Page 1

RISH Master 3440i/3440iDL 0.2S

RISH Master 3440i/3440iDL 0.2S

Operating Manual

as per IEC62053-22

Page 2

Page 3

Section

Touch Screen Digital Multi-Function Meter

Installation & Operating Instructions

Contents

1. Introduction

2. Measurement Reading Screens

3. Programming

3.1 Password Protection

3.2 Menu selection

3.2.1 System Parameter selection screen

3.2.1.1 System type

3.2.1.2 Potential transformer Primary value

3.2.1.3 Potential transformer secondary value

3.2.1.4 Current transformer Primary value

3.2.1.5 Current transformer Secondary value

3.2.1.7 Demand integration time

3.2.1.8 Auto Scrolling

3.2.1.9 Low current noise cutoff

3.2.1.11 Energy resolution

3.2.1.12 Energy digit reset count

3.1.1 Change Password

INDEX

DMAN-00IM-0683_Rev.C 08/2018

3.2.1.13 Energy Update Rate

3.2.1.6 System Frequency

3.2.1.10 Number of Poles

3.2.1.14 Meter Version

1

Page 4

3.2.4.1 Relay 1 output selection menu

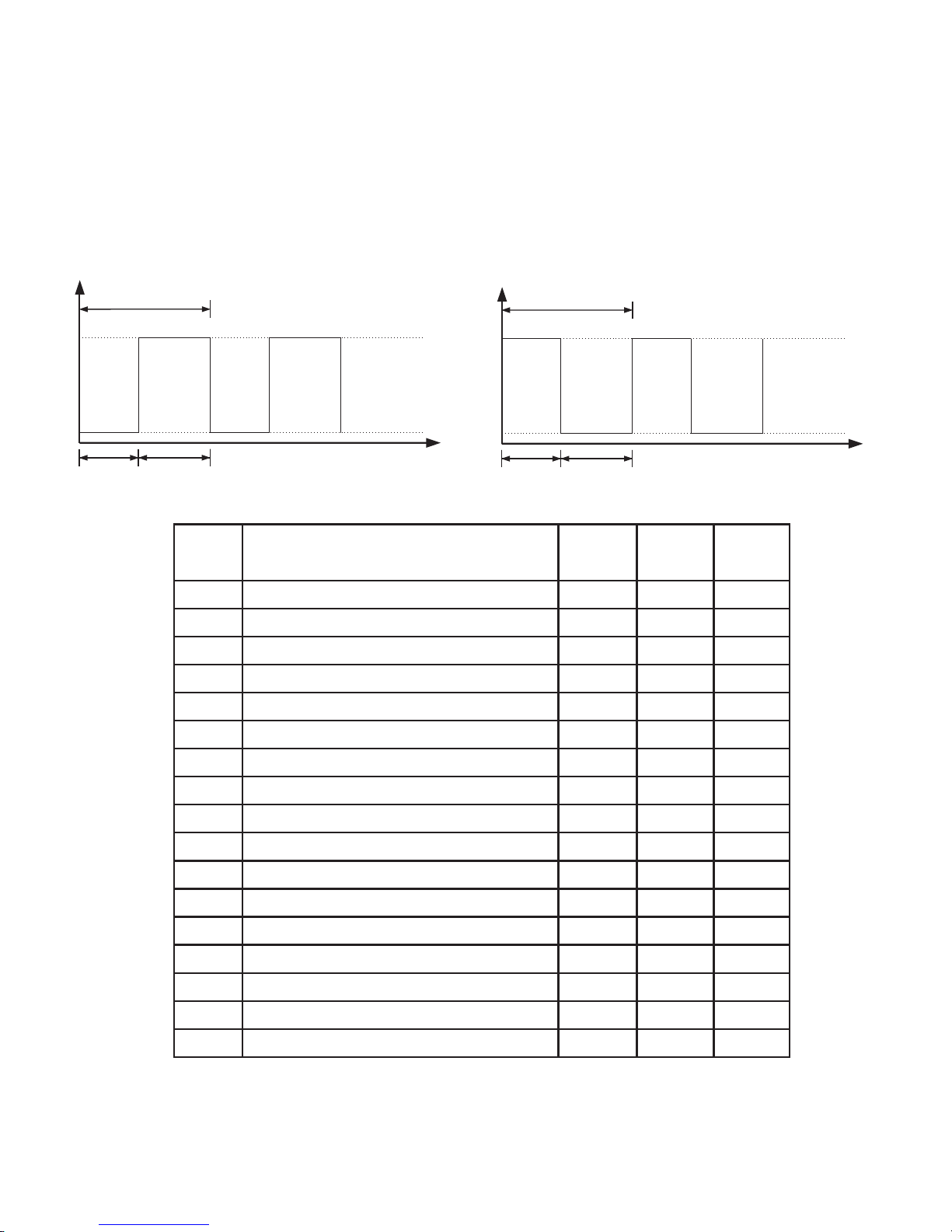

3.2.4.1.1 Pulse output

3.2.4.1.1.1 Assignment of Energy to Pulse (Relay 1)

3.2.4.1.1.2 Pulse Duration Selection

3.2.4.1.1.3 Pulse Rate

3.2.4.1.2 Limit output

3.2.4.1.2.1 Assignment of Limit Output1 to Parameter

3.2.4.1.2.5 Limit Conguration

3.2.4.1.2.6 Trip point selection

3.2.4.1.2.7 Hysteresis selection

3.2.4.1.2.8 Energizing delay time

3.2.4.1.2.9 De-energizing delay time

3.2.4 Output Option selection screen (menu)

3.2.3.1 Resetting Parameter

3.2.3 Reset Parameter selection screen

3.2.2 Communication Parameter selection screen

3.2.2.1.1 Address Setting

3.2.2.1.2 RS 485 Baud rate

3.2.2.1.3 RS 485 Parity selection

3.2.2.1 Modbus Setting

3.2.2.2 Ethernet Setting

3.2.2.2.1 IP Address Setting

3.2.2.2.2 Subnet Mask Setting

3.2.2.2.3 Default Gateway Setting

3.2.2.2.4 Server Port Setting

3.2.4.1.2.2 Energy Count Conguration

3.2.4.1.2.3 Energy Trip point

3.2.4.1.2.4 Energy Count On Delay

2

Page 5

3.2.4.2 Relay 2 output selection menu

3.2.4.3 Parameter setting for Analog Output-1

3.2.4.4 Parameter setting for Analog Output-2

3.2.8 Brightness & Contrast

3.2.4.1.4 RTC Relay

3.2.4.1.4.1 Weekdays Selection

3.2.4.1.4.2 Timer Conguration

3.2.4.1.4.3 On Time

3.2.4.1.4.4 Off Time

3.2.5.1 Event Based Datalog

3.2.5.2.1 Status

3.2.5 Datalogging Option Selection

3.2.5.2 Time Based Datalog

3.2.5.3 Load Prole Datalog

3.2.5.2.2 Time Interval

3.2.5.2.3 Parameters

3.2.6.1 Sag Threshold

3.2.6 Power Quality Settings

3.2.6.2 Swell Threshold

3.2.6.3 Sag & Swell Hysteresis

3.2.6.4 Overcurrent Threshold

3.2.6.5 Overcurrent Hysteresis

3.2.7 Date & Time Settings

3.2.4.1.3 Timer

3.2.4.1.3.1 Number of Cycles

3.2.4.1.3.2 Timer Conguration

3.2.4.1.3.3 On Delay

3.2.4.1.3.4 Off Delay

3

Page 6

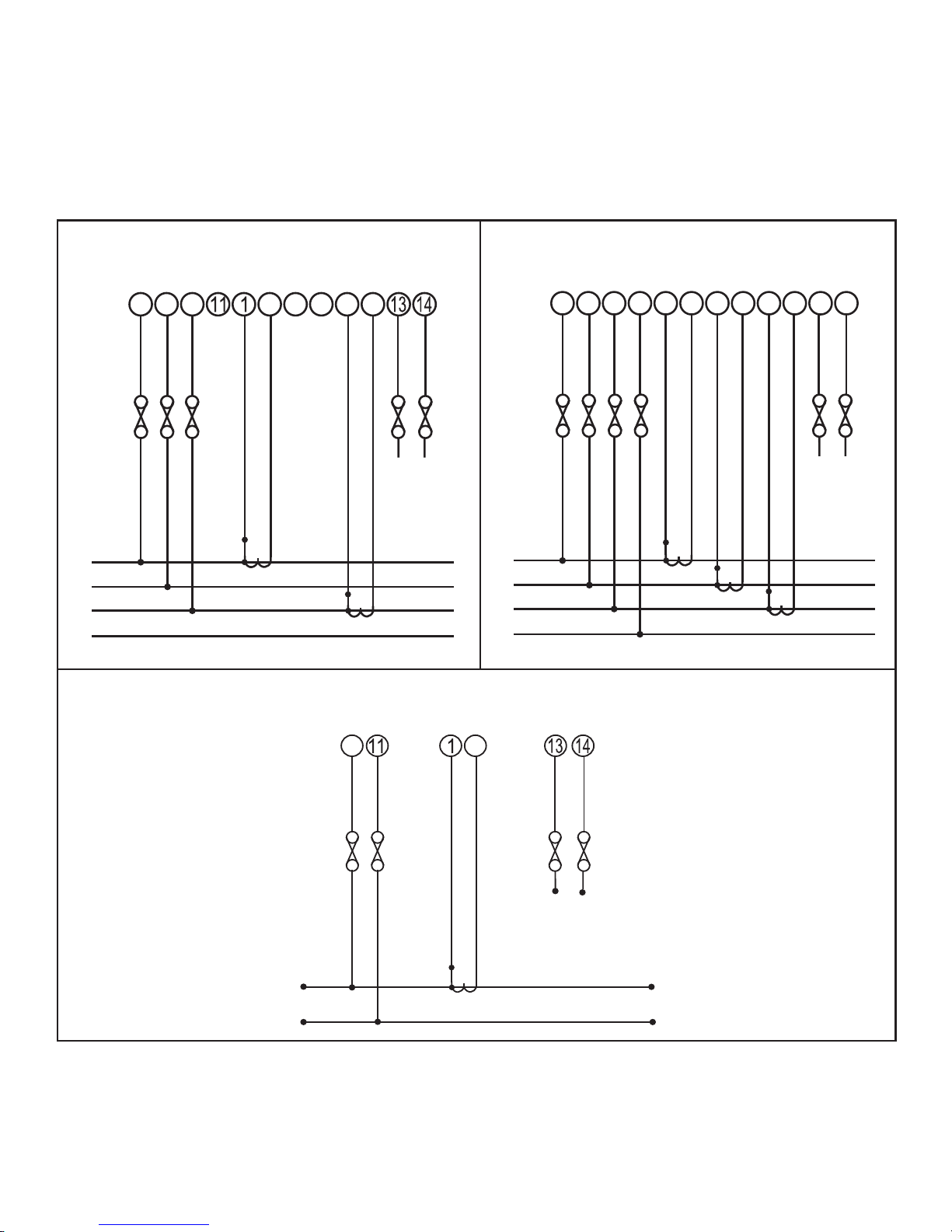

13.

Specication

11. Installation

11.1 EMC Installation Requirements

11.2

Case Dimensions and Panel Cut-out

11.3

Wiring

11.4 Auxiliary Supply

11.5 Fusing

11.6 Earth / Ground Connections

12.

Connection Diagrams

14.

Connection for Optional Pulse output / RS 485 /Analog Output / Ethernet

10.

Phasor Diagram

Relay Output

9.

Pulse output

9.1

Limit switch

9.2

7. Analog Output

6.3 Number of Interruption

6.2

On - Hour.

6.1

Run - Hour.

5. Phase Rotation Error screen.

4. Touch screen calibration.

6. Run Hr, On Hr & No. of Interruptions

Timer Output

9.3

PQ Measurement

8

3.2.9 RGB Color Code

3.2.10 Factory Reset

4

Page 7

1. Introduction

This instrument is a panel mounted 96 x 96mm DIN Quadratic Digital metering system for the

measurement of important electrical parameters like AC voltage, AC Current, Frequency,

Power, Energy(Active / Reactive / Apparent) . The instrument integrates accurate measurement

of technology (All Voltage & Current measurements are True RMS upto 15th Harmonic) with

320x240 Pixels touch screen TFT LCD display.

This instrument can be congured and programmed at site for the following: PT Primary, PT

Secondary, CT Primary, CT Secondary (5A or1A) and 3 phase 3W or 3 Phase 4W system.

The front panel has a 3.5” Touch Screen through which the user can move across the available

measurement readings, reset the energy, Min/Max (System Voltage and System Current) and

congure the product settings.

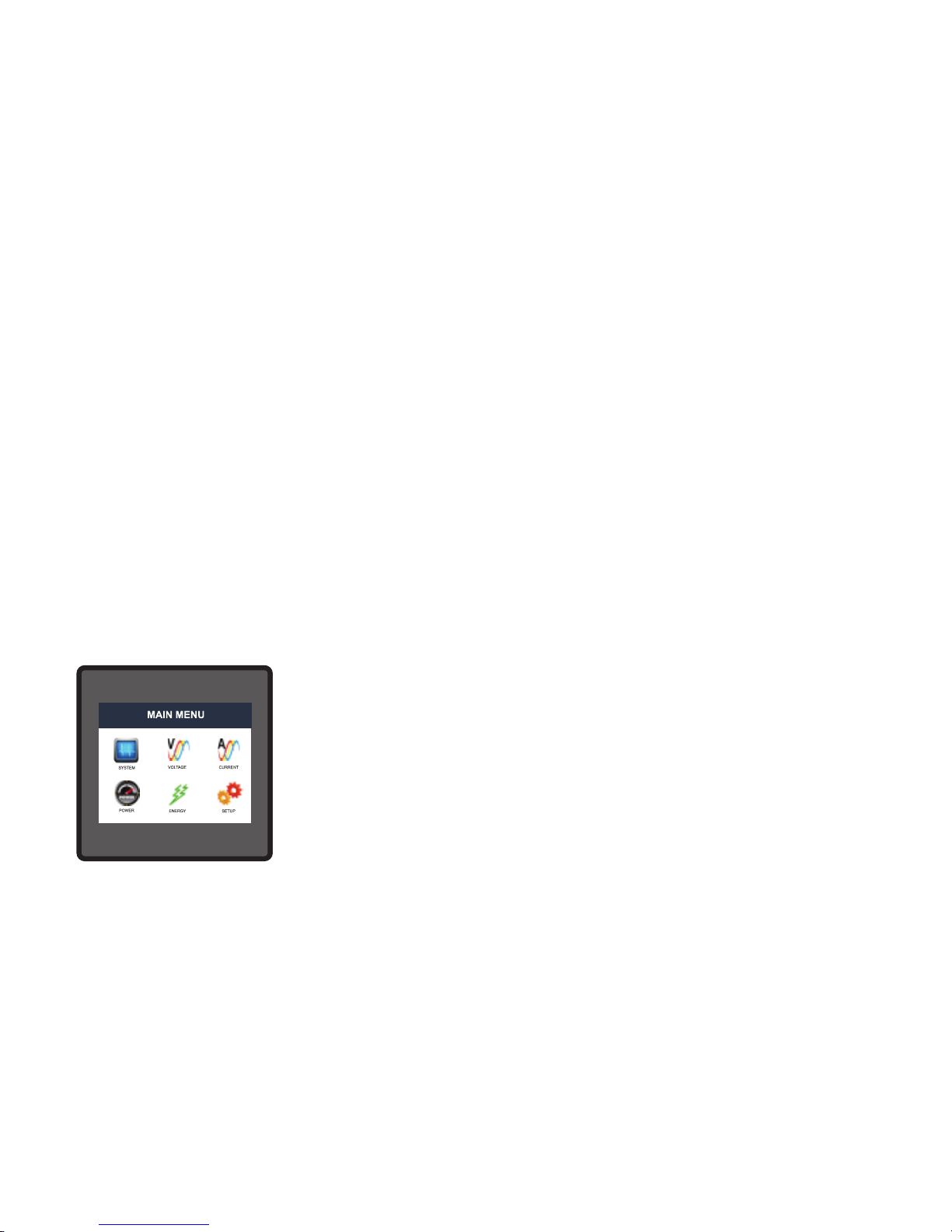

Main menu is divided into 6 submenus. Each submenu contains a list

of options. By touching the icons on main menu, submenus can be

accessed. System submenu can be used to access RTC, harmonics,

Power Quality events and other system parameters like system

power, min, max voltage and current, THD, run hour, on hour and

number of interruptions. Voltage, current and power submenu contain

measurement of basic elecrical parameters. Energy submenu gives

the total energy and Setup submenu can be used for complete meter

settings.

5

Page 8

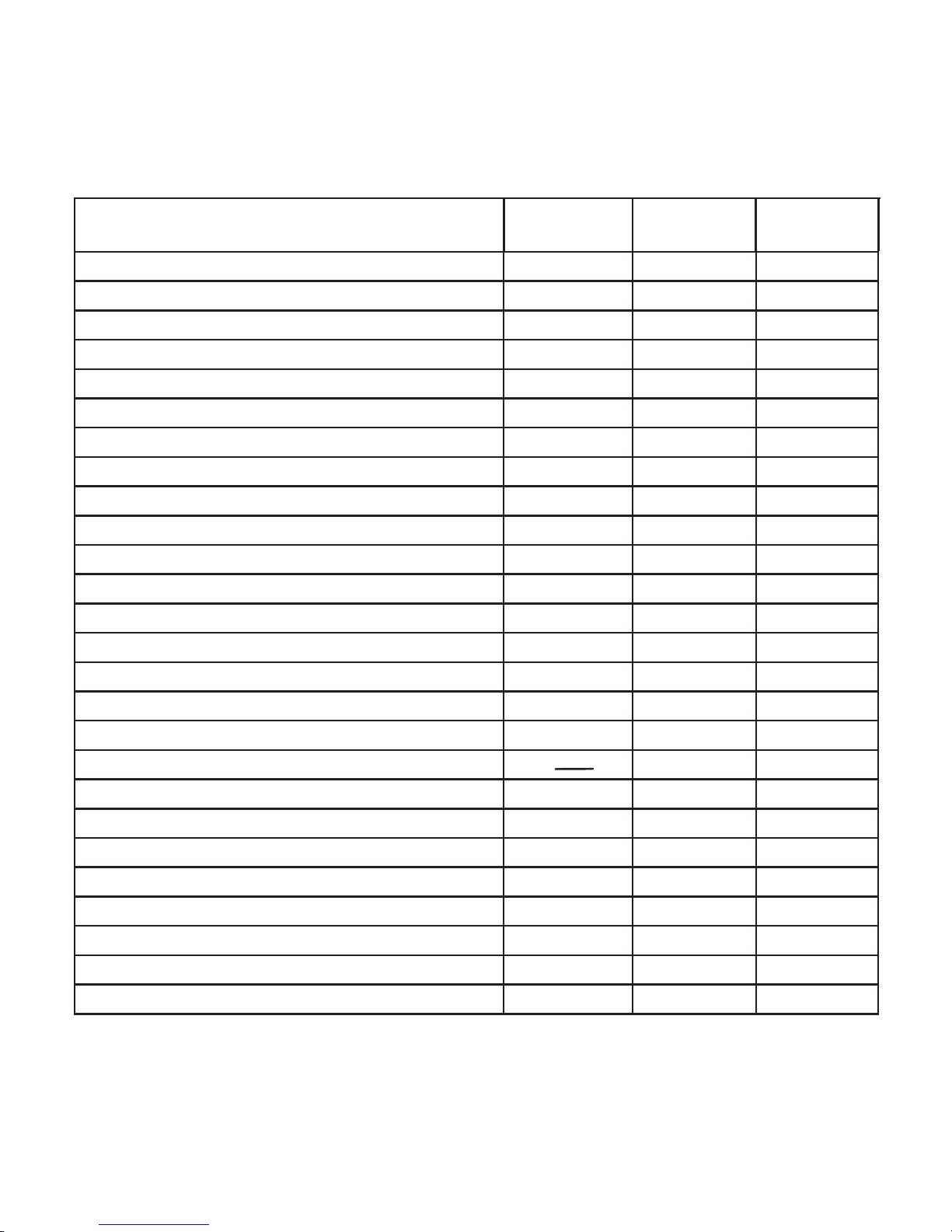

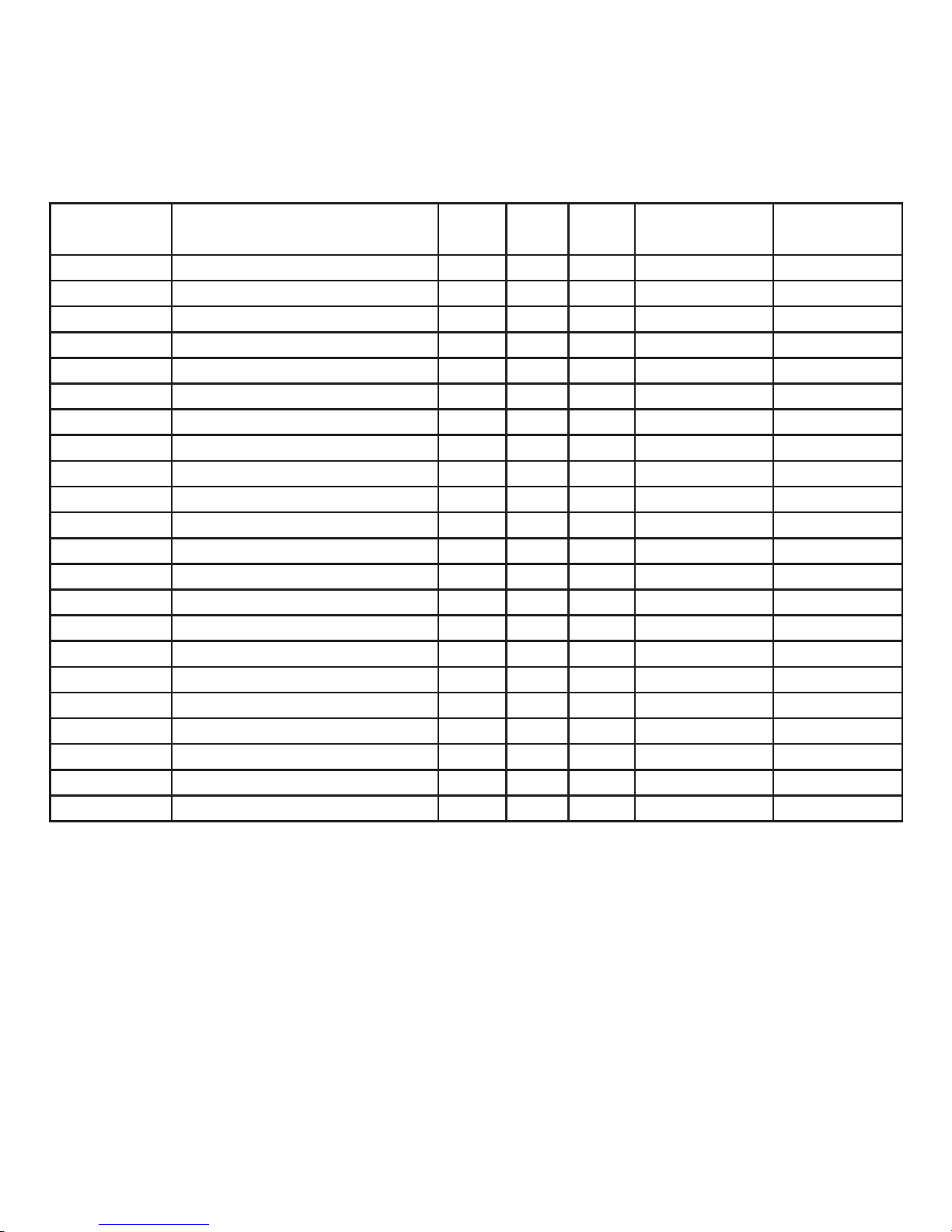

TABLE 1:Measurement Parameters for both models

System Voltage

System Current

Frequency

Voltage VL1-N(4wire only)

Voltage VL2-N(4wire only)

Voltage VL3-N(4wire only)

Voltage VL1-L2

Voltage VL2-L3

Voltage VL3-L1

Current L1

Current L2

Current L3

Volts

Amps

Hz

Volts

Volts

Volts

Volts

Volts

Volts

Amps

Amps

Neutral Current ( 4 wire only )

Amps

Amps

Active Import Energy (8 Digit resolution)

kWh

kWh

Active Export Energy (8 Digit resolution)

Active Power (System / Phase (4 wire only) )

Reactive Power (System / Phase (4 wire only))

Apparent Power (System / Phase (4 wire only))

Power Factor (System / Phase (4 wire only))

Phase Angle ( Phase(4 wire only))

Kwatts

KVAr

KVA

Degree

kVArh

Inductive Reactive Energy (8 Digit resolution)

kVArh

Capacitive Reactive Energy (8 Digit resolution)

kVAh

Apparent Energy (8 Digit resolution)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

Units of

Measurement

Date,Time

RTC

%

Individual Harmonics V

Individual Harmonics I

%

RM3440i

RM3440iDL

Sag, Swell & Overcurrent Events

-

Measured Parameters

6

Page 9

*Note : THD Parameters are L-N in case of 3P 4W & L-L in case of 3P 3W .

KW Import Demand

KVAr Cap. Demand

KW Export Demand

KVAr Ind. Demand

Max Current Demand

Max kVA Demand

Max KW Import Demand

Max KW Export Demand

Max KVAr Ind. Demand

Max KVAr Cap. Demand

Run Hour

On Hour

Number of Interruptions

Phase Reversal Indication ( 4 wire only )

KW

KW

Amps

KVA

KW

KW

KW

KW

KW

KW

Hours

Hours

Counts

Amps

Current Demand

KVA Demand

KVA

I1 THD

I2 THD

V1 THD*

V2 THD*

V3 THD*

%

I3 THD

System Voltage THD

System Current THD

%

%

%

%

%

%

%

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

( for 3 / 4 wire)

count,sec,sec

Timer1 No. of Cycles, ON, OFF delay

Timer2 No. of Cycles, ON, OFF delay

Measured Parameters

Units of

Measurement

count,sec,sec

TABLE 1:Continued...

RM3440i

RM3440iDL

7

Page 10

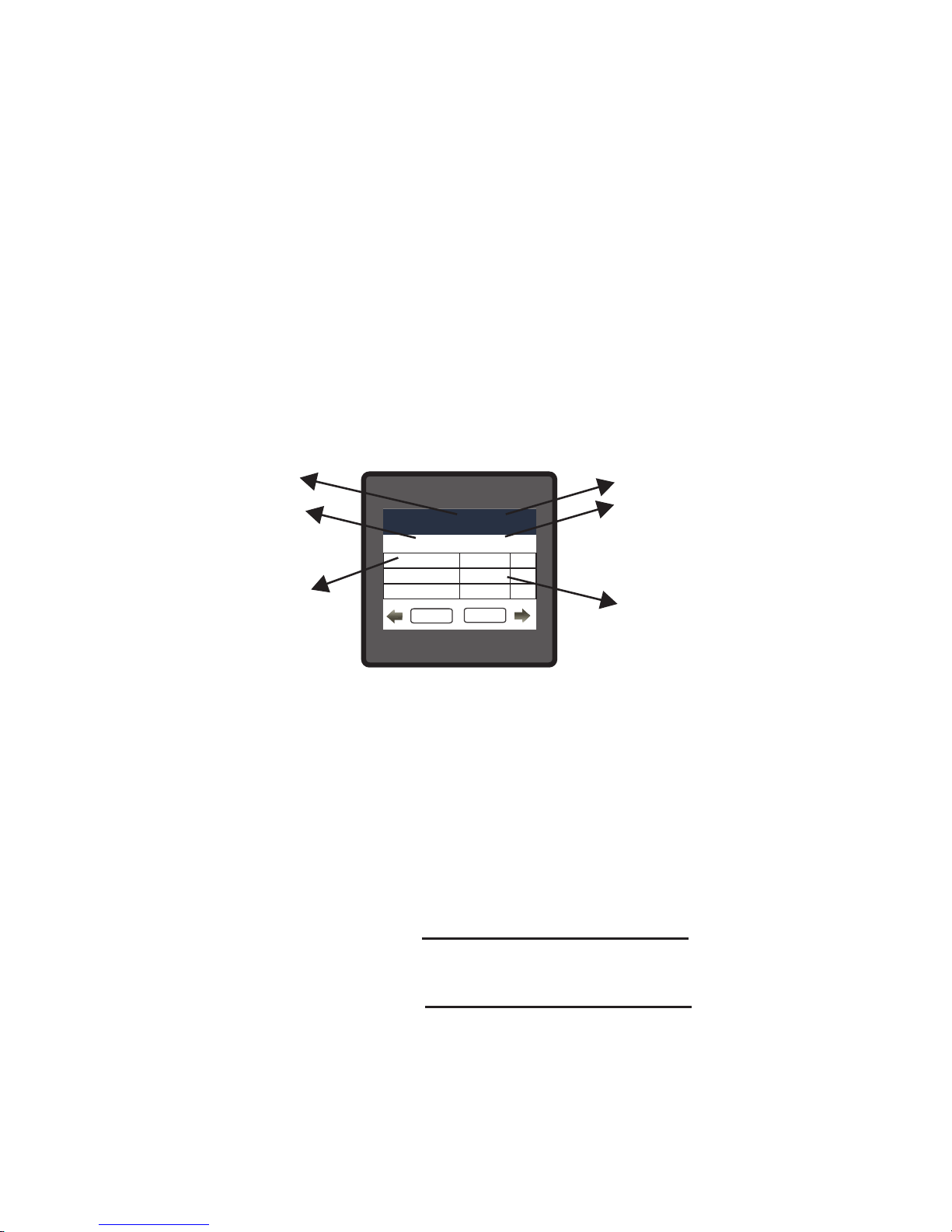

2. Measurement Reading Screens

In normal operation the user is presented with one of the measurement reading screens out of

several screens. These screens from particular submenu may be scrolled through one at a time

in incremental order by touching the “ key” and in decremental order by touching “ key”

on that screen.

APPARENT

ENERGY

REACTIVE ENERGY

INDUCTIVE

REACTIVE ENERGY

CAPACITIVE

ACTIVE ENERGY

EXPORT

ACTIVE ENERGY

IMPORT

RESET

PARAMETERS

COMMUNICATION

MAIN MENU

SYSTEM

SYSTEM TYPE

PT PRIMARY

PT SECONDARY

CT SECONDARY

DEMAND

NOISE CUTOFF

AUTO SCROLL

(Sec 3.2.1.1)

(Sec 3.2.1.2)

(Sec 3.2.1.3)

(Sec 3.2.1.5)

(Sec 3.2.1.7)

INTEGRATION

TIME

LOW CURR.

CURRENT

VOLTAGE

SYSTEM

Max. VOLTAGE

PHASOR

RUN HOUR

A

A

SYSTEM

PARAMETERS

And CURRENT

Min. VOLTAGE

And CURRENT

ON HOUR

No. OF

INTERRUPTIONS

CT SECONDARY

DEMAND

AUTO SCROLL

(Sec 3.2.1.5)

(Sec 3.2.1.7)

INTEGRATION

TIME

POWER

SYSTEM

POWER

SYSTEM

RTC

(Sec 3.2.2.3)

PHASE VOLTAGE

% THD

Line Current

OPTIONS

(Sec 3.2.4)

POWER

CHANGE

PASSWORD

(Sec 3.1)

ENERGY

AA

A

B

A

B

LINE CURRENT

% THD

DIAGRAM

Line to Neutral

VOLTAGE

(Sec 3.2.2.3)

WAVEFORM

WAVEFORM

CURRENT

PHASE

WAVEFORM

EXPORT

ACTIVE DEMAND

IMPORT

ACTIVE DEMAND

APPARENT

DEMAND

CURRENT

DEMAND

PHASE

POWER FACTOR

PHASE ACTIVE

POWER

PHASE APPARENT

POWER

PHASE REACTIVE

POWER

PHASE

ANGLE

Parameter Screens Single Phase

SYSTEM

RPM

FREQUENCY

FACTOR

THD.VOLTAGE

AND CURRENT

DEMAND

AUTO SCROLL

(Sec 3.2.1.7)

TIME

TIMER 1

POWER QUALITY

EVENTS

INDIVIDUAL

HARMONICS

TIMER 2

TIMER

STATUS

NOTE: SCREENS MARKED WITH # ARE AVAILABLE ONLY IN RM3440iDL

#

#

#

#

#

8

Page 11

APPARENT

ENERGY

REACTIVE ENERGY

INDUCTIVE

REACTIVE ENERGY

CAPACITIVE

ACTIVE ENERGY

EXPORT

ACTIVE ENERGY

IMPORT

RESET

PARAMETERS

COMMUNICATION

MAIN MENU

SYSTEM

SYSTEM TYPE

PT PRIMARY

PT SECONDARY

CT PRIMARY

CT SECONDARY

DEMAND

NOISE CUTOFF

AUTO SCROLL

(Sec 3.2.1.1)

(Sec 3.2.1.2)

(Sec 3.2.1.3)

(Sec 3.2.1.4)

(Sec 3.2.1.5)

(Sec 3.2.1.7)

INTEGRATION

TIME

LOW CURR.

CURRENT

VOLTAGE

SYSTEM

Max. VOLTAGE

PHASER

RUN HOUR

A

A

RPM

SYSTEM

PARAMETERS

And CURRENT

Min. VOLTAGE

And CURRENT

ON HOUR

No. OF

INTERRUPTIONS

DEMAND

AUTO SCROLL

(Sec 3.2.1.7)

INTEGRATION

TIME

SEQUENCE *

PHASE

INDIVIDUAL

HARMONICS

SYSTEM

RTC

(Sec 3.2.2.3)

VOLTAGE

% THD

Line Current

Neutral

OPTIONS

(Sec 3.2.4)

POWER

CHANGE

PASSWORD

(Sec 3.1)

ENERGY

A

A

B

B

LINE CURRENT

% THD

DIAGRAM *

Line to Line

VOLTAGE

Line to Neutral

VOLTAGE*

NOTE 1: SCREENS MARKED WITH * ARE AVAILABLE ONLY IN 4W SYSTEM (NOT IN 3 WIRE SYSTEM)

(Sec 3.2.2.3)

WAVEFORM

VOLTAGE

WAVEFORM

CURRENT

L3 PHASE

WAVEFORM *

L2 PHASE

WAVEFORM *

L1 PHASE

WAVEFORM *

EXPORT

ACTIVE DEMAND

IMPORT

ACTIVE DEMAND

APPARENT

DEMAND

CURRENT

DEMAND

PHASE

POWER FACTOR*

L3 PHASE

POWER *

L2 PHASE

POWER *

L1 PHASE

POWER *

PHASE

ANGLE*

Parameter Screens 3 Phase

NOISE CUTOFF

LOW CURR.

FREQUENCY

SYSTEM

CT SECONDARY

DEMAND

(Sec 3.2.1.5)

INTEGRATION

TIME

POWER FACTOR

THD.VOLTAGE

AND CURRENT

CT SECONDARY

(Sec 3.2.1.5)

POWER

SYSTEM

DEMAND

AUTO SCROLL

(Sec 3.2.1.7)

INTEGRATION

TIME

TIMER 2

POWER QUALITY

EVENTS

TIMER

STATUS

TIMER 1

Current*

A

NOTE 2: SCREENS MARKED WITH # ARE AVAILABLE ONLY IN RM3440iDL

#

#

#

#

#

9

Page 12

MODBUS

(Sec 3.2.2.1)

ANALOG OUTPUT 1

(Sec 3.2.4.3)

PT PRIMARY

(Sec 3.2.1.2)

PT SECONDARY

(Sec 3.2.1.3)

CT PRIMARY

(Sec 3.2.1.4)

CT SECONDARY

(Sec 3.2.1.5)

AUTO SCROLL

(Sec 3.2.1.8)

NOISE CUTOFF

(Sec 3.2.1.9)

LOW CURR.

(Acc. To Table 7.1)

DEMAND

(Sec 3.2.1.7)

INTEGRATION

TIME

RESET MAX V & I

RESET MIN V & I

RESET RUN,ON-HR

RESET AUX INTRR.

RESET ALL

PASSWORD

SYSTEM

(Sec 3.2.1)

Setup Parameter Screens

PARAMETERS

ENTER

SYSTEM

(Sec 3.2.1)

PARAMETERS

PARAMETERS

COMMUNICATION

(Sec 3.2.2)

PARAMETERS

(Sec 3.1)

SYSTEM TYPE

(Sec 3.2.1.1)

BRIGHTNESS

& CONTRAST

(Sec 3.2.8)

CHANGE

PASSWORD

(Sec 3.1.1)

RESET

(Sec 3.2.3)

PARAMETERS

OPTIONS

OUTPUT

(Sec 3.2.4)

(Sec 3.2.4.1)

RELAY

OUTPUT 1

RESET DEMAND

RESET ENERGIES

RS485

(Sec 3.2.1.11)

ENERGY ON

RESET COUNT

(Sec 3.2.1.12)

ENERGY DIGIT

RGB

COLOR

CODE

(Sec 3.2.9)

(Sec 3.2.4.2)

RELAY

OUTPUT 2

ANALOG OUTPUT 2

(Sec 3.2.4.4)

(Acc. To Table 7.1)

A

C

POWER QUALITY

SETTINGS

(Sec 3.2.6)

DATALOG

OPTIONS

(Sec 3.2.5)

EVENT BASED

(Sec 3.2.5.1)

TIME BASED

(Sec 3.2.5.2)

LOAD PROFILE

(Sec 3.2.5.3)

SAG

(Sec 3.2.6.1)

THRESHOLD

SWELL

(Sec 3.2.6.2)

THRESHOLD

OVERCURRENT

(Sec 3.2.6.3)

HYSTERESIS

SAG & SWELL

(Sec 3.2.6.4)

THRESHOLD

(Sec 3.2.6.5)

OVERCURRENT

HYSTERESIS

DATE &

TIME

(Sec 3.2.7)

PARAMETERS

ETHERNET

(Sec 3.2.2.2)

PARAMETERS

A

A

B

FREQUENCY

(Sec 3.2.1.6)

SYSTEM

RATE

(Sec 3.2.1.13)

ENERGY UPDATE

VERSION

(Sec 3.2.1.14)

METER

POLES

(Sec 3.2.1.10)

NUMBER OF

RESET TIME LOG

RESET LP LOG

RESET SAG LOG

A

D

FACTORY

RESET

(Sec 3.2.10)

*NOTE: ETHERNET Parameters (Sec 3.2.2.2) are available only if Ethernet card (add on) is inserted.

RESET SWELL LOG

RESET OvI LOG

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

*NOTE: ETHERNET Parameters marked # are available only for RM3440iDL

10

Page 13

(Acc. To Table 2)

(Sec 3.2.4.1.2.1)

PARAMETER

SELECTION

CONFIGURATION

SELECTION (Hi-E

(Sec 3.2.4.1.2.5)

TRIP POINT

10% to 100%/120%

(Sec 3.2.4.1.2.6)

HYSTERESIS

0.5% to 50%

(Sec 3.2.4.1.2.7)

ENERGIZING

DELAY

1s to 10s

(Sec 3.2.4.1.2.8)

1 s to 10s

(Sec 3.2.4.1.2.9)

DE-ENERGIZING

DELAY

(Sec 3.2.4.1.1)

LIMIT

OUTPUT

(Sec 3.2.4.1.2)

PARAMETER

SELECTION

(Sec 3.2.4.1.1.1)

PULSE RATE

(Pulse Divisor Rate)

1, 10, 100, 1000

PULSE RATE

R

(Sec 3.2.4.1.1.3)

PULSE

DURATION

60,100,200

(Sec 3.2.4.1.1.2)

PULSE

OUTPUT

Output Options Parameters

If

PARAMETER

=37/38/39/40/41

Hi-DE,Lo-En,Lo-DE)

CONFIGURATION

SELECTION

(Sec 3.2.4.1.2.2)

TRIP POINT

10 to 9999999

(Sec 3.2.4.1.2.3)

ON DELAY

1 to 9999 s

(Sec 3.2.4.1.2.4)

(En,De-En)

(Sec 3.2.4.1.3)

RTC

OUTPUT

(Sec 3.2.4.1.4)

TIMER

OUTPUT

CONFIGURATION

SELECTION

(Sec 3.2.4.1.3.2)

ON DELAY

(Sec 3.2.4.1.3.3)

OFF DELAY

1 to 9999 s

(Sec 3.2.4.1.3.4)

(En,De-En)

(Sec 3.2.4.1.3.1)

NO OF CYCLES

(0 TO 9999)

1 to 9999 s

CONFIGURATION

SELECTION

(Sec 3.2.4.1.4.2)

ON TIME

(Sec 3.2.4.1.4.3)

(Sec 3.2.4.1.4.4)

(En,De-En)

(Sec 3.2.4.1.4.1)

WEEKDAYS

00:00 to 23:59

SELECTION

OFF TIME

00:00 to 23:59

A

C

Rs485 ADDRESS

(Sec 3.2.2.1.1)

RS485 PARITY

(Sec 3.2.2.1.3)

RS485

BAUD RATE

RS485

(Sec 3.2.2.1.2)

BAUD RATE

IP ADDRESS

(Sec 3.2.2.2.1)

DEFAULT

(Sec 3.2.2.2.3)

SUBNET MASK

(Sec 3.2.2.2.2)

SERVER PORT

(Sec 3.2.2.2.4)

B

A

A

B

GATEWAY

Modbus

Parameters

Ethernet

Parameters

ON/OFF STATUS

(Sec 3.2.5.2.1)

PARAMETERS

(Sec 3.2.5.2.3)

TIME

(Sec 3.2.5.2.2)

INTERVAL

B

D

Time Datalog

Parameters

#

#

#

#

#

#

#

#

#

#

#

#

#

Yes

No

#

#

#

#

*NOTE: ETHERNET Parameters marked # are available only for RM3440iDL.

11

Page 14

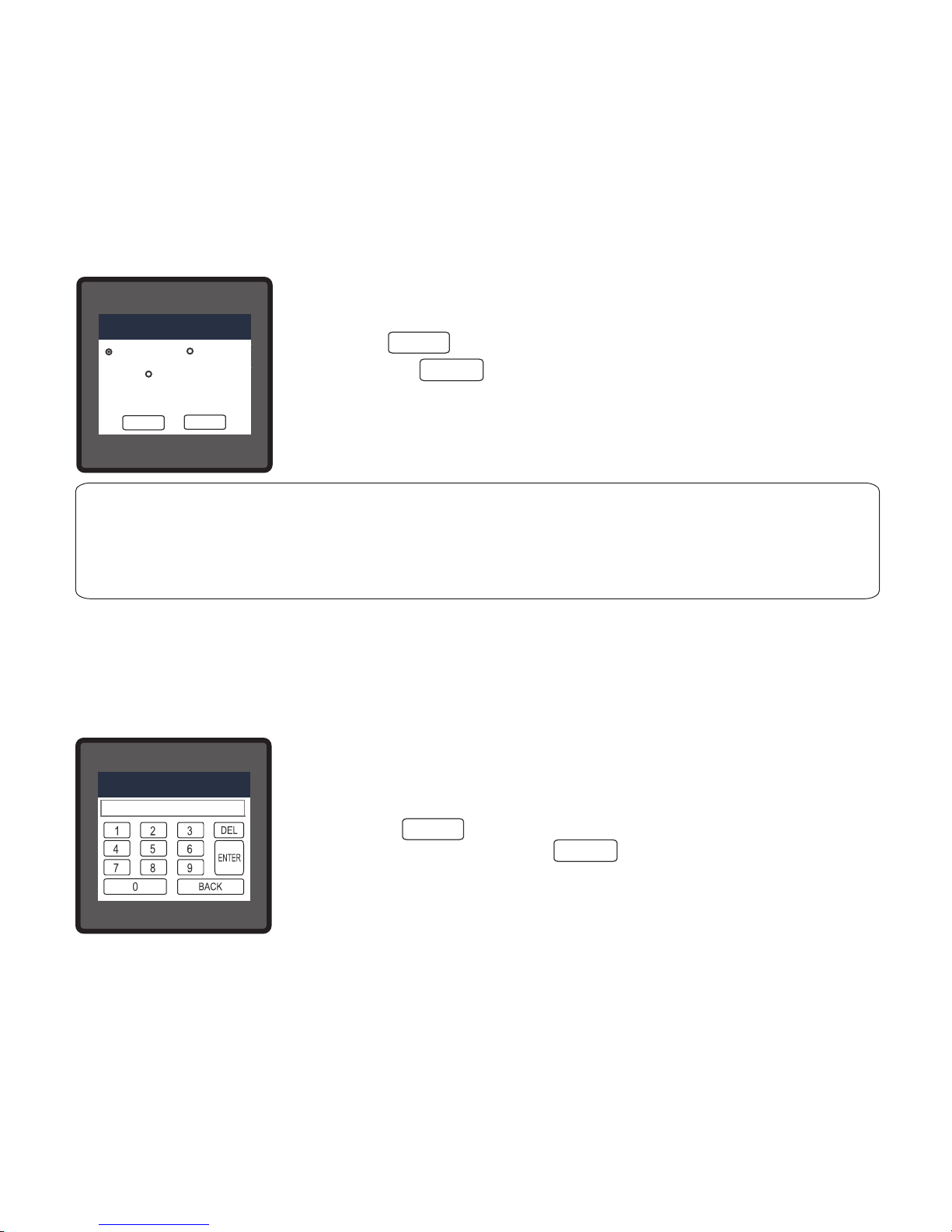

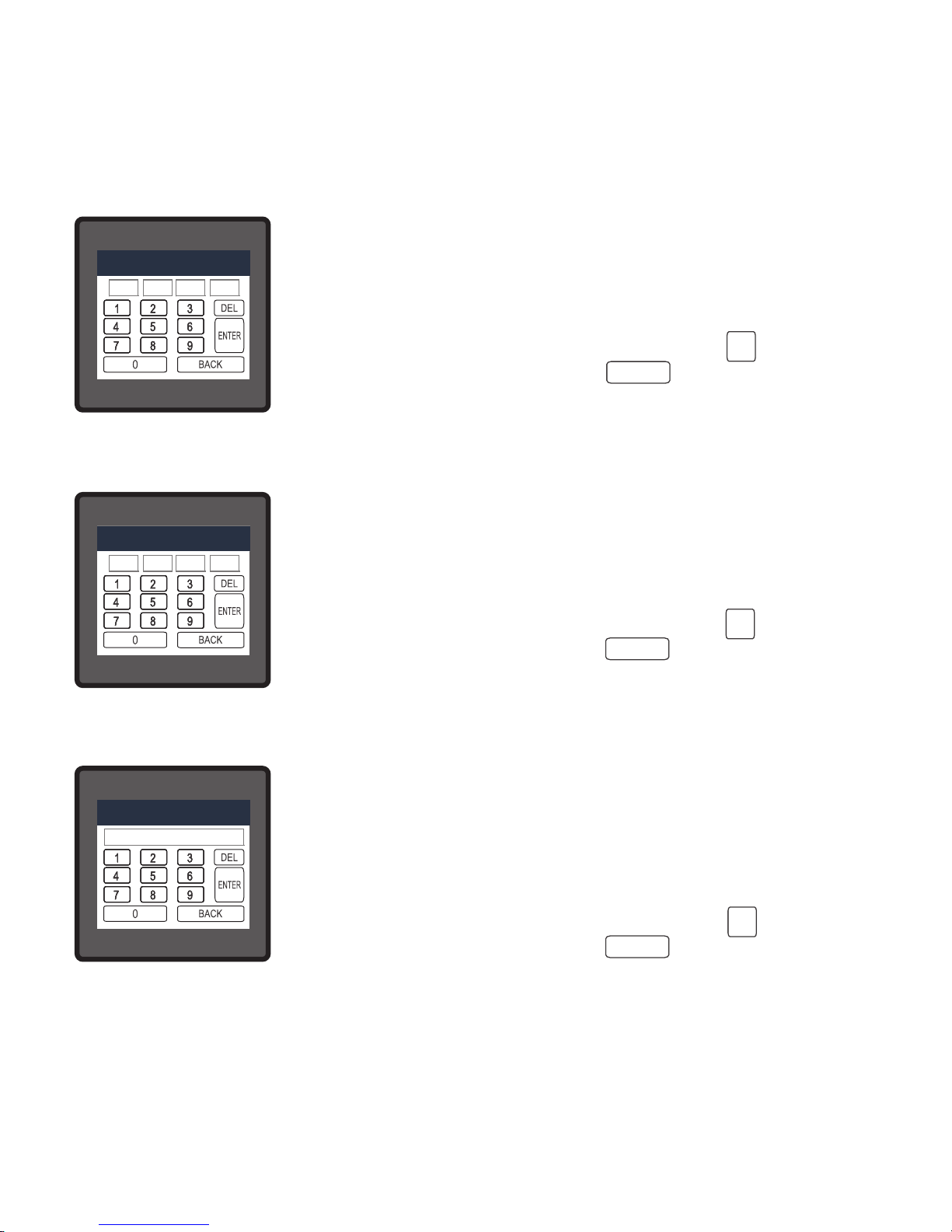

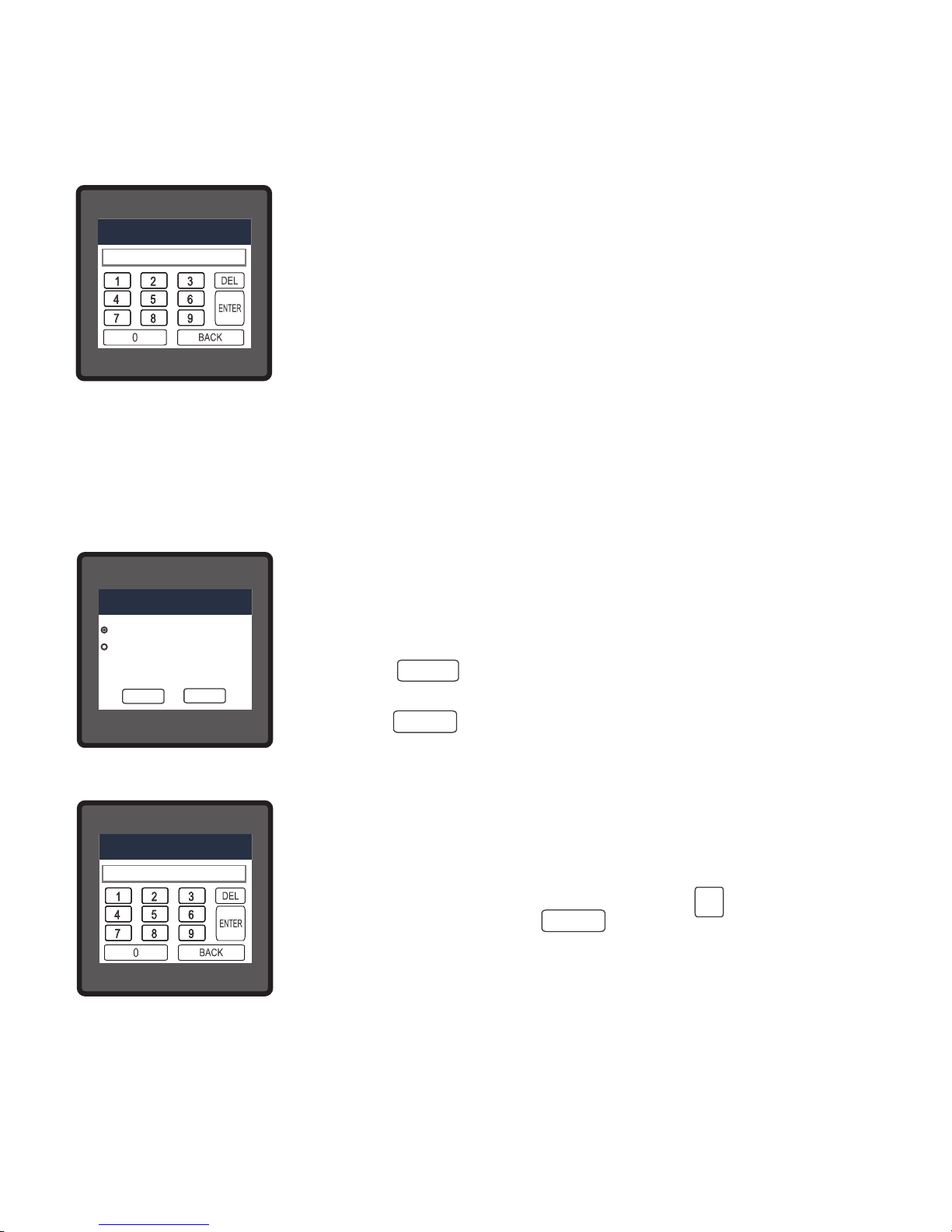

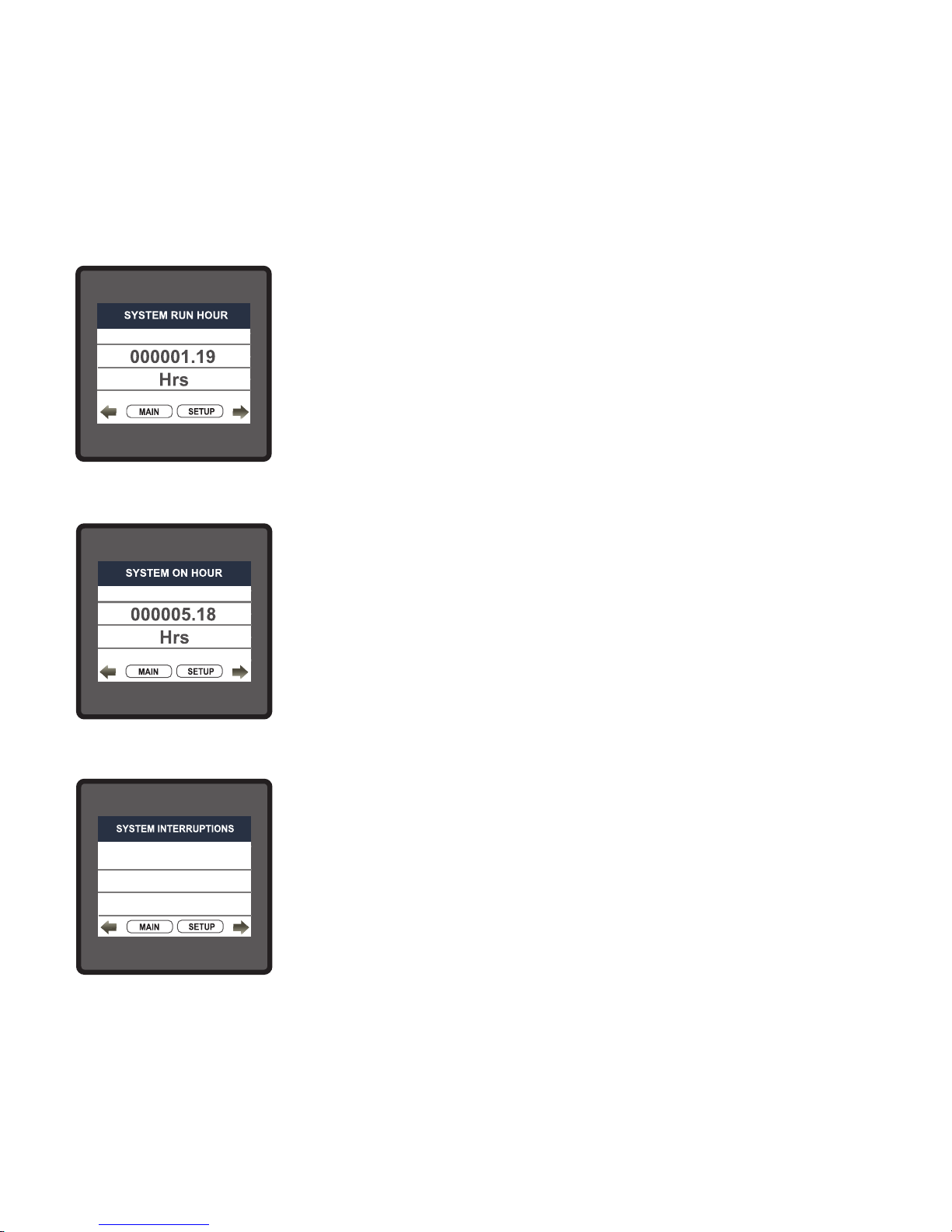

3.1. Password Protection

Password protection can be enabled to prevent unauthorised access to set-up screens, by

default password is “0000”.

Password protection is enabled by selecting any four digit number.

3. Programming

The following sections comprise step by step procedures for conguring the instrument for

individual user requirements. To access the set-up screens touch on the “ SETUP ” icon in

Main Menu. This will take the User into the Password Protection Entry Stage(Section 3.1).

After touching “ SETUP” icon Password protection screen is

displayed. Screen consists of 0 to 9 digit input keypad for entering the

password very similar to any calculator in touchscreen mobile.“Enter

Password” is displayed on screen at start so that user can enter

password using displayed keypad.

Touching “ key” will display 1 in display area, similarly user can

enter remaining 3 digits.

For deleting any digit while entering password, user can touch “ key”.

After entering the complete password user needs to conrm password by touching “ key’’.

DEL

ENTER

ENTER

1

If Entered password is correct then “Password Accepted” is displayed on screen & user will on

screen & user will enter into setup menu.

Password conrmed.

If Entered password is wrong then “Password Rejected” is displayed on screen & user need to

re-enter the password After wrong password is entered, user needs to touch “ key ” for

trying another password.

Password Incorrect.

12

Page 15

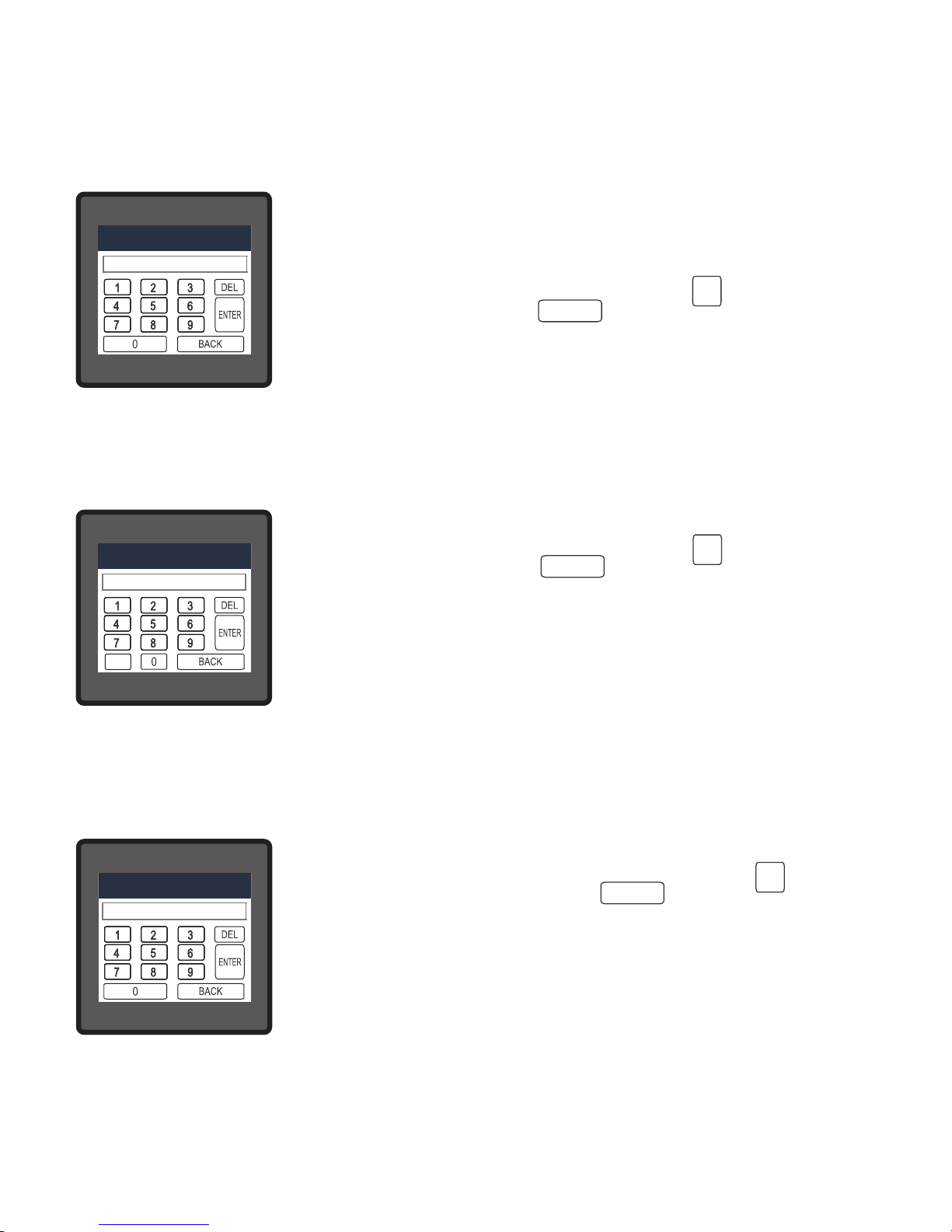

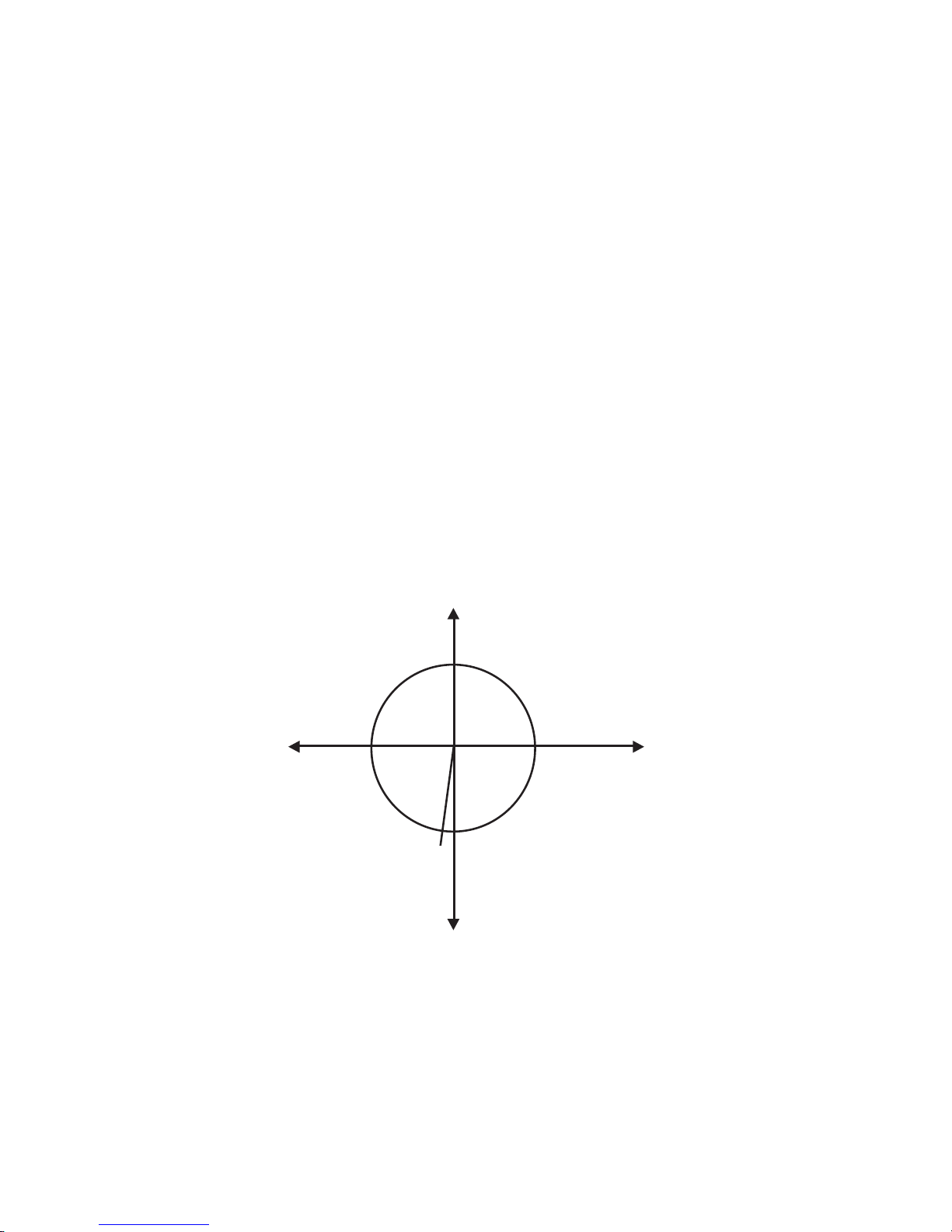

Change Password Option is the second last option in list of “SETUP”

submenu, so can be accessed by a simple touch on “ Change

Password” button.

In this screen user rst needs to enter the current password.

3.1.1 Change Password

After input of correct password,“PASSWORD ACCEPTED”is

displayed & now user can enter the new 4 digit password.

After entering new password user needs to touch “ key” to

conrm.

After conrming “PASSWORD CHANGED” is displayed on screen,

which ensures successful changing of the password.

New Password conrmed.

3.2 Menu selection.

After entering in the SUBMENU 6 - SETUP, user will be asked to enter password & after

input of correct password list of following parameters will be displayed on screen :-

ENTER

13

Page 16

Touching on SYSTEM PARAMETER will open the system parameters list screen.Then these

screens from particular parameter may be scrolled through one at a time in incremental order

by touching the “ key” and in decremental order by touching “ key” on given touch

screen.

3.2.1 System Parameters Selection

After entering in the “SYSTEM PARAMETERS”, List of following parameters will be displayed :-

3.2.1.1 SYSTEM TYPE

3.2.1.2 PT PRIMARY

3.2.1.3 PT SECONDARY

3.2.1.4 CT PRIMARY

3.2.1.5 CT SECONDARY

3.2.1.7 DEMAND INTEGRATION TIME

3.2.1.8 AUTO SCROLL

3.2.1.9 LOW CURRENT NOISE CUTOFF

3.2.3 RESET PARAMETERS

3.2.4 OUTPUT OPTIONS

3.2.1.11 ENERGY RESOLUTION

3.2.1.12 ENERGY DIGIT RESET COUNT

3.2.5 DATALOGGING OPTIONS

3.2.6 POWER QUALITY SETTINGS

3.2.7 DATE & TIME SETTINGS

3.2.10 FACTORY RESET

3.2.8 BRIGHTNESS & CONTRAST

3.2.9 RGB COLOR CODE

3.2.1.6 SYSTEM FREQUENCY

3.2.1.10 NUMBER OF POLES

3.2.1.13 ENERGY UPDATE RATE

3.2.1.14 METER VERSION

3.2.1 SYSTEM PARAMETERS

3.2.2 COMMUNICATION PARAMETERS

14

Page 17

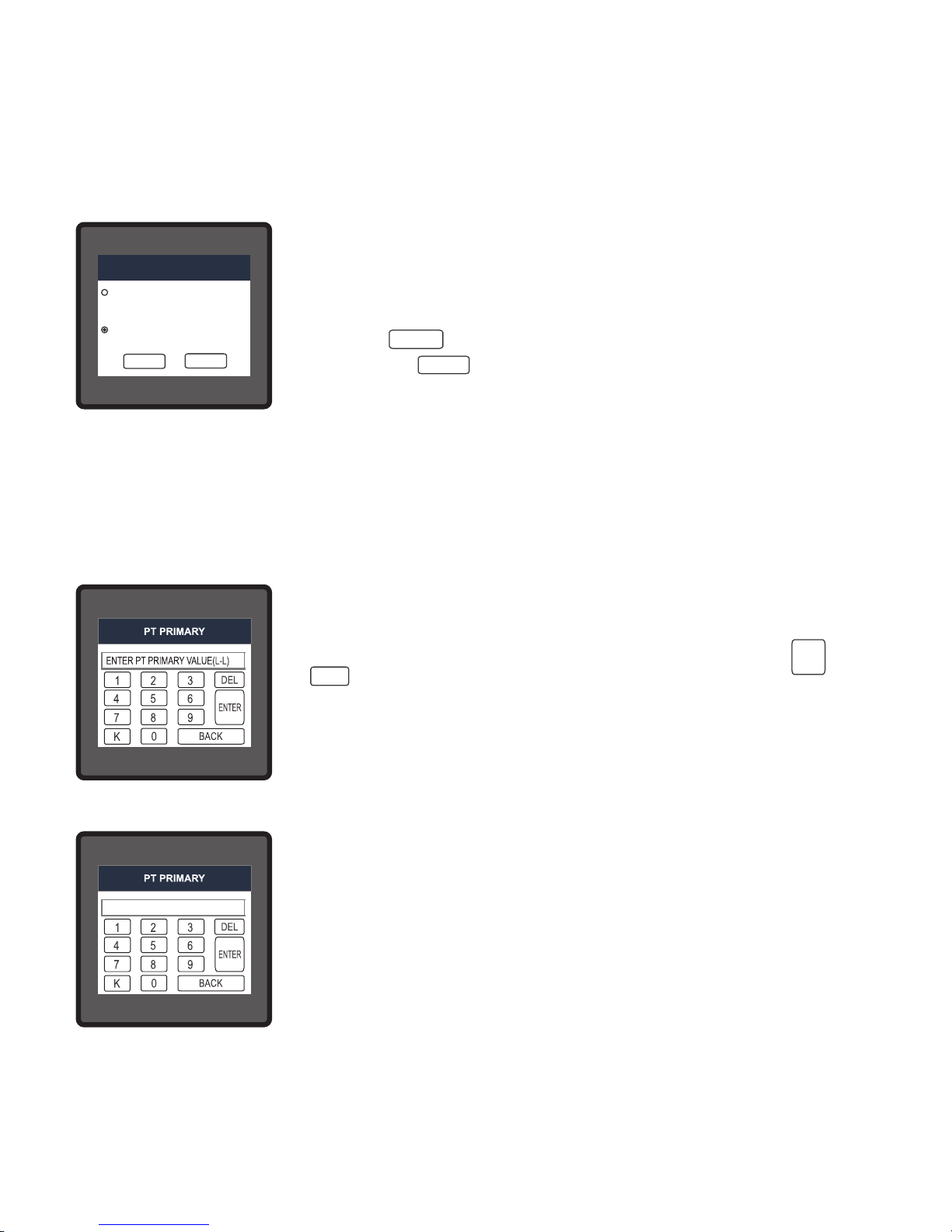

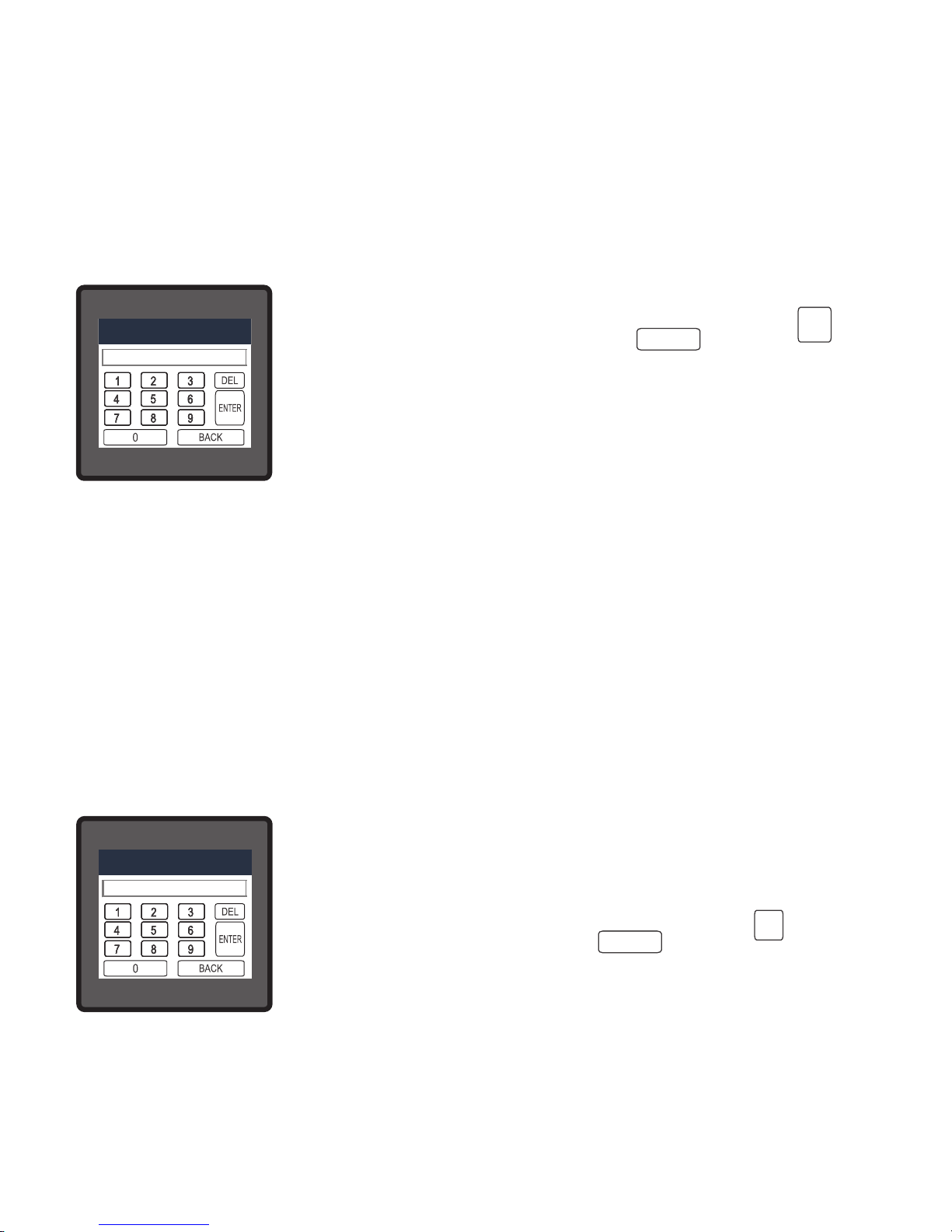

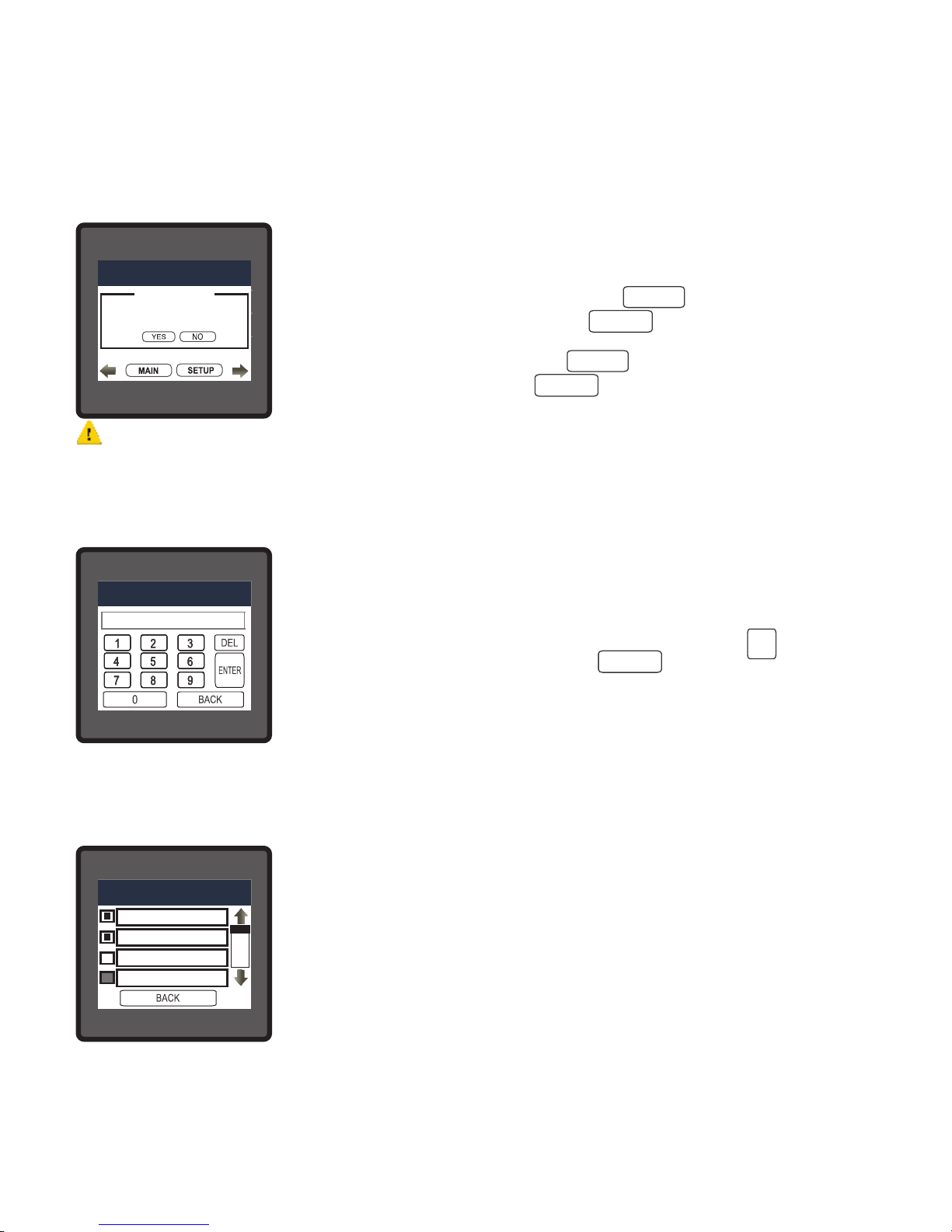

3.2.1.2 Potential Transformer Primary Value

The nominal full scale voltage will be displayed as Line to Line Voltages for 3 Phase 3 wire and

3 Phase 4 wire and 1 Phase 2 wire for Single Phase.

This screen can be accessed only from system parameters list menu.

Here again 0 to 9 digit input keypad is provided to set value of PT

Primary, & user can conrm this value with a simple touch “ key”.

“ key” is used to multiply value by 1000.

In case presently displayed Potential Transformer Primary value

together with the Current Transformer Primary value, previously set,

would result in a maximum power of greater than 666.6 MVA per

phase,”Invalid value” will be displayed. Then the valid range will be

displayed.

Valid range of PT primary setting value is

100V L-L to 692.8KV L-L.

If value outside the range is entered, It will display “INVALID VALUE”

followed by correct range of parameter.

Note : Changing PT Primary would erase the Sag and Swell data of

PQ events.

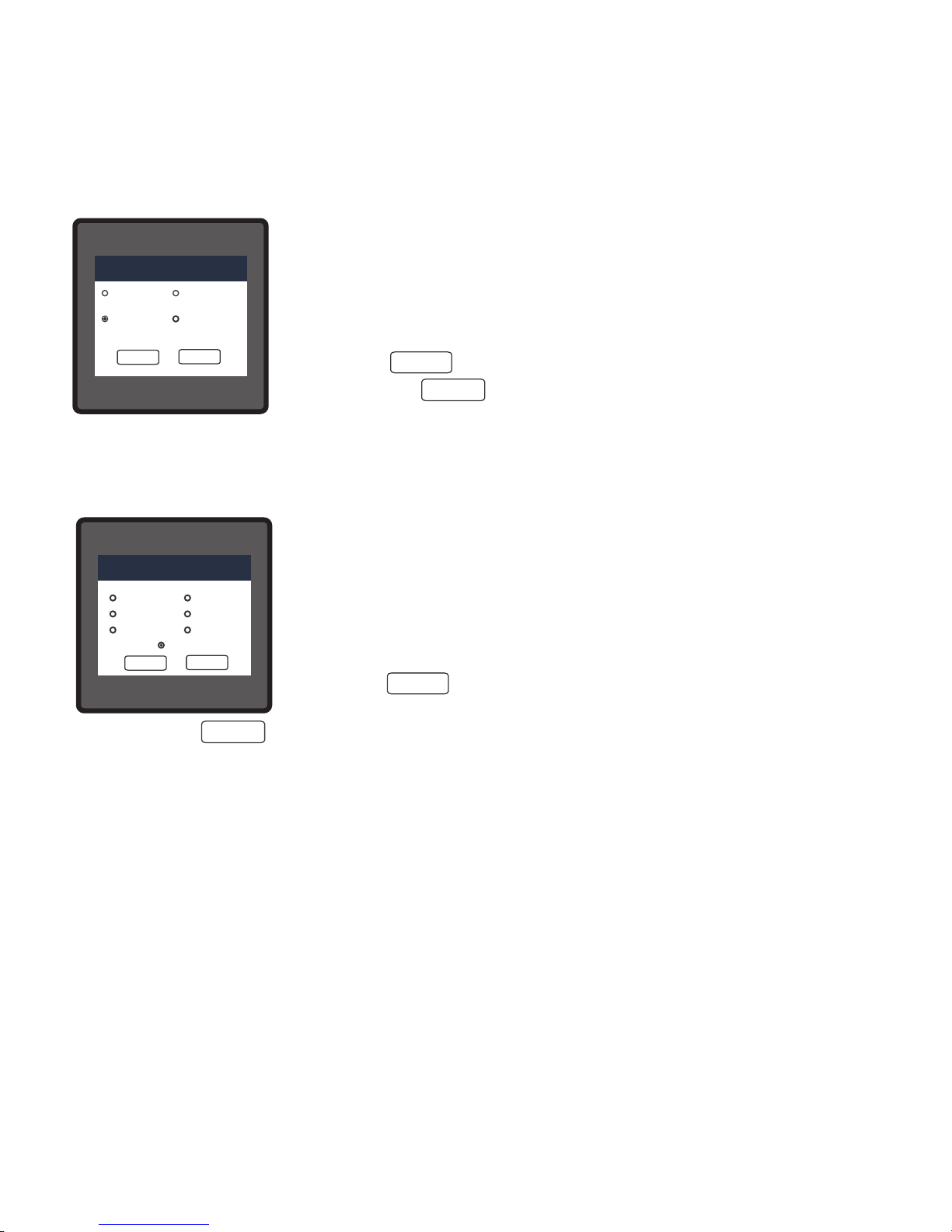

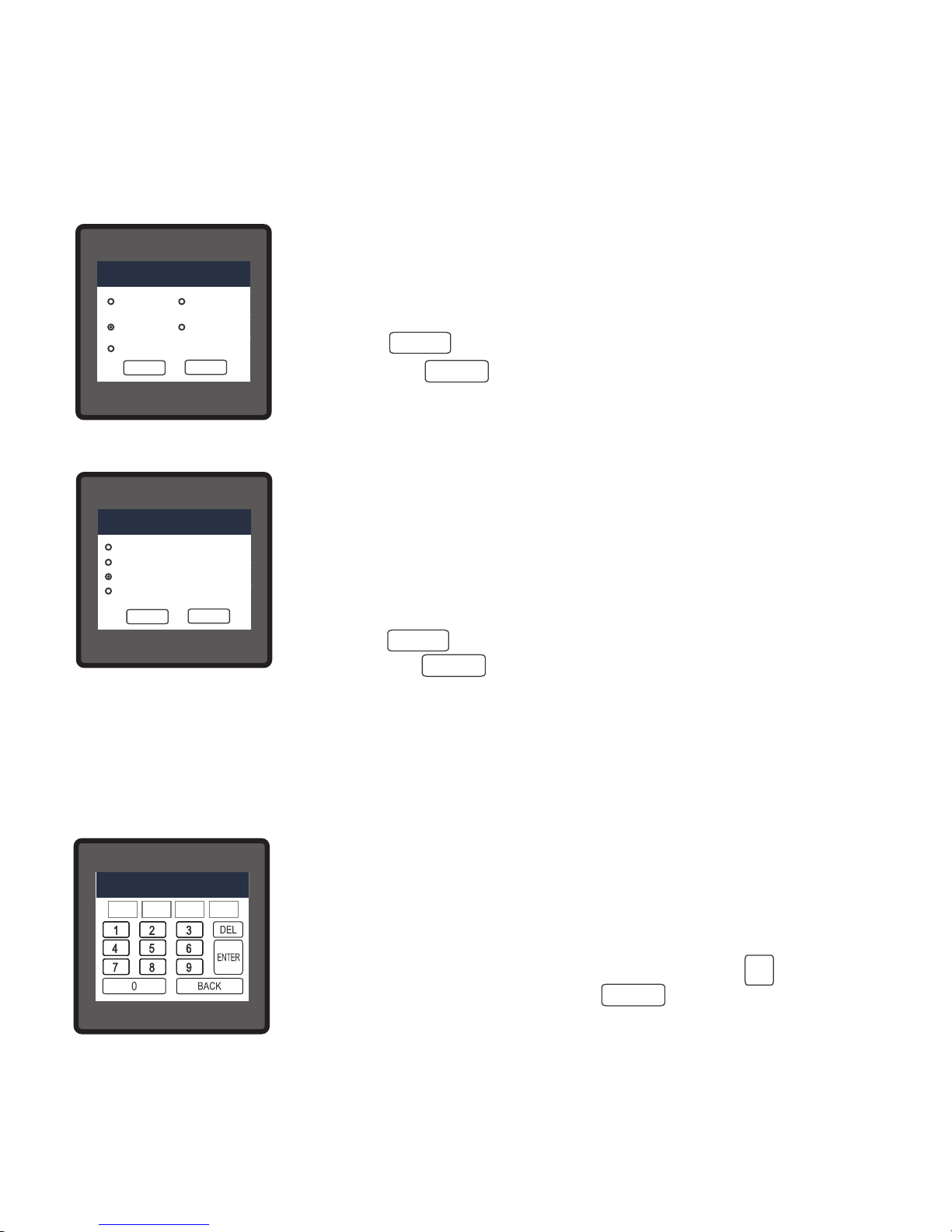

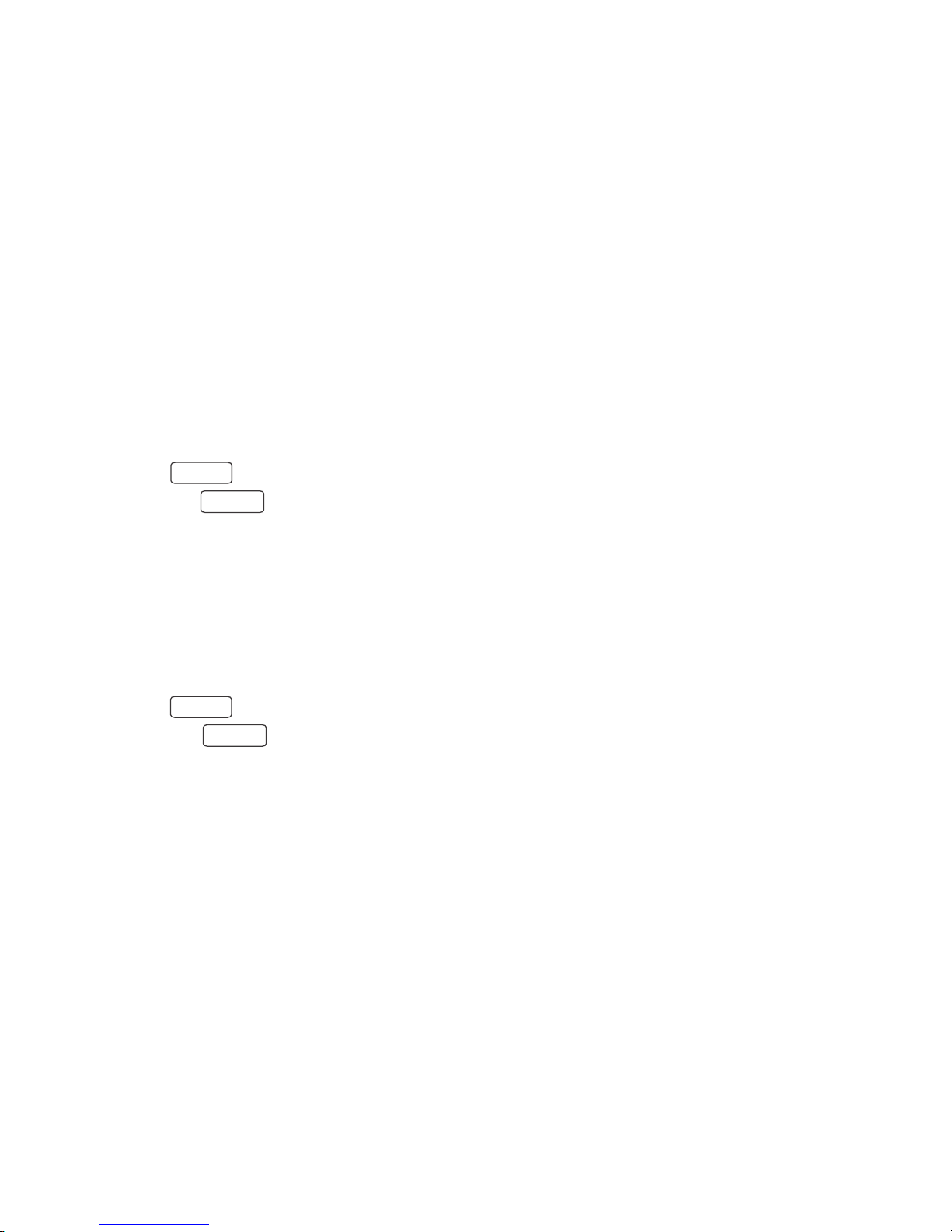

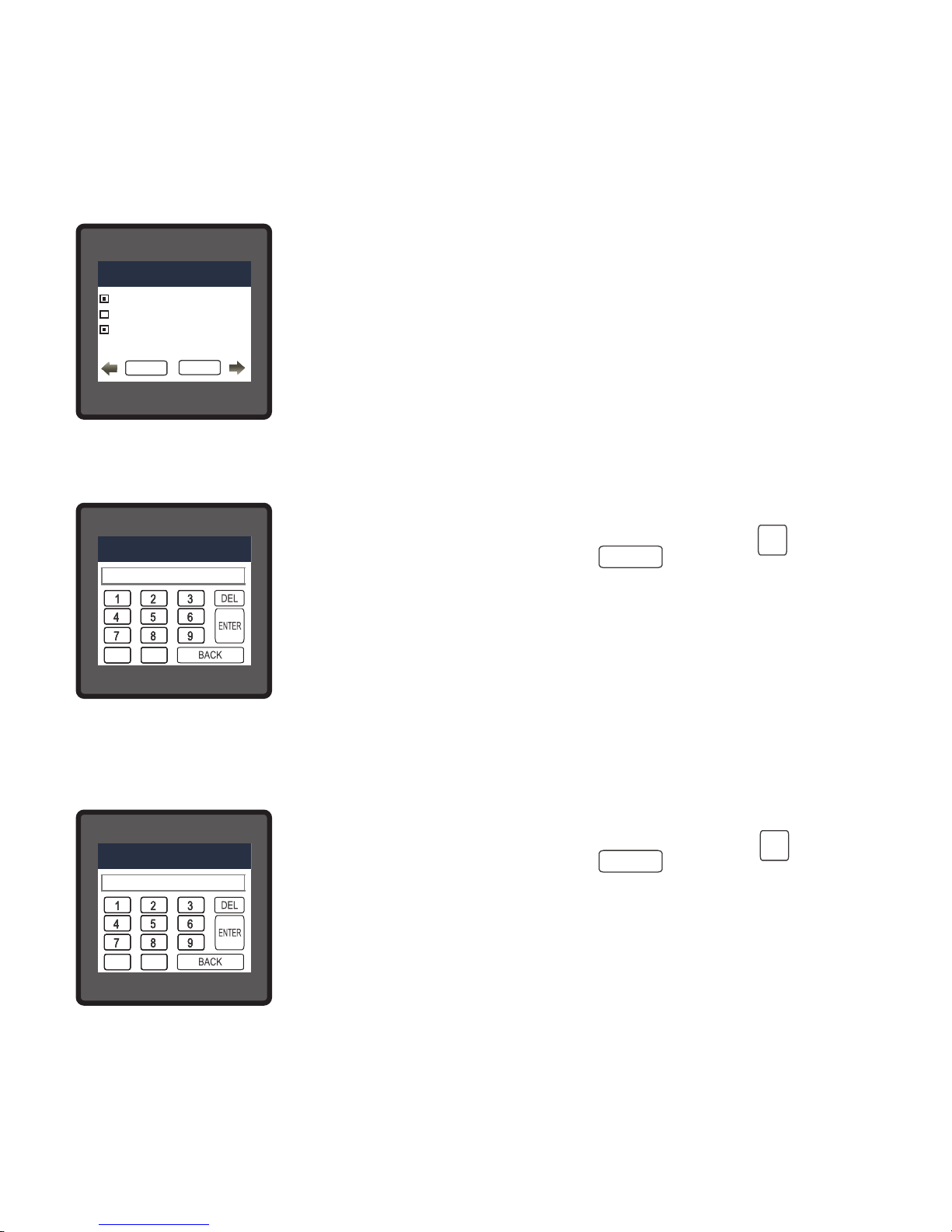

3.2.1.1 System Type

This screen is used to set the system type.

Two types: 3 phase 3 wire & 3 phase 4 wire system are displayed on

screen (for RM3440i). Touching radio button in front of particular type

will select that type.

Touch on “ key” will conrm the system type.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

Note : If system type is changed, relay parameter selection & analog output selection will be set

to NONE and all the PQ event data (sag/ swell/ overcurrent) would be erased.

SYSTEM TYPE

3-PHASE 4 WIRE

FOR 3 PHASE STAR CONNECTED LOAD

3-PHASE 3 WIRE

FOR 3 PHASE DELTA CONNECTED LOAD

OK

BACK

OK

BACK

VALID RANGE IS : 100.0 TO 692800

K

ENTER

15

Page 18

INVALID VALUE

PT SECONDARY

The Valid range of instrument is from 100 to 600V.

If value outside the range is entered, It will display “INVALID VALUE”

followed by correct range of parameter.

Note : Changing PT Secondary would erase the Sag and Swell data

of PQ events.

3.2.1.3 Potential Transformer secondary Value

The value must be set to the nominal full scale secondary voltage which will be obtained from

the the Transformer when the potential transformer(PT)primary is supplied with the voltage

dened in 3.2.1.2 potential transformer primary voltage. The ratio of full scale primary to full

scale secondary is dened as the transformer ratio.

This screen can be accessed only from system parameters list menu. Here again 0 to 9 digit

input keypad is provided to set value of PT Secondary, & user can conrm this value with a

simple touch on “ key”.

ENTER

3.2.1.4 Current Transformer Primary Value

The nominal Full Scale Current that will be displayed as the Line currents. This screen enables

the user to display the Line currents inclusive of any transformer ratios, the values displayed

representthe Current in Amps.

This screen can be accessed only from system parameters list menu.

Here again 0 to 9 digit input keypad is provided to set value of CT

Primary & user can conrm this value with a simple touch on “ key”

and “ key” is used to multiply value by 1000. In case presently

displayed Current Transformer Primary Value together with the

Potential Transformer Primary Value results in a maximum power of

greater than 666.6 MVA, “invalid value” will be displayed. Example: If

primary value of PT is set as 692.8kV L-L (max value) then primary

value of Current is restricted to 1157A.

ENTER CT PRIMARY VALUE

ENTER

K

CT PRIMARY

16

Page 19

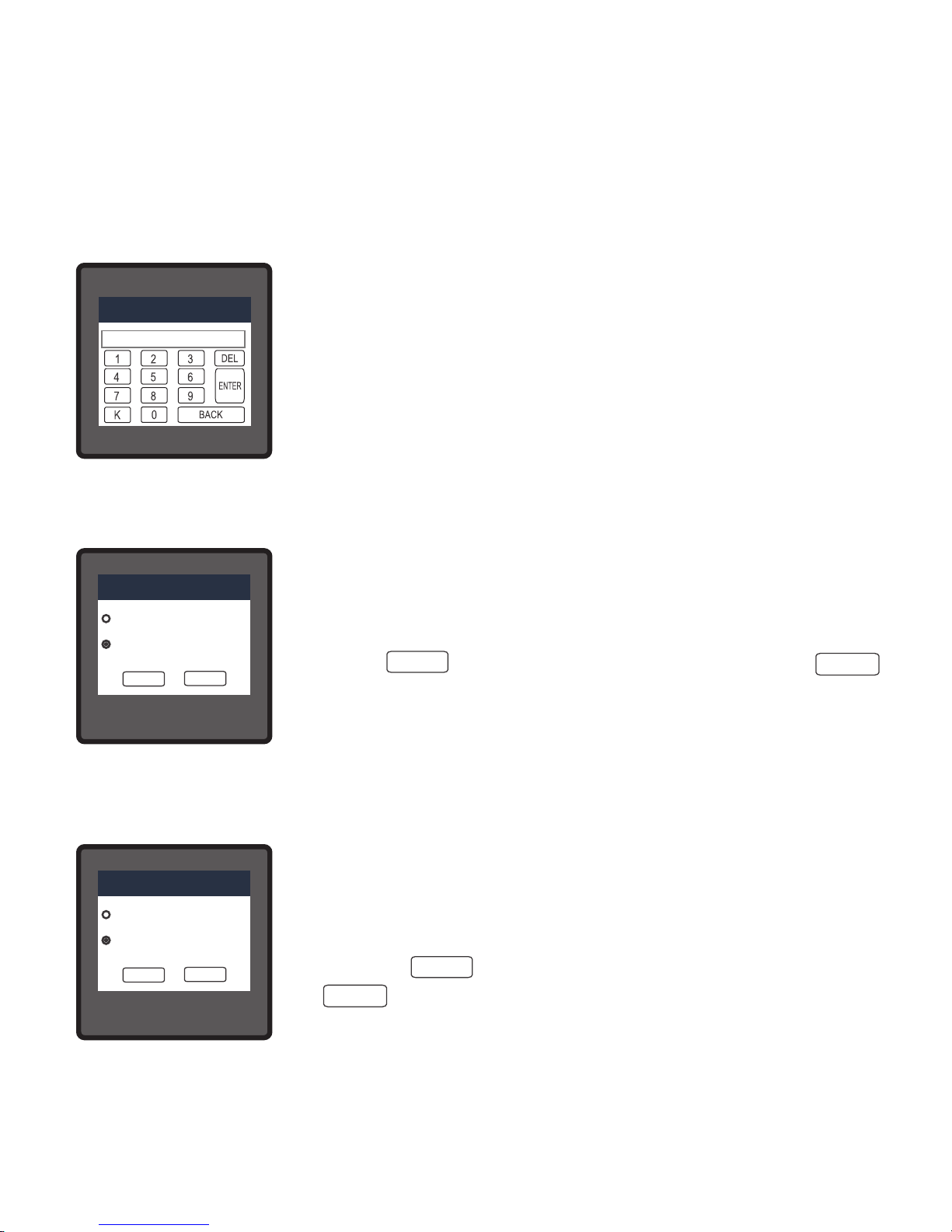

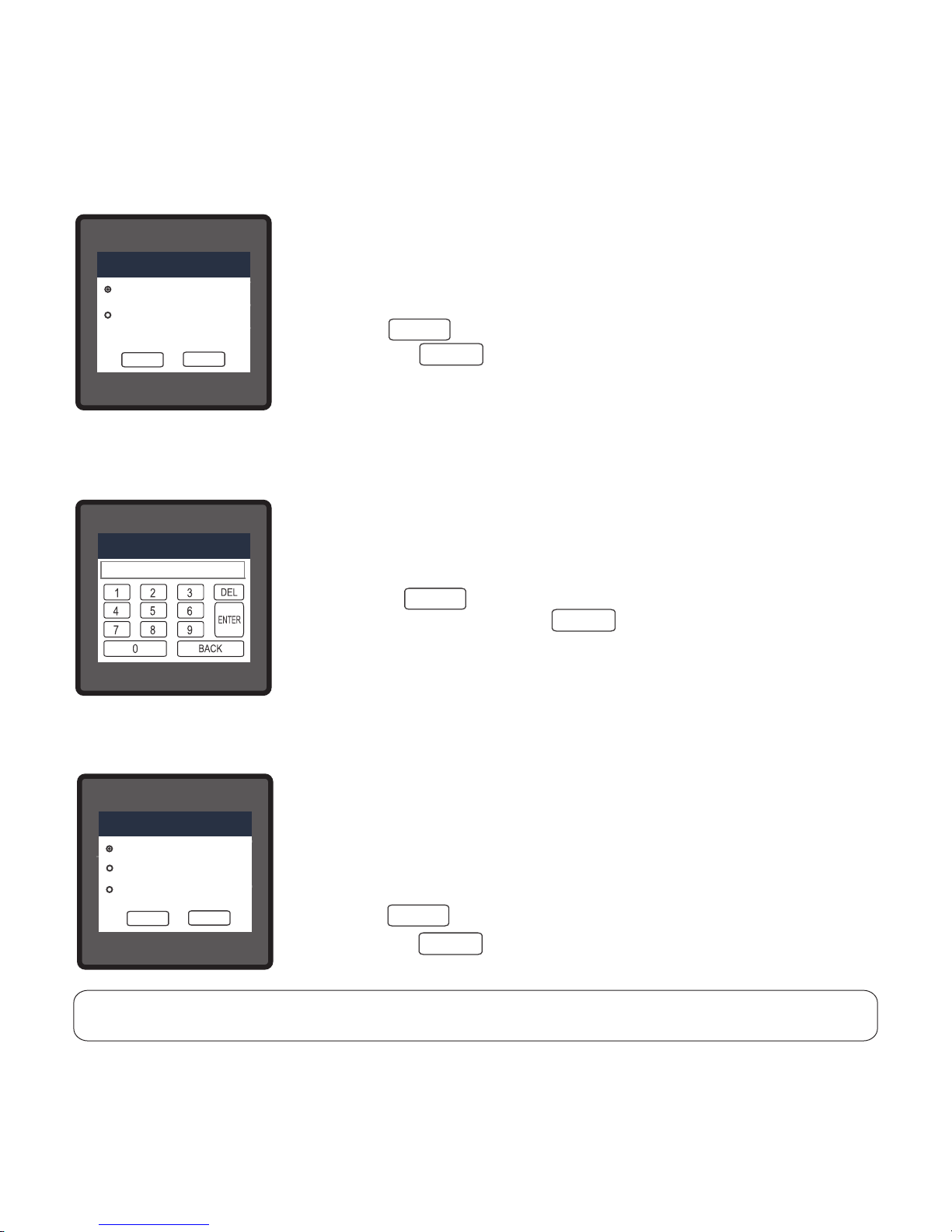

3.2.1.5 Current Transformer Secondary Value

This screen is used to set the secondary value for Current

Transformer. Two options: 1 AMPERE & 5 AMPERE are displayed on

screen. Touching radio button in front of particular option will select

that option.

Touch on “ key” will conrm the setting. Touching the “

key” will keep the old selected setting and will return to previous

menu.

Note : Changing CT Secondary would erase the Overcurrent data of

PQ events.

OK

OK

BACK

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

CT SECONDARY

1 AMPERE

5 AMPERE

OK

BACK

The “Maximum Power” restriction of 666.6 MVA refers to 120% of nominal current and 120% of

nominal voltage, i.e, 462.96 MVA nominal power per phase.

Valid range of CT primary setting value is from 1 to 9999. If value

outside the range is entered, It will display “INVALID VALUE” followed

by correct range of parameter.

Note : Changing CT Primary would erase the Overcurrent data of PQ

events.

INVALID VALUE

3.2.1.6 System Frequency

OK

OK

BACK

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

CT SECONDARY

1 AMPERE

5 AMPERE

OK

BACK

This screen is used to set the frequency of the input.

Two options : 50 & 60 Hz are displayed on screen.

Touching radio button in front of particular option will select that

option.

Touch on “ key” will confirm the setting. Touching the

“ key” will keep the old selected setting and will return to

previous screen.

CT PRIMARY

17

Page 20

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

CT SECONDARY

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VVVV

0.000

0.000

AUTO - SCROLL

ALL

VOLTAGE

POWER

NONE

SYSTEM

CURRENT

ENERGY

OK

BACK

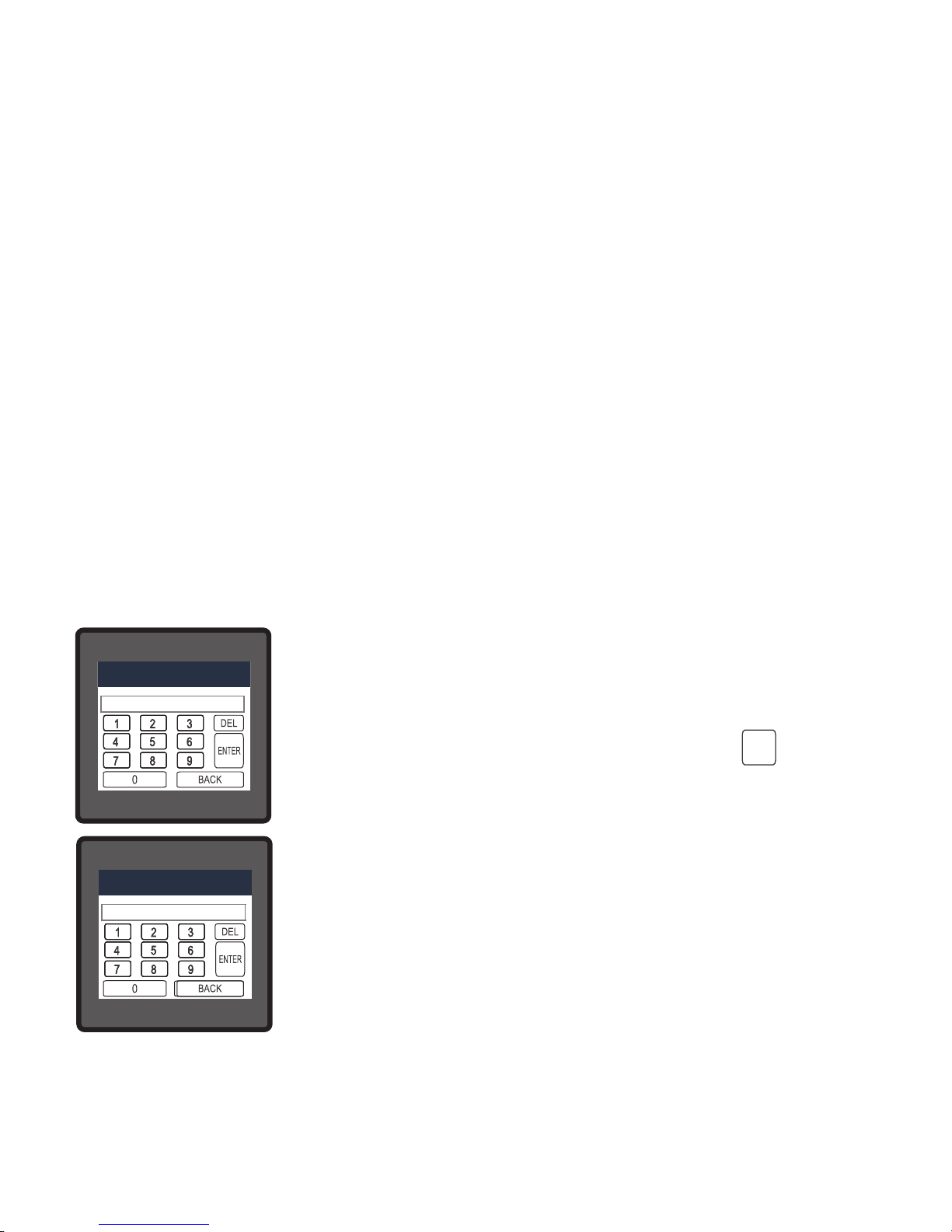

3.2.1.7 Demand Integration Time

This screen is used to set the period over which current and power

readings are to be integrated.

Four options: 8, 15, 20, 30 Minutes are displayed on screen.

Touching radio button in front of particular option will select that

option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

OK

OK

OK

OK

OK

BACK

BACK

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

0.000

0.000

DEMAND INTEGRATION TIME

8 MINUTES

15 MINUTES

20 MINUTES

30 MINUTES

MAINMAINMAINMAINMAINMAIN

OK

BACK

3.2.1.8 Auto Scrolling

This screen allows user to enable screen scrolling. Seven options :

ALL, SYSTEM, VOLTAGE, CURRENT, POWER, ENERGY & NONE

are displayed on screen. Touching radio button in front of particular

option will select that option. Selecting particular option means, only

screens which are under that submenu will be scrolled automatically.

Selecting NONE will disable Auto-Scroll.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will return to previous menu.

While in Auto-scrolling mode, touch sense for entire screen will be disabled except for the top

right most corner where “A” symbol would be displayed stating that meter is in Auto-scroll mode.

Touching on “A” will show two options “ON” and “OFF”. Touching on “ON” will continue auto

scrolling & touching on “OFF” will stop auto-scrolling & return to normal mode.

18

Page 21

BACK

OK

OK

3.2.1.10 Number of Poles

This screen enables to set No. of poles of a Generator of which RPM is to be measured and to

which the instrument is connected to monitor its parameters.

INVALID VALUE

NUMBER OF POLES

The valid range of number of poles is from 2 to 40.

If an odd value or a value outside the range is entered, It will display

“INVALID VALUE” followed by the correct range of parameter.

Touch on “ key” will conrm the setting and will return to

previous menu. Touching the “ key” will keep the old selected

setting.

3.2.1.9 Low Current noise cutoff

This screen allows the user to set Low noise current cutoff in mA.

Two options, 0 MILLI-AMPERE & 30 MILLI-AMPERE are displayed on

screen. Touching radio button in front of particular option will select

that option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LOW CURRENT NOISE CUTOFF

0 MILLI-AMPERE

30 MILLI-AMPERE

OK

BACK

BACK

OK

OK

BACK

OK

OK

depending as per the user’s requirement.

This setting is applicable for all types of energy.

Three options: WATT, KILO-WATT & MEGA-WATT are displayed on

screen. Touching radio button in front of particular option will select

that option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

3.2.1.11 Energy Resolution

This screen enable user to set energy in terms of Wh / kWh / MWh on Rs485 Output

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

ENERGY ON RS485

WATT (W)

KILO-WATT (KW)

MEGA-WATT (MW)

OK

BACK

Note :

Default value is set to ‘WATT’ i.e. Energy on Modbus will be in terms of

Wh/VArh/VAh respectively.

19

Page 22

3.2.1.12 Energy Digit Reset Count (Rollover Count)

This screen enables the user for setting maximum energy count after which energy will rollover

to zero. This rollover count values are 7, 8 and 9 Digits.

Touching radio button in front of particular option will select that

option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

OK

OK

BACK

Note :-

1) If Energy Resolution is set to MW & energy digit reset count is set to 9, Energy

screen on display will show “-------” i.e energy overow when energy crosses the

8 digit count.

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

ENERGY DIGIT RESET COUNT

7 DIGITS

9 DIGITS

8 DIGITS

OK

BACK

3.2.1.14 Meter Version

3.2.1.13 Energy Update Rate

This screen allows user to enter energy update rate in minutes. After entering particular value in

minutes, the energy will be updated on modbus location from 30145 to 30165 of 3X register and

40145 to 40165 of 4X register as per value that user has entered.

INVALID VALUE

ENERGY UPDATE RATE

BACK

OK

OK

The valid range of number of poles is from 1 to 60 minutes.

If a value outside the range is entered, It will display “INVALID

VALUE” followed by the correct range of parameter.

Touch on “ key” will conrm the setting and will return to

previous menu. Touching the “ key” will keep the old selected

setting.

If Energy Rate is set to 2 then energy will get stored after 2 minutes

on the modbus.

The meter version is available on the SYSTEM PARAMETERS screen as read only.

20

Page 23

3.2.2.1.1 RS485 Address Setting

This screen applies to the RS 485 output only. This screen allows the

user to set RS485 address parameter for the instrument. This screen

can be accessed only from Communication Parameters List menu.

Here again 0 to 9 digit input keypad is provided to set RS485 address

& user can conrm this value with a simple touch on “ key”.

The range of allowable address is 1 to 247.

If value outside the range is entered, it will display “INVALID VALUE”

followed by the correct range of parameter.

3.2.2.1.3 RS485 PARITY

3.2.2.1.1 RS485 ADDRESS

3.2.2.1.2 RS485 BAUD RATE

3.2.2 Communication Parameter Selection :

After entering in the “COMMUNICATION PARAMETERS” list of following parameters will be

displayed

ENTER RS485 ADDRESS

RS485 ADDRESS

RS485 ADDRESS

INVALID VALUE

3.2.2.1 MODBUS PARAMETERS

3.2.2.2.3 DEFAULT GATEWAY

3.2.2.2.1 IP ADDRESS

3.2.2.2.2 SUBNET MASK

3.2.2.2 ETHERNET PARAMETERS

3.2.2.2.4 SERVER PORT

3.2.2.1 Modbus Parameters Setting

ENTER

21

Page 24

3.2.2.1.2 RS 485 Baud Rate

This screen allows the user to set Baud Rate of RS 485 port.

Five options: 2400, 4800, 9600, 19200, 57600 Bauds are displayed

on screen. Touching radio button in front of particular option will

select that option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and

will Return to previous menu.

BACK

OK

OK

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

CT SECONDARY

5 AMPERE

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

VL2

V

0.000

0.000

0.000

RS485 BAUD RATE

57600

38400

4800

9600

19200

OK

BACK

3.2.2.1.3 RS 485 Parity & Stop bit Selection

This screen allows the user to set Parity & number of stop bits.

Four options: ODD PARITY WITH ONE STOP BIT, NO PARITY WITH

ONE STOP BIT, NO PARITY WITH TWO STOP BITS, EVEN PARITY

WITH ONE STOP BIT are displayed on screen.

Touching radio buttion in front of particular option will select that

option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

RS485 PARITY & STOP BITS

ODD PARITY WITH ONE STOP BIT

NO PARITY WITH ONE STOP BIT

NO PARITY WITH TWO STOP BIT

EVEN PARITY WITH ONE STOP BIT

OK

BACK

OK

OK

BACK

3.2.2.2.1 IP Address Setting

192

IP ADDRESS

ENTER

3.2.2.2 Ethernet Parameters Setting

These settings are available only when the addon Ehernet card is connected to the instrument.

168 001 037

The user can enter a valid IP Address value for each octet, i.e.

0 to 255.

Any value other than these would be indicated red and the previous

value will get restored.

The user can conrm the address by touching the “ key” and

cancel the change by touching the “ key”.

BACK

22

Page 25

3.2.2.2.2 Subnet Mask Setting

255

SUBNET MASK

ENTER

255 255 000

The user can enter a valid Subnet Mask value for each octet, i.e.

0 to 255.

Any value other than these would be indicated red and the previous

value will get restored.

The user can conrm the setting by touching the “ key” and

cancel the change by touching the “ key”.

BACK

3.2.2.2.3 Default Gateway Setting

192

DEFAULT GATEWAY

ENTER

168 001 001

The user can enter a valid Default Gateway value for each octet, i.e.

0 to 255.

Any value other than these would be indicated red and the previous

value will get restored.

The user can conrm the setting by touching the “ key” and

cancel the change by touching the “ key”.

BACK

3.2.2.2.4 Server Port Setting

INVALID VALUE

SERVER PORT

ENTER

This screen allows the user to enter the server port for the IP

settings.

The allowable range for server port value is 0 to 9999.

If value outside the range is entered, it will display “INVALID VALUE”

followed by the correct range of parameter.

The user can conrm the value by touching the “ key” and

cancel the change by touching the “ key”.

BACK

23

Page 26

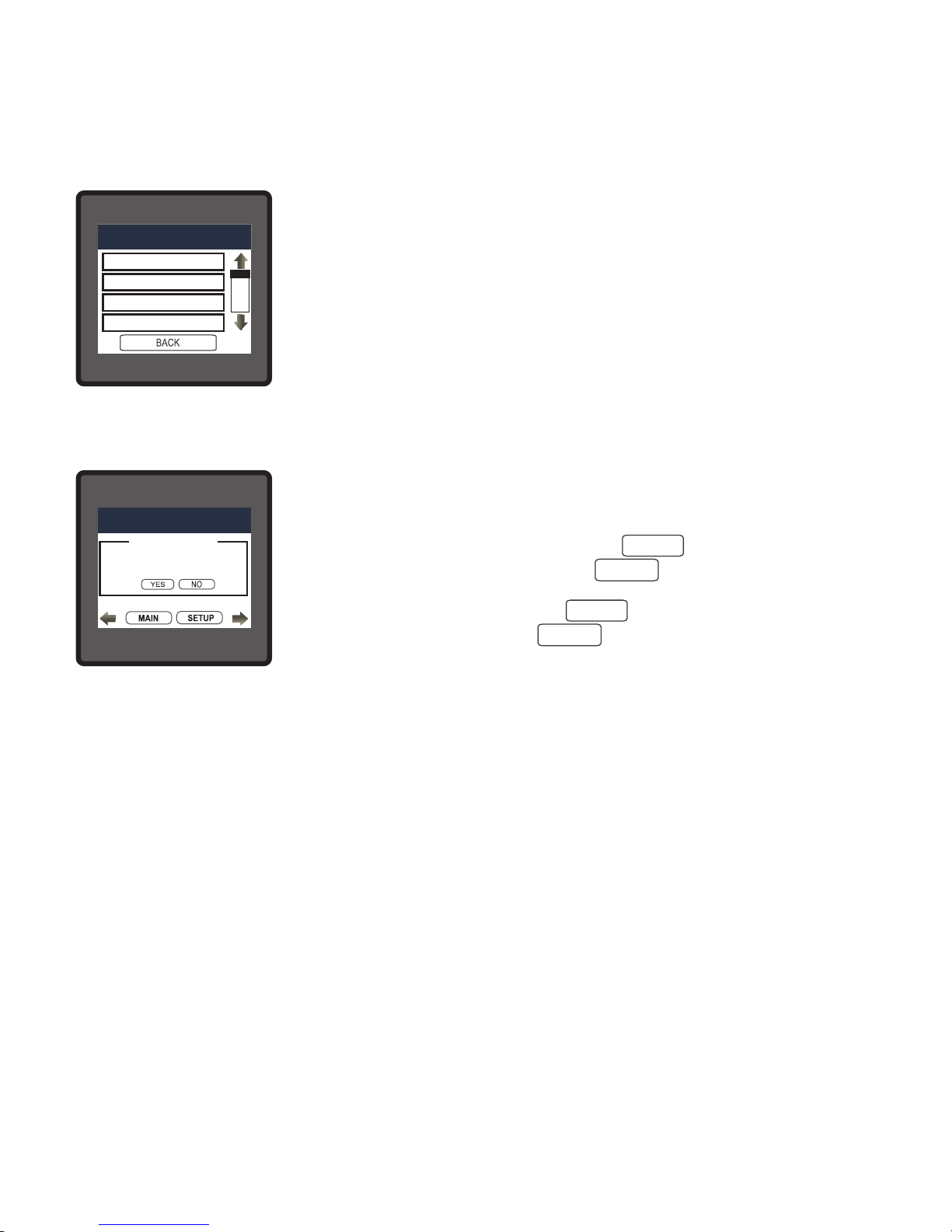

3.2.3.1 Resetting Parameter

These screens allow the users to reset all the parameters eg:Energy, Min, Max, Demand, Run hour, On hour, No. of Interrupts, Sag

Data, Swell Data, Overcurrent Data.

Touching “ down” key scrolls list in upward direction. This screen is

displayed after repeatedly touching “ down” key.

Touching “ Up” key scrolls list in downward direction.

User needs to touch on the specic parameter to be reset.

3.2.3 Reset Parameter Selection:-

Touching on any parameter will display the conrmation dialog, now a

touch on “ key” will conrm the resetting of that particular

Parameter.

Touching on “ key” will move back to Reset parameters menu.

For example resetting All Energies will display a conrmation dialog

as shown in the screen beside. User can reset other parameters in

similar manner

YES

NO

24

Page 27

3.2.4. Output Option selection menu

After entering in the “OUTPUT OPTIONS”, List of following parameters will be displayed :-

3.2.4.1 RELAY-1

3.2.4.2 RELAY-2

3.2.4.3 ANALOG-1

3.2.4.4 ANALOG-2

3.2.4.1 Relay1 output Selection menu

This screen applies to the Relay1 Output option Selection .

Four options : PULSE OUTPUT, LIMIT OUTPUT, TIMER & RTC

RELAY displayed on screen.

Touching any option will open screens of parameters related to that

option.

Touch on “ key” will take back to Output Options

screen.

3.2.4.1.1 Pulse output

After entering in the “PULSE OUTPUT”, List of following parameters will be displayed :-

3.2.4.1.1.1 ENERGY

3.2.4.1.1.2 PULSE DURATION

3.2.4.1.1.3 PULSE RATE

These settings are used to assign Relay1 in Pulse output mode.

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

0.000

0.000

RELAY-1

PULSE OUTPUT

LIMIT OUTPUT

OUTPUT OPTIONS

OUTPUT OPTIONS

TIMER OUTPUT

RTC OUTPUT

25

Page 28

3.2.4.1.1.1 Assignment of Energy to pulse output (Relay 1) :

This screen allows the user to assign energy to pulse output (for Relay 1)

Following six options are displayed: Import Energy ( Active ) Export Energy ( Active )

Capacitive Energy (Reactive) Inductive Energy (Reactive)

Apparent Energy

Touching radio button in front of any particular option will select that

option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

3.2.4.1.1.2 Pulse Duration Selection:

This screen applies only to the Pulsed output mode of both the relays.

This screen allows the user to set Relay energisation time in

milliseconds.

Three options: 60, 100, 200 ms are displayed on screen. Touching

radio button in front of particular option will select that option.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

3.2.4.1.1.3 Pulse Rate

This screen applies only to the Pulsed output mode of both the relays.

The screen allows user to set the energy pulse rate divisor.

Divisor values can be selected through 1,10, 100,1000.Touching radio

button in front of particular value will select that value.

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will

return to previous menu.

Pulse rate divisor is set to 1, when Energy on Rs485 is set to kWh or

MWh.

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

V

VVV

0.000

0.000

RELAY-1 PULSE RATE DIVISOR

1

10

100

1000

OK

BACK

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

RELAY-1 PULSE DURATION

60 MILLI-SECONDS

100 MILLI-SECONDS

200 MILLI-SECONDS

OK

BACK

OK

OK

OK

OK

OK

OK

BACK

BACK

BACK

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2

VL2

VL2

RELAY-1 ENERGY ASSIGNMENT

APPARENT ENERGY

IMPORT ENERGY(ACTIVE)

EXPORT ENERGY(ACTIVE)

CAPACITIVE ENERGY(REACTIVE)

INDUCTIVE ENERGY(REACTIVE)

OK

BACK

26

Page 29

3.2.4.1.2 Limit output

This screen is for Limit output mode selection. It allows the user to set Limit output

corresponding measured value. After entering in Limit Output rst time(was disabled previously),

only “PARAMETER:” is displayed on screen. Now a simple touch on “PARAMETER:” will open

list of parameters, Refer TABLE 2 “Parameter for Analog & Limit output” for assignment. Now

after assignment of any parameter, list of following setting parameters will be displayed:-

3.2.4.1.2.1 LIMIT OUTPUT PARAMETER

3.2.4.1.2.2 ENERGY COUNT CONFIG

3.2.4.1.2.3 ENERGY TRIP POINT

3.2.4.1.2.4 ENERGY COUNT ON DELAY

3.2.4.1.2.5 PARAMETER CONFIG

3.2.4.1.2.6 TRIP POINT

3.2.4.1.2.1 Limit Parameter selection

This option allows the user to set Relay1 limit to corresponding measured parameter. A simple

touch on “PARAMETER” row will open screen having list of parameters. (Refer TABLE 2

“Parameters for Analog & Limit output”)

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will return to previous menu.

BACK

OK

OK

3.2.4.1.2.7 HYSTERESIS

3.2.4.1.2.8 ENERGIZING DELAY

3.2.4.1.2.9 DE-ENERGIZING DELAY

27

Page 30

Selecting Active Import/ Active Export/ Capacitive/ Inductive/ Apparent

Energy as Limit Output Parameter (see Section 3.2.4.1.2.1) allows the

user select one of the following configurations:

ENERGIZED RELAY (To Energize the Relay)

DE-ENERGIZED RELAY (To De-Energized the Relay)

Touch on “ key” will conrm the setting and take back to the

previous screen.

Touch on “ key” will take back to the previous screen.

3.2.4.1.2.2 Energy Count Conguration

3.2.4.1.2.3 Energy Trip Point

This screen is used to trip the relay using the energy count.

The relay trips after the lapse of “ON Delay” time (see Section

3.2.4.1.2.4) from the moment the energy count reaches the value of

Energy Trip Point set by the user in addition to its value at the

moment the Energy Trip Point is set.

Example: if the value set for Energy Trip Point is 888 and the

value of the corresponding parameter at the moment this value is set

is 1077, then the relay will trip after x sec of the moment the value of

the parameter becomes 1965 (= 1077 + 888), where x is the ON

Delay (see Section 3.2.4.1.2.4).

Caution:Once the relay has tripped, then to reactivate the Energy Tripping function,

the user has to either reset the energy or re-enter the energy count.

ENTER

BACK

Here 0 to 9 digit input keypad is provided to set the Energy Trip Point

& user can confirm this value with a simple touch on “ key”. and

cancel the change by touching the “ key”.

The valid range is 10 to 9999999.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER TRIP POINT

RELAY-1 TRIP POINT

INVALID VALUE

RELAY-1 TRIP POINT

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

RELAY-1 CONFIGURATION

ENERGIZED RELAY

DE-ENERGIZED RELAY

OK

BACK

OK

OK

BACK

This screen is used to set the Limit Configuration for Energy Count.

28

Page 31

3.2.4.1.2.4 Energy Count ON Delay

Here 0 to 9 digit input keypad is provided to set the Energy Count On

Delay & user can confirm this value with a simple touch on “ key”.

and cancel the change by touching the “ key”.

The valid range is 1 to 9999 seconds.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

Selecting Limit Output Parameter (see Section 3.2.4.1.2.1) other than

Active Import/ Active Export/ Capacitive/ Inductive/ Apparent Energy

allows the user select one of the following configurations:

High Alarm & Energized Relay

High Alarm & De-Energized Relay

Low Alarm & Energized Relay

Low Alarm & De-Energized Relay

3.2.4.1.2.5 Parameter Conguration

ENTER

BACK

SET ON DELAY IN SEC

RELAY-1 ON DELAY

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

RELAY-1 CONFIGURATION

OK

BACK

HIGH ALARM & DE-ENERGIZED RELAY

LOW ALARM & ENERGIZED RELAY

HIGH ALARM & ENERGIZED RELAY

LOW ALARM & DE-ENERGIZED RELAY

OK

OK

BACK

Touch on “ key” will conrm the setting and take back to the previous screen.

Touch on “ key” will take back to the previous screen.

(For details refer to section 9.2)

3.2.4.1.2.6 Trip Point

This screen applies to the Trip point selection for parameters other than Active Import/ Active

Export/ Capacitive/ Inductive/ Apparent Energy selected in Section 3.2.4.1.2.1. It allows the

user to set Trip point for instruments.

This screen allows the user to set ON Delay time in seconds for Relay Limit Assigned

Parameter. Refer Section 3.2.4.1.2.3 for details.

29

Page 32

The allowable range is 10% to 120% for High Alarm, 10% to 100%

for Low Alarm (refer TABLE 2).

Here 0 to 9 digit input keypad is provided to set the Trip Point & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

If value outside the range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER TRIP POINT IN %

RELAY-1 TRIP POINT

ENTER

BACK

3.2.4.1.2.7 Hysteresis

Here 0 to 9 digit input keypad is provided to set the Hysteresis & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

The allowable range is 0.5% to 50.0 % of Trip point.

If value outside the range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

(For details refer to section 9.2)

3.2.4.1.2.8 Energizing Delay

This screen allows the user to set Energizing Delay time in seconds for Relay Limit Assigned

Parameters.

SET HYSTERESIS IN %

RELAY-1 HYSTERESIS

.

ENTER

BACK

Here 0 to 9 digit input keypad is provided to set the Energizing Delay

& user can confirm this value with a simple touch on “ key”. and

cancel the change by touching the “ key”.

The allowable range is 0 to 9999 seconds.

If value outside the range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

(For details refer to section 9.2)

ENTER

BACK

SET ENERGIZING DELAY IN SEC

RELAY-1 ENERGIZING DELAY

This screen applies to the Hysteresis selection. This screen allows the user to set Hysteresis for

relay output.

30

Page 33

3.2.4.1.2.9 De-Energizing Delay

This screen allows the user to set De-Energizing Delay time in seconds for Relay Limit

Assigned Parameters.

Here 0 to 9 digit input keypad is provided to set the De-Energizing

delay & user can confirm this value with a simple touch on “ key”.

and cancel the change by touching the “ key”.

The allowable range is 0 to 9999 seconds.

If value outside the range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

(For details refer to section 9.2)

SET DE-ENERGIZING DELAY IN SEC

RELAY-1 DE-ENERGIZING DELAY

ENTER

BACK

3.2.4.1.3 Timer Output

After entering in the “TIMER OUTPUT”, List of following parameters will be displayed :-

3.2.4.1.3.1 NUMBER OF CYCLES

3.2.4.1.3.2 TIMER CONFIGURATION

3.2.4.1.3.3 ON DELAY

These settings are used to assign Relay1 in Timer output mode.

3.2.4.1.3.4 OFF DELAY

3.2.4.1.3.1 Number of Cycles

The value decides how many times the timer will repeat the switching

after it has been started in the timer based relay output option.

Here 0 to 9 digit input keypad is provided to set the No. of Cycles &

user can confirm this value with a simple touch on “ key”. and

cancel the change by touching the “ key”.

The value for this parameter can range from 0000 to 9999.

ENTER THE NO. OF CYCLES

RELAY-1 NO. OF CYCLES

ENTER

BACK

31

Page 34

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

If the value is set as 0000, the timer will keep repeating the cycles

until 9999 cycles are complete or the timer is stopped by the user.

Refer Section 9.3 for more details.

INVALID VALUE

RELAY-1 NO. OF CYCLES

Note: 1) To turn ON the relay in timer mode, visit “TIMER STATUS” submenu of SYSTEM

submenu in measurement screens.

2) The live status of No. of Cycles, ON & OFF delay is aslo available to the user in “TIMER 1”

and “TIMER 2” submenu of SYSTEM submenu in measurement screens for relay 1 and relay 2,

respectively.

3.2.4.1.3.2 Timer Configuration

The option decides the relay configuration for timer output. Two

options are available:

1. ENERGIZED RELAY: Energize on start

2. DE-ENERGIZED RELAY : De-energize on start.

Touch on “ key” will conrm the setting and take back to the

previous screen.

Touch on “ key” will take back to the previous screen.

3.2.4.1.3.3 On Delay

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

RELAY-1 TIMER CONFIGURATION

ENERGIZED RELAY

DE-ENERGIZED RELAY

OK

BACK

OK

OK

BACK

The value decides the time in seconds taken by the relay in timer

configuration before tripping after it is started.

Here 0 to 9 digit input keypad is provided to set the On Delay & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

The valid range is 1 to 9999 seconds.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

SET ON DELAY IN SEC

RELAY-1 TIMER ON DELAY

32

Page 35

3.2.4.1.3.4 Off Delay

Here 0 to 9 digit input keypad is provided to set the Off Delay & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

The valid range is 1 to 9999 seconds.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

SET OFF DELAY IN SEC

RELAY-1 TIMER OFF DELAY

3.2.4.1.4.1 Weekdays Selection

This screen allows user to select the days of the week on which the

relay behaves as configured for RTC Relay settings.

Touch on “ key” will conrm the setting and take back to the

previous screen.

Touch on “ key” will take back to the previous screen.

3.2.4.1.4 RTC Output

After entering in the “RTC OUTPUT”, List of following parameters will be displayed :-

3.2.4.1.4.1 WEEKDAYS SELECTION

3.2.4.1.4.2 RELAY CONFIGURATION

3.2.4.1.4.3 ON TIME

These settings are used to assign Relay1 in RTC output mode.

3.2.4.1.4.4 OFF TIME

OK

OK

BACK

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

CT SECONDARY

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

RELAY-1 WEEKDAYS SELECTION

OK

BACK

Sunday Monday

Tuesday

Wednesday

Thursday Friday

Saturday

The value decides the time in seconds taken by the relay in timer configuration before coming

out of the trip state after it has tripped.

33

Page 36

3.2.4.1.4.2 Relay Conguration

The option decides the relay configuration for RTC output. Two

options are available:

1. ENERGIZED RELAY: Energize on start

2. DE-ENERGIZED RELAY : De-energize on start.

Touch on “ key” will conrm the setting and take back to the

previous screen.

Touch on “ key” will take back to the previous screen.

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

CT SECONDARY

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

LINE-NEUTRAL VOLTAGE

VL2

VL2VL2

RELAY-1 RTC CONFIGURATION

ENERGIZED RELAY

DE-ENERGIZED RELAY

OK

BACK

OK

OK

BACK

3.2.4.1.4.3 On Time

Here hour and minute settings can be done separately by touching

the corresponding value which will open the keypad.

The 0 to 9 digit input keypad is provided to set the On Time & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

The valid range for hour is 0 to 23 and that for minute is 0 to 59.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

RELAY-1 ON TIME

3.2.4.1.4.4 Off Time

MINUTE

00

06

HOUR

RELAY-1 OFF TIME

MINUTE

00

18

HOUR

On Time is the time on which the relay becomes active.

Off Time is the time on which the relay deactivates.

Here hour and minute settings can be done separately by touching

the corresponding value which will open the keypad.

The 0 to 9 digit input keypad is provided to set the Off Time & user

can confirm this value with a simple touch on “ key”. and cancel

the change by touching the “ key”.

The valid range for hour is 0 to 23 and that for minute is 0 to 59.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

34

Page 37

3.2.4.2 Relay 2 Output Selection

Conguration of Relay 2 for Pulse/ Limit/ Timer/ RTC Output is same as Relay 1. If you Select

the Pulse output option for Relay 1 same setting will be applicable for Relay 2.

3.2.4.3 Parameter setting for Analog Output 1 ( Optional )

This option allows the user to set analog output 1 to corresponding measured parameter. A

simple touch on “ANALOG-1”row will open screen having list of parameters.(Refer TABLE 2

“ Parameter for Analog & Limit output ”)

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will return to previous menu.

BACK

OK

OK

3.2.4.4 Parameter setting for Analog Output 2 ( Optional )

This option allows the user to set analog output 2 to corresponding measured parameter. A

simple touch on “ANALOG-2”row will open screen having list of parameters.(Refer TABLE 2

“ Parameter for Analog & Limit output ”)

Touch on “ key” will conrm the setting.

Touching the “ key” will keep the old selected setting and will return to previous menu.

BACK

OK

OK

35

Page 38

3.2.5 Datalog Option Selection

3.2.5.1 Event Based Datalog Setup

Touching the “EVENT BASED DATALOG” option of Section 3.2.5

will provide a confirmation dialog.

If logging is turned off, then touching “ ” will turn on the

Event Based Datalogging while touching “ ” will make no

change.

If it is turned on, then touching “ ” will turn off the Event

Based Datalogging while touching “ ” will make no change.

After entering in the “DATALOGGING OPTIONS”, List of following

options will be displayed :-

3.2.5.1 EVENT BASED DATALOG

3.2.5.2 TIME BASED DATALOG

3.2.5.3 LOAD PROFILE DATALOG

Any of these can be selected for logging of data.

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

CT SECONDARY

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

DATALOGGING OPTIONS

MAIN

SETUP

EVENT BASED DATALOG

TIME BASED DATALOG

LOAD PROFILE DATALOG

DATALOGGING OPTIONS

EVENT BASED DATALOG

ARE YOU SURE YOU WANT TO START

EVENT BASED DATALOGGING

NO

OK

YES

NO

OK

YES

3.2.5.2 Time Based Datalog Setup

Following Time based datalog parameters can be set by touching the “TIME BASED DATALOG”

option of Section 3.2.5:

3.2.5.2.1. STATUS SELECTION

3.2.5.2.2. TIME INTERVAL

3.2.5.2.3. PARAMETER SELECTION

36

Page 39

3.2.5.2.1 Time Based Datalog Status Selection

Touching the “STATUS” option of Section 3.2.5.2 will provide a

confirmation dialog.

If logging is turned off, then touching “ ” will turn on the Time

Based Datalogging while touching “ ” will make no change.

If it is turned on, then touching “ ” will turn off the Time Based

Datalogging while touching “ ” will make no change.

TIME BASED DATALOGGING

TIME BASED DATALOG

ARE YOU SURE YOU WANT TO START

TIME BASED DATALOGGING

NO

OK

YES

NO

OK

YES

Caution: The settings for time based logging (see Section 3.2.5.2.2 & Section 3.2.5.2.3) are not

editable if time based datalog selection is turned ON (see Section 3.2.5.2.1).

3.2.5.2.2 Time Interval Selection

The value decides the time interval between two successive time

datalog entries.

Here 0 to 9 digit input keypad is provided to set the Time Interval &

user can confirm this value with a simple touch on “ key”. and

cancel the change by touching the “ key”.

The valid range is 1 to 60 minutes.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER INTERVAL IN MIN

DATALOG TIME INTERVAL

3.2.5.2.3 Parameter Selection

The parameter for time based datalogging can be selected out of the

available options by first touching the checkbox infront of it to enable

the selection and then touching the corresponding button to get the

available parameters.

Maximum 30 and minimum 1 parameter(s) can be chosen.

The list of available parameters is given in TABLE 3.

TIME DATALOG PARAMETERS

1. INPUT VOLTAGE VL1

2. INPUT VOLTAGE VL2

3. INPUT VOLTAGE VL1

4. INPUT VOLTAGE VL1

37

Page 40

TIME DATALOG PARAMETERS

INPUT VOLTAGE VL1

INPUT VOLTAGE VL2

INPUT VOLTAGE VL3

INPUT CURENT IL1

When the button (for which the checkbox is selected) is touched, the

list of available parameters (Table ) appear. The user can scroll for the

required parameter and select the same by touching it.

The number of parameters selected for datalogging appears on the

“TIME BASED DATALOGGING” screen (Section 3.2.5.2) for

PARAMETERS setting option.

Only these selected parameters will get logged.

3.2.5.3 Load Profile Datalog Setup

Touching the “LOAD PROFILE DATALOG” option of Section 3.2.5 will

provide a confirmation dialog.

If logging is turned off, then touching “ ” will turn on the Load

Profile Datalogging while touching “ ” will make no change.

If it is turned on, then touching “ ” will turn off the Load Profile

Datalogging while touching “ ” will make no change.

DATALOGGING OPTIONS

LOAD PROFILE DATALOG

ARE YOU SURE YOU WANT TO START

LOAD PROFILE DATALOGGING

NO

OK

YES

NO

OK

YES

38

Page 41

3.2.6 PQ Event Settings

3.2.6.1 Sag Threshold Setting

After entering in the “PQ EVENT SETTINGS”, List of following options

will be displayed :-

3.2.6.1 SAG THREHOLD

3.2.6.2 SWELL THRESHOLD

3.2.6.3 SAG & SWELL HYSTERESIS

3.2.6.4 OVERCURRENT THRESHOLD

3.2.6.5 OVERCURRENT HYSTERESIS

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

CT SECONDARY

LINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGELINE-NEUTRAL VOLTAGE

DATALOGGING OPTIONS

MAIN

SETUP

EVENT BASED DATALOG

TIME BASED DATALOG

LOAD PROFILE DATALOG

Here 0 to 9 digit input keypad is provided to set the Sag Threshold &

user can confirm this value with a simple touch on “ key” and

cancel the change by touching the “ key”.

The valid range is 10 to 90 % of nominal voltage.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER SAG THRESHOLD IN %

SAG THRESHOLD

0

.

3.2.6.2 Swell Threshold Setting

Here 0 to 9 digit input keypad is provided to set the Swell Threshold &

user can confirm this value with a simple touch on “ key” and

cancel the change by touching the “ key”.

The valid range is 110 to 150 % of nominal voltage.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER SWELL THRESHOLD IN %

SWELL THRESHOLD

0

.

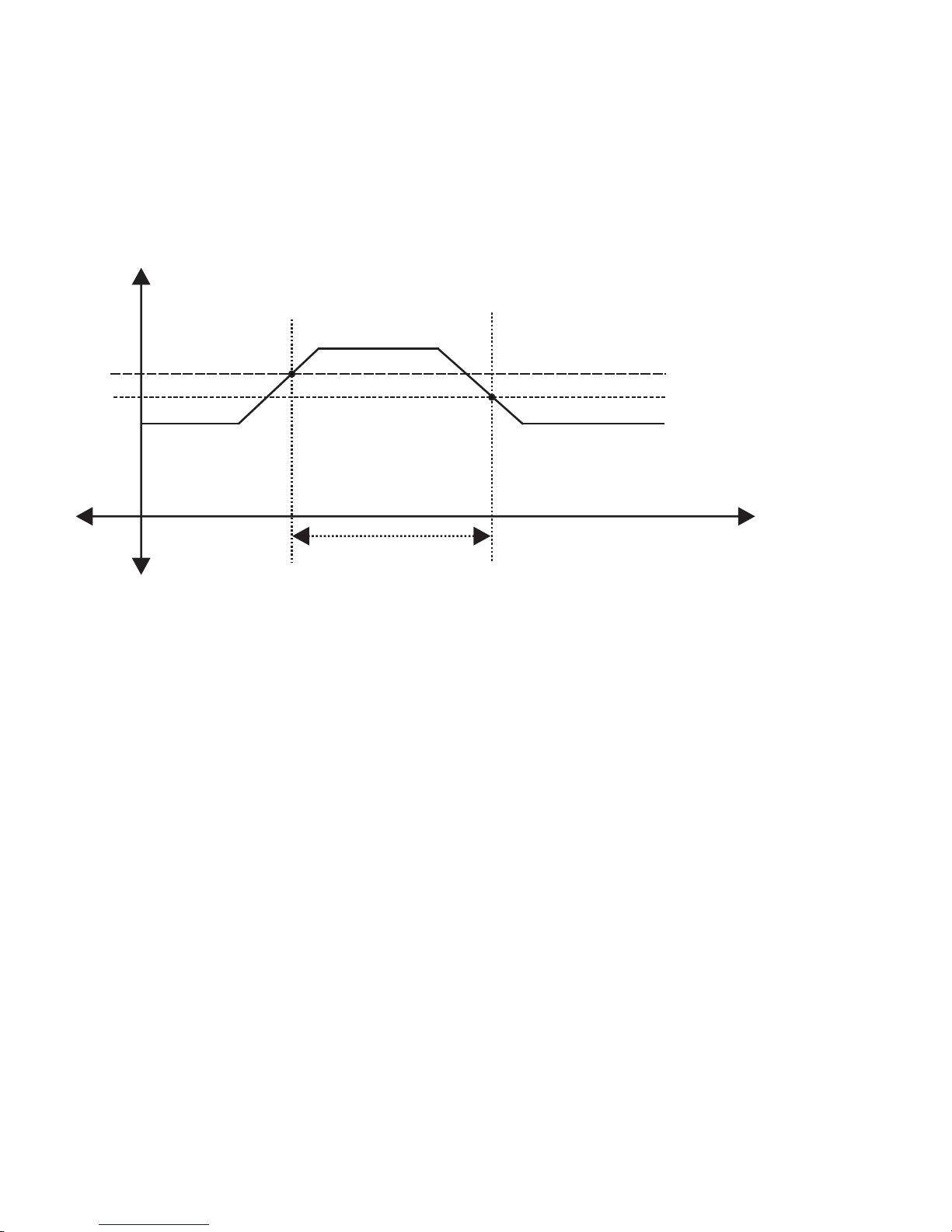

The value decides the threshold for swell detection.(Refer section 8 for details)

The value decides the threshold for sag detection.(Refer section 8 for details)

Note : Changing Swell Threshold would erase the Swell data of PQ events.

Note : Changing Sag Threshold would erase the Sag data of PQ events.

39

Page 42

3.2.6.3 Sag & Swell Hysteresis Setting

Here 0 to 9 digit input keypad is provided to set the Sag & Swell

Hysteresis & user can confirm this value with a simple touch on

“ key” and cancel the change by touching the “ key”.

The valid range is 1 to 20 % of nominal value.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER SAG & SWELL HYST IN %

SAG & SWELL HYSTERESIS

0

.

3.2.6.4 Overcurrent Threshold Setting

Here 0 to 9 digit input keypad is provided to set the Overcurrent

Threshold & user can confirm this value with a simple touch on

“ key” and cancel the change by touching the “ key”.

The valid range is 110 to 150 % of nominal current.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER OVR CRNT THRESHOLD IN %

OVERCURRENT THRESHOLD

0

.

The value decides the common hysteresis for sag & swell detection. Hysteresis is the difference

in magnitude between the start and end threshold.(Refer section 8 for details)

The value decides the threshold for overcurrent detection.(Refer section 8 for details)

Note : Changing Sag & Swell Hysteresis would erase the Sag & Swell data of PQ events.

Note : Changing Overcurrent Threshold would erase the Overcurrent data of PQ events.

40

Page 43

3.2.7 Date & Time Settings

After entering in the “DATE AND TIME SETUP”, the user will be able

to change the DATE, MONTH, YEAR, HOUR & MINUTE individually

by touching the corresponding option.

The range for date is 10-10-2000 to 31-12-2099 and that for time is

00:00 to 23:59.

Touching an option gives 0 to 9 digit input keypad to set the

corresponding value & user can confirm this value with a simple touch

on “ key” and cancel the change by touching the “ key”.

If invalid value is entered, it will display “INVALID VALUE” followed by

correct range of the parameter.

ENTER

BACK

ENTER THE DATE

DATE AND TIME SETUP

0

DATE AND TIME SETUP

2000

DATE

YEAR

01

MONTH

01

HOUR

11

MINUTE

10

3.2.6.5 Overcurrent Hysteresis Setting

Here 0 to 9 digit input keypad is provided to set the Overcurrent

Hysteresis & user can confirm this value with a simple touch on

“ key” and cancel the change by touching the “ key”.

The valid range is 1 to 20 % of nominal current.

If value outside this range is entered, it will display “INVALID VALUE”

followed by correct range of parameter.

ENTER

BACK

ENTER OVR CRNT HYSTERESIS IN %

OVERCURRENT HYSTERESIS

0

.

The value decides the hysteresis for overcurrent detection.Hysteresis is the difference in

magnitude between the start and end threshold.(Refer section 8 for details)

Note : Changing Overcurrent Hysteresis would erase the Overcurrent data of PQ events.

41

Page 44

3.2.8 Brightness & Contrast

The brightness & contrast of the TFT LCD screen can be varied by

the user by sliding the sliders. Touching the “ key” will conrm

the current brightness contrast setting.

Touching the DEFAULT key will set brightness and contrast as per

factory settings. Touching the BACK key will move back to the setup

menu without making any changes.

3.2.9 RGB Color Code (only for 3 Phase 3 Wire / 4 Wire)

This screen allows user to set the values of Red, Green and Blue

components of colors used to display the parameters of all three

phases.

Different colors can be assigned to each phase using combination of

Red, Green and Blue component values. L1,L2,L3 will be set to the

assigned color.

To set these values, touch the corresponding rectangular section, 0 to

9 digit input keypad will appear. After entering the value using this

keypad,user can conrm this value with a simple touch on “ key”.

“ key” is used to go back to previous screen.

OK

OK

140

R B

G

L1

L2

L3

RGB COLOR CODE

0 0

255 204191

0 255 0

RGB COLOR CODE

VALID RANGE IS : 0 to 255

The allowable range for these values is 0 to 255. If a value outside this range is entered, it will

display “ VALID RANGE IS : 0 TO 255”.

NOTE : Colors similar to background are not recommended.

42

Page 45

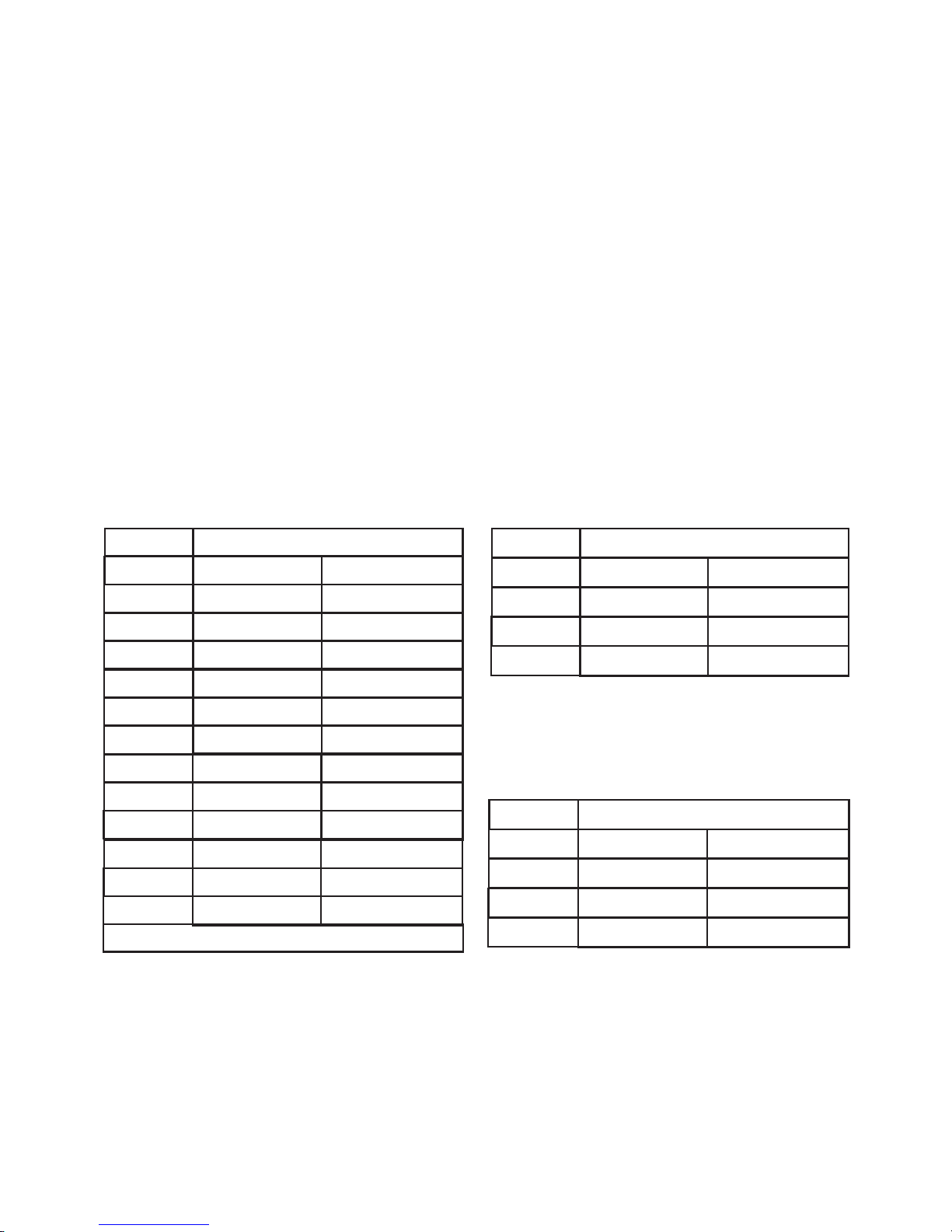

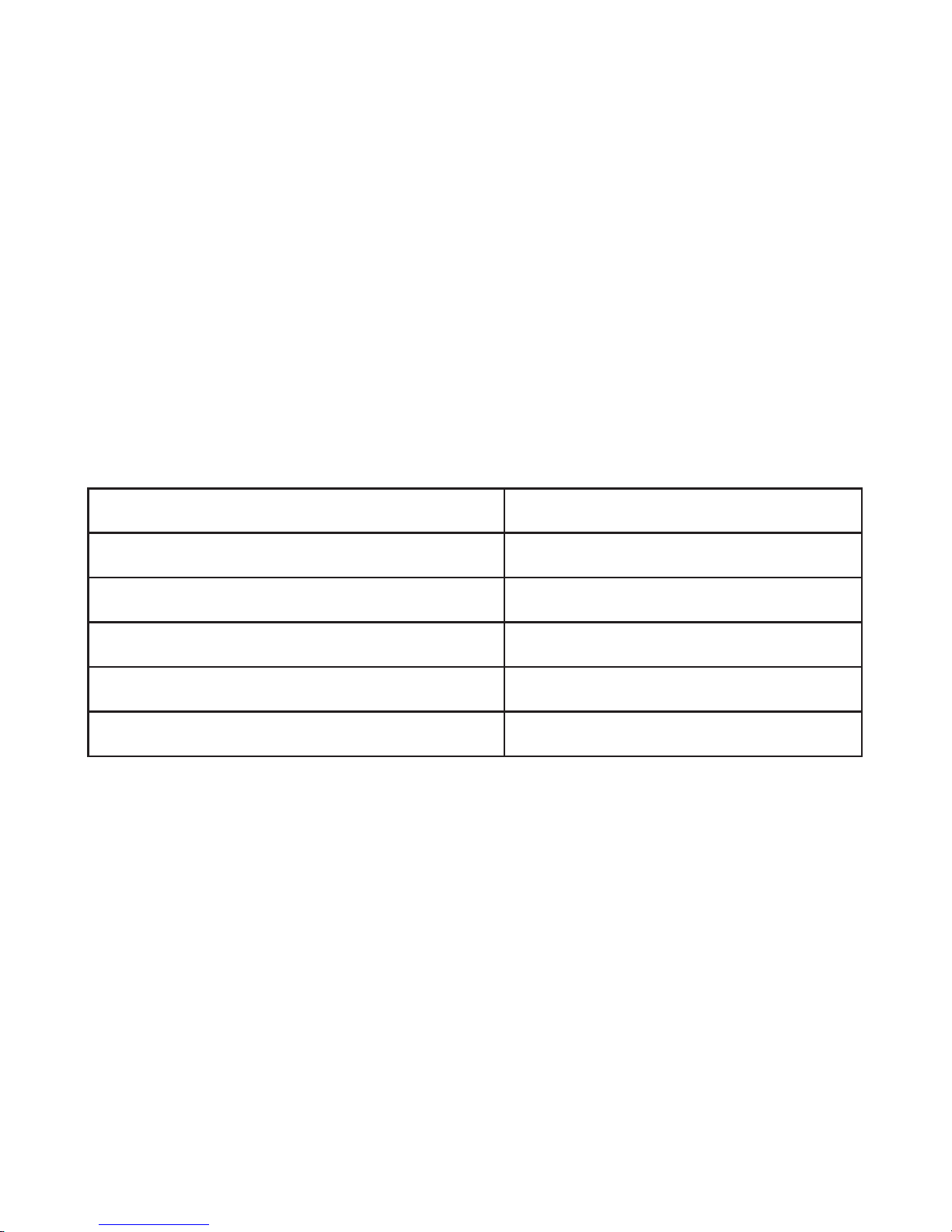

COLOR

R

G

B

Light Blue

Maroon

Pink

Purple

Red

Silver

Violet

White

Yellow

255 255 0

255 255 255

143 0 255

191 191 191

255 0 0

161 33 240

255 191 204

176 48 97

173 217 230

COLOR

R

G

B

Dark Pink

Dark Purple

Dark Red

Dark Violet

Dark Yellow

Gold

Gray

Green

Indigo

74 0

0 255 0

128 128 128

212 176 56

156 135 13

148 0 212

140 0 0

48 26 51

232 84 128

130

Standard color combinations

COLOR

R

G

B

Brass

Blue

Brown

Black

Bronze

Copper

Dark Blue

Dark Brown

Dark Green

0 51

102 66 33

0 0 140

184 115 51

166 41 41

204 128 51

181 166 66

0 0 255

0

0

0

33

3.2.10 Factory Reset

Touching the “FACTORY RESET” option of Section 3.2 will provide a

confirmation dialog.

Touching “ ” allows the user to erase all data from the meter

and set all setup parameters to their default values while touching

“ ” will make no change.

SETUP

FACTORY RESET

THIS WILL RESET ALL DATA

DO YOU WANT TO CONTINUE?

NO

OK

YES

MAIN MENU

43

Page 46

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

CT SECONDARY

OK

5 AMPERE

1 AMPERE

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

LINE-NEUTRAL VOLTAGE

VOLTAGE

MAIN

VL2

VL2

VL2

V

VVVV

0.000

0.000

0.000

IMPORTANT.

Performing touch

screen calibration.

Press & hold the center

of the filled circle

Touch screen to

continue.

4 Touch screen calibration

This instrument is able to perform calibration to ensure the proper operation of the units touch

screen functionalities. The calibration procedure will correct the problem of out of tolerance

touch screen malfunction. Note that errors corrected by this calibration procedure are specic

only to touch screen operation.

For starting touch screen calibration, touch the screen any where for 1

sec at system reset. After that touch screen calibration will start & the

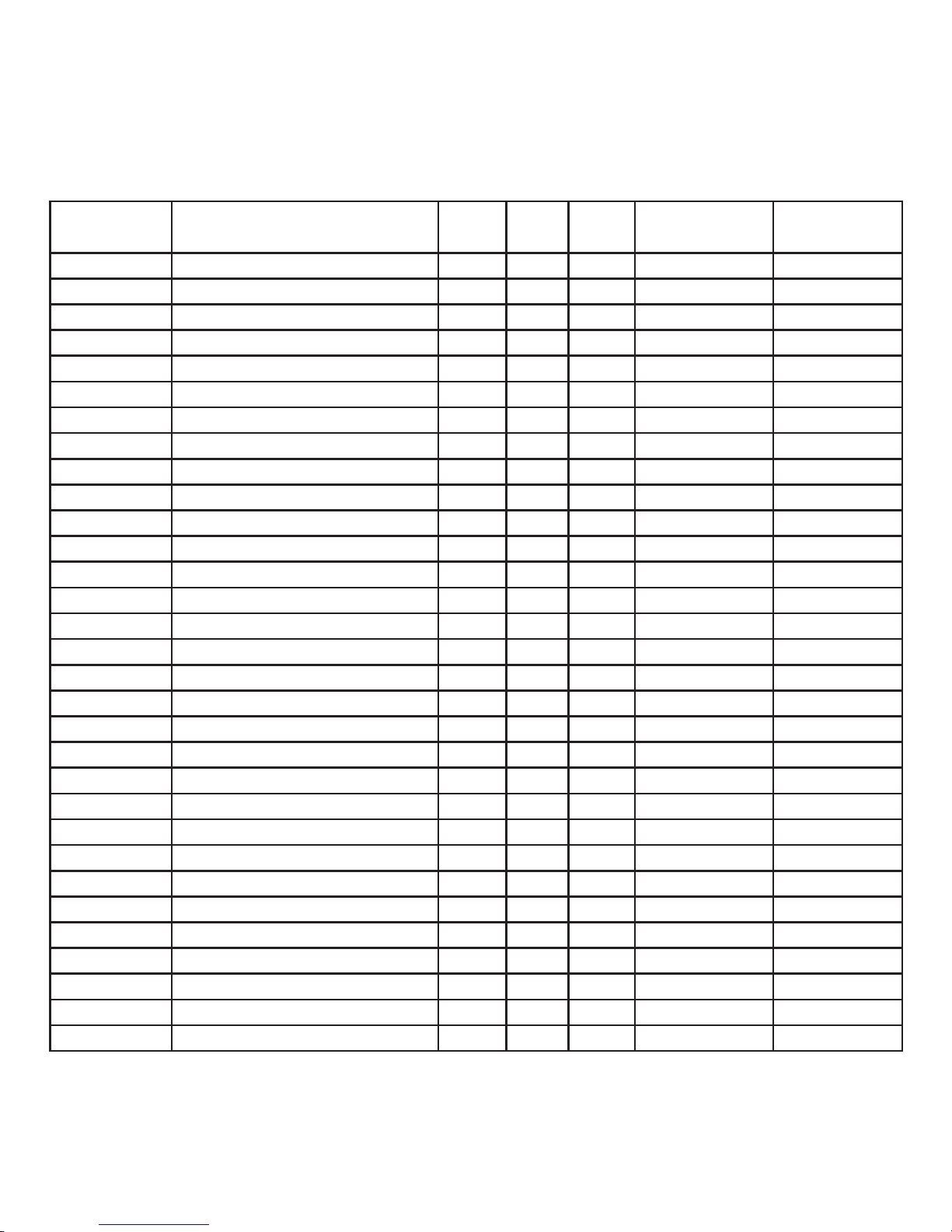

message shown besides will be displayed. Touch the screen to