risk för skador genom strömstötar vid felaktig eller defekt anslutning av aggregatet.

IT Osservare le prescrizioni relative al collegamento dell’azienda fornitrice di elettricità competente. Il conduttore di protezione che collega la copertura al telaio deve essere sempre collegato su entrambe le estremità. In caso di collegamento assente o errato del dispositivo

vi è il pericolo di lesioni dovute a scossa elettrica.

ES Deben tenerse en cuenta las normas de conexión de la compañía eléctrica competente. El conductor de protección, que conecta

la cubierta y el chasis, debe conectarse siempre a ambos conectores. En caso contrario, con una conexión errónea o defectuosa del

aparato, existe un peligro de lesión por descarga eléctrica.

FI Huomioi energiayhtiön liitäntäohjeet. Muussa tapauksessa laitteen virheellinen tai viallinen liitäntä saattaa aiheuttaa sähköiskusta johtuvan loukkaantumisvaaran.

DK Følg altid tilslutningsvejledningen fra det ansvarlige elselskab. Beskyttelseslederen, som forbinder dækslet med chassiset, skal altid

være tilsluttet i begge stik. Hvis ikke dette er tilfældet, er der risiko for at få elektrisk stød som følge af forkert eller defekt tilslutning af

enheden.

IE Ní mór rialacháin nasctha na cuideachta cuí a sholáthraíonn an chumhacht a leanúint. Ní mór go mbeadh an seoltóir cosanta idir an

cochall agus an fráma nasctha leis an dá nascóir plocóide. Mura mbíonn, tá baol gortaithe ó thurraing leictreach má tá an nasc leis an

aonad lochtach nó má tá sé nasctha ar cearr ar bhealach ar bith.

PT Seguir as orientações da respectiva empresa de fornecimento de energia elétrica. O condutor de proteção que interliga a cobertura

com o chassi deve estar sempre conectado em ambas as extremidades. Caso contrário, haverá risco de choque elétrico se a conexão

do aparelho apresentar falha ou estiver incorreta.

HR Potrebno je pridržavati se pravila o priključivanju odgovarajućeg napona isporučitelja električne energije. Zaštitno uzemljenje između

poklopca i okvira mora uvijek s biti spojeno na priključne točke poklopca i okvira. Ukoliko zaštitno uzemljenje nije propisno spojeno ili je

oštećeno, postoji opasnost od ozljeda uzrokovanih strujnim udarom.

MT Għandhom jiġu osservati r-rekwiżiti tat-tqabbid tal-kumpanija tal-provvista tal-elettriku lokali. Il-konduttur protettiv li jqabbad il-hood

max-xażi għandu jkun imqabbad dejjem biż-żewġ plugs. Inkella jkun hemm ir-riskju ta’ xokk elettriku jekk ikun hemm konnessjoni mhux

tajba jew difettuża.

PL Przestrzegać przepisów odpowiedniego Zakładu Energetycznego. Przewód ochronny łączący pokrywę z obudową musi być zawsze

podłączony z obu stron. W przeciwnym razie, w przypadku błędnego lub wadliwego podłączenia urządzenia, istnieje niebezpieczeństwo

porażenia prądem elektrycznym.

CZ Dodržujte předpisy příslušného dodavatele elektrické energie pro připojení elektrického zařízení. V každém případě musí být připojeny oba konektory ochranného vodiče, který spojuje přední plášť jednotky a její rám. Jinak hrozí při chybném nebo vadném připojení

přístroje nebezpečí úrazu elektrickým proudem.

BG Трябва да се спазват предписанията за свързване към захранването на компетентното електроснабдително дружество.

Заземяващият проводник, който свързва капака и рамата, във всички случаи трябва да се свърже към двата конектора. В противен случай съществува опасност от нараняване вследствие на токов удар в случай на неправилно или неизправно свързване

на уреда или неизправна електрическа мрежа.

GR Πρέπει να τηρούνται οι κανονισοί σύνδεσης της σχετικής εταιρείας παροχής ηλεκτρικού ρεύατος. Ο προστατευτικός αγωγός

εταξύ του καλύατος και του πλαισίου πρέπει να συνδέεται πάντα και στις δύο υποδοχές βύσατος. Σε αντίθετη περίπτωση, υπάρχει

κίνδυνος τραυατισού από ηλεκτροπληξία εάν η σύνδεση της ονάδας είναι ελαττωατική ή εσφαλένη.

RO Trebuie respectate cerinele de racordare ale companiei locale de alimentare cu energie. Conductorul de protecie dintre capac și

carcasa trebuie să fie conectat întotdeauna la ambele prize. În cazul în care conexiunea aparatului este incorectă sau defectuoasă, există

pericol de rănire prin electrocutare.

2 Rittal enclosure cooling unit

Page 3

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

HU Az illetékes áramszolgáltató csatlakoztatási előírásait figyelembe kell venni. A burkolatot és a vázat összekötő védővezetéket minden

esetben mindkét csatlakozóhoz csatlakoztatni kell. Ellenkező esetben, a berendezés hibás vagy meghibásodott csatlakoztatása esetén

áramütés veszélye áll fenn.

LT Privalu laikytis atsakingos elektros tiekimo tinklų bendrovės parengtų instrukcijų. Apsauginis laidininkas, jungiantis gaubtą ir korpusą,

visada turi būti prijungtas prie abiejų jungčių. Įrenginio jungties pažeidimo ar defekto atveju kyla pavojus susižaloti gavus elektros smūgį.

EE Järgige vastutava elektrivarustuse ettevõtte vooluvõrku ühendamise eeskirju. Juhtkaitse, mis ühendab katet ja alusraami, peab igal

juhul olema mõlemast pistikust ühendatud. Vastasel korral tekib seadme puudulikul või defektsel ühendamisel vigastusoht elektrilöögi tõttu.

LV Ievērojiet izmantotā elektropiegādes uzņēmuma pieslēguma noteikumus. Starp pārsegu un rāmi esošajam nulles vadam vienmēr ir

jābūt pievienotam abiem elektriskajiem spraudņiem. Pretējā gadījumā, ja iekārtas savienojumā ir radusies kļūme vai ja tā ir pieslēgta nepareizi, pastāv risks ciest no elektriskās strāvas trieciena.

SI Upoštevati je treba predpise za priključevanje naprav pristojnega podjetja za distribucijo električne energije. Ozemljitveni priključek, ki

povezuje pokrov in ohišje, je treba v vsakem primeru namestiti na oba vtiča. V nasprotnem primeru pri napačni priključitvi ali okvarjenem

priključku obstaja nevarnost nastanka poškodb zaradi električnega udara.

SK Treba dbať na predpisy príslušného dodávateľa elektrickej energie týkajúce sa zapojenia. Ochranný vodič, ktorý spája kryt a spodnú

časť zariadenia, musí byť v každom prípade zapojený do oboch zásuviek. V opačnom prípade hrozí pri chybnom alebo nedostatočnom

zapojení zariadenia nebezpečenstvo úrazu elektrickým prúdom.

RU Необходимо соблюдать указания по подключению компетентного энергопредприятия. Провод заземления, соединяющий

кожух и основание, должен быть обязательно подключен с двух сторон. В противном случае при отсутствующем или поврежденном подключении имеется опасность поражения током.

DE Bitte beachten Sie die maximal zulässigen Hebegewichte für Personen. Ggf. ist eine Hebevorrichtung zu verwenden.

EN Please observe the maximum permissible weight to be lifted by one person. Use suitable lifting devices, if needed.

FR Veuillez tenir compte du poids de levage maximal autorisé pour les personnes et le cas échéant utilisez un appareil de levage.

NL Neem het maximaal toegestane tilgewicht voor personen in acht. Gebruik eventueel een hefwerktuig.

SE Observera de maximalt tillåtna lyftvikterna för personer. Vid behov ska en lyftanordning användas.

IT Prestare attenzione ai carichi massimi consentiti per le persone. Se necessario, utilizzare un dispositivo di sollevamento.

ES Rogamos tenga en cuenta el peso máximo permitido que puede levantar una persona. En caso necesario deberá utilizarse un dis-

positivo de elevación.

FI Huomioi sallittu enimmäisnostopaino. Käytä tarvittaessa nostolaitetta.

DK Overhold den maksimalt tilladte løftevægt for personer. Brug en løfteanordning, hvis vægten overskrider den tilladte løftevægt.

IE Cloígh leis an uasmheáchan is ceadmhach do dhuine amháin a chrochadh. Úsáid gairis ardaithe atá oiriúnach, más gá.

PT Por favor, considerar o peso máximo permitido a ser levantado por uma pessoa. Caso necessário, utilizar equipamento adequado.

HR Obratite pažnju na najveću dopuštenu masu koju smije podizati jedna osoba. Ako je potrebno, preporuča se upotreba opreme za

podizanje i premještanje.

MT Jekk jogħġbok innota l-piżijiet ta’ rfigħ massimi permessibbli għan-nies. Jekk ikun hemm bżonn, jeħtieġ li jintuża apparat tal-irfigħ.

PL Prosimy o nieprzekraczanie maksymalnych dopuszczalnych ciężarów podnoszonych przez ludzi. W razie potrzeby należy zastoso-

wać urządzenie podnośnikowe.

CZ Dodržujte maximální přípustné hmotnosti zvedaných břemen stanovené pro osoby. Případně použijte zvedací zařízení.

BG Спазвайте максимално допустимата товароносимост на човек при транспортиране на охладителя. Ако се налага, използ-

вайте подемно устройство.

GR Παρακαλούε τηρείτε το έγιστο επιτρεπόενο βάρος που πορεί να αρθεί από ένα άτοο. Χρησιοποιήστε κατάλληλες συσκευές

ανύψωσης, εάν είναι απαραίτητο.

RO Respectai greutăile de ridicare maxim admise pentru o persoana. Dacă este necesar, utilizai dispozitive de ridicare.

HU Vegye figyelembe az egy személy számára maximálisan megengedett emelhető tömegeket. Szükség esetén emelőberendezést kell

használni.

LT Žmonės neturėtų kelti pernelyg sunkaus svorio. Prireikus reikia naudoti kėlimo įrangą.

EE Arvestage inimestele maksimaalselt lubatud tõstekaaludega. Vajaduse korral kasutage tõsteseadeldist.

LV Lūdzu, ievērojiet ierobežojumus attiecībā uz maksimālo svaru, ko ļauts celt vienai personai. Izmantojiet atbilstošas celšanas ierīces,

kad tas ir nepieciešams.

SI Upoštevajte največjo dovoljeno težo, ki jo oseba lahko varno dvigne. Po potrebi uporabite dvižno napravo.

SK Dodržiavajte maximálne limity pre osoby na zdvíhanie bremien. V prípade prekročenia tohto limitu použite zdvíhacie zariadenie.

RU При транспортировке вручную обращайте внимание на максимально допустимый вес. При необходимости используйте

подъемное устройство.

Rittal enclosure cooling unit 3

Page 4

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

DE Das Kühlgerät ist nur standsicher, solange Haube und Chassis miteinander verbunden sind. Sichern Sie daher insbesondere das

Chassis gegen Umfallen, bevor Sie die Haube abnehmen.

EN The cooling unit only stands safely while the hood and chassis are joined to each other. Ensure that the frame, in particular, is secured

against tipping before removing the hood.

FR Le climatiseur est stable uniquement si le capot et le châssis sont reliés entre eux. S’assurer pour cela que le châssis ne puisse pas

tomber avant d’ôter le capot.

NL Het koelaggregaat is alleen stabiel zo lang kap en chassis met elkaar zijn verbonden. Zorg er daarom voor dat als u de kap verwijdert,

het chassis niet kan omvallen.

SE Kylaggregatet står endast stabilt så länge huven och chassit är förbundna med varandra. Säkra därför framför allt chassit så att det

inte välter, innan du tar av huven.

IT Il condizionatore è stabile solo se la copertura e il telaio sono collegati tra loro. Mettere pertanto il telaio in sicurezza da eventuali cadute

prima di rimuovere la copertura.

ES El refrigerador sólo se encuentra suficientemente estable, cuando la cubierta y el chasis se encuentran conectados el uno con el

otro. Por este motivo es importante proteger especialmente el chasis de una caída, antes de retirar la cubierta.

FI Jäähdytin on vakaa vain, kun kehikko ja runko on kiinnitetty toisiinsa. Tue erityisesti runko kaatumisen varalta ennen suojuksen irrottamista.

DK Køleenheden står kun sikkert fast, hvis dækslet og chassiset er forbundet med hinanden. Sørg derfor for at sikre chassiset, så det

ikke vælter, før dækslet tages af.

IE Ní bhíonn an t-aonad fuaraithe ina sheasamh go sábháilte ach amháin nuair atá an cochall agus an fonnadh nasctha le chéile. Cinntigh

go ndaingnítear an fráma, go háirithe, sula mbaintear an cochall de, sa chaoi nach n-iompóidh sé.

PT O condicionador de ar estará fixo apenas quando a cobertura estiver conectada ao chassi. Antes de remover a cobertura, certificarse de que o chassi esteja seguro e não possa tombar.

HR Rashladna jedinica stoji sigurno samo ukoliko su poklopac i kućište međusobno ispravno spojeni. Obratite posebnu pažnju da je

okvir osiguran od prevrtanja prije nego uklanjate poklopac rashladne jedinice.

MT L-unità ta’ tkessiħ hija stabbli biss meta x-xażi u l-hood it-twila jkunu mqabbdin ma’xulxin. Oqgħod attent/a b’mod partikolari li xxażi ma jegħlibx qabel tneħħi l-kappa.

PL Urządzenie jest stabilne tylko wówczas, gdy pokrywa i obudowa są ze sobą połączone. Dlatego przed zdjęciem pokrywy należy

zabezpieczyć obudowę przed przewróceniem się.

CZ Chladicí jednotka je stabilní jen v případě namontovaného pláště na chladicí jednotce. Před sejmutím pláště proto zajistěte samotný

rám jednotky proti převrhnutí.

BG Климатикът е стабилен само когато капакът и рамата са свързани помежду си. Затова укрепете най-вече рамата срещу

падане, преди да свалите капака.

GR Η ονάδα ψύξης στέκεται ε ασφάλεια όνο όταν το κάλυα και το πλαίσιο έχουν συνδεθεί εταξύ τους. Βεβαιωθείτε ότι ειδικά

το πλαίσιο είναι ασφαλισένο έναντι ανατροπής πριν αφαιρέσετε το κάλυα.

RO Aparatul de răcire este stabil numai dacă sunt interconectate capacul și carcasa. În acest scop, asigurai carcasa împotriva căderii,

înainte de a scoate capacul.

HU A hűtőberendezés csak akkor áll biztonságosan, ha a burkolat és a váz egymással össze van kötve. Ezért a vázat biztosítsa eldőlés

ellen, mielőtt a burkolatot leveszi.

LT Šaldymo įrenginys stabilus tol, kol gaubtas sujungtas su korpusu. Todėl prieš nuimdami gaubtą, įsitinkinkite, kad korpusas yra stabilus ir nenukristų.

EE Jahutusseade on kindlalt püsti vaid siis, kui kate ja alusraam on omavahel ühendatud. Kindlustage ümberkukkumise vastu alusraam

enne katte mahavõtmist.

LV Dzesēšanas bloka droša novietošana tiek paveikta pārsegu pienācīgi savienojot ar konstrukciju. Pārliecinieties par to, lai rāmis būtu

pasargāts pret sasvēršanos, pirms pārsega noņemšanas.

SI Hladilna naprava je stabilna, dokler sta pokrov in ohišje klime povezana. Preden snamete pokrov, je zato potrebno ohišje še posebej

zavarovati, da se ne prevrne.

SK Klimatizačné zariadenie je stabilné len vtedy, ak sú kryt a spodná časť spojené. Najmä spodnú časť preto zaistite pred prevrátením

ešte skôr, ako odstránite kryt.

RU Холодильный агрегат устойчив в вертикальном положении, когда кожух и основание соединены между собой. Поэтому

перед удалением кожуха защитите основание агрегата от опрокидывания.

4 Rittal enclosure cooling unit

Page 5

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

DE Vor dem Abnehmen der Haube muss das Gerät mind. 10 Min. abkühlen, um Verbrennungen an heißen Oberflächen zu vermeiden.

EN Before removing the hood, allow the unit to cool for at least 10 minutes to eliminate the risk of burns from hot surfaces.

FR Avant d’ôter le capot, l’appareil doit refroidir pendant au moins 10 minutes pour éviter les brûlures sur les surfaces brûlantes.

NL Voor het afnemen van de kap dient het apparaat minstens tien minuten af te koelen, zodat u zich niet brandt aan hete oppervlakken.

SE Innan huven tas av måste aggregatet svalna i minst 10 minuter för att undvika att personer bränner sig på heta ytor.

IT Far raffreddare il dispositivo per almeno 10minuti prima di rimuovere la copertura per evitare eventuali ustioni al contatto con le su-

perfici bollenti.

ES El aparato debe haberse enfriado durante un mínimo de 10 minutos antes de proceder a retirar la cubierta, con el fin de evitar quemaduras.

FI Ennen kehikon irrottamista laitteen on annettava jäähtyä vähintään 10 minuuttia, jotta vältetään kuumien pintojen aiheuttamat palovammat.

DK Lad enheden køle af i mindst ti minutter, før dækslet tages af, for at undgå risiko for at brænde sig på varme overflader.

IE Sula mbaintear an cochall de, lig don aonad fuarú ar feadh deich nóiméad ar a laghad chun an baol dó ó dhromchlaí teo a sheachaint.

PT Antes de remover a cobertura, deixar o aparelho arrefecer durante, no mínimo, 10minutos para evitar risco de queimadura nas

superfícies quentes.

HR Prije uklanjanja poklopca pričekajte barem 10 minuta da se uređaj ohladi, kako bi se uklonila opasnost od opekotina uzrokovanih

vrućim površinama.

MT Qabel tneħħi l-għatu, l-apparat għandu jitħalla jibred għal mill-inqas 10 min biex tevita ħruq minħabba uċuh jaħarqu.

PL Przed zdjęciem pokrywy urządzenie musi się chłodzić przez minimum 10 minut, aby nie doszło do poparzenia przez gorące po-

wierzchnie.

CZ Před sejmutím pláště jednotky je nutno nechat chladicí jednotku minimálně 10 minut vychladnout, aby nedošlo k popálení o horké

povrchy.

BG Преди да бъде свален капакът, уредът трябва да се остави да изстине най-малко 10 минути, за да се избегнат изгаряния

от горещите повърхности.

GR Πριν αφαιρέσετε το κάλυα, αφήστε τη ονάδα να ψυχθεί για τουλάχιστον 10 λεπτά για να εξαλειφθεί ο κίνδυνος εγκαυάτων

από καυτές επιφάνειες.

RO Înainte de scoaterea capacului, aparatul trebuie lăsat să se răcească cel puin 10 min., pentru a evita arsurile cauzate de contactul

cu suprafeele fierbini.

HU A burkolat levétele előtt a berendezést legalább 10 percig hagyja lehűlni a forró felületek miatti égési sérülések elkerülése érdekében.

LT Prieš nuimdami gaubtą, turite palaukti bent 10 minučių, kol įrenginys atvės, kad nenusidegintumėte prisilietę prie karštų paviršių.

EE Enne katte mahavõtmist peab seade vähemalt 10 minutit jahtuma, et vältida põletusi kuumade pindade tõttu.

LV Pirms pārsega atvēršanas, ļaujiet iekārtai atdzist vismaz 10 minūtes, lai izvairītos no apdedzināšanās riska, ko rada uzkarsušās virs-

mas.

SI Preden snamete pokrov, naj se naprava najmanj 10 minut ohlaja, da se izognete nevarnosti opeklin na vročih površinah.

SK Pred odstránením krytu musí zariadenie minimálne 10 minút chladnúť, inak môže dôjsť k popáleniu na horúcich povrchoch.

RU Перед снятием кожуха дать агрегату остыть в течение ок. 10 мин., во избежание ожога о горячие поверхности.

DE Verwenden Sie niemals brennbare Flüssigkeiten zur Reinigung des Geräts.

EN Never use flammable liquids for cleaning.

FR Ne jamais utiliser de liquides inflammables pour le nettoyage.

NL Gebruik geen brandbare vloeistoffen voor het reinigen.

SE Använd inga brännbara vätskor för rengöring.

IT Non utilizzare liquidi infiammabili per la pulizia.

ES No utilice líquidos inflamables para realizar la limpieza.

FI Älä käytä puhdistukseen palavia nesteitä.

DK Brug aldrig brændbare væsker til rengøring.

IE Ná húsáid leachtanna inlasta riamh i gcomhair glanta.

PT Nunca utilizar líquidos inflamáveis para efetuar a limpeza.

HR Nikada ne koristite zapaljive tekućine za čišćenje.

Rittal enclosure cooling unit 5

Page 6

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

MT Tużax likwidi li jieħdu n-nar għat-tindif.

PL Do czyszczenia urządzenia nie stosować łatwopalnych cieczy.

CZ Nepoužívejte k čištění žádné hořlavé kapaliny.

BG Не използвайте запалими течности за почистване.

GR Μη χρησιοποιείτε ποτέ εύφλεκτα υγρά για τον καθαρισό.

RO Nu utilizai lichide inflamabile pentru curăare.

HU Tisztításhoz ne használjon gyúlékony folyadékot.

LT Valydami nenaudokite degių skysčių.

EE Ärge kasutage puhastamiseks põlevaid vedelikke.

LV Nekad neizmantojiet uzliesmojošus tīrīšanas līdzekļus.

SI Za čiščenje ne uporabljajte vnetljivih tekočin.

SK Na čistenie nepoužívajte horľavé kvapaliny.

RU Никогда не используйте горючие жидкости для чистки агрегата.

DE Das Kühlgerät ist ausschließlich zum Kühlen von geschlossenen Schaltschränken sowie zur professionellen Nutzung gemäß DIN EN

61000-3-2 vorgesehen. Eine andere Verwendung ist nicht bestimmungsgemäß. Das Gerät darf nicht an Orten installiert und betrieben

werden, die der allgemeinen Öffentlichkeit (siehe DIN EN 60335-2-40, Absatz 3.119) zugänglich sind. Das Gerät ist nur für den stationären

Betrieb ausgelegt.

EN The cooling unit is intended exclusively for cooling closed control cabinets as well as for professional use in accordance with DIN

EN 61000-3-2. Any other use is not permitted. The unit must not be installed and operated in locations which are accessible to the general

public (see DIN EN 60335-2-40, paragraph 3.119). The unit is designed solely for stationary use.

FR Le climatiseur est prévu uniquement pour rafraîchir les armoires électriques étanches dans un cadre professionnel conformément a

la norme EN 61000-3-2. Toute autre utilisation est non conforme. Le climatiseur ne doit pas être installé et exploité dans des lieux accessibles au public (voir norme EN 60335-2-40, paragraphe 3.119). Le climatiseur est uniquement destiné à l'exploitation statique.

NL Het koelaggregaat is uitsluitend bestemd voor het koelen van gesloten schakelkasten en voor professioneel gebruik volgens DIN EN

61000-3-2. Elke andere toepassing wordt gezien als niet-voorgeschreven gebruik. Het apparaat mag niet worden geïnstalleerd op plaatsen die openbaar (zie DIN EN 60335-2-40, paragraaf 3.119) toegankelijk zijn. Het apparaat is alleen ontworpen voor stationair gebruik.

SE Kylaggregatet är endast avsedd för kylning av slutna golvskåp i enlighet med DIN EN 61000-3-2. Annan användning är inte tillåten.

Aggregatet får inte installeras och köras på platser som är tillgängliga för allmänheten (se DIN EN 60335-2-40, stycke 3.119). Aggregatet

är konstruerat uteslutande för stationär drift.

IT Il condizionatore è destinato esclusivamente al raffreddamento degli armadi di comando chiusi e per uso professionale secondo EN

61000-3-2. Ogni altro impiego è da intendersi non conforme alla sua destinazione d’uso. L’apparecchio non deve essere installato e utilizzato in aree accessibili al pubblico (vedere la norma DIN EN 60335-2-40, paragrafo 3.119). L’apparecchio può essere utilizzato solo da

fermo.

ES El refrigerador se ha diseñado exclusivamente para la refrigeración de armarios de distribución estancos, para su uso según lo detallado en la normativa DIN EN 61000-3-2. Cualquier otro uso no está permitido. El equipo no debe ser instalado ni puesto en funcionamiento en entornos accesibles al público en general (ver DIN EN 60335-2-40, párrafo 3.119). El equipo está diseñado para un funcionamiento estacionario.

FI Jäähdytysyksikkö on tarkoitettu yksinomaan suljettujen koteloiden jäähdytykseen sekä ammattikäyttöön DIN EN 61000-3-2 mukaisesti. Mikään muu käyttö ei ole sallittua. Laitetta ei saa asentaa ja käyttää yleisessä käytössä olevissa paikoissa (katso DIN EN 60335-240, kohta 3.119). Laite on suunniteltu ainoastaan kiinteään käyttöön.

DK Køleenheden er kun beregnet til køling af lukkede indkapslinger og kun til professionelt brug i henhold til DIN EN 61000-3-2. Enhver

anden brug er ikke tilladt. Enheden må ikke installeres eller opereres på lokaliteter med offentlig adgang (Se DIN EN 60335-2-40, paragraf

3.119) Enheden er udelukkende designet til stationært brug.

IE Nil an t-aonad fuaraithe ceaptha ach amháin d'fhuarú na gcaibinéad rialaithe dúnta agus d'úsáid ghairmiúil eile i gcomhréir le DIN EN

61000-3-2. Ní cheadaítear d’aon úsáid eile. Ná suiteáiltear agus ná oibrítear an t-aonad i suíomhanna arb inrochtana don phobal i

gcoitinne iad (féach DIN EN 60335-2-40, mír 3.119). Is le húsáid dho-aistrithe amháin a dearadh an t-aonad.

PT A unidade de refrigeração destina-se exclusivamente à refrigerar gabinetes de controle fechados, bem como para uso profissional

de acordo com a DIN EN 61000-3-2. Qualquer outro uso não é apropriado e não é permitido. O aparelho não deve ser instalado e operado em locais acessíveis ao público em geral (consulte a norma DIN EN 60335-2-40, seção 3.119). O aparelho foi projetado apenas

para o uso em instalação fixa.

HR Klima uređaj namijenjen je isključivo hlađenu nanizanih ormara te profesionalnoj uporabi sukladno DIN EN 61000-3-2. Drugačija uporaba nije dozvoljena. Uređaj se ne smije instalirati i raditi na mjestima gdje je dostupan javnosti (DIN EN 60335-2-40, paragraph 3.119).

Uređaj je namijenjen isključivo za unutarnju upotrebu.

MT It-tagħmir refriġeranti għandu jintuża esklussivament biex ikessaħ l-armarji magħluqin kif ukoll għall-użu professjonali skont DIN EN

61000-3-2. Użu ieħor ta’ dan huwa ħażin. L-apparat ma għandux jiġi installat u ma għandux jitħaddem f’postijiet li huma aċċessibbli għallpubbliku (ara DINEN60335-2-40, Paragrafu3.119). L-apparat huwa ddisinjat biss għal tħaddim stazzjonarju.

PL To urządzenie chłodnicze jest przewidziane wyłącznie do chłodzenia zamkniętych szaf sterowniczych oraz do użytku profesjonalnego zgodnie z normą DIN EN 61000-3-2. Każde inne zastosowanie jest niezgodne z przeznaczeniem. Urządzenie nie może być instalo-

6 Rittal enclosure cooling unit

Page 7

Warn- und Sicherheitshinweise / Safety instructions and warnings / Consignes de sécurité

Rittal Blue e enclosure cooling units

Hazards and their prevention according to IEC 60417/ISO 7000/ISO 7010

wane i użytkowane w miejscach ogólnodostępnych (patrz EN 60335-2-40, punkt 3.119). Urządzenie jest przystosowane wyłącznie do

użytkowania stacjonarnego.

CZ Chladicí jednotka je určena výhradně k chlazení uzavřených rozváděčových skříní a k profesionálnímu použití v souladu s ČSN EN

61000-3-2. Jiné použití není použití v souladu s určením. Zařízení se nesmí instalovat a provozovat na místech, která jsou veřejně přístupná (viz DIN EN 60335-2-40, oddíl 3.119). Zařízení je navrženo jen pro stacionární provoz.

BG Охладителното устройство е предназначено само за охлаждане на кутии и шкафове както и за професионална употреба

съгласно DIN EN 61000-3-2. Не се разрешава всякаква друга употреба. Уредът не трябва да се монтира и работи в местата,

които са достъпни за широката общественост (виж DIN EN 60335-2-40, параграф 3.119). Уредът е предназначен единствено за

стационарна употреба.

GR Η ονάδα ψύξης προορίζεται αποκλειστικά για ψύξη κλειστούς πίνακες ελέγχου καθώς και για επαγγελατική χρήση σύφωνα ε

το DIN EN 61000-3-2. Οποιαδήποτε άλλη χρήση δεν επιτρέπεται. εν επιτρέπεται η εγκατάσταση και η λειτουργία της συσκευής σε

σηεία, τα οποία είναι προσβάσιες στο ευρύ κοινό (δείτε DIN EN 60335-2-40, σηείο 3.119). Η συσκευή έχει σχεδιαστεί αποκλειστικά

για στατική χρήση.

RO Climatizorul este conceput doar pentru racirea dulapurilor inchise precum si pentru o utilizare industriala conform normelor DIN EN

61000-3-2. Orice alta utilizare nu este permisa. Unitatea nu trebuie instalata si folosita in locatii la care are acces publicul larg. (vezi DIN

EN 60335-2-40, paragraf 3.119). Unitatea este proiectata doar pentru utilizare stationara.

HU A hűtőberendezés kizárólag zárt kapcsoló- és vezérlőszekrények hűtésére, valamint a DIN EN 61000-3-2 szabvánnyal összhangban

történő professzionális alkalmazásra használható. Minden más alkalmazás tilos. A berendezést tilos olyan helyre telepíteni és üzemeltetni,

amely szabadon hozzáférhető laikusok számára (lásd DIN EN 60335-2-40, 3.119 bekezdés). A berendezést kizárólag fixen telepítve és

álló helyzetben szabad telepíteni és üzemeltetni.

LT Vėsinimo agregatas skirtas tik uždaro tipo skydų vėsinimui, taip pat profesionaliam naudojimui pagal DIN EN 61000-3-2. Bet koks

kitas naudojimas yra draudžiamas. Agregatas negali būti sumontuojamas ir eksplotuojamas viešai prieinamose vietose (pagal DIN EN

60335-2-40, punktas 3.119). Prietaisas skirtas tik stacionariam naudojimui.

EE Jahutusseadmed on ettenähtud ainult kinniste kilpide jahutamiseks ja professionaalseks kasutamiseks vastavalt standardile DIN EN

61000-3-2. Muu laadne kasutus ei ole lubatud. Seadmete kasutus üldkasutatavates ruumides ei ole lubatud (vaata DIN EN 60335-2.40,

§ 3.119). Seade on ettenähtud ainult statsionaarseks paigalduseks.

LV Dzesēšanas bloks paredzēts tikai sadaļņu ar slēgto kontroli dzesēšanai, kā arī profesionālai lietošanai saskaņā ar DIN EN 61000-3-

2. Jebkura cita izmantošana nav atļauta. Iekārtu nedrīkst uzstādīt un izmantot publiski pieejamās vietās (skatīt standarta DIN EN603352-40, paragrāfu 3.119). Iekārta ir izstrādāta tikai stacionārai lietošanai.

SI Hladilna naprava je namenjena samo za hlajenje vrstno povezanih ohišij, kot tudi za profesionalno uporabo skladno z DIN EN 610003-2. Vsaka druga uporaba ni dovoljena. Naprava ne sme biti nameščena in delovati na lokaciji ki je dostopna širši javnosti (glej DIN EN

60335-2-40, odstavek 3.119). Naprava je namenjena izključno za stacionarno uporabo.

SK Chladiaca jednotka je určená pre chladenie uzavretých rozvádzačových skríň ako aj iných zariadení, ktoré sú v súlade s normou DIN

EN 61000-3-2. Iné použitie nie je prípustné. Zariadenie nesmie byť inštalované a používané vo verejne dostupných priestoroch (viď DIN

EN 60335-2-40, odstavec 3.119). Zariadenie je určené na stacionárnu prevádzku.

RU Агрегат предназначен исключительно для охлаждения закрытых распределительных шкафов, а также для профессионального использования согл. DIN EN 61000-3-2. Использование в других целях не соответствует его прямому назначению.

Агрегат нельзя устанавливать и эксплуатировать в местах, доступных для постронних лиц (см. DIN EN 60335-2-40, абзац 3.119).

Агрегат предназначен для только для стационарного применения.

Rittal enclosure cooling unit 7

Page 8

Contents

EN

Contents

1 Notes on documentation .................. 9

1.1 CE labelling.................................................. 9

1.2 Storing the documents................................. 9

1.3 Symbols used .............................................. 9

2 Safety notes ..................................... 9

3 Device description ............................ 9

3.1 Functional description ................................ 10

3.1.1 How it works ....................................................... 10

3.1.2 Control ................................................................ 10

3.1.3 Bus mode ........................................................... 10

3.1.4 Safety equipment ................................................ 10

3.1.5 Condensation ..................................................... 11

3.1.6 Filter mats ........................................................... 11

3.1.7 Door limit switch ................................................. 11

3.1.8 Additional interface X3 ........................................ 11

3.2 Proper use, foreseeable misuse ................. 11

3.3 Scope of supply......................................... 12

4 Assembly and connection .............. 12

4.1 Choosing the installation site...................... 12

4.2 Assembly instructions ................................ 12

4.2.1 General ............................................................... 12

4.2.2 Layout of the electronic components in the

enclosure ............................................................ 12

4.3 Fitting the cooling unit ................................ 13

4.3.1 Cutting out on the enclosure ............................... 13

4.3.2 External mounting of the cooling unit ................... 13

4.4 Notes on electrical installation .................... 13

4.4.1 Connection data ................................................. 14

4.4.2 Electrical Box connection .................................... 14

4.4.3 Overvoltage protection and supply line load ........ 14

4.4.4 Door limit switch ................................................. 14

4.4.5 Notes on the flicker standard .............................. 15

4.4.6 Potential equalization .......................................... 15

4.5 Carrying out the electrical installation.......... 15

4.5.1 Bus connection (only in conjunction with several

units with an e-Comfort controller) ....................... 15

4.5.2 Connection X3 for serial interface ........................ 15

4.5.3 Installing the power supply .................................. 16

7 Inspection and maintenance .......... 25

7.1 General ...................................................... 25

7.2 Cleaning the filter mat................................. 25

7.3 Compressed air cleaning............................ 26

8 Storage and disposal ..................... 28

9 Technical specifications ................. 29

10 Appendix: Cut-out and hole sizes .. 34

5 Commissioning ............................... 17

6 Operation ....................................... 17

6.1 Control using the e-Comfort controller ....... 17

6.1.1 Properties ........................................................... 17

6.1.2 Eco mode ........................................................... 18

6.1.3 Launching test mode .......................................... 18

6.1.4 General information about programming ............. 18

6.1.5 Editable parameters ............................................ 20

6.1.6 Programming overview ....................................... 21

6.1.7 Defining system messages for evaluation ............ 22

6.1.8 Setting the master/slave identifier ........................ 22

6.1.9 Evaluating system messages .............................. 23

6.1.10 Reset the e-Comfort controller ............................ 25

8 Rittal enclosure cooling unit

Page 9

1 Notes on documentation

1 Notes on documentation

These assembly instructions are aimed at tradespersons

who are familiar with assembly and installation of the

cooling unit, and at trained specialists who are familiar

with operation of the cooling unit.

1.1 CE labelling

Rittal GmbH & Co. KG confirms the conformity of the

cooling unit with the European Union's Machinery Directive 2006/42/EC and EMC Directive 2014/30/EC. A corresponding declaration of conformity has been issued.

This can be found at the end of this document, or on the

Rittal homepage.

1.2 Storing the documents

The assembly and operating instructions as well as all

other applicable documents are an integral part of the

product. They must be issued to everyone who works

with the unit and must always be available and on hand

for operating and maintenance personnel.

1.3 Symbols used

Please observe the following safety instructions and other notes in this guide:

Symbol for an instructed action:

The bullet point indicates that you should perform an

action.

– To ensure problem-free opening and closing of the en-

closure door, use a ride-up door roller. This raises the

door slightly and balances out the weight of the cooling unit, to prevent buckling of the door and associated seal problems.

– The heat loss of the components installed in the enclo-

sure must not exceed the specific useful cooling output of the cooling unit.

– Cooling units must be transported in an upright posi-

tion and protected from tipping over.

– Shipping braces must be used when transporting a

unit that has already been mounted (on the enclosure).

A wooden structure made from square timbers or

boards to support the cooling unit at the bottom is

suitable for this purpose. The pallet should be big

enough to prevent the enclosure and cooling unit

overturning. If the cooling unit is mounted on a door,

ensure the door is kept closed during transport.

– Use only original spare parts and accessories.

– Do not make any changes to the cooling unit other

than those described in these instructions or associat-

ed instructions.

– Risk of burn injuries! On cooling units with automatic

condensate evaporation, the surface of the thermal el-

ement will get very hot during operation, and will re-

main so for some time afterwards.

– The mains connector of the cooling unit must only be

connected and disconnected with the system de-en-

ergized. Connect the protective device specified on

the rating plate.

EN

Safety and other instructions:

Danger!

Immediate danger to life and limb!

Caution!

Potential threat to the product and its

environment.

Note:

Useful information and special features.

2 Safety notes

Please observe the following general safety instructions

when assembling and operating the unit:

– Assembly, installation and servicing may only be per-

formed by properly trained specialists.

– Screw the enclosure to the floor to prevent it from tip-

ping over when the cooling unit is installed.

– Do not obstruct the air inlet and air outlet of the cooling

unit inside and outside the enclosure (see also section4.2.2 "Layout of the electronic components in the

enclosure").

3 Device description

Depending on the model chosen, your cooling unit may

vary in appearance from the illustrations contained in

these instructions. However, the functions are identical

in principle.

Rittal enclosure cooling unit 9

Page 10

EN

11

5

6

7

2

3

4

1

10

9

8

PSA

H

pressure

switch

Condenser fan

Expansion valve (4)

Temperature

control

Filter dryer (5)

Internal circuit

Compressor (2)

External circuit

Evaporator fan

Evaporator coil (1)

Condenser (3)

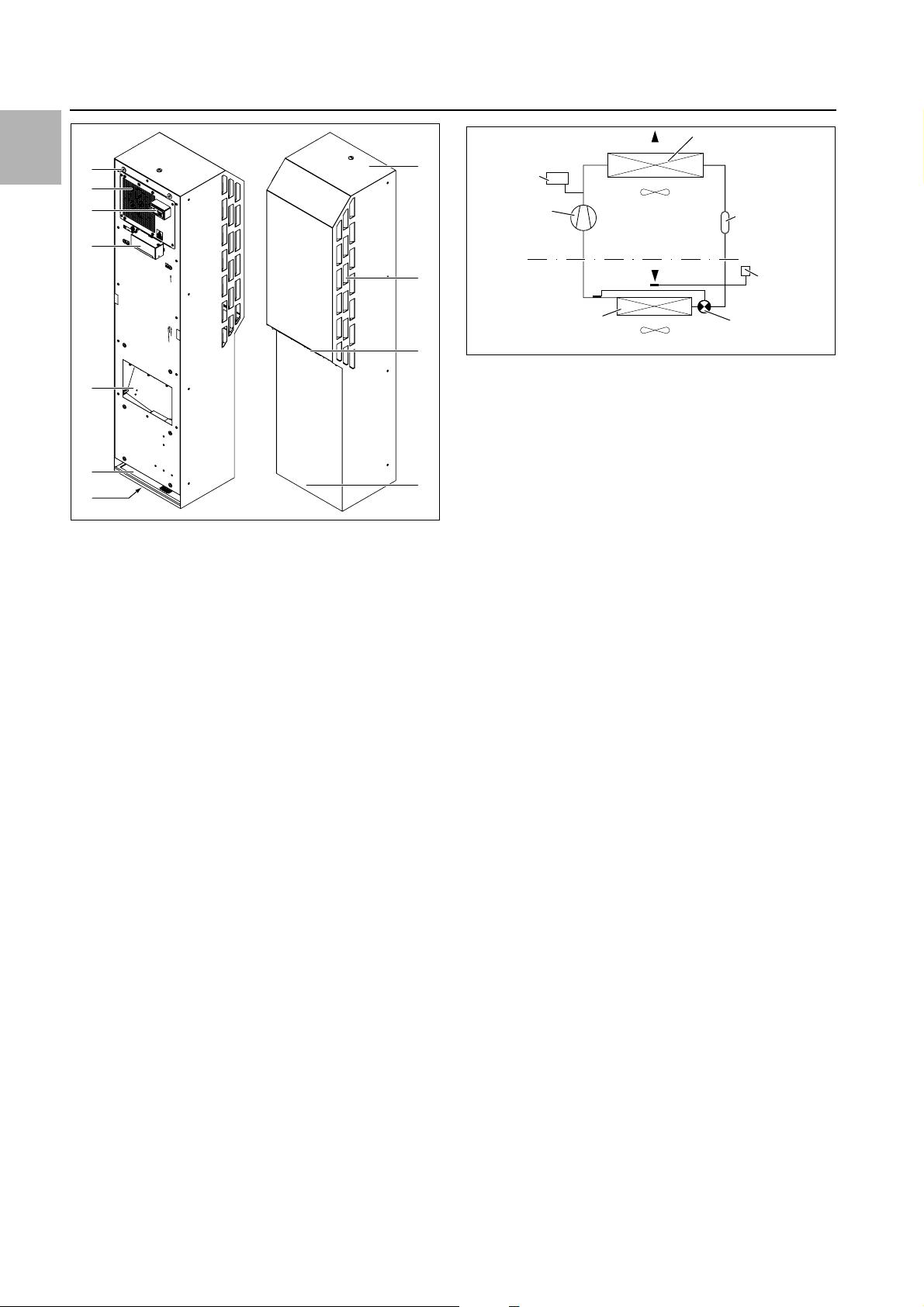

3 Device description

Fig. 2: Cooling circuit

In the evaporator coil (1), the liquid coolant is converted

to a gaseous state. The energy needed for this purpose

is taken from the enclosure air in the form of heat, which

has the effect of cooling the enclosure air. In the compressor (2), the coolant is heavily compressed, so that it

achieves a higher temperature inside the condenser (3)

than the ambient air. This means that excess heat may

Fig. 1: Device description

Key

1 Blind rivet nut

2 Evaporator fan

3Display

4 Electrical box

5 Evaporator air outlet

6 Metal air filter

7 Air inlet external circuit

8 Condensate discharge

9 Metal air filter

10 Louvred grille for condenser air

11 Housing

3.1 Functional description

Enclosure cooling units are designed to dissipate heat

from enclosures by cooling the air inside the enclosure

and so protect the temperature-sensitive components.

They are built into the side or rear panel or into the door

of the enclosure.

3.1.1 How it works

The cooling unit (compression refrigeration system) is

comprised of four main components (fig. 2): the evaporator (1), the coolant compressor (2), the condenser (3),

and the control or expansion valve (4), which are connected by suitable pipework. This circuit is filled with a

readily boiling substance, the refrigerant. Coolant R134a

(CH

FCF3) is chlorine-free. Its ozone destruction poten-

2

tial is 0, making it very ecofriendly. A filter dryer (5) which

is integrated into the hermetically sealed cooling circuit

provides effective protection against moisture, acid, dirt

particles, and foreign bodies within the cooling circuit.

10 Rittal enclosure cooling unit

be emitted to the ambient air via the surface of the condenser, as a result of which the temperature of the coolant drops and it is converted back into liquid. It is re-injected into the evaporator coil via a thermostatic expansion valve (4), which causes it to cool down further, and

is then once again able to absorb the energy from the

enclosure air in the evaporator coil. The whole cycle begins again.

3.1.2 Control

Rittal enclosure cooling units are fitted with a comfort

controller for setting the functions of the cooling unit (display plus extended functions, see section6 "Operation").

3.1.3 Bus mode

The serial unit interface X2 allows you to create a bus

connection with up to ten cooling units using the masterslave cable (shielded, four-wire cable, Model No.

3124.100). This allows you to implement the following

functions:

– Parallel unit control (the cooling units in the network

can be switched on and off simultaneously)

– Parallel door status message ("door open")

– Parallel collective fault message

Data is exchanged via the master-slave connection.

During commissioning, assign an address to each unit

that also includes the identifier "master" or "slave".

3.1.4 Safety equipment

– In the cooling cycle, the cooling unit has a tested pres-

sure-operated switch to EN 12 263 which is set to

maximum PS (admissible pressure); this operates via

an automatic reset device whenever the pressure

drops again.

– Temperature monitoring prevents the evaporator coil

from icing over. If there is a risk of icing, the compres-

Page 11

3 Device description

sor switches itself off and automatically switches itself

back on again at higher temperatures.

– The refrigerant compressor and the fans are equipped

with thermal winding shields to protect against excess

current and excess temperatures.

– In order to allow a reduction of pressure inside the

compressor and hence a safe restart, once it has been

switched off (e.g. upon reaching the set temperature

via the door limit switch function or via de-energizing),

the device will switch back on with a delay of 180 seconds.

– The device has floating contacts on the connection

pins (terminals 3 – 5), via which system messages

from the device may be polled, e.g. using a PLC (2 x

normally open contacts e-Comfort controller).

3.1.5 Condensation

At high levels of humidity and low temperatures inside

the enclosure, condensation may form on the evaporator coil.

The cooling units (except 3303.xxx) have automatic,

electric condensate evaporation. The thermal component used for this purpose is based on self-regulating

PTC technology. Condensate arising on the evaporator

coil is collected in a tank in the external circuit of the

cooling unit, and partially evaporated via the airflow.

When the water level rises, the water enters the PTC

thermal component and is evaporated (through-flow

heater principle). The water vapor streams out of the

cooling unit with the airflow from the external fan. The

PTC thermal component is permanently connected and

has no switch point. It is protected against shortcircuits

with miniature fuses (F1.1, F1.2). If the fuse has tripped,

any condensation is drained off via the safety overflow.

Note:

No external voltage must be applied to the

door contacts (terminals 1 and 2).

3.1.8 Additional interface X3

Note:

The electrical signals at the interface are of an

extra-low voltage (not extra-low safety voltages to EN 60 335).

For incorporating the cooling unit into superordinate

monitoring systems, the IoT interface, together with the

Blue e IoT adaptor, can be connected to the 9-pole

SUB-D connector (available as accessories: IoT interface Model No. 3124.300, Blue e IoT adaptor Model No.

3124.310).

3.2 Proper use, foreseeable misuse

The cooling unit is intended exclusively for cooling

closed control cabinets as well as for professional use in

accordance with DIN EN 61000-3-2. Any other use is

not permitted.

– The unit must not be installed and operated in loca-

tions which are accessible to the general public (see

DIN EN 60335-2-40, paragraph 3.119).

– The unit is designed solely for stationary use.

The cooling unit is state of the art and built according to

recognised safety regulations. Nevertheless, improper

use can pose a threat to the life and limb of the user or

third parties, or result in possible damage to the system

and other property.

EN

3.1.6 Filter mats

The cooling unit condenser is finished all over with a dirtrepelling, easy-to-clean RiNano coating. These UL listed, type NEMA 12/3R/4 models only accept Rittal's

metal filters. See section7.2 "Cleaning the filter mat" for

additional information regarding filters. These filters may

be cleaned with suitable detergents and reused.

3.1.7 Door limit switch

The cooling unit may be operated with a floating door

limit switch connected. The door limit switch is not included with the supply (available as an accessory, Model

No. PS 4127.010).

The door limit switch function causes the fans and the

compressor in the cooling unit to be switched off after

approximately 15 seconds when the enclosure door is

opened (contacts 1 and 2 closed). This prevents the formation of condensation inside the enclosure while the

enclosure door is open. In order to prevent damage to

the unit, it is equipped with an ON delay: The evaporator

fan cuts back in with a delay of approximately 15 seconds after the door has been closed, while the condenser fan and compressor switch on after approximately 3

minutes.

Consequently, the cooling unit must only be used properly and in a technically sound condition! Any malfunctions which impair safety should be rectified immediately.

Proper use also includes the observance of the documentation provided, and compliance with the inspection

and maintenance conditions.

Rittal GmbH & Co. KG is not liable for any damage which

may result from failure to comply with the documentation provided. The same applies to failure to comply with

the valid documentation for any accessories used.

Inappropriate use may be dangerous. Examples of inappropriate include:

– Use of the cooling unit over long periods with the en-

closure open.

– Use of the cooling unit when it is standing on the

ground.

– Use of impermissible tools.

– Improper operation.

– Improper rectification of malfunctions.

Rittal enclosure cooling unit 11

Page 12

4 Assembly and connection

EN

– Use of accessories not approved by Rittal GmbH &

Co. KG.

3.3 Scope of supply

Please check the delivery for completeness. Each unit is

supplied with an accessory box which includes mounting hardware, literature, electrical boxes, foam tape and

connectors.

4 Assembly and connection

4.1 Choosing the installation site

When choosing the installation site for the enclosure,

please observe the following:

– The site for the enclosure, and hence the arrangement

of the cooling unit, must be carefully selected so as to

ensure good ventilation (distances between units, distances between the unit and the wall and the ground

must be at least 7 7/8" (200 mm) in each case).

– The cooling unit must be installed and operated in a

vertical position (maximum deviation: 2°).

– The internal and ambient temperature must be within

the limits specified on the rating plate.

– The mains connection data as started on the rating

plate of the unit must be guaranteed.

– The site must be free from excessive dirt and moisture.

4.2.2 Layout of the electronic components in the enclosure

Caution! Risk of condensation!

When arranging the components inside

the enclosure, please ensure that the

cold airflow from the cooling unit is not

directed at active components. Please

also ensure that the cold airflow is not

directed at the warm exhaust airflow

from active components such as converters. This may lead to an air shortcircuit and therefore prevent adequate

climate control, or may even cause the

cooling unit’s internal safety devices to

cease cooling operation.

Note:

These models are UL Type NEMA 12/3R/4

(outdoor) approved only as installed in the

external mounting position. See section4.3

"Fitting the cooling unit".

4.2 Assembly instructions

4.2.1 General

– Check the packaging carefully for signs of damage.

Traces of oil on damaged packaging are an indication

of refrigerant loss and leakages. Packaging damage

may be the cause of a subsequent functional failure.

– The enclosure must be sealed on all sides (IP 56 or

NEMA 12/3R/4). Increased condensation will occur if

the enclosure is not airtight.

– In order to avoid excessive condensation inside the

enclosure, we recommend installing a door limit

switch (e.g. PS 4127.010) which deactivates the cooling unit when the enclosure door is opened (see section3.1.7 "Door limit switch").

Fig. 3: Never direct the cold airflow at active components

Air diversion components are available as accessories. It

is important to ensure even air circulation inside the enclosure. Under no circumstances should air inlet and

outlet openings be obstructed, otherwise the cooling

performance of the unit will be reduced. Ensure the distance "x" (see fig. 4) from electronic components and

other installed enclosures so that the required air circulation is not obstructed and prevented.

12 Rittal enclosure cooling unit

Page 13

4 Assembly and connection

x

y

Fig. 4: Air circulation inside the enclosure

Model No. Dimension x

[mm]

3303.xxx 131 200

3304.xxx/3305.xxx 162 200

Dimension y

[mm]

4.3.1 Cutting out on the enclosure

Stick the supplied drilling template onto the side panel

or door of the enclosure using adhesive tape.

There are dimensioning lines on the drilling template for

your cooling unit (see section10 "Appendix: Cut-out

and hole sizes").

Risk of injury!

Carefully deburr all drilled holes and cut-

outs to prevent injuries caused by sharp

edges.

Mark, drill and deburr the holes.

Make the cut-outs including the line width as per the

drilling template.

Deburr the cut-outs.

4.3.2 External mounting of the cooling unit

Cut the supplied sealing tape to the correct length and

stick it carefully along the back of the unit so that no

gaps are left at the joints. The joints should be located

at the bottom of the unit.

EN

3329.xxx 184 200

Tab. 1: Dimension "x"

4.3 Fitting the cooling unit

The enclosure cooling unit may be externally mounted

on the enclosure.

Fig. 5: Installation method

To this end, cut the side panel or door of the enclosure

as per the drilling template included with the supply, and

drill the relevant holes.

Fig. 6: Attach the sealing tape

Screw the supplied threaded studs into the blind nuts

on the rear of the unit.

Secure the unit using the supplied washers and nuts.

Fig. 7: Secure the cooling unit

4.4 Notes on electrical installation

When performing the electrical installation, it is important

to observe all valid national and regional regulations as

well as the provisions of the responsible power supply

company. Electrical installation must only be carried out

by a qualified electrician who is responsible for compliance with the existing standards and regulations.

Rittal enclosure cooling unit 13

Page 14

EN

4 Assembly and connection

4.4.1 Connection data

– The connected voltage and frequency must corre-

spond to the values stated on the rating plate.

– The cooling unit must be connected to the mains via

an all-pin isolating device, which ensures at least 1/8"

(3 mm) contact opening when switched off.

– No additional temperature control may be connected

upstream of the unit at the supply end.

– Install a circuit breaker or time delay fuse as specified

on the rating plate to protect the cable and equipment

from short-circuits.

4.4.2 Electrical Box connection

Loosen and remove the two screws and washers on

top of the electrical box and remove the cover.

Remove knockouts from the electrical box to allow for

all required cables.

After the unit is mounted, attach the electrical box to

the rear of the unit. Use the two self threading screws

and the washers from the dispatch box according to

your model.

Fig. 8: Dismantling the cover of the electrical box

Snap the plastic grommet(s) into the holes for the non-

main power to protect the cables from the edges of

the holes.

Install 1/2" conduit and conduit connector (not includ-

ed) as required for the installation.

Route the main power cable through conduit and into

box leaving a minimum of 6" (152 mm) for lead wire.

Connect the cable to the X1 connector and attach to

unit.

Fig. 9: Attaching the connector to the electrical box

Attach the cover on the electrical box using the two

previously removed screws and washers.

4.4.3 Overvoltage protection and supply line load

– The unit does not have its own overvoltage protection.

Measures must be taken by the operator at the supply

end to ensure effective lightning and overvoltage protection. The mains voltage must not exceed a tolerance of ±10 %.

– In accordance with IEC 61 000-3-11, the unit is in-

tended solely for use at sites with a continuous current-carrying capacity (incoming mains power supply)

of more than 100 A per phase and with a supply voltage of 400/230/115 V. If necessary, the power supply

company must be consulted to ensure that the continuous current-carrying capacity at the point of connection to the public grid is sufficient for connection of

such a unit.

– The fans and compressors in single- and threephase

units are intrinsically safe (thermal winding protection).

The same also applies to the transformer versions of

types 3304.5x8, 3305.5x8 and 3329.5x8 and to special- voltage units which are likewise equipped with a

transformer.

– Install the time delay fuse specified on the rating plate

to protect the cable and equipment from short-circuits. Select a suitable circuit-breaker in accordance

with the information specified on the rating plate: Set

it to the minimum specified value. This will achieve the

best short-circuit protection for cables and equipment.

Example: Specified setting range 6.3 – 10 A; set to

6.3 A.

4.4.4 Door limit switch

– Each door limit switch must only be assigned to one

cooling unit.

– Several door limit switches may be connected in par-

allel and operated on one cooling unit.

– The minimum cross-section for the connection cable

is 22 AWG for a cable length of 6.5' (2 m).

14 Rittal enclosure cooling unit

Page 15

4 Assembly and connection

– The line resistance to the door limit switch must not

exceed a maximum of 50 .

– The door limit switch only supports a floating connec-

tion; no external voltages.

– The contact of the door limit switch must be closed

when the door is open.

The safety extra-low voltage for the door limit switch is

provided by the internal power pack: Current approx.

30 mA DC.

Connect the door limit switch to terminals 1 and 2 of

the connector.

4.4.5 Notes on the flicker standard

The flicker limits specified in standard EN 61 000-3-3 or

-3-11 are adhered to, provided the supply impedance is

less than approx. 1.5 .

Where necessary, the unit operator should measure the

connected impedance or consult the responsible power

supply company. If there is no way of influencing the

supply impedance and sensitive installed components

(e.g. BUS) are subjected to interference, a line reactor or

starting-current limiting device should be connected upstream of the cooling unit to restrict the startup current

of the cooling unit.

Caution!

Regarding the last slave unit in the

group, do not, under any circumstances,

connect the remaining socket of the Y

cable 3124.100 into interface X3 of the

cooling unit!

4.5.2 Connection X3 for serial interface

For incorporating the cooling unit into superordinate

monitoring systems, the IoT interface, together with the

Blue e IoT adaptor, can be connected to the 9-pole

SUB-D connector (available as accessories: IoT interface Model No. 3124.300, Blue e IoT adaptor Model No.

3124.310).

EN

4.4.6 Potential equalization

If, for EMC reasons, the unit is to be integrated into the

existing potential equalization system at the customer, a

conductor with a larger nominal crosssection can be

connected to the potential equalization connection point

(attachment points) on wallmounted cooling units.

According to the standard, the PE conductor in the

mains connection cable is not classified as an equipotential bonding conductor.

4.5 Carrying out the electrical installation

4.5.1 Bus connection (only in conjunction with several units with an e-Comfort controller)

When using several cooling units, the serial device interface X2 can be used to connect up to ten cooling units

with the bus cable (Model No. 3124.100).

Note:

The electrical signals at the X2 interface are of

an extra-low voltage (not extra-low safety

voltages to EN 60 335-1).

When interconnecting, please note the following:

De-energize the cooling units to be connected.

Ensure proper electrical insulation.

Make sure the cables are not laid in parallel to power

lines.

Make sure that the lines are short.

Rittal enclosure cooling unit 15

Page 16

EN

X2

IoT Interface

Blue e adaptor for

IoT Interface

RTT

Master

Adr.: 09

X1

X2

X3

X1

X2

X3

X1

X2

X3

X1

X2

X3

X2

X3

X2

X2

X2

X2

X2

X2

St. St. St.

Bu.

St.

Bu.

X2

Adr.: 11 Adr.: 12RTT

Slave

RTT

Slave

Adr.: 19RTT

Slave

St.

Bu.

St.

Bu.

3

1

2

X10

L1

L2

N

PE

1

2345

1

X10

X10 X10 X10 X10

X2 X2 X2 X2 X2 X2

X2

L1

PE

1

2345

L1

L2

N

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

L2

N

PE

1

23

4

5

X10

2

3

4

56

1

Adr.: 06 Adr.: 11 Adr.: 12 Adr.: 13 Adr.: 14 Adr.: 15

22 2 2 2

34432

Adr.: 16

4 Assembly and connection

Fig. 10: Connection example: Master-slave operation

Legend

1 IoT Interface (Model No. 3124.300)

2 Blue e adaptor for IoT Interface (Model No. 3124.310)

3 Master-slave bus cable (Model No. 3124.100)

RTT Rittal TopTherm cooling units

X1 Supply connection/door limit switch/alarms

X2 Master/slave connection Sub-D, 9-pole

X3 Serial interface Sub-D, 9-pole

St. Sub-D connector, 9-pole

Bu. Sub-D jack, 9-pole

Adr. Address

Fig. 11: Connection example: Door limit switch and master-slave operation

Legend

1 Master cooling unit

2 Slave cooling units

4.5.3 Installing the power supply

Complete the electrical installation by following the

wiring plan on the rear of the cooling unit (see fig. 1 on

page 10).

If you would like the system messages from the cool-

ing unit to be evaluated via the system message relay,

you should also connect a suitable low-voltage cable

to connection clamps 3 – 5.

16 Rittal enclosure cooling unit

3 2-door enclosure with two door limit switches

4 Enclosure with door limit switch

Page 17

Fig. 12: Electrical wiring plan no. 1

3303.508/3303.518/3304.508/3304.518/3305.518/

3303.518/3329.508/3329.518

3304.548/3305.548/3329.548

12

4

3

5 Commissioning

Once all the assembly and installation work is com-

plete, switch on the power supply to the cooling unit.

The cooling unit starts running:

– The software version of the controller first appears for

approx. 2 sec. Then the enclosure internal tempera-

ture appears in the 7-segment display.

You can now make your individual settings on the unit,

e.g. set the temperature or assign the network identifier,

etc. (refer to section6 "Operation").

6 Operation

You can operate the cooling unit using the controller on

the rear of the device (fig. 1, item 3, page 10)

6.1 Control using the e-Comfort controller

EN

Fig. 13: Electrical wiring plan no. 2

Legend

X1 Main terminal strip

X2 Master/slave connection

X3 Optional interface

K1 Relay collective fault 1

K2 Relay collective fault 2

Door Door limit switch (without door limit switch: terminal 1, 2

open)

Note:

For technical data refer to the rating plate.

AC

cos φ = 1

I max. = 2 A

U max. = 250 V

Tab. 2: Contact data

5 Commissioning

Caution! Risk of damage!

DC

L/R = 20 ms

I min. = 100 mA

U max. = 200 V

U min. = 18 V

I max. = 2 A

The oil must collect in the compressor in

order to ensure effective lubrication and

cooling. Do not operate the cooling unit

for at least 30 min. after assembling the

equipment.

Fig. 14: e-Comfort controller

Key

1 Programming button, also display of the set temperature

unit (degrees Celsius)

2 Set button

3 Programming button, also display of the set temperature

unit (degrees Fahrenheit)

47-segment display

6.1.1 Properties

– Rated operating voltage:

– 115 V or

– 230 V or

– 400/460 V, 3-phase, supports multiple voltages

without rewiring

– Integral start-up delay and door limit switch function

– Monitoring of all motors (compressor, condenser fan,

evaporator fan)

– Phase monitoring for three-phase units

– Master-slave function with a maximum of ten units.

One device functions as a master unit. Once the set

temperature is reached by one of the connected slave

devices or in the event of the door limit switch function,

the affected slave unit will report to the master unit that

switches all the other cooling units on or off as re-

quired.

– Switching hysteresis: adjustable from 2 – 10 K, preset

to 5 K, where 5 K is the hysteresis value.

Rittal enclosure cooling unit 17

Page 18

6 Operation

ON

Status

internal fan

Internal

temperature

Time

Setpoint

-5 K

Setpoint

-10 K

OFF

10 min.

30 sec.

10 min.

EN

– Visualisation of the current internal enclosure temper-

ature and all error messages in the 7-segment display

– The IoT interface (Model No. 3124.300) together with

the Blue e IoT adaptor (Model No. 3124.310) can be

incorporated into superordinate remote monitoring

systems.

The cooling unit operates automatically, i.e. after switching on the power supply, the evaporator fan (see fig. 2)

will run and circulate the internal enclosure air. The compressor and condenser fan are regulated by the e-Com-

6.1.3 Launching test mode

The e-Comfort controller is equipped with a test function

whereby the cooling unit commences cooling operation

independently of the set temperature or door limit switch

function.

Simultaneously press buttons 1 and 2 (fig. 14) for at

least 5 sec.

The cooling unit will commence operation. Test mode is

completed after approximately 5 minutes. The unit

switches off and changes to normal operation.

fort controller. The e-Comfort controller has a 7-segment display (fig. 14, item 4). After switching on the

power supply, the current software version initially appears on this display for approx. 2 seconds, followed by

a preset option (e.g. t10) or the temperature.

In regular operation, the display shows both the temperature (in degrees Celsius or Fahrenheit – users may

switch between the two) and any error messages.

The current internal enclosure temperature is usually displayed permanently. In the event of an error message,

this alternates with the temperature display.

The unit is programmed using buttons 1 – 3 (fig. 14). The

relevant parameters also appear in the display.

6.1.2 Eco mode

All Rittal TopTherm cooling units with e-Comfort controller from firmware 3.2 have the energy-saving eco mode,

which is disabled in the delivered state of UL Type 12/

3R/4 cooling units. The evaporator fan runs continuously.

If required, eco mode can be enabled on the control display. For this purpose switch the parameter from 0 to 1

in the programming level (see tab. 3).

The eco mode is used to save energy in the heat exchanger if there is no thermal load, or there is a low thermal load in the enclosure (e. g. standby operation, no

production or weekend). During this process the evaporator fan in the internal circuit is switched off as appropriate if the actual internal enclosure temperature drops

to 10 K below the specified setpoint temperature. To en-

6.1.4 General information about programming

Using buttons 1, 2 and 3 (fig. 14) you can change 24parameters within the preset ranges (min. value, max. value).

Tables 3 and 4 show the parameters which can be altered. Fig. 16 on page 21 shows which buttons must be

pressed.

Note on switching hysteresis:

With a low hysteresis and short switching cycles, there is a risk that cooling may not be

adequate or that only partial sections of the

enclosure are cooled. If the cooling unit is

oversized and compressor running times are

<1minute, the switching hysteresis is automatically increased to protect the cooling unit

(see message "LH" in section6.1.9 "Evaluating system messages").

Note on temperature settings:

With the e-Comfort controller, the temperature is preset at the factory to 95 °F (+35 °C).

In order to save energy, and due to the risk of

increased condensation, do not set the temperature lower than that actually necessary.

Note on useful cooling power:

Interactive performance diagrams for calculating the useful cooling power may be found

at www.rittal.com.

sure the internal temperature is reliably measured during

this process, the fan starts cyclically for 30 sec. (see

fig. 15). If the internal temperature drops to a range 5 K

below the setpoint set again, the fan switches back to

continuous operation.

In principle, the programming is identical for all editable

parameters.

To enter programming mode:

Press button 2 ("Set") for approx. 5 seconds.

The controller is now in programming mode. While in

programming mode, if you do not press any buttons for

approx. 30 seconds, the display will first flash, then the

controller will switch back to normal display mode. "Esc"

in the display indicates that any changes made have not

been saved.

Press the programming buttons (°C) or (°F) to

switch between the editable parameters (see tables3

and 4).

Press button 2 ("Set") to select the displayed parame-

ter for editing.

The current value of this parameter is displayed.

Fig. 15: Eco mode

18 Rittal enclosure cooling unit

Page 19

Press one of the programming buttons (°C) or

(°F).

"Cod" will appear in the display. In order to be able to

change a value, you must enter the authorisation code

"22".

Keep the programming button (°C) held down until

"22" appears.

Press button 2 ("Set") to confirm the code.

You can now alter the parameter within the preset limits.

Press one of the programming buttons (°C) or

(°F) until the required value appears.

Press button 2 ("Set") to confirm the change.

You can now alter other parameters in the same way.

There is no need to re-enter the authorisation code "22".

To exit programming mode, press button 2 ("Set")

again for approximately 5 seconds.

"Acc" will appear in the display to indicate that the

changes have been saved. The display then switches

back to regular operation (internal enclosure temperature).

You can also program the e-Comfort controller using a

diagnosis software package (Model No. 3159.100),

which is supplied with a connection cable to the PC. The

cable connector on the rear of the e-Comfort controller

display serves as an interface.

6 Operation

EN

Rittal enclosure cooling unit 19

Page 20

EN

6 Operation

6.1.5 Editable parameters

See also fig. 16 on page 21.

Progr.

level

1 St Internal enclosure

2 Fi Filter mat monitor-

3 Ad Master-slave

4 CF Switch between

5 H1 Setting for switch-

6 H2 Differential for er-

Display

screen

Parameter Min.

temperature setpoint T

i

ing

identifier

°C/°F

ing difference

(hysteresis)

ror message A2

Max.

value

68 °F 131 °F 95 °F The internal enclosure temperature setting is

10 60 99

0 19 0 See section 6.1.8 "Setting the master/slave

0 1 0 The temperature display can be switched be-

2 10 5 The cooling unit is preset in the factory to a

3 15 5 If the internal enclosure temperature exceeds

value

Factory

setting

(= off)

Description

preset at the factory to 95 °F (35 °C) and may be

altered within a range of 68 – 131 °F (20 –

55 °C).

To enable filter mat monitoring, the display

should be set to a minimum of 10 K above the

temperature difference shown in programming

mode "Fi"; filter mat monitoring is disabled at the

factory (99 = off).

Not applicable for NEMA 3R/4 units!

identifier"

tween °C (0) and °F (1). The LED displays the

current unit of temperature.

switching hysteresis of 5 K. This parameter

should only be changed in consultation with us.

Please contact us for advice.

the set value by more than 5 K, then error message A2 (internal enclosure temperature too

high) appears on the display terminal. If necessary, the differential may be altered here within

the range of 3 – 15 K.

26 ECO Eco-mode opera-

tion

27 PSO Changing the au-

thorisation code

Tab. 3: Editable parameters

0 1 0 Eco mode OFF: 0 / Eco mode ON: 1

0 15 0 This parameter allows you to change the "22"

authorisation code (factory setting).

The new code results from the sum of 22 +

PSO.

20 Rittal enclosure cooling unit

Page 21

6.1.6 Programming overview

= 5 sec.

6 Operation

EN

= 5 sec.

Fig. 16: Programming overview

Rittal enclosure cooling unit 21

Page 22

6 Operation

EN

6.1.7 Defining system messages for evaluation

System messages are shown on the display screen of

the e-Comfort controller via the displays A1 to A20 and

E0.

Progr.

level

7 A1 0 2 0 Enclosure door open

8 A2 0 2 0 Internal temperature of enclosure too high

9 A3 0 2 0 Filter monitoring (Not applicable for NEMA 3R/4 units!)

10 A4 0 2 0 Ambient temperature too high/low

11 A5 0 2 0 Icing hazard (Message disabled if ambient temperature <10 °C)

12 A6 0 2 1 PSA

13 A7 0 2 2 Evaporator coil

14A8 021 Condensate warning

15 A9 0 2 1 Condenser fan blocked or defective

16 A10 0 2 1 Evaporator fan blocked or defective

17A11022 Compressor

Display

screen

Min.

value

Max.

value

Factory

setting

Type or location of fault

A more detailed explanation of the system messages

may be found in section 6.1.9 "Evaluating system messages".

See also fig. 16 on page 21.

H

pressure switch

18A12021 Condenser

19 A13 0 2 1 Ambient temperature sensor

20 A14 0 2 1 Icing temperature sensor

21A15021 Condensate warning temperature sensor

22 A16 0 2 1 Internal temperature sensor

23 A17 0 2 1 Phase monitoring

24A18020 EPROM

25 A19 0 2 0 LAN/Master-Slave

Tab. 4: System messages that can be evaluated via relays

The system messages A1 – A19 may also be evaluated

via two floating system message relays. In this way, one

is interrupted, the corresponding relay will drop out and

open the contact.

of the two system message relays may be allocated to

each system message.

System message relays with normally open contact, see

wiring diagrams in section 4.5.3 "Installing the power

supply":

– Terminal 3: NO (normally open, relay 2)

Program system messages with the value

0: System message is not sent to the system mes-

sage relay, but merely appears in the display

1: System message is evaluated by relay 1

2: System message is evaluated by relay 2

– Terminal 4: C (connection of the supply voltage to the

system message relay)

– Terminal 5: NO (normally open, relay 1)

6.1.8 Setting the master/slave identifier

When several cooling units are connected together

(maximum ten), one of the cooling units must be defined

The definition NO refers to the de-energised state. As

soon as power is applied to the cooling unit, both system message relays (relay 1 and 2) energise.

as the "master" and the others as "slaves". For this purpose, assign a corresponding identifier (address) to

each cooling unit which will enable the cooling unit to be

identified in the network.

This is the normal operating state of the cooling unit. As

soon as a system message occurs or the power supply

If one of the slave units reaches the set temperature or if

the door limit switch function is activated, the affected

22 Rittal enclosure cooling unit

Page 23

6 Operation