Installation and Programming Manual

ProSYS version 7.xx

ii ProSYS Installation and Programming Manual

CE Declaration of Conformity

Hereby, RISCO Group declares that this control panel (ProSYS 128, ProSYS 40, ProSYS

16), with wired accessories (including cables) and wireless accessories, is in compliance with

the essential requirements and other relevant provisions of Directive 1999/5/EC.

For the CE Declaration of Conformity please refer to our website: www.riscogroup.com.

Compliance Statement

Hereby, RISCO Group declares that the ProSYS series of control panels and accessories are

suitable for use in systems designed to comply with:

EN50131 Grade 3, Environmental Class II

EN50136 Series; GSM/LAN ATS 5; PSTN ATS 2

UK versions of ProSYS comply with PD6662 :2010

ProSYS Installation and Programming Manual iii

Table of Contents

CHAP TER 1 INTRO DUCING PROSYS ............................................................................................................................. 5

WHAT IS PROSYS? .............................................................................................................................................................. 5

INSTALLING PROSYS .......................................................................................................................................................... 6

ABOU T WIRE....................................................................................................................................................................... 6

PROSYS ARCHITECTURE AND CAPABILITIES ........................................................................................................................ 9

PROSYS FEA TUR ES ........................................................................................................................................................... 10

CHAP TER 2 MOUN TING AND WIRING THE MAI N PAN EL ...................................................................................... 16

STEP 1: MOUNTING T HE MAIN PANEL................................................................................................................................. 16

STEP 2: WIRING THE MAIN PANEL ...................................................................................................................................... 18

CHAPTER 3 INSTALLING EXTERNAL MODULES AND DEVICES .......................................................................... 29

STEP 3: IDENTIFYING AND WIRING KEYPADS AND EXPANSION MODUL ES ............................................................................ 29

STEP 4: ADDING MODULES ................................................................................................................................................ 31

STEP 5: APPLYIN G POWE R ................................................................................................................................................. 35

CHAPTER 4 PROGRAMMING THE PROSYS ............................................................................................................... 36

USING THE PRO SYS MAIN PAN EL PROGRAMMING OPTIONS ............................................................................................... 36

USING THE LCD KEYPA D .................................................................................................................................................. 37

PROGRAMMING FROM THE LCD KEYPAD ........................................................................................................................... 38

CHAPTER 5 USING THE INSTALLER PROGRAMMING MENUS ............................................................................. 45

INSTALLER PROGRAMMING MEN U CONVENTIONS............................................................................................................... 45

SYSTEM ............................................................................................................................................................................ 46

ZONES............................................................................................................................................................................... 62

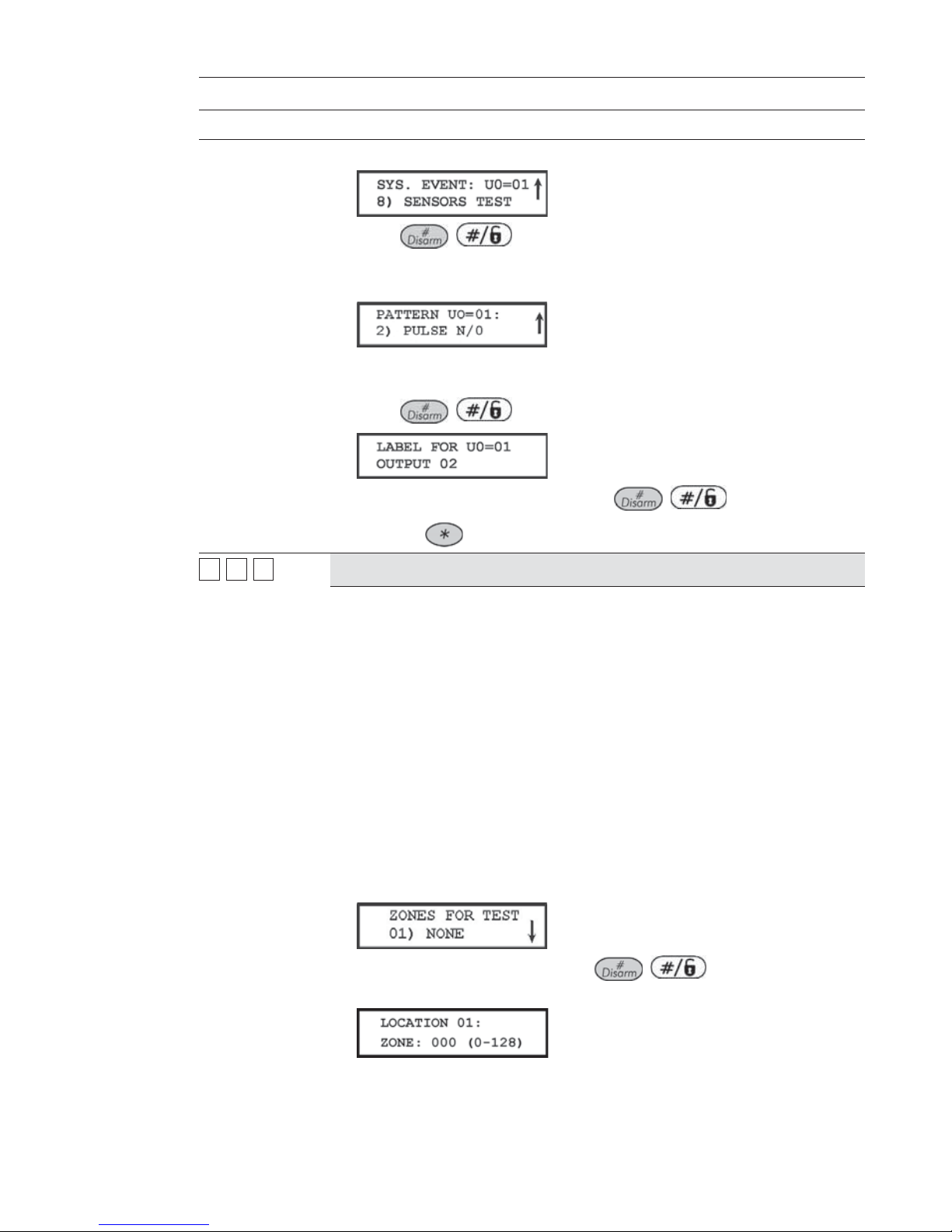

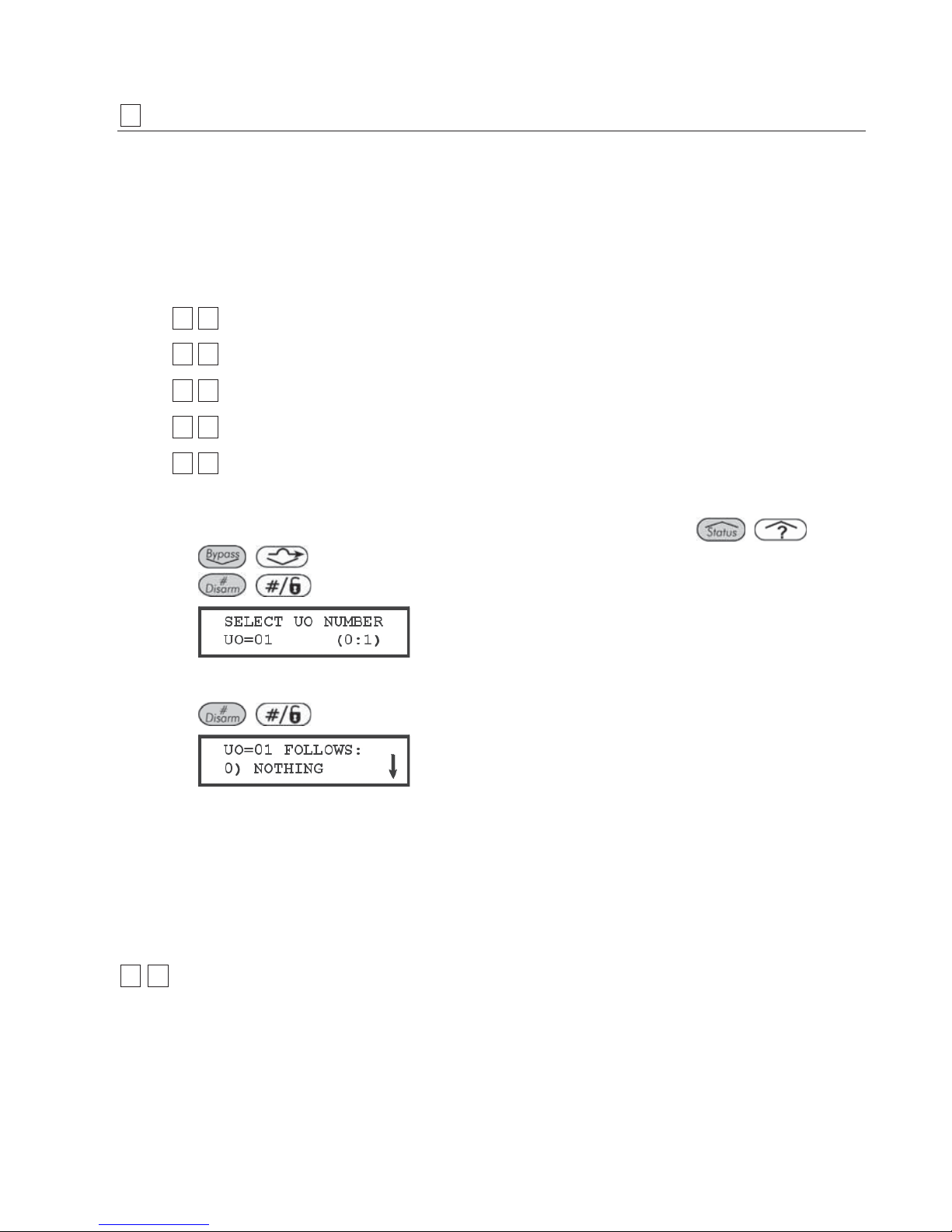

UTILITY OUT PUT ............................................................................................................................................................... 93

CODE MAI NTENA NC E ...................................................................................................................................................... 103

DIALER ........................................................................................................................................................................... 110

REPORT CODES ............................................................................................................................................................... 137

ACCESSORIES .................................................................................................................................................................. 154

MISCELLANEOUS ............................................................................................................................................................. 171

ACCESS CONTROL ........................................................................................................................................................... 182

EXIT PROGRAMMING ....................................................................................................................................................... 187

CHAP TER 6 INS TALL ER PROGRAM MING WITH IN TH E US ER FUNCT IONS M ODE ....................................... 189

APPENDIX A : TECHNICAL DATA .............................................................................................................................. 200

APPENDIX B : PROSYS ACCESSORIES ...................................................................................................................... 204

APPENDIX C REPORT CODES ..................................................................................................................................... 208

APPENDIX E : EVENT LOG MESSAGES ..................................................................................................................... 215

APPENDIX F : INSTALLER PROGRAMMING MAPS ................................................................................................ 225

iv ProSYS Installation and Programming Manual

Table of Figures

FIGURE 1: PROSYS ARCHITECTURE AND CAPABI LITI ES ......................................................................................................... 9

FIGURE 2: LCD KEYPAD ........................................................................................................................................................12

FIGURE 3: MOUNTING THE MAIN PAN EL ...............................................................................................................................16

FIGURE 4: MAI N PANEL WIRING DIAGRAM .............................................................................................................................18

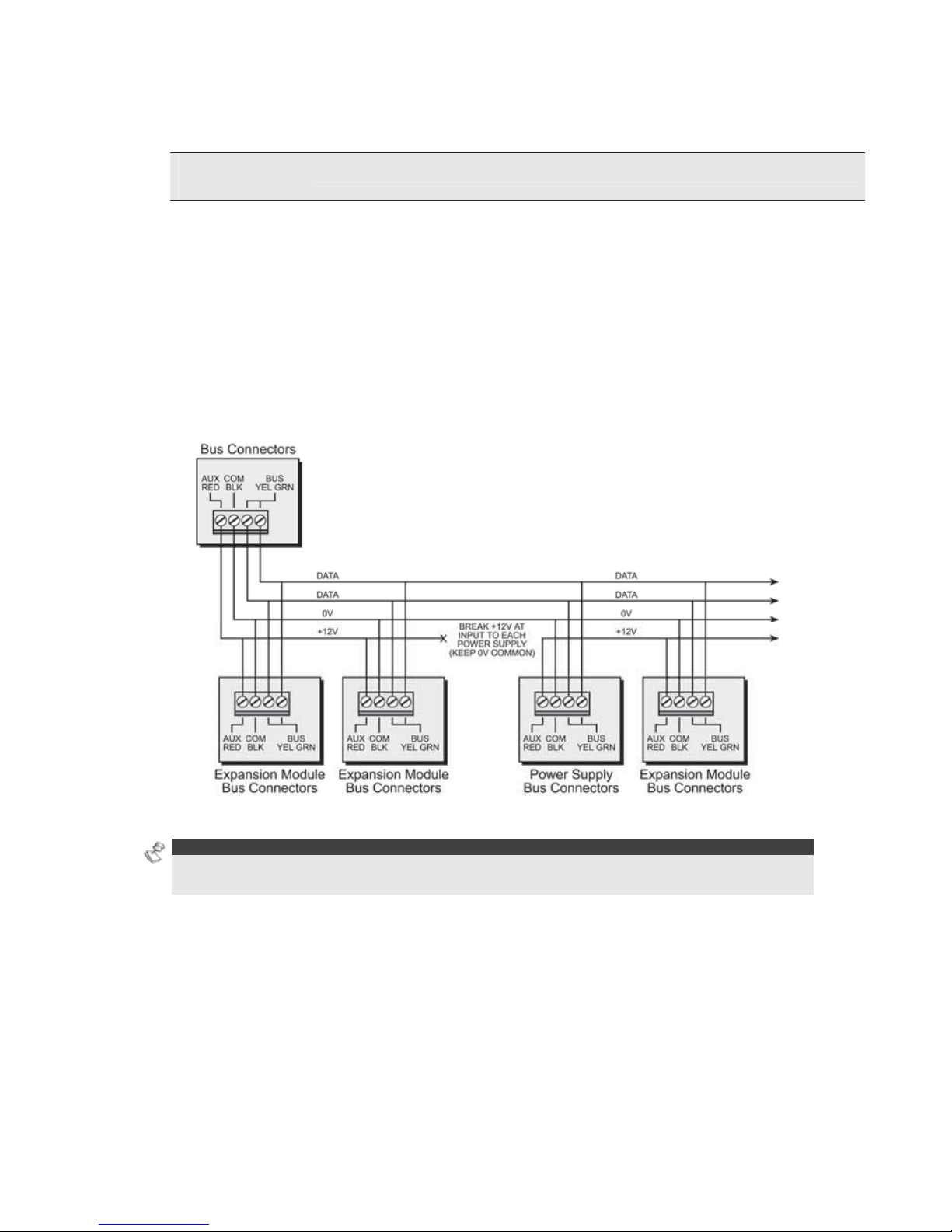

FIGURE 5: 4-WIRE EXPAN SION BUS .....................................................................................................................................19

FIGURE 6: ZONE CONNECTION DIAGRAMS .............................................................................................................................21

FIGURE 7: WIRING THE BOX TAMPER ....................................................................................................................................24

FIGURE 8: CONNECTING THE J10 CONNECTOR .....................................................................................................................25

FIGURE 9: GROUNDING THE METAL BOX ...............................................................................................................................26

FIGURE 10: GROUNDING TH E MET AL BOX DOOR ...................................................................................................................26

FIGURE 11: DIP SWI TCH SETTINGS .......................................................................................................................................29

FIGURE 12: KEYPAD INSTALLATION FRONT VIEW...................................................................................................................30

FIGURE 13: 8 Z ONE EXPANSIO N MODUL E .............................................................................................................................31

FIGURE 14: 16 ZONE EXPANSION MODULE ...........................................................................................................................31

FIGURE 15: UTILIT Y OUT PUT MODULE UO4 (SHOWING AN EXAMPLE OF UO4 WIRING) ........................................................32

FIGURE 16: UTILITY OUTPUT MODULE E08 ...........................................................................................................................32

FIGURE 17: UTILITY OUTPUT MODULE X-10 ..........................................................................................................................32

FIGURE 18: 1.5A POWER SUPPLY MODULE PS.....................................................................................................................34

FIGURE 19: 3A POWER SUPPLY MODULE PS ........................................................................................................................34

FIGURE 20: THE LCD KEYPA D FAC E .....................................................................................................................................37

ProSYS Installation and Pr ogramming Manual 5

Chapter 1 Introducing ProSYS

This chapter provides a basic introduction to the ProSYS system and its architecture and

capabilities, as described in the following sections:

♦ What is ProSYS?, below

♦ Installing ProSYS, page 6

♦ About Wire, page 6

♦ ProSYS Architecture and Capabilities, page 9

♦ ProSYS Features, page 10

What is ProSYS?

ProSYS is an integrated security system with unrivalled flexibility and advanced

expansion capabilities, together with being simple to install, program and maintain.

ProSYS features integrated Dual-Path and Triple-Path reporting, with integrated Advanced

Communication Modules (ACM) for IP communication, Advanced GSM/GPRS modules

(AGM) for advanced cellular communication all in one box, and an IP/GSM Receiver package

for Monitoring Stations (MS).

Additional accessories include integrated Access Control, Interactive Voice Module, 868/433

MHz Wireless expansion, Bus detectors providing Remote Control & Diagnostics, Program

Transfer Module, Printer adaptors for parallel printers and more.

ProSYS provides a new level of remote service and installation convenience, with unique

Remote Diagnostic capabilities, Auto-Install™ Technology and Bus Test which checks

communication quality of the bus and enables pinpointing intermittent wiring faults.

ProSYS can be programmed and/or controlled through the Upload/Download software

installed on a PC computer with a Windows operating system.

6 ProSYS Installation and Programming Manual

Installing ProSYS

This ProSYS Installation and Programming Manual details how to install the ProSYS

hardware and to program the ProSYS Main Panel, as described in the following main steps:

♦ Step 1: Mounting the Main Panel (Chapter 2)

♦ Step 2: Wiring the Main Panel (Chapter 2)

♦ Step 3: Identifying and Wiring Keypads and Expansion Modules (Chapter 3)

♦ Step 4: Adding Modules (Chapter 3)

♦ Step 5: Applying Power (Chapter 3)

♦ Step 6: Programming the ProSYS (Chapters 4 and 5)

♦ Step 7: Programming within t he User Functions Mode (Chapter 6)

NOTE:

While this manual describes all of the above steps, the section on programming the Main Panel comprises

the bulk of the information, as it covers all the programmable functions that can be performed using the

keypad.

ETL NOTE:

This document describes how to install, wire and program the ProSYS security system and the

accessories attached, to comply with UL compatible standards as tested and listed by ETL.

The system is listed to the following standards:

Central-Station Burglar Alarm Units, ANSI/UL 1610

Digital Alarm Communicator System Units - ANSI/UL1635

Police Station Connected Burglar Alarm Units and Systems - ANSI/UL365, Household

Fire Warning System Units - ANSI/UL985

Proprie tary Burgla r Alarm Units and System s ANSI/UL1076

Household Burglar-Alarm System Units, ANSI /UL 1023

Preliminary Standard for Household Burglar Alarm System Units - ULC C1023 Standard for

Residential Fire Warning System Control Units - ULC-S545-02

About Wire

The proper use of wire and cable is necessary for the successful installation and operation of

the ProSYS system. It is important to select wire of the correct thickness to minimize power

loss and ensure reliable system operation. Take into account both the installation's current

requirements and the wiring distances involved. The following tables provide useful

information to help make your installation trouble-free.

ETL NOTES:

Wiring shall be done according to the National Electrical code ANSI/NFPA 70. Use a min gauge of 22AWG

for all wiring.

Make sure to route wires away from any sharp edges or other parts which can cause.

ProSYS Installation and Pr ogramming Manual 7

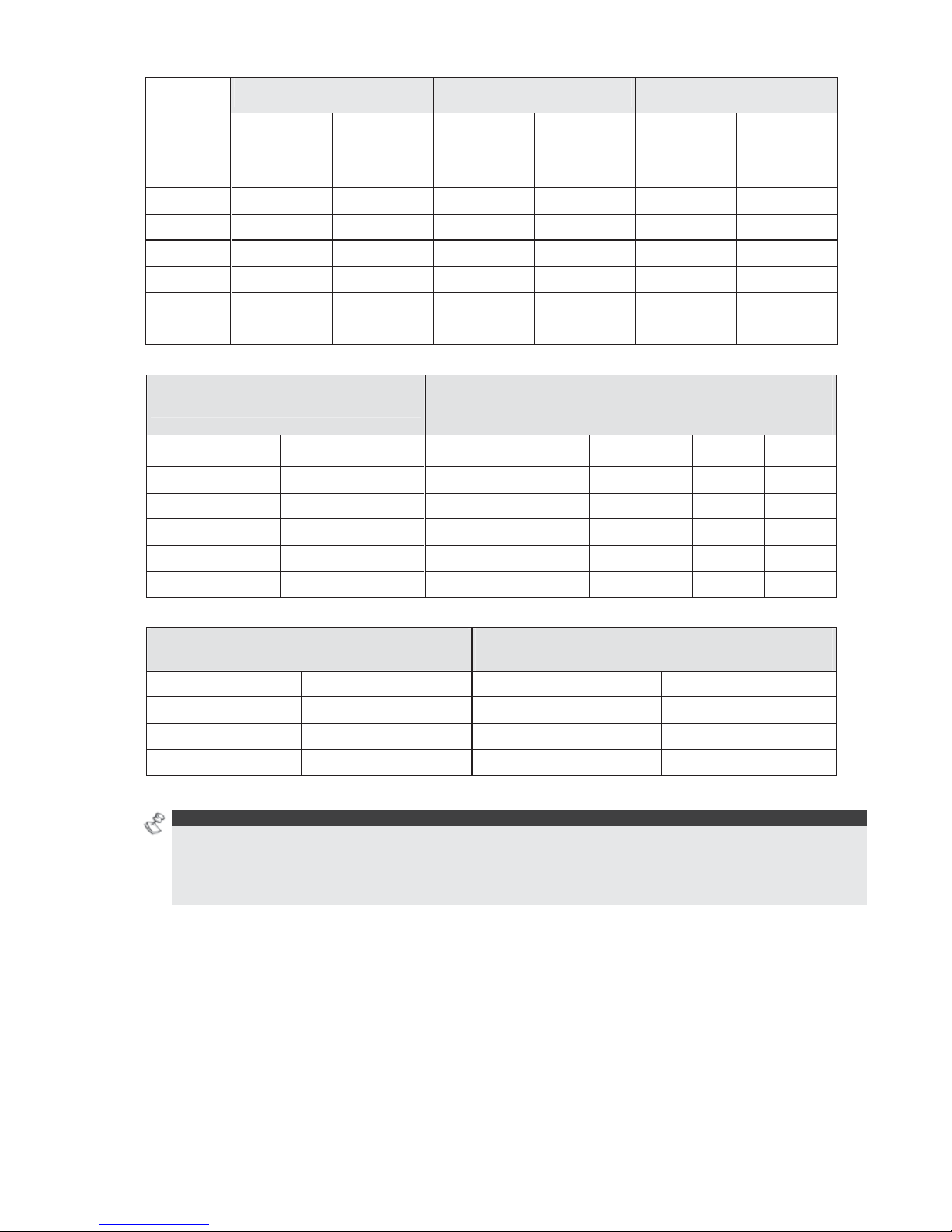

AWG

Gauge

Size

Wire Diameter Resistance: Feet Resistance: Meters

Inches Millimeters Ω Per F oo t Ω Per 1000

Feet

Ω Per Meter Ω Per 100

Meters

24 0.020 0.50 0.026 26.0 0.085 8.5

22 0.025 0.64 0.016 16.0 0.052 5.2

20 0.031 0.80 0.010 10.0 0.032 3.2

19 0.035 0.90 0.008 8.0 0.026 2.6

18 0.040 1.00 0.006 6.0 0.020 2.0

16 0.050 1.27 0.004 4.0 0.013 1.3

14 0.064 1.63 0.0025 2.5 0.008 0.82

Table A-1: Wire Facts

One-Way Wire Distance Between

ProSYS and Plug-In Transformer

AWG (American Wire Gauge)

For best results use the indicated wire size

or larger (numerically lower) size

In Feet In Meters 22 20 18 16 14

Up to 15 feet Up to 5 meters

15 - 25 feet 5 - 8 meters

25 - 40 feet 8 - 12 meters

40 - 60 feet 12 - 20 meters

60 - 100 feet 20 - 30 meters

Table A-2: Wiring Between the ProSYS Main Panel and the 16.5 VAC/40VA Plug-In Transformer

Wire Gauge

Max Combined Length of ALL Expansion BUS

Wiring

24 AWG 7/02mm 150 meters 492 feet

22 AWG 16/02mm 200 meters 656 fe et

20 AWG 24/02mm 333 meters 1092 fee t

19 AWG 28/02mm 400 meters 1312 fee t

Table A-3: Wire Gauge

NOTES:

For maximum system stability, it is best NOT to exceed a total of 300 meters (1000 feet) of wire when

wiring the Expansion BUS.

For a distance of more than 300 meters, refer to RISCO Group’s customer support service for detailed

information.

8 ProSYS Installation and Programming Manual

Total

Auxiliary

Power

(Max Current

Draw per

Branch)

Desired Wire Gauge in Particular Branch

32/02 mm

18 AWG

28/02 mm

19 AWG

24/02 mm

20 AWG

16/02 mm

22 AWG

7/02 mm

24 AWG

Max Run Max Run Max Run Max Run Max Run

Meters Feet Meters Feet Meters Feet Meters Feet Meters Feet

20mA 1195 3920 945 3100 750 2460 472 1550 296 970

30mA 793 2600 628 2060 500 1640 314 1030 197 646

40mA 597 1960 472 1550 375 1230 236 775 148 485

50mA 478 1568 378 1240 300 984 189 620 118 388

60mA 296 1300 314 1030 250 820 157 515 98 323

70mA 341 1120 270 886 214 703 135 443 84 277

80mA 299 980 237 775 187 615 118 388 74 243

90mA 264 867 209 687 166 547 105 343 66 215

100mA 239 784 189 620 123 492 94 310 59 194

Table A-4: Total Auxiliary Power

NOTE:

The wire lengths indicated represent the one-way distance between the source of power and the last detector

in the branch.

Max External

Siren Current

(Max current

draw per

branch)

Desired Wire Gauge in Particular Branch

32/02 mm 28/02 mm 24/02 mm 16/02 mm

Max Run Max Run Max Run Max Run

Meters F eet Meters Feet Meters Feet Meters Feet

100mA 238 780 191 625 151 495 94 310

200mA 229 390 95 313 76 248 47 155

300mA 79 260 63 208 50 165 31 103

400mA 59 195 48 157 38 124 24 78

500mA 48 156 38 125 30 99 19 62

650mA 37 120 29 96 23 76 15 48

Table A-5: Maximum External Siren Current

NOTE:

The wire lengths indicated represent the one-way distance between the ProSYS and the external siren in

the branch.

ProSYS Installation and Pr ogramming Manual 9

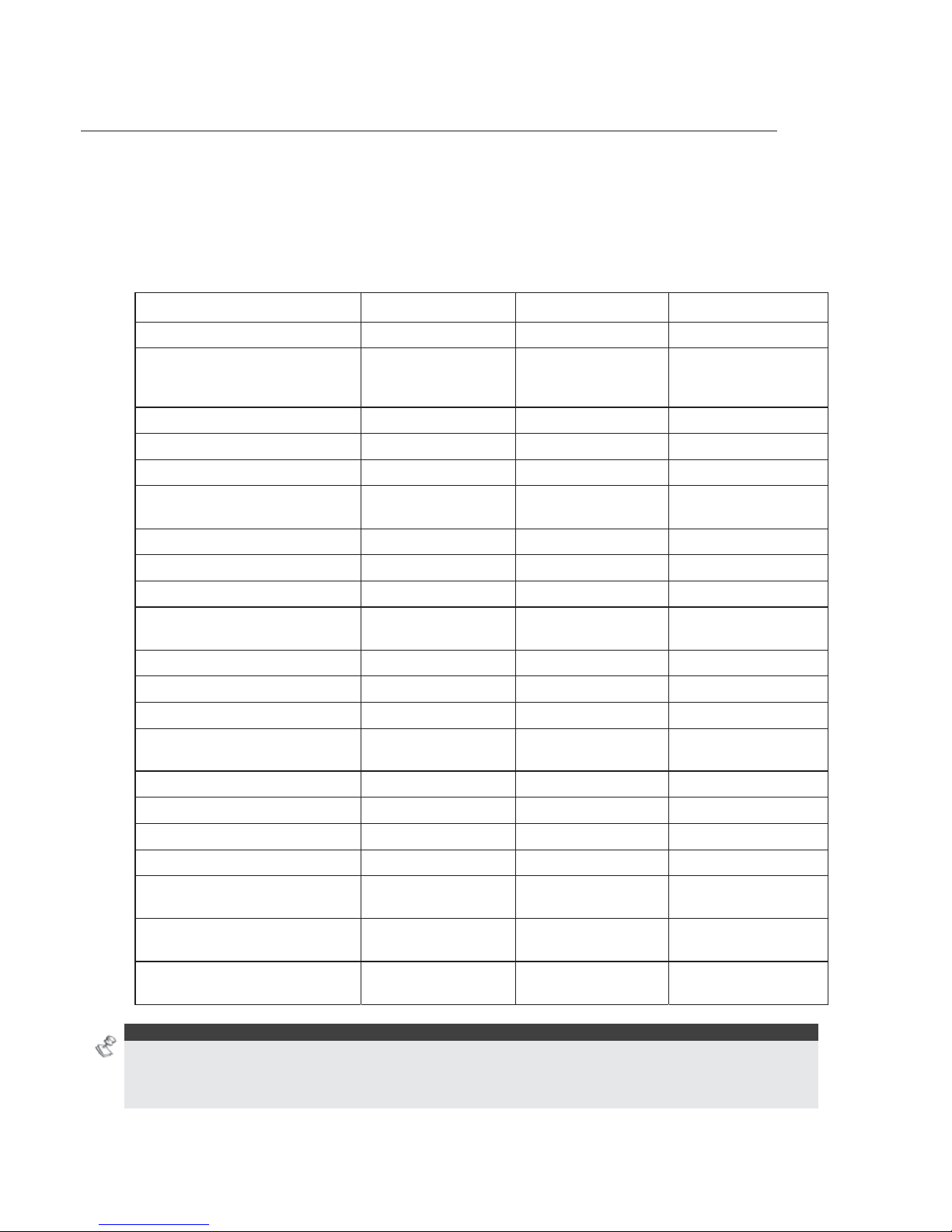

ProSYS Architecture and Capabilities

The following diagram provides an overview of the ProSYS's architecture and capabilities.

Examine this figure before beginning your ProSYS installation to obtain an overall picture of

the full extent of the ProSYS system's capabilities.

Figure 1: ProSYS Architecture and Capabilities

10 ProSYS Installation and Programming Manual

ProSYS Features

This section describes the features of the ProSYS system, including features specific to each

ProSYS model.

Feature-Specific Limitations

Each ProSYS model has several feature-specific limitations, as described in the following

table:

Feature ProSYS 16 ProSYS 40 ProSYS 128

Total Zones 8-16 8-40 8-128

Main Expansion Zones (wired

or wireless)

1x8

(EZ or WR)

4x8 or 2x16 or

2x8 + 1x16

(EX or WR)

1x8 + 7x16

(EX or WR)

Max BUS Zones 16 32 32

Max Current 1,5 A 1,5 A 1,5 A

Number of Expansion BUSes 2 2 2

Total Number of Expansion

Modules

64 (32 for ea ch data

BUS)

64 (32 for each data

BUS)

64 (32 for ea ch data

BUS)

Box NC Tamper Input 1 1 1

Bell Tamper EOL Input 1 1 1

Total Utility Outputs 6-22 6-38 6-70

Utility Output Expansion

Modules

Up to 2 modules

(max 16 UO)

Up to 4 modules

(max 32 UO)

Up to 8 modules (max

64 UO)

Partitions/Areas 4 4 8

Groups Per Partition/Area 4 4 4

User Codes 00-29 00-59 00-98

Access Control Modules

(# of Doors)

2 (4 doors) 4 (8 doors) 8 (16 doors)

Proximity Key Reader 16 16 16

Keypads 8 12 16

Accoun t Numbers 8 8 12

Follow Me Numbers 8 8 16

Event Log

256 Built-in (No

Possible Expansion)

512 (with Expansion) 999 (with Expansion)

GSM/GPRS Communication

Module

1 1 1

IP Communication Interface

(ACM)

1 1 1

NOTES:

The zone expansion modules can be either with wire or wireless.

All panels can work with a battery of up to 17AH according to the applicable regulations.

The relay output should have the option to supply COM positive -12V or negative -0V.

ProSYS Installation and Pr ogramming Manual 11

Main Panel

The Main Panel is the foundation of the system's operation and has the following features:

♦ 8 basic hardwired zones

♦ 6 Utility Outputs:

1 x relay (programmable output) (3 Amps)

1 x 500mA transistor (Open Collector)

4 x 70mA transistors (Open Collector)

♦ Box tamper input (normally open)

♦ Bell tamper input (using a 2.2KΩ end-of-line resistor)

♦ Two different 4-wire BUSes with "quick connectors" from the Main Panel, which is the

initial point for all system. If one BUS is shorted or there is any kind of problem that

interrupts the BUS data, the other one continues to operate normally

♦ Power for the operation of an external sounder

♦ Offers the required type of voltage for one or more electronic sirens, bells, or

loudspeakers, respectively

♦ Supports more than 20 zone types

♦ 6 zone terminations, including: closed-circuit (NC), open-circuit (NO), end-of-line

(EOL) resistors, double end-of-line (DEOL) resistors, triple end-of-line (TEOL)

resistors (refer also to Chapter 2, Mounting and Wiring the Main Panel) and BUS

zone.

♦ Event log (on board up to 256 events)

Zone Expansion

♦ Support for additional 16 (ProSYS 16), 32 (ProSYS 40) or 120 (ProSYS 128) wired or

wireless zones

♦ 8-Zone or 16-Zone wired/wireless-868MHz expansion modules

♦ 6 zone terminations, including closed-circuit (NC), open-circuit (NO), end-of-line (EOL)

resistors, double end-of-line (DEOL) resistors and triple end-of line(TEOL) resistors

♦ BUS zones support and BUS Zones expander

♦ Supports more than 20 zone types

♦ Forced setting zone capability

Wireless Devices

When using wireless zones, the ProSYS 8/16 Wireless expansion modules respond to

different wireless detectors, such as:

♦ PIR/PET detectors

♦ Smoke detectors

♦ Door contacts/Door magnet/universal transmitter/door contact +universal

♦ Up to 32 rolling code 4-buttons keyfobs

♦ Double key panic keyfob

♦ Flood detector

♦ Shock detectors

♦ CO detectors

♦ Gas detectors

♦ Glassbreak detectors

♦ External PIR WatchOUT detectors

The Wireless expansion module includes the following features:

12 ProSYS Installation and Programming Manual

♦ Super heterodyne technology

♦ Programmable supervision time

♦ Tamper detection

♦ Low battery in transmitters detection

♦ Signal jamming indication

♦ Programmable supervision time

Partitions/Areas

♦ Up to 8 independent partitions/areas

♦ Any zone can be assigned to any partition/area

♦ Each partition/area supports both zone sharing and cross zoning.

♦ Each partition/area can be assigned with its own account number

Groups

Groups are combined zones within a partition/area that are used for partial arming.

♦ Up to four groups of zones can be defined for each partition/area.

♦ Group arming is performed by using the Function keys on the keypad (A, B, C, and D).

Each key represents a different group of zones.

♦ Each zone can be assigned to any of the 4 groups

♦ Users can arm any of the four groups individually

♦ Group setting is performed by using the function keys on the keypad or using a keyfob

Keypads

The ProSYS can support up to 16 keypads, with a choice of four styles (LCD, two LED types,

and one LCD proximity type) from which virtually all system features can be accessed.

Figure 2: LCD Keypad

Each keypad is equipped with:

♦ Three Emergency Key zones (Panic, Fire, and Auxiliary Emergency)

♦ The ability to produce a Duress (Ambush) Code

♦ Double tamper-protected

♦ Internal buzzer

♦ Audible feedback for keypad operations

♦ Easy-to-use hot-key sequences for simple zone bypassing

♦ A one-key Quick-Arm feature for both "Stay" and "Away"

♦ In partitioned systems, keypads can be selectively assigned to specific partitions

♦ 4 function keys (A,B,C,D) can be programmed to carry a sequence of commands

ProSYS Installation and Pr ogramming Manual 13

User Codes and Authority Levels

♦ 1 engineer code

♦ 1 sub engineer code

♦ 1 Grand Master code

♦ Up to 99 user codes (ProSYS 128)

♦ 8 Authority levels

♦ Double code option for high security

♦ Codes can be defined to 4 or 6 digits (By default 6 digits)

Programmable Utility Outputs

♦ Supports additional 16 (ProSYS 16), 32 (ProSYS 40) or 64 (ProSYS 128) outputs

♦ 4-relay or 8-transistor expansion output modules

♦ Outputs operation follows system events, codes or scheduling programs.

♦ Output can follow up to 5 zone events (All/Any definition)

♦ X-10 Module: The ProSYS also supports the connection of an X-10 Transmitter

module to its 4-wire Expansion BUS. X-10 technology converts the ProSYS's

programmable output events into a protocol understood by the Transmitter module.

When triggered, this module generates activation and control signals along existing

AC premises wiring to the appropriate X-10 Receiver modules, appropriately placed

and connected within the premises to control lighting and appliances. X-10 Transmitter

modules are available for the ProSYS, supporting either 8- or 16-premises Receiver

modules.

Communication

♦ On-board Digital Communicator

♦ Numerous transmission formats to MS including ADEMCO Contact ID and SIA.

♦ Account number for each partition with additional backup accounts.

♦ 3 MS link up options using:

PSTN report

GSM report

IP report

GPRS report

SMS report

♦ Flexible split reporting for backup

♦ Call Save mode from which non-urgent reports can be collected over a designated

time period and then transmitted all at once (windowing), and support daily system

testing, along with reports of entry into, and exit from, the system's Installer

Programming mode

♦ Follow Me report: In addition to standard communication with the MS, the ProSYS

employs a Follow-Me feature in which the system can report a homeowner at work, or

a business owner at home, that there has been an alarm at a specific location by voice

message over the phone, SMS or Email.

Advanced Digital Voice Module

The Advanced Digital Voice module provides audible information about the status of your

ProSYS system and enables any remote, touch-tone (DTMF) telephone to act as a keypad

for the system. The Advanced Digital Voice Module can be used in the following situations:

♦ Upon event occurrence, such as alarm activation, the Advanced Digital Voice module

informs you of a security situation, such as intrusion or fire, by calling you and playing

14 ProSYS Installation and Programming Manual

a pre-recorded Event announcement. You can then acknowledge the event and

remotely operate the system.

♦ Remotely operating the system, which includes:

O Partition arming and disarming

O Zone bypassing

O UO activation/deactivation

O Changing Follow-Me numbers

O Performing Listen and Talk options that enable you to listen in to your property

and talk back, if necessary

Power Supply Expansion Module

Although the ProSYS's Main Panel provides 600mA of auxiliary power (900mA for Bell), the

use of a number of additional system modules and detectors will likely exceed this limitation.

As a result, the ProSYS permits the addition of up to eight remote Power Supply expansion

modules, each operating from AC power and connected to the BUS.

There are 2 types of power supply modules. One provides a total current capacity of 1.5

Amps and the other is a switched power supply that provides a total current capacity of 3

Amps. Both modules have connections for powering auxiliary devices and triggering bells,

electronic sirens, or loudspeakers during an alarm. Each Power Supply expansion module

also supports its own standby battery and is supervised for the loss of AC, a low battery

condition, tamper input, the failure of its auxiliary output power, and the loss of sounder loop

integrity.

Access Control Expansion Module

One of ProSYS's most unique features is its integration with an Access Control sub-system.

With a maximum connection of eight such Access Control modules, a total of 16 readers is

possible (each module supporting up to two readers). Each reader can operate with

magnetic, proximity, bar code, touch, and/or Weigand technology. Up to 999 users can be

accommodated, and up to 1000 "transactions" can be stored in a module.

Scheduling

Through the use of the system's built-in clock, it is possible to automate system operations at

the same time on selected days of the week or at a specific time within the subsequent 24hour period or during vacation periods.

The system operations include:

♦ Scheduling automatic arming and disarming (of one or more partitions).

♦ Scheduling automatic operation of Utility Outputs.

♦ Restricting users from disarming during predefined time periods.

Event Logging

The ProSYS has the capability of storing up to 999 significant events, including arming,

disarming, bypassing, alarms, troubles, restorals, and resets. These events are logged in

order according to date and time, and when applicable, according to Zone, Partition, Area,

User Code, Keypad, etc. When appropriate, such events can be displayed on an LCD keypad

or uploaded to the MS via the Upload/Download software and printed for further analysis.

ProSYS Installation and Pr ogramming Manual 15

Printer Module

A Printer module, designed to interface between the ProSYS's 4-wire Expansion BUS and a

Centronics-type parallel printer, enables the printing of all significant system events as they

occur, including access control activities, if applicable. Each event includes the date, time and

if applicable, the affected partition and the user involved.

Advanced Installation Tools

♦ Auto Installation: For quick and easy installation, the system performs automatic

installation of the modules connected to the BUS. The system searches for the

modules by automatically verifying their connection and operation through the BUSscanning feature and prompts the user to approve each module connection. The auto

installation feature is performed automatically after defaulting the system or can also

be performed manually.

♦ Self Monitoring

The BUS Test enables the system to verify the connection and the operation of

the modules connected to the BUS by indicating the efficiency of each one on a

0-100% scale. Each result is individually displayed on the LCD keypad (or via

the Upload/Download software).

A watchdog feature, which periodically and automatically performs a

comprehensive self-test and reports when operating faults are found.

A Maintenance Mode which, when selected, performs an active self-check on

many of its components.

One-man walk testing capabilities, enabling an Installer or technician to check

the operation of each contact and detector which, when tripped, produces

audible feedback and is visibly logged at the keypad from which the test was

initiated.

♦ System programming

Local keypad keys

Program Transfer Module: Used to store the programmed configuration of any

ProSYS without the need for power.

Local/Remote Upload/Download software

False Alarm Reduction

In an effort to deter false alarms, the ProSYS provides various programmable features,

including the following programmable features: cross zoning, swinger shutdown,

audible/visual entry/exit delays, fire alarm verification, dialer delay before an alarm

transmission, cancel report option, double knock, soak test and exit termination zone.

16 ProSYS Installation and Programming Manual

Chapter 2 Mounting and Wiring the

Main Panel

This chapter covers the first two steps of the ProSYS installation procedure, as

follows:

Step 1: Mounting the Main Panel, below

Step 2: Wiring the Main Panel, page 18

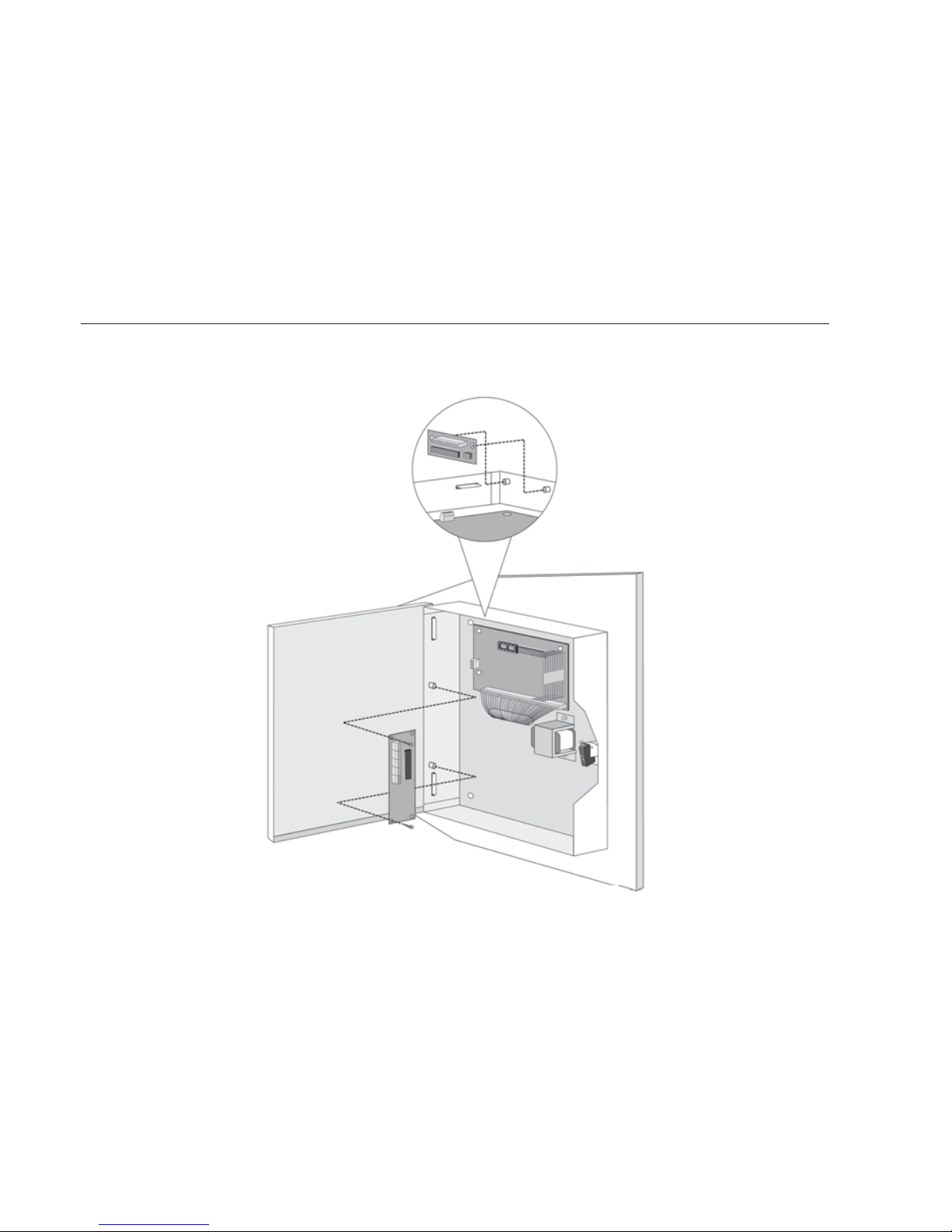

Step 1: Mounting the Main Panel

The ProSYS Main Panel . should be installed inside a metal box Attach the box to the

wall using the proper hardware, as shown below.

Figure 3: Mounting the Main Panel

The mounting location should be:

Dry.

Near an AC power supply (switched off).

With a good earth connection.

With access to the customer's phone lines.

ProSYS Installation and Pr ogramming Manual 17

Safety Precautions

When mounting the Main Panel, the following safety precautions are relevant:

When the Main Panel is powered on, mains voltage is present on the main PCB. To prevent

risk of electric shock, disconnect all power (AC transformer and battery) and phone cords

before servicing. Under no circumstances should mains power be connected to the PCB

other than to the main terminal block.

For AC mains connection, a readily accessible disconnect device shall be incorporated in the

building installation wiring.

The equipment should be installed in accordance with the National Fire Protection

Association's Standard #74 (N.F.P.A. Batterymarch Park, Qulncy, MA 02269) and local

National Electrical Codes.

For continued protection against risk of fire, replace fuses only with fuses of the same type

and rating.

There is a risk of explosion if a battery is replaced with an incorrect type. Dispose of used

batteries according to the proper instructions. (The Main Panel is designed to work with a

12 V, 7 Amp-hour sealed lead battery as a backup for the primary power supply.)

Do no short the terminals of the transformer together. This causes the internal fuse to blow.

The transformer must be connected to a 230 VAC, 24-hour outlet not controlled by a switch

other than an approved over-current protection device.

The Main Panel is designed with reverse polarity protection on the battery charging circuit.

However, prolonged improper connection of the battery to the Main Panel will result in

damage. The power should remain disconnected until all connections have been made

and checked for accuracy.

Discharging Static Electricity

Please note that it is important to discharge static electricity that may have built up in

your body before you touch a circuit. To do this, touch the earth. (Refer also to What

Makes a Good Ground? in Chapter 2, Mounting and Wiring the Main Panel.)

Following Local Regulations

Be sure to follow your local regulations regarding fire protection, electrical installation,

noise pollution, and security systems installation.

What Makes a Good Ground?

Grounding provides a degree of protection against lightning and induced transients for

any piece of electronic equipment that may, due to lightning or static discharge,

experience permanent or general malfunctions. The ideal ground is considered to be a

unified earth ground in which an 8-foot copper-clad rod, located close to the existing

power and telephone ground rods, is sunk several feet into the earth. Appropriate

hardware and clamps are then used to electrically connect each of these rods together

and then to the ground terminal of the device to be protected.

It may be possible to use an existing electrical ground on the premises if one is close

enough to the Main Panel. Ideally, that ground can be obtained at the metal service

panel where the incoming electrical power originates. When connecting the ground

wire, use a solid 14-gauge wire [or larger (numerically lower) size] connected between

the ProSYS's GND terminal and an acceptable electrical ground connection. Keep this

wire as short as possible and do not run it in conduit, coil it, bend it sharply, or run it

alongside other wiring. If you must bend it or change its direction, it should have a

radius of at least 8 inches at the point from which it is bent. If in doubt, you may want

to enlist the help of a licensed electrician in matters concerning such grounding.

18 ProSYS Installation and Programming Manual

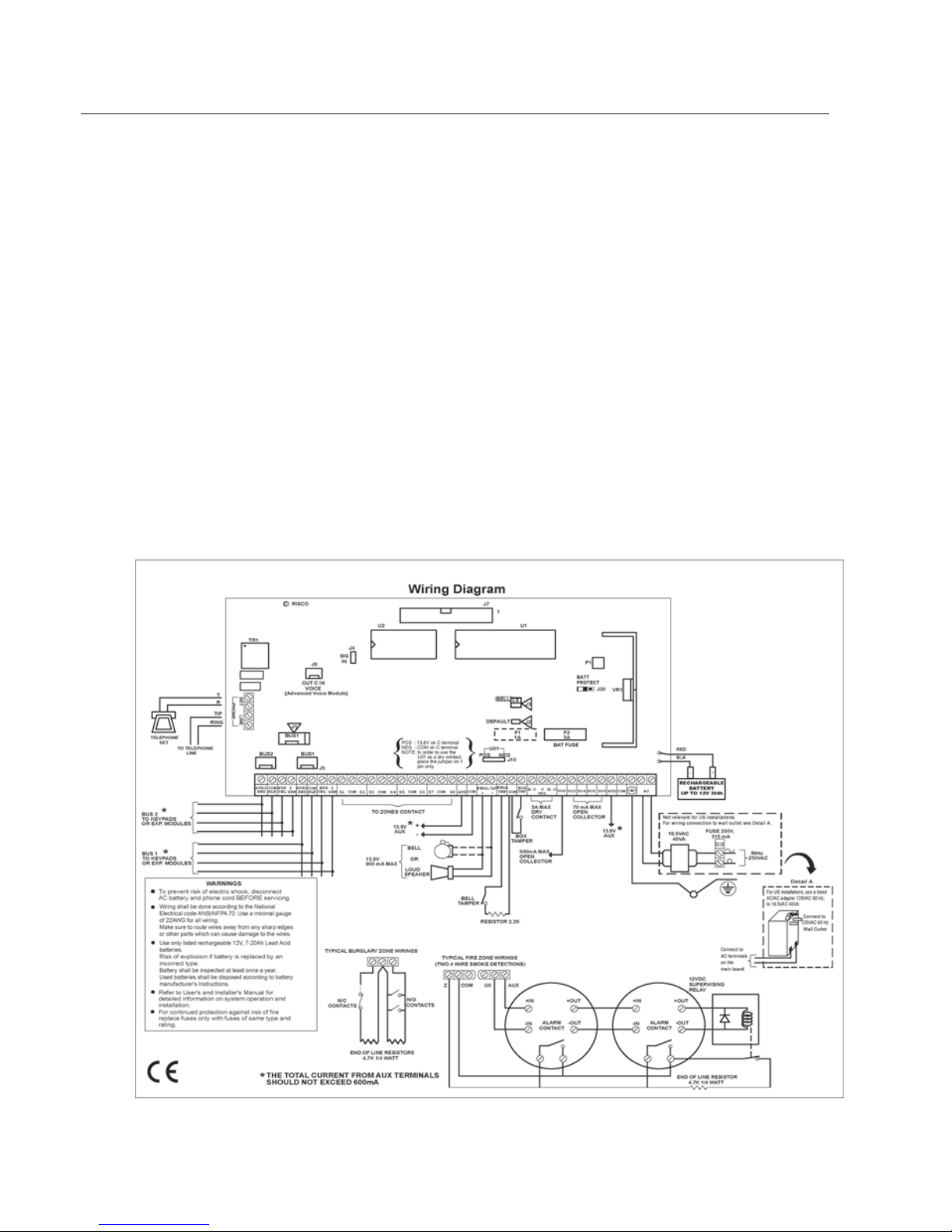

Step 2: Wiring the Main Panel

This step explains the various wiring and connection procedures that must be

performed when wiring the Main Panel, as follows:

Wiring the Main Panel, page 18

Wiring the Zones to Sensors and Detectors (Zone Terminals Z1 through Z8), page 19

Wiring the Auxiliary Devices, page 22

Wiring the Bell Sounders, page 23

Wiring the Bell Tamper, page 23

Wiring the Box Tamper, page 24

Wiring External Triggerable Devices, page 24

Connecting the J10 Connector, page 25

Connecting to Ground (Earth), page 26

Connecting Telephone Lines, page 26

Jumper Settings, page 27

Connectors, page 28

Connecting AC Power, page 28

IMPORTANT: Before wiring the Main Panel, ensure that the connection to the power

supplies, mains or battery, is switched OFF during wiring.

Wiring the Main Panel

Figure 4: Main Panel Wiring Diagram

ProSYS Installation and Pr ogramming Manual 19

The second set of four terminals on the left of the Main Panel represent the Expansion

BUS. These support the connection of keypads and expansion modules.

The connections are terminal-to-terminal with color-coded wires, as follows:

BUS

Terminal

Description

AUX RED

+12V power for BUS expansion modules

COM BLK

Black 0V common for BUS expansion modules

BUS YEL

Yellow DATA connection for BUS expansion modules

BUS GRN

Green DATA connection for BUS expansion modules

To prevent a possible drop in voltage due to multiple keypads and long wire runs, use

a quality 4-conductor cable with an appropriate gauge size (refer to the table of gauge

sizes in Chapter 1, Introducing ProSYS).

The parallel wiring system supports parallel connections from any point along the

wiring (refer to

Figure 5 below). The maximum wire run permitted is 300 meters (1000

feet) for all legs of the BUS.

Figure 5: 4-Wire Expansion BUS

NOTE:

The ProSYS has 2 separate BUS connections. If one BUS is shorted or there is any kind of

problem that interrupts the BUS data, the other BUS will continue to operate normally.

Wiring the Zones to Sensors and Detectors

(Zone Terminals Z1 through Z8)

To wire the zones to sensors and detectors:

1 Connect up to 8 hardwired zones, using twisted-pair or 4-conductor cable wiring.

2 Connect each zone to the appropriate Zone (Z) terminal and its related COM terminal.

Each pair of zones shares a COM terminal. For example, Z1 and Z2 share a COM

terminal, as do Z3 and Z4, and so on.

20 ProSYS Installation and Programming Manual

NOTES:

It is recommended that you use an End-of-Line Resistor at the far end of each hardwired zone

to prevent short-circuits (16 resistors are supplied).

For a zone with a tamper switch, you can use a Double End-of-Line Resistor to save additional

Main Panel connections (refer to

Figure 6 on page 21).

3 Terminate unused zones at the Main Panel.

4 Connect the power to the sensors and/or detectors, as described in Wiring the Auxiliary

Devices, page 22.

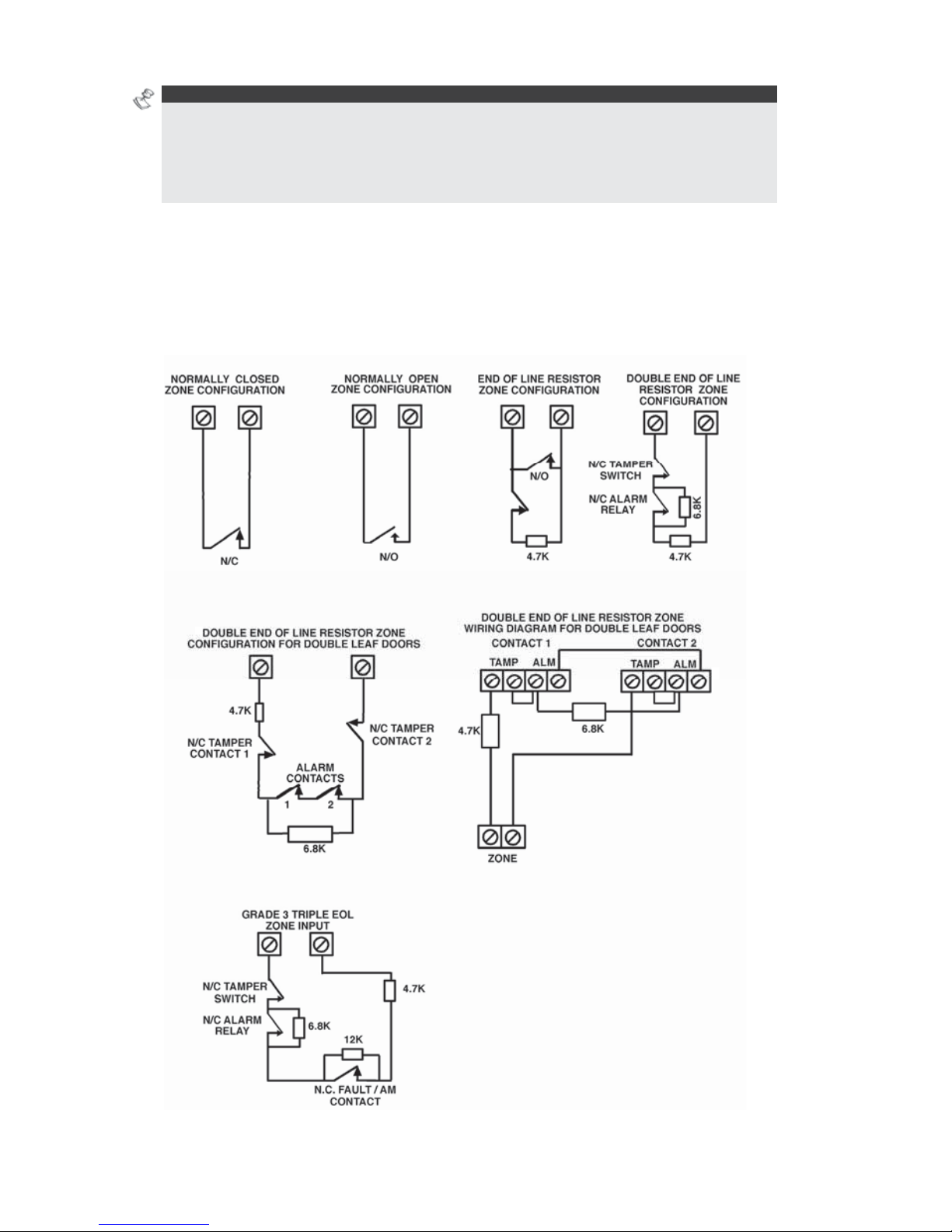

The following diagrams illustrate the various possible zone connections depending on

the zone expanders.

Connection on the main units or on the G3 zone expanders (ProSYS EZ8G3, EZ16G3):

ProSYS Installation and Pr ogramming Manual 21

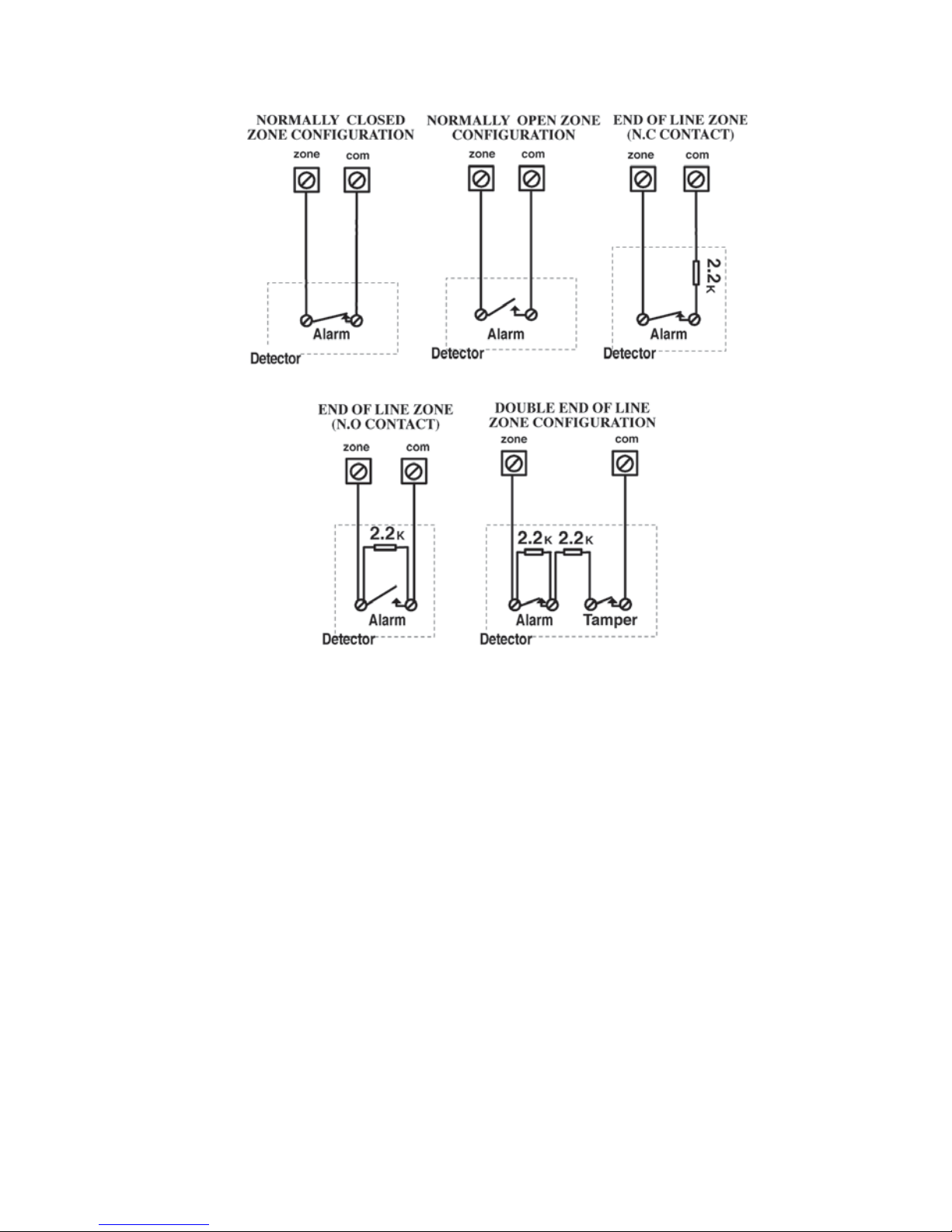

Connections on Zone Expanders (ProSYS EZ8, ProSYS EZ16):

Figure 6: Zone Connection Diagrams

22 ProSYS Installation and Programming Manual

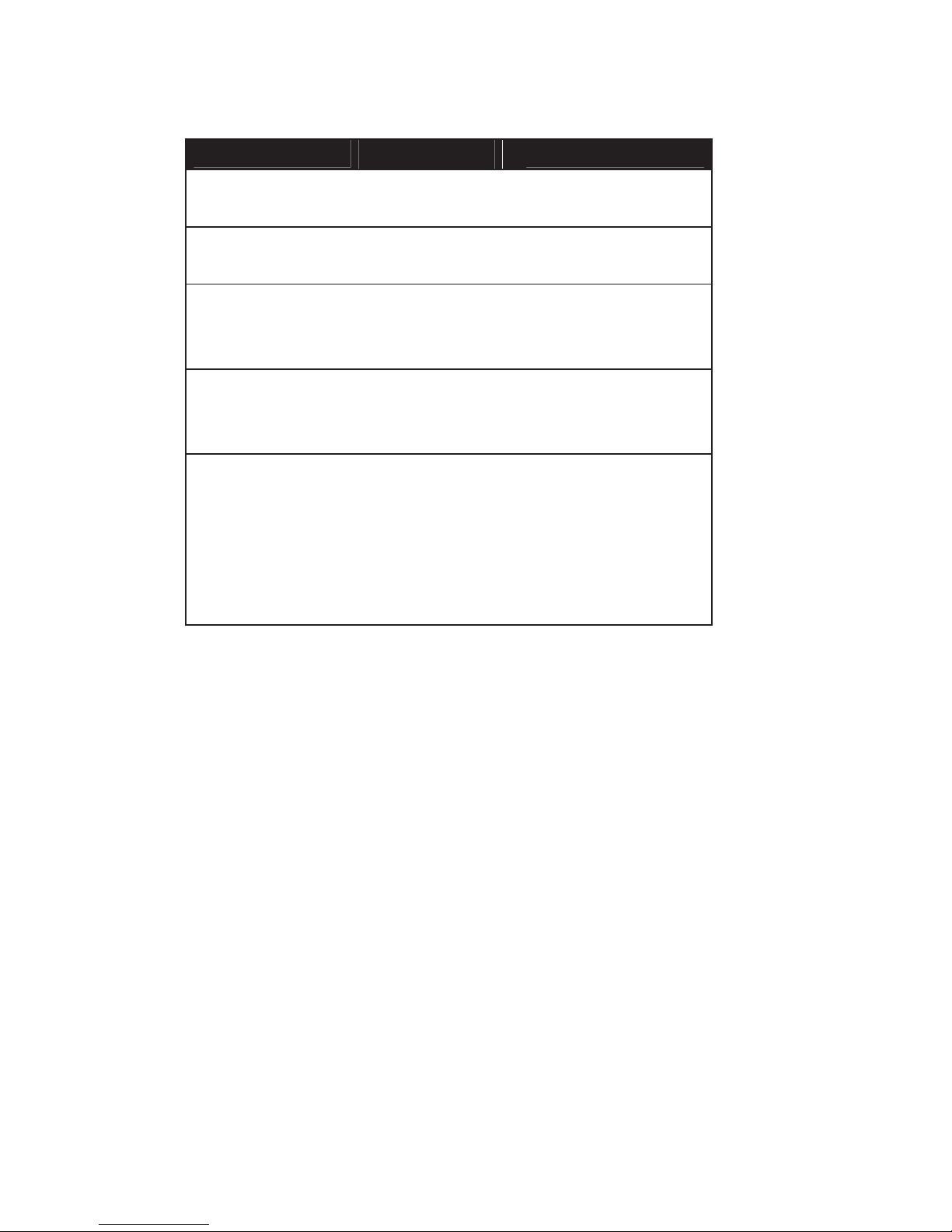

The following table

indicates the EOL limit values when the ProSYS panel detects a status

difference. Please respect the EOL standard values given in the installation manual to prevent

unexpected alarms.

Zone Type

Impedance (KΩ)

Zone Mode

NO

47.1<R Ready

R<47.1 Trip

NC

6.97<R Trip

R<6.97 Ready

EOL

6.97<R Trip

3.07<R<6.97 Ready

R<3.07 Trip

DEOL

13.95<R Tamper

6.97<R<13.95 Trip

3.07<R<6.97 Ready

TEOL

47.1<R Tamper

19.92<R<47.1 Anti Mask

13.95<R<19.92 Fault

6.97<R<13.95 Trip

3.07<R<6.97 Ready

R<3.07 Tamper

TEOL uses normally-closed (NC) contacts in a zone to distinguish between alarm, tamper

condition and fault/AM condition using 4.7K and fault/AM condition using 4.7KΩ + 6.8KΩ +

12KΩ End-of-Line resistors.

Wiring the Auxiliary Devices

To wire auxiliary devices:

Use the Auxiliary Power AUX (+) COM (-) terminals to power PIRs, glass-break detectors

(4-wire types), smoke detectors, audio switches, photoelectric systems and/or any device

that requires a 12V DC power supply.

ProSYS Installation and Pr ogramming Manual 23

NOTES:

The total power from the AUX terminals should not excee d 600mA.

To connect a 4-wire smoke detector or devices that require resetting after an alarm condition,

connect the Auxiliary power AUX and UO terminals (refer to Figure 4 on page 18, for smoke

detector wiring). Remember to define the UO as Switched Auxiliary (refer to the Switch AUX

parameter described in Chapter 5, Quick Key [3][1][14]). Using the Installer Programming

Menus).

In addition, when connecting a 4-wire smoke detector, observe the wiring guidelines mentioned

in the previous sections, along with any local requirements applicable to smoke detectors.

To prevent a possible drop in voltage due to current requirements and distances involved,

make sure to use the appropriate wire gauge (refer to the table of gauge sizes in Chapter 1,

Introducing ProSYS).

To incre ase your power supply when employing multiple auxiliary devices, you can use the

optional Pow er Supply expansion module (refer to the Wiring Power Supply Expansion

Modules section in Chapter 3, Installing External Modules and Devices).

If the auxiliary outputs are overloaded (exceed 600mA) and are shut down, you must

disconnect all loads from the outputs for a period of at least 10 seconds before you reconnect

any load to the auxiliary outputs.

Wiring the Bell Sounders

To wire the bell sounders:

1 Connect a suitable wire to the internal sounding device(s) inside the building (bell, electronic

siren, or loudspeaker).

2 Ensure that you note the polarity when connecting electronic siren(s) and/or polarized bells.

!

WARNING:

To avoid Bell Loop Trouble, if NO connection is made to an internal sounder, use a 2200Ω

resistor in its place.

NOTE:

It is important to position the BELL/LS Jumper (J3) correctly. The position varies depending

on the type of internal sounder.

3 For a loudspeaker without a built-in sound driver, position the jumper J3 so that it covers both

pins. The Main Panel produces a continuous oscillating voltage for burglary and panic alarms

and an interrupted oscillating voltage for fire alarms.

4 For a bell or an electronic siren with a built-in sound driver, position the jumper J3 so that it

does NOT cover both pins. A steady 12V DC is produced at the sounder terminals during

burglary and panic alarms. A slow pulsing voltage is produced during a fire alarm.

Wiring the Bell Tamper

To wire the bell tamper:

Connect the bell tamper to the BELL TMP and COM terminals on the Main Panel, as

illustrated in

Figure 4: Main Panel Wiring Diagramon page 18.

24 ProSYS Installation and Programming Manual

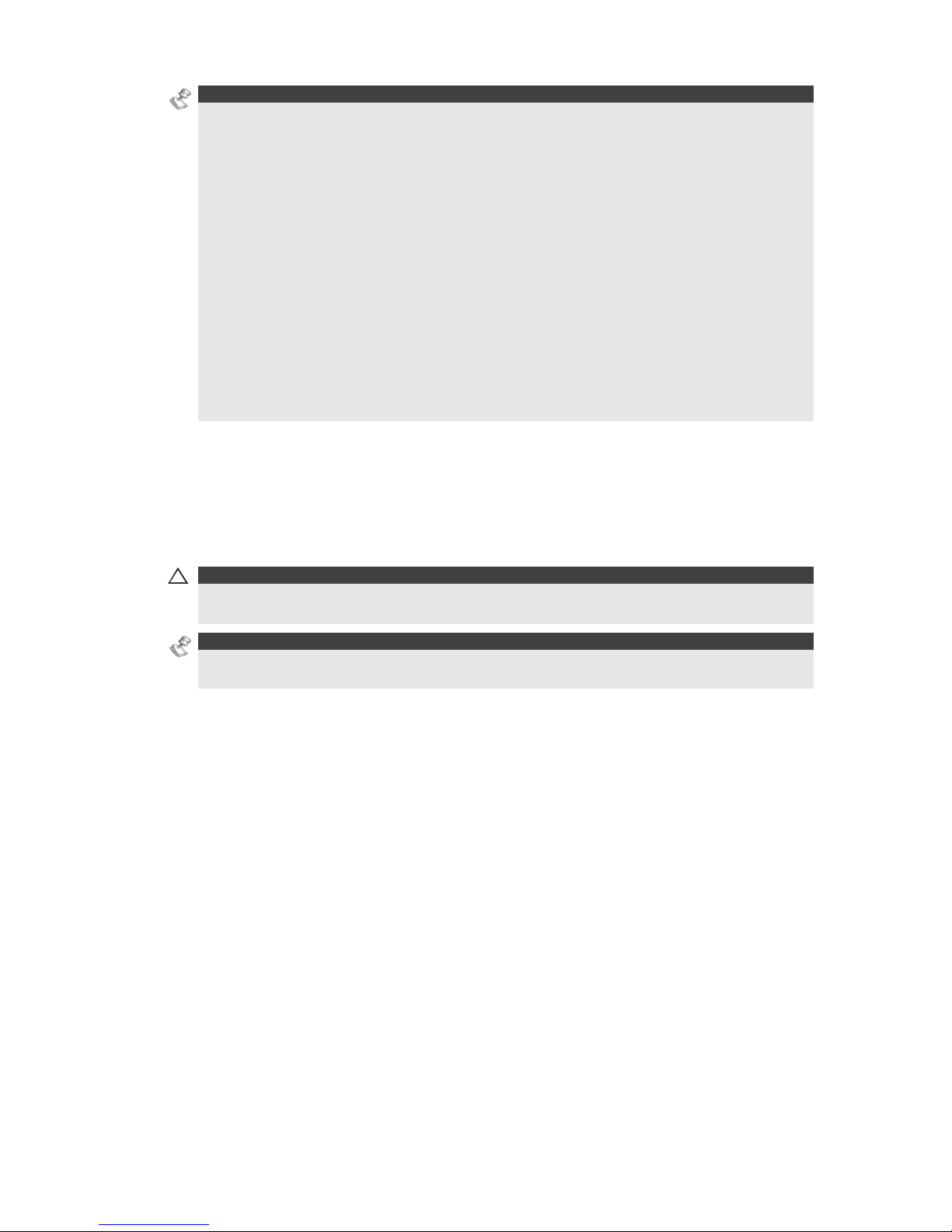

Wiring the Box Tamper

To wire the box tamper:

Connect the box tamper to the BOX TMP and COM terminals on the Main Panel, as

illustrated in

Figure 4 on page 18. Refer also to the diagram shown below.

Figure 7: Wiring the Box Tamper

Wiring External Triggerable Devices

To wire external triggerable devices:

Wire the external triggerable devices that you want to activate to the outputs UO1-UO6, as

follows:

O UO1: Refer to the J10 connector instructions, described in the next section. For

additional details, refer to Chapter 3, Installing External Modules and Devices.

O UO2-UO6: Connect the positive connection of the device to AUX (+) and the

negative connection to the UO's (-) terminals.

ProSYS Installation and Pr ogramming Manual 25

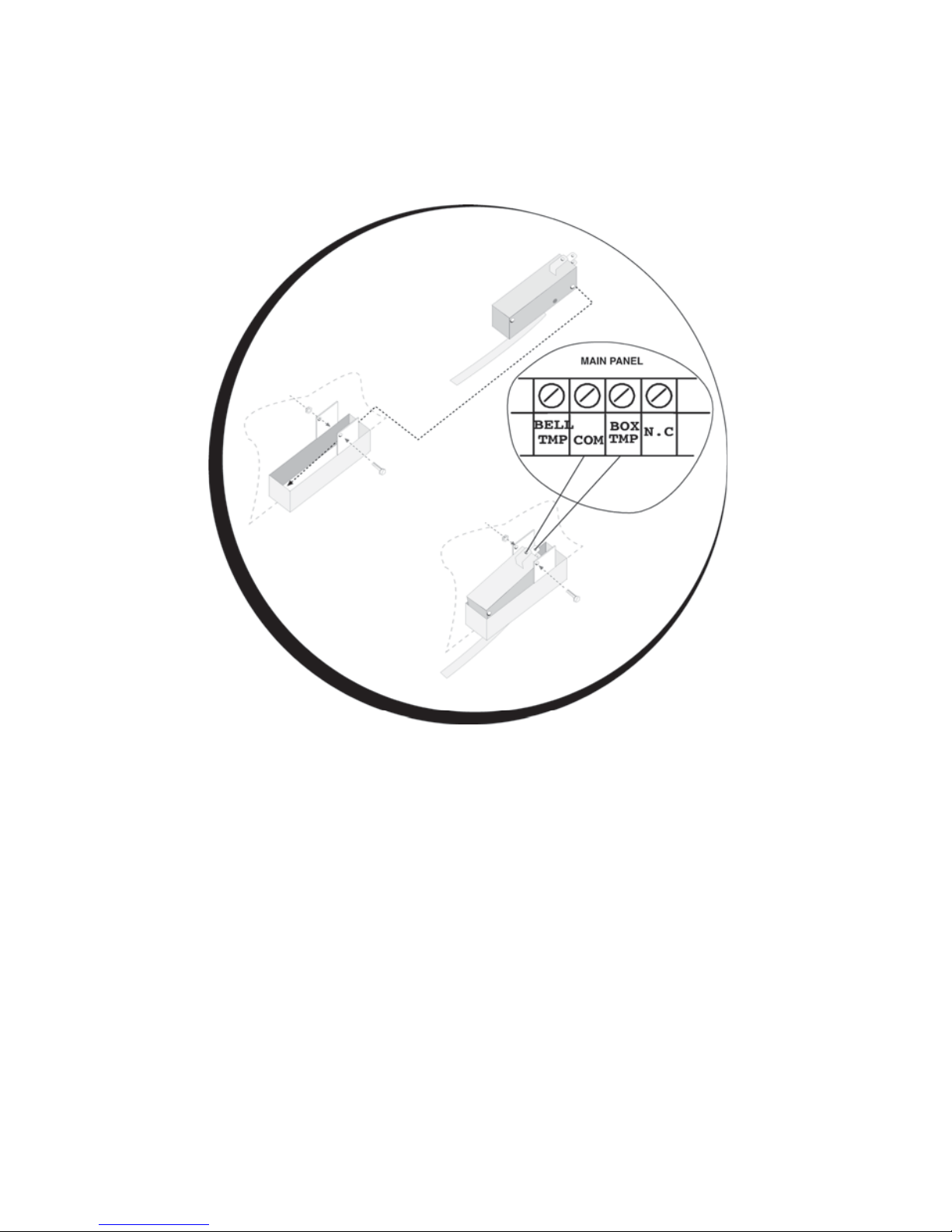

Connecting the J10 Connector

POS NEG

Figure 8: Connecting the J10 Connector

The J10 connector (jumper) determines the UO1 connection (behavior), which is

normally used for an external siren connection, as follows:

Positive (POS): When the J10 connector is placed on POS, the C terminal on UO1 receives

13.8V.

NOTE:

The maximum current for UO1 and the bell should not exceed 900mA.

Negative (NEG): When the J10 connector is placed on NEG, the C terminal on UO1 receives

COM.

If the J10 connector is placed only on 1 pin, the UO1 acts as a dry contact.

26 ProSYS Installation and Programming Manual

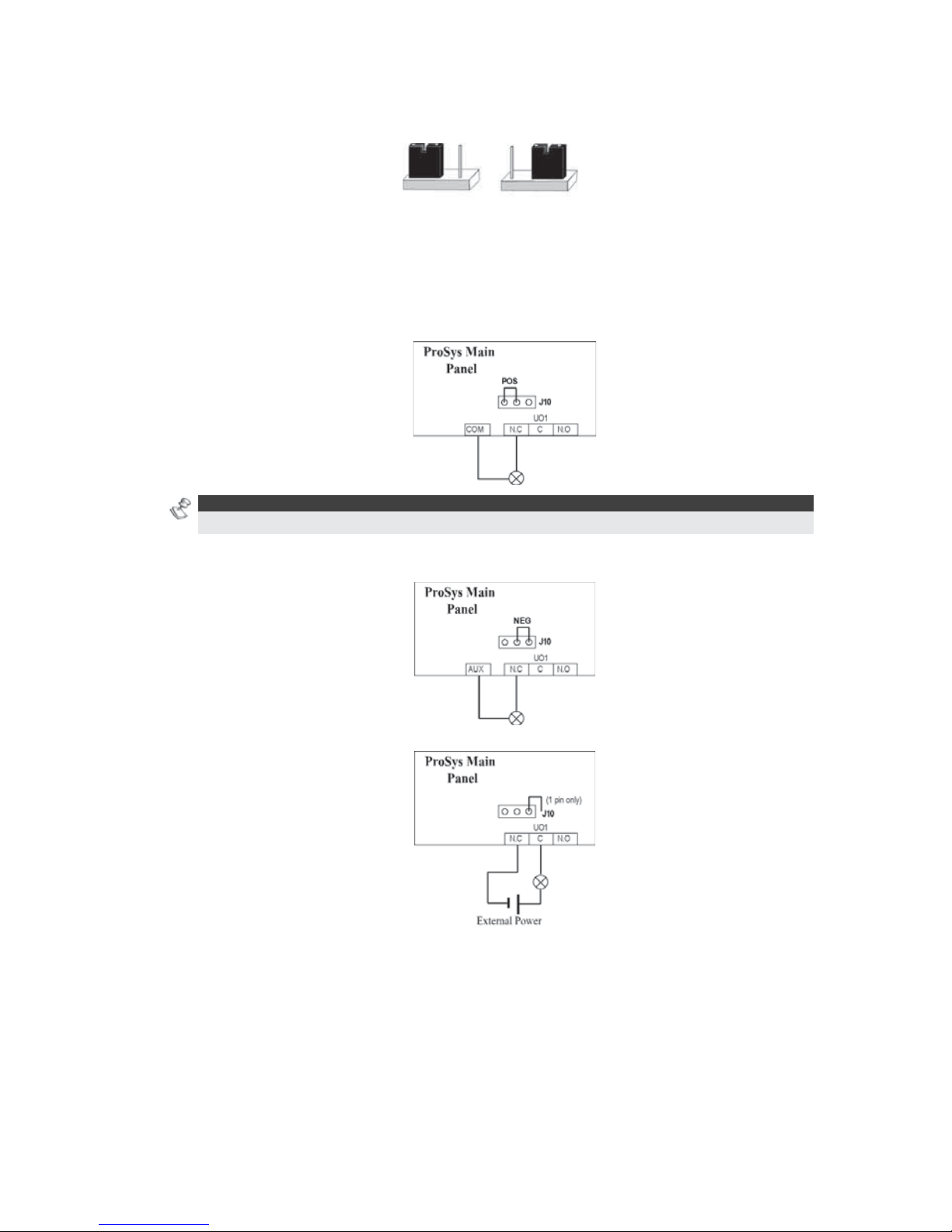

Connecting to Ground (Earth)

To connect to ground (earth):

Connect the metal box and the door of the metal box to mains earth (ground), as shown in

the diagrams on the following page. Refer also to What Makes a Good Ground?, page 17.

!

IMPO RTA NT:

Connecting to ground must be performed according to the local National Electrical Code.

Figure 9: Grounding the Metal Box Figure 10: Grounding the Metal Box

Door

Connecting Telephone Lines

These lines are typically derived from an installed RJ31X jack.

To connect telephone lines:

1 Connect the incoming telephone line to the Main Panel's LINE terminals.

2 Connect any telephone on the premises to the SET terminals.

ProSYS Installation and Pr ogramming Manual 27

Jumper Settings

The ProSYS is equipped with internal jumpers. Use the following table to configure the

jumpers according to the desired configuration.

Jumpers Po

siti

on

Function

DEFAULT (J2)

Enables to default the panel and restore the ProSYS

codes (Grand master, installer and sub installer) to the

manufacturers default settings.

Position the jumper plug over both pins when

reinstating factory installed defaults values to the

Grand master, installer and sub installer codes or for

installing programming using the Program Transfer

Module (refer to Chapter 4, Programming the

ProSYS).

(Default)

Maintains the last programming setting and disables

the restoring of the ProSYS codes (Grand master,

installer and sub installer) to the manufacturers default

settings.

Position the default jumper plug over one pin for

safekeeping.

BELL/

LOUDSPEAKER

(J3)

The J3 jumper determines whether a bell or

loudspeaker sound will be heard.

Loudspeaker: The ProSYS produces a continuous or

interrupted oscillating voltage, depending on the type

of alarm.

(Default)

Bell: The ProSYS produces a steady 12V DC voltage

or a slow pulsating voltage, depending on the alarm

type. Refer to Wiring the Bell Sounders, page 23, for

further details

BATTERY

PROTECTION

(J20)

(Default)

Battery Discharge Protection is Activated: If a

continuous AC power outage occurs, the ProSYS

automatically disconnects the battery when its backup

battery voltage drops below 10.05 VDC, in order to

prevent "deep discharge” that may damage the

battery.

NOTE :

In this position, the ProSYS will not start to operate from

a battery power supply, unless connected to the Mains

first.

Battery Discharge Protection is Disabled; The battery

may be totally discharged during continuous AC

failure, thus battery replacement may be required (no

deep discharge protection).

NOTE :

In this position, the ProSYS will start to operate from a

battery power supply whether it is connected to the

Mains or not.

28 ProSYS Installation and Programming Manual

Jumpers Po

siti

on

Function

UO1 (J10)

Determines the UO1 connection (behavior), see

Connecting the J10 Connector, page 25.

Default: 1 PIN

Connectors

Connector Function

J1, J5

BUS 1 Plug in connector.

J8

BUS 2 Plug in connector.

J4

SIG In connector. The J4 SIG IN voice connector enables the

transfer of audio data between the Voice module RP200VC and

the phone line.

J6

The J6 connector is used to connect the Advanced Digital Voice

Module (rp128ev00uka) to the ProSYS.

Connect the Voice module to the VOICE connector (J6) on the

Main Panel via the supplied cable. This connector transmits

signals from the Voice module to the telephone line during remote

communication and is essential for normal operation of the Voice

module.

Connecting AC Power

To connect AC power:

1 Connect the 230V AC to the mains fuse (SLOW BLOW 315 mA) input terminal block

according to the Local National Electronic Code.

2 Fasten the AC cord to the metal bo x using adjustable clamps.

!

IMPORTANT:

Do NOT apply mains power at this time.

Be sure to connect the live wire of the AC power through the AC fuse. The size of the conductors

must not be less than 0.75mm2 (18AWG).

ProSYS Installation and Pr ogramming Manual 29

Chapter 3 Installing External

Modules and Devices

This chapter describes steps 3 to 5 of the ProSYS installation procedure, as follows:

Step 3: Identifying and Wiring Keypads and Expansion Modules

Step 4: Adding Modules, page 31

Step 5: Applying Power, page 35

Step 3: Identifying and Wiring Keypads and

Expansion Modules

This section explains how to program a unique ID number to identify each keypad and

expansion module in the system and how to install a keypad, as follows:

Programming Device ID Numbers, below

Installing a Keypad, page 30

Programming Device ID Numbers

To program device ID numbers:

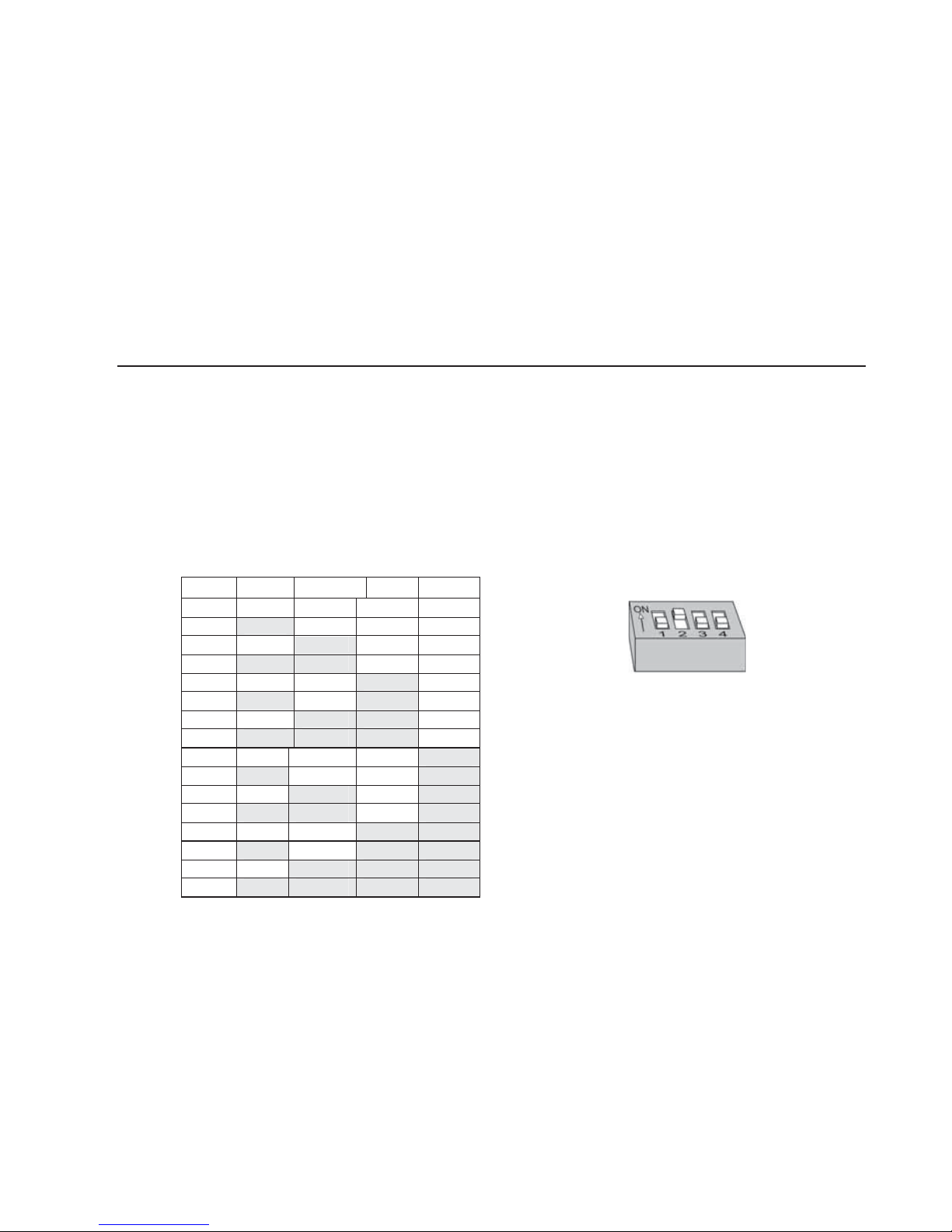

Program each device's ID number by setting the dip switches, as follows:

I 1 2 3 4

01

OFF OFF OFF

OFF

02

ON OFF OFF

OFF

03

OFF ON OFF

OFF

04

ON ON OFF

OFF

05

OFF OFF ON

OFF

06

ON OFF ON

OFF

07

OFF ON ON

OFF

08

ON ON ON

OFF

09 OFF OFF OFF ON

10 ON OFF OFF ON

11 OFF ON OFF ON

12 ON ON OFF ON

13 OFF OFF ON ON

14 ON OFF ON ON

15 OFF ON ON ON

16 ON ON ON ON

Figure 11: Dip Switch Settings

Assign the same ID numbers to the different

categories of devices (meaning keypads and

expansion modules) in the order they are

added to the system.

This means that you must assign the ID of 01

to the first keypad as well as to the first Zone

Expander, the first Utility Output and the first

Power Supply module. A second module in

any of these categories receives the ID of 02.

Up to 16 keypads can be added to the system,

each assigned ID numbers from 01 to 16. Up

to 8 of the other types of devices can be

added to the system, each assigned ID

numbers from 01 to 08.

30 ProSYS Installation and Programming Manual

Installing a Keypad

NOTE:

For information on installing the Touchscreen keypad, refer to the ProSYS Touchscreen Keypad

Instruction manual that is incl uded with the product.

To install a keypad:

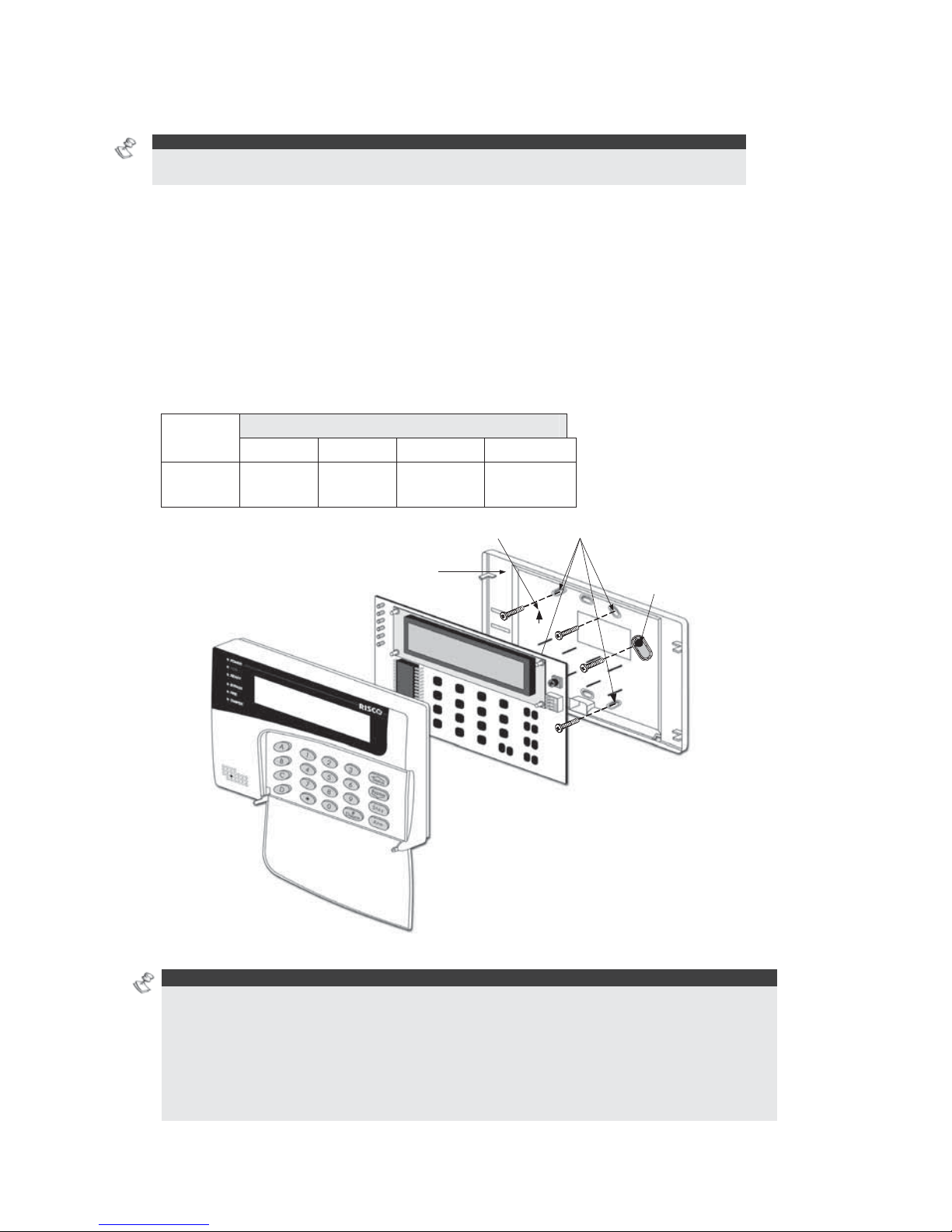

1 Open the Keypad Cover: Remove the back of the keypad cover, and using a

screwdriver, press in each of the retaining clips to separate the back cover from the

keypad. Take care not to touch the circuitry of the keypad buttons.

2 Set the Dip Switches: Program the keypad ID by setting the dip switches according to

the table displayed in

Figure 11 on page 29. Dip switch settings are per ID number

(01 = first keypad, 02 = second keypad, and so on).

3 Connect the BUS Wiring: Connect the wires from the appropriate terminals in the

keypad to the appropriate connector on the Main Panel's Expansion BUS terminals.

The connections are terminal-to-terminal with the terminals clearly marked. The wires

are color-coded, as follows:

UP

Orientation arrow

Wall fixing points

Back panel

Tamper protected fixing

point

Figure 12: Keypad Installation Front View

NOTE S:

A trimmer is located on the right side of the keypad (next to the dip switches) that enables you

to adjust the brightness and contrast of the LCD display. Therefore, it is recommended to leave

the keypad open while powering up in order to adjust the LCD display.

To prevent a possible drop in voltage due to multiple keypads and long wire runs, use a quality

4-conductor cable with an appropriate gauge size (refer to the table of gauge sizes in Chapter

1, Introducing ProSYS).

The maximum wire run permitted is 300 meters (1000 feet) for the total BUS wiring.

EXPANSION BUS TERMINALS

AUX COM BUS BUS

Color

RED BLK

(Black)

YEL

(Yellow)

GRN

(Green)

ProSYS Installation and Pr ogramming Manual 31

4 Set the Tamper Switch: Before mounting the keypad on the wall, locate the

rear-mounted Tamper Switch and make sure that it is vertically oriented.

5 Replace the Cover:

O Carefully replace the keypad's printed circuit board in its cover.

O Join the cover and base by hooking the tops together and then snapping the bottom in

place, returning the retaining clips to their positions.

Step 4: Adding Modules

This section explains how to add the various ProSYS modules, as follows:

Wiring Zone Expansion Modules, below

Wiring Utility Output Modules, page 32

Wiring Power Supply Expansion Modules, page 34

Wiring Additional Modules, page 35

Wiring Zone Expansion Modules

Figure 13: 8 Zone Expansion Module Figure 14: 16 Zone Expansion Module

To wire Zone expansion modules:

1 Set the Dip Switches: Assign a unique ID to each Zone expansion module by setting

the dip switches, using Jumper Settings on page 29.

NOTE:

The ID for the first Zone expansion module is 01, for the second 02, and so on.

2 Connect the BUS Terminals: Connect the first four terminals at the left of the Zone

expansion module to the Main Panel's 4-wire BUS terminal, as follows:

EXPANSION BUS TERMINALS

AUX COM BUS BUS

Color

RED BLK

(Black)

YEL

(Yellow)

GRN

(Green)

NOTES:

The parallel wiring system supports pa ra llel connections from any point along the wiring (refer

to Chapter 2, Mounting and Wiring the Main Panel).

The maximum wire run permitted is 300 meters (1000 feet) for the total BUS wiring.

3 Connect the Zone Terminals (8-Zone Expander Z1-Z8; 16-Zone Expander Z1-Z16): Refer

to steps 1 to 3 in the Wiring the Zones to Sensors and Detectors section in Chapter 2,

Mounting and Wiring the Main Panel.

4 Supply Po wer to the Aux iliary Devices: Refer to step 4 in the Wiring the Zones to Sensors

and Detectors section in Chapter 2, Mounting and Wiring the Main Panel.

32 ProSYS Installation and Programming Manual

Wiring Utility Output Modules

Figure 15: Utility Output Module UO4 (Showing an Example of UO4 Wiring)

Figure 16: Utility Output Module E08 Figure 17: Utility Output Module X-10

To wire Ut ility Output modules:

1 Set the Dip Switches: Assign a unique ID to each Utility Output expansion module by setting

the dip switches, using

Figure 11 on page 29.

NOTE:

The ID for the first Utility Output expansion module is 01, for the second 02, and so on. The

first Utility Output in the Utility Output expansion module (defined as ID 01) will always be Utility

Output 07.

2 Connect the BUS Terminals: Connect the first four terminals at the left of the Utility

Output expansion module to the Main Panel's 4-wire BUS, as follows:

EXPANSION BUS TERMINALS

AUX COM BUS BUS

Color

RED BLK

(Black)

YEL

(Yellow)

GRN

(Green)

3 Set the Tamper (TAMP COM): The Utility Output expansion module can be contained in

a metal cabinet. Tamper the cabinet, as follows:

ProSYS Installation and Pr ogramming Manual 33

O Connect one (or more) normally open (NO) momentary-action pushbutton switches

in a series between the TAMP and COM terminals in order to short-circuit these

terminals while the cabinet door is closed.

NOT ES:

It is not necessary to use a tamper switch if another module sharing the same cabinet is

equipped with one .

Do NOT use an End-of-Line Resistor in the tamper switch circuit.

O If a tamper switch is not used, connect a wire jumper between the two terminals.

4 Mount the Utility Output Expansion Modules: Mount one or more Utility Output

expansion modules in the Main Panel cabinet, depending on space availability.

Alternativ ely, mount them in a separate cabinet.

5 Connect the Triggerable Device to the Utility Output:

O Connect one wire to the COM terminal of the UO device to be operated and connect the

other wire to the GND.

O Connect the NO or NC switch to the AUX terminal.

6 Wire the Relay Connections: The Relay module has 4 relays (UO1, UO2, UO3, and

UO4), which can be connected as follows:

O Connect one wire of the device to be operated to the UO terminal.

O Connect the other wire of the device to be operated to the AUX terminal.

For instructions about programming the relay operation, refer to the Utility

Output section in Chapter 5, Using the Installer Programming Menus.

7 Wire the Triggers: The Open Collector modules have 8 outputs (UO1 through UO8).

For instructions about programming their operation, refer to the Utility Output section in

Chapter 5, Using the Installer Programming Menus.

8 Wire the X-10:

O Connect the 4-wire BUS between the Main Panel and the X-10 module.

O Connect an RJ25 cable (4-wire telephone cable) between the RJ11 connector on the

X-10 module and the X-10 transmitter.

O Plug the X-10 transmitter into the AC power.

O Plug the X-10 receiver into the AC power close to the device that will be operated.

O Connect the X-10 receiver to the device.

For more information about programming and setting the ID of the X-10

module, refer to the instructions supplied with the module

34 ProSYS Installation and Programming Manual

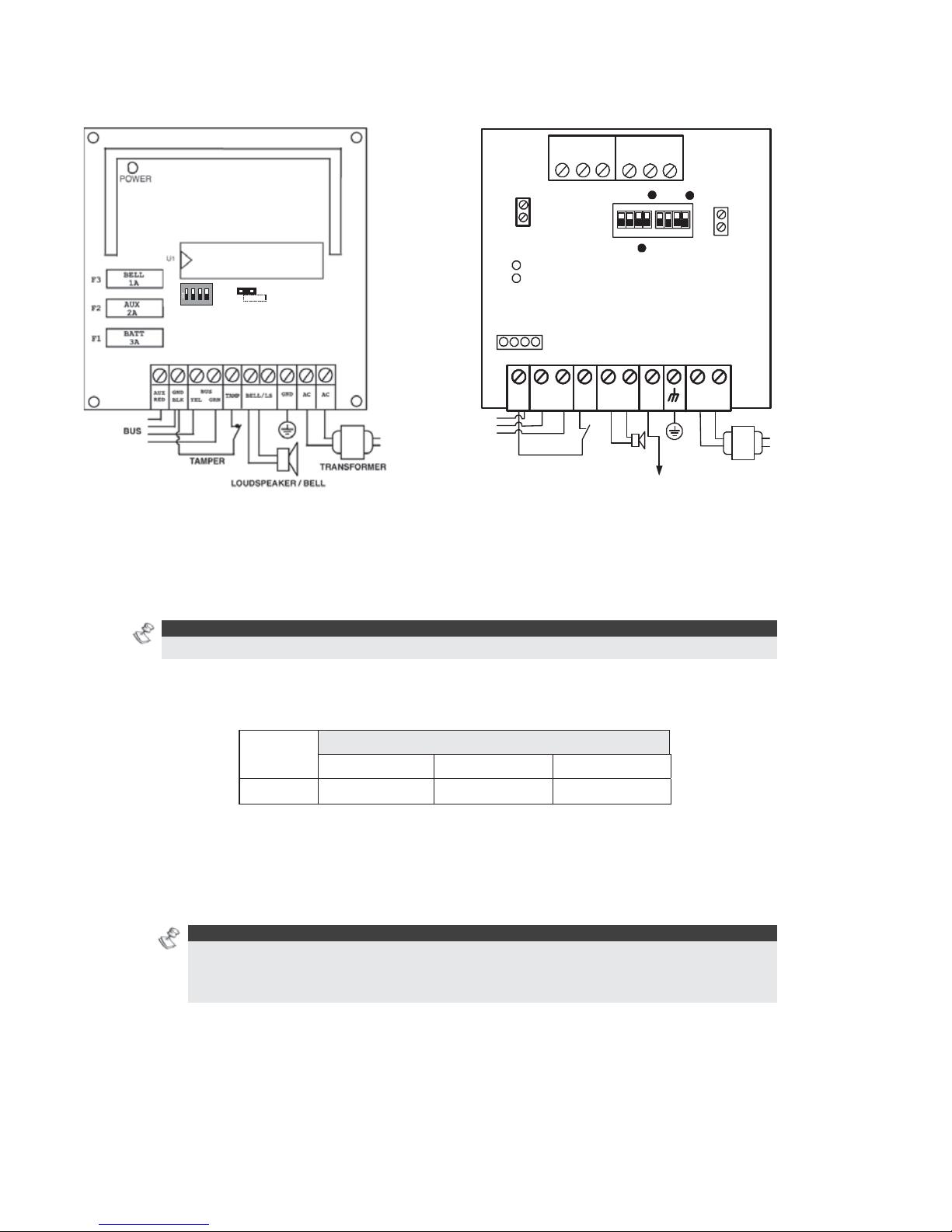

Wiring Power Supply Expansion Modules

ON

1234

ON

OFF

SW1

BELL

LS

(PS LED)

(UO LED)

AC

AUX

RED

BELL LS

+ -

TAMP

BUS

YEL GRN

COM

BLK

BUS

BELL/ LS

(Bell/Loudspeaker

Jumper)

OC

(Over Current LED)

BAT

(Battery Jumper)

PS

Battery

Connections

Loudspeaker/

Bell

Power to Accessories

and Detectors

Transformer

1234

1234

ON

N.O

N.C

C

UO 1

C

UO 2

N.O

N.C

Figure 18: 1.5A Power Supply Module PS Figure 19: 3A Power Supply Module PS

To wire Power Supply expansion modules:

1 Set the Dip Switches: Assign a unique ID to each Power Supply e xpansion module

by setting the dip switches, using

Figure 11 on page 29.

NOTE:

The ID for the first Power Supply expansion module is 01, for the second 02, and so on.

2 Connect the BUS Terminals: Connect only three of the first four terminals at the left of

the Power Supply e xpansion module to the Main Panel's 4-wire BUS, as follows (refer also

to Figure 2-3 in Chapter 2, Mounting and Wiring the Main Panel):

EXPANSION BUS TERMINALS

COM BUS BUS

Color

BLK (Black) YEL (Yellow) GRN (Green)

3 Set the Tamper (TAMP COM): The Power Supply e xpansion module can be contained in

a metal cabinet. Tamper the cabinet, as follows:

O Connect one (or more) normally open momentary-action pushbutton switches in a

series between the TAMP and COM terminals.

NOT ES:

It is not necessary to use a tamper switch if another module sharing the same cabinet is

equipped with one.

Do NOT use an End-of-Line Resistor in the tamper switch circuit.

O If a tamper switch is not used, connect a wire jumper between the two terminals.

4 Connect the Internal Siren BELL/LS (+) (-):

O Connect a suitable wire to the internal device(s) to be driven by the Power Supply

expansion module (bell, electronic siren, or loudspeaker).

ProSYS Installation and Pr ogramming Manual 35

O Use a larger wire gauge if the distance separating the siren and the module is

significant. Take the siren(s) current draw into account as well when selecting a wire

gauge (refer to the table of gauge sizes in Chapter 1, Introducing ProSYS).

NOTE:

Any internal siren(s) connected to the Power Supply expansion module will operate exactly

like the siren(s) connected to the Main Panel.

O Position the BELL/LS Jumper (J3), as follows:

♦ For a loudspeaker without a built-in siren driver, position the jumper J3 so that it

covers both pins. The module produces a continuous oscillating voltage for

burglary and panic alarms and an interrupted oscillating voltage for fire alarms.

♦ For a bell or electronic siren, with a built-in sound driver, position the jumper J3 so

that it does NOT cover both pins. A steady 12V DC is produced at the siren

terminals during burglary and panic alarms. A slow pulsing voltage is produced

during a fire alarm.

5 Supply Power to the Auxiliary Device AUX (+) COM (−): The Power Supply

expansion module can power PIRs, glass-break detectors (4-wire types), audio

switches, and photoelectric systems. It can also power any device located too far from

the Main Panel and/or whose operation requires a continuous supply of 12V DC via

the AUX (+) and COM (−) terminals. (Refer to Chapter 2, Mounting and Wiring the

Main Panel).

6 Connect the Flying Leads (RED and BLACK): Connect these leads (at the proper

time) to the positive (+ RED) and negative (− BLACK) terminals of the appropriate

Standby Battery for the Power Supply expansion module.

Wiring Additional Modules

For details about wiring the following modules, refer to the installation and

programming manual that is supplied with each module:

Advanced Digital Voice Module

Access Control Module

Proximity Key Reader

Fast PSTN Modem 2400 BPS

ProSound Sounder

Advanced Communication Module (ACM)

GSM/GPRS Module (AGM)

BUS Zones detectors (WatchOUT, Lunar Industrial, WatchIN, iWise)

BUS Zone Expander

Step 5: Applying Power

After you have completed wiring the modules, you can apply power and program the

system according to the instructions in the next chapter.

36 ProSYS Installation and Programming Manual

Chapter 4 Programming the ProSYS

This chapter explains the ProSYS programming options, how to use the keypad elements,

and the basics about programming via the keypad, as described in the following sections:

Using the ProSYS Main Panel Programming Options, below

Using the LCD Keypad, page 37

Programming from the LCD Keypad, page 38

Using the Program Transfer Module, page 43

For detailed information about each Programming option, refer to Chapter 5, Using the

Installer Programming Menus.

Using the ProSYS Main Panel Programming

Options

You can program the ProSYS in any of the following ways:

LCD Keypad: Use any of the LCD keypads described in this manual. Each keypad needs a

unique ID to identify it in the system. Refer to Chapter 3, Installing External Modules and

Devices, for details about how to set the keypad ID using dip switches. Instructions for

programming the ProSYS from an LCD keypad are provided on pages 37 through 42.

Program Transfer Module (PTM): (Model ProSYS EE) The PTM is a tiny circuit board into

which a copy of the Main Panel's configuration can be copied and stored as well as

transferred to any installation when temporarily plugged into its 4-wire BUS. Refer to page

43 for detailed instructions about using the Program Transfer Module.

Upload/Download (U/D): This is a software application that enables you to program the

ProSYS from a PC computer. It offers the following two alternatives:

O Working locally, through a portable computer connected to the Main Panel

O Working at a remote site, communicating with the Main Panel via one of the following

options:

O A phone line and modem

O TCP/IP network using the ACM module

O GPRS using the AGM a phone line and modem

O When using the Upload/Download software, the following is required:

O IBM compatible PC

O Upload/Download software

O BUS adapter cable and plug to connect between the PC serial COM port and the

ProSYS J1 connector (for on-site use)

O Modem with access to a phone line (for remote use)

O USB/485 converter for on-site use (p/n RP128EUSB00A) to connect between a

PC USB port and the ProSYS J1 serial connection. For additional details, refer

to a RISCO Group’s technical support representative.

Full details and operating instructions for the U/D software are available in the

Upload/Download User's Manual, provided with the software (p/n 5IN128UD).

ProSYS Installation and Pr ogramming Manual 37

Using the LCD Keypad

#/

?

Figure 20: The LCD Keypad Face

The LCD keypad is a visual interface tool that helps you operate the ProSYS Main Panel. The

LCD keypad contains six LED indicators and a variety of keys. Their typical uses are

described in the following table:

NOTE:

For information regarding the TouchScreen keypad please refer to the instructions supplied with the

product.

Item Key/LED Programming Mode/Function

1 Power LED

This LED indicates the following:

• LED ON = power on

• Slow flashing LED = an active programming session

• Fast flashing LED = system trouble

2 Arm LED

This LED indicates that the system is armed. All partitions must

be disarmed (LED unlit) to enter the Installer Programming

mode.

3 Ready LED

These LEDS are off (unlit) during programming operations.

These LEDs on the keypads (other than the one being used for

actual programming) flash during programming operations.

4 Bypass LED

5 Fire LED

6 Tamper LED

38 ProSYS Installation and Programming Manual

Item Key/LED Programming Mode/Function

7 A, B, C, and D

Use these keys for defining groups and macros. Refer to the

Groups section in Chapter 1, Introducing ProSYS for further

details.

8

Use this key to exit the current programming selection and

move up to the next higher level in the programming hierarchy.

9 LCD Program

Display

The LCD program display consists of two lines. The top line

displays information about the main selection mode, and the

bottom line displays information and/or data about the specific

option set. Such data may be changed through keypad entry.

When programming, up to 16-characters can be entered into a

line, as required.

10 0 through 9 Use the numbered keys, 0 through 9, to key in numbers and/or

special characters when labeling zones, areas, and partitions.

(For information about how to use the keypad for labeling

zones, areas, and partitions, refer to Chapter 5, Using the

Installer Programming Menus.)

11

/

/

Press either one of these keys to move back and forth through

the programming level functions.

These keys also change the position of the flashing cursor.

When editing a selection, the cursor moves to the left or right

respectively.

12

/

Use this key to toggle forward through the programming

choices within a selection.

13

/

Use this key to toggle backward through the programming

choices within a selection.

14

/

Use this key to enter selected information into the system or to

accept the current selection and access the lower level of

options in the programming hierarchy.

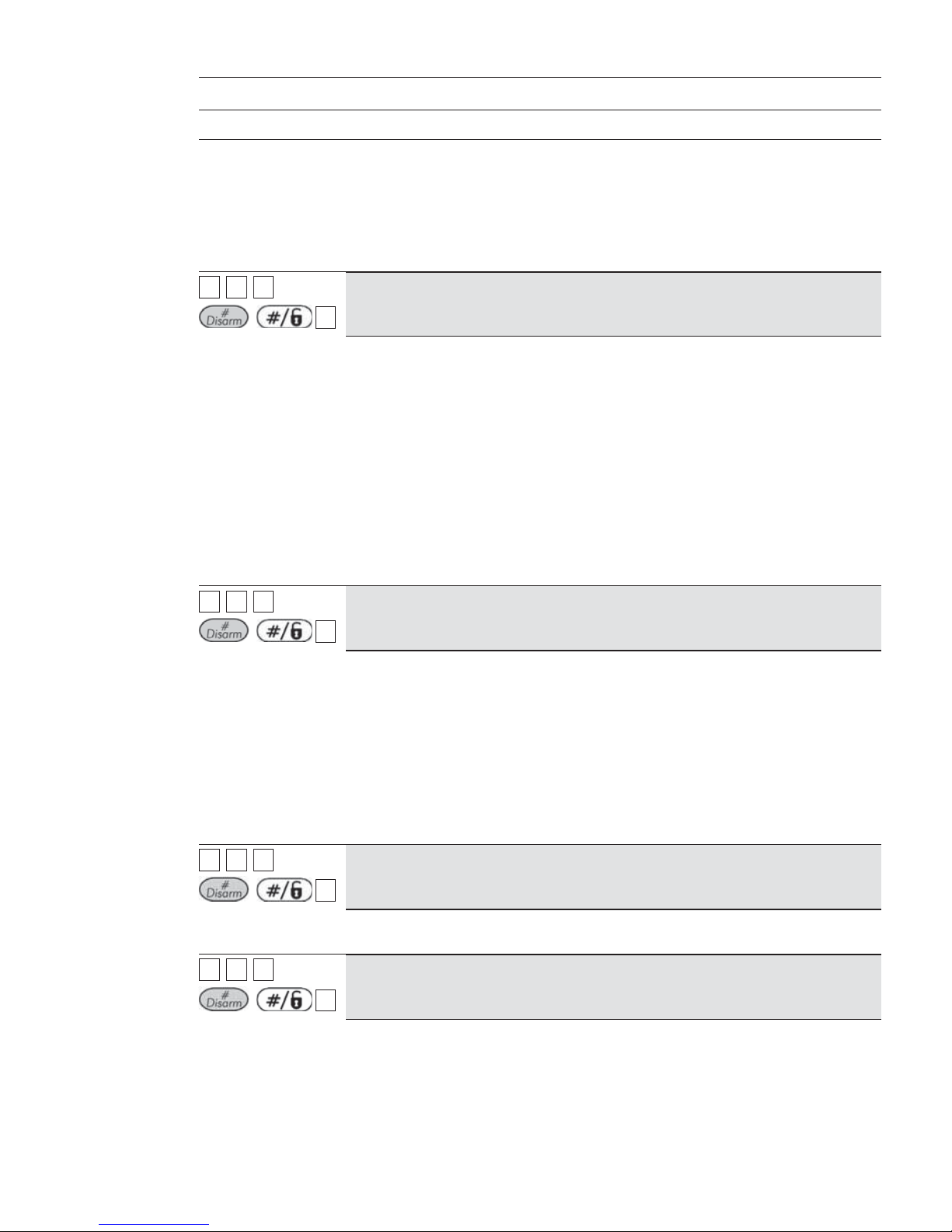

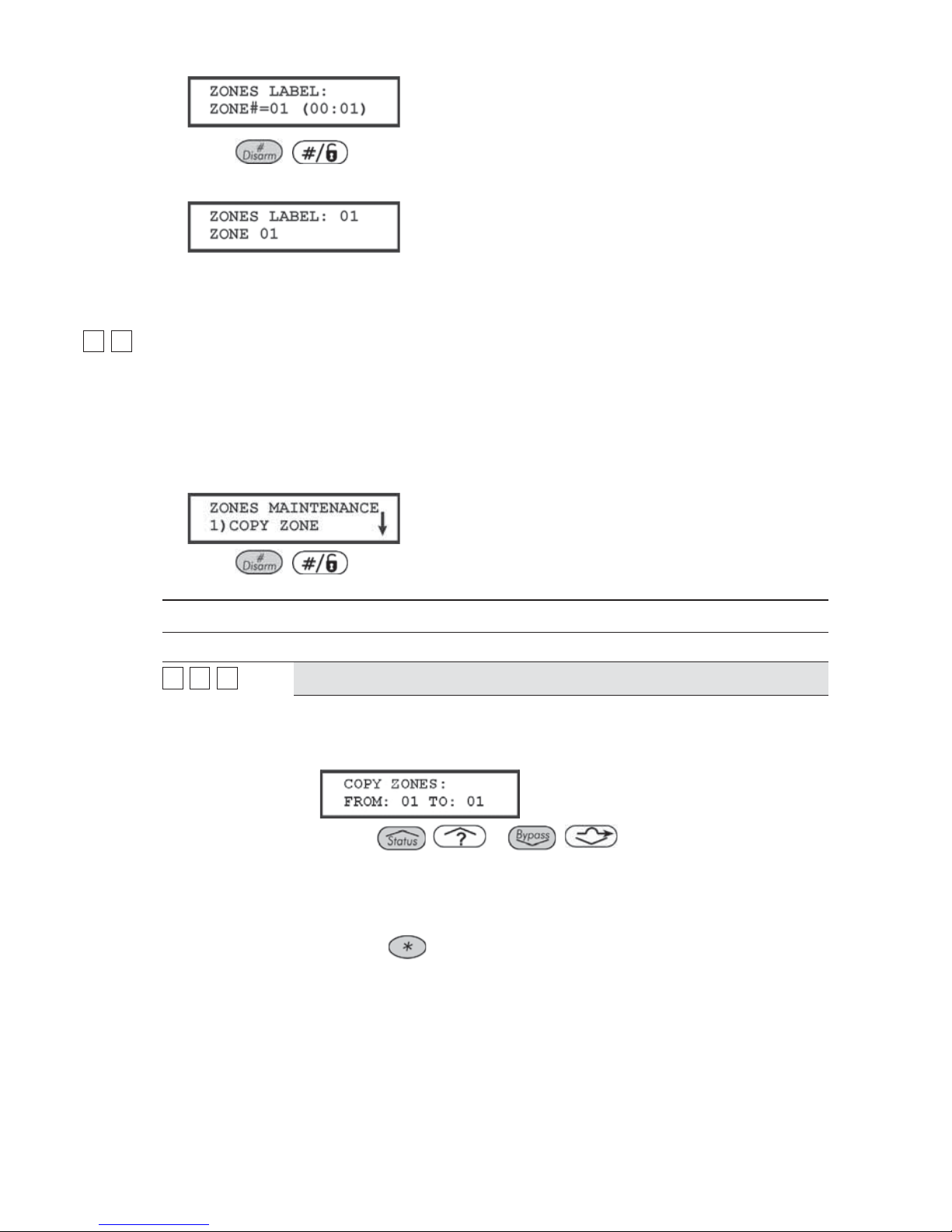

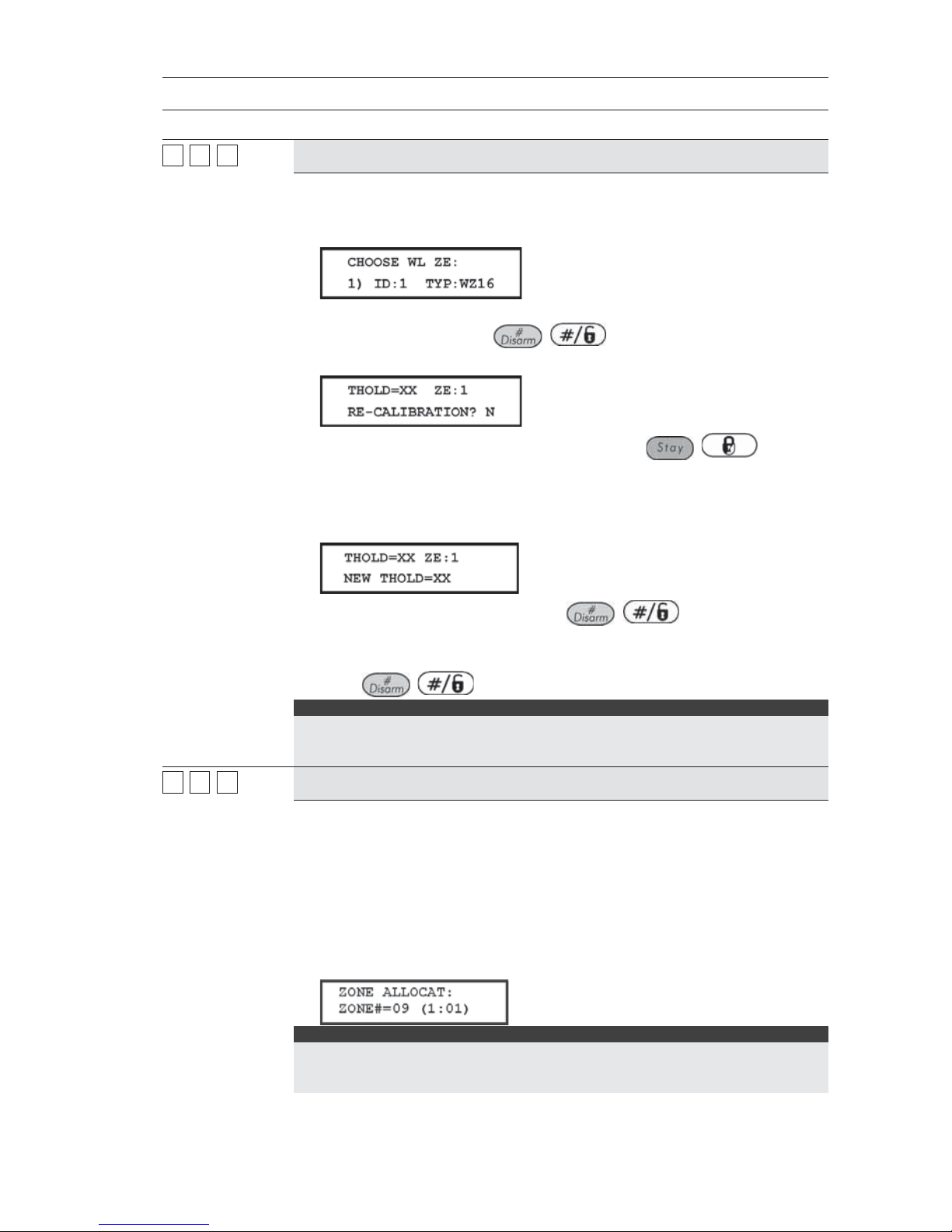

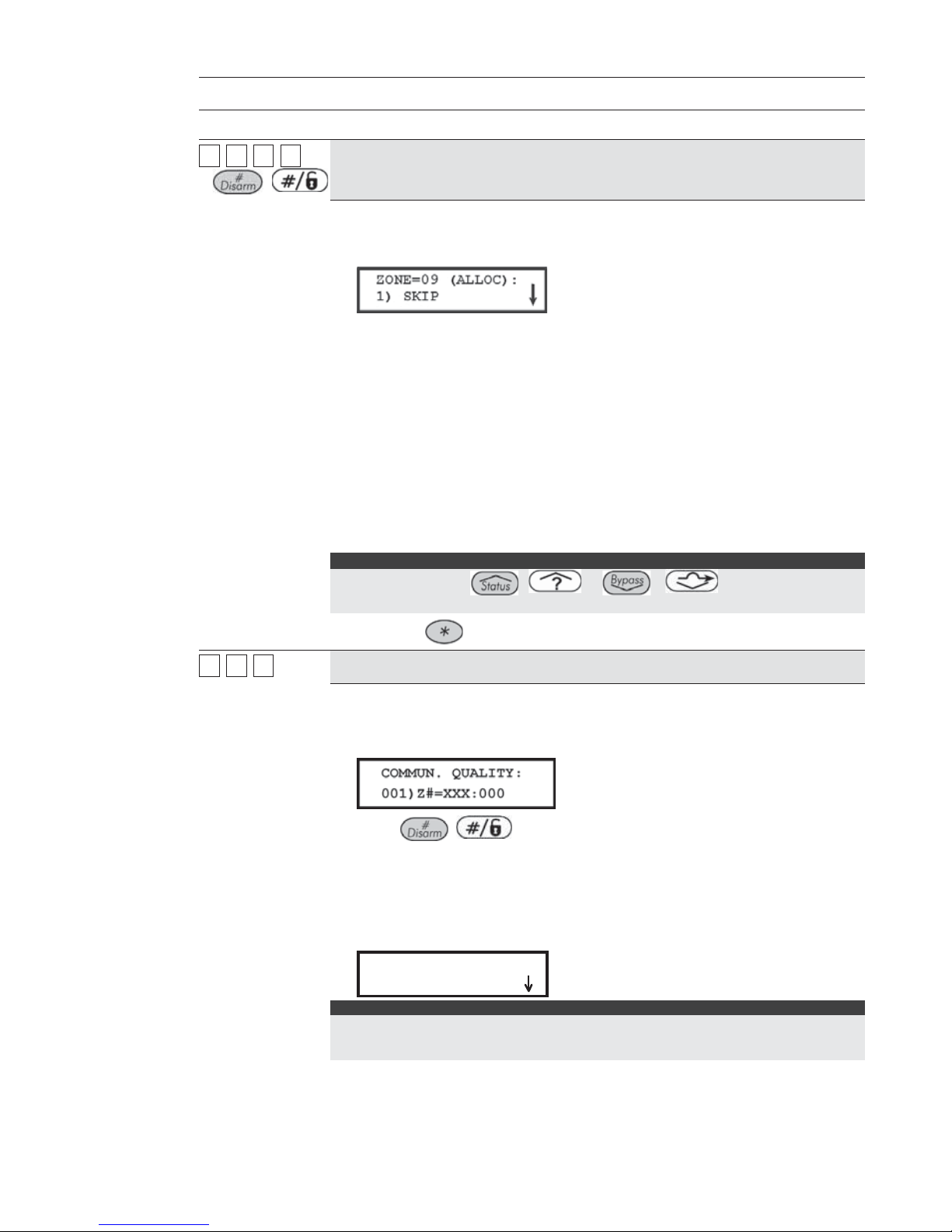

Programming from the LCD Keypad

This section explains how to use the keypad to access the Installer Programming menu as

well as how to restore the manufacturer's defaults, as described in the following sections:

Accessing the Installer Programming Menu, below

Restoring Manufacturer's Programming Defaults, page 41

Keypad Timeout, page 43

Using the Program Transfer Module (PTM), page 43

Accessing the Installer Programming Menu

This section describes how to access the Installer Programming menu for the first time or

after the Main Panel has been defaulted, as well as how to access it from the regular

operation mode.

If the Main Panel has been defaulted, you must enter the Installer Programming menu as if it

is the first time. In this case, after you enter your Installer code, the system automatically

enters the automatic accessories setting process by performing the BUS scan. (Refer to the

ProSYS Installation and Pr ogramming Manual 39

Accessories: Auto Settings section of Chapter 5, Using the Installer Programming Menus for

further details).

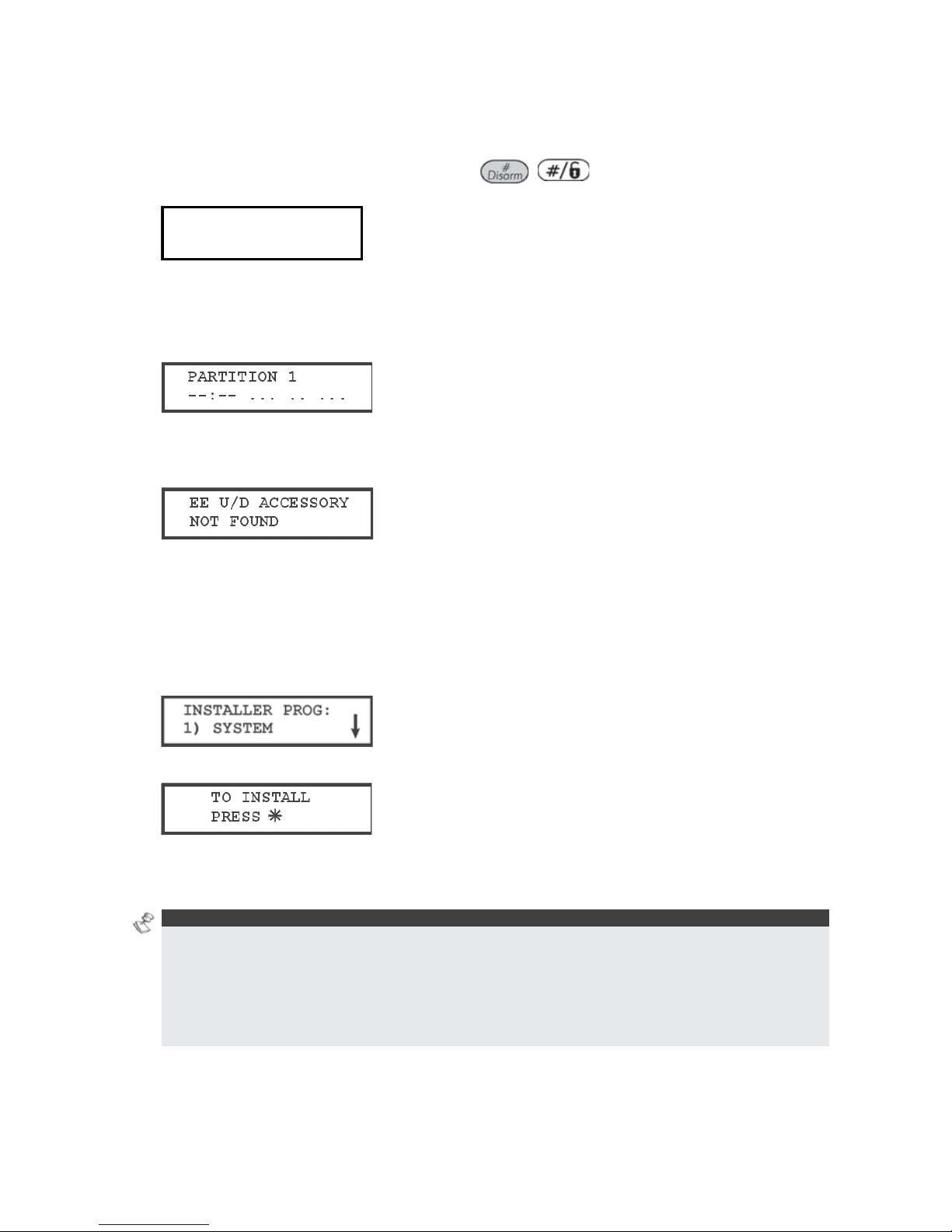

To access the Installer Programming Menu for the first time (or after the

Main Panel has been defaulted):

1 When you power up the system, the following display appears:

PLEASE WAIT…PLEASE WAIT…

After a brief wait, the following display appears:

TO INST ALL

TO INST ALL

PRESS *

PRESS *

TO INST ALL

TO INST ALL

PRESS *

PRESS *

2 To program the system to recognize the keypad, press

. The following display appears,

prompting you for the Installer code:

3 Enter the default Installer code, depending on the ProSYS model:

O ProSYS 128: [0][1][2][8]

O ProSYS 40: [0][1][4][0]

O ProSYS 16: [0][1][1][6]

The code appears as ,,,, on the keypad display, as follows:

4 The system enters the automatic accessories setting process, and the following display

appears:

NOTE:

Refer to Accessories: Auto Settings section of Chapter 5, Using the Installer Programming Menus for

further details.

The Power/ LED begins flashing slowly at this point, indicating that you have entered a

programming session.

To access the Installer Programming Menu from the regular operation mode:

When you power up the system, the following display appears:

PLEASE WAIT…PLEASE WAIT…

After a brief wait, the keypad displays the regular operation mode, as follows:

1 Press . The keypad displays the first User Functions option, as follows:

40 ProSYS Installation and Programming Manual

2 Press [7] to select the Installer option or use the

/

key. The keypad displays

the first option, as follows:

3 Press [1] Advanced. The keypad prompts you for the Installer code, as follows:

4 Enter the default Installer Code, de pending on the ProSYS model:

O ProSYS 128: [0][1][2][8]

O ProSYS 40: [0][1][4][0]

O ProSYS 16: [0][1][1][6]

The code appears as ,,,, on the keypad display, as follows:

5 Press

/

. The keypad displays the following message:

Then the first main Installer Programming menu option is displayed, as follows:

The Power/

LED begins flashing slowly at this point, indicating that you have entered a

programming session.

The main Installer Programming menu options are available, as follows:

[1] SYSTEM

[2] ZONES

[3] UTIL OUTPUT

[4] CODE MAINT

[5] DIALER

[6] REPORT CODES

[7] ACCESSORIES

[8] MISCELLANEOUS

[9] ACCESS CONTROL

[0] EXIT PROGRAM

Each of the main Installer Programming menu options enables you to access and

program all of the ProSYS options. Refer to Appendix E, Installer Programming Maps for

a complete list of all the programming options. Each option is also discussed in detail in

Chapter 5, Using the Installer Programming Menus.

ProSYS Installation and Pr ogramming Manual 41

Restoring Manufacturer's Programming

Defaults

You may find it useful to be able to remove all changes made to the Main Panel's

programming and restore the default settings provided by the manufacturer. Restoring

defaults requires performing both of the procedures below. The first procedure enables the

restoring option and the second procedure is the actual restoring process.

To enable the restore to the manufacturer's defaults:

1 From the Installer Programming menu, select the System option by pressing [1] or pressing

the

/ key. The System menu option is displayed, as follows:

2 Select the Default Enable/Disable option by scrolling down to the option using the

/

key or press [7]. The following display appears:

3 Toggle to the Default Enable option using the / key until the following is

displayed:

NOTE:

The Default option for the Default Enable/Disable parameter is Enable.

4 Select the option by pressing the / key.

NOTE:

On the Main Panel, the J2 default jumper must be in its position on one of the J2 pins.

5 Press and then press [0]. The keypad prompts you to save the changes by

displaying the following message:

6 Confirm saving the data by pressing the / key. A short beep will sound, and the

keypad displays the following messages:

7 Next, the system will perform a Tamper Test. The following display appears:

TESTIN G:

TESTIN G:

PLEASE WAIT

PLEASE WAIT

TESTIN G:

TESTIN G:

PLEASE WAIT

PLEASE WAIT

42 ProSYS Installation and Programming Manual

If a tamper occurs in the system (Bell, box or other) the display will show a list of the

tamper faults in the system.

It is advisable to scroll down the list and fix the tamper before exiting the installer

programming mode to prevent tamper alarm.

8 After reviewing the tamper fault list press / key. The following display

appears:

Quit with

Tamper? N

Quit with

Tamper? N

Selecting Yes will result in exiting the installer programming menu and activating a tamper

alarm in the system.

When the save function is complete and no tamper fault exists, the keypad displays the

regular operation mode, as follows:

If, while exiting, the following display appears, this means that the J2 default jumper on

the Main Panel is NOT in its position on one of the J2 pins, but wrongly positioned on both

J2 pins.

To restore the Main Panel to the manufacturer's defaults:

1 Disconnect all power from the Main Panel.

2 Remove the J2 default jumper from its position on one of the J2 pins.

3 Position the J2 default jumper on both of the J2 pins.

4 Reconnect the power to the mains and backup battery to the Main Panel. The keypad sounds

a long beep and all of the LEDs flash once. The following message is displayed on the keypad

for 20 seconds:

And then the following message is displayed:

5 On the Main Panel, reposition the J2 default jumper on one of the J2 pins (where it resides for

safekeeping).

6 Proceed to reprogram the Main Panel, as required.

NOTE S:

Remember that the Installer Code has been restored to the manufacturer's default setting, depending

on the ProSYS model:

• ProSYS 128: [0][1][2][8]

• ProSYS 40: [0][1][4][0]

• ProSYS 16: [0][1][1][6]

In addition, the default operation will occur only when the system is defined as Enabled, as described

in the procedure on page 41.

ProSYS Installation and Pr ogramming Manual 43

Keypad Timeout

If, after 15 minutes, no entry is made to a keypad that has been placed in the Installer

Programming mode, it will produce an audible reminder, consisting of several beeps in rapid

succession, along with the following display:

Pressing any key stops the beeping. To re-enter the Installer Programming menu, you must

key in your Installer code again and press

/

.

Using the Program Transfer Module (PTM)

The Program Transfer Module (PTM) is used to create and apply standard programming

templates.

In addition, you can use the PTM on powered-up, properly functioning Main Panels, which

have been previously programmed.

To create a Programming Template by copying from a programmed Main Panel:

♦ Use a programmed Main Panel to create a Programming Template to be applied to other

Main Panels. The programming on the Main Panel is ready for copying.

To install a Programming Template on a Main Panel:

♦ Use an existing Programming Template on a PTM to install programming on a Main Panel.

At least one LCD keypad must be installed on the Main Panel.

To copy from a programmed Main Panel into the PTM: