Risco WatchU Quick Start Manual

Dual Technology Outdoor Detector

Introduction

RISCO Group's Dual Technology Outdoor detector, WatchU, is a unique detector with signal

processing based on two Passive Infrared (PIR) channels and two Microwave (MW) channels.

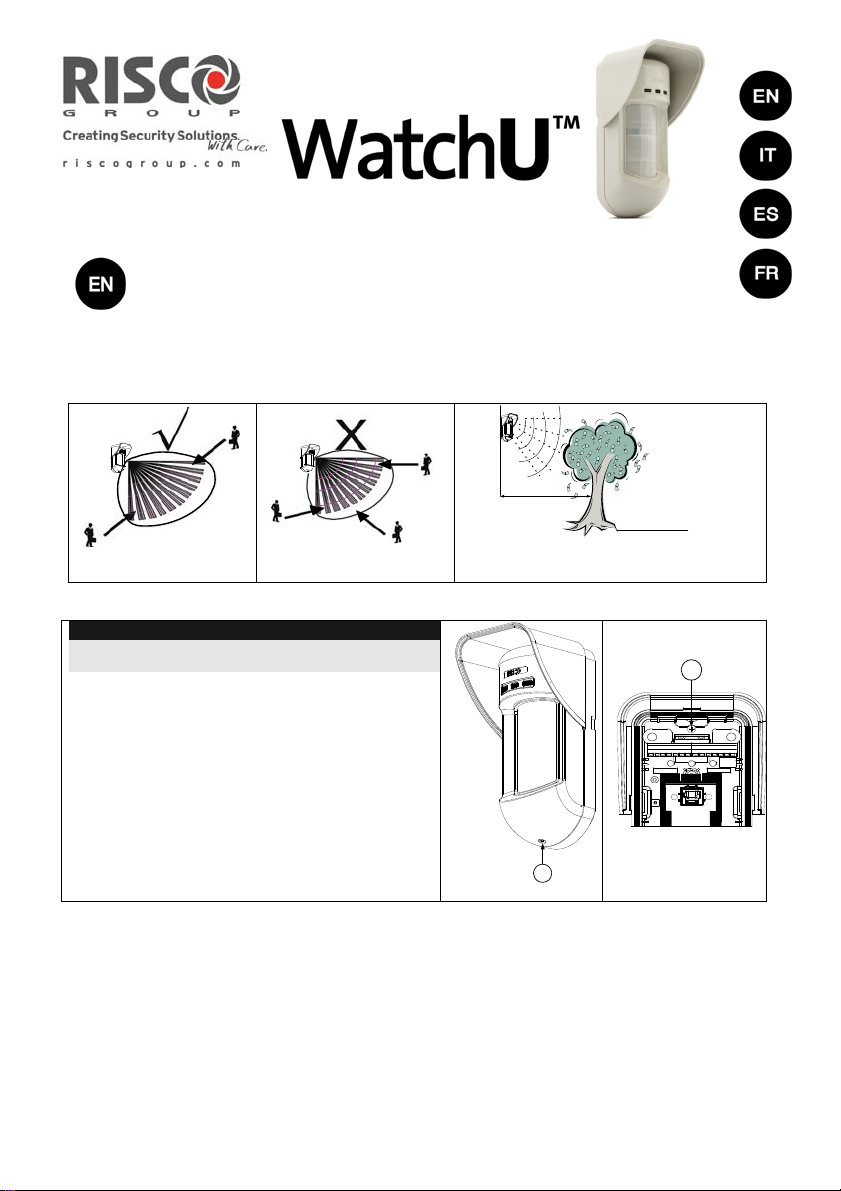

Mounting Considerations

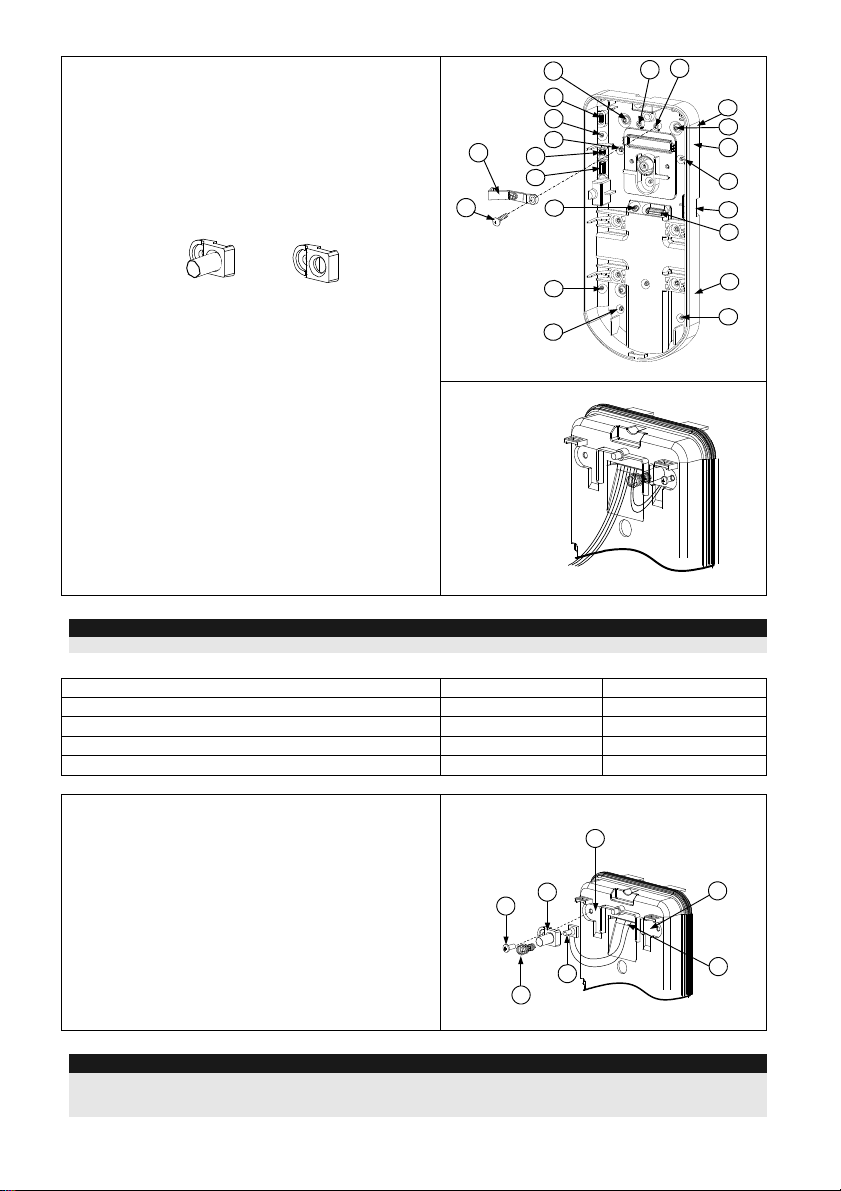

Wall Mount Installation

Note:

The installation knockouts numbering are marked on the

back plate.

1. Open WatchU front cover

(unlock C1, Figure 1).

2. Release internal base (unlock I1, Figure 2).

3. Select mounting installation as follows:

Flat Mounting:

Open knockouts on external base (Figure 3).

B1 - B4: Wall mounting knockouts

T1: Back tamper knockout

W2 / W3: wires entry knockouts

5m (16')

Keep distance of

minimum 5m (16')

from moving objects

C1

Figure 1

Out of

Detection Range

Figure 2

I1

1

45° angle Mounting (Left side mounting)

a. Open knockouts on external base (Figure 3)

L1, L2: Left mounting knockouts

T3: Left tamper knockout

W5 / W6: Wire entry knockouts

b. Remove tamper spring.

c. Replace tamper bracket (Item 1) with

supplied flat tamper bracket (Item 2).

Item 1 Item 2

Tamper

Lever

B

A

T5

T1

T3

L1

B1

W5

W6

W3

T6

T4

T2

R1

(not visible)

B2

W9

W2

d. Insert Tamper lever B onto T5 and T3 and

secure screw A (Figure 3).

4. Insert external wires through external base W2,

W3 (Flat Mounting) or W5, W6 (Left

side

mounting) (Figure 3).

5. Secure external base to the wall.

L2

B4

Figure 3

6. Insert external wires and tamper wires through

internal base (Figure4).

7. Secure internal base to external base (lock I1,

Figure2).

8. Close the front cover (Lock C1, Figure1) after

wiring and setting DIP switches.

9. Walk test the detector.

Figure 4

Note:

For 45° right side installation use the equivalent units on the external base as follows:

Knockouts Description

Left Right

Mounting Knockouts L1, L2 R1, R2

Tamper spring knockouts T1,T3 T2,T4

Tamper screw anchor T5 T6

Wiring Knockouts W5, W6 W7, W8

Changing Back Tamper position

The back tamper is by default secured on the right

Left Side

Tamper

6

side of the internal base (rear view). If you wish to

move it to the left side (rear view), do the following

(Figure 5):

1. Remove tamper screw 1 in order to release

3

1

the tamper from position 7.

2. Ensure tamper spring 2 rests over tamper wire

base 4.

3. Ensure plastic tamper bracket 3 rests over

both 2 and 4.

4. Secure tamper screw 1 into 3 over position 6.

4

2

Figure 5

Notes:

1. Verify that you hear a "Click" when attaching the tamper spring to the wall.

2. For pole installation, the tamper can be moved to the bottom right-hand side of the internal base.

R2

(not visible)

B3

Right Side

Tamper

7

5

2

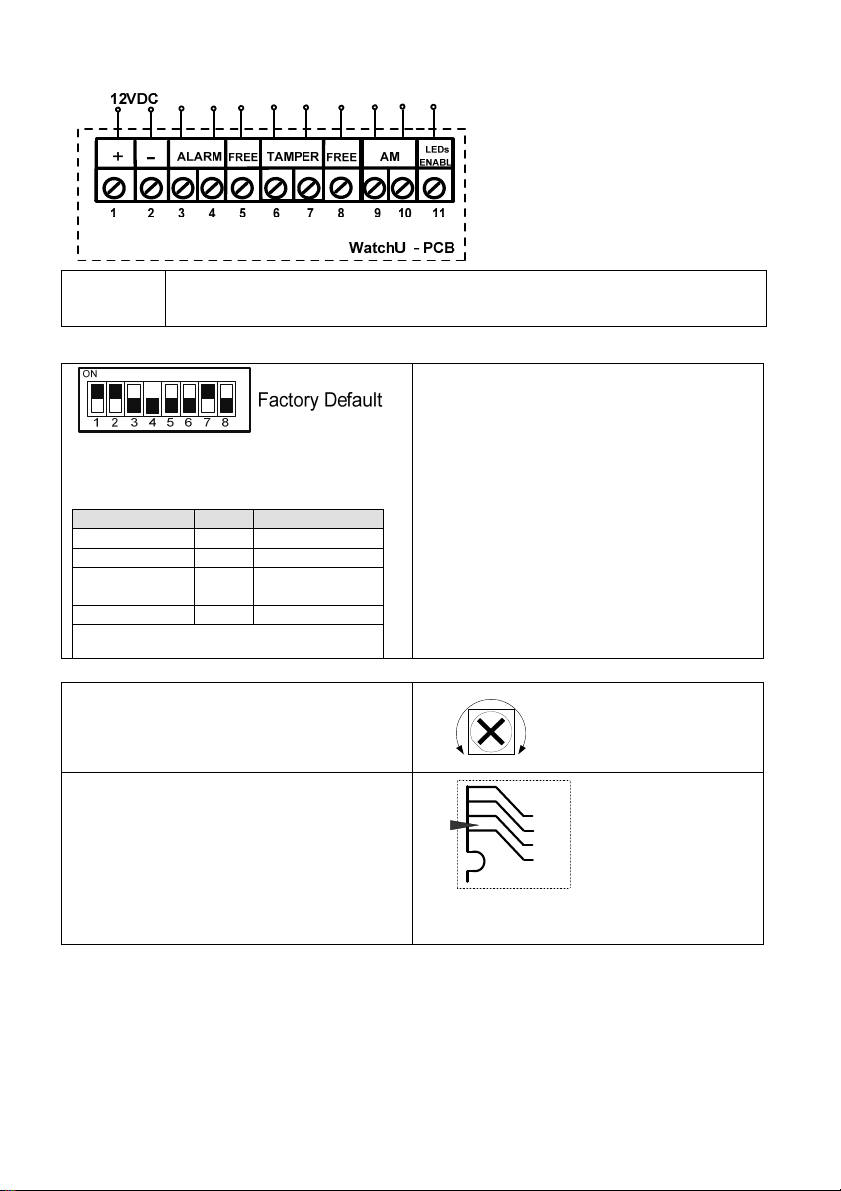

Terminal Wiring

LED

ENABLE

Used to remotely control the LEDs when DIP1 is set to ON.

Enable: input is +12V OR no terminal connection

Disable: Connect the input to 0V

DIP Switch Settings

DIP 1: LEDs operation

On: LEDs Enabled

Off: LEDs Disabled

DIP 2-3: Detection Sensitivity

Sensitivity DIP2 DIP3

Low Off Off

Mid Off On

Normal

On Off

(Default)

Maximum* On On

* In maximum sensitivity sway recognition is

disabled to achieve maximum sensitivity

DIP 4: Anti masking Sensitivity

On: High

Off: Low

DIP 5: Detector's optics

On: Barrier / Long range

Off: Wide angle

DIP 6: Red LED /3 LED

On: Red LED only

Off: 3 LEDs

DIP 7: Anti masking operation

On: Enabled

Off: Disabled

DIP 8: N/A

Microwave Adjustment

Adjust Microwave coverage area by using the

trimmer on the PCB.

Walk test

Two minutes after applying power, walk test

the protected area to verify proper operation.

For installations on uneven surfaces slide the

PCB inside the internal base to the

appropriate setting according to the desired

height (1.0m, 1.5m, 2.2m, 2.7m) as printed on

the bottom left corner of the PCB.

MAX

MIN

PCB

1.00M

1.50M

2.20M

2.70M

3

LEDs Display

LED State Description

YELLOW

GREEN

RED

All LED s

Notes:

1. DIP-Switch 1 should be in ON position to enable LED indications.

2. Only one LED is active at any one time. For example, in the case of both PIR and MW detection, either the

steady YELLOW LED or the steady GREEN LED is displayed (the first to detect), followed by the Alarm RED

LED.

Steady Indicates PIR detection

Flashing Indicates AM (Anti mask) detection

Steady Indicates MW detection

Steady Indicates ALARM

Flashing (One

Unit initialization on power up

after another)

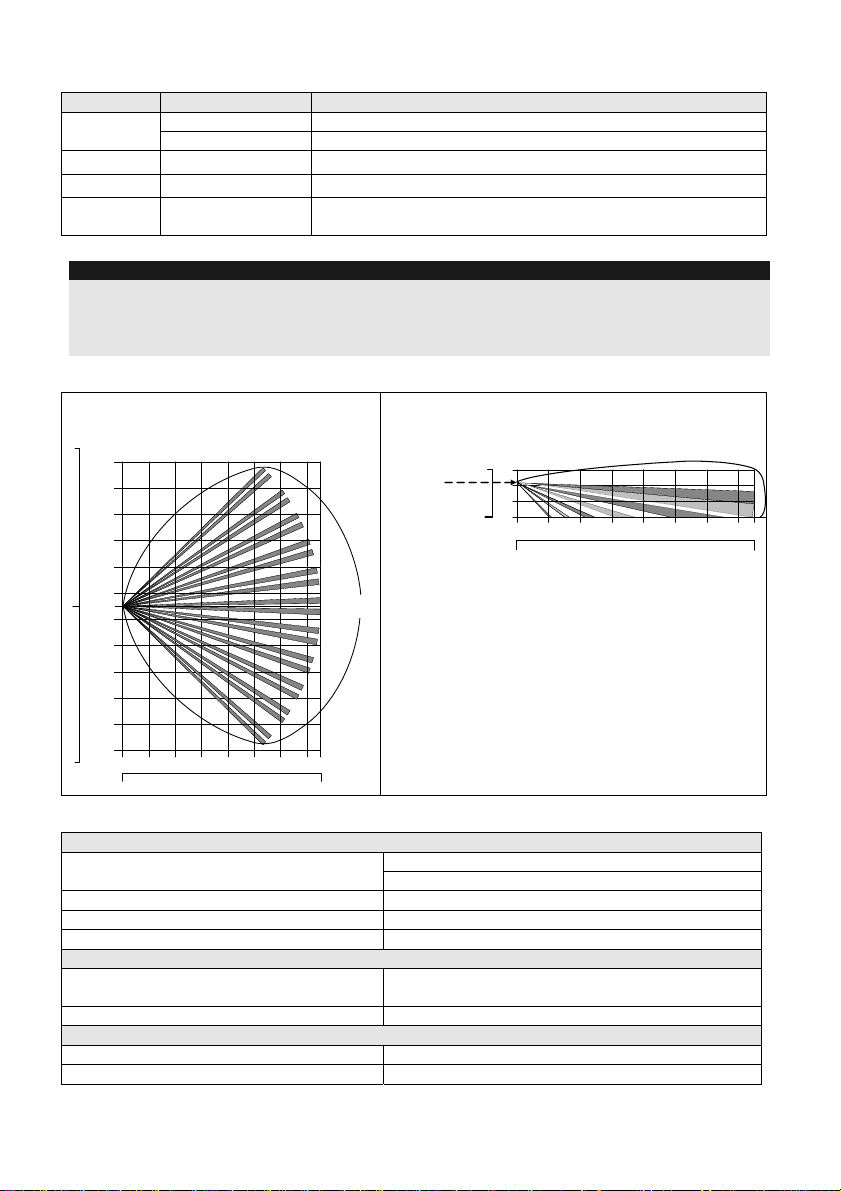

Lens Types

Wide angle lens (RL300) /

40

11

9

30

7

20

5

3

10

1

0

0

1

3

10

5

20

7

9

30

11

40

Feet

0

Top view

2468100121415

10

20

30 40 50

90°

Typical

Installation

Height:

2.2m (7'2")

Wide angle lens (RL300):

Side View

Feet

3

10

1

0

0

Meters

2468100121415

Feet

0

20

10

30 40 50

Technical Specification

Electrical

Current consumption 45mA at 12 VDC (Stand by)

70mA at 12 VDC (MAX with LED ON)

Voltage requirements 9 -16 VDC

Alarm contacts 24 VDC, 0.1A

AM contacts 24 VDC, 0.1A

Physical

Size:

220 x 115 x 123mm (8.7 x 4.5 x 4.85 in.)

LxWxD

Weight 0.632 Kg (1.4lb)

Environmental

RF immunity (30MHz to 2GHz): 40V/m

Operating/Storage temperature -30°C to 60°C (-22°F to 140°F)

* PIR technology is limited in rough environmental conditions.

4

Introduzione

Il rivelatore da esterno Doppia Tecnologia WatchU di RISCO Group è un dispositivo a

microprocessore che elabora i segnali rilevati tramite due canali all’infrarosso passivo (PIR) e due

canali a microonda (MW).

Considerazioni per l’installazione

[Vedi pagina 1]

Installazione a parete

[Vedi Figure 1-4, pagine 1-2]

Nota:

I numeri di riferimento dei fori a sfondare per

l’installazione sono marcati sulla base posteriore.

1. Aprire il coperchio frontale del WatchOUT.

(Svitare C1, figura 1).

2. Sganciare la base interna (svitare I1, fig. 2).

3. Selezionare l’altezza di installazione come

segue:

Installazione piana

Aprire i fori a sfondare della base esterna (fig. 3)

B1 - B4: Fori a sfondare per installazione

a parete.

T1: Foro a sfondare per il tamper

antirimozione

W2 / W3: Fori a sfondare per il

passaggio cavi

Installazione angolare di 45°

(installazione a sinistra)

a. Aprire i fori a sfondare della base esterna

(fig. 3)

L1, L2 : Fori a sfondare per lato

sinistro

T3: Foro a sfondare per tamper lato

sinistro

b. W5 / W6: Fori a sfondare per passaggio

caviRimuovere la molla del tamper

c. Sostituire la staffa (Item 1) con l’altra

fornita (Item 2).

Item 1 Item 2

d. Inserire la leva B del tamper in T5 e T3 e

stringere la vite A (figura 3)

4. Inserire I cavi esterni attraverso la base

esterna W2, W3 (Installazione piana) o

W5,

W6 (Installazione a sinistra) (figura 3).

5. Fissare la base esterna alla parete.

6. Inserire i cavi esterni e i cavi del tamper

attraverso la base interna. (figura 4).

7. Fissare la base interna a quella esterna

(bloccare I1, figura 2).

8. Chiudere il coperchio frontale (bloccare

C1, figura 1) dopo aver cablato l’unità e

predisposto i microinterruttori.a.

Nota:

Per installazioni a 45° lato destro usare le equivalenti predisposizioni sulla base esterna come segue:

Descrizione fori a sfondare Sinistra Destra

Fori a sfondare per il fissaggio della base L1, L2 R1, R2

Foro a sfondare per la molla del tamper T1,T3 T2,T4

Punto di fissaggio vite tamper T5 T6

Fori a sfondare per passaggio cavi W5, W6 W7, W8

5

Loading...

Loading...