D T

A M

G r a d e

3

H i g h

C e i l i n g

M o u n t

D e t e c t o r

I n s t a l l a t i o n

G u i d e

M o d e l : R K 2 0 0 D T G 3

DT AM Grade 3

Model: RK200DTG3

High Ceiling Mount Detector Installation Guide

General Description

The Industrial LuNAR DT AM Grade 3 (RK200DTG3) is a dual technology ceiling detector with a mounting height of

up to 8.6m (28ft) that incorporates RISCO Group’s Anti-Cloak™ Technology (ACT™). The detector has an Intelligent

Digital Signal Processing method that automatically adjusts the alarm threshold and pulse count verification

according to actual intruder crossing speed and environmental factors, providing superior detection and false

alarm immunity.

The Ind. LuNAR RK200DTG3 can operate as a regular relay detector connected to any control panel, or as an

addressable BUS detector when connected to RISCO Group’s ProSYS control panel via the RS485 BUS.

Ind. LuNAR RK200DTG3 Features

♦

PD6662, EN50131-1, EN50131-2-4 Grade 3

♦

Addressable Dual Technology detector with Anti-Cloak™ Technology

♦

Up to 8.6 m (28ft) mounting height

♦

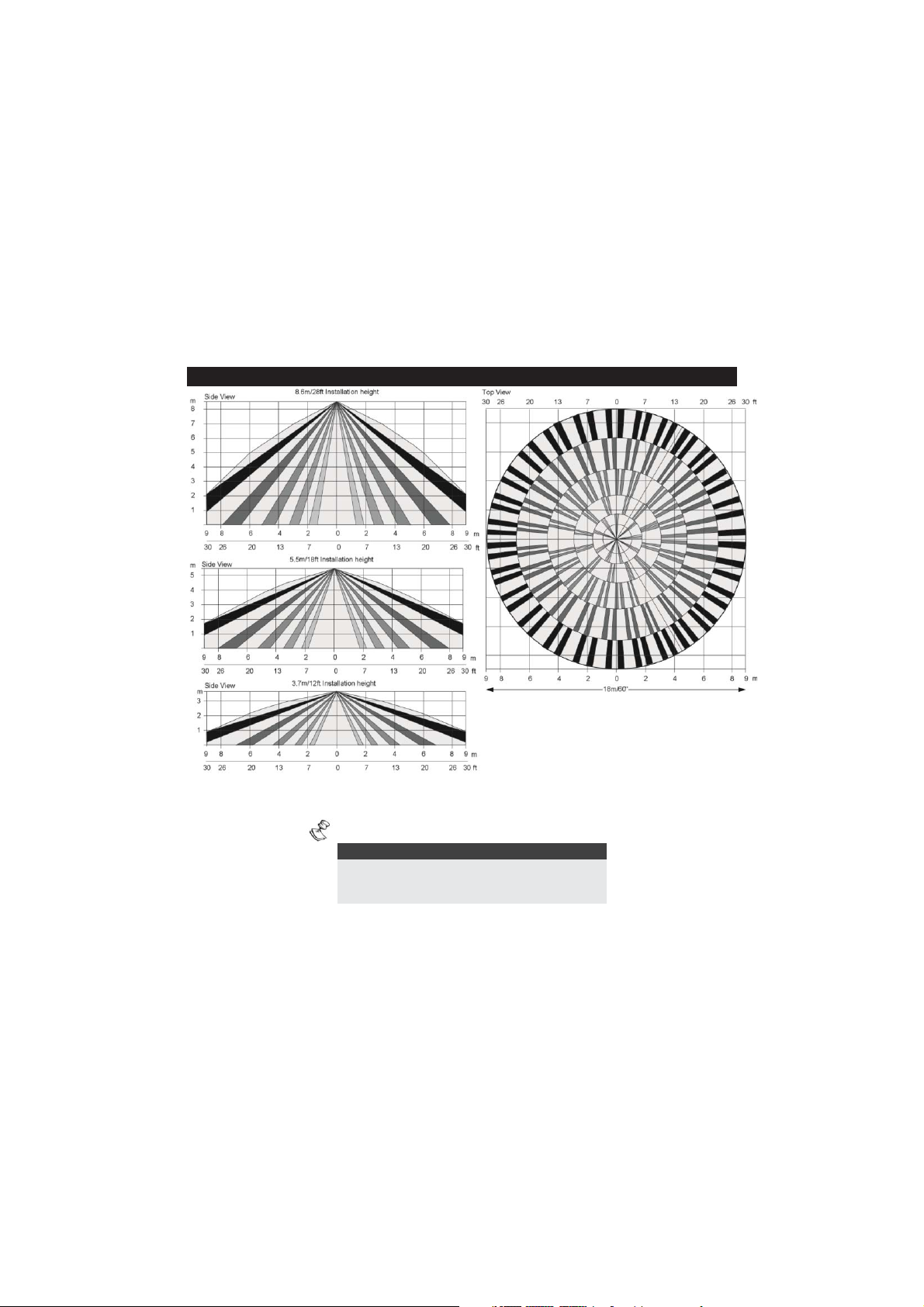

3600 by 18m (60ft) diameter coverage pattern

♦

3 independent PIR channels for customized coverage

♦

Intelligent Digital Signal Processing – alarm verification and decision thresholds adjusted according to

actual intruder crossing speed

♦

Built-in Triple EOL resistors, jumper selectable

♦

Active IR for Anti-Masking meeting EN50131 requirements

♦

Ceiling and cover tampers

♦

"Green Line" setting – for disabling the MW when the premises are occupied

♦

Opto–relays for low current consumption and long life

♦

Remote and Local Self Test

♦

Remote SET input

♦

Remote RC control input

♦

PIR coverage optimization by sliding the lenses

♦

Microwave Range Adjustment manually (analog trimmer) and remotely (digital setting)

♦

Trouble Indication (by LEDs or via communication)

♦

3 Triple color LEDs for easy walk testing

♦

Advanced Remote control and diagnostics

♦

Reduced Power Consumption when connected to RISCO Group’s ProSYS

2 Ind. LuNAR RK200DTG3 Installation Guide

Remote Control and Diagnostic Features

*

♦

Remote microwave adjustment enables one-man walk test.

♦

Diagnostic tools include detector input voltage reading and status of each PIR channel and MW

channel (signal voltage and noise levels), AM channel (signal voltage), SW version verification.

♦

Remote display and control of detector settings: MW adjustment, ACT on/off, LEDs on/off.

♦

Remote trouble indication (Pass/Fail) for the PIR, MW and power supply input

♦

Control of MW bypass (during MW trouble) and MW disable during Disarm ("Green Line") when

connected to ProSYS.

*Via the optional Bi-Directional Infrared Remote Control, or the ProSYS Upload/Download Software and

Keypad.

Detection Method

The Ind. LuNAR RK200DTG3 detection is based on:

♦ PIR (Passive Infra-Red) - which responds to changes in the IR radiation caused when an intruder crosses

the protected area.

♦ MW (Microwave) - which transmits signals and analyzes the frequency changes of the reflected echo

from an intruder using Doppler Effect.

ALARM is initiated only when both technologies trigger simultaneously (except for certain situations in the ACT

mode-see page 4 – “How ACT™ Works”), thus greatly reducing the possibility of false alarms.

How ACT™ Works

Anti-Cloak™ Technology (ACT™) provides the benefits of DT (Dual Technology) while avoiding its

drawbacks. This patent pending innovation has created a new standard for detectors. Dual Technology, a

combination of PIR +MW, was an important development for the security industry...but, it has 2 major

weaknesses:

IR emission blocking cloaks employed by intruders enable avoidance of detection.

PIR sensitivity is reduced when the protected area’s ambient temperature approaches body temperature.

Responding to requests from its customer base to solve these pressing problems, RISCO Group developed

ACT™ -a revolutionary anti-cloak solution.

Ind. LuNAR RK200DTG3 Installation Guide 3

ACT™ prevents the alarm system from being bypassed, by neutralizing attempts to camouflage IR radiation.

Using unique pattern recognition algorithms, ACT™ distinguishes between the weak IR signal of a moving

intruder and the background noise and thermal interferences that may cause false alarms.

Once the presence of an intruder is recognized, ACT™ switches the system automatically from dual channel

PIR/MW mode to single channel MW mode for a predetermined period of time, in order to trigger an alarm

utilizing the MW channel, and then returns to dual channel mode.

In the second case, when the ambient temperature approaches body temperature, the ACT™ switches to

microwave-only detection.

Offering significantly higher detection capabilities as well as immunity from false alarms, ACT™ thwarts even

the most sophisticated burglars.

Ind. LuNAR RK200DTG3 Configuration Options

The Ind. LuNAR RK200DTG3 can be configured and/or diagnosed remotely via one of the options:

4 Ind. LuNAR RK200DTG3 Installation Guide

Manual

configuration

Remote

Control

Device

ProSYS Bus

Control

ACT Mode

LEDs

MW Sensitivity

(by trimmer)

Diagnostics

-

Status/Trouble/Info Reports

-

AM Diagnostics

-

-

MW Bypass

-

-

MW Disable on Disarm ("Green

Line")

-

-

LED Display

The three Tri color LEDs in the Ind. LuNAR RK200DTG3, operate as herein described:

Ind. LuNAR RK200DTG3 Installation Guide 5

LED

STATE

MEANING

Red

Steady

Detector alarm (simultaneous PIR and MW

detection)

Flashing with low frequency

Indicates malfunctioned communication with

ProSYS

Flashing with high frequency

AM detection

Green

Steady

Microwave detection

Flashing

Trouble in the MW channel

Orange

Steady

PIR detection

Flashing

Trouble in the PIR channel

All LEDs

Flashing with change of color

Upon power up

♦

Before installation, study the space to be protected carefully in order to choose the exact location of

the unit for the best possible coverage.

♦

Never install the Ind. LuNAR RK200DTG3 in an environment that causes an alarm condition in one

technology.

♦

Avoid installations where rotating machines (e.g. fans) are normally in operation within the coverage

pattern. Point the unit away from glass exposed to the outdoors and objects that may change

temperature rapidly.

♦

Do not mount the detector in direct sunlight or near any heat sources. Detection sectors should be

pointed either towards a wall, floor but not towards windows or curtains. The installation surface

should be solid, smooth and vibration free

♦

Eliminate interference from nearby outside sources.

INSTALLATION

Preliminary steps:

6 Ind. LuNAR RK200DTG3 Installation Guide

♦

For optimum detection, select a location likely to intercept an intruder moving across the coverage

pattern.

♦

Recommended mounting heights that allow 18m (60ft) detection, are from 3.7m to 8.6m.

♦

The detector must be mounted on the ceiling, preferably in the center of the room.

Typical Ind. LuNAR RK200DTG3 detection coverage and installation height, are illustrated below:

Ind. LuNAR RK200DTG3 Installation Guide 7

NOTE:

When installing the Ind. LuNAR RK200DTG3 detector in a

room occupied with high volume interfering elements, MW

detection may be affected.

8 Ind. LuNAR RK200DTG3 Installation Guide

Ind. LuNAR RK200DTG3 Installation Guide 9

Installation Process:

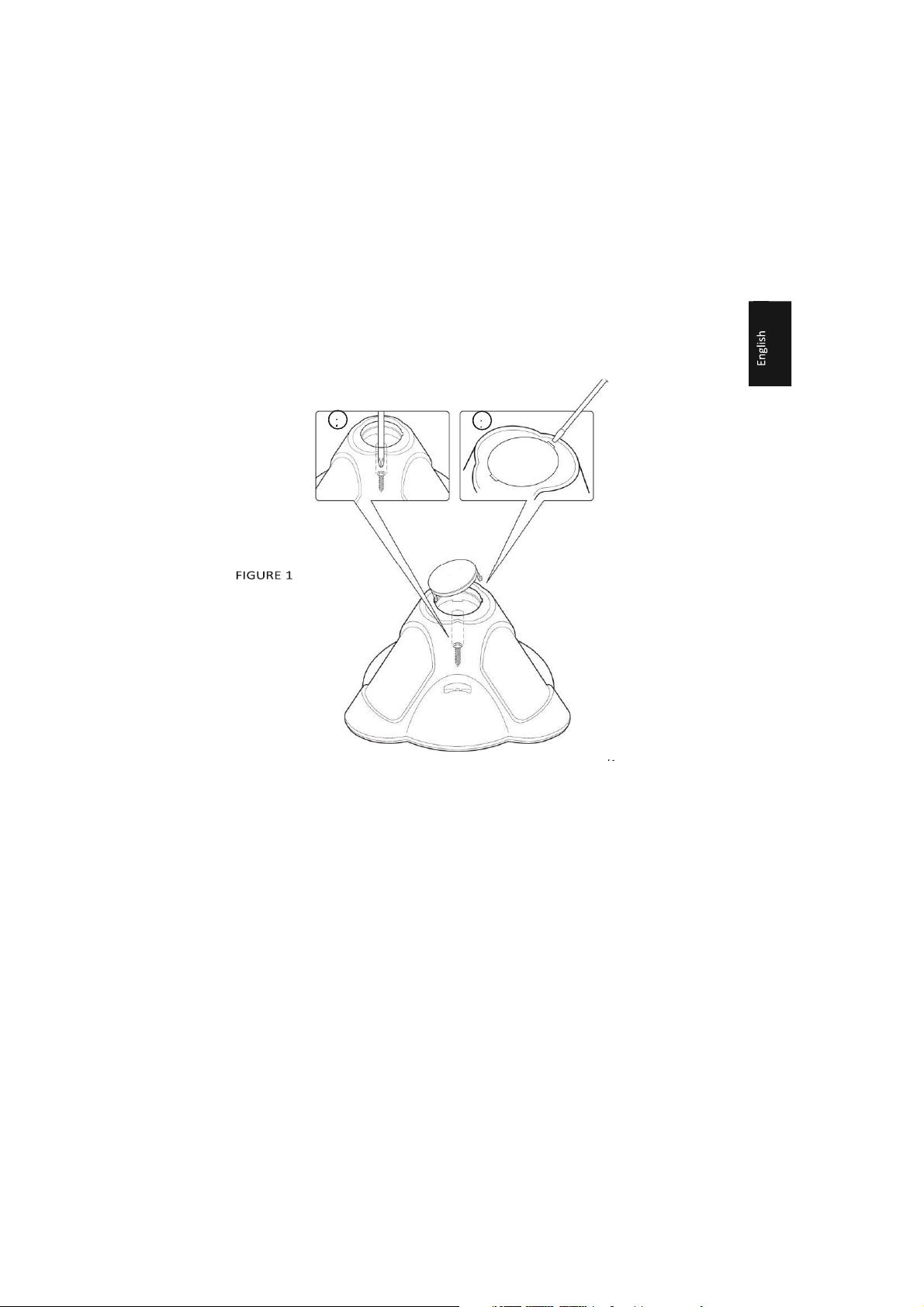

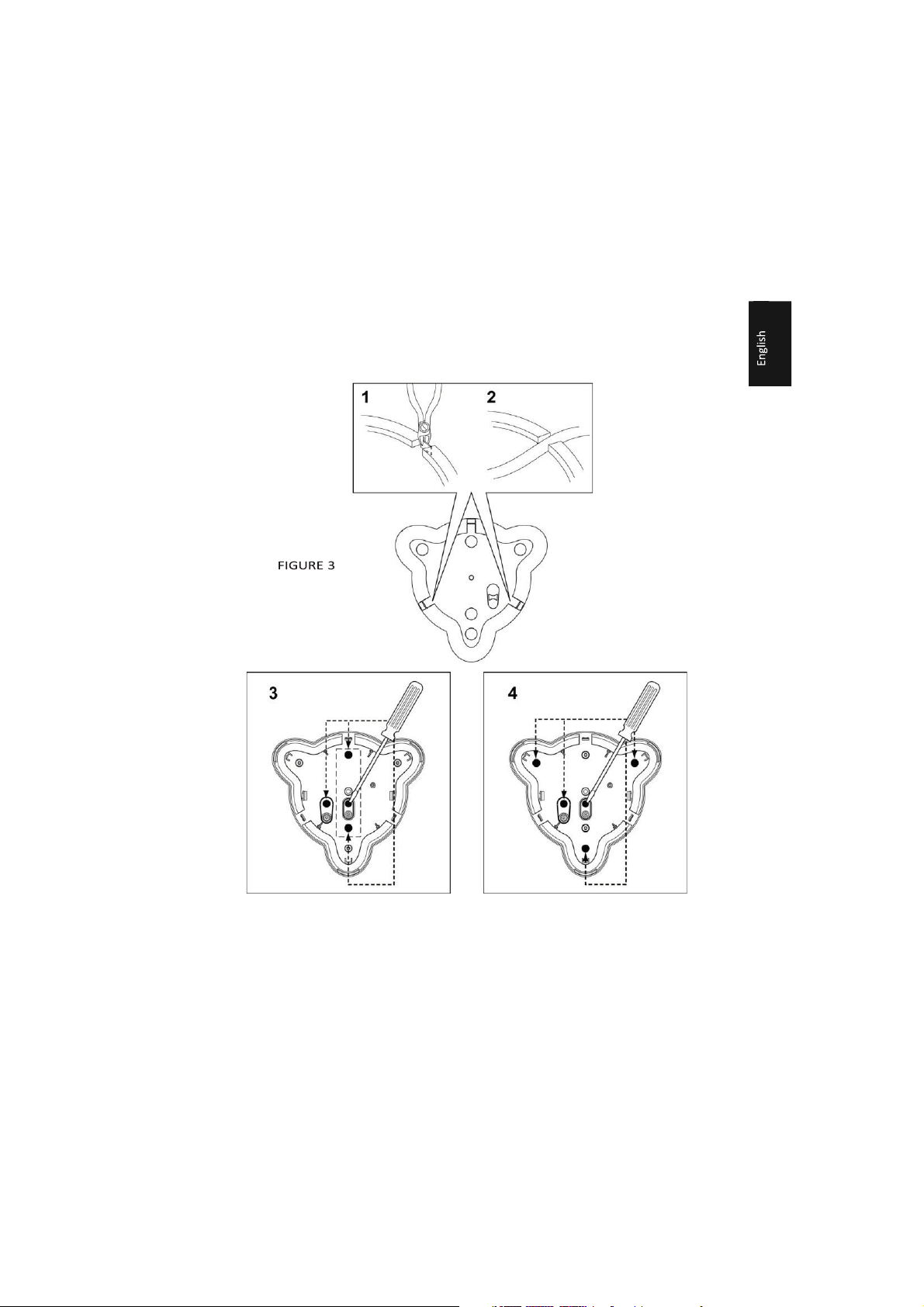

To open the detector (Figure 1), remove the cover by inserting a screwdriver (1) in the recess between the

detector’s protection cap and the cover. The cover will remain attached to the base of the detector.

Using a Philips screwdriver, release the upper cover screw (2) and gently pull upward the detector’s upper

cover.

10 Ind. LuNAR RK200DTG3 Installation Guide

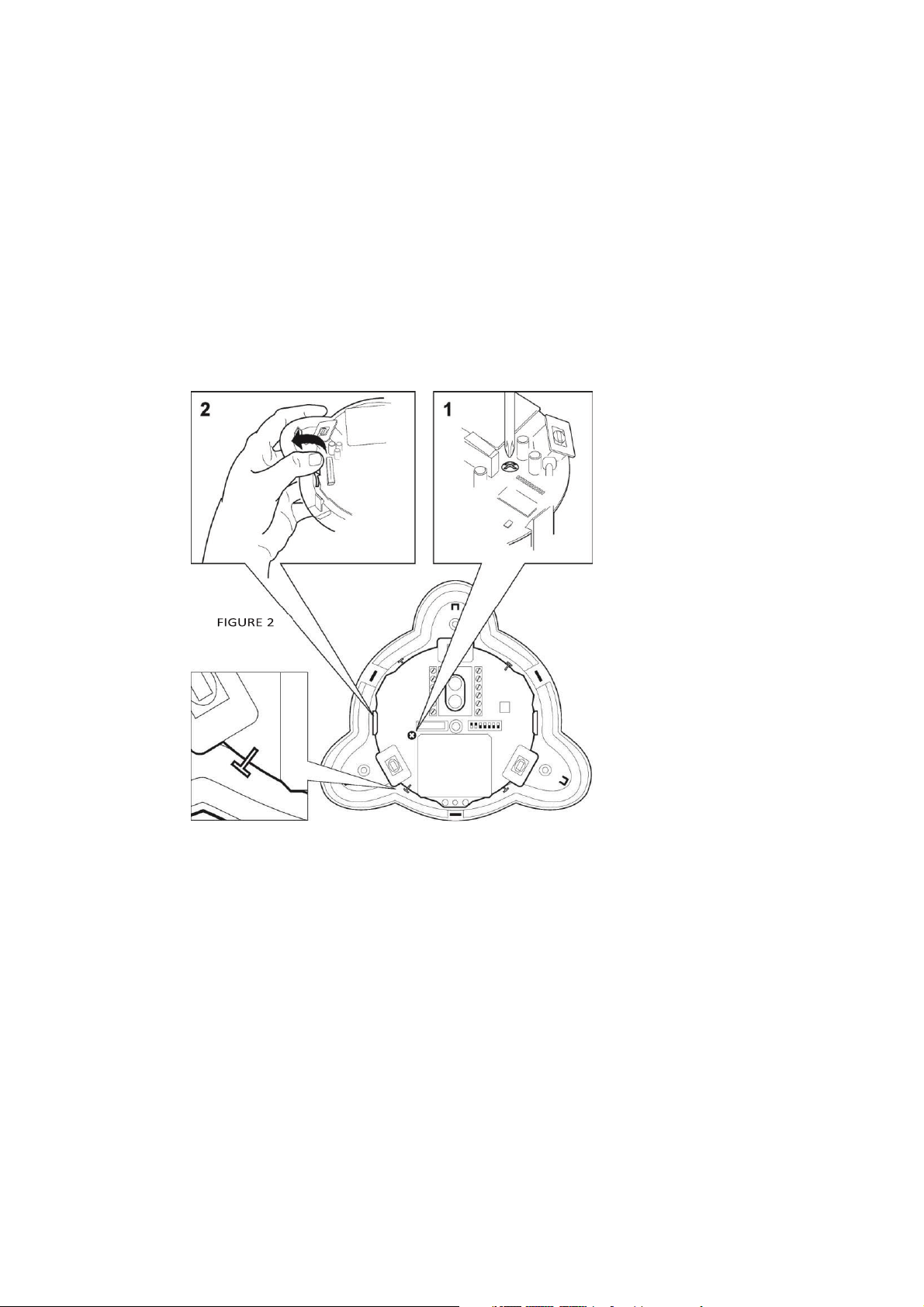

Release the PCB holding screw (Figure 2) located on the right hand side of the PCB (1), pull gently the two

release clips (2) outward and remove the PCB.

Ind. LuNAR RK200DTG3 Installation Guide 11

using a screwdriver.

Do not touch the PIR

sensors!

Do not remove

the white filters from

their

position! They are

essential for

correct operation

of the detector.

If required, open (Figure

3) the wiring channels

knockout using a cutter

(1, 2) and knockout holes

in the rear cover (3, 4)

12 Ind. LuNAR RK200DTG3 Installation Guide

Ind. LuNAR RK200DTG3 Installation Guide 13

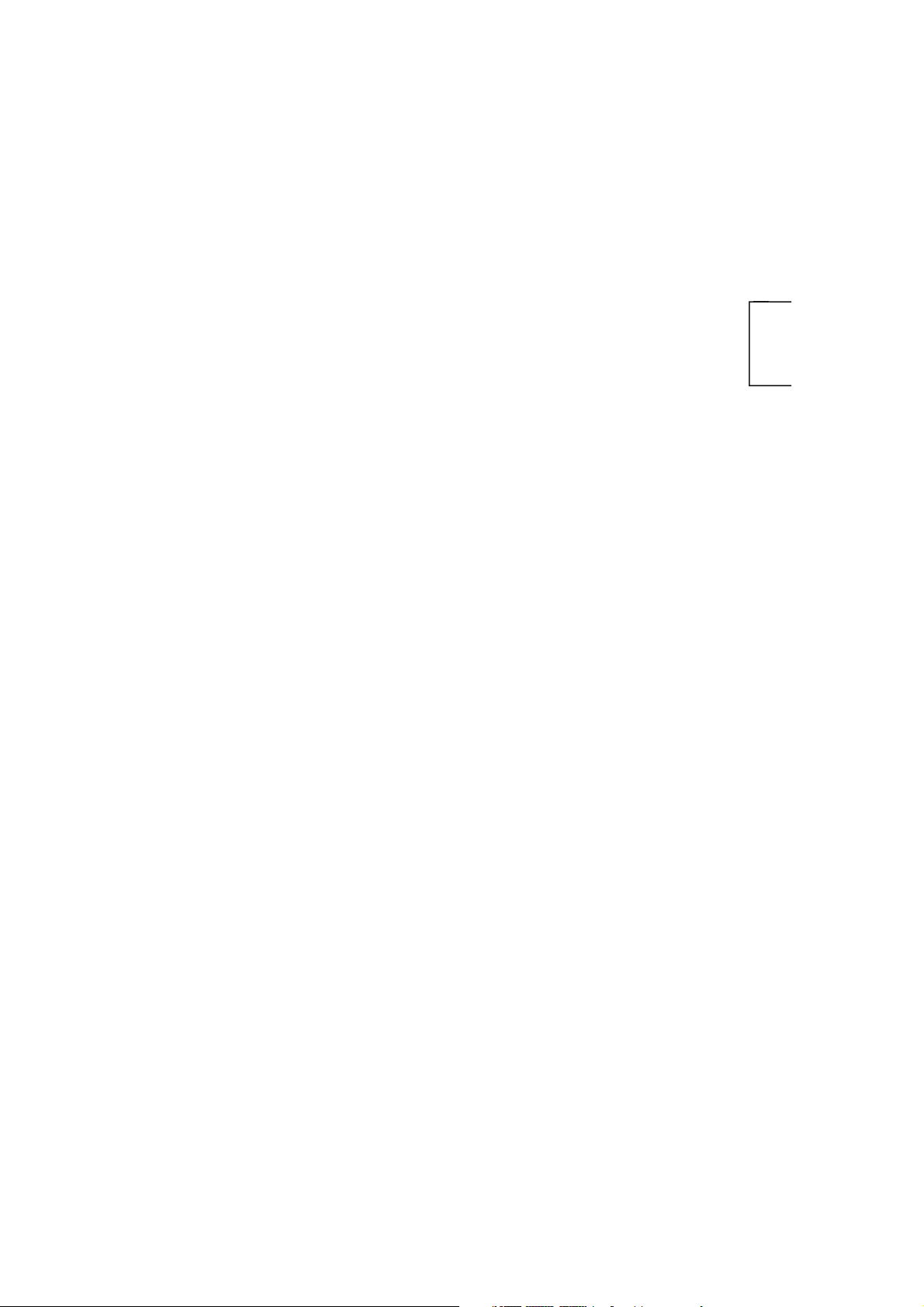

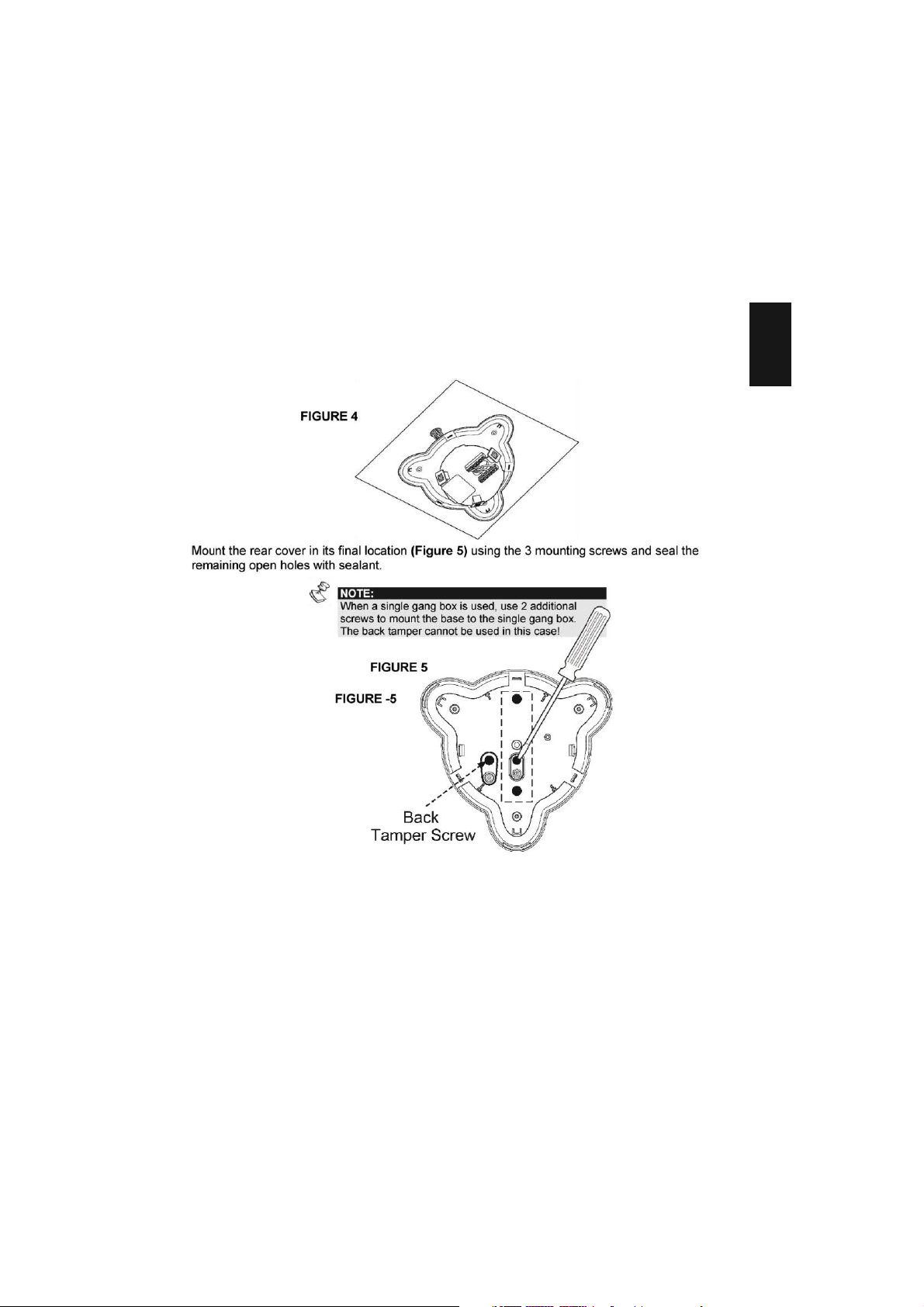

Insert the cable via the cable opening (Figure 4) and connect the desired wires as described in “Step 4-

Wiring”.

14 Ind. LuNAR RK200DTG3 Installation Guide

Return the PCB to its previous location and verify that it is well secured by the holding clips and the screw.

Ind. LuNAR RK200DTG3 Installation Guide 15

NOTE:

For a ceiling tamper, affix the back tamper screw as

shown in Figure 5.

Perform lens adjustment and DIP switch settings as described in “Lens Adjustment” on page 12 and on page

15.

Mount the top cover on the detector’s base.

Tighten the top cover’s central screw.

Replace the detector’s protection cap.

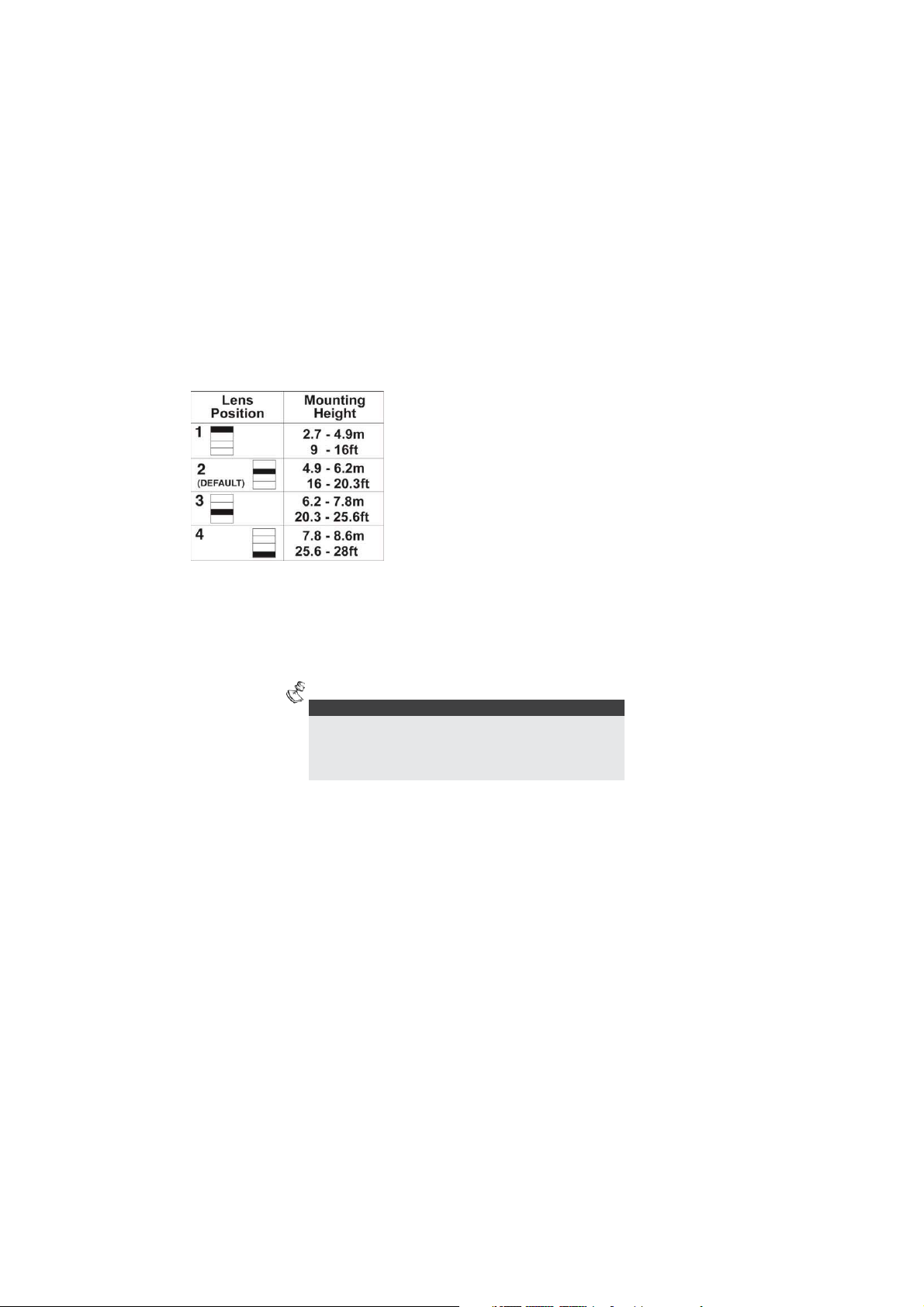

Lens Adjustment:

The Ind. LuNAR RK200DTG3 has three - Fresnel lenses attached to the cover, located in sensor protective

sleeves. Adjust the position of the lenses based on the ceiling mounting height as follows:

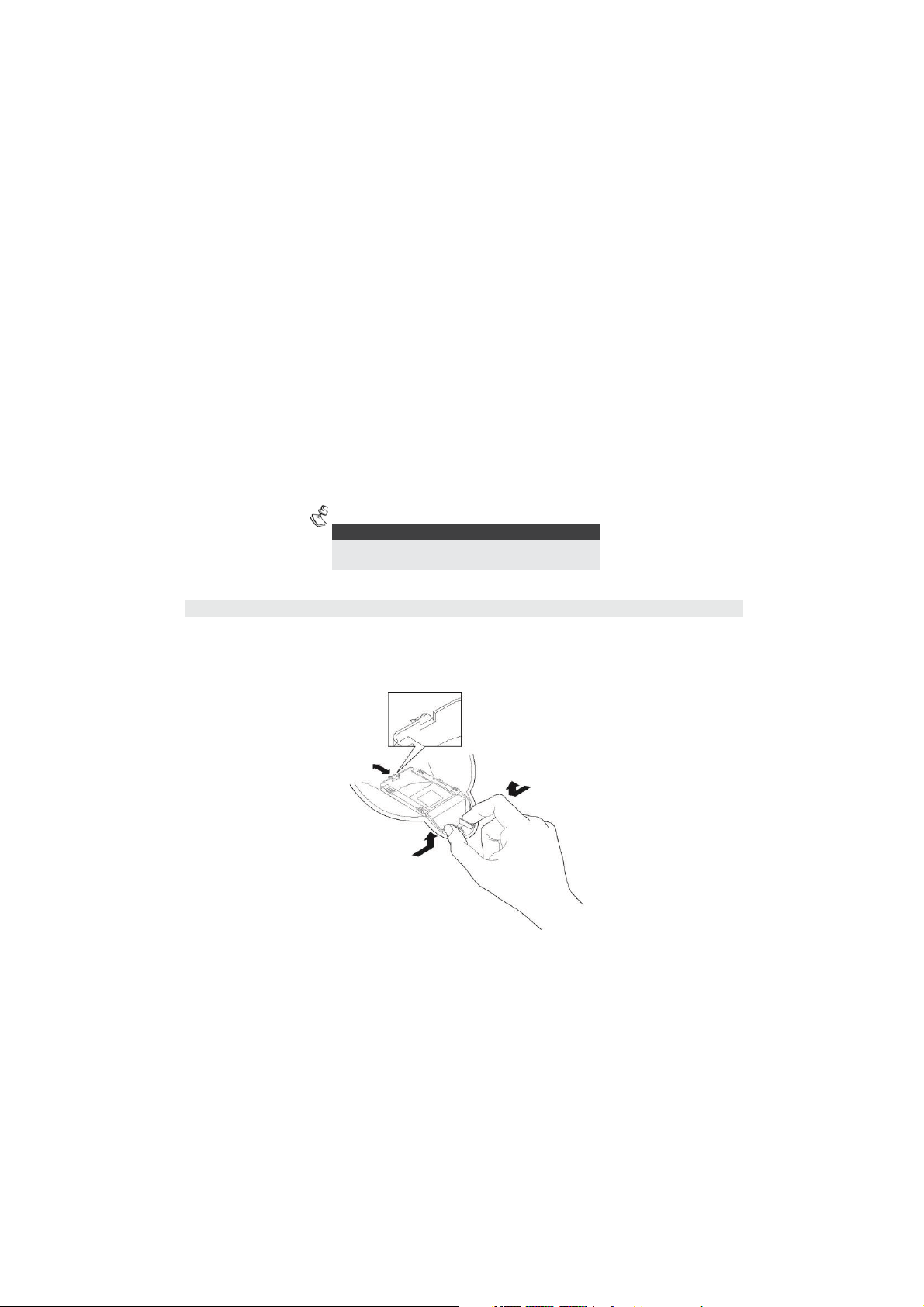

Press the 2 clips attaching the sleeve (Figure 6) to the detector’s cover, and gently pull out the sleeve.

16 Ind. LuNAR RK200DTG3 Installation Guide

FIGURE 6

Remove the lens from the sleeve (Figure 7) by gently lifting it from the holding pins that secure it to the sides

of the sleeve.

FIGURE 7

Place the two pins, which are located on both sides of the sleeve into the matching slots on the lens. Use the

following table to select the desired lens position.

Ind. LuNAR RK200DTG3 Installation Guide 17

NOTES:

Below 3.7m mounting height, the coverage diameter starts

decreasing, and at 2.7m height coverage diameter is 15m (50ft). For

customized coverage, it is possible to set the position of each lens to a

different height, according to the installation conditions.

Return the protective sleeve back into place on the detector front cover.

Repeat steps 1 to 5 for the remaining 2 lenses.

18 Ind. LuNAR RK200DTG3 Installation Guide

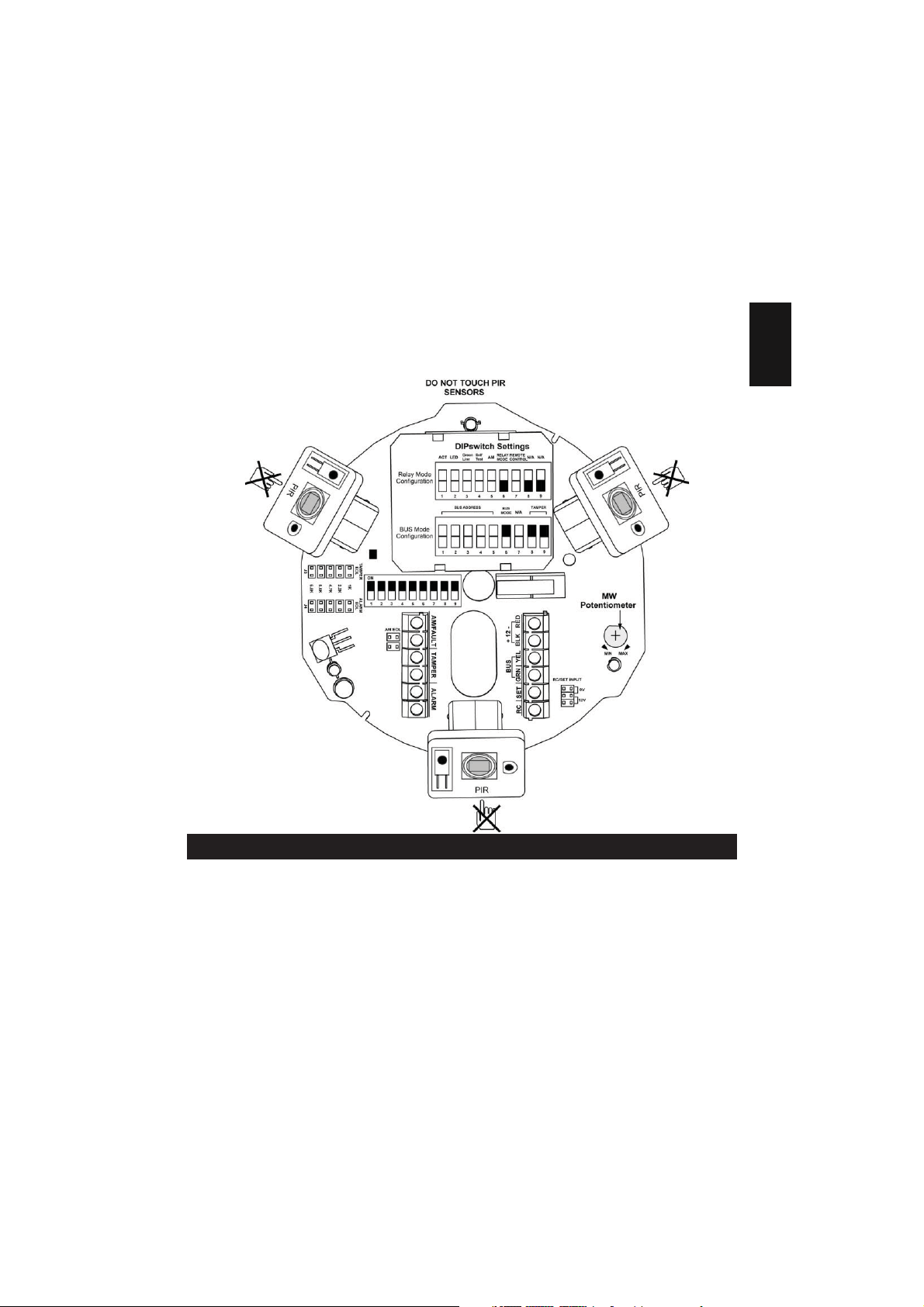

Selectors and Jumpers

Ind. LuNAR RK200DTG3 Installation Guide 19

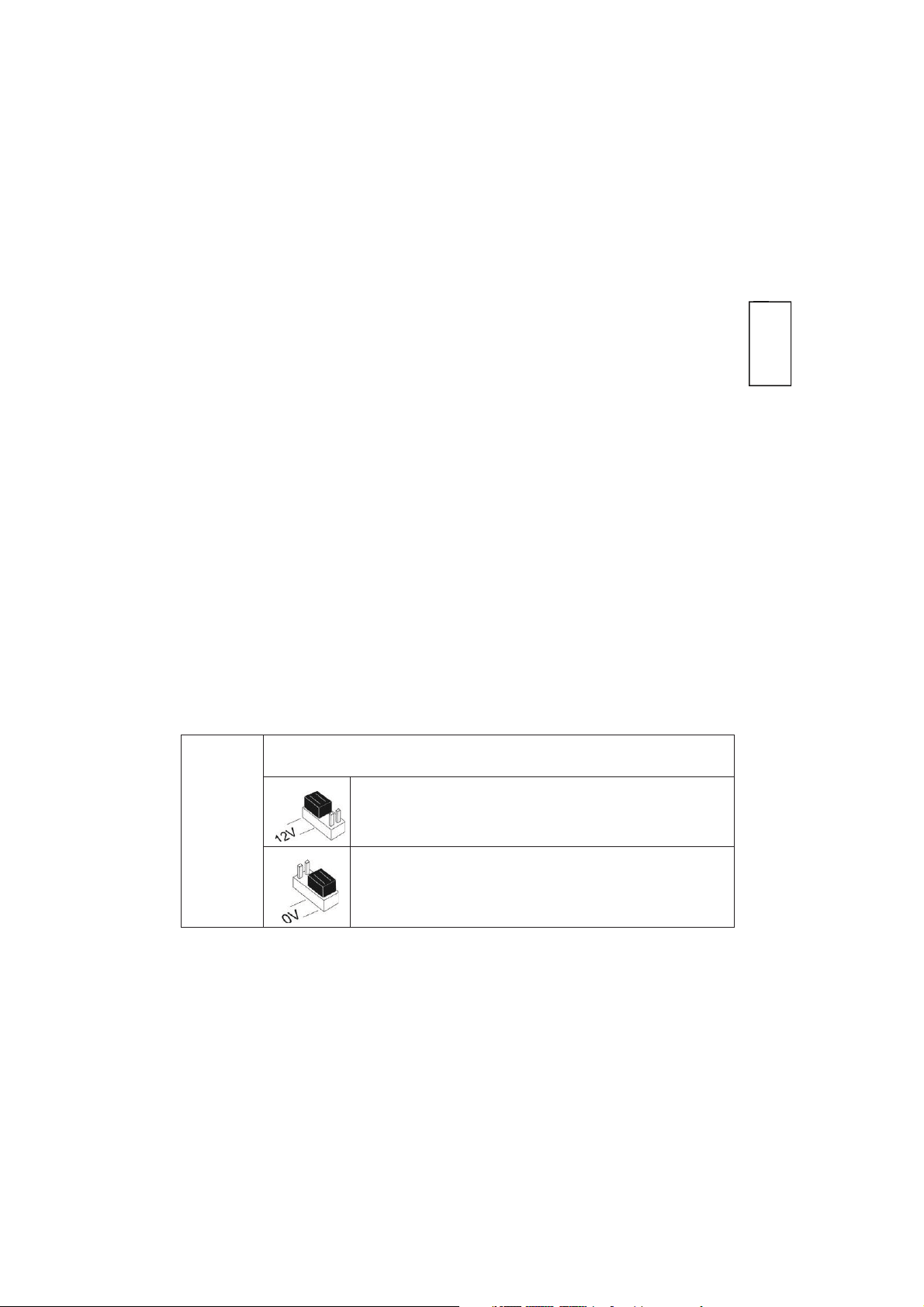

RC/SET INPUT

Used to determine the polarity of the external inputs.

0V: The GND has to be connected in order to activate the function.

12V: 12v has to be connected in order activate the function.

GND or N.C. has no influence on the RC/SET status. (see Relay

mode DIP switches configuration)

20 Ind. LuNAR RK200DTG3 Installation Guide

12v or N.C. has no influence on the RC/SET status. (see Relay

mode DIP switches configuration)

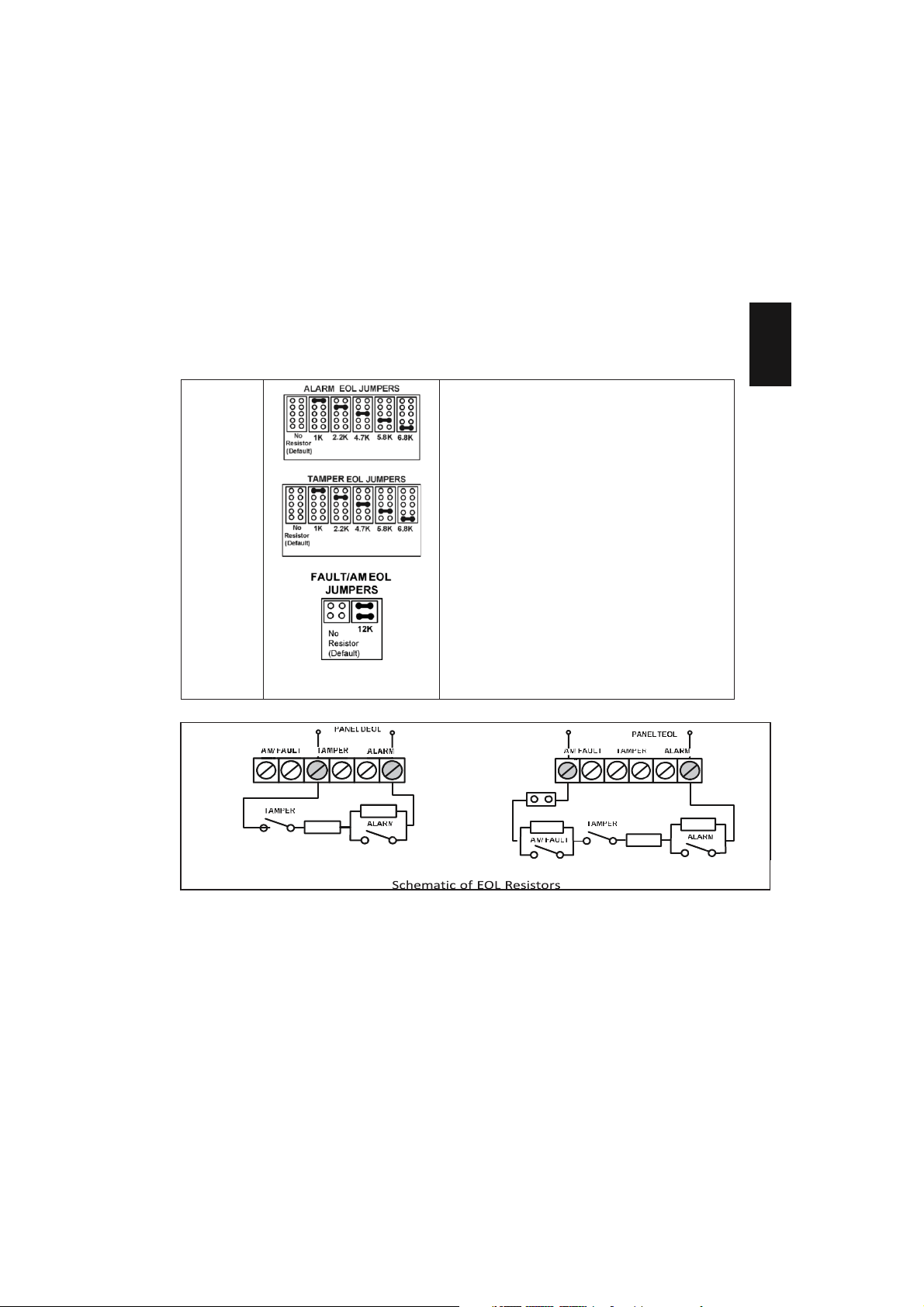

EOL RESISTORS

JUMPERS

The jumpers are used when connecting the detector to

a DEOL or TEOL Zone. The jumpers allow the selection

of TAMPER, ALARM E.O.L resistors (1K, 2.2K, 4.7K, 5.6K

or 6.8K), according to the control panel settings. An

additional double jumper allows the connection of 12K

FAULT/AM E.O.L resistor (see EOL Resistors Schematic).

Follow the terminal block connection diagram when

connecting the detector to a Double/Triple

End Of Line (DEOL/TEOL) Zone

Ind. LuNAR RK200DTG3 Installation Guide 21

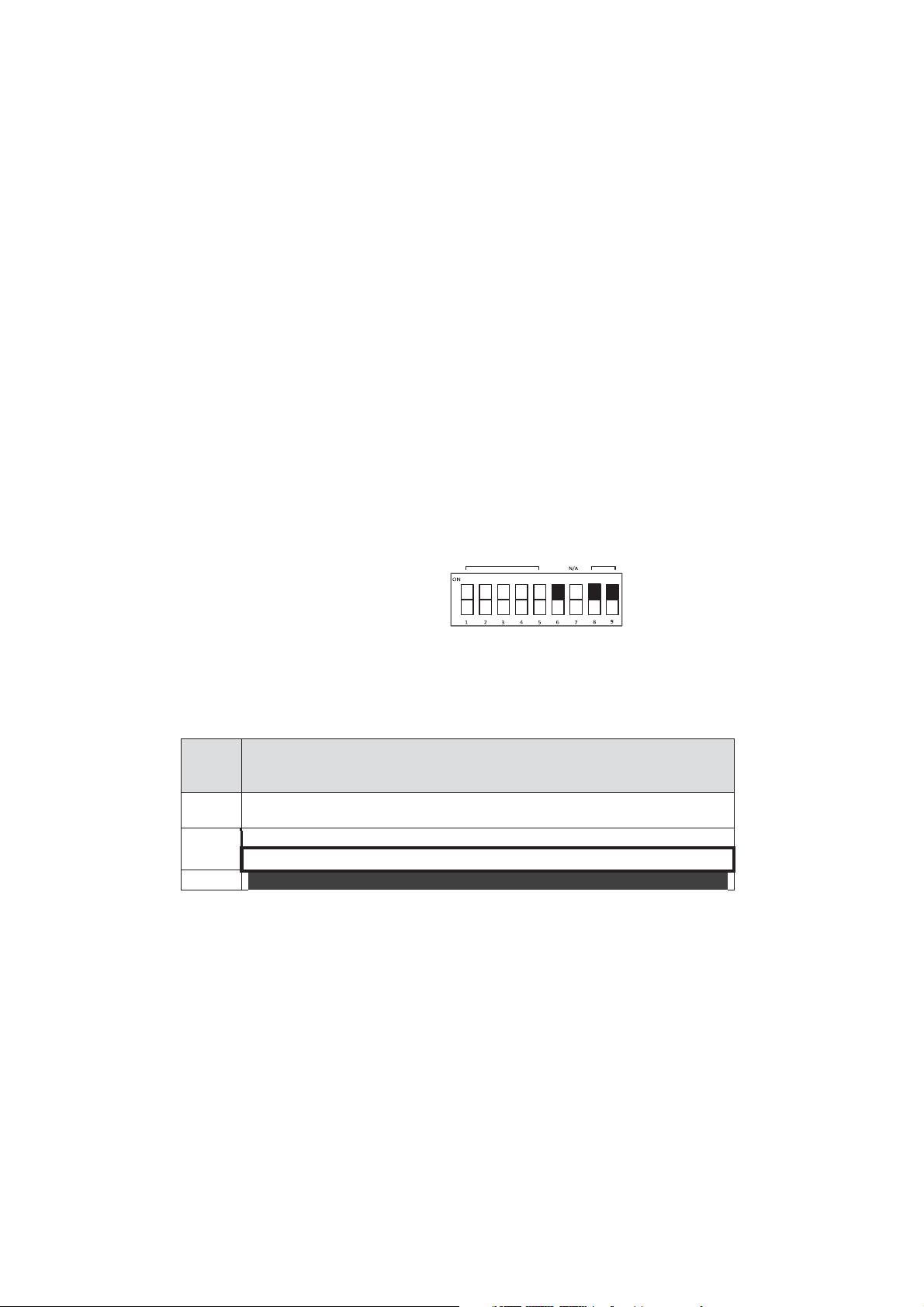

1 2 3 4 5 6 7 8 9

DIP Switch Settings

The Ind. LuNAR RK200DTG3 has a 9 position DIP switch that changes functionality for use in Relay mode or in

BUS operation mode. Set the DIP switch according to the tables below:

Factory Default Settings:

ON

22 Ind. LuNAR RK200DTG3 Installation Guide

Relay Mode Configuration (DIP

switch 6=OFF)

:

Number

Green Self RELAY REMOTE

ACT LED AM N/A

N/A Line Test

MODE CONTROL

ON

1 2 3 4 5 6 7 8 9

DIP switch Description

1 Used to determine the operation of the ACT

DIP switch ON: ACT is enabled

DIP switch OFF: ACT is disabled (default factory)

2 Used to determine the operation of the detector’s LEDs Dip switch ON: LEDs are

enabled (default factory)

DIP switch OFF: LEDs are disabled

3 Used to determine the operation of the "Green Line" (See Note below)

DIP switch ON: "Green Line" is enabled

DIP switch OFF: "Green Line" is disabled (default factory)

4 Used to determine the type of Self Test (See Note below) DIP switch ON: Local

Self Test:

In case the local self test fails, the FAULT/AM Relay is activated for a period of 2.5 secs. DIP

switch OFF: Remote Self Test (default factory):

In case the remote self test passes, the Alarm Relays are activated for a period of 5 secs.

In case the test fails, FAULT/AM Relay is activated for a period of 2.5 seconds.

5 Used to determine whether Active IR Anti-Masking is active. (See Note below)

DIP switch ON: Enable

DIP switch OFF: Disable (default factory)

IMPORTANT:

If the AM is enabled via DIP Switch 5, the cover must be fitted within 1 minute from applying the power.

If the detector is already powered up and DIP Switch 5 is turned on, the unit must be down powered to

reset the AM calibration.

6 Used to determine the detector’s connection mode DIP switch OFF: Relay mode

Used to determine if the Remote Control communication is enabled or disabled.

Ind. LuNAR RK200DTG3 Installation Guide 23

DIP switch

Number

Description

Used to set the detector ID number. (See Table 1)

Set the ID number in the same way as for any other ProSYS accessory.

Used to determine the detector’s connection mode.

DIP switch ON: ProSYS connection – BUS configuration

NOTE:

DIP switch ON: RC communication is always enabled.

DIP switch OFF: RC communication depends on the voltage applied to the terminal block 7 “RC”

(default factory)

8-9 DIP switches OFF

When an activation signal is applied to the RC input of the terminal block, RC is enabled.

IMPORTANT:

Turn dipswitch 7 “OFF” after installation and when leaving the site for security reasons. This will prevent

unauthorized use of a remote control unit that may be used to disable the detector.

NOTE:

See Set Terminal Blocks for activation details.

BUS Mode Configuration (DIP

MODE switch 6=ON):

1-5

6

24 Ind. LuNAR RK200DTG3 Installation Guide

BUS ADDRESS TAMPER

BUS

Upon power up or normal operation, the Ind. LuNAR RK200DTG3 waits 10 seconds for ProSYS

communication. Communication problem may occur due to bad wiring, wrong address, or ProSYS not

configured properly; RED LEDs will continuously flash until the problem is solved.

7

Not applicable (RC communication is automatically enabled when entering Walk Test mode in the

ProSYS and disabled otherwise).

8-9

DIP Switch ON: in order to enable the detector to report the tamper status to ProSYS.

01

OFF

OFF OFF OFF OFF

17 OFF OFF OFF

OFF

ON

02

ON

OFF

OFF

OFF

OFF

18

ON

OFF

OFF

OFF

ON

03

OFF

ON

OFF

OFF

OFF

19

OFF

ON

OFF

OFF

ON

04

ON

ON

OFF

OFF

OFF

20

ON

ON

OFF

OFF

ON

05

OFF

OFF

ON

OFF

OFF

21

OFF

OFF

ON

OFF

ON

06

ON

OFF

ON

OFF

OFF

22

ON

OFF

ON

OFF

ON

07

OFF

ON

ON

OFF

OFF

23

OFF

ON

ON

OFF

ON

08

ON

ON

ON

OFF

OFF

24

ON

ON

ON

OFF

ON

09

OFF

OFF

OFF

ON

OFF

25

OFF

OFF

OFF

ON

ON

10

ON

OFF

OFF

ON

OFF

26

ON

OFF

OFF

ON

ON

11

OFF

ON

OFF

ON

OFF

27

OFF

ON

OFF

ON

ON

12

ON

ON

OFF

ON

OFF

28

ON

ON

OFF

ON

ON

13

OFF

OFF

ON

ON

OFF

29

OFF

OFF

ON

ON

ON

14

ON

OFF

ON

ON

OFF

30

ON

OFF

ON

ON

ON

15

OFF

ON

ON

ON

OFF

31

OFF

ON

ON

ON

ON

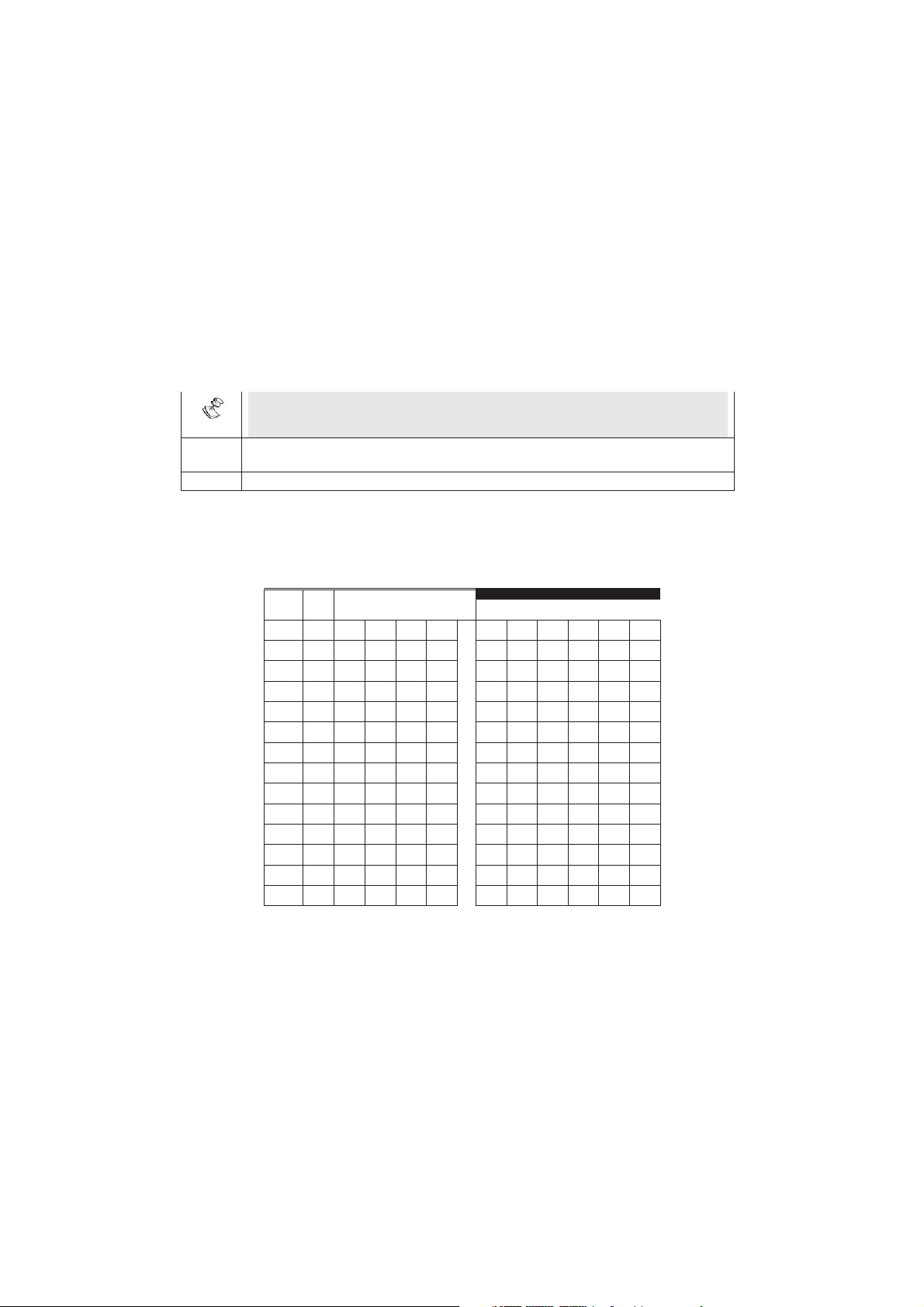

Table 1: ID Settings for BUS connection

Ind. LuNAR RK200DTG3 Installation Guide 25

Terminal Blocks

TERMINAL BLOCK 1

DESCRIPTION

+12V (RED)

Power supply positive (+) input voltage

- (BLK)

Common to control panel power supply

BUS (GRN)

Used for data communication with the ProSYS

BUS (YEL)

Used for data communication with the ProSYS

Used to remotely SET/UNSET the detector.

When an activation signal (see RC/SET Activation jumper for settings) is applied to the SET input

of the terminal block:

Removing an activation signal will cause a Self Test (if the Remote Self Test DIP switch 4 was

previously OFF).

1 2 3 4 5

ID

1

2

3

4

5

ID

SET כ

16 ON ON ON ON OFF 32 ON ON ON ON ON

AM will be disabled (if the AM DIP switch 5 was previously ON)

MW module is enabled (if the Green Line DIP switch 3 was previously ON).

26 Ind. LuNAR RK200DTG3 Installation Guide

Used to enable/disable the remote control communication, only when DIP switch 7 is “OFF”.

When an activation signal (see RC/SET input jumper for settings) is applied to the RC input of the

terminal block, Remote Control will be enabled.

Note: DIP switch 7 “ON” constantly enables RC communication.

WARNING:

Turn DIP switch 7 “OFF” after installation and when leaving the site for security reasons. This

will prevent unauthorized use of a remote control unit that may be used to disable

detector.

כ

Not relevant in BUS mode

TERMINAL BLOCK 2

DESCRIPTION

AM/FAULT

Normally closed output

The AM/FAULT output opens in the following events:

Input voltage is low (6VDC-8VDC)

TAMPER

Normally closed output

ALARM

Normally closed output

RC כ

(REMOTE

CONTROL)

the

Detector is masked (ALARM also opens in this case)

Self Test failed

Ind. LuNAR RK200DTG3 Installation Guide 27

NOTE:

To perform the walk test, first enable the LEDs.

NOTE:

If the PIR/MW LEDs do not TURN ON, probably it means that there

is a problem with either the lens (PIR) position, or MW adjustment!

NOTE:

Adjust the MW to the lowest possible setting that will still

provide enough coverage for the entire protected area!

Walk Test

Two minutes after applying power (warm-up period), walk test the detector over the entire protected area

to verify proper operation of the detector and observe the Tri - color LED. The edge of the microwave

pattern is determined by the first red LED activation (both PIR and MW LEDs are triggered).

Adjust the microwave sensitivity by turning the PCB potentiometer (using a screwdriver), or by using the

Remote Control device. Walk test the unit from all directions to determine all the detection pattern

boundaries.

28 Ind. LuNAR RK200DTG3 Installation Guide

IMPORTANT:

Turn DIP switch 7 “OFF” after installation and when leaving

the site for security reasons. This will prevent unauthorized

use of a remote control unit, that may be used to disable the

detector.

Troubleshooting

When using the Remote Control device, it is recommended to perform the LuNAR Self Test; for further

instructions refer to the Remote Control Instructions.

Upon completion of installation and testing stages, ensure that all switches are in their desired positions.

This section describes possible system problems and their solutions:

Always perform the following preliminary checks before referring to the troubleshooting table:

Ind. LuNAR RK200DTG3 Installation Guide 29

Trouble

Meaning

Response

ProSYS Configuration of detectors

fails/not accepted by the system

ID configuration

problem

Disconnect all power sources, configure

the desired IDs and reconnect power

again

Tamper indication while working in

the BUS mode

Tamper connection

malfunction

Verify that both DIP 8 and 9 are in ON

position

Perform a complete visual inspection of the Ind. LuNAR RK200DTG3, for signs of mechanical damage, loose

connections or torn wires.

Check the connections of the incoming AC power source.

30 Ind. LuNAR RK200DTG3 Installation Guide

Tamper indication in the Relay or

BUS mode

Tamper probably

not closed

Visually verify that ceiling tamper and

spring are correctly installed

Walk test cannot be initiated via the

ProSYS keypad

Wrong code

Insert the appropriate code

Green LED doesn’t operate during

Walk test

MW channel does not

function

Ind. LuNAR

RK200DTG3

configured (via the

ProSYS) to the

“MW

DISARM”

during ProSYS’s

DISARM mode

Normal behavior

Ind. LuNAR

RK200DTG3

operating in

Bypass mode

due to “Bypass

MW channel

mode”

Reset the detector.

If MW channel trouble reoccurs, replace

the detector with a new one

Coverage

Coverage pattern consists of 192 fingers (96 Fresnel facets) divided

into 3 lens sections.

Each lens section has 4 adjustable vertical positions for variable

mounting height and customized coverage.

360° by 18m (60ft) diameter. When moun

3.7m, the coverage diameter starts to decrease up to 15m (50ft).

Variable Mounting Height

From 2.7m to 8.6m (9’ to 28’), 4 lens positions according to installation

height

RFI immunity

According to EN50130-4

-

Specifications

is

disable on

ting the detector under

Ind. LuNAR RK200DTG3 Installation Guide 31

Operating voltage

9 to 16VDC

Current consumption

20mA at 12VDC, 30mA at 16 VDC, Maximum 40mA with all LEDs on.

Alarm and AM contacts

Opto-relay NC, 100mA, 24 VDC

Tamper contacts

NC, 500mA, 24 VDC

Alarm Time

2.2 seconds

Warm-up time

2 minutes

Optical Filtering for white light

protection

Pigmented Fresnel lens

Operating temperature

-20° C to 55° C (-4° F to 131° F)

Storage temperature

-20° C to 60° C (-4° F to 140° F)

Dimensions (Height x Diameter)

99mm x 194mm (3.9’’x 7.6’’)

The Ind. LuNAR RK200DTG3 detector is suitable for use in installations

complying with PD6662, EN50131-1 and EN501312-4 Grade 3, Class II.

32 Ind. LuNAR RK200DTG3 Installation Guide

DT AM Grade 3

Modello: RK200DTG3

Descrizione Generale

Il LuNAR industriale DT AM Grado 3 (RK200DTG3) è un rivelatore doppia tecnologia da soffitto che può essere

installato fino ad una altezza di 8.6 metri e integra la rivoluzionaria tecnologia Anti-Cloak™ Technology (ACT™) di

Rivelatore da Soffitto

Manuale di Installazione

RISCO. Il rivelatore ha un’intelligente elaborazione digitale del segnale che configura automaticamente le soglie di

♦

Conforme alle normative europee PD6662, EN50131-1, EN50131-2-4 Grado 3

♦

Rivelatore doppia tecnologia indirizzato con tecnologia Anti-Cloak™

♦

Installazione fino a 8.6 metri di altezza

♦

Copertura di 3600 con 18 metri di diametro

♦

3 rivelatori PIR indipendenti per una copertura programmabile

♦

Elaborazione Digitale del Segnale – verifica dell’allarme e modifica delle soglie di allarme in

funzione del movimento dell’intruso all’interno dell’area protetta

♦

Resistenze di fine linea selezionabili tramite ponticelli

♦

IR attivo Anti-Mask conforme alle specifiche tecniche europee EN50131

♦

Interruttori antimanomissione contro l’apertura e la rimozione

♦

Configurazione "Green Line" per dis abilitare le emissioni della sezione microon da ad impianto

disinserito

♦

Relè opto isolati a basso assorbimento di corrente e lunga durata

♦

Auto-test locale o remoto tramite comando remoto

♦

Ingresso di stato impianto inserito/disinserito (SET)

♦

Ingresso per l’abilitazione del dispositivo di controllo remoto (RC)

♦

Ottimizzazione della copertura PIR tramite lo spostamento delle Lenti

♦

Portata Microonda regolabile manualmente tramite potenziometro (regolazione analogica) e

in remoto (regolazione digitale)

♦

Indicazione di anomalia (tramite LED o in remoto)

allarme e il conteggio degli impulsi in funzione del movimento dell’intruso all’interno dell’area protetta rispetto ai

fattori ambientali, garantendo la migliore rivelazione possibile.

Il Ind. LuNAR RK200DTG3 può funzionare sia come unità “stand alone”, collegabile a qualsiasi centrale d’allarme, sia come

Accessorio BUS, collegabile via BUS RS-485 ai sistemi d’allarme RISCO serie ProSYS.

Caratteristiche del Ind. LuNAR RK200DTG3

2

♦

3 LED con tricolore per effettuare agevolmente la prova di copertura

♦

Controllo e diagnostica remota avanzata

♦

Limitazione dell’assorbimento in corrente se collegato ai sistemi d’allarme ProSYS

Ind. LuNAR RK200DTG3 - Guida all’installazione

*

Caratteristiche di Controllo e Diagnostica Remota

♦ Regolazione remota della microonda.

♦ Le utilità di diagnostica includono la lettura della tensione di alimentazione del rivelatore,

lo stato dei 3 canali PIR (Infrarosso) e del canale MW (microonda) (tensione del segnale

e livelli di rumore) e la verifica della versione del firmware.

♦ Visualizzazione remota e controllo della configurazione dell’unità per quanto riguarda la regolazione

della microonda, l’ACT (on/off) e i LED (on/off).

♦ Indicazione remota di anomalia per la sezione PIR, MW e l’ingresso di alimentazione.

♦ Controllo ed esclusione microonda MW (in caso di anomalia MW) e disabilitazione

microonda MW durante il periodo in cui l’impianto d’allarme è disinserito (funzione

“Green Line”), se collegato via bus ai sistemi d’allarme ProSYS.

*Tramite il dispositivo bidirezionale di controllo all’infrarosso (opzionale) o il software di teleassistenza se

l’unità è collegata via BUS ad un sistema d’allarme ProSYS.

Sistema di Rilevazione

La rilevazione del Ind. LuNAR RK200DTG3 si basa sulle seguenti tecnologie:

♦ PIR (Infrarosso Passivo) – rileva il cambiamento di temperatura che viene generato da un intruso che

attraversa l’area protetta dal sensore.

Ind. LuNAR RK200DTG3 - Guida all’installazione 3

♦ MW (Microonda) – trasmette segnali e analizza la variazione di frequenza degli stessi

causata da un intruso che si muove all’interno dell’area protetta. Questa tecnologia

lavora con il principio dell’effetto Doppler.

L’ALLARME viene generato solo quando entrambe le tecnologie di rilevazione vengono attivate simultaneamente

(ad eccezione del funzionamento con ACT – consultare la pagina 4 – “Come funziona l’ACT™”), riducendo

drasticamente la percentuale di allarmi impropri.

4

Come funziona l’ACT™

Anti-Cloak™ (ACT™) è la prima vera innovazione della tecnologia di rivelazione volumetrica antintrusione

dall'introduzione della tecnologia ad Infrarosso Passivo. Offrendo i benefici di un rivelatore a Doppia

Tecnologia ma allo stesso tempo sopperendo ai suoi punti deboli, questa innovazione, in attesa di brevetto,

costituisce un nuovo standard nella tecnologia dei rivelatori antintrusione.

I rivelatori a doppia tecnologia Microonda e Infrarosso Passivo sono stati un importante sviluppo per

l'industria della sicurezza per la loro capacità di riduzione degli allarmi impropri. Essi però hanno due grandi

punti deboli:

Gli intrusi possono evitare di essere rilevati dal canale IR bloccando le radiazioni infrarosse del proprio corpo

con un grosso ombrello, un cartone o altro.

La sensibilità del PIR si riduce notevolmente quando vengono protette aree in cui la temperatura ambientale

raggiunge quella del corpo umano.

In risposta alle richieste dei clienti di risolvere queste problematiche, RISCO ha sviluppato la rivoluzionaria

tecnologia chiamata ACT™.

ACT™ previene la neutralizzazione del sistema di allarme quando il canale all'infrarosso dei normali rivelatori

a doppia tecnologia viene messo in condizione di non rilevare un intruso. Utilizzando algoritmi che analizzano

la forma d'onda e la frequenza dei segnali infrarossi, ACT™ identifica il segnale particolarmente basso di un

intruso in movimento rispetto ad interferenze termiche che potrebbero essere causa di allarmi impropri.

Una volta che la presenza di un intruso è stata rilevata, ACT™ commuta automaticamente il rivelatore da

doppia tecnologia al funzionamento in solo Microonda per un periodo di tempo determinato al fine di

attivare l'allarme con il solo canale Microonda.

Nel secondo caso, quando la temperatura dell'ambiente protetto si avvicina alla temperatura del corpo

umano, ACT™ commuta in microonda singola.

ACT™ garantisce rilevazione dell’intruso anche in condizioni critiche ed elevata immunità ai falsi allarmi.

5 Ind. LuNAR RK200DTG3 - Guida all’installazione

Locale sul

rivelatore

Dispositivo

Remoto

Da centrale

ProSYS

Modo ACT

Abilitazione LED

Sensibilità MW

(via trimmer)

Diagnostica

-

Stato/Anomalie/Informazioni

-

Diagnostica AM

-

-

Esclusione MW se in anomalia

-

-

Disabilita MW in disinserito

(Funzione "Green Line")

-

-

Opzioni di Configurazione del Ind. LuNAR RK200DTG3

Il Ind. LuNAR RK200DTG3 può essere configurato e/o testato in remoto tramite le opzioni elencate nella

tabella che segue:

6 Ind. LuNAR RK200DTG3 - Guida all’installazione

Indicatori LED

LED

STATO

SIGNIFICATO

Acceso

Rivelatore in allarme (rilevazione simultanea su

canale PIR e MW)

Lampeggiante lento

Anomalia di comunicazione con la centrale

ProSYS

Lampeggiante veloce

Rilevazione circuito Anti-Mask (AM)

Acceso

Rilevazione canale Microonda (MW)

Lampeggiante

Anomalia canale Microonda (MW)

Acceso

Rilevazione canale Infrarosso (PIR)

I tre LED tricolori del Ind. LuNAR RK200DTG3, riportano le informazioni che seguono:

Rosso

Verde

Arancio

Ind. LuNAR RK200DTG3 - Guida all’installazione 7

Lampeggiante

Anomalia canale Infrarosso (PIR)

Tutti i LED

Lampeggianti con cambio di colore

Alimentazione iniziale

♦

Prima di procedure con l’installazione, studiare attentamente l’area da proteggere al

fine di trovare la corretta locazione del rivelatore per la migliore copertura possibile.

♦

Non installare mai il LuNAR in un ambiente con un disturbo che causa una condizione

d’allarme persistente in una delle due tecnologie.

♦

Evitare installazioni in presenza oggetti in movimento (ad esempio ventole) che

operano normalmente nell’area coperta dal rivelatore. Puntare l’unità lontano da

vetrate che danno all’esterno o oggetti che possono cambiare temperature

rapidamente.

♦

Non installare il rivelatore in posizioni che possano essere colpite da raggi solari diretti

o vicino a sorgenti di calore. Le zone di rilevazione dovrebbero essere posizionate

davanti a pareti, pavimenti ma non di fronte a tendaggi. La superficie di installazione

deve essere solida, liscia ed esente da vibrazioni.

♦

Per un’ottima rilevazione scegliere la posizione di installazione in modo che l’eventuale

intruso si introduca nell’area prot

♦

L’altezza di installazione consigliata, per una copertura con un diametro di 18 metri, và

da 3.7 a 8.6 metri. Installato a 2.7 metri di altezza il rivelatore ha una copertura

caratterizzata da un diametro di 15 metri.

♦

Il rivelatore và montato a soffitto, preferibilmente al centro dell’area da proteggere.

INSTALLAZIONE

Fase preliminare:

etta attraversando le zone sensibili del rivelatore.

8 Ind. LuNAR RK200DTG3 - Guida all’installazione

I diagrammi di copertura tipici e le relative altezze di installazione sono di seguito illustrate:

Ind. LuNAR RK200DTG3 - Guida all’installazione 9

NOTE:

Quando il rivelatore Ind. LuNAR RK200DTG3 viene

installato in un ambiente ove sono presenti elementi che

causano interferenze, la MW potrebbe avere una

copertura ridotta o un funzio namento anomalo.

Procedura di installazione:

1. Per aprire il rivelatore (Figura 1), inserire un cacciavite nella fessura tra il tappo di protezione superiore e

il coperchio. Il coperchio rimarrà agganciato alla base del sensore.

2. Con il cacciavite svitare la vite del coperchio e tirare a sé il coperchio.

10 Ind. LuNAR RK200DTG3 - Guida all’installazione

3. Allentare la vite di fissaggio della scheda elettronica (Figura 2) posizionata sul lato destro della scheda (1),

premere verso l’esterno le 2 clip di sblocco (2) e rimuovere la scheda elettronica.

Ind. LuNAR RK200DTG3 - Guida all’installazione 11

Non

toccare

con le dita

l’elemento

FIGURA 2

piroelettrico !

Non rimuovere i filtri bianchi di protezione dei PIR dalla loro posizione. Essi sono

indispensabili per il corretto funzionamento

del sensore.

4. Se necessario, aprire con una tronchesina (Figura 3) le predisposizioni per il passaggio cavi (1, 2) e con un

cacciavite i fori a sfondare situati nella base del contenitore (3, 4).

12 Ind. LuNAR RK200DTG3 - Guida all’installazione

FIGURA 3

Ind. LuNAR RK200DTG3 - Guida all’installazione 13

NOTA:

Se si utilizza una scatola elettrica per montare il

rivelatore, usare 2 viti aggiuntive per fissare la base

del rivelatore alla scatola.

In questo caso verificare che sia possibile utilizzare il

tamper antirimozione!

5. Inserire il cavo facendolo passare (Figura 4) tramite gli appositi passaggi ed effettuare i collegamenti

descritti nel paragrafo “Fase 4- Cablaggio”.

FIGURA

6. Installare la base del contenitore (Figura 5) nella posizione finale usando 3 viti di fissaggio e sigillare i

restanti fori aperti con del sigillante.

4

14 Ind. LuNAR RK200DTG3 - Guida all’installazione

NOTA:

Per montare il tamper antirimozione a soffitto, posizionare

la vite del tamper come mostrato in Figura 5.

7. Inserire la scheda elettronica nella posizione originale e verificare che sia bloccata dalle clip e dalla vite di

fissaggio.

8. Effettuare la regolazione delle lenti e la predisposizione dei microinterruttori come descritto nel paragrafo

“Regolazione delle Lenti” alla pagina 12 e “Configurazione Microinterruttori” alla pagina 15.

9. Montare il coperchi del rivelatore sulla base.

10. Stringere il coperchio tramite l’apposita vite centrale.

11. Riposizionare il tappo di protezione del rivelatore.

Regolazione delle Lenti:

Il Lunar ha tre lenti di Fresnel pigmentate integrate nel coperchio del rivelatore inserite all’interno di una

sezione plastica che protegge gli elementi piroelettrici. Regolare la posizione di queste tre lenti in funzione

dell’altezza di installazione come di seguito spiegato:

Ind. LuNAR RK200DTG3 - Guida all’installazione 15

1. Premere le 2 clip di sblocco del supporto plastico (Figura 6) che mantiene la lente tirandolo verso

l’esterno.

2. Rimuovere la lente sganciandola dai supporti laterali (Figura 7) che la fissano alla sua custodia plastica.

16 Ind. LuNAR RK200DTG3 - Guida all’installazione

3. Posizionare i 2 supporti laterali posizionati ai lati della custodia plastica negli appositi fori della scala

verticale della lente facendo riferimento alla tabella seguente.

FIGURA 7

Ind. LuNAR RK200DTG3 - Guida all’installazione 17

NOTE:

Al di sotto dei 3.7 metri di altezza di installazione il diametro di copertura

di 18 metri inizia a diminuire fino ad arrivare a 15 metri ad una altezza di

installazione di 2.7 metri.

Per una copertura personalizzata è possibile predisporre la posizione di

ognuna delle 3 lenti ad altezze differenti in funzione delle condizioni di

installazione.

4. Riposizionare la custodia plastica della lente nel coperchio del Lunar.

5. Effettuare la stessa procedura per le altre 2 lenti.

18 Ind. LuNAR RK200DTG3 - Guida all’installazione

Ind. LuNAR RK200DTG3 - Guida all’installazione 19

RC/SET

INPUT

Usa

ti per impostare la polarità dei comandi di attivazione per gli ingressi RC e SET.

Posizionato sul lato 12V richiede come comando di attivazione una

tensione positiva. Fare riferimento alla sezione relativa il Cablaggio

Morsettiera, morsetti RC e SET.

Posizionato su 0V richiede come comando di attivazione un riferimento

negativo di alimentazione 0V. Fare riferimento alla sezione relativa il

Cablaggio Morsettiera, morsetti RC e SET.

Predisposizione Ponticelli

20 Ind. LuNAR RK200DTG3 - Guida all’installazione

Ind. LuNAR RK200DTG3 ha un banco di microinterruttori a 9 posizioni le cui funzioni cambiano a seconda della

modalità di funzionamento impostata, RELE’ o BUS.

Ind. LuNAR RK200DTG3 - Guida all’installazione 21

N. Micro interruttore

Descrizione

1

Usato per determinare lo stato del sistema ACT

Microinterruttore ON: l’ACT è abilitato

Microinterruttore OFF: l’ACT è disabilitato (impostazione di fabbrica)

2

Usato per determinare il funzionamento dei LED

Microinterruttore ON: I LED sono abilitati (impostazione di fabbrica).

Microinterruttore OFF: I LED sono disabilitati.

1 2 3 4 5 6 7 8 9

ON

Configurazione di fabbrica:

DISP.

Auto

AM N/A N/A

Modo Collegamento a Relé

(Microinterruttori 6, 8 e 9=OFF):

CTRL

ACT LED

Green

MODO

22 Ind. LuNAR RK200DTG3 - Guida all’installazione

3

Usato per determinare il funzionamento della funzione "Green Line" Microinterruttore ON: La

funzione "Green Line" è abilitata.

Quando la funzione Green Line è attiva (Microonda spenta), il rivelatore si attiva usando la sola

sezione ad infrarossi (PIR).

NOTA: Per avere maggiori dettagli sull’attivazione della funzione fare riferimento al morsetto

SET nella sezione cablaggio morsettiere.

Microinterruttore OFF: La funzione “Green Line” è disabilitata. La sezione a microonda (MW) è

sempre accesa. (impostazione di fabbrica)

4

Usato per testare le tecnologie di rilevazione.

Microinterruttor

Se non viene rilevata alcuna attivazione del canale PIR per 1 ora, il rivelatore eseguirà un auto

test. Se il test fallisce, l’uscita a relè FAULT/AM verrà attivata per 2,5 secondi.

Microinterruttore OFF (Auto

A conferma che l’auto

secondi. Nel caso in cui l’auto

avere maggiori dettagli sull’attivaz

Test remoto fare riferimento al morsetto SET

nella sezione cablaggio morsettiere.

5

Usato per determinare lo stato di funzionamento dell’Anti-Mask.

Microinterruttore ON: Il circuito di Anti

NOTA: Per avere maggiori de

Mask fare riferimento

al morsetto SET nella sezione cablaggio morsettiere.

Microinterruttore OFF: Il circuito di Anti-Mask è disabilitato.(impostazione di fabbrica)

IMPORTANTE:

Se l’Anti-Mask (AM) viene abilitato tramite il microinterruttore 5, il coperchio del rivelatore deve

essere chiuso correttamente entro 1 minuto da quando viene alimentato. Se il rivelatore è già

alimentato e il microinterruttore 5 viene spostato su ON, togliere e ridare alimentazione al rivelatore

per resettare correttamente la stabilizzazione del circuito di Anti-Mask.

6

Usato per stabilire il modo di collegamento del rivelatore

Microinterruttore OFF: Modo Relé

e ON (Auto-Test locale):

-

-Test remoto) - (impostazione di fabbrica):

-test remoto è stato superato l’uscita a relé di allarme si attiverà per 5

-test sia fallito si attiverà l’uscita a relé FAULT/AM. NOTA: Per

ione dell’Auto-

ttagli sullo stato di funzionamento dell’Anti-

-Mask è abilitato.

Usato per abilitare o disabilitare il dispositivo remoto.

attivazione al morsetto RC del rivelatore (0V o 12V in funzione della polarità 7 configurata tramite il

ponticello RC/SET INPUT). (impostazione di fabbrica).

Ind. LuNAR RK200DTG3 - Guida all’installazione 23

Microinterruttore ON: Dispositivo remoto SEMPRE abilitato.

Microinterruttore OFF: Il dispositivo remoto viene abilitato solo se presente un segnale di

IMPORTANTE:

Per la sicurezza del sistema, spostare il microinterruttore 7 in posizione OFF dopo l’installazione. Questo

eviterà che un male intenzionato, in possesso di un dispositivo di controllo remoto, disabiliti le funzioni di

rilevazione del sensore.

8-9 Microinterruttori su OFF

IMPORTANTE:

Scollegare l’alimentazione del rivelatore prima di configurare i Microinterruttori. Alimentare

nuovamente l’unità dopo aver completato la configurazione!

24 Ind. LuNAR RK200DTG3 - Guida all’installazione

N. Microinterruttore

Descrizione

1-5

Usati per impostare l’indirizzo ID del rivelatore. (Consultare la Tabella 1)

6

Imposta il modo di collegamento del rivelatore.

Microinterruttore ON: Modo di collegamento via BUS PROSYS

All’alimentazione, in modo normale di funzionamento, il LuNAR attende 10 secondi per la

comunicazione con la centrale ProSYS. Problemi di comunicazione possono essere causati da

cablaggio errato, indirizzo errato, o sistema ProSYS non configurato correttamente; in queste

condizioni tutti i LED del rivelatore lampeggeranno fino alla soluzione del problema.

7

Non applicabile. Il dispositivo di controllo remoto RC viene automaticamente

abilitato entrando nel menù Test Sensori della centrale ProSYS e disabilitato quando

si esce dal menù.

8-9

Microinterruttore ON: Abilita il rivelatore a comunicare lo stato del tamper alla centrale

ProSYS.

Modo collegamento via BUS ProSYS INDIRIZZO ID RIVELATORE TAMPER

MODO

BUS (Microinterruttore 6, 8 e 9=ON):

Ind. LuNAR RK200DTG3 - Guida all’installazione 25

01

OFF

OFF OFF OFF OFF

17 OFF OFF OFF

OFF

ON

02

ON

OFF

OFF

OFF

OFF

18

ON

OFF

OFF

OFF

ON

03

OFF

ON

OFF

OFF

OFF

19

OFF

ON

OFF

OFF

ON

04

ON

ON

OFF

OFF

OFF

20

ON

ON

OFF

OFF

ON

05

OFF

OFF

ON

OFF

OFF

21

OFF

OFF

ON

OFF

ON

06

ON

OFF

ON

OFF

OFF

22

ON

OFF

ON

OFF

ON

07

OFF

ON

ON

OFF

OFF

23

OFF

ON

ON

OFF

ON

08

ON

ON

ON

OFF

OFF

24

ON

ON

ON

OFF

ON

09

OFF

OFF

OFF

ON

OFF

25

OFF

OFF

OFF

ON

ON

10

ON

OFF

OFF

ON

OFF

26

ON

OFF

OFF

ON

ON

11

OFF

ON

OFF

ON

OFF

27

OFF

ON

OFF

ON

ON

12

ON

ON

OFF

ON

OFF

28

ON

ON

OFF

ON

ON

13

OFF

OFF

ON

ON

OFF

29

OFF

OFF

ON

ON

ON

14

ON

OFF

ON

ON

OFF

30

ON

OFF

ON

ON

ON

15

OFF

ON

ON

ON

OFF

31

OFF

ON

ON

ON

ON

5

Tabella 1: Predisposizione Indirizzi ID

ID 1

2 3

4 5

ID

1 2

3 4

16 ON

ON ON

ON OFF

32 ON

ON ON

ON ON

26 Ind. LuNAR RK200DTG3 - Guida all’installazione

Cablaggio Morsettiere

MORSETTIERA 1

DESCRIZIONE

+12V (RED)

Ingresso di alimentazione positiva (+)

- (BLK)

Comune da collegare all’alimentatore della centrale

BUS (GRN)

Usato per la comunicazione dei dati con la ProSYS

BUS (YEL)

Usato per la comunicazione dei dati con la ProSYS

Controllo remoto dello stato impianto.

Stato Inserito: Quando viene applicato un **”Segnale di Attivazione” a questo morsetto, il circuito di An

viene disabilitato (se il microinterruttore 5 è su ON).

Stato Disinserito: Se all’ingresso non viene collegato niente il circuito Anti-Mask viene abilitato (se il

microinterruttore 5 è su ON) e la sezione a microonda viene disabilitata “funzione Green Line” (se il

microinterruttore 3 è su ON). Rimuovendo un **”Segnale di Attivazione” a questo morsett o, verrà anche

attivato l’Auto-Test remoto (se il microinterruttore 4 è su OFF).

Usato per abilitare/ disabilitare il dispositivo a d infrarossi di Con trollo Remoto (RC) tramite una uscita della

centrale d’allarme, solo quando il microinterruttore 7 è in posizione “OFF”.

Quando viene applicato un **”Segnale di Attivazione” al morsetto RC, il Dispositivo di Controllo Remoto

verrà abilitato.

Nota: : il microinterruttore 7 in posizione “ON” abilita costantemente il dispositivo di Controllo Remoto R

** Per Segnale di Attivazione si intende quanto segue:

Viene applicato un riferimento di alimentazione 0V e il ponticello RC/SET INPUT è nella posizione 0V

IMPORTANTE:

Per garantire la sicurezza del sistema, spostare il microinterruttore 7 in posizione OFF dopo l’installazione. Questo eviterà ch

male intenzionato, in possesso di un dispositivo di controllo remoto, possa disabilitare le funzioni di rilevazione del sensore

כ

Non rilevante nella configurazione BUS ProSYS.

SET כ

RC כ

(Dispositivo di

Controllo Remoto ad

Infrarossi)

-

Viene applicata una tensione 12Vcc e il ponticello RC/SET INPUT è nella posizione 12V

-

Ind. LuNAR RK200DTG3 - Guida all’installazione 27

MORSETTIERA 2

DESCRIZIONE

AM/FAULT

Uscita Normalmente Chiusa

L’uscita AM/FAULT si attiva per i seguenti eventi:

L’ingresso di alimentazione è sotto gli 8 V

TAMPER

Uscita tamper Normalmente Chiusa

ALARM

Uscita di allarme Normalmente Chiusa

NOTE:

Per effettuare la prova di movimento ovvero la prova di

copertura del rivelatore, abilitare il funzionamento dei LED.

Il rivelatore è mascherato (anche l’uscita di ALLARME viene attivata) Auto-test del

rivelatore è fallito

Prova di Movimento (Walk Test)

28 Ind. LuNAR RK200DTG3 - Guida all’installazione

1. Dopo due minuti dalla alimentazione (periodo di riscaldamento), verificare la copertura del rivelatore

NOTA:

Se il LED del PIR (Giallo) o della MW (Verde) non si Illumina indica

un problema di regolazione della Lente del PIR o del

potenziometro di sensibilità della MW. Effettuare le regolazioni e

riprovare.

muovendosi all’interno dell’area da proteggere e osservare i LED a tre colori dell’unità. L’accensione

del LED rosso determina la corretta copertura del rivelatore (attivazione PIR e MW).

2. Regolare la sensibilità della microonda (MW) ruotando con un cacciavite il potenziometro posizionato

sulla scheda elettronica del prodotto o tramite il dispositivo di comando remoto ad infrarossi.

Camminare in tutte le direzioni all’interno dell’area da proteggere per determinare l’area coperta dal

rivelatore.

Ind. LuNAR RK200DTG3 - Guida all’installazione 29

NOTA:

Regolare la sensibilità della microonda al valore minimo

possibile per coprire l’area da proteggere !

3. Utilizzando il Dispositivo di Controllo Remoto a infrarossi, si raccomanda di effettuare l’Auto Test del

IMPORTANTE:

Per garantire la sicurezza del sistema, spostare il

microinterruttore 7 in posizione OFF dopo l’installazione.

Questo eviterà che un male intenzionato, in possesso di un

dispositivo di controllo remoto, possa disabilitare le funzioni

di rilevazione del sensore.

Anomalia

Spiegazione

Soluzione

La configurazione dei rivelatori

non viene accettata dalla centrale

ProSYS

Problema di

configurazione

dell’indirizzo ID del

rivelatore

Scollegare tutte le sorgenti di

alimentazione (rete elettrica e

batterie), verificare la configurazione

dell’indirizzo ID dei rivelatori e ridare

alimentazione.

LuNAR. Per maggiori informazioni fare riferimento alle Istruzioni fornite con il Dispositivo di Controllo

Remoto.

Una volta terminata la fase di installazione e test dell’unità, assicurarsi che tutti i microinterruttori siano

posizionati correttamente per le funzioni richieste.

Ricerca Guasti

Questo paragrafo descrive le possibili problematiche del prodotto e le rispettive soluzioni.

Ricordarsi di effettuare tutti i controlli preliminari descritti in questo manuale prima di fare riferimento alla

tabella Ricerca Guasti che segue.

Effettuare una ispezione preliminare del rivelatore per rilevare eventuali danni meccanici, connessioni

allentate, o cavi danneggiati.

Controllare le connessioni alla sorgente di alimentazione e verificare che ci sia la corretta alimentazione al

rivelatore.

30 Ind. LuNAR RK200DTG3 - Guida all’installazione

Segnalazione di Tamper

(manomissione) utilizzando il

modo di collegamento BUS ProSYS

Connessione del

Tamper errata per il

funzionamento in modo

BUS ProSYS

Verificare che i microinterruttori 8 e 9

siano in posizione ON.

Segnalazione di Tamper

(manomissione) nel modo di

funzionamento Relé o BUS

L’interruttore del

Tamper è

probabilmente aperto

Verificare che la molla di chiusura

dell’interruttore del tamper del

contenitore sia posizionata

correttamente.

La Procedura di Test Sensori

(Prova di Movimento) non viene

attiv

ata dalla tastiera della

centrale ProSYS

Il codice inserito è errato.

Inserire un codice abilitato ad

effettuare la procedura di test sensori.

Il LED verde non si accende

durante la prova di movimento

(test sensori). Il canale

Microonda (MW) non funzi

(nessuna rilevazione)

1. LuNAR è configurato

(via centrale ProSYS)

per disabilitare la

sezione microonda a

sistema

disinserito

Il funzionamento è corretto, il LED

verde della microonda non deve

illuminarsi.

2. Il LuNAR sta operando

in modo

Microonda a causa di

un’anomalia

del canale microonda

(MW)

Togliere l’alimentazione al sensore e

darla nuovamente, se il problema

persiste, sostituire il rivelatore.

ona

Esclusione

Ind. LuNAR RK200DTG3 - Guida all’installazione 31

Specifiche Tecniche

Copertura

Il diagramma di copertura include 192 elementi sensibili

(96 zone) suddivisi in 3 ottiche. Ogni ottica ha 4 posizioni

per la regolazione verticale per adattarsi all’altezza di

installazione o a coperture personalizzate.

360° e 18m di diametro. Al di sotto dei 3.7 metri di altezza

di installazione il diametro di copertura di 18 metri inizia a

diminuire fino ad arrivare a 15 metri ad una altezza di

installazione di 2.7 metri.

Altezza di installazione variabile

Frequenza sezione MW

Tipo di segnale emesso MW

Potenza Max. irradiata MW

Da 2.7m a 8.6m, 4 posizioni per ogni ottica in

funzione dell’altezza di installazione 10.587 GHz.

Tipo pulsato

13.5 dBm erp

Immunità RFI

Conforme alla normativa EN50130-4

Alimentazione

Da 9 V a 16 V

Assorbimento di corrente

20mA a 12 V, 30mA a 16 V, Massimo 40mA con tutti i

LED accesi.

Contatti di allarme

NC, 100mA, 24 V

Contatti tamper

NC, 500mA, 24 V

Tempo di allarme

2.2 secondi

Tempo di preriscaldamento

2 minuti

Filtro ottico per la protezione

contro le luci bianche

Lenti di Fresnel pigmentate

Temp. di funzionamento

Da -20° C a 55° C

Temp. di funzionamento

certificate

Da 5° C a 40° C

Temp. di stoccaggio

Da -20° C a 60° C

Dimensioni (Altezza x Diametro)

99mm x 194mm

32

Ind. LuNAR RK200DTG3 - Guida all’installazione

Ind. LuNAR RK200DTG3 - Guida all’installazione

DT AM Grau 3

Modelo: RK200DTG3

Detector para instalação em tetos altos

Guia de instalação

34

♦

PD6662, EN50131-1, EN50131-2-4 Grau 3

♦

Detector com Dupla Tecnologia (Microondas + Infravermelho Passivo) com Tecnologia Anti-Cloak™

♦

Altura de montagem de até 8.6 m (28 pés)

♦

Padrão do diâmetro de cobertura de 360° por 18m (60 pés)

♦

3 canais de Infravermelho Passivos para uma cobertura ajustável para cada necessidade

♦

Processamento I nteligente do Sinal Digita l – verificação do alar me e limiares de decisão a justados segundo a atual

velocidade de passagem do intruso

♦

Resistências de fim de linha triplas embutidas, selecionável através de jumper.

♦

Anti-Mascaramento através de Infravermelho Ativo, atendendo aos requisitos EN50131

♦

Tampers de teto e tampa

♦

Configuração “Green” – para desativar o Microondas quando o sistema estiver desarmado

♦

Opto-relés para baixo consumo de corrente e longo ciclo de vida

♦

Autoteste local e remoto

♦

Entrada de SET (ajuste) remoto

♦

Entrada para habilitar/desabilitar o controle remoto

♦

Ajuste das lentes para maior eficiência da cobertura do Infravermelho Passivo

Descrição Geral

O Industrial LuNAR DT AM Grau 3 (RK200DTG3) é um detector de teto de Dupla Tecnologia com uma altura de

montagem de até 8.6m (28 pés), que incorpora a Tecnologia (ACT™) Anti-Cloak™ do RISCO Group. O detector

possui um método de Processamento Inteligente do Sinal Digital que ajusta automaticamente o limiar do alarme e

a verificação do contador de pulsos, segundo a real velocidade de passagem do intruso e fatores ambientais,

proporcionando uma melhor detecção e imunidade a falsos alarmes.

O Ind. LuNAR RK200DTG3 pode funcionar como um detector convencional de relé conectado a qualquer painel de

controle, ou como um acessório direcionável do BUS quando conectado ao painel de controle do ProSYS do RISCO

Group, através do BUS RS485.

Características do Ind. LuNAR RK200DTG3

2 Ind. LuNAR RK200DTG3 – Guia de Instalação

♦

Ajuste do Alcance de Microondas manualmente (Através de Trímmer - Analógico) ou remotamente

(configuração digital)

♦

Indicação de Problemas (por LEDs ou via comunicação)

♦

3 LEDs tricolores para um teste de caminhada fácil

♦

Avançado Controle Remoto e Diagnóstico

♦

Consumo de Corrente reduzido quando conectado ao ProSYS do RISCO Group

♦

Ajuste remoto do canal de microondas permite habilitar o teste de caminhada por uma pessoa.

♦

Ferramentas de diagnóstico incluem a leitura da voltagem de entrada ao detector e o estado de

cada canal de Infravermelho Passivo do canal de microondas (voltagem do sinal e níveis de

ruído), canal AM (voltagem do sinal), verificação da versão do Software.

♦

Apresentação remota e controle da configuração do detector: ajuste do microondas, ACT Ativo /

Inativo, LEDs Ativo / Inativo.

♦

Indicador remota de problemas (Passa / Falha) para o Infravermelho Passivo, o microondas e a

entrada de alimentação de energia

♦

Controle da anulação do canal de Microondas (durante problema de Microondas) e de desabilitar

o canal de Microondas durante o Desarme ("Green Line") quando conectado ao ProSYS.

*

Características de Controle Remoto e Diagnóstico

Ind. LuNAR RK200DTG3 – Guia de Instalação 3

*Através do Controle Remoto Infravermelho Bidirecional opcional, ou do Software Upload/ Download do

ProSYS e o teclado numérico.

Método de Detecção

A detecção do Ind. LuNAR RK200DTG3 está baseada em:

♦ IVP (Infravermelho Passivo) – que responde as mudanças na radiação de Infravermelho causadas

quando um intruso cruza a área protegida.

♦ Microondas – que transmite sinais e analisa as mudanças de freqüência do eco refletido de um

intruso usando o Efeito Doppler.

Um ALARME é iniciado somente quando ambas as tecnologias são acionadas simultaneamente (exceto em

certas situações no modo ACT – ver página 4 – “Como Funciona o ACT™”), reduzindo assim em grande

escala a possibilidade de falsos alarmes.

Como Funciona o ACT™

A Tecnologia Anti-Cloak™ (ACT™) proporciona os benefícios de um detector DT (Dual Technology – Dupla

Tecnologia) enquanto evita as suas desvantagens. Esta inovação (Patente Pendente) criou um novo padrão

para os detectores.

A Dupla Tecnologia, uma combinação de Infravermelho Passivo + Microondas, foi um importante

crescimento para a indústria da segurança... Mas possui 2 grandes pontos fracos:

A emissão de Infravermelho dos intrusos pode ser bloqueada, evitando a detecção.

A sensibilidade do Infravermelho Passivo é reduzida quando a temperatura do ambiente da área protegida

se aproxima à temperatura do corpo.

4 Ind. LuNAR RK200DTG3 – Guia de Instalação

Configuração

Manual

Controle

Remoto

Controle Bus

ProSYS

Modo ACT

LEDs

Respondendo às solicitações de seus clientes para solucionar estes problemas urgentes, o RISCO Group

desenvolveu a ACT™ - uma revolucionária solução anti-camuflagem.

O ACT™ impede que o sistema de alarme seja anulado – neutralizando as tentativas de camuflar a radiação

de Infravermelho. Usando algoritmos de reconhecimento de padrão único, a ACT™ distingue entre o sinal

fraco de Infravermelho de um intruso em movimento e o ruído de fundo e as interferências térmicas que

podem causar falsos alarmes.

Uma vez verificada a presença de um intruso, a ACT™ troca automaticamente o sistema do modo de dupla

tecnologia Infravermelho Passivo/Microondas para o modo de canal único de Microondas por um período

de tempo predeterminado, com a finalidade de ativar um alarme usando o canal Microondas, e depois

retorna ao modo de canal duplo.

No segundo caso, quando a temperatura do ambiente se aproxima à temperatura do corpo, o ACT™ passa a

detecção somente por microondas.

Oferecendo uma capacidade de detecção excepcionalmente alta, assim como imunidade a falsos alarmes, a

ACT™ frustra até aos mais sofisticados intrusos.

Opções de Configuração do Ind. LuNAR RK200DTG3

O Ind. LuNAR RK200DTG3 pode ser configurado e/ou diagnosticado remotamente através de uma das

seguintes opções:

Ind. LuNAR RK200DTG3 – Guia de Instalação 5

Sensibilidade Microondas

(Através do

trimmer)

Diagnóstico

-

Estado/Problema/Informes de

Informação

-

Diagnóstico Antimáscara

-

-

Anulação Microondas

-

-

Microondas Desativadas ao

Desarmar ("Green Line")

-

-

LED

ESTADO

SIGNIFICADO

Constante

Alarme do detector (detecção Infravermelha

Passivo e Microondas simultâneo)

Visualização dos LED’s

Os três LEDs tricolores no Ind. LuNAR RK200DTG3, operam como descrito a seguir:

Vermelho

6 Ind. LuNAR RK200DTG3 – Guia de Instalação

Piscando em baixa freqüência

Indica mau funcionamento da comunicação com

o ProSYS

Piscando em alta freqüência

Detecção Anti-máscara

Constante

Detecção microondas

Piscando

Problema no canal de Microondas

Constante

Detecção Infravermelho Passivo

Piscando

Problema no canal Infravermelho Passivo

Todos os LEDs

Piscando com mudança de cor

Ao ativar

Verde

Laranja

-se

Ind. LuNAR RK200DTG3 – Guia de Instalação 7

♦

Antes de instalar, estude cuidadosamente o espaço a ser protegido para escolher a localização

exata da unidade para a melhor cobertura possível.

♦

Nunca instale o LuNAR num ambiente que cause uma condição de alarme em uma das

tecnologias.

♦

Evite as instalações onde máquinas rotativas (por exemplo, ventiladores) estejam normalmente

em operação dentro da área de cobertura. Aponte a unidade para longe de vidros expostos ao

exterior e a objetos que podem mudar rapidamente de temperatura.

♦

Não monte o detector com luz direta do sol nem perto de nenhuma fonte de calor. Os setores de

detecção devem apontar em direção a uma parede, ou a um assoalho mas nunca em direção a

janelas ou cortina

s. A superfície de instalação deve ser sólida, lisa e sem vibrações.

♦

Elimine a interferência de fontes exteriores próximas.

♦

Para uma ótima detecção, selecione uma localização propensa a interceptar um intruso

movendo-se através do padrão de cobertura.

♦

A altura de montagem recomendada, que permite um diâmetro de detecção de 18m (60 pés), é

de 3.7m até 8.6m.

♦

O detector deve ser montado no teto, preferentemente no centro do recinto.

INSTALAÇÃO

Passos preliminares:

A típica cobertura de detecção do Ind. LuNAR RK200DTG3 e a altura de instalação são ilustradas

abaixo:

8 Ind. LuNAR RK200DTG3 – Guia de Instalação

Ind. LuNAR RK200DTG3 – Guia de Instalação 9

NOTAS:

•

Quando o detector Ind. LuNAR RK200DTG3 é

instalado em um local que contenha uma quantidade

de fatores que causem interferência, a detecção por

Microodas pode ser afetada

•

As distâncias podem variar de acordo com as

condições térmicas ambientais.

Processo de Instalação:

Para abrir o detector (Figura 1), retire a tapa inserindo uma chave de fenda (1) no encaixe entre a tampa

de proteção e a capa. A capa permanece unida à base do detector.

Usando uma chave de fenda Philips, libere o parafuso superior da tapa (2) e puxe suavemente para cima a

tapa superior do detector.

10 Ind. LuNAR RK200DTG3 – Guia de Instalação

Libere o parafuso que mantém o PCB (Figura 2) localizado no lado direito do PCB (1), puxe suavemente os

dois clipes de liberação (2) para fora e retire o PCB.

Ind. LuNAR RK200DTG3 – Guia de Instalação 11

instalados nos sensores de Infravermelho,

eles são essenciais para evitar falsos alarmes

causados por luz branca

Não Retire os filtros contra luz branca

12 Ind. LuNAR RK200DTG3 – Guia de Instalação

Se requerido, abra (Figura 3) o furo pré-marcado dos canais de fiação usando um alicate de corte (1, 2) e os

furos pré-marcados na tampa posterior (3, 4) usando uma chave de fenda.

FIGURA 3

Ind. LuNAR RK200DTG3 – Guia de Instalação 13

Introduza o cabo através da abertura do cabo (Figura 4) e conecte os cabos desejados como descrito no

“Passo 4- Fiação”.

Monte a tampa posterior em sua localização final (Figura 5) usando os três parafusos de montagem e sele

os furos abertos remanescente com um material impermeabilizante.

14 Ind. LuNAR RK200DTG3 – Guia de Instalação

FIGURA

4

NOTA:

Para um tamper de teto, fixe o parafuso do tamper

traseiro, como demonstrado na figura 5

Retorne o PCB à sua localização anterior e verifique que tudo está bem assegurado pelos clipes de

sustentação e pelo parafuso.

Execute o ajuste da lente e a configuração dos Interruptores Dip como descrito em “Ajuste de Lentes”

nesta página e “Configuração dos Interruptores Dip” na página 15.

Monte a tampa superior na base do detector.

Aperte o parafuso central da tampa superior.

Recoloque a tampa de proteção do detector.

Ind. LuNAR RK200DTG3 – Guia de Instalação 15

Ajuste de Lentes:

O LuNAR tem três lentes Fresnel unidas à tampa, localizadas em mangas protetoras do sensor. Ajuste a

posição das lentes baseando-se na altura de montagem em teto como segue:

Pressione os 2 clipes que unem a manga (Figura 6) à tampa do detector, e retire suavemente a manga.

FIGURA 6

Retire as lentes da manga (Figura 7) levantando-a suavemente dos pinos de sustentação que a asseguram

nos lados do protetor de elemento piroelétrico.

16 Ind. LuNAR RK200DTG3 – Guia de Instalação

FIGURA 7

Coloque os dois pinos, que estão localizados

em ambos os lados do protetor de elemento

piroelétrico ranhuras apropriadas na lente. Use a seguinte tabela para selecionar a desejada posição da

lente.

Retorne o protetor de elemento piroelétrico a seu lugar na tampa dianteira do detector. Repita os

passos 1 a 5 para as 2 lentes remanescentes.

Ind. LuNAR RK200DTG3 – Guia de Instalação 17

NOTAS:

•

Abaixo da altura de montagem de 3.7m, o diâmetro de cobertura começa a diminuir, e na altura de

2.7m, o diâmetro de cobertura é de 15m (50 pés).

•

Para uma cobertura personalizada, é possível fixar a posição de cada lente numa altura diferente, segundo as

condições de instalação.

•

Todos os detectores da RISCO Group que possuem o sistema de anti-máscara através de Infravermelho Ativo,

possuem uma proteção contra luz branca diretamente em cima do sensor piroelétrico, isso não é uma

proteção para transporte. Não retire a proteção contra luz branca, pois isso além de não melhorar o

desempenho, torna o detector passivo de disparos falsos gerados por rajadas de luz.

18 Ind. LuNAR RK200DTG3 – Guia de Instalação

ENTRADA DE

CONTROLE

Usado para determinar a polaridade das entradas externas.

Jumpers de controle

Ind. LuNAR RK200DTG3 – Guia de Instalação 19

REMOTO/SET

12V: Para ativar o funcionamento é necessário aplicar 12V. GND

0V: Para ativar o funcionamento é necessário aplicar GND. 12v ou

Desligado não tem influência no estado do Controle remoto/SET.

ou Desligado não tem influência no estado do Controle

remoto/SET.

(veja as configurações dos dipswitches no modo Relé)

(veja as configurações dos dipswitches no modo Relé)

20 Ind. LuNAR RK200DTG3 – Guia de Instalação

JUMPERS

RESISTÊNCIA

EOL

Os jumpers são usados ao conectar-se o detector a

uma Zona DEOL ou TEOL. Os jumpers permitem a

seleção de resistências EOL de TAMPER, ALARME (1K,

2.2K, 4.7K, 5.6K ou6.8K), de acordo com as

configurações do painel de controle. Um jumper duplo

adicional permite a conexão de uma resistência EOL de

12K FALHA/AM (ver Diagrama de Resistências EOL).

Siga o diagrama de conexão do bloco de terminais ao

conectar o detector a uma Zona de Duplo/Triplo Fim

-

de-Linha (DEOL/TEOL).

Diagrama Esquemático das Resistências EOL

Configuração dos Interruptores DIP

O Ind. LuNAR RK200DTG3 tem um interruptor DIP de 9 posições que muda de funcionalidade para uso no

modo de operação Relé ou BUS. Configure o interruptor DIP de acordo com as tabelas abaixo:

Ind. LuNAR RK200DTG3 – Guia de Instalação 21

Número do

Interruptor DIP

Descrição

1

Usado para determinar a operação do ACT

Interruptor DIP ON:

Interruptor DIP OFF: ACT está desativado (predeterminado em fábrica)

2

Usado para determinar a operação dos LEDs do detector

Interruptor DIP ON: LEDs estão ativados (predeterminado em fábrica) Interruptor DIP OFF:

LEDs estão desativados

3

Usado para determinar a função "Green Line" (veja nota abaixo)

Interruptor DIP ON: "Green Line" está ativada

Interruptor DIP OFF: "Green Line" está desativada (Ajuste de fábrica)

4

Usado para determinar o tipo de Autoteste (veja nota abaixo) Interruptor DIP

ON: Autoteste Local:

No caso de falhar o autoteste local, o Relé FALHA/AM é ativado por um período de 2.5

segundos.

Interruptor DIP OFF: Autoteste Remoto (predeterminado em fábrica):

No caso de o autoteste remoto ser bem sucedido, os

período de 5 segundos. No caso de o teste falhar, o Relé FALHA/AM é ativado por um período

de 2.5 segundos.

5

Usado para determinar se o Anti-Mascaramento por Infravermelho Ativo está ativado.

(veja nota abaixo)

Inter

Interruptor DIP OFF: Desativado (predeterminado em fábrica)

IMPORTANTE:

1 2 3 4 5 6 7 8 9

ON

Configuração Predeterminada em Fábrica:

Configuração do Modo Relé (Interruptor DIP

:

6=OFF)

ACT está ativado

ruptor DIP ON: Ativado

22 Ind. LuNAR RK200DTG3 – Guia de Instalação

Relés Alarme são ativados por um

Caso o Jumper do AM esteja habilitado através do Dipswitch 5, a tampa do detector deve ser

colocada dentro de 1 minuto após a ligação da alimentação el

alimentado eletricamente e o Dipswitch 5 esteja ligado, a unidade deve ter a sua alimentação

desligada e re

6

Usado para determinar o modo de conexão do detector

Interruptor DIP OFF: Modo Relé

Usado para determinar se a comunicação do Controle Remoto (RC) está ativada ou

desativada.

Interruptor DIP ON: A comunicação do RC está sempre ativada.

étrica. Caso o detector já esteja

-ligada, para re-iniciar a calibração do sistema de Anti-Máscara (AM).

7

Interruptor DIP OFF: A comunicação do Controle Remoto depende da voltagem aplicada ao

bloco de terminais “RC” (Ajuste de fábrica)

Quando um sinal de ativação é aplicado à entrada do Controle Remoto do bloco de

terminais, o controle remoto estará ativado.

Passe o interr uptor 7 para “OFF” depois da instalação e quando sa ir do local por razões de se gurança.

Isto evitará o uso não-autorizado de uma unidade de controle remoto que pode ser utilizada para

8-9 Não Aplicável – Dipswitches desligados

IMPORTANTE:

LuNAR RK200DTG3. Ligue as fontes de energia ao completar a configuração!

Consulte os ajustes de do bloco de terminais para detalhes de ativação.

BUS

Configuração do Modo BUS

Ind. LuNAR RK200DTG3 – Guia de Instalação 23

desativar o detector.

Desconecte todas as fontes de energia antes de configurar os interruptores DIP do Ind.

NOTE:

IMPORTANTE:

BUS ADDRESS TAMPER

N/A

Número do

Interruptor

DIP

Descrição

1-5

Usado para configurar o número de ID do detector. (Ver Tabela 1)

Configure o número de ID da mesma maneira como para qualquer outro acessório do ProSYS.

6

Usado para determinar o modo de conexão do detector.

Interruptor DIP ON: Conexão ProSYS– Configuração BUS

NOTE:

Ao ser ativado ou em operação normal, o LuNAR espera 10 segundos para a comunicação com o

ProSYS. Pode ocorrer um problema de comunicação devido à má fiação, endereço errado, ou se o

ProSYS não foi devidamente configurado; todos os LEDs piscarão continuamente até ser

solucionado o problema.

7

Não aplicável (a comunicação RC é automaticamente ativada ao passar para o modo teste de

caminhada no ProSYS e desativada em caso contrário).

8-9

Interruptor DIP ON: A fim de habilitar o detector para informar o estado do tamper ao ProSYS.

MODE (Interruptor DIP 6=ON):

ID 1 2 3 4 5 ID 1 2 3 4 5

Tabela 1: Configuração do ID para a conexão BUS

24 Ind. LuNAR RK200DTG3 – Guia de Instalação

01

OFF

OFF

OFF

OFF

OFF

17

OFF

OFF

OFF

OFF

ON

02

ON

OFF

OFF

OFF

OFF

18

ON

OFF

OFF

OFF

ON

03

OFF

ON

OFF

OFF

OFF

19

OFF

ON

OFF

OFF

ON

04

ON

ON

OFF

OFF

OFF

20

ON

ON

OFF

OFF

ON

05

OFF

OFF

ON

OFF

OFF

21

OFF

OFF

ON

OFF

ON

06

ON

OFF

ON

OFF

OFF

22

ON

OFF

ON

OFF

ON

07

OFF

ON

ON

OFF

OFF

23

OFF

ON

ON

OFF

ON

08

ON

ON

ON

OFF

OFF

24

ON

ON

ON

OFF

ON

09

OFF

OFF

OFF

ON

OFF

25

OFF

OFF

OFF

ON

ON

10

ON

OFF

OFF

ON

OFF

26

ON

OFF

OFF

ON

ON

11

OFF

ON

OFF

ON

OFF

27

OFF

ON

OFF

ON

ON

12

ON

ON

OFF

ON

OFF

28

ON

ON

OFF

ON

ON

13

OFF

OFF

ON

ON

OFF

29

OFF

OFF

ON

ON

ON

14

ON

OFF

ON

ON

OFF

30

ON

OFF

ON

ON

ON

15

OFF

ON

ON

ON

OFF

31

OFF

ON

ON

ON

ON

ON

16

ON

ON

ON

ON

OFF

32

ON

ON

ON

ON

Ind. LuNAR RK200DTG3 – Guia de Instalação 25

Blocos de Terminais

BLOCO TERMINAL 1

DESCRIÇÃO

+12V (RED)

Voltagem de entrada positiva (+) da fonte de alimentação

- (BLK)

Comum à fonte de alimentação do painel de controle

BUS (GRN)

Usado para comunicação de dados com o ProSYS

BUS (YEL)

Usado para comunicação de dados com o ProSYS

Usado para ativar/desativar remotamente o detector.

Quando um sinal de ativação (ver os ajustes de ativação do Jumper de RC/SET) é aplicado à ent

LED no bloco de terminais os LEDs serão desativados.

Os LED’s de AM serão desabilitados(Se o Dipswitch 5 de AM for ajustado em ON)

O módulo de Microondas é habilidado (Se o Dipswithc 3 de GreenLine for ajustado como ON).

Removendo o sinal de ativação será causado um teste Self Test (Se o Dipswith 4 de Self Test est

previamente ajustado na posição OFF)

.

IMPORTANTE:

Usado para ativar/desativar a comunicação do controle remoto, somente quando o interruptor

estiver em “OFF”.

Quando um sinal de ativação (ver Jumper de controle dos LED’s) é aplicado à entrada do RC no

de terminais, o Controle Remoto será ativado. Nota: O interruptor DIP 7em “ON” ha

constantemente a comunicação do RC.

Passe o interruptor 7 para “OFF” depois da instalação e quando sair do local por razões de segurança. Isto evitará o uso

autorizado de uma unidade de controle remoto que pode ser utilizada para desativar o detector.

כ