Page 1

Quick Programming Setup

ProSYS Ver 7.xx

For detailed information please refer to the full ProSYS Installer Manual

provided on our website: www.riscogroup.com

Page 2

2 ProSYS Quick Programming Setup

Table of Contents

Introduction.......................................................................................................................... 3

I. Suitable Locations ............................................................................................................ 3

II. Installing Hardware (Devices) ......................................................................................... 3

1. BUS Connection ......................................................................................................... 3

2. Setting Zone Inputs Connection ................................................................................ 5

3. Wiring Auxiliary Devices (Sensors) ........................................................................... 6

4. Wiring Internal Bell ..................................................................................................... 6

5. Bell Tamper Wiring (Terminal Bell TMP) ................................................................... 6

6. Wiring UO1 to Activate Any External Stand-alone Siren .......................................... 7

7. Wiring Important BUS Accessories ........................................................................... 7

III. Programming the System ............................................................................................. 10

Power Up and Enter Installer Mode ............................................................................. 10

Identifying the Connected Devices (including BUS Detectors) ................................. 11

Programming: SYSTEM ............................................................................................... 11

Programming: Wireless ZONES .................................................................................. 12

Programming: ZONES Wired & Wireless (Attributes) ................................................ 13

Programming BUS Detectors ...................................................................................... 14

Programming: Dialer (For PSTN Dialing) .................................................................... 17

Programming: PROG OUTPUTS .................................................................................. 18

Codes (Changing the Installer code) ........................................................................... 19

System Backup ............................................................................................................. 19

Exiting Programming Mode ......................................................................................... 19

Installer Programming Menu Maps ................................................................................... 20

Technical Specifications ................................................................................................... 26

CE Declaration of Conformity ...................................................................................... 27

Compliance Statement ................................................................................................. 27

RISCO Group Limited Warranty .................................................................................. 28

Contacting RISCO Group ............................................................................................. 28

Page 3

ProSYS Quick Programming Setup 3

Introduction

This simple setup procedure guide covers all common ProSYS programming steps (based on

factory default settings) required in order to have a working system.

UL Note:

For more comprehensive instructions for UL installations refer to the installer manual (5IN1383).

I. Suitable Locations

Decide where to position your ProSYS control panel. A central location is often the best place,

making wiring to expanders and accessories easier. It is advisable to prepare a plan of

expander/accessory physical locations in advance to the installation, as this will determine which

type of expander is required at each location.

The control panel location should be:

• In a dry place near an AC power supply (switched off).

• With a good earth connection.

• With access to the customer’s phone lines.

• With access to the routing of cables for the system from detection devices.

Warning:

If connecting remote power supplies, do NOT connect the Red wire (+12v) between the Power Supply Unit and

ProSYS.

For UL installations, the AC adapter is not to be connected to a wall outlet controlled by an external switch.

Recommended locations for mounting the panel shall be in accordance with the National Electrical Code,

ANSI/NFPA 70, the Standard for Installation and Classification of Burglar and Holdup Alarm Systems, UL 681,

and the Standard for Central-Station Alarm Services, UL 827

II. Installing Hardware (Devices)

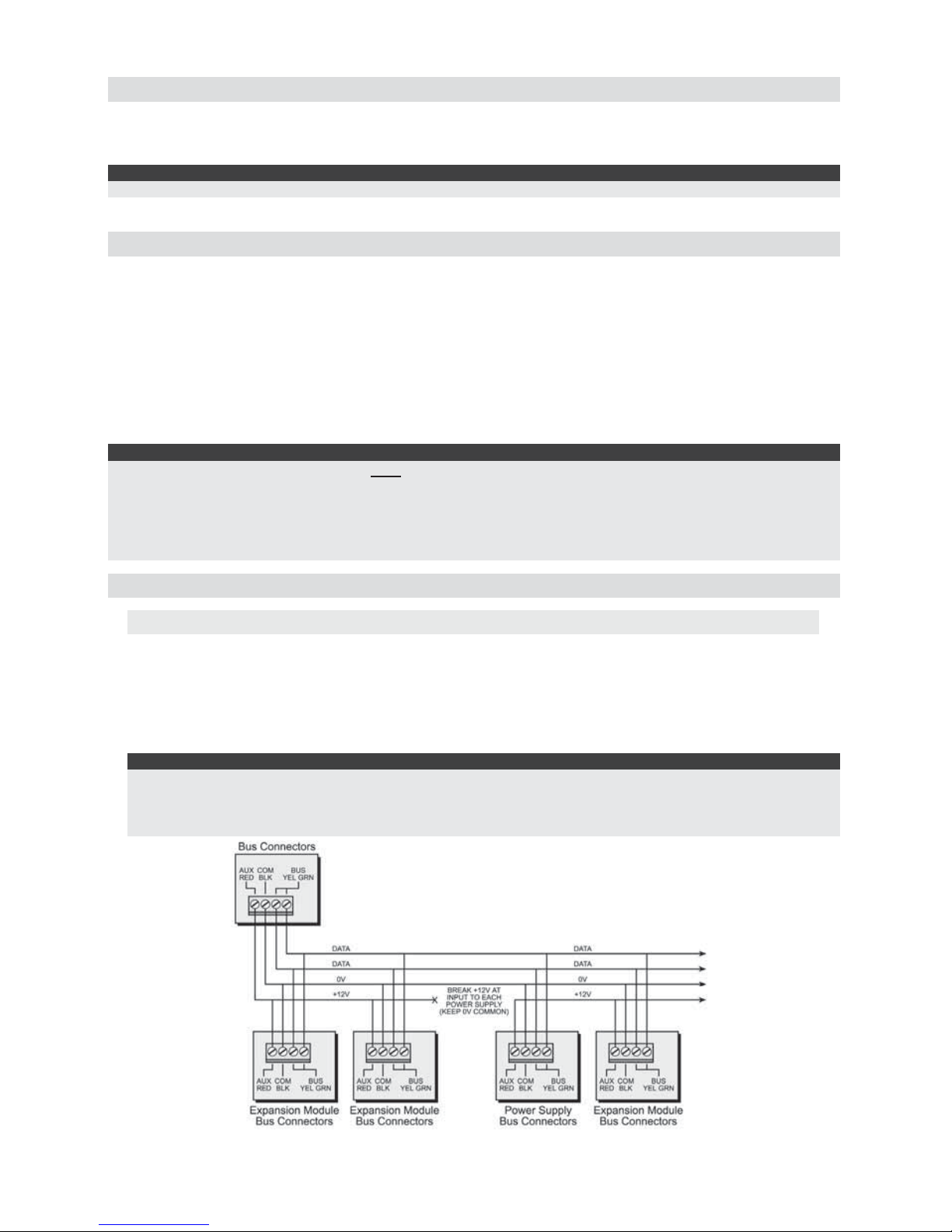

1. BUS Connection

The set of four terminals on the left of the Main Panel represent the Expansion BUS. These

terminals support the connection of keypads and expansion modules. The connections are

terminal-to-terminal with color-coded wires, as follows:

AUX RED +12V power

BUS 1 YEL Yellow DATA

COM BLK Black 0V common BUS 1 GRN Green DATA

Notes:

The parallel wiring system supports parallel connections from any point along the wiring. The maximum wire

run permitted is 300 meters (1000 feet) for all legs of the BUS.

The ProSYS has 2 separate BUS connections. If one BUS is shorted or there is any kind of problem that

interrupts the BUS data, the other BUS will continue to operate normally.

Page 4

4 ProSYS Quick Programming Setup

1.1 Setting BUS Accessory ID Numbers

Each accessory has its ID category number, which is defined by dipswitches. Before setting

power on, define each module’s ID number by setting the dipswitches as follows:

ID

Dipswitches

ID

Dipswitches

1 2345 12345

01 OFF OFF OFF OFF OFF 17 OFF OFF OFF OFF ON

02 ON OFF OFF OFF OFF 18 ON OFF OFF OFF ON

03 OFF ON OFF OFF OFF 19 OFF ON OFF OFF ON

04 ON ON OFF OFF OFF 20 ON ON OFF OFF ON

05 OFF OFF ON OFF OFF 21 OFF OFF ON OFF ON

06 ON OFF ON OFF OFF 22 ON OFF ON OFF ON

07 OFF ON ON OFF OFF 23 OFF ON ON OFF ON

08 ON ON ON OFF OFF 24 ON ON ON OFF ON

09 OFF OFF OFF ON OFF 25 OFF OFF OFF ON ON

10 ON OFF OFF ON OFF 26 ON OFF OFF ON ON

11 OFF ON OFF ON OFF 27 OFF ON OFF ON ON

12 ON ON OFF ON OFF 28 ON ON OFF ON ON

13 OFF OFF ON ON OFF 29 OFF OFF ON ON ON

14 ON OFF ON ON OFF 30 ON OFF ON ON ON

15 OFF ON ON ON OFF 31 OFF ON ON ON ON

16 ON ON ON ON OFF 32 ON ON ON ON ON

Notes:

1: Most accessories have 4 Dipswitches while the BUS Detectors have 5 Dipswitches

2: IDs 9-16 are available for keypads, proximity key readers and BUS Detectors. ID 17-32 is only available for

BUS Detectors.

3. You may have up to 128 BUS detectors. Each detector must have a unique ID on the BUS zone expander

that it is connected to, therefore each ID can be used twice or more - once on each BUS zone expander.

Devices are split into ‘Families’. Each ‘Family’ of devices has sequential identification numbers

which are set by the Dipswitches. The first module in each category is defined as ID= 1. If a

Dipswitch is changed on any device, it is necessary to remove power from that device and repower.

Families that have sequential ID numbers are:

• Keypads

• Zone Expanders (8 Wired Zone Expander, 16 Wired Zone Expander, 8 Wireless Zone

Expander, 16 Wireless Zone Expander)

• Outputs (8 Open Collector Outputs, 4 Relay Outputs, X-10 Outputs)

• Power Supplies (3Amp Power Supplies and 1.5 Amp Power Supplies)

• BUS Zones

For example: Each Zone Expander (Hardwired Expander and Wireless Expander) has

sequential numbering such as 1,2,3,4 etc…

ID1 (First Zone Expander) = DIP Switch ‘1 off, 2 off, 3 off, 4 off’ = [↓↓↓↓]

ID2 (Second Zone Expander) = DIP Switch ‘1 on, 2 off, 3 off, 4 off’ = [↑↓↓↓]

ID3 (Third Zone Expander) = DIP Switch ‘1 off, 2 on, 3 off, 4 off’ = [↓↑↓↓]

ID4 (Fourth Zone Expander) = DIP Switch ‘1 on, 2 on, 3 off, 4 off’ = [↑↑↓↓]

The first zone on ‘Zone Expander’ 1 will be ZONE 09

The last zone on ‘Zone Expander’ 1 will be ZONE 16 or 24 (depending on 8/16 zones on the

zone expander).

The first zone on ‘Zone Expander’ 2 will follow on from the last zone on ‘Zone Expander’ 1. See

NOTE 1 below.

Notes:

1: On Wireless Zone Expanders, there are two banks of Dipswitches. One bank for ZONE ID number and one

bank for Wireless KEYFOB ID number. Wireless Keyfob ID numbers can be 1, 2, 3 or 4.

2: The main unit can support a maximum load of 1.4 Amp. If more current is required install additional

power supply modules (1.5 or 3 Amp).

3: On 3 AMP Supervised Power Supplies, there are two programmable outputs. These programmable outputs

belong to the ‘Output’ family. There are two Dipswitches on the 3 AMP PSU, one for the PSU ID and one

for the OUTPUT ID.

Page 5

ProSYS Quick Programming Setup 5

Maximum number of Devices possible:

ProSYS16 ProSYS40 ProSYS128

Total number of zone expanders 1x8 4x8 or 2x16 or 2x8 + 1x16 1x8 + 7x16

Outputs expanders 2 4 8

Keypads 812 16

Power Supply

88 8

ProSound Siren

88 8

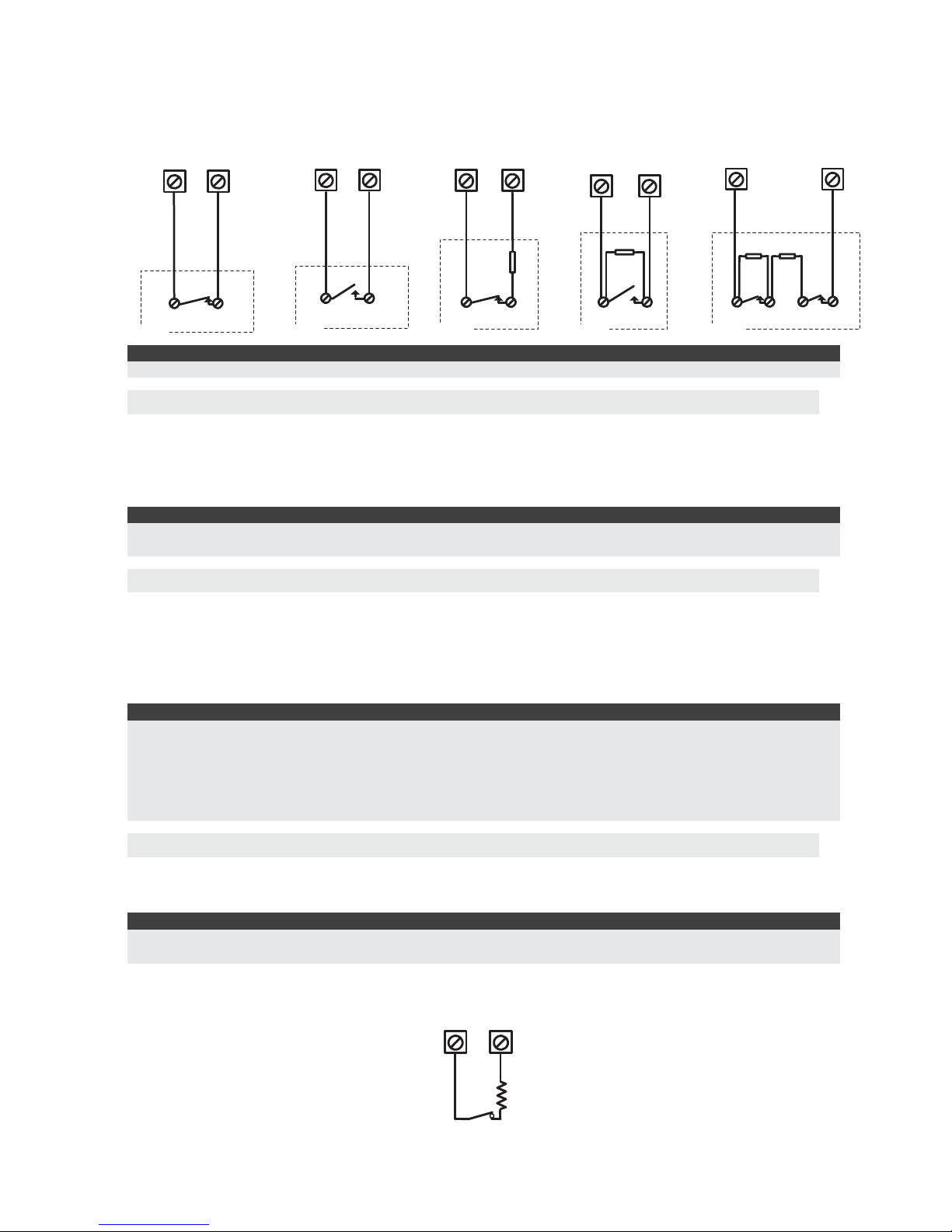

2. Setting Zone Inputs Connection

The following diagrams illustrate the various possible zone connections.

Notes:

It is recommended that you use an End-of-Line Resistor at the far end of each hardwired zone to prevent

short-circuits (16 resistors are supplied).

For a zone with a tamper switch, you can use a Double End-of-Line Resistor to save additional Main Panel

connections.

For UL installations use only UL listed EOL resistors, Risco P/N KTRESUL.

For UL installations use only listed cables for the connection of detectors and accessories.

2.1 Connection on the main unit (ProSYS 7), G3 zone expanders (ProSYS

EZ8G3, EZ16G3) or Inputs on iWISE BUS

Note:

TEOL uses normally-closed (NC) contacts in a zone to distinguish between alarm, tamper condition and

fault/AM condition using 4.7 KΩ +6.8 KΩ + 12 KΩ End-of-Line resistors.

Notes:

The values in the diagram above refer to ProSYS version 7.xx.

NO and NC cannot be used in UL installation.

Zone expander EZ16G3 is not UL listed.

Note:

When connecting non-RISCO TEOL

detectors to the ProSYS panel, a 20KΩ

resistor to the fault terminal (instead of

the 12KΩ as depicted at left) is required.

Page 6

6 ProSYS Quick Programming Setup

2.2 Connection on the main unit (ProSYS 5), Zone expanders (ProSYS EZ8,

EZ16)

END OF LINE ZONE

(N.O CONTACT)

zone com

ALARM

2.2 K

DETECTOR

NORMALLY OPEN ZONE

CONFIGURATION

ALARM

zone com

DETECTOR

NORMALLY CLOSED

ZONE CONFIGURATION

ALARM

zone

com

DETECTOR

END OF LINE ZONE

(N.C CONTACT)

2.2 K

zone com

ALARM

DETECTOR

DOUBLE END OF LINE

ZONE CONFIGURATION

com

2.2 K

ALARM TAMPER

zone

2.2 K

DETECTOR

Note:

The values in the diagram above refer to ProSYS version 5.xx and below.

3. Wiring Auxiliary Devices (Sensors)

Use the Auxiliary Power AUX (+) COM (-) terminals to power PIRs, glass-break detectors (4wire types), smoke detectors, audio switches, photoelectric systems and/or any device that

requires a 12V DC power supply.

The total power from the AUX terminals should not exceed 600mA.

Note:

If the auxiliary outputs are overloaded (exceed 600mA) and are shut down, you must disconnect all loads from

the outputs for a period of at least 10 seconds before you reconnect any load to the auxiliary outputs.

4. Wiring Internal Bell

The Bell/LS terminal provides power to the internal siren. When connecting an internal sounding

device, pay attention to the polarity.

It is important to position the BELL/LS Dip Switch SW1 correctly. The position varies depending

on the type of internal siren.

A maximum of 900 mA may be drawn from this terminal.

Notes:

1. To avoid Bell Loop Trouble, if no connections are made to an internal siren, use a 2.2KΩ resistor in its

place.

2. Loudspeaker should not be used in UL installations.

3. For UL installations use UL listed sirens, for example: Outdoor siren: Honeywell AB12., Indoor siren:

Honeywell 747 or Honeywell Wave 2.

4. For UL985 installations the fire temporal pattern must be defined as YES (Quick key [1][2][14]).

5. Bell Tamper Wiring (Terminal Bell TMP)

Connect the bell tamper to the BELL TMP and COM terminals on the Main Panel using 2.2KΩ

resistor in serial.

Important:

If you DO NOT use the terminal TMP BELL, remember to connect a 2.2KΩ resistor (Resistor colors: Red, Red,

Red) BELL between TMP and COM.

PROSYS MAIN PANEL

BELL

TMP

COM

2.2 K EOL

RESISTOR

BELL TAMP ER

Page 7

ProSYS Quick Programming Setup 7

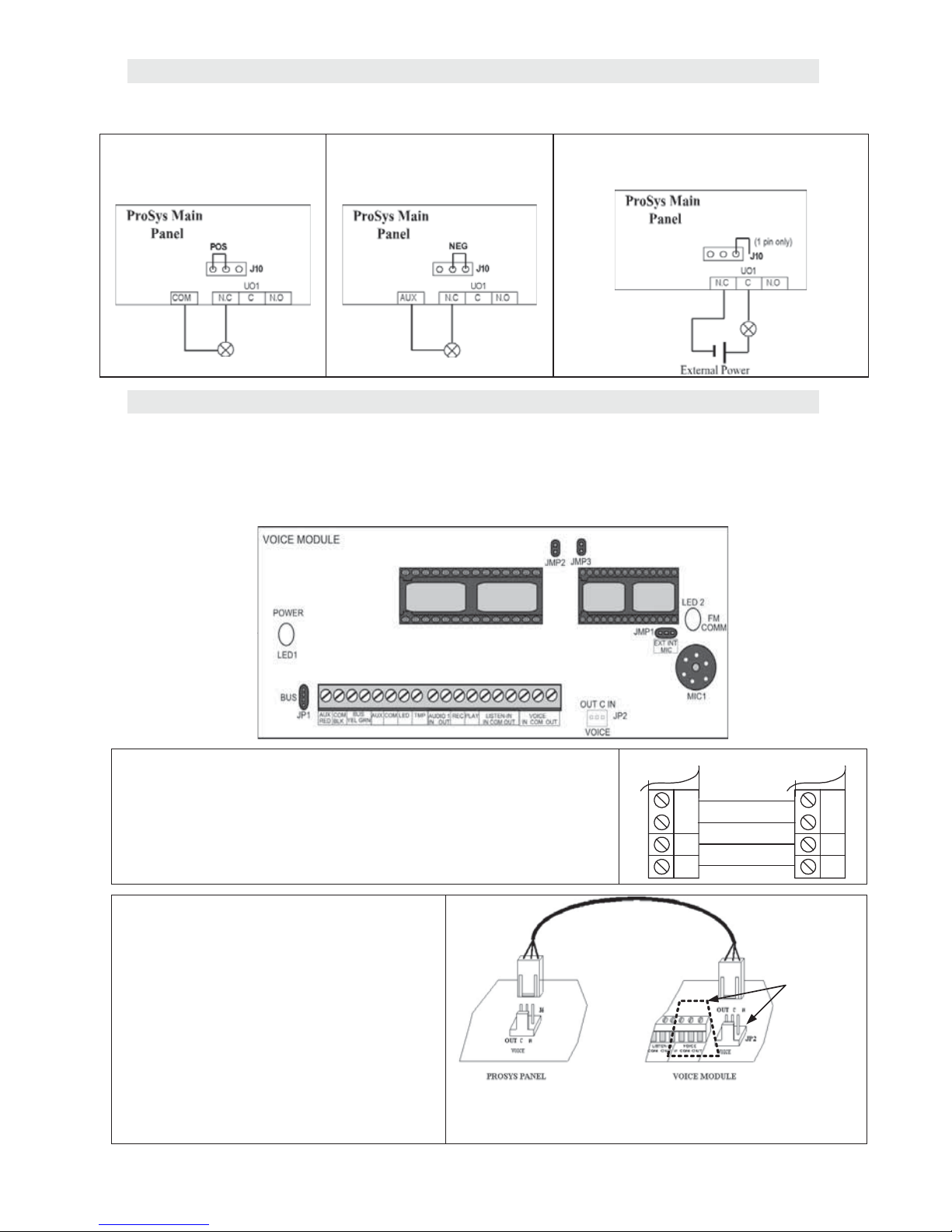

6. Wiring UO1 to Activate Any External Stand-alone Siren

Output UO1 has 3 terminals C, N.C. and N.O. and can be configured to provide a positive

voltage, negative voltage or a contact depending on the J10 jumper located on the main board.

Positive (POS): When the J10

connector is placed on POS,

the C terminal on UO1 supplies

13.8V

Negative (NEG): When the J10

connector is placed on NEG,

the C terminal on UO1 supplies

COM

Single pin: If the J10 connector is placed

only on 1 pin, the UO1 acts as a dry contact.

7. Wiring Important BUS Accessories

7.1 Wiring the Voice Module

The Voice Module provides native audible information about the status of your ProSYS system,

and enables any remote, touch-tone (DTMF) telephone to act as a keypad for the system.

The diagram below shows the main components of the electronic form of voice:

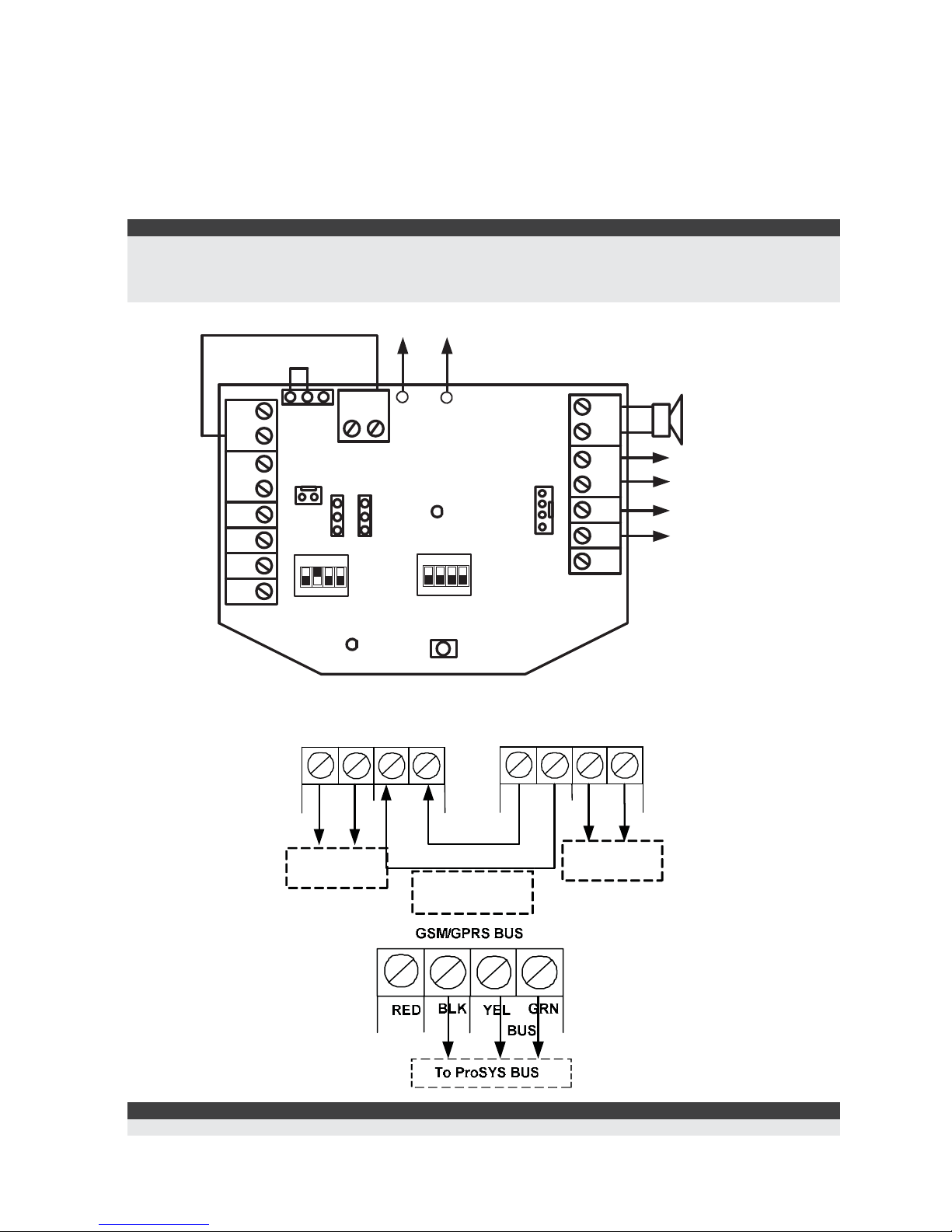

BUS Connection – JP1

The connection to the main BUS can be made through the

terminals of the module voice AUX (RED), COM (BLK), BUS

(YEL) and BUS (GRN) as illustrated.

When placed near the ProSYS main unit you can use the supplied

4-wire cable that is dedicated to connecting with the voice module

(JP1) to the BUS ProSYS

ProSYS

AUX

RED

COM

BLK

BUS

YEL GRN

Voice

Module

AUX

RED

COM

BLK

BUS

YEL GRN

Voice Connection – JP2

Connects the Voice module (JP2) to the

VOICE connector on the ProSYS Main

Panel via the supplied cable (essential for

normal operation of the Voice module).

Through this connector, the module

transmits the voice audio signals to the

central ProSYS who then sends them on

the telephone line for remote

communication with the phone numbers

dedicated to Follow Me destinations. This

connection is necessary for the proper

functioning of the module.

Identical

Connectors

Page 8

8 ProSYS Quick Programming Setup

7.2 ProSound - BUS Siren Connection

Connect the siren according to the diagram. Set the related Dipswitches for BUS mode

operation.

Dipswitch CONFIG 2 should be in ON position for ProSound BUS connection

Dipswitch CONFIG 4: Defines the siren sound rhythm (ON = Slow, Off = Fast)

Dipswitch ID1: 1-3: Set ID BUS Number. Up to 8 sirens can be connected to the ProSYS

Dipswitch ID1 4: Set different siren sound

Notes:

The PROX and TRBL outputs are deactivated in BUS mode configuration.

To protect the battery against deep discharge, the battery will automatically disconnect below 10.5 VDC.

The siren will not operate when a battery is not connected.

The ProSound is not UL listed.

BUS

GRN

YEL

COM

BLK

SPEAKER

AUX

RED

LED

TRBL

PROX

TAMPER

F

R

C + C - ST

123 4

ON

ID1

TAMPER

PS

+

-

BLK

RED

MAN

AUTO

C +

C -

TRIG S TROB

LED2

POWER

To Internal

Speaker

To

ProSYS

Panel

BUS

123 4

ON

CONFIG

INT EXT

To

Battery

(To Int.

Tam per)

7.3 Wiring the GSM

Important:

Do NOT make any connection to the RED Power terminal from the security panel.

PHONE

LINESE

T

PHONE

LINESE

T

ProSYS Main GSM/GPR S Module

Telephone cable to bring

the voice mess ages from

the ProSYS to the m odule

BUS GSM

/

GPRS

To PSTN Line from

the Wall

To telephone set

Page 9

ProSYS Quick Programming Setup 9

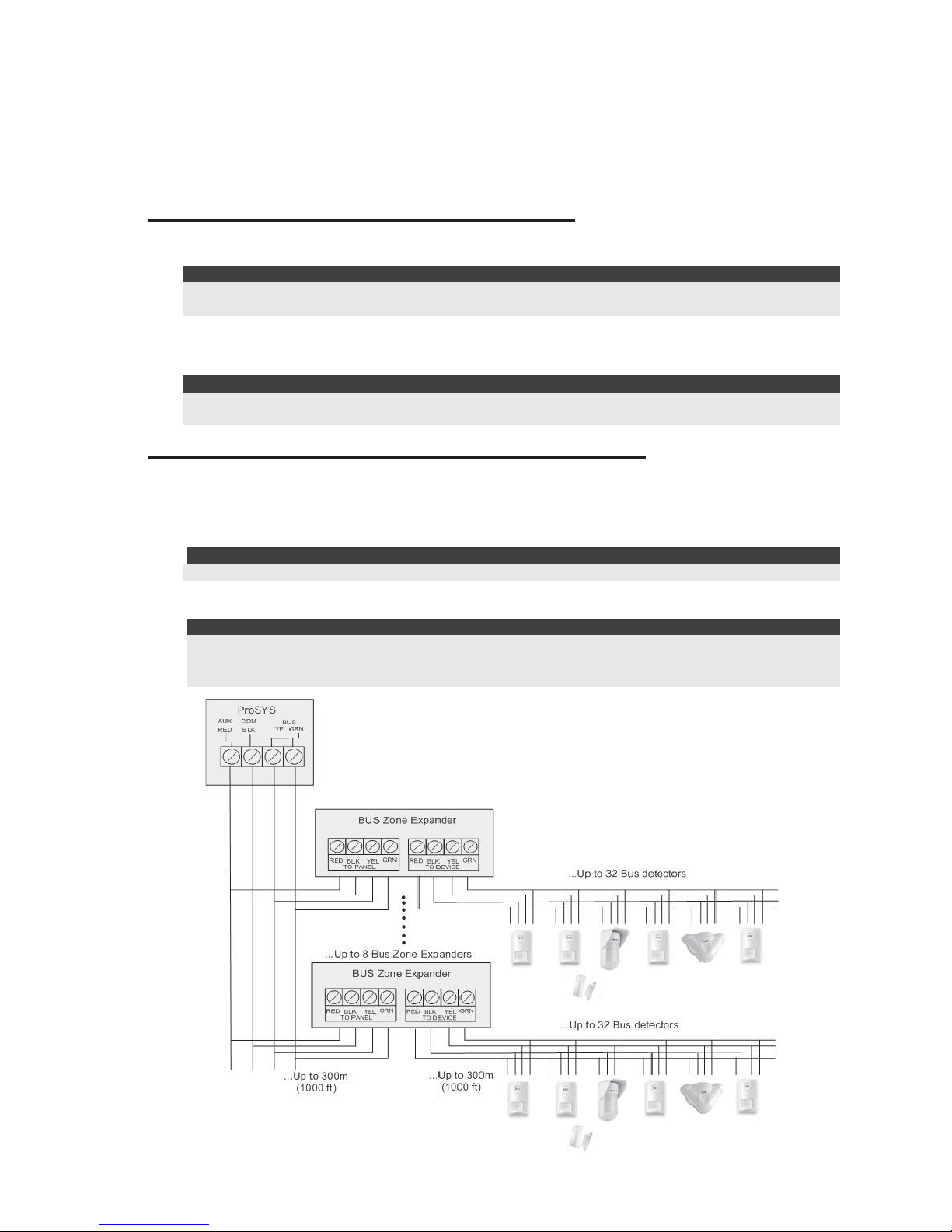

7.4 Wiring BUS Detectors

The ProSYS supports integration of BUS detectors. Up to 32 addressable BUS detectors can be

assigned to the main unit without the need to add any additional hardware zone expanders

(using virtual zones).

To assign more than 32 BUS detectors (up to 128) you need to add BUS Zone Expanders.

For full installation instructions refer to the instructions supplied with each BUS detector.

Connecting BUS Detectors to the ProSYS panel:

1. Set the BUS detector ID number (1-32) using the detector's Dipswitches.

Note:

For WatchOUT, LuNAR, and WatchIN set the switch that defines the detector operation mode to BUS

mode.

2. Wire the BUS terminals (RED), COM (BLK), BUS (YEL) and BUS (GRN) to the ProSYS

BUS.

Note:

For maximum operation stability, it is best NOT to exceed a total 300 meters (1000 feet) of wiring from

the BUS detector to the ProSYS panel.

Connecting BUS Detectors using a BUS Zone Expander:

1. Set the BUS Zone Expander ID number (1-8) using the Dipswitches SW1 1-3.

2. Using SW2 Dipswitches, set the number of zones this expander will support (8,16,24,32)

3. Wire the BUS Zone Expander terminals marked as TO PANEL to the ProSYS BUS.

4. Set the BUS detector ID number (1-32) using the detector's Dipswitches.

Note:

Do not repeat the same ID twice on the same BUS zone expander.

5. Wire each detector's BUS terminals to the relevant BUS zone expander's terminals

marked as TO DEVICE.(see figure below)

Note:

For maximum operation stability, it is best NOT to exceed a total of:

• 300 meters (1000 feet) of wiring from the BUS Zone Expander to the ProSYS panel.

• 300 meters (1000 feet) of wiring from the BUS Zone Expander to the last BUS detector.

Page 10

10 ProSYS Quick Programming Setup

III. Programming the System

Power Up and Enter Installer Mode

1. Connect Mains power. The keypad displays "Partition 1".

2. Press

[7][1] to go into the installer programming menu.

3. If a Master/Manager code is required, press [1][2][3][4]

(Default Master Code).

4. You are prompted for the Installer Code.

For ProSYS16, press [0][1][1][6]

(Default Installer Code)

For ProSYS40, press [0][1][4][0]

(Default Installer Code)

For ProSYS128, press [0][1][2][8]

(Default Installer Code)

5. You are now in the Installer Programming mode. Move to the section "Identifying the

connected devices" as described below.

Quick Keys shown (in square brackets) can be pressed when at the ‘Main Menu’ instead

of using the Up/Down keys.

Notes:

If required, you can default the panel to manufacturer's default settings as follows:

1. Disconnect all power from the main panel.

2. Position the default Dip Switch 2 to ON position.

2. Connect the Mains power. Wait until the keypad displays “To Install Press * ”.

3. Press * and enter the default installer code, depending on the ProSYS type. The system automatically

enters the automatic accessories settings process.

4. Change the position of Dip Switch 2 to OFF position .

5. Move to the section "Identifying the connected devices" as described below.

Navigating through the menus:

When navigating through the ProSYS menus, the following keys are used:

-

- to enter numeric values where required

- to scroll up or down through the menu options displayed

- Enter / Save (to move into the displayed menu or to save the data that

you have changed)

- to toggle displayed menu options from ‘N’ to ‘Y’ and vice-versa

- to go back / quit / don’t save

If you do not know where you are in the menu structure, press

repeatedly to return to the

main menu.

Entering Text Descriptions (Labels):

Key [1] = 1ABCDEFGHIJKLM

Key [2] = 2NOPQRSTUVWXYZ

Key [4] = 1abcdefghijklm

Key [5] = 2nopqrstuvwxyz

Key

= Move cursor Left

Key

= Move cursor Right

Key

= Save

Page 11

ProSYS Quick Programming Setup 11

Identifying the Connected Devices (including BUS Detectors)

Automatic Settings (QUICK KEYS = [7][5])

Note:

In most cases, when entering Installer mode with the default Dip Switch 2 in ON position , the system will

‘assume’ that this is a ‘virgin’ installation and take you immediately to Auto Settings. If the keypad is

already showing “AUTO SETTINGS”, skip to step 3 below.

1. Using the / keys, select [ACCESSORIES] and press .

2. Using the

/ keys, select [AUTO SETTINGS].

3. Press

to begin the Auto Settings process in which it identifies all the devices on

the BUS.

4. Verify that the Keypad displays all the devices you have connected. If a device does not

appear, ensure that you have given it a unique ID within its “family”.

5. Press

to accept what is being displayed and move on to the next device found.

6. Repeat steps 4 and 5 until all devices have been shown.

Bus Test (QUICK KEYS = [7][3])

The BUS test will send multiple test commands to each device connected to the system to

ensure good connectivity.

1. Using the / keys, select [BUS TEST] and press .

2. Using the

/ keys, check that every device shown reports 99% or higher.

Note:

If a low reading is experienced, check connections with the device and repeat the BUS test.

Programming: SYSTEM

SYSTEM - Timers (Entry/Exit Times etc)

QUICK KEYS = [1][1]

1. Using the / keys, select [TIME DEFINE] and press .

2. Using the

/ keys, select the required timer option and press .

Note:

Some options have more menu levels which are accessed by pressing the [#] key.

3. Using the numeric keys, change the selected option to the desired value and press

.

SYSTEM - Controls (Audible Panic, Installer Reset, EN Settings, etc.)

QUICK KEYS = [1][2]

1. Using the / keys, select [SYSTEM CONTROL] and press .

2. Using the

/ keys, select the option required and press .

3. Using the

key, select [Y] (Yes) or [N] (No)

4. Repeat step 2 and 3 until all required options have been set, then press

.

Page 12

12 ProSYS Quick Programming Setup

SYSTEM - Set Clock

QUICK KEYS = [1][3]

1. Using the / keys, select [SET CLOCK] and press .

2. Using the

/ keys, select [SYSTEM TIME] and press .

3. Using the numeric keys, enter the current time and press

.

4. Using the

/ keys, select [SYSTEM DATE] and press .

5. Using the numeric keys, enter the day (01 to 31).

6. Using the

key, select the current month.

7. Press the

button once to advance the cursor one position right.

8. Using the numeric keys, enter the current year and press

.

Programming: Wireless ZONES

ZONES - Wireless Calibration (Wireless Receiver background noise threshold setting)

QUICK KEYS = [2][9][5]

1. Using the / keys, select [MAINTENANCE] and press .

2. Using the

/ select [WL CALIBRATE] and press .

3. Using the

/ select the Wireless Receiver and press .

4. Using the

key, choose [Y] (Yes) to ‘Re-Calibrate’ the Wireless Receiver and press

.

5. After a short while, the measured background noise will be shown.

6. Add 10 to the displayed ‘NEW THOLD’ (New Threshold) by using the numeric keys and

press

.

Explanation:

The Calibration measurement above shows the amount of background ‘noise’ that the receiver

can ‘hear’ on the same frequency as the RISCO wireless devices. This ‘noise’ could be

neighboring devices of another system or other devices operating on the same frequency

nearby. These are ‘unwanted’ signals that the ProSYS wireless receiver must be told ‘not to

listen to’.

The threshold (set above) is the absolute minimum signal strength needed to be heard from a

wireless device in order for the receiver to effectively ‘hear it’. This ‘threshold’ is set at ten above

the background ‘noise’ (recommended) making the receiver ignore the unwanted signals.

With this threshold set, the ProSYS receiver will only hear its own devices which are nearer and

have a signal strength greater that the threshold level set.

ZONES - Wireless Zone Allocation (Enrolling the wireless devices)

QUICK KEYS = [2][9][6]

1. Using the / keys, select [MAINTENANCE] and press .

2. Using the

/ keys, select [WL ZONE ALLOC] and press .

3. Using the numeric keys, enter the desired zone number and press

.

4. Using the

/ keys, select [(RE)WRITE] and press .

5. Depending on the wireless device enrolled, please do one of the following:

Page 13

ProSYS Quick Programming Setup 13

♦ For Wireless PIRs, Door Contacts, Flood Detectors, Shock Detectors - Close the

tamper

♦ For Wireless Smoke Detectors, Fit the batteries and lid, then do nothing for 10-30

seconds

♦ For Wireless PANIC Pendants, press the button(s) for 10 seconds (Cannot be

Supervised)

6. Using the

/ keys, select [SUPERVISED] or [NONE SUPERVISED] for this

wireless device.

7. Repeat steps 3 to 6 until all required wireless devices have been enrolled.

ZONES - Wireless Communication Test (Signal strength of the wireless devices)

QUICK KEYS = [2][9][7]

1. Using the / keys, select [MAINTENANCE] and press .

2. Using the

/ keys, select [WL COMM TEST] and press .

3. Activate all wireless devices in turn.

4. Using the

/ keys, observe the signal strength received from each device

zone number.

Note:

Make sure that the signal strengths are at least 10 units higher than the receiver threshold level.

Programming: ZONES Wired & Wireless (Attributes)

The bold sub headings below are ‘Main Menu’ headings.

The

key is pressed to move into the various sub menus.

To return to the ‘Main Menu’ headings at any time, press [*] repeatedly.

1. Using the Up/Down keys, select [ONE BY ONE] and press .

2. Using the numeric keys, enter the desired zone number and press

.

PARTITIONS

3. Using the numeric keys, select or deselect the relevant partitions to which this zone will

belong to and press

.

GROUP SETS

4. Using the [A], [B], [C] or [D], keys, select the required group and press .

ZONE TYPE

5. Using the Up/Down keys, select the required zone type and press .

ZONE SOUND

6. Using the / keys, select the required zone sound option and press .

Note:

This determines if the zone will ‘be silent’, ’cause Bell to activate’, ‘cause Buzzer to activate’, ‘cause Bell

and Buzzer to activate’, ‘create keypad bleep for chime’ etc… when the zone is opened/causes an alarm

condition.

‘Buzzer’ refers to the sound emitted from the Keypad(s).

Page 14

14 ProSYS Quick Programming Setup

ZONE TERMINATION (Only applicable for hard wired zones)

7. Using the

/ keys, select the required zone termination type and press

.

ZONE RESPONSE

8. Using the / keys, select the required response time and press .

ZONE LABELS (Zone description text)

QUICK KEYS = [2][8]

9. Using the / keys, select [LABEL] and press .

10. Using the numeric keys, enter the desired zone number and press

.

11. Using the keys listed below, enter the required text for the zone description and press

. (See page 10 for entering text descriptions.)

12. Repeat steps 10 and 11 for all zones requiring description text.

Programming BUS Detectors

The following section describes the flow of adding BUS detectors to the ProSYS. BUS detectors

can be programmed to the main unit or to a BUS zone expander.

Programming BUS detectors on the Main BUS

Step 1: Adding BUS Detector to the Main Unit

QUICK KEYS = [7][1][9][5]:

Note:

If you have already performed Auto Settings skip to Step 2 below: Assign BUS Detectors to a Zone ID and

set basic parameters.

1. From the main installer menu press [7][1][9][5] to access the BUS Zone category.

2. Using the

/ keys select a BUS detector ID number as set by the detector's

Dipswitches (01-32)

Note:

The bottom line in the display shows "(0:yy) Type: None". In the 0:yy designation, the 0 represents

that the BUS detector is on the main unit and is not assigned to a BUS Zone Expander. The yy

represents the BUS detector ID number (up to 32) as set by the detector's DIP switches.

3. Using the / keys move to the Type field. Use the key to select the

detector's type.

4. Repeat steps 2 and 3 for other BUS detectors.

Note:

If required you can add virtual zones to the system. Virtual zones are cost effective. They enable to use up

to 32 BUS Zones on the main unit without adding physical zone expanders. To add a Virtual BUS zone

expander select type VBZ08 or VBZ16 when adding a zone expander (Quick key [7][1][2]).

Step 2: Assign BUS Detectors to a Zone ID and set basic parameters

Each BUS zone detector should be assigned to a zone. BUS zones on the main unit can be

assigned to a virtual zone or to a physical wired zone. They cannot be assigned to wireless

zones or zones located on a BUS zone expander

1. From the main installer menu press [2] to enter the Zones menu.

2. Using the

/ keys, select [ONE BY ONE] and press .

Page 15

ProSYS Quick Programming Setup 15

3. Using the numeric keys, enter the desired zone number and press .

Note:

You can select any zone number that is not defined on a Wireless Zone Expander or a BUS Zone

Expander.

4. Press to access the Partitions category.

5. Define Partitions, Groups, Zone Type and Zone Sound.

6. In the Termination category select BUS Zone and press

. The following is

displayed:

Z:001 LINK TO:

(0:yy) TYPE:NONE

Z:001 LINK TO:

(0:yy) TYPE:NONE

7. Select the BUS zone number (designated by yy) to assign to the programmed zone. The

TYPE field will be updated automatically when selecting the zone.

8. Press

. Define a label and press to confirm.

9. Repeat steps 3-8 for all required BUS zones.

Step 3: Programming the BUS Detectors Full Parameters

1. From the main Installer menu select [2] Zones > [0] Miscellaneous > [3] BUS Zone

Parameters.

2. Select the zone number that the BUS zone was assigned to and press

.

3. Configure the parameters for the relevant BUS detector

Programming BUS Detectors on a BUS Zone Expander

Step 1: Adding the BUS Zone Expander to ProSYS

QUICK KEYS = [7][1][2]:

Note:

If you already performed Auto Settings skip to Step 2 below: Assign BUS Detectors to a Zone ID and set

basic parameters.

1. From the main installer menu press [7][1][2] to enter the add BUS zone expander menu.

2. Using the

/ keys select a BUS Zone Expander ID.

3. Using the

/ keys move to Type. Use the key to select a type (BZE08,

BZE16, BZE24 or BZE32 zone expander) based on the Dipswitches you set on the

expander. Press

.

4. Using the

key, select the detector type of each BUS detector connected to this

BUS zone expander.

Note:

The bottom line in the display shows "(x:yy) Type: None" . In the x:yy designation, the x represents

the BUS Zone Expander ID number and the yy represents the BUS detector ID number that is

connected to the zone expander, as set by the detector's Dipswitches.

5. Press to move to the next BUS detectors.

Step 2: Assign BUS Detectors to a Zone ID and set basic parameters

1. From the main installer menu press [2] to enter the Zones menu.

2. Using the

/ keys, select [ONE BY ONE] and press . The following is

displayed:

ZONE ONE BY ONE:

ZONE=001 (X:YY)

ZONE ONE BY ONE:

ZONE=001 (X:YY)

Page 16

16 ProSYS Quick Programming Setup

3. Using the numeric keys, select a zone number whose designation (x:yy) is equivalent to

the one defined for the BUS detector. (The x represents the BUS Zone Expander ID

number and the yy represents the BUS detector ID number as set by the detector's ID

Dipswitches).

Press

to access the Partitions category.

4. Define Partitions, Groups, Zone Type and Zone Sound.

5. In the Termination category select a BUS Zone and press

.

6. Press

. Define a label and press to confirm.

7. Repeat steps 3-7 for all required BUS zones.

Step 3: Setting the BUS Detectors Parameters

1. From the main Installer menu select [2] Zones > [0] Miscellaneous > [3] BUS Zone

Parameters.

2. Select the zone number that the BUS Zone was assigned to and press

.

3. Configure the parameters for the relevant BUS detector.

Programming the Input on the iWISE BUS Detector

The iWISE BUS detectors have additional input on board.

1. Add iWISE BUS detector to the system as described in the Programming BUS Detectors

section.

2. From the main installer menu press [2] to enter the Zones menu.

3. Using the

/ keys, select [ONE BY ONE] and press .

4. Using the numeric keys, enter the desired zone number and press

.

Note:

You can select any zone number that is not defined on a Wireless Zone Expander or a BUS Zone

Expander.

5. Press to access the Partitions category.

6. Define Partitions, Groups, Zone Type and Zone Sound.

7. In the Termination category select one of the following options: BUS Zone Input N/C,

BUS Zone Input EOL, BUS Zone Input DEOL, BUS Zone Input N/O, BUS Zone Input

TEOL. Press

.

8. Press

. Select the BUS zone that the input zone belongs to. The Type field will be

updated automatically when selecting the zone.

9. Press

. Define the loop response time.

10. Press

, assign a label and press .

11. Repeat steps 3-10 for all required iWISE inputs.

Note for iWISE BUS Detectors:

The iWISE BUS detectors have additional input. The parameters of this input are the same as any other

regular wired zone in the system, with the exception that this input should be linked to one of the zones in

the system. For further information refer to instructions supplied with the product.

Page 17

ProSYS Quick Programming Setup 17

Programming: Dialer (For PSTN Dialing)

The bold sub headings below are ‘Main Menu’ headings.

The

key is pressed to move into the various sub menus.

To return to the ‘Main Menu’ headings at any time, press

repeatedly.

DIALER - Link-Up (MS Telephone numbers and Communication format)

QUICK KEYS = [5][1]

1. Using the / keys, select [LINK-UP] and press .

2. Using the

/ keys, select [MS LINK-UP] and press .

3. Using the

/ keys, select [MS 1 LINK-UP] and press .

4. Using the

/ keys, select [PSTN/VOICE] and press .

Note:

It is the assumption that a regular phone line is used for communication to MS.

5. Using the numeric keys, enter the Primary MS phone number and press .

6. Using the

/ keys, select [MS 2 LINK-UP] and press .

7. Using the

/ keys, select [PSTN/VOICE] and press .

Note:

It is the assumption that a regular phone line is used for communication to MS.

8. Using the numeric keys, enter the Secondary MS phone number and press .

DIALER - Accounts (Site Code/ID)

QUICK KEYS = [5][2]

1. Using the / keys, select [ACCOUNTS] and press .

2. Using the

/ keys, select the relevant Partition and press .

3. Using the

/ keys, select [FOR ACR 1] and press .

4. Using the numeric keys, enter the Site Code/ID for Partition 1 / MS 1 and press

.

5. Using the

button, select ‘Y’ or ‘N’ to apply the Site Code/ID to all partitions and

press

.

Note:

If each partition requires a different Site Code/ID, repeat step 3 - 5 selecting the relevant partition

DIALER - Communication Format (Transmission protocol to MS)

QUICK KEYS = [5][3]

1. Using the / keys, select [COMM FORMAT] and press .

2. Using the

/ keys, select [FOR MS 1] and press .

3. Using the numeric keys, enter the transmission format code and press

.

Note:

0420 for Contact/Point ID – 0700 for SIA

4. Using the / keys, select [FOR MS 2] and press .

5. Using the numeric keys, enter the transmission format code and press

.

Note:

0420 for Contact/Point ID – 0700 for SIA

Page 18

18 ProSYS Quick Programming Setup

DIALER - Control (Yes/No Options for the Dialer)

QUICK KEYS = [5][5]

1. Using the / keys, select [CONTROL] and press .

2. Using the

/ keys, select [MS ENABLE].

3. Using the

key, change ‘N’ (No) to ‘Y’ (Yes) and press .

4. Using the

/ keys, select [UD ENABLE].

5. Using the

key, change ‘N’ (No) to ‘Y’ (Yes) and press .

6. Using the

/ keys, select [FM ENABLE].

7. Using the

key, change ‘N’ (No) to ‘Y’ (Yes) and press .

DIALER - Auto Codes (MS Report Codes)

QUICK KEYS = [5][0][1]

1. Using the / keys, select [AUTO CODES] and press .

2. Using the

/ keys, select [CONTACT ID] or [SIA] and press .

3. Using the

key, change ‘N’ (No) to ‘Y’ (Yes) and press .

Note:

The ‘AutoCodes’ function should ONLY be performed after all Zone programming has been completed.

Once the Auto Codes function is performed, the ProSYS will quickly look through all current

zone parameters and automatically fill in the correct MS codes for the relevant zone

programming.

Any subsequent zone parameter changes will require you to perform Auto Codes again.

DIALER - Follow Me (Used to define events to Follow Me phones be phone, SMS or

Email)

QUICK KEYS = [5][7][4]

1. Using the / keys, select a Follow Me number and press .

2. Define the following parameters for each Follow Me number:

♦ Type: Configure the format of the message sent to the Follow Me destination, in an

occurrence of an event.

♦ Partitions: Specify the partitions that will initiate the Follow Me report due to a

certain event that occurred in the assigned partitions.

♦ Events and their restore: Specify which events will activate this Follow Me

destination in the partitions assigned to the Follow Me destination.

Programming: PROG OUTPUTS

The bold sub headings below are ‘Main Menu’ headings.

The

key is pressed to move into the various sub menus.

To return to the ‘Main Menu’ headings at any time, press [*] repeatedly.

PROG OUTPUTS - Define (Example for STU)

QUICK KEYS = [3][1]

1. Using the numeric keys, enter the ‘UO’ (Utility Output) number and press .

Note:

Outputs 1-6 are on main ProSYS panel.

Page 19

ProSYS Quick Programming Setup 19

2. By using the / keys, select the Category in which this output will activate and

press

.

3. By using the

/ keys, select the Event in which this output will activate and

press

.

4. By using the numeric keys, select the Partitions that will cause this output to activate and

press

.

5. By using the

/ keys, select the Switching Mode that this output will follow

and press

.

6. By using the

key, select the Partition(s) Condition when this output will activate

and press

.

7. By using the

key, select the Partition(s) Condition when this output will deactivate

and press

.

8. Using the keys listed on page 10, enter the required text for the Output description and

press

.

9. Repeat steps 1-9 for all Outputs that require programming.

Codes (Changing the Installer code)

Press [*] repeatedly to return to the ‘Main Menu’.

QUICK KEY = [4]

1. Using the / keys, select [CODES] and press .

2. Using the

/ keys, select [INSTALLER] and press .

3. Enter a new Installer code and press

.

4. Repeat the new Installer code and press

to confirm.

System Backup

1. Fit the 12V Rechargeable Battery and secure the ProSYS Panel lid.

Exiting Programming Mode

1. Press [*] repeatedly to return to ‘Main Menu’.

2. Press [0]

to EXIT and SAVE your settings.

Note:

The system will not allow exit from the Installer mode if a ‘Tamper’ or ‘System Fault’ condition exists.

Correct any tamper and/or system fault conditions before attempting to exit the Installer mode.

The system is now programmed and ready for use.

For more comprehensive and detailed instructions, please refer to the ProSYS Installation Manual

(5IN1383).

For User Functions, please refer to the ProSYS User Manual.

Page 20

20 ProSYS Quick Programming Setup

Installer Programming Menu Maps

[1] System

[11] Time Define

[111] Ex/En Delay 1 [115] S. Aux Break [119] More

[112] Ex/En Delay 2 [116] WL MOD. Times [1191] Phone Line Cut

Delay Time

[113] Bell Timeout [117] Z. Test Times [1192] Guard Delay

[114] Bell Delay [118] AC Off Delay

[12] System Control

[1201] Quick Arm [1215] Code GM [1229] GM AUT/PAR

[1202] Quick UO [1216] Audible Jam [1230] Double Code

[1203] Allow Bypass [1217] Technician

Tmpr

[1231] Disarm Stop FM

[1204] Quick Bypass [1218] Technician

Reset

[1232] Global Follower

[1205] False Code

Trouble

[1219] N/A [1233] Area

[1206] Bell Sqk [1220] Day Light

Saving

[1234] DIS Keypad Auto

Disarm Exists

[1207] Bell 30/10 [1221] Forced KSW [1235] Aud Prx TMP

[1208] Alm Phone

Cut

[1222] Pager [1236] AM=Tamper

[1209] 3 Min Bypass [1223] Arm Prewrn [1237] Prox AM=Tamper

[1210] Dbl Ver Fire

Al

[1224] L.Batt.Arm [1238] SIRN AUX=TMP

[1211] Aud Panic [1225] ENG Tamper [1239] GSM Pre-Alarm

[1212] Buzz->Bell [1226] Blank Display [1240] Dis. GSM Bat

[1213] Alarm ZE Cut [1227] 24H Bypass

[1241] Exit restart

[1214] Fire Temp

Pattern

[1228] IMQ Install

[1241] Auto Stay

[13] Set Clock

[131] System Date [132] System Time

[14] Windowing

[141] Window Start [142] Window Stop [143] Window Days

[15] System Labels

[16] Tamper Sound

[161-5] Tamper

Sound

[17] Default

Enb/Disb

[18] Service Info

[181] Service [182] Service Phone

[19] System

Version

Page 21

ProSYS Quick Programming Setup 21

[2] Zones

[21] One by One

[22] Partitions/Group

[23] Zone Type

[23zz00] Not used [23zz08] I+Ex(Op)/En [23zz16] Special

[23zz01] Ex/En1 [23zz09] I+En

Follower

[23zz17] Pulsed KSW

[23zz02] Ex/En2 [23zz10] I+Instant [23zz18] Exit Termination

[23zz03] Ex(Op)/En [23zz11] UO Trigger [23zz19] Latch KSW

[23zz04] En Follower [23zz12] Day Zone [23zz20] EN.Fol+Stay

[23zz05] Instant [23zz13] 24 Hours [23zz21] KSW Delay

[23zz06] I+Ex/En1 [23zz14] Fire [23zz22] Latched KSW Dly

[23zz07] I+Ex/En2 [23zz15] Panic

[24] Zone Sound

[241] Silent [243] Buzzer Only [245] Door Chime

[242] Bell Only [244] Bell+Buzzer [246] Bell/A Buz/D

[25] Termination

[2501] N/C [2505] BUS Zone [2509] BZ Input DEOL

[2502] EOL [2506] TEOL [2510] BZ Input N/O

[2503] DEOL [2507] BZ Input N/C [2511] BZ Input TEOL

[2504] N/O [2508] BZ Input EOL

[26] Loop Response

[27] Cross Zone

[271] Zone Crossing

[28] Labels

[29] Maintenance

[291] Copy Zone [294] Delete Par. [297] WL Comm. Test

[292] Delete Zone [295] WL Calibrate [298] Zone Self Test

[293] Add/Copy Par. [296] WL Zone Alloc [299] Soak Test

[20] Miscellaneous

[201] Forced Arming [202] Pulsed Counter [203] BUS Zone Prms.

Page 22

22 ProSYS Quick Programming Setup

[3] Utility Output

[30] Nothing

[31] System

[3101] Bell Follow [3107] AC Loss Fol [3113] D Key Reader

Comm

[3102] No Tel Line [3108] Sensors Test [3114] Switch AUX

[3103] Comm. Fail [3109] Voice Module [3115] GSM Error

[3104] Trouble Follow [3110] Battery test [3116] GSM:PSTN Loss

[3105] GND Pulse [3111] Bell Burglary [3117] GSM:Low Bat

[3106] Low Bat. Fol [3112] Scheduler

[32] Partition

[3201] Ready Follow [3209] Buzzer Follow [3217] Disarm Follow

[3202] Alarm Follow [3210] Chime Follow [3218] Bell Follow

[3203] Arm Follow [3211] Ex/En Follow [3219] Bell Stay Off

[3204] Burglary Follow [3212] Fire Trouble

Follow

[3220] Zone Bypass

[3205] Fire Follow [3213] Day (Zone)

Follow

[3221] Auto Arm Alarm

[3206] Panic Follow [3214] Gen Trouble

Follow

[3222] Zone Loss Alarm

[3207] Special

Emergency Follow

[3215] Stay Follow

[3208] Duress Follow [3216] Tamper Follow

[33] Zone

[331] Zone Follow [333] Arm Follow [334] Disarm Follow

[332] Alarm Follow

[34] User Code

[3401] Pulse N/C [3403] Pulse N/O [3404] Latch N/O

[3402] Latch N/C

[4] Code Maintenance

[41] Authority

[42] Partition

[43] Grand Master

[44] Installer

[45] Sub-Installer

[46] Code Length

Page 23

ProSYS Quick Programming Setup 23

[5] Dialer

[51] Link Up

[511] MS Link Up [512] U/D Phones

[52] Cust.

Accounts No.

[53] Comm Format

[54] Access & ID

[541] Access Code [542] ID Code [543] MS Lock

[55] Control

[5501] MS Enable [5507] User Initiate [5513] Show Handshake

[5502] FM Enable [5508] Callback U/D [5514] Audible Kissoff

[5503] U/D Enable [5509] Autobatch [5515] UD GSM Enable

[5504] Call Delay [5510] Answer

Machine

[5516] X.Modem Enable

[5505] Dial Tone [5511] UL Installation

[5506] Call Save [5512] Show Kissoff

[56] Parameters

[561] MS Retries [564] Dial Tone Time [567] Pulse Duty Cycle

[562] FM Retries [565] Redial Wait [568] Swinger Limit

[563] Rings to U/D [566] Dial Method [569] VM Retries

[57] Report Split

[571] MS Arm/Disarm [573] MS Non Urgent [575] Email (See Email

table)

[572] MS Urgent [574] Follow Me [576] Event Log

[58] Alarm Restore

[581] On Bell Time Out [582] Follow Zone [583] At Disarm

[59] Periodic Test

[591] MS Test [592] UD Test

[50] More

[501] Auto Codes [502-6] ACM

Parameters (See ACM

table)

[6] Report Codes

[61] Emergency Key

[62] Zones

[63] Accessory

Tamper

[64] Main Trouble

[65] PS Trouble

[66] Arm Codes

[67] Disarm Codes

[68] Miscellaneous

[69] Special Comm

[60] Accessory Code

Page 24

24 ProSYS Quick Programming Setup

[7] Accessories

[71] Add/Delete

module

[711] Keypad [717] Printer Module [7194] Siren

[712] Zone Expander [718] Access Control [7195] BUS Zones

[713] Utility Output [719] More [7196] GSM

[714] Power Supply [7191] Dig Key

Reader

[7197] X. Modem

[715] Event Logging [7192] Advanced

Digital Voice

[716] WL Button [7193] ACM

[72] Verify Module

[73] BUS Test

[74] BUS Scanning

[75] Auto Settings

[8] Miscellaneous

[81] Keyfobs

[811] WL Button Param [812] WL Button

Allocation

[82] Siren

[821] Strobe Control [823] Strobe Arm SQK [826] Proximity Level

[822] Strobe Blink [824] Siren LED [827] Bat. Load Test

[83] GSM

(See GSM table)

[9] Access Control

[91] Door Define

[91dd1] Partitions [91dd3] Door Fire [91dd5] Door Label

[91dd2] Door Time [91dd4] Door Input

[92] Card Code Pos.

[93] Special Code

ACM

[502] ACM

Parameters

[5021] ACM IP

Address

[5027] Gateway IP [50203] DNS 1 IP

[5022] ACM UD Port [5028] Software

Update IP

[50204] DNS 2 IP

[5023] ACM AUX1 Port [5029] Software

Update Port

[50205] NTP IP

[5024] ACM AUX2 Port [5020] More [50206] NTP Port

[5025] ACM AUX3 Port [50201] U/D IP Mask [50207] NTP UPD Time

[5026] Subnet IP Mask [50202] ACM Net

Name

[503] ACM Control

[5031] ACM Config [5033] ACM AUX1

Config

[5035] ACM AUX3

Config

[5032] ACM UD Config [5034] ACM AUX2

Config

[504] ACM MS

Polling

[5041] ACM MS

Primary

[5042] ACM MS

Secondary

[5043] ACM MS Backup

[505] ACM Function

[506] View ACM

Config

Page 25

ProSYS Quick Programming Setup 25

Email

[575] Email

[5751] Mail IP

Address

[5754] Email Prefix [5757] SMTP Password

[5752] Mail SMTP

Port

[5755] Email Domain

[5753] Mail POP3

Port

[5756] SMTP User

Name

[83] GSM

[831] GSM

Parameters

[8311] GSM Mode

[83111] GSM Backup

[83112] GSM Only

[83113] GSM Main

[8212] GSM Times

[83121] PSTN Lost

[83122] GSM Lost

[83123] SIM Expire Date

[8313] Prefix

[8313 1 to 2] PBX Prefix

[8313 3 to 8] Prefix

Constant

[83139] Remove Prefix

[83130] Add Prefix

[8314] PIN Code

[8315] GPRS

[83151] APN Code

[83152] GPRS User

Name

[83153] GPRS Password

[83154] GPRS MS

Polling

[831541] GPRS Primary

[831542] GPRS

Secondary

[831543] GPRS Backup

[8316] Email

[83161] SMTP IP

Address

[83162] SMTP Port

[83163] SMTP User

Name

[83164] SMTP Password

[83165] SMTP Email

Prefix

[83166] SMTP Email

Domain

[8317] Caller ID

[8318] RSSI Level

[832] GSM Control

[8321] Disable In.

Call

Page 26

26 ProSYS Quick Programming Setup

Technical Specifications

Main

Input Power:

16.5VAC 40VA by an external class 2 listed AC/AC adapter)

Current Consumption:

60 mA, typical / 70 mA, maximum

Notes:

1. For US installations, use a listed AC/AC adapter 120VAC 60 Hz, to 16.5VAC 40VA.

2. The main unit current consumption does not include the Aux and the Battery charge.

Rechargeable Standby

Battery:

12 Volts up to 17.2 Amp-Hours (AH), typical

Power Outputs: Auxiliary Power: 12 Volts DC @ 600 mA, maximum (from all AUX

terminals)

Bell/LS (External): 12 Volts DC @ 900 mA, maximum (For UL

installation 300mA maximum)

Programmable Voltage: UO1: Relay (programmable output) (24V, 3 Amps)

UO2: 12V 500 mA transistor

UO3-UO6: Open Collector Active Pull-Down, 70 mA, max

8 LED Keypad (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 75 mA maximum

16 LED Keypad (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 75 mA maximum

LCD Keypad

Current Consumption:

13.8VDC +/-10%; 100 mA maximum

Proximity LCD Keypad

Current Consumption:

13.8VDC +/-10%; 250 mA maximum

Touchscreen Keypad

Current Consumption:

13.8VDC +/-10%; 30 mA typical / 180 mA maximum

Touchscreen Keypad with Proximity

Current Consumption:

13.8VDC +/-10%; 30 mA typical / 280 mA maximum

8 zone expansion module

Current Consumption:

13.8VDC +/-10%; 25 mA, typical / 30 mA, maximum

16 zone expansion module

Current Consumption:

13.8VDC +/-10%; 27 mA, typical / 45 mA, maximum

BUS Zone Expansion

Current Consumption:

13.8VDC +/-10%; 20 mA, typical

8,16 wireless zone expansion module (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 40 mA maximum

Frequency:

868.6-868.7 MHz (narrowband operation in EU) or 433.92 MHz

4 relay output expansion module

Current Consumption:

13.8VDC +/-10%; 25 mA typical / 160 mA maximum

Contacts:

4 Form C (SPDT) Relays.

Contact rating:

5 A / 24V DC

8 transistor output expansion module

Current Consumption:

13.8VDC +/-10%; 25 mA typical / 40 mA maximum

Contacts:

Open Collector, Active Pull-Down, 70 mA maximum

1.5A Power Supply Expansion Module (Not UL Listed)

Input Power:

16.5 Volts AC @ 40 VA (via transformer)

Current Consumption:

180 mA maximum

Rechargeable Standby

Battery:

12 Volts up to 17 Amp-Hours (AH), typical

Power Outputs:

Auxiliary Power: 12 Volts DC @ up to 1.5A*

Bell/LS (External) Sounder Output:12 Volts DC @ 900 mA, maximum

*: Total current Bell+Aux=1.5A

Page 27

ProSYS Quick Programming Setup 27

Fuses:

F1: Battery power 3.0 A

F2: Auxiliary power 2.0 A

F3: Bell/loudspeaker power 1.0 A

3A Power Supply Expansion Module

Input Power:

16.5VAC @ 50VA (via 230VAC / 16.5VAC/50Hz transformer)

Rechargeable Standby

Battery:

12V Up To 21 Amp-Hours (AH)

Power Outputs:

Auxiliary Power: 3A @13VDC

Bell/LS (External) Sounder Output: 1.7A @13VDC

Overload Protection:

Automatic Electronic Protection

On board Utility Outputs:

2 relays, 12VDC @ 3A max Dry Contact Relays

Event Log Expansion Module

Current Consumption:

13.8VDC +/-10%; 30 mA, maximum

Printer Module (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 10 mA, maximum

X-10 Transmitter Module (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 30 mA maximum

Access Control Module (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 100 mA maximum

Input power:

13.8V DC + 10%

Readers Consumption:

5V / 150 mA maximum

Relay:

24V DC / 1 A maximum

Proximity Key Reader (Not UL Listed)

Current Consumption:

13.8VDC +/-10%; 70 mA, typical / 180 mA maximum

Advance Digital Voice Module

Current Consumption:

13.8VDC +/-10%; 38 mA typical / 70 mA maximum

Voice Message Unit

Input Power:

8V DC to 14V DC

Current Consumption:

9 mA (standby) /

60 mA (active speaking - normal volume) /

130 mA (active speaking - full volume)

GSM/GPRS Communication Module

Input Power:

13.8VDC ±10%

Battery: Lead Acid (rechargeable), 12VDC/1.2Ah

Current Consumption:

During Communication - 300mA, During Standby - 70mA

Advanced Communication Module (ACM)

Current Consumption:

9-16 VDC +/-10%; 300mA@13VDC

Fast PSTN Modem 2400 BPS (Not UL Listed)

Current Consumption:

100 mA maximum

CE Declaration of Conformity

Hereby, RISCO Group declares that this control panel (ProSYS 128, ProSYS 40, ProSYS 16), with

wired accessories (including cables) and wireless accessories, is in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC.

For the CE Declaration of Conformity please refer to our website: www.riscogroup.com.

Compliance Statement

Hereby, RISCO Group declares that the ProSYS series of control panels and accessories are suitable

for use in systems designed to comply with PD6662:2004 Security Grade 3, Environmental Class II.

(Security Grade 2 when using Wireless accessories).

The ProSYS series of control panels and accessories comply with the relevant parts of the EN50131

series of standards.

The ProSYS series of control panels and accessories comply with DD243:2004.

Page 28

28 ProSYS Quick Programming Setup

RISCO Group Limited Warranty

RISCO Group and its subsidiaries and affiliates ("Seller") warrants its products to be free from defects

in materials and workmanship under normal use for 24 months from the date of production. Because

Seller does not install or connect the product and because the product may be used in conjunction with

products not manufactured by the Seller, Seller cannot guarantee the performance of the security

system which uses this product. Seller's obligation and liability under this warranty is expressly limited

to repairing and replacing, at Seller's option, within a reasonable time after the date of delivery, any

product not meeting the specifications. Seller makes no other warranty, expressed or implied, and

makes no warranty of merchantability or of fitness for any particular purpose.

In no case shall seller be liable for any consequential or incidental damages for breach of this or any

other warranty, expressed or implied, or upon any other basis of liability whatsoever.

Seller's obligation under this warranty shall not include any transportation charges or costs of

installation or any liability for direct, indirect, or consequential damages or delay.

Seller does not represent that its product may not be compromised or circumvented; that the product

will prevent any personal injury or property loss by burglary, robbery, fire or otherwise; or that the

product will in all cases provide adequate warning or protection.

Seller, in no event shall be liable for any direct or indirect damages or any other losses occurred due to

any type of tampering, whether intentional or unintentional such as masking, painting or spraying on

the lenses, mirrors or any other part of the detector. Buyer understands that a properly installed and

maintained alarm may only reduce the risk of burglary, robbery or fire without warning, but is not

insurance or a guaranty that such event will not occur or that there will be no personal injury or

property loss as a result thereof.

Consequently seller shall have no liability for any personal injury, property damage or loss based on a

claim that the product fails to give warning. However, if seller is held liable, whether directly or

indirectly, for any loss or damage arising under this limited warranty or otherwise, regardless of cause

or origin, seller's maximum liability shall not exceed the purchase price of the product, which shall be

complete and exclusive remedy against seller.

No employee or representative of Seller is authorized to change this warranty in any way or grant any

other warranty.

WARNING: This product should be tested at least once a week.

Contacting RISCO Group

RISCO Group is committed to customer service and product support. You can contact us through our

website www.riscogroup.com or as follows:

United Kingdom

Tel: +44-(0)-161-655-5500

support-uk@riscogroup.com

Belgium (Benelux)

Tel: +32-2522-7622

support-be@riscogroup.com

Brazil

Tel: +55-11-3661-8767

support-br@riscogroup.com

Italy

Tel: +39-02-66590054

support-it@riscogroup.com

USA

Tel: +1-631-719-4400

support-usa@riscogroup.com

China (Shanghai)

Tel: +86-21-52-39-0066

support-cn@riscogroup.com

Spain

Tel: +34-91-490-2133

support-es@riscogroup.com

Poland

Tel: +48-22-500-28-40

support-pl@riscogroup.com

China (Shenzhen)

Tel: +86-755-82789285

support-cn@riscogroup.com

France

Tel: +33-164-73-28-50

support-fr@riscogroup.com

Israel

Tel: +972-3-963-7777

support@riscogroup.com

All rights reserved.

RISCO Group reserves the right to amend the software and features without prior notice.

No part of this document may be reproduced in any form without prior written permission from the

publisher.

© RISCO Group 04/11 5IN1286 C

Loading...

Loading...